Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

AeroFarms and Nokia Unveil Partnership for Next Generation AI-Enabled Plant Vision Technology

AeroFarms and Nokia Bell Labs today unveiled a groundbreaking multi-year partnership to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels.

August 5, 2021

NEWARK, N.J.--(BUSINESS WIRE)--AeroFarms and Nokia Bell Labs today unveiled a groundbreaking multi-year partnership to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels.

As part of this partnership, AeroFarms, a Certified B Corporation and global leader in indoor vertical farming, contributes its commercial growing expertise, comprehensive environmental controls, an agriculture-focused data platform, and machine vision core foundation. Nokia Bell Labs, the world-renowned industrial research arm of Nokia, contributes its groundbreaking autonomous drone control and orchestration systems, private wireless networks, robust image and sensor data pipelines, and innovative artificial intelligence (AI) enabled mobile sensor technologies. This combination of innovative technologies allows AeroFarms to reach the next level of imaging insights that further enhance its capabilities as an industry leading operator of world-class, fully-connected smart vertical farms that grow the highest quality plants all year round.

AeroFarms and Nokia Bell Labs have been working together since 2020 and have reached an important milestone of achieving a proof of concept for this state-of-the-art integrated system and testing the technologies with AeroFarms’ current commercial crop varieties. Together, they are now ready to scale this system to all of AeroFarms’ crops and future indoor vertical farms, including the next ones in Danville, Virginia and Abu Dhabi, UAE.

The integration of Nokia Bell Labs’ AI-enabled drone-based sensors and advanced machine learning, computer vision and data analytics technologies with AeroFarms’ existing machine vision tools enhances and elevates AeroFarms’ position as an agriculture platform and capabilities organization dedicated to solving food and agriculture supply chain challenges.

David Rosenberg, CEO at AeroFarms, said: “With Nokia Bell Labs, we have developed the next-generation system that can image every plant every day in a cost-effective way at scale. This level of detailed imaging and insights helps us be better farmers by monitoring our plant biology dynamically and allowing us to course correct as needed to ensure the highest level of quality all year round. When I watch the drones autonomously imaging our plants, I am blown away by how this truly represents the power of harnessing leading-edge technologies and bringing brilliant problem solvers together from diverse groups to grow the best plants possible.”

Roger Buelow, CTO at AeroFarms, said: “AeroFarms’ expert team of plant scientists and engineers have been working together for two years with Nokia Bell Labs’ top researchers and engineers to train these complex learning systems with a nuanced understanding of plant biology. We have created a cross-disciplinary understanding at an industrial scale to develop the latest imaging technology to help accelerate our ability to introduce new crops and ensure the highest quality for our commercial operations.”

Nokia Bell Labs’ machine vision technology has enabled the most precise data capture yet, down to the level of individual plants, using leaf size segmentation, quantification, and pixel-based scanning to identify consistency and variation. Going beyond what even the human eye can perceive, this state-of-the art imaging technology enables the gathering of immense insights about a plant including its leaf size, stem length, coloration, curvature, spotting, and tearing. The end-to-end system is flexible and robust, built to take advantage of Nokia’s industry-leading 5G private wireless network with cloud processing technology, designed for low latency and high privacy in an on-premises network. It also provides intelligent industrial analytics capabilities as an integrated service that can be deployed quickly and efficiently anywhere.

Thierry Klein, VP, Integrated Solutions and Experiences Research Lab at Nokia, said: “Nokia Bell Labs is driven to solve hard and impactful problems, and together with AeroFarms, we are building the ability to see and identify plant interactions at unprecedented levels. The fundamental technologies of this partnership are our strength, and vertical farming is just the beginning. With the AeroFarms platform, we are exploring the power of network driven intelligence for industrial outcomes. These capabilities can expand into a multitude of indoor industrial operations, including logistics, warehousing, distribution hubs, and manufacturing.”

The multi-year partnership between AeroFarms and Nokia is anchored on shared values as mission-driven companies with the vision to scale technologies for the greater good. AeroFarms’ vertical farming platform is more sustainable than traditional farming with up to 390 times greater productivity per square foot annually, while using up to 95% less water and zero pesticides. In addition, vertical farming provides local food options for communities, reducing the environmental impact of trucking and shipping produce long distances and helping combat food waste.

Additional resources

AeroFarms website

Nokia Bell Labs website

About Nokia

At Nokia, we create technology that helps the world act together. As a trusted partner for critical networks, we are committed to innovation and technology leadership across mobile, fixed and cloud networks. We create value with intellectual property and long-term research, led by the award-winning Nokia Bell Labs. Adhering to the highest standards of integrity and security, we help build the capabilities needed for a more productive, sustainable and inclusive world.

About AeroFarms

Since 2004, AeroFarms has been leading the way for indoor vertical farming and championing transformational innovation for agriculture. On a mission to grow the best plants possible for the betterment of humanity, AeroFarms is a Certified B Corporation with global headquarters in Newark, New Jersey. Named one of the World’s Most Innovative Companies by Fast Company two years in a row and one of TIME’s Best Inventions in Food, AeroFarms patented, award-winning indoor vertical farming technology provides the perfect conditions for healthy plants to thrive, taking agriculture to a new level of precision, food safety, and productivity while using up to 95% less water and no pesticides ever versus traditional field farming. AeroFarms enables local production to safely grow all year round, using vertical farming for elevated flavor. In addition, through its proprietary growing technology platform, AeroFarms has grown over 550 varieties and has developed multi-year strategic partnerships ranging from government to major Fortune 500 companies to help uniquely solve agriculture supply chain needs. For additional information, visit: https://aerofarms.com/.

On March 26, 2021, AeroFarms announced a definitive business combination agreement with Spring Valley Acquisition Corp. (Nasdaq: SV). Upon the closing of the business combination, AeroFarms will become publicly traded on Nasdaq under the new ticker symbol "ARFM". Additional information about the transaction can be viewed here: https://aerofarms.com/investors/.

No Offer or Solicitation

This press release does not constitute an offer to sell or a solicitation of an offer to buy, or the solicitation of any vote or approval in any jurisdiction in connection with a proposed potential business combination among Spring Valley and AeroFarms or any related transactions, nor shall there be any sale, issuance or transfer of securities in any jurisdiction where, or to any person to whom, such offer, solicitation or sale may be unlawful. Any offering of securities or solicitation of votes regarding the proposed transaction will be made only by means of a proxy statement/prospectus that complies with applicable rules and regulations promulgated under the Securities Act of 1933, as amended (the “Securities Act”), and Securities Exchange Act of 1934, as amended, or pursuant to an exemption from the Securities Act or in a transaction not subject to the registration requirements of the Securities Act.

Forward Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “might,” “will,” “estimate,” “continue,” “contemplate,” “anticipate,” “intend,” “expect,” “should,” “would,” “could,” “plan,” “predict,” “project,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this press release, including those regarding the expected benefits of the partnership, improvement of plant yields and quality and Spring Valley’s proposed acquisition of AeroFarms are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of the respective management of AeroFarms and Spring Valley and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AeroFarms and Spring Valley. These forward-looking statements are subject to a number of risks and uncertainties, including changes in domestic and foreign business, market, financial, political, and legal conditions; the inability of the parties to successfully or timely consummate the proposed transaction, including the risk that any regulatory approvals are not obtained, are delayed or are subject to unanticipated conditions that could adversely affect the combined company or the expected benefits of the proposed transaction or that the approval of the stockholders of Spring Valley or AeroFarms is not obtained; failure to realize the anticipated benefits of the proposed transaction; risks related to the expansion of AeroFarms’ business and the timing of expected business milestones; the effects of competition on AeroFarms’ business; the ability of Spring Valley or AeroFarms to issue equity or equity-linked securities or obtain debt financing in connection with the proposed transaction or in the future, and those factors discussed in Spring Valley’s Annual Report on Form 10-K, Quarterly Report on Form 10-Q, final prospectus dated November 25, 2020 and definitive proxy statement/prospectus dated July 26, 2021 under the heading “Risk Factors,” and other documents Spring Valley has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that neither Spring Valley nor AeroFarms presently know, or that Spring Valley nor AeroFarms currently believe are immaterial, that could also cause actual results to differ from those contained in the forward-looking statements. In addition, forward-looking statements reflect Spring Valley’s and AeroFarms’ expectations, plans, or forecasts of future events and views as of the date of this press release. Spring Valley and AeroFarms anticipate that subsequent events and developments will cause Spring Valley’s and AeroFarms’ assessments to change. However, while Spring Valley and AeroFarms may elect to update these forward-looking statements at some point in the future, Spring Valley and AeroFarms specifically disclaim any obligation to do so. These forward-looking statements should not be relied upon as representing Spring Valley’s and AeroFarms’ assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Contacts

AeroFarms Contacts

Investor Relations:

Jeff Sonnek

ICR

Jeff.Sonnek@icrinc.com

1-646-277-1263

Media Relations:

Marc Oshima

AeroFarms

MarcOshima@AeroFarms.com

1-917-673-4602

AppHarvest Names Julie Nelson EVP, Operations to Build Industry-Leading Manufacturing and Supply Chain Capabilities and Drive Performance Across Network of Farms

AppHarvest to leverage Nelson’s proven experience at PepsiCo, McKinsey to drive productivity across the company’s network of high-tech indoor farms and optimize operations to support profitable growth

August 5, 2021

AppHarvest to leverage Nelson’s proven experience at PepsiCo, McKinsey to drive productivity across the company’s network of high-tech indoor farms and optimize operations to support profitable growth

MOREHEAD, Ky., Aug. 05, 2021 (GLOBE NEWSWIRE) -- AgTech leader AppHarvest (NASDAQ: APPH, APPHW), a public benefit company and certified B Corporation focused on farming more sustainably using up to 90% less water than open-field agriculture and only recycled rainwater, has named Julie Nelson its executive vice president, operations. Nelson will lead efforts to scale AppHarvest’s network of farms and to build manufacturing and supply chain capability to ensure efficient delivery of consistent, high-quality products to major grocers and restaurants.

“Julie’s deep experience optimizing complex manufacturing and distribution networks for major consumer goods companies and her proven ability to drive productivity across the supply chain will help us to deliver improved profitability as we scale,” said AppHarvest President David Lee.

Nelson will play an integral role as an executive management committee member, reporting to President David Lee, and will aid in developing company strategy, establishing operations and driving efficiency to reach productivity and cost goals while ensuring quality and customer satisfaction.

“Julie has battleground-tested experience in scaling operations across sites,” said AppHarvest Founder & CEO Jonathan Webb. “Her recent focus on improving sustainability in the food and beverage supply chain by reducing food waste, energy consumption and greenhouse gas emissions makes her a natural fit at AppHarvest.”

Nelson joins AppHarvest most recently from McKinsey & Company, following a long tenure with PepsiCo, where she led supply chain teams in the North American beverage business and the global operations team. Her focus areas included network optimization, scaling new digital technologies and end-to-end value chain productivity.

“AppHarvest’s mission aligns with my personal values,” Nelson said. “AppHarvest’s vision of combining the best that nature offers boosted with world-class technology to sustainably and affordably grow nutritious fruits and vegetables is inspiring, and I look forward to building a best-in-class operational team in support of this mission to build a climate-resilient food supply.”

Nelson holds a bachelor of science in economics from the Wharton School of the University of Pennsylvania and an MBA from Harvard Business School. She is an advisory council member for the West Virginia University Global Supply Chain Management Program.

About AppHarvest

AppHarvest is an applied technology company in Appalachia developing and operating some of the world’s largest high-tech indoor farms, designed to grow non-GMO, chemical pesticide-free produce, using up to 90 percent less water than open-field agriculture and only recycled rainwater while producing yields up to 30 times that of traditional agriculture on the same amount of land without agricultural runoff. The company combines the best that nature offers boosted with world-class technology including artificial intelligence and robotics to improve access for all to nutritious food, farming more sustainably, building a domestic food supply, and increasing investment in Appalachia. The company’s 60-acre Morehead, Ky. facility is among the largest indoor farms in the U.S. For more information, visit https://www.appharvest.com/.

MEDIA CONTACTS: Travis Parman, Travis.Parman@appharvest.com;

Blair Carpenter, Blair.Carpenter@appharvest.com

IMAGE/VIDEO GALLERY: Available here

Lead Photo: Julie Nelson will be joining AppHarvest as its executive vice president, operations.

Vertical Farming Congress Raises Expectations

The 2nd Vertical Farming World Congress on 20-22 September will now be held entirely online, to ensure complete certainty for participants and to avoid potential travel disruption.

August 4, 2021

The 2nd Vertical Farming World Congress on 20-22 September will now be held entirely online, to ensure complete certainty for participants and to avoid potential travel disruption.

“We have the most fantastic programme, featuring numerous industry leaders and innovators alongside awards, workshops, panels, exhibits and networking,” commented organiser Richard Hall, Chairman of food and drink consultancy Zenith Global.

Highlights include:

Industry leadership panel with Infarm, Kalera, Plenty and YesHealth

Future visions from 80 Acres, Bowery, CubicFarms, IGS, Vertical Field and Vertical Future

Market overview from Hort Americas and Rabobank

Regional pioneers from Chile, India and Japan

Retailer and investor panels with IKEA and Metro plus KPMG and S2G

Key innovators from the United States and United Kingdom to Malaysia and Sweden

Association leaders from North America, Europe, Africa and Japan.

“Our theme of Raising Expectations really does reach for the stars with a science briefing on space crop production from NASA. More stars will be celebrated by the first Vertical Farming World Awards. Future stars will be nurtured by an intensive half day workshop with Agritecture on Planning an Urban Farming Business,” added Richard Hall.

“We have also developed stellar new online features that worked so well last year, including virtual vertical farm visits, quick fire Vertical Venture delegate presentations and informal regional networking receptions. With the added advantages of time efficiency and recorded content, we feel the event should prove immensely valuable to any business wanting the latest insights on this rapidly taking off sector,” he concluded.

The Congress is sponsored by several leading industry suppliers including platinum sponsors Vertical Future and IGS Limited, gold sponsor CubicFarm Systems and silver sponsor Roto-Gro International.

Full programme and booking details are available online at www.zenithglobal.com/events/vfwc2021, with concessions for start-ups or company groups of 4 or more and early discounts up to 13 August. For further information, email events@zenithglobal.com.

Infarm Appoints Crop Genetics Specialist

Berlin-based urban farming specialist Infarm has appointed plant geneticist Pádraic Flood to lead its crop genetics team and help adapt various staple crops for vertical farming.

By Fred Searle

August 4, 2021

Berlin-based urban farming specialist Infarm has appointed plant geneticist Pádraic Flood to lead its crop genetics team and help adapt various staple crops for vertical farming.

A former research scientist at Wageningen University and the renowned Max Planck Institute for Plant Breeding Research, Flood will spearhead Infarm’s ongoing efforts to improve the quality, flavour and freshness of its vertically farmed produce.

Flood has a PhD from Wageningen in natural genetic variation in plant photosynthesis, and over the past decade he has used genetics to understand a range of key scientific questions ranging from photosynthesis to how plants adapt to extreme environments.

At Infarm he will lead the development of a breeding programme to adapt grains, legumes and other staple crops for vertical farming.

The company said the aim of the programme is to help return the land currently devoted to these staples to nature and biodiversity, while trying to have a positive impact on both people and the planet through more sustainable agriculture.

Infarm was founded in Berlin in 2013 by Osnat Michaeli and brothers Erez and Guy Galonska.

With a multinational team of more than 1,000 people globally, the vertical farming business has partnered with more than 30 major food retailers around the world.

To date, it has deployed more than 1,300 ‘in-store ‘farms’ as well as large-scale Growing Centres, producing various herbs, micro greens and leafy greens.

It claims to have saved more than 60 million litres of water and 60,000 square metres of land when compared with conventional production.

Lead Photo: Pádraic Flood will lead development of breeding programme to adapt grains, legumes and other staple crops for vertical farming

Babylon Micro-Farms Partners With Harvest Table, Providing Fresher, Hyper-Local Food Options To Top Universities Across America

Babylon Micro-Farms, the intelligent, accessible and market-leading indoor micro-farm company, is excited to announce their partnership with Harvest Table Culinary Group, the pioneering collegiate food service company.

July 30, 2021

Babylon Micro-Farms, the intelligent, accessible and market-leading indoor micro-farm company, is excited to announce their partnership with Harvest Table Culinary Group, the pioneering collegiate food service company. To kick off the partnership, Babylon installed their micro-farms in Harvest Table colleges and universities, including University of Virginia, Wake Forest University, Elon University, and Springfield College, serving over 40,000 students.

With the food hall climate continuing to evolve year to year, several universities are beginning to increase the amount of sustainable and healthy food options for their students across campus. Babylon is stepping in to help make university life more sustainable and healthy, with the installation of their micro-farms in the food halls. These micro-farms produce the freshest, high-quality selection of crops for kitchens to use in preparing their menus. Food from Babylon Micro-Farms is not only good for your health, but also for the environment, as they grow food locally with few pollutants, less water, food waste, and is pesticide free.

Harvest Table Culinary Group has a track record of culinary excellence, taking pride in their fresh and responsibly-sourced ingredients. President of Harvest Table, Mary Thornton comments, “Our partnership with Babylon Micro-Farms enables us to bring the Harvest Table effect to life for our students and their guests across the country. As we return to a new normal in the fall, there is a ripe opportunity for collaboration with student groups to further support the cause of local foods.”

Since 2017, Babylon Micro-Farms has delivered a simple, yet engaging indoor growing experience, helping companies such as hospitals, senior living communities and universities showcase their commitment to providing fresh, nutritious produce and sustainability to their students and other customers. The goal through their on-site farming service is to make growing simple for anyone. Babylon is the most affordable, efficient, and advanced vertical farming platform available, remotely managed through the cloud with unparalleled customer service. To date, the company operates a network of 45 farms in the Mid-Atlantic region of the USA with a further 106 farms due to be installed by Q1 2022.

Babylon’s CEO, Alexander Olesen shares, “Harvest Table represents the thought leader in the education space and we're extremely happy to partner with them. This partnership demonstrates how we can grow at scale and this is the first step in our plan to get into as many universities as possible.”

Agrify Corporation (AGFY) Stock Is Popping High In Pre-Market: What’s Going On?

Shares of the Agrify Corporation (AGFY) stock are popping high in the pre-market trading session on August 4, 2021. AGFY stock price saw a push of 9.56% to reach $21.31 a share at the time of this writing.

By Muhammad Ali

August 4, 2021

Shares of the Agrify Corporation (AGFY) stock are popping high in the pre-market trading session on August 4, 2021. AGFY stock price saw a push of 9.56% to reach $21.31 a share at the time of this writing. It seems that stock is continuing the rising momentum as it went up by 5.53% at the previous closing. Let’s understand the reason behind this bull.

What’s Happening?

Agrify Corporation is the hardware and software solution provider for indoor agriculture in the United States. There is no AGFY stock-specific news to justify the bullish sentiment in today’s date. According to a recent announcement, AGFY stock will release its second-quarter 2021 financial results on August 12, 2021, at 5:00 p.m ET.

Recently Craig-Hallum analyst rated AGFY stock as “Buy” and set a price target of $25 per share. The analyst thinks that this stock will expand by offering its products in the future. Furthermore, he is hopeful that Agrify’s revenue from SaaS will be more than double by 2025.

Agrify University: AGFY stock’s Learning Program

AGFY stock on July 19, 2021, did announce the launch of Agrify University that expands on 3,500 sq. ft. This is the innovative and project-based learning program of Agrify stock equipped with Agrify’s latest farming technology and cultivation methods. The hands-on project-based learning will help cannabis cultivators to cultivate cannabis more efficiently.

David Kessler, Agrify’s Chief Science Officer is leading this project. There will be available on-site, on-demand learning options for people to enhance their knowledge of the latest scientific indoor agriculture methods. The management is optimistic that this project will expand the Agrify ecosystem.

Financial View of the AGFY stock:

AGFY stock showed extraordinary improvement in its first-quarter 2021 revenue. The revenue was 600% higher as compared to the first quarter 2020 revenue. The sales backlog jumped from $59 million in Q4 2020 to $82 million in Q1 2021. The management expects that its full-year revenue will be between $48 million to $50 million.

Wrap Up:

Agrify stock is hot among investors despite any specific reason. The management is focusing on the expansion and overall growth of the stock. Previous financial results were exceptional in terms of revenue and sales backlog. The upcoming financial results next week will further clarify the position of the stock.

Vertical Gardening: A Modern Farming Method

Many of our communities are transforming into industrial and urban centres as the earth’s population increases. This growth, coupled with climate change, poses new challenges to the human populace to produce enough food as farmland acreage decreases and consumers’ demands increase.

July 25, 2021

Many of our communities are transforming into industrial and urban centres as the earth’s population increases. This growth, coupled with climate change, poses new challenges to the human populace to produce enough food as farmland acreage decreases and consumers’ demands increase.

Over the past decade, scientists and agronomists have been developing methods to produce double or triple the amount of food, using the same scale of land or less a farmer may cultivate. One of these approaches currently gaining much attention and adaptation is the vertical gardening or farming method.

NAREI staff harvesting and inspecting various crops planted in the vertical stack stand model, using PVC gutters

The notion of farming indoors is not strange to us, since greenhouse agricultural systems have been widely adopted for some time now. These houses have been used for years, providing conditions for numerous commercial crops (such as tomatoes, strawberries, peppers, and cucumbers) to thrive at its maximum production index. Cultivating under shaded facilities compared to outdoor farming fields can aid in year-round production, but few or none of these greenhouses have been constructed as multi-storey facilities.

Vertical farming is a method that uses vertically inclined surfaces to produce food, instead of the traditional method of growing vegetables on a single level in a greenhouse or open field. The National Agricultural Research and Extension Institute (NAREI) is currently evaluating the cost and productivity of various vertical-farming models. The experiment is being conducted at NAREI’s compound, Mon Repos, ECD.

NAREI staff harvesting and inspecting various crops planted in the vertical stack stand model, using PVC gutters

The vertical models installed under the tunnel house are: vertical stack stand using PVC gutters, vertical trellis made of nylon, barrel model using recycled plastic drums, and vertical wall using recycled plastic bottles.

Using vertical farming techniques have numerous advantages, such as: year-round production; reducing soil erosion and runoffs; maximising the use of abandoned structures or unused spaces; minimising crop failures due to harsh weather conditions and reduces the use of fossil fuels, since less farm mechanisation is needed. It also creates new urban employment openings; adds energy back to the grid via methane generation; returns farmlands to nature, aiding in restoring ecosystem functions; reduces pest and disease indices; reduces the need for abundant use of pesticides and herbicides, and offers the possibility of a sustainable food-production engine for our communities.

The experiment is being done to ascertain yields of a wide variety of crops needed to sustain large populations, without exhausting existing resources. With the success of this study, local households in Guyana can better utilise yard space to produce their foods at a cheaper cost and local farmers can increase productivity to reach consumer demand. In addition to that, this method can be utilised to combat major challenges faced due to climate variation in Guyana, such as flooding.

Farm Tech Investing Is Accelerating Faster Than Ever – New Report

‘Farm tech’ investing soared to $7.9 billion in 2020, topping 2019 investments by $2.3 trillion, or 41%, according to AgFunder’s latest Farm Tech Investment Report.

By Jessica Pothering & Louisa Burwood-Taylor

August 4, 2021

We’ve been watching the surge of investor interest in upstream, close-to-the-farm technologies since the Covid-19 pandemic started. We now have numbers that show just how significant that farm tech investor interest is.

‘Farm tech’ investing soared to $7.9 billion in 2020, topping 2019 investments by $2.3 trillion, or 41%, according to AgFunder’s latest Farm Tech Investment Report. [Disclosure: AgFunder is AFN‘s parent company.]

To put this in perspective, farm tech’s acceleration was about six percentage points greater than agrifoodtech overall — that’s foodtech and farm tech combined — and 37 percentage points higher than global VC’s year-over-year increase in 2020 (which Crunchbase pegged at just 4%.)

Much of the investment activity was led by two sectors: Ag Biotechnology and Novel Farming Systems (mostly the indoor farming of crops and insects). Investors pumped more than $1.5 billion into each category. Ag Biotech companies attracted particular interest from investors: 173 deals closed, representing 58% growth from 2019. Novel Farming Systems deal activity grew by 47% year-over-year.

As difficult as 2020 was globally (2021 hasn’t been pretty in many parts of the world), the pandemic seems to have buoyed farm tech because it “exposed cracks in the industrial agricultural system,” particularly the vulnerability of the food supply chain, Infarm’s CEO Erez Galonza told AFN in an interview featured in the report. The German hyper-local vertical farming venture, whose modular units can be found in grocery stores across Europe, secured $170 million from investors last year.

“[The pandemic] highlighted the need for resilient, localized solutions,” he added.

Farm tech funding 2012-2020

Yellow bar denotes projected total by end of 2021 as more 2020 data come to light. Credit: AgFunder

SPACs for best-funded farm tech categories

Perhaps the biggest winner, in that sense, was US-based high-tech greenhouse operator, AppHarvest. The company announced plans to go public last September via a special purpose acquisition company, or SPAC. It officially listed on the Nasdaq stock exchange in January, just weeks after shipping its first harvest.

AppHarvest recently purchased robotics leader and AgFunder portfolio company Root AI, making founder Josh Lessing the publicly listed company’s new CTO. Read more here.

AppHarvest kicked off a SPAC trend for Farm Tech companies, and Novel Farming ventures specifically. We’ve since seen four other agrifoodtech companies announce plans to go public through SPACs: agbiotech companies Benson Hill and Gingko Bioworks and novel farming ventures AeroFarms and Local Bounti. (Keep up to date with agrifoodtech SPAC news here.)

It is interesting to see public listing activity happening in the two agrifoodtech sectors that surged the most in terms of deal activity last year; it signals that there could be more to come if the process proves successful for these early case studies. For now, it’s certainly providing an exit opportunity to early agtech ventures that bet on deep technologies requiring significant amounts of time (and certainly hefty commitments of resources) to become revenue-generating, much less profitable.

That in and of itself is a significant milestone for a maturing agtech industry.

Pandemic pivots

It isn’t all about Ag Biotech and Novel Farming Systems; the biggest deals of 2020 were in the Agribusiness Marketplace sector. Boston-based Indigo Ag raised two investment rounds, totaling $535 million last year, and San Carlos, Calif.-based Farmers Business Network raised $250 million.

Indigo Ag’s executive team told AFN that because it deals directly with the food supply chain, the company confronted an immediate shock from the pandemic.

“The global pandemic was an external challenge that required our team, like many others, to quickly adapt to ensure that our customers and employees were supported,” they said in a special interview featured in the report. “While we were fortunate that our operations were not significantly impeded by the pandemic, we did have to quickly expand our support services and tap our creativity to enable our farmers, buyers and partners to manage their business with confidence during the early stages of Covid-19.”

The company launched a transport support hotline for grain growers, carriers and shippers to ensure the supply of grain could continue to move as efficiently as possible. It also focused on developing pricing tools, access to grain marketing advisors, and even a podcast to help growers grapple with pandemic-related market volatility.

Indigo Ag isn’t a stranger to unchartered business terrain. The company has put itself in the middle of the evolving but murky carbon markets. “With new players entering the carbon space nearly weekly – many taking less rigorous approaches to verification and measurement – Indigo has remained steadily focused on enabling farmers to make informed decisions about how, when and why to participate in the carbon market,” the Indigo Ag team told AFN.

They added: “By leveraging our scientific insight, technological capabilities, and use of industry-leading carbon accounting protocols, Indigo ensures farmers are supported with the right tools and information to take advantage of the opportunity to raise a new and increasingly valuable crop: carbon.”

Food’s sustainable future

Verification of carbon-capture accounting is indeed getting increased attention and scrutiny. It’s likely to be a key theme in the agriculture industry going forward, and it’s one of AgFunder’s key trends to watch in 2021, alongside overall food system sustainability.

“We can invent a new, sustainable food industry, feeding the planet all the while protecting its biodiversity, and combatting climate change,” the executive team behind French insect farming venture Ynsect told AFN. The company sees insects as a crucial component of food’s sustainable future.

“Insects can aid food security and be a part of the solution to food shortages, given their high nutritional value, low requirements for land and water, low emissions of greenhouse gases, and the high efficiency at which they can convert feed into food,” the Ynsect team argued in an interview featured in the report.

Investors seem to agree: Ynsect scored the largest amount of funding in the novel farming sector in 2020, raising $222 million in 2020, taking its Series C total to $372 million, to build an industrial-sized farm for its Molitor mealworms near the city of Amiens. Ynsect went on to acquire Dutch insect farming company Protifarm in April of this year.

Many of the world’s consumers may as yet be skeptical of insects as a protein source. But consumer consciousness and demand for high-quality, low-environmental impact foods is certainly a trend influencing the evolution of Farm Tech, as evidenced by the range of startups that attracted funding in 2020.

Ag Biotech ventures like Benson Hill, GreenLight Biosciences, and Pivot Bio secured investor backing for helping to diversify crop input technology away from environmentally-harmful synthetic chemicals.

Novel Farming ventures are developing highly efficient and resource-conservative approaches to growing fresh foods.

Farm Management Software, Sensing & IoT companies like ICEYE, Aclima and Cervest are illuminating climate change impacts and helping companies anticipate and forecast climate-related disruptions.

Food preservation technologies like Apeel Sciences’s are helping reduce food waste, as are e-grocery services like Misfits Market and Imperfect Foods, which sell “ugly produce” that would otherwise be wasted among their fresh foods and grocery offerings.

Companies like Celtic Renewables are turning farm waste into a resource through the production of biofuels.

“As companies increasingly make commitments to improve their environmental impact – and governments at all levels enact policies to encourage climate-smart agriculture,” said the Indigo Ag team, “the opportunity for agriculture to act as a climate solution will only become more apparent.”

Sustainability, Global Trade, Climate Change – WIA Summit Covers THE Industry Topics

At its 10th anniversary event this fall, the Women in Agribusiness Summit (WIA) will continue the tradition it is known for – providing key ag industry business knowledge to help women excel in the sector.

August 3, 2021

Kelly Lockwood Primus, Opening Speaker

BOSTON - At its 10th anniversary event this fall, the Women in Agribusiness Summit (WIA) will continue the tradition it is known for – providing key ag industry business knowledge to help women excel in the sector. This in-person conference – to be held September 21-23 at the Hyatt Regency Minneapolis – features a robust agenda, expert speakers, plenty of networking and a special off-site reception.

Opening speaker Kelly Lockwood Primus, CEO of Leading NOW, will start the business discussion with The Career Advice You Probably Didn’t Get. This presentation will include Leading NOW’s research on women’s leadership, what's missing from conventional career advice and the barriers women face in achieving executive positions.

“Through our research, we have identified traits for success in leadership. These include integrity, transparency, confidence and more, but most importantly, women need to focus on what we call The Missing 33%™,” said Lockwood Primus, who is an advisor to global organizations seeking to change mindsets, behaviors and cultures. “This is the business acumen that sets them apart, and we will discuss this in detail at the Women in Agribusiness Summit this fall.”

Others who will share the stage with Lockwood Primus include Scott Sigman, principal advisor at EASE, who will focus on connecting the dots in global trade and examining alternative transport paths; Shawn Jarosz, CEO of TradeMoves, who will speak to why international trade matters to food & ag; and Beth Sauerhaft of American Farmland Trust, who will moderate a panel of esteemed experts in a discussion on sustainability and climate change.

Interspersed with this critical industry content will be the annual highlights that the WIA community has grown to expect and anticipate: Ag Innovation Hour, Executive Profiles and the Female Producer Panel. Through these, attendees will hear from soybean and egg farmers, and a specialty meats producer. They also will gain valuable career insights from accomplished female executives and be enlightened about the latest agtech innovations that are disrupting the sector.

Other sessions at the 10th annual Women in Agribusiness Summit include:

• The Fragile Ecosystem: Our Decisions Impact the World

• Understanding the Plant-Based Consumer

• Transforming the Workplace

• The Future of North American Agriculture

• Grain Industry Overview

Women in Agribusiness initiatives have fostered a year-round community of engaged executives, leaders and professional women. Learn more and register at womeninag.com , and visit us on Twitter, Facebook, and LinkedIn.

Welcome To Our Farm Within A Farm

But now all of the hard work and waiting has come to fruition as we are now ready to welcome you into our new Micro Farm: A Farm Within a Farm.

August 5, 2021

What is CEA?

Over the past year or so you may have heard us at Vertical Harvest referring to our “conversion” project – the construction of which has been the cause of some product delays and shortages. But now all of the hard work and waiting has come to fruition as we are now ready to welcome you into our new Micro Farm: A Farm Within a Farm.

The idea emerged when we noticed an increase in demand from our local chefs and grocery stores to supply more microgreens and petite greens. This happened to align with an internal ambition we have been fostering to implement a fully Controlled Environment Agriculture (CEA) system within our greenhouse. The new compartment has 4,000 sq feet of rack systems growing micro and petite greens fully independent of the whims of nature.

This farm is our next iteration for creating efficient and scalable growing systems. As we are seeing greater fluctuations in our local and national climates it has become increasingly important to us to delve into the capabilities of a growing system that is fully self-contained and not dependent on external changes in light and temperature. Instead, the greens will be nurtured in light and temperature conditions that are ideal to their growth cycles. This space has also increased our greenhouse production by 200%, meaning we can get our community more of the greens it loves both at home and when dining out.

Though our Maine greenhouse will incorporate some different technology, it will have a tray system that is very similar to this new compartment; so we have also reserved a portion of this new space to trial products and improve growing methods to ensure that our Westbrook greenhouse will have all the resources and information needed to hit the ground running when it plants its first seeds. We are already growing in the new space, training our employees on the new system, and getting our greens to customers. Vertical Harvest has always integrated different techniques and changed to growing demands, this project has been challenging and rewarding and will go on to influence all of our future greenhouses.

How Next-Gen Agri-Techniques Could Deliver Multi-Fold Productivity Gains And Combat Hunger In India

We have come across hydroponics, where plants are grown in inert medium like rocks or coir and are fed with nutrient rich water is probably the most well researched method. And there is aquaponics, where fish are reared in water along with plants.

By Dr. Richard Lobo

August 3, 2021

In the early 1700s, Thomas Jefferson wrote in a letter to George Washington, “Agriculture is our wisest pursuit because it will, in the end, contribute most to real wealth, good morals, and happiness.”

Farming has, over the years, changed the course of human civilisation, and then we took on a high premium on land as a key factor of agricultural production. The quality of soil, its fertility, nurture, and value has been a key social and political conversation over centuries.

Over the ages, advances were recorded through mechanisation, irrigation, and fertilisers, and all revolved around improving land and soil quality. However, the latest advances of today are bringing the centrality of land itself in question.

Yes, we are talking about farming practices and methods that do not use land at all. We have come across hydroponics, where plants are grown in inert medium like rocks or coir and are fed with nutrient rich water is probably the most well researched method. And there is aquaponics, where fish are reared in water along with plants.

However, the most interesting among them is aeroponics – growing of plants in air, with the roots not touching the soil but getting their nutrients and water from a nutrient laden mist that is created around the roots periodically.

This method of agriculture was conceived in order to find a way of growing food in space. While the term was coined by Dutch biologist Frits Warmolt in 1957, it only saw some traction in the mid-eighties when patents were filed and aeroponically food was sold in European markets.

Today Asian countries like Vietnam are adopting aeroponics in a big way for a low cost certified disease-free organic produce.

The global Aeroponics market was valued at $578.70 million in 2018, and is projected to reach $3.53 billion by 2026, growing at a CAGR of 25.60 percent from 2019 to 2026.

While not much data is available for aeroponics in India, we can get an idea from how the hydroponics market in the country is expected to grow at a compound annual growth rate (CAGR) of 13.53 percent between 2020 and 2027, according to a report by DataM Intelligence.

Less land and scalable agriculture

Aeroponics technique is also known as vertical farming as the crops can be grown in vertically stacked layers in smaller spaces. This gives a huge opportunity for farmers with smaller land holdings to grow crops in enclosed places by taking away the primacy of land and its cyclicality out of the equation. It also allows farming without lower capital investment as much less land is required.

In a predominantly agrarian country like India, aeroponics holds the potential to contribute to the development of the sector and boost production. The technique requires only 10 percent of the area traditional farming needs.

According to NASA, aeroponically grown plants can be harvested three times faster and the yields are more consistent. As nutrients are sprayed onto the plants and roots, and there's plenty of oxygen and other gases in the growing chamber for roots to absorb.

There are a wide variety of fruits and vegetables that can be grown using aeroponics system. Cucumbers, tomatoes, leafy vegetables, pumpkins, gourds, melons, strawberries, and various herbs can be grown with the help of these techniques in closed spaces.

Less water and sustainable farming

Farming in closed spaces has other advantages. Since nutrients are delivered through a mist, water usage is low. Aeroponics uses almost 90 percent less water than in traditional farming. Also, due to the controlled environment and better use of space, aeroponic farms are able to reduce the carbon footprint of food production.

Farming in a confined space gives the farmer control over pest and locust attacks and sudden heat waves.

In a country like India, space is always an issue. There is a constant pressure on agricultural land and its conversion to other uses and we are losing about 3,000 acres of farmland to real estate or industrial development every day. With Aeroponics the discussions around farming can move away from land constraints to focussing more on sustainable farming techniques.

Sustainability will be a key factor in India’s farming future. India may face devastating climate change effects, including killer heat waves and severe floods, in the next 80 years, says a recent study published in the journal 'Earth Systems and Environment'. The effects of climate change are now becoming severe at an alarming rate.

A farming system that uses less water, operates in a controlled environment leading to lesser wastage can be a boon for the cause of sustainability, especially in a populous country like India.

As aeroponics promises to solve multiple problems through its innovative approach to farming and it is time the technology got its due attention.

AeroFarms' David Rosenberg Discusses Growth, Investment, and More

From diving into publicly traded waters and launching a rebrand to introducing several new items and opening a research and development (R&D) hub, it’s safe to say that AeroFarms has come farther than CEO and Co-Founder David Rosenberg envisioned since the beginning days of 2004.

By Melissa De Leon Chavez

July 29, 2021

NEWARK, NJ - From diving into publicly traded waters and launching a rebrand to introducing several new items and opening a research and development (R&D) hub, it’s safe to say that AeroFarms has come farther than CEO and Co-Founder David Rosenberg envisioned since the beginning days of 2004.

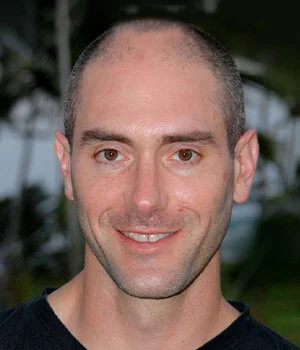

David Rosenberg, Co-Founder and Chief Executive Officer, AeroFarms

“When I co-founded the company, I thought of this as a supply chain play. I looked at the inefficiencies and thought, if we could enable local food production at scale, we could disintermediate parts of the supply chain and enable local food production and access to fresh food, starting with leafy greens,” David shares with me.

Fast-forward to today, and AeroFarms is consistently breaking ground, physically and conventionally, in the U.S. and overseas.

“Our new AeroFarms AgX project in Abu Dhabi is two-fold. One, we expect to have a strong presence in the Middle East. Two, it aligns with our value proposition where there's not much farmland. There's not as much fresh water and there's relatively low-cost, abundant energy. Additionally, we're using our presence there to really innovate. We're building the world’s largest indoor vertical farming R&D facility of its kind that is going to have a tremendous amount of innovation in it, from genetics to automation exploration,” he tells me. “We're also doing a lot in the U.S. We just opened a building expansion here in Newark where we have our global headquarters. That's another 25,000-square-foot facility for prototyping and R&D, so we have much going on Stateside as well.”

AeroFarms has revealed several advancements, from diving into publicly traded waters and launching a rebrand to introducing several new items and opening a new research and development (R&D) hub

AeroFarms has a diverse, partner-fueled style that can be seen blueprinted in David's own background. Far from a straight line to agriculture, the executive was drawn to the produce industry by a love of problem-solving.

“My last company was a nanotech company in construction, which focused specifically on waterproofing and corrosion inhibition. From that I learned how much water goes to agriculture and thought I could make a difference. I love when there could be technological solutions to existing issues, and it’s a pattern I have found across industries,” David imparts.

With a background as a multi-business serial entrepreneur from Columbia Business School, it’s no wonder that David and his team have an unorthodox approach to indoor ag, employing several outside minds to expand laterally and vertically the possibilities of the industry.

“What surprised me is that fully controlled agriculture enables us to understand and give a plant exactly what it wants, when it wants, and how it wants it. As a consequence, we're competing on taste and texture in unique ways. So, I used to think our competitive advantage was local and fresh when, it turns out, we have unique tastes that allow us to go further and distinguish us from any other grower out there,” the CEO and Co-Founder muses.

AeroFarms most recently expanded its leafy greens product assortment for both baby leafy greens and microgreens as it seeks to redefine indoor-grown fresh produce and all it could impact

It's the result of having a team comprised of skilled farmers, plant geneticists, and R&D scientists that pushed the company into a whole new ring of investing: public trading.

“One of the reasons we're going public is it allows us to continue innovating on the tech side and make continued advancements to reduce capital cost, operating costs, and improve quality. We are investing millions a year in R&D. AeroFarms is involved in some cutting-edge, pioneering work, which attracts a lot of interest in this space. We’re also working with other big companies to accelerate innovation cycles, such as Dell and others—companies you don't typically associate with agriculture. We're partnering with them and developing some breakthrough stuff,” David points out, bringing us back to thinking out of the box and of traditional teams.

Among the areas AeroFarms is looking to further transform includes automation across seeding, harvesting, cleaning, packaging, and beyond, as well as biological development, working to understand what plants need to help realize their full potential.

“There's a strong lens towards technical innovation. I see a lot of players in the industry looking at produce as an execution play, not realizing there's a lot more room to reduce capital and operating costs,” he shares.

It is in that spirit that AeroFarms has continued to launch new products, most recently expanding its leafy greens product assortment for both baby leafy greens and microgreens, as it seeks to redefine not just indoor-grown fresh produce, but all it could impact.

AeroFarms is looking to further transform areas such as automation across seeding, harvesting, cleaning, packaging, and beyond, as well as biological development.

“We're very mission focused,” David concludes of the company’s driven success. “We have a program with past offenders where we've successfully taken people who were previously incarcerated and given them good jobs with a better pathway in life. We also have internal programs where computer literacy and financial literacy training continue to foster growth. Environmentally, we're focused on how to do more with less. How do we continue to grow a plant using less energy, less water, less nutrients, and zero pesticides? I think these commitments and our mission to grow the best plants possible for the betterment of humanity are why we're attracting so many new employees as we seek to build a better future.”

As we continue to eye such movers and shakers throughout fresh produce, continue to follow AndNowUKnow.

Common Farms (Hong Kong): “It's A Marathon And Not A Sprint For Us”

The product demand keeps growing. Inevitably, the pandemic has accelerated this demand for food quality and availability in Hong Kong.

By Rebekka Boekhout

July 23, 2021

The product demand keeps growing. Inevitably, the pandemic has accelerated this demand for food quality and availability in Hong Kong. “I think it’s because of the following reasons. One being that Common Farms can deliver with consistency, speed, and quality. Secondly, as people aren’t traveling they have disposable income to spend locally. The customers we serve are booked out for months. Lastly, pricing for imported produce fluctuates, which over time has a great impact on our customers.”

Lead Photo: Jessica Fong

Read the rest of the article here!

15 of The Coolest Urban Farms Around The World

But many cities have amazing urban farms within their city borders. They not only offer an amazing break from busy city life, but they’re also often really sustainable!

July 23, 2021

When we think of farms, we usually think of the countryside. But many cities have amazing urban farms within their city borders. They not only offer an amazing break from busy city life, but they’re also often really sustainable! On top of that, it’s also a powerful tool against world hunger. We have listed our favorite Urban farm that our spotter wrote about from around the world down below.

Amsterdam – Amsteltuin

Workshop at the vineyard (by RTVA)

Amsteltuin is a vineyard in Amsterdam! Okay, a vineyard is not exactly a farm, but plants still grow and the grapes can still be harvested. They offer a little vacation right out of the city center. They sell picnic baskets with local products that you can enjoy in between the vines! How cute is that?

Berlin – Charlottenburger Ziegenhof

Goats at Charlottenburger Ziegenhof (by Rainer Jensen)

Charlottenburger Ziegenhof is located in a backyard in Berlin. They are a community-based farm that wants to motivate anyone who is interested to take care of the animals and produce on the little farm. They teach people about sustainability through their work on the farm and host workshops for those who don’t want to get their hands dirty.

Florence – Orti Dipinti

The beds in which the crops are grown at Orti Dipinti (by Laura Pirovano)

Orti Dipinti is located in Florence and one of the smallest urban farms on this list. It’s located on an old running track so they had to bring the soil in. The crops are grown in wooden crates by the volunteers from the neighborhood. But their work doesn’t stop at planting and harvesting! They also have a mission to educate about nutrition, sustainability, and the role that urban farming can play in those subjects. If you don’t have the green fingers you can always check out their little shop to buy fresh products.

Glasgow – North Kelvin Meadow

Children building a treehouse at North Kelvin Meadow (by North Kelvin Meadow)

North Kelvin Meadow is a beautiful communal green space in Glasgow. It used to be a football field! Today they have fruit trees, over 30 raised beds that people can rent to grow their own crops, 2 honey beehives, and 6 bumblebee homes. The space is used by the whole community almost daily.

London – Mudchute Farm

Sheep at Mudchute Farm with a view of London (by Helen Graves)

Mudchute Farm is London’s biggest urban farm. They have plenty of animals you would expect at a farm (pigs, sheep, chickens) and some you might not (hello llamas). They spin their own wool and your kids can cuddle with the animals! Interested in finding out more about keeping chickens, laying hedges, spinning wool, or other countryside activities? They offer courses on all of them!

Milan – Cascina Cuccagna

People at the bar of Cascina Cuccagna (by Radio Mamma)

Cascina Cuccagna is a true hidden gem in Milan. It’s a whole concept that features way more than just an urban farm. You’ll find a very good restaurant, a self-service bar with homemade bakery snacks, a wonderful garden growing vegetables, a hostel, bike and wood workshops, a wine shop, a farmer’s market offering selected local produce, and various events. It’s the perfect spot to leave the hustle and bustle of the city behind.

Oslo – Losæter

Losaeter creative greenhouse (by Monica Løvdahl)

Losæter is located in Oslo. It all started in 2011 as an art project and has since grown into a lush green mix of Oslo’s unique urban farm, a cultural meeting point, a knowledge exchange platform, and a funky wild park. They literally brought soil into the city and have been thriving ever since then.

Rome – CoBrAgOr

People eating at the restaurant of CoBrAgOr (by CoBrAgOr)

CoBrAgOr in Rome combines an amazing restaurant with an urban farm. The acronym means ‘Cooperativa braccianti agricoli organizzati’, a cooperative of the farmers who cultivate the 40-hectare area surrounding this agritourism in the Insugherata Natural Reservation on Monte Mario, the highest hill in Rome. They also have a shop where you can shop their fresh products daily.

Rotterdam – Op Het Dak

Yoga class at Op Het Dak (by Gianni Tahamata)

Rotterdam is a pioneer when it comes to urban farming. Op het dak is one of many urban farms in the city. Op het dak means on the rooftop in Dutch. And that’s exactly where this farm is located! The rooftop is filled with flowers and plants, organic vegetables, edible flowers, and herbs. They are all used in the dishes that their little restaurant serves. They also have beehives that produce honey on a yearly basis!

The Hague – Pluk! & De Heemtuin

Plants for sale at Pluk! (by Sanne Verhoef)

Pluk! De Heemtuin is a small farm located a little out of the city center of The Hague. They combine the small farm with a café and the Heemtuin where kids (and adults) can run around freely. Their animals all found their home at Pluk after being abandoned by their previous owners. You can come and pick your own fruit and vegetables, your kids can learn more about food and the animals or you can just enjoy a coffee on their terrace.

Toronto – Riverdale Farm

Riverdale Farm entrance (by Mother Goose)

The Riverdale Farm is located in Toronto, smack in the middle of downtown. The small farm is open year-round and it specializes in pioneer breeds of farm animals like horses, cows, goats, and sheep that are hard to find on commercial farms. Y0u can also find the oldest building in the city here!

Vancouver – Southlands Heritage Farm

A rider is getting her horse ready at the Southlands Heritage Farm (by Art Zaratsyan)

Southlands Heritage Farm is located within the border of Vancouver. this farm has made it their mission to guide us all into making healthier, more sustainable choices. Take a stroll through their gardens, hand-feed their chickens and goats, walk through the barn to greet the ponies and horses, and stop by their farmer’s market on the way out for some fresh produce, eggs, honey, and jams. They also offer several programs to educate on the topic of urban farming and nutrition.

Zurich – Frau Gerolds Garten

The bar at Frau Gerolds Garten (by Dimitri Burkhard)

Frau Gerolds Garten is more than just an urban farm. It’s a whole concept of a community located in Zurich. It’s a restaurant, bar, shopping area, and urban gardening project all in one. The food for the restaurant is partly grown on-site, with the rest being organic and locally sourced. There is a community thread running throughout, and locals are invited to grow their own veg on site.

Success Story: Fork Farms Putting Down Roots In Wisconsin

Fork Farms was founded in 2010 as an independent contractor building rooftop and indoor gardens for schools and food programs in New York. In 2014, Fork Farms moved back to Wisconsin (the home state of co-founder and president Alex Tyink) and the first Flex Farm prototype was built out of wood in a garage

By: Wisconsin Economic Development Corporation

July 28, 2021

Products: Flex Farms are fully self-contained vertical hydroponic systems with 288 unique growing spaces. The company’s patented technology takes indoor vertical hydroponic growing to a new level by maximizing growth and minimizing required inputs. Flex Farms grow food faster, in less space with less water and electricity. They are portable and only require a standard electrical outlet and less than 10 square feet of space. By carefully controlling everything plants need to thrive, each Flex Farm can grow more than 394 pounds of produce annually. The Flex Farm Grow Supplies Box Subscription program delivers all the supplies a customer needs to grow every three months right to their door.

Company founded: Fork Farms was founded in 2010 as an independent contractor building rooftop and indoor gardens for schools and food programs in New York. In 2014, Fork Farms moved back to Wisconsin (the home state of co-founder and president Alex Tyink) and the first Flex Farm prototype was built out of wood in a garage.

Location: In 2020, Fork Farms moved its headquarters to TitletownTech in Green Bay. TitletownTech is a partnership between the Green Bay Packers and Microsoft that builds and funds early-stage high-growth businesses. Fork Farms believes TitletownTech is an incredibly innovative model that significantly bolsters the local startup economy. The depth of support is unprecedented and will provide Fork Farm’s significant acceleration and lift to the organization’s mission of unleashing the power of fresh food production.

Employees: 15

Backstory: A decade ago, a simple bag of lettuce grown on a rooftop in Brooklyn, New York, ignited a chain of events that would lead to the cognizance of the true power of “good food” and its ability to bring about happier, healthier people through the power of fresh food production. Fork Farms has since blossomed from an independent contractor building rooftop gardens to a garage-based Flex Farm prototype made out of wood, and most recently into partnerships with the Green Bay Packers and Microsoft. With over 600 Flex Farm installations completed in 29 states, Israel and Canada, Fork Farms is poised to continue its passionate endeavor towards real and sustainable change.

Wisconsin’s business environment: “Wisconsin’s business environment has helped Fork Farms grow significantly,” says Tyink. “We outsource a significant amount of our overhead to Wisconsin businesses to allow us to rapidly respond to our expansion needs. Our Wisconsin fulfillment partners have the ability to scale their operations to meet the increase in demand for our products. Our relationship with these partners also allows us to explore how we can scale our consumable products to provide more affordable solutions breaking down barriers to entry into vertical hydroponic growing. In the next year, we will be making significant investments in content that deepens and enriches the experience with indoor vertical hydroponic growing.”

AppHarvest: Management Estimates Vs. The Market

APPH's management projects appealing unit economics and a long runway for future growth. If management's projections are accurate, in five years APPH will be generating over $100mm in annual free cash flow and be able to reinvest 100% of that cash at a rate of return over 15%.

By Carleton Hanson

July 28, 2021

Summary

AppHarvest is a vertical farming company that is ramping up its operations.

AppHarvest's management has rosy projections for profitability and growth, but the market is skeptical about the company's future.

If management's estimates are accurate, AppHarvest looks appealing on a future cash flow basis.

AppHarvest has meaningful downside risk.

I am considering starting a small, "coffee can" position in the company.

I look for companies that generate consistent free cash flow and that can reinvest cash at a high rate of return. AppHarvest (APPH) does not fit the bill in its current state. The company only started to generate revenue in 2021 and is years away from generating free cash flow. APPH's management projects appealing unit economics and a long runway for future growth. If management's projections are accurate, in five years APPH will be generating over $100mm in annual free cash flow and be able to reinvest 100% of that cash at a rate of return over 15%. APPH's business model is unproven but I would be excited to own shares in a company with their projected return profile.

What is AppHarvest?

APPH is an indoor farming company based in Appalachia. The company grows tomatoes in a 60-acre indoor farm located in Morehead, KY. By growing their produce indoors, APPH is able to avoid using pesticides, recycle water, and optimize the controlled environment for higher crop yields. APPH can grow 365 days a year and crops are protected from adverse weather events. The company reports that it can produce yields as high 30x those of conventional outdoor farms while using 90% less water and a fraction of the soil and fertilizer. APPH sells exclusively to Mastronardi Produce Limited, another indoor farming company that has an extensive distribution network across the United States.

APPH is a new company, and only began harvesting from their Morehead facility this year; there isn't much data yet on their operational metrics. As of Q1, the company had about $300mm in cash on their balance sheet, but APPH is investing heavily into building additional farms. There are two farms currently under construction in KY and six additional sites have been identified as future farm locations. APPH's goal is to have 12 farms completed or under construction by the end of 2025. A standard 60-acre facility costs about $120mm to build and APPH estimates that a fully functional farm can bring in annual revenues above $40mm with gross margins as high as 40% and EBITDA margins around 35%.

(Source: Analyst Presentation)

Management raised facility EBIDTA estimates to over $23mm on the Q1 conference call, with the excess coming from increases revenue and lower input costs. Some of this upward revision is also due to the acquisition of robotics company Root AI, which management expects to improve farm efficiency and automation in the future.

Putting together the farm unit economics and the target number of farms, five-year projections look like this:(Source: Analyst Presentation)

APPH has a market cap of $1.2 billion. If the projections above are accurate, APPH will be generating more than $100mm in free cash flow by 2026 and have a proven, profitable model that they can leverage to build more farms with an expected cash return above 15%. $1.2 billion is a cheap enough price to pay for a company with that return profile.

Let's Take Management's Projections at Face Value; How Much Should We Pay For APPH?

The big question is: Are management's estimates accurate? I will talk more about this risk later in the article, but for now let's say that the future plays out exactly as management projects. In this scenario, what would be a fair price to pay for APPH shares today? Using company estimates, we can put together a rough 5-year DCF. I am going to use a 15% discount rate in my equation. This might be controversial, but there are a number of other companies that I own that I expect to return at least 15% a year. If I am going to tie up capital in APPH while I wait for management to execute their plan, I am going to treat the opportunity cost as 15% a year. The results look like this:

The netted cash amount is inconsequential for just five years. In the scenario where management's estimates have been accurate, the company would be in a great position at the end of 2026. They have a proven business model, are generating ample free cash flow, and could continue to expand their operations by building more farms. I think a multiple of 25-30x FCF is reasonable in this scenario, resulting in a market cap of between $1.4-$1.6 billion and a share price between $14-$16. Due to a fairly steady decline in APPH's share price over the last month, a $14 price target is a 16% premium to the current price and $16 would be a 33% premium. For this scenario, I'll split the difference, slap a $15 price target on the stock, and estimate the company is undervalued by 25%.

The Market is Skeptical

Using management's estimates and my DCF assumptions, my "base case" price target for APPH is around $15/share. Despite some initial excitement about the company when it came public via a SPAC, the market is skeptical about this base case:(Source: Seeking Alpha)

APPH is trading more than 70% below its 52-week high and has significant short interest; why might the market be pessimistic about APPH's future? I think the market has two main concerns. First, APPH is only just beginning their operations; the unit economics and long-term growth plans presented by management are just projections at this point. Perhaps the farms will have higher maintenance costs than expected or produce a lower yield over a prolonged period. Interest rate changes could make future expansion projects more expensive. APPH might incur greater than expected SG&A costs. With no operating history, investors are forced to rely on management estimates or make their own projections with limited information. In this case, uncertainty about the future works against APPH's share price in the short term.

Secondly, despite their advanced indoor farm technology and investments in artificial intelligence software, at the end of the day APPH sells commodity products (tomatoes and eventually other produce). It is hard to find a convincing competitive advantage that is unique to APPH that will help them stand out in the market place. There are dozens of other indoor farming companies in various stages of development and production, so APPH's technology isn't unique. Companies like Plenty, AeroFarms, and Local Bounti come to mind, but there are many others as well. APPH's location (Kentucky), cited by the company as a large competitive advantage, will be diminished by the growth in indoor farming. Kentucky might be closer to New York than Mexico or California, but if other companies have the ability to start up small urban farms (like Plenty), then in not too many years I could see more farms popping up closer to major urban areas and reducing APPH's location advantage. SA author Jamie Louko recently did a deeper dive on APPH vs the competition in this article, and I think he brings up good points, especially around APPH's scale and progress in building their farms and securing funding for future work. I'm not sure the market is convinced these advantages will be enough, especially in today's market where traditional farming remains the primary competition.

Investment Thesis (and Risks)

Is the market right to be skeptical about APPH's future, or is the market being short-sighted and creating a favorable investment opportunity? I think the answer to both questions is yes. On the one hand, it is reasonable to remain cautious about APPH's unit economics until the company has been operating multiple farms for multiple years. Without a strong unit economic base, I see limited downside protection for investors. APPH still has a sizable cash position on their balance sheet and owns their one operating farm, but much of the cash is already allocated to completing their two in-progress farms, and their existing farm won't be of much value if the unit economics end up being a lot worse than anticipated. APPH needs to complete more than three farms to overcome their overhead costs, so their long-term success is going to be dependent on a successful progression of new farm construction. New farm construction will be impacted by the future availability of credit and/or the company's share price (if they decide to an equity raise). Finally, APPH would be negatively impacted by short-term drops in vegetable commodity pricing. Tomato pricing has been relatively stable over the last 15-20 years, but swings of 15-25% or more have happened regularly and will likely continue to happen. An APPH investment has real risks that the market is keenly aware of.

On the other hand, I see a lot to like about the company if management is able to execute on their plans. In this scenario, APPH is only a few years away from consistent cash flow generation and will have a long runway for reinvestment at high rates of return. It is rare to find a company today that can reinvest 100% of their free cash flow to grow their business; often companies resort to paying a dividend or buying back shares with excess cash. These outcomes are "fine" for investors, but aren't going to generate the same 15-20% ROI that APPH would be able to get from additional farm construction. The most optimistic outlook makes me think of investing in Walmart or McDonalds in their early stages, when they were building new stores or opening new franchises at a brisk pace and reaping solid returns on those investments.

I can also envision scenarios where APPH makes an unexpected leap forward and expands into an adjacent industry. Company president David Lee made a comment on the Q1 conference call that suggested he sees the potential of their in-house AI and robotic solutions to be licensed to other companies. This would provide another source of high-margin revenue. He even went as far as to say that APPH's solution could be what "AWS is to Amazon" (source). APPH's investment in Root AI shows their commitment to solving technological problems presented by indoor farming and to continuing to optimize their day-to-day operations. If APPH expands into a true tech-focused company that is able to build a platform of tools that other future companies will want to use, that would be a huge and unexpected win for the company. I would take this projection with a huge grain of salt and say it is unlikely to materialize, but I think APPH's technology has value and at least has the potential to be monetized in the future.

Conclusion