Shipping Container Farm | Hydroponic Shipping Container | Container Farms for Sale | DIY Shipping Container Farm | Container Farming | Complete Hydroponic Systems | Hydroponic Container | Shipping Container Hydroponic Farm | Commercial Vertical Hydroponic Systems | Commercial Hydroponic Systems For Sale | Pre-Owned Freight Farm Leafy Green Machine

Oops! This is an old page…

To view our current inventory hydroponic farms and equipment, please click here

(CAN7) - Late 2021 Freight Farms Greenery S - Ontario, Canada

Manufacturer: Freight Farms

Model: Late 2021 Greenery S

Delivered In 2022

Location: Ontario, Canada

Price: $125,000 USD

Manufactured in Boston by Freight Farms, the Greenery S is the third version of their revolutionary shipping container farm. Freight Farms has sold over 500 farms located across the globe, from Alaska to the Middle East.

The technology in the farm provides precise control to optimize the lighting, water, and environment to produce perfect plants. Our planet wins through 90% less water usage, energy-efficient LED lighting, and a footprint that is just 0.3% of conventionally farmed land for equivalent yield.

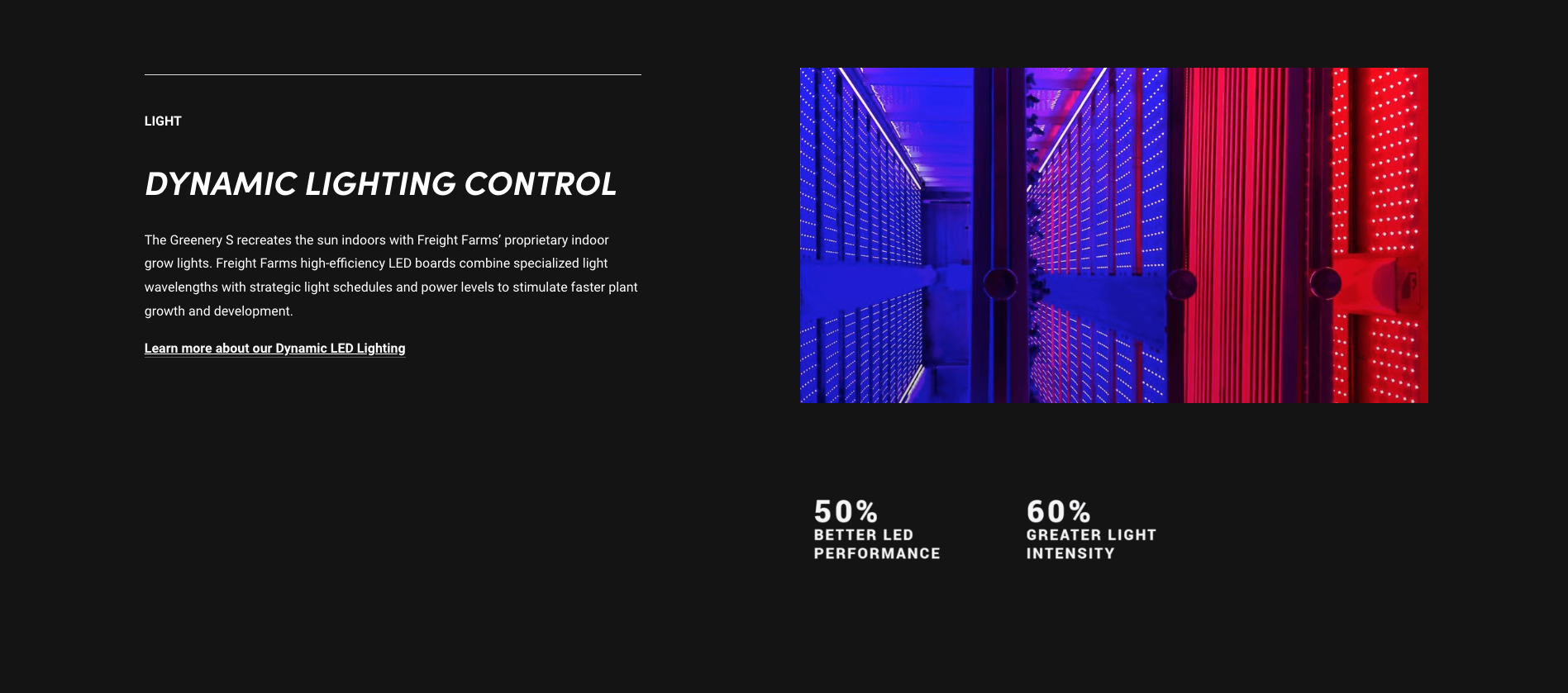

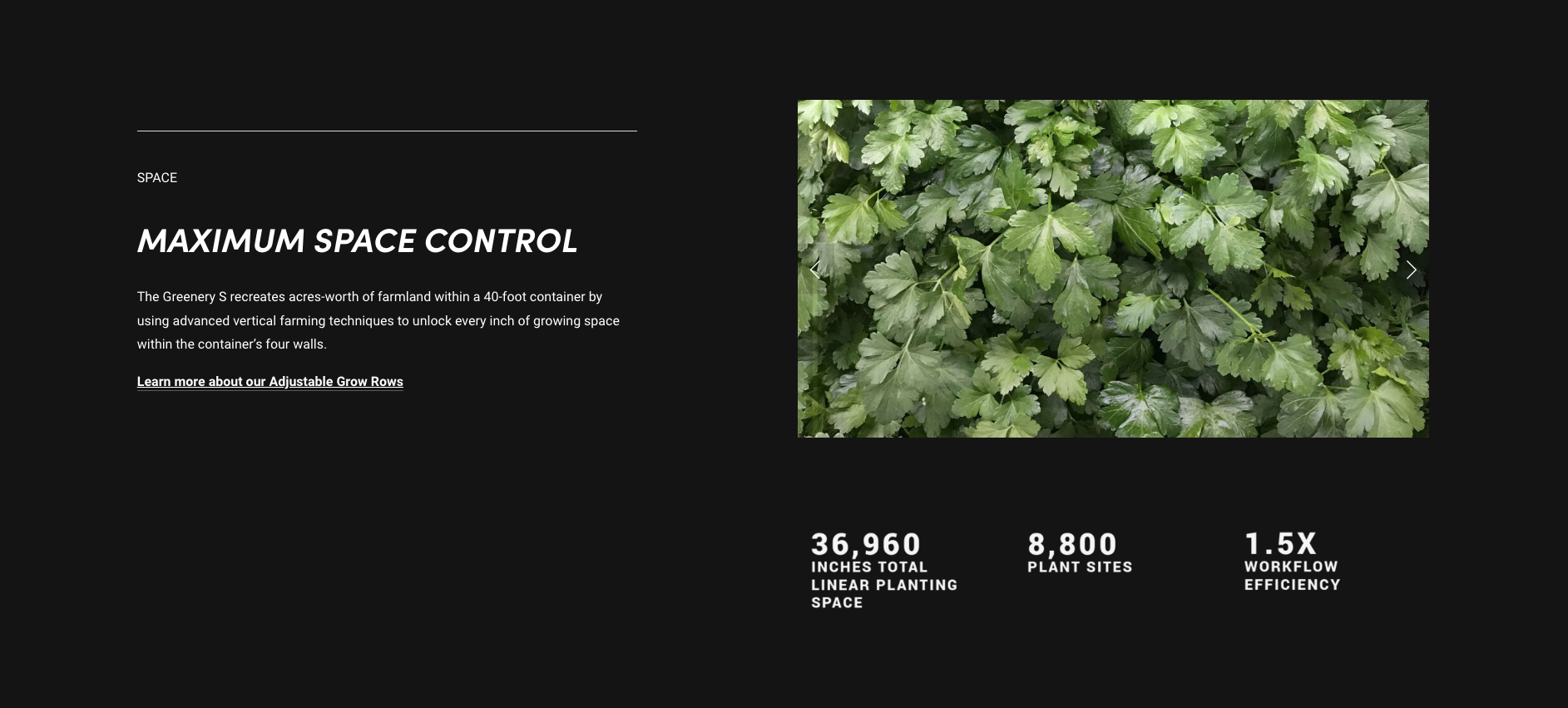

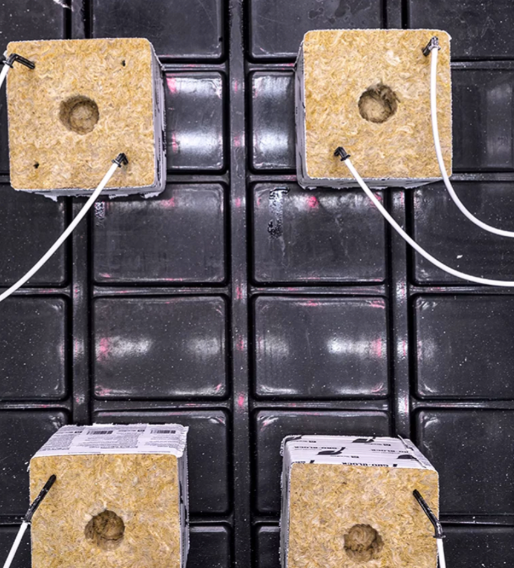

The life cycle starts with non-GMO seeds in a nursery for approximately 3 weeks. The seedlings are transplanted into a substrate in vertical towers which maximizes space. Water then carries specific nutrients to the plants and LED lights replicate the sun for another 4 weeks before they reach their peak. Using hydroponic methods in a laboratory-like environment, we can safely harvest our greens with very limited handling.

Automated, efficient systems in a controlled environment provide extraordinary productive capabilities. The Greenery S can grow 4,000 lettuce heads per month in 320 square feet using less than 5 gallons of water per day.

About Freight Farms

Freight Farms invented container farming and have the largest network of connected farms in the world. In 2013, Freight Farms released the first hydroponic container farm into the market. Since then, Freight Farms has grown to have a footprint of over 600 farms in use, located in 49 states, and 4 US territories, and integrated farms into 38 companies. The company is now on its third generation of container farms. Its first generation, Leafy Green Machine, went through six iterations before giving way to the Greenery and now the Greenery S.

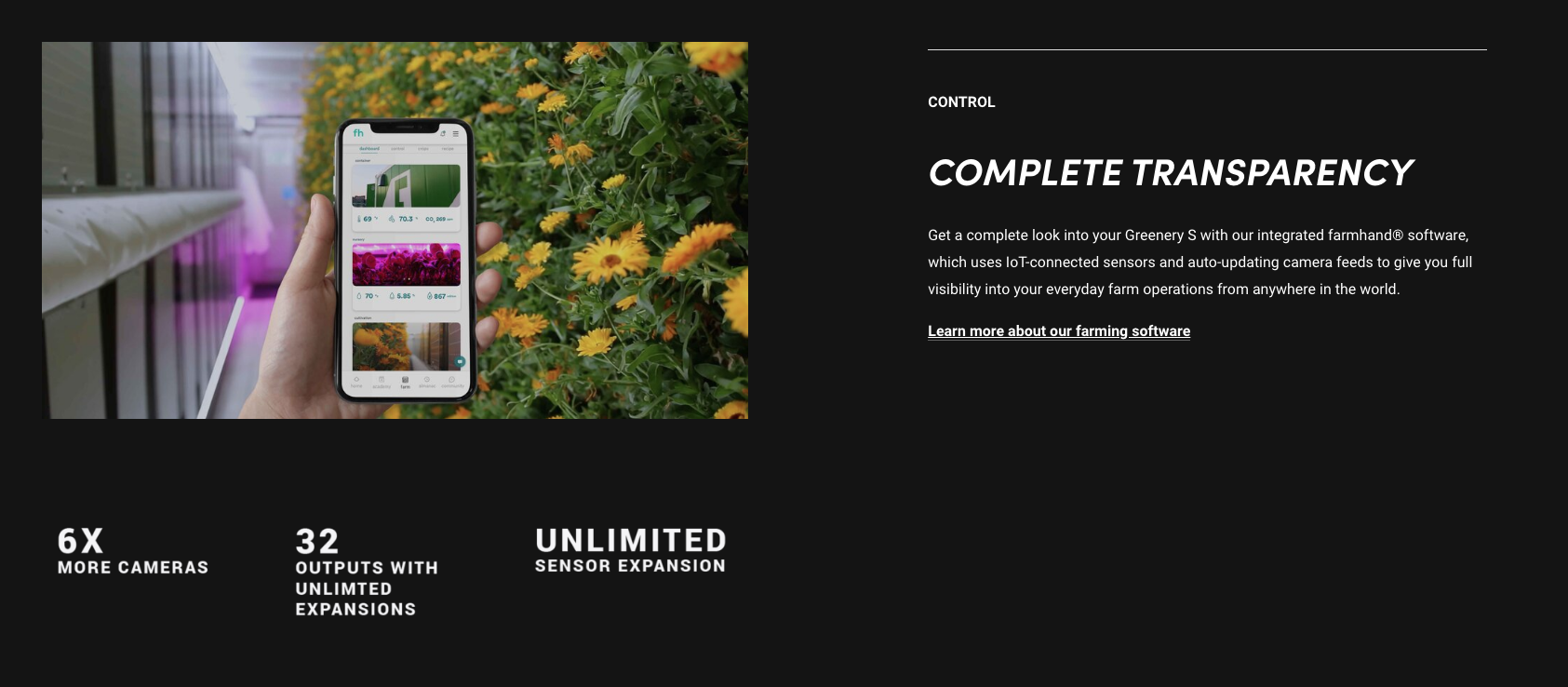

AgTech Breakthrough named Freight Farms the 2022 “IoT Monitoring Solution of the Year” for its farmhand® IoT automation software. More information is available at www.freightfarms.com.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(NM2-3) - Two - Grow Pod Solutions - GrowMax G201 - Produce and Cannabis Shipping Container Farms - New Mexico

Manufacturer: Grow Pod Solutions

Model: GrowMax G201

Location: New Mexico

Price: $80,000 USD For Each Container

For the best production of premium Produce and Cannabis, The GrowMax G201 is loaded with premium features and fittings. Manufactured in California by Grow Pod Solutions, the GrowMax G201 is the most versatile 1 tier version of their revolutionary shipping container farms.

The technology in the container farm provides precise control to optimize the lighting, water, and environment to produce perfect plants. The cost savings for the operation are outstanding through 90% less water usage, energy-efficient LED lighting, and a footprint that is just 0.3% of conventionally farmed land for equivalent yield.

Year-round farming using hydroponic methods in a laboratory-like environment, can now safely harvest many types of produce with very limited handling. Automated, efficient systems in a controlled environment provide extraordinary productive capabilities. The GrowMax G201 can grow 1,000s of plants per year in 320 square feet using less than 5 gallons of water per day

Please Note: Indoor Grown, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(NC2) - 2021 Freight Farms Greenery S - North Carolina

Manufacturer: Freight Farms

Model: 2021 Greenery S

Location: North Carolina

Price: $100,000 USD

Manufactured in Boston by Freight Farms, the Greenery S is the third version of their revolutionary shipping container farm. Freight Farms has sold over 500 farms located across the globe, from Alaska to the Middle East.

The technology in the farm provides precise control to optimize the lighting, water, and environment to produce perfect plants. Our planet wins through 90% less water usage, energy-efficient LED lighting, and a footprint that is just 0.3% of conventionally farmed land for equivalent yield.

The life cycle starts with non-GMO seeds in a nursery for approximately 3 weeks. The seedlings are transplanted into a substrate in vertical towers which maximizes space. Water then carries specific nutrients to the plants and LED lights replicate the sun for another 4 weeks before they reach their peak. Using hydroponic methods in a laboratory-like environment, we can safely harvest our greens with very limited handling.

Automated, efficient systems in a controlled environment provide extraordinary productive capabilities. The Greenery S can grow 4,000 lettuce heads per month in 320 square feet using less than 5 gallons of water per day.

Link To Download The Complete Product Brochure

About Freight Farms

Freight Farms invented container farming and have the largest network of connected farms in the world. In 2013, Freight Farms released the first hydroponic container farm into the market. Since then, Freight Farms has grown to have a footprint of over 600 farms in use, located in 49 states, and 4 US territories, and integrated farms into 38 companies. The company is now on its third generation of container farms. Its first generation, Leafy Green Machine, went through six iterations before giving way to the Greenery and now the Greenery S.

AgTech Breakthrough named Freight Farms the 2022 “IoT Monitoring Solution of the Year” for its farmhand® IoT automation software. More information is available at www.freightfarms.com.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(NJ3) - 10' - 2019 Bespoke Lightweight Mobile Hydroponics Container Farm On Trailer - New Jersey

Small Lightweight Mobile Hydroponics Container Farm On Trailer

Specs:

Exterior Dimensions 10’L x 5’W x 6’H, Add 8” for overall Height, add 2’ length for tongue. Interior Finished Dimensions 10’L x 5’W x 6’H

16” o.c. steel tube framing throughout

Insulation R-16

Aluminum Outer Shell:

(1) 36” x 72” RV-style door with Flush lock

(1) 48” x 72” RV-style backdoor with padlock

(2) 15” ST225 radial tires

Complete Recirculatory NFT System:

33 plants per week capacity

200 plants full capacity

2 trays per week microgreen capacity

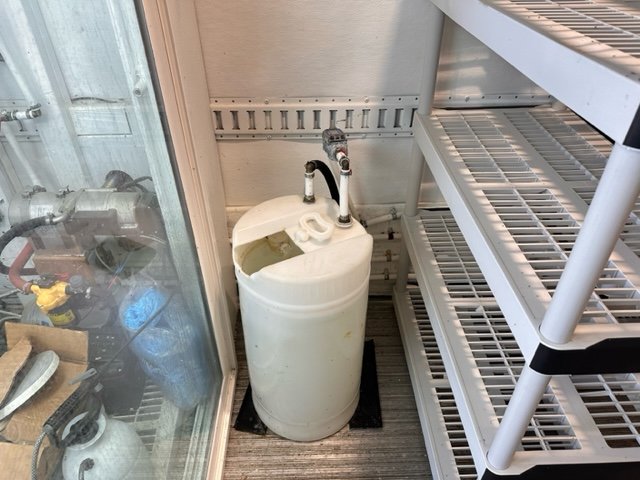

50-gallon tank

Inline reusable nylon mesh filters

Stealth RO filter

(13) 50w full spectrum 4’ LED grow lights

(1) Infinity 8” recirculatory fan ( variable speed)

(1) Infinity 12” recirculatory fan ( variable speed)

(14) Infinity 4” Shelf fans

1 Ton Pioneer Heat pump

(1) Supplementary Humidifier

(1) Energy Recovery Ventilator (ERV)

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(NJ2) - 34' - 2022 Bespoke Lightweight Mobile Shipping Container Farm On Trailer - New Jersey

34' Bespoke Lightweight Mobile Shipping Container Farm On Trailer - New Jersey

Operation And Site Preparation

Operation:

This unit is currently in operation in New Jersey and produces about 800 heads of assorted lettuce and leafy greens and 22 (10x20) trays of microgreens per week. Can be sold as a turnkey operation or just the Bespoke Lightweight Mobile Hydroponics Trailer.

Turnkey operation includes a commerce website, reusable containers, bags and cool packs, (for delivery), trays, domes, nutrients, seeds, beneficial bacteria, and a mobile 10x5 trailer with an NFT system that produces 32 heads weekly and is used for farmers market events (details below) and more.

Site:

This unit is a completely mobile lightweight trailer. A permanent location is optional. Park on a Fairly level 45’ x 10’ lot It is currently parked with an external tank but can be fitted with 1 or 2 tanks to the undercarriage to make a more convenient mobile solution.

Water: RO Filter Water supply via garden hose or hard connection will be required

Electric: External 100 Amp Single-phase connection required

Specialty: Ethernet or Wi-Fi connection (to remotely control the environment and dosing)

Specs:

V Nose Triple Axle Cargo Trailer

Exterior Dimensions: 34’L x 8.5’W x 10’H, Add 1’ for overall Height, add 2’ length for tongue. Interior Finished Dimensions: 34’L x 7’9”W x 9’4”’H

16” o.c. steel tube framing throughout

Insulation: R-23

Aluminum Outer Shell:

5k Bullydog jack

(4) 5000 lb D-Rings welded to the frame (for transport) (2) 36” x 78” RV style doors with Flush locks

(6) 15” ST225 radial tires

Climate Control: Bard Heat Pump

● 3 Ton Bard heat pump

● Electric heater package

● Integrated dehumidifier

● Integrated Energy Recovery Ventilator (ERV) allows for up to 400 CFM of fresh air and exhaust through the main unit while maintaining superior indoor temperature and humidity levels

● Low ambient control and outdoor thermostat kit ( for operating in extreme cold weather areas)

● EER Efficiency rating 11.1

● CFM 1150

● Refrigerant R-410A

Supplementary Dehumidifier:

● Honeywell dehumidifier

● ~50 pints/day at 70 degrees

● CFM 160

● Refrigerant R-410A

Fans:

● (4) Terrabloom Inline duct fans, Variable adjustable speed

● 2 Floor fans

● Exhaust /Air exchange rate - Continuous through the ERV CO2 generator

● Titan Controls Ares 8 LP

Lighting:

Main lighting;

● General LED throughout

● Over-counter work light

Cultivation lighting:

● (88) 15-watt Maxsisun, Full spectrum, 700 pcs LED chip on board lighting, Dimmable with Mean well drivers

● (8) computer-controlled arrays ( 2 per grow row)

● IP65

● PPE (μmol/J): 2.5

Nursery lighting;

● (8) Bios, Icarus LLi Full spectrum LED strip lighting

● 2 computer-controlled arrays

● Programmable wavelength

● Dusk/ Dawn dimmable programmable

● IP66

● PPE (μmol/J): 2.9

Nursery Workstation:

● Dimensions - 96”L x 32”D x 48”H

● Materials - 430 and 380 Stainless Steel Seedlings

● (2) levels

● Tray capacity - (16) 10 x 20 trays ( variable cell sizes 200 cell, 288cell, microgreens)

Irrigation:

● Ebb & Flow system

● (2) 20-gallon tanks ( one tank for each level) RO Autofill

● (2) Water Pumps - Flow rate 750 gal/hr

● Aeration - (1) 800 gal/ per hour oxygenator (split evenly in 2, one for each of the 2 tanks)

● BluLab - EC, Temperature, pH monitor

● Manual Dosing

Cultivation:

Main Tank:

● (1) main tank 130-gallon capacity. RO Autofill

● OPTIONAL - Run a dual tank system with (2) 60-gallon tanks. Divide the entire cultivation capacity into 2 separate systems. Circulation Pumps

● (2) Hayward - gal/hr pumps

● (1) nutrient mixing/nutrient analysis pump ( sends main tank sample to the sample tank) Filtration

● (2) Spin down micro mesh reusable filter

● (2) Gutter stainless steel debris mesh filter Capacity

● (9-15) average, 10 Plants per column

● (80) Columns per row ( 800 plants)

● (4) Aluminum frames Grow Rows, with lateral rack and pinion moveability

● (1) Double-sided hanging light wall with lateral movability

● (320) total Columns, 3200-4800 plants at full capacity

Irrigation:

● Vertical Drip system:

● (320) Bespoke, white, UV-protected, HDPE columns. Dimensions 3” x 3” x 96”

● Each column contains 3 inert reticulated foam sections (3 sections for ease of use and cleaning)

● Each foam section contains its own felt wick

● Plumbing - NSF61 PVC

● (320) Drip emitters - Self-flushing, Clog-resistant, 2 gal/hr, Bespoke quick change design

● (2) Water Pumps - Flow rate 750 gal/hr

● Aeration - (3) 800 gal/ per hour oxygenator (split evenly in 3)

● BluLab - EC, Temperature, pH monitor, doser

● (4) Peristaltic dosing pumps, programmable flow rate

Microgreens Station:

Shelving unit:

● Dimensions - 48”L x 24”D x 115”H

● Materials - chromed steel

Capacity:

● (11) Levels, 14” H storage under the first shelf level

● (4) trays per level

● Total microgreen Tray capacity - (44) 10 x 20 trays

Water:

(1) Stealth RO filter

(1) 2 x 2 Stainless steel sink

Electric:

The unit provides a 100 amp electrical panel accessible from inside the unit. Every breaker is GFCI-protected.

Computer Controls and Electronics:

Lighting control:

● TrolMaster Hydro-X Plus Controller

● (8) program devise station

Nursery Pump Control:

● (2) TrolMaster Hydro-X Plus Controller

● (2) Lighting control adapter

Main Pump Control:

● (1) HD Repeat plug-in timer

Nutrient Pump Control:

● (1) HD Repeat plug-in timer

HVAC control:

● TrolMaster Hydro-X Plus Controller

● (1) Thermostat Station

CO2 control:

● TrolMaster Hydro-X Plus Controller

● (1) Co2 Devise station

Humidity Control:

● TrolMaster Hydro-X Plus Controller

● (1) Humidistat station

Main tank dosing control:

● (1) Bluelab Pro controller, connect

● Bluelab Peripod M4

Nursery tank monitoring:

● (1) Bluelab Guardian, connect

Smoke/Fire:

● TrolMaster Hydro-X Plus Controller smoke sensor

● (1) Remote fire alert WiFi

● (1) TP-Link wireless dual band Gigabit router

Audio:

● (1) Bose 321 system, CD player, AM/FM radio, two speakers, and an Acoustimass subwoofer

● Aux input for a multitude of phones, iPads, and other devices

Other options to be included if sold as a turn-key operation

Freezer:

● TrolMaster Hydro-X Plus Controller

Araven Food storage containers:

● 200 4.2 qt Name branded containers ● 100 2.6 qt Name branded containers

Choice Black Jumbo Insulated Nylon Tote cooler bag ● 100 Name branded bags

Microgreen Trays:

● (44) 10 x 20 trays with holes

● (44) 10 x 20 trays without holes

● (34) 10 x 20 clear 1” domes

● (10) 10 x 20 clear 3” domes

Nursery Trays:

● (16) 10 x 20 trays with holes

● (16) 10 x 20 -200 cell inserts

● (16) 10 x 20 clear 1” domes

● (4) 10 x 20 clear 3” domes

Nutrients:

● (16) 10 x 20 trays with holes

Media:

● (3000) 3⁄4” peat plugs

● (500) 1” Groden plugs

Seeds:

● Microgreen seeds

● Lettuce seeds

● Leafy green seeds

● Misc

Other:

● Mycorrhizae

● Photosynthesis-beneficial bacteria

● ClearZona

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(C-OK16-17) - Two - Grow Box Central - Cannabis Shipping Container Farms - Oklahoma

Manufacturer: Grow Box Central

40-Foot HC Shipping Container Farm

Location: Oklahoma

Price: $60,000 USD Each

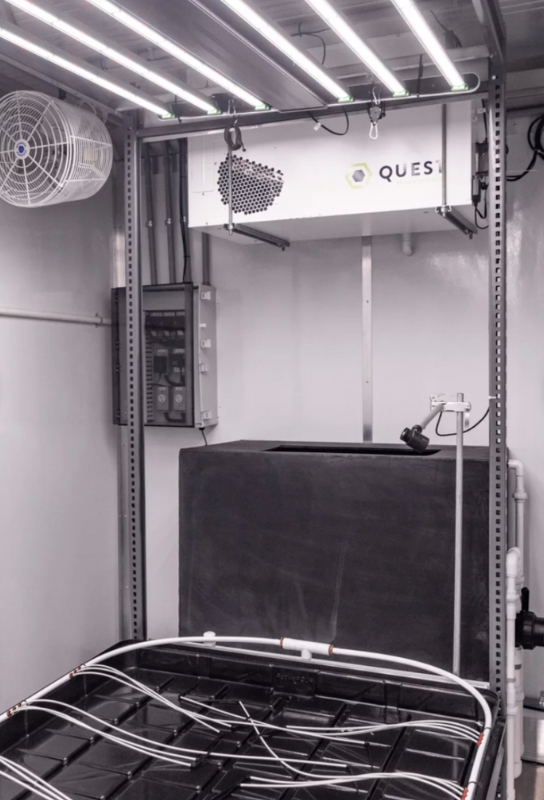

Both Containers Are In Excellent Condition With Brand-New HVAC Mini-Split Systems And Are Ready For Planting

SPECIFICATIONS

Size:

They are 40’ long, 8’ wide, and 9’6” tall. They are high-cube shipping containers

Electrical:

220V outlets: lights/dehumidifier

110V outlets: fans, pumps, and air

Walls and Ceiling:

2 x 3 framing

2″ closed cell spray foam walls, ceiling, and floor

Mold-resistant backer walls and ceiling

FRP walls and ceilings

Floors:

Installed new 3/4″ flooring

White epoxy finish

HVAC:

2 x 2-ton mini-split units

Dehumidifier:

Quest 225-pint ceiling-mount dehumidifier

Spray Foam Insulation:

2″ closed cell insulation for the floor and ceiling

Fans:

12 x Hurricane oscillating wall-mounted fans

Exterior Doors:

Two insulated steel doors are located at each end of the container

Paint Coating:

Container roof painted with Polybrite 95 reflective coating

LIGHTING

Horticulture Lighting Group HLG 600 Rspec 600W 120V LED Quantum Board Grow Light with Samsung LM301H, Inventronics Driver, Growing Lights for Indoor Plants, Full Spectrum, Dimmable, Highest PPF

HIGHEST EFFICIENCY FARMING LIGHTS: Agricultural LED lights have a high output of 1529 PPF at 2.60 μmol/j, making this one of the highest-efficiency grow lights on the market, with third-party lab results to prove it. This vegetation light is custom-designed to fit a 4×4-foot grow tent perfectly, or wherever else your plants’ happy place happens to be. ETL/UL Certified

BETTER CANOPY PENETRATION: Full Spectrum White + Deep Red LED light diffuses evenly, making it ideal for full veg/flower cycles plus healthy, uniform growth so there will be no more brown tips. Footprints are Veg 5×5 ft at 28” and Flower 6×6 ft at 40”; Dimensions are 26” x 21.5″ x 2.75″; Recommended mounted height is 28-36 inches above canopy

DIMMABLE GROW LIGHT: The dimming knob allows output to be adjustable from 100 watts to 600 watts. It also features a reliable passive cooling design for reduced heat, which means better temperature control for your indoor herb garden.

COMMERCIAL LED GROW LIGHTING: HLG 600 Rspec Commercial Indoor Horticulture LED grow light is designed to replace a 1000W HID and uses our 4 full-spectrum white light Quantum Boards with Samsung LM301H and Deep Red 660nm LED diodes

DESIGNED & ASSEMBLED IN USA: Grow lighting leader HLG designed the first high-density modular light engine for horticulture and, through constant innovation, has led the way in developing efficient, effective growing lights. This HLG indoor grow lamp comes with a 3-year warranty.

OPTION AVAILABLE

10 new Mars Hydro units that are not hung up in the containers

The TS3000, as the biggest LED grow light in the TS series, offers enough coverage for a 4×4-foot area with an affordable price and quality yield. in return, it’s able to be applied to both home cultivation and commercial vegetable cultivation.

Wattage: 450w

Veg Coverage: 5×5 ft

Flower Coverage: 4×4 ft

The overwhelming choice for most growers is a grow tent, small room, cabinet & closet, plant shelves, and budget option for commercial vegetative cultivation

High-Performance Lighting

All of the production units (Flowering, Veg, and Clone) come equipped with industry-leading LED lighting. We are also willing to work with customers with different lighting options.

Climate-Controlled Facilities

In each of the units, you have the ability to wirelessly dial-up custom temperatures and humidity levels to maximize and enhance your product. We work with each client to ensure the correct amount of cooling or heating, depending on the lighting used and ambient climate conditions.

Complete Turn-Key Solutions

Each unit is a 100% turn-key solution. Once the unit arrives and power is hooked up, it is ready to grow. This makes our equipment ideal for setting up a complete, ready-to-go operation, saving you time and money.

Remote Monitoring and Control

All units come equipped with remote monitoring for control of climate control systems, lights, and airflow systems. Additional sensors and controls can be implemented upon request.

It’s about control

As the industry evolves, regulatory pressures will change, and indoor growth means you have more control—and more ways to adapt to changes—than any outdoor operation. But most importantly, it gives you greater control over your crop, your time, and your profitability.

Control environmental conditions: This means you can control temperature, lighting, humidity, and access during all aspects of cultivation. With container farming systems, control is built in.

Control pests and parasites: spiders, mites, thrips, flies, gnats—and many others—can destroy an entire crop or cause you to need expensive countermeasures. Indoor growth minimizes the chances of these issues, using container farming systems to further press our advantage.

Control airborne pathogens: A variety of airborne pathogens (Verticillium, mildews, botrytis, and others) are a serious threat to a valuable crop. This is another area where indoor, controlled growth minimizes risks and creates the healthiest possible environment.

Control regulatory standards: We can comply more easily with cGMP (current good manufacturing process) and other FDA or USDA standards within a container farming environment than we can outdoors. Adherence may or may not be mandatory, but someday it might be nationwide.

Consistency is critical. When you can dictate the environment, you can create a more valuable yield that consumers will identify with and flock toward.

Harvest more crops per year: Since you are indoors and aren’t subject to the whims of Mother Nature, you can add extra harvest cycles and continuously produce more crops and profit every year.

Control access: Security is an obvious and ongoing issue at cannabis facilities. Indoor facilities using container farming systems are much easier to lock, surveil, and control than outdoor facilities—or even indoor grow centers that occupy the center of a building where access is easier.

CONSTRUCTION PHOTOS

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(MI7) - 2018 Freight Farms Leafy Green Machine - Michigan

Model: 2018 Leafy Green Machine

Manufacturer: Freight Farms

Location: Michigan

Price: $65,000 USD

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

Restauranter who want to grow custom greens for rotating menus 365 days a year. Farm to Table? How about a Parking Lot to Table?

Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space - The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either a trap rock or a concrete pad.

Electrical - 60 amp, 120/240-volt single phase or 120/208V three-phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor - 15 to 20 hours a week for farming and upkeep.

It is recommended to grow smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs, and heartier greens like kale and Swiss chard.

Crop examples include Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields - 400 - 450 heads of lettuce weekly

12 heads per tower (256 vertical towers)

Visit Freight Farms (Website) for more information.

About Freight Farms

Freight Farms invented container farming and have the largest network of connected farms in the world. In 2013, Freight Farms released the first hydroponic container farm into the market. Since then, Freight Farms has grown to have a footprint of over 550 farms in use, located in 49 states, and 4 US territories, and integrated farms into 38 companies. The company is now on its third generation of container farms. Its first generation, Leafy Green Machine, went through six iterations before giving way to the Greenery and now the Greenery S.

AgTech Breakthrough named Freight Farms the 2022 “IoT Monitoring Solution of the Year” for its farmhand® IoT automation software. More information is available at www.freightfarms.com.

Please: Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(WA4) - CleanTec Custom Mycology Lab and Microgreen Shipping Container Farms - Solar Powered

Manufacturer: CleanTec Sustainable Systems

Location: Washington State

Price: $100,000 USD

The Most Efficient, Cost-Effective,

And Simple Mushroom Farms On The Planet

Over a five-year R&D phase, CleanTec has created the most simple and effective system for large-scale mushroom farming.

These shipping container farms are a combination of basic equipment, inside a beautiful well-lit working space on a mobile platform.

The units are fully assembled and ready to use in a turn-key capacity.

No building permits required.

The units are considered, "machines" by law and they do not add value to a property as a structure would, so you skip the building department and get straight to producing within days of delivery.

This two-unit farm has the capacity to output 1000 lbs+ of mushrooms per month.

Each machine includes space and everything needed to output over one thousand pounds of mushrooms each month at full operational capacity.

Scalable and Modular by design

Farms can be scaled by simply adding new units next to the existing ones with the required equipment inside.

Climate-proofed and ready for any location

With 360 degrees of insulation and an overbuilt climate system, units are designed to be used in any location around the world, regardless of the climate.

The 12+ Solar panels on one unit can power all electrical inside two units. Includes a professional-grade charge controller, inverter, service box, and battery system.

The Scalable Two-Unit Farm:

CleanTec Lab & Inoculation Unit

CleanTec Fruiting Chamber Unit

Lab & Inoculation Unit

Climate-controlled inoculating space, complete with everything involved in the mushroom work - pasteurization pressure cooking equipment, and more.

Lab Space + Equipment

A CleanTec Lab & Inoculation Myco-Unit model includes:

Climate-controlled lab space with hardware needed to grow mushrooms at scale

Large-scale pasteurizer, gas range, steel tables for working space

Shelving space to store bags through the inoculation phase.

Complete Control From Anywhere At Your Fingertips

Using a mobile application, most of the equipment in the units is controlled digitally. This also allows you to remotely manage and monitor climate conditions in each unit.

Scalable & Easy-To-Use

Each system is scalable, so production can be scaled to meet demands. The Lab and equipment and processes are easy for anyone to use, regardless of existing mushroom growing knowledge.

Featured Lab Equipment:

Space for Inoculating Substrate Bags

Large-Scale Pasteurizer System

Adjustable height Flow Hood over the work area.

Sink and gas Range with Exhaust Hood

Fruiting Chamber Unit:

Sealed insulated & climate-controlled fruiting chamber space with over 800 square feet of shelving for fruiting bags. Output capability is over 1000 pounds of fresh mushrooms per month. Sealed + Climate Controlled

The Fruiting Chamber model creates the perfect climate for mushrooms with basic, yet innovative & extremely efficient equipment:

Proprietary radiant heat system & super-cooled A/C system

Atomizing humidifiers &water-proof coated outdoor-grade interior/exhaust fans

Over 800 square feet of shelving make the perfect space for fruiting mushrooms

Insulated + Easy To Clean

Regardless of the environment outside, mushrooms will stay safe inside the unit with 3-5 inches of mold-resistant insulation & our innovative, overbuilt climate control system. Aluminum floors and plastic walls/ceilings make these units very easy to regularly clean.

Featured Fruiting Chamber Equipment:

Over 800 square feet of shelving for fruiting space

Efficient & Functional Working Space

CleanTec Super-Cooled A/C System

Hose Reel for easy Cleaning and misting

Best Up-Front and Operating Costs, Super Energy Efficient

CleanTec has developed a process for growing mushrooms to work in conjunction with our units. Whether you're new to growing mushrooms or a seasoned vet, we'll show you the process that we've found works best within our units. We teach you everything we know about growing mushrooms when you become a client.

Simple software and equipment make the equipment easy so that anyone, regardless of their current mushroom knowledge can grow mushrooms at scale with CleanTec Mushroom Farm systems.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(MS1-2-3-4-5-6-7-8-9) - Nine - Cannabis Shipping Container Farms - Mississippi

Complete Cannabis Grow System

Manufacturer: Container Grow Box

Location: Mississippi

Price: $600,000 USD

Six - 40′ Dry/Cure Containers

40 Ft One Trip Iso Containers 9’6’ with 8′ Mechanical room

Polyurethane Epoxy White Paint Exterior

Urethane Insulation (walls, ceiling & underfloor) R14

Class A Fire-rated interior PVC Panels

Steel Man Door with Push Bar & lock

Poly Urea Nonslip Floor / Class A fire-rated

100 Amp Electrical Panel

6 x 110v Duplex Outlets – 4 On Each Side Fan Outlet

5 x 4 FT LED Commercial Wrap around lights

Trol Master Hydro X PRO Controller & Sensors

5 Ton BTU Bard HVAC

6 x 130 Pint Dehumidifiers

12 x Wachsen Drying Cart SS304 4 leveln and 5′ SS Table with 30” SS Work Sink

40′ Flower Container

40 Ft One Trip Iso Container 9’6’ with 8′ Mechanical room

Polyurethane Epoxy White Paint Exterior

Urethane Insulation (walls, ceiling & underfloor) R14

Class A Fire-rated interior PVC Panels

Steel Man Door with Push Bar & lock

Poly Urea Nonslip Floor / Class A Fire Rated

200 Amp Electrical Panel 208/240

16 x 110v Duplex Outlets

4 x 4 FT LED Commercial Wrap around lights

16 x Oscillating Fans

Trol Master Hydro X PRO Controller & Sensors

Hydrologic EVO Reverse Osmosis system

Nuravine Dosing system

5 Ton Bard Hvac

2 x 130 Pint Dehumidifiers

30 Ft Rolling Bench Center Grow with flood tables

8 x Fluence Spider 2i LED Grow lights

5′ SS Table with 30” SS Work Sink

40′ Mother Clone Container

40 Ft One Trip Iso Container 9’6’ with 8′ Mechanical room

Polyurethane Epoxy White Paint ExteriorUrethane Insulation (walls, ceiling & underfloor) R14

Class A Fire-rated interior PVC Panels

Steel Man Door with Push Bar & lock

Poly Urea Nonslip Floor / Class A Fire Rated

200 Amp Electrical Panel 208/240

16 x 110v Duplex Outlets

4 x 4 FT LED Commercial Wrap around lights

6 x Oscillating Fans

Trol Master Hydro X PRO Controller & Sensors

Hydrologic EVO Reverse Osmosis system

Nuravine Dosing system

5 Ton Bard Hvac

1 x 70 Pint Dehumidifiers

2 x 130 Pint Dehumidifiers

2 x 2′ Waschen rolling bench

4 x Waschen Cloning Carts with Lightstick LED

6 x Fluence Spider 2i LED Grow Lights

5′ SS Table with 30” SS Work Sink

40′ Irrigation Container

40 Ft One Trip Iso Container 9’6’

Polyurethane Epoxy White Paint Exterior

Urethane Insulation (walls, ceiling & underfloor) R14

Class A Fire-rated interior HDPE Plywood Panels 1/2″

Steel Man Door with Push Bar & lock

Poly Urea Nonslip Floor / Class A Fire Rated

100 Amp Electrical Panel 208/240

4 x 4 FT LED Commercial Wrap around lights

24000 BTU Mini Split HVAC & Heat Pump

2 x 650 CFM Exhaust Can Fans

7 x Open Top Cone Bottom Plastic Tank – 54 US Gallons

1 x Closed Top Cone Bottom Plastic Tank – 300 US Gallons. Stand included

1 x Waterite Vectamaxx RSR 2400GPD RO System

1 x DAB Esybox Mini3 – Electronic Pressurization System NPT / DV / G

KRAUS Standard PROTM 30-inch 16 Gauge Undermount Sink

1 x Kitchen Faucet, Black Kitchen Faucet with Pull Down Sprayer

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(C-OK11-12-13-14-15-CK) - Five - Grow Pod Solutions - GrowMax G201 - Produce and Cannabis Shipping Container Farms - Oklahoma

Manufacturer: Grow Pod Solutions

Model: GrowMax G201

Location: Oklahoma

Price: $80,000 USD For Each Container

For the best production of premium Produce and Cannabis, The GrowMax G201 is loaded with premium features and fittings. Manufactured in California by Grow Pod Solutions, the GrowMax G201 is the most versatile 1 tier version of their revolutionary shipping container farms.

The technology in the container farm provides precise control to optimize the lighting, water, and environment to produce perfect plants. The cost savings for the operation are outstanding through 90% less water usage, energy-efficient LED lighting, and a footprint that is just 0.3% of conventionally farmed land for equivalent yield.

Year-round farming using hydroponic methods in a laboratory-like environment, can now safely harvest many types of produce with very limited handling. Automated, efficient systems in a controlled environment provide extraordinary productive capabilities. The GrowMax G201 can grow 1,000s of plants per year in 320 square feet using less than 5 gallons of water per day

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(C-OK7-8-9-10-CK) - Four - Grow Pod Solutions - GrowMax G201 - Produce and Cannabis Shipping Container Farms - Oklahoma

Manufacturer: Grow Pod Solutions

Model: GrowMax G201

Built: March 2021

Location: Oklahoma

Price: $80,000 USD For Each Container

For the best production of premium Produce and Cannabis, The GrowMax G201 is loaded with premium features and fittings. Manufactured in California by Grow Pod Solutions, the GrowMax G201 is the most versatile 1 tier version of their revolutionary shipping container farms.

The technology in the container farm provides precise control to optimize the lighting, water, and environment to produce perfect plants. The cost savings for the operation are outstanding through 90% less water usage, energy-efficient LED lighting, and a footprint that is just 0.3% of conventionally farmed land for equivalent yield.

Year-round farming using hydroponic methods in a laboratory-like environment, can now safely harvest many types of produce with very limited handling. Automated, efficient systems in a controlled environment provide extraordinary productive capabilities. The GrowMax G201 can grow 1,000s of plants per year in 320 square feet using less than 5 gallons of water per day

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(C-OK2-3-4-5-6-CK) - Five - Grow Pod Solutions - GrowMax G201 - Produce and Cannabis Shipping Container Farms - Oklahoma

Manufacturer: Grow Pod Solutions

Model: GrowMax G201

Location: Oklahoma

Price: $80,000 USD For Each Container

For the best production of premium Produce and Cannabis, The GrowMax G201 is loaded with premium features and fittings. Manufactured in California by Grow Pod Solutions, the GrowMax G201 is the most versatile 1 tier version of their revolutionary shipping container farms.

The technology in the container farm provides precise control to optimize the lighting, water, and environment to produce perfect plants. The cost savings for the operation are outstanding through 90% less water usage, energy-efficient LED lighting, and a footprint that is just 0.3% of conventionally farmed land for equivalent yield.

Year-round farming using hydroponic methods in a laboratory-like environment, can now safely harvest many types of produce with very limited handling. Automated, efficient systems in a controlled environment provide extraordinary productive capabilities. The GrowMax G201 can grow 1,000s of plants per year in 320 square feet using less than 5 gallons of water per day

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(FL8) - 2022 Freight Farms Greenery S - Florida

Manufacturer: Freight Farms

Model: 2022 Greenery S

Location: Florida

Price: $125,000 USD

Upgrade: Reverse Osmosis System With Pump

Manufactured in Boston by Freight Farms, the Greenery S is the third version of their revolutionary shipping container farm. Freight Farms has sold over 500 farms located across the globe, from Alaska to the Middle East.

The technology in the farm provides precise control to optimize the lighting, water, and environment to produce perfect plants. Our planet wins through 90% less water usage, energy-efficient LED lighting, and a footprint that is just 0.3% of conventionally farmed land for equivalent yield.

The life cycle starts with non-GMO seeds in a nursery for approximately 3 weeks. The seedlings are transplanted into a substrate in vertical towers which maximizes space. Water then carries specific nutrients to the plants and LED lights replicate the sun for another 4 weeks before they reach their peak. Using hydroponic methods in a laboratory-like environment, we can safely harvest our greens with very limited handling.

Automated, efficient systems in a controlled environment provide extraordinary productive capabilities. The Greenery S can grow 4,000 lettuce heads per month in 320 square feet using less than 5 gallons of water per day.

About Freight Farms

Freight Farms invented container farming and have the largest network of connected farms in the world. In 2013, Freight Farms released the first hydroponic container farm into the market. Since then, Freight Farms has grown to have a footprint of over 600 farms in use, located in 49 states, and 4 US territories, and integrated farms into 38 companies. The company is now on its third generation of container farms. Its first generation, Leafy Green Machine, went through six iterations before giving way to the Greenery and now the Greenery S.

AgTech Breakthrough named Freight Farms the 2022 “IoT Monitoring Solution of the Year” for its farmhand® IoT automation software. More information is available at www.freightfarms.com.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(C-OH1) - Three - Custom-Built Shipping Container Cannabis Farms - Ohio

Three Custom-Built Shipping Container Cannabis Farms

Location: Ohio

Price: $150,000 USD

One (1) - 20 Foot Container Farm

Two (2) - 40 Foot Container Farms

The 20-foot container was used for cloning & mother plants. This includes a beautiful rack system with grow lights that were dismantled to use the smaller pod as a dry room.

The 40 ‘ containers: One was for vegging & the other one for growing.

The lights were upgraded to a better quality for better growth. We would alternate them according to our needs. Included is a sliding rack.

All three containers have air conditioning & humidifiers.

All three containers have been cared for & cleaned appropriately.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(C-CA5) - Ten - Custom-Built Shipping Container Cannabis Farms - Unique Growing System - California

Are you tired of dealing with the challenges of traditional cannabis cultivation setups?

Look no further! These pre-owned, cutting-edge pre-built shipping container cannabis farms offer the ultimate solution for a hassle-free and highly productive cultivation experience.

Turnkey Solution: These pre-built cannabis farms are the epitome of convenience. Each container is meticulously designed and pre-equipped with all the essential components for a successful growing operation.

With TreeHouse LA's 520 mod. You get top-of-the-line, name-brand equipment, (Luxx leds, quest dehues, max can fans, American standard AC units), no generic Chinese, no expense spared, serviceable in the United States.

All systems are optimally balanced for performance bringing you 36 lights of fully functional/supported lighting that can bring 40+ lbs per month output per set,

Every container set includes Optimal Growing Environment:

Achieve cannabis cultivation perfection with our state-of-the-art container design. A team of experts has meticulously created an environment that precisely replicates the ideal conditions for cannabis growth. You'll have precise control over temperature, humidity, CO2 levels, and lighting, ensuring your plants thrive throughout their life cycle.

Space-Saving Design:

Urban spaces, limited land, or expanding facilities— These containers are the perfect fit! Their compact and stackable nature allows you to maximize space utilization without compromising on production capacity. Whether you need one or multiple units, these pre-built farms scale effortlessly to meet your needs.

Mobility and Flexibility:

Adaptability is the name of the game in the cannabis industry. With these container farms, you can easily relocate your operation whenever necessary. Their mobility opens up endless possibilities for temporary setups, expansion to new markets, or responding to changing regulations.

Sustainable Solution:

Embrace eco-friendly cultivation with our green-focused approach. They employ energy-efficient systems, utilize renewable energy sources, and implement water-saving technologies.

Minimize your carbon footprint and be part of a greener future while growing top-tier cannabis crops.

Security and Control:

Your investment deserves the utmost protection. These shipping container farms feature robust security measures, including access controls, surveillance systems, and alarm monitoring. Rest assured that your crops are safe and secure at all times.

Expert Support and Training:

You're never alone in your cannabis cultivation journey. A team of seasoned experts is dedicated to your success. They offer comprehensive training sessions to familiarize you with the system and provide ongoing support to troubleshoot any challenges along the way.

Compliance and Regulation:

They understand the importance of compliance in the cannabis industry. The pre-built farms are designed to meet and exceed industry standards and regulations, helping you maintain a seamless and legally compliant operation.

Elevate your cannabis cultivation game today with these pre-built shipping container farms. Experience the future of sustainable, efficient, and high-yield cannabis production.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

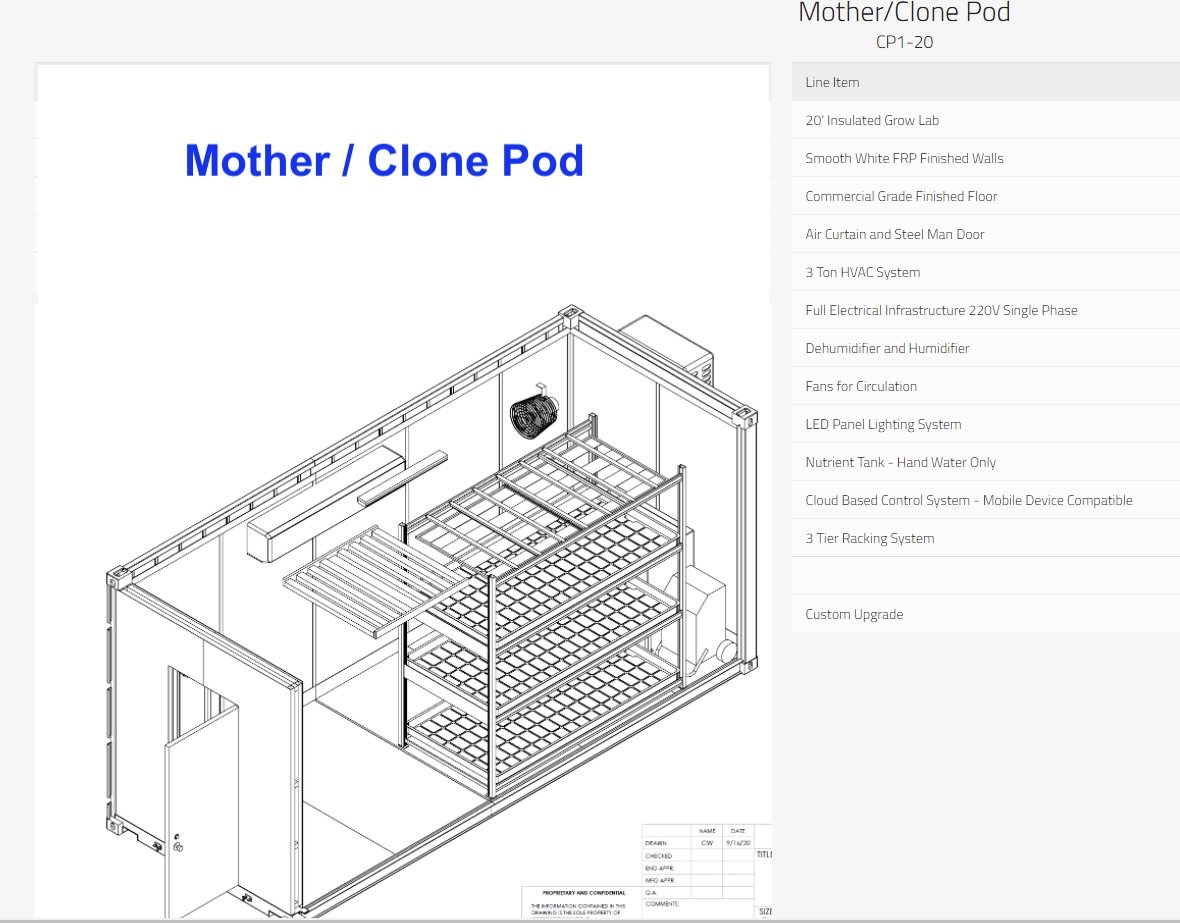

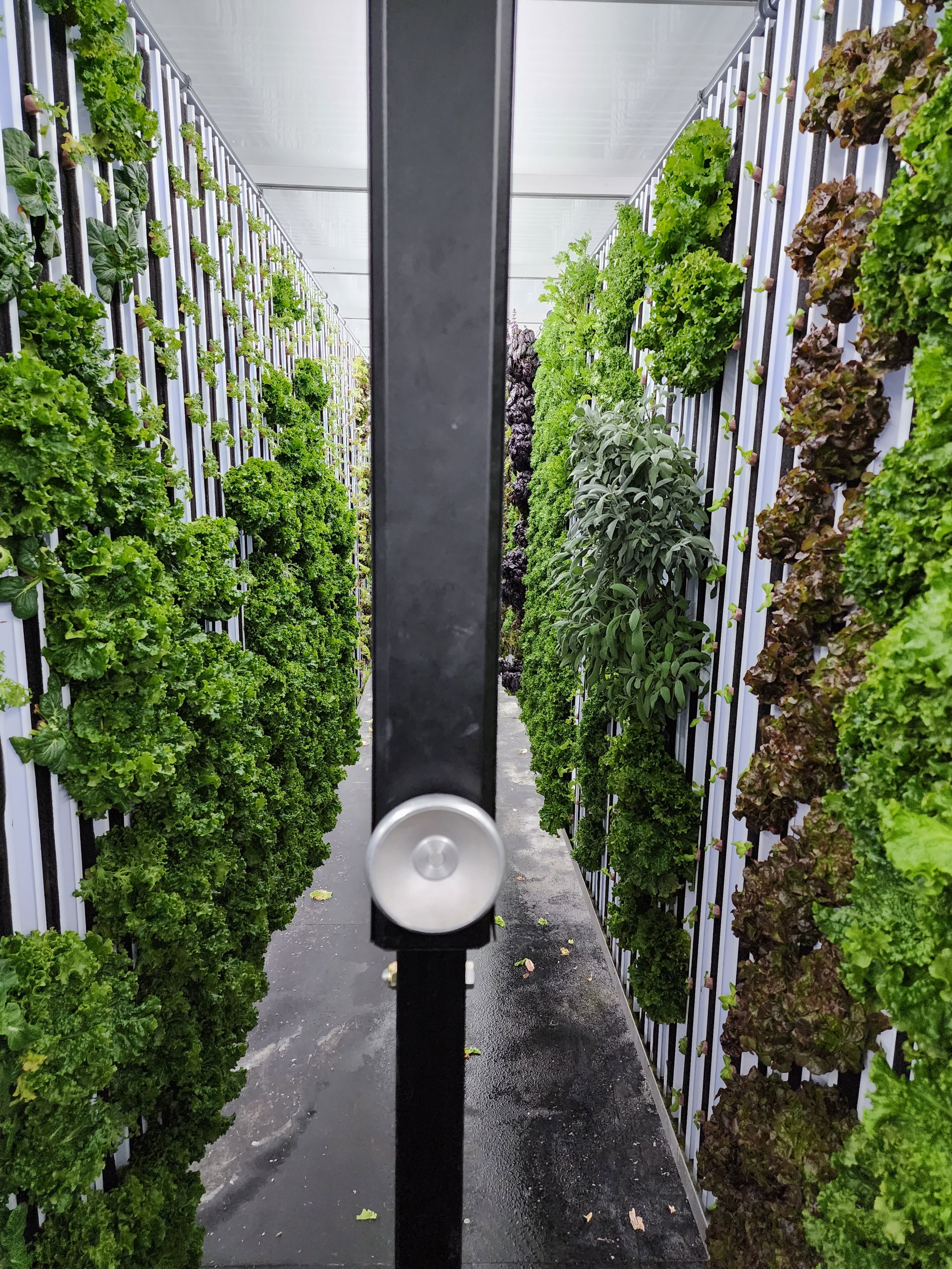

(C-CA4) - Grow Pod Solutions - 20' Cannabis Mother Clone Pod - California

Model: 20' Cannabis Mother Clone Pod

Manufacturer: Grow Pod Solutions

Never Used

Location: California

Price: $48,000 USD

20' Insulated Grow Lab

Smooth White FRP Finished Walls

Commercial Grade Finished Floor

Air Curtain and Steel Man Door

3 Ton HVAC System

Full Electrical Infrastructure 220V Single Phase

Dehumidifier and Humidifier

Circulation Fans

LED Panel Lighting System

Nutrient Tank - Hand Water Only

Cloud Based Control System - Mobile Device

Compatible

3 Tier Racking System

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(C-CA3) - Grow Pod Solutions 20' Cannabis Grow Max - California

Model: 20' Cannabis Grow Max

Manufacturer: Grow Pod Solutions

Never Used

Location: California

Price: $60,000 USD

Air Curtain and Steel Man Door

Dehumidifier and Humidifier

Full Electrical Infrastructure 220V Single Phase

Commercial Grade Finished Floor

Cloud-Based Control System - Mobile Device Compatible

Carbon Filter

CO2 System a n d Regulator (tank not included)

Smooth White FRP Finished Walls

Nutrient Tank

Circulation Fans

4x8 Plastic Trays

Adjustable Lighting

Automated Irrigation

3-Ton HVAC System

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(UAE4) - Custom-Built Microgreens And Baby Leafy Greens Shipping Container Farm - Abu Dhabi, United Arab Emirates

Microgreen Racks:

A structure made of aluminum and galvanized steel with 12 channels and 36 LED lights in each rack. Each channel is 3.67 meters long and 2.5 meters tall from the ground to the roof. The channels are 28.5 cm wide. One rack contains full spectrum lights, and three racks contain red and blue spectrum led lights.

In order to prevent any infection from spreading to the other plants, each of the 4 racks has its own sump with a storage capacity of 82 litter, pump, separate aeration system, disc filter, and UV filter. Water flows through channels (Nutrient Film Technique) and back to sumps via gravity.

Six baby leaf varieties and ten microgreen varieties are currently grown in the system. These racks can accommodate 288 10x20-inch trays, with a monthly production capacity of 300 kg and an 8–10 day harvesting window.

The entire facility has a food-grade floor that is non-slippery and simple to mop.

Vortex Fan and Hanging Fans:

To distribute cold air throughout the entire farm, a single central vortex fan (Max-Fan 10 Inch, Exhaust Fan for Grow Tent and Hydroponic Ventilation) is connected to a 4.5-ton air conditioner using a plastic tube. For the best airflow inside the farm, there are also 36 tiny fans with an airflow of 0.9m/sec that are attached to each rack.

Air Conditioners:

In order to increase capacity and redundancy, the farm has two air conditioners: a 1.5 Ton Mitsubishi brand air conditioner and a 4.5 Ton General brand air conditioner.

Dehumidifiers:

To maintain the ideal humidity level inside the farm, two dehumidifiers with various dehumidification capacities are mounted in two different places. Santa Fe and Quest dehumidifiers are the two types. In order to reuse the dehumidifier water for farm irrigation and maintenance, drainage lines from both dehumidifiers are connected to the main sump.

Air Purifier System:

To reduce the risk of airborne pathogens, there are two air purifier systems installed in this facility.

Main Sump With The Auto Dosing System:

Along with the auto dosing unit system, which includes the main sump pump, UV filter, aeration system, Disc filter, and water inlet line connection from the dehumidifiers, air conditioners, and outdoor water chiller, food-graded main sump has the capacity to store 500 litter of water. Additionally, it includes the return valve to the main sump as well as the nutrient water lines from the main sump to the measuring sensors. In order to supply nutrient water, it also has a food-graded water line that runs from the main sump to sub sumps attached to each rack.

Water Heater And Storage Shelves:

The Ariston brand water heater, used for sanitizing and cleaning purposes, is located in the farm facility's entrance area. It is set up on the storage shelves so that we can keep a small quantity of daily necessities, accessories, and the farm operations file, which contains data on the production schedule, device calibration, and work instructions.

Automation Controller System:

All of the farm's environmental and hydrological parameters are controlled by a system and program under the Auto grow brand. It has a Wi-Fi connection, allowing us to track all of the parameters online at any time. It is connected to various sensors so that it can continuously gather accurate farm values. This system is made to automatically adjust the various parameters based on the target values.

Transformer, Harvesting Rack, and Ladder:

As some of the accessories inside the farm are US specifications (110V), a transformer is used inside the facility to convert 230V to 110V. Additionally, we have a harvesting rack that can hold twelve 10*20-inch trays, reducing the amount of time that growers must spend going back and forth to the racks and enabling them to harvest several trays at once. Considering that the height of the rack is 2.5 meters off the ground, a ladder is typically used to access its upper channels.

Germination Chamber:

With a stack of four trays, the germination chamber has room for 84 trays at once. The germination chamber has a germination rack inside a plastic sheet and a small humidifier to increase the humidity. To precisely measure both parameters, a temperature and relative humidity meter are also attached. To maintain a higher temperature and lower humidity for accelerated germination, plastic sheet is used. Trays are only kept in the germination chamber for a maximum of 48 hours.

Water Chiller:

In order to prevent plants from being disturbed by irrigation water of a different temperature, a water chiller is connected to the incoming water supply line. It also has a built-in small storage tank that enables a constant flow of chilled water to the farm.

Drop Seeder and Quick Harvester:

A drop seeder consists of a frame and interchangeable clear plexiglass plates. Holes in the plate allow you to accurately seed an entire tray in one motion Each tray takes 20 seconds, allowing the grower to seed several trays quickly. We also have the quick harvester, which uses a serrated blade to cut the harvested crop precisely and cleanly. It is powered by a cordless drill/screwdriver. The harvester's basket is located at the back, and a pick-up reel made of macramé-braided strings pulls the cut leaves in that direction. This harvester has a universal holder for the majority of drill/screwdrivers, making the process easier and enabling growers to harvest multiple trays at once.

Spare Parts/Consumables list:

Along with a variety of baby leafy seed and microgreen seeds, the farm also has germination, cleaning, sanitizing, and harvesting equipment. The farm has the FSMS-related documents, digital TPM sheets, and production plan. The day-to-day activities of the microgreen farm can be handled by two growers who work there full-time.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(IL2) - 2021 Freight Farms Greenery S - Illinois

Model: 2021 Greenery S

Manufacturer: Freight Farms

Location: Illinois

Price: $ 125,000 USD

About Freight Farms

Freight Farms invented container farming and have the largest network of connected farms in the world. In 2013, Freight Farms released the first hydroponic container farm into the market. Since then, Freight Farms has grown to have a footprint of over 550 farms in use, located in 49 states, and 4 US territories, and integrated farms into 38 companies. The company is now on its third generation of container farms. Its first generation, Leafy Green Machine, went through six iterations before giving way to the Greenery and now the Greenery S.

AgTech Breakthrough named Freight Farms the 2022 “IoT Monitoring Solution of the Year” for its farmhand® IoT automation software. More information is available at www.freightfarms.com.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.

(MA5) - 2022 Freight Farms Greenery S - Massachusetts

Manufacturer: Freight Farms

Model: 2022 Greenery S

Location: Massachusetts

Price: $125,000 USD

Upgrades:

- Inline canister filter housings installed in both towers that can take filters to reduce debris (likely requires pump power upgrades to prevent air locking but very effective at stopping debris from circulating through towers)

- Brass micropump connectors retrofitted for pH Down so that more caustic solutions like sulfuric acid can be utilized without leaks

- New micropumps installed week before last (prior spec'd ones sometimes locked in on position)

- New sensor housings retrofitted

- New left send pump installed 1 month ago

- New climate module for cultivation installed week before last

Extras:

- Comes with 4 unopened boxes of extra wicking strips so that strips can be rotated without delays for cleaning (can take a set out, put these new ones in, clean the removed ones, and so on)

- Comes with an unused new pH sensor to replace the existing one if needed

- If the buyer is local/within 100 miles or so, can offer some additional extras (pH and EC pens, leftover fresh growing plugs, nutrients, etc.)

About Freight Farms

Freight Farms invented container farming and have the largest network of connected farms in the world. In 2013, Freight Farms released the first hydroponic container farm into the market. Since then, Freight Farms has grown to have a footprint of over 550 farms in use, located in 49 states, and 4 US territories, and integrated farms into 38 companies. The company is now on its third generation of container farms. Its first generation, Leafy Green Machine, went through six iterations before giving way to the Greenery and now the Greenery S.

AgTech Breakthrough named Freight Farms the 2022 “IoT Monitoring Solution of the Year” for its farmhand® IoT automation software. More information is available at www.freightfarms.com.

Please Note: Secondhand Farms, LLC, as a broker, represents the buyer and seller of the equipment listed. All material is intended for informational purposes only and is compiled from sources deemed reliable but is subject to errors, omissions, changes in price, condition, sale, or withdrawal without notice. No statement is made as to the accuracy of any description or measurement. Photos may be virtually staged or digitally enhanced and may not reflect actual shipping container farm conditions.