Beginner’s Guide to Hydroponic Farming in the Greenery™

Learn how to farm in the most advanced hydroponic container farm on the market, the Greenery, and the labor requirements you can expect.

A career in farming has historically been associated with unpredictable schedules and long hours. However, through Freight Farms’ innovative technology, design, and automation, we've streamlined farm operations and significantly reduced the time required to manage a farm.

What some might consider a part-time job – 25 to 35 hours per week – is now all that’s needed to run a profitable farm, making this field more accessible than ever before.

In this guide, we’ll walk you through the steps to completing a crop cycle in our hydroponic container farm and the labor requirements you can expect. But first, let’s start with the basics.

What is Hydroponics?

Hydroponics is a farming technique where plants are grown in nutrient-rich water rather than soil.

This method of swapping soil for a different growing media to support the roots of the plant allows us to bring food production indoors. By growing food hydroponically, we can control the climate, lighting, and nutrient conditions that the crops receive, allowing anyone to grow nutritious, consistent food year-round.

What is the Greenery?

The Greenery is a vertical hydroponic farm built inside a shipping container, designed specifically for people looking to farm in their communities.

Featuring a state-of-the-art controlled environment agriculture system that gives farmers complete control of the elements, our container farm makes it possible to grow delicious food 365 days a year.

Unlike traditional farms, the plants in the Greenery grow vertically indoors without soil and obtain their nutrition from nutrient-rich water while powerful LED lights stimulate growth. This independence from land, climate, and season allows the Greenery to bring the power of food production to anywhere in the world.

4 Steps to Farming in the Greenery

Completing a crop cycle in our hydroponic container farm, the Greenery, can be broken down into four simple steps:

Plant seeds

Transplant seedlings

Harvest

Repeat

While routine maintenance is crucial to ensure smooth farming operations, the bulk of your time will be spent handling the plants. During the first few months of operations, anticipate dedicating over 35 hours per week to the farm as you familiarize yourself with the technology.

With continuous support from Freight Farms' dedicated farmer support team, you'll have expert guidance every step of the way as you establish your farm. As you become familiar with the Greenery, your time commitment is expected to decrease to 25 to 35 hours per week.

Step 1: How to Start Your Seeds

The nursery station is where you’ll start your seeds. The nursery station’s table is the center for general farm operations and home to the farm’s young plants. Unlike anywhere else in the Greenery, the nursery station uses horizontal seedling troughs and an ebb-and-flow hydroponic system to nourish up to 4,608 seedlings at a time.

To start your seeds hydroponically, follow these steps:

Insert your grow plugs into the black trays

Distribute the recommended amount of seeds into each plug (the amount will differ based on their germination rate)

Place the newly seeded trays in the nursery station troughs where they’ll stay for an average of three weeks

Cover the trays with humidity domes (these domes will stay on the tray for approximately one week until they germinate)

By yourself, this process should be completed within 2 hours. When your farm is at full capacity, you’ll seed an average of 1,000 plants per week.

Step 2: How to Transplant Your Seedlings

On average, your seedlings will be ready to transplant after three weeks in the nursery station. This means they’ll be transferred from the nursery station into the cultivation area.

Designed for growing and nourishing large plants, the cultivation area features drip irrigation, plant panels, and a mobile rack system. Combined, these components create 220 square feet of production space.

Each plant panel in the cultivation area has five channels that are equipped with a porous foam growing medium and an anti-drip wicking strip, giving plants a structure on which to grow while ensuring moisture remains at the roots.

Depending on which transplanting method you find easiest, you can transplant your seedlings directly in the plant panels hanging in the cultivation area or you can detach the panels individually and bring them to your worktable to lay horizontally.

To transplant your seedlings into the plant panels, follow this process:

Before inserting the seedlings into the panel, it's crucial to ensure they are spaced correctly. Begin by placing your seedlings on top of the plant panel and arranging them in alignment with the spacing light in the nursery station. This light tool guides you on optimal plant placement depending on which crop you’re growing.

Once they’re all laid out, simply push the grow plugs into the foam of the panel and keep the plants angled upward at a 45-degree angle.

Transplanting 1,000 plants will take up 22 plant panels. With a fluid work rhythm, this process should take about 4 to 6 hours. When you get into the full swing of your operations, you will be transplanting once a week.

Step 3: How to Harvest Your Plants

Harvesting is the step where you’ll see the most variation in timing since harvesting techniques vary by crop. The process involves either trimming a plant to allow it to continue growing on the vertical farm walls or harvesting the entire plant, roots included, from the plant panel.

Typically, you'll start by harvesting in bulk and then proceeding to package the produce. Due to differences in packaging styles, some harvesting methods may take longer than others. Overall, harvesting and packaging will consume 6 to 8 hours per week.

Step 4: Repeat

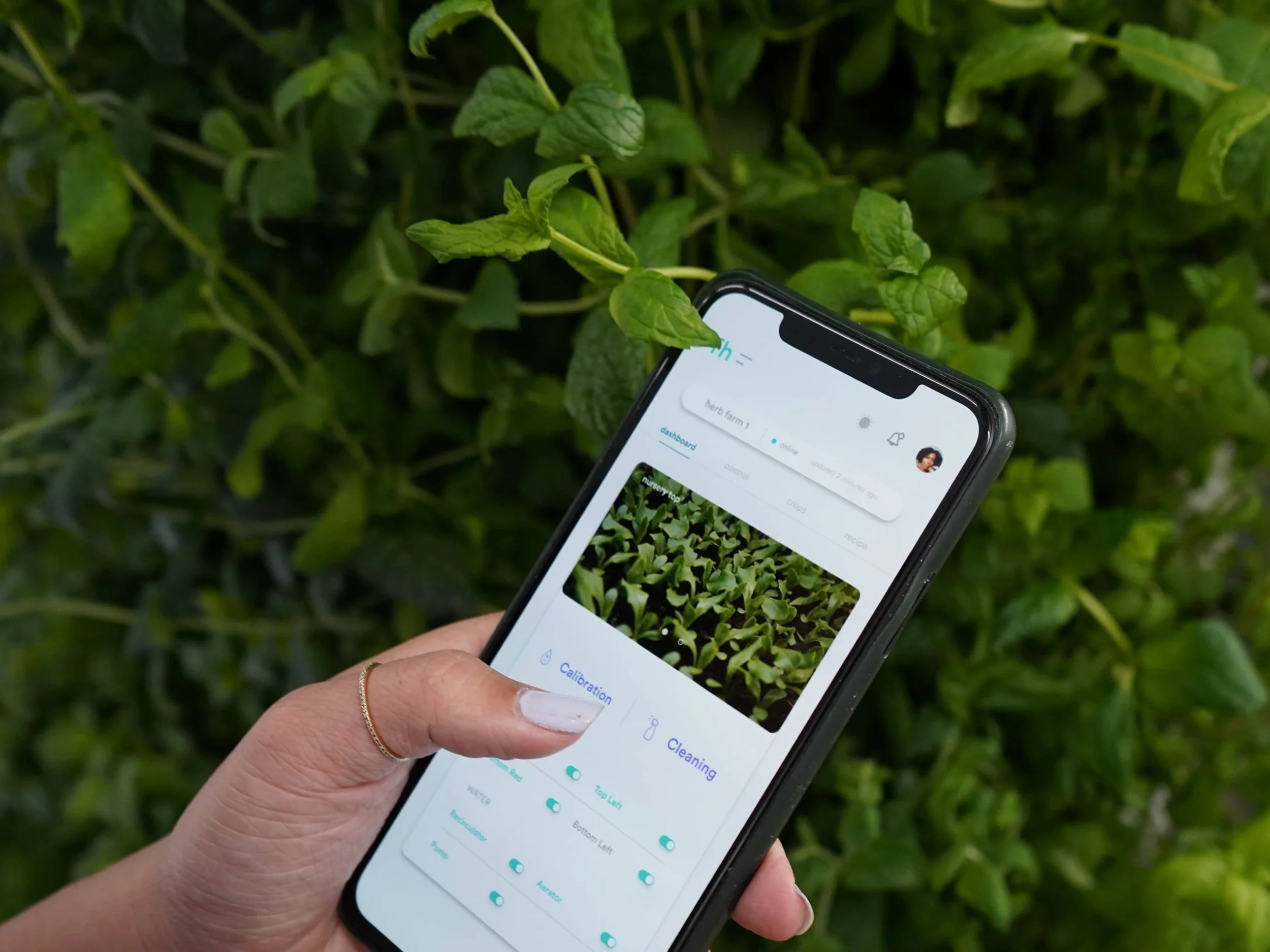

As you continue to seed, grow, and harvest, you'll gradually enhance your efficiency and understanding of the crops' requirements and cycles. You'll also have assistance every step of the way with farmhand® – our farm automation software and companion technology to the Greenery.

Maintenance Requirements

Along the way, you'll need to stay on top of some general maintenance.

Weekly, you should allocate 3 to 5 hours for cleaning and preparation, along with an hour for minor maintenance. Additionally, you can expect to dedicate approximately 12 hours per month to cleaning, sanitation, and general upkeep.

Consistent maintenance is key to preventing larger issues from developing in your farm. Over time, these tasks will become second nature as you settle into your routine. And remember, the Freight Farms team is always here to assist you as you familiarize yourself with these essential responsibilities.

Maintenance Schedule

Every week

Clean your filters, gutter screens, and drain covers to make sure there aren’t any clogs.

Every Other Week

Care for your plants' environment by incorporating additives into the water to promote strong plants and prevent pests.

Once a Month

Check supply inventory for things like nutrients and grow plugs. Clean and sanitize emitters, gutters, and your seedling trough.

Every Three Months

Maintain optimal water quality for your plants by regularly refreshing the water in both farm tanks, cleaning them thoroughly, and inspecting your pumps. Perform a climate sensor calibration and replace the A/C filters.

Every Six Months

Check to make sure your farm is still properly leveled. Change out the saturation strips in your plant panels.

Start Hydroponic Farming Today with Freight Farms

No matter which cause you champion — sustainability, local business development, or food security — hydroponic growing systems are a platform to build businesses and strengthen communities.

Hydroponic farming removes many of the variables involved in soil farming, making it easy for someone with no previous farming knowledge to get involved in growing food.

Connect with an account executive today to learn more about the Freight Farms technology and how you can start growing fresh food for your local community – no green thumb required!