Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Countertop Nanofarming? New Kitchen Device Grows Fresh Produce Indoors

A new device could bring fresh, homegrown produce directly to the kitchen.

Countertop Nanofarming? New Kitchen Device Grows Fresh Produce Indoors

A new device could bring fresh, homegrown produce directly to the kitchen.

The Replantable Nanofarm is an at-home agriculture kit designed for people who want freshly-picked produce but don't have the time and space for a garden.

As the name suggests, Replantable is a small, indoor farm, about the size of a mini-fridge, which could easily be placed on a kitchen countertop. The set is composed of a grow cabinet, water tray, plant pad and harvest light. And with a few steps, homeowners could grow their crops in the machine.

"The nanofarm started off as a simple hydroponics system where users plant seeds and add fertilizer manually. We chose hydroponics because it is convenient to do indoors and allows us to avoid the use of pesticides," Ruwan Subasinghe, co-founder of the Atlanta, Georgia-based company, told Digital Trends.

"As we made prototypes and sent models to early customers, the consistent feedback was that it was still too much work. We started developing technology that would take more and more of the work off the user's hands. Where we ended up is the 'set and forget' system we're bringing into production."

The device simplifies farming into three steps: setting the number of weeks required to grow the crops, pressing the "Start" button, and pressing the "Harvest" button. Anyone could use the device, especially those without gardening experience, Subasinghe said.

The Replantable Nanofarm is made of powder-coated steel and natural wood, and its doors are corrosion-resistant and made of marine-grade aluminum to make sure that they won't break or rust. The device is also fitted with a smoked glass door to keep most of the light inside the device, and features a "whisper-quiet" ventilation system that pumps carbon dioxide to the crops while venting oxygen-rich air into the home.

The device has been under beta testing and will be launched via a Kickstarter campaign on Aug. 22, where it will be priced at $350.

Farming on the moon and meat grown in a lab. Six thoughts on the future of food.

As a technologist turned restaurateur, Kimbal Musk thinks daily about the future of food.

As a technologist turned restaurateur, Kimbal Musk thinks daily about the future of food.

Kimbal Musk (Courtesy of The Kitchen)

His own collection of restaurants, named The Kitchen and Next Door, aim to shake up food distribution by sourcing ingredients locally and providing fresh, natural food at sensible prices. His company, also called The Kitchen, builds hundreds of school gardens to teach children in low-income communities about healthy eating.

“No one wins in the industrial food system,” Musk said. “It’s awful at the individual level, and at the economic and community level.”

Musk’s last name should sound familiar. His older brother, Elon Musk, is the founder and chief executive behind technology firms Tesla and SpaceX. Musk sits on the boards of both of his brother’s companies, as well as the board of Mexican fast-casual chain, Chipotle. His career, in many ways, straddles the line between food and technology. (He and Elon originally made their fortune founding Zip2, a company that Compaq acquired in 1999.)

Musk spoke about his business ventures and restoring trust in the food industry last month at the World Future Society’s annual summit. Innovations caught up with him after the conference to pick his brain further. Here are six of Musk’s bold thoughts on the future of our food.

1. Vertical farming is poised for prime time — and outer space.

There is no question that Musk is a strong proponent of vertical farming, by which crops are grown in tall stacks under LED lights inside massive indoor facilities. The practice is being driven in large part by a desire to grow produce locally and thereby eliminate the need to ship items long distances. It would allow major urban centers, such as New York City or Chicago, to eat local fruits and vegetables during all four seasons. Musk said that 2015 marked the first year when vertical farming companies could sell produce at a profit, meaning the declining cost of the technology makes the practice feasible for the mass market. And when future generations eventually inhabit the moon, vertical farming may be how people eat fruits and veggies there. At least that’s what Musk told the audience of futurists late last month.

Lettuce farming in a modern hydroponic vertical farm, which uses only 1 percent of water a normal soil based farm would require.

2. Farming could soon be cool again.

Young Americans have not been bullish on careers in farming since roughly the Great Depression. Family farms have declined precipitously and corporate farms have been on the rise in the last 80 years, as The Washington Post previously reported. Musk sees an opportunity for that to change. The U.S. Department of Agriculture will offer $20 million each year in grants for new farmers until at least 2018. And thanks to aforementioned vertical farming, budding green thumbs need not move to rural communities to break into the agriculture business. For those who do desire the great outdoors, however, there may soon be ample land up for grabs. The average age of farm owners continues to increase, and more farmland will become available as those individuals lay down their shovels. “There will be an avalanche of supply of farmland over the next 5 to 10 years, or maybe at the latest 15 years,” Musk said. “It’s going to be a very exciting time in farming.”

3. The next million-dollar ideas will come from disrupting the food industry.

Of course, farming is just one end of the global food supply chain. Musk believes the industry is ripe for disruption all along the pipeline, from those who process ingredients into products to those who distribute them to restaurants that serve them. He compared it to the Internet in the 1990s. “You don’t know exactly what opportunity is in front of you, but you want to be in that industry. You want to be at the start of that wave,” Musk said. “My advice for any entrepreneur or innovator is to get into the food industry in some form so you have a front-row seat to what’s going on.” Successful entrepreneurs in the food business are also more likely to hail from Minneapolis or Memphis than Silicon Valley or New York, Musk added. America’s heartland and its food consumption habits more accurately reflect the country at large. “If you’re a vegan fast food joint in LA, you just don’t speak the same language as the heartland,” Musk said.

4. Trust in the food system requires greater transparency.

Musk focused much of his World Future Summit speech on trust and the idea that we no longer have much in our food. Whether it’s genetically modified produce or hard-to-pronounce chemical ingredients, Musk said that people often aren’t aware of what they’re eating or how it was made. In a world where vegetables are grown in warehouses and meat is made of plants (more on this in a minute), Musk said that building trust through transparency is absolutely crucial. “The problem with industrial food is zero transparency. The system thrives on the fact that there is no transparency,” Musk said. He hopes the next generation of food growers and manufacturers take a different approach. “If I were these guys, I would be thinking very much about transparency. What is the true impact of their product? What is the true nutrition of their product? Even if they have to use some futuristic ingredient, for lack of a better word, they’re very clear about what it is rather than hiding it from the consumer.”

5. Community impact requires entrepreneurs to go deep, not broad.

You don’t often meet entrepreneurs who think local. Take Musk’s older brother, who is trying to send people into space and eliminate their need to drive cars here on Earth. Musk said he, too, had a mind for global domination as a tech entrepreneur, but the same broad approach does not work in food. Shopping for groceries and dining at restaurants are still inherently local, and having an impact on the food people choose to consume has to be local as well. That’s why when Musk builds school gardens in a city, he constructs dozens of them at a time. He’s slated to open 50 in Pittsburgh and 100 in Indianapolis, for example. “When I look at a community and think about how we can bring this community to a real-food culture and get them thriving again, you have to go deep,” he said.

6. Our taste for meat will force us to look beyond animals.

Can a burger made from pea protein replace meat?

The beyond burger from Beyond Meat aims to replicate the texture, color and taste of a beef burger. (Jayne Orenstein, Joe Yonan/The Washington Post)

Successful efforts have been made to engineer meat in a laboratory or replicate it using plant-based ingredients. These aren’t frozen veggie burgers; we’re talking about an innovation beyond that. “Meat” that doesn’t come from cows, pigs and chickens could one day be more widely eaten, a shift that both animal welfare advocates and environmentalists would likely celebrate. After all, the increasing number of livestock that is necessary to sate the world population’s meat consumption has had a well-documented, negative impact on the environment. For his part, Musk is much more enthusiastic about plant-based meat products, questioning whether the lab-grown variety is something consumers will ever trust. He also says simply eating less meat is one path forward. “I am a fan of less and better meat rather than replacing meat,” he said. “That’s just me personally.”

Read more from The Washington Post’s Innovations section.

By Steven Overly

IKEA is selling hydroponic grow kits to grow vegetables inside. Urban farmers unite!

Ikea & hydroponic grow kits!

No soil necessary. It's the hallmark of hydroponic gardening, plants held in place while their roots dangle in nourishing water.

IKEA is using is mass marketing capabilities to bring this, newly miniaturized, technology to the masses.

It is with the idea that it should be affordable to grow your own food. An aspiring gardener can suit up and get to it, even in a high-rise apartment building, for around $50.

The system is a basic grow tray with small pods to put your seeds in. Once seeded, keep an eye on the water level and make sure they get enough light. You'll have veggies soon.

One of the scientists that worked with IKEA to help create the hydroponic system is Helena Karlén, lecturer at the Swedish University of Agricultural Sciences. She reveals the challenge "to make growing plants in a hydroponic system simple, so that anyone could succeed," adding, "we were also very interested, not only that they grow, but also the taste... they should taste good, very good actually."

Vertically farming vegetables and living in the city just got synergistic on the cheap.

By Ian Crossland

IKEA Launches Indoor Garden That Can Grow Food All Year-Round

If you’ve always wanted to grow your own veggies and herbs, but don’t have a yard where you can set up a garden, IKEA has the perfect product for you

If you’ve always wanted to grow your own veggies and herbs, but don’t have a yard where you can set up a garden, IKEA has the perfect product for you. The furniture retailer just unveiled its new KRYDDA/VÄXER hydroponic garden, which allows anyone to easily grow fresh produce at home. Check out the video: https://youtu.be/Sv9wD2HNSnA

The system allows customers to sprout and grow plants without any soil. Seeds can be sprouted using the absorbent foam plugs that come with the system, which keeps them moist without over-watering. Once the seeds have germinated, you can simply transfer the entire plug into its own pot and fill it with a scoop of water-absorbing pumice stones. These pots fit into a growing tray equipped with a solar lamp, providing year-round nourishment for the plants even in rooms without direct sunlight. (Or, if you choose to do things the old-fashioned way, you can simply place the tray in a convenient window.) The growing tray is even equipped with a built-in water sensor to help you ensure your plants are neither under- or over-watered.

IKEA claims the system is so simple that anyone — regardless of their experience with gardening — can successfully use it. While it’s not yet clear how much the set will cost, IKEA plans to launch the indoor gardening set in April. It’s worth noting that this is not the first indoor hydroponic garden to hit the market, although it may be a good option for people who aren’t exactly sure where to get started.

While the new system is a departure from IKEA’s usual catalog of items like bookshelves and tables, it’s in keeping with the company’s trend toward sustainability and away from a traditional retail business model. IKEA’s head of sustainability famously proclaimed earlier this year that the Western world had hit “peak home furnishings” and spoke about helping customers live more eco-friendly lives. Hopefully that means more products like this compact indoor garden are on the horizon.

How Vertical Farming Is Revolutionising The Way We Grow Food

Traditional farming is taking a huge toll on the environment...

Gizmodo Australia 3/05/2016

Traditional farming is taking a huge toll on the environment -- a problem that's set to worsen due to our ever-growing global population. Yet there are some high-tech solutions. Here's what you need to know about the burgeoning practice of controlled-environment agriculture and how it's set to change everything from the foods we eat to the communities we live in.

As a practice, traditional farming is not going to disappear any time soon. It will be quite some time -- if ever -- before other methods completely supplant it. But it's crucial that alternatives be devised to alleviate the pressure imposed by conventional farming methods.

An Unsustainable Practice

Negative environmental effects of traditional farming include the steady decline of soil productivity, over-consumption of water (including water pollution via sediments, salts, pesticides, manures, and fertilisers), the rise of pesticide-resistant insects, dramatic loss of wetlands and wildlife habitat, reduced genetic diversity in most crops, destruction of tropical forests and other native vegetation, and elevated levels of carbon dioxide and other greenhouse gases. And as urban sprawl continues unabated, vast swaths of productive farmland are being eliminated. Estimates place the amount of farmland lost to development since 1970 at a whopping 30 million acres.

There are economic and social concerns as well. In addition to relying on huge federal expenditures, Big Agriculture has resulted in widening disparity among farmer incomes, concentrating agribusiness into fewer hands, and limited market competition. What's more, farmers have very little control over prices, while progressively receiving smaller and smaller portions of consumer dollars. From 1987 to 1997, for example, more than 155,000 farms were lost in North America. As noted by the U.S. Department of Agriculture, this "contributes to the disintegration of rural communities and localised marketing systems."

Controlled-environment Agriculture

As a solution, an increasing number of horticulturalists and entrepreneurs are turning to controlled-environment agriculture (CEA), and the related practice of vertical farming. While not a total panacea, these high-tech farms are doing much to address many of the problems associated with conventional farming practices.

One company that's leveraging the power of CEA is IGES Canada Ltd. Headed by President and Executive Director Michel Alarcon, IGES is working to own and operate a number of CEA facilities in both populated and remote communities. The company's overriding mandate is to rebuild resilient communities and dramatically reduce CO2 emissions.

As Alarcon explained to io9, environmentally-controlled farms like the one implemented by IGES have a number of inherent advantages. Compared to conventional farms (and depending on the exact configuration and technologies used), they're around 100 times more efficient in terms of their usage of space, 70-90% less reliant on water, with a lower CO2 footprint. Foods are grown without the use of pesticides, they're nutrient-rich, and free from chemical contaminants. And because they can be built virtually anywhere, CEAs can serve communities where certain foods aren't normally grown.

Alarcon plans to introduce his company's technology to northern regions of Canada, where they would serve aboriginal populations. Conceivably, such facilities could be installed in any number of extreme environments, including the desert or in regions stricken by drought.

These facilities, which are used by IGES to produce broad leaf products like micro-greens, herbs, and soft fruit, can produce 912 metric tons per year in a 10,000 square meter space. And that's via horizontal farming, IGES's preferred method of CEA. With increased roll-out of these facilities, the company can supplant foreign food imports during winter months.

"The savings from a reduction in transportation costs will enable the price of our food to be less than organic food prices," says Alceron.

(Credit: Goldlocki/Hochgeladen von Rasbak/CC BY-SA 3.0)

Operations like the ones visualized by IGES Canada likely will have a profound impact on local communities. CEAs will make certain foods available year-round, providing a variety of healthy food sources, while creating local employment and promoting cultural preservation.

IGES Canada will soon be initiating a crowd financing campaign, while expanding its equity financing partner base.

(Credit: Goldlocki/Hochgeladen von Rasbak/CC BY-SA 3.0)

Startup costs for ventures like these can be intense. A few years ago in Vancouver, a company sought to install a massive greenhouse for vertical lettuce production on top of a city-owned parking structure, but failed. Some of it had to do with investors and contracts with the city, but it was also hampered by high startup costs relative to the resulting crop yields. As Foodshare Senior Coordinator Katie German explained to io9, many of the farms are also set up to grow food for restaurants -- growing for high price points -- and are not necessarily concerned about making food more accessible (which the high startup costs requires). Currently, the Vancouver company is trying to sell their failed $US1.5 ($2) million greenhouse on craigslist.

AeroFarms is currently building the world’s largest vertical farm in Newark, NJ. (Credit: AeroFarms)

At the same time, there have been a number of successful implementations, including Green Sense Farms in Portage, Indiana. They're currently leasing a 30,000-square-foot warehouse in an industrial park which can serve a five-state Midwestern region. According to its CEO, Robert Colangelo, "By growing crops vertically, we are able to achieve a higher yield, with a smaller footprint."

Other successful examples include plant factories set up by the Mirai Group, and the Zero Carbon Food's operation in which a WWII bomb shelter was converted into a high-tech underground farm.

"The whole system runs automatically, with an environmental computer controlling the lighting, temperature, nutrients and air flow," noted Steven Dring, co-founder of the company, in a Bloomberg article.

Tools of the Trade

Environmentally-controlled farming is more than just a glorified form of hydroponics. These facilities employ a number of sophisticated techniques and technologies to produce nutritious and tasty foods at reasonably high yields.

Polarised Water

One critical component of the IGES model is the use of polarised water, which enables water to hold on to a greater amount of nutrients.

"The injection of energy in water modifies the bond angle of hydrogen and oxygen atoms and makes the molecular structure more attractive to nutrients, and therefore carry a higher amount of these nutrient to root and plant leaf surface and increasing growth rate," explained Alarcon.

This process also increases redox effect (oxidation) and elimination of bacterial and microbial pathogens.

CO2 Injection

Carbon dioxide (CO2) is an essential component of photosynthesis, a process also called carbon assimilation.

Photosynthesis is a chemical process that uses light energy to convert CO2 and water into sugars in green plants. These sugars are then used for growth within the plant, through respiration. The difference between the rate of photosynthesis and the rate of respiration is the basis for dry-matter accumulation, i.e. growth, in the plant.

"In greenhouse production the aim of all growers is to increase dry-matter content and economically optimise crop yield," Alarcon told io9. "CO2 increases productivity through improved plant growth and vigour."

For the majority of greenhouse crops, net photosynthesis increases as CO2 levels increase from 340 -- 1,000 ppm (parts per million). According to Alarcon, most crops show that for any given level of photosynthetically active radiation (PAR), increasing the CO2 level to 1,000 ppm will increase the photosynthesis by about 50% over ambient CO2 levels.

Ambient CO2 level in outside air is about 340 ppm by volume. All plants grow well at this level, but as CO2 levels are raised by 1,000 ppm, photosynthesis increases proportionately, resulting in more sugars and carbohydrates available for plant growth.

And CEAs provide an excellent venue for our excess CO2.

Microalgae Photobireactor

These bioreactors employ a light source and photosynthesis to cultivate phototrophic microorganisms (those that use energy from light to fuel metabolism), including plants, mosses, microalgae, cyanobacteria, and purple bacteria.

(Credit IGV Biotech/CC BY-SA 3.0)

It typically allows for much higher growth rates and purity levels than in natural habitats. Photobioreactors transform CO2 into highly nutritious plant food which is readily absorbed by plants.

Climate Control

The internal environment of CEAs must be carefully maintained, including steady temperature, humidity, and isolation from external air. Climate control minimizes plant environmental stress and exposure to harmful pests.

Lighting

Similarly, optimal multi-spectrum lighting and light exposure can be applied year-round, regardless of season and natural light availability. Recently, LED grow lights have evolved to offer multi spectrum lighting range, thus enabling a broader range of plant varieties to thrive in this environment.

Scalability

These facilities are also highly scalable. IGES Canada's operations are scalable from a 1/4 acre (250m2) operation to multiples of 3 acres (10,000m2) facilities.

Tempering Expectations

According to Timothy Hughes, an organic horticulture specialist working in Toronto, the potential social benefits to enviro-controlled farming are enormous.

"Local, dense food production spaces would provide permanent green-sector employment, as well as an excellent educational model -- providing a wider knowledge base for students and employees alike," Hughes told io9. "From one farm, you could produce vegetables, fruit, honey, fish, and textiles, for example. And by expanding the variety of crops produced, you're ensuring overall success through diversity."

At the same time, however, Hughes says that environmentally-controlled farming may be technologically flashy, but it's not as efficient as it's being touted. He points to high building maintenance and energy costs, along with ongoing technological investments.

"In terms of plant life, these systems are often reliant on technology, such as powering the hydroponics," he says. "This could be a bad thing for struggling or remote communities when reliant on these types of technology -- we're only beginning to understand these kinds of vertical farms because they haven't been built beyond traditional greenhouses."

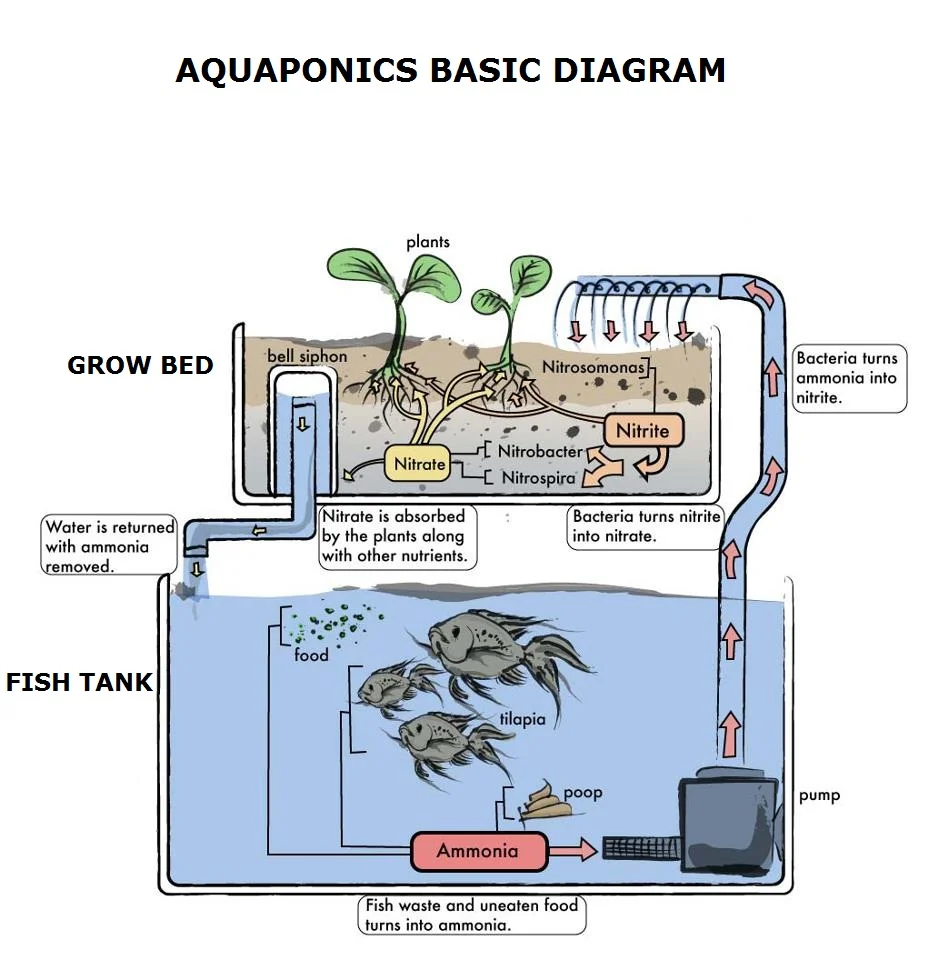

Hughes would rather see the money spent on labour and horticultural infrastructure innovations than on enormously expensive megastructures. He points to permaculture as a possible alternative -- aquaponics in particular. Aquaponics is a system of symbiotically growing hydroponic vegetables and fish. This delivers two high-value crops while sharing resources, reducing or totally eliminating waste, and increasing energy efficiency during production.

(Credit: Johnson State College)

"I believe this maintains a scientific approach, through taking a lesson from more traditional farming -- which we know works -- and augmenting it," says Hughes. "Current greenhouses are already quite technologically advanced and have a huge amount of research put into them in terms of light technology and environmental controls. Why not build upon what we already have?"

Currently, aquaponics is in use, but not widely. Hughes envisions growing this to a larger scale, in more urban spaces, with a greater and denser mass of growing space.

"Vertical farming systems have a lot to offer, but you can further increase productivity and value through increasing biodiversity, and by doing so furthering the benefit to local communities," he says. "Biodiversity is important to the survival of all organisms, but is especially beneficial when replicating or improving a healthy growing environment. By using an Integrated Pest Management system to monitor crops and greenhouse systems, other organisms (such as pollinating and beneficial insects) can thrive in a constructed ecosystem."

And then there's the issue of soil -- or lack thereof. According to Katie German, there has been some pushback from organic farmers about not having any soil, and farming is fundamentally about soil and biology.

"If you don't have soil fertility you might be going with synthetic fertility -- which has a whole myriad of implications in regards to how it was produced and where that might negate other ways of reducing pollution," says German. She points to the work of Elliot Coleman, a veteran organic farmer who says you can't have organic food without soil.

Lastly, German says many of us are guilty of failing to acknowledge the ongoing importance of farms.

"If we talk about urban food production innovation, but lose the conversation and struggle for farmland preservation, then we are doomed," she told io9. "I think sometimes these high-tech environmentally controlled farms are sexy, but we have to make soil sexy. The UN released this report that said if we really want to feed the whole world then we need to shift to small scale organic agriculture. Which isn't sexy like growing butter lettuce in a shipping container outside of your farm-to-table restaurant."

In response to these concerns, IGES Canada says that their offering, along with those of other CEA ventures, are a complement to traditional agriculture.

"The goal isn't to grow every crop using this method, just generally the leafy greens and soft fruits," explained Patrick Hanna, IGES's Director of Marketing and Promotional Campaigns. "Cities still require farmers to provide wheat, soy, potatoes, peppers, and so on. I am of the opinion our system compliments them."

Hanna points out that some 80% of the world's arable land is currently being used by farming. And with the expected population growth, we need to find solutions to this looming issue.

"On the topic of small scale organic production, I actually agree that is the future and we intend to use this system to augment that for small scale communities, in partnership with local farmers," adds Hanna. "We see the problems created by 'Big Ag' and have developed a system to mitigate a large segment of the problems created by that unsustainable, large scale, decentralized model."

Sources:leafcertified.org|USDA

5 Ways Vertical Farms Are Changing the Way We Grow Food

No soil? No problem. Vertical farms are sprouting around the world.

No soil? No problem. From Japan to Jackson, Wyoming, plucking fresh lettuce is as easy as looking up. Vertical farms have been sprouting around the world, growing crops in places where traditional agriculture would have been impossible.

Vertical farms are multiple stories, often have a hydroponic system and some contain artificial lights to mimic the sun. These green hubs are attractive in a variety of ways since food can be produced with less water (since it just recirculates), creates less waste and takes up less space than traditional farming, ultimately leaving a smaller footprint on the environment.

Additionally, the United Nations projects that the world's population will reach 9.6 billion people by 2050, 86 percent of whom will live in cities. For swelling cities, these urban farms give city dwellers greater access to fresh, nutritious food-year round, reducing the distance it has to travel to get to forks. Here are five more reaons why the sky's the limit with vertical farms.

1. Vertical farms can defy any weather: In perpetually wintry Jackson, Wyoming, residents will soon be able to find fresh tomatoes, lettuce and other produce that's not hauled in by delivery trucks. The Vertical Harvest farm is a three-story 13,500 square foot hydroponic greenhouse that will sit on a mere 30 by 150-foot plot adjacent to a parking lot. Utilizing both natural and artificial lighting (especially since the area is blanketed in snow most of the year), three stories of plant trays will revolve inside the building as well as the ceiling in a carousel-like system to maximize light exposure. The company aims to supply 100,000 pounds of year-round produce that's pesticide-free, and will use 90 percent less water than conventional farming because it recycles its water.

Construction of the $3.7 million greenhouse kicked off last November and has already pre sold crops to restaurants, grocery stores and a hospital. In the video below, E/Ye Design architects and Vertical Harvest co-founders Penny McBride and Nona Yehia talk about their innovative building and their mission to hire adults with developmental disabilities to spur local employment.

2. Vertical farms are a great response to climate change: Urban farming has been touted by many as a solution to increasingly extreme weather caused by warmer global temperatures. In very parched California, the Ouroboros Farms in Pescadero employs an unusual group of farmers: Catfish. The farm uses an "aquaponics" system, where 800 catfish swim and dine on organic feed, and as they create waste, the crops above suck up this nitrogen-rich fertilizer. All this means no soil, pesticides or other toxins are required for the stunning variety of vegetables that are produced at the farm, from spicy greens to root vegetables. In case you're wondering, nothing goes to waste; these fish are also sold as food. The farm also saves 90 percent less water than traditional farming.

"I honestly believe [aquaponics] is the evolution of farming," Ken Armstrong, the founder of Ouroboros Farms, said in the video below, "because of its ability to grow faster and more densely with fewer resources it will be the methodology of growing in the future."

3. Vertical farms adapt to disaster: We previously featured Japanese plant physiologist Shigeharu Shimamura, who converted an abandoned, semiconductor factory into the world’s biggest indoor farm, Mirai. Shimamura built the farm in 2011 in response to the food shortages caused by the Tohoku earthquake and tsunami that devastated Japan, and sparked the Fukushima nuclear disaster which irradiated much of the region's farmland.

At 25,000 square feet, the farm can yield up to 10,000 heads of lettuce a day. That’s 100 times more per square foot than traditional methods, and uses 99 percent less water usage than outdoor fields.

A press release said that the building is powered by special General Electric LEDs that “generate light in wavelengths adapted to plant growth. While reducing electric power consumption by 40 percent compared to fluorescent lighting, the facility has succeeded in increasing harvest yields by 50 percent,” and meant that Mirai was able to offset the cost of pricy LEDs. Watch how it all works:

4. Vertical farms are becoming more advanced: It's only the beginning for vertical farms in terms of technology. At the New Buffalo, Michigan branch of Green Spirit Farms, some plants grow under pink-tinted LED lights which "provide the correct blue and red wavelengths for photosynthesis," according to Harbor Country News. It's so efficient, the farm can currently grow 10 tons of lettuce in only 500 square feet of space. Green Spirit Farms president Milan Kluko also told New Scientist that he and his colleagues are developing a smartphone or tablet app that can adjust nutrient levels or soil pH balance, or sound an alarm when a water pump is malfunctioning, for example. "So if I'm over in London, where we're looking for a future vertical farm site to serve restaurants, I'll still be able to adjust the process in Michigan or Pennsylvania," he said.

Farm Manager Mike Kennedy making sure our fresh & local veggies (kale) are on the right time zone - they are now! pic.twitter.com/V4sNEzd6HR— Green Spirit Farms (@greenspiritfarm) March 8, 2015

5. Vertical farms are saving lives: Vertical farms are being used beyond food. In fact, they're being used to aid human health. Caliber Biotherapeutics in Bryan, Texas is home to the world's largest plant-made pharmaceutical facility. This 18-story, 150,000 square foot facility contains a staggering 2.2 million tobacco-like plants stacked 50-feet high, that will be used for making new drugs and vaccines. Because the indoor farm is so carefully monitored and tightly controlled by technicians, these expensive plants are shielded from possible diseases and contamination from the outside world.

Barry Holtz, the CEO of Caliber, told NPR that the facility is also efficient when it comes to water and electricity: "We've done some calculations, and we lose less water in one day than a KFC restaurant uses, because we recycle all of it."

Plants at Caliber Biotherapeutics grow in a "pink house" under blue and red LED lights. The tobacco-like plants will be used for making new drugs and vaccines. Photo Credit: Caliber Biotherapeutics