Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

New "Lego-Like" Vertical Growing System Offers Flexibility And Small Footprint

New "Lego-Like" Vertical Growing System Offers Flexibility And Small Footprint

16 June 2017, by Gavin McEwan, Be the first to comment

A German firm has launched the latest format in high-density soil-less urban growing.

Image: Aponix

The modular Aponix Vertical Barrel uses an NFT hydroponic system and is designed particularly for urban farming facilities operating on limited space.

"There are no fixed structures necessary for the set-up, like tables or racks, so the barrels can be positioned and moved easily to provide flexibility," explained its inventor Marco Tidona.

The units are constructed out of a single "Lego-like" part that forms 1/6th of a ring segment, any number of which can then be stacked vertically, topped with a lid that incorporates irrigation using a simple sprinkler or spray nozzle, he added.

The entire barrel can sit ona stand or even be hung from above, and rapidly dismantled after use for washing and re-planting.

"Many barrels can be connected in line and be powered by a central reservoir with organic or mineral liquid nutrient solution and a pump for irrigation," Tidona said, and suggested herbs, lettuce or strawberries as candidate crops.

He added: "Aponix is expanding and is currently looking for sales and manufacturing partners."

Jason Wargent Sees Crop Farming Going Vertical And Joining The Urban Landscape. A flood of Innovation is About To Be Unleashed

Jason Wargent Sees Crop Farming Going Vertical And Joining The Urban Landscape. A flood of Innovation is About To Be Unleashed

Posted in Rural News June 21, 2017 - 08:08am, Guest

By Jason Wargent*

The past 50 years have seen huge change in agriculture and food production. Rapid increases in the use of farmable land and intensification of the use of agricultural inputs have both contributed to the significant yield improvements achieved for staple crops since the 1960s. Now we are in a new phase where the magnitude and diversification of agricultural innovation must be maximised to meet the growing challenges of the 21st century. Not only have we reached the peak of ‘simple’ agricultural intensification, but we also face significant climatic uncertainty, combined with a rapidly growing global middle class.

Taken together, the demands of modern and future agriculture are arguably very different to those at the start of the Green Revolution. An expanding middle class has obvious implications for demands on food quality and safety; in New Zealand, numerous horticultural players have developed strong market positions by supplying premium products at a premium price, e.g. novel kiwifruit varieties and wine possessing characteristic properties. The New Zealand farming experience highlights that there is ample opportunity to produce high-value food that tells a story about food quality, sustainability, geography, tradition or nutrition.

As land availability decreases in many parts of the world, and land costs increase, pressure for the pace of agricultural evolution to accelerate is mounting. That said, new paradigms for premium agricultural production are emerging.

Despite the fact that indoor farming has been part of the agricultural landscape for nearly 200 years, we arguably sit at the front end of a next great ag-revolution, where food is grown within a highly diverse, ultra-technological, indoor ecosystem of cropping environments. Indoor farming now has wide interpretations of meaning; the most historical incarnation is that of glasshouse production, used for hothouse tomato cultivation. Protected cultivation can also be equally applied to the use of tunnel or ‘hoop’ houses, usually clad in plastic materials or netting.

Both environments have seen huge innovation growth in the last 30 years, from the introduction of sodium-based artificial-lighting sources into glasshouses to increase crop productivity to the development of ‘smart’ polymer-incorporated claddings for tunnel houses, which can regulate the lighting or temperature environment for crops within. However, both types of crop system still rely on ambient local climatic conditions to greater and lesser extents, e.g. sunlight (therefore day length) and temperature.

The quest to optimise every aspect of a crop’s production cycle led innovators in the 1980s to conceive the first prototype ‘plant factories’, where crops were grown completely indoors, using artificial lighting and environmental-control systems. Some of this innovation was driven by the space race, and the desire of agencies such as NASA to develop food production systems which were fully closed loops, in which food crops could be grown from seed to harvest using artificial light and circulating nutrient processes, such as those exploited in hydroponic systems. Those early enclosed systems have subsequently inspired a generation of entrepreneurs and technologists in the present, where a range of indoor farming categories are flourishing.

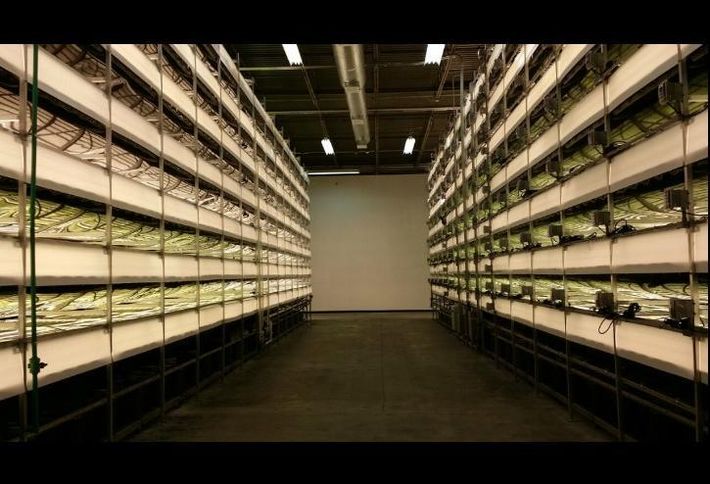

One of the most talked-about categories is ‘vertical farming’, the practice of incorporating vertically stacked layers or shelves of crops, often to maximise space-use efficiency in limited-footprint buildings, e.g. converted or purpose-built warehouses in urban areas. Vertical crops are farmed in their entirety under isolated, controlled conditions, thus creating an exciting vacuum of opportunity for agri-tech. Vertical farming has begun to capture imaginations, with visions of former industrial spaces glowing with floor-to-ceiling LED lighting. There are now likely as many physical manifestations of vertical farming as there are opportunities or motivations associated with adoption of the practice.

Controlling the environment

As discussed earlier, full control over a crop is a clear advantage of fully-indoor production: it means complete mitigation of climatic influence, and therefore the potential to extend or manipulate cropping seasons. Climatic isolation also means buffering food supply (and arguably food quality) from turbulent, one-off events, such as exceptionally dry or wet weather periods, or from pest and disease pressures. Equally, there is the opportunity for control and enhancement of food quality and nutrition.

Plants are composed of highly complex, responsive signalling networks, capable of acclimating to an environment on the basis of different cues or stimuli. As many as 200,000 secondary metabolite compounds have been identified in plants, many of which are associated with implications for produce taste or nutritional qualities. As our understanding of the associated plant biology grows alongside advances in agricultural technology, those stimuli required to nudge plants into a particular taste or nutritional profile can be deduced, and then deployed in a controlled environment.

Related Topics - Rural NewsMassey UniversityinnovationfoodJason Wargent

An oft-mentioned advantage of vertical farming is the strong potential for localising produce-to-purchaser dynamics. In urban environments, shipping times from vertical farm to customer have been quoted in minutes, as opposed to hours or days. The potential to fully integrate food production into what is a typical consumer lifestyle — an urban one — is a tantalising proposition for many food retailers and marketers. The reality of nutritious herbs being grown one block away from a major city food market could be a food marketer’s dream. That said, there are still a very limited number of published life-cycle analysis studies focused on vertical farming. Understanding the cradle-to-grave impacts of vertical farming from a sustainability perspective will allow for greater consumer understanding, and for tech advances to underpin exploitation of the related opportunities, e.g. energy efficiencies, nutrient re-use, co-location with larger-scale customers, packaging and storage. The question as to how a consumer comprehends the very nature of an indoor farm, set against the ‘locally grown’ perspective, will be an interesting value proposition to unravel over time. Does a local indoor farm carry the same cachet as an outdoor, sunshine-bathed farm?

As well as the attraction of isolating seasonal downsides or exploiting urban co-location, arguably one of the most exciting and valuable opportunities for vertical farming is the pure potential to foster agri-innovation of all kinds. Certainly, vertical farming would not exist now without the already-substantial innovation leaps that have taken place to date, for which there can be broader applications beyond full-indoor farming itself. Growing crop plants to full yield in an isolated environment requires an understanding of the very essence of agriculture: nutrients, water and light must all be understood and calibrated to a crop’s needs, and in a cost-effective manner. An obvious reality with full-indoor farming is that there is a capital expenditure that would dwarf many agriculture operations on a per-unit area basis. So the challenges are twofold: ensure cost-efficiency following the associated capex, and employ a substantial amount of cutting-edge, ‘grow-how’ to produce products that meet a premium price point.

Light could be the hottest topic in indoor farming: plants require light for autotrophic nutrition, and fully-indoor spaces lack it. The rise of LED lighting for crop growth has been exponential in the last five years, following not just the expanding interest in light for unlit indoor spaces but also as a replacement for more historical, heavy-duty supplementary lighting sources. LEDs offer the ability to control the light environment (or spectrum) to a far greater extent than has previously been possible.

One exciting challenge with LEDs revolves around the aim to blueprint the lighting requirements for different crops. Getting the light right for increased crop productivity or quality indoors requires innovation and experimentation — for instance, an appropriate mix and intensity of, say, red and blue light will be different for tomatoes versus capsicums. Similarly, ensuring that higher-value herbs that are grown indoors maintain aromatic or taste compositions that meet (or exceed) consumer expectations will require careful tuning of the light environment.

Urban co-location

The win-win for agriculture in general is that the pressure to innovate for fully-indoor farming will very likely lead to new knowledge or IP, which could be exploited in the future for all manner of farming. From the development of soilless plant production techniques to advances in energy efficiency and automation, not only must indoor farming deliver food that meets a premium price point, but also practitioners must maximise crop yields per unit area of production space — aims that sit at the very heart of agriculture challenges and opportunities this century. Given the current economics of establishing and maintaining a fully-indoor space, this maximisation of quality and yield is arguably vital for indoor farming to grow.

The US has been one of the most active parts of the world (as well as Asia) in nurturing fully-indoor farming projects. At present, however, the scale of full-indoor (vertical) farming operations is still a very small proportion of all farming space by volume. The types of crops which currently sit within a feasibility range for vertical farming also have certain limits at present. For example, shorter-rotation, higher‑value products such as herbs or baby greens are particularly amenable to vertical farming, whereas row/field crops such as corn or soy are largely untouched to date, although some micro-pasture full-indoor container systems have been developed for grasses. However, there have been few limits to date regarding the innovation endeavours of indoor farming entrepreneurs: for example, the farming of vaccines for the pharmaceutical industry. We are likely sitting at the narrow end of the funnel right now, with greater innovation leaps yet to come.

Indoor farming cannot (and arguably does not aim to) replace field-based farming. Significant scale will take a number of years to achieve, and there is a strong case for indoor farming to differentiate in terms of the categories of crops produced, the price-points and the geographical locations. While such a complementation-style model is the likely norm right now, it is hard to predict where indoor farming will reach to in the future given the opportunities and the entrepreneurial nature of the sector at present. The potential for hybrid-exchanges of agri-tech in and out of indoor farming to drive advances in other farming forms is strong.

In addition to production and innovation, one other vital outcome from the advent of indoor farming can be education. With urban co-location, and the intersection of multi-disciplines (science, engineering and marketing, to name a few), one weighty additional responsibility for indoor farmers is the translation and communication of the realities and opportunities of farming to a younger generation of future innovators. Using tools such as container/urban food gardens in schools, site visits and educational partnerships, further integration of farming into large urban areas is a necessary path for our farming needs and traditions to build and evolve over the next 50 years.

Jason Wargent is an associate professor at the Institute of Agriculture and Environment, Massey University. This article is an essay in Massey University's 2017 New Zealand Land & Food Annual - No free lunch. It is reposted here with permission. The New Zealand Land & Food Annual 2017, Edited by Claire Massey, published by Massey University Press, RRP: $39.99, available in bookshops nationwide.

NatureFresh™ Farms Receives Top Honors For TOMZ®, OntarioRed™, and Yellow Bell Peppers at Greenhouse Vegetable Awards

NatureFresh™ Farms Receives Top Honors For TOMZ®, OntarioRed™, and Yellow Bell Peppers at Greenhouse Vegetable Awards

Leamington, ON (June 19th, 2017) – Long known as the Tomato Capital of Canada, Leamington, Ontario once again hosted its annual Greenhouse Vegetable Awards this past weekend. Showcasing the best greenhouse vegetables from leading North American growers, family owned NatureFresh™ Farms took home many top honors including the coveted ‘Best Overall Tomato’.

“Receiving these awards is more than just about showcasing the best that we grow, it is about our commitment to pushing the category in the right direction in delivering consistent flavor across the category”, commented Peter Quiring, Owner & President. “The TOMZ® Red Cherry Tomato is a game changer; super sweet, bite-sized, crunchy, with the perfect balance of acidity, the real winners are the consumers who can enjoy this premium snacking tomato year-round, it’s hands down our grower’s choice”, said Quiring.

NatureFresh™ Farms took top honors in the following categories:

- Best Overall Tomato; TOMZ® Red Cherry Tomato

- Best Bite Sized Tomatoes; TOMZ® Red Cherry Tomato

- Best Cocktail Tomato; TOMZ® Sweet Red Cocktail Tomato

- Best Beefsteak Tomato; OntarioRed™ Red Beefsteak Tomato

- Best Yellow Bell Pepper

This is the second year in a row that NatureFresh™ Farms has won the Best Cocktail Tomato Award as well as the Best Yellow Bell Pepper Award, which is a fantastic accomplishment considering strong competition from other varieties in the market place.

“Our retail customers love our TOMZ® Snacking Tomato program because of the unique and flavorful varieties we grow,” said Matt Quiring, Executive Retail Accounts Manager. “It’s not just about selecting the right seed to grow, it is about the growing environment, the plant nutrition, and the grow to market strategy we employ year-round from our farms to ensure we deliver the best we grow, regardless of the season. Our TOMZ® Red Cherry is the best snacking tomato available on the market, hence why it won the Best Overall Tomato Award”, said Quiring.

NatureFresh™’s TOMZ® Snacking Tomatoes were a finalist for Best New Vegetable Award at the United Fresh Convention in Chicago recently.

“We trial more than 300+ different varieties each year to ensure we are always delivering the most flavorful varieties available worldwide”, said Benny Teichroeb, Trial Program Coordinator. NatureFresh™ Farms conducts its product research & development in its 2.5 acre Trial Greenhouse & Discovery Center in Leamington.

All funds raised from the Greenhouse Competitions go to R.E.A.CH. International. This local charity has raised hundreds of thousands of dollars to build schools & clinics, drill water wells, and sponsor and care for impoverished children in Uganda, Africa.

To learn more about NatureFresh™ Farms, visit NatureFresh.ca.

-30-

About NatureFresh Farms™ -

NatureFresh Farms™ has grown to become one of the largest independent, vertically integrated greenhouse vegetable growers in North America. Growing in Leamington, ON and Delta, OH, NatureFresh™ Farms prides itself on exceptional flavor & quality. Family owned NatureFresh Farms™ ships Non-GMO greenhouse grown produce year-round to key retailers throughout North America.

SOURCE: Chris Veillon | chris@naturefresh.ca

Director of Marketing | NatureFresh™ Farms

Protix Raises $50m in Largest Insect Farming Investment on Record

Protix Raises $50m in Largest Insect Farming Investment on Record

JUNE 14, 2017 LOUISA BURWOOD-TAYLOR

Protix, a Netherlands-based company, has raised €45 million ($50.5 million) in equity and debt funding to expand its insect farming business. This is the largest investment in the nascent insect farming industry to-date, according to Protix and its investors.

Dutch food and agriculture bank Rabobank invested in the round alongside Aqua-Spark, the sustainable aquaculture investment fund, Dutch government-backed Brabant Development Agency (BOM) and other private investors.

Protix farms insects predominantly for animal and aquaculture feed, with feed products in over 12 countries, ranging from pig and poultry to pet food specialties. It has four products — feed ingredients Protix Protein X, Protix Lipid X, Protix Chitin X, and a fertilizer Protix Flytilyzer X — which are all currently derived from Black Soldier Fly (BSF). It is also moving into the food sector.

Insects are increasingly seen as a viable and low-impact protein alternative, because they can be reared on waste and are much more resource efficient versus other sources of protein and feed such as soy, corn, forage fish and meat.

Aqua-Spark, which is investing in Protix for its potential to replace fishmeal with insects for aquaculture feed, had been looking deeply at insect production for a long time, surveying over 45 insect producers globally, according to Mike Velings, founder of the Dutch open-ended fund. Aquaculture feed demand is set to increase eight times before the end of the century, according to Aqua-Spark, in what some analysts value as a $100 billion industry, where neither wild forage fish nor soy are viable long-term solutions.

“We took the time to find the right partner and one that could take this to scale because we think insects have the potential to really become a mainstream ingredient in fish feed,” he said. “But the main problem for us in looking at the sector was the ability for these players to scale, because that’s really not easy.”

Insect farms are tough to scale because they are capital intensive; operators need a lot of capital to build the insect factories in what Velings calls a “chicken and egg situation” where you don’t have the offtake to get finance to pay for construction, but you need the finance to get the offtake.

Securing feedstock — the waste you feed the insects such as unsold fruits or grain byproducts — can also be tricky in the right quantities, he added.

Protix cofounder and CEO Kees Aarts, a former McKinsey & Co employee, says that Prolix has cracked the scalability challenge by optimizing the three consecutive processes of industrial insect production: breeding, rearing, and processing.

“Through advanced data monitoring and proprietary technology, we’ve been able to optimize these processes,” he told AgFunderNews. “The combination of highly talented people, data infrastructure, and automation have created modular designs that can scale quickly and produce at the highest standards.”

The technology that Prolix has developed over the past eight years is of key importance to the scalability and success of the business, according to Velings, who believes Protix is head and shoulders ahead of the rest in the industry.

“They are incomparable with other names in the sector, sometimes because they’re raising a different type of insect, but also because they’re at a very different stage of development,” Velings added.

Protix would not divulge much about the technology used in its farms, but it involves a completely controlled environment, monitored and automated with sensors, much like you might see in indoor vertical leafy greens farms.

“We started with a rigorous and well-designed trial and error phase along all stages of the insect growth. We stand out because of the combination of technologies, operations, and R&D,” said Aarts. “Our differentiation lies in that golden combination of a range of technologies, operating protocols and talented people, augmented by the sensor-data infrastructure.”

Also vital to its scalability and technological development going forward, is the company’s joint venture with Swiss food technology group Buhler.

Announced earlier this year, the JV, Buhler Insect Technology Solutions, will manufacture and sell equipment and provide know-how to any feed or ingredient producer in the industry in an effort to scale the industry overall.

The JV will leverage Buhler’s generations of engineering knowledge and Protix’s insect rearing operational expertise, which involves proprietary equipment and processes, including methods for separating and extracting proteins and lipids from insects.

“It’s all about the modularization of proprietary Protix and Buhler technologies and the development and supply of insect production technologies and equipment,” Aarts said of the JV. “Together, we can develop both sustainable and cost effective solutions for large-scale insect producers and processors that cover the whole value chain. Protix will play a supporting role in the long run by providing young larvae to customers of our joint venture and operational support services. This way the industry will accelerate vastly due to setting the dominant design, standards of operations and increase of total production capacity. We have seen a strong increase in demand over the last months since the nascence of our joint venture.”

Protix will use the funding from this latest round to expand its production capacity, especially for aquaculture, deepen its biological and technical R&D, and diversify to other markets like food. It is also on the lookout for potential M&A opportunities. The company wouldn’t disclose exactly what types of companies it was looking to acquire, but Aarts said it would make acquisitions that strengthened its position in the industry.

Protix has now raised €70 million to-date.

Other insect-for-feed farming businesses to raise funding in recent months include French startup Ynsect, which raised $15.2 million in Series B funding last December, and AgriProtein, a South Africa-based business, which raised $17.5 million in the same month.

These #4 Start-Ups Are Promoting Hydroponics in India

These #4 Start-Ups Are Promoting Hydroponics in India

Hydroponics or growing plants in water or sand, rather than soil, is done using mineral nutrient solutions in a water solvent

Image credit: Pixabay

Feature Writer, Entrepreneur.com

June 8, 2017

You're reading Entrepreneur India, an international franchise of Entrepreneur Media.

Only an expert gardener knows how difficult it can be to grow plants and how much extra care it takes with special attention to soil, fertilizer and light. One can’t get the process right and expect good yields without getting his/her hands dirty. But, to make their work a lot easy and convenient, many start-ups in India are working on hydroponics farming.

Hydroponics or growing plants in water or sand, rather than soil, is done using mineral nutrient solutions in a water solvent.Additionally, this indoor farming technique induces plant growth, making the process 50 per cent faster than growth in soil and the method is cost-effective. Mineral nutrient solutions are used to feed plants in water.

Here’s a list of four start-ups in India that are innovating agriculture methods and leading the way in indoor farming.

Letcetra Agritech

Letcetra Agritech is Goa’s first, indoor hydroponics farm, growing good quality, pesticide-free vegetables. The farm in Goa’s Mapusa is an unused shed and currently, produces over 1.5 to 2 tons of leafy vegetables like various varieties of lettuce and herbs in its 150 sq metre area. The start-up is founded by Ajay Naik, a software engineer-turned-hydroponics farmer. He gave up his IT job to help farmers in the country.

BitMantis Innovations

Bengaluru-based Iot and data analytics start-up BitMantis Innovation with its IoT solution GreenSAGE enables individuals and commercial growers to conveniently grow fresh herbs throughout the year. The GreenSAGE is a micro-edition kit that uses hydroponics methods for efficient use of water and nutrients. It is equipped with two trays to grow micro-greens at one’s own convenience.

Junga FreshnGreen

Agri-tech start-up Junga FreshnGreen has joined hands with InfraCo Asia Development Pte. Ltd. (IAD) this year to develop hydroponics farming methods in India. The project started with the development of a 9.3-hectare hydroponics-based agricultural facility at Junga in Himachal Pradesh’s Shimla district.

Junga FreshnGreen is a joint venture with a leading Netherlands-based Agricultural technology company – Westlandse Project Combinatie BV (WPC) — to set up high-technology farms in India. Their goal is to create a Hydroponics model cultivating farm fresh vegetables that have a predictable quality, having little or no pesticides and unaffected by weather or soil conditions. They will be grown in a protected, greenhouse environment.

Future Farms

Chennai-based Future Farms develops effective and accessible farming kits to facilitate Hydroponics that preserve environment while growing cleaner, fresher and healthier produce. It focuses on being environment friendly through rooftop farming and precision agriculture. The company develops indigenous systems and solutions, made from premium, food grade materials that are efficient and affordable.

Nidhi Singh

A self confessed Bollywood Lover, Travel junkie and Food Evangelist.I like travelling and I believe it is very important to take ones mind off the daily monotony .Read more

Lawn Island Farms Brings Local Food Movement To The Front Yard

Lawn Island Farms Brings Local Food Movement To The Front Yard

June 14, 2017 6:00 AM

By Sarah Armaghan sarah.armaghan@newsday.com

Rosette Basiima Adams of Lawn Island Farms cultivates organic lettuce in the front yard of Cassandra Trimarco's Bay Shore home on Saturday, June 10, 2017. Photo Credit: Steve Pfost

A Long Island couple is aiming to grow the local food movement while bringing it even closer to home — straight to homeowners’ front lawns.

Rosette Basiima Adams, 34, developed a green thumb in her native Uganda, where she began farming on her family’s plot around age 4. The idea of growing her own food was familiar, as she didn’t encounter grocery stores until immigrating to Long Island nearly a decade ago.

After working at a Community Supported Agriculture farm in Amityville, she decided she and her husband, James Adams, could do it themselves. Adams, 42, who quit his job at a swimming pool company last year, said he was looking for a way to “do something meaningful” and started researching urban farming.

That’s when Lawn Island Farms was born.

To bypass the high cost of farmland, the Adamses searched for residents willing to forego traditional clean-cut landscaping in favor of edible vegetation. They put up flyers in local shops advertising the unusual exchange. They are currently farming on two properties. The Adamses plant and tend the crops and the residents get a portion of the output.

“I believe the whole agricultural system is whacked out and people are really starting to become aware of it with all the pesticides and everything,” Adams said. “The solution to it is just to do more things like small farmers do.”

Cassandra Trimarco, 34, a physician assistant, who recently purchased a home on Hyman Avenue in Bay Shore, jumped at the chance to have her entire front lawn transformed. Last month, the Adamses planted a crop of non-genetically modified produce, such as lettuce, arugula, spinach, mustard greens, bok choy, and sunflowers without the use of pesticides. The first bounty is expected this month.

Trimarco said while some neighbors have complained about her use of the space, she sees an incredible value and lesson in sustainable agriculture.

“I’ve always been into nutrition and seen food as medicine. And it’s less landscaping for me. Why waste the space?” Trimarco said. “I want to make people aware and show people that you can grow your own food and make the land useful.”

In return, the Adamses will give Trimarco $30 worth of produce each week. Their second plot is on church land in Bay Shore that had once been used as a community garden.

The food not shared with landowners will be sold at farmers markets, the Adamses, of West Babylon, said. They are also in talks with area restaurateurs interested in serving the locally grown greens.

“It all comes from a community focus,” Basiima Adams said. “People knowing where their food is coming from is key.” She likes the added flexibility of being able to be around more for the couple’s 9-year-old twins, Curtis and Daisy.

While the Adamses say the farming is “very hard work” and time-consuming, they are not looking to expand their business much beyond the two current farms, but rather, inspire other Long Islanders to consider using their own yards to be self-sustaining.

“Everybody needs food, so why would you have a lawn instead of having food?” Basiima Adams said. “We want people to start thinking about different ways to feed their families and take care of the planet and the community at the same time.”

For more information, visit lawnislandfarms.com.

AgFuse’s Farmer Founder Is Dedicated To Building Social Network For Farmers Despite Challenges

AgFuse’s Farmer Founder Is Dedicated To Building Social Network For Farmers Despite Challenges

The farming community and Silicon Valley have built quite the relationship during the last few years as innovators and entrepreneurs continue to identify major opportunities for new technology to disrupt the agriculture sector. But for one South Carolina peanut farmer, simply getting acquainted wasn’t enough; he wanted to launch his own startup, too.

Pat Rogers, a fifth-generation peanut and cotton producer operating in Blenheim, SC, is the creator and visionary behind AgFuse, a social networking site created for farmers that features a variety of crop, geographic, and product-based groups. It operates similarly to Facebook, providing users with a news feed and allowing them to follow other users and groups that pique their interest.

Why AgFuse?

Launched in 2015, Rogers conceived the idea for his farmer-focused networking app while attending the InfoAg conference in St. Louis. Surrounded by many other producers and industry officials, he realized that the rural and dispersed geographic nature of farming made it hard for colleagues to connect, share information, and support one another.

Since launching, he has relied primarily on freelance support to develop and update the website and app, which has recently undergone a major update including a range of new features like group subscriptions, news feeds showing suggested and trending topics, and providing easier access to the info that users want most. Also, AgFuse now offers invitation-only “ghost” groups, which are ideal for companies or organizations seeking a central networking spot that isn’t public.

Why do farmers need a dedicated social media platform?

“There’s a lot of information on the internet and existing social media networks for farmers, but you have to hunt for it and you can’t always be sure that it’s good information,” Rogers recently told AgFunderNews. “Plus, sometimes those things can be more of a distraction than a tool. I want to build a digital Swiss army knife for farmers, a centralized location where all of the information on the internet is flowing to the user.”

Being able to customize the information to the specific crops or livestock that the farmer deals with is another added bonus to a farmer-focused outlet.

Challenges & Future Plans

Launching and growing AgFuse has not been without its challenges. He decided early on that an app-based platform would be ideal for farmers, who typically lack spare time to spend in front of a computer. Farmers need to consume essential information in the field when the issues arise, not later that day after they get home, he says.

One of the biggest obstacles Rogers faces is achieving a critical mass of users that will cultivate interaction and connectivity on the platform. He’s relied on fine-tuning the interface, a developed marketing strategy, an word-of-mouth to increase the platform’s membership, which now totals roughly 2,000 farmers across 63 countries.

“Many of the users from foreign countries are seeking production knowledge. They want to connect with US-based farmers and learn about their practices,” says Rogers. “Some of our earliest users are from Australia.”

And while this was to be expected, an unforeseen challenge he’s faced is getting a better feel for the production timeline and the amount of time it takes to create, revise, and promote a social networking site for farmers.

“When we make changes, it seems like it takes a lot longer to push out the finished product than we initially estimated. People want to know to expect the update and I have a hard time knowing exactly what to tell them,” he explains. “It’s kind of like farming; it’s a never ending job and there’s always work to be done!”

He has many plans for the future of AgFuse, including a platform for publishing articles that’s similar to Medium, to give industry experts a platform for sharing knowledge and connecting with farmers. He’s also considered doing live Q&A sessions with experts or agtech companies, providing them with opportunities to answer farmers’ questions about each technology.

Technology Perspective

While diving into the tech arena head first has given Rogers better insight into what it takes to launch and grow a startup, he’s also become a careful observer of trends in the space and how his farming colleagues perceive the plethora of new agtech tools on the market.

“I think in some areas there is over-saturation. There is so much new tech coming out that the average farm is overwhelmed and doesn’t know the best place to spend their money and attention,” he explains. “Farmers are aware of this issue because it happens to them very year in terms of chemicals and fertilizer programs. There is always some new, bigger and better thing.”

Surprisingly, for many farmers, money isn’t always the issue when considering adopting a new technology. It comes down to an arguably more precious resource: time. For farmers, finding spare time or achieving optimum time management is just as precious as a perfectly timed rain or a successful harvest.

“When I think about my own operation, there are a lot of things I want to try, but I have limited funds and more importantly limited time. And, any farmer who has done this long enough knows that the guys who thrive and survive are the ones who know how to allocate resources. A lot of times, that means sitting tight and watching your neighbor.”

This mentality is a common approach to agtech adoption based on Rogers’ observations. Farmers are keen to hear about other users’ experiences with a particular data management platform before they fork over their cash and commit to learning how to use the new tool.

Next to time, failing to recognize a clear value proposition is another common trend among farmers’ perceptions of agtech. He and many of his colleagues would like to see startups providing a clearer cost-benefit analysis on how the product will pay for itself and put more profits in their wallets.

And, as far as education goes, farmers find it lacking.

“It took me a year to figure out my current data management tool and then they changed it,” Rogers says, preferring not to name the company. “If it took me a year and I have been using the product for three years total, you better have a really doggone good product if you expect me to switch to something else and start all over again.”

He would like to see companies offer free trials or use periods in exchange for switching platforms, something to ease the hassle and headaches that will surely result. He also thinks many farmers would prefer to engage with many agtech tools in a service-based relationship as opposed to a purely product-based one.

“If somebody could ever figure out how to franchise a data management company that has local stores or offices that could go around and help farmers pull information off their equipment, run it through a program, and analyze the data, it would be gold.”

Time, once again, is the primary factor in this equation. Many farmers are thrilled about agtech’s potential, but don’t have enough time to master the technologies and glean their full potential. Having someone with serious savvy assist them with the process and confirm their conclusion would help underscore the value proposition while providing confidence that the tool is operation optimally.

“I think farmers have a voice in the agtech sector. And I often think about the famous Henry Ford quote: ‘If I had listened to my customers, then I would have built them a faster horse.’ Sometimes farmers don’t necessarily know what the newest thing is and they don’t know that they need it yet. When it comes to adoption, it’s really about communication of the benefits.”

The Vertical Farming Summit

The Vertical Farming Summit

The future of food is being developed in tech hubs and cities around the world. If you’re not currently in one of those places, going to live events is a great way to learn more about vertical farming and urban agriculture.

If you haven’t been able to make it to any in person AgTech events, Chris created this online event for you.

Check out: The Vertical Farming Summit!

Chris Powers recently had the honor and the opportunity to interview a lot of innovators who are working hard to build the future of food

The Vertical Farming Summit will be live June 16-25th with a number of additional sessions and live trainings happening that week.

Here’s what you’ll learn during the summit:

- A methodology for developing your vertical farming business and planning for success.

Lessons on building a mission driven, venture backed startup around fresh food.

Creative new forms of distribution for gourmet plants and mushrooms.

How to use crop data to unlock higher profits.

How to turn waste into opportunity and using organics in hydroponic systems

The Power of a Plant: A Teacher's Odyssey to Grow Healthy Minds and Schools

How to turn your positive environmental impact into a competitive advantage in the new economy.

How to build your network and land exciting new opportunities in urban agriculture.

Farm Marketing -- How to boost sales and profits using automation and customer research.

The 12 steps to becoming an urban or vertical farmer.

Legal considerations when setting up a farm / agtech business.

Why sunlight isn’t free and other insights from AeroFarms.

Closed loop technology and how to start growing your own food at home.

AVA, Urban futurism and the impacts of digitization on agriculture.

Insights from successful agricultural businesses.

Projects that you should be paying attention to and following.

Top resources and recommendations for learning about urban agriculture and vertical farming.

How to pitch your vertical farming business to investors.

How to start small and scale up intentionally.

… and many more sessions to be announced.

This summit will be 100% online, which means you can learn about these exciting topics and connect with the speakers from anywhere you can get a connection.

The Vertical Farming Summit will be streaming for free from June 16-25th to reach as many people as possible.

If you can’t make all the sessions you can grab an All-Access Pass.

Chris Powers is excited to share all of these expert interviews with you and is looking forward to seeing you in the summit!

About the author: Chris Powers is an entrepreneur and urban agriculture advocate who is using digital marketing to share knowledge about emerging technologies in food.

Sign Up For The Virtual Summit and The Blog to Learn More

Going Indoors To Grow Local

Going Indoors To Grow Local

Alberta company wants to license its hydroponics-aquaponics system to others

Posted Jun. 15th, 2017 by Barbara Duckworth

Nutraponics employees include aquaculturalist Geoff Harrison, left, plant specialist Stephanie Bach and CEO Tanner Stewart. The company grows fresh produce at its facility near Sherwood Park, Alta. | Barbara Duckworth photo

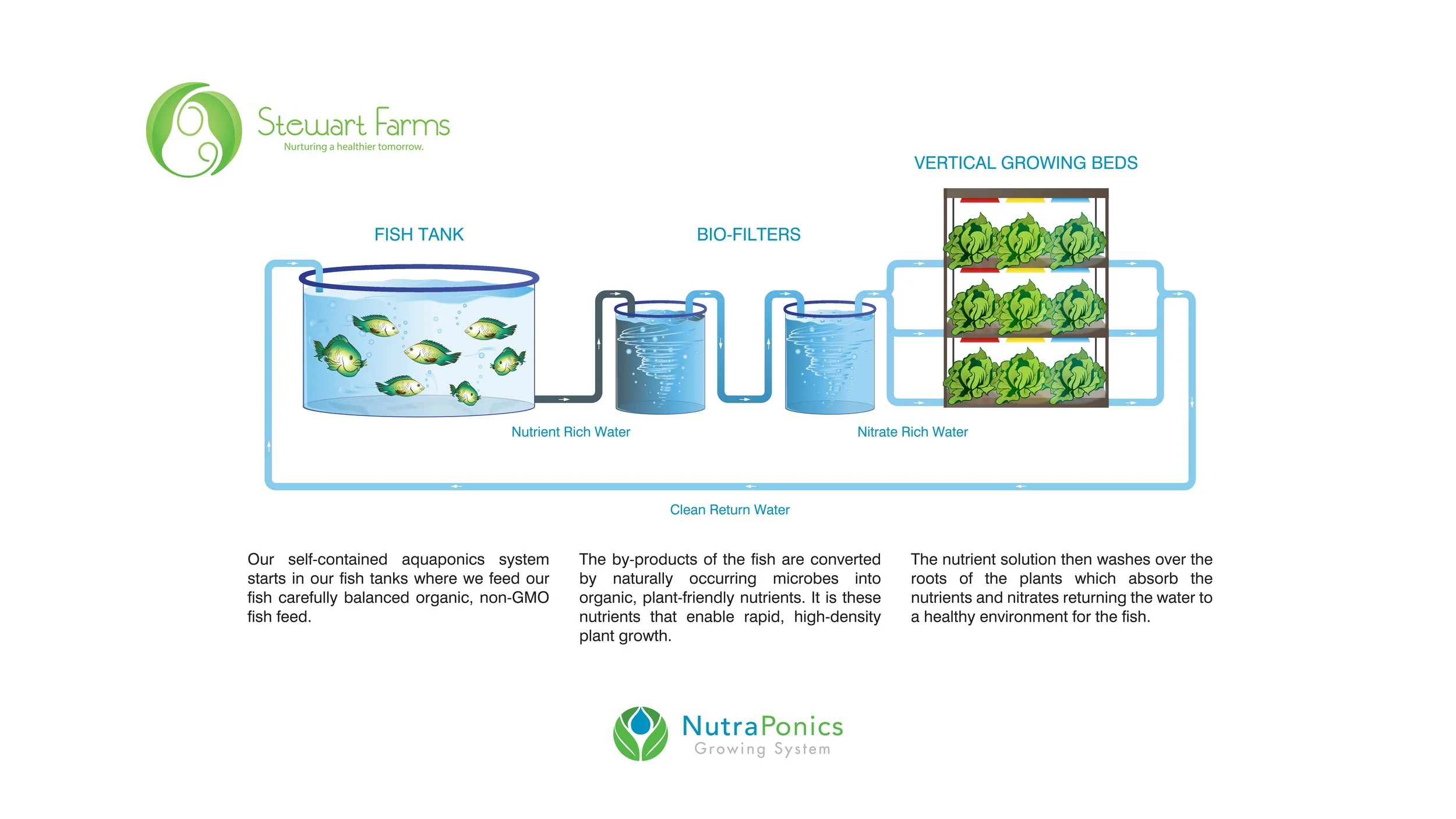

SHERWOOD PARK, Alta. — Providing fresh local produce to Canadians year round could be achieved with a new farming concept that combines horticulture with aquaculture.

NutraPonics, which opened in 2015 near Sherwood Park, is dedicated to supplying the local produce market and supporting local suppliers.

Since last December, it has been selling fresh romaine lettuce, kale, Swiss chard, basil and arugula every week.

The produce is marketed through the Organic Box, a privately owned company in Edmonton that supplies its customers with individually selected orders of locally grown food through online sales and from a store front.

“Everything is marketed as local. We are 32 kilometres from the Organic Box, so that is as local as you can get,” said Stephanie Bach, a plant scientist with the company.

Added chief executive officer Tanner Stewart: “We are hoping to provide less need for products from very far away.”

Stewart, who invested in the company three years ago, is among about 50 private shareholders in the company, which plans to franchise the concept of growing produce indoors in a controlled environment.

“Our model is to not build our own farms and create a massive amount of in-house production,” Stewart said.

“Our business model is to build and license these facilities.”

Former CEO Rick Purdy and a company owner started the system. Purdy researched hydroponics to grow food in water and added aquaponics to use byproducts from fish to create a new growing system.

This farm is considered a demonstration facility, where staff can research the best use of the fish, water and plant development.

There are three tanks full of tilapia fish. The nutrient-enriched water from the tanks is delivered to the plants, which are grown in five layers in a controlled atmosphere.

About 1000 sq. metres of growing space are available, where plants are under red and blue LED lights and fed hydroponically.

Under Bach’s supervision, seeds are planted in a special volcanic rock growing medium from Ontario. They sprout within a week and are then transplanted to the main growing rooms. The plants can be harvested within four weeks for same day pickup by clients.

The company employs about 10 people and while each person might have an official job description, the reality is everyone helps with the fish as well as planting and harvesting.

There is no plan at this time to sell the fish.

“The economics of land-based fish farms is fairly fixed,” said Stewart.

“In order to do business, you really have to look at 200 tonnes of production per year to reach economies of scale. This is two tonnes a year.”

This farm sits on 19 acres, but Stewart envisions any empty urban warehouse as a viable growing operation.

NutraPonics is an agriculture company which sells proprietary growing technologies. These technologies utilize symbiotic relationships between plants and fish known as aquaponics to grow nutrient-rich herbs, vegetables and fish in an enclosed, controlled environment. For more information please visit http://www.nutraponics.ca/home

Whitehorse, Yukon, will be the location of the next farm. The goal in the northern community is to grow and sell produce year round at a competitive price with less freight and a longer shelf life.

Stewart also hopes to develop a facility near his hometown in New Brunswick.

The produce is sold at a competitive price. For example, a bundle of romaine lettuce is offered at $6.25 in a 284 gram package.

“You have to be careful in an emerging industry like ours.” Stewart said.

“You really have to make sure you are focused on this as a business, you need to grow your produce at a certain price and you need to make sure your consumers are going to be happy to buy it at that price.”

He estimated that start-up costs are comparable to any new farm and considers this a stable business model with a decent rate of return on investment.

The difference could be a faster turnaround time from construction to the time saleable product is ready.

“Once we get up and running and all the capital costs are done, then we can produce on a consistent basis, week after week, in fairly short order after we turn the building on,” he said.

Indoor Farming Plus Made In USA LED Grow Lights: Profile 1.

Indoor Farming Plus Made In USA LED Grow Lights: Profile 1.4

GREENandSAVE Staff | Posted on Thursday 15th June 2017

This is one of the profiles in an ongoing series covering next generation agriculture. We are seeing an increased trend for indoor farming across the United States and around the world. This is a positive trend given that local farming reduces adverse CO2 emissions from moving food long distances. If you would like us to review and profile your company, just let us know! Contact Us.

Company Profile: Greensgrow Farms

Greensgrow Farms is an urban farm centered around serving its Philadelphia community.

Here is some of the “About Us” content:

Greensgrow is a nationally recognized leader in urban farming and is open to the public year round. Green roof on a composting toilet, honey bee hives atop tool shed, Milkshake the pig, an abandoned house turned office space, an unused church kitchen turned small food business incubator and a deck made from old pallets and water bottles. A laundry list of crazy ideas? Yes. And a day in the life of Greensgrow.

Greensgrow is an Idea Farm that has given birth to our CSA, the Community Kitchen, Greensgrow West and other projects resulting in permanent jobs and sustainable income. One thing that is for certain. There is no typical day at Greensgrow. We have never accepted the idea that “that’s just the way things are”. Instead we believe that’s there’s a way things could be and that we can make them happen if we’re willing to work hard enough, laugh loud enough and be open enough to learn from our mistakes.

We borrow ideas, make them uniquely our own and happily share them with you. Rethinking land, abandoned space, ideas, oil barrels, PVC, tools and trash is what we do. Veggie waste composts into fertilizer, a shipping container grew into a garden shop and rain gutters find a life as a farm. Many things we own, from our 6000 square foot greenhouse to our mobile market trucks, have come from a previous owner. Because we don’t over capitalized on equipment we have been free to change things up. Everything we buy goes through a stringent cost benefit analysis to prove that it can be used at an optimal level. Some people call this cheap, we call it smart.

Here is the link to learn more: http://www.greensgrow.org/.

To date, the cost of man made lighting has been a barrier for indoor agriculture. A new generation of LED lighting provides cost effective opportunities for farmers to deliver local produce. Warehouses and greenhouses are both viable structures for next generation agriculture. Here is one example of next generation made in USA LED grow light technology to help farmers: Commercial LED Grow Lights.

5 Repurposed Warehouses Turned Indoor Farms That Need No Land Or Sun To Grow Crops

5 Repurposed Warehouses Turned Indoor Farms That Need No Land Or Sun To Grow Crops

June 15, 2017 Chuck Sudo, Bisnow, Chicago

Earth's population is expected to reach 8.5 billion people by 2030. That is 8.5 billion mouths to feed. With dwindling land resources and soaring farming costs across the country, vertical indoor farms may be a solution to feeding the world. Often repurposed from former warehouses, the indoor farms need no sunlight or pesticides and require less water to grow produce.

Following are five indoor farms leading the pack.

1. AeroFarms

AeroFarms, Newark, N.J.

Location: Newark, New Jersey

Produce Grown: Baby greens and herbs

Company/Owner: AeroFarms At 70K SF, the world's largest indoor vertical farm cost $39M to build, and uses LED lights and computer controls to tailor the lighting for each plant. A closed-loop aeroponic system mists the roots of the greens and reduces water usage by 95%. Constant monitoring of nutrients allows AeroFarms to grow a plant from seed to harvest in half the time of a traditional farm. AeroFarms produces 2 million pounds of produce a year.

2. Gotham Greens

Courtesy of Gotham Greens rooftop greenhouse in Chicago

Location: Gotham Greens operates greenhouses in Brookln, Queens and Chicago's Pullman neighborhood.

Produce Grown: Eight types of lettuce, tomatoes, arugula, basil and bok choy Company/Owner: Gotham Greens A pioneer in the indoor farming industry, Gotham Greens built its first rooftop greenhouse in Greenpoint, Brooklyn, and installed solar panels, LED lighting, thermal curtains and a recirculating irrigation system to offset electrical use and reduce water usage. Gotham Green's newest greenhouse in Chicago is located on top of the Method home products plant and cost $8M to build. At 75K SF (or two acres), it produces a crop yield equal to that of a 50-acre farm.

3. Green Sense Farms

Green Sense Farms, Portage, Indiana

Location: Portage, Indiana

Produce Grown: Micro and baby greens, lettuce and herbs Company/Owner: Green Sense Farms Green Sense's 30K SF farm is capable of growing produce for up to 20 million people within a 100-mile radius. The farm is equipped with customized LED lights from Dutch technology firm Royal Philips and grows its produce in automated carousels, while computerized controls provide perfect conditions for year-round farming. Green Sense CEO Robert Colangelo believes his model is scalable and last year raised over $400K in equity crowdfunding to help build a nationwide network of similar indoor farms.

4. Bowery Bowery

Bowery Farming, Kearny, N.J.

Location: Kearny, New Jersey

Produce Grown: Baby kale, arugula, butterhead lettuce and basil. Company/Owner: Bowery Dubbing itself the world's "first post-organic greens" grower, Bowery uses LED lights to mimic sunlight, grows its greens in nutrient-rich water trays stacked from floor to ceiling, uses data analysis to monitor plantings from seed to harvest and robotics to harvest the crops. Investors love what Bowery is doing so much that the company announced Wednesday that it raised $20M to expand its operations in the U.S. and overseas. Bowery raised $7.5M in February from a pool of investors including "Top Chef" judge and chef Tom Colicchio.

5. Local Roots Farms

A shipping container farm from Local Roots Farms

Location: Vernon, California

Produce Grown: Baby and micro greens Company/Owner: Local Roots Farms Local Roots Farms is innovating urban farming design and building indoor farms from 40-foot-long shipping containers. These portable indoor farms are capable of producing the equivalent of a five-acre farm. Local Roots believes this model will disrupt food deserts around the world by setting up the container farms where they are needed most.

FreshTEC Achievement Award for Peter Quiring

NatureFresh Farms' TOMZ Best New Vegetable Finalist

FreshTEC Achievement Award for Peter Quiring

Thousands of produce industry executives are arriving in Chicago this week to attend the United Fresh Produce Association’s Annual FreshMKT & FreshTEC Expos & Convention June 13-15. During the festivities on Tuesday, June 13, greenhouse vegetable grower and NatureFresh Farms owner & president Peter Quiring will be receiving the FreshTEC Achievement Award for his contributions to the produce industry over the last 20 years.

“Peter’s contributions to greenhouse technology have advanced the industry significantly,” said United Fresh President & CEO Tom Stenzel. “His competitive drive and commitment to invest in technology advancements in controlled growing environments are what set him apart. We’re proud to honor Peter with this FreshTEC Achievement Award.”

“It is a great honor to be recognized by your peers,” said Peter Quiring. “Innovation in the way we build our greenhouses and how we grow our vegetables is what has driven my companies for many years. Implementing the latest in technology has allowed us to be a more efficient operation from start to finish”, stated Quiring.

In addition to receiving the FreshTEC Award for Achievement, NatureFresh™ Farms has been named a Finalist for the Best New Vegetable Award for its TOMZ® Snacking Tomato Program.

“We saw a need in the market place to create a category wide program that would give consumers consistent quality, regardless of the season”, said Chris Veillon, Director of Marketing. The TOMZ® Program is unique in that it provides consumers up to 7 different types of specialty tomatoes under one brand: Red/Yellow/Orange Grape, Red Cherry, Mixed Snacking, Mixed Grape, and Sweet Red Cocktail Tomatoes. Grown in NatureFresh™’s new state of the art greenhouse in Delta, OH from October to July and in NatureFresh™’s high tech greenhouses in Leamington, ON March to November, the company is ensuring that locally grown snacking tomatoes are available year-round.

“Consumers want summer-like flavor in July, November, and February and the TOMZ® Program does just that!”, commented Veillon.

The TOMZ® Program is built on the following principles:

- TOMZ® is promoting the category as a whole, not just one item

- Driven by Flavor; 7 unique products under one brand

- Reduced food miles creates extended shelf life

- Creating a consumer connection with multiple flavors

- Same seed | same grower | same farms = consistency

- High impact packaging colors to brighten the produce aisle

- Geo-targeted consumer facing digital content to raise awareness

- Available year-round: Delta, OH & Leamington, ON

“We believe that the TOMZ® Program can strengthen the snacking category as a whole. It is not just about one tomato with flavor, it is a complete line of fresh tomatoes with flavor”, said Ray Wowryk, Director of Business Development.

NatureFresh™ Farms continues to sample its TOMZ® Tomatoes at all #GreenInTheCity tour stops this year with the company’s mobile Greenhouse Education Center.

NatureFresh™ Farms will have its complete line of greenhouse grown tomatoes, bell peppers, and cucumbers on display at the FreshMKT Trade show during the United Fresh Convention in Chicago, June 14-15. Attendees are invited to visit Booth 3231.

To learn more about NatureFresh™ Farms, visit naturefresh.ca.

Going Vertical to Increase your Yields? Let’s Look at the Realities… You Might be Surprised!

Author | Joe Swartz

Going Vertical to Increase your Yields? Let’s Look at the Realities… You Might be Surprised!

We are certainly living in a time of unparalleled technological advancement in general but certainly in the agricultural field.

We’re constantly looking for that latest and greatest “thing” to make our lives easier or to solve one of our existing problems. In controlled environment agriculture, we’ve sought to improve our overall yields and quality by altering the growing environment. We’ve made tremendous improvements to that end by providing more optimum levels of temperature, light, C02, nutrients, dissolved oxygen and more. For the most part, I would consider this all highly successful.

We have also modified our growing systems to effectively manage our plant populations – our greenhouse “real estate,” if you will.

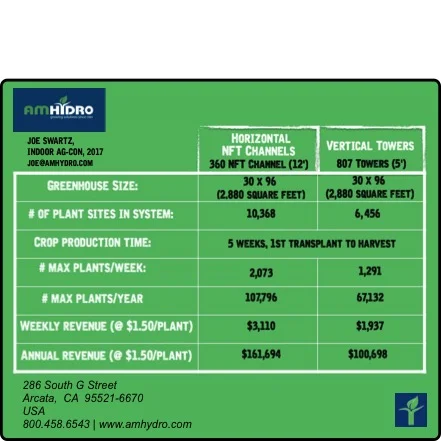

To this end, one of the latest and most heralded “cool, flashy, and sexy” technologies attempting to increase production is to hang NFT channels vertically—- essentially stacking production UP, instead of OUT. We’ve seen quite a bit of this “vertical revolution” these past few years.

Initially, these “towers” were promoted for use in greenhouses. Despite significant issues with inconsistent growth (due to insufficient light reaching the plants toward the bottom), we began to see this technology proliferate and it began to move indoors as well. At the present time, these towers are a staple in many of the major “shipping container” farms, as well as some indoor growing applications.

Over the past 30 years, we’ve seen them all. This recent “farming revolution” has certainly received a lion’s share of publicity and accolades from the media and others. The claim is that these vertical tower systems are “revolutionary technology” and are to be the “future of food.” However, many questions have been raised about the actual effectiveness, sustainability or productivity of trying to install growing systems and crops into a metal box or stacking them up inside a building that was not designed for horticultural production. Despite the “cool factor” of making such a choice, wouldn’t it make more sense to put our production into a properly designed growing environment, such as a greenhouse? This is certainly a very valid question, one that I will be addressing in depth in an upcoming article. In the meantime, let’s look at the effectiveness (?) of hanging our plants vertically.

NFT vs Towers

So why DO we see so many shipping containers and indoor farms promoting the use of vertical towers?

The practice is based on the concept that hanging NFT growing channels vertically, up and down, utilizes more growing space and achieves higher plant populations. “Look!” they say, “When we plant the crops on a vertical plane, we achieve higher production than those horizontal NFT systems!”

It makes sense, doesn’t it, that growing plants vertically would allow more plants per square foot. I mean, a vertical tower would provide more plants and thus higher production, right?

Actually, the answer is no.

When you look closer and break it down, the numbers tell a very different story.

Here are two similar growing systems. One is a horizontal NFT system, demonstrating proper real estate management, and the other is a system of vertical hanging NFT towers-utilizing vertical height in an attempt to get more plants in a given footprint.

When we look at these two systems, we can see that we actually get MORE plants and HIGHER overall production with horizontal NFT in EXACTLY the same footprint.

So how do we do this? By properly utilizing our technologies and real estate management.

It’s really as simple as that.

I know this appears to fly in the face of logic and common sense, but when you examine the data, you see that it’s true.

Despite outward appearances, the horizontal NFT system actually contains almost 4 thousand more plant sites than the vertical towers, all while still maintaining the proper parameters for crop growth.

Given the same crop growth rates in both systems, the horizontal system yields over 40 thousand MORE harvestable crop plants per year than the vertical tower system.

40 thousand more.

If we’re selling lettuce for example, at $1.50 per head, we are looking at more than $60,000 per year in additional revenue……all with essentially the same production costs.

Do I want a simple technology that yields $60,000 more in revenue per year?

You bet I do.

High Quality – High Yields – Consistent Production. Every day, all the time.

This is why you MUST look closely at ALL technologies……….what they CAN do for you…….as well as what happens when you fail to evaluate them properly.

Failure to correctly analyze just his one technology can mean the difference in over $60,000 PER YEAR in additional revenue in the same amount of growing area, with the same basic financial inputs. That’s a STAGGERING difference!

Proper “real estate management” at correct growth parameters = good crops! You can’t replicate this with a vertical system!

With the technological explosion going on around us, it is easy to see the “flash” of a particular technology but miss the substance. Don’t make this mistake. When looking at those “cool” or “sexy” technologies, did deeper.

Take a good look at the crops.

Are they of appropriate market size? What is the quality like? Are the plants all consistent throughout the crop?

Look beyond the wall of green. Look at the individual crops.

Could you sell these on the open market at a price point that is economically sustainable?

If you don’t know the answers to these and other questions, I strongly suggest that you look a little deeper. We can all TELL you about our technologies, and what’s effective. But, if we can’t also SHOW you, then none of what we say is credible. Evaluating with this critical eye will serve you well as you decide on the technologies to best serve your needs.

Indoor Farming Plus Made In USA LED Grow Lights: Profile 1.3

Indoor Farming Plus Made In USA LED Grow Lights: Profile 1.3

GREENandSAVE Staff

This is one of the profiles in an ongoing series covering next generation agriculture. We are seeing an increased trend for indoor farming across the United States and around the world. This is a positive trend given that local farming reduces adverse CO2 emissions from moving food long distances. If you would like us to review and profile your company, just let us know! Contact Us.

Company Profile: Farmbox Greens

Farmbox Greens is Seattle's first indoor vertical farm.

Here is some of the “About Us” content: At Farmbox Greens we approach agriculture in an innovative way. We grow in square feet, not acres. We use energy efficient LEDs and a fully climate controlled environment to produce the freshest produce that can be on your plate within hours of harvest.

Since planting the first seeds of our urban farm in 2011 we’ve set out to change where and how great produce is grown. We’ve created a sustainable farm where the harvest cycle is days not months. Our farm uses 90 percent less water than traditional farming, is pesticide and herbicide free and is fresh year round.

Seattle’s first indoor vertical farm to grow produce, we make fresh local greens more accessible. We use a small amount of space (just a few hundred square feet) to grow thousands of pounds of greens annually. We work hard to grow local produce because we think it tastes better. Go ahead and taste it, we think you’ll agree!

Here is the link to learn more: http://www.farmboxgreens.com/.

To date, the cost of man made lighting has been a barrier for indoor agriculture. A new generation of LED lighting provides cost effective opportunities for farmers to deliver local produce. Warehouses and greenhouses are both viable structures for next generation agriculture. Here is one example of next generation made in USA LED grow light technology to help farmers: Commercial LED Grow Lights.

LEDs For Vertical Farming: Buying Guide For Lights

LEDs For Vertical Farming: Buying Guide For Lights

Posted on June 13, 2017

Exclusive vertical farming content delivered straight to you? Sign up here.

Big Changes in Vertical Farming!

It’s easier than you think to pick the right lights for your vertical farm.

Trying to figure out the right LED lights to buy can be an overwhelming experience. There are more specs, stats, and engineering minutiae packed into product pages for LED lights than anyone running a business should have to parse through.

This article is for people who want to start their own indoor vertical farm and it’s going to drill down on the important characteristics of the lights for a business. In other words, this isn’t an exposition on the science or engineering of LEDs – despite what LED manufacturers would have you believe, you don’t need to geek out to get this right and you don’t need “cutting-edge technology.” In fact, what I want to do is try and cut through all the science and marketing-speak and put this in terms of the factors that will influence a practical business decision.

For perspective, the conclusions drawn from this piece are from a very small farm and are probably only applicable to farms costing less than $1 million (and maybe not even all of those). Once you go beyond that, some of the business decisions change. I recognize this.

I’d also note, that for our business, we’ve always had more success with going out and getting things done than staying home and planning/optimizing. These conclusions also reflect that. But hey, we’ve been making money selling our produce while people that started at the same time as us are still at home fiddling with their systems.

Before we get started, this article gives a good overview about what makes LEDs great, but my understanding of commercial lighting has increased exponentially since it was first written.

If you would like to get into the science behind this, I’d recommend the book LED Lighting For Urban Agriculture by Toyoki Kozai.

Our Test

GE, Philips, and Total Grow lights are all used in commercial farms and all come highly recommended. By using these lights, we knew they were vetted for quality and the reputation of the brands meant that we wouldn’t have to worry if their spec sheets were accurate.

For background – when selecting these lights, our plan was to originally grow a range of plants including microgreens, lettuces, and herbs and we got the same lights (***this is not what you would do if you knew what you were buying for – we were at a different stage in our business model when we made that choice***) for all of them. With these plants in mind, we knew that for everything but the neediest herbs, we wouldn’t need to go over 400 μmol/sec/m2 (this is a measure of photosynthetic photon flux per unit area, often abbreviated as PPF and is the most important metric for determining the quality of lights) and that staying lower would be better for the micros and more efficient for the lettuce.

We did 2 test runs of different loose leaf lettuce blends, started from seed under the Philips lights before finishing them off under the different brands. We controlled for light height, light amount (daily light integral)*, humidity, temperature, duration, and feeding times.

To start, here are the lighting profiles for our layout provided by the vendors.

Philips

GE

Total Grow

*While the DLI’s were slightly different, we took this difference into account when evaluating the overall values of the lights across different factors.

Yield

For us, this was the most important factor. We wanted to know if any of these lights lead to more (or better looking) food.

After harvest, we weighed our lettuce from each of the three systems and found… that the Total Grows had a small edge. The microgreens under the Total Grows looked a lot better too but we didn’t measure that accurately. As part of this, we’d also included some cheapo LEDs that were only 6000k in the experiment, though not with as many controls in place. While all three name brand lights looked better than the yields from these lights, it wasn’t by much.

Cost

This was our second most important consideration for obvious reasons. Here are the list prices for the lights we looked at (and as with anything, when you go commercial, there’s some wiggle room):

Philips: $121+/light, $726/shelf. These are the Gen 2 lights and they can be had for slightly less than this number, but you also have to buy female connectors and wiring. The price noted here reflects that.

GE: $349/light, $698/shelf. This includes clips for hanging them, jumper cables, and the pre-wired plug. And remember, these are 8 feet long.

Total Grow: $32/light, $1050/shelf. In addition to the lights, you are also paying for the socketed cord the lights plug into and you can get hanging infrastructure that I did not include the cost of here because I didn’t end up needing it.

And of course, expect to add at least another $50-$100 for shipping each product depending on how many of these you get.

Warranty And Expected Lifetime Hours

The warranty is the more important thing here in my opinion because it is what the company is actually willing to put money behind, but each are important.

Philips: 3 year warranty. 25,000 hours at 100% efficiency that gradually drops after this point (this might be true of the other lights tested, but only Philips mentioned it).

GE: 5 year warranty. 36,000 hours.

Total Grow: 5 year warranty. 50,000 hour service life.

Energy Efficiency

This turned out to be an incredibly important factor in my decision. My farm is built inside of a refurbished garage and is limited to the breaker that was already installed: 15 amps. That means I had to be able to run the whole farm on around 11 amps (both because wattage fluctuates and because I run a space heater when the exhaust fan kicks on below certain temperatures). So, the lower the amperage draw, calculated by dividing watts by volts, the greater the area I could light at a given level

The below measurements are in joules/second which is a good approximation for watts. It also applies to 1 light for each of these brands, not what is needed to light our whole shelf.

Philips: 2.17 µmole/J (x6 lights needed for our grow space)

GE: 2.33 µmole/J (x2 lights needed for our grow space)

TotalGrow: 1.3 µmole/J (and remember, we need at least 30 of these for the grow space). Another thing to note with these lights is that the housing heated up noticeably more than the other brands.

However, all of these lights were so efficient that it didn’t actually end up mattering for my space. That calculus changes the more lights you have.

Ease of Use

This ended up mattering probably a little more than it should for us compared to a mature venture. The reason for this is because we knew we were going to be moving stuff around, just kind of playing and making frequent adjustments. No one wanted to waste time fiddling with everything and more flexibility means more testing and iterating is easier down the road.

Philips: You have to wire these things yourself, which takes less than 10 minutes/light but has a learning curve that’s steeper than I would have liked requires some basic tools and a soldering iron. You could do it without the solderer, but I feel much more confident in the wiring with it. One thing to take into account when buying plugs, try and get ones that will all fit on your power strip. We didn’t think that far ahead and have some wasted outlets as a result.

We hung these with s hooks from the frame. I only feel ok about how secure they are. When we re-do the space, these will get directly mounted onto the shelves and will eliminate this problem.

GE: Super easy. Just unpack and plug in. We used s hooks into the mounting clips for these as well. That’s definitely not how they were intended to be used but we wanted to be able to move everything around and that would have been too hard if we screwed or nailed these things into our shelves (which even being able to do is another benefit of building your own shelving).

Total Grow: So you have to unbox a lot more lights which added a negligible amount of time but was still a bit of a pain. And if we were covering 10k square feet instead of 130, it might be an actual factor in terms of costing a few hours of pay to do. And once that was done, we had a rather unwieldy socketed cord to maneuver into place. This would have been much easier if we would have used their custom built mounting option (that they suggested and was well worth the price, we just switched our grow site dimensions too far along in the process) so that’s no fault of their design. Overall, not as easy as the GE lights, but definitely easier than the Philips ones.

Feeling/Durability

Philips: These have nice metal frames and thick plastic protecting the diodes and overall feel very good although one of mine buzzes loudly. I don’t know if that’s because of mishandling from previous projects, bad wiring (it was purchased and used before the others), or a fault in manufacturing.

GE: These are made of a thick plastic and overall feel a lot less durable than the Philips or Total Grow lights. I wouldn’t quite say they were fragile though. Also, being 8 ft long, they have a slight bow when not properly supported.

Total Grow: Wow. These blew me away with how solidly they were put together. In terms of durability from dropping or water, I have the most confidence in these lights by a significant amount.

Company

Philips/GE: I ended up ordering both of these through Hort Americas. Hort Americas has great customer service and worked with me to get detailed product information and talk me through the right products for my farm. They had helpful alternative suggestions and cost saving ideas.

TotalGrow: TotalGrow (Venntis Technologies) gave me some of the best customer support that I’ve ever received in my life. They will work with any farm to customize their spectrum and setup for the space and help you with your design process.

Conclusion: I would definitely encourage either ordering from Hort Americas or TotalGrow as opposed to some other web site.

Overall

To keep this from wandering too much more, I ended up choosing the GE lights for cost and energy use reasons. The fact that they were easy to install was icing on the cake.

The results of the yield test lead me to another conclusion. Pretty much any home grower or someone looking to just get a system going and tinker with it will be set with shop lights of the right spectrum. Small commercial growers should probably get a dedicated horticultural bulb, but probably don’t need to worry too much about getting the latest and greatest, because really, despite the hype, it didn’t end up making a huge difference.

I also know that the company that manufactures the TotalGrow lights has improved both the cost, energy use (by 10%), and output (10-25%) of their product so I expect them to be a much better option once their new generation of lights is out.

However… if you were to drastically increase the scale of your facility beyond what we did at Rosemont, the calculus changes. The minor yield differences suddenly start equalling thousands of dollars/year. Same for the increased electrical cost.

Still, even at that scale, I think you would be fine with any of the lights mentioned. Probably the most important factor would be the best bulk buy price you could negotiate with your distributor.

Helpful links:

https://fluence.science/science/how-to-compare-grow-lights/

http://hortamericas.com/catalog/horticultural-lighting/arize-lynk-ge-led-grow-lights/

Buy Philips GreenPower LED Grow Lights

http://totalgrowlight.com/products/broad_grow_bulb.html

From Forgotten WWII Tunnels To Urban Farm: Q&A With Growing Underground

Photo from Growing Underground

From Forgotten WWII Tunnels To Urban Farm: Q&A With Growing Underground

by Brittany Lane - Photo from Growing Underground

Today, miles of empty tunnels run beneath the streets of London. The government constructed them over one hundred feet beneath the surface to serve as shelter during the air raids of WWII. However, after the war, many of these tunnels were left abandoned. Funding to convert them into tube lines ran dry.

Over time, the spaces took on various identities – from the storage of government documents to temporary accommodations for Caribbean immigrants. One of the more recent applications, though, is breathing new life into a space once associated with a dark history.

Growing Underground grows fresh micro greens and salad leaves in one of these quiet tunnels beneath the bustling streets of Clapham, South London. A combination of hydroponics and LED technology, the closed-loop farm grows crops year-round in a controlled environment with no pesticides. Due to hyper-local production, the team boasts that the produce can be in your kitchen within four hours of being picked and packed.

Unreasonable visited the underground farm and spoke with Steven Dring, co-founder of Growing Underground, about discovering the potential of urban farming and unleashing a degree of belligerence to make it succeed.

So, take me back to your corporate life. I want to hear a little bit about your journey and various work experiences along the way.

S: I worked for a PLC for 17 years, joining as a 20 year old. Literally, I was being promoted year after year. They then paid for my education as well, so there was all this buy-in and gratitude. They were a great employer in that sense. It was just the fact that I changed in terms of my views on sustainability and my views on where we were going as a planet. So as I was changing, the bits within the business that really didn’t sit with me just became more pronounced.