Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

WEBINAR: How And Where To Site Your Indoor Farm | Indoor Ag-Conversations

JOIN OUR DECEMBER CONVERSATION!

LEARN MORE

Join our expert panel to discuss key factors to

consider when securing a location for your operation, including:

Consideration and determination of critical municipal requirements when siting an indoor vertical farm (zoning laws, water/energy sources)

How renewable energy, like solar and wind, is being incorporated into current indoor farming operations

Are vacant former retail facilities viable options for indoor vertical farms and if so, what are the key steps in acquiring such buildings

How to site an indoor farm within an existing and operational building

Critical areas to consider when investigating a building to be used as an indoor vertical farm

Moderator:

Kim Lovan, Managing Director and Co-Founder, NextGen Ag Team, Black & Veatch

Panelists:

Jake Counne, Founder, Wilder Fields

Tim McGuinness, Chairman, Sterling Advisory Group and Former Senior Vice President, International Council of Shopping Centers (ICSC)

Jim Pantaleo, Indoor Farm Operator | Advisor

LEARN MORE & REGISTER

SPECIAL THANKS TO OUR INDOOR AG-CON 2020

EXHIBITORS, SPONSORS, MEDIA ALLIES & INDUSTRY PARTNERS

Indoor Ag-Con, 950 Scales Road, Building #200, Suwanee, GA 30024, United States

Babylon Microfarms Bets On Automation For The Future of Vertical Farming

What started as a humble tabletop farm at the University of Virginia has since evolved into a major company to watch in the vertical farming space, particularly when it comes to the software piece of the process

What started as a humble tabletop farm at the University of Virginia has since evolved into a major company to watch in the vertical farming space, particularly when it comes to the software piece of the process. Babylon Microfarms has over the last few years garnered quite a bit of attention for its controlled-environment farms the company now licenses to hospitals, cafeterias, and other other foodservice operations.

Based in Charlottesville, Virginia (though soon moving HQ to Richmond, VA) Babylon makes a “plug-and-play” system for hydroponic farming that automates much of the grow process and makes controlled-environment farming more accessible. The company raised a $2.3 million seed round in January of this year and, its current product is a standalone farming unit that grows leafy greens.

Of late, however, the bulk of founders Alexander Olesen and Graham Smith’s focus is on software: namely, using it to automate the growing process, which removes the more complicated aspects of vertical farming that would be off-putting to the average user.

“Growing is a cumbersome experience for many,” Olesen explained to me over the phone this week. “Removing the friction of the user experience and combining that will some of the remote management [will make] smaller forms of vertical farming possible.”

Were the average person to try and build their own high-tech grow system, it would require significant expertise in horticulture, hardware infrastructure, and software development. To name just a few examples, that would include calculating one’s one LED light recipe (which takes the place of sunlight in controlled-environment ag), controlling the temperature of the farm, and understanding how much nutrient to feed each crop and when to do that. Everyday would require a certain amount of trial and error for every plant variety.

All of this makes for prohibitively high costs when it comes to commercial greenhouse production. Olesen noted that for controlled-environment farming to go mainstream, it has to be less technically complicated for the user.

Babylon’s software is one solution addressing those complications. The company’s “seed-to-sale” system automatically dispenses the right amount of nutrients, light, and water for each crop, simultaneously collecting data on the plants so that the system can make adjustments as needed. The entire system can be controlled remotely via a mobile app.

Up to now, the company has drawn comparisons to the likes of Farmshelf, Farm.One, and InFarm, all companies that license a hardware-software farming combination out to foodservice and hospitality operations.

But Babylon’s founders told me they aren’t necessarily interested in the hardware aspect going forward. Smith says they would prefer something like teaming up with a hardware manufacturer that wants to make vertical farms but perhaps needs more expertise in software to complement their hardware capabilities.

Such a scenario is actually on its way to becoming a reality. At CES this past year, hardware giant LG announced plans for a smart-farming appliance for the consumer kitchen. At the same time, GE Appliances showcased its Home Grown concept, which featured grow systems using hydroponics and soil-based methods. Prior to CES, Miele acquired Agrilution in another play for smart farms in the appliance space.

All of these hardware developments suggest great opportunity for the accompanying software. While many companies in the vertical farming space try to do both right now, Babylon’s future focus on being “an enabling company” that offers software and services may prove a wiser bid for the long term. Besides building out distribution of its own farms, Babylon is currently interested in working with other businesses, particularly those making hardware, that want to enter the vertical farming space.

There will be no one product that wins, Olesen said, adding that instead, it will be a combination of tools working together to make vertical farming more accessible to everyone.

FILED UNDER: AG TECH BUSINESS OF FOOD EDUCATION & DISCOVERY FEATURED FOODTECH

MODERN FARMER VERTICAL FARMING

PODCAST: DeMario Vitalis - Leaving Hydroponics Better Than How He Found It

New Age Provisions is an urban farm that uses state of the art hydroponic technology to farm the freshest culinary herbs, lettuces, leafy greens, and cannabis

THIS WEEK IN VERTICAL FARMING

THIS WEEK'S EPISODE

Season 2 | Episode 3

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show Founder of New Age Provisions, DeMario Vitalis.

New Age Provisions is an urban farm that uses state of the art hydroponic technology to farm the freshest culinary herbs, lettuces, leafy greens, and cannabis. In this episode,

Harry and DeMario discuss DeMario’s inspirational story, the success he’s achieving and how he’s bringing awareness to possibilities for minority farm owners.

DeMario speaks to challenges he’s had to overcome, how ‘food deserts’ are affecting communities throughout the world and the importance of having a supportive family and community.

VERTICAL FARMING PODCAST

Listen & Subscribe

Vertical Farming Podcast

Hosted by: Harry Duran

The Vertical Farming Podcast is the #1 show dedicated to the Vertical Farming market. Tune in every week for fascinating conversations with CEOs, Founders and luminaries from the exciting and fast-growing world of Vertical Farming. Vertical farming is a revolutionary approach used to produce food and medicinal plants in vertically stacked layers such as in a skyscraper, used warehouse, or shipping container.

It facilitates production of huge quantities of nutritious and quality fresh food without relying on favorable weather, high water usage, skilled labor, and high soil fertility.

This ensures reliable yield and consistency in crop production year-round with climate control, and no effects of external environment factors such as diseases, pests, or predator attacks. The Vertical Farming industry is projected to generate $12.77 Billion, Globally, by 2026 with a compound annual growth rate (CAGR) of 24.6%. Subscribe and learn more by visiting http://verticalfarmingpodcast.com/

Challenges With Airflow Strategies In Vertical Applications

As the industry continues to search for ways to maximize efficiencies, the utilization of LED lighting is becoming increasingly common. Aside from energy efficiency gains, one of the many benefits of migrating to LED’s is the ability to also maximize space utilization

As the industry continues to search for ways to maximize efficiencies, the utilization of LED lighting is becoming increasingly common. Aside from energy efficiency gains, one of the many benefits of migrating to LED’s is the ability to also maximize space utilization.

With less radiant heat and more consistent PPFD, cultivators are able to move lighting much closer to the plant canopy (in some cases less than 6”), which makes vertical, or multi-tier, cultivation far more feasible than with HID lighting.

The obvious benefit to tiered applications is the ability to increase canopy square footage without additional building square footage. Although there are some drawbacks to multi-tier growing, there can also be great reward, and so we’re seeing more and more of our clients choose to go this route in their facilities.

From an HVAC perspective

The challenge with multi-tier cultivation is twofold: first, we must ensure homogeneity to the entire canopy at multiple heights (that all plants at all levels are seeing the same conditions), and second, we must ensure that the HVAC system is getting adequate access to the hot, humid canopy air to ensure that it operates at full capacity.

When standalone dehumidifiers are in use (as opposed to integrated dehumidification systems), it’s doubly important. Dehumidifiers are typically ceiling-mounted and getting the humidity from the lower tier all the way to the ceiling is both difficult and absolutely vital to the proper operation of the dehumidification system. These requirements can be challenging even in single tier applications, so when the complication of airflow obstructions associated with multiple tiers of canopy are added into the mix, the need for specialized expertise becomes even more evident.

Unfortunately, it can be exceptionally difficult for cultivators to find and incorporate a well-designed airflow system for their racking design. While something is certainly better than nothing, one-size-fits-all strategies without the proper engineering can be difficult to dial in, often resulting in improper air speed over the canopy, uneven temperatures, higher than necessary cost or higher than necessary energy use in both HVAC and the air distribution system itself.

The variables must be considered

Various lengths of ductwork, various canopy heights, and various distances from the lighting source will all result in variances in airflow requirements. The speed of the airflow, the diffusion of the airflow, and the temperature of the air will all impact VPD and plant transpiration. As even LED lights vary in wattage and sensible heat output, so should the amount of air being displaced over the canopy to ensure that temperature goals are met.

While certain components of racking airflow systems can be utilized in multiple applications, some care must be taken in each application to ensure that the components being applied are appropriate—from duct diameter to static pressure and fan selection to diffusion strategies. And this is only contemplating what is required to deliver cooler, dryer air to the canopy. Delivering the hot, humid air to the air conditioning and dehumidification system must also be considered. Luckily, these are all challenges that can be addressed with the right experience and engineering expertise, and it doesn’t have to cost an arm and a leg.

The racking airflow design should be an integral part of the HVAC design

We are very happy to help any cultivator retrofit their existing racking systems with a well-designed airflow system, regardless of the HVAC system in use. With the proper engineering behind them, these retrofits can solve homogeneity and airflow challenges quite nicely and at a reasonable cost.

By the same token, what we find is that the most cost-effective and energy efficient multi-tier airflow strategies are those incorporated from the get-go as part of the HVAC design. Looking at it objectively, of course these systems should be incorporated at the HVAC design level when possible. Incorporating airflow over the canopy is a natural extension of the HVAC system. However, historically the industry has seen it as a separate challenge, or as a component of the racking systems themselves, and has largely considered only canopy air movement without considering how to ensure the HVAC system impacts the design.

Consistent airflow is achievable if designed right

The fact of the matter is, integrating the airflow systems with the racking systems is the easiest part. The hard part is making sure the airflow systems themselves are correctly designed to achieve their actual purpose: helping provide a cultivation environment that is consistently perfect.

When the multi-tiered airflow strategies within a room are considered as part of the HVAC design, all of the various airflow systems in the room are working in harmony instead of competing and interfering with each other, ensuring that everything operates as it was intended. This approach also minimizes the amount of equipment being utilized to achieve air distribution goals, which minimizes capital costs, overall connected electrical load, and energy use. It can even boost the energy efficiency of the HVAC system itself, by ensuring that air handlers have greater access to the hot, humid air at the canopy.

In any multi-tier application, a well-engineered racking airflow system design is an absolute requirement. However, we must stop thinking of these systems as components of racking, or as a design afterthought, and start thinking of them as an important part of the overall HVAC strategy.

Whether designing the system at the beginning of the room HVAC design or incorporating it after the fact, engineering and expertise that implements the racking airflow system as a vital component of the overall HVAC strategy will always yield the best results.

For more information:

Surna

Tel. +1 303 993 5271

www.surna.com

Staying On Track When The Path Keeps Zigzagging

On January 6, 2020, when I pulled the trigger to turn this dream of mine called “Second Chances Farm” into reality by hiring the first cohort of returning citizens who were formerly incarcerated, I had no idea how challenging 2020 would be

A Second Chances Farms Blog

by Ajit Mathew George

Sir Richard Branson is often credited with the saying, “If dreams don’t scare you, they are too small.” As the year 2020 draws to an end, I admit to you that my dreams for Second Chances Farm have scared me far more often than I want to admit. What a ride it has been.

On January 6, 2020, when I pulled the trigger to turn this dream of mine called “Second Chances Farm” into reality by hiring the first cohort of returning citizens who were formerly incarcerated, I had no idea how challenging 2020 would be. All startups are nerve-racking, but as a veteran entrepreneur, I thought I knew what I was getting into. But COVID scattered my best-laid plans like a tropical hurricane. We had to learn how to pivot to stay alive in these trying circumstances – to carve out a track when the path continued to zigzag.

It often seems that planning beyond the Coronavirus is an exercise in futility, especially in communities that are disparately devastated by the pandemic. Yet, our plans for Second Chances Farm in Opportunity Zones in Wilmington, North Philadelphia, Chicago and Las Vegas, all of which are in fresh-food deserts, will hopefully upend neighborhoods plagued by economic inequities and innovate in a way that transforms lives and social outcomes while addressing urban blight and economic decline.

Second Chances Farm hopes to jumpstart the lives of formerly incarcerated persons by providing a path of hope for the hopeless and by becoming a model for compassionate capitalism. We believe the best way to stop people from re-offending and returning to prison is to help them see a future worth working toward.

Fulfilling my dream depends upon that concept of “compassionate capitalism.” At Second Chances Farm, we’ve established a for-profit business model that is sustainable long-term because it is profitable. That’s the capitalism part.

But inextricably interwoven in the model is compassion – for our returning citizens, our disadvantaged neighbors, and local people living in food deserts. That’s why we’re located in an Opportunity Zone in the poorest area of Wilmington. That’s why we invest time developing partnerships that support the delivery food to Riverside, Wilmington, New Castle, and other forgotten neighborhoods. That’s why we’re investing in educating children and their parents on ways to eat healthy.

Of course, I strongly support non-profits in their mission and work to help people in crisis. But our business model is different: we want to give people the tools to become entrepreneurs in their own right – again, capitalists – to be successful in the future. And we hope, in turn, they may take on that mission to reach out to help nurture and train others going forward.

If there is any reason why we continue to be disrupters for good with our social impact project, please read this letter — published with permission — that I received this past weekend from someone I don’t know.

November 28, 2020

Dear Mr. George:

I am writing to you in hopes I can gather information regarding Second Chances Farm.

My nephew is presently in Pauling County Jail. His life’s story you most likely have heard and seen time and again. He got into a wrong group; trying to find acceptance by someone. Liam got himself in trouble with stealing, drugs took them) while he was dreaming for help inside... some direction... abusive home life starting at a very young age.

Liam is 19; had no childhood, as you and I may have known it. He is a good good soul. Just a rotten home life.

Liam almost graduated from high school but all the above was instrumental in why he didn’t. While in school he found agriculture very interesting and was going to further that education after graduation. He went from getting student of the month(s) to where he is... It’s a long painful life story.

His grandmother (my sister) he adores... he talks with her often (every day). I have been trying to help her deal with this crisis in her life mostly because she is battling breast cancer during all of Liam’s problems.

While looking for an agricultural future for him once released, my sister and I came across Second Chances Farm! We have been so excited about your wonderful program and I decided I’d write to you get more information on top of the very informative info on your site. Starting with the first step to completing what has to be done... I imagine an application to start. Would you be so kind as to provide me with this info and anything else to start the process of getting accepted into your stellar program.

Mr. George, this young man’s life. I know with the proper mentoring and guidance, can change and he can be a stellar human being if given the chance... he needs to know he belongs, self-worth and love.

I am hopeful with your help; giving Liam a second chance would be the beginning of a life yet to be lived. Thank you for any and all considerations. I will continue to pray that my prayers are being heard.

Sincerely, with thankfulness for your continued success in making this world a better place.

Susie Fricano

Greensboro, Georgia

This poignant letter embodies the compelling reasons why Second Chances Farm is needed in communities throughout the United States.

Today, less than a year after we opened our doors at 3030 Bowers Street, Second Chances Farm, LLC is the first commercial indoor hydroponic vertical farm in Delaware and one of the leading “smart farms” in the United States. More than 40 returning citizens have come to work, and some have come to stay. We’re a business, a support system, and a family. We are a public benefit corporation, certified minority business enterprise, a qualified opportunity fund and a Foreign Trade Zone. Our compassionate capitalism has created something entirely new: a for-profit solution to a non-profit problem.

For more information:

Second Chances Farm

www.secondchancesfarm.com

4 Dec 2020

PODCAST: Greenhouse Structures

This podcast will cover these questions and more. What is the budget for your greenhouse project?

Does the land have sufficient exposure to natural light? What kind of crop will you be growing?

Joe Swartz & Nick Greens | 12/4/2020

This podcast will cover these questions and more:

What is the budget for your greenhouse project?

Does the land have sufficient exposure to natural light?

What kind of crop will you be growing?

WEBINAR: Indoor Ag Science Cafe December 8th 11 AM Eastern Time

Indoor Ag Science Cafe is an open discussion forum, planned and organized by OptimIA project team supported by USDA SCRI grants

December Indoor Science Cafe

December 8th Tuesday 11 AM Eastern Time

Please Sign Up!

"Crop Growth Monitoring and Simulation-Based

Resource Use Optimization"

Dr. Murat Kacira & KC Shasteen

University of Arizona

Please sign up so that you will receive a Zoom link info.

Indoor Ag Science Cafe is an open discussion forum, planned and organized by OptimIA project team supported by USDA SCRI grants.

Sign Up Here

Center of Excellence Announces: Indoor Farming "Best in Class" Awards!

Indoor Farming

"Best in Class" Awards!

Who Can Enter

Indoor vertical farms

Plant factories

Greenhouses

Grow system solution manufacturers

Lighting companies

How to Enter

Go to: https://indooragcenter.org/awards/

Deadline for Submissions: January 15, 2021

Companies that score the highest in each category will be nominated for an “Indoor Ag Center Best in Class Award” (TM).

Learn More

Our vision is to accelerate the growth of the indoor farming industry. We believe we can do that by recognizing excellence. Consequently, we have embarked upon an ambitious program to collect bench-marking data on indoor farm operations and equipment used to run vertical farms and greenhouses. Each year we will review the data and publicly recognize key stakeholders for their excellence in several categories.

Become a Member of the Center of Excellence for Indoor Ag

Know an organization or an individual who would like to join the Center? Please forward this email.

Anyone can sign up for our mailing list or a free or paid membership by going to: https://indooragcenter.org

We are dedicated to providing unbiased insights on indoor and vertical farming.

Join the Center of Excellence

AUSTRALIA: A Brilliant Plan To Turn Parking Garages Into Rooftop Gardens

“It’s the third-largest land use in the city,” he says. Community space, on the other hand, ranks dead last. Bates Smart crunched the numbers and found that, in total, parking takes up nearly 1,200 acres of space, or more space than New York’s Central Park

Sourced from Fast Company

There are more than 41,000 parking spaces in the central business district of Melbourne, Australia. Many of them could be put to better use, says Julian Anderson, a director at the large Australian architecture firm Bates Smart.

“It’s the third-largest land use in the city,” he says. Community space, on the other hand, ranks dead last. Bates Smart crunched the numbers and found that, in total, parking takes up nearly 1,200 acres of space, or more space than New York’s Central Park. And if it’s not bad enough that these parking spaces take up so much space and encourage more driving, they also sit empty most of the time. “You think, my god, there’s one and a half times Central Park wrapped up in car parking in central Melbourne,” Anderson says. “What can we do to unlock this?”

One potential solution, he says, is to convert some of that parking into much-needed community space such as playgrounds, community gardens, and rooftop parks. And with a new mechanism his firm is developing in consultation with the city government, there may be a way to incentivize the owners of these parking spaces to make that happen.

Anderson says there are at least 20 standalone parking garages in central Melbourne that would be good candidates for reuse. Bates Smart has developed concepts for a few garages to serve as models for how this conversion could work, with some minor structural revision. One, located near the city’s main sports stadium, imagines the space converted into a series of playgrounds and gymnasia, with basketball courts and other recreational spaces. Another, in the city’s Chinatown, uses the ground floor as a market space and the rooftop as an outdoor eatery with open-air cinema. Anderson calls these potential projects a new kind of “vertical urban space.”

Source:https://www.fastcompany.com/90579163/a-brilliant-plan-to-turn-parking-garages-into-rooftop-gardens

Tagged: green roof, green roof benefits, living roof, living roof benefits, rooftop parks, rooftop garden, Melbourne, sustainability, resilience

RotoGro Executes Binding $10 Million Technology License Agreement With Verity Greens

The agreement is designed to provide RotoGro with a foothold in the expanding indoor urban vertical farming space as a technology and services provider

RotoGro executes binding $10 million technology license agreement with Verity Greens

RotoGro executed a binding Technology License Agreement with Verity Greens Inc. for the granting of manufacturing and technology use licenses. The agreement provides RotoGro with a foothold in the expanding indoor urban vertical farming space as a technology and services provider globally.

The agreement also facilitates the payment of annual software licensing fees and a long-term net profit share from the sale (by Verity) of perishable foods cultivated at facilities utilizing RotoGro technology for the initial 20-year term of the agreement. All of which are expected to generate long-term sustained recurring for RotoGro.

The agreement is designed to provide RotoGro with a foothold in the expanding indoor urban vertical farming space as a technology and services provider. It facilitates RotoGro providing Verity Greens with the opportunity to use and manufacture the company's patented and proprietary cultivation technology in the perishable foods field, consistent with the company's strategy to engage in less capital-intensive business partnerships and collaborations.

Read the complete agreement here.

For more information:

RotoGro

info@rotogro.com

www.rotogro.com

3 Dec 2020

CANADA - VIDEO: Agritech Startup Reimagines Hydroponic Farming

Dunya Habitats is developing modular “tiny farms” that stand about two metres high that can be combined in clusters

BY: OBJ staff

Dec 2, 2020

A team of entrepreneurs incubating their early-stage company in Kingston is hoping its modular hydroponic farming solution will help reduce food insecurity around the world – particularly in places acutely affected by climate change and shortages of arable land.

Dunya Habitats is developing modular “tiny farms” that stand about two metres high that can be combined in clusters. They allow farmers to grow produce year-round in any climate, ranging from freezing locales in the Canadian Arctic to drought-prone regions of sub-Saharan Africa, and are currently being tested in Kingston, Atlantic Canada, and Alberta.

“Hydroponics is a proven method. We’ve helped to optimize it,” says Sumi Shanmuganathan, chief strategy officer at Dunya Habitats.

Hear more of Shanmuganathan’s conversation with OBJ’s Mark Van Dusen by watching the video above

TAGS: Hydroponics.

CANADA: CEA Supplier Sustainitech Finds Capital Partner

Sustainitech's energy-efficient indoor farming system uses HIFI (High Intensity Farming Indoor) containers that realize increased crop density over industry-standard greenhouses and hydroponic vertical farms

FullCycle Climate Partners just announced their investment in Sustainitech, a controlled environment agriculture company based in Toronto. Sustainitech's energy-efficient indoor farming system uses HIFI (High Intensity Farming Indoor) containers that realize increased crop density over industry-standard greenhouses and hydroponic vertical farms. "Their technology consumes less electricity per unit of agricultural produce to achieve high crop yields at industry leading prices," they say.

"Sustainitech is an indoor farming technology developer focused on growing environments that are competitive to modern greenhouse farming. Their horizontal farming complex is designed to enable flexible and crop agnostic farming, creating the ability to grow high value produce up to 6ft tall, not possible in vertical farming," they say.

"With climate change's long-term impact on crop yield, this investment is particularly well-timed, given the new US administration's focus on infrastructure solutions to address climate change. Secular growth and political priorities are expected to have valuable implications for low-carbon technologies like Sustainitech and others in the FullCycle portfolio," they explain.

In a move expected to spur further development into the carbon-neutral economy, President-Elect Biden appointed John Kerry to lead the Presidential Envoy for Climate, and his $2 trillion clean energy investment package totals 20x the clean-energy spending in Mr. Obama's 2009 economic-recovery package.

"Climate change is a threat to global food security. The innovations pioneered at Sustainitech will allow communities to count on access to a wide variety of fresh, low-cost, and nutritious produce while reducing the climate impact from their food supply chain. We see Sustainitech playing a pivotal role in growing a wide range of crops in any climate at industry-leading costs and best in class energy usage," FullCycle Founder and Managing Partner, Ibrahim AlHusseini said in a statement announcing the investment.

Sustainitech fits well within the FullCycle portfolio. Their unit economics exceed FullCycle's IRR thresholds, and their Carbon-Return-on-Investment (CROI20) of Short-Lived Climate Pollutants (SLCP's) meets FullCycle's requirement of gigaton level carbon abatement. With this investment, FullCycle acquired substantial equity as well as exclusive rights to invest in the roll-out of Sustainitech's projects worldwide.

"As the demand for building larger facilities grows, we needed to find the right capital partner to scale us from the present through to a high growth future. Only FullCycle offers the right instruments, tools, and values to allow us to chart a path to a multi-billion-dollar horizon while keeping our focus on a sustainable future," said Sustainitech CEO Joey Hundert.

FullCycle also announced the appointment of Ann M. Veneman to their Board of Advisors. Previously Veneman was the United States Secretary of Agriculture, the first and only woman to hold that position to date. "I have spent much of my career in agriculture, and look forward to identifying promising and sustainable climate-friendly solutions," said former US Secretary of Agriculture Ann M. Veneman.

26 Nov 2020

Self-Sustainable Planter + Composter For Indoor Gardening

The planter features a companion app, which treats gardening as a game, showing the stages of plant growth as “levels” for your real-life veggies. If you were a teen in the late 2000s, you might remember the popular Facebook game, Farmville? Imagine that concept but in real life

02-12-2020 09:13 | Yanko Design

To reduce their environmental impact, my parents have started composting their food waste. Great idea, but there are two small problems with their set-up: one, my parents aren’t gardeners, so the resulting manure is usually scattered on empty soil beds (which the weeds appreciate), and two, the composter lives in the backyard, which means they keep a plastic container on the back porch for their discarded orange peels and wilted salad (not the prettiest sight). Overall, the composter is not living up to its full potential, because it doesn’t suit my parents’ lifestyle.

Segue to the Sustainable Family Farm, a miniature composter and planter that is best suited for indoor life. When I saw this design, my first thought was Ah-hah, the perfect Christmas gift for my parents … in theory, since it hasn’t entered the market yet. A mini-composter isn’t a novel idea; in fact, you can make your own with a plastic jug, soil, and some worms. However, the Sustainable Family Farm sets itself apart in two ways: first, by integrating seamlessly into the household regardless of the members’ gardening/composting experience, second, by making gardening into a fun experience for the family.

The product accomplishes this first point by utilizing all the food waste in the household without requiring a lot of additional effort. All you have to do is dump your compostable scraps into the plant incubator and monitor your veggies’ growth. The amount of maintenance that goes into the gardening depends on the seeds you choose — and there plenty of low maintenance options, like basil or cilantro. The Sustainable Family Farm accomplishes its second goal, making gardening a fun activity with the power of smartphones. The planter features a companion app, which treats gardening as a game, showing the stages of plant growth as “levels” for your real-life veggies. If you were a teen in the late 2000s, you might remember the popular Facebook game, Farmville? Imagine that concept but in real life. Or, you know … regular farming. (Jeez, I’ve exposed myself as a phone-addicted city-dweller.)

The Sustainable Family Farm, I think, is one of the most accessible urban planter concepts I’ve seen. Its low maintenance process makes it as easy as possible for anyone to grow herbs or small vegetables. You just need to buy the seeds and worms to get started – the circle of life takes care of the rest.

This concept won the European Product Design Award in “Home Interior Products/Household Appliances” and “Design for Society/Design for Sustainability.” An earlier version of this design was also featured on Yanko Design.

Designer: Chaozhi Lin

Click here for more information.

Photo Courtesy of Yanko Design

Global CEA Census Report Shows Continued Positivity Despite COVID-19

Autogrow and Agritecture Consulting have released the 2nd Annual Global CEA Census Report highlighting positive signs of growth despite the global pandemic

1 December 2020: Autogrow and Agritecture Consulting have released the 2nd Annual Global CEA Census Report highlighting positive signs of growth despite the global pandemic.

Data captured over an 8-week period show 95% of growers have an optimistic outlook for the next 12 months with all types of operations including greenhouses, shipping containers, tunnel, and vertical farms showing profitability.

“The optimism reflects what we have seen across many areas of the industry including increased technology adoption and increased consumer expenditure on fresh produce. And despite the challenges we’re seeing an overwhelming number of new entrants into the market,” says Autogrow CEO Darryn Keiller.

“What has not changed is the high percentage of new growers, almost 50%, that have no experience in agriculture before starting their business. That lack of experience has an impact on new technology solutions created and the need for more education to be available to support them. It also shows a real desire to make a difference considering their willingness to start during a pandemic.”

Respondents from 58 countries shared their views on their farming practices, financials, and the impact of COVID-19. The report also gave insight on three key growth regions around the world – India, the UK, and MENA (Middle East & North Africa).

"The results of the 2020 Census confirmed our hypothesis that the UK, India, and MENA regions are the emerging hotspots for CEA, albeit for different reasons. In the UK, Brexit is driving investment towards CEA to combat supply chain risks, while in India rising population and increased premium consumer demand for clean food are driving CEA. In the MENA region, government responses to COVID-19 have accelerated policies and incentives for developing scalable CEA solutions,” explains Agritecture Consulting Founder Henry Gordon-Smith.

“All of these regions present great opportunities for the CEA industry to grow and make a meaningful impact on their respective local conditions.”

Other takeaways from the Census:

68% of respondents are salad green growers

88% of growers surveyed are below age 50

29% of respondents receive funding from multiple sources

For a copy of the FREE report - https://engage.autogrow.com/census

INDIA: This Goa Couple Grow Their Veggies & Fish Without Using Soil or Chemicals!

On 185 square meters of greenhouse and rooftop garden, in their house at Dona Paula, Panaji, they produce 120 kilograms of fish a year and grow 3,000 plants consisting of vegetables and fruits

AUTHOR: GUEST CONTRIBUTOR

December 1, 2020

Goa-based Peter Singh is 74-years-old, and his wife Neeno Kaur is 65. They are a power couple, setting an example of how to be self-reliant with food, and at the same time, converting biodegradable waste into something useful.

On 185 square meters of greenhouse and rooftop garden, in their house at Dona Paula, Panaji, they produce 120 kilograms of fish a year and grow 3,000 plants consisting of vegetables and fruits.

For the last four years, they have been practicing aquaponics at home, a combination of aquaculture (raising fish in tanks), with hydroponics (cultivating plants in water).

However, they do with a twist. “We do aquaponics with permaculture,” says Peter Singh, explaining his system to a bunch of enthusiasts earlier this year.

(L) Peter Singh in his air-conditioned greenhouse that has plants which require a cooler climate. (R) Ornamental fish are grown in a fish tank

He adds, “We compost our kitchen and garden waste and use it in our aquaponics. Plants are potted in a layer of gravel, 1/3rd of coco peat, and 2/3rd of compost. So, our plants get compost plus fish waste, which results in a higher yield. I don’t use any chemicals for this, and I am taking care of my waste and my food.”

One may wonder why they are doing it. For them, the answer is simple–they want to eat organic and be sure of how their food is grown.

Moreover, both have a background in agriculture.

“I was studying Mathematics at the Delhi University; the idea was to stay in Delhi, but then we thought of moving back to our farms in Jalandhar, Punjab. We worked on different forms of agriculture, in which different fruit and timber trees were planted, we did intercropping in the orchard of oilseeds and pulses, produced seeds for the national seed corporation, had a dairy farm, did beekeeping and even exported the honey,” explains Singh.

They moved to Goa seven years ago and found it difficult to source organic vegetables. The majority of the vegetables in the state come from the neighboring city of Belgaum in Karnataka. So, they decided to grow their food in this unique way.

“As we have limited space in Goa, we experimented and discovered aquaponics. We downloaded papers from universities, and read about it. And came up with this model,” says Singh.

They opine that they are still experimenting and bring in changes accordingly. As they have the technical know-how and a background in farming, they are quite confident of their system.

How this system works

Peter Singh explaining the model

This system of aquaponics which involves the fish tank, NFT pipes, (Nutrient Film Technique) which are used to grow vegetables, water-pumps, and artificial grow lights, may look complicated. But Singh makes it easier to understand. He has also made a model of this system that can fit in any balcony or even in any corner of the living room.

“This unit of 2 ft by 6 ft and 6 ft high, with artificial lighting of 200 watts uses 250 litres of water and can grow 180 plants. One can grow lettuce, kale, bok choy or any other vegetable. One fish tank can sustain five kilograms of fish mass so that you can have ten fresh-water fish of ½ kg each,” elaborates Singh.

The system works mainly on electricity, water, and fish waste.

Singh explains, “In a fish tank, the fish waste is mainly ammonia. In this system, aerators circulate the water and create a current. The fish waste settles at the bottom, and the pipes take this waste into the bio-filter, which breaks the ammonia into nitrates and nitrites for plants to use.”

The water gets further filtered and goes back to the fish. It also has aeroponic towers which work as the nursery of plants. It is also a space-saving system as it is vertical.

“Because of heavy nitrogen, green vegetables grow very well. We have lettuce, bok choy, and celery. Also, this system uses 10 percent of the water used in traditional soil-based farming, as water is constantly getting re-used. The only loss is in the evaporation. There’s no need of watering, no weeding, one only has to feed the fish twice a day,” says Neeno Kaur.

The entire system has three fish tanks on the ground floor. One is of 3,000 litres of water; second is 1,500 litres, and the third is 4,000 litres. They raise three types of fresh-water fish—rohu, catla, and chonak or sea bass. If one does not eat fish, Singh suggests using ornamental fish.

The rooftop garden

On their roof, they have a greenhouse of 12ft by 24ft, which has 2,000 plants. The greenhouse in the back garden is 6 ft by 16 ft and has 500 plants. A roof-top garden has 25 fruit trees, 300 onions, and an assortment of chillies, lemons, tomatoes, aloe, chives, creepers like ivy gourd, bottle gourd, cucumber, bitter gourd, ladyfinger, brinjal.

Along a boundary on the ground floor, they have mango, banana, and papaya. They also have an air-conditioned tunnel of 8 ft by 12 ft in their greenhouse, with 1,000 plants of lettuce, kale, bok choy, basil, parsley, cabbage, and broccoli. For the whole system, they spend around Rs 14,000 per month.

The aquaponics system doesn’t require cleaning of water as the water gets filtered in the process. And all the fittings are made by Singh himself. He has also part-time workers for about six hours a day. He adds, “We spend Rs 6,000 on electricity, Rs 4,000 on feeding the fish, and another Rs 4,000 on labour.”

They won the first prize for Most Innovative Stall at the Aqua Goa Mega Fish Festival 2020 held in February.

Agriculture expert from Goa, Miguel Braganza opines, “Peter Singh’s aquaponics is good for those who can afford it as the basic cost of the unit is Rs 30,000. Also, it is ideal for those who eat salads and continental cuisine.”

Regarding the cost, Singh states that it is high “because we pump water from the ground floor to the greenhouse on the roof. If it is on the same floor, this is much lower.”

They also have plans for solar panels and making fish feed at home to be self-sustainable. He adds, “If we automate the system, and put in solar power, then costing will go down substantially. We are also working on growing feed for fish. So our whole system becomes self-dependent.”

However, they are also trying to monetise from this system, by conducting two-day training programmes priced at Rs 5,000. Singh adds, “We also custom design and help set up aquaponics systems, of any scale, from small home systems to commercial systems, charging 10 per cent of the capital cost for the design.”

(L) Bok Choi grown in aeroponic towers. (R) Gourds grown on the roof.

Recently, they started selling these vegetables from their home. A basket contains two bunches of lettuce, a baby bok choy, three sticks of celery, sprigs of parsley, basil, and a small bunch of mint, priced at Rs 100. They will also add kale and Swiss chard to it. From next month, their air-conditioned model will produce about 300 packs of greens a month at Rs 120 each.

Singh and Kaur are hopeful that more people will learn from this system and eat healthy food as it is the need of the hour.

He concludes, “This method is independent of the weather, rain, hail, and sun; it is protected from predators and is the future of agriculture. It doesn’t need land, soil, or chemicals, and produces vegetables and fish wherever you are.”

Also Read: Experts Answer: Can a Hydroponics Farm Be a Good Business? Here’s How!

This shows that aquaponics could be next best thing in agriculture due to urbanisation and loss of agricultural land. It is estimated that the market of aquaponics will grow with the awareness to eat healthy food.

According to a report by Assocham and Ernst & Young, organic products market in India have been growing at a CAGR (Compound Annual Growth Rate) of 25 percent, expected to touch ₹10,000-₹12,000 crore by 2020 from the current market size of ₹ 4,000 crore. As aquaponics is a part of the organic market, the future looks bright for this new-age form of agriculture.

During the current nationwide lockdown to tackle COVID-19, Peter Singh is selling their produce once a week from their home by maintaining social distancing. He says, “We slowed down the sale of our produce in the first week, and worked out a weekly production schedule, which includes a weekly harvest and transplantation. This means we will be able to supply every week all year round.”

Lead photo: Peter Singh is 74, and his wife Neeno Kaur is 65. Together, they grow 3,000 plants on just 185 sqm by a method that’s independent of the rain, hail, and sun!

(Written by Arti Das and Edited by Shruti Singhal)

JAPAN: Producing Electricity While Producing Wine Thanks To A Greenhouse

Fujisan Winery is building the new greenhouse as part of a sustainability model on how they operate as a company and contribute to the Sustainable Development Goals as adopted by the Fujinomiya Administrative County where the winery is located

The ASX-listed ClearVue Technologies has landed its first order in relation to a greenhouse project.

The order for about 30 square meters of ClearVue’s insulated window or glass units, or “IGUs” incorporating solar photovoltaic cells came from the Japanese company Fujisan Winery, which is located at the base of tourist mecca Mount Fuji in Japan.

Fujisan Winery is building the new greenhouse as part of a sustainability model on how they operate as a company and contribute to the Sustainable Development Goals as adopted by the Fujinomiya Administrative County where the winery is located. The greenhouse is to be located on the Asagiri Plateau at the southwest base of Mt Fuji with spectacular views across the plateau to the Mt Fuji volcano itself. The region is a key destination for tourists and visitors to Mt Fuji.

The greenhouse is to be used by the winery to grow produce and vine stock on-site and may be used for corporate events and promotion for the winery. In addition to the greenhouse, Fujisan Winery will build a new 40 seat fine dining restaurant adjacent to the greenhouse and other outbuildings as part of a larger winery expansion project.

The ClearVue IGU panels are currently being manufactured for expected delivery in Japan by the end of December 2020 with the installation of the glazing into the newly constructed sustainable greenhouse anticipated to commence by late January 2021. The greenhouse is expected to be opened with the winery restaurant in or around March 2021.

Commenting on the greenhouse, Architect for the project, Paul Ma has said: “We specialize in the master planning of sustainable resort projects. When we first met with ClearVue founder Victor Rosenberg we were simply blown away by the potential for deployment of the ClearVue technology and product into our sustainable architectural design projects. We have watched with interest the continued commercialization of the ClearVue product to this point and can now explore how we might deploy it in our client work.

The greenhouse project in Japan whilst small is a great project for us to use as an example for such future project work and represents a great showpiece for Fujisan Winery who have a deep commitment to sustainability in their wine production and business operations. The region in which they operate the winery also has a stated commitment to meet the UN Sustainable Development Goals and seeks the same from its constituents. The winery expansion project will explore several different sustainable solutions in addition to the ClearVue technology and will itself become a destination and showcase for sustainable design worldwide.

Commenting on the Fujisan Winery greenhouse project, ClearVue CEO Ken Jagger has said: “We are very pleased to be working with the Paul Ma Design team on this leading-edge sustainable design project. The innovative and high-profile nature of the project and this use of the ClearVue product is an exciting development for the Company. We very much look forward to both updating the market on the Fujisan Winery greenhouse as it progresses and to a long working relationship with the Paul Ma Design team on future projects.”

For more information:

ClearVue PV

http://www.clearvuepv.com/

27 Nov 2020

Infarm Drives Expansion of Urban Farming in Japan

The first farms will be installed by Infarm at Summit's Gotanno location, in conjunction with the store's rebuilding in December 2020, and produce will be available for purchase at Summit Gotanno store at the end of January 2021

NEWS PROVIDED BY

02 Dec, 2020

Infarm's rapid growth in Asia continues with new agreement to offer freshly-harvested produce to Summit supermarkets in the Tokyo metropolitan area

Following partnerships announced with East Japan Railway Company (JR East), food retailer, Kinokuniya and distributor Muroo Co. Ltd, Infarm produce to appear at partner retail locations starting in January 2021.

TOKYO, Dec. 2, 2020 /PRNewswire/ -- Infarm, the world's fastest-growing urban farming network, announced today a partnership with Summit Inc., a wholly-owned subsidiary of Sumitomo Corporation Group to offer fresh produce grown and harvested at the company's Summit Store (supermarket), one of Tokyo's leading supermarket chains. With annual revenue (as of March 2020) of USD 3B, Summit Inc. has 120 retail locations across the Tokyo metropolitan area. The first farms will be installed by Infarm at Summit's Gotanno location, in conjunction with the store's rebuilding in December 2020, and produce will be available for purchase at Summit Gotanno store at the end of January 2021.

This announcement marks Infarm's second major partnership in Japan. The company first expanded into the market through partnerships with East Japan Railway Company (JR East), food retailer, Kinokuniya, and national food distributor, Muroo Co. Ltd, announced in February 2020. Infarm produce will first be available to Kinokuniya consumers on January 19, 2021, at the Aoyama International flagship store and on January 23, 2021, at the Nishi-Ogikubo store located at the JR Nishiogikubo station. Additional Kinokuniya stores are expected to follow through 2021.

"We are very pleased to partner with Infarm. Since last year, we have been communicating with Erez and Mr. Hiraishi, and our business vision and chemistry matched with each other, which led to this partnership. We look forward to serving our customers with Infarm vegetables at our Gotanno store, an important flagship store for Summit," commented Junpei Yamamoto, Executive Officer of Summit Inc.

"Japan's busy urban centers present a unique opportunity to improve the way millions of people get access to fresh, sustainable produce. We're proud to partner with Summit as we continue to grow in this dynamic market. Summit's commitment to offering high-quality food to customers at all price points, while reducing waste and making shopping enjoyable, aligns perfectly with Infarm's vision to make fresh nutritious food available to everyone," commented Erez Galonska, co-founder and CEO of Infarm.

According to some estimates, Japan relies on imports for about 60% of its food, contributing to a tremendous amount of cumulative food miles, while annual food waste has been estimated to have reached more than 6.12 million tons[1]. In addition, Japan has one of the highest rates of pesticide use in the world according to estimates offered by the FAO.[2] By partnering closely with Japanese clients, Infarm hopes to make a positive contribution to retailer efforts to reduce the negative environmental impact of produce with fresh food that is grown as closely as possible to the point of consumption.

"We continue to experience positive momentum in Japan and believe our approach to farming will be attractive to Tokyo consumers. Our clients can be sure that our harvesters have taken care of each plant as if it were in their very own garden, full of flavour and pesticide-free. We're convinced that Infarm shoppers will taste and notice the difference," said Ikuo C. Hiraishi, Managing Director, Infarm Japan.

Infarm has developed the world's most advanced, easily scalable and rapidly deployable modular farms that can transform any retail space and fulfil any market demand. Each in-store farm offers a controlled environment with growing recipes that bring out the natural flavour and properties of each plant.

The individual farms are connected and remotely controlled from a central farming platform that gathers up-to-the-minute information about each plant's growth and learns, adjusts and improves itself continuously, so each plant grows better than the one before.

Infarm staff regularly visit the farms to harvest mature plants, place them at the point of sale, and plant new seedlings for the next cycle. Consumers have access to the plants at their freshest points, still alive with their roots, free of pesticides and full of nutrients and flavour.

"Flavour for me is a primary concern - as I want to offer each of my customers a unique experience that both surprises and delights the palate. Being able to use herbs and lettuces freshly harvested from Infarm gives me a personal garden to be creative and make my dishes sparkle - it's an experience that can really transform your cooking as a chef or for your family at home," said Tim Raue, Infarm client and Michelin-starred chef of Restaurant Tim Raue in Berlin.

Founded in 2013, Infarm is one of the world's largest urban farming platforms harvesting and distributing more than 500,000 plants each month across its network. Infarm currently operates across Canada, Denmark, France, Germany, Japan, Luxembourg, the Netherlands, the United Kingdom, the United States and Switzerland where it has deployed more than 1,200 farms in stores and distribution centres. Since 2013 the company has raised more than 300 million USD.

About Infarm

Infarm was founded in Berlin in 2013 by Osnat Michaeli and the brothers Erez and Guy Galonska. Passionate to become self-sufficient and eat better, they were growing their own food, enjoying all the flavour and nutrients, without the chemical pesticides and transport kilometres. With the aim to share the goodness of own-grown produce with everyone, they developed a smart modular farming system, that allows distribution of farms throughout the urban environment, growing fresh produce in any available space and fulfilling any market demand. Today, with cutting edge R&D, patented technologies, and a leading multi-disciplinary team, Infarm is growing a worldwide farming network helping cities become self-sufficient in their food production while significantly improving the safety, quality, and environmental footprint of our food.

With a multinational team of 700 people globally, Infarm has partnered with more than 30 major food retailers including Albert Heijn, Aldi Süd, Amazon Fresh, Auchan, Casino, E.Leclerc, Edeka, Empire Company Ltd (Safeway, Sobeys, ThriftyFoods), Farmdrop, Intermarché, Irma, Kaufland, Kinokuniya, Kroger, Marks & Spencer, Metro, Migros, Selfridges, Selgros, Summit and Whole Foods Market in Canada, Denmark, France, Germany, Japan, Luxembourg, the Netherlands, the United Kingdom, the United States and Switzerland, deployed more than 1200 farms in stores and distribution centres, saved more than 40,000,000 litres of water and 50,000 square meters of land, while harvesting 500,000+ plants monthly and growing.

About Summit

Summit Inc. was established in 1963 in Tokyo, 100% owned by Sumitomo Corporation. Summit has spread across the Tokyo metropolitan area with 120 supermarkets. The annual revenue as of March 2020 is USD 3B.

[1] https://www.gov-online.go.jp/eng/publicity/book/hlj/html/202005/202005_09_en.html

[2] http://www.fao.org/faostat/en/#data/EP/visualize

SOURCE Infarm

Sky-High Vegetables: Vertical Farming Sprouts In Singapore

Entrepreneur Jack Ng says he can produce five times as many vegetables as regular farming looking up instead of out. Half a ton of his Sky Greens bok choy and Chinese cabbages, grown inside 120 slender 30-foot towers, are already finding their way into Singapore's grocery stores

November 9, 2012

Singapore is taking local farming to the next level, literally, with the opening of its first commercial vertical farm.

Entrepreneur Jack Ng says he can produce five times as many vegetables as regular farming looking up instead of out. Half a ton of his Sky Greens bok choy and Chinese cabbages, grown inside 120 slender 30-foot towers, are already finding their way into Singapore's grocery stores.

The idea behind vertical farming is simple: Think of skyscrapers with vegetables climbing along the windows. Or a library-sized greenhouse with racks of cascading vegetables instead of books.

Ng's technology is called "A-Go-Gro," and it looks a lot like a 30-foot tall Ferris wheel for plants. Trays of Chinese vegetables are stacked inside an aluminum A-frame, and a belt rotates them so that the plants receive equal light, good airflow, and irrigation. The whole system has a footprint of only about 60 square feet or the size of an average bathroom.

Troughs of bok choy stack up vertically at the 30-feet urban farm in Singapore. The veggies rotate along the A-frame to ensure they receive even light. Courtesy of MNDSingapore.

Advocates, whose ranks are growing in cities from New York City to Sweden, say vertical farming has a handful of advantages over other forms of urban horticulture. More plants can squeeze into tight city spaces, and fresh produce can grow right next to grocery stores, potentially reducing transportation costs, carbon dioxide emissions, and risk of spoilage. Plus, most vertical farms are indoors, so plants are sheltered from shifting weather and damaging pests.

But is vertical farming just a design fad, or could it be the next frontier of urban agriculture? That depends on your angle — and location.

Implementing these "farmscrapers" on a commercial scale has been challenging, and making them economical has been almost impossible.

It's still up for debate whether vertical farms are more efficient at producing food than traditional greenhouses, says Gene Giacomelli, a plant scientist at the University of Arizona, who directs their the Controlled Environment Agriculture Center.

The limiting factor is light. The total food produced depends on the amount of light reaching plants. Although vertical farms can hold more plants, they still receive just about the same quantity of sunlight as horizontal greenhouses.

"The plants have to share the existing light, and they just grow more slowly," Giacomelli tells The Salt. "You can't amplify the sun."

For American cities, like New York and Chicago, Giacomelli thinks putting plain-old greenhouses on rooftops could be just as efficient as vertical farms – and a lot easier to implement.

In fact, two companies are already working on that approach. Gotham Greens is producing pesticide-free lettuce and basil for restaurants and retailers from rooftop greenhouses in Brooklyn, while Lufa Farms grows 23 veggie varieties in a 31,000-foot greenhouse atop a Montreal office building.

But for the island of Singapore, where real estate is a premium, vertical farming might be the most viable option. "Singapore could be a special case, where land value is so exceptionally high, that you have no choice but to go vertically," Giacomelli says.

An illustration of the 177-feet vertical farm by Plantagon currently in the works for Linkoping, Sweden.

The Sky Greens vegetables are "flying off the shelves," reports Channel NewsAsia — perhaps because the vertical veggies are fresher than most available in Singapore, which imports most of its produce from China, Malaysia, and the U.S. They do, however, cost about 5 to 10 percent more than regular greens.

"The prices are still reasonable and the vegetables are very fresh and very crispy," Rolasind Tan, a consumer, told Channel NewsAsia. "Sometimes, with imported food, you don't know what happens at farms there."

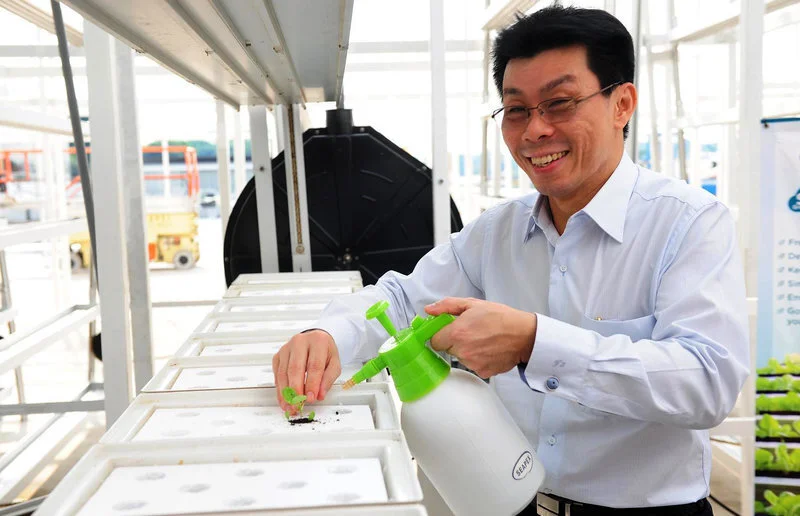

Lead photo: Senior Minister of State Lee Yi Shyan transplants some leafy green seedlings at the grand opening of Singapore's first commercial vertical farm. Courtesy of MNDSingapore.

Utah Farm Using Robotic Vertical Farming To Feed Their Animals For Less

"The key is you can eliminate the weather challenges and it can give you a predictable optimized crop every time," said Steve Lindsley, the president of Grōv Technologies

The Future of Farming Is Here In Utah, All Thanks To Something Called

Robotic Vertical Farming

By: Jordan Hogan

Posted at 8:19 AM, Nov 29, 2020

and last updated 7:08 AM, Nov 30, 2020

MOSIDA, Utah — A Utah tech company, Grōv Technologies, is working with a local farm, Bateman and Mosida Farms, to produce food for their cows more efficiently.

It's being done in towers that handle the whole growing process from start to finish.

The farm produces milk and meat from their cows, but raising them takes a lot of feed and a lot of time.

Now, technology is making part of the process easier.

Olympus Tower farms made by Grōv are a form of robotic vertical farming.

"The key is you can eliminate the weather challenges and it can give you a predictable optimized crop every time," said Steve Lindsley, the president of Grōv Technologies.

It starts with wheat seeds being loaded into trays. Then, they're wheeled up to the top of the tower to start a six-day journey back down to the bottom of the tower for harvest.

Along the way, they're watered with precision and given light from special LEDs that don't give off any heat.

The whole process is automated too, meaning it can run without the help of many traditional farmhands.

Grōv says each one of the towers produces 6,000 lbs of food each time it goes through its cycle. That saves money, time, water and energy. The benefits don’t stop there either — they are then passed on to the consumer.

"Each of these machines represents between 35 and 50 acres of land, so in this case here, it's the same as 50 acres of land but it's only covering 875 square feet of the ground and it uses 95% less water to grow the crops," said Lindsley.

Saving water and space is something that's becoming increasingly important as the demand for more homes increases and climate change increases the chances for extreme drought in the summer months.

"One of the biggest challenges farmers have around the world is how do they deal with the weather, the climate, and the uncertainties that come with that," Lindsley said.

The new technology couldn't have come at a better time for the farm either.

"In the first weeks and the first month of the COVID-19 Pandemic things started to go a little bit crazy," said Brad Bateman, a farming operations partner at Bateman Mosida Farms.

He said the farm wasn't able to order in a lot of their feed at the beginning of the pandemic, threatening the cows' food supply.

Now they can rely on their own production of feed, and this model of farming could be adopted beyond farms in the future.

"The vision that I see is there’s probably one of these in the back of every supermarket growing fresh food right in the store," said Bateman.

Grōv Technologies told FOX 13 they plan on rolling out this technology worldwide once they reach agreements with other farms.

What COVID Means For Indoor Ag Lending

Contain works with a pool of lenders to help indoor farmers find lease financing for their farm builds

By Nicola Kerslake

"This year has been strange for everyone, and lenders are no different. They live in a world of rules, and stats and data. And there’s almost no way to account for a once-in-a-lifetime pandemic in that world view," says Nicola Kerslake, Founder and CEO of Contain Inc. Contain works with a pool of lenders to help indoor farmers find lease financing for their farm builds.

"Ahead of this week’s Thanksgiving holiday here in the US, we caught up with some of those lenders to talk about surviving 2020 and looking forward to 2021," Nicola adds.

Nicola Kerslake, Founder and CEO of Contain Inc.

Nicola states that indoor farmers generally find credit from three sources: banks, private lenders and government lenders. During March and April, many lenders effectively shut up shop for new loans and leases: “we saw volumes drop by 90%” said one of the private lenders that Contain works with.

Government funding

As government funding supplied by the CARES Act kicked into action, banks were preoccupied with dispersing the paycheck protection program (PPP) loans that kept many small businesses afloat for a while, leaving less time to work on private lending. At a Brookings Institute event in April, KeyBank’s CEO said that it usually completes around 50 loans per month, but this leaped to 37,000 in the first half of April alone, thanks to the PPP program.[1] Elsewhere, several online business lenders, such as Kabbage and OnDeck, stopped initiating loans altogether.

"Now that the dust has settled, private lenders are back to business, with a few tweaks. Universally, the lenders that we spoke with saw indoor agriculture as a beneficiary of the COVID-era: “everyone has to eat, so farming looks like a better option now” one told us. They’re especially interested in seeing farms that supply to supermarket- and institutional buyers," Nicola affirms.

Other beneficiaries include testing labs and home gym equipment providers, whilst restaurants, gyms and salons were of course the worst hit. Lenders remain loath to issue new loans in these sectors, and are instead focusing on helping their existing borrowers navigate through difficult times. Nicola adds, "For instance, one lender told us he had allowed affected businesses to defer a few months’ payment to the end of their leases."

There are a few tweaks

Lenders are taking the time to check on local lockdown restrictions, concerned that unpredictable mandates could swiftly curtail farms’ ability to sell produce. Some are insisting on higher deposits for loans, and on stronger overall balance sheets. This approach is especially hard on startup farms, which generally have less capital of their own to deploy than longer-standing farms.

What will 2021 bring?

"Most of the lenders we spoke with were cautiously optimistic, citing resilient business results in areas that remain open and the promise of imminent vaccine rollouts. Across the market as a whole, rates are expected to stay low for the foreseeable future. Despite this, as one lender put it: “we’re not even going to be able to start talking about ‘normal’ again until the second quarter of next year"," Nicola says.

For more information:

Contain Inc.

Nicola Kerslake, Founder and CEO

nicola@contain.ag

www.contain.ag

Publication date: Mon 30 Nov 2020

Author: Rebekka Boekhout

© VerticalFarmDaily.com