Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Agriculture must transform to feed a hotter, more crowded planet, UN says on World Food Day

To bolster food security in a changing climate, countries must address food and agriculture in their climate action plans – Secretary-General Ban Ki-moon - Agriculture must transform to feed a hotter, more crowded planet, UN says on World Food Day

Agriculture must transform to feed a hotter, more crowded planet, UN says on World Food Day

Geothermal energy is converted into electricity and used to heat the Gourmet Mokai glasshouse in New Zealand which grows tomatoes and peppers. UN Photo/Evan Schneider

16 October 2016 – To mark World Food Day 2016, the United Nations is highlighting the close links between climate change, sustainable agriculture, and food and nutrition security, with the message: “The climate is changing. Food and agriculture must, too.”

“As the global population expands, we will need to satisfy an increasing demand for food,” said Secretary-General Ban Ki-moon in his message commemorating the Day.

“Yet, around the world, record-breaking temperatures, rising sea levels and more frequent and severe droughts and floods caused by climate change are already affecting ecosystems, agriculture and society's ability to produce the food we need,” he added.

Mr. Ban pointed out that the most vulnerable people are world's poorest, 70 per cent of whom depend on subsistence farming, fishing or pastoralism for income and food.

“Without concerted action, millions more people could fall into poverty and hunger, threatening to reverse hard-won gains and placing in jeopardy our ability to achieve the Sustainable Development Goals (SDGs),” he emphasized.

To bolster food security in a changing climate, countries must address food and agriculture in their climate action plans – Secretary-General Ban Ki-moon

According to the UN chief, agriculture and food systems must become more resilient, productive, inclusive and sustainable.

“To bolster food security in a changing climate,” he continued “countries must address food and agriculture in their climate action plans and invest more in rural development.”

The Secretary-General explained that targeted investments in those sectors would build resilience and increase the incomes and productivity of small farmers – lifting millions from poverty. “They will help to reduce greenhouse-gas emissions and safeguard the health and well-being of ecosystems and all people who depend on them, underscored Mr. Ban.

Next month, the historic Paris Agreement on climate change will enter into force – providing a much-needed boost to global efforts to reduce global greenhouse-gas emissions, limit temperature rise and promote climate-compatible sustainable agriculture.

“On this World Food Day, I urge all Governments and their partners to take a holistic, collaborative and integrated approach to climate change, food security and equitable social and economic development,” stressed Mr. Ban.

“The well-being of this generation and those to come depends on the actions we take now. Only by working in partnership will we achieve a world of zero hunger and free from poverty, where all people can live in peace, prosperity and dignity,” he concluded.

Food security and nutrition top international agenda

Food is the most basic human right” said Food and Agricultural Organization (FAO) Director-General José Graziano da Silva at a dedicated special event Friday in Rome, “yet nearly 800 million people still suffer from hunger in the world.”

He noted that without food security and adequate nutrition for all, sustainable development simply could not be achieved, which is why the 2030 Agenda called for the eradication of hunger and all forms of malnutrition, as well as the promotion of sustainable agriculture.

“But these objectives are clearly at risk, as climate change advances,” he continued. “Droughts and floods are more frequent and intense. We have seen first-hand their terrible impacts in the past months, as El Niño hit Africa, Asia and other parts such as the Dry Corridor of Central America. We have also just witnessed the extensive damage caused by Hurricane Matthew in Haiti,” he added.

Echoing the Secretary-General, the top FAO official, natural disasters and extreme weather events are more likely to happen – and yet more difficult to predict, with the poorest suffering most.

“The vast majority of them are small holders and family farmers that live in rural areas of developing countries,” elaborated Mr. da Silva. “They are the least equipped to deal with the threats. Even under normal circumstances, these people barely manage to survive,” he added.

Mr. Griaziano da Silva revealed that FAO would propose to its Council Session next December the establishment of a new Department on Climate Change. He also shared news that FAO had been accredited to the Green Climate Fund.

“We cannot allow the impacts of climate change to overshadow our vision of a world free of hunger and malnutrition, where food and agriculture contribute to improving the living standards of all, especially the poorest,” he concluded. “No one can be left behind."

'Climate change is not waiting. Neither can we'

Speaking at the event, Italian Prime Minister Matteo Renzi linked the fight against hunger to politics. "Italy maintains that the fight for food security is, at this point in history, a question of politics with a capital 'P'," he said in an FAO COP22, said the talks would be "action-oriented" and geared towards implementing the Paris Agreement with a “special emphasis on adaptation, primarily for countries of the South and for small island States."

In a special message read out at the event, Pope Francis linked the impact of climate change to people migrating from rural areas of developing countries. "The most recent data tell us that the numbers of 'climate refugees' are growing, swelling the ranks of the excluded and forgotten, who are being marginalized from the great human family," the pontiff said.

For her part, Executive Director of the World Food Ertharin Cousin Programme (WFP) said that climate change was already stretching the international humanitarian system financially and operationally, “so moving beyond disaster relief to managing risk is an urgent task for all of us. Climate change is not waiting, neither can we."

UN Special Envoy on El Niño and Climate, Macharia Kamau, spoke about building stronger solidarity and better partnerships while Kanayo F. Nwanze, President of the International Fund for Agricultural Development (IFAD) stressed the need to bolster rural smallholder producers against the impacts of climate change.

Why Cities Are the Future for Farming

Self-described nerd farmer Caleb Harper wants you to join his league of high-tech growers

Urban Explorer

Opinion: Why Cities Are the Future for Farming

Self-described nerd farmer Caleb Harper wants you to join his league of high-tech growers.

National Geographic Emerging Explorer Caleb Harper holds lettuce grown at the MIT Media Lab, where he operates a climate-controlled “digital farm” using aeroponics, a network of sensors, and LED lighting.

By Caleb Harper

PUBLISHED October 14, 2016

The landscape of our food future appears bleak, if not apocalyptic.

Humanity’s impact on the environment has become undeniable and will continue to manifest itself in ways already familiar to us, except on a grander scale. In a warmer world, heavier floods, more intense droughts, and unpredictable, violent, and increasingly frequent storms could become a new normal.

Little wonder that the theme for this year's World Food Day, which happens on Sunday, is “Climate is changing. Food and agriculture must too.” The need for an agricultural sea change was also tackled at the recent South by South Lawn, President Obama’s festival of art, ideas, and action (inspired by the innovative drive of Austin’s SXSW), where I was honored to present.

As our global agricultural system buckles under its own weight, we’re losing our farmers and we’re not creating more. In the U.S. alone, only 2 percent of the population is involved in farming, with 60 percent of our farmers above the age of 58. We’re also experiencing a dramatic move away from rural areas, our traditional growing centers. The UN estimates that by 2050, 6.5 billion people will be living in cities, nearly double what it is today.

Those of us at the helm of agricultural innovation simply must tack into these winds of change—and I see the tremendous potential of the city as a sustainable solution. After all, the domestication of plants gave rise to the first human settlements—our original cities were literally rooted in agriculture. Since then, city life has parted ways with it entirely, as urbanites have become almost completely disconnected from their food sources. But the reintegration of farming into the city is beginning to close the circle. Urban farming could not only feed future generations, but also create appealing clean-tech jobs for the waves of new “immigrants” that cities across the world will see in coming years.

Food Computers: Are These Devices the Future of Agriculture?

Harper takes us on a tour of his lab, which he envisions could be adapted for individual home use, shipping container-size for cafeterias and restaurants, and warehouses of “food data centers” capable of industrial-scale production.

Detractors of urban farming often scramble to point out that the production potential of urban farms is so minimal as to be insignificant. From where I’m standing, this is a dangerously shortsighted perspective. There are two major roles for urban agriculture: yes, the actual production of food intended to feed large numbers, but also the cumulative social benefit of cultivating what we eat. While I anticipate that eventually high-tech urban farming will account for at least 30 to 40 percent of an individual’s diet, the invaluable “product” of human-centered endeavors like farm stands and school and urban gardens lies in weaving communities together and building a foundation for food education.

Of course, we can’t expect a community garden to have the same production capacity as a conventional, massive monoculture farm or—wait for it—a multitiered, digitally integrated vertical farm. That doesn’t mean the community garden has no true value; the amount of calories it yields shouldn’t be the sole metric of its worth.

Instead, we need a renewed appreciation of the myriad benefits of growing food in the city. They range from the healing effect on veterans tending to patches in community gardens, witnessing the transformation of their plants, to the physical benefits of getting a student outside in a school garden while seeing the lessons of the classroom come to life in a burgeoning vegetable.

During World War II, victory gardens were planted both in private residences and public parks to boost morale as much as food supply. That tradition continues in the work of modern pioneers like Ron Finley, the “gangsta gardener” of Los Angeles, who similarly empowers communities by planting beautiful, defiant gardens in abandoned lots, traffic medians, and along curbs, and Will Allen, the founder of a Milwaukee non-profit center for urban agriculture training—teaching people to grow food in neighborhoods that are essentially food deserts dominated by drive-thrus.

Harper inspects a developing chocolate bell pepper. His team creates specific conditions—he calls them climate recipes—to produce plants with unique qualities of color, size, texture, taste, and nutrient density. A pepper grown in his Massachusetts lab could have the features of one grown in, say, Central America.

At the same time, technological leaps in urban agriculture are attracting bright, science-minded youth in droves and paving the path for high-volume production in cities. We’re seeing vertical farms—controlled environment agriculture—get smarter and larger. These aren’t necessarily new methods, but we are reaching a point at which they are becoming more energy efficient and cost effective. At the most cutting edge are “agri-culturing” companies like Modern Meadow and Perfect Day, culturing meat from mammalian cells and fermenting milk from yeast, moving meat and dairy production into cities.

At the MIT Media Lab, where I run the Open Agriculture Initiative, we’re developing digital farming through what we call “the food computer.” Along with aeroponic technology, we use a network of sensors to monitor a plant’s water, nutrient, and carbon needs and deliver optimal light wavelengths—not just for photosynthesis but to change flavor. This allows us to recreate climates that yield, for example, the sweetest strawberries.

Our entire endeavor is open source. We’re now piloting it outside the lab in Boston schools, and we see a near future where farmers can build their own food computers, using instructional videos and schematics already available online, and larger-scale units for restaurants, cafeterias, and industrial production—all in the city. By bringing agriculture home, we’ll have access to fresher, more nutritious food and potentially reduce spoilage and waste.

Our ultimate #nerdfarmer goal is to develop a database of climate “recipes”— for example, the ingredients for mimicking the Mexican climate that produces those sweet strawberries. We hope to pair that database with assembly kits for “personal” food computers that will be increasingly accessible, with the goal of creating and networking a billion farmers by providing access to the tools and the data required to both grow their own food and generate even more data to share—a sort of global “climate democracy” to see us through a world in flux.

Yet even at our post at the high-tech end of the spectrum, we share a common goal with even the smallest, most traditional city garden—to serve our community by creating a new lexicon of food values for the future.

The Future of Vertical Farming In 5 Inspiring Examples

Recent studies show that the human population will reach 11 billion by 2100, putting strain on: farming, health, living conditions and sustainability.

October 12, 2016

Recent studies show that the human population will reach 11 billion by 2100, putting strain on: farming, health, living conditions and sustainability.

On 11 July 1987 there were five billion people on earth inspiring the UN Development Program to launch a special day in 1989 to highlight overpopulation.

Cities are now expanding, decreasing the countryside and farmland. This has led to innovative approaches such as vertical farming to deal with land shortage.

#1 Urban Crops: Belgian Company Specialising in Indoor Growing Systems

Photo Credit: Urban Crops

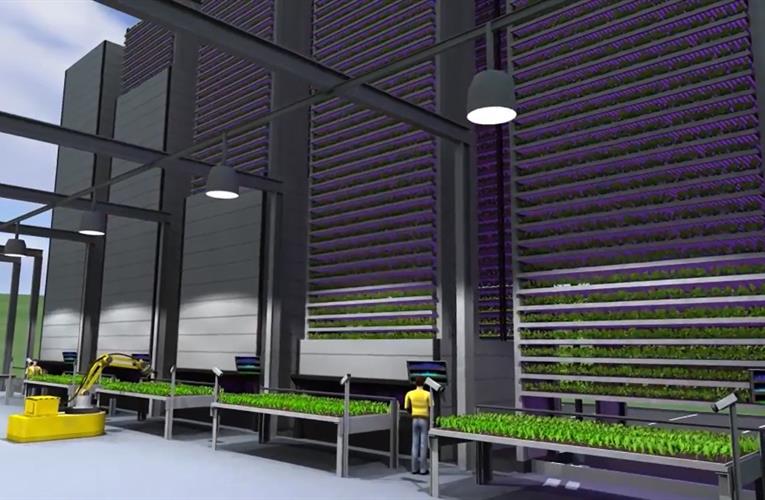

Inspired by the US and Asia’s growing investment in robotized plant factories with artificial lighting (PEAL), Belgian-based Urban Crops began creating a huge automated plant factory inside a climate chamber.

With 30 towers, a production of 126,000 crops per day is maintained. The crops use RFID technology in the crates where robots can pick the crates from a conveyor belt and understand in what state the crops are in, handling them accordingly.

They have three concepts: the large Plan Factory, Farm Flex and Farm Pro. The two latter examples are smaller in scale and focus on efficient food production, particularly in urban areas.

#2 Plantagon Agritechture and Sweco Architects

Plantagon Agritechture and Sweco Architects have a project called ‘World Food Building’ in Linköping, Sweden, which is a16 stories tall “plantscraper.”

Specialising in Urban Agriculture and Industrial Vertical Farming, Plantagon has developed a vertical space-efficient greenhouse for cities, delivering locally grown organic food directly to the consumer.

The company hopes to make headway in the Asian market:

”Asia is the main market for our solutions. In a dense city environment access to land is extremely low and the price is extremely high. This is something that is especially true in Singapore, but also in other mega-cites around Asia.”

#3 Elon Musk Building Vertical Farms in Brooklyn, New York

Elon Musk and Tobia Peggs launched Square Roots, a vertical urban farm using shipping containers to invest in young farmers and sustainability.

The farms will include greens and herbs for young entrepreneurs to “get hands-on experience running a vertical farming business,” said Peggs.

Using technology from vertical farming startups Freight Farms and ZipGrow, Square Roots plans to use LED lights and water growth rather than soil.

#4 Aerofarms: World’s Largest Vertical Farm in Newark, New Jersey

Photo Credit: AeroFarms

Photo Credit: AeroFarms

The largest vertical farm is Aerofarms, a 14,164 square meter facility in Newark, New Jersey, run by Aerofarms. The farm has the potential to produce 2 million pounds of lettuce every year, without soil or natural sunlight.

By using LED lights, this ensures consistent growth in the 69,000 square foot warehouse.

In November Aerofarms will partner with Farmigo, the organic wholesaler to sell greens in grocery stores within New York.

#5 Sky Greens, Singapore

Photo Credit: Sky Greens

Sky Greens is a vertical farm three stories high in a greenhouse that produces five to 10 times more per unit area compared to normal farms. The greenhouse and low-carbon hydraulic system grows lettuces and cabbages year-round.

Their mission is to provide improved agricultural solutions with minimal impact on land, water and energy resources, help cities with food supply security and to promote low carbon footprint agriculture into urban living.

Do you think vertical farming is a long-term solution to land shortage, or is the rate of over-population putting strain on all types of farming?

Underground Farms and Lab Grown Meat: Can Science Feed Us If the Climate Fails?

What’s the world to do?

By Sami Grover

Published: October 11, 2016

From cutting usable coffee farming land in half by 2050 to crippling droughts becoming ever more commonplace, no discussion of global climate change is complete without warnings of impending doom, the collapse of civilization and an inevitable rise in the price of coffee.

Given that the world is almost certainly on course to blow through 1.5 degree global warming target agreed to at the Paris climate talks, we have good reason to worry. As rainfall patterns change, as droughts and extreme storms increase, and as growing regions shift, both small-scale and industrial farmers will find that the crops and growing methods they’ve relied on for years may no longer be effective under different growing conditions.

So what’s the world to do?

Already, many farmers are doing interesting and innovative work to adapt to the changing climate. Whether it’s breeding new, drought tolerant crops or using satellite technology to enhance precision irrigation, there’s a lot of potential for innovation within our existing food and farming infrastructure. Some innovations — like the use of cover crops and compost to add organic matter to the soil — may even help slow the march of climate change in the first place, sequestering significant amounts of carbon underground while improving soil fertility and water retention.

But innovating within the existing paradigm can only take us so far. Other farmers, scientists and entrepreneurs are looking at reinventing the farm entirely, using cutting edge technology to partially or even completely separate farming and food production from a reliance on an increasingly unstable climate.

Greens growing on floating beds in an experimental aquaponics farm in a project called The Plant in Chicagoon June 21, 2012. Urban farming is being taken to new heights in this abandoned Chicago pork processing plant where environmentalists hope to get off the grid using the waste from one crop to feed and power another.

Indoor farming, for example, was once thought of as the sole preserve of illegal grow rooms out West. Increasingly, however, urban growers are raising edible crops under artificial light, often using soilless hydroponic or aeroponic techniques.

Growing Underground, for example, is an underground farm located 33 meters below the streets of Clapham, London in an old, disused bomb shelter. Using LED lighting and hydroponics in a pesticide free environment, the start up offers salad greens and herbs to local restaurants and retailers. As the marketing copy on their website suggests, there are multiple climate benefits, including reduced vulnerability to unpredictable weather and the potential for cutting greenhouse gas emissions too:

“Thanks to a controlled environment, each tiny leaf tastes as amazing as the last. Our greens are unaffected by the weather and seasonal changes, and thanks to our prime location, we reduce the need to import crops and drastically reduce the food miles for retailers and consumers.”

Of course, growing salad greens indoors is one thing, but what about animal protein? Absent of the world turning vegan, there is likely to still be demand for meat and dairy for some time to come. And given that many modern-day “ethical” consumers are not keen on indoor factory farming conditions, one could envision a conflict between animal rights and climate resilience.

Futurists and animal rights activists have long heralded the dawn of lab grown or synthetic meat. In 2013, a team of Dutch scientists even unveiled a lab grown burger and invited a lucky few to taste it. There was only one problem: It cost $330,000 to produce. Prices are likely to come down, however, and the Washington Post recently reported that synthetic meat may be hitting the supermarket shelves within the next few years.

Lab-grown meat and underground farms are by no means the only ways we may feed ourselves in a changing climate. From aquaponics (a virtuous circle of fish farming and hydroponics) to climate resilient GMOs, we can expect to see new and innovative models emerging as our weather patterns shift.

As we usher in these new ways of growing, of course, we’ll need to keep an eye out for potential negative consequences too. Are GMOs safe? (It depends on who you ask.) Will lab grown meat be palatable to consumers? (Well, a lot of people eat at McDonalds now…) Won’t indoor farms be incredibly inefficient? (Innovation in LED lighting has greatly reduced the energy footprint of indoor growing. Thanks Colorado!) And perhaps most importantly, if rich countries can feed themselves with fancy new technology, how do we make sure that cash poor regions — whose populations have done least to contribute to climate change — are not left behind to starve.

None of these innovations reduce the need to fight global climate change in the first place. Still, given all the doom and gloom headlines about our impending societal collapse, it’s encouraging to see that new solutions are emerging. The farm of the future may look very different from the past. But at least we’ll still be able to eat.

Sami Grover is a writer, and creative director at The Change Creation, a brand creation agency that works with entities who make the world better, fairer or truer. Clients include Larry’s Beans, Burt's Bees, Canaan Fair Trade and Jada Pinkett Smith/Overbrook Entertainment.

The Age of Vertical Farming Is Officially Upon Us

Agricultural evolution as opposed to a revolution?

FARMING EVOLUTION

The world population is currently ballooning, and the problem is only expected to get worse as the decades go by. With the world population expected to be 11 billion by 2100, how are we going to feed more of these hungry mouths?

Part of the answer will definitely be changing the way we grow our food. And a new trend is expected to assist on that front—vertical farming.

Vertical farming doesn’t promise to radically change the way we farm, only make it more efficient, productive, and take up less space. An example is Urban Crops, a new startup that grows plants using a mixture of indoor farming techniques and hydroponics. Their facility is in Waregem, in eastern Belgium. Here, plants grow under a purple light delivered by LED lamps. The light is a mixture of blue and red lamps that seems to create the optimal conditions for growth.

Those plants are fed with a hydroponic system that delivers water laced with special minerals and nutrients.

The whole system can turn a 50 square meter space (540 square feet) into 500 square meters of usable farm space. Their 30 square meter (323 square feet) facility is able to produce 220 lettuce plants every day, using only 5% of the water needed in traditional farming.

GROWING TREND

But Urban Crops is not alone in this farming revolution. More and more companies are investing in facilities that try to do the same thing.

The biggest facility right now is a 14,164 square meter (3.5 acre) facility in Newark, New Jersey, run by Aerofarms. This facility can produce up to 2 million pounds of fresh, leafy greens a year, and is equivalent to 139,931 square meters (13,000 acres) of actual farmland.

A Swedish project wants to top even that. Plantagon Agritechture and Sweco Architects have revealed a project called the Plantagon World Food Building in Linköping, Sweden. That is a “plantscraper” 16 stories tall.

Meanwhile, Target has revealed a partnership with MIT to bring vertical farming techniques to stores. The partnership wants in-store vertical farms, that will make supermarket-bought produce fresher and, possibly, healthier.

Vertical Farmers Take Over In Belgium

“We are just trying to imitate nature. It’s not as futuristic as it might sound”

Vertical farmers take over in Belgium

posted October 10, 2016 at 10:45 pm by AFP

By Marine Laouchez

WAREGEM, Belgium―As cities expand, eating up swathes of countryside in the process, agricultural pioneers are finding new ways to grow the fresh produce we need, in containers, empty buildings and any other spare space they can find to create new vertical farms.

“We are just trying to imitate nature. It’s not as futuristic as it might sound,” insists a smiling Maarten Vandecruys, the youthful founder of Urban Crops, a new Belgian company specializing in indoor growing systems with the help of LED (light emitting diodes) lamps.

Behind him, in a spooky, futuristic purple halo of light, stand rows of shelves dedicated to horticulture. It is a closed environment with no natural light.

The purple glow is the result of red and blue lamps and is believed to provide the optimal growing conditions.

Vandecruys prides himself on the completely automated agro-system he has set up in Waregem, in eastern Belgium.

At the Urban Crops lab, a conveyor belt circulates containers of germinated plants which are placed in a special substrate, using no earth to reduce the risks of disease linked to animal-life and other external factors.

The containers are introduced to a closed room, the walls of which are lined with shelves.

Under the artificial light the plants develop in a controlled environment, fed through a hydroponic system―water laced with the ideal mix of mineral salts and essential nutrients.

No pesticides are required in this much more sterile environment and, as the LED lamps don’t heat up, they can be placed close to the plants, allowing for tight layers of plants.

Evolution not revolution

According to Vandecruys the future of vertical farming is to expand to an industrial scale.

“It’s just an evolution,” not an agro-industrial revolution, he says, a natural progression from fields to greenhouses, then from greenhouses to vertical farms.

With his system, a 50 square-meter space (540 square feet) can be transformed into 500 square meters of usable “land.” And the plants grow two to three times faster than outdoors, further increasing yields.

In the Urban Crops laboratory, up to 220 mature lettuce plants are produced each day in a 30-square-meter room using just five percent of the water required in traditional agriculture.

However for Samuel Colasse, a teacher and researcher at the Carah agronomic research center in Hainaut, eastern Belgium, the concept of urban farming is “currently not very convincing” in countries like France and Belgium where the distances between the fields and the towns “aren’t enormous.”

But in a highly urban environment like New York “there are projects which work pretty well,” he says.

And in hostile climatic conditions, or in some military or refugee camp situations such “somewhat futuristic” ideas could be envisioned, Colasse adds.

His own laboratory has produced everything from bananas to rhododendrons.

Endless uses

For Urban Crops the uses of its vertical farming technology are virtually boundless.

The company can foresee its products being used in pharmaceutical labs to produce plants with medicinal qualities, in supermarkets which could sell their own hyper-fresh produce―and at the same time cut out the transport costs―or in isolated communities in Scandinavia and elsewhere.

For now its clients have more modest ambitions.

A top restaurant, for example, wants to experiment with the flavor, texture, size and color of its ingredients through subtle changes to the light, temperature and nutrients during the growing process.

Urban Foods claims to have produced a type of salad rocket the taste of which “explodes” at the back of the throat.

And for the domestic oddesses, or gods, there are individual shelving and lighting set ups to grow-your-own herbs or cherry tomatoes.

Japan's 'agri-tech' Farming Revolution

Business analysts forecast the “agri-tech” market is primed for extensive growth internationally over the decades ahead.

By Allan Croft

TECHNOLOGY OCT. 10, 2016 - 06:41AM JST

TOKYO —

Japan’s high-tech agricultural businesses are to gather at the Agri World trade fair held in Tokyo this week (Oct 12-14) to showcase the industries next generation of technologies such as plant factories, robotic automation and IT systems, claimed as advancing the “fourth industrial revolution” into the sector.

Business analysts forecast the “agri-tech” market is primed for extensive growth internationally over the decades ahead. As global population is expected to reach 9 billion by 2050, food needs would require a doubling of agricultural production, state U.N. World Food Programme experts.

Offering technological solutions, “agri-tech” businesses are marketing a wide variety of products and services for meeting industry demands, to generally increase productivity, lower costs, use less resources such as energy, water and pesticides, and improve produce quality and availability.

There is also a strong demand for labor saving and assistive agricultural equipment driven by a different demographic trend, that of ageing agricultural farmers, whereby according to U.N. figures, in developed countries the average age is 60, and where in Japan it has risen to 67.

Overall Japan has a shrinking agricultural sector, demonstrated by government data showing the number of full-time farmers at 1.7 million in 2014, declining from 2.2 million a decade earlier. Workforce and skills shortages are compounded by the lack of young people becoming farmers. Also, due to the increasing rate of farmers retiring, the overall amount of uncultivated farmland within Japan has doubled over the past two decades, increasing to 420,000 hectares in 2015.

Japan’s reliance on food imports is a further factor of concern, currently estimated at 60%, prompting recent government targets for boosting domestic production to 55% by 2050. Agricultural production at present is valued at around 1 trillion yen of which the government aims to increase to 10 trillion yen by 2020, raising food self-sufficiency as a major agricultural policy.

Another government initiative is 4 billion yen budgeted over the year through March for promoting farming automation technology in order to raise crop yields and make-up for workforce deficits. Specifically, the financial subsidy supports the development of 20 robot types, such as devices which separate over-ripe fruits during harvesting, to enable large reductions in manual farm labor.

As physical activities bring more difficulties for a greater number of aging farmers, technological innovations to assist with and replace workers performing agricultural tasks is an urgent priority.

Japanese tech companies are heavily investing in agricultural technology as a big opportunity for profits in both domestic and global markets such as India and the APAC countries, attracting small scale start-ups to big corporations such as Mitsubishi, Fujitsu, and Panasonic, to name but a few.

There is also a trend for farmland in Japan to be cultivated by “business farmers” and “agribusiness,” at around 50% today, leading to 80% by 2025, according to government estimates.

As an indicator of growth potential in the “agri-tech” sector, the global market for agricultural robots is projected to reach $73.9 billion by 2024, up from $3 billion in 2015, predicted by Tractica, a market intelligence firm. Driverless tractors are trended to gain the highest revenue at $30.7 billion by 2024, with agricultural drones comprising the most amount of units shipped.

The applications of farming technologies are wide ranging and often interconnect. A typical farm scenario could involve a driverless tractor in a rice paddy field utilising a global positioning system, both synchronised to automate cultivation and fertilization after monitoring the soil conditions.

For work that is harder to be automated, wearable robotics put on like a backpack have been designed to assist harvesting and carrying produce, more so for elderly and female farmers.

As well as automating work, high-tech farming technologies provide accurate information which farmers can use to make decisions managing crops. For example, a combination of high resolution drone images, historical weather data from geo-satellites and sensors in the field would generate real-time alerts on mobile devices to inform farmers when to reduce a mandarin orchards water supply, so the trees absorb less water from the soil, therefore increasing sugar levels of the fruits.

The valuable experience and techniques of veteran farmers could also be more accessible to newer farmers via the web, such as learning resources about harvesting times with databases and photos.

Many news items about “agri-tech” businesses have featured in both the Japanese and international media, with reports of indoor “vertical farms” and automated greenhouses gaining the most coverage. There is often a focus on robotic automation, also the use of IT systems and sensors to measure and control growing processes, evidently enhancing work efficiencies, crop yields and produce quality.

For example, GRA Inc is a medium-size Japanese business with an automated indoor greenhouse facility producing strawberries, providing a reliable quality and increased supply all year round.

The company joins conventional farming expertise and technological innovation, employing local farmers as advisors and management, founded by a former IT administrator turned agriculturalist.

Based in Miyagi Prefecture, the business started a few months after the Tōhoku disaster. In an area famous for its strawberries, thousands of greenhouses were destroyed and damaged ensuing huge losses for farmers. The business has therefore helped to modernise and revitalise regional trade.

Such stories show the real potential for young tech-savvy farmers to work alongside older, more experienced farmers, toward overcoming the challenges confronting Japan’s agricultural industry.

Allan Croft is a freelance writer focusing on the latest science, tech and green news in Japan and Asia.

As Arable Land Disappears, Here Come The Vertical Farmers

As arable land disappears, here come the vertical farmers.

As arable land disappears, here come the vertical farmers

Waregem (Belgium) (AFP) - As cities expand, eating up swathes of countryside in the process, agricultural pioneers are finding new ways to grow the fresh produce we need, in containers, empty buildings and any other spare space they can find to create new vertical farms.

"We are just trying to imitate nature. It's not as futuristic as it might sound," insists a smiling Maarten Vandecruys, the youthful founder of Urban Crops, a new Belgian company specialising in indoor growing systems with the help of LED (light emitting diodes) lamps.

Behind him, in a spooky, futuristic purple halo of light, stand rows of shelves dedicated to horticulture. It is a closed environment with no natural light.

The purple glow is the result of red and blue lamps and is believed to provide the optimal growing conditions.

Vandecruys prides himself on the completely automated agro-system he has set up in Waregem, in eastern Belgium.

At the Urban Crops lab, a conveyor belt circulates containers of germinated plants which are placed in a special substrate, using no earth to reduce the risks of disease linked to animal-life and other external factors.

The containers are introduced to a closed room, the walls of which are lined with shelves.

Under the artificial light the plants develop in a controlled environment, fed through a hydroponic system -- water laced with the ideal mix of mineral salts and essential nutrients.

No pesticides are required in this much more sterile environment and, as the LED lamps don't heat up, they can be placed close to the plants, allowing for tight layers of vegetables.

- Evolution not revolution -

According to Vandecruys the future of vertical farming is to expand to an industrial scale.

"It's just an evolution," not an agro-industrial revolution, he says, a natural progression from fields to greenhouses, then from greenhouses to vertical farms.

With his system, a 50 square-metre space (540 square feet) can be transformed into 500 square metres of usable "land". And the plants grow two to three times faster than outdoors, further increasing yields.

In the Urban Crops laboratory, up to 220 mature lettuce plants are produced each day in a 30-square-metre room using just five percent of the water required in traditional agriculture.

However for Samuel Colasse, a teacher and researcher at the Carah agronomic research centre in Hainaut, eastern Belgium, the concept of urban farming is "currently not very convincing" in countries like France and Belgium where the distances between the fields and the towns "aren't enormous".

But in a highly urban environment like New York "there are projects which work pretty well," he says.

And in hostile climatic conditions, or in some military or refugee camp situations such "somewhat futuristic" ideas could be envisioned, Colasse adds.

His own laboratory has produced everything from bananas to rhododendrons.

For Urban Crops the uses of its vertical farming technology are virtually boundless.

The company can foresee its products being used in pharmaceutical labs to produce plants with medicinal qualities, in supermarkets which could sell their own hyper-fresh produce -- and at the same time cut out the transport costs -- or in isolated communities in Scandinavia and elsewhere.

For now its clients have more modest ambitions.

A top restaurant, for example, wants to experiment with the flavour, texture, size and colour of its ingredients through subtle changes to the light, temperature and nutrients during the growing process.

Urban Foods claims to have produced a type of salad rocket the taste of which "explodes" at the back of the throat.

And for the domestic goddesses, or gods, there are individual shelving and lighting set ups to grow-your-own herbs or cherry tomatoes.

Swedish furniture giant IKEA has already jumped vertically onto the home-farming bandwagon, launching its own range of assemble-yourself vegetable kits.

Singapore Can Play Key Role in Food Technology

Singapore can play a key role in food technology.

Singapore can play key role in food technology: Khaw

PUBLISHED OCT 7, 2016, 5:00 AM SGT

Singapore may have a small agriculture sector and has to import over 90 per cent of its food, but it can play a role in food security.

Making this point yesterday, Coordinating Minister for Infrastructure and Minister for Transport Khaw Boon Wan said Singapore is keen to share its technology and R&D with other Asean member states.

"Even though the agriculture sector is small in Singapore, we can contribute and play our part in food security," he said at the opening ceremony of the 38th Meeting of the Asean Ministers on Agriculture and Forestry (AMAF) yesterday at Marina Mandarin hotel.

"As an urbanised state, Singapore promotes the development of urban farming solutions and progressive farming technologies."

There is potential for the city-state to be a "living lab" for new food production technologies, Mr Khaw added.

Singapore, for instance, has been developing indoor vertical farms that can produce five times more leafy greens than conventional farming systems.

At the same time, the Agri-Food and Veterinary Authority of Singapore is collaborating with A*Star to study whether a novel food packaging material can extend the shelf life of chilled poultry meat.

The annual meeting is where representatives from Asean nations gather to discuss cooperation in food, agriculture and forestry. The last time Singapore chaired the meeting was in 2006.

Yesterday also marked the opening of the 16th meeting of the AMAF Plus Three (China, Japan and South Korea).

Professor Paul Teng, adjunct senior fellow in food security in the Centre for Non-Traditional Security Studies at the S. Rajaratnam School of International Studies, said Singapore can take the lead in using biotechnology to produce new crop varieties that are more weather- and pest-resilient.

And while vertical farming is good to have, it will contribute to only a small part of any country's food security, said Prof Teng.

He added: "Extensive crops like rice, soya beans and maize require large swathes of countryside."

In his speech, Mr Khaw highlighted anti-microbial resistance as an emerging concern which can significantly affect food security and safety as well as the food trade.

Anti-microbial resistance refers to micro-organisms, such as bacteria and fungus, that have become resistant to anti-microbial substances.

Asean ministers yesterday agreed to promote the prudent use of anti-microbials and enhance surveillance and research in this area.

The next AMAF will be held Thailand next year.

A version of this article appeared in the print edition of The Straits Times on October 07, 2016, with the headline 'Singapore can play key role in food technology: Khaw'. Print Edition | Subscribe

Jill Theriault and Laura Saueracker Want to Use New Technology to Grow Greens All-Year-Round

Imagine buying a bunch of kale or a basket of fresh, locally grown strawberries — in the dead of February!

Imagine buying a bunch of kale or a basket of fresh, locally grown strawberries — in the dead of February.

It sounds far-fetched, but it’s possible, thanks to new technology that allows farmers to grow plants in small, enclosed spaces with LED lights.

Jill Theriault and Laura Saueracker — two Edmonton-area grandmothers with a passion for farming — want to bring more of this new technology to Alberta and start their own company: Range Road Garden Farms.

“You go into the grocery store and see stickers from Mexico and Chile and you wonder... why aren’t we growing fresh vegetables here?” Saueracker said.

“We can fix this.”

The pair plan to buy an indoor farming system from ZipGrow Canada, the Canadian distributor for the Wyoming-based company, Bright Agrotech.

The “zip farm” would allow them to grow spinach, kale, lettuce and herbs on tall towers facing LED lights instead of the sun.

Plants are hung on the towers, where they receive nutrient-rich water via a wicking strip.

ZipFarms are unquestionably expensive. A beginner system costs $27,850, as well as an additional $6,200 for a plumbing package.

But compared to traditional farming, planting vertically has multiple benefits.

By eliminating soil, you get rid of bacteria and insects, which means you don’t need to spray your plants with pesticides.

The system uses less water than a traditional field would.

Growing locally means smaller shipping costs and reduced fossil-fuel consumption, which is better for the planet.

Perhaps the biggest advantage is larger yields, thanks to the ability to grow vertically.

“You can grow so much more in a smaller space,” Theriault said.

All in the family

Both women have farming in their family histories.

Saueracker grew up on a farm in Middle Musquodobit, N.S., where she helped her mother tend to a small greenhouse.

Theriault, who grew up mostly in Cold Lake, spent her summers on her mother’s farm in southern Alberta, which still exists today.

The women met through their husbands, who worked together for the Canadian Forces.

Since the ZipFarm units aren’t yet available in Alberta, they plan to start growing in a greenhouse located about five kilometres south of Miquelon Lake. Assuming they raise the $10,000 by Oct. 21 (as of Monday, they were about 25 per cent there), they’ll purchase the growing systems in November.

Farming for the future

If projects like these pan out, they could be used to help combat food insecurity, particularly in northern Canadian communities.

A new report from the non-profit alliance, Food Secure Canada, suggests that people in some remote, northern communities have to spend more than half of their incomes on healthy groceries. (FSC arrived at this statistic by asking residents in three northern Ontario communities to report their food costs.)

Eventually, Theriault and Saueracker hope they could take units north and teach people how to use them. Or work with big growers to work with niche markets.

For now, though, they’re focused on selling their greens to local restaurants and to the public at farmers’ markets.

“We’re still in the start-up phase,” Saueracker said.

Vertical Farming Takes Shape

Vertical farms evolve to end hunger.

Vertical farming takes shape

Vertical farms evolve to end hunger.

We can certainly do more to reduce food wastage in our supply chains. It is not just Bangladesh where a lot of the produce goes to waste due to inefficient marketing and distribution channels; it is estimated that about half of all perishables in countries like Indonesia, Vietnam, Cambodia and Thailand go to waste before they reach retail markets. According to the World Bank, as much as 25 percent to 33 percent of all food produced in the world is wasted, which is equivalent to 1 billion metric tons. So, while all the focus and hype around food security seems to revolve around greater productivity, why aren't policymakers concentrating more on preserving the food already produced, which is then allowed to go to waste? This issue has been on the cards for many years and unfortunately, we have not seen much in terms of concrete policy interventions to bring about qualitative change in policy that would help farmers get their produce to markets faster.

While the world debates on and on about food security, technology is lending a hand to turn things around. Urban, concrete structures are being transformed into farms. For instance, in Newark (New Jersey, USA), a 69,000ft former steel factory has been converted into the world's largest urban farm. Once completed, it will grow anywhere up to 2 million pounds of kale, arugula and romaine lettuce annually. Technology is driving this new nascent sector but the implications are obvious. Climate-induced changes threatening to alter the topography of Asian farmlands in the decades to come and weather becoming more and more erratic with more droughts, floods, typhoons, etc. it is time to think outside the box. If we are to end 'global hunger' (one of the UN's 17 Sustainable Development Goals) over the next 15 years, urban farming will have to take centre-stage along with food wastage to meet the hungry mouths of the future.

Japan, a tech-driven nation, has introduced the world's first indoor farm. The setting is a 25,000ft abandoned semiconductor factory in Miyagi province. The technology comes from an American company that uses tall towers of LED-light trays, which it is claimed, consumes 95 percent less water to grow green produce than it would ordinarily take (i.e. if they were grown traditionally in fields) because the company claims to use mist instead of water to grow plants. If the technology is as good as claimed, it can yield 75 times more crops without the use of pesticides. Media reports have stated that the indoor farm produces 10,000 heads of lettuce daily which makes this farm 100 times more efficient than a comparable traditional farm.

The question of vertical and/or indoor farming is no longer confined to the realm of science fiction but science fact. The benefits of vertical farming are already being reaped by Bangladesh farmers in certain areas. According to a report published by the Voice of America in February, 2015, “In Chandpur village in southwest Bangladesh, lush vines sprouting pumpkins and gourds cover the tin roofs of small homes. This bounty sprouts from an unlikely source: large plastic sacks on the ground and other containers. In the southwest of the country, most of the coastal belt suffers from salinity that renders the land useless. And it is in this setting that vertical gardening is taking root among hundreds of villagers with the use of plastic sacks, giant containers made of plastic sheets and bamboo, etc.” WorldFish Centre, a non-government organisation working with villagers believes that vertical gardens work in Bangladesh because we suffer from heavy monsoon that dilutes salt in soil. And from July to October, the soil is inundated with 1.5 metres of rain due to the heavy rains. The flushed soil is collected by villagers in the post-rainy season which is then put into containers to grow vegetables. While the above scenario illustrates what is possible in rural areas, can we ignore the urbanisation trends globally? In 2008, we were confronted with the news that more than half the world population was living in urban areas. Indeed, projections point to the fact that two out of every three people will be living in an urban setting by 2050, and 40 percent of the projected urban growth between now and then will take place in countries like China, India and Nigeria. Bangladesh too is experiencing rapid urbanisation with roughly a tenth of the population living in the capital city Dhaka.

Vertical farming, as we are seeing in more advanced economies, is making inroads into agriculture. The higher start-up costs because infrastructure has to be bought or leased and costs associated with training up of personnel and maintenance of infrastructure begs the question whether this can be successfully replicated in economies such as ours. But one should remember that as the technology matures, costs should come down. At the end of the day, it is all about boosting food production and with more and more people moving to the cities, every initiative to enhance urban food security becomes imperative to policymakers. New technology initiatives being undertaken elsewhere should be looked into by our policymakers and city planners to make the best use of available urban space for productive uses.

The writer is Assistant Editor, The Daily Star.

Ag Company Grown in Portage Has Global Aspirations

The founder of a Portage-based commercial farming operation believes his indoor farming methods can be a sustainable solution throughout the world

Ag Company Grown in Portage Has Global Aspiration

By Dan McGowan, Writer/Reporter

PORTAGE -

The founder of a Portage-based commercial farming operation believes his indoor farming methods can be a sustainable solution throughout the world. Chief Executive Officer Robert Colangelo says Green Sense Farms LLC's vertical farming model allows consumers to buy produce right where its grown, which can be in a building "virtually anywhere." The company's goal is to first build networks throughout the U.S., Canada, Scandinavia and China and then continue to spread globally. Plants, which are grown on racks that reach as high as 24 feet, are kept in constant growing conditions through lighting, watering and feeding processes Green Sense Farms says uses only a fraction of the resources of traditional farming techniques.

In an interview with Inside INdiana Business, Colangelo said "we are the modern, new farmer."

Colangelo is a third-generation Chicagoan but says he's happy to be a transplant in the Indiana agribusiness community, which has been very supportive of what he's trying to accomplish. He adds that northwest Indiana is an "iconic" location to have a business. "We're at the bottom of Lake Michigan on the Crossroads of America, Interstate-94 and 65, they tell me that we can reach 80 percent of the U.S. population in a day's drive from where we're located."

Colangelo tells Inside INdiana Business all future farms will be located "where large volumes of meals are sold," which includes grocery chain hubs, military bases, corporate campuses, schools or hospitals. "We put our farm here (in Porter County) originally, because we were close to the Midwest distribution center for Whole Foods in Munster," he said. "What we've learned is that close isn't good enough. You really want to be inside the distribution center." The Portage farm, Colangelo says, is the largest commercial, indoor vertical farm in the country.

The company's first farm in China opened in August and through a partnership with Ivy Tech Community College, Colangelo says ground will be broken soon on a new farm in South Bend, which will supply area universities, hospitals and grocery stores. He says 10 other spots are currently in the development pipeline.

Green Sense Farms says some characteristics of the markets it continues to scout include:

- large population centers

- high numbers of educated consumers who pay a premium for produce that is GMO-, pesticide- and herbicide-free

- produce travels a great distance

- growing seasons are short

- resources like land, clean water and clean air are limited

Colangelo says recently-loosened crowd-funding regulations have opened up his company to more potential investors. Indeed, Green Sense Farms has launched an online fundraising campaign, which has led to commitments totaling more than $200,000 in two weeks. You can connect to more about the crowdfunding efforts by clicking here.

Urban Produce To Hire Indoor Growers

Prospective growers will attend Urban Produce University in Irvine to prepare to work for prospective licensees in China, Canada, Mexico and Japan in 2017, according to a news release

By Mike Hornick October 03, 2016 | 1:44 pm EDT

Urban Produce, Irvine, Calif., plans to hire Controlled Environmental Agriculture indoor organic vertical growers to support its licensees as part of phase two of the company’s expansion program.

Prospective growers will attend Urban Produce University in Irvine to prepare to work for prospective licensees in China, Canada, Mexico and Japan in 2017, according to a news release.

Urban Produce, which launched in January 2015, holds patents in seven countries including the U.S. and Canada.

“As we move into the next phase of our business we look forward to building vertical growing units all over the world,” Ed Horton, President and CEO, said in the release.

With world population projected to increase 70% by 2050, Urban Produce’s plans for expansion aim to help combat global hunger and eradicate food deserts.

“Our goal of sustainability incorporates our atmospheric water generation and the use of solar-generated power in order to build anywhere,”

Certhon And Korean Lettuce Producer Sign Agreement

The Korean lettuce producer and Certhon, leading expert in designing and implementing complete greenhouse projects, signed an agreement to develop and realize a high-tech automated hydroponic greenhouse facility

Certhon and Korean lettuce producer sign agreement

30 September 2016

In the presence of Dutch Prime Minister Mark Rutte and Minister for Agriculture Martijn van Dam, a Korean lettuce producer and Certhon signed an agreement .This agreement was signed September 27th at the Netherlands-Korea Trade Dinner in Seoul during an economic mission in South Korea to confirm the collaboration between the companies.

The Korean lettuce producer and Certhon, leading expert in designing and implementing complete greenhouse projects, signed an agreement to develop and realize a high-tech automated hydroponic greenhouse facility of 1,4 ha. Moreover, there is a desire for the construction of a demonstration greenhouse of approx. 3000 m2 for hydroponic lettuce production, located in Gyeonggi-do (South Korea). Certhon will take the lead in the outline, design and realization of the project.

The companies signed the agreement during an economic mission in South Korea, led by prime minister Mark Rutte, accompanied by sixty Dutch companies of the top sectors Agri Food, Horticulture and Creative Industries to further strengthening the already close bonds between the Netherlands and South Korea.

The US Start-Up Helping Indoor Farming Become A Growth Industry

What makes indoor farming attractive is its resource-efficiency compared with conventional farming methods.

Not so long ago, in the basement of a building in Copenhagen’s trendy meatpacking district, you could find a hydroponic garden growing leafy greens - such as romaine lettuce, pea shoots, and parsley. Oh, and dill, lots of dill. (This is Denmark, after all.)

The project was called the Farm, and it was the brainchild of Space 10, a “future-living lab and exhibition space”. Its remit is to explore possible solutions to major global challenges in order to “create opportunities for a better and more sustainable way of living”. That includes the future of food – and indoor farming in particular.

Hence the Farm – which, in its own way, typifies a shift in thinking about farming methods. According to the UN’s Food and Agriculture Organization (FAO), the global population will hit nine billion by 2050. And to feed all those people, food production must increase by 60 to 70 percent by 2050. Little wonder, then, that seemingly radical ideas like indoor farming are being considered as possible solutions.

What makes indoor farming attractive is its resource-efficiency compared with conventional farming methods. In fact, according to Agrilyst, which creates “intelligent indoor farming platforms”, hydroponics requires about 10 times less land and 20 times less water than conventional farming.

The trouble is, indoor farming still gobbles up a lot of energy and resources – which is what makes Agrilyst’s indoor farm-management platform interesting. The US start-up claims it enables farmers to monitor and optimise plant performance, and use fewer resources and less energy in order to produce a greater yield. Another way of putting it is that Agrilyst’s platform helps farmers become more sustainable and profitable.

The platform tracks and analyses indoor farm data in one place – enabling farmers to monitor and maintain optimal plant performance, and therefore reduce operating expenses. In particular, farmers receive real-time analytics and data aggregated from hardware, such as crop sensors, as well as lab results and spreadsheets.

At the same time, Agrilyst uses the data aggregated on the platform, coupled with academic research and industry knowledge, to develop new solutions for optimising performance. Its aim is therefore to make indoor farming easier, greener, and more productive.

From an environmental perspective, the platform’s appeal is apparent: it uses data analytics and recommendations to help indoor farmers to reduce energy and resource use. The economic case is clear, too: by aggregating data from indoor farms around the world, Agrilyst provides growers with insight and intelligence to improve performance – in turn helping to increase yield and profits.

Critically, the social aspect stems directly from this: by increasing yield and quality, indoor farmers can provide their communities with better tasting, healthier, and safer produce, while contributing to the global need for increased food production.

Platforms such as Agrilyst’s seem to make it easier than ever for farmers to say hello to hydroponics. Indeed, if you’ll excuse the pun, indoor farming is fast becoming a growth industry. Experiments in indoor farming may be taking place in the basement of buildings in Copenhagen. But they won’t be underground for much longer.

This innovation is part of Sustainia100; a study of 100 leading sustainability solutions from around the world. The study is conducted annually by Scandinavian think-tank Sustainia that works to secure deployment of sustainable solutions in communities around the world. This year’s Sustainia100 study is freely available at www.sustainia.me – Discover more solutions at @sustainia and #100solutions

This Singapore Device Turns Your Home Into An Urban Farm

Creator Brian Ong hopes his device will help people grow and eat more fresh, wholesome food

This Singapore device turns your home into an urban farm

Creator Brian Ong hopes his device will help people grow and eat more fresh, wholesome food

26 Sep, 2016

The late founder of modern Singapore, Lee Kuan Yew, rolled out a plan in 1967 to transform the republic into a “garden city”; today, parks and gardens green spaces adorn the city’s urban landscape amidst the ever-growing high-rise developments.

Even in HDB flats, many Singaporeans are fond of keeping potted plants along the dreary-looking corridors.

But the problem with urban life is that time constraints create unhealthy gardening habits. So unless it’s cactus or a similarly resilient plant, many plants die from the neglect and lack of water.

Brian Ong, a Masters of Architecture graduate from the Singapore University of Technology (SUTD), has created a device that helps urban farmers/botanists automate plant care.

There is no team behind Hydra. Ong as a one-man inventor, and was spurred to embark on this project because of his own pain point.

“This project started off when I was in university. As my schedule got busier, my plants began to suffer as a result. As I could not find any suitable watering solutions for the indoor garden (the systems I came across on the market had various shortcomings), I decided to design one for myself,” says Ong, in an interview with e27.

Another factor was the growing trend of urban farming, In a nutshell, the concept revolves around urban dwellers growing high-quality produce within confined spaces, in a sustainable fashion.

“More people are striving to grow their own mini edible gardens to provide a small but steady stream of herbs and vegetables to their kitchen,” he says.

Ong took to taking apart and scrutinised the shortcomings of current indoor watering systems on the market.

“Some systems are difficult to install in existing indoor setups – for example, drip systems that require a connection to a tap,” he says.

“Other systems are not very discreet – for example, capillary action solutions (water channelling) that have one bottle per pot or gravity solutions that require the water source to be placed above the pots. Some systems also run on battery power, which is not good for everyday use,” adds Ong.

The solution

Thus, the findings came to one clear-cut conclusion – Hydra needs to be a simple plug and play device.

Hydra essentially acts as a hub and “is designed to be simple to install in any existing indoor/balcony garden setup and easy to maintain. It draws water from a bucket on the ground and distributes it to up to 10 plants via tubes once a day,” says Ong.

“Each output’s watering volume can also be adjusted independently of one another, so the needs of different plants can be catered to,” he adds.

For those who seek to build a mini indoor farm, Ong says it is also possible to water more than 10 plants if the pots are set up in a way that allows water to be drained from one pot to the next. Water can also be pumped up to a 2.25 metres height.

The user also can plug in multiple sources of water, so it’s possible to water plants for weeks without refilling the water source(s). And once the system has been properly rigged up, the user can start calibrating the sequence.

First, the current time and water dispensing time have to be set. Then comes dispensing volumes, which can be set in three different ways: visual dispensing (see a rough gauge of much will be dispensed), preset volumes, and volumetric dispensing (meaning specific user set volumes).

It’s not smart

One surprising thing about Hydra is that — despite the trend of IoT devices such as this — it is not smart.

Ong opted for the low-tech route because “a smart watering system would have incorporated soil moisture sensors in each pot, which would have increased costs and led to a whole bunch of wires running around the place.”

The goal, Ong emphasises, is to create a simple automated watering machine without bells and whistles.

Development

Hydra has been in development for close to 11 months. The initial funding for the prototype and samples for various parts amounted to around S$2,000 (US$1,470).

Ong is seeking to raise capital via Kickstarter. Currently, it has raised nearly half of its S$55,000 (US$40,400).

So if you would like to go on a long holiday without fretting about your plants withering away, Hydra might be a good fit for the home.

Just remember to cover the water source(s) or your home will be ground zero for a Zika mosquito breeding spot.

Indoor Farms: Where Venture Capital Doesn’t Always Make Sense

So where should startup indoor farms look for early stage funding?

This week I took part in NYC AgTech Week, a week-long event that attracted indoor agriculture enthusiasts from across the globe for a series of presentations, tours, and panel discussions. On Tuesday evening, indoor ag software startup Agrilyst hosted a panel discussion on funding for indoor farms and other agtech startups.

For an area of agtech that gets so much hype, if AgFunderNews click rates are anything to go by, we are always amazed at the relatively low volumes of funding that go into it. In 2015, indoor agriculture startups — encompassing physical indoor farms and any hardware or software products serving them — raised $77 million, and during the first half of this year that figure was just $21 million. That’s from a total $4.6 billion in agtech investment in 2015 and $1.8 billion in the first half of 2016.

Having said that, the subsector has captured some of agtech’s largest deals, and this week’s $30 million Series C from BrightFarms is no exception. BrightFarms says this is the largest equity funding round for a US indoor ag company. The largest deal on record was 2014’s $100 million investment from private equity behemoth KKR into Sundrop Farms, the Australian greenhouse project. New Jersey-based vertical farming group AeroFarms has also raised big money, with Goldman Sachs and Prudential contributing $40 million to a $70 million debt financing for a specific farm project last year and the company has raised more in equity funding for the business too.

These deals are so big because scaling an indoor farming business is no small feat. The time it takes to do so is a big question for venture capital firms and has kept many away, argued James Smits from Beta Bridge Capital, who was speaking on the panel. Venture capital investors typically want to hold investments for around five years, but scaling an indoor farming company could take at least that time.

Beta Bridge, which focuses on seed stage investments, is instead accessing the indoor ag market through software and invested in Agrilyst’s seed round earlier this year. Agrilyst is likely to behave a lot like any other SaaS platforms in Smits’ portfolio and very different from asset-heavy indoor farming businesses.

There are of course some VCs that have invested in indoor farming startups, and the main players all have VCs in their investor line-up. It’s particularly suitable at the growth stage, such as Catalyst Investors in BrightFarms’ latest round. In this case, BrightFarms has de-risked its business model with proven technology in existing facilities and long-term produce purchase agreements with grocery making it a very different proposition to investing in a startup indoor farm with little operating history.

So where should startup indoor farms look for early stage funding? If you look at the investor base of indoor farms so far, you’ll notice there’s actually a very broad range of investors available to the sector, including family offices and impact investors. They may have longer investment time horizons and missions than a typical VC, and so can stick with the business through the early stages and into growth.

Regional investors are another potential source of funding such as NYS Innovation Venture Capital Fund, a New York state-funded vehicle, which is looking closely at the agtech space. Speaking on the panel from the fund, Lindsay Freeman Avagliano said that the fund’s mission was to make a positive impact on communities in New York through funding local innovation. The relatively new fund, which has $100 million to deploy, will reserve follow-on funding for the majority of investments it makes, she told the audience.

Then there are other routes altogether, namely project financing and debt for specific initiatives like the Goldman Sachs deal. This funding can be longer term and support the construction of facilities and purchase of equipment — instead of providing equity funding for a startup’s general overheads.

Speaking to this on the panel was Angela Ferrante from SparkFund, which offers loans to businesses to purchase energy efficient tools for their businesses, and has loaned to indoor farms to purchase LED lighting. This is a novel way of getting access to the equipment you need without giving away equity.

There’s also the crowdfunding route, which is a great way to find mission-oriented individual investors, who are passionate about the space.

So while venture capital might not always make sense for indoor ag startups, there are other options for startups to consider.

By Louisa Burwood-Taylor

What do you think? Where do you think indoor farming startups should seek funding? Get in touch Media@AgFunderNews.com.

Vertical Farming Market worth 3.88 Billion USD by 2020, at a CAGR of 30.7%

Lighting functional device expected to lead the vertical farming market

Arshad Singh

Vertical Farming Corporate Communicator at MarketsandMarkets

Vertical Farming Market worth 3.88 Billion USD by 2020, at a CAGR of 30.7%

Sep 21, 2016

The factors which are driving the vertical farming market include need for high quality food with no use of pesticides, less dependency on the weather, increasing urban population, and need for year round production. The largest market in the functional device segment is lighting market owing to the high acceptance of LEDs to replace traditional lighting. LEDs have been developed which provide optimum electromagnetic spectrum for photosynthesis, consume less energy, and have minimal heat signatures which keeps the energy requirement for temperature maintenance at a minimum.

Download Free PDF Brochure @http://www.marketsandmarkets.com/pdfdownload.asp?id=221795343

The vertical farming market is estimated to reach USD 3.88 billion by 2020, at a CAGR of 30.7% between 2015 and 2020.

Lighting functional device expected to lead the vertical farming market

Lighting as a functional device, in terms of value, is expected to hold the largest share of the vertical farming market by 2020. The traditional lighting system is being replaced by LED lighting system which is more efficient, emits electromagnetic spectrum ideal for photosynthesis and generates low heat. The increased acceptance of LED lighting system by end users is driving the growth of this market.

Hydroponics as a growth mechanism segment dominates the vertical farming market

The market for hydroponics as a growth mechanism is expected to be the largest between 2015 and 2020. This is mainly because of the benefits associated with it such as quicker growth, faster harvest, higher yield, and low nutrient wastage as mineral nutrients are dissolved in water and are fed directly to a plant’s root system without any involvement of soil.

APAC expected to hold the largest market share and grow during the forecast period

The APAC vertical farming market is expected to hold the largest share by 2020 owing to major driving forces such as growth in urban population, less availability of cultivable land, government initiatives, and demand for food with low impact on environment, the vertical farming market is growing in this region.

Global Vertical Farming Market, by Functional Device

- Lighting

- Hydroponic Components

- Climate Control

- Sensors

Global Vertical Farming Market, by Growth Mechanism

- Aeroponics

- Hydroponics

- Others

This research report categorizes the global vertical farming market based on functional devices, growth mechanism, and regions. This report describes the drivers, restraints, opportunities, and challenges with respect to the vertical farming market. The Porter’s five forces analysis has been included in the report with a description of each of its forces and their respective impact on the vertical farming market.

Major players involved in the development of vertical farming market Aerofarms (U.S.), FarmedHere (U.S.) Koninklijke Philips N.V (The Netherlands), Illumitex Inc. (U.S.), Sky Greens (Singapore), and others.

Independence LED Lighting

LED Grow Light Plant Growth Time Lapse For Basil With Aquaponics.

Inside Look: Independence LED Lighting Creates Better Produce!

Next-Generation Food Supply! See this time-lapse video showing 30 days growth in the controlled environment under Independence LED lighting. The LED Grow lighting creates a heavier and leafier product, which in this case is basil.

To view state-of-the art Horticulture LED Lighting for advanced Agriculture learn more here: http://independenceled.com/led-grow-lights/

LED Grow Lights can dramatically change the economics of indoor framing for warehouse and greenhouse facilities. Independence LED Lighting is ideal for Horticulture LED Lighting that advanced Agriculture LED Lighting for Indoor Farming such as the production of cost-effective Indoor Vegetables at Grow Operations.

Since LED lighting for commercial farming is “green” and on the rise, we welcome content submission such as LED grow light videos, LED grow lights photographs, and LED grow light production case studies.

Submit LED horticulture and LED agriculture content here via: Contact GREENandSAVE

Buyers to Gain Product Consistency Thanks to Vertical Growing Solution

Work is beginning on a £2.5 million purpose-built facility at the institute in Invergowrie, which will be the first in the UK to house automated growth towers for vertical, indoor farming.

Achieving the optimum light environment to maximise growth and enhance plant quality and consistency is no longer the stuff of dreams. A new initiative from the James Hutton Institute, near Dundee and Intelligent Growth Solutions is set to make this a reality. Produce Business UK investigates

Work is beginning on a £2.5 million purpose-built facility at the institute in Invergowrie, which will be the first in the UK to house automated growth towers for vertical, indoor farming. The facility involves the creation of four towers, each nine metres tall. It will incorporate an automated system allowing trays to move up and down the tower, to provide access for maintenance, seeding and harvesting. What makes the system unique is the degree of control over the light environment that can be achieved.

Lighting gap

Intelligent Growth Solutions has been exploring this concept for several years. Founder and CEO Henry Aykroyd believes there is a gap in the market: lighting companies think about lights, researchers focus on plants, and growers are concerned about economics. All are separate but together they could provide a viable growing concept.

Aykroyd is convinced of the importance of vertical growing since it could avoid the need for pesticides, and takes up a relatively small area. By taking advantage of the decreasing cost of LEDs, and combining this with research expertise and integrated automation, Aykroyd felt he could change the way vertical growing was viewed.

A pilot scheme was set up in Scotland, near the world-famous plant research establishment, The James Hutton Institute. And following negotiations with the institute, planning permission was obtained for the project. A wide range of leafy plants will be grown using semi-hydroponic systems. Water consumption will be kept to a minimum and temperatures carefully regulated. Researchers from James Hutton will be closely involved at all stages, investigating growth patterns so as to identify optimum plant growth within the light spectrum.

Sensory development

Dr Robert Hancock of the institute explains. “What Intelligent Growth Solutions has done is to create a much better lighting system. This is possible due to major improvements in LED technology that have taken place. Up until now, growers have focused on areas of the light spectrum which drive photosynthesis.