Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Indoor Farmers Face Uncertainty Over Organic Labeling

The National Organic Standards Board have kicked the can down the road on hydroponic and aquaponic farming. The group was supposed to decide on April 21 if the systems can be considered organic. The only decision they made was to learn more about the farming process and have pushed their decision until the fall.

APR 24, 2017 @ 06:03 PM

Indoor Farmers Face Uncertainty Over Organic Labeling

Debra Borchardt , CONTRIBUTOR

Opinions expressed by Forbes Contributors are their own.

Indoor farms can stack plants vertically and grow more crops than a traditional outdoor farmer. (Photo by Shutterstock)

The National Organic Standards Board have kicked the can down the road on hydroponic and aquaponic farming. The group was supposed to decide on April 21 if the systems can be considered organic. The only decision they made was to learn more about the farming process and have pushed their decision until the fall.

This has left current hydroponic and aquaponic farmers that consider themselves organic in limbo. They can continue to call themselves organic until a decision is reached, but in the meantime the uncertainty is troubling.

“It's more about organic, certified farmers wanting to maintain their market share,” said JP Martin of GrowX, an aeroponic farming system. “The fertilizers are identical,” he said, “So the argument that they use different nutrients breaks down.”

Terra Tech is an indoor farming company that grows leafy greens and its crop that has some soil exposure has been certified organic. Chief Executive Officer Derek Peterson said, "If they came back and had some sort of ruling that disallowed organic, it would be tremendously hurtful. We would lose shelf space." He noted that the demand for non-organic produce continues to drop because the price premium is down for organic. "It's more affordable so the demand has increased," he said.

He's right. The market has grown tremendously. The USDA said that there was a 13% increase between the end of 2015 and 2016 of organic farms. This is the highest growth since 2008.

The point of contention is whether food grown without soil can be considered organic. The USDA admits that obtaining organic certification for crops is challenging and the guide is over 60 pages long. There is a lot of detail regarding the soil, but there isn't a hard and fast rule that the food must be grown in soil.

“It's really about where the nutrients are coming from and less about the methodology,” said Martin. He said it just boils down to money and market share because hydroponic farming has been around for years. If anything, the indoor farming is much more organic than outdoor farming according to Martin.

5 Control System Questions With Darryn Keiller of Autogrow

5 Control System Questions With Darryn Keiller of Autogrow

Darryn Keiller, CEO of control company Autogrow, came to the company from a consulting background, and has led the New Zealand-based company to a sub $3mn equity raise since taking the helm. Ahead of his presentation at Indoor Ag-Con on May 3-4, we caught up with Darryn to ask him about big data and the future of controls in controlled environment agriculture.

1. Autogrow has created a dedicated system – RoomBoss – for controlled environment applications. What drove you to do that?

Market need. Urban and vertical systems are on the rise; from a control and automation perspective innovators in this space have either a) been sourcing from industry vendors existing technology created for Greenhouse production or b) building their own. What is needed is a technology approach that is purpose designed for systems using LED / HPS grow lights, CO2 management and integrates dosing control and all other automation requirements. The Room Boss is a Beta product that also anticipates controlling automated harvesting and robotics. It’s an Internet of Things based platform, not just a device.

2. How much of the hoopla over the application of big data in the industry is well-founded and how much is just hype?

Certainly, there is no shortage of hype. Along with machine learning, deep learning, etc. in every other sentence. The opportunity to apply these data methodologies and techniques to solve real world problems in agriculture is real. The time-line to make these effective and beneficial on a prolific basis is a lot longer than everyone would like. Part of this is due to the slow rate of market adoption and part of it is the technology development itself. Its potential is well-founded.

3. What’s the most common mistake you see beginning farmers make when picking a control system?

The first thing is considering the control and automation side of things last – this happens all the time. And it then leaves the farmer trying to find a solution with what’s left of their budget. Automating your production is key to consistently great crops and profitability through using less labour and managing inputs like water, energy and nutrients. The second part is thinking ahead – if you purchase a limited system now, then what happens when you decide to scale your operations? Sometimes spending a little more now is better than having to “rip and replace” technology later. The approach is to obtain technology that is flexible and modular, that grows as you grow.

4. What do you expect control systems to look like in five years’ time?

I expect most indoor growing environments will be fully automated with no human component except pre-planting and post-harvest. All automation and control to be cloud delivered and all physical automation will be carried out through a variety IoT devices and multi-functions sensors. This will include automated robotic harvesting – it’s already here when you look at examples like Urban Crop Solutions of Belgium or integration of machine vision solutions for crop monitoring, pest and pathogen detection as examples.

5. What’s the biggest advantage that being a Kiwi gives you?

We’re a nation of innovators, inventors and entrepreneurs – it’s how Autogrow began 24 years ago. As a nation, we have a deep history in horticulture, agriculture and pastoral production including R&D in genomics, biologics and technology. We even have our own Rocket company which despite the name was founded and is based in New Zealand. A nation of 4.5m we feed 40m people, exporting 95% of what we produce to 100 countries, every month, including beef, wool, seafood, dairy products and fruit. Because of our location, we travel the World and we embrace the idea of boundarylessness – no limits! Autogrow now exports to 30 countries around the globe.

SEE DARRYN SPEAK AT THE 5TH ANNUAL INDOOR AG-CON ON MAY 3-4, 2017

Indoor Ag-Con Features Container Farm Tours From Indoor Farms of America & Modular Farms

Indoor Ag-Con Features Container Farm Tours From Indoor Farms of America & Modular Farms

Indoor agriculture's premier conference now features tours of live vertical farming operations on site, as well as 50+ exhibition booths & 40+ speakers

We’re excited to have our participants experience these farms on site”

— Nicola Kerslake, Founder, Newbean Capital

LAS VEGAS, NEVADA, USA, April 24, 2017 /EINPresswire.com/ -- Farm tours are a popular feature of agriculture trade shows, but Indoor Ag-Con – the indoor agriculture industry’s premier conference – likes to do things a little differently. It will instead be featuring two container farm tours at its next event, at the Las Vegas Convention Center on May 3-4, 2017.

The tours will be operated by two leading container farming equipment suppliers, Indoor Farms of America and Modular Farms. Their staff will be on hand from 8.30am to 5.30pm on each of May 3 and May 4 to walk participants through the farms and answer questions about their equipment. Their farming approaches are quite different from one another, and will allow participants to identify the best fit for their vertical farming needs. “We’re excited to have our participants experience these farms on site” commented Nicola Kerslake, founder of Newbean Capital, the event’s host.

Indoor Farms of America is based in Las Vegas, NV, and utilizes vertical aeroponic technologies in its container farm products, which range from the truck-mounted farm that it will be showcasing at Indoor Ag-Con to a farm specially adapted to meet the needs of disabled veterans. The farms offer 40 plants/ft2 of grow area, are designed to be used in both controlled environment and greenhouse settings and use just 3% of the water of a traditional farm. It recommends that customers grow leafy greens, herbs, chili & sweet peppers, peas, strawberries, cherry tomatoes and beans in its systems, and is continually adding more crops to the list. The Company’s website is at www.indoorfarmsamerica.com.

Canadian Modular Farms has developed a series of modular units, such as, ones for refrigerated storage and for growing microgreens, that work with its primary unit, a specially designed 40’x10’x10’ composite steel box. The eight unit options can be combined to create the optimal farm for each customer. Its units are based on hydroponic growing and include ZipGrow towers, with over 300 towers packed into its production-only macro farm unit. The Company’s website is at www.modularfarms.co.

The farms will be displayed at Indoor Ag-Con, a two-day event held at the Las Vegas Convention Center, and tailored toward corporate executives from the technology, investment, vertical farming, greenhouse growing, and food and beverage industries, along with hydroponic, aquaponic and aeroponic startups and urban farmers. The event is unique in being crop-agnostic, covering crops from leafy greens and mushrooms to alternate proteins and legal cannabis.

The farms will join industry majors such as Argus Controls, Autogrow, BrightFarms, Certhon, Dosatron, DRAMM, Hort Americas, Philips Lighting, Priva, and Transcend Lighting in a 50+ booth exhibition hall. The event includes two full days of speakers, including executives from CropKing, Driscoll’s, Fresh Box Farms, Grobo, Helical Holdings, Intravision, Kalyx Development, MedMen, Plenty, Shenandoah Farms and Village Farms among a 40+ strong speaking faculty.

Indoor Ag-Con has also hosted events in Singapore, SG and New York, NY in the past year, and is currently planning its first event in Dubai. Since it was founded in 2013, Indoor Ag-Con has captured an international audience and attracted some of the top names in the business. Events have welcomed nearly 2,000 participants from more than 20 countries.

Newbean Capital, the host of the conference, is a registered investment advisor; some of its clients or potential clients may participate in the conference. The Company is ably assisted in the event’s production by Rachelle Razon, Sarah Smith and Michael Nelson of Origin Event Planning, and by Michele Premone of Brede Allied.

5th Annual Indoor Ag-Con

Date – May 3-4, 2017

Place – South Hall, Las Vegas Convention Center, Las Vegas, NV

Exhibition Booths – available from $1,499 at indoor.ag

Registration – available from $399 at indoor.ag

Features – Two-day seminar, an exhibition hall, and after-party

For more information, please visit www.indoor.ag/lasvegas or call 775.623.7116

Nicola Kerslake

Newbean Capital

775.623.7116

email us here

Philips Lighting Results Show LED Growth

Philips Lighting Results Show LED Growth

24 April 2017, by Matthew Appleby, Be the first to comment

LEDs now represent 61% of Philips Lighting sales, with first quarter sales at 1,690 million euros.

Philips Lighting announced the company’s 2017 first quarter results.

"Our comparable sales growth improved in comparison to previous quarters, driven by double-digit growth in our business groups LED and Home and a return to growth in Europe and the Rest of the World, despite ongoing challenging conditions in some markets," said CEO Eric Rondolat.

"We continued to increase our operational profitability and free cash flow compared to the first quarter of last year, demonstrating the rigorous implementation of our strategy.

"These results reinforce our confidence that the company is well positioned to achieve its 2017 outlook and medium term goals," Rondolat added.

On a comparable basis, the decline in sales slowed to -0.8%, an improvement compared to previous quarters. Europe and the Rest of the World delivered growth, while the Americas was impacted by an accelerated decline in conventional lighting and softer market conditions.

Business groups LED and Home achieved double-digit growth, driving total LED-based sales growth of 19% and total LED based-sales now representing 61% of total sales.

A Self-Proclaimed City Boy Is Helping Farmers Grow Their Businesses

A Self-Proclaimed City Boy Is Helping Farmers Grow Their Businesses

April 24, 2017

Written by Erin Booke, The Dallas Morning News

Nick Burton is a self-proclaimed city boy, a businessman first and a farmer second. He’s also an educator, a mentor and the kind of friend that wants others to succeed.

When someone is struggling with their business and needs some advice, people often say, “Oh, do you know Nick? You should really talk to Nick.”

Burton, 39, runs Blue Collar Paris Victory Gardens in Paris, Texas, where he grows vegetables hydroponically and in soil. It used to be a nursery but now functions as the source of his subscription-based salad delivery business, Victory Lunch Club.

A New Mexico native, Burton moved to Texas in 2001. He started a lawn and landscaping business and grew from there. The “self-development junkie” says he became addicted to business coaching, which ranges from speaker training to technical expertise to image consulting.

“Whenever I got outside coaching, that’s when my business took off,” he says. “And whenever I couldn’t afford it was when I needed it most.”

Nick Burton stands in a high tunnel greenhouse at Paris Victory Gardens in Paris, Texas. In addition to Paris Victory Gardens, Burton has started State of the Soil to help other farmers start and grow their businesses.

(Smiley N. Pool/Staff Photograher)

State of The Soil

Now Burton's the coach. Earlier this year, he launched another business, a passion project called State of the Soil. The series of virtual seminars is designed to educate farmers on business and marketing tactics. Recordings of the webinars are available any time online for a fee, but live webinars are available for free a few times a year. (The next free weekend is May 26-28.) As a farmer, Burton feels obligated to pass along where he has made mistakes and to give back to the agricultural community.

“Farmers are not used to having to pay for training because of the USDA and other programs,” Burton says. “But with that they are not getting great education, especially when it comes to the business side of things.”

Farming, by nature, can be a solitary career choice — and a calling for many — that’s full of trial and error and a lot of learning the hard way. Farmers are not used to networking or asking for help, and they're driven more by pride in their work than by market demands.

“I want to give people permission to tell their story, and sometimes I have to give people permission to make a profit," Burton says. "But a lot of these are small family farms, and if they don’t succeed, they are going to lose it all.”

Nick Burton demonstrates how hydroponically grown lettuce is harvested in a grow house at Paris Victory Gardens.

(Smiley N. Pool/Staff Photographer)

No Whining Allowed

Burton is all about the tough love, however. He wants to help farmers build a community full of collaboration, innovation and support, but only if they are willing. No whining allowed.

“When we didn’t have good sales, I didn’t blame the market, I blamed myself,” he says. “Many people just grow what they like, but they have to grow what the market demands. It’s not about the farmer, it’s about the client.”

Burton doesn’t advocate one type of farming, even though there’s often infighting and debate among farmers about topics such as hydroponics vs. soil. “Whenever farmers say these things publicly, they are not helping each other out,” he says. “Everyone is so passionate about what they do, but there’s no one right way to do everything. Unless you’re out there just spraying chemicals on everything, I don’t have a problem with it.”

Red Butter lettuce seedlings sprout in a grow house at Paris Victory Gardens.

(Smiley N. Pool/Staff Photographer)

Network of Experts

And while Burton runs State of the Soil, he doesn’t do it alone. He has tapped others in the agriculture community to share their stories and expertise. There are about 38 speakers for 2017 (and more than 40 for 2018) who will talk about such topics as market development, funding, restaurant sales, farmers market sales, media relations, food trends, farm-to-table events, social media, photography, technology and even work-life balance. An all-access pass is $129, and you can watch the webinars any time.

Jeff Bednar, owner of Profound Microfarms in Lucas, teaches a seminar on agricultural real estate for State of the Soil. He owned a real estate company and then branched out into real estate education before deciding to buy land and start growing. He, his wife, Lee, and his two young daughters grow vegetables, mostly leafy greens, hydroponically, aquaponically (with fish) and even vermiponically (with worms).

Andrea Shackelford, executive chef at Harvest Seasonal Kitchenin downtown McKinney, teaches a seminar on selling to restaurants and developing relationships with chefs. Tim Kelly of SunTx Capital in Dallas offers details on funding and investing. Other speakers are from across the country and around the globe.

Nick Burton walks through a grow house at Paris Victory Gardens.

(Smiley N. Pool/Staff Photographer)

Not Just for Newbies

State of the Soil clients have ranged from newcomers with no growing background to longtime farmers looking for that extra push. “I see it as a very healthy mix,” Burton says, “people interested in farming for all kinds of reasons.”

Terry Foster of Houston runs Home Town Roots, an urban, indoor vertical farm that specializes in greens and supplies restaurants. Foster, 60, left his corporate job in the oil fields in 2014 to start a second career because he’s “old, tired and crusty,” he says, and “has lost all his mind but still has a strong back.”

He heard Burton speak and then signed up for State of the Soil. He says what he learned was worth much more than he paid.

“The knowledge I had of social media would fit on half a pinhead,” Foster says. “He’s trying to show us dinosaurs how to use social media to market ourselves.”

Foster has since updated his website and developed a Facebook page and and Instagram account.

Plants waiting for their new greenhouae home. Getting close.

In 2016, Piper Klee of McKinney started Urban Dirt Co., building raised-bed gardens for people in their backyards and helping maintain them. Klee had a background in corporate sales, not farming, so she needed to pick someone’s brain.

“Nick is full of information and knows people. He started giving me information, and we spent hours driving around, meeting people,” she says. “People give away information for free in this industry. They want people to succeed. They are generous with their information, and Nick is more generous than most.”

Her biggest takeaway from the State of the Soil classes was encouragement. “It was good to see that I’m not the only one doing this,” she says. “And it wasn’t just people who’d been farming their whole lives. There were accountants and bankers turned growers.”

Klee is originally from Colorado, where she says almost everybody grows food in their yard. North Texas is on the cusp of this movement, she says, and there’s just enough information to get going.

“That’s why we have to have State of the Soil because we are not Colorado or Oregon,” she says. “We have to find a way to share information.”

And Burton clearly doesn’t mind sharing. He sees it as an obligation. “I’ve got a complete abundance mentality,” he says. “I think there’s room for everyone.”

Rice U. Team Cultivates Ideas For Indoor Farming

Rice U. Team Cultivates Ideas For Indoor Farming

APRIL 12, 2017POSTED IN: NEWS RELEASES

David Ruth - 713-348-6327

david@rice.edu

Mike Williams - 713-348-6728

mikewilliams@rice.edu

Rice U. team cultivates ideas for indoor farming

Hydroponic garden graces university’s Oshman Engineering Design Kitchen

HOUSTON – (April 12, 2017) – Some engineering design projects click, hum or make no sound at all. Lettuce Turnip the Beet may be the first at Rice University to gurgle.

“The pumps are always going,” said design team member Dominique Schaefer Pipps. “The water never stops moving, keeping the plants alive.” The punningly named Team Lettuce Turnip the Beet has designed and built what is known technically as a “produce cultivation machine,” which resembles an oasis of greenery at Rice’s Oshman Engineering Design Kitchen (OEDK).

Sprouting from tiers of PVC pipes are lettuce, garlic and other vegetables, grown hydroponically — that is, without soil — and kept fresh by a pump circulating 55 gallons of water. The project was commissioned by a “zero-resource house” on the campus of Chalmers University of Technology in Gothenburg, Sweden. Previously, Chalmers partnered with another Rice team to create BioBlend, a variation on the in-sink garbage disposal that separates food waste from water and simplifies the composting process.

“The emphasis is on using as few resources as possible, using little energy and wasting nothing,” said Sanjiv Gopalkrishnan. He and Schaefer Pipps, along with team members Jared Broadman and George Dawson, are all seniors in mechanical engineering at Rice.

Dominique Schaefer Pipps tends to her team’s hydroponic experiment, a capstone design project required of most senior engineering students at Rice. Photo by Jeff Fitlow

The team achieved its goal to produce sufficient food to make one salad per week for one year, all in an apartment environment. The original prototype was built last November after two months of brainstorming. It’s a much bulkier, space-consuming model and has been moved outdoors to a fenced-in area behind the OEDK. It remains overgrown with sprawling tomato plants, broccoli and Swiss chard.

“We wanted to minimize power consumption and environmental impact, but maximize nutritional content and yield,” Dawson said. “The machine should coexist with humans in a rather small living environment. Noises, lights and smells shouldn’t interfere with the sleep cycle or life in general, and basic maintenance should be kept simple.”

According to the team, the device consumes about 900 watts, about as much power as a microwave or medium window air conditioner, and runs off one outlet even after replacing fluorescent lights with LED growing lights to improve the health of plants farther away from the fixtures.

The new prototype stands 8 feet tall, but its wooden frame and six levels of vinyl pipes are nearly flush with the wall. The biggest change is using square rather than round plastic pipes, which have a larger internal surface area and move more water. The frame is held together with pegs and friction and uses no glue or nails; the entire device weighs around 70 pounds.

George Dawson, a member of Lettuce Turnip the Beat, a senior engineering design team at Rice, works on its hydroponic garden. The team’s initial goal was to produce sufficient food to make one salad per week for one year in an apartment environment. Photo by Jeff Fitlow

“That makes transporting it easy. We have to get it to Sweden. This is like Ikea for toddlers, with really big parts,” Broadman said.

The team will install sensors to automatically monitor pH levels, nutrients, temperature and other factors before the device is installed in Sweden. The current setup uses one reservoir but the students expect a multiple-reservoir system, each with varying levels of nutrients, could permit fine-tuning the nutrient requirements of various plants.

The team is advised by Matthew Elliott, a lecturer in mechanical engineering, who said, “My job is easy. We meet once a week for updates. The students have taken care of everything.”

Team Lettuce Turnip the Beet will compete in the annual George R. Brown School of Engineering Design Showcase at Rice University’s Tudor Fieldhouse April 13. The showcase opens to the public at 4:30 p.m.

-30-

See the team’s web page at http://oedk.rice.edu/Sys/PublicProfile/34366121/4029765

Follow Rice News and Media Relations via Twitter @RiceUNews

Video:

Video produced by Brandon Martin/Rice University

Related materials:

Oshman Engineering Design Kitchen: http://oedk.rice.edu

George R. Brown School of Engineering: https://engineering.rice.edu

Images for download:

http://news.rice.edu/files/2017/04/0417_LETTUCE-1-web-1knd3s0.jpg

Rice University engineering students created a produce cultivation machine at the Oshman Engineering Design Kitchen on campus. From left: Jared Broadman, George Dawson, Dominique Schaefer Pipps and Sanjiv Gopalkrishnan. (Credit: Jeff Fitlow/Rice University)

http://news.rice.edu/files/2017/04/0417_LETTUCE-2-web-19ebcxm.jpg

Rice University engineering students expect to bring their hydroponic experiment to a “zero-resource house” on the campus of Chalmers University of Technology in Gothenburg, Sweden. (Credit: Jeff Fitlow/Rice University)

http://news.rice.edu/files/2017/04/0417_LETTUCE-3-web-1ep5mws.jpg

Dominique Schaefer Pipps tends to her team’s hydroponic experiment, a capstone design project required of most senior engineering students at Rice University. (Credit: Jeff Fitlow/Rice University)

http://news.rice.edu/files/2017/04/0417_LETTUCE-4-web-14oa51u.jpg

George Dawson, a member of Lettuce Turnip the Beat, a senior engineering design team at Rice University, works on its hydroponic garden. The team’s initial goal was to produce sufficient food to make one salad per week for one year in an apartment environment. (Credit: Jeff Fitlow/Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,879 undergraduates and 2,861 graduate students, Rice’s undergraduate student-to-faculty ratio is 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for happiest students and for lots of race/class interaction by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance. To read “What they’re saying about Rice,” go to http://tinyurl.com/RiceUniversityoverview.

- See more at: http://news.rice.edu/2017/04/12/rice-u-team-cultivates-ideas-for-indoor-farming/#sthash.yBzLqW2o.dpuf

Edible Gardens Enliven Industrial Properties, Accelerate Valuations

Edible Gardens Enliven Industrial Properties, Accelerate Valuations

Urban farms can help to attract new industrial businesses, accelerate property values, and engender camaraderie between co-workers.

Lara Hermanson, Co-Founder & Principal, Farmscape

Q2 2017

Landscaping, within industrial parks, has dual problems of being both expensive and visually underwhelming. Bright green lawns need mowing and fertilizing, while water is either in too much abundance or so sparse it’s impossible to maintain decent-looking grass. Bushes and trees need to be carved into lollipop shapes and noisy blowers tidy up — right when you need to get on the phone. The results are that these outdoor spaces aren’t welcoming, let alone inspiring, to clients and employees. One solution to address all these issues is for industrial parks to introduce an “urban farm.” Businesses can ditch the mediocre lawn and join an increasing number of corporate, commercial, and industrial properties to create a fun, urban farm for employees and clients to enjoy. Vegetable crops, fruit trees, and herbs require less water than a thirsty lawn, especially when you consider they prefer low-water drip irrigation systems. Employees love the fresh food, and clients enjoy doing business with a team that thinks differently about environmental (and cost-effective) sustainability. The positive effects are multi-loaded for the industrial park and its surroundings:

Increased Employee Retention

A “green” environment usually results in more productive employees. The gardens enable employees to break away at lunch or after hours and learn from local farmers how to maintain crops. Not only are employees learning more about agriculture while they decompress during downtimes, they’re also connecting and brainstorming work ideas with other employees with whom they normally don’t interact. For employees that have no home garden, this gives them the additional advantage to dig, weed, and then take the fruits and vegetables home to eat for dinner.

New Business Doors Opening

One such urban farm exists near the entryway to a Fremont tech park. When the farm was created in 2014, neighboring businesses began to stop by to take a look. Another firm across the street asked for a farm of their own…but bigger. The original farm was then expanded in order to “keep up with the Joneses.” As the gardens grew in size, the number of visitors did as well. Nowadays, it’s common for visiting clients to request a garden tour before their meeting, which also helps build unique business relations and conversations they’d usually not experience. In plain terms, carrots and apples can seal the deal.

Oracle office,

PleasantonMagnet for Business Relocations

Let’s face it; industrial properties aren’t known for their visual appeal. Yet, these farm environments greatly affect productivity and efficiency; the more enticing the outside landscape, the more employee morale increases. Considering the low cost of installing and maintaining an urban farm, it’s a no-brainer for landlords to include this unique amenity. The fragrant, abundant grounds create a more vibrant community and lure young tech firms to sign leases — they’re drawn like bees to honey. It’s the same reaction you’d expect from wanting to relocate to a home on a street adorned by lush gardens versus bare minimum yards.

Sustainability and Price Efficiency

With the ongoing drought/flood cycle in California, corporations are obviously re-thinking their landscaping and water usage. Urban farms handle both issues with smart-drip irrigation, which uses less water than traditional lawns and cost significantly less after initial setup. Additionally, the typical urban farm will yield three to four pounds of organic produce per square foot annually. With corporate gardens starting around 300 square feet, that’s 900–1,200 pounds of food annually for the cafeteria or an employee farmer’s market, grown right at the office. Although paid farmers maintain the beds, the employees are also involved in maintenance, obviously at no cost to the company, while everyone gains the holistic and heart-healthy benefits.

Neighborhood Attributes and Property Valuations

Good landscaping can increase property values by 7 percent. Excellent landscaping has been proven to accelerate valuations by up to 28 percent. The gardens create a sense of place for communities and increase employee morale and well-being as well as pride of ownership. In addition, city planning submissions are usually granted faster approval. At any given submission meeting, it is common for up to 300 community members to attend and voice their support for these urban gardens. This helps the installation process move rapidly, while reducing time and cash wasted in standard resubmit fees.

Spin-Off Effects

Attracting new industrial businesses, accelerating property values, and engendering enthusiasm among locals and a new wave of camaraderie between co-workers are among the impacts of implementing urban farm gardens. The areas become strong, attractive hubs for new leaseholders, while fostering employees’ creativity. A small project could encompass eight to 10 raised beds, six orchard trees, and mulching. If the land size is vast and covers several acres, ornamental gardens, vineyards, and row crops can be architecturally enhanced. Companies can now enjoy the perks of rural farm life with none of the typical responsibility, while sharing the produce with their employees and clients and attracting new business with gift-giving apples.

Lara Hermanson, Co-Founder & Principal, Farmscape

Lara Hermanson is co-founder and Principal at Farmscape, one of the nation’s largest urban-farming companies. Farmscape has worked on over 600 urban farming projects including Levi’s Stadium, AT&T Park, and Oracle.

For Earth Day, A Look Back At Some of The Best Green Building Designs

For Earth Day, A Look Back At Some of The Best Green Building Designs

April 22, 2017 04:00PM

It’s Earth Day, and there are plenty of ways to celebrate across the city. But while we’ve got you here, why not have a look back at some the most interesting green developments out there?

1. A proposed vertical farm on the High Line

This mixed-use concept at the Rem Koolhaas parcel at 511 West 18th Street would include residences, an art gallery and the kicker: 10 levels of indoor farming terraces. You can read more about the project here.

2. A “net-zero” public school

In 2015, city built a 444-seat Staten Island elementary school that runs solely on the energy it produces, in a project the developer calls a “laboratory for ideas for future construction.” Learn more here.

3. Green architecture

The infamous New York architect Robert Scarano, once banned from building in NYC after making false statements to the city to dodge zoning laws, is back and now he is building green. In 2014, his Brighton Beach project attempted to become the first multifamily structure to score a Living Building certification.

4. Hipster farmers

Eight floors above the ground at Barclays Center in downtown Brooklyn, workers at the condo building at 550 Vanderbilt Avenue are installing plots of soil on a south-facing terrace. The plots will allow residents to grow their own vegetables.

5. Design for modular green skyscraper wins competition

A conceptual high-rise intended for use in sub-Saharan Africa would taking farming vertical and help eliminate hunger. Now, the architects behind the tower, Pawel Lipiński and Mateusz Frankowski, have won the the eVolo Skyscraper Competition for their design. Check it out here.

6. A Parisian garden on top of an old car plant

Parc André Citroën opened for public use in 1992 and was built atop the old André Citroën car manufacturing plant, which functioned from 1915 to 1970. A large lawn anchors the park, while smaller structures like gardens, greenhouses, and meditative spaces act as the park’s border. It’s really beautiful as well.

7. A wooden skyscraper in London

London Mayor Boris Johnson just received a proposal to solve London’s eco-crisis: an 80-story eco-friendly skyscraper made of wood. The project would house hundreds of units of low-cost housing while becoming the second-tallest building in London behind the Shard.

8. A sustainable home within a greenhouse

Stockholm residents Marie Granmar and Charles Sacilotto live in what they call Naturhus – an environmentally friendly house built within a functioning greenhouse.

Houston’s Hope Farms Breaks Ground

Houston’s Hope Farms Breaks Ground

Linked by Michael Levenston

Recipe for Success Foundation celebrated Earth Day 2016 by officially breaking ground on Hope Farms.

Houston’s New Urban Farming Project Will Provide Fresh Produce, Farmer Training, Nutrition Education and Community Gathering Space in Historic Sunnyside

By Jovanna David

Press Release

Apr 22, 2016

Excerpt:

Located on seven acres in the heart of Houston’s historic Sunnyside neighborhood, the new Hope Farms will use organic methods to generate significant food crops in the midst of one of the city’s largest food deserts, while training military veterans to become successful agri-entrepreneurs.

Hope Farms is a critical component in achieving Recipe for Success Foundation’s mission to change the way children understand, appreciate and eat their food and to mobilize the community to provide healthier diets for children.

Visitors got a sneak peak of the Rolling Green Market that will operate from Hope Farms and deliver significantly reduced priced fresh fruits and vegetables directly to families who live in the food insecure neighborhoods of Houston. The Rolling Green Market is an innovative solution to help overcome food insecurity and access issues. Through its mobile outreach and education efforts it will serve as a dynamic, unifying element to Recipe for Success Foundation’s Seed-to-Plate Nutrition Education™ Program and the new Hope Farms.

Civic Farms To Break Ground On 20,000 sq.ft. Vertical Farm At Biosphere 2

Civic Farms To Break Ground On 20,000 Sq. ft. Vertical Farm At Biosphere 2

Vegetables can soon be reaped again from the Biosphere 2 complex of the University or Arizona. Tomorrow, on Earth Day, Civic Farms will break ground for anew 20,000 sq. ft. vertical farm inside Biosphere 2’s West Lung.

Civic Farms has come to an agreement with the University of Arizona to lease the cavernous space for a nominal fee of $15,000 a year. The new vertical farming operation has announced that it will invest more than $1 million in the facility and dedicate $250,000 over five years to hire student researchers in conjunction with the UA’s Controlled Environment Agriculture Center.

The brain behind the project is Paul Hardej, Illumitex' VP of Turnkey Horticulture Lighting Solutions and former co-founder of the recently dissolved indoor grow op FarmedHere. Hardej unraveled his new plans this week in an article on Tucson.com. "Half the 20,000-square-foot space to be devoted to production, with areas given over to research and scientific education. A variety of leafy greens and herbs such as kale, arugula, lettuce and basil will be packaged and sold to customers in Tucson and Phoenix"

In the article on Tucson.com, Hardej furthermore said that he recognizes the irony of growing food in artificial light at the giant Biosphere 2 greenhouse. He is convinced, however, that growing plants with artificial lighting can become as economical as growing them in sunlight. "[Indoor] Farming is much more productive and much more predictable than in a greenhouse [...] A vertical farm can be 20 to 100 times more productive. The overall direction globally is indoors".

The Civic Farms groundbreaking ceremony will take place tomorrow the special Earth Day event at Biosphere 2.

Click here for the complete article on Tucson.com, which also features CEAC's Gene Giacomelli and Murat Kacira.

Publication date: 4/21/2017

This Japanese Smart Farm is Getting Even Smarter

This Japanese Smart Farm is Getting Even Smarter

By John Hopton

April 21, 2017

Perfect lettuce is grown with help from robots and the Internet of Things

For all Japan’s advancements, it is still common to see older people in the country bending over awkwardly in fields, picking crops by hand – a vision of the past. Twenty miles west of Kyoto, though, stands a smart farm that’s very much a vision of the future.

SPREAD‘s Kameoka Plant grows 21,000 heads of lettuce a day using multistage hydroponics and artificial lighting.

A network of connected devices, the Internet of Things at work under the roof of one slick indoor farm, ensures full control and data analysis of variables like lighting, temperature and humidity, as well as the flow of liquid nutrients.

But, if this smart farming is not smart enough, it will soon get considerably smarter. Before the end of 2017, SPREAD will open the Techno Farm™.

The world’s first robot farm

The company envisages that its super high-tech farm will reduce running costs by around 30 percent. Most impressively, though, it will be run almost entirely by robots.

The new plant in Kizugawa, Kyoto prefecture, will produce 30,000 heads of lettuce per day, which will be tended to by robots that have been brought lettuce seedlings by stacker cranes.

The robots will take care of tasks like trimming and watering, before making sure that fully grown lettuce is harvested and delivered to the factory’s packaging line.

Several countries now have smart farms, but this will be the world’s first robot farm.

A vision of the future? Source: Wide Open Country/Twitter

SPREAD says it has, “developed the most advanced vegetable production system created by

taking advantage of the cultivation techniques and accumulated know-how with the cooperation of technology equipment manufacturers.”

The company showcased that production system at CeBIT 2017 in Hanover, Germany, last month. The opening of the plant is scheduled for winter 2017.

Is a smart farm an ethical farm?

Despite the obvious cost to jobs in the local area, SPREAD believes its methods will contribute to humanity, as well as, to technological advancement (and not just by giving us more lettuce).

SPREAD claims its mission is to “create a sustainable society where future generations can have peace of mind.”

“By developing a system that can produce high quality food, rich in nutritional value anywhere in the world in a stable way, we will build an infrastructure that can supply food to all people equally and fairly around the globe,” says the company site.

Spread says lettuce costs will be the same as regular produce. Source: Spread

Japan probably has more of a need to develop an automated labor force than most other countries do, given that its population is actually declining. Japanese people famously live long, and a future in which there are not enough younger workers to support older, retired people looms large.

Nevertheless, Spread’s global marketing manager, JJ Price, told the Guardian: “Our new farm could become a model for other farms, but our aim is not to replace human farmers, but to develop a system where humans and machines work together. We want to generate interest in farming, particularly among young people.”

The company hopes eventually to take its technology around the world. Meanwhile, Japanese shoppers can rest assured that even lettuce produced by such a futuristic smart farm will cost the same as lettuce always has.

[See More: How Agriculture Technology Has Helped Feed Our Growing Population]

How Vertical Farming Could Save the Planet

How Vertical Farming Could Save the Planet

Inside the growing trend of indoor urban farms

4/21/17

"Take a leaf; just use your hand." Tom Colicchio directed a group of guests at dinner at River Park, instructing us to smell then take a bite of a garnish adorning our plates of tuna crudo. "That's amazing—something I hadn't seen before. That's wasabi arugula." The spicy, acidic burst from those leaves hushed the room. In a single bite, the chef explained why he's chosen to be a part of Bowery Farming, a modern farming company that just put its produce on the market.

The three-course meal showed off everything from three kinds of basil—lemon, Thai and Genovese—to pac choy (i.e., bok choy) and the startlingly good wasabi arugula, which Colicchio serves at his recently opened Fowler & Wells. It was all grown inside a New Jersey-based warehouse, using LED lights and zero pesticides. Bowery is just one of the many vertical farming companies that has sprouted up over the last few years. With Earth Day upon us, we're taking a peek inside this growing trend, which just might be the future of farming as we know it.

RELATED How Rooftop Farm Brooklyn Grange Got off the Ground »

Having truly landed only five months ago—first at NYC's Foragers Market and recently launching in tri-state area Whole Foods, where it sells two kale varieties, lettuce, arugula, basil and a spring mix—Bowery has already started to take off. It's also planning a new farm in the tristate area, with long-term goals to expand country- and eventually worldwide, making its greens local for customers everywhere. And though it might be one of the most ambitious, Bowery is definitely not alone.

There's AeroFarms, also based in New Jersey, Edenworks in Brooklyn, FreshBox Farms in Massachusetts and Green Sense Farms in Indiana, to name a few. Vertical farms have been cropping up at a rapid pace, and as the world's population continues to rise while also becoming increasingly urban, this indoor agriculture will undoubtedly become more crucial.

"How do you provide fresh food to urban environments in a way that's more efficient but sustainable?" That's the question that led Bowery cofounder Irving Fain to start the company with Brian Falther and David Golden. Sure, Fain admits there are many pieces to this complicated puzzle, rattling off issues like limiting food waste, eating less meat and helping developing countries increase their yield. But he believes his farm's proprietary hardware and software, which helps them to track and fine-tune their processes in real time, can effectively provide quality produce to our urbanizating population.

Though each organization has its own approach, the basic premise is to grow produce in a regulated, indoor environment, stacking beds on top of each other to maximize square footage. By controlling the plants' temperatures, airflow, water, nutrients and growing mechanisms, these farms are able to cultivate their crops much more efficiently than standard outdoor farms. And thanks to these ideal conditions, their growing season lasts an astounding 365 days a year.

"We're over 100 times more productive than the same square footage of farmland," Fain notes.

Falther calls Bowery a hydroponic farm, which means its plants are grown in water fortified with specific nutrients. Edenworks uses a version of this method called aquaponics, creating an ecosystem of aquatic animals and produce working to feed each other.

"Our fish generate manure, which is naturally broken down by a microbiome of soil bacteria into the nutrients that our vegetables need. The vegetables filter the water as they grow, then clean water is sent back to the fish, and around it goes," Edenworks cofounder and CEO Jason Green explains. Over at AeroFarms, they use an aeroponic mist on their plants.

Figuring out how best to grow produce in an environment devoid of natural light and soil is an issue all of these farms face.

But, as Fain points out, "the reality is that organic standards were written at a time when a lot of the technology we have access to today didn't even exist." He urges people to rethink agricultural possibilities, describing Bowery as "post-organic."

Another challenge is ensuring the produce grown on these futuristic farms retains its familiar flavor. That wasn't a problem at last night's dinner, though, and if you've picked up a box of greens at Whole Foods lately, you might not even realize it was grown in one of these vertical farms.

"It's a new paradigm for farming," Colicchio said, "and it's something I'm really excited about."

Shanghai Planning Huge Vertical Farm, Looking to change The Way It Feeds Its 24 Million Residents

Shanghai Planning Huge Vertical Farm, Looking to change The Way It Feeds Its 24 Million Residents

BY ALEX LINDER IN NEWS ON APR 21, 2017 3:30 PM

As Shanghai continues to expand outward, replacing agriculture with urbanization, a US-based design firm is looking to reimagine the way that Shanghai grows food to feed its 24 million people.

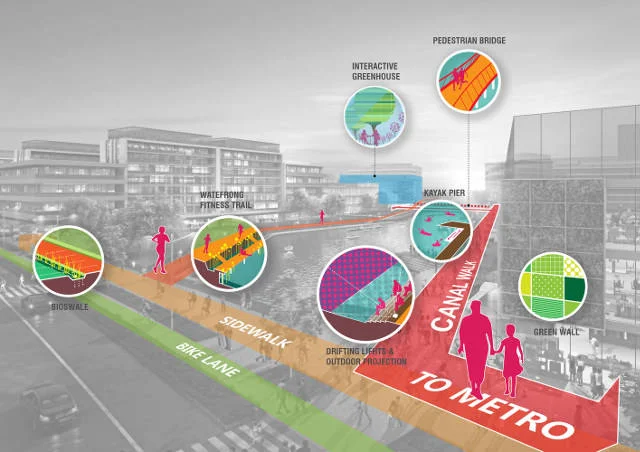

The Sasaki planning and urban design firm is turning heads with its masterplan for a 250-acre urban agricultural district in Pudong called Sunqiao, which will include, most spectacularly, towering vertical farms that grow lots of leafy vegetables

Sunqiao will include residential, commercial and public spaces integrated with an urban farm spread out across several buildings that will hydroponically produce spinach, kale, bok choi and watercress under LED lights and nutrient-rich water. Those veggies will then be sold to local grocers and restaurants.

Michael Grove, a principal at Sasaki, told Business Insider that the firm expects to break ground on the project by 2018, though there is no timeline yet. Grove said that the biggest problem they will face will be designing buildings that block out as little sun as possible.

While this project may seem ambitious, it's not quite on the level of Italian architect Stefano Boeri who wants to cover China with "forest cities" starting with the smoggy Hebei capital of Shijiazhuang

For China, the future certainly looks green.

[Images via Sasaki]

This 100-Hectare Vertical Urban Farm Will Feed 24 Million People

Shanghai is planning an urban vertical farm that will feed millions. The centre aims to educate people on the benefits of food sustainability. Sasaki Architects will create the 100-acre farm that will be interactive and hands-on. The population of Shanghai is 24 million and the company aims to feed every one of them.

This 100-Hectare Vertical Urban Farm Will Feed 24 Million People

SHAWNTAE HARRIS APRIL 20, 2017

BY: SHAWNTAE HARRIS

Shanghai is planning an urban vertical farm that will feed millions. The centre aims to educate people on the benefits of food sustainability.

Sasaki Architects will create the 100-acre farm that will be interactive and hands-on. The population of Shanghai is 24 million and the company aims to feed every one of them.

The biggest city in China lost a lot of green space due to the urbanization of the city. The city lost almost “123,000 square kilometers of farmland to urbanization – a land area equivalent to nearly the entire state of Iowa,” wrote Sasaki. The green space will fit in between the chaos of the big city and tall buildings.

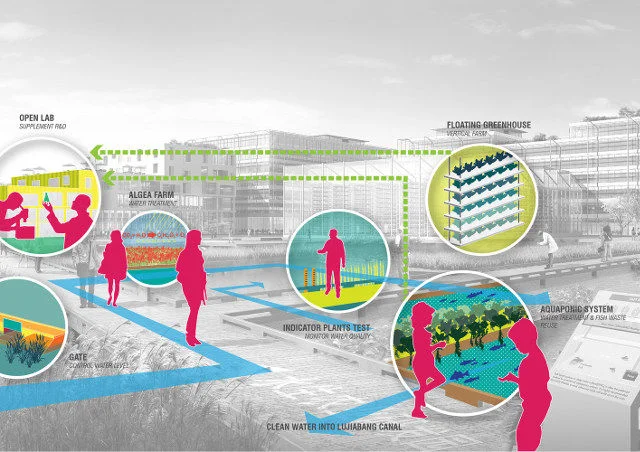

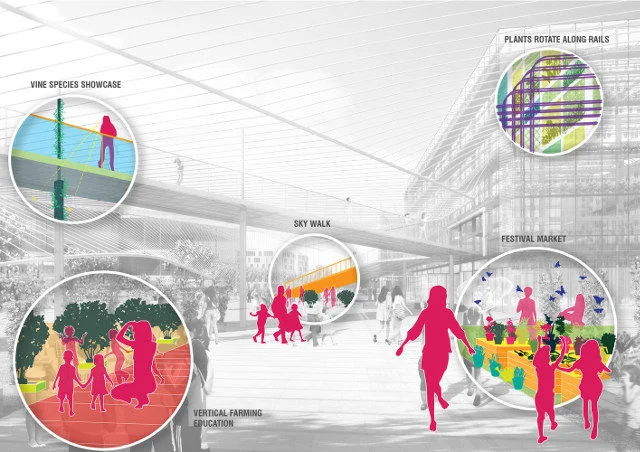

The layout will include growing centers like algae farms, floating greenhouses, vertical walls and seed libraries. “As cities continue to expand, we must continue to challenge the dichotomy between what is urban and what is rural. Sunqiao seeks to prove that you can have your kale and eat it too,” explained Sasaki to Inhabitat.

“This approach actively supports a more sustainable food network while increasing the quality of life in the city through a community program of restaurants, markets, a culinary academy and pick-your-own experience.”

The food sustainability will educate on large scale food production. There will be family-friendly events that will be held to teach kids about the values and importance of food supply.

A tour of the interactive greenhouses and a science museum will be held. As well as a tour of the sea life and plant growth to stimulate the water.

Shanghai needs more hands on food education. In recent years residents of Shanghai have turned creative to create green spaces. Many have built little gardens on their balconies or rooftop to create organic, fresh foods. Without the proper education, Shanghai food sustainability will not prosper.

Shanghai Recently Changed Food Laws

On March 20th Shanghai implemented a new restaurant food safety law, and in the last month the food hotline received over 14,000 calls. This is a 47 per cent increase from last year.

“Some businesses are trying hard to cover up violations. And tip-offs from insiders really save us a lot of time in investigation,” saidShen Ruoqing, head of the Center of Complaints and Reports at the Shanghai FDA. “The recent scandal of the famous bakery Farine is such an example.”

A reported insider told Shen one particular business was hiding expired food in a residential complex, in order to not get caught. Stricter rules will be implemented by the government soon.

In the meantime, the residents of Shanghai can look forward to the new urban farm and the benefits that it will bring to the health and well being of the community.

Netherlands Begins Construction On Europe’s First Commercial Vertical Farm

20 April 2017

Netherlands Begins Construction On Europe’s First Commercial Vertical Farm

Image source: chipmunk_1/Flickr

Europe, Worldwide, Agriculture, Tech. & Innovation, Sustainable Innovation Forum

The farm in Dronten, the Netherlands, will serve one of Europe’s biggest supermarket chains with lettuce grown using LED horticultural lighting.

To date, the only vertical farms in Europe using LED-based lighting have so far been research centres or specialist producers serving restaurants.

The new facility in Dronten – built by fresh fruit and vegetables company Staay Food Group – will be the first vertical farm in Europe to operate commercially.

The facility will serve one the continent’s largest supermarket chains in addition to being used for testing and optimising processes for future, larger vertical farms, and is scheduled to begin operating in the latter half of this year.

The 900 square metre indoor vertical farm will have over 3,000 square metres of growing space, and will use Philips GreenPower LED horticultural lighting.

As the farming happens indoors, any harmful insects or other pests will be prevented from reaching the crops – as a result no pesticides will be required in the process.

Staay and Philips Lighting collaborated with vegetable breeder Rijk Zwaan to carry out the extensive research required to determine the best combination of lettuce varieties and growth recipes in order to improve crop quality and yields

Udo van Slooten, Managing Director of Philips Lighting Horticulture LED Solutions, said: “Our plant specialists at our GrowWise research centre in Eindhoven are testing with seeds of a selection of the most suitable lettuce varieties to define the best growth recipes and to optimise the crop growth even before the farm is running”.

Wim Grootscholten, Manager of Marketing and Business Development at Rijk Zwaan, said: “The tests we are conducting within this project are enabling us to identify which varieties are optimal for growing in a vertical farm, and also which varieties offer the best taste and texture.”

Vertical farming also allows for the locating of food production close to – or even within – urban areas, where food consumption id concentrated.

Grootscholten went on to say: “It will help us with our continuous challenge to offer solutions for the growing world population. We believe that vertical farms will become increasingly important, because in the future we see more economic and environmental pressure to produce fruit and vegetables, such as lettuce, closer to where end customers are located.”

Farms located nearer consumers will help to reduce emissions and transport-related costs.

Similar facilities are also on the rise in the U.S., Vertical Fresh Farms has been farming commercially on a small scale in Buffalo, New York for a few years and Aerofarms in Newark, New Jersey, is currently developing the largest vertical farm in the world, with expected harvests of over 900,000 kilograms each year.

A report by PS Market Research projects that vertically farmed food market will take off in the next few years, generating $6.4 billion of total revenue by the year 2023.

To receive similar news articles, sign up to our free newsletter here.

How Freight Farms Is Taking Off From Boston To Canada

SEB EGERTON-READ · APRIL 19, 2017

Freight Farms sell a solution where 40’ x 8’ x 9.5’ shipping containers are outfitted innovative tools and technologies to produce consistent, high-volume harvests of leafy greens, herbs and a number of other select crops 365 days per year. Based in South Boston, this highly innovative idea was derived by co-founders Jon Friedman and Ben McNamara partly when they discovered that New England, despite its wealth and prosperity, relied on imports from outside the region for close to 90% of its food, while nearly 15% of all households reported not having enough to eat.

Using solar energy to provide the majority of the electricity required to grow crops, the containers are designed to be self-sustaining and are sold to individuals, not necessarily farmers by trade, but people who want to grow food for themselves and/or their community. The freight farm containers are small enough to be squeezed between buildings, placed at the end of parking lots, or almost anywhere in urban terrains.

The Freight Farm equipment set offers a hydroponic system, which they call the Leafy Green Machine, a soil-free growing method that utilised recirculated water with nutrient levels to grow plants. LED lights are optimised for each growing cycle, while a smartphone app called Farmhand allows the container owners to manage conditions remotely and connect with live cameras to monitor the plants.

The idea was simple. Give individuals a base and template to enable a distributed food growing network in cities. Boston may not be the obvious ‘hub’ for farming activity, but Freight Farms has spread across the north-east USA and into Canada, and there are now more than 100 of the company’s containers operating in the US alone.

The container’s growing conditions are controlled via a mobile app. Credit: Freight Farms

Investing and owning a Leafy Green Machine isn’t an inexpensive proposition, rather it’s an entrepreneurial investment opportunity. Purchasing one of the containers reportedly costs a business up to $85,000, while annual operating costs may reach $13,000. However, in a New England context where demand for locally grown food is increasing (close to 150 farmer markets operate in the state of Massachusetts alone), which offers significant business potential for new local growers, especially if they can run on low operating costs with minimal demand for land, water and chemical fertilisers.

In Boston in particular, enabling policy support has been a factor, where a recent mayor legally expanded zoning laws within the city to allow farming in freights, on rooftops and in other specific ground-level open spaces. One of the most overt examples the city’s positive stance on urban farming is at the iconic Fenway Park, where Green City Growers run the 5000-sq ft Fenway Farms above the iconic home of the Boston Red Sox.

There are legitimate questions about the role of urban farming, in particular hydroponic techniques, in the future of food. Will urban farming ever be able to grow the volume and variety needed to account for a significant percentage of the consumption of the city’s inhabitants? The answer to that question is, at best, unknown. However, there’s no doubt that hydroponic, aquaponic and aeroponic urban farming methods are gaining traction because they speak to a new way of thinking about how food is grown, distributed and consumed. In a context where land and water is scarce, and where people are increasingly inquisitive for information about what they eat, it seems increasingly likely that at least some portion of the food consumed within urban areas will be grown by a distributed network across the city in containers, warehouses and rooftops. The story of Freight Farms, and their growth across the north-east USA and Canada is just another hint in that direction.

Vertical Farming Is Taking Off: Europe’s First Commercial Vertical Farm Under Construction In The Netherlands

Vertical Farming Is Taking Off: Europe’s First Commercial Vertical Farm Under Construction In The Netherlands

April 19th, 2017 by Rogier van Rooij

Innumerable layers of vertically stacked crops, growing at insane speeds thanks to the meticulous administration of exactly the right quantities of water, nutrients, and a precise spectrum of light. Vertical Farming has so far been more successful in gaining media attention than in producing food, but this is about to change. Until recently, the only operational vertical farms were small-scale installations in research labs. Facilities aimed at developing the technology were involved, especially in refining the required lighting and climate control equipment. But this year, 2017, appears to usher in the next stage in the development of vertical farming. For the first time, larger scale commercial production is being undertaken.

Vertical Fresh Farms has been farming commercially on a small scale in Buffalo, New York for a few years, but a larger scale commercial facility is currently under construction in the Netherlands. Fruit and vegetables supplier Staay Food Group is erecting a 900 square meter vertical farm, which will have a total cultivation area of 3000 square meters.

Based in the town of Dronten, the facility is producing lettuce for ‘one of the largest supermarket chains of Europe.’ The lettuce is grown using Philips GreenPower LED horticulture lightning technology, and besides tech-multinational Philips, vegetable breeder Rijk Zwaan was involved in the development of the facility. The farm is expected to come online somewhere during the latter half of 2017.

This is good news for the environment because no pesticides are required in the process. Farming happens indoors, preventing any harmful insects or other pests from reaching the plants. Furthermore, vertical farming allows for locating food production closer to, or even in cities, where food consumption is concentrated. As a result, suppliers can save on transport emissions as well as on transport costs. The farm in Dronten packs the lettuce on location, which reduces the shipment distance even further.

The Dutch commercial facility is not the only sign that vertical farming is on the rise. Aerofarms in Newark, New Jersey, is currently bringing online the largest vertical farm in the world, with expected harvests of up to 2 million pounds a year. In Shanghai, plans have just been released for a massive 250-acre city farm, on which construction should start in 2018.

This growth of the vertical farming sector appears to be driven by two key components: an increasing demand for organic, pesticide-free food, and innovation, especially in the power consumption of the LED-technology required to grow indoors. A report by PS Market Research forecasts that the market for vertically farmed food will grow rapidly in the coming years. Their calculations give $6.4 billion of total revenue by the year 2023.

About the Author

Rogier van Rooij Optimistic, eager to learn and strongly committed to society's wellbeing, Rogier van Rooij wants to share with you the latest cleantech developments, focussing on Western Europe. After graduating cum laude from high school, Rogier is currently an honours student at University College Utrecht in the Netherlands.

Innovative, Efficient Indoor Farm In New Jersey

Innovative, Efficient Indoor Farm In New Jersey

By: ALISON MORRIS

POSTED: APR 18 2017 05:41 PM EDT

NEW YORK (FOX 5 NEWS) - Could the answer to the global food crisis be hidden in a warehouse in New Jersey? A local indoor farming startup is producing affordable crops there year-round, independent of the weather.

And food safety is paramount. That means outside clothes or jewelry can't come in. A visit to Bowery's farm starts with a uniform and some hand sanitizer. This vertically integrated farm in Kearny, New Jersey, is producing some seriously clean greens.

CEO and co-founder Irving Fain describes the farm as "post-organic" and says it is completely chemical free: no pesticides, herbicides, fungicides, or insecticides. Fain says it is the purest produce you could possibly get.

Innovative, efficient indoor farm in New Jersey

He founded the farm a few years ago along with David Golden and Brian Falther. They've brought in $7.5 million in funding from some rock star investors, including Top Chef Tom Colicchio.

The farm is now producing crops 365 days a year regardless of the weather, using a lot less water. Fain says it is 100 times more productive than the same square footage of outdoor land. The farm grows twice as fast as the field, with more crop cycles every year, more yield in every crop cycle, and uses 95 percent less water.

Their hope is to help solve the global food crisis. Fain says the planet's population will be 9 billion to 10 billion by 2050, so it will need 50 percent to 70 percent more food to feed everyone.

While that change is happening, 70 to 80 percent of people are living in cities. They saw that urbanization and became obsessed with the question: how do you provide fresh food to urban environments in a more efficient and sustainable way? The answer: start with LED lights. Fain says the lights they use mimic the sun, so it's as if the plant is growing in the absolute healthiest environment for its entire life. He says that the price of those lights dropped while their efficiency went up about 5 years ago, making indoor growing commercially viable.

Fain says Bowery sells 5-ounce clamshells for $3.99 or even $3.49, which is pretty standard, if not lower, than what you find out in the field. Throw in the Bowery Operating System, which creates optimal growing conditions, and Bowery is able to churn out fresh, affordable, and delicious greens.

And the farm is growing. Fain says they're already experimenting with different types of crops and other SKUs outside of the leafy green category.

Right now you can find Bowery lettuce and basil in tri-state Whole Foods and in Foragers Market in New York City. The lettuce you'll find there has often been harvested the same day it hits the shelves.

Urban Gardening Kit Has Everything You Need To Grow Your Own Food

From Ikea’s indoor gardening offerings to a shipping container community farm in Brooklyn, New York,urban agriculture is having quite the moment. Now, GrowKit, billed as an “Urban Agriculture Kit for Beginners,” wants to make farming accessible to city dwellers starved for space.

Urban Gardening Kit Has Everything You Need To Grow Your Own Food

Small spaces welcome

BY SELINA CHEAH APR 18, 2017, 4:17PM EDT

From Ikea’s indoor gardening offerings to a shipping container community farm in Brooklyn, New York, urban agriculture is having quite the moment. Now, GrowKit, billed as an “Urban Agriculture Kit for Beginners,” wants to make farming accessible to city dwellers starved for space.

Developed by Porto, Portugal-based startup Noocity, the kit gives city residents a chance to grow and harvest their own food, even if they don’t have any experience with farming. The compact and portable package includes everything needed to begin an organic, edible garden—from a Growbag with all the necessary equipment and potting soil to a Growpack with the plants and fertilizer. There’s also a set of audio guides, detailing step-by-step instructions.

This garden uses up to 80 percent less water than a conventional vegetable patch because of its sub-irrigation system, which provides water to the plants’ roots. It also has a water reservoir, so the garden can self-water for up to three weeks.

Noocity, which debuted a larger self-watering gardening system called Growbed in 2015, is currently running an Indiegogo campaign for Growkit. One Growkit is going for $74. Here’s the demo video.

Sustainable Farming Blossoms In The Lowcountry

The sun is rising on a new form of farming in the Lowcountry. In the heart of Summerville, there's an up and coming farm that sits in a residential neighborhood. Stefanie Swackhamer and her team at Tiger Corner Farms says their whole operation is one big science experiment. "Traditional farmers grow in the dirt," she said. "Hydropantic farmers grow in the water."

Sustainable Farming Blossoms In The Lowcountry

SUMMERVILLE, S.C. (WCIV) — The sun is rising on a new form of farming in the Lowcountry.

In the heart of Summerville, there's an up and coming farm that sits in a residential neighborhood.

Stefanie Swackhamer and her team at Tiger Corner Farms says their whole operation is one big science experiment.

"Traditional farmers grow in the dirt," she said. "Hydroponic farmers grow in the water."

Chief Engineer Evan Alusie said the 40-foot crates allow them to farm in an environmentally friendly way.

“Indoor farming gets red of the use of manure-based fertilizing so you reduce the risk of pathogens to humans,” he said.

Inside each crate, lettuce and other leafy plants are blooming at an unbelievable size.

“The roots hang in the air, and get misted every so often," Stefanie said. "That's how they gain their nutrients to be able to grow.”

They use LED lights to stimulate the growth of their plants.

One benefit to container farming is the ability to grow plants outside of their traditional season.

“Lettuce, you can't grow in the summer here, it's way too hot outside." Matt Daniels explained. "In here, everything is temperature controlled. The lights are on a set schedule for optimal growth.”

They’re growing fresh vegetables available to folks right here in the Lowcountry, putting the veggies in the mouths of those in need.

Stefanie, a former high school teacher, said she wanted to plant seeds outside of the classroom.

“There are a lot of students that don't have good quality produce available to them on a regular basis,” she said. "Right now everything we harvest gets donated back into the community."

The team at Tiger Corner is looking for interns. Students who are interested in S.T.E.M. are wanted. You can contact them at tigercornerfarmsmfg.com.