Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Fresh Veggies Grown Close to Home, Without Pesticides — And Without Dirt

Fresh Veggies Grown Close to Home, Without Pesticides — And Without Dirt

Civic Farms touts having “pioneered the vertical farming industry.” The company says its proprietary growing systems, licensed patented technologies, and optimized processes for cultivation and harvesting processes maximize the efficiency and efficacy of growing indoors.

TUCSON (CN) – An ambitious project of emerging agricultural technologies that produce food without soil is taking shape at Biosphere 2, the University of Arizona’s research complex north of Tucson.

Civic Farms, an Austin-based company, this summer will start building a vertical farm in one of two 20,000-square-foot domes – or “lungs” – that regulated pressure inside a sealed glass structure during experiments to study survivability in the 1990s.

The company will invest $1 million to renovate the Biosphere’s west lung, unused for years, and outfit the space with stacked layers to grow soil-free plants in nutrient-laden circulating water under artificial lights.

At full capacity, the vertical farm will produce 225,000 to 300,000 lbs. a year of leafy greens and herbs such as lettuce, kale, arugula and basil, said Paul Hardej, CEO and co-founder of Civic Farms.

“Biosphere itself is a fantastic facility and food production is a big part of what it was originally intended to do,” he said.

As the world population continues to rise, particularly in cities, along with consumer interest in the origins of food, vertical farming is gaining traction as a commercially viable way to increase crop production in a fully controlled indoor environment.

“People want know what they eat and what’s in their food and how healthy and good it is for them,” Hardej said. “Growing food in city centers or close to city centers where people live makes perfect sense.”

Under an agreement with the university, Civic Farms will grow crops in half the space it will lease for $15,000 annually. Research and scientific education will comprise the other half and the company will contribute $250,000 over five years for those efforts.

“We envision that a portion of the lung will be open and accessible to the public so people can come in see how and what it is to have a vertical farm,” said John Adams, the Biosphere’s deputy director.

Civic Farms touts having “pioneered the vertical farming industry.” The company says its proprietary growing systems, licensed patented technologies, and optimized processes for cultivation and harvesting processes maximize the efficiency and efficacy of growing indoors.

The Biosphere already draws nearly 100,000 annual visitors to expansive grounds originally intended to showcase a self-sustaining replica of Earth, or Biosphere 1.

Set on a 40-acre campus against the backdrop of the rugged Santa Catalina Mountains, the Biosphere’s 91-foot steel-glass structure serves as a global ecology laboratory enclosing an ocean, mangrove swamp, rain forest, savanna and coastal desert.

In the early 1990s, a crew of scientists was locked inside the sealed structure in privately funded scientific experiments designed to explore survivability with an eye toward space colonization. Problems with the experiments and management disputes eventually halted the highly public venture.

The University of Arizona took over the property, about 30 miles north of Tucson in the town of Oracle, in 2011.

The Biosphere’s Adams views the planned vertical farm as a good fit for research initiatives.

“For the next 10 years, Biosphere’s focus is very much on food, energy, water – and the nexus,” he said.

Civic Farms’ Hardej said the university’s myriad resources were strong incentives for his company’s new enterprise in Arizona. A big plus are the concepts being developed at the university’s Controlled Environment Agriculture Center on North Campbell Avenue, where scientist Murat Kacira grows leafy crops indoors under LED lights.

“There’s so much interest in this technology platform because it provides the capability to grow food with consistency,” Kacira, a professor of agricultural-biosystems engineering, said of vertical farm systems.

Inside the lab where lettuce and basil grow in hydroponic beds under the glow of blue and red LED lights, Kacira and his students monitor the conditions in which seedlings mature.

“The environment is fully controlled in terms of providing temperatures needed, or humidity needed, carbon dioxide or the light intensity or the quality needed for the plant production,” Kacira said.

Not being at the mercy of Mother Nature makes vertical farms more productive than conventional farms, as well as more efficient at using natural resources such as water, he said. “You’re circulating it inside the environment, so the efficiency is much higher.”

Still, Kacira said, the technology is energy-intensive, given the use of artificial lights and the need to condition the environment. And although large-scale commercial operations are relatively rare, he said, advances in scientific research and the high-tech industry are making it a feasible platform to help supplement food production in cities.

“Our food transportation is coming from long distances, and by the time it gets to the consumer, especially leafy crops, the freshness may not be there,” Kacira said.

Vertical farms are a relatively new concept that hold great potential, Hardej said it. With a projected global population of 9.5 billion, mostly urban, by 2050, he views vertical farms as an increasingly important part of the world’s food system.

His own vertical farm aims to provide the Tucson and Phoenix markets with high-quality produce grown sustainably and without pesticides, Hardej said.

In time, he plans to incorporate more energy-efficient solutions into his operation.

“For commercial scale, those technologies still need to be perfected,” he said.

His company plans to begin growing the leafy greens by year’s end.

Seeds Of Change: Mini Gardens Help Drive The Growth Of Food At Home

Seeds Of Change: Mini Gardens Help Drive The Growth Of Food At Home

May 31, 2017 11:59 AM ET

KRISTEN HARTKE

Seedsheets are made of weed-blocking fabric, a thick layer of soil and dissolvable pods full of organic seeds.

Courtesy of Seedsheet

The short, but intense, growing season in Vermont might be a drawback for some, but for native son Cam MacKugler, it has turned out to be the key to developing his container garden kit startup, Seedsheet.

"Up here in Vermont," says MacKugler, "we don't have a lot of time to grow our food, so the goal is to get as much as you can as quickly as possible."

A house-sitting stint on a co-worker's farm in 2012 is what inspired MacKugler, an architect working in sustainable design in Middlebury, a small town in western Vermont. "I was paid with access to the backyard garden," he says, "and I was looking at the companion planting [an agricultural system for maximizing space and crop productivity] and how well it was designed — the arrangement of tomatoes and basil and zucchini. The idea for Seedsheet almost immediately came to me."

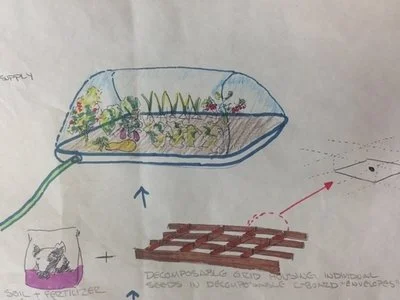

Sketching out the concept with crayons that were handy in the farmhouse, MacKugler was intrigued by the idea of foolproof gardening that would appeal to people living in cities with little or no outdoor space, but who still wanted the experience of harvesting their own crops.

When MacKugler first came up with the concept of Seedsheet, he sketched out the concept with crayons that were handy in the farmhouse where he was inspired by the garden.

Courtesy of Seedsheet

As MacKugler says, "We're kind of the Blue Apron of agriculture. It's not meal delivery, it's farm delivery."

A 2017 gardening industry survey produced by GardenResearch.com shows that 1 in 3 U.S. households now produces something edible at home, whether it's a pot of herbs on the windowsill or a raised-bed kitchen garden. In fact, consumer interest in growing food has translated to a $1 billion increase in sales in just five years, surpassing sales for flower gardening.

It's that all-important 18- to 34-year-old demographic — millennials — who are driving much of that growth, says Michelle Simakis, editor of Garden Center Magazine.

"Some millennials did not grow up gardening with their parents, so they aren't necessarily gardening as a hobby or to beautify their homes like previous generations did," says Simakis. "They are planting vegetables and fruit because they want to know where their food comes from and are interested in cooking with produce that's better than what they can find in stores."

As a millennial himself, MacKugler's instinct for the Seedsheet concept is all about making that "Green Acres" dream come true, but within the confines of modern urban living. His instincts are proving correct: 100 percent of Seedsheet customers live in cities, from Washington, D.C., to San Francisco.

"Most people here in Vermont think we're crazy, but that's because they've been raised as gardeners and don't see the need for this kind of product," he says.

His original concept involved spacing different types of seeds within two layers of dissolvable film, which were placed on top of soil and then watered. MacKugler had it tested by friends and family, who liked the basic idea — except for the weeds that sprouted alongside the seedlings, making it difficult to know what needed to be plucked. A new design using a 12-inch circle of recyclable weed-blocking fabric dotted with four or eight dissolvable pods filled with organic seeds and a thin layer of soil solved the weed problem.

"Companies in the lawn and garden industry are aware they need to provide products that guarantee ease and success for first-time gardeners," says Paul Cohen, research director of gardenresearch.com. Noting that he'd seen MacKugler demonstrating his product on a recent episode of the budding-entrepreneur reality TV show Shark Tank, Cohen says, "I expect to see a lot more of these types of products in the future."

MacKugler is particularly mindful of making first-time gardeners feel successful. "Our main goal is to choose varieties that will grow really quickly. We're figuring out which plants can grow together and reach maturity around the same time so people can coordinate cooking meals around the harvest."

MacKugler and his team focus on fast-growing varietals like Glacier tomatoes, while Ruby Streaks mustard greens and Valentine's Day radishes can be ready to eat in about a month.

Seedsheets are recipe-focused. For example, the one for hot sauce includes seeds for cayenne peppers, red carrots, Napoli carrot and purple bunching onions.

Courtesy of Seedsheet

"You can grow a lot of food in a small amount of space," asserts MacKugler. "People will say, 'You can't grow tomatoes in a bucket,' but it's actually very easy."

Indeed, besides MacKugler's kits, Simakis notes there are already a variety of other options popping up in the small garden marketplace. Both IKEA and Miracle-Gro offer countertop units, while would-be gardeners with a little more space can opt for LED-powered, indoor hydroponic growing kits. But she also sees that the millennial interest in growing food may be tied to loftier goals.

"Making gardening easy is important, but I think more companies are starting to promote the importance of gardening to help the environment, and generally speaking, the millennial generation is drawn to causes," she says.

For MacKugler, his own interest in sustainable design and supporting the local community means sourcing organic seeds and relying on the expertise of an important segment of the nearby population: farmers.

Because Vermont's farmers are typically out of work during the winter and early spring until planting season starts, they are becoming the biggest asset for his young company, where everything from custom machinery to seed assembly procedures needs to be built from the ground up. And with up to 600 kits being made per hour, MacKugler says, "We're selling more kits now than we actually have people in our town."

Curating seeds specifically for recipes has also been an important focus for MacKugler, highlighting another millennial trend: home cooking. A recent survey by online grocer Peapod shows that millennials are now twice as likely to cook at home than baby boomers, but they are more in need of inspiration than older, more experienced cooks. The "Hot Sauce Seedsheet" is one recipe-based kit designed to feed that need, with four seed varieties that grow together in a standard 12-inch pot: the Ring-O-Fire Cayenne Pepper, Dragon Red Carrot, Napoli Carrot and Purple Bunching Onions. The kit comes with recipes for spicy carrot juice and, of course, hot sauce.

"Our goal is to cultivate an understanding of how gardening works," says MacKugler. "Everyone should be able to call themselves a gardener, no matter where they live."

AeroFarms Raises $34m of $40m Series D from International Investors for Overseas Expansion

AeroFarms Raises $34m of $40m Series D from International Investors for Overseas Expansion

MAY 30, 2017 LOUISA BURWOOD-TAYLOR

US indoor agriculture group AeroFarms has raised over $34 million, according to a Securities & Exchange Commission Filing. The funding is the first close of a targeted $40 million Series D round.

AeroFarms grows leafy greens using aeroponics –- growing them in a misting environment without soil –- LED lights, and growth algorithms.

The round takes AeroFarms’ total fundraising efforts to over $130 million since 2014, according to AgFunder data, including a $40 million debt facility from Goldman Sachs and Prudential.

AeroFarms attracted new, international investors in this latest round, including Meraas, the investment vehicle of Sheikh Mohammed bin Rashid, vice president of the United Arab Emirates and the ruler of Dubai.

The round marks the first investment for ADM Capital’s new growth stage agriculture-focused Cibus Fund, and global asset management firm Alliance Bernstein also invested. Existing investors Wheatsheaf Investments from the UK and GSR Ventures from China also joined the round.

The filing also revealed that AeroFarms had renamed its holding company to Dream Holdings, as part of its move from an LLC to a C-Corp, referencing its new retail brand Dream Greens. The Dream Greens brand hit the shelves of ShopRite, Whole Foods, FreshDirect, and Newark chain Seabras in February. Before that, the business was selling its greens into food service under the AeroFarms brand.

AeroFarms’ global list of investors is representative of its plans to expand globally, David Rosenberg, CEO, told AgFunderNews.

“We want to expand domestically and overseas, and we are excited about the potential for Meraas to help us expand into that region,” he said.

AeroFarms is not the only group to consider building indoor farms in the Middle East; Pegasus Agriculture Group, is a hydroponics-based indoor ag company that is based in Abu Dhabi, with facilities across the Middle East and North Africa. Egyptian Hydrofarms is another local example, and Indoor Farms of America recently made its first farm sale in the region.

AeroFarms also wants to add to its 120-strong team of plant biologists, pathologists, microbiologists, mechanical engineers, system engineers, data scientists and more. In particular, the company wants to add team members to its research & development department, with a view to improving the quality and operating costs of the business, according to Rosenberg. “This is where the data science and software platforms we’re using can really pull the business together.”

AeroFarms just completed construction of its ninth indoor farm, with four in New Jersey including its state-of-the-art 69,000 square foot flagship production facility in Newark. It also has plans to build in the Northeast of the US.

For more about AeroFarms, read our earlier interview with CEO David Rosenberg here.

Social Entrepreneurs Grow A 'Computer Garden' At Zahn Innovation Center

Social Entrepreneurs Grow A 'Computer Garden' At Zahn Innovation Center

CONTRIBUTOR - I cover for-profit social enterprises and impact investing

A "computer garden" for urban farming that grows food without soil or harmful chemicals. That's the mission of SyStem, a fledgling New York City startup founded by two engineering students at The City College of New York.

"Our mission is to grow food for people in the future," says Alex Babich, a junior electrical engineering major, who founded the company with Adrian Logan.

Wild bloom Photography

SyStem's radishes (Photo credit: Wildbloom Photography)

It's also the winner of this year's Zahn Social Impact Prize, awarded earlier this month. That's a business pitch competition run by the Zahn Innovation Center, a semester-long incubator for City College students and graduates.

The co-founders created what Babich calls a "food computer"--a three-foot-wide by two-foot-deep box with a computer in it, along with an automated controlled environment for growing plants hydroponically. Various sensors monitor such factors as the temperature, humidity, the CO2 in the atmosphere, and the water's pH level. If, say, the latter is too low, the system will pump up the pH solution. "For whatever plant you want, you put in a recipe--software programmed to take the plant through the whole life cycle successfully," he says.

Ultimately, the startup aims to address a looming crisis--as world population increases, there will be less land available on which to grow food for more people. At the same time, the effects of climate change are likely to make it harder to produce enough sustenance. "We're developing ways to bring food closer to where people live and grow it in a more efficient way," says Babich.

But to develop technology capable of providing food on a large scale, according to Babich, time is of the essence. "That's why it's so important to be working on this type of technology now," he says. The plan is to build a modular system that has a central computer. Thus, you could create a large system with many modular sections or, with just a few, build a much smaller one in, say, someone's home.

Recently, Logan and Babich grew their first crop--radishes, which took about eight days to pop. "They came out really well," says Babich. Next step: Over the summer, they plan to develop their hardware platform. Plus, they're working with a fellow Zahn startup City LABscape to build the hardware for that company. City LABscape, which recently won the Standard Chartered Women + Tech4NYC Prize, has developed a curriculum and prototype for hands-on indoor agriculture STEM education for middle and high school students, using small hydroponic-growing systems.

SyStem's founders met each other in a CCNY engineering class and discovered they worked together well. One day, after he learned about the Zahn Center, Babich told his friend that he was interested in doing "something with an app." Logan wasn't crazy about the idea. Then Babich told him, "I really think it would be cool if there were a skyscraper growing plants automatically." So they tossed around ideas, like, for example, a computer that could grow plants, and were accepted into the Zahn program. A semester -long incubator, it takes 24 teams through a boot camp that trains them in how to move from an idea to building a prototype and forming the beginnings of a business.

Then they applied for Zahn's summer-long, a full-time accelerator program, which accepts 10 startups and is aimed at launching their business. Each of those teams gets $10,000, so they can spend the summer working on their startups, instead of at a summer job.

Vertical Farms Grow Amid Skyscrapers In A Plan to Help Feed China’s Largest City

Vertical Farms Grow Amid Skyscrapers In A Plan to Help Feed China’s Largest City

Laura Brehaut | June 1, 2017 9:39 AM ET

More from Laura Brehaut | @newedist

Sasaki Associates

The hydroponic vertical farm will be dedicated to growing Shanghai staple greens such as kale, lettuce and spinach.

As Shanghai sprawls outward, architecture firm Sasaki Associates has announced plans for a farm that grows upward. The hydroponic vertical farm will be built amid the skyscrapers of China’s largest city. Like most vertical farms in use today, it will be dedicated to growing staple leafy greens such as kale, lettuce and spinach, according to Dezeen.

Space-saving is the aim of the project, Dezeen reports. Sasaki Associates intends the multi-storey farm to act as an alternative to the vast swaths of land — and associated costs — required for traditional agriculture. The project will also incorporate urban farming techniques such as algae farms, floating greenhouses and a seed library.

Vertical farms exist in cities worldwide, providing fresh produce, fish, crabs and other foods to residents in cities such as Anchorage, Berlin, Singapore and Tokyo. Advocates say that vertical farms have a reduced carbon footprint, use fewer pesticides and guzzle less water than traditional farming. Opponents argue that there are many unanswered questions about the practice, and question its economic viability.

Construction of the Shanghai project is expected to start in late 2017 as part of a new development — the Sunqiao Urban Agricultural District. The district will also feature markets, a culinary academy, interactive greenhouses and an education centre for members of the community.

Strawberry Imports May Become Unnecessary For Russia

Strawberry Imports May Become Unnecessary For Russia

It is now possible to grow strawberries all year round across Russia, from Kaliningrad to Yakutia, with a total of 6 harvests a year, as reported by agroinfo.com

The Russian company Fibonacci presented an innovative product for agriculture: the automated vertical farm BerryFarm800, which makes year-round strawberry cultivation possible.

BerryFarm800 is capable of producing 6 harvests of this delicious fruit per year, including during the winter months. The 800 sections of the agro-farm, with space for 76,800 bushes, yield 15 tonnes of strawberries a month.

Managing the farm does not require special knowledge or a lot of staff. BerryFarm800 only requires 5 people because all processes are automated.

Also, remote control of all farm parameters is possible thanks to a program developed specifically for BerryFarm800.

Another advantage of the system is that there is no need to build a greenhouse. The BerryFarm800 can operate in any ready-made commercial space: warehouses, production rooms, and so on. The farm is totally independent of climatic conditions.

Another advantage is the quick installation and the start of its operation, 2 months from the time of ordering.

The Russian company's product has no equal in the world, and according to expert assessments, it could have a significant impact on Russia's food policy. It could even make the import of strawberries completely unnecessary.

"Nowadays, in a context marked by sanctions and fierce import policies, this product is economically attractive to all consumer groups. The equipment can be delivered to any country, allowing customers to grow quality strawberries for private or commercial purposes," stated a Fibonacci representative.

Cloud Controlled Mini-Farms | AUDIO Interview - Smallhold

Cloud Controlled Mini-Farms | AUDIO Interview - Smallhold

31 May 2017

Very soon, grocery stores will be cloud-controlled mini-farms with shelves of growing produce -- according to the co-founders of the Brooklyn startup Smallhold. Hear how their ideas for vertical farming could impact your home, your supermarket and even outer space.

Click Above for Audio

We farm for you by growing produce 3/4 of the way and then deliver it to miniature vertical farm units (the size of shelving units) at your place of business to be harvested onsite as fresh, local food.

Smallhold gives you a networked farm, complete with sensors, climate control mechanisms, and hydroponics. Our horticulturalists run the farm from afar, growing for you right up until you pick and serve your produce.

From Slaughterhouse To Vertical Farm: The Plant Is Innovating In Sustainability And The Circular Economy

From Slaughterhouse To Vertical Farm: The Plant Is Innovating In Sustainability And The Circular Economy

May 30, 2017 Chuck Sudo, Bisnow, Chicago

In 1906, Upton Sinclair’s “The Jungle” depicted the harsh conditions workers toiled under inside the slaughterhouses of the Union Stock Yard and Packingtown. A century later, this area that gave Chicago its brawny identity as “hog butcher for the world” is now home to several new food businesses focusing on sustainability, and The Plant in Back of the Yards is its epicenter.

Chuck Sudo/Bisnow - The Plant, a vertical farm in Back of the Yards, was once a slaughterhouse.

This 94K SF former slaughterhouse was abandoned and slated for demolition when John Edel — through his company Bubbly Dynamics — bought it in 2010 and slowly repurposed the building into a vertical farm and food production business committed to a "circular economy," a closed loop of recycling and material reuse. Today, the Plant is home to several businesses where the waste stream from one business is repurposed for use by another business elsewhere in the building.

Chuck Sudo/Bisnow

Whiner Beer Co. brews its beer at The Plant and opened a taproom whose bar, tables and chairs were made from reclaimed wood.

The Plant’s tenants are a who’s who of local food producers. Pleasant House Bakery is a popular company that bakes breads, desserts and Yorkshire-style meat pies that are sold wholesale at farmers markets and at Pleasant House’s Pilsen pub. Arize Kombucha distributes nearly 500 gallons of fermented probiotic tea monthly to area grocery stores. Four Letter Word Coffee, a boutique coffee roaster, has a roastery on the second floor. Whiner Beer Co. specializes in Belgian-style ales and operates a taproom inside the Plant. Justice Ice makes crystal-clear ice for use by Chicago’s best bars and restaurants for their cocktails. The Plant also has an outdoor farm, an indoor aquaponic farm that grows an average of five pounds of greens a week, an indoor tilapia farm and hatchery, a mushroom farm capable of growing 500 pounds of oyster mushrooms a month, and an apiary for making honey.

Chuck Sudo/Bisnow

The Plant has an outdoor farm and an indoor aquaponics farm on the basement level.

Chuck Sudo/Bisnow

With all of that happening, waste is bound to pile up. And the Plant repurposes over 90% of the waste byproducts created by its tenants. Waste from the fish farm and carbon dioxide from kombucha production is used to fertilize the greens in the aquaponics farm, which in turn filters the water that goes back to the tilapia farm. Spent grain from the brewery is used to feed the fish and for Pleasant House’s baking purposes. The Plant’s tenants even repurpose as many building materials as possible. The bar, tables and seating inside Whiner Beer Co.’s taproom was made from reclaimed wood. Pleasant House uses scrap wood to fire its ovens. Sections of the former slaughterhouse's hanging rooms (where beef and pork were processed assembly line-style and aged) are now bathrooms that comply with the Affordable Care, and other sections are being rebuilt into an information center that will open in the fall.

Chuck Sudo/Bisnow

The Plant is in the process of installing a digestible aerator that will produce methane and fertilizer for The Plant's internal uses and outside uses.

The linchpin in the Plant's circular economic model is a 100-foot-long anaerobic digester. This machine is capable of breaking down biodegradable material without oxygen to create methane gas to power the Plant's electrical generation systems, algae and duckweed to feed the tilapia, produce enough process heat for use by the brewery, coffee roaster and baker, and make fertilizer for the outdoor farms. The digester is capable of producing 2.2 million BTUs of biogas. On a smaller level, the Plant is also experimenting with making biobriquettes, a hockey puck-sized brick of biomass from spent grain and coffee chaff, that can be used as fuel in the bakery's ovens instead of wood.

The Plant's circular economy has the possibility of being adapted on a larger scale. A French food engineer and Brazilian urban engineer spent their internships at the Plant analyzing material flows in order to create methodologies to determine if the Plant's closed loop system can be used for developing more efficient urban ecosystems and sustainable cities.

Related Topics: The Plant, Bubbly Dynamics, John Edel, union stock yard, packingtown, Chicago stockyards, Chicago sustainability, Chicago adaptable reuse

Jakartans To See More Urban Farming

Jakartans To See More Urban Farming

Agnes Anya | The Jakarta Post

Jakarta | Tue, May 23, 2017 | 08:05 pm

A man waters plants in a vertical garden in Cikini, Central Jakarta. The city administration plans to build 75 more such gardens, in addition to the existing 150. (Courtesy of Jakarta Fisheries, Agriculture and Food Security Agency/-)

Jakartans will have a greener city soon as the city administration is promoting urban farming in the capital.

The Jakarta administration plans to introduce "green aisle" program in 75 areas to grow vegetables, medicinal plants and potted fruit plants this year, aiming at not only beautifying the city but also to ensure food security.

"We want residents to know that farming is easy. In the future, we hope that they can produce vegetables for their own families," Fisheries, Agriculture and Food Security Agency agriculture division head Diah Meidiantie said.

The administration has allocated Rp 5 billion (US$ 375,855) for the program.

Last year, the agency disbursed Rp 6 billion to establish 150 urban gardens in the capital's five municipalities and Thousand Islands regency.

"However, this year, Thousand Islands won’t join the program as the local residents are struggling to care for the existing ones," Diah said, explaining that the difficulty was caused by a lack of clean water in the regency.

Topics :

Future Food-Tech Is Returning to New York City

Future Food-Tech Is Returning to New York City

The Future Food-Tech Summit is returning to New York City on June 7 and 8, 2017. Investors, start-ups, technology companies, and food and ingredients manufacturers will convene to develop solutions to meet the global food challenge during the two-day event.

Among this year’s Future Food-Tech speakers are Andrew Ive of Food-X, David Lee of Impossible Foods, Nicholas Chia of Mayo Clinic, Zachary Ellis, Jr., of PepsiCo, and Susan Mayne of the Food and Drug Administration.

Panel discussions will address key questions: How can we create systems that enable access to sustainable, safe and nutritious food for all? How are retailers partnering to create the right digital experience for customers? What role can restaurants have in bringing new food experiences to customers? What is the role of governments in producing dietary guidelines and supporting research and investment in alternative proteins?

The event will include panel discussions, fireside chats, networking breaks, technology showcases, and other presentations encouraging discussion around solutions to meet the global food challenge.

Future Food-Tech is an annual event which is held in London, New York City, and San Francisco. The Summit is intended to create a forum for networking, debate, discussion, and learning while giving new food innovators the opportunity to pitch their early to mid-stage companies to an audience of global food businesses, technology integrators, and venture capital investors.

If you have a great story to tell, a game-changing solution to showcase, or would like to share your expertise on one of the panels, please call Rethink Events on +44 1273 789989 or email Stephan Groves for more information.

Click here to register for Future Food-Tech NYC.

Emphasizing Product Quality Over Narrative, an Urban Farming Enterprise Thrives

Emphasizing Product Quality Over Narrative, an Urban Farming Enterprise Thrives

Michael Ableman, Co-founder of Sole Food Street Farms, an urban farming social enterprise in Vancouver, Canada. Photo courtesy of Sole Food Street Farms.

May 30, 2017 | Trish Popovitch

Careful planning, adequate startup capital and experience working on a traditional rural farm are just three of the elements that veteran urban farmer, and co-founder of Vancouver’s Sole Food Street Farms, Michael Ableman feels are necessary to be successful in the new urban agriculture movement. Founded in 2008, Sole Food Street Farms would be considered by many growers as established and successful, but for Ableman there is still much work to be done both at Street Farms and in the development of the city farm movement.

“The skill level required to be a farmer is not something you get just by wearing the right clothes, having the right tools and having started last year. It takes five to ten years to develop that skill level,” says Ableman. “What we’re trying to do is demonstrate that it is in fact possible to have a credible model of agriculture in the city, so the scale and production levels, the volume we produce, the number of people we employ is significant.”

Employing 20 to 30 well trained local residents (most recovering from addiction or managing mental health issues) and producing 25 tons of food every year for sale though farmers’ markets, a CSA and to approximately 50 of Vancouver’s top restaurants and eateries, Street Farms offers a viable agricultural model for city farming based on scale and sustained success.

Street Farms may occupy approximately five acres of space in an urban slum, and it may employ one of North America’s most underserved populations but despite that, Ableman is adamant that his customers should buy his product because of its quality and not its narrative. “We’re not asking people to buy our food out of some sense of charity, or a belief system or our story, which is a good story, but we’re asking them to buy because it is high quality food. We don’t get a pass to be not good farmers,” says Ableman. The farm averages $350,000 in annual income from sales and programming.

For Ableman, who came into the project as a consultant and now acts as Managing Director, the city farm is a social catalyst and its sustainability lies in its larger social mission. “Our experience has proven giving people a reason to get out of bed each day, meaningful employment, a place for people to come to learn new skills, a community that depends on them […]. Really it’s been the people of that community that in many ways helped themselves,” says Ableman. “We provided the setting for it to happen.” A study by Queens University in 2013 calculated that for every dollar Street Farms pays a member of staff, it creates a $2.20 savings to local health, social and legal services.

Street Farms employees grow their fresh produce in custom built growing boxes. As the farm reduces to a skeleton crew in the winter months, Ableman sees the boxes as a way to keep folks employed and meeting their recovery goals. “The boxes address a number of problems. They address short-term leases, they address contaminated soil…if you have to move at short notice…. We get more requests for the boxes than the produce growing in them. We’re looking at trying to find a warehouse. Our idea would be to start manufacturing and distributing them within the next year,” says Ableman. This value added product must be cost effective and currently Ableman and his team are working on how to reduce the per unit cost to make them both affordable to buy and reasonable to make.

Much of what Ableman and fellow founder Seann Dory have learned in the last few years, as well as Ableman’s urban agriculture manifesto and some general advice on urban farming are surmised in Street Farm: Growing Food, Jobs, and Hope on the Urban Frontier, a book Ableman released last year which he feels will help would-be city farmers to realize the true scope of commercial growing. “I’m not trying to be discouraging,” says Abelman. “I’m trying to give people a better shot at being successful.”

With over 40 years of farming experience and deep roots in the sustainable city farming movement that stretch back to the 1980s, Ableman hopes that his project in Vancouver will encourage more social enterprise-focused urban farms and for growers to realize that in today’s social and economic climate, profit as priority is old hat.

“We have a responsibility to be self sustaining economically but I also think we have an obligation in any business to address the broader goals and needs of our community and our society,” says Ableman. “I don’t believe it is enough to be in business just to be in business. We all have an obligation to extend the work we do beyond just making money. No-one that lives on this planet, at this time, can solely live and survive without considering the impact of their actions.”

Agrilyst Fulfills Digital Need for Indoor Farming

Agrilyst Fulfills Digital Need for Indoor Farming

KELLY MARSHALL - MAY 26, 2017

Two years ago Allison Kopf left her job of finding ways to be innovative in greenhouse spaces to start a company that would fill a gaping need she saw. While she could find many programs for outdoor crops, Agrilyst is a software program specifically created for indoor farming.

The software is very specific, Kopf explains. It can be difficult to control variables in an outdoor setting, but inside data about temperature and irrigation can be exact, and it can be replicated, meaning finding ideal circumstances using data points is a reality that is making a huge difference for their customers.

The Agrilyst software does three things. It’s an API so it can connect to hardware a grower may already have and sync with sensors already in play. It also offers a way to digitize paperwork that used be done by hand, such as when and where things are planted. Last, it can analyze data across the spectrum, making accessible and actionable reports a grower can see and learn from over time.

Although her product fills and empty niche, Kopf credits the Pearse Lyons Accelerator program she’s been a part of for the last three months with helping her get the product into the hands of customers. “The Pearse Lyons Accelerator has been phenomenal for us. In the last 100 days or so we’ve actually doubled our revenue. I think what they did a really good job at doing was choosing companies who were similarly staged, because what we could do was not only learn from Dr. Lyons and the team at Alltech, but also from each other.”

Learn more about Alltech’s Pearse Lyons program and the Agrilyst software in Jamie’s interview with Kopf below

AeroFarms To Open World’s Largest Indoor Farm In Camden

AeroFarms To Open World’s Largest Indoor Farm In Camden

By Gillian Blair - May 30, 2017

Credit: AeroFarms

AeroFarms will soon surpass itself as the world’s largest indoor vertical farm with a second and larger New Jersey location in Camden. Set to be operational by 2018, Farm No. 10 will be 78,000 square feet on the 1500 block of Broadway. They are still working on the design of the facility and will need to gain local zoning approvals, but the biggest victory was already won when AeroFarms LLC was awarded an $11.14 million grant in tax incentives by the New Jersey Economic Development Authority.

Farm No. 9 in Newark, New Jersey, is currently the world’s largest indoor vertical farm based on annual growing capacity and where, in a converted steel mill, they harvest up to 2 million pounds a year. AeroFarms is able to germinate seeds in 12 to 48 hours–a process that typically takes 8 to 10 days–and focuses on growing leafy greens like baby kale and arugula and packaging under the name “Dream Greens” for distribution locally in North Jersey and Manhattan. Farm No. 10 in Camden will supply South Jersey and Philadelphia.

The greens are grown “aeroponically,” meaning the roots grow downward, dangle in the air, and are misted with water and minerals. And the process dispenses with premium elements like land and water: “We can grow on one acre what would normally take 130 acres on a field farm. And we use 75 percent less water [than hydroponics],” said Co-founder and CEO David Rosenberg.

AeroFarms has come far since Farm No. 1 in a converted kayak shop in Ithaca, New York, where Ed Harwood, an associate professor in the Cornell University School of Agriculture, became interested in growing things without the elements that grow things: soil, sunlight, a lot of water. Now Co-founder and Chief Scientific Officer, his biggest breakthrough was developing the root mister that doesn’t clog. Also developed for this practice of vertical farming is a cloth made of recycled soda bottles on which the seeds germinate and through which the roots grow downward.

Even the lighting is specially calibrated and everything is monitored electronically. AeroFarms recently won a “vision” award at the Global Food Innovation Summit in Milan which was an especially exciting honor as it recognizes “the coolest vision of how the world should work,” said Mr. Rosenberg.

The tax incentives enabling AeroFarms to open their second facility in Camden are part of the Grow New Jersey Assistance Program Grants which incentivize businesses to relocate or start-up in economically challenged areas, infusing the local economy, workforce, and property with capital, opportunities, and improvements.

Have something to add to this story? Email tips@jerseydigs.com. Stay up-to-date by following Jersey Digs on Twitter and Instagram, and liking us on Facebook.

The Urban Farmer: Interview With João Igor of CoolFarm

The Urban Farmer: Interview With João Igor of CoolFarm

In Future trends Posted on May 25, 2017

Created out of necessity, CoolFarm now offers smart farming solutions that allow you to plug, play, and produce fresh food all year round. Get the inside scoop on how co-founder João Igor has discovered a novel way to make agriculture an integral part of urban life.

If you haven’t heard about urban farming, you must have been living under a rock for the past few years! City-based agriculture offers the opportunity to have healthy food in abundance, at a fraction of the cost, by growing only what we need, close to home.

Urban ag startups have boomed in the last few years, offering everything from unorthodox growing setups to soil sensors, hydroponics and all manner of crop data analytics. We’ve recently spoke to João Igor of CoolFarm, a Portuguese startup operating in the smarter food and in the greenhouse sustainable agriculture area. Here’s their take on the potential for urban farming.

“I found myself suffering from health problems due to the fast food that we consume inside cities, I’ve also seen my friends and family suffering from the same issues. I wanted to do something to fight this, and I ended up in finding the right team of co-founders for this project.”

Together, we started building the CoolFarm technology in order to make farming easier and to bring fresh and nutritious food to cities, close to the people.

New Sustainable Model

CoolFarm offers indoor farming solutions for production of high quality food. Their solutions provide maximum efficiency and profitability. Their control system, called CoolFarm in/control is plant-centred. Using an intuitive dashboard, growers are able to monitor and contnrol all their farms at once, anywhere, anytime. Artificial intelligence and machine learning algorithms ensure optimized crop production, as well as efficient management of resources.

“We also offer to the market the CoolFarm Eye, an innovative cloud based optical sensor made to capture plants’ area and plant greenness, monitoring crops through time,” explains João. “Using the Eye, growers can make wiser and straight forward decisions to achieve the best results.”

2017 marks the launch of CoolFarm in/store, a closed and vertical system with a clean and climatized environment inside, perfect to grow premium seedlings, microgreens, leafy greens, herbs and flowers. Reportedly, it uses 90% less water than common agriculture and it does not need pesticides or herbicides. It is modular, with each module covering nearly 100 square meters of the production area.

Intelligent and highly intuitive, the system is aimed at growers, food distributors, grocery and supermarket chains, research centers, medical centers, and communities.

The system is equipped with two columns of movable hydroponic growing beds, one vertical lift, a fertigation system, topnotch sensors to measure all the variables concerning the plants, LED grow lights, CoolFarm in/control system and an antechamber.

Cities Turning Green

Throughout the world, urban farming is becoming an integral part of the urban landscape. CoolFarm is part of the booming trend. However, in order to emerge into a viable industry solution, CoolFarm needs agents and distributors worldwide, as well as adequate support from governments.

“Stakeholders must jointly address food and sustainability issues, and promote novel technologies and solutions for better farming,” says João. Although there is an urgent need for producing health, tasty, environmentally sustainable food, redesigning the agricultural system would not be straightforward.

As a creative person and as a designer my job is to build new and intuitive solutions, as well as to communicate them in the best way; as a tech guy I need to bring top notch technology, like robotics, for fields in need.

Sprouting Imaginative Solutions

The European startup ecosystem has bred numerous success stories, and CoolFarm is one of them. “We’ve gained a lot of attention, especially from the media, which is essential for any startup business trying to create brand awareness.” They also learned a lot about marketing, business, and securing funding and capital.

However, the biggest lesson, by far, is avoiding money from people that don’t understand complex markets such as agriculture.

“In general, European incubators and accelerators are good. We have excellent people behind the scene, and Europe doesn’t lack experience or knowledge.”

Apparently, launching a startup in Europe was the right decision: the team now counts nearly 20 people creating indoor farming solutions, from horticulturists and biologists, software and hardware engineers, web, mobile and product designers, marketing and business experts.

If you want a sustainable business in agriculture, avoid money from people who don’t understand such a complex market.

Early product is strong, but their roadmap is much more exciting. “We want to install the in/store solution at universities, hospitals, supermarkets, cruises, buildings,” says João, adding that they want to grasp a significant portion of the market with their new product. “The next 18 months are going to be game changing for CoolFarm. Watch and see!”

La Bajada Urban Youth Farm Grows Good In West Dallas

La Bajada Urban Youth Farm Grows Good In West Dallas

POSTED 5:39 PM, MAY 21, 2017, BY TIM ROBERTS

DALLAS — Nothing like a Sunday afternoon brunch, with a great purpose. The La Bajada Urban Youth Farm hosted its first ever “Farm to Community Brunch” with local chefs providing the meal and all the proceeds going to help La Bajada, a community garden in West Dallas.

“These youth interns get paid to come work on this farm and grow food and then we share the food with the community,” said Elizabeth Dry, the executive director of Promise of Peace Gardens who works with the La Bajada Urban Youth Farm.

Yeah, it gives them a hands on, outdoors education they wouldn’t otherwise get.

“Coming here I’m not really used to being outdoors with the nature so learning how to plant and grow different seeds and getting my hands dirty was new to me,” said Grace Zamora, one of the students. “So it was difficult but I’m having a lot of fun doing it.”

And for these kids there’s an even bigger purpose than learning how to farm and making a little extra cash.

“I see all of us as great leaders and it’s up to us to change how people see West Dallas,” another student, Jave Garcia, said. “It isn’t a place of crime, it isn’t a place of violence, it’s a place where normal people live and have great dreams and they try to aspire to their dreams and make them come true.”

Just goes to show there’s a lot more growing in this garden in the middle of the city than just plants.

Coffee Grounds Used To Feed A Hungry City

Coffee Grounds Used To Feed A Hungry City

In an Australian first, Port Melbourne based coffee company Red Star Roasters has partnered with urban food production company Biofilta, to transform a disused Melbourne carpark into a pop-up espresso bar and thriving vertical urban food garden. The garden is converting the by-product from Melbourne's unique coffee culture coffee grounds into thousands of dollars of fresh edible produce for charity kitchens.

The Red Star Urban Garden Espresso Bar, located at The Holy Trinity Anglican Church at 160 Bay Street, Port Melbourne, features an innovative vertical food garden that uses soil made from composted green waste and coffee grounds, to grow a full range of vegetables and herbs including basil, beans, eggplant, capsicum, kale, lettuce, oregano, rhubarb, spinach, strawberries, thyme, tomatoes, zucchinis, beetroot, broccoli, bok choy and many others. Coffee grounds are collected from the espresso bar, mixed with garden clippings, cardboard packaging, soil and worms to create a rich compost onsite. The compost is then returned to the vertical gardens, to grow food. The produce is then harvested and donated to the South Port Uniting Care?s Food Pantry and Relief Service in South Melbourne. Diane Embry, the Agency's Chief Executive Officer, says, the donations enables us to provide fresh produce to people in our community who are experiencing disadvantage, social isolation and homelessness.

The garden itself is unique - with vertically stacked growing beds that are self-watering and an innovative aeration loop to keep the plants and soil oxygenated and healthy. The garden is ultra water efficient and spatially compact, and by going vertical the garden produces a large amount of food on a very small footprint, effectively doubling food yield per square metre. The vertical garden is integrated into the espresso bar coffee grounds used to feed a hungry city and café patrons are surrounded with edible gardens, aromatic herbs and flowers as they read the paper and have a coffee. In the past 12 months, the garden has produced well over 100 kilograms of vegetables and herbs from 10 square metres of garden area. However, because of the vertical design, the garden is only using 5 square metres of space. This means the garden is producing 10 kg of food per 1 sqaure metre of garden every year and at an average cost of between $5 to $10 per kg for vegetables at the Supermarket, the garden is producing $50 to $100 of food per metre square each year.

It is great having a garden that saves you money while feeding you and the family at the same time. Australia imports over 40,000 tonnes of coffee beans per annum, resulting in a huge waste stream of used coffee grounds that go to landfill. Red Star and Biofilta have worked out a way to divert this useful by-product into food to feed a hungry city and are now looking to replicate the model with cafes and restaurants who are interested in saving on food bills and growing fresh produce onsite. 100% of coffee grounds from the Red Star Urban Garden Espresso Bar are either used in the garden, or given away for free to customers to use in their gardens at home.

Creating A Zero-Coffee-Waste Café!

CEO of Biofilta, Marc Noyce said - Thousands of tonnes of coffee grounds are produced each week in Australia's cafés and restaurants, and most ends up in landfill. Red Star and Biofilta have shown how this wonderful material can be composted to soil and help feed hungry cities at the same time. Both companies are looking for more opportunities to repeat the formula with any café or restaurant who are interested in ethically sourced coffee, and have a spare space, wall, rooftop or balcony to turn.

For more information call:

Diane Falzon, Falzon PR- 0430596699

Marc Noyce, CEO, Biofilta - 0417 133 243

Chris McKiernan, Director, Red Star Coffee - 0418 136 301

Kimbal Musk Says Food Is The New Internet

Kimbal Musk Says Food Is The New Internet

Former tech entrepreneur Kimbal Musk’s ambitions for innovation in sustainable farming are as grand as his brother Elon’s for space travel and electric cars

URBAN COWBOY | Kimbal Musk at Koberstein Ranch in Colorado. “He’s got good judgment overall and has been put through the ringer a few times,” says his brother, Elon. PHOTO: MORGAN RACHEL LEVY FOR WSJ. MAGAZINE

By Jay Cheshes

May 25, 2017 10:52 a.m. ET

ON A BRISK WINTER morning, Kimbal Musk is an incongruous sight in his signature cowboy hat and monogrammed silver K belt buckle—his folksy uniform of the past few years—as he addresses a crowd outside a cluster of shipping containers in a Brooklyn parking lot. Inside each container, pink grow lights and fire hydrant irrigation feed vertical stacks of edible crops—arugula, shiso, basil and chard, among others—the equivalent of two acres of cultivated land inside a climate-controlled 320-square-foot shell. “This is basically a business in a box,” Kimbal says, presenting his latest venture to its investors, friends and curious neighbors.

Square Roots, his new incubator for urban farming, aims to empower a generation of indoor agriculturalists, offering 10 young entrepreneurs this year (chosen from 500 applicants) the tools to build a business selling the food they grow. It will take on and mentor a new group annually, with more container campuses following across the country. “Within a few years, we will have an army of Square Roots entrepreneurs in the food ecosystem,” he says of the enterprise, launched last November with co-founder and CEO Tobias Peggs—a British expat with a Ph.D. in artificial intelligence—across from the Marcy Houses, in Bedford-Stuyvesant (where Jay Z, famously, sold crack cocaine in the 1980s).

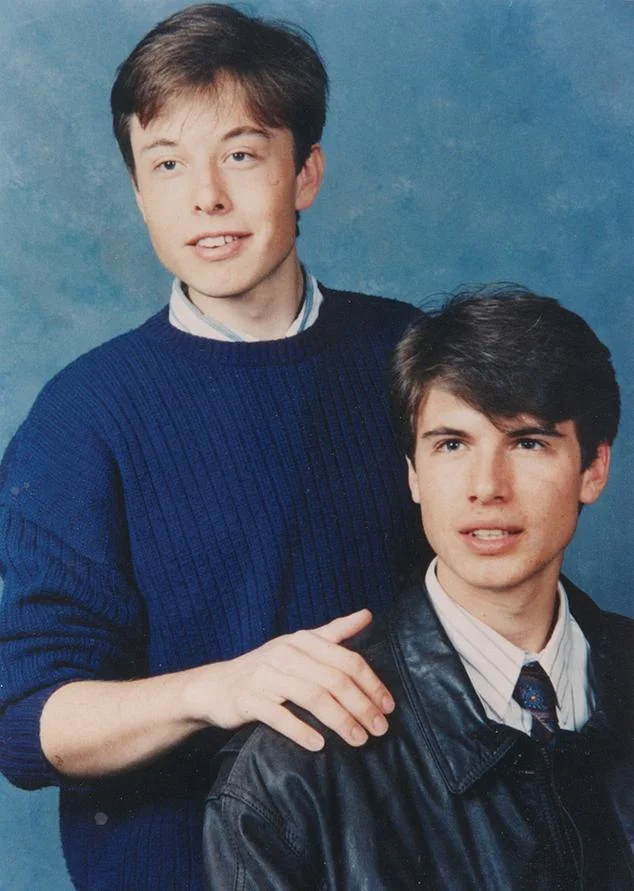

Clockwise from far left: Elon (left) and Kimbal, at 17 and 16. PHOTO: COURTESY OF KIMBAL MUSK

Entrepreneurial drive runs in the family for Kimbal, 44, a close confidante of his brother, Elon, and a board member (and major shareholder) at Tesla and SpaceX. “If something happens to me, he can represent my interests,” says Elon of his kid brother (one year younger) and worst-case-scenario proxy. “He knows me better than pretty much anyone else. He’s got good judgment overall and has been put through the ringer a few times.”

Kimbal, a veteran of the tech world, has in recent years shifted his focus to food—or the “new internet,” as he called it in a 2015 TEDx Talk. With the missionary zeal his brother brings to electric sports cars and private space travel, Kimbal has launched a series of companies designed to make a lasting impact on food culture, through restaurants, school gardens and urban farms.

‘‘I want to reach a lot of people. We’ve put too much emphasis on preciousness with food.’’

—Kimbal Musk

Since 2010, a nonprofit venture supported by the Musk Foundation has built hundreds of Learning Gardens in American schools, installing self-watering polyethylene planters where kids learn to grow what they eat. Meanwhile, his Kitchen family of restaurants—promising local, sustainable, affordable food—is rapidly expanding across the American heartland, with five locations opening this year, including new outposts in Memphis and Indianapolis. Kimbal hopes to have 50 “urban-casual” Next Door restaurants, 1,000 Learning Gardens and a battalion of container farms by 2020. “I want to be able to reach a lot of people,” he says. “I think we’ve put too much emphasis on preciousness with food—and the result is a real split between the haves and have nots.”

The Musk brothers grew up in South Africa during the last gasp of the apartheid era. Kimbal, the more gregarious sibling, got his start selling chocolate Easter eggs at a steep markup door-to-door in their Pretoria suburb. “When people would balk at the price, I’d say, ‘You’re supporting a young capitalist,’ ” he recalls. While Elon spent hours programming on his Commodore VIC-20, Kimbal tinkered in the kitchen. “If the maid cooked, people would pick at the food and watch TV,” he says. “If I cooked, my dad would make us all sit down and eat ‘Kimbal’s meal.’ ”

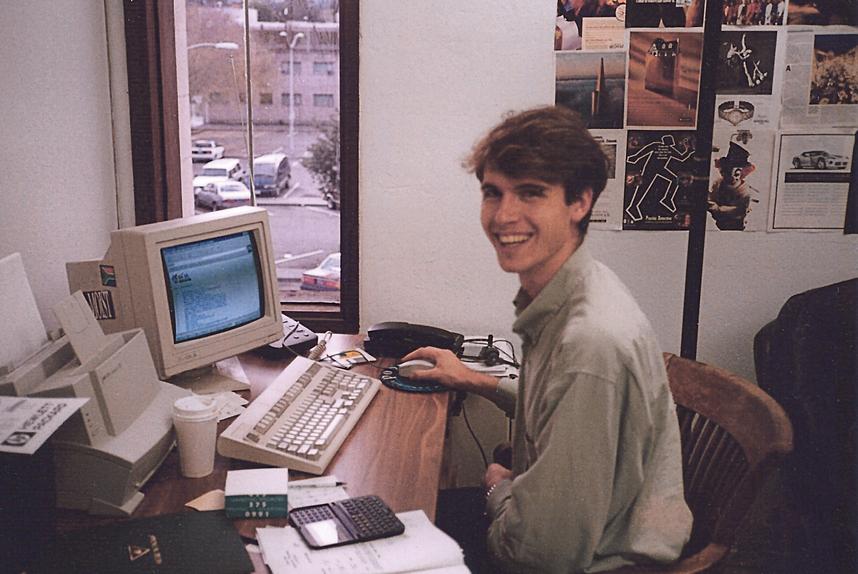

Kimbal in the kitchen, 2002. PHOTO: COURTESY OF KIMBAL MUSK

After high school, the brothers moved to Canada, both enrolling, for a time, in Queen’s University in Kingston, Ontario (Kimbal studied business, Elon physics). In 1995, they founded a company together in Palo Alto, California, the online business directory Zip2. “I had come over as an illegal immigrant,” Kimbal says of the move. “We slept in the office, showered at the YMCA.”

The brothers were close but also intensely competitive. Sometimes work disputes would get physical. “In a start-up, you’re just trying to survive,” says Elon. “Tensions are high.” Once they could afford it, Kimbal cooked for the whole Zip2 team in the apartment complex they shared. In 1999, the Musks sold their business to Compaq for $300 million. Though they remain investors and advisers in each other’s companies, their official partnership ended there.

HOME FRONT | Kimbal’s mother, Maye (right), with her parents at the family farm near Pretoria, South Africa, 1978. PHOTO: COURTESY OF KIMBAL MUSK

After Elon launched the payment site that would later become PayPal , Kimbal, on a lark, enrolled in cooking school. He finished his studies at the French Culinary Institute in New York in late summer 2001 with no intention of pursuing a career in food. A few weeks later, after two planes flew into the Twin Towers, he spent the next six weeks as a volunteer cook, feeding firefighters out of the kitchen at Bouley. At the end of it he wanted nothing more than to open his own restaurant. “After that visceral experience, I just had to do it,” he says.

Searching for a dramatic change in scenery, post-9/11, Kimbal and his new wife at the time, lighting artist Jen Lewin, set out on a cross-country road trip looking for a place to put down roots and raise a family. They settled on Boulder, Colorado, “a walkable town, a great restaurant town,” says Kimbal at the 140-year-old Victorian home they bought there in 2002 (they have two sons and have since divorced).

The house he now shares with food-policy activist Christiana Wyly—with a cherry-red Tesla parked out back—is a few blocks from the original Kitchen, an American bistro he launched in 2004 with chef-partner Hugo Matheson, a veteran of London’s River Cafe. The Kitchen sourced ingredients from local farmers, composted food waste, ran on wind power and used recycled materials in its décor. For its first two years, the two partners worked full-time as co-chefs, taking turns composing the menu, which changed every day. Eventually, the daily grind became too much for Kimbal. “I got a little bored with the business,” he says.

Kimbal in his Zip2 office, 1996. PHOTO: COURTESY OF KIMBAL MUSK

By 2006, he was back working in tech, as CEO of a social-media-analytics start-up. The Kitchen might have remained a sideline if not for a series of unlikely events. On February 10, 2010, at a TED conference in California, he listened to Jamie Oliver admonish America for its childhood obesity problem. Four days later, while barreling down a slope in Jackson Hole, Wyoming, Kimbal flipped his inner tube and broke his neck. In the hospital, wondering if he’d ever walk again, he began to reconsider his life, with Oliver’s comments rattling around in his head. “The message I heard was: The people who have no excuse should be doing something about this—and I was one of those people,” says Kimbal. “I told myself, If I get through this I’m going to focus on food and doing things at scale.” Apart from losing some feeling in his fingers, he made a full recovery.

Since then Kimbal has become a cheerful crusader for “real food,” as he calls it, sharing his message on the lecture circuit. “He’s a compelling speaker,” says food writer and activist Michael Pollan. “Particularly in his passion for kids, his recognition that if we’re going to change our approach to eating in this country, it’s about showing kids where food comes from, how to grow it, how to prepare it.”

“In 2004, there were very few local farmers that would work with us,” says Kimbal. “We opened the Kitchen before farm-to-table was a term. We showed that you could be busy and profitable while creating a new supply chain. Now there’s a huge backlash against processed food, industrial food. Real food is simply food you trust to nourish your body, nourish the farmer and nourish the planet.”

Bowery Reinvents Farming for Urban Landscapes

Bowery Reinvents Farming for Urban Landscapes

May 26, 2017 by Annie Pilon In Green Business

Agriculture is one of the oldest industries out there. But businesses are still finding new ways to update this industry in order to get fresh produce to the people who need it most.

Bowery Indoor Farming

Bowery is one such business. The farming startup made its goal to get fresh produce to consumers in big cities in a sustainable way. To achieve that goal, the company uses hardware and proprietary software to set up vertically stacked gardens that operate indoors year-round.

This solves a couple of different problems. First, many city dwellers live in food deserts, or places where there isn’t a whole lot of fresh produce available. Secondly, traditional agriculture uses massive amounts of water and other resources. And Bowery’s high tech approach allows the business to function in a way that’s both sustainable and not reliant on outdoor weather.

A Great Example of Innovation

What this business shows is that you can put a new spin on almost any industry, as long as you’re willing to get a little creative. Throughout the years, people have come up with plenty of new tools to update agriculture or make certain processes more efficient. But if you’re willing to look at things in a new way, and innovate based on your observations, you can still find ways to update almost any business model.

Image: Bowery

Canadian Microgreens Grower Makes Impact Within The Lettuce Category

Canadian Microgreens Grower Makes Impact Within The Lettuce Category

Small but mighty: microgreens are fairly new in the produce category, but they’re already being widely embraced in foodservice and in consumer’s homes. For what they lack in size, they make up for in a powerful flavor profile.

Large inventory on small footprint

Greenbelt Microgreens grows a wide inventory on its mere 6.5 acres. Of that, 4.5 acres is located in Ontario, Canada and 2 acres in Maple Ridge, BC. Owner, Ian Adamson began researching and perfecting the viability and production of microgreens in 1998 and was ready to open for business in 2010. Seven years were spent in perfecting the process and achieving proper nutrient-rich soil to grow strong, healthy greens. The proprietary soil mixture comes from a farm in Quebec. “That’s how we get the shelf life, because of the quality of the soil,” said Michael Curry, Vice President of Greenbelt Microgreens.

Fast growth cycle, long shelf life

Maintaining a proper cold chain is key – it’s all about food safety; the company is Canada GAP certified. Curry says their 13-day shelf life is key. Movement and processing of the cut greens right into cold storage, plus the ability to grow organically is something he says retailers are looking for. “That’s why we’re jumping on it,” he said, noting that 80 per cent of the organic product sold in Canada is imported.

It’s an opportunity for Greenbelt Microgreens to harness, and they’re able to grow year- round under glass, which mimics growing in an open field. “It’s a 10-day growth cycle,” Curry explained. “We can grow an incredible amount in an acre, year round.” He noted that they’re experimenting the implementation of LEDs. “We’re all about soil and sunshine but LEDs are proven very effective in the winter to keep the growing cycle the same - yields as well,” he said. With the reduction in sunshine this past winter, it’s an important investment, since last January he said there was only about 50 hours of sunlight for the month.

Living lettuce and wide range of greens

Part of their inventory includes organic living lettuce as well as their namesake organic microgreens: arugula (the most popular), basil, buckwheat, broccoli, cilantro, radish, daikon radish, kale, pea shoots, red choi, red mizuna, red radish, shunkigu, sunflower and wheatgrass. At one time it seemed like the idea of consuming what should be a full head of broccoli harvested after only 10 days was unheard of, but thegoal is to get the customer to think of their products as a whole salad, whether it’s a clamshell of the mixed microgreens, mixed lettuce or a head of living lettuce.

Living lettuce is sold in sleeves, which customers can take home, keep watered and harvest whenever they wish. The microgreen salads come in four different mixes. “That’s totally unique – nobody’s got that on the market,” said Curry. “Millennials seem to love having plants growing in their kitchen.” Customers are making friends with salad.

For more information:

Michael Curry

Greenbelt Microgreens

Ph: 416 710 7547

China Subverts Pollution With Contained Vertical Farms – And Boosts Yield

China Subverts Pollution With Contained Vertical Farms – And Boosts Yield

Agriculture, China, Eat & Drink, News, Urban Farming

- by Lacy Cooke

Around one fifth of arable land in China is contaminated with levels of toxins greater than government standards, according to 2014 data. That’s around half the size of California, and it’s a growing problem for a country that faces such levels of pollution they had to import $31.2 billion of soybeans in 2015 – a 43 percent increase since 2008. Scientists and entrepreneurs are working to come up with answers to growing edible food in a polluted environment, and shipping container farms or vertical gardening could offer answers.

The toxins in China’s environment have made their way into the country’s food supply. In 2013, the Guangdong province government said 44 percent of rice sampled in their region contained excessive cadmium. Around 14 percent of domestic grain contains heavy metals such as lead, arsenic, and cadmium, according to research from scientists in 2015.

Related: Arctic town grows fresh produce in shipping container vertical garden

Could shipping container farms offer a way around this contamination? Beijing startup Alesca Life Technologies is testing them out. They turn retrofitted shipping containers into gardens filled to the brim with arugula, peas, kale, and mustard greens, and monitor conditions remotely via an app. They’ve already been able to sell smaller portable versions of the gardens to a division of a group managing luxury hotels in Beijing and the Dubai royal family.

Alesca Life co-founder Stuart Oda told Bloomberg, “Agriculture has not really innovated materially in the past 10,000 years. The future of farming – to us – is urban.”

And they’re not alone in their innovation. Scientist Yang Qichang of the Institute of Environment and Sustainable Development in Agriculture at the Chinese Academy of Agricultural Sciences is experimenting with a crop laboratory, testing which light from the visible light spectrum both helps plants flourish and uses little energy. His self-contained, vertical system already yields between 40 and 100 times more produce than an open field of similar size. He told Bloomberg, “Using vertical agriculture, we don’t need to use pesticides and we can use less chemical fertilizers – and produce safe food.”

Via Bloomberg

Images via Alesca Life Technologies