Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

"We Store CO2 From The Outside Air To Make Plants Grow Faster"

“Our ultimate goal is to make greenhouses independent of fossil fuels while improving their crop yield”, says Jarle. This ambitious goal is the main motivation behind their unique, yet a straightforward new product: an environmental climate system that provides plants inside of the greenhouse with outside CO2.

Bringing captured CO2 into the greenhouse with zeolites

“In short, we capture CO2 from the air outside and then release it inside the greenhouse. As our system includes the greenhouse to be a closed system, all the CO2 inside will increase plant growth. This new technology does not give any emissions to its surroundings while in use and the solution is 100% climate-neutral”, Jarle Skjæveland with GreenCap Solutions explains. The company recently launched their product, and they are working on several projects in Norway and abroad.

“Our ultimate goal is to make greenhouses independent of fossil fuels while improving their crop yield”, says Jarle. This ambitious goal is the main motivation behind their unique, yet straight forward new product: an environmental climate system that provides plants inside of the greenhouse with outside CO2. On top of that, it allows for the reuse of condensed water, which further reduces costs for growers.

GreenCap Solution’s technical team combines decades of energy in the oil and gas industry, which is now taken to the greenhouse industry. For the past four years, they have been working on the carbon-capturing technique. Last year, they started working with the first greenhouse company to apply the technique: Lauvsnes Gartneri, a tomato greenhouse in Finnøy, Norway. The second project they started this year is with a Norwegian cucumber grower.

Zeolites: a tried method

For the capturing of the CO2 molecules, the company uses zeolites, a porous mineral that can adsorb large quantities of gas. Zeolites occur naturally but are also produced industrially. “Using zeolites as carbon adsorbent is nothing new. It was already used in the 1960s for industrial applications. Our invention is effectively using the energy and storing the CO2 for greenhouse application, in combination with climate control within the greenhouse,” Jarle explains.

Inside the greenhouse, the CO2 is transported by a constant air flow. “With the greenhouse closed on a sunny day, the temperature might get too high. For that reason, we have a circulation system that shifts the air every 10 minutes. Air tubes underneath the plants produce a constant low-speed airflow. This way, the temperature inside can be a comfortable 24 C even in a hot climate,” Jarle adds.

Vertical farming in Saudi Arabia

This technique comes in handy as the company recently started a new project in Saudi Arabia. This time not with a greenhouse but with a vertical farm that grows eight layers of lettuce. “When we visited Saudi Arabia some months ago, we noticed that some people were skeptical as to our technology would work in a hot climate too. With this new project, we are proving that our technique works, not only for different crops in different growing systems but also in different climates. And the additional benefit is that there we can make better use of solar power as well, taking advantage of the natural resources available.”

In many European countries, growers generally have a combined heat power (CHP) that already provides additional CO2 to growers. But according to Jarle, the systems can be combined easily. “Our technique is twofold: either we replace the current CO2 source or we add it to the closed growth environment. Both work fine together, but with our system, growers can stop using fossil fuels completely while still giving that beneficial CO2 to their plants. Besides, many countries do not need the extra heat provided by the CHP, at least not year-round. In that case, working with a CHP is not cost-effective.”

Already within the horticultural industry, GreenCap’s environmental climate control system can have many different applications. But the company is already investigating other possible usages of their carbon adsorbent technique. “CO2 is used in other industries too, so we are investigating other expansion already, such as companies absorbing their CO2 emission. However, horticulture is such a vast and rapidly growing industry. Imagine this huge industry, that is so essential for the food production of the entire world, being totally emission-free. That is what we’re working for.”

A promotional video of GreenCap Solution's system can be watched here.

For more information:

GreenCap Solutions

www.greencap-solutions.com

Publication date: Fri 4 Jun 2021

Author: Jenneken Schouten

© HortiDaily.com

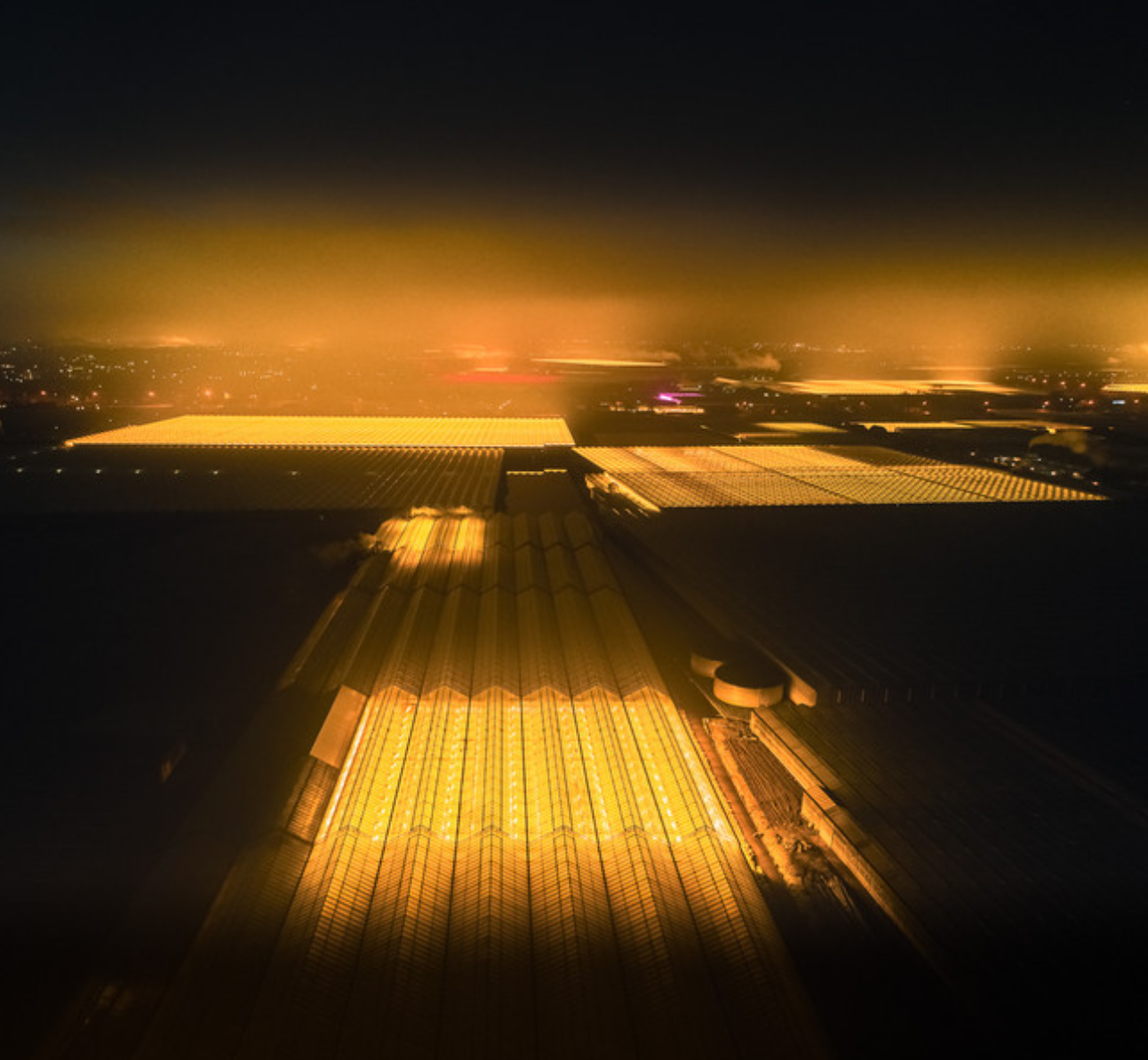

Leamington Greenhouse Growers Struggle With Venting With Light Pollution Limits

Venting limits are imposed by local municipalities to address light pollution concerns

A recent Horti Daily article discussed the problems with limited venting experienced by many greenhouses in the Leamington, Ontario area. Venting limits are imposed by local municipalities to address light pollution concerns. Venting is a strategy used by greenhouses to remove warm air from the greenhouse as temperatures rise, especially in the warmer months. Venting limits make it difficult for greenhouses to remove warm air and maintain optimal temperatures in greenhouses. An unintended consequence with artificial lights is that opening greenhouse side walls and roofs allows light escaping, causing light pollution to the neighboring area outside.

Greenhouse growers are constantly juggling and adjusting growth parameters like light, temperature, and CO2 to create an optimal growth environment for their plants. Choosing to vent or not is always a double-edged sword. On the one hand, venting is an inexpensive way to manage air exchange in order to keep temperatures cooler in the warm months from spring through fall. On the other hand, venting with artificial lights on results in light pollution. Venting also makes it impractical to supplement the greenhouse grow area with CO2 by atmospheric enrichment (also known as CO2 gassing) since the CO2 gas quickly escapes outside.

The problem with venting is not usually an issue for Leamington greenhouses in the colder months when the vents are closed, thereby enabling CO2 gassing as the facility is sealed and reduces artificial light pollution. CO2 gas levels in the grow rooms can be maintained at 1200 parts per million (ppm) to optimize growth. However, in the warmer months when venting occurs, it is very difficult to maintain 400 ppm (the level of natural CO2 in the air) even if CO2 gas is pumped into the grow area since nearly all of it escapes outside during venting.

CO2 Delivery Solutions™ can help Leamington greenhouse growers solve the CO2 supplementing problem when venting.

CO2 Delivery Solutions™ enables Leamington greenhouses to provide their plants with added CO2 which enhances growth and yields. This capability is achieved by misting an aqueous CO2 solution directly on to the plants, with or without venting. This technology allows CO2 to be controlled independently, rather than its delivery being co-dependent on the control of other growth parameters like light and temperature. This enhances a grower’s ability to optimize environments in a simpler and more effective manner. While CO2 Delivery Solutions™ cannot solve the artificial light pollution problem when Leamington greenhouses need to vent, it can certainly solve the lack of optimal CO2 problem during those months and help tip the balance towards more optimal yields year-round.

Visit co2delivery.ca for more information.

Polygreens Podcast Episode: 008 -CO2 GRO

CO2 from a gas tank and water from the facility source are plugged into the Aqueous CO2 Infusion System, which comes as an in-situ system or can be integrated into booms

CO2 from a gas tank and water from the facility source are plugged into the Aqueous CO2 Infusion System, which comes as an in-situ system or can be integrated into booms. The CO2 completely dissolves in the water creating a saturated aqueous CO2 solution.

The aqueous CO2 solution is targeted directly on to the plant's leaves by misting micro droplets that create an aqueous CO2 film on leaf's surface. This film isolates the leaf surface from the atmosphere and creates a diffusion gradient that favors the transport of CO2 into the leaf and other gasses out of the leaf.

The carbon is used by the plant for photosynthesis to grow and the oxygen is given off to the atmosphere.

Listen

Nick Greens

The Nick Greens Grow Team has participated in many changes since they started developing indoor controlled agricultural environments in 2010. Our goal is to expand the vertical farming industry by helping ag-entrepreneurs manage their businesses better, avoid common mistakes, and improve crop yields based on what we have observed and developed over the past decade.

YouTube

Strawberry And Tomato Responses To Light And CO2 Control

Carbon dioxide enrichment has long been known as a tool to boost greenhouse crop yield but the benefits depend on the crop and production environment especially light. In this webinar, Cornell University researchers will discuss

Date: October 25, 2019

Time: 12 p.m. - 1 p.m. EDT

Presented by: Neil Mattson and Jonathan Allred

Register Here

Carbon dioxide enrichment has long been known as a tool to boost greenhouse crop yield but the benefits depend on the crop and production environment especially light. In this webinar, Cornell University researchers will discuss:

The basics of greenhouse CO2 enrichment.

Current research underway to determine the response of tomatoes and strawberries on light and CO2.

Experimental results from two years of studies on day-neutral strawberry cultivar selection and response to HPS and LED supplemental lighting.