Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

This Urban Farmer Feeds Old Age Homes Through His Hydroponic Farm

Hydroponics is a subset of hydroculture. It is a method of growing plants using mineral nutrient solutions in water. These plants grow directly in water and require no soil. The two important factors to be controlled include the nutrients in the water, as well as the air temperature.

This Urban Farmer Feeds Old Age Homes Through His Hydroponic Farm

The produce from his hydroponic farm will help feed underprivileged senior citizens in old age homes and NGOs, with none of it being commercially sold for profits.

Ever wondered what it would be like to grow your vegetables at home? One might looked puzzled and say, “Sure! But in an urban setting? Is there even enough space?”

Well, one program manager based in Singapore is on a mission to change the concept of traditional agriculture by practicing hydroponic farming on unused spacious rooftops.

Srihari Kanchala is not only focused on growing produce locally but aims to impact the lives of senior citizens. The produce from his hydroponic farm will help feed underprivileged senior citizens in old age homes and NGOs, with none of it being commercially sold for profits.

“Urban farming seemed to be the best option not only to promote locally grown vegetables and fruits but also utilize unused open spaces, in the concrete jungle that the cities have turned into,” says Srihari

What is hydroponic farming?

Hydroponic farming

Hydroponics is a subset of hydroculture. It is a method of growing plants using mineral nutrient solutions in water. These plants grow directly in water and require no soil. The two important factors to be controlled include the nutrients in the water, as well as the air temperature. Even though the effort one has to put in is double than that of outdoor agriculture, the method allows an urban farmer to grow veggies efficiently year-round.

This method of farming uses water and space efficiently. Most experts deem it the ultimate future of farming.

Read more: This Software Engineer Sold His Company to Start a Vertical Hydroponic Farm in Goa

Is Urban farming a new concept?

Well, no! You can trace the history of urban agriculture to 3,500 BC when Mesopotamian farmers set aside plots in their growing cities to carry out farming. During World War II, urban farmers had what came to be called ‘victory gardens’ that produced crops to feed underprivileged neighborhoods too. One of the prime reasons for the implementation of this concept is the lack of clean produce. It is expected to pick up pace in India.

Speaking about the inspiration behind Urban Chennai, Srihari told Milaap, “One of the biggest examples of the urban citizens helping each other during crisis was Chennai floods. That inspired me to do something and contribute back to the society.”

The idea behind the initiative is to encourage and promote small communities to grow healthy fruits and vegetables locally. “I believe that food brings people closer, which in turn brings communities together,” he says.

Srihari’s goal is to help apartments, gated communities, and corporate offices with large terrace spaces join hands and grow healthier vegetables, not only for their personal use but also share what’s left with underprivileged communities that can’t afford meals.

The financial capital investment for hydroponics even though on the higher end of the scale, is

cost effective and energy efficient. It can provide more yields, ensuring surplus locally grown produce at a lesser cost.

Charity and experiments, all begin at home. So, Srihari wants to start this project by transforming 1,000 sqft of his family rooftop and convert it into a model urban farm and community space.

Technology used after funding

Srihari has received financial help from his family – his father, Mr Gopikrishnan, his father-in-law, Mr Chandrasekaran and his cousin, Mr Sreevatsava, all of whom are based in Chennai.

The urban farmer’s 1,000 sqft greenhouse is built using polycarbonate instead of plastic sheets. This helps the farm withstand the heavy rains and storms that Chennai is infamous for.

To ensure natural ventilation, it has side openings and an insect mesh over the top. The power requirement for the greenhouse is very minimal.

To ease problems of controlling leaf temperature, Srihari has installed Aluminet screens on the top that bounce off 50% of the sunlight. This helps them control the temperature and ensures the plants don’t burn out.

Control panel and automation tools that ensure very minimal work is required.

Without these aluminet screens, the greenhouse temperature would be 8-10 degrees above the temperature outside. So, even the process of controlling temperature is 100% natural without the use of huge mechanical exhaust fans.

An installed RO Unit(Reverse Osmosis water filter) ensures clean water supply to plants.

This 1,000 sqft place can grow 1600 plants at any given point. Once the plants are transplanted into the grow systems, they don’t need any manual work as they are irrigated automatically until harvest.

There are sensors that monitor the amount of nutrients given to the plants and control it as per requirements. So, the urban farmer only intervenes at the harvest stage.

This urban farm grows vegetables such as tomatoes, brinjals, capsicums and greens like spinach and lettuces. In addition, a lot of herbs like basil, fenugreek, coriander, and curry leaves are also grown.

“I see this project as a means of bringing huge difference. The whole thing seems more personal and fulfilling,” he says.

A newly imported vertical Aeroponics system from Germany is now allowing them to grow more plants in a space as tiny as 20sqft in a vertical tower. Is aeroponics the future then? Well, it’s hard to predict but it certainly more water efficient than hydroponic farming.

(L) Aeroponics (R) Foggers that automatically turn on when the humidity inside the greenhouse goes below 50.

You can connect to Srihari at Srihari@me.com

FFAR Partners With AeroFarms on $2M Precision-AG Research Project

FFAR Partners With AeroFarms on $2M Precision-AG Research Project

09/07/17 5:00 PM By Daniel Enoch

KEYWORDS AEROFARMS DAVID ROSENBERG FFAR GRANT PRECISION FARMING ROGER BUELOW SALLY ROCKEY VERTICAL FARMS

WASHINGTON, Sept. 7, 2016 – The Foundation for Food and Agriculture Research today announced a $1 million grant to New Jersey-based AeroFarms LLC, a leading vertical farming company, for a research project on precision agriculture. Aero Farms will match FFAR’s grant for a total investment of nearly $2 million.

Sally Rockey, executive director of FFAR, a non-profit established in the 2014 farm bill, made the announcement at USDA headquarters in Washington where she was joined by ag research and industry leaders, including AeroFarms CEO David Rosenberg.

The project aims to improve crop production by defining the relationships between stressed plants, the phytochemicals they produce and the taste and texture of the specialty crops grown. FFAR says the work will result in commercial production of improved leafy green varieties and yield science-based best practices for farming.

“With more than half the world living in urban areas, continuing to provide nutritious food to the burgeoning population must include envisioning our cities as places where abundant, nutritious foods can be grown and delivered locally,” Rockey said. “We look forward to seeing this grant to AeroFarms catalyze innovation in vertical farming and plant production for the benefit of urban farmers and the communities they serve.”

FFAR said AeroFarms Chief Technology Officer Roger Buelow will be collaborating with scientists from Rutgers and Cornell universities to “take advantage of the precision that is possible in indoor vertical farming systems, where ‘stressors’ from light to humidity to temperature can be controlled consistently and precisely to improve specialty crop characteristics such as taste and nutritional quality.”

Sen. Debbie Stabenow, the top Democrat on the Senate Agriculture Committee, congratulated FFAR on the research partnership.

"Urban agriculture has incredible potential to spur economic opportunity, increase access to healthy food, and inspire the next generation of farmers,” Stabenow said in a statement. “I'm pleased that the foundation is committed to new techniques to grow food in innovative ways."

(The photo above the story shows, from the left, AeroFarms CEO David Rosenberg; USDA Acting Undersecretary for Research, Education and Economics Ann Bartuska; United Fresh Produce Association CEO Tom Stenzel; Parag Chitnis, deputy director, USDA’s National Institute of Food and Agriculture; FFAR Executive Director Sally Rockey; and AeroFarms Chief Technology Officer Roger Buelow.)

#30

For more news, go to: www.Agri-Pulse.com

Lawn Island Farms: Babylon Couple Turns Yards Into Crops

Lawn Island Farms: Babylon Couple Turns Yards Into Crops

Jim and Rosette Adams of Babylon are on a mission to bring locally grown food to Long Islanders tables, by growing it in their front yards.

The Adams’ fledgling company, Lawn Island Farms, has been growing produce and selling it to farmer’s markets and local businesses for about a year, but their unique approach has attracted national media attention. They tout the health benefits of locally grown vegetables.

“Unfortunately too many people don’t even realize how corrupted or compromised [their produce is],” Jim said, noting cancer-causing pesticides as one of the most pressing concerns related to factory farming.

Jim got the idea for the company after he met his wife, Rosette, in her home country of Uganda 10 years ago. There, he came to appreciate how she grew up in a culture of self-sustained farming.

“She has the experience from growing up in Uganda and I got to see, kind of, the world through her eyes when she came here and that changed me a lot,” Jim said.

This fresh perspective also alerted Jim to the perils of not knowing exactly where our food is coming from and how it’s being produced. After reading The Urban Farmer, he was inspired to begin farming locally. The book details how people can convert their property into a sustainable and profitable food source.

“There are over 40 million acres of lawn in North America,” the book’s website states. “In their current form, these unproductive expanses of grass represent a significant financial and environmental cost. However, viewed through a different lens, they can also be seen as a tremendous source of opportunity.”

Jim and Rosette brought this idea to Jack Jack’s Coffee House in Babylon, where owners Mike Sparacino and Vanessa Viola pointed them to a community farm behind St. Peter’s by-the-Sea Episcopal Church, effectively giving them the idea to launch Lawn Island Farms.

The Adams’ then hung a sign in that same coffee shop asking for anyone with enough land to let them convert their lawns into crops, which led them to Bay Shore resident Cassandra Trimarco.

For the price of $30 of produce a week as well as free landscaping, Ms. Trimarco allowed the Adams’ to transform the front lawn of her Hyman Avenue home into a miniature farm. The reactions of the community were varied, with some neighbors complaining that the lawn was now an eyesore.

“We did get, in the beginning, a lot of gossip going around,” Jim said of the initial controversy surrounding the converted lawn. But that attention was what would eventually raise their profile.

“That’s when CBS News and Fox came by,” he recalled. “That was the story, because it was controversial.”

Currently, the Adams’ hyper-local farming endeavor consists of the land behind St. Peter’s and Trimarco’s yard, with the produce being sold to the Bay Shore Farmer’s Market and the Sayville Farmer’s Market, as well as Henley’s Village Tavern in Bay Shore, Empowering Goods in Lindenhurst, as well as Jack Jack’s, where it all began.

Jim and Rosette have also begun to take a more tech savvy approach to their business. Lawn Island Farms can now be found on the Farmzie app, which seeks to create a network of small farmers and increase small farm sustainability. Users can connect to Lawn Island and buy produce directly from them. They also offer restaurants a grow-to-order option in order to better suit their specific needs.

Lawn Island Farms’ approach to local farming has garnered interest from people all over the island, with inquiries coming in from Patchogue, Port Jeff, Middle Island, Wading River and elsewhere. But at the moment, the Adams’ simply can’t meet the demand on their own.

“My plate is full, I’ve gotten a lot of offers which is amazing, but I hardly have time to even go look at them,” Jim said of the outpouring of requests they’ve received. That’s why they want others to take action and begin growing food on their own.

“I want more people to do it, because it’s not just about us and our business,” he said. “It’s about local food for the people.”

To learn more about converting your lawn into a sustainable food source check out the website of Jim and Rosette’s friend Linda Borghi, Farm-A-Yard.com

Vertical Farms May Be the Future of Your Food

Vertical Farms May Be the Future of Your Food

Dariusz September 6, 2017 News, Technology

Many of us do not give too much thought to where our food comes from, and this is not a failing on our part. The food industry has done a great job at distancing consumption from production, so our blind eye to it is understandable. Our meat and produce are all grown on far-off farms, sometimes even in other countries. A company called Plenty Inc. is looking to change all that using vertical farms located outside major cities.

VERTICAL FARMS WILL INCREASE FOOD QUALITY AND LOWER COSTS

A company called Plenty Inc is hoping to disrupt the way that we think about the produce we eat. This Bay Area company has plans to bring incredibly high quality food to consumers at fractions of the cost associated with higher-end food. The way it plans on doing this is really rather intuitive: bring the farm to more populated areas. However, as those of you who live in a city or other densely populated area will know, there is just no room for a farm. So where will these farms be?

Plenty Inc will utilize vertical farms to make it feasible to have large growing operations close to consumers. The farms themselves will be state of the art and capable of producing large amounts of food.

IS THIS ALL REALLY NECESSARY?

Vertical farms will likely be increasingly popular solutions as population sizes increase and consumer tastes evolve toward fresher and cheaper food. Since these farms will be so close to consumers, the quality of the actual product at the time of consumption will be noticeably better. Any readers who are gardeners will be able to confirm that the fruits and vegetables they grow in their backyards are often far tastier than store-bought produce. By reducing the time in transit and shortening the gap between harvest and consumption, Plenty Inc’s vertical farms make food taste better.

While many might suppose this would rack up costs quickly – nightmarish images of some store’s pricing of organic kale are flooding my head even as I write this – the same factors that make the food taste better will drive down its cost. Much of these savings will derive from the significantly reduced cost of transporting these goods. Transportation costs can be staggeringly high at times, especially with needed refrigeration. While traditional farming and food sourcing benefit from things like subsidies and economies of scale to help keep their prices low, local vertical farms will likely win the price war because of simplified logistics, better products, and shorter grow times.

I would not be surprised if in the future more vertical farms near cities provide a large portion of the world’s produce. The concept just makes too much common – and economic – sense to ignore.

Urban Farms, Beacons of Self-Reliance, Change The Buffalo Landscape

Buffalo’s urban farms have grown mostly organic crops as they’ve nurtured community involvement, including in some of the city’s poorest neighborhoods. (Mark Mulville/Buffalo News)

Urban Farms, Beacons of Self-Reliance, Change The Buffalo Landscape

By Scott Scanlon | Published 12:04 p.m. September 8, 2017

Mayda Pozantides slings burgers two nights a week in an Allentown restaurant but her career aspirations involve something much more grounded.

She wants to be a full-time farmer in the City of Buffalo.

Pozantides, 30, and her boyfriend, Anders Gunnersen – operations director with Buffalo Reddy BikeShare – bought a patch of land three years ago on the East Side. They spent two years stripping it of brush, rock and chunks of blacktop. This year, they brought in new soil and planted a large slate of vegetable crops.

"I used to be a teacher and Anders used to do environmental education," Pozantides said. "We want to bring that element to the farm. We're building slowly."

Groundwork Market Garden – a roughly 2-acre plot at Genesee and Leslie streets – is among several urban farms that have emerged in the city during the last decade.

While not self-sustaining, each in its own way has helped inspire the creation of community and residential gardens across the city, underlined the importance of access to healthy, affordable food, and helped serve as a linchpin in ongoing efforts to revitalize neighborhoods.

Each faces similar challenges: the cost and work involved in creating proper soil conditions; access to a cheap, dependable water supply after city regulations ended their use of hydrants; and looking to boost crop yields as they battle deer, woodchucks, rabbits and a limited Western New York growing season.

Dogs and fencing have slowed the critters. Grant money from the U.S. Department of Agriculture has helped some farms build high tunnels – also called hoop houses – that allow planting and harvesting even in the winter months. A cooperative called the Farmer Pirates is among those providing compost to help bring urban farm soil into a more hospitable pH to grow fruits and vegetables.

"A lot of the farmers have reasons they're farming that are other than financial…," said Megan Burley, farm business management educator with Cornell Cooperative Extension of Erie County. "Still, without a margin, there is no mission."

Mayda Pozantides takes a cover off of some vegetables at the Groundwork Market Garden on Genesee Street. This marks the first year the farm has yielded crops. (Mark Mulville/Buffalo News)

Urban farm owners in Buffalo all aim to serve as beacons of the local food movement, symbols of simple self-reliance, and examples that simple ideas that can work at the grassroots level. Some have a spiritual mission; all, a social one.

Eleven urban farms help lead the way in Buffalo. Several will be stops on the ninth annual GObike Buffalo Tour de Farms bicycling event next Saturday, Sept. 16. For more information and to sign up, visit tourdefarmsbuffalo.org.

5 LOAVES FARM

1172 West Ave.; 5loavesfarm.org

“Garden Egg” eggplant is among the immigrant-favored crops grown at 5 Loaves Farm on the West Side. (Mark Mulville/Buffalo News)

Matt Kaufmann is the farm manager for this Upper West Side farm, which since 2012 has expanded from three lots at West and West Delevan avenues to a couple more lots a block north.

The nonprofit farm is ministry of Buffalo Vineyard Church and is tended by Kaufmann; assistant manager Seth Brown, the lone paid farmhand; and a collection of volunteers from schools, community groups, the mayor's summer youth program, Buffalo Urban Ministries Partnership and 716 Ministries.

More than 80 vegetable varieties are in the ground here. They include amaranth, Asian cucumber and original white, egg-sized eggplant – all popular with recent immigrants in the neighborhood. Produce from the farm goes to 40 members of the 5 Loaves CSA, the Tapestry Charter School lunch program and the Lexington Food Co-Op. Much of it also is sold from 8 a.m. to 1 p.m. Saturdays through October at the Elmwood Village Farmers Market.

COMMON ROOTS URBAN FARM

309 Peckham St.; commonrootsurbanfarm.com

Terra Dumas started the farm five years ago and brought on partner Josh Poodry, who also owns a landscaping business, two years ago. The farm sits on 11 lots where nearly 40 vegetable varieties are grown for 83 CSA members and a farm stand on the property. The stand is open 4 to 7 p.m. Thursdays and 11 a.m. to 3 p.m. Saturdays through mid-October.

The owners dug a well on the site this year to better supply their crops with water and also erected a hoop house that has boosted tomato production. Students from SUNY Buffalo State and the nearby School 31 are among those who will help Dumas and Poodry tend the farm this fall.

FARMER PIRATES

Foot of Gittere Street, off Sycamore Street; farmerpirates.com

The Farmer Pirates are a farm collective that has purchased lots on the East Side in an effort to promote healthy eating and self-reliance. Those who tend urban farms and large gardens are welcome to participate. Farms in the fold include Common Roots, Wilson Street, the homestead off Gittere Street and the planned Michigan Riley Farm off Michigan Avenue, north of the Buffalo Niagara Medical Campus.

"Growing food in the city is often cited for its potential economic benefit," the Pirates say on their website. "Whether or not urban farming is an economically viable profession, let alone holding the potential for economic development, the real value growing food in the city is the potential to improve quality of life and strengthen communities."

GROUNDWORK MARKET GARDEN

1698 Genesee St.; facebook.com/groundworkmg

Mayda Pozantides says the Groundwork Market Garden wind tunnel, along Genesee Street, has produced 300 to 500 pounds of tomatoes weekly in recent weeks. (Mark Mulville/Buffalo News)

Cornerstones of the farm this first growing season have become a large wind tunnel that holds about 300 tomato plants, as well as the recent purchase next door of a three-story, 40,000-square-foot former manufacturing building that will be turned into a mixed-use project that helps support the farm.

Pozantides and Gunnersen sell their produce to the 20 members of their CSA – as well as neighbors who stop by Tuesday evenings for CSA pickups. They also sell produce at the North Buffalo Farmers Market from 3 to 7 p.m. Thursdays through October at Holy Spirit Church, 85 Dakota St., near Hertel and Delaware avenues.

JOURNEY'S END BREWSTER STREET FARM

Jan Rai and other refugees who farmed in their native country help tend a small farm behind the Tri-Main Center as part of a Journey's End program. (Mark Mulville/Buffalo News)

36 Brewster St.

Refugee farmers – mostly from Bhutan of Nepalese descent, Congo, Palestine and Syria – help tend two patches on a small side street behind the Tri-Main Center at Main Street and Jewett Parkway. They earn a small wage as part of the Journey's End Green Schools for New Americans program, Program Manager Beth Drouhard said.

Sixteen farmers tend more than 30 vegetables at the farm, which includes a hoop house. Produce here helps feed 20 CSA members and those who stop by a market table from 1:30 to 6 p.m. Thursdays in the Tri-Main Center. The program also will provide free produce at 2 p.m. Wednesday alongside the Brewster Street farm, while supplies last.

MASSACHUSETTS AVENUE PROJECT (MAP)

389 Massachusetts Ave.; mass-ave.org

Established in 1992 and incorporated in 2000, this nonprofit farm operation on the West Side is the largest urban farm force in the city. Since 2003, its Growing Green program has provided jobs and training to more than 700 low-incomeyouths ages 14 to 20.

MAP looks to open its new $2 million Farmhouse & Community Food Resource Center next spring. It will include a teaching kitchen, meeting and training space. The farmhouse has swallowed nine of a dozen tracts on its main farm, limiting production this season. Its produce is available at two weekly MAP Mobile Food Markets: 4 to 6 p.m. Thursdays through October at Elim Christian Fellowship, 70 Chalmers Ave.; and 11 a.m. to 1 p.m. Fridays at the Moot Senior Center, 292 High St.

"The construction is really limiting us," Development Director Erin Carmina said. "Next year we'll be in full swing," including other farm plots on Winter and Breckenridge streets.

PELION URBAN FARM

206 Best St., facebook.com/PelionCommunityGarden

Pelion Urban Farm grows fruit, vegetables and flowers. (John Hickey/Buffalo News file photo)

Garden Manager Caesandra Seawell has led the transformation of four vacant city lots across the street from City Honors into an outdoor school and community garden.

The garden – a key part of the school's fifth- and sixth-grade curriculum – includes a rain garden, a dozen raised beds for vegetables, fruits, and herbs, edible flowers, and cherry, plum, peach, and native serviceberry trees.

Bordering neighbors also have been encouraged to plant crops in raised beds on the site. Produce here is tended by volunteers and students. Some of it makes it home to families, Seawall said, though much of it doesn't even make it across the street and back to school.

PROMISE VALLEY FARM

462 Elk St.; between Orlando and Babcock streets; facebook.com/SenecaGospelMission

Seneca Gospel Mission is a Christian ministry that started in a Seneca Street storefront in 1936 and moved to the Valley Neighborhood of South Buffalo two years later. Promise Valley started as a small garden tended by children and became an official urban farm last year with the hiring of Farm Manager Aaron Belleville.

"The produce goes to 12 CSA members; our NeighborShare program allows donations to subsidize costs to qualified local residents in Seneca Babcock and the Valley neighborhoods which have no fresh food access and oftentimes lower incomes," said John Brown, resident executive director of Seneca Gospel Mission.

The mission is installing a commercial kitchen and continues renovation of its ministry center for future food education and ministry programs. "We're also raising funds for a hoop house for next season," Brown said.

URBAN FRUITS AND VEGGIES

Dupont Street at Glenwood Ave.; urbanfv.com

More than 20 raised beds sit on a corner parcel and a second site nearby on Glenwood. Owner Allison DeHonney started this venture in late 2013 as both a nonprofit and limited liability company farm. DeHonney and farm manager Sandra Bynum gather vegetables from the urban farm, coupled with fruit from a pair of growers in Niagara and Erie County, to provide to corporate wellness programs for eight companies, including New Era Cap and Lawley insurance, and the new Neat restaurant in Clarence.

DeHonney also looks to build greenhouses, starting as early as this fall, at Zenner and East Ferry streets, as part of a Bailey Green sustainability and revitalization project spearheaded by Harmac Medical Products.

WEST SIDE TILTH FARM

246 Normal Ave., at Vermont Street; facebook.com/westsidetilthfarm

Started as an urban farm this year to provide its West Side community with naturally grown produce using sustainable practices. Vegetables, herbs, micro greens and mushrooms are produced at this farm, much of it in a new hoop house.

"We got our first batch of oyster mushrooms last week, which is exciting," said Carrie Nader, who owns the farm with her partner, Alex Wadsworth.

Much of their produce makes its way to the new Roost restaurant on Niagara Street and 100 Acres Kitchen in the Hotel Henry. Their salad mix is served at both Lexington Co-Opp salad bars. The farm stand, around the corner at 235 Vermont St., will be open 5 to 7 p.m. Fridays through September.

WILSON STREET URBAN FARM

Six of Janice and Mark Stevens' children help them on the family's Wilson Street Farm; a seventh, Alex Ash, helps her husband, Dan, tend the homestead farm for Farmer Pirates. (Derek Gee/Buffalo News file photo)

Wilson Street, between Broadway and Sycamore Street; wilsonstreeturbanfarm.wordpress.com

Janice and Mark Stevens, parents to seven children, operate this nine-year-old farm, which launched the urban farm movement of recent years in Buffalo. "We grow everything but corn," Mark Stevens said. Produce is sold at a farm stand that has closed for this season, as well as to 14 CSA members through October. The farm also helps supply several restaurants and Five Points Bakery.

Steven is a carpenter who does contracting work, helping the family subsist on the East Side. "The farm is not self-sustaining but Janice and I come from a homesteading background. We're terrible salespeople who love to eat what we grow, so we eat up most of our profits."

He's from Olean; she's from Rochester. "We're really about building a good community, a good neighborhood," he said. "All of the urban farms have a slightly different slant on things. We're more on the community building aspect of it. Whether we make a living is not exactly our point on things."

email: refresh@buffnews.com

Twitter: @BNrefresh, @ScottBScanlon

Story topics: urban farms

Vertical Harvest To Partner In Pennsylvania Project

Vertical Harvest To Partner In Pennsylvania Project

60,000 sq.ft. Vertical Greenhouse To Bolster Lancaster's Less Fortunate

Inspired by Vertical Harvest in Jackson Hole, a group of Pennsylvania entrepreneurs has announced an ambitious plan to realize a similar community-supporting vertical glasshouse downtown Lancaster. By partnering with their industry peers in Wyoming, the group soon hopes to break ground for the construction of the 60,000 square feet project on the side of an existing parking garage.

The Lancaster Urban Farming Initiative was founded by a group of entrepreneurs with a shared social ambition to re-develop underutilized infrastructure with urban farming projects to bring in jobs, gain availability of local produce and provide beautification of the downtown area.

Soon after they started their in-depth analysis of opportunities and locations, Lancaster mayor Rick Gray got acquainted with their initiative and composed the idea for a vertical farm at the local Orange Tree parking garage. "He showed us a picture of the Vertical Harvest greenhouse in Jackson Hole and asked us if we could do the same. And a few years later here we are, about to complete our feasibility study for a similar farm and design, only three to four times larger in size", representatives of the initiative said.

The project will be built onto the side of the garage, using a space that really cannot be used for anything else. The walk faces the famous Lancaster Central Market which is the oldest continually operating Market in America. It is the heart of the city and walking out, visitors will soon see an impressive vertical greenhouse rather than a brick wall.

Vertical Harvest will partner in the non-profit Lancaster vertical farm that is touted as bringing in jobs to mentally underdeveloped and disadvantaged and disabled people, as well as veterans, people with Down syndrome, autism or those who are unemployed or underemployed. "We want to provide them with a rewarding job in high tech agriculture. We will also create partnerships with local hospitals and industries to support the local community and its access to local, healthy food."

Aside from providing jobs, local food and making underdeveloped parts of the downtown area walkable again, the Farming Initiative also hopes to sprout the development of indoor agriculture in general by becoming a technology leader. Their facilities will grow a variety of crops in several production systems. It will serve as a dedicated testing space to trial new innovative vertical growing systems. The group said it will incorporate the latest in hydroponic and LED systems, and might even consider bringing in cogeneration to supply the greenhouse with a sustainable energy source.

The Lancaster Urban Farming Initiative is currently in the process of completing funding. Up next is going through the design phase, which is expected to take a while, since building a vertical greenhouse is also a challenge in terms of strict building codes and complex architecture. Nonetheless, the group hopes to kick off the construction early to mid 2018.

Follow the development at www.lancasterufi.org and www.facebook.com/lancasterufi

The Lancaster Urban Farming Initiative Board of Directors:

- President - Corey Fogarty - Federal Taphouse Holdings LLC

- Vice President - Todd Bartos, Esq. - Aspire Ventures / Spruce Law Group LLC

- Secretary - Gordon Kautz II - Kautz Construction / KC Green Roofing

- Treasurer - Scott Arment, CPA - Stutz Arment LLP

- Mary Ann Garrett - Owl Hill Learning Centers

- Ross Martin-Wells, Ph.D - Rijuice LLC

- Mark Pontz - Fine Living Lancaster

- Fritz Schroeder - Lancaster County Conservancy

- Joe Sheldon - Gordon Food Service

- Scott E. Kuhn - Wells Fargo Bank

- Publication date: 9/6/2017

Author: Boy de Nijs

Copyright: www.hortidaily.com

This Brilliant Floating Farm Actually Heals The World’s Oceans

Founded by commercial fisherman Bren Smith and Emily Stengal, an expert in sustainable food systems, the revolutionary GreenWave vertical farming system cultivates an underwater ecosystemcomprised of seaweed and shellfish.

This Brilliant Floating Farm Actually Heals The World’s Oceans

85% of the world’s fisheries have been pushed beyond their limits – and the future of ocean life looks grim. Fortunately, GreenWavehas developed a revolutionary floating farm that actually regenerates our oceans while providing jobs and a sustainable source of food. The vertical aquaculture farm yields bountiful crops of shellfish and seaweed – species specifically selected to absorb greenhouse gas and filter out harmful chemicals.

Founded by commercial fisherman Bren Smith and Emily Stengal, an expert in sustainable food systems, the revolutionary GreenWave vertical farming system cultivates an underwater ecosystemcomprised of seaweed and shellfish. The farm requires zero input, and it actually restores ocean ecosystems by sequestering carbonand fixing excess nitrogen (which leads to algae blooms and oceanic dead zones).

The open-source farming system enables anyone with a boat and around $20,000 to set up their own restorative ocean farm within a year. The Greenwave system won the Fuller Challenge in 2015 and it was recently honored with the 2017 INDEX: Award, which recognizes innovative designs that improve life.

Hot and Hungry Cities: The Future of Urban Food Wars

When people think about food insecurity, they often associate it with the impact of climate change on rural areas. Make no mistake, drought and conflict, as well as an enduring lack of infrastructure that limits farmers from selling what they produce, continues to devastate sub-Saharan Africa. But these factors also push people to migrate to cities. By 2030, urban areas will triple in size and will have a significant impact on productivity of agriculture in farmlands that were once used to supply food to these megacities.

Hot and Hungry Cities: The Future of Urban Food Wars

SEPTEMBER 6, 2017 | JOHANNA MENDELSON FORMAN

JOHANNA MENDELSON FORMAN

DISTINGUISHED FELLOW, MANAGING ACROSS BOUNDARIES, STIMSON CENTER

This century will be defined by two trends: how we manage climate change and how we manage the rise of megacities. Over the next 20 years, the global urban population will grow from 3.5 to 5 billion people. The strain on resources and the environmental stresses that accompany the growth of cities – especially in brimming urban centers like Dhaka, Bangladesh; Lagos, Nigeria; and Mexico City – will create even more challenges as access to food and clean water become increasingly limited. It is no wonder that in 2015 the National Intelligence Council determined that food security is a national security matter. Countries facing severe shortages of food or affected by climate change are also the most vulnerable to destabilizing conflicts that affect U.S. interests around the globe.

Yet it is only recently that food security practitioners, traditionally focused on rural areas, have begun to turn their attention to megacities. In the world’s massive urban centers, migration from rural areas – often the result of vulnerable populations fleeing conflict or environmental degradation – has created new challenges to ending global poverty and hunger.

Many of these urban migrants will be forced out of the countryside by the ongoing impact of droughts, conflict, and the lack of opportunities for employment in rural areas. But consider this: roughly 60 percent of the world’s cropland lies just on the outskirts of cities. China is expected to lose one-quarter of the global cropland because of the expansion of cities into peri-urban areas that once were the source of local farming and food supplies. The disappearance of productive land near urban centers will impact the availability of staple crops like maize, rice, soy, and wheat – the basis of global food security. This is especially true in countries like Nigeria or China, where projections for crop loss due to urbanization means that the states will have to import more food.

When people think about food insecurity, they often associate it with the impact of climate change on rural areas. Make no mistake, drought and conflict, as well as an enduring lack of infrastructure that limits farmers from selling what they produce, continues to devastate sub-Saharan Africa. But these factors also push people to migrate to cities. By 2030, urban areas will triple in size and will have a significant impact on productivity of agriculture in farmlands that were once used to supply food to these megacities.

More than other challenges we face in this century, food security is complex precisely because to ensure access and availability of food requires that many other factors align, such as good governance and the resilience of infrastructure. It requires more changes in behavior, the development of new farming technologies, and a radically different approach to land use.

Most important to a country’s ability to feed its citizens is the quality of its governance. Weak or failing states are incapable or lack the political will to support the needs of their citizens to obtain food or to gain technical assistance from NGOs and foreign governments to enable them to grow more crops, have better access to technology, or even basic information about weather. Many countries are unable to enforce land rights because adequate legal protections are not in place. Especially in sub-Saharan Africa and Southeast Asia, conflicts will continue to drain state resources and extend this cycle. Conflicts that show no signs of ending send a troubling signal to private sector investors who are essential partners in many programs geared toward expanding a nation’s capacity to grow and market food – and make it more widely accessible to vulnerable populations.

Mobile phone companies and software producers are among the business interests most able to help conditions in Asia and Africa, which happen to be the two fastest growing markets for these technologies. By 2025, there will be more than 360 million smartphones in Africa. With small farmers producing 80 percent of the food in developing countries, integrated agricultural data apps are playing a powerful role in helping farmers set prices for their goods. M-Farm, a messaging application, is doing this for more than 7,000 users. These apps also help women in urban market settings with information about competitive pricing of crops. Syngenta, and agriculture biotechnology company, created a text-driven app, Kilimo Salama, that is providing up-to-the-minute information to farmers in Kenya. These same applications also play a significant role in protecting crops by alerting growers of adverse weather events.

In the near-term, food security assistance must address the immediate needs of those moving into cities. This challenge will only grow as the world’s population continues to urbanize.

Technological advances in urban farming are now beyond mere experiments. They are becoming disrupters of more traditional approaches to agriculture. Vertical farms both afford crops and provide employment for many people who reside in cities.

Food security requires complex, multi-system approaches that still seem out of reach to most of the countries slated to be megacities by 2030. Plans for addressing these needs must consider how food production and consumption can be transformed to be both carbon neutral, abundant, and available to the world’s growing appetite. Failure to address these challenges in the short run will create conditions that are ripe for more conflicts and more climate migrants. We could be looking at new era of urban food wars if we do not address the issues of how to feed 9 billion people by mid-century.

THE AUTHOR IS JOHANNA MENDELSON FORMAN

Johanna Mendelson Forman is a Distinguished Fellow at the Stimson Center’s Managing Across Boundaries Program in Washington, D.C. and an Adjunct Professor at the School of International Service at American University. She is also a member of the Council on Foreign Relations. Her work has been informed by field experience in Haiti, Guatemala, Colombia, Iraq, and throughout Sub-Saharan Africa as a senior official at the U.S. Agency for International Development, the United Nations Foundation,... Read More

Learn more about The Cipher's Network here

Indoor Farm Thrives In North York Industrial Unit

Indoor Farm Thrives In North York Industrial Unit

Jonah Krochmalnek's crops require less water than traditional farming methods, and taste delicious all year-round.

By ALEX MCKEEN | Staff Reporter

Tues., Sept. 5, 2017

Jonah Krochmalnek is a 26-year-old farmer. He pulls up to work every day ready to plant, tend and harvest a variety of organic greens and herbs.

He produces loads, too. In a given year — he doesn’t have to worry about seasons on his farm — Krochmalnek estimates he could grow 16,000 kilograms of pea shoots, if they were his only crop.

Living Earth Farms, the company Krochmalnek started four years ago is no ordinary farm.

That’s because it isn’t on a remote country road where plants have space to stretch out and soak up sunlight, but in an unassuming, 2,300-square-foot industrial unit in North York, the same area where Krochmalnek grew up and lives still.

Living Earth is an indoor, vertical farm where crops grow in stacked rows seven layers high with special red and blue LED lights designed for optimal growing conditions shining down on them. It’s the first of its kind to be organic certified in Ontario.

“It took a long time to figure all this out because there’s no book on this type of thing,” Krochmalnek said.

Jonah Krochmalnek is on the owner and operator of Living Earth Farm, an indoor vertical farm in Toronto. (ANNE-MARIE JACKSON / TORONTO STAR) | ORDER THIS PHOTO

His farm is closed to the public because Krochmalnek works there alone and doesn’t have the means to run an educational component yet.

Indoor farming is a new industry, especially in Canada where Krochmalnek runs one of the first such businesses to get off the ground. He sells wholesale to distributors all year — a pot of living basil goes for $2.40 ($4-$5 retail) and a 100-gram clamshell of a variety of microgreens sells for $10 (restaurants buy them for around $15).

Since he grows indoors, he has to automate as much of the growing process as possible, and ensure that it’s efficient enough to make money.

In fact, most of what makes up Living Earth Farms was put together by Krochmalnek himself, from the giant fans that control humidity, to the sub-irrigation system that keeps plants watered without risking contamination.

His choice of red and blue LED lights was informed by NASA research aimed at figuring out how to grow food in space.

“This is probably somewhat of a model that will be used if we go to Mars,” he said. Since the lights he uses are energy efficient, his hydro bill has never exceeded $1,600 (usually it’s closer to $1,000-$1,200).

By growing indoors, Krochmalnek is able to produce food year-round. It’s kind of like having a greenhouse — only it requires a seventh of the space to produce the same yield and uses about 95 per cent less water than traditional farms for crops like lettuce.

“In the winter something like basil takes me 16 days to grow. In a greenhouse, almost double that,” Krochmalnek said.

The quality, he said, is “not even close.”

“My basil tastes like summer. Basil in the winter grown in a greenhouse tastes like water.”

The reason for the difference is simply that the space Krochmalnek has designed is ripe for growing. It’s, as Krochmalnek describes it, the “perfect plant environment.”

“Let’s say you want to be in a tropical sunny place to go on vacation generally. This is like plant vacation. The plants have it easy here,” he said.

Well before he ever imagined making a living by designing and operating a plant paradise (he studied business, not agriculture), Krochmalnek cherished a love of gardening.

His dad showed him how to keep a garden at age 14 and he was instantly hooked.

“Whenever I had a summer job I would bring my cherry tomatoes to people at the office, and their face would light up, and that’s the best feeling,” he said.

Krochmalnek began to see agriculture as a career possibility only after he took part in Downsview Park’s urban farming initiative, Fresh City Farms, and loved it.

He chose indoor farming in an attempt to make farming within the city viable, and now he can’t imagine doing anything else.

“It’s 100 per cent certain that this will be part of the future. It won’t be the whole future for agriculture, but it’ll be a big part for leafy greens and perishable crops,” he said.

Rhonda Teitel-Payne, co-coordinator of Toronto Urban Growers, said that, while urban farms like Krochmalnek’s are unlikely to be sufficient to feed cities, they play an important role in food security, and connecting people to the food system.

“We are going to see more and more farmers, more rooftop growers, more vertical systems because people are running out of options in terms of access to land,” she said. Though land is scarce, interest is growing.

Vertical farming is “very new but there are a lot of people who are thinking about it, talking about it,” Teitel-Payne said.

Looking forward, Krochmalnek has imminent plans to hire his first employee, and longer-term ideas about possible expansion.

In the meantime, he hasn’t stopped gardening for joy, in addition to business. Three potted eucalyptus plants sat under his LED lights last month, not for selling “just for fun.”

Krochmalnek marvelled at the genetic differences that caused them to come out looking like a motley trio.

“These are all from the same batch of seeds,” he said. “And they all grew differently.”

Kimbal Musk: Food Is the Next Big Thing

Kimbal Musk: Food Is the Next Big Thing

Elliot Volkman

- Aug 10, 2017

Twenty years ago an internet pioneer made a fortune for being on the cutting edge of a booming industry, and today he is suggesting food will be the next big thing. Kimbal Musk, entrepreneur, venture capitalist, and environmentalist, and yes, sibling to Elon Musk, took the stage at last year’s Life is Beautiful to discuss the reality of food today and how the changing market can lead to large opportunities.

“We produce 30 percent more than we need to eat, in fact measured by the cheeseburger index, we are growing more than two-and-a-half cheeseburgers per person than we need. And the result is massive: obesity around the world 800 million in 1980 had obesity, today 2.1 billion people in the world are obese. And it’s a tragedy for those people and an economic disaster for the world,” said Musk.

According to Musk, the problem is not the food output overall, but industrial or processed foods. These foods are high in calories, lead to obesity, but at the same time lead to malnutrition for those who consume it. However, thanks to the internet, the world is becoming more informed about what Musk refers to as real food.

The Changing Supply and Demand of Real Food

Fast food chains are closing, and sales on microwavable and frozen foods are dropping. According to Musk, 45 percent of Americans want organic foods, but less than one percent of farms in the US are supply it. With information readily available, demand for organic food is rising, but there is still a separation based on age groups. More and more millennials want to see healthier local foods, are curious about where their food comes from, and want natural food. On the other hand, Musk says that baby boomers still see healthier food as slim shakes, fat-free, low-sugar, etc., which certainly has nothing to do with the mass amounts of marketing designed to convince people of such.

“The global software industry, which is where I started, is about a $400 billion industry. And while that sounds very big, it’s the size of the seafood market. When you look at food as a whole, it’s 10 percent of the global GDP and almost $5 trillion ($4.8T) in size. Think about all those friends you know of that mad a lot of money in software, multiply that by 10, that’s the opportunity in food,” said Musk.

In addition to the increase in demand, supply will see a change as well. In Iowa, 25 percent of the farmland is owned by a woman over the age of 75, and 26 percent is owned by a man over the age of 75. This means over the next 5-10 years there will be an avalanche of supply for farm land. Musk also highlights how 25 million acres of land are also used for ethanol, something the EPA has been looking into.

Although the EPA does not regular farm lands, Musk suggests this may change due to the increasing pollutants entering the global water supply as a result of nitrogen based fertilizers. If these changes to occur, and if ethanol producing farms are reduced, there will once again be a large supply of fertile farm lands.

Future Farming

The future of farming consists of as much technology as it does understanding the earth. From engineers building automated machines to do an otherwise unscalable skilled trade, to data scientists analyzing data from satellites regarding soil fertility, moisture, and crop harvest times, technologists will have an opportunity to take a piece of a booming industry. Musk ends his talk with a simple statement. For those who feel they missed out on the internet and .com boom of the past, real food is the opportunity they should pursue.

Life is Beautiful takes place in late September in downtown Las Vegas. Tickets are available now. More information, including the set times to expect each panel or activity, will be available on the website in the near future, but right now, you can browse all the events in the Life Is Beautiful lineup, from music, art, and food to ideas and comedy.

Tags: artisan foodsBusinessFoodKimbal MuskLIBLife Is BeautifulLife is Beautiful Festivalorganic foodStartupVideo

The Future Of Farming Is Here And It Is Happening In Lakewood

The Future Of Farming Is Here And It Is Happening In Lakewood

Infinite Harvest is growing crops in an efficient, environmental friendly way.

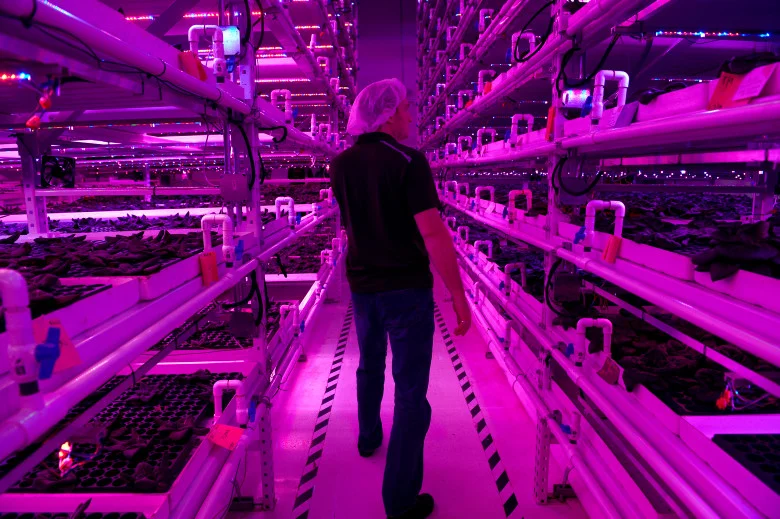

Tommy Romano walks through the grow room at Infinite Harvest, a vertical farm, Aug. 29, 2017 in Lakewood. Kathryn Scott,

By JOSEPH RIOS | jrios@denverpost.com | The Denver Post

September 5, 2017

Unless you’re a vertical farmer, the “fields” inside Infinite Harvest in Lakewood are unlike anything you’ve ever seen. Step inside under the glow of the blue LED lights and you might think you’re in a spaceship. Then you see the tens of thousands of plants growing in rows that stretch toward the ceiling.

Walk down the aisles of the 5,400-square-foot building, and you’re flanked by green, leafy plants growing on white tiers.

Infinite Harvest’s crops are grown in a controlled environment — lights, humidity, temperature, gases (think carbon dioxide), nutrients and fertigation, can all be regulated. Fertigation provides nutrients to plants and soil through an irrigation system.

“We can’t control the sun, but we can control the LED lights. The only thing unnatural (about our farming methods) is our ability to control the environment,” said founder Tommy Romano.

Infinite Harvest’s methods also differ in other ways from those used on many traditional farms, Romano said.

“We don’t use any pesticides or herbicides, no foliar sprays whatsoever. What you eat is 100 percent plant. We have a phrase that we pretty much use: We are ‘going beyond organic,’” Romano said.

“Going beyond organic” means producing crops in a way that is better for the environment, Romano said. He estimates Infinite Harvest uses 95 percent less water than a traditional farm with the same harvest.

“We bring the water right to the plants rather than letting it seep through the soil. We don’t spray, we don’t irrigate through sprinkler systems. We save a lot of water from that standpoint,” Romano said.

Infinite Harvest, which was 5 years old when it made Lakewood its home in 2014, is currently growing about 60,000 plants. Romano said it has the capacity to feed roughly 2 percent of the more than 140,000 people who live in Lakewood, based on average annual consumption rate. It’s owned by a group of shareholders interested in boosting efficiency in modern farming. One example of Infinite Harvest’s efficiency: It can grow and harvest year-round with no worry about weather damage.

“I don’t care if it’s the middle of January or the middle of July. You get the same thing,” said operations manager Nathan Lorne.

Infinite Harvest grows lettuce, kale, basil, arugula and other crops sold as fresh produce to local restaurants. Its harvests are also making their way into the kitchens of area schools. Buyers are interested in the farm-to-kitchen freshness, Lorne said.

“From the time we harvest it’s usually on someone’s lunch or dinner plate at the restaurants within 24 hours,” Romano said. “That freshness factor produces a lot more flavor.”

The business is attractive to employees too, because it offers year-round work rather than the seasonal work found at many traditional farms.

According to “Vertical Farming Market: Global Opportunity Analysis and Industry Forecast, 2017-2023,” a report by Research and Markets, the global vertical farming market is projected to reach $6.4 billion by 2023. In 2016, the global vertical farming market was valued at $1.5 billion.

“People are starting to understand that there is a demand for this. There is a viable business. We’re just still working on all of the kinks, technology-wise, and teaching the market more about this type of product,” Romano said.

Romano’s interest in feeding people in the distant future inspired his business. The former aerospace engineer focused on space habitat and colony design while working toward his master’s degree at the University of Colorado Boulder. While there, he wrote a thesis about how to feed a colony on Mars.

“I figured, well, if I can do this in such an adverse environment on Mars and produce healthy, sustainable crops, why aren’t we doing that here?” he said. “We have more people to feed here than we do on Mars.”

Nanochemistry Innovator Debuts GrowBlade™ Flat-Panel Growlights at NYC AgTech Week

Nanochemistry Innovator Debuts GrowBlade™ Flat-Panel Growlights at NYC AgTech Week

September 05, 2017 10:54 AM Eastern Daylight Time

SAN FRANCISCO--(BUSINESS WIRE)--Light Polymers, a nanochemistry startup with R&D operations in Silicon Valley, Taiwan and Korea, is debuting their GrowBlade™ flat-panel horticulture lighting at the third annual NYC AgTech Week.

Light Polymers is debuting their GrowBlade™ horticulture lighting at the annual NYC AgTech Week. #nycagtechweek

Tweet this

Hosted by the NYC Agriculture Technology Collective, NYC AgTech Week 2017 includes tours, workshops and presentations that engage attendees on the bleeding edge of urban agriculture knowledge and development. AgTech Week 2017 kicks off on September 16th followed by 6 days of events across the city. Light Polymers is also September’s featured sponsor for Agritecture, a leading urban agriculture blog and a founding member of the collective.

Light Polymers’ GrowBlade™ flat-panel grow lights are part of a new generation of LED lights that improve the productivity of multi-layer indoor cultivation for leafy greens and herbs, seedlings, clones, grafts and tissue culture. GrowBlade™ flat panels are made possible by our proprietary Crystallin® lyotropic coating and suspension chemistry which is water-based, lowering manufacturing costs.

“Our self-aligning coatings can be applied with high yield and low cost. The coating packs phosphor particles in a dense layer maximizing light conversion, allowing us to lower both production and operating costs. The result is GrowBlade™ light panels that are cheaper, thinner and more efficient than conventional grow lights. These advancements mean lower initial costs, lower operating costs and improved productivity for indoor farms,” said Sandor Schoichet, VP of Grow Products at Light Polymers.

About Light Polymers

Light Polymers is a nanochemistry company with deep domain knowledge of lyotropic liquid crystals, which have use in many applications including LCD and OLED flat panel displays, LED lighting, building materials and biomedical applications. Founded in 2013 in San Francisco, Light Polymers’ water-based coating and suspension chemistry is game-changing for a number of industries. For more information, visit http://www.lightpolymers.com/

About NYC AgTech Week 2017:

The Third Annual NYC AgTech Week will showcase the efforts of entrepreneurs, farmers and technologists who are advancing urban agriculture in New York City and beyond. The week commences with a brunch kick-off at Agritecture’s office at 40 Bushwick Ave and continues from September 16-21 at locations around the city. AgTech Week will feature farm tours, workshops, demos, networking and the ever popular Locavore Feast. Shown here is a recap video from the 2016 edition of NYC AgTech Week.

Why Agtech Grows In Brooklyn

Aug. 30, 2017 12:59 pm

Why Agtech Grows In Brooklyn

We've seen an abundance of agtech activity in the borough. But why here?

A rooftop greenhouse in Brooklyn. (Photo courtesy of @oneminutemeal)

By Nina Sparling / CONTRIBUTOR

The Brooklyn landscape is going green — and not just on rooftop farms. Of late, the borough has seen an explosion of innovation about how to grow fresh, healthy food in the heart of the city.

Digging beds on rooftops and harvesting baby radishes under the summer sun is rather 2010. This year, Blue Planet Consulting will reveal its +farm — a build-it-yourself, modular hydroponic farm unit for the home. Agrilyst is refining its workflow and data management software for indoor farms to automate aspects of the industry. Re-Nuble brought its fertilizer for hydroponic and soil applications derived from wholesale food waste to market in late 2016.

The agriculture technology industry (agtech for short) has seen extraordinary growth in Brooklyn in the past several years. Local entrepreneurs are pushing the boundaries of what urban agriculture looks like despite the fact that New York appears an unexpected home for such disruption in farming space. Nevertheless, Brooklyn has become a fertile environment for the future of food.

But why Brooklyn and not, say, Bakersfield?

It started with farm-to-table. Eaters borough-wide (and further afield) started thinking about where food comes from. Michael Pollan pleaded citizens to “vote with your fork.” “Local” food rose to — and perhaps surpassed — the level of “organic.”

Consumers began to embrace what industry leaders like Dan Barber and Alice Waters had espoused for decades: Where food comes from matters. And Brooklyn has necessary ingredients like the intersection of passionate chefs and a thriving network of farms.

“It’s hard not to be inspired by that pulsing entrepreneurial spirit,” Meg Savage, head of business development at food mag Edible told Technical.ly. “This is a community that cares about it’s food and where it is coming from … and longing for more advances.”

Edenworks microgreens. (Courtesy photo)

For businesses in the agtech space, the consumer and demand side provides plentiful momentum for continued growth and innovation.

“Rather than having a burden on the food system creating this large carbon footprint of having to bring food from as far as California, people are interested in how can we grow the same thing here,” Tinia Pina, founder of the organic fertilizer company Re-nuble said in an interview.

But operators — the industry word for farmers — in the agtech space are thinking about supply, too. Projections suggest the global population will exceed 9.7 billion by 2050. With New York City populations predicted to grow 9.5 percent by 2040, many agtech companies are focused on how to provide fresh and healthy food in ever more dense urban environments. “There is definitely a need to have more resource efficient localized production, distribution and consumption of resources related to food,” said Pina.

Most companies growing high-tech crops focus on leafy greens and fresh herbs. In New York, this makes sense, suggested Allison Kopf, founder of Agrilyst. “We have an interesting agricultural economy where it is a really big agricultural state. But the things that New York can specialize in year-round is very limited because of the climate and different sort of seasonality.”

The first agtech companies cropped up in Brooklyn in the 2009–2011 period. Industry leaders like EdenWorks, Gotham Greens and AeroFarms played a key role in laying the groundwork for innovation. “Smaller companies are following suit based on the population and population needs,” said Liz Vaknin, cofounder of Our Name is Farm, a digital and experiential marketing company. “In general, Brooklyn is an open-minded type of place to test out concepts.”

Seeds. (Photo courtesy of @oneminutemeal)

The result is something like an ecosystem.

“Once you have investors and customers then you have technology companies that are interested in selling products to that industry,” said Kopf. “You have companies like us and others sprouting up. A lot of it had to do with the market opportunity that is New York and the supporting resources that needed to exist just sort of do exist [here].”

And ample room for innovation and development remains.

Agtech is still young. Many of the companies involved are just a few years old, if that. Excitement from investors is growing, but solid investment requires education and transparency.

“There is definitely room for more collaboration between operators,” said Re-Nuble’s Pina. “It’s hard, each farm has its own intellectual property that they’re trying to keep defensible so they can raise money. But in driving conversation with local stakeholders at the municipal and corporate levels, we need to work together to show how we can make the supply chain more sustainable.”

Funding is a major concern across the board. “We need intelligent capital especially on the loan side,” said Kopf of Agrilyst. “This is a massive infrastructure investment — far too often farms are trying to secure venture capital. But then banks have to understand the technology. Traditional farm loans don’t work the same way yet.”

Local policymakers are beginning to catch on. The Brooklyn Borough President’s office just announced $2 million in funding for an urban agriculture incubator. Further public infrastructure involvement could be a game changer. “If government money is available, the terms are going to be different than private equity money or venture capital funds,” said Vaknin. “All together, that kind of creates a perfect storm for robust growth.”

Edenworks microgreens. (Courtesy photo)

Reddit Cofounder & Joe Montana Invest in $6m Seed Round for Stealthy iUNU

Reddit Cofounder & Joe Montana Invest in $6m Seed Round for Stealthy iUNU

AUGUST 22, 2017 | EMMA COSGROVE

Seattle-based greenhouse software company iUNU has raised $6 million from Initialized Capital and Liquid 2 Ventures, run by Reddit-cofounder Alex Ohanian and NFL hall-of-famer Joe Montana, respectively. Second Avenue Partners and Fuel Capital also joined the round.

The round sees iUNU come out of stealth for the first time since pivoting from a plasma lighting business.

iUNU’s greenhouse software platform “Luna” uses computer vision and artificial intelligence to continuously build detailed models of plants to monitor the health and progress of flowers, leafy greens, and succulents.

“It’s about measuring the plant from the most basic level, trying to measure a multitude of variables to give us a true metabolic growth rate,” said founder and CEO Adam Greenberg.

Luna can detect growth down to the millimeter and, using multispectral photography, creates 3D models of plants to analyze and improve growing recipes — the light, water, temperature and nutrition given to any plant — with each new planting.

Greenberg, who’s father worked in floral greenhouses as a botanist, said that greenhouse recipes are rarely optimized over time. With Luna, recipes not only optimize automatically, but growers can make small adjustments and see the effect in a matter of hours.

Luna measures growth rate, color, readiness — meaning ration of flowers to buds — and space utilization in the greenhouse, but iUIU isn’t looking to replace enterprise resource planning (ERP) systems.

“This solution turns greenhouses into data-driven manufacturing plants. It is both a seriously practical and crucial commercial application of AI to a fundamental industry,” said Alexis Ohanian of Initialized Capital.

The hardware required is a moving camera plus sensors, which allow for high granularity 4k images and 3D models. Growers pay a subscription fee based on the size and complexity of the operation. Greenberg says that these tools are meant to “scale” each individual grower.

“We think that one of the bottlenecks is that growers can’t run around and get to as many problems as they want every day. We want to point their attention to where it is most needed,” said Greenberg.

Luna alerts the grower to problems, but it doesn’t tell them how to react. “Those are highly trained eyeballs, so we don’t want to do their job for them. We want to enable them to do their job better.”

The company has recently completed three years of testing in large-scale commercial greenhouse operations of up to 800,000 sq. ft. and the artificial intelligence element of Luna will take that learning and adapt to each individual space over time, with growers owning their own data.

Greenhouse growers have a particular term for the roughly 20% of their crop that is thrown out on average: “scrap and dump.” According to Greenberg, scrap refers to when crops die and dump refers to when they become overripe in the greenhouse. He is looking to reverse that trend by increasing the capacity of each grower to monitor large commercial operations.

Founded in 2013, iUNU has offices in San Francisco and San Diego along with its Seattle headquarters.

In a past iteration of the company, iUNU sold plasma lighting to indoor farming operations. In 2014 the company received a $50,000 investment from Village Capital’s Agtech Accelerator program.

USDA Secretary Impressed By NH Agriculture Innovation

September 2, 2017 | CONCORD, N.H. | The Associated Press

USDA Secretary Impressed By NH Agriculture Innovation

New Hampshire may not be part of the nation's farm belt, but U.S. Agriculture Secretary Sonny Perdue says he's impressed with what he saw in the Granite State.

Perdue on Friday toured Lef (pronounced Leaf) Farms to learn how year-round, indoor farming can be far more efficient than traditional agriculture operations. The Concord Monitor reports (http://bit.ly/2eOsXx1 ) that the hydroponic farm aims to produce 3,000 pounds of leafy greens every 24 hours.

Perdue says New Hampshire farmers are taking "two- and twenty- and hundred-acres and making a sustainable lifestyle out of a product that we all need."

Perdue was in New England on a two-day "Back to Our Roots" trip to discuss the 2018 Farm Bill with farmers and other agriculture producers.

Scotts Miracle-Gro Sells Off International Operations To Focus On Core Business and Hydroponics

Scotts Miracle-Gro Sells Off International Operations To Focus On Core Business and Hydroponics

The lawn-and-garden giant also anounced pending acquisition of "marquee brand" in hydroponics, an ancillary sector of the cannabis industry

PUBLISHED: AUG 31, 2017 | By Alicia Wallace

Scotts Miracle-Gro has shed its Australia and European businesses in a deal that frees up the company to direct its attention on lawn-and-garden products and an ambition to become “the world’s most successful hydroponic gardening business.”

The Marysville, Ohio-based Scotts Miracle-Gro Co. on Thursday completed the previously announced sale of its overseas operations to Exponent Private Equity LLP. The $250 million deal includes operations in Australia, Austria, Belgium, France, Germany, Poland and the United Kingdom, leaving Scotts in a position where close to 100 percent of its sales and profits would come from North America, officials have said.

Related stories

The sale to Exponent and a previous divestiture of Scotts LawnService allows Scotts to dedicate its money and attention to its long-established core business and its high-flying venture into hydroponics. Scotts has spent hundreds of millions of dollars plucking up sector leaders and folding them into subsidiary Hawthorne Gardening Co. in a move to capitalize on the ancillary wings of the fledgling U.S. marijuana industry.

“The integration of acquisitions under the Hawthorne umbrella is proceeding as planned, and we are in the closing stages of completing the acquisition of a marquee brand in another category of hydroponics,” Jim Hagedorn, Scotts chief executive officer, said in a statement.

“Our goal remains the same: to create the world’s most successful hydroponic gardening business.”

Scotts’ jaunt into hydroponics started in Boulder, Colo., where it invested in AeroGrow International, a maker of indoor garden systems. Scotts now owns a majority stake of AeroGrow.

The international deal comes a year after Scotts shuttled its LawnService business into a joint venture with TruGreen. Scotts took a 30 percent stake in that venture and has received $290 million in cash as a result — including an $87 million dividend announced Thursday.

Walker Celebrates Opening Of Aquaponics Facility

Walker Celebrates Opening Of Aquaponics Facility

Gov. Scott Walker Thursday joined employees of Superior Fresh LLC. to celebrate its grand opening.

Owners say the 3.75-acre aquaponics facility will produce more than 2 million pounds of fresh Atlantic salmon, rainbow trout and leafy green vegetables annually.

“The complexity of the farm, ranging from automation to water chemistry and biology, has created some very exciting, high-end jobs,” said Walker.

The facility combines aquaculture and hydroponics whereby waste from fish will be used to supply nutrients for plants grown hydroponically. 99 percent of the purified water is recirculated.

Owners, Todd and Karen Wanek stated, “We want to lay the groundwork for sustainable food production, not by reinventing the wheel, but by refining processes and lessons learned to create a one-of-a-kind business.”

Superior Fresh has partnered with UW-Madison, UW-Stevens Points, UW-La Crosse, and UW-River Falls for research opportunities for students. The facility includes the first indoor Atlantic salmon farm in the United States and a 123,000-square foot greenhouse. The company employs nearly two dozen people and plans to expand operations throughout the world once the Northfield facility becomes fully operational.

UK’s First Commercially Viable Vertical Farm Being Assembled

UK’s First Commercially Viable Vertical Farm Being Assembled

Food will be grown in a stacking system in a new building at Invergowrie

September 2, 2017

An indoor farm being built on the outskirts of Dundee is expected to be growing salad leaves and herbs by the end of the year.

The futuristic construction nearing completion at the James Hutton Institute (JHI) at Invergowrie will be the UK’s first commercially viable vertical farm.

It is being built by Intelligent Growth Solutions, (IGS) in collaboration with global automation business, Omron.

The company has just closed its facility at Guardbridge where it was working on prototype models which involved combining efficient smart lighting with automation and power to grow fresh produce in vertical towers.

IGS chief executive Henry Aykroyd said that the Guardbridge project had led to strong relationships with local universities and scientists at JHI who aimed to improve the plant science involved with this technology.

“Vertical farming allows us to provide the exact environmental conditions necessary for optimal plant growth,” he said.

“By adopting the principles of Total Controlled Environment Agriculture (TCEA), a system in which all aspects of the growing environment can be controlled, it is possible to eliminate variations in the growing environment, enabling the grower to produce consistent, high quality crops with minimal wastage, in any location, all year round.”

The company will initially be growing salad leaves and herbs and the long term goal is to grow a higher volume of lower value products such as tomatoes and cucumbers. IGS then aims to roll out the technology and create other vertical farms across the country.

Food will be grown in a stacking system with LED lighting, and nutrition will come via hydroponics. Mr Aykroyd saidautomation, energy reduction technology and advanced biological research would be the three key pillars to success.

He added: “Partnering with two leading experts, Omron and the James Hutton Institute, to deliver this provides the very best opportunity for a new approach to vertical farming.”

JHI chief executive Professor Colin Campbell said: “This initiative combines our world-leading knowledge of plant science at the James Hutton Institute and IGS’ entrepreneurship to develop efficient ways of growing plants on a small footprint with low energy and water input.”

nnicolson@thecourier.co.uk

The Finish Line Debuts On-Campus Farm

The Finish Line Debuts On-Campus Farm

Posted: Aug 24, 2017 4:23 PM CDTUpdated: Aug 24, 2017 4:23 PM CDTBy Dan McGowan, Senior Writer/Reporter

(Image of The Finish Line's Urban Farm courtesy of the city of Indianapolis.)

INDIANAPOLIS - Indianapolis-based The Finish Line Inc. (Nasdaq: FINL) has marked the opening of a 7.3-acre farm on its corporate campus on the city's east side. The athletics retailer says the farm is one of the largest in an urban setting in the state. The urban farm is a collaboration with Greenfield-based Brandywine Creek Farms and will produce cantaloupe, tomatoes, cucumbers, bell peppers and zucchini and include space for 250,000 bees.

The vegetables grown on the farm will be distributed by Brandywine Creek Farms evenly to the wholesale market, to retailers and to charity. Total Rewards by Finish Line Senior Director Kim Kurtz says "by growing and sharing this produce, we will develop a healthier community together including our Finish Line family and our nearby neighbors."

The goal, officials say, is to provide employees and the public with fresh and affordable food that can be stored at room temperature.

Agrotechnology Prepares For its Arrival in Brazil And The US

Agrotechnology Prepares For its Arrival in Brazil And The US

The Alicante company Agrotechnology Group has accelerated its plans for international growth. The biofertilizer company is preparing its entry into Brazil and the US, two of the World's main markets.

With it the company plans to reach a turnover of 40 million euros in 2021, which means quadrupling its current size, according to Enrique Riquelme, CEO of the company. The group closed the first half of the year with a 40% growth in revenues.

The company has focused this growth on new markets. "In five years the international business has gone from 10% to 55% and the goal is to reach 80% at the end of the strategic plan in 2021," says Riquelme.

The company has committed its strategy to Latin America and North America, regions where a 40% growth is expected over the next three years in the biofertilizer business for organic crops. "There are no export tariff barriers, but there are phytosanitary ones, and being able to export to zero waste standards is what food companies are looking for to open new markets," explains the manager.

As for its expansion to the US, the company already has products registered for marketing. "It is a mature market but the legislation is simpler than in Europe", emphasizes Riquelme. He acknowledges that the competition is complicated, with giants of the sector such as Monsanto, but maintains that its segment of customers is different from that of the multinational.

Together with the US, the company plans to open offices in Brazil, Argentina, Poland, Germany and Italy, in addition to those already in Chile, Mexico and Peru. "Then China will arrive," he announced.