What the Heck Is… Vertical Farming?

Our weekly series What The Heck Is… sheds light on the strange unexplained acronyms and unfamiliar buzzwords that creep into our everyday lives.

Farming, something humans have been doing for thousands of years, is struggling to adapt to our modern world. Radical solutions are needed to keep up with our fast-growing world population.

What’s wrong with regular farming?

Firstly it’s expensive, both in financial cost and the cost of land required to grow food at scale.

It’s environmentally unfriendly, not just with chemicals and pesticides being poured into the ground, but also the fact that farms only generate a few harvests a year. During winter most of the world’s farmland is simply being wasted.

Plus farming is creating food in the places that we don’t really need it.

More than 50% of the world’s population lives in cities, and this will rise to 80% by 2050, but all the food is being created in rural areas because of the land required to grow at scale.

The result is that transport costs, the environmental impact of transporting this food, and the fact that 30% of all farmed food is wasted because it spoils before it can be eaten, make traditional farming a costly exercise.

So is there a better way?

What the heck is vertical farming?

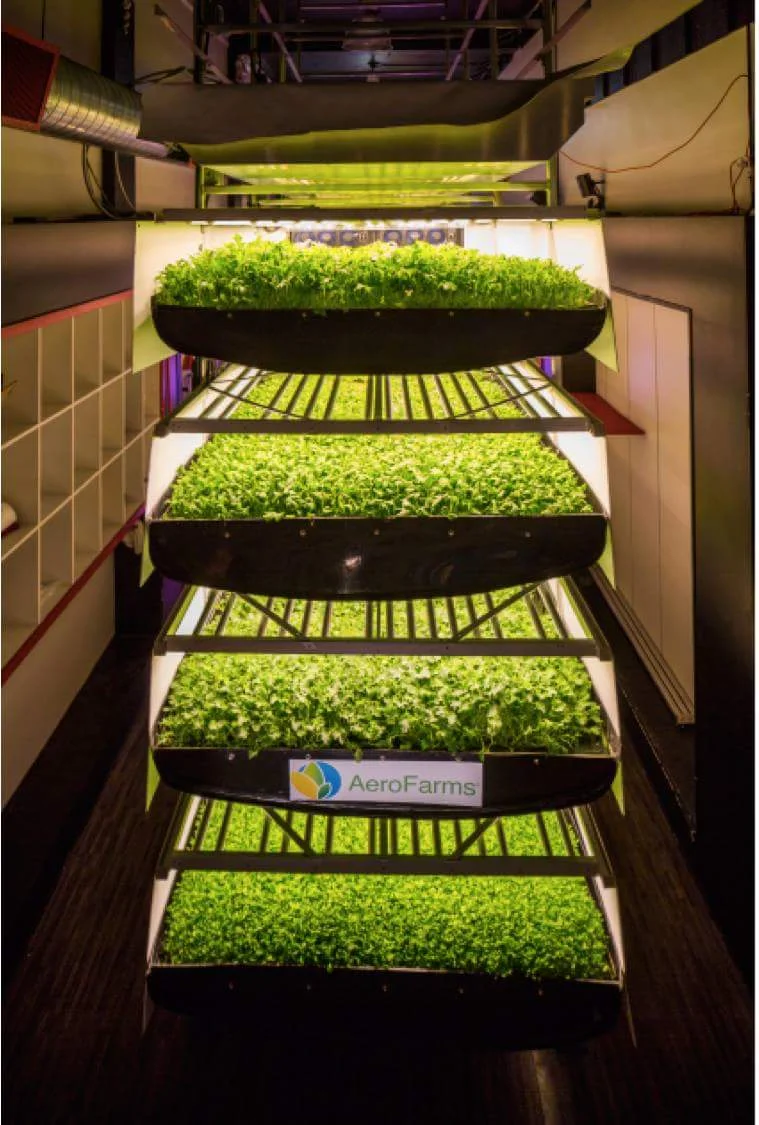

As its name suggests, vertical farming is a new way of growing of food can be stacked vertically, rather than horizontally, and uses technology to solve the problems with traditional farming.

Think trays of crops stacked in warehouses, with their water, pesticides and even sunlight controlled by a computer, giving them exactly what they need to grow and dramatically boosting the quantity of food produced.

The theory suggests that these vertical farms could even be built inside skyscrapers or existing buildings, creating food where it is needed and reducing the environmental impact of farming.

We say theory, because at the moment that’s exactly what vertical farming is.

AeroFarm hasn't started vertically farming on an industrial scale, yet.

Putting theory into practice

Today there are several vertical farms in the early stages of construction.

In the US, Vertical Harvest based in Jackson, Wyoming, is up-and-running planning to vertically grow 100,000 pounds of vegetables every year.

If they achieve that goal it will offset 3% of the produce currently being shipped into the town.

But it’s early days and they have yet to prove that they can vertical farm this amount of food at such a scale.

AeroFarms in Newark, New Jersey, has even grander goals. The company plans to harvest 2m pounds of veg a year from their 69,000 sq ft warehouse, using 95% less water and 50% less fertiliser than a traditional farm… once production starts in September 2016.

The projects share two things in common:

Neither has proved that they can yet produce the quantity of food they promise, at an acceptable price and with a sustainable business model.

And both are supported by millions of dollars in venture capital investments and government subsidies.

What does it mean for your food shop?

If vertical farming works, the price you pay for food could fall – as transport costs disappear and farming becomes less wasteful – as we enter a new era of locally-sourced food.

Or, the price of your food could skyrocket – if the cost of the technology is passed onto shoppers, or if the efficiencies of vertical farming are never realised.

With millions being spent on vertical farming and dozens of vertical farms coming online over the next few months and years, it won’t be long until we discover if the food of the future will be grown in a warehouse.

Our weekly series What The Heck Is… exists to shed light on the strange unexplained acronyms and unfamiliar buzzwords that creep into our everyday lives.

By Oliver Smith