Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Fourth Indoor Hydroponic Farm For Brick Street In The Works

Fourth Indoor Hydroponic Farm For Brick Street In The Works

The St. Pete city farm's new addition aims to feed the community through bi-monthly shares.

August, 18, 2017

If you’ve been itching to get your hands on hyper-local greens and herbs from Brick Street Farms, listen up. The high-tech, Best of the Bay-nominated St. Petersburg city farm, located in the Grand Central District, is gearing up to expand its year-round bounty to the community through a fourth indoor hydroponic farm.

Selling everything from rainbow chard to tarragon — vertically grown inside the controlled environment that is Brick Street’s upcycled freight containers — to the public was part of the plan from the beginning. But keeping up with retail demand hasn’t been easy, according to co-owner Shannon O’Malley, considering the farm has doubled its restaurant accounts since CL first wrote about the operation in November 2015. Among O’Malley and her husband Bradley Doyle’s notable customers is the private kitchen of the Tampa Bay Rays.

Farm 4, which is being built and hopes to have shares available by the end of October (fingers crossed), is meant to serve Brick Street’s new annual membership program. Whereas many community-supported agriculture programs offer harvest shares from November to April, this one keeps the fresh green stuff coming all year long.

Participants receive 26 bi-weekly shares of greens, herbs and edible flowers — as well as raw, local wildflower honey — with their $695 membership purchase (that may sound like a lot, but keep reading). Expect a large paper grocery bag’s worth per share.

“It’s about $13.50 a week for an annual supply of fresh greens and herbs,” O’Malley says.

Pickups take place at the farm every two weeks on alternating Saturday mornings for a couple of reasons: 1) Each share easily keeps in the fridge for that period of time, and 2) It allows Brick Street, which harvests every Saturday, to accommodate more members.

In addition to a rotating haul of hydroponic produce, another perk for members is access to presale tickets for any farm event going forward. O’Malley says they have another Prohibition-style dinner in the works with Locale Market’s FarmTable Kitchen, and that they’re also in preliminary talks with St. Petersburg Distillery to do something. Plus, when farm No. 4 is ready to debut, a big launch event with membership tours is planned.

There isn’t a cut-off date to become a member per se, but the wife-and-husband team encourage folks to sign up before the end of September. A limited number of shares are available, after all.

“We’re just excited that we have something that’s gonna really support the community,” O’Malley says. “There’s been so much demand, but we’re working on increasing our production.”

Memberships allow Brick Street Farms to make its sustainable bounty available to the public

Hydroponics Proposals See Little Agreement From Organic Advisory Board

Hydroponics Proposals See Little Agreement From Organic Advisory Board

In a webcast discussion, members did not see eye-to-eye on whether plants grown outside of traditional soil environments could receive the USDA certification.

Author Megan Poinski@meganpoinski

August 17, 2017

Listening to the National Organic Standards Board’s discussion Monday afternoon on hydroponic crops, one thing was clear: There is no consensus on whether crops grown without soil should be able to be certified organic.

“Clearly, this is not an easy subject to resolve,” said Tom Chapman, the board's chairman. “It’s been on the board’s agenda since 1995.”

The panel, which advises the U.S. Department of Agriculture on issues dealing with certified organic food and ingredients, has passed the hydroponic issue from meeting agenda to meeting agenda for years. The board has discussed and failed to act on proposals several times. An April vote on the issue was deferred, with members saying they needed more time, research and input from stakeholders in the organic community.

Freightliner's new Cascadia® is designed to be even more aerodynamic than ever, improving fuel economy and your company's bottom line. Getting the most out of every gallon of fuel starts before the truck travels its first mile. Spec'ing the truck properly pays off.

Monday’s meeting was a web conference call for members of the public to listen to board members discuss where they stood on potential proposals on hydroponics, aquaponics and container-grown produce. No votes were taken and no finalized proposals were discussed. The next time the board may take action on the issue is at its fall meeting from Oct. 31 to Nov. 2.

The regulations dealing with whether hydroponic crops can be certified organic are unclear. Last November, the Cornucopia Institute filed a formal legal complaint against USDA, claiming while the NOSB has barred hydroponics from bearing the organic seal, USDA has allowed more than 100 foreign and domestic growers to receive the certification.

In 2010, the NOSB issued a recommendation that stated “Hydroponics...certainly cannot be classified as certified organic growing methods due to their exclusion of the soil-plant ecology intrinsic to organic farming systems and USDA/(National Organic Program) regulations governing them.”

A motion to allow hydroponic crops to be considered organic was on the table for the fall NOSB meeting in 2016, but not voted on because it was unlikely to pass. Instead, members passed a resolution that stated a consensus of members wanted to prohibit hydroponic systems from being used that were entirely water-based.

On Monday, Chapman said he’d be likely to support the 2010 recommendation — but the problem is that it doesn’t truly address what’s prohibited. Are there substances that can be used for growing more hydroponic-based crops? And if so, what would be allowed?

“Clearly, this is not an easy subject to resolve. It’s been on the board’s agenda since 1995.”

Tom Chapman Chairman, National Organic Standards Board

“We know this is a controversial topic, so I’ve tried to find things that are on common ground for the whole NOSB and work our way up from it,” said member Steve Ela.

There wasn’t much common ground, however. Some members of the board said they would support certifying hydroponic systems.

When discussion moved to aquaponic systems — where fish live in the tanks of the liquid used to grow crops — members were divided. Some said they should be prohibited because of the untreated waste from the fish going straight into the crops, which would not be permitted for organic crops growing in soil. But others said there has not been much study on any negative impacts, so not enough is known to take a stance on this issue.

Heated discussion also took place on how much soil or water would be needed in container-grown crops. A potential "compromise" proposal from the NOSB’s Crops Committee set limits to what would be needed for an organic crop – only 20% could be supplied by liquid feeding, no more than 50% of nutrients could be added after the crop was planted, and at least 50% of the container would have to be from a substrate such as compost. Supporters said this was based on similar limits set in the EU, which has also struggled with the issue.

Members had mixed opinions. Some felt one of the main benefits of organic farming was using the crops to improve soil over time — something that this sort of farming would not do. Others said setting hard limits of amounts that can be used in a container and not allowing more flexibility could be detrimental. Another group on the panel said the fact that some growers using these methods are already certified as organic would cause economic harm.

“There doesn’t seem to be a middle ground that’s acceptable,” Chapman said.

Members of the Crops Committee pledged to revisit their proposals before the fall meeting, but there are no guarantees that the issue will be included on the agenda — or would be voted on even if it’s there. After the board did not vote on anything dealing with hydroponics at its April meeting, many said they thought it would be unlikely to see any action on the issue at all this year.

Follow Megan Poinski on Twitter

Editorial: Research at UMass With Global Reach

Editorial: Research at UMass With Global Reach

Evan Chakrin, a University of Massachusetts Amherst junior studying horticulture, harvests butterhead bibb lettuce from a hydroponic raft bed Aug. 4 at the UMass Hydrofarm he co-founded with Dana Lucas, a senior majoring in sustainable food and farming. GAZETTE FILE PHOTO

August 17, 2017

Two students at the University of Massachusetts Amherst have turned a modest grant and an old greenhouse into the first hydroponic farm on campus to show off sustainable agriculture techniques.

An award-winning geoscientist at UMass will use a $94,375 grant from the Massachusetts Environmental Trust to gather and study water samples with the goal of better understanding the impact of droughts.

Those are examples of research that spills outside the university’s classrooms to address real-world issues such as local food production and climate change.

Evan Chakrin and Dana Lucas are co-leaders of the student-run hydrofarm in a small greenhouse next to Clark Hall in the central residential area of campus. Started last winter, the farm grows food without using soil. Nutrients are dissolved into the water surrounding the plants’ roots, and the system uses less water than an irrigated field. It also keeps nutrients from running off fields to other water sources.

“It’s basically just using chemistry to grow plants,” says Chakrin, a junior studying horticulture. “We can totally control whatever we waste.”

One Friday this month, he harvested 10 pounds of lettuce that he planned to donate to the Amherst Survival Center. Also during its first year, the hydrofarm has supplied food to on-campus restaurants, including the vegetarian Earthfoods Cafe. Other crops include kale, tomatoes and strawberries.

Lucas is a senior majoring in sustainable food and farming. Since it was elevated in 2013 from a concentration to a full-fledged major within the Stockbridge School of Agriculture, enrollment in the major has increased from 50 to 140 full-time students.

She started cultivating the idea for a hydroponic farm on campus in 2015, and with Chakrin received a $5,000 grant and use of the greenhouse from the Stockbridge School in December. They started germinating seeds and later in the winter began selling food they harvested. The revenue is used to buy more seeds and equipment.

In the fall, the pair will teach a course for 12 undergraduate students who want practical experience. “The techniques we use here are are the main hydroponic techniques used,” says Chakrin. “This work is directly applicable to any of their food production goals.”

He hopes to attract students interested in urban food production, even if they are not enrolled in the Stockbridge School. One of the benefits of hydroponics is that it can used almost anywhere to grow food locally.

Chakrin and Lucas also have a consulting service, which they call Farmable, to coach people who want to farm in urban areas. “Anywhere is farmable and this concept will revolutionize how urbanites are able to access food,” Lucas says.

Water is also an important ingredient in the research by hydrogeologist David Boutt, an associate professor in the Department of Geosciences. His grant — funded by the sale of the state’s environmentally themed license plates — will help develop an isotope mapping tool to study the composition of water samples and learn more about the effects of droughts. A public database will help water managers assess the sustainability of freshwater resources.

Boutt says, “By measuring the isotopic composition, we can start to describe the source of that moisture — did it come ultimately from the Arctic? Or the Gulf of Mexico?”

The data is important not just to better assess how droughts may affect an area, but also in relation to global warming. “As the Arctic is warming, more and more of that moisture is moving to New England,” Boutt says. “With this database we can start to track this and understand how the hydrological cycle is changing the source of moisture to the region.”

Boutt is seeking water samples from wells and streams in the region. Anyone interested may call him at 413-545-2724 or email dboutt@geo.umass.edu.

He will have an international forum to discuss his research next year after being named the Birdsall-Dreiss Distinguished Lecturer for 2018 by the hydrogeology division of the Geological Society of America. His topics will include groundwater and climate change, the role of groundwater flow in hydrologic processes and how water and lithium factor in the global transition from fossil fuels to green energy.

Chakrin, Lucas and Boutt put a face on the many people studying and teaching at the university who are determined to make a difference by applying what they learn locally to global problems.

Purdue Students Created “Hydro Grow”

Purdue Students Created “Hydro Grow”

August 17, 2017

People will produce faster and fresh food in their homes with the help of the Purdue student’s inventions. A mechanical engineering student named Scott Massey working on a NASA-funded project tasked with growing plants in outer space. Scott Massey said, “I think I realized that if I really had this one shot at life, why not try something new and take a risk?”. With the help of the co-founder and classmate Ivan Ball Scott Massey developed Hydro Grow.

The Hydro Grow is a business whose task is to provide easier access to people to freshly grown produce in their homes. The vertical tower Gropod named can produce a variety of vegetables as well as fruits faster rate than a traditional farm could.

Scott Massey said, “People want to know how their food is developed, and there’s just a general hunger for that knowledge”. Further, he said, “This is a product that lets people have the comfort to know that what they have is naturally grown, and they can be present every step of the way”.

The Gropod is still in its prototype phase. Scott Massey stated that they are looking to start selling the product in just a few months.

The process is simple Massey said, just people need to insert a seed into the Gropod’s slots and pour water into the tower and then let it grow. Ball said, “It will continue to grow until it’s ready for harvest”. Further, Ball added, “You can continually keep your produce fresh”. Ball said, “With a hydroponic system like we have, you’re actually able to continuously recycle the water over and over again by spraying the roots directly”.

Hydroponics quickly becoming one of the next targets for sustainable agriculture, it is a global industry that continues to grow.

Hydroponics – Future of Urban Food | CV Prakash | TEDxPESITBSC

Hydroponics – Future of Urban Food | CV Prakash | TEDxPESITBSC

Posted on August 16, 2017 by adminlfad

Simplified Hydroponics – Who Can Grow?

Where can you grow?

Why?

Grow Local, Eat Local.

Lt. Cdr CV Prakash is a former underwater weapons specialist of the elite Submarine arm of the Indian Navy.

Upon retirement CV learnt Hydroponics from the best of growers in Australia and is a pioneer in the field of Hydroponics in India. A hands-on Grower, Food Park designer, Auditor & Trainer in Hydroponics, CV’s “Pet Bharo Project” is credited for India’s first commercial hydroponically grown strawberries, spinach and herbs.

He is credited for building India’s first state-of-the-art Hydroponics Greenhouse and is one of the most widely read academic paper authors. His mission is clear- to bring simple yet sustainable technology that can help almost everybody grow clean, residue free, nutritious food. The best part about his technology being that it has very little entry barriers and reaches the poorest of the poor.

He believes that “it’s not enough to just have know how, but one must do how and show how”.

This talk was given at a TEDx event using the TED conference format but independently organized by a local community. Learn more at http://ted.com/tedx

Posted in Hydroponics · Tagged English, Food, Gardening, Global issues, Health, india, plants, TEDxTalks

Hydroponics: the future of farming

Hydroponics: the future of farming

AUG 16 2017

hydroponics uses mineral nutrient solutions to feed plants in water – without the need for soil.

In 2015, the United Nations predicted that the world population will grow to 9.6bn by 2050 and 70% of the population will live in cities.

For anyone in the UK wanting to give the technology a try, Ikea introduced a line of indoor hydroponic garden products earlier this year, as part of the Krydda/Växer collection.

In 2015, the United Nations predicted that the world population will grow to 9.6bn by 2050 and 70% of the population will live in cities.

However, such a population increase comes hand in hand with the need to produce more food to feed them. Some estimates suggest 70% more food will be needed. But with 80% of cultivated land already in use and the rapid urbanisation of countries set to continue, the challenge of producing more food in a sustainable way will become ever more pressing.

One solution is hydroponic technology, a niche method of food production that allows producers to grow plants without soil. A subset of hydroculture, this method uses mineral nutrient solutions to feed plants in water without the need for soil.

Hydroculture subset: what are the benefits?

The earliest published work on growing plants without soil was Francis Bacon’s 1627 book Sylva Sylvarum. Water culture quickly became a popular research technique following the publication, but it was not until the 1920s that the idea really took hold.

In 1929, William Frederick Gericke of the University of California at Berkeley began promoting the idea that solution culture could be used for agriculture crop production. Gericke was able to grow tomato vines to a height of 25ft in his garden using mineral nutrient solutions instead of soil. In the present day, this technology is being used worldwide.

Using hydroponic technology to produce plants has a number of benefits when compared with traditional cultivation methods. In hydroponics, the roots of the plant have constant access to an unlimited supply of oxygen, as well as access to water. This is particularly important as a common error when growing food is over or under-watering. Hydroponics eliminates this error margin, as quantities of water, mineral salts, and oxygen are controlled.

Other benefits of hydroponic technology include the ability to better control the plant’s nutrition, a visible improvement in quantity and yields, a shortening of the growth interval for many plants, a high propagation success rate, savings on fertilisers, the absence of pesticides and herbicides, and a more efficient use of space. As the world’s population continues to grow, it is this last point that makes the technology such a useful one.

Carbon footprints: sustaining the population

Hydroponics has the potential to sustain a large proportion of the world’s population and to allow third world countries to feed their own people, even in places where soil is poor and water is scarce. The technology can also be used as a valuable source of food production in places where space is scarce.

In Guangzhou, China, 14 hydroponic tanks have been installed on a rooftop measuring 1,600ft², producing hundreds of pounds of vegetables every year. The tanks are part of a study that is trying to show residents and developers in the Chinese city that their rooftops have the potential to produce a steady supply of vegetables that may even be cheaper than store-bought alternatives. Published in July in the journal Agronomy for Sustainable Development, the results of the study outline a comprehensive business model for hydroponic rooftop farming, a method that is already in use across the US, Canada, and Europe.

By 2020, Guangzhou’s population is expected to almost double, from 9.62 million in 2010 to 15.17 million. With this population expansion comes the need to produce more food, create jobs, and reduce the carbon footprint of transporting food into cities.

Research associate at the Worldwatch Institute Wanquing Zhou was quoted by Quartz as saying: “There is a need for rooftop farms not only in Chinese cities, but all major cities that have the resources (rooftop spaces, water, sunlight) and yet are heavily dependent on food produced long distances away.”

Being able to grow and produce food within cities for urban populations eliminates the carbon footprint generated through the transport of food from rural areas to city centres.

Food production: growing a garden

On the other side of the Pacific Ocean, the cities of New York, Chicago, and Montreal have all seen some success with rooftop hydroponic farms. Gotham Greens has four rooftop hydroponic greenhouses in New York and Chicago, which produce leafy greens, herbs, and tomatoes. Canada-based company Lufa Farms was credited with opening the world's first commercial rooftop greenhouse in 2011 and now boasts a second greenhouse in the city, which yields 120tn of produce every year.

As consumer demand for sustainably produced (and sourced) food continues to grow, rooftop hydroponic farms like these ones in North America should continue to pop up in cities across the world. Rapid urbanisation in countries such as China and the resulting decrease in land available for agricultural activities will force populations to come up with novel ideas and technologies to cater for larger populations in smaller spaces.

The progression of hydroponic technology since Gericke first promoted the idea in the late 1920s has made soilless farming possible within urban environments. This simple but effective method is key to addressing the issue of sustainable food supplies as the world’s population continues to expand.

For anyone in the UK wanting to give the technology a try, Ikea introduced a line of indoor hydroponic garden products earlier this year, as part of the Krydda/Växer collection.

Ikea's website claims: “Anyone can grow a garden”, and the collection has everything you need to get your fingers green and start growing your own herbs and lettuces.

Urban Hydroponic Farms Offer Sustainable Water Solutions

Urban Hydroponic Farms Offer Sustainable Water Solutions

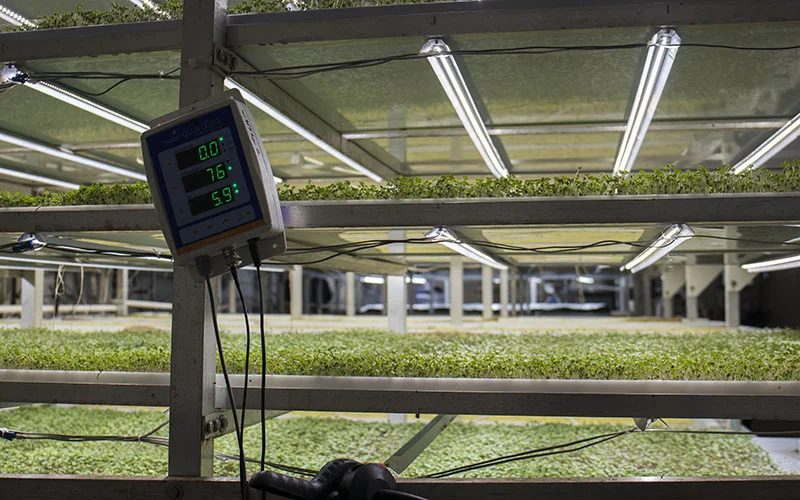

At Local Goods in California, Ron Mitchell’s monitoring system checks the plants’ water supplies for temperature, pH levels and electric conductivity. (Photo by Jackie Wang/News21)

By Nicole Tyau | News21 Tuesday, July 11, 2017

BERKELEY, Calif. – Tucked behind a Whole Foods in a corner warehouse unit, Ron and Faye Mitchell grow 8,000 pounds of food each month without using any soil, and they recycle the water their plants don’t use.

Hydroponic farming grows crops without soil. Instead, farmers add nutrients to the water the plants use. This method can produce a wide variety of plants, from leafy greens to dwarf fruit trees.

According to a study by the Arizona State University School of Sustainable Engineering and the Built Environment, hydroponic lettuce farming used about one-tenth of the water that conventional lettuce farming did in Yuma, Ariz. A similar study from the University of Nevada, Reno, found that growing strawberries hydroponically in a greenhouse environment also used significantly less water than conventional methods.

(Video by Jackie Wang/News21)

The Mitchells started production of Local Greens in February 2014. They primarily grow microgreens such as kale, kohlrabi and sprouted beans while using the same amount of water as two average households and the same amount of electricity as three in a month, they said.

“Who knows what you’re getting when you’re using soil?” Faye said. “Hydroponics is a fully contained system, so we know exactly what’s in our water, what we want in it and what we don’t want in it, and we can control that.”

Ron installed a water filtration system he customized. He removes fluoride, a common additive in municipal water, and chlorine, a common disinfection byproduct, before adding oxygen and other plant-specific nutrients.

At Local Greens, Ron and Faye Mitchell mostly cultivate microgreens, which grow to about 10 inches before they are cut and sold in the area. (Photo by Jackie Wang/News21)

To make use of the warehouse’s tall ceilings, the Mitchells stack six trays of microgreen seeds on top of each other. At one end, an irrigation spout controls the amount and type of water sent through the trays.

“Some plants don’t need or want nutrients because they have it in their seed,” Ron said. He explained that pea shoots don’t need any additives, but sunflowers require copious amounts of nutrients to grow quickly.

Ron Mitchell, 67, said the stacked trays inside his hydroponic farming facility in California allow them to grow twice as much. (Photo by Jackie Wang/News21)

The water the plants don’t use is captured at the other end of the tray and reused for the next watering, with the nutrients replenished as needed. The additional nutrients in the water are organic and naturally-occurring since they don’t have to spray pesticides or herbicides in their controlled warehouse environment, Faye said.

The number of greenhouse farms has more than doubled since 2007, according to the 2012 U.S. Department of Agriculture Census of Agriculture. Some hydroponics advocates see the practice as a solution to a global food and water crisis.

“I don’t think it could take over the farming industry entirely because of the types of plants and vegetables people want to eat,” Faye said. “But I definitely think it could make a dent in the farming industry and make its place and replace certain types of farms for a more efficient and, in some cases, less expensive system.

Editor’s note: This story was produced for Cronkite News in collaboration with the Walter Cronkite School-based Carnegie-Knight News21 “Troubled Water” national reporting project scheduled for publication in August. Check out the project’s blog here.

The Origins of Hydroponic Farming

Hydroponics is not a new concept. It preceded the earliest tillage practices on farms, and plants have been grown in lakes and oceans from time immemorial.

The Origins of Hydroponic Farming

In this hydroponic system in Spain, lettuces are grown in plastic troughs without any soil, substrate or other material around their roots. The nutrient solution is recirculated to eliminate drainage loss and seepage of nutrients into the soil, and to reduce the cost of fertiliser. Photo: Prof Gert Venter

AGRICULTURAL NEWS - Hydroponics is not a new concept. It preceded the earliest tillage practices on farms, and plants have been grown in lakes and oceans from time immemorial.

The origins of today’s hydroponics can be dated back to the 15th century, when Leonardo da Vinci, born in 1452, deduced the following:

“To develop, plants need mineral elements that they absorb from the soil by means of water. Without water, the plants do not survive, even if the soil has the mineral elements they need.

Water is as if it were the soul of plants, as minerals are as if they were the soul of soil. If we could transmit to the soul of plants [the water], the strength of the soul of soil [the minerals], perhaps we would not need it [the soil] to make plants survive and multiply.

I believe that, in a future that does not belong to me, that [this] will be possible. So, it is advisable to add fertiliser and irrigate periodically the lands for us to get a healthy and productive plantation.”

The Early Years

Hydroponics, as we know it, developed slowly since the Middle Ages until water culture became a favourite research technique during the 17th century, after the posthumous publication of a book on the subject by the scientist and philosopher, Francis Bacon.

In 1699, researchers found that plants grew better in water that was less pure than in distilled water.

By 1842, a list of nine elements believed to be essential for plant growth had been compiled, and this resulted in the development of soilless cultivation techniques. Solution culture then quickly became a standard research and teaching technology and is still widely used today.

In the 19th century, scientists showed renewed interest in the nutrient requirements of plants. Complete nutrient solutions were developed over time, but it was only in the 1920s that Prof WF Gericke of the University of California in the US began to focus on commercial plant production using dissolved nutrient solutions instead of soil.

He coined the name ‘hydroponics’ by combining two Greek words, hydros (water) and ponos (work).

At the time, greenhouse growers replaced their greenhouse soil at frequent intervals, or maintained it by adding large quantities of commercial fertilisers.

To solve this difficulty, researchers replaced natural soil systems with either aerated nutrient solutions or artificial soil, called substrates, consisting of chemically inert aggregates, moistened with nutrient solutions.

The Later Years

Between 1925 and 1935, extensive development took place in modifying plant physiologists’ methods for large-scale crop production, but hydroponics was not widely accepted due to the high cost of constructing concrete growing beds.

During the Second World War, the US army started using hydroponics to produce food for troops stationed on islands in the South Atlantic and the Pacific, due to the prohibitive cost of transportation.

After the war, interest in hydroponics boomed when gravel culture hydroponics was used to grow tomatoes, cucumbers and other vegetables. However, these systems had shortcomings and many were eventually abandoned.

Grow Your Own All Organic Food With The Permacube

Grow Your Own All Organic Food With The Permacube

90% of Americans used to grow at least some of their own food. Now, this number has dropped to 10%. The consequences of this shift are detrimental. Here is one company that is trying to change this.

Over the last 100 years, American society has quickly transitioned from an agrarian society to an industrial one. Our environment, wallets, health, and independence are feeling the negative effects of this change.

PermaCube helps people take back control of their food and energy needs by bringing independence in the form of the world’s most efficient, sustainable food and energy production system. PermaCube offers an all-in-one structure that provides fresh, organic, non-GMO food that a family requires — right from the backyard.

It is nearly impossible to sustainably supply food around the country and world. People have begun to rely more on local markets as sustainability has become more important. Yet, most of the food in local grocery stores are still shipped in from around the globe, meaning we are still not receiving the best, freshest produce, and the majority of it is not 100% organic or GMO-free.

The PermaCube system contains everything needed to meet the food and energy requirements of a four to six person family. Powered by solar energy and merging aquaculture and hydroponics, PermaCube offers an off-the-grid source of sustainable, locally produced, 100% organic food and clean water.

The design is comprehensive and holistic. Each PermaCube contains enough room for 72 square feet of growing space, while also having room for 12 chickens and 50-70 fish. All of the components of PermaCube work in tandem in a aquaculture and hydroponics — a hydroponics grow system requires fertilizer, and fish waste that would otherwise build up in a pure aquaculture system works perfectly.

A filtration system and atmospheric water generator ensure you will always have clean, potable water available. Together, vegetables from the hydroponic garden, fish, chickens, and their eggs provide between $1200 and $1400 of 100% organic, GMO-free food each month — straight from your personal self sustaining farm.

Food production is an integral aspect of every human life. Putting organic, non-GMO foods in our body sustains not only the earth, but also our health.

Green Machine: Madar Farms’ Plug-and-Play Harvests

Green Machine: Madar Farms’ Plug-and-Play Harvests

Dubai start-up has ambitious plans to provide Gulf food security by combining technology and hydroponics

Photos Credit: Clint Egbert/Gulf News

Andrew Staples, Chief Business Reporter | Gulf News | DUBAI | Published: 18:33 July 29, 2017

The Arab world struggles to feed its population. In the Gulf Cooperation Council (GCC) nations, arable lands accounts for just 1 per cent of the total land, yet agriculture and irrigation use more than 50 per cent of the water supply. And still the GCC imports 90 per cent of its food.

That’s the starting point for Dubai start-up Madar Farms’ ambitious plans to develop sustainable agriculture within the GCC by combining latest hydroponics techniques with high-tech control.

“I think we all know that we have a problem here in the region,” said Madar Farms co-founder and CEO Abdul Aziz Al Mulla. “But I think the scale and imminence of the problem is what really scared me. Over the last 20 years we’ve lost the majority of our water resources.

“We’re not talking about a problem that’s going to hit us now. We’re talking about in 10 years, 20 years. But at the same time intervention is so large scale and takes such a large period of time to actually convert that I felt a very strong need that something had to be done now. Something at a large scale.”

Ultimately, the start-up, which began operations in February, wants to build a fully automated robotic hydroponics farm. Right now, it’s operating three units built into re-used 20-foot shipping containers at its headquarters in Warsan 3, near Dubai Municipality’s nursery, and is on its fourth harvest.

Container hydroponics isn’t a new development, Al Mulla is quick to point out. It’s already been used successfully in other parts of the world.

“We always tell people there’s no magic in hydroponics,” said Al Mulla, a Kuwaiti entrepreneur who began getting interested in food security while working for consultancy McKinsey. “Everyone thinks it’s some kind of new technology. It’s not. It’s all the same, It’s just the delivery mechanism and it’s how accessible you make it that’s the differentiating factor.”

What’s new is combining container hydroponics with a mobile app that maximises efficiency by monitoring crop growth and advising workers in necessary tasks to ensure consistent growth and maximum yield. It will also help Madar monitor and manage hundreds of containers — among their retail models are options for customers to have Madar maintain containers for them, or to store and manage them. The app will be produced in English, Arabic, Hindi, Urdu and Tagalog.

Combining the two allows Madar to grow crops using less than 1 per cent of the water used in traditional methods, and do to so in a manner that makes the process easy and consistent. At the moment they’re concentrating on producing leafy greens such as lettuce, cabbage, herbs, and intend to add legumes and berries in the near future.

“You want people to convert from unsustainable farming habits to sustainable farming habits, but not only that, you want to produce a higher quality produce and all the spiel that comes with that. In order to encourage them to do so, you need to make it as accessible as possible to drive adoptability.”

Madar’s three operating units have served as a proving ground for the concept of a plug and play solution for its small team, who are quick to point out that their background is in business, not agriculture. “We don’t want someone to have an agricultural background. We want them to be able to do it if they know nothing about farming, and we want them to be able to do it consistently and in a standardised fashion. And we want them to be able to upscale as fast as possible.”

Come September, Madar will begin distributing units to customers; they already have orders to carry them through to year-end.

Each container will sell for between $85,000 and $95,000, depending on requirements (Madar is still refining the assembly process to bring costs down). Al Mulla estimates return on investment for each container at between four and seven years, depending on the cost of electricity.

They’re looking into building smaller units in re-used aircraft cargo containers, suitable for installation in restaurants.

The containers have considerable power requirements, which form a significant proportion of operating costs.

But Al Mulla is clear the containers are a stepping stone to a larger platform; they help increase awareness of the method and build the market, but will not solve the problem he is concerned with.

“When we talk about food security, which is our long-term aim, you have to produce a quantity of food, but the right mixture of food of high quality to feed and entire population. That’s our long-term goal and it’s what we’re going to get to. Growing leafy greens isn’t going to get us there.”

Madar’s next phase is a large-scale automated hydroponics factory. They intend to break ground in the third quarter of 2018.

“We take out the labour aspect completely. This automates using robots for transplanting, harvesting and packaging in a 40,000 square foot plant where we can grow 3,000 kilogrammes a day.”

That too is small scale compared to the target if food security for the region, but Al Mulla envisages a chain of plants, producing not only leafy greens but wheat, root crops and fruit. He’s looking also into automated fish farming.

Food Hygiene

Madar operates a strict sanitary process in its hydroponics containers. Al Mulla dons surgical gloves before handling equipment, and asks Gulf News’ reporter and photographer to don face masks and refrain from touching anything.

This is not only a matter of avoiding contamination of the plants, but of standardising the conditions, and the nutrient-laden water flowing through the stone-wool and cotton holders in which the plants grow.

Since there’s no spraying, and fertilisers are delivered through the roots, the sanitised conditions mean the plants can be eaten directly, without washing — something Al Mulla happily demonstrates back in his office as he offers around a pair of freshly harvested lettuces.

In fact, he says, washing the plants actually decreases their cleanliness; tap water is dirtier than they are (though still, of course, perfectly safe).

Film Studio, Hydroponic Lab Are Among $3.7 Million in Improvements For Astoria Public Schools

Students at P.S. 84 and I.S. 126 will receive $160,000 for hydroponic science labs. They’ll learn about hydroponics, a method that allows people to grow plants in a water-based solution rather than soil. Students will also learn how biology, agriculture, technology and nutrition intersect.

Film Studio, Hydroponic Lab Are Among $3.7 Million in Improvements For Astoria Public Schools

P.S. 84 and I.S. 126 will receive funding for hydroponic labs from Councilman Costa Constantinides. Photo via Shutterstock

By Angela Matua | amatua@qns.com | Friday, July 28, 2017 | 2:15 PM

Public schools in Astoria will receive millions for infrastructure improvements and new additions like a film studio and science lab.

Councilman Costa Constantinides and Queens Borough President Melinda Katz announced that they are allocating nearly $3.7 million to the School Construction Authority for a number of enhancements.

Young Women’s Leadership School of Astoria at 23-15 Newtown Ave. will receive $375,000 for a new educational film studio. P.S. 300 at 28-37 29 St. will receive a new science lab with a $500,000 allocation from Katz and $300,000 will go toward renovating the bathrooms at I.S. 141.

“I am proud to have partnered with Borough President Katz to invest almost $3.7 million in our most important resource, our children,” Constantinides said. “Our investment this year includes more advanced technology and studying tools. New and improved school infrastructure will help encourage students to spend more time studying and learning while enjoying their overall school experience.”

The councilman, who is the chair of the committee on environmental protection, allocated $1.1 million for solar panels at P.S.122. It will be the first school in Astoria to install solar panels.

Students at P.S. 84 and I.S. 126 will receive $160,000 for hydroponic science labs. They’ll learn about hydroponics, a method that allows people to grow plants in a water-based solution rather than soil. Students will also learn how biology, agriculture, technology and nutrition intersect.

Nearly $900,000 was allocated to update technology in all Astoria public schools and $200,000 will upgrade the lunchroom at P.S. 122. Originally constructed as a gymnasium, the walls of the cafeteria consist of exposed brick and concrete, amplifying loud sounds.

“Queens has some of the best schools in the state, but to continue their success our schools need to have first-class facilities that will enable our children to reach their full potential,” Katz said in a statement. “This capital investment of millions of dollars will go a long way toward ensuring our kids learn in facilities with modern laboratories and studios, with up-to-date technology and with the quality playground space.”

Farmer Josh is Bringing Ultra Local Food to NYC (and Asking Hard Questions About Our Food System)

Farmer Josh is Bringing Ultra Local Food to NYC (and Asking Hard Questions About Our Food System)

JULY 11, 2017 by EMILY MONACO

Josh Lee may have grown up on a farm in North Carolina, but he never expected to end up a farmer himself -– especially not in New York City. And yet that’s exactly what the fifth-generation farmer has done with Green Top Farms, a “seed-to-salad” delivery service that brings ultra fresh, ultra local food to offices throughout NYC, in the hopes of helping people think more about where their food comes from.

Fifth-Generation Farmer From NC to NYC

At 18, Lee left the farming life behind, and he was never encouraged to return.

“Even though I was farming every summer, it wasn’t something that I was encouraged to stay and do,” he says. “’You’ve got to go to college; be a doctor or a lawyer, some sort of professional career.’”

For Lee, the calling came from education, and so he became a special education teacher in New York City. But while Lee was living and working in the Bronx, he never quite abandoned his farming roots. He kept up an interest in the industry, particularly in new developments like vertical farming, which allows growers to produce food in vertically stacked layers, thus using a smaller footprint of space – within a shipping container or building, for example.

“I kind of became in-tune with vertical farming and urban farming in general, when I saw this Colbert Report back in 2008,” he says. “I just thought that was the coolest thing I’d ever seen.”

While Lee still had no intentions of going back into farming – at least not until he was retired – vertical farming piqued enough of an interest for him to set up a Google Alert, which yielded maybe an article every few months. Of course, that was all about to change.

Taking Vertical Farming to New Heights

Over the years, Lee’s Google Alert yielded more and more information, and in 2014, Lee decided to join the trend. He left teaching to found Green Top Farms, a hydroponic urban growing experiment. The farm grows microgreens, which are harvested daily and paired with local, seasonal ingredients to create delicious salads, which can either be ordered individually or, the company’s specialty, for “farm-to-work” salad bars, delivered right to your office.

“I don’t know if in a blind taste test it tastes better,” says Lee, “but for me, knowing where food comes from, it always tastes better, because it comes with a story, something behind it.”

Image care of Green Top Farms

Over the past three years, the project has grown exponentially, and now, Green Top Farms is looking for more space. The company’s new Kickstarterproject was created with the hope of moving into a new 1,000 square foot location that will combine hydroponic farming and kitchen.

“Right now we are completely squeezed where we are,” says Lee. “We have a very small growing operation, and everything we’re growing is being used.”

But while Lee and his colleagues can be applauded for their success, they are still encountering one major problem – a problem that’s plaguing not just these local food producers, but America’s food system on the whole: transparent sourcing. While Lee and his colleagues know exactly where their microgreens come from, they have to rely on external sources for their other salad ingredients, and sometimes, no matter how hard they try, even they don’t know where these foods are coming from.

Local Food Is A Question of Education

It was when Lee was first teaching that he realized what a huge problem the lack of transparency in our food system is.

“That’s where I really saw the night and day contrast with how I grew up and my relationship with food and farming and the kids I was teaching and their relationship to food and farming,” he says of the Bronx high schoolers he was working with.

“I remember interrupting the whole lesson several times to explain the difference between a fruit snack and a real fruit or explain why they spell cheese with a z in some of these ‘cheez’ snacks: because it’s not real cheese.”

Lee’s roots in education persist in his new career: he continues to teach people about these important issues through Green Top Farms.

“I tell our customers, ‘Well, we know where some of it comes from, but we don’t know where all of it comes from, and we think that’s a problem, so help us move in that direction of more transparency.’”

All deliveries are made with zero-emission vehicles. They go faster than regular bikes, so couriers can deliver more food in the same amount of time.

Fixing Our Food System One Salad At A Time

Green Top Farms is, at its core, a micro-solution to a macro-problem. From the depletion of the rainforests to the death of pollinators to the record rates of diabetes, problems related to food and nutrition are skyrocketing in this country, problems that Lee believes are all inextricably linked.

“I personally think that all of those problems come from the fact that we’re really just not in touch with what we’re eating,” he says.

“If you’re really serious about having a better food system, then we not only have to change some of the things we’re doing in farming and improve our distribution so that we’re not wasting so much food, we also have to change the way we’re eating,” he says. “And that’s on all of us.”

Green Top Farms is doing its part to reconnect people with their food: not only by growing it close to where people live, but in being open about all the work that still needs to be done. But at least as far as Lee is concerned, it’s a true labor of love.

“I’ve never been so broke, I’ve never eaten so well, and I’ve never been so happy, all at once,” he says. “I’m living my dream life, for sure.”

No Soil, No Sunshine, No Problem! Meet the Farmer of the Future, Growing Real Food Indoors

No Soil, No Sunshine, No Problem! Meet the Farmer of the Future, Growing Real Food Indoors

Kate Good

July 26, 2017

Okay, let’s be real – most of us have no clue what it takes to grow food … or much about farming, generally. But, despite our potential ignorance of the tenets of farming, most of us would say that in order to grow crops you need dirt, water, and sunshine. With these three things at the ready, all you have to do is add a few seeds, sit back and wait for tomatoes! Ah, how wonderfully simple (we guess…)!

Now, regardless of whether or not we know what it takes to grow food, there is one thing that the majority of people in the U.S. are wholly unaware of – where our food comes from. Chances are, you picture the above farming ideal when you think about the produce that ends up in your grocery store. In reality, most of our food is grown on a large-scale industrial farmwith the help of giant tractors and heavy machinery.

The bulk of the food grown in the U.S. is made up of things called “commodity crops,” such as corn, wheat, and soy. The majority of these crops are never fed to people but instead redirected to livestock, used in packaged foods, or relegated to the biofuel industry. In order to make these crops, which are grown en masse with little to no biodiversity, resistant to pests and disease, they’re frequently doused with herbicides, pesticides, and synthetic fertilizers. Once a field of monocultures has been farmed repeatedly, the soil becomes depleted of nutrients and therefore, the nutrition content and quality of the food goes down. Crops also become less resistant to bugs and infection, leading to the need for higher strength pesticides and herbicides – plus more fertilizer to make up for the depleted soil.

On top of this, produce that is grown in the U.S. travels an average of 1,500 miles to get from farm to grocery store – that’s like half the distance of the country. In order to make this possible, they have to be locked in refrigeration units and or frozen themselves, so when you finally get to the tomatoes in your grocery store – it more than often tastes like a potato with the consistency of a peach.

Adding insult to injury, our industrialized food system is failing to feed people – around one in nine people worldwide go to bed hungry every night and countless communities – many of which are in urban areas – are deemed “food deserts,” completely devoid of healthy, fresh, affordable foods.

So, if you’re like us, you’ve probably figured that mass producing food isn’t exactly the answer to feeding the growing population of Americans. In fact, our reckless industrial farming practices are rendering us less able to produce food, especially in the face of changing climate conditions.

But, since we need dirt, water, and sunshine to grow food … seems like we’re pretty set in our ways. Right? Well, Rob Laing, farmer of the future and CEO of Farm.One might beg to differ.

In a recent episode of the #EatForThePlanet with Nil Zacharias podcast, Rob explains how he is pioneering the world of hydroponics, a system of growing plants without many of the traditional inputs. Basically, using just a finely tuned solution of water, Farm.One can grow crops without soil or even sunlight. In fact, Farm.One is a unique indoor farm in downtown Manhattan, which uses hydroponics to reduce water use by around 95 percent, and advanced climate control technology to grow a wide variety of plants year-round without pesticides, pollution, soil contamination, herbicides, manure or waiting in cold storage.

His specialty is microgreens and specialty herbs, which he grows on demand for some of New York City’s top rated chefs, but he sees the future of farming as going far beyond this.

Listen in to hear how Rob thinks technology can transform the food system and help to create a more sustainable, healthy world!

Image source: Farm.One

You can listen to the full episode on the following platforms: iTunes, Google Play, Stitcher

If you like this episode, be sure to subscribe to the #EatForThePlanet with Nil Zacharias podcast for new episodes with food industry leaders, health, and sustainability experts, as well as entrepreneurs and creative minds who are redefining the future of food.

Grow Your Salad in Your Closet With The GrowChef Hydroponic Garden

GrowChefis a small indoor garden that promises to let you harvest a full pot of greens every day. Because why pay $15 for a salad when you can just make your own fresher version?

Grow Your Salad in Your Closet With The GrowChef Hydroponic Garden

By Lulu Chang — Posted on July 25, 2017 12:20 pm

WHY IT MATTERS TO YOU

Who needs a supermarket when you have GrowChef? This indoor hydroponic garden will let you make salad more often.

The nearest farmer’s market? Your kitchen. Thanks to the GrowChef, you can enjoy the goodness of fresh farm produce, even in the midst of an urban jungle. Heralded as the “ultimate hydroponic food generator,” the GrowChefis a small indoor garden that promises to let you harvest a full pot of greens every day. Because why pay $15 for a salad when you can just make your own fresher version?

Designed to live just about anywhere in your home, no matter how cramped your space may be, the GrowChef can be hung on a wall, set on a floor or a window sill, or even hidden away in a closet. Because of its three-color LED illumination, this little garden creates enough light on its own so you don’t have to worry about placing it in a sunny spot. And while it measures just 24 inches long, 30 inches tall, and 12 inches wide, it claims to produce the same harvest as a three-meter long garden bed.

Of course, because this is a 21st-century invention, the GrowChef comes with an app that allows you to monitor the progress of your plants. And given that you can grow up to 51 plants at once, that’s a lot of monitoring. Luckily, you don’t have to worry about potting any of these plants, as there’s no soil involved. There’s just nutrient solution and vermiculite, the former of which you replenish once a month.

The three tiers of the GrowChef correspond with three stages of growth for your plants. When you’ve just slid new pods into their slots, they go to the very top, where they’ll receive the most light. As they begin to grow, they can be moved to the second tier, where they can continue to develop. And finally, when they’re almost ready for harvest, you can move them to the bottom tier, which really gives the plants room to blossom.

“I’m delighted to bring people a new original opportunity to have fresh herbs on your plate every day,” said founder Viktor Pjatnitski of the hydroponic garden. “GrowChef helps you to eat healthier, [and] reduce your shopping list and expenses. After two and a half years of experiments, we’ve figured out how to perfect the hydroponic farm to constantly provide you with ready-to-eat plants.”

You can pre-order the GrowChef now from Kickstarter for $210, with an estimated shipment date of March 2018.

Indigenous Hydroponics System A Boon For Organic Farming

Agrico, a private local Qatari agricultural development company established in 2011 with the aim of helping Qatar achieve food security, operates a 120,000sqm (12 hectare) organic farm in Al Khor. Its first production was in May 2012.

Agrico managing director Nasser Ahmed al-Khalaf at his organic hydroponics farm in Al Khor. PICTURE: Joey Aguilar

Indigenous Hydroponics System A Boon For Organic Farming

July 25 2017 10:15 PM | QATAR | Joey Aguilar

A local farm in Qatar has developed a highly sophisticated hydroponics system capable of producing various types of organic vegetables and fruits in a bid to help the country achieve food security, it is learnt.

Organic eggplants at the 120,000sqm hydroponics farm in Al Khor

Speaking to Gulf Times, Agrico managing director Nasser Ahmed al-Khalaf said they made a lot of modifications in hydroponics farming to produce an all-organic fresh produce to meet the growing demand in Qatar.

Agrico, a private local Qatari agricultural development company established in 2011 with the aim of helping Qatar achieve food security, operates a 120,000sqm (12 hectare) organic farm in Al Khor. Its first production was in May 2012.

“The Asians, European or Western people have not developed a system that would be suitable for this area, especially for Qatar,” he stressed. “What we did is to develop our own system which is suitable for our environment.”

The local farm owner noted that vegetable-exporting countries in Asia, Europe, and America have the technology and knowhow in their region but inapplicable in the Gulf.

Al-Khalaf explained that regions with winter seasons such as Europe, especially those in the northern part, only have heating systems.

But in Qatar, he said they developed a cooling system that can reduce the temperature inside the greenhouse down to 16 degrees, depending on the variety of vegetables and fruits.

Some varieties need 16, 18 or 20 degrees, during a certain time of the day, for the plant to give the right texture, size, and taste, among others.

“Our vegetables they can last for a month on shelf without changing,” he said, adding that they can produce an average of 6 tonnes daily during the summer, which is 30% less compared to their production in the winter. The farm plans to produce more in the near future.

With this technology, he said Qatar has become one of the largest producers of organic vegetables in the world using what he described as a very promising and one-of-its-kind hydroponics technology.

Agrico Organic Farm in Al Khor produces 14 types of tomatoes.

“As long as you are providing the right temperature, right humidity, right amount of light (sun radiation), right fertiliser, and right amount of water, then you can grow anything,” al-Khalaf added. “I guarantee that all types of vegetables can be grown, I have tried this myself and we have been successful on this.”

Agrico has started growing five types of fruits, including papaya and lemon (experimental stage). It expects the plants to bear fruits in a year or two.

As Agrico products continue to supply more than 150 supermarkets and small outlets in Qatar, he said “there will be a lot of surprises soon.”

“We are going to produce root crops, fresh leaf and herbs such as coriander, parsley, green onion, basil, and mint, among others,” he said, adding that producing iceberg lettuce and other types, carrots, potatoes, and white onion, in the next few months.

While Qatar currently imports various types of fresh vegetable and fruits from European, Asian, and American countries, he expressed confidence that the country will soon achieve self-sufficiency.

He noted that even before the economic blockade imposed by the Saudi-led group on June 5, Qatar already has plans to import fresh produce in the future.

System suitable for livestock, poultry, fish farming

Apart from vegetables and fruits, local farm owner Nasser Ahmed al-Khalaf said the cooling system they developed is also suitable for livestock, poultry and fish farming.

“It is an integrated system, we take advantage of the vegetable greenhouses and in between we cool an empty wasted area using the cold air that comes out from the greenhouse,” he added.

Al-Khalaf explained that they harness this cold air, which comes out of the greenhouse, for testing an area of his farm for growing fruits. This can bring down the temperature from 45 degrees, for example, to 27 degrees in an open field.

The system, from temperature, humidity to sun radiation and water irrigation, has to be monitored round-the-clock seven days a week, according to the farm owner.

“Even if I am abroad I get a warning from my mobile phone if any abnormality happens,” he noted.

Vertical Farming Tour Visits Delval Programs

Vertical Farming Tour Visits Delval Programs

Chris Filling, hydroponics greenhouse manager, leads a tour of DelVal's greenhouses during an educational tour conducted by the state Department of Agriculture. Delaware Valley University photo

DOYLESTOWN, Pa. — As interest in vertical farming continues to grow, the Pennsylvania Department of Agriculture has been conducting an educational tour for its urban agriculture partners featuring hydroponics and aquaponics programs in Pennsylvania.

Delaware Valley University was the first stop on the tour, which kicked off Tuesday in the Philadelphia area.

Guests toured the University’s hydroponics and aquaponics greenhouses to see how DelVal is preparing students for these industries.

In hydroponics, growers use soilless systems for more precise control of inputs. In aquaponics, fish provide nutrients for plants in a soilless system.

These systems allow growers to produce food in unconventional places, using less space and resources.

“The hydroponics and aquaponics industries have tremendous potential to help solve pressing challenges, such as how to feed a growing population with limited resources,” said Chris Tipping, DelVal’s interim dean of agriculture and environmental sciences.

“At DelVal, we’re educating our students about these industries, and we’re also reaching out into the larger community to partner with other educational programs,” Tipping said. “There’s a real sense of excitement about hydroponics and aquaponics in Pennsylvania.”

Scott Sheely, special assistant for workforce development for the state Department of Agriculture, was part of organizing the tour.

“As schools, government officials and businesses look at ways to apply the technology to grow food in cities, there has been a demand for education on urban agriculture,” Sheely said.

“The Pennsylvania Department of Agriculture invited its urban agriculture partners to join it in visiting sites across Pennsylvania to learn more about this technology and how it is being used in the region,” he said.

“DelVal was chosen as a stop because the university is investing in research and education in hydroponics and aquaponics,” Sheely said.

DelVal President Maria Gallo and Tipping addressed the group.

DelVal is currently building a new specialization in hydroponics and aquaponics within its established Department of Plant Science, thanks to the support of DelVal trustee Kate Littlefield.

“This support was used to renovate two greenhouses as well as to provide the opportunity to create the first endowed professorship in DelVal history,” Tipping said. “This professor will lead the program.”

The tour also visited sites in Lancaster on Wednesday and Harrisburg on Thursday. Other stops included W.B. Saul High School, Metropolis Farm, Aero Development, Garden Spot Village, Steelton-Highspire High School, Ladder & Vine and Messiah College.

For Additional Information, please click on the link below:

Aquaponics at Home: A Modern Farmer Review of Turnkey Aquaponics Systems for All Levels

Back to the Roots, a self proclaimed urban homesteading company based in Oakland, California, offers goods ranging from stoneground corn flakes to organic mushroom kits. They now also offer a cute little tabletop aquaponics kit that contains everything you need to raise sprouts, herbs and a single (inedible) fish (minus the actual fish) in your kitchen window.

Aquaponics at Home: A Modern Farmer Review of Turnkey Aquaponics Systems for All Levels

By Brian Barth on July 18, 2017

Back to the Root's "Water Garden" kit makes a great entry to kitchen aquaponics.

Aquaponics—an environmentally-friendly mash-up of aquaculture and hydroponics—is just beginning to take off at a commercial level. But for homesteaders and hobbyists, it’s more feasible than ever to raise catfish and tomatoes together, whether in your garden, greenhouse, or a sunny window. Poopy fish water provides irrigation and nutrients to the produce, which in turn filter the water for the fish. What could be better?

I once built my own backyard aquaculture system, a semi-disaster which I detailed in a previous post. I wasn’t even attempting the hydroponics part, but just building a self-sustaining system to raise tilapia was a months-long slog of equipment failures and fish kills. I was trying to save money by going the DIY route, but in retrospect I would have been better off with a pre-fab model, one where professional engineers have worked out the kinks in the design.

There weren’t many on the market seven years ago when I started tinkering in my garage with visions of fish tacos dancing in my head. Today, though, there are a plethora. Some are suited for raising nothing more than a couple goldfish and a bouquet of herbs in your kitchen. Others are big enough to supplement a market gardener’s income with sales of hydroponic produce and organically grown fish. Here’s a brief rundown of the options.

Water Garden 2.0 by Back to the Roots, $99

Back to the Roots, a self proclaimed urban homesteading company based in Oakland, California, offers goods ranging from stoneground corn flakes to organic mushroom kits. They now also offer a cute little tabletop aquaponics kit that contains everything you need to raise sprouts, herbs and a single (inedible) fish (minus the actual fish) in your kitchen window. The kit includes a 3-gallon tank, filter, pump, hydroponic growing medium, fertilizer, fish food, and a coupon for a free betta fish, a fancy-looking aquarium fish also known as a Siamese fighting fish. Educational materials are included for classroom use.

Nelson and Pade Aquaponics Awarded 2017 Sustainable Product of the Year

The Wisconsin Sustainable Business Council awarded Nelson and Pade, Inc.® the 2017 Sustainable Product of the Year Award for small business. This is the second time that this prestigious honor was presented to Nelson and Pade, Inc.®, recognizing their Clear Flow Aquaponic Systems®.

Nelson and Pade Aquaponics Awarded 2017 Sustainable Product of the Year

MONTELLO, WI (PRWEB) JULY 13, 2017

Tom Eggert, Executive Director of the WI Sustainability Council (middle), presenting the 2017 Sustainable Product of the Year Award to John Pade and Rebecca Nelson, co-founders of Nelson and Pade.

The Wisconsin Sustainable Business Council awarded Nelson and Pade, Inc.® the 2017 Sustainable Product of the Year Award for small business. This is the second time that this prestigious honor was presented to Nelson and Pade, Inc.®, recognizing their Clear Flow Aquaponic Systems®.

The award was presented at the 2017 Sustainable Business Awards Celebration at Inpro Corporation. Rebecca Nelson, co-founder of Nelson and Pade, Inc.®, shares “We are truly honored to have been nominated and awarded the Sustainable Product of the Year Award in both 2014 and 2017. This recognition demonstrates our commitment to sustainability in Wisconsin and around the world.“

Nelson and Pade, Inc.® is the most trusted name in aquaponics, an innovative method of food production that combines aquaculture (fish farming) and hydroponics (soilless plant culture). In aquaponics, microbes naturally convert the waste from fish farming into an all-natural fertilizer for plant culture. Nelson and Pade, Inc.’s Clear Flow Aquaponic Systems® are designed to maximize these natural processes to grow fresh fish and vegetables year ‘round in any climate. To date, Clear Flow Aquaponic Systems® are used by individuals, entrepreneurs, schools, Universities and food banks in almost 30 countries.

Nelson and Pade, Inc.’s Clear Flow Aquaponic Systems® with ZDEP® (Zero Discharge/Extra Production) have revolutionized the aquaponics industry, providing users with a science-based, proven and profitable aquaponic systems. They are highly productive and continually produce fresh fish and vegetables, 365 days/year, without the use of pesticides, herbicides or chemical fertilizers. Two US patents are held by Nelson and Pade, Inc.® for their innovative designs.

When comparing lettuce production using 1 acre of Clear Flow Aquaponic Systems® to 1 acre of lettuce farming in the Gila Valley, Arizona, Nelson and Pade, Inc.’s systems grow 6 times more lettuce per acre using 1/6 of the water on an annual basis. The same system also produces 40,000 lbs. of fish. These systems are energy efficient as well, with a majority of the water flow achieved through gravity.

Nelson and Pade, Inc.® has its business campus in Montello, WI, where the systems, which are 90% made in the USA, are manufactured. Also on site is a state-of-the-art 14,000-sq. ft. greenhouse facility which houses commercial aquaponic systems for demonstration, a large classroom and the University of Wisconsin-Stevens Point: Aquaponics Innovation Center. Tours of the facility are available.

In addition to manufacturing systems, Nelson and Pade, Inc.® also offers the Nelson and Pade Grower Program and the Aquaponics Master Class®, which has been attended by individuals from over 100 countries.

For more information, visit http://www.aquaponics.com or contact Nelson and Pade, Inc., PO Box 761, Montello, WI 53949, USA, 608-297-8708, info@aquaponics.com

Hydroponic Paradox: Saving Water With Water

Hydroponic Paradox: Saving Water With Water

June 6, 2017

by Mary Allen

The local food movement has deep roots in urban centers, but the juxtaposition of urbanites’ locavore enthusiasm with the shortage of arable land in cities raises the question: how local is local enough? In terms of geography, there is no consensus or regulation around what “local food” should be. Depending on your definition (or marketing strategy), the term could refer to anything from food produced in your own backyard to food produced 100 miles away or simply within the state.

Community gardens and urban farming are obvious—if partial—answers to this paradox. And while urban farming is nothing new, there’s no denying that in recent years, rooftops gardens, vertical farms, and the like have become increasingly seductive to enterprising young farmers. Consumers, the media, and even investors are climbing on board with new urban farming initiatives as 21st century innovation pushes the limits of how and where food is grown.

This hydroponically grown basil has never touched soil or seen sunlight. | Image Source: @plantnasty

Hydroponic farming, a system in which plants are grown without soil and are nourished instead by a mineral solution, has enjoyed a groundswell of entrepreneurial energy in particular. As hydroponics are well suited to indoor spaces and environments that would otherwise be unfit for plant life, city centers are primed for the proliferation these wunderkind farms.

From the sweeping Alexander Ranch greenhouse in California and Bowery’s warehouse farm in New Jersey, to the intimate indoor Farm.One nestled at the heart of the Manhattan’s Institute of Culinary Education and the shipping container farms of Square Roots in a parking lot in Brooklyn, hydroponic farms of all shapes and sizes are cropping up across the country. The hyperlocality they offer to city-dwellers means not only that the food travels fewer miles, thus reducing the transportation footprint, but that the produce can be harvested and delivered on the same day.

Baby kale and butterhead lettuce from the behemoths Gotham Greens and Bowery can be found in grocery stores. Square Roots farmers hand-deliver their greens to offices around New York City. Farm.One, which is a specialty grower of microgreens and garnishes, serves high-end chefs and restaurants from just a subway ride away. With greens being among the most perishable of produce, this rapid delivery is especially attractive from a food waste reduction standpoint. Hydroponics becomes a compelling alternative to soil-based urban farming practices in light of its unique sustainability solutions.

Namely, it is remarkably water efficient. Seventy percent of humans’ water usage is allocated to farming and animal agriculture. Nitrate-ladened fertilizer runoff from traditional agriculture is also one of the main causes of water pollution, catalyzing algae blooms that ultimately create dead zones in our rivers, lakes, and oceans. In hydroponics, water is continuously recycled, making these systems anywhere from 90 to 98 percent more water efficient than traditional farming while eliminating fertilizer runoff. Needless to say, this drastic improvement in water efficiency makes hydroponic farming especially interesting in places like California where water is in short supply.

Hydroponic farming can be tremendously space efficient, too. In an interview with the Natural Gourmet Institute, Gotham Greens’ Nicole Baum enthusiastically notes, “Our half acre rooftop farm on top of Whole Foods Market in Brooklyn actually produces that of a 10 acre soil based farm!” Even more impressively, Bowery asserts that it produces over one hundred times more food than a traditional farm on the same footprint of land.

Part of the reason that hydroponic farms are able to grow so much more is that the plants have continuous ideal growing conditions—just the right temperature, just the right light, with no hungry animal intruders and no winter. The clean, climate controlled environments also eliminate the need for pesticides and insecticides. For the odd pest that does wander in, farmers enlist beneficial insects, such as ladybugs, to keep the peace. Being pesticide-free is a point of pride for Farm.One, Square Roots, Gotham Greens, and Bowery alike, something Bowery refers to as “post-organic.”

Rock wool is made from spun fibers of molten rock. This is one medium that hydroponic farmers use in lieu of soil to germinate seeds. | Image Source: @plantnasty

And here we encounter the discomfort hydroponic farming engenders among the soil-loyalists in the good food movement. A central tenant of organic farming is to “feed the soil, not the plant.” With hydroponics, of course, there is no soil, just plants—and manufactured mineral solution. The long term viability of an entirely human-fabricated growing environment is a big question mark for many. So while the notion of “post-organic” produce may thrill the food tech enthusiasts, strong advocates of pre-agroindustrial sustainable farming practices balk at the idea of food grown in plastic containers with artificial light.

Despite its water-saving potential, indoor hydroponic farming poses its own sustainability risks. These operations rely on LEDs, which stay on approximately 18 hours per day. Does drastically reducing water usage and water pollution justify the carbon footprint of all that electricity? It’s a question that hydroponic farmers are already taking into consideration. Farm.One, for instance, purchases carbon offsets to help mitigate this environmental cost.

But then there’s the actual cost. For all its efficiencies, hydroponics is a capital intensive process in a highly competitive market. A small bag of greens from Square Roots is $5. As Square Roots Cofounder and CEO Tobias Peggs explained at the monthly open house, the heavier a plant is—the more biomass it has—the more costly it is to grow. At this point in the game, hydroponic growers are focusing on greens. Fruits, vegetables, and tuber roots are not quite financially viable. But as the technology continues to improve, the price points continue to drop.

According to Rob Laing, CEO and founder of Farm.One, the price of LEDs is roughly halving every four years. Farm.One keeps their profit margins viable by selling high-end microgreens and garnishes, but Laing is hopeful that, “in five years time people can use the techniques that we’re using and similar equipment to grow lettuce and kale underneath a bodega.” Peggs is even more sanguine: “We think, two years from now, we’ll be able to economically grow strawberries, tomatoes, and blueberries as well.”

Technology is not the only thing setting hydroponics on the fast track to improvement; robust data collection is supercharging production capacity. Modern hydroponic farms are outfitted with sensors to monitor the plants, water, air, and light, and the farmers are growing not just crops but databases of information about how different factors influence flavor and plant health.

Farm.One's Red Rubin Basil, Saltwort, Red Veined Sorrel & Stems | Image Source: @farm.one

With different light recipes and nutrients, farmers can adjust certain variables to bring out different flavors. Some farms are even using machine learning to integrate and deploy these learnings. It’s a prospect that is remarkable to some and off-putting to others. As Dan Barber said in a conversation with co-founder of Square Roots Kimbal Musk at the Food for Tomorrow conference, “When Kimbal says you can dial in the flavor and colors you want, I don’t know that I want that kind of power,” Barber said. “I’d rather have a region or environment express color and flavor.” Agree to disagree perhaps. New Yorkers might not be as enthused about the taste of the subway expressing itself in their salad greens.

So what role will hydroponics play in the future of food? “People on both sides of the issue tend to overstate how big hydroponic farming is going to be,” Laing told Food Future Co. “It’s part of the solution.” He reminds us that hydroponics works well for greens but not at all for crops like wheat or corn. It can’t replace pig farms (leave that to Memphis Meats). It can’t replace olive groves. What hydroponics can do, however, is expand the possibilities for local food in urban spaces. It has many promising implications for sustainable food production. It may even serve as a more viable on-ramp for the next generation of farmers. Who knows? At the rate technology and data are changing the world, we really may be able to buy a locally grown, freshly harvested strawberry in the dead of winter from the corner bodega.

A Life And Career Unexpected

A Life And Career Unexpected

Dr. James Rakocy didn’t plan to spend his life in aquaponics, but it turned into a life-long passion.

June 28, 2017 | Chris Manning

Photo courtesy of James Rakocy

As a child growing up in Milwaukee, Wisconsin, Dr. James Rakocy did not plan on a career in aquaponics. While his family had a home garden and he enjoyed fishing and raising fish in an aquarium, his life took him in other directions. First, he joined the Peace Corps and served in Africa by teaching at a secondary school. Then, he was a teacher in Poughkeepsie, New York, before getting a master’s degree in environmental biology at the University of North Carolina. Finally, he took a job in environmental consulting with a focus on water quality.