Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

How An Indoor Farm in Midtown Anchorage Could Help At-Risk Youth

How An Indoor Farm in Midtown Anchorage Could Help At-Risk Youth

Author: Devin Kelly

To help disadvantaged teens and young adults land jobs, an Anchorage mental health provider is staking out ground in the high-tech farming fields of hydroponics and vertical gardening.

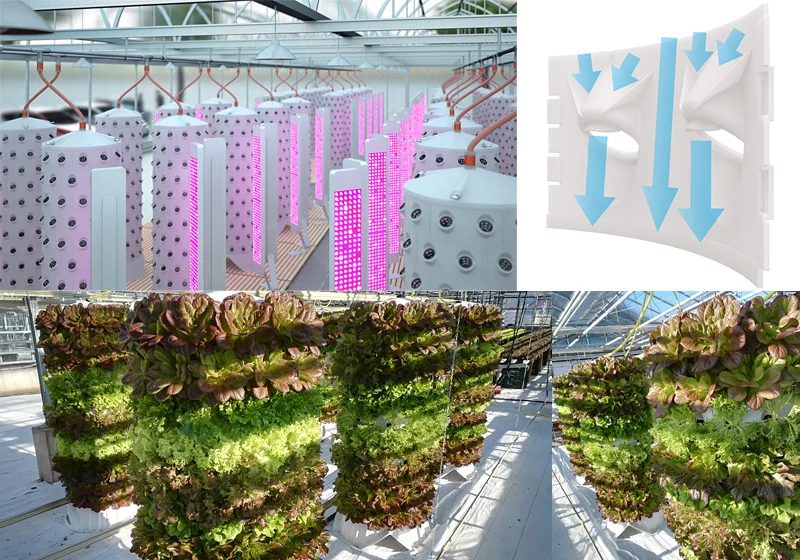

Inside a warehouse off Arctic Boulevard last month, violet light bathed rows of tall white columns. Leafy greens poked out in vertical rows, marked with handwritten labels for romaine lettuce and parsley.

Michael Sobocinski, the chief operating officer of Anchorage Community Mental Health Services, gestured to the columns.

"Each of these towers, you can see up here, has nutrient solution," Sobocinski said, surrounded by the drip-drip-drip sound of small hoses. He showed how water nourishes the roots, collects in a gutter and then recirculates back to a nutrient tank that feeds back into the hydroponic system.

The columns are yielding pounds of fresh veggies. The twist: The gardeners will be largely young adults coming out of foster care, mental health treatment, the juvenile justice system or even homelessness. Sobocinski and his team hope the inside garden will be a turning point for youth at risk of falling through the cracks.

Seeds of Change, as the program is called, has been incubating for years, but it's now on the cusp of becoming reality. Anchorage Community Mental Health Services, a well-established nonprofit that offers a wide range of services to adults and children, is managing the project.

The idea came from Sobocinski, who previously worked at residential children's psychiatric treatment centers in Denver. In that job, Sobocinski saw a lot of kids who grew up hungry. Some of his clients were fishing food out of dumpsters to help feed their siblings.

A horticultural therapist also showed him that young people tend to respond well to working with plants, he said.

In 2014, after years of research and planning, Anchorage Community Mental Health Services bought the building at 26th Avenue and Arctic Boulevard. At least from the outside, it's nondescript — a kitchen cabinet manufacturing company used to be housed there.

Renovating the 11,000-square-foot building to suit an indoor farming operation cost about $3 million. The construction money came from a grant through the state Department of Health and Social Services. More than $100,000 came from the Alaska Mental Health Trust Authority for planning, development and startup staffing costs.

Once fully up and running, Seeds of Change should yield 50 to 70 tons of produce a year, Sobocinski said.

To staff it, Anchorage Community Mental Health Services plans to hire up to 20 people between the ages of 16 and 24. The wages will likely range between $12 and $13 an hour for 10 to 15 hours of work a week, Sobocinski said.

Priority will go to teens and young adults aging out of Alaska's foster care, juvenile justice or mental health treatment systems. Too many kids are coming out of tough circumstances and getting lost in young adulthood, Sobocinski said.

"When you turn 18, by and large, the system of care says, 'Congratulations, you're an adult,' " Sobocinski said. "And so programs and eligibility that work when you were 17 may not necessarily work when you're 18."

All the workers will have access to mental health services through Anchorage Community Mental Health, though they don't have to be clients, Sobocinski said.

As well as working in the greenhouse, the hired youths are expected to attend classes on life skills, like getting an apartment, interviewing for jobs and maintaining good credit.

The positions will last between six and nine months. Finding the workers full-time jobs from there is key, Sobocinski said.

At the same time, finding work for about 20 teens is a "drop in the bucket," said clinical program manager Seina Johndro, who will be running the life-skills component of the greenhouse program.

"There's a huge need for programs like this in town," Johndro said.

Seeds of Change doesn't include apartments or places for young workers to live. But housing is a critical piece, Sobocinski said. He said the organization is still exploring ways to connect participants with housing.

In recent years, Anchorage social service agencies have made forays into food to help clients. The Downtown Soup Kitchen started a bakery and garden to offer work to the women who stay there, as well as a culinary arts program.

But vertical gardening is a novel approach even for the state's farming community. At first, the idea was a more traditional greenhouse, Sobocinski said. But when that plan fell through, Sobocinski and other officials turned to hydroponic growing.

"It's going to give us very big yields, and it's a good use of space," Sobocinski said.

Anchorage Community Mental Health Services bought the system from Bright AgroTech, a Wyoming-based company. The company has also offered startup support, said Johndro, the clinical program manager.

Alaska Seeds of Change is located in a former cabinetry business in Midtown. The location now also houses the drop-in center for Alaska Youth Advocates, which formerly had space at the Anchorage People Mover Transit Center and then briefly at Covenant House Alaska. (Erik Hill / Alaska Dispatch News)

With the help of the Foraker Group, which advises nonprofits, Anchorage Community Mental Health Services also gauged whether there would be demand for the produce.

One fact they learned: Alaska imports 90 to 95 percent of its food.

"I don't think there's any risk of oversupply of locally produced, Alaska-grown products," said Danny Consenstein, the executive director of the Department of Agriculture's Alaska Farm Service Agency.

No marketing contracts have been signed yet. But Sobocinski said his organization is talking to a local restaurant owner as well as grocery chains about buying produce. He thinks businesses may be interested in having a "Seeds of Alaska" stamp on a menu.

Sobocinski said he's confident the operation will be able to support itself by the end of the year and make enough to reinvest in new programs.

For the teens and young adults slated to work in the garden, there's a lot of hands-on work to do, said Ryan Witten, the greenhouse manager. The workers are also expected to learn how to market and sell the produce.

At the moment, the only young people working in the greenhouse were employees of Alaska Youth Advocates, a supportive program for at-risk youth that is part of Anchorage Community Mental Health Services. The program recently moved to the greenhouse building after its floor in the Anchorage transit center closed.

Quavon Bracken, 19, has been an outreach worker with Alaska Youth Advocates for about three years. He had friends in "really bad living situations," he said, but until he got the job, he didn't know how to help them.

Standing in the greenhouse, Bracken, who's headed to University of Alaska Anchorage as a business administration student this spring, said he's looking forward to learning more about marketing. He also helped set up the greenhouse and expected to be part of the hiring team for the teens who will work there.

By early February, the first harvest was on its way. Greenhouse managers were preparing to pick dill and chervil.

About this Author

Devin Kelly covers Anchorage city government and general assignments.

Vertical Farming: A High-Growth Trend

Every year, Americans care more about where our food comes from. Organic food sales are growing by double-digit percentages annually. And the “eat local” movement is still picking up steam

Vertical Farming: A High-Growth Trend

by Samuel Taube, Investment U Research TeamFriday, February 3, 2017

Every year, Americans care more about where our food comes from. Organic food sales are growing by double-digit percentages annually. And the “eat local” movement is still picking up steam.

But if you live in a big metro area, how local or natural can you really eat? For years, the answer was “not very.” Then vertical farming started to enter the commercial mainstream.

As the name implies, vertical farming means using hydroponic technology, grow lights and other agricultural innovations to build multilevel indoor farms. It allows farmers to grow fresh organic produce in the middle of our ever-growing cities. And in many cases, it’s more efficient than traditional farming.

As demand for locally grown organic food continues to outstrip supply, vertical farming is poised to become a tremendous investment opportunity. In this piece, we’re looking at why - and how to get in early.

Why Vertical Farming Matters

There are two almost unstoppable trends propelling the growth of vertical farming. First, local organic food is getting more popular every year. Second, more people are moving to cities, suburbs and other areas that can’t support traditional agriculture.

As our Editor-in-Chief wrote over the holidays, organic food is quite scarce in our country. That’s not some kind of environmentalist statement. It’s a simple fact. We want more naturally grown stuff than we can produce right now.

That’s why the organic food business has experienced such consistent growth recently. Last year, for the first time ever, a solid 5% of the total food sales in America were organic.

Now, the above graph just shows the growing market for organic food. It wouldn’t be relevant to organic farming... if most people lived near farmland. But they don’t. Four out of five Americans live in an urban area... and that number is constantly going up.

As you can see from the graph below, the U.S. as a whole has never experienced de-urbanization in recent memory. The pace of migration to cities has slowed at times, but it’s never gone below zero.

Plus, American cities are geographically huge compared to those elsewhere in the world. Most major U.S. cities are surrounded by huge rings of suburbs. These can sprawl out for dozens or hundreds of miles.

That means that our city dwellers can get their food in one of two ways. They can load it up with preservatives and truck it in from faraway rural areas. Or they can grow it in the city with vertical farming.

At the moment, the former option still feeds most of America’s urban population. But the demand for fresh, local and organic produce is still growing. So will the necessity of vertical farming.

Technical analysis is the study of price and volume activity in the stock market, and there are three powerful tools that will help you find buying opportunities in the market.

Any investor can become a technical analysis pro by using these simple buy and sell indicators.

We’ve also done the research for you and found three stocks hitting these urgent buy signals right now.

How to Invest

It’s tough to find pure plays on vertical farming. That’s a common problem among emerging technologies. Not many S&P 500 companies are willing to bet everything on a new industry.

Fortunately, several food retailers and gardening companies have made big investments in urban agriculture. These companies offer investors indirect plays on vertical farming.

Whole Foods (Nasdaq: WFM) is a major buyer and financer of vertically farmed produce. Its Local Producer Loan Program has lent tens of millions of dollars to local farming projects. And for the last few years, many of those projects have been urban and indoors.

Then there’s Scotts Miracle-Gro (NYSE: SMG), perhaps the nation’s most prominent gardening supply company. Almost 10% of Scotts’ revenue comes from its hydroponic equipment division. That has given the company an important stake in two investing trends: marijuana production and vertical farming.

As you can see, these two vertical farming “brokers” have done quite well for themselves in the past year.

If you live in a city today, chances are that you’re eating food grown in a place you’ve never been - by people you’ll never meet. And if you’re into organic food, then you’re likely paying a pretty penny for the logistical cost of getting it into the city without preservatives.

But that may soon be changing. As the trends of urbanization and organic food continue to grow, city dwellers need a new way to feed themselves. In a few years, your apples might be grown a few blocks from your apartment. And if you invest in the right grocers and gardening companies today, then you can profit from this futuristic transition.

Global Vertical Farming Market 2017- AeroFarms, Gotham Greens , Bright Farms, Vertical Harvest

Worldwide Vertical Farming Market 2017 Research report is an in-depth analysis of 2017 global Vertical Farming market on the current state

Global Vertical Farming Market 2017- AeroFarms, Gotham Greens , Bright Farms, Vertical Harvest

by John Coates | @ | February 2, 2017 10:41 am

Worldwide Vertical Farming Market 2017 Research report is an in-depth analysis of 2017 global Vertical Farming market on the current state.

First of all, the report (2017 Vertical Farming Market) provides a basic overview of the Vertical Farming industry 2017 including – definitions, classifications, Vertical Farming market by applications and Vertical Farming industry chain structure. The 2017’s report on Vertical Farming Industry analysis is provided for the international Vertical Farming market including development history, Vertical Farming industry competitive landscape analysis, and major regions development status on Vertical Farming scenario.

After that, 2017 Worldwide Vertical Farming Market report includes development policies and plans are discussed. Vertical Farming market 2017 report also covers manufacturing processes and cost structures on Vertical Farming Scenario. This report also states Vertical Farming import/export, supply, Vertical Farming consumption figures as well as cost, price, Vertical Farming industry revenue and gross margin by regions (United States, EU, China, and Japan).

Then, the report focuses on global major leading Vertical Farming industry players with information such as company profiles, product picture and specification, capacity, Vertical Farming production, price, cost, Vertical Farming Market revenue and contact information.

Top Manufacturers Analysis in Vertical Farming market 2017:-

1 AeroFarms

2 Gotham Greens

3 Bright Farms

4 Vertical Harvest

5 Home Town Farms

6 Infinite Harvest

7 Lufa Farms

8 Beijing IEDA Protected Horticulture

9 FarmedHere

10 Garden Fresh Farms

11 Metro Farms

12 Green Sense Farms

Click Here for Report Sample: https://market.biz/report/global-vertical-farming-market-2017/41119/#requestforsample

Global Vertical Farming Market 2017 Analysis: By Product

1 Aeroponics

2 Hydroponics

3 Others

2017 global Vertical Farming market report also covers – Upstream raw materials, equipment and Vertical Farming downstream consumers analysis. Furthermore, the 2017 Vertical Farming market development trends, and marketing channels are analyzed on Vertical Farming scenario.

Finally, The Report (2017 Worldwide Vertical Farming Industry)- Feasibility of new investment projects is assessed, and overall Vertical Farming market research conclusions are offered.

Aglanta Announces Panel About Closed Vertical Farming Operations

Aglanta Announces Panel About Closed Vertical Farming Operations

The event is highlighted by three vertical growing operations that weren't forced to shut down.

February 2, 2017

ATLANTA, GA - Recently, Aglanta's organizers posted an open letter from Paul Hardej about the closure of FarmedHere’s 90,000 square foot Bedford Park facility. After the post, they received inquiries about how and why this happened - and what does this mean for the industry?

Those of you were who were left wondering these question are in luck: Agritecture is pleased to announce that itwill be moderating an exclusive panel - An Examination of Shuttered Vertical Farming Facilities - according to a press release. This panel will held at the Aglanta Conference on Feb. 19 and panelists will include:

- Paul Hardej, Co-Founder of FarmedHere

- Mike Nasseri, Harvest Supervisor at LocalGarden

- Matt Liotta, CEO of PodPonics

Podponics and LocalGarden, like FarmedHere, each operated a vertical farming facility that is now closed. Podponics operated a large facility in Atlanta before declaring bankruptcy and closing their Atlanta facility in June 2016 - while Local Garden operated a large rooftop vertical farm in Vancouver that declared bankruptcy back in 2014.

If you clicked on any of those above links, you may have found you have some questions that you would like answered from our panelists. If so, please comment or drop us a note for what you’d like to know as we prepare for this discussion. There will also be a subsequent Q & A for those in attendance at #Aglanta.

Register here: aglanta.eventbrite.com

Underground Greens Grower Secures Online Retail Deal

Underground Greens Grower Secures Online Retail Deal

1 February 2017, by Gavin McEwan, Be the first to comment

London urban farming pioneer Growing Underground launches its first retail range of international-themed salad mixes via Ocado.com from today (1 February).

Its five-strong series of salad mixes consists of:

- English – English mustard leaves, broccoli shoots and pea shoots;

- Italian – salad rocket, garlic chives and pea shoots;

- Indian – fennel, coriander and pea shoots;

- Asian – purple radish, coriander and pea shoots;

- Japanese – wasabi mustard, pink stem radish and pea shoots.

Based in a World War II bomb shelter 30m beneath Clapham High Street, Growing Underground was founded five years ago by entrepreneurs Steven Dring, Richard Ballard and Chris Nelson, and is backed by chef Michel Roux Jr.

So far the business has been supplying micro-herbs and salads to London wholesalers, farmers' markets and Michelin-starred restaurants. Growing in a fully controlled, pest-free environment enables it to provide crops of consistent quality year-round, it says.

New produce trials are ongoing, and the farm has the capacity to quadruple its growing space as demand increases.

Co-founder Steven Dring said: "We've been working for years to perfect what we do and we're so excited about this retail range. Sustainable, low-energy growing of exceptional produce is a central part of our ethos and we're delighted that through this partnership with the UK's leading online supermarket we can now share our amazing micro-herbs with consumers.

"We're so pleased that Ocado have put their faith in a small start-up that is working hard to promote innovation and sustainability in British farming, and are very encouraged by what this could mean for the future of the industry."

We Proudly Announce

We Proudly Announce

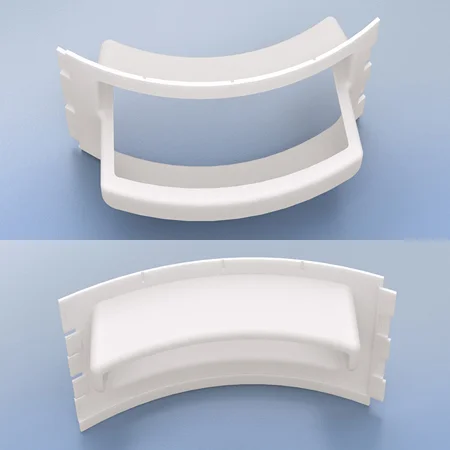

The series production of the 2. generation of our barrel parts is now up and running and we are ready to ship! This includes the standing base, the new lids and the two 2-inch net pot adapter parts to grow lettuce and herbs

All parts incorporate the improvements of the last two years of development and support from professional growers:

- An inside wing structure, directing the liquid to the root areas of your plants, also allowing for much higher barrels.

- A new connection mechanism between the adapter parts ensuring a tight more exact fit, easier assembly, facilitating to stack and handle barrel ring segments.

- A new irrigation option - an inverted sprinkler, and a new lid.

- Materials used: ASA as the main material for the 1/6th parts being the most robust and uv-resistant option and PVC for lids and stands.

If you are interested in running or testing the barrel concept please get in touch now. Here you can find pricing and shipping information and more detailed images of the parts and how it looks in production (scroll down).

In 2017 we plan to extend the barrel concept further into new soil-less adapter parts, that can be used for bigger plants and more versatile grow space set-ups. And we will even extend into a nifty movable soil-based wickerbed version. Click here for more information.

PCT Announcement

In the meantime the PCT announcement of our patent has been published (WO2016/156334) extending the priority phase to localize IP internationally. This is a major milestone to protect new partnerships.

We are currently looking for strong partners to manufacture and/or set up sales channels outside Germany/Europe! For more information please get in touch with us!

Trade shows and events 2016/2017

- GreenTech June 2016 in Amsterdam

- AgTech Week NYC September 2016 in New York City with demo of the aponix vertical barrel.

- CropWorld October 2016 in Amsterdam

- Upcoming 9-10 May 2017, meet us at the Global Forum for Innovations in Agriculture in Utrecht.

Latest mentions

- Read about Marco's and other opinions on the upcoming agri-food revolution.

- UrbanAg News: Aponix extended the NFT idea into the 3rd dimension with their vertical barrel

- National television visiting the aponix underground testing farm (5min video, German).

- Aponix winner at Green Product Award, category freestyle

- Staatliche Lehr- und Versuchsanstalt für Gartenbau Heidelberg (LVG) testing barrels in parallel to NFTs.

The Aponix Vertical Barrel

The aponix vertical barrel can be used as growing component like an NFT in an existing liquid nutrient cycle for high density growing.

Barrels can be build using simple and compact plant adapter parts, being assembled into barrel ring segments. By stacking ring segments you set up your grow spaces without the need for additional fixed table- or rack structures. The available cubic growing space determines the number of grow spaces you can run. Of course multiple barrels can be connected inside your production facility providing >60 grow spaces per sqm. Please check this page for some integration examples.

Barrels can be rotated. Hanging and standing versions are available. Currently each barrel is powered by one top sprinkler or a spray nozzle. Nutrient solution is running down the inside from the top lid being directed by an internal wing structure towards each root area of your plants, practically turning the barrel into a giant vertical 3D-NFT. For more details please check our FAQs.

Modular Farms Newsletter #6

January has undoubtedly been the busiest month in the history of our young company. For each calendar day that passed we were introduced to more and more people that are driven to reshape the agricultural landscape, both domestically and abroad, via the use of ZipGrow technology, Modular Farms and other sustainable farming practices

Modular Farms Newsletter #6

January has undoubtedly been the busiest month in the history of our young company. For each calendar day that passed we were introduced to more and more people that are driven to reshape the agricultural landscape, both domestically and abroad, via the use of ZipGrow technology, Modular Farms and other sustainable farming practices. At this rate, 2017 is poised to be a huge year for the indoor farming industry as a whole, and we are honored to be amongst the cohort of businesses that are helping to educate and empower the next generation of hydroponic farmers to make a difference in their communities.

Recently, we had the privilege of taking some of our FarmWalls out of our office and showcasing them at various places throughout our community. The first stop on tour was at an event hosted by 4Life Natural Foods in Kensington Market - an urban Toronto grocery store focused on selling locally sourced, sustainable organic produce. We partnered with 4Life to assist in the development and construction of a 5000 square foot indoor ZipFarm that will be located on the roof of their downtown location.

The FarmWall we showcased at the event gave the grocer's patrons a chance to get a first-hand look, feel and taste of the produce that will be available to them year-round once construction of the rooftop farm is complete. Needless to say, a lot of excitement ensued from those who bravely trekked through the hideous snowstorm to attend that evening.

The second, and more permanent, stop on the FarmWall tour was at the Institute of Management and Innovation, located at the University of Toronto's Mississauga campus. Under the guidance of our Plant Health Technician, Kevin, the Sustainability Management grad students have been eagerly putting their studies into practice by utilizing the 2-tower system as a part of their Capstone project. We are overjoyed with the amount of interest that the students are having with the project, and are excited to see and taste the fruits of their labour!

This month marked the end of an era for Modular Farms, as we watched our beloved beta farm get unplugged, decommissioned and whisked away from our office on the back of a truck. On the bright side, we took solace in the fact that it was on its way to Cornwall, where the Smart Greens team will be using it to educate and train the first generation of Canadian Modular Farmers. As much as our team will miss working and growing in the ol' girl, the farm's departure from our Brampton office signifies our official transition from farmers to manufacturers, as we begin getting the first set of Modular Farms off the production line and into the eager hands of our customers.

As most of you already know, unlike other containerized indoor farming providers, who simply re-purpose used shipping containers, we custom build our farms from the ground up. Aside from the extra room allotted to farmers for working, the fact that our farms are made in-house allows us to meticulously observe and scrutinize the entire manufacturing process. This ensures that the farms our customers are receiving meet all of our stringent quality control requirements; and, as you can see from the above video, it also ensures that we will have a steady stream of memorizing time-lapses of the farms being assembled for years to come!

This month also featured our CEO's yearly overseas pilgrimage out east to the annual Indoor Ag-Con event in Singapore, where he was once again honoured as a featured speaker. The event this year was mainly focused on the accelerating innovation in the industry, from plant biology to innovative farm designs and new business models. Once the event concluded, Eric also had the pleasure of venturing slightly south for the official ribbon-cutting of Modular Farms' new office and manufacturing facility in Australia!

Stay tuned for the next installment of our newsletter!

Hundred-Story Food-Growing Tower Is Dream of Weed Entrepreneur

Hundred-Story Food-Growing Tower Is Dream of Weed Entrepreneu

According to Rick Byrd, the future of farming is tall, dirtless and local.

Byrd's vision of skyscraper farms to feed city dwellers begins with a much different kind of crop: marijuana.

The 45-year-old is chief executive officer and founder of Pure Agrobusiness Inc., a company that sells equipment to grow legal cannabis, a market worth $6 billion in 2016 and expected to reach $50 billion by 2026, according to Cowen & Co.

Because cannabis has higher profit margins than food, and pot is mostly grown inside, Byrd said he hopes the innovations perfected by PureAgro, with the help of customer feedback, could one day revolutionize food production. It's just a question of how much it costs.

Pot is "the perfect catalyst to bring in what I think really needs to change in farming," Byrd said in an interview. "You can't have the average produce truck going 1,500 miles to get to your plate. And there's no way, obviously, to farm the amount of acres that we would need to feed New York City unless we go vertical."

Byrd imagines a 100-story glass skyscraper filled with floors of stacked beds of fruits, vegetables and grain. The same technology that currently enables vertical indoor farms to raise primo weed can one day produce perfect tomatoes or succulent lettuce, Byrd said. Paper or mesh holds up the plants, substituting for soil. Powerful lights do the work now done by the sun, but better. Data calibrate the exact light spectrum and nutrients for the plants to thrive, and machines drip just enough water. Harvests are frequent -- four or five a year, compared with one outdoor.

Making urban farms vertical instead of horizontal could cut agriculture's reliance on fossil fuels and diminish risks from pests, pesticides and an increasingly haywire environment, Byrd said.

Because price is less of a problem with cannabis, pot growers are better able to adapt to new, more expensive technology. An ounce of kale, for instance, costs 49 cents at Whole Foods Market. An ounce of cannabis can run $150 to $200, according to data from BDS Analytics, a research firm. When technology expenses fall low enough, a tipping point arrives, and food farmers can take advantage of what the pot producers already use. With legal weed pushing down pot costs, even marijuana growers will need cheaper technology, Byrd said.

"Who do you think is going to implement technology? Obviously the cannabis guys," Byrd said.

In some places, Byrd's dream of vertical food production is already happening. Specialty items -- basil leaves, for example -- are raised in air farms in places like Brooklyn, New York. Sky Greens, in Singapore, began operating in 2012 to reduce reliance on food imports. Plants are grown using hydroponics -- without soil -- in an aluminum frame. In the offices of Tokyo-based human-resources company Pasona Group Inc., 20 percent of the space is used to grow vegetables. Ten thousand square feet of growing beds and lights share space with conference rooms and offices. The building produces 100 different kinds of fruits and vegetables.

When Byrd first came across plans for farm-filled buildings nearly a decade ago, he thought they were far-fetched, he said. That was around 2008, as Byrd completed building the first LEED platinum certified home with actor Adrian Grenier, of "Entourage" fame, in a project that was featured on Discovery's Planet Green channel. Due to the show's exposure, Byrd received architectural plans for eco-friendly buildings from all over the world, including farms in 100-story high-rises.

"It didn't pencil out then," he said. "Then came the cannabis boom."

The problem with growing indoor food, or pot, is missing out on free resources like rain and sun.

"Why would you ever block a non-carbon-emitting source of photosynthetic active radiation that grows plants at no cost?" said Paul Sellew, CEO of Little Leaf Farms, a greenhouse that cultivates produce in Devens, Massachusetts. "It's a fad, and it will pass."

But climate change is making outdoor conditions less predictable, said Christiana Wyly, operating partner at Satori Capital, a private equity firm.

Byrd, who likes to wear blue and black Armani and said he doesn't smoke marijuana, said PureAgro, based in Denver and Los Angeles, recently began working with an investment bank. That's unusual for a business working with marijuana, which is legal in some form in 28 states but taboo with the federal government. Shares of publicly traded Scotts Miracle-Gro Co., an agricultural supply company and PureAgro's competitor, rose 48 percent last year. Now comes the uncertainty of the Trump administration, and a attorney general nominee in Alabama Sen. Jeff Sessions, who's expressed hostility to legal weed in the past, over how they plan to deal with federal drug law.

Given that the majority of the world's population lives in urban centers, it will eventually be necessary to grow food nearby, said Al Shay, an instructor in the Department of Horticulture at Oregon State University in Corvallis.

But the strength of the land-based farm lobby has kept the indoor industry from spreading more, he said. The cannabis industry could be the spark, he said.

"People toyed around with batteries in cars for a long time," Shay said. "It wasn't until Elon Musk came along with Tesla and made it highly efficient and super sexy."

The Ag Tech Market Map: 80+ Startups Powering The Future Of Farming And Agribusiness

JANUARY 30, 2017

The Ag Tech Market Map: 80+ Startups Powering The Future Of Farming And Agribusiness

Corporate investors such as Mitsui, Monsanto, and Syngenta have backed startups improving irrigation, crop spraying, harvesting, and more.

As population growth increases the need to ramp up food production, tech startups are creating a range of agricultural software, services, farming techniques, and more aimed at bringing more data and efficiency to the sector.

We used CB Insights data to identify more than 80 private companies in agriculture tech and categorized them into eight main categories.

We define ag tech as technology that increases the efficiency of farms (in the form of software), sensors, aerial-based data, internet-based distribution channels (marketplaces), and tools for technology-enabled farming. We only include companies that primarily target the agricultural sector.

Farming & Ag Tech Webinar

Tech companies are gradually changing farms and making agriculture more efficient. Register now to see trends, investment data, and more on this growing industry.

The breakdown is as follows:

- Farm Management Software: This includes software like that produced by Andreessen Horowitz-backed Granular that allows farmers to more efficiently manage their resources, crop production, farm animals, etc.

- Precision Agriculture and Predictive Data Analytics: These startups include those that focus on using big data and predictive analytics to address farm-related issues and make better farm-related decisions in order to save energy, increase efficiency, optimize herbicide and pesticide application (such as Prospera, which uses machine vision and artificial intelligence), and manage risk, among other uses.

- Sensors: Startups in the sensor category include Arable, which offers smart sensors that collect data and help farmers monitor crop health, weather, and soil quality.

- Animal Data: These companies provide software and hardware specifically aimed at better understanding livestock, from breeding patterns (Connecterra) to genomics (TL Biolabs).

- Robotics and Drones: This category includes drone companies and related drone services that cater to agricultural needs (such as TerrAvion), as well as robots or intelligent farm machines that perform various farm functions more efficiently (such as Blue River Technology, backed by Monsanto Growth Ventures, Syngenta Ventures, and Khosla Ventures, among others).

- Smart Irrigation: These startups, including Hortau, provide systems that help monitor and automate water usage for farms using various data exhausts.

- Next Gen Farms: A growing category of companies that utilize technology to provide alternative farming methods to enable farming in locations and settings that cannot support traditional farming. Examples include AeroFarms for vertical farming and BrightFarms for new greenhouses.

- Marketplaces: These startups offer marketplaces relevant to agriculture by connecting farmers directly to suppliers or consumers without any middlemen. While some are e-commerce platforms, others use tech to facilitate physical marketplaces (La Ruche Qui Dit Oui).

Some companies may overlap with different categories and are grouped according to their main use case.

Track all the Ag Tech startups in this brief and many more on our platform

Startups are working to change how our farms work. Sign up for a free trial and look for Ag Tech Startups in the Collections tab.

Modular Aeroponic Farms Open Door to Clean Energy Urban Agriculture Modular Aeroponic Farms Open Door to Clean Energy Urban Agriculture

Modular Aeroponic Farms Open Door to Clean Energy Urban Agriculture

Andrew Burger 01/29/2017

Generally speaking, agriculture is rich in opportunities for clean, efficient energy self-generation and, more broadly and significantly, improvements at the nexus of energy, water and food production and use.

The opportunities gain in significance as the climate changes, urbanization continues and people and families, whether by choice or necessity, continue to leave rural areas, farming and ranching to seek out new lives and livelihoods in cities and metropolitan areas.

Agriculture-clean energy entrepreneurs are capitalizing on the confluence of these trends amidst broad-based popular movements to produce food and energy locally, even in cities. Indoor Farms of America (IFOA) on Jan. 27 announced the latest iteration of its soon-to-be-released aeroponic “Container Farms” will be self-sufficient in terms of both energy and water.

Energy and Water-Efficient Indoor Farming

Incorporating IFOA’s patented food-grade aeroponic growing equipment, the Las Vegas, Nevada-based company’s aeroponic indoor “farms” are designed for use in totally enclosed, controlled growing environments and greenhouse operations.

Aeroponics entails growing plants without the use of soil or an aggregate growing medium. Akin to hydroponics and aquaponics, aeroponics uses less water. Reducing the cultivation method to its most basic level, plant’s are suspended and their roots and lower stems sprayed, or misted, with a water solution rich in nutrients.

In addition to being highly efficient in terms of use of space and water, the ability to control environmental conditions enables a much wider variety of high quality greens and fruits to be grown in any given climate/geographic area all year round.

IFOA’s vertical aeroponic equipment offers growing capacities in excess of 40 plants per square foot of floor space at an operating height of just 8 feet, according to the company. Modular and scalable, they can be configured as bi-level and multi-level vertical farms, a key selling point in densely populated urban areas where land is comparatively scarce and expensive. The company has also developed a mobile, “Farmers’ Market” version.

Growing Strawberries in New York – in Winter

Among its U.S. installations, IFOA recently installed an aeroponic “warehouse farm” in Salamanca, New York. Outdoor temperatures were around four degrees Fahrenheit (-15.56°C).

“The use of our patented mineral uptake system allows them to use rocks from the lands they own and speaks to their culture in meaningful ways, while lessening dependence on costly supplemental inputs into the system to yield food that tastes fantastic,” IFOA president Ron Evans explained.

Evans pointed out that the Salamanca, New York farm’s unnamed owners “are particularly focused on operating a very green farm.” That extends to energy.

The upstate New York farm employs geothermal heating, enabling high quality fruits and vegetables to be grown all year long. That includes strawberries, which the farm’s owners are just starting to grow.

Looking ahead, IFOA says it will be shipping multiple container farms internationally this spring. “We are continually humbled by the visits we receive to our facility in Las Vegas from the brightest people in agriculture. It is what drives us to keep making it better, to fulfill our purpose as a company,” company president Ron Evans said in a statement.

Marc Oshima: "Food Is A Fundamental Right"

Let’s Build a Better Food Policy, which will be hosted in partnership with George Washington University and the World Resources Institute on February 2, 2017

Marc Oshima: "Food Is A Fundamental Right"

Marc Oshima, Chief Marketing Officer and Co-Founder of AeroFarms, is speaking at the third annual D.C. Food Tank Summit, Let’s Build a Better Food Policy, which will be hosted in partnership with George Washington University and the World Resources Institute on February 2, 2017.

Mr. Oshima has an extensive background in marketing for retail industries, brand management, and media. Prior to founding AeroFarms, an award-winning clean-technology company that builds and operates responsible, state-of-the art indoor vertical farms in urban environments around the world, Mr. Oshima led the marketing for The Food Emporium and Citarella Gourmet Markets. He has created partnerships with the James Beard Foundation, Museum of Food & Drink, City Harvest, and Le Fooding.

Food Tank had the chance to speak with Mr. Oshima about his work developing AeroFarms and passion for improving America’s food system.

Marc Oshima, Chief Marketing Officer and Co-Founder of AeroFarms

Food Tank (FT): What originally inspired you to get involved in your work?

Marc Oshima (MO): A combination of both professional and personal experience has helped shape my passion for improving our food system. I have been in food retail and marketing for years, and have also been involved with the Marketing Advisory Committee for the Food Bank for NYC, and have seen the challenges of not knowing where your next meal may come from. Here at AeroFarms, with our indoor vertical farming approach, we are focused on democratizing access to nutritious, great-tasting produce that is safely and locally grown all year round.

FT: What makes you continue to want to be involved in this kind of work?

MO: I see first-hand the impact that we are having within the community—creating year-round jobs, addressing food deserts, educating students about agriculture, bringing better product to the market—and I want to help inspire and lead our team to scale our farms around the world.

FT: Who inspired you as a kid?

MO: My parents, teachers, and coaches helped inspire me to grow and be curious. In particular, my middle-school math teacher Mr. Cook helped me develop critical thinking and taught me how to come up with different creative approaches to problems, and to appreciate that there could be more than one solution.

FT: What do you see as the biggest opportunity to fix the food system?

MO: There is such a disconnect between the real challenges of farming and the global macro pressures of an increasing population and urbanization, decreasing access to arable land and fresh water, worker welfare, food safety, food security, and we need to increase awareness of these issues. Fundamentally, I think that we need to develop a greater connection and appreciation for how and where our food is grown, and that will help foster new breakthroughs.

FT: Can you share a story about a food hero who inspired you?

MO: There are many, but one that stands out is Dr. Lucy Cabrera who is the former CEO of the Food Bank for NYC. For over 20 years, Dr. Cabrera lead that organization to help distribute over 70 million pounds of food annually and help raise awareness that one out of five New Yorkers is food challenged and at risk. She helped me appreciate more than ever that food is a fundamental right, and I am inspired to help address that every single day.

FT: What’s the most pressing issue in food and agriculture that you’d like to see solved?

MO: There is an artificially-depressed cost of food, where the externalities and true costs of farming and environmental negative impacts are not factored in.

FT: What is one small change every person can make in their daily lives to make a big difference?

MO: Vote with your wallet, and make informed purchases to buy responsibly grown food.

FT: What advice can you give to President Trump and the U.S. Congress on food and agriculture?

MO: Access to healthy, delicious food is not about party lines—it is a fundamental right for every American, and we need to figure out how to come together to work collectively.

Indoor Farms of America Bringing Fully Off-Grid Containerized Vertical Aeroponic Farms To Market

Indoor Farms of America announces today the company is now preparing to launch a version of its Container Farms that will be energy independent and water independent, allowing deployment of the farms anywhere in the world

Indoor Farms of America Bringing Fully Off-Grid Containerized Vertical Aeroponic Farms To Market

Wisconsin State Farmer

11:11 p.m. CT - Jan. 27, 2017

Las Vegas — Indoor Farms of America announces today the company is now preparing to launch a version of its Container Farms that will be energy independent and water independent, allowing deployment of the farms anywhere in the world.

"We have been working on this for quite some time, and these enhancements to our farm products will be available in production form by the end of Q1 this year", according to David Martin, CEO of Indoor Farms of America.

"From the beginning of our company's existence, we have been, and remain on a path of improvement of what we know to be the best indoor agricultural equipment in existence, and to bring it to every corner of the world in a cost effective manner. We are achieving milestones each month in that regard." states Martin.

The company has container farms in operation across the U.S. and will be shipping multiple container farms to countries around the globe this spring. "We are continually humbled by the visits we receive to our facility in Las Vegas from the brightest people in agriculture. It is what drives us to keep making it better, to fulfill our purpose as a company," commented Ron Evans, President of IFOA.

Sales and delivery of larger vertical indoor farm formats produced by IFOA, such as those in warehouse facilities, has increased rapidly, and the company is working with some of the largest companies in the world that produce or process food due to the extremely attractive financial metrics the equipment represents, according to Martin. He added: "We recently installed a warehouse farm in Salamanca New York, when outside temps were four degrees, and the owners are amazed at what their new farm represents. They have compared our equipment to every other form of indoor growing, and chose us hands down. They are particularly focused on operating a very green farm, and use geothermal for heating of their facility, which means superior fresh greens of any kind, and strawberries, which they are starting to grow, all year long no matter what the weather is like outside."

"The use of our patented mineral uptake system allows them to use rocks from the lands they own and speaks to their culture in meaningful ways, while lessoning dependence on costly supplemental inputs into the system to yield food that tastes fantastic." said Evans.

The company will be exhibiting its patented vertical aeroponic equipment, which provides growing capacities in excess of 40 plants per square foot of floor space in an operating height of just 8 feet, at numerous events in coming months.

Upcoming events in February, including at the World Ag Expo in Tulare, CA from February 14th to the 16th, and at the Aglanta show for indoor agriculture being held in Atlanta, GA on February 19th will allow more folks to see and touch this amazing crop growing equipment, according to Evans.

For more information, visit the company website at indoorfarmsamerica.com.

Hydroponics Towers To Be Built In Lafayette

Hydroponics Towers To Be Built In Lafayette

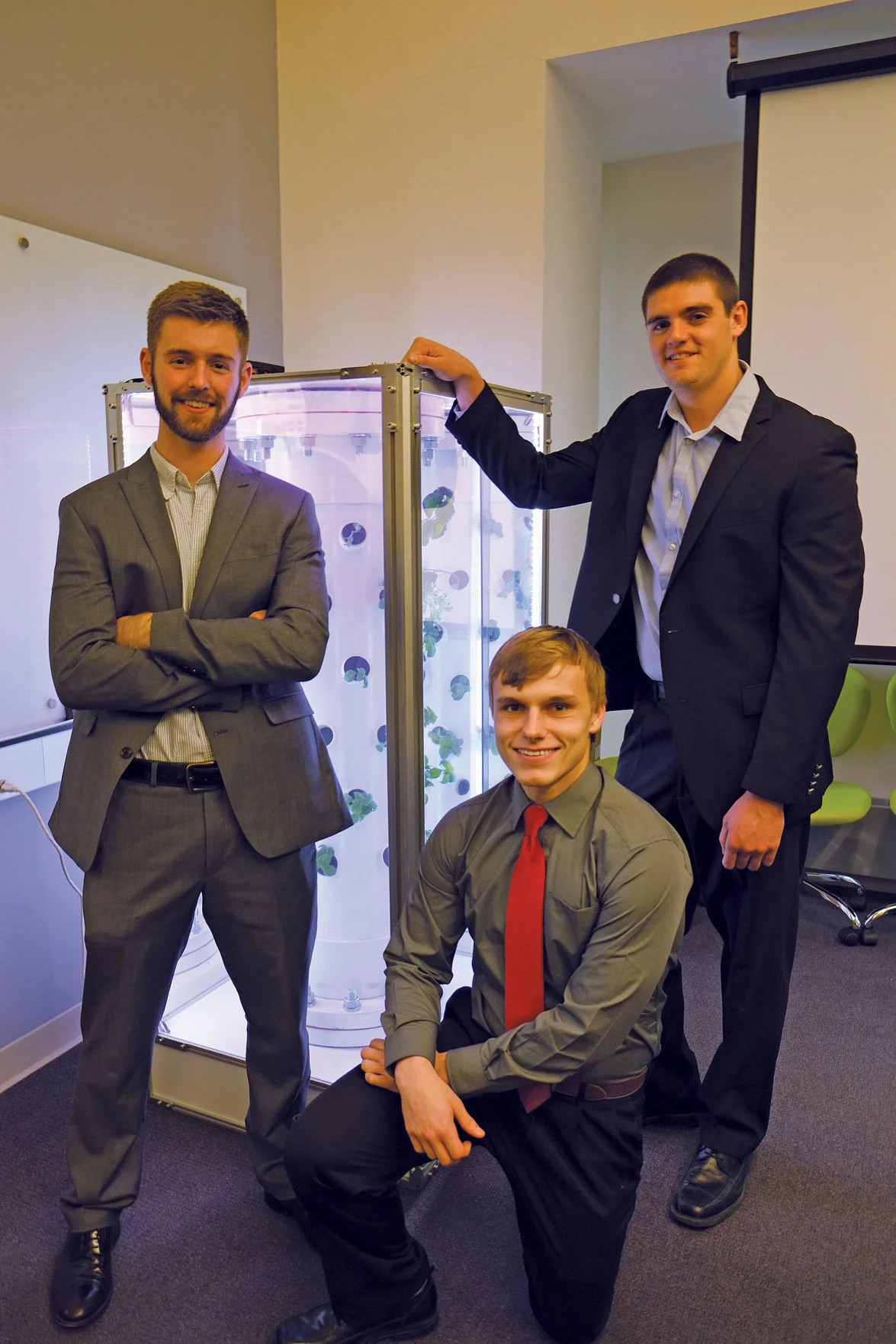

Hydroponics Towers To Be Built In LafayetteA Purdue entrepreneur in hydroponics is working in conjunction with the non-profit Red Giant Union to bring nine-foot hydroponics towers to Lafayette.

Scott Massey, Purdue senior and founder and CEO of Hydro Grow LLC, has developed a household hydroponics garden that could replace the traditional refrigerator. Cups containing different seeds are inserted into a tower “Keurig-style,” allowing the user to grow fresh produce in the comfort of their own kitchen. Massey and his team are currently working on the second generation model of the Hydro Grow system, which is based on artificial intelligence, or AI.

“The system would actually be aware of what plants were growing in it and it would adapt its environmental conditions to the specific preferences of that plant,” said Massey. “The sunlight, the pH of the water, the electroconductivity of the water, the humidity; our system will automatically adapt to it without the user having to do anything other than placing the cup into the system.”

The AI component will also take the average values of different plants to create the optimal overall environment. As a result, each garden becomes customized to the user.

“(The AI) is something that really no one in the world, as far as I’m aware, is even considering developing right now, because no one thinks it’s possible,” said Massey. “But we’ve found a pretty good way to do it.”

Massey has recently formed a partnership with Red Giant Union, a non-profit group that is striving to create an urban food system in Lafayette focusing on fresh produce, community involvement and sustainability. The executive director and founder of Red Giant Union, Austin Kasso, is currently fundraising for a community garden called the Tower Farms that will consist of nine-foot hydroponics towers housed at 419 N. Third Street in downtown Lafayette, across from the bus depot. The garden would provide fresh produce and a place for community interaction.

Kasso said that Red Giant Union is working with various local groups to create the community-centered garden. The West Lafayette Farmer’s Market will theme their next market in May on hydroponics and the Tower Farms to promote the fundraising campaign within the community. The Tippecanoe Extension is also helping to promote the project in addition to many other groups.

“People think, ‘One dollar can’t make a difference,’ but it does,” said Kasso. Getting 10,000 people with one dollar to donate involves the community and “inspires engagement with the project.”

Massey’s and Kasso’s mutual interests are what led to their strategic partnership. Massey will be applying his knowledge and experience in hydroponics to help make the vertical gardens a reality.

Hydro Grow LLC is rapidly expanding, and Massey won $35,000 through competitions in a single month. He is looking for people to assist him as his project evolves. Massey said all disciplines are welcome and he will find a way for them to “contribute to the project.”

Interested individuals can contact Massey at hydrogrow.site@gmail.com. More information on Hydro Grow LLC is available at www.hydrogrow.site and through the previously published Exponent article titled, ‘Purdue entrepreneur creates next kitchen appliance: a hydroponics garden,’ available at purdueexponent.org.

Cornell Students Prepare To Become Leaders In Controlled Environment Agriculture

Cornell Students Prepare To Become Leaders In Controlled Environment Agriculture

RELATED LINKS

Farm Of The Future: What Grows In Las Vegas Stays In Las Vegas

Farm Of The Future: What Grows In Las Vegas Stays In Las Vegas

January 23, 2017 | 12:16 PM ET

SARAH FELDBERG

Urban Seed plans to grow 25 different crops, from bell peppers to beets to alpine strawberries, in high-tech greenhouses smack in the middle of Las Vegas.

Courtesy of Urban Seed

Every day, Border Grill restaurant at Mandalay Bay Resort and Casino in Las Vegas uses a case of tomatillos and at least a case of cilantro. The tomatillos go into dishes like the pozole verde, a spicy stew with chicken and hominy. The cilantro goes into the green rice, the guacamole, the Yucatan pork roasted in banana leaves and just about everything else.

"The Mexican kitchen is very produce heavy," says Border Grill co-chef/owner Mary Sue Milliken. A lot of the ingredients that she and partner Susan Feniger use most frequently also suffer the greatest in transit. Radishes, jicama, that delicate cilantro, they all die so fast, Milliken says.

Nearly every last piece of produce in the kitchen and on the plate at Border Grill's two Las Vegas locations comes from somewhere else. Most of it is trucked in from California — farm to table, with some freeway in between.

But as winter takes hold across the country, a new farm is working to change that. Come spring, Milliken and other chefs like her will be able to source fresh fruits and vegetables harvested blocks from the Las Vegas Strip.

Last July, Urban Seed broke ground on its first farm, an assemblage of high-tech greenhouses located on a small plot of land smack in the center of Las Vegas. Eventually the space will hold six 6,500-square-foot greenhouses that will produce 25 different crops, from bell peppers to beets to alpine strawberries.

If an agriculture company launching in the desert sounds counterintuitive, that's entirely the point.

"The whole world thinks Vegas can't grow food," says Rachel Wenman, vice president of Urban Seed. "We really feel that if you can grow food in Las Vegas, then you can grow food anywhere."

Urban Seed will be the largest local farm in terms of yield, but isn't the first company to attempt farming in the desert. An Australian farm made headlines last fall for growing produce using solar-powered greenhouses and seawater desalinated onsite. The Sahara Forest Project has constructed saltwater-cooled greenhouses in Qatar and is working on a new farm in Jordan. In Las Vegas, the University of Nevada Cooperative Extension has a one-acre outdoor research orchard, and Las Vegas Herbs grows hydroponic microgreens in a 5,000-square-foot greenhouse.

Urban Seed, however, is taking a different approach. The company's strategy for growing in Las Vegas, where summer temperatures regularly top 110 degrees and annual rainfall amounts to just over four inches, is based around a proprietary aeroponic system focused on producing large amounts of food using limited space and resources. The growing system layers plants vertically, but unlike the vertical indoor farms catching on in other cities, its Las Vegas location will be single story and will rely on the area's plentiful sunlight – not artificial LED lights.

To develop Urban Seed's technology, a team of growers and engineers spent years in research and development, testing various indoor farming methods like aquaponics and hydroponics. Eventually they arrived at their current model, where plants are stacked inside of A-frames and grown aeroponically, with roots suspended in the air and water and nutrients delivered via fog. Each varietal gets its own custom nutrient mix, a secret-sauce smoothie to mimic optimal growing conditions.

"They get the exact environment, the exact nutrients that they need," says Wenman.

Each A-frame is also a closed loop that recaptures and recycles excess moisture. While a conventionally grown head of lettuce uses about 13 gallons of water to reach maturity, in an Urban Seed greenhouse, lettuce will grow on just 22 ounces, based on testing of the technology at facilities in Los Angeles, Las Vegas and Arizona.

Stacking the plants also maximizes growing space. In a 24-square-foot area, Wenman projects that Urban Seed will be able to grow more than 500 heads of lettuce in 30 days, compared with roughly 50 lettuce heads that might grow during that time on a traditional outdoor farm.

That number might sound hyperbolic, but it's actually pretty conservative when you compare it to estimates for vertical indoor farms currently getting lots of buzz. In Newark, for example, AeroFarms claims per-square-foot yields that are 130 times those of field farms.

"In the same amount of space indoors, you can raise 10 to 100 times what you can do outdoors," says Dr. Dickson Despommier, a professor emeritus at Columbia University and author of The Vertical Farm: Feeding the World in the 21st Century. Although Urban Seed's founders call their model a vertical farm, Despommier – who literally wrote the book on the subject – doesn't think the term applies because its buildings in Las Vegas are single story.

The key benefit to growing indoors is the controlled environment: no variance in weather, water, temperature or humidity, no pesky insects, no pests raiding the field for free snacks. When that indoor farm is placed in an urban center, there's also no long-distance shipping, cutting down on the carbon footprint and allowing food to be harvested at peak ripeness, when it tastes the best and packs the most nutritious punch.

With about 42 million annual visitors and a local population of around 2 million, as a test market, Las Vegas is ripe for new sources of produce.

"The longer the produce has to sit in the field and then in the warehouse and then [go through] three or four middlemen and then, finally, getting into the hands of chefs, the more flavor that is lost along the way," says Border Grill's Milliken, who is part of Urban Seed's culinary advisory board.

When the company begins harvesting in spring or early summer, its first customers will be chefs who'll turn the morning's harvest into the evening's menu.

"Just by virtue of the proximity and the freshness it should be better than everything I'm buying, says Milliken. "Having that proximity gives us an opportunity for the flavor to be enhanced so much."

AFBF Entrepreneur of the Year is Vertical Harvest Hydroponics

AFBF Entrepreneur of the Year is Vertical Harvest Hydroponics

Goal of Vertical Harvest Hydroponics is to produce hydroponic vegetables in 40 foot insulated shipping containers.

Jan 20, 2017

Vertical Harvest Hydroponics of Alaska is the American Farm Bureau Federation’s Farm Bureau Entrepreneur of the Year. Team leads Linda Janes and Dan Perpich won AFBF’s Rural Entrepreneurship Challenge by beating three other teams from across the nation.

Janes and Perpich took home a total of $30,000 in prize money, including $15,000 from sponsor Farm Bureau Bank to produce hydroponic vegetables housed in 40 foot insulated shipping containers.

The four finalists each received $15,000 in October for advancing in the competition.

Levrack of Nebraska won the People’s Choice award with 73% of the vote. The award earned Levrack an additional $10,000 in prize money. Levrack produces efficient storage systems for farm shops. Members of the live audience at the finals competition and members of the general public voted online to select the People’s Choice winner. Ryan Stauffer, Austin Stauffer and Peter Miller were team leads for Levrack.

Windcall Manufacturing of Nebraska, led by Martin Bremmer, and Grow Bioplastics of Tennessee, led by Tony Bova, were the other two finalists who competed in the final round of the challenge in Phoenix.

The final four teams competed for the award by pitching their business ideas to a panel of judges before a live audience. The finalist businesses were chosen from 356 applicants.

The challenge, now in its third year, provides opportunities for individuals to showcase business innovations being developed in rural regions of the U.S. It is the first national business competition focused exclusively on rural entrepreneurs working on food and agriculture businesses. The top challenge teams were selected by 40 judges with expertise in business development, equity investment funding management, agribusiness lending and entrepreneurial coaching.

Semi-finalists in the competition were awarded $10,000 each in October, thanks to the sponsorship of Farm Credit Council. They are: Demeter Inc., Irwin, Ohio; Farmzie, Raleigh, North Carolina; Gardens 4 Education, Hanford, California; Inland Sea Company LLC, Ames, Iowa; Lowcountry Street Grocery, Charleston, South Carolina; and Performance Livestock Analytics Inc., Osage, Iowa.

“Entrepreneurs – whether on the farm or in the community – are the lifeblood of the rural economy,” said Todd Van Hoose, CEO, Farm Credit Council. “That’s why we’re excited to partner again with the Farm Bureau for the third annual Rural Entrepreneurship Challenge. This competition recognizes and awards the best and brightest start-ups focused on supporting rural communities and agriculture. We look forward to following the progress of these talented individuals and wish them the best.”

The top 10 challenge teams were selected by 15 judges with expertise in business development, agribusiness lending and entrepreneurial coaching.

Source: AFBF

Open Letter from Paul Hardej

Open Letter from Paul Hardej

A Note Regarding the Closure of FarmedHere

Paul Hardej, a Co-Founder of FarmedHere, has been a supportive member of the AVF through his involvement with two of our highly active members: Illumitex and Indoor Harvest. His previous venture, FarmedHere, just announced the closure of FarmedHere's 90,000 sq foot Bedford Park facility.

While this may appear to be a setback for the industry, we at AVF feel that vertical farming is stronger than ever. Our detractors will point to negative developments like this one as a weakness of our entire practice. Yet we all know that the industry is full of successful vertical farming businesses. We are glad to share this Open Letter from Paul Hardej on this subject.

What follows is a note from Paul Hardej:

Austin, TX

1/17/2017

Open Letter

Dear Vertical Farming Colleagues:

It’s not unusual that the first movers and shakers in a new industry come across unexpected challenges. As we all recently learned, FarmedHere is closing its vertical farming operations in Chicago. I had the honor of co-founding FarmedHere in 2009, when it was unheard of for commercial farming to be located in city centers. When we started FarmedHere there were no regulations, financing, qualified labor force, nor proven business model for vertical farming. All we had was the promise of technology for growing plants under artificial light. By 2010 we had our first city farm up and running as an ultra-local grow operation, harvesting greens one day before store delivery and farm-to-store direct distribution. It was truly a disruptive model to the traditional food distribution and farming industry.

Despite these challenges, we forged ahead and made great progress. For example, we went through many months of public hearings and complex legal processes to obtain government approval on the city, county, state, and federal levels. In addition, we obtained the first vertical farm USDA organic certification. Ultimately, we scaled our sales of several lines of leafy greens to about 100 grocery stores in the Chicago metropolitan market. In early 2015 due to a misalignment with some of the new FarmedHere investors on the future of FarmedHere, I moved to other ventures but remained optimistic for continued FarmedHere success.

Since vertical farming is a rather unique blend between highly efficient manufacturing and technological farming, its success depends on the following: strong and smart capital, innovative sales and marketing, and a solid management team, working creatively with stakeholders from the local government, growers, technology providers, and customers. While the vertical hydroponic grow technology was proven to work at scale, FarmedHere missed on the business-side, with some of the other necessary ingredients to expand on its initial success.

In 2017 there are many examples of profitable vertical farms across the country and abroad. As demand for local and organic food grows, so will the industry. There are numerous reasons vertical farming is in demand – food safety and transparency, consistency, availability, high quality, nutritional value, not to mention a push towards sustainability. But it’s going to take all of us working together and exchanging ideas and sharing experiences. Like the industry, I’m evolving to keep up with innovation and technology. I am very positive about the future and looking forward to working with all of you.

I would like to thank all the creative builders, architects, growers, angel investors and organic grocery stores who made it possible for FarmedHere to impact the food system with a positive and permanent change. Let’s all remember FarmedHere for what it achieved and how it paved the way for many successful vertical farms all around the World.

Keep on growing,

Paul Hardej

As: Co-Founder of FarmedHere, LLC

Farmer Tip: Start Small and Take More Risks

Farmer Tip: Start Small and Take More Risks

by Amy Storey | Jan 19, 2017 | Business Mgt & Operations

Considerations of Starting Small

Whether you’re bootstrapping, testing out the feasibility of a farm, or limited to a certain space, there are several good reasons to start small. Farms that start small and scale up take a different approach to the startup process than farms that start big. Kieran Foran knows that well.

Kieran Foran co-founded Fresh Farm Aquaponics with Spencer Curry several years ago. The two use aquaponics to teach schools and non-governmental organizations how to grow their own food. Kieran has a unique look into managing a small startup business and joined us a few weeks ago to discuss that.

Looking back on the founding and growth of Fresh Farm Aquaponics, Kieran has two pieces of advice for small farmers.

1. Don’t be afraid to take risks.

While risks are usually seen as a bad thing for businesses, Kieran thinks that he could have spared more of them in the early days of the business.

“I would tell myself – if I was starting over – to take more risks.”

The reason? Every farm has a learning phase, and a small farm is a perfect place to learn. Many of a new farmers lessons come from trial and error. Kieran says that failures make up for the bulk of Fresh Farm Aquaponics’ learning curve.

The advantage of the small farmer is that they have a bit more freedom to experience those mistakes; the costs are limited to the size of the farm. The smaller the farm, the easier it is to come back. Which brings us to Kieran’s second piece of advice:

2. Start small and work towards your goal.

If you know what your goal is, it doesn’t matter where you start. Starting small can even have benefits. Kieran advises starting small to new farmers.

“Know what you want your end goal to be and then what’s the minimum to reach that goal,” advises Kieran.

Kieran and Spencer, for example, wanted to be a full-fledged commercial farm. They knew they couldn’t start at their goal size, so they started as a backyard farm, and used the profits to scale up.

How to start small

This scaling approach is common among small farmers, many of whom start with limited financing. We advise a 50/50 capitalization strategy (50% down payment on a loan to avoid exorbitant monthly payments down the road). This means that if you only have $10,000 to fund your farm, you’re limited to $20,000 in start-up costs.

Interested in learning more about starting and funding a small farm?

Just because you’re starting small doesn’t mean you aren’t a business. You still have to do feasibility studies, business planning, and financial planning for your business. Research your markets and choose sales models. These may determine your ability to scale up in the future!

China Is Setting An Example For The Entire World

China is setting an example for the entire world. During the visit of a Macfrut delegation to the new Easyhome Ankang supermarket in Beijing, the attention of the visitors was caught by the hydroponic lettuce cultivation system.