Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Different Type of Agriculture to Bring Better Quality Vegetables to Your Table

Different Type of Agriculture to Bring Better Quality Vegetables to Your Table

October 17, 2017 | Bryce Mansfield

Local family growing vegetables without soil

DRAFFENVILLE, KY- Better quality vegetables grown without soil —One family wants to bring that to west Kentucky by using a different type of agriculture. It’s called aquaponics.

Aquaponics is a combination of hydroponics and aquaculture. Hydroponics is the process of growing plants without soil and aquaculture is the process of raising fish specifically to grow plants.

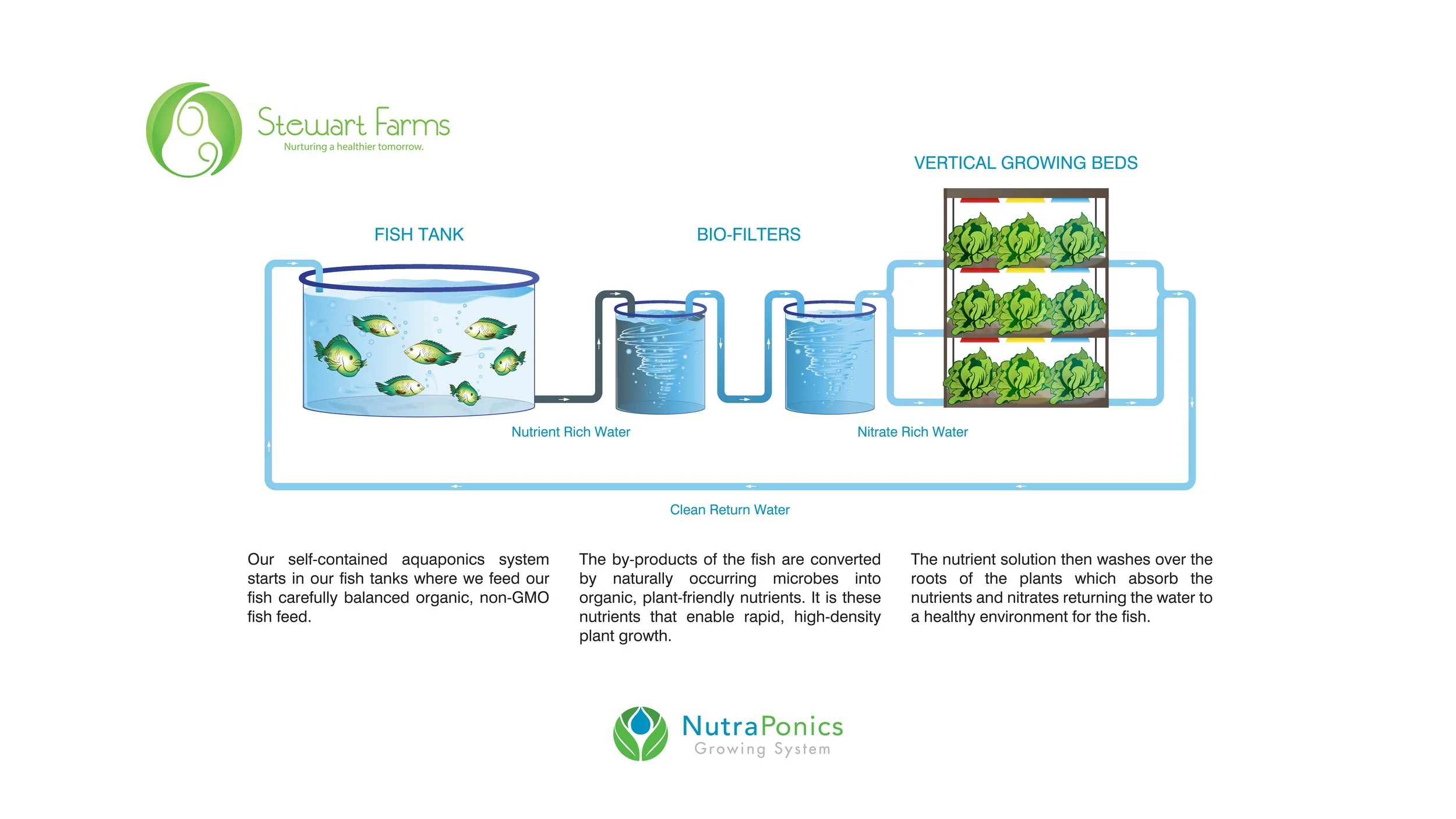

How does it work? Fish — tilapia most commonly — are raised in a holding tank. Bacteria is filtered from their waste, and the bacteria is used to fertilize different vegetable plants. The water is then filtered and recycled back into the fish tank, and the whole process repeats itself in a cycle.

This process is going to be fundamental to one local family, who will bring this type of agriculture to west Kentucky for the very first time.

Leaving nursing after 26 years to pursue a lifelong dream isn’t easy. For Tammie McCullough, it’s worth taking that leap.

“I was nervous about leaving the corporate world, but I’m fortunate I get this opportunity. I always wanted to own my own business and work for myself, and now it’s coming true,” McCullough said.

She and her husband turned this journey into a family adventure.

“My son had just graduated college. He wasn’t sure exactly what direction he wanted to go in life, and my dad is retired so he’s always looking for something to do. So, it was a perfect family fit,” McCullough said.

Her son, Tyler McKenty, said he looks forward to getting everything in place so they can get started.

“It makes me feel good, kind of a sense of purpose. Like I’m not just out there working to be working. I actually want to do this. I can go to work every day, happy. Knowing what I have to do and get it done,” McKenty.

For McCullough, this business adventure is a start she dreamed of years ago and she has a message for those who have dreams of their own.

“Follow your dreams. Don’t give up, and just take that leap of faith. It can be a reality,” McCullough said.

The family hopes to have the greenhouse up and running by the start of the new year.

For more information on west Kentucky Aquaponics, click here.

For more information on this story and others, follow Bryce Mansfield on Facebook by clicking here.

How To Invest In Leafy-Green Indoor Agriculture

How To Invest In Leafy-Green Indoor Agriculture

Editor’s Note: B. David Vosburg is CFO and SVP Strategy of Crop One Holdings, an indoor farming technology company and producer of high-quality leafy greens in the Boston, MA area of the US under the brand FreshBox Farms. Vosburg is a serial entrepreneur and has an MBA from Yale University.

The lettuce industry in the US is worth just under $6 billion per year. If it follows the tomato industry, 50% of leafy greens will be grown indoors by 2030, a $3 billion opportunity. This transformation is inevitable with the ongoing trend of higher efficiency LEDs.

Indoor farming in cities and suburbs is giving new meaning to the term “local.” These operations are producing crops which had previously been grown only in certain geographies, because of the constraints of available land, water, and weather. This industry is now able to grow anything year-round, anywhere in the world.

In our growing units, we have measured a 99% reduction in water usage, and a 90%+ reduction in land use, compared to Salinas Valley lettuce farms, and since most indoor operations grow locally without any pesticides/herbicides/fungicides and 30 day+ shelf lives, indoor farming is a difficult proposition not to believe in.

And investors are starting to put some big bucks behind it. Indoor farming startups growing fruits and vegetables globally have raised $285 million since the start of 2017, with particularly large rounds for US-based vertical farms pushing the sector to its highest ever investment levels, according to AgFunder data.

The question is, who will win this market in the end?

No doubt you’ve seen several indoor agriculture companies that claim to be the best at growing leafy greens (lettuces, herbs, etc.) indoors. For any number of reasons, they claim to be better than their peers who are also vying for your funding dollars. But how do you tell the difference between them?

Here are seven simple metrics that will tell you if the company is worth your investment dollars.

1. Capital Density (CAPEX/plant site)

Most companies will tell you they grow more capital efficiently than everyone else, but you have to do the math. Calculate the number of plant sites they have per square foot, and the CAPEX required (all-inclusive) to build/buy that square foot of grow space.

Things to look for include companies that grow in vertical channels: the encasement and spacing take up so much space, they’re not able to achieve anything close to market-leading densities. Think cubic feet, not square feet.

If then it appears that that company is growing produce for a fraction of their competition’s Capex per farm, you will know they have a better ability to scale and turn over capital faster. For example, if a company grows for 25% of their competition’s CAPEX/plant site – the farm location — they can scale to four times the size with the same capital and will turn over that capital four times as fast.

2. Form Factor

There are now many players in the space building indoor farms in various formats: Pond greenhouses, Aquaponics, Warehouse growers, and Modular growers; each with its own inherent set of risks, particularly around contamination.

Pond greenhouses grow with sunlight — and at times some LED augmentation — in one, large single pond. They are the most susceptible to contamination as all plants share the same room. From a build-out perspective, it can take over 2.5 years to build one farm!

Aquaponics growers do control for contamination. However, plants are provided nutrients from fish feces, which can lead to contamination. The water temperature at which fish live is in the upper 70s Fahrenheit, several degrees above what is ideal for lettuce, so these growers will be limited in what they can grow and the yields they can achieve.

Warehouse growers can mass produce plants because they can grow them at high density to be some of the most efficient indoor farmers. Contamination can be a risk here as well; if a pest gets into a warehouse, an entire building of produce could be lost or recalled, costing the company tens or hundreds of thousands of dollars. There are several examples of hydroponic warehouse growers that have lost entire operations to a single pest or pathogen.

Modular growers come in many flavors, from divided warehouses to shipping containers. These growers can find a balance between controlling for infestation while growing efficiently. They can also match warehouse growers for density. In whatever shape or size they come, this appears to be the preferred growing approach for indoor farming – assuming that density inside the modular unit can be achieved. However, watch out for modular growers that sub-divide their farms into too many rooms as this will increase labor costs.

Be aware of form factors and decide which style best suits your investment needs.

3. Energy Efficiency (g/KWH)

Energy can be one of the most expensive components, if not the most expensive, of a completely indoor growing operation. This is a large part of the input costs of a labor efficient, completely indoor, growing operation. The common unit of measurement is how many grams of product a company can grow with one KWH of energy input.

What to watch for: many US companies have access to state-level agricultural energy pricing which can be as low as $.015 per KWH. Make sure the company is not ‘efficient’ because they simply have a low energy rate. We’ve all suffered through the end of subsidies in other industries, especially clean-tech!

Identify the number of grams that can be grown on the farm in a given month, then divide this by the number of KWH consumed per month. If the number is south of 40 or 50 – half the peak scientists have achieved in R&D labs– do not proceed unless there is a very clear technology roadmap showing how the company will achieve higher numbers soon.

4. Automation

Hiring is another expensive cost for indoor growers and will only increase in many urban places where indoor agriculture is applied. Automation is, therefore, going to become a critical aspect of reducing costs to increase gross margins. Some of the questions to ask:

1. How many dollars are spent in labor to grow one pound of lettuce?

2. How many hours does it take one person to seed, transplant, harvest, pack, and clean per unit of production?

3. Does the company use automation, and do they own that technology?

4. What is the company doing to find experienced/appropriate labor?

5. Plant Science

Farms grow living organisms. This is not an industry that produces widgets, no matter what anyone tells you. An experienced plant scientist is critical to any successful indoor farm. Identify this person and understand their background, knowledge, experience, and ability to control mold/fungus/pests as well as grow indoors in controlled environment and leverage plant stressors for yield.

The right person will understand every lever that can be pulled to increase yield and reduce costs: light spectrum, humidity, CO2, various micro-nutrients, water oxygenation, micro-pulsing, shadow-less lighting, sunsetting/sunrising, photoperiod and much more. This can contribute to a 50%-75% increase in yield over the competition, something competitors cannot finance their way out of.

Look for companies building competitive advantages around the non-commoditized aspects of growing – lighting, HVAC, and automation have plenty of very clever people around the world focused on improving efficiency in their own industries.

6. Commercial Approach

Brand is King. Those who have the consumer’s mindshare will be the ones to take home the value. Currently, grocery stores in the US are white-labeling many leafy green products so they can switch suppliers at will and reduce retail costs while maintaining margins. The consumer and the grocery store benefit; lettuce growers do not.

If the consumer is unaware of the brand, the company is not worth financing and will never be able to have the leverage to negotiate the price necessary for a venture return — and possibly not even a profitable business.

Ask a company about its consumer-facing products or plans.

7. Speed of Evolution

How quickly can a company change technologies? LEDs, farm management practices, controls and different types of automation are developing exponentially, industry-wide. Can you responsibly invest in a company that takes over two years to build out infrastructure?

The number of lumens/watt an LED produces is projected to quadruple in the next fifteen years, an annual compounded efficiency improvement rate of 10%. This means investing in a two-year project today will result in having lighting technology that is 21% less efficient than new entrants.

Keep track of technological advances and ask companies how they’re planning to stay on top.

Data Analysis, Tech And Fish Waste Make Urban Farms Viable

Data Analysis, Tech And Fish Waste Make Urban Farms Viable

Brexit boosts business in ex-bomb shelter that controls plants’ every growth variable

Nothing lost: Kate Hofman, chief executive of GrowUp, surrounded by produce nurtured by fish waste

09-25-17 | by Jennifer Thompson

The rows of plants under pinkish lights, tended inside a Dutch warehouse by white-coated workers, bring to mind more a sci-fi film set than a farm. Indeed, the start-up behind the scheme, PlantLab, prefers to describe itself as a “development company” rather than an agricultural business.

Urban farming itself is not new — people have always grown produce or raised livestock in towns and cities, from necessity, as a hobby or to reduce food miles. Now, however, city agriculturalists are harnessing technologies such as light-emitting diode (LED) bulbs, 3D printers and data analysis to speed up growth and create farms virtually anywhere.

In London, in a former bomb shelter underneath Clapham Common, for example, Growing Underground cultivates leafy greens, such as watercress, rocket and coriander.

Built to shelter up to 8,000 people during the second world war, its tunnels now house rows of plants. “It was all [done using] standard agricultural equipment, save for LEDs,” says Steve Dring, co-founder of Growing Underground. LEDs provide the right level of light and heat in an energy efficient manner.

Affordability has proved a big factor for spurring innovation. PlantLab grew out of an older traditional horticultural company, growing greens and soft fruits under glass and greenhouses but was officially launched in 2010 as LED lighting became more affordable. Growing Underground also works on a fast turnround, with a series of ‘mini harvests’.

Tanks of tilapia fish at GrowUp's aquaponics project provide nutrients for plants © Charlie Bibby/FT

Seeds spend three days in a dark, warm and humid environment to fool them into thinking they are surrounded by soil. They then grow for six to 12 days under the light before being harvested for the capital’s restaurants and more recently the London food stores of Marks and Spencer.

A few miles from Clapham, Kate Hofman and her team at GrowUp are also revamping existing equipment and concepts for an ambitious aquaponics project.

Having taken a sabbatical from her career as a management consultant to undertake a masters degree in environmental technology and business, Ms Hofman and co-founder Tom Webster wanted to create an economically viable and environmentally friendly food production system.

Tilapia fish at GrowUp's aquaponics project are reared with a smart monitoring system © Charlie Bibby/FT

The concept of aquaponics, which combines raising fish with growing plants for a mutually beneficial exchange of nutrients, has been around for thousands of years. Technology, however, is bringing a new precision to the process.

GrowUp, established in 2013, operates from a warehouse in east London housing 12 tanks each holding 3,000 litres of water and up to 400 tilapia fish. The waste of the fish nurtures plants growing above — including kale, watercress, and basil — while the plants filter the water, and a smart monitoring system gives complete control over elements such as humidity and temperature.

The impetus from the start was to create something that could succeed as a business.

“We’ve focused on how do you take that technology and make it commercial,” says Ms Hofman. “We were both interested in how hydroponics could be used to grow food commercially. The reality is most of our food production across the world happens on an industrial scale.” GrowUp is currently looking for a location for a second farm, expected to have around ten times the capacity of the original site. This would allow them to begin supplying supermarkets. Ms Hofman says the prospect of Brexit following the UK’s vote last year to leave the EU, has increased interest in the concept of localising food production and technology-driven farming projects have made some inroads into supply chains.

“It was quite obvious there were mathematical patterns in plant growth.” ARD REIJTENBAGH, CHIEF PARTNERSHIP OFFICER AT PLANTLAB

Advances in data analysis are also making these kinds of farms more productive. “It was quite obvious there were mathematical patterns in plant growth,” says Ard Reijtenbagh, chief partnership officer at PlantLab.

Increasing interest in data collection prompted PlantLab’s founders to consider the optimum circumstances in which to grow plants.

They designed and supply so-called ‘plant production units’, as well as software and growing recipes, where growing conditions are tightly controlled: more than 80 potential variables, across the light spectrum, and including humidity and even the movement of air can be altered. The control is so thorough that they can determine the level of iron or zinc in plants.

The combination of technology and farming can also have other benefits.

Nerve Centre, an arts centre in Northern Ireland, runs a ‘digital farm’ project to teach students with learning difficulties entrepreneurship and digital skills.

Students construct aquaponics systems using laser cutters and 3D printers and supply the produce to restaurants. They have just taken delivery of 100 juvenile carp, which may fetch between £60 and £70 each once they are fully grown in two years. John Peto, the centre’s director of education, says: “Some [students] have no interest in growing food but they’re really interested in using computers.” He also expects the cultivation of fish to have a therapeutic effect.

Wisconsin Indoor Fish Farm Uses Water for Greenhouse

Wisconsin Indoor Fish Farm Uses Water for Greenhouse

Sept. 1, 2017, at 12:04 p.m.

Wisconsin Indoor Fish Farm Uses Water for Greenhouse

NORTHFIELD, Wis. (AP) — A new fish farm and greenhouse operation in western Wisconsin is promising to change the seafood industry with its indoor aqua-hydroponics system.

The Leader-Telegram reports that fish farm-greenhouse enterprise Superior Fresh in Northfield opened its indoor Atlantic salmon farm Thursday.

The 1-acre fish farm can produce up to 120,000 pounds (55 metric tons) of Atlantic salmon and 40,000 pounds (18 metric tons) of rainbow trout each year.

The nutrient-rich water that the fish create is transported to a nearby 123,000-square-foot greenhouse to help grow leafy greens. At full production, the farm is expected to grow about 2 million pounds (907 metric tons) of fresh greens annually.

The operation holds about 1.4 million gallons of water.

Company chief operating officer Brandon Gottsacker says the enterprise needed a nearly $20 million investment.

Information from: Leader-Telegram, http://www.leadertelegram.com/

Copyright 2017 The Associated Press. All rights reserved. This material may not be published, broadcast, rewritten or redistributed.

Surbana Jurong Unveils 'Floating Ponds' that Could See Farms In Parks, Rooftops

Surbana Jurong Unveils 'Floating Ponds' that Could See Farms In Parks, Rooftops

Fish farms could soon sprout at a park or rooftop near you, if Surbana Jurong's blueprint for a new vertical farming concept catches on.

04 Sep 2017 07:57PM (Updated: 04 Sep 2017 11:24PM)

SINGAPORE: Fish farms could soon sprout at a park or rooftop near you, if Surbana Jurong's blueprint for a new vertical farming concept catches on.

The infrastructure consultancy unveiled on Monday (Sep 4) its design for Floating Ponds - vertical farms that can be tucked into Singapore's urban spaces, such as rooftops and underneath viaducts, or be integrated into parks and buildings.

The system will allow farms to rear more fish while taking up less space than conventional farms, Surbana Jurong said.

A closed-loop farming system, the Floating Ponds tap solar energy to grow algae on rooftops. The algae is then used to feed the fish, and nutrient-rich water from the tanks can be used to grow vegetables. More than 90 per cent of the water in fish tanks is recycled, reducing the need to top up fresh water.

"You can build these facilities within the city. The logistic cost and the uncertainty of whether you will find a catch if you go to the ocean are therefore eliminated," said Surbana Jurong group CEO Wong Heang Fine.

A three-storey prototype was developed in partnership with Singapore fish farm Apollo Aquaculture Group. Since its implementation last year, the fish farm has seen its yields increase by more than three times.

"This is something we’re not (just) talking about, we’re really demonstrating it. And I think this puts us at an advantage."," said Apollo deputy CEO Lucky Phua.

The farm plans to double its capacity to six storeys, which could potentially lead to a yield of up to 5,000 tonnes of food fish annually.

Surbana Jurong said it is in discussions with government agencies to implement the new system in urban areas in the future. It also has plans to expand overseas, such as to India, China and Africa, Mr Wong said.

"A lot of these countries are looking at food resilience as an issue for them to resolve," said Mr Wong. "So this particular Floating Pond as an intensified way of doing farming - whether it’s vegetables or seafood - will come in very useful for them."

Source: CNA/am

Read more at http://www.channelnewsasia.com/news/singapore/surbana-jurong-unveils-floating-ponds-that-could-see-farms-in-9184138

Aquaponics Farmers Band Together to Set Their Industry Apart

Aquaponics Farmers Band Together to Set Their Industry Apart

Growers that add fish to their vegetable mix say they're combining the benefits of an ecosystem with the resource-efficiency of an water-based operation.

BY LELA NARGI | Agroecology, Climate, FARMING, Seafood

08.30.17

Kimberly Aney, a recent graduate of the agriculture program at SUNY Cobleskill in Upstate New York, has dreams of building a small farm that grows fish and lettuce in concert with one another. She says she sees the practice, known as aquaponics, as a cheap, clean, and compact alternative to the inefficiencies she observed on the dairy farm on which she grew up.

In southern Oregon, Michael Hasey extends the growing season of his 40-acre organic farm with an aquaponics system that produces greens and tilapia throughout the winter. It’s a way to squeak out an extra margin, rest his fields, and, he believes, improve both his own soil and the environment at large.

And, in New Orleans, Marianne Cufone uses her in-ground aquaponics system—in which ponds full of fish provide nutrients for the trays of herbs, cucumbers, and melons floating above them, and vice versa—partly as an educational tool. She wants more people to know about the myriad benefits she’s reaped while farming this way: about the hyper-local crops, the reliable fresh food in flood-prone regions, and the minimal waste inherent in the system.

Diagram courtesy of Aquaponics Phillipines. (Click image for a larger version.)

Unlike modern hydroponic farms, which can feed plants regular quantities of synthetic fertilizers, aquaponics harks back to early growing methods developed in Asia and South America that blend aquaculture (or fish farming) with agriculture. The practice functions in an ecosystem in which the fish eat things like duckweed and, when they’re housed outside, insects; their waste feeds the plants; and the plants filter the water for the fish. Any remaining waste is composted and, as in the case of Hasey’s farm, added back to the soil in which he grows his row crops.

Cufone also has a larger goal. What began as a community-based mission has expanded into a national effort as she seeks to drum up awareness about aquaponic farming in her role as executive director of the Recirculating Farms Coalition (RFC), and to mobilize other farmers using the technology to become more vocal about its virtues and its future.

First, though, she has to find them.

Marianne Cufone. (Photo by Dulce Fernandes)

“Even though [aquaponic farmers] have been operating in the U.S. for more than 30 years, we don’t have a good count,” Cufone says. That applies both to commercial operations such as Hasey’s that sell to regional supermarkets and also to backyard, or “recreational,” farms like the one Aney would like to set up. The latter are especially difficult to track. RFC wants to see aquaculture acknowledged as a positive addition to American agriculture and thereby boost its lobbying power. Haney, an RFC member, calls aquaponics, “the answer” to generating year-round income for farmers constrained by the seasons.

Cufone is currently working on a map of the larger outfits, and reaching out to organizations that keep track of the smaller ones. So far, estimates put the number of commercial aquafarms operating nationally at between 40 and 100, although Cufone says it’s likely higher if one includes backyard operations.

Cufone’s work comes at a critical juncture for American aquaculture. For over a decade, the USDA Organic label, through some third-party licensing organizations like Oregon Tilth, has been conferred upon compliant aquaponic and hydroponic farms. Recently, traditional “dirt first” organic farmers have been pushing the USDA’s National Organic Standards Board (NOSB) to make aquaponics and hydroponics ineligible for the Organic label.

Some opposed to the change, such as Maine farmer and author Eliot Coleman, say that food that isn’t grown in “biologically active, fertile soil” doesn’t deserve to use the moniker for which generations of farmers have built up a market.

One of the biggest targets of some dirt-first lobbyists is scaled-up operations that raise hydroponic produce in places like Mexico. They say these vast international operations siphon off revenue from American farmers as they drive down the price of organics. Aquaponic farmers, who claim to use best organic practices and challenge the assertion that their farms do not give back directly to the soil, may be caught in the crossfire of a bigger, thornier debate.

“Aquaponic farmers employ microbiology in their systems, in the same way dirt farmers do, and the waste [from it] builds beautiful topsoil,” says Hasey. In the process, “We grow copious amounts of food without taxing the land. It’s incredibly sustainable.” Sustainability is also Cufone’s virtue of choice when discussing aquaponics—both for lowering water and energy usage in produce growing as well as for raising fish. Cufone began her career in fisheries management and has seen aquaponics develop to the point where she thinks it now provides a viable, clean way for fishermen to grow some of the protein they can no longer catch in depleted oceans.

Stacy Tollefson is a professor of agricultural and biosystems engineering at the University of Arizona. Along with Cufone, she was part of the most recent task force advising NOSB on the organic certification of aquaponic and hydroponic farms. The way she sees it, what organics-seeking consumers want most of all is pesticide-free produce.

And water-based systems “open the doors to more people getting access to that,” she says. “The traditional agriculture approach says organics have to be grown in soil—but that was when there was no other way to do it. There are still old-school philosophical folks who say, ‘You’re not saving the soil!’ But I think we are doing a lot to not damage the earth.” (The dirt first response to this: That still doesn’t mean it fits the historical definition of organic; they’re contemplating changing their own labeling if hydroponic and aquaponic farmers continue to be able to earn “organic” status.)

Cufone agrees with Tollefson, and also cites what she sees as another overlooked benefit to aquaponics. “The U.S. Department of Agriculture is always talking about attracting new people to farming. Well, this is one part of the industry that’s growing,” she says. She hopes RFC will play a pivotal role in bringing aquaponics further into the mainstream. “When I first learned about recirculating systems, I brought a bunch of people together in a room and had a conversation about the viability of the industry. At the end of two days I asked, ‘If you had $1 million, what would you do?’ And every one of them said, ‘Start an organization that would advertise our industry, and help change policy about it.’”

In the six years since RFC was founded, Hasey has come to rely on it to represent him and his needs. “As a farmer, I spend all day with my head in the plants. I just don’t have time to go out and campaign and get involved in issues,” he says. Both he and Cufone hope the organization will provide their segment of the farm industry with the necessary traction to grow, and thrive.

Top photo courtesy of Recirculating Farms Coalition.

Israel Agritech Market Map: 400 Startups Putting The Tech in Agritech

There are now more than 400 Israel agritech startups working on innovations for the global agriculture sector, according to new research from Start-Up Nation Central, an Israeli NGO and Greensoil Investments, a local agritech venture capital firm.

Israel Agritech Market Map: 400 Startups Putting The Tech in Agritech

AUGUST 10, 2017 LOUISA BURWOOD-TAYLOR

For a young nation built on the collectivist agricultural ethos of the Kibbutz movement, it’s perhaps no surprise that Israel’s agricultural technology startup ecosystem is booming.

There are now more than 400 Israel agritech startups working on innovations for the global agriculture sector, according to new research from Start-Up Nation Central, an Israeli NGO and Greensoil Investments, a local agritech venture capital firm.

These agritech startups are innovating across a range of challenges such as drought and water efficiency, as well as crop productivity and waste.

While Israel’s agritech funding footprint might look relatively small compared to other leading markets such as the US — according to AgFunder, Israeli agritech startups raised just 2% of funding dollars in 2016 ($51.7m), accounting for 3.3% of deal-flow (19 deals) in 2016, while US startups raised 58% of funding dollars and 48% of deal-flow — this is still impressive with a population of 8.5 million next to the US’s 323 million.

Israel is undoubtedly an innovation hub, and there are many serial entrepreneurs moving into agritech bringing experience, tech, methodologies, and connections from other sectors into the agritech vertical.

Companies like ATP Labs and Agritask were founded by people moving from military data analytics and sensor technology, respectively, into the peaceful and impactful area of agritech.

Israeli agritech is also growing in terms of incoming investments. Since the beginning of 2017, there have been many large investments such as Prospera’s $15 million Series B financing, Taranis’ $7.5 million Series A, a strategic $15 million investment in Hinoman, and others.

Currently, Start-Up Nation’s online, searchable startup database includes more than 5,500 profiles of active, innovative startups across all tech verticals, including agritech.

Along with Greensoil Investments, Start-Up Nation Central has used the Start-Up Nation Finder platform to build a taxonomy that identifies different sub categories in agritech. This has been visualized in an Israeli agritech market map along with a representative, and non-exhaustive, selection of companies in each category.

Here is a description of each category according to Start-Up Nation and Greensoil, and some company examples.

• Biotech – Typically involves breeding of plants and bacteria with improved traits to help plant growth. Some companies use genetic technologies for that. These include companies such as Groundwork BioAg, Rootility, and Kaiima.

• Smart farming – Data-based technologies making use of big data and predictive analytics to help farmers make better decisions on daily farm issues (irrigation, pest management, risk management, etc). Some of the more known companies are Taranis, Phythech, Cropx, and Prospera

• Crop protection – Biological or chemical substances used for protecting the crops from pests & diseases, nontoxic and environmentally friendly. Companies like Biofeed which lures insects away or EdenShield.

• Machinery and Robotics – Companies that build all kinds of robotics, machinery, and equipment used primarily to automate farm work, harvest crops and to sort it. Metomotion is one example with a robotic system developed for greenhouses.

• Irrigation & water management – Israel is well known for water innovation, but there are new companies that are creating innovative irrigation methods and water efficiency, such as Neotop which covers water reservoirs and Emefcy which created an Energy-efficient Wastewater Treatment.

• Post-harvest – Technologies to reduce post-harvest losses in diverse ways (e.g. storage, packaging, treatments and climate management technologies). An example for these companies can be found in Amaizz which deals with drying produce or Valentis Nanotech, which produces polymeric films for coating.

• Farm to consumer – Companies that leverage new business models to shorten and simplify the supply chain by connecting the farm to the end consumer. Usually done through digital platforms. A good example would be Avenews-GT, which builds a digital trading platform connecting food wholesalers with producers.

• Novel farming systems – Innovative systems for growing plants, new types of greenhouses, urban farming, hydroponics, and aquaponics. It could be small scale growing in the case of Flux or lighting solutions for farmers such as FloraFotonica.

• Livestock – Companies that create technology for farm animals and pets. With mass vaccination companies such as adst Technologies and Eggxyt’s pre-hatch sex detection for chicks

• Waste technologies – Processing livestock manure, fertilizer run-off, harvest, and food waste to reduce harmful substances and reuse the materials. Companies like 3PLW and HomeBiogas which convert organic waste to bioplastic and cooking gas, respectively.

• Special crops – Companies which deal with medicinal plants from growing human tissue repair plants, such as Collplant to cannabis-based products, in the case of Corsica Innovations

• Aquaculture – These are companies that develop technologies to grow things in water – algae (e.g., Algalo), fish or sea food (e.g., BioFishency)

“The Israel agritech market map displays the wide variety of Israeli agritech innovation and the growth of this sector”, says Eitan Elkin, Start-Up Nation Central’s director of marketing, “The number of companies behind it and the fact that most of them were founded in recent years really brings to attention of the boom which this industry enjoys in Israel and the appeal it has to many entrepreneurs.”

Click here to download your own free copy of the Israel Agritech market map.

About Start-Up Nation Central

Start-Up Nation Central is an independent, nonprofit and nonrevenue organization committed to leveraging deep knowledge of the Israeli innovation ecosystem to connect business, government, and NGO leaders from around the world to people and technologies in Israel to help them solve their most pressing challenges while creating value for the Israeli innovation ecosystem.

Start-Up Nation Central has curated the largest and most up-to-date collection of Israeli innovators and entrepreneurs, providing critical information on over 6,000 companies across dozens of industries. To search Start-up Nation’s Finder, click here.

About Greensoil Investments

With offices in Raanana and Toronto, and $100m under management, GreenSoil Investments funds companies in the agro & food technologies and building innovation sectors. Founded in 2011, GreenSoil’s agro & food technologies fund has a portfolio of six promising companies and is the largest dedicated fund in this space in Israel.

Urban Aquaponic Farmer and Chef Redefines Local Food in Orange County, CA

Urban Aquaponic Farmer and Chef Redefines Local Food in Orange County, CA

Heads of lettuce gain their sustenance through aquaponics channels at Future Foods Farms in Brea. Photo courtesy Barbie Wheatley/Future Foods Farms.

In a county named for its former abundance of orange groves, chef and farmer Adam Navidi is on the forefront of redefining local food and agriculture through his restaurant, farm, and catering business.

Navidi is executive chef of Oceans & Earth restaurant in Yorba Linda, runs Chef Adam Navidi Catering and operates Future Foods Farms in Brea, an organic aquaponic farm that comprises 25 acres and several greenhouses.

Navidi’s road to farming was shaped by one of his mentors, the late legendary chef Jean-Louis Palladin.

“Palladin said chefs would be known for their relationships with farmers,” Navidi says.

He still remembers his teacher’s words, and now as a farmer himself, supplies produce and other ingredients to a variety of clients as well as his restaurant and catering company.

Navidi’s journey toward aquaponics began when he was at the pinnacle of his catering business, serving multi-course meals to discerning diners in Orange County. Their high standards for food matched his own.

“My clients wanted the best produce they could get,” he says. “They didn’t want lettuce that came in a box.”

So after experimenting with growing lettuce in his backyard, he ventured into hydroponics. Later, he learned of aquaponics. Now, aquaponics is one of the primary ways Navidi grows food. As part of this system he raises Tilapia, which is served at his restaurant and by his catering enterprise.

Just like aquaponics helps farmers in cold-weather climes grow their produce year-round, the reverse is true for growers in arid, hot and drought-prone southern California.

“Nobody grows lettuce in the summer when it’s 110 degrees,” Navidi says.

But thanks to aquaponics, Navidi does.

Navidi also puts other growing methods to use at Future Foods Farms. He grows San Marzano tomatoes in a greenhouse bed containing volcanic rock (this premier variety was first grown in volcanic soil near Mount Vesuvius in Italy). Additionally, he utilizes vertical growing methods.

For Navidi, nutrient density is paramount—to this end, he takes a scientific approach in measuring the nutrition content of his produce. In the past, he and his staff used a refractometer, but now rely on a more precise tool—a Raman spectrometer. This instrument uses a laser that interacts with molecules, identifying nutritional value on a molecular level.

With a Raman spectrometer, Navidi measured the sugar content of three tomatoes—one from a grocery store, one from a high-end market, and one that he grew aquaponically. Respectively, measurements read 2.5, 4.0 and 8.5.

Navidi wants his customers to know about these nutritional differences, so he educates his Oceans & Earth diners through its menu and website. Future Foods Farms also offers internship opportunities to students from California State University, Fullerton. Interns conduct research and learn about cutting-edge ways to grow food.

Navidi believes aquaponics and other innovative growing methods can lead to a more robust local food system in Orange County. But he also sees some of southern California’s undervalued resources—namely, common weeds such as dandelion and wild mustard—helping the region become a major local foods player.

“We need more research on nutrients in weeds,” he says. “Dandelions and mustard are power weeds, and need little water.”

While these wild plants are important, they’re no substitute for policy. Navidi would like to see farmers in the county pay lower rates for water, and believes that a revised zoning code is needed for a county that is urban and becoming more so.

“Now, urban farming is happening all over,” he says. “We need changes to our zoning laws—politicians realize that.”

New zoning rules could help others in Orange County venture into aquaponics, something Navidi feels is necessary not only for the county, but for the country.

“For America to be sustainable, it needs aquaponics,” he says.

Ultimately, Navidi’s goal is to provide the best product possible, with an eye toward simplicity, health and wholesomeness.

“Any fine-dining chef is concerned with the quality of their product,” he says. “There’s nothing better than real food. I try to grow the most nutrient-dense tomato possible. Just add sea salt and black pepper—that’s all you need.”

Made in London: GrowUp Urban Farm's Tilapia Fish and Microgreens In Beckton

For the unfamiliar, aquaponics combines aquaculture - farming fish - and hydroponics - cultivating plants in water - where the greens are fed using waste water from the fish, and this example iin Beckton s what Hofman describes as a “fully ethical and sustainable model.”

Made in London: GrowUp Urban Farm's Tilapia Fish and Microgreens In Beckton

Victoria Stewart goes behind the scenes at an aquaponic urban farm in Beckton

Kate Hofman and Tom Webster

- VICTORIA STEWART

- When I think of city farms in London I think of tiny replicas of country farms - a few animal pens here and there, a few veg boxes, a farm cafe perhaps. What I don’t picture is what I find at GrowUp Urban Farm in Beckton, E6, which is essentially a warehouse divided into two main rooms, one with huge blue circular tanks filled with tilapia fish swimming around inside, and the other with silver shelves stacked on top of each other and brimming with bright green micro coriander, sunflower shoots and baby kale. On a trip there last week it felt as if I’d been jolted into the future.

GrowUp, currently the largest aquaponic farm set up for commercial use, is the brainchild of co-founders Kate Hofman, a former management consultant who now runs the business, and Tom Webster, a former trained biologist who runs the tech side of things. As well as them, there are 11 employees and some university students working alongside.

For the unfamiliar, aquaponics combines aquaculture - farming fish - and hydroponics - cultivating plants in water - where the greens are fed using waste water from the fish, and this example iin Beckton s what Hofman describes as a “fully ethical and sustainable model.”

Setting it up took months of research, “personal sweat” and equity, and outside investment from Centrica’s social impact fund, angel investors, and WRAP, the waste resources and action programme.

Here Hofman talks about why left management consultancy to set up the business, and why it’s important to be flexible when it comes to using technology to run a business like this one.

How many products do you harvest, and what are they?

As well as our tilapia, which are fresh water fish, we grow pea shoots, baby kale, baby watercress, sunflower shoots, custom mixed salads and frilly baby leaf salad. We also do microgreens: micro radish, micro coriander, micro fennel, micro basil, micro rocket and micro mustard.

Who buys your produce?

We sell our greens directly to restaurants in London, indirectly through a distributor called First Choice, to retailers including Whole Foods and online at FarmDrop, and to a couple of catering customers. The majority of the tilapia goes to a Thai restaurant chain called Rosa’s Thai Cafes.

Why did you start the business? Did you always want to work in the food industry?

Tom trained as a biologist and went onto work as an engineering and sustainability consultant. After he got really interested in food production, we were introduced by a friend and I managed to convince him that it was a good idea to set up a business. I have always been really passionate about food and about sustainability, but I used to work as a management consultant for IBM. I really liked my job but I didn’t feel like I was doing much with a purpose so I decided to take a sabbatical to do a masters in environmental technology and business at Imperial College, where I came across urban farming and aquaponics. It was like a big lightbulb moment - I loved the way that the system took the waste from one side and used it to grow something in the other.

Is this a new technique?

It had been around for quite a while but this was in 2011 and there were very few examples of commercial farms. For so long in Asia, people have been flooding rice paddies, putting fish in them and letting the fish fertilise the plants and eat the bugs and then draining the fields. So from a business perspective I was interested in how you take this technology and this concept of growing that’s been around for hundreds of years to solve some of the sustainability challenges that are going to happen in our food system.

Is growing like this the future?

This is part of the future, I think. I do not think that all food is going to be grown like this going forward, nor do I think the future of what we do is huge Skyscrapers growing food on every level. In a book called Hungry City, Carolyn Steel calculated that if you wanted to feed London using vertical skyscraper farms, you’d have to build 200 Shards to produce enough food. So then of course that throws up all sorts of questions like why? How would you find the space? How could you make enough money from producing food to compete with residential or commercial properties? So I don’t think that’s the future of food, but I do think it’s about finding the available resources and space to grow the right food for people and to do that more locally.

When did you first sell your products?

I was first interested in it in 2011, we set the business up in 2013, and we began selling produce about a year ago.

How many products have you sold since you started?

Here we can produce around 20,000kgs a year of all of our greens. To put that in perspective, one wholesaler might sell around 20,000kgs of baby kale every 3 months. So we think that if we can build 9 farms, and each of those farms is 10 times the size of this, we’ll be able to do about 2% of the demand for baby leaf produce. We can produce 4 tons - 4000kg - a year of tilapia here, and in perspective, most commercial farmers would start of upwards of 100 tons. So there are really exciting opportunities for us to expand. This system is also designed just for tilapia, but technically it’s possible to grow other types of fresh water fish too.

What’s the reaction been like?

It’s definitely taken my grandma about 4 years to work out how to describe to people what I do! But anyway I think we get a very positive reception when we tell and show people what we do because it’s really interesting and it’s a little bit zeitgeisty, too - it’s cool how fascinated people are about seeing that you can produce food in this way (as a lot of people have a very idealised idea of how their food is being produced). People have all sorts of questions, including some about the ethical side of farming the fish which we’re always happy to talk about - we have guidelines on how we do that. I think farmed fish offers a really good opportunity to provide a sustainable source of protein, and I think globally we’ve got a growing middle class population who want to eat more protein, and we need to find more sustainable ways of producing it.

How important to you was it to produce something in London?

I’m from London and I’ve lived here all my life, so I’ve always felt that it would be where I wanted to start a business. London has a well deserved reputation as a city that loves food, and whose consumers care about where their food comes from. Starting the business in London has given us access to a fantastic range of customers that we can work with, and allowed us to showcase our business to the world.

What’s it like setting up a business in London?

We’ve had a great level of support from the local borough and GLA (Greater London Authority), but finding the right space for a business like ours is more challenging in London because space is at a premium - there’s no question it’s more expensive! And some of the costs we’re pleased to bear - for example, we’re a London Living Wage Employer - but we see those costs, representing the true price of equitable food production, as part of the challenge of building a resilient food system. If we can make it work in London, we can make it work anywhere!

Which other London producers you admire?

I’m fortunate enough to live near to Spa Terminus and Maltby Street Market in Bermondsey, and every week there are some amazing producers there. I’m a particular fan of Kappacasein - how brilliant to have a local cheesemaker! If I’m out and about I almost always have a bag of Snact Fruit Jerky with me. They make fruit snacks from fruit that would otherwise go to waste and I really admire their ethics - they even have compostable packaging!

How does a typical day pan out for a London urban farmer?

Once I’ve dropped my baby at nursery and walked the dog, I’m into the office on the farm in E6 to catch up with colleagues about farm operations, sales and any other developments that we’re working on. We’re always keen to show new restaurant and retail customers what we do, and give them a chance to taste our fantastic produce, so I might be giving a farm tour or going out to visit a customer. If I’m at the farm at lunchtime then we quite often grab whatever has just been freshly harvested and use that to make up a big mixed salad with whatever everyone has brought from home. Then in the afternoon I might try and grab some time at my desk to catch up on emails or work on a proposal - but I’m equally as likely to be working with my business partner on strategy or talking to a member of the farm team about a process that needs improving.

For more information on GrowUp Urban Farm visit growup.org.uk; Follow them on Twitter and Instagram

Follow Victoria on Twitter @vicstewart and Instagram @victoriastewartpics

Print Your Own Aquaponics Garden With This Open Source Urban Farming System

Print Your Own Aquaponics Garden With This Open Source Urban Farming System

Derek Markham (@derekmarkham) Lawn & Garden June 29, 2017

Aquapioneers has developed what it calls the world's first open source aquaponics kit in a bid to reconnect urban dwellers with the production of their food.

Combining open source, digital fabrication, DIY, and urban farming, this startup's project aims to put the tools for zero-mile food into the hands of everyone. Aquapioneers, based in Barcelona, Spain, is focused on getting more people to grow more of their own food right at home, while at the same time enabling a 90% reduction in garden water consumption and a doubling of plant growth rates.

The Aquapioneers system resembles the Open Source Beehives project and the AKER open source urban ag kit in its construction, as the aquaponics plans are designed to be downloaded and "printed" locally with a CNC router at a Maker Space or Fab Lab, which keeps shipping costs and emissions down, while also allowing for easy assembly and a low-maintenance growing experience.

"With this system in place, carbon-intensive worldwide shipping is no longer necessary, reducing dramatically our environmental footprint and contributing to mitigate climate change. In fact only the data will travel, not the material" - Guillaume Teyssié, co-founder of Aquapioneers.

With this aquaponics setup, the entire growing ecosystem waters and fertilizes itself, thanks to the (almost) closed loop created by the conjoined 50-liter fish tank and 70 x 30 x 30 cm (~27.5" x 11.8" x 11.8") grow bed, which feeds the food crops with the waste from the fish while the plants' roots clean the water for the fish. The fish do need to be fed, and the Aquapioneer system is designed to employ an LED grow light, which requires an electricity input, but it could be illuminated by the sun instead, enabling the carbon footprint of food grown in it to be kept as low as possible.

"Cities are growing bigger and they lack sufficient space. Aquaponics comes as a perfect solution for this, as it allows vertical farming and utilizing unused public and private space." - Loic Le Goueff, co-founder of Aquapioneers

"We aim to revolutionize urban agriculture and promote food self-sufficiency in cities." - Le Goueff

© Aquapioneers

Aquapioneers is currently in a crowdfunding phase in a bid to raise at least €15,000 to finalize and fully document the open source plans. Backers of the campaign at the $43 level will receive early access to both the design files for printing locally, as well as a manual for successfully operating an Aquapioneers ecosystem. The team will release the files into the public domain under a Creative Commons license several weeks after the end of the campaign. More information is available at Aquapioneers.

.

Vertical Farming Tour Visits Delval Programs

Vertical Farming Tour Visits Delval Programs

Chris Filling, hydroponics greenhouse manager, leads a tour of DelVal's greenhouses during an educational tour conducted by the state Department of Agriculture. Delaware Valley University photo

DOYLESTOWN, Pa. — As interest in vertical farming continues to grow, the Pennsylvania Department of Agriculture has been conducting an educational tour for its urban agriculture partners featuring hydroponics and aquaponics programs in Pennsylvania.

Delaware Valley University was the first stop on the tour, which kicked off Tuesday in the Philadelphia area.

Guests toured the University’s hydroponics and aquaponics greenhouses to see how DelVal is preparing students for these industries.

In hydroponics, growers use soilless systems for more precise control of inputs. In aquaponics, fish provide nutrients for plants in a soilless system.

These systems allow growers to produce food in unconventional places, using less space and resources.

“The hydroponics and aquaponics industries have tremendous potential to help solve pressing challenges, such as how to feed a growing population with limited resources,” said Chris Tipping, DelVal’s interim dean of agriculture and environmental sciences.

“At DelVal, we’re educating our students about these industries, and we’re also reaching out into the larger community to partner with other educational programs,” Tipping said. “There’s a real sense of excitement about hydroponics and aquaponics in Pennsylvania.”

Scott Sheely, special assistant for workforce development for the state Department of Agriculture, was part of organizing the tour.

“As schools, government officials and businesses look at ways to apply the technology to grow food in cities, there has been a demand for education on urban agriculture,” Sheely said.

“The Pennsylvania Department of Agriculture invited its urban agriculture partners to join it in visiting sites across Pennsylvania to learn more about this technology and how it is being used in the region,” he said.

“DelVal was chosen as a stop because the university is investing in research and education in hydroponics and aquaponics,” Sheely said.

DelVal President Maria Gallo and Tipping addressed the group.

DelVal is currently building a new specialization in hydroponics and aquaponics within its established Department of Plant Science, thanks to the support of DelVal trustee Kate Littlefield.

“This support was used to renovate two greenhouses as well as to provide the opportunity to create the first endowed professorship in DelVal history,” Tipping said. “This professor will lead the program.”

The tour also visited sites in Lancaster on Wednesday and Harrisburg on Thursday. Other stops included W.B. Saul High School, Metropolis Farm, Aero Development, Garden Spot Village, Steelton-Highspire High School, Ladder & Vine and Messiah College.

For Additional Information, please click on the link below:

Aquaponics at Home: A Modern Farmer Review of Turnkey Aquaponics Systems for All Levels

Back to the Roots, a self proclaimed urban homesteading company based in Oakland, California, offers goods ranging from stoneground corn flakes to organic mushroom kits. They now also offer a cute little tabletop aquaponics kit that contains everything you need to raise sprouts, herbs and a single (inedible) fish (minus the actual fish) in your kitchen window.

Aquaponics at Home: A Modern Farmer Review of Turnkey Aquaponics Systems for All Levels

By Brian Barth on July 18, 2017

Back to the Root's "Water Garden" kit makes a great entry to kitchen aquaponics.

Aquaponics—an environmentally-friendly mash-up of aquaculture and hydroponics—is just beginning to take off at a commercial level. But for homesteaders and hobbyists, it’s more feasible than ever to raise catfish and tomatoes together, whether in your garden, greenhouse, or a sunny window. Poopy fish water provides irrigation and nutrients to the produce, which in turn filter the water for the fish. What could be better?

I once built my own backyard aquaculture system, a semi-disaster which I detailed in a previous post. I wasn’t even attempting the hydroponics part, but just building a self-sustaining system to raise tilapia was a months-long slog of equipment failures and fish kills. I was trying to save money by going the DIY route, but in retrospect I would have been better off with a pre-fab model, one where professional engineers have worked out the kinks in the design.

There weren’t many on the market seven years ago when I started tinkering in my garage with visions of fish tacos dancing in my head. Today, though, there are a plethora. Some are suited for raising nothing more than a couple goldfish and a bouquet of herbs in your kitchen. Others are big enough to supplement a market gardener’s income with sales of hydroponic produce and organically grown fish. Here’s a brief rundown of the options.

Water Garden 2.0 by Back to the Roots, $99

Back to the Roots, a self proclaimed urban homesteading company based in Oakland, California, offers goods ranging from stoneground corn flakes to organic mushroom kits. They now also offer a cute little tabletop aquaponics kit that contains everything you need to raise sprouts, herbs and a single (inedible) fish (minus the actual fish) in your kitchen window. The kit includes a 3-gallon tank, filter, pump, hydroponic growing medium, fertilizer, fish food, and a coupon for a free betta fish, a fancy-looking aquarium fish also known as a Siamese fighting fish. Educational materials are included for classroom use.

Nelson and Pade Aquaponics Awarded 2017 Sustainable Product of the Year

The Wisconsin Sustainable Business Council awarded Nelson and Pade, Inc.® the 2017 Sustainable Product of the Year Award for small business. This is the second time that this prestigious honor was presented to Nelson and Pade, Inc.®, recognizing their Clear Flow Aquaponic Systems®.

Nelson and Pade Aquaponics Awarded 2017 Sustainable Product of the Year

MONTELLO, WI (PRWEB) JULY 13, 2017

Tom Eggert, Executive Director of the WI Sustainability Council (middle), presenting the 2017 Sustainable Product of the Year Award to John Pade and Rebecca Nelson, co-founders of Nelson and Pade.

The Wisconsin Sustainable Business Council awarded Nelson and Pade, Inc.® the 2017 Sustainable Product of the Year Award for small business. This is the second time that this prestigious honor was presented to Nelson and Pade, Inc.®, recognizing their Clear Flow Aquaponic Systems®.

The award was presented at the 2017 Sustainable Business Awards Celebration at Inpro Corporation. Rebecca Nelson, co-founder of Nelson and Pade, Inc.®, shares “We are truly honored to have been nominated and awarded the Sustainable Product of the Year Award in both 2014 and 2017. This recognition demonstrates our commitment to sustainability in Wisconsin and around the world.“

Nelson and Pade, Inc.® is the most trusted name in aquaponics, an innovative method of food production that combines aquaculture (fish farming) and hydroponics (soilless plant culture). In aquaponics, microbes naturally convert the waste from fish farming into an all-natural fertilizer for plant culture. Nelson and Pade, Inc.’s Clear Flow Aquaponic Systems® are designed to maximize these natural processes to grow fresh fish and vegetables year ‘round in any climate. To date, Clear Flow Aquaponic Systems® are used by individuals, entrepreneurs, schools, Universities and food banks in almost 30 countries.

Nelson and Pade, Inc.’s Clear Flow Aquaponic Systems® with ZDEP® (Zero Discharge/Extra Production) have revolutionized the aquaponics industry, providing users with a science-based, proven and profitable aquaponic systems. They are highly productive and continually produce fresh fish and vegetables, 365 days/year, without the use of pesticides, herbicides or chemical fertilizers. Two US patents are held by Nelson and Pade, Inc.® for their innovative designs.

When comparing lettuce production using 1 acre of Clear Flow Aquaponic Systems® to 1 acre of lettuce farming in the Gila Valley, Arizona, Nelson and Pade, Inc.’s systems grow 6 times more lettuce per acre using 1/6 of the water on an annual basis. The same system also produces 40,000 lbs. of fish. These systems are energy efficient as well, with a majority of the water flow achieved through gravity.

Nelson and Pade, Inc.® has its business campus in Montello, WI, where the systems, which are 90% made in the USA, are manufactured. Also on site is a state-of-the-art 14,000-sq. ft. greenhouse facility which houses commercial aquaponic systems for demonstration, a large classroom and the University of Wisconsin-Stevens Point: Aquaponics Innovation Center. Tours of the facility are available.

In addition to manufacturing systems, Nelson and Pade, Inc.® also offers the Nelson and Pade Grower Program and the Aquaponics Master Class®, which has been attended by individuals from over 100 countries.

For more information, visit http://www.aquaponics.com or contact Nelson and Pade, Inc., PO Box 761, Montello, WI 53949, USA, 608-297-8708, info@aquaponics.com

A Life And Career Unexpected

A Life And Career Unexpected

Dr. James Rakocy didn’t plan to spend his life in aquaponics, but it turned into a life-long passion.

June 28, 2017 | Chris Manning

Photo courtesy of James Rakocy

As a child growing up in Milwaukee, Wisconsin, Dr. James Rakocy did not plan on a career in aquaponics. While his family had a home garden and he enjoyed fishing and raising fish in an aquarium, his life took him in other directions. First, he joined the Peace Corps and served in Africa by teaching at a secondary school. Then, he was a teacher in Poughkeepsie, New York, before getting a master’s degree in environmental biology at the University of North Carolina. Finally, he took a job in environmental consulting with a focus on water quality.

Rakocy, now retired and living in Thailand, says he didn’t really like any of the jobs he had before his career in aquaponics started. While working at his consulting job, he came across a magazine about aquaculture, an article detailed a program at Auburn University where the students helped save a pond's ecosystem by using an aquaculture system. This sparked his interest, and as a result, he applied to Auburn’s Ph.D. program. He embarked on studies that would ultimately lead him to a 30-year career at the University of the Virgin Islands and a lifetime of studying and advancing aquaponics at events like the recent National Greenhouse Manufacturers Association Spring Meeting, where he was a presenter.

“I never had a plan B,” he says with a laugh.

An Unexpected Career

In 1980, when Rakocy graduated from Auburn with his Ph.D. in aquaculture, the timing was perfect. A job opening at the University of the Virgin Islands (UVI) in aquaculture seemed to fit exactly what he wanted to do next, so he accepted the position. Unknown to Rakocy, a professor already working at the university had built an aquaponics system in his backyard.

“It was a really basic system,” Rakocy says. “It was one of the first tries at an aquaponics system. [The previous professor] was growing tomatoes in it and raising tilapia in a swimming pool. He had some pretty good results, and the university wanted him to begin incorporating that work at the [research] station.”

That professor, however, quit right around the time Rakocy started at UVI. Upon hearing the news, Rakocy proposed taking on the aquaponics project, as he knew the university wanted to continue it even as the professor who had built the rudimentary system had left.

“It helped that I knew that supervisor, who also had a degree from Auburn,” he says.

Rakocy also notes that other fortunate circumstances bolstered his ability to spend his career researching aquaponics. When he needed funds for new research endeavors, he rarely faced any pushback — resulting in 30 years of uninterrupted funding. And after seven years, Rakocy found himself in charge of the entire University of the Virgin Islands research station. At other land grant universities with more competition, he feels he may have never had a chance to study aquaponics for as long, and as thoroughly, as he did.

“Although [the director job] did cut into my research time because of all the administration work,” he says with a laugh.

Dr. James Rakocy

The Virgin Islands also proved to be an ideal place for the research. Rakocy says the island is fairly dry and there aren’t many ponds or much running water in the area to draw water from.

“What we were trying to do was create an industry from scratch,” Rakocy says. “I was forced to use something that utilized very little water, and aquaponics was it.”

Now, he sees more people interested in it both as a hobby and commercially. The benefits he learned about back the 1980s are going mainstream.

A Pioneering Career In Research

At UVI, Rakocy’s work focused on vegetables and herbs; his previous forays into aquaponics focused on water chestnuts and some edible plants. The first aquaponics system he and his team at UVI constructed used three and half oil barrels — a production setup Rakocy says has become more widely used in recent years. In four and a half months, the first system produced 100 pounds of food.

“We made a ton of mistakes, but we reduced it,” Rakocy says. “We had no idea how to design it, how many fish we needed or what kind of plants would work.”

Next, he and his team built six systems for controlled experiments. According to his notes, each system contained two hydroponic tanks with a total growing area of 154 ft2 (14.3 m2), and a 3,000-gal (11.4 m3) fish tank. After experimenting with those tanks, Rakocy and his team built another system with two hydroponic tanks with a total growing area of 768 ft2 (71.4 m2) with a 3,000-gal (11.4 m3) fish tank.

Years of trialing ultimately lead to UVI developing the first-ever commercial scale system in 1999. It contained six hydroponic tanks and had a growing area 2,303 ft2 (214 m2) and four fish rearing tanks, each with a water volume of 1,320 gal (5.0 m3). Per Rakocy’s notes, the goal was to stagger fish production in the aquaponics system to keep nutrient generation relatively consistent. After more long-term trialing — including one trial that lasted three years — larger fish tanks were installed.

It was this initial commercial system that is the basis for the current commercial-scale UVI aquaponics system.

“I had three professional researchers working for me,” Rakocy says. “I wasn’t able to do as much of the field work once I started directing the research, but I was still involved.”.

Rakocy’s interests stem from a love of fishing

Photo courtesy of James Rakocy

While at UVI, Rakocy authored or co-authored 96 papers on aquaponics research. He also co-edited Volumes 1 and 2 of the Tilapia Aquaculture in the Americans and wrote “Aquaponics Q&A,” a 235-page book primer with basic information for those interested in aquaponics.

At the time Rakocy started his career at UVI, he says there was not much aquaponics research being pursued by universities in the U.S. or elsewhere. He remembers there only being a small trial and paper from Southern Illinois University and another paper from a small university in Germany. According to Rakocy, the work he was doing was back in 1980 was not understood the way it is now.

“It was absolutely in its infancy,” he says. “No one knew what aquaponics was. In fact, no one called it aquaponics. We just called it an integrated system."

Rakocy says he isn’t sure what he would have ended up doing had his career in aquaponics not manifested itself in the way and time that it did. All he knows is that he wouldn’t have been happy in any of his jobs before his job at UVI. He goes as far as to compare his career, and ultimate success studying aquaponics, to the 2005 Woody Allen movie “Match Point.” The film examines the impact of luck and circumstances on life.

“You know how a tennis ball could fall on one side or the other?” he says. “The whole premise of that movie is that a lot of what happens in your life has to do with luck. And I lucked out.”

Looking At The Future

From his base in Thailand — he says he retired there because he didn’t want to retire in Florida like everyone else — Rakocy now works on a project called The Aquaponics Doctors. Along with Dr. Wilson Lennard, an Australian with a background in biology who started research aquaponics in the mid-2000s. Together, they offer consulting on everything from how to set up an aquaponics system to what crops to grow to what system components might be cheaper and more efficient. Their goal is to help make aquaponics a larger part of the growing community. On the research side, UVI no longer has a dedicated program as when Rakocy ran it, but there are six universities in North America with fully functioning aquaponics programs.

One area of the world Rakocy says he hopes embraces aquaponics fully is in the Middle East. He and Lennard have consulted on projects in Abu Dhabi and Rakocy says that region of the world is perfect for aquaponics because of its relative lack of water. Not unlike the Virgin Islands, Rakocy says, the Middle East lacks the water necessary to produce food in the quantities it needs.

“They don’t have any water and aquaponics is very conservative on water,” he says. “The only water we lose is from vaporization and some from removing sludge. But there are techniques where you can get water back into the system.”

“All you do is harvest your plants and feed your fish and plants,” he says. “It’s a very stable system.”

In addition to his work consulting and helping plan projects, Rakocy travels the world and speaks on aquaponics at different conferences while also squeezing in some well-deserved travel time for himself. To date, he has been invited to speak on aquaponics in countries like Canada, Norway and Saudi Arabia. He has also given presentations in Brazil, China and Thailand. In short, Rakocy has been all over the world lecturing on aquaponics. His hope now is for aquaponics to expand beyond hobbyists and smaller growers producing one or two bays of crops. Currently, he says commercial growers using aquaponics are confined to niche markets and specialty crops. Most aquaponic food sales, he says, are direct, local and in relatively small quantities.

“What’s so appealing about aquaponics to people — especially to home gardeners — is that you can raise plants easily and incredibly productively,” Rakocy says. “There’s no weeding. And if you follow the UVI method, there’s very little monitoring.”

One day, Rakocy hopes, bigger commerical growers will also adopt aquaponics and more researchers will take on the challenge of improving the technology. But he’s also happy to have gotten this far.

Sensing Opportunity in Drought, Two Horticulture Classmates Launch Eco Conscious Aquaponics Farm

Sensing Opportunity in Drought, Two Horticulture Classmates Launch Eco Conscious Aquaponics Farm

June 21, 2017 | Pamela Ellgen

The Eco Conscious Aquaponics team in their greenhouse in Goleta, CA. Owners Julian Cantando and Clayton Garland (pictured center left and center right) decided to launch the farm at the height of the California drought. Photo credit: Pamela Ellgen.

In 2016, at the height of the California drought, Julian Cantando and Clayton Garland envisioned a more sustainable farming model than traditional soil-based agriculture, which has always thrived in California.

“Last year was the seventh year of the drought, the lake was down, and the threat of not having water was real, at least for other farmers who aren’t on a well. It was kind of a bleak situation,” Cantando says.

He and Garland were classmates in the Horticulture Program at Santa Barbara City College and often discussed going into business together.

“We had always been talking after class about doing something in the realm of sustainable agriculture, but we didn’t really know what we wanted to do,” he says. “The opportunity presented itself and we jumped on it.”

After graduation, the pair rented a greenhouse at The Orchid Ranch perched on cliffs overlooking the Pacific Ocean, purchased pre-owned equipment for an aquaponics operation, and opened Eco Conscious Aquaponics. They grow lettuces, microgreens, and vegetables, including watercress, sorrel, celery, fennel, and bok choy. They also have some soil-based plants in the greenhouse, including opuntia (known as prickly pear cactus in the culinary world), cape goose berry, and miracle berry.

“We get a lot of feedback that our produce has a better flavor profile because it gets all the water that it needs and all of the nutrition that it needs,” Cantando says. “Our system is 100% irrigation, which means the plant roots are sitting in water. They never get stressed out, so it’s a really tender, beautiful plant.”

Eco Conscious Aquaponics plants its seeds in coconut fiber, a sustainable byproduct of the coconut industry. The inert medium retains water and has high porosity, like a sponge, while also holding air even when fully saturated. Coconut fiber also has an ideal pH and is inhospitable to fungal growth.

Unlike other aquaponic operations that grow and harvest fish for food, Eco Conscious Aquaponics uses long-lived fish such as catfish, koi, and goldfish, which will not be harvested and exist only to supply nutrients to the plants.

It is an entirely organic operation and pest management is handled with marigold plants to deter insects and yellow sticky tape to snare flies.

The Eco-Conscious Aquaponics founders are young; Cantando is 23 and Garland is 30 and the farm is entirely self-funded. Both founders hold off-farm jobs to pay the bills.

Nevertheless, the farm is completely self-sufficient and generates around $5,000 in monthly revenue, with up to $3000 in monthly expenses. They reinvest 20 percent of profits back into the business.

As with any startup, getting the word out about their product was an early hurdle. They went door to door connecting with local restaurants in Santa Barbara and offering samples to chefs. They also began selling to farmer’s markets in Santa Barbara and Santa Ynez. Staying diligent and consistent was the key to getting clients. Delivering freshly harvested, delicious, consistent produce has been the key to keeping clients.

“It’s as fresh as it gets,” Cantando says. And, they have had terrific responses from local chefs. “That’s why we are still here.”

He acknowledges that operating in Santa Barbara where people are environmentally conscious and can afford to care about what’s on their plate is crucial to their success.

In the future, Eco Conscious Aquaponics hopes to expand their operation to additional locations, diversify what they grow, and possibly pursue soil-based agriculture. “I don’t [see] anything wrong with growing in soil as long as the water is available and it’s a sustainable practice,” Cantando says.

—————

General information on aquaponics: Aquaponics uses up to 90 percent less water than soil-based operations, making it especially viable in drought-prone areas. It is a system of aquaculture in which farmed fish supply nutrients for hydroponic plants, which act as a biofilter for the water. Just as important, plants receive adequate hydration for superior flavor. Additionally, it is a closed-loop system with no fertilizer runoff.

Going Indoors To Grow Local

Going Indoors To Grow Local

Alberta company wants to license its hydroponics-aquaponics system to others

Posted Jun. 15th, 2017 by Barbara Duckworth

Nutraponics employees include aquaculturalist Geoff Harrison, left, plant specialist Stephanie Bach and CEO Tanner Stewart. The company grows fresh produce at its facility near Sherwood Park, Alta. | Barbara Duckworth photo

SHERWOOD PARK, Alta. — Providing fresh local produce to Canadians year round could be achieved with a new farming concept that combines horticulture with aquaculture.

NutraPonics, which opened in 2015 near Sherwood Park, is dedicated to supplying the local produce market and supporting local suppliers.

Since last December, it has been selling fresh romaine lettuce, kale, Swiss chard, basil and arugula every week.

The produce is marketed through the Organic Box, a privately owned company in Edmonton that supplies its customers with individually selected orders of locally grown food through online sales and from a store front.

“Everything is marketed as local. We are 32 kilometres from the Organic Box, so that is as local as you can get,” said Stephanie Bach, a plant scientist with the company.

Added chief executive officer Tanner Stewart: “We are hoping to provide less need for products from very far away.”

Stewart, who invested in the company three years ago, is among about 50 private shareholders in the company, which plans to franchise the concept of growing produce indoors in a controlled environment.

“Our model is to not build our own farms and create a massive amount of in-house production,” Stewart said.

“Our business model is to build and license these facilities.”

Former CEO Rick Purdy and a company owner started the system. Purdy researched hydroponics to grow food in water and added aquaponics to use byproducts from fish to create a new growing system.

This farm is considered a demonstration facility, where staff can research the best use of the fish, water and plant development.

There are three tanks full of tilapia fish. The nutrient-enriched water from the tanks is delivered to the plants, which are grown in five layers in a controlled atmosphere.

About 1000 sq. metres of growing space are available, where plants are under red and blue LED lights and fed hydroponically.