Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

EAT LOCAL + HEALTHIER + GREENER + FRESHER

As Americans increasingly reject cheap, processed food and embrace high-quality, responsibly-sourced nutrition, hyper-local farming is having a moment

EAT LOCAL

EAT FRESHER

EAT HEALTHIER

EAT GREENER

Photo: AeroFarms

image taken by photographer Holly Challinor, Jones Food Company Ltd.

HELIPONIX

TOP USAGE OF FARMLAND BY STATE

ALL OF THE AG LAND IN THE WORLD

AUSTRALIA - VIDEO: Shipping Container Farm Teaching TAFE Students More Than Just Agriculture

Nestled beside a building on a TAFE campus in Toowoomba is an ugly metal shipping container, but it's no ordinary storage shed

August 16, 2021

By Lucy Cooper

Nestled beside a building on a TAFE campus in Toowoomba is an ugly metal shipping container, but it's no ordinary storage shed.

Key points:

TAFE is using a shipping container farm to teach students about alternative farming

All features of the farm are controlled by an app

Agriculture, hospitality, and IT students are using the "grow pod" in their studies

Step inside and it's bursting with greenery.

Packed floor to ceiling with vegetables and herbs like basil, kale, mint and mustard, this state-of-the-art modular farm is changing the future of agriculture, all with the push of a button.

TAFE Queensland school manager Elaine Wallace said the "grow pod" aimed to change students' perspectives on traditional farming.

"Often when people think about agriculture, they think, 'Oh, I don't want to go stand in the sun all day picking vegetables, that's a bit too dirty for my liking," Ms. Wallace said.

"This is just one of those technologies that really enables students to get involved in something different and something up and coming."

Student Kallia Stebbins said when she first saw the vertical farm she was amazed by the technology.

"I didn't realise that you can grow crops like this, compared to just out in the middle of a field," she said.

"Now that I've seen this, it's very cool. I'm very interested to learn more about it."

A farm controlled from the palm of a hand

The container farm is controlled remotely with an app.

To switch the lights on inside, Ms Wallace simply whips out her phone.

"If we have a look at our monitors, it tells us that our irrigation cycle has started up, so we can set the cycle to however long or short we need it," she said.

"It's drip irrigation from the top filter through to the bottom and it's caught in the gutter that is at the bottom.

"We have pumps that will feed nutrients into the water and then, of course, we've got our lights, which are LED lights, and they are also set on a timer, so they are grow lights."

'Absolutely no limits'

It's not just agricultural students reaping the benefits of the multidisciplinary project.

Information technology students studied the app controlling the farm, while electrical students looked at how the farm kept running.

Hospitality and cookery teacher Nev Siebenhausen said his students also gained valuable first-hand experience in paddock to plate catering.

"For our students, it's a great opportunity to obviously shorten up the duration and travel on the product," he said.

"It's great for our guys to see different ways it can be grown."

Mr Siebenhausen said the walk up the hill from the grow pod to the hospitality school reduced carbon miles and cut waste by 70 percent for produce like basil, which had a short lifespan.

Any leftover produce is donated to the food relief charity, Oz Harvest.

Talks are also underway to trial sensory herbs for community service students to study the calming effects on people.

"The possibilities are endless," Ms. Wallace said.

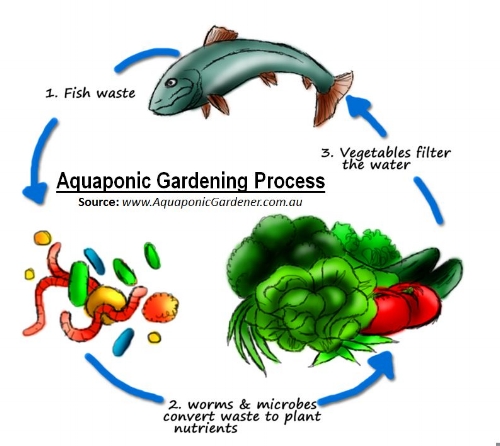

VIDEO: Aquaponics Greenhouse Fueled By Renewable Energies

This is the Ekoponics system. The aquaponics greenhouse is built with an Ekodome Cosmos geodesic dome frame system, while the renewable energy station is made with an Ekodome Seed dome frame

This is the Ekoponics system. The aquaponics greenhouse is built with an Ekodome Cosmos geodesic dome frame system, while the renewable energy station is made with an Ekodome Seed dome frame.

Solar panels and vertical wind turbine-powered pumps provide energy to the system to recycle water and nutrients in a closed-loop system that provides productive and sustainable food production. It is still developing, but continuous R&D in aquaponics will help sustain healthy food production.

For more information:

Ekodome

www.ekodome.com

11 Aug 2021

USA: VIDEO: Veteran Finds Peace, Purpose In Unique Kind of Farming

John Miller's routine may seem a bit "scaled-down" compared to his former life as a combat soldier. Miller spends much of his time in a 40-foot-long shipping container converted into a hydroponic farm field. Hydroponics involves growing plants without soil.

KENTUCKY

August 2, 2021

LOUISVILLE, Ky. — As John Miller prepared to leave the Air Force, the combat veteran admits he had no idea what he was going to do next.

What You Need To Know

John Miller served 14 years in the Air Force

The Louisville resident is the owner of Falls City Farms

Miller has found peace and purpose in hydroponic farming

In the future, Miller hopes to expand and employ fellow veterans

John Miller's routine may seem a bit "scaled-down" compared to his former life as a combat soldier. Miller spends much of his time in a 40-foot-long shipping container converted into a hydroponic farm field. Hydroponics involves growing plants without soil.

A close-up of Miller's baby kale. (Spectrum News 1/Jonathon Gregg)

“In essence, we sell a lot of things what we would consider baby," Miller explained. Little white turnips is just one crop of many growing inside Falls City Farms. “Right now I’m just pulling off the plug to turnips and then clean up any of the leaves."

The Iraq War combat veteran grows, prunes, packages, and sells a variety of greens to Louisville restaurants, online and at local markets.

“Here is our wasabi arugula, this is one of our fresh herbs, our dill, this would be our romaine trio," Miller said while touring his indoor farm.

Scaled-down? Maybe, but the hydroponic farm has helped Miller overcome what can be a sizable challenge for soldiers adapting to life after service.

“I got into this post-military, trying to find my next thing because I didn’t know what I was going to do when I got out," Miller said.

Miller served 14 years in the Air Force. His wife Amy is still active with 17 years to her credit. In his pursuit to figure out the next chapter of his life, Miller learned about hydroponic farming from a marine veteran in San Diego.

Falls City Farm grows a lot of produce in just 320 square feet. (Spectrum News 1/Jonathon Gregg)

His operation encompasses 320 square feet and boasts 6,600 individual plant spaces. Crops grow thanks to a sophisticated watering system and good-old-fashioned artificial sunlight.

“Because we are in a shipping container, the plants and the crops don’t get any of the big yellow sun outside so we have to create that inside," he said. "So we do LED lighting because it is better from an energy standpoint as well as heat."

Miller has lots of time and enough room to think about his life as a soldier and his new career as a farmer.

“If I am being frank with you, I miss being surrounded by other airmen and folks I used to lead," he said. "But it is calming to be in here with the plants and at the end of the day, that’s one of the reasons I chose this path.”

He was after peace and a purpose, and now his purpose includes bringing other veterans aboard.

“A lot of veterans, as we know, suffer from trying to find that next mission. Hopefully, one day soon be able to bring fellow veterans in here to teach them the art of farming through hydroponics to help them find peace and purpose as well," Miller said.

At first, Falls City Farms may appear to be a small operation, it’s only until you spend time on the inside do you see all the big ideas growing.

“I fell in love with the sense of a day’s accomplishment of work, a sense of comfort of being inside a greenhouse," Miller said.

SINGAPORE - VIDEOS: How IoT And Machine Learning Are Automating Agriculture

A new generation of farmers is tapping the internet of things and machine learning to operate self-sustaining urban farms with minimal supervision

A New Generation of Farmers Is Tapping The internet of Things And Machine Learning To Operate Self-Sustaining Urban Farms With Minimal Supervision

By Aaron Tan, TechTarget

21 Jul 2021

A new generation of farmers is turning to technologies such as the internet of things (IoT) and machine learning to automate agricultural production, alleviating the need to toil on the land while keeping a watchful eye on their crops.

Joining their ranks is Phoebe Xie, director, and co-founder of Singapore-based agrotechnology startup AbyFarm. Teaming up with technology service provider SPTel, Xie is building a smart hydroponics farm in a greenhouse that uses a plethora of IoT sensors, including video cameras, to keep the farm humming around the clock.

“To run a self-regulating farm at the optimal temperature with optimal water and nutrient supply, and to control the quality and taste of vegetables and fruits, we need IoT sensors,” she said, adding that the farm and its sensors collect and monitor thousands of data points, including humidity and temperature.

With the data and in certain environmental conditions, processes and actions are automatically triggered to protect crops from the elements. For instance, if the temperature or humidity gets too high, fans, water curtains, and roof shades are activated in the greenhouse.

Xie said the smart farm, located at a rooftop carpark in Singapore, is also equipped with sensors that monitor the pH and electrical conductivity levels of water. Among the sensors, which are connected to a Lora low-power wide area network, is a dozer that automatically releases acidic or alkaline nutrients to maintain optimal pH levels.

Whereas the farmers of old had to physically inspect their crops, AbyFarm’s agronomists and farmers can do so remotely using video cameras and image recognition technology to identify crops that might be succumbing to disease.

“If the image recognition finds that a plant is likely to be sick, the farmer will be alerted to go onsite to check how the plant is right now,” said Xie, adding that agronomists will also advise farmers on taking corrective actions to prevent disease or restore the health of their crops.

Like any machine learning system, AbyFarm’s algorithms get smarter over time. Each time a crop is affected by disease, data about the occurrence and corrective action is fed into the system, enabling its algorithms to formulate solutions for other farmers with similar crop issues – without consulting an agronomist.

With that, said Xie, even those who are new to the field can use the system to guide them on treating diseased crops, which can be isolated from other crops to prevent cross-infections.

AbyFarm’s automated farming system, which is hosted on SPTel’s private cloud, can also advise farmers on the best time to transplant their crops after germination and harvest them later for sale, said Xie.

Heng Kwee Tong, vice-president for engineering and customer solutions at SPTel, said the company has built up a software-defined platform to help companies like AbyFarm overcome the challenges of deploying applications such as IoT.

“The common struggle that companies like AbyFarm face with building an IoT solution is that it is quite intensive in terms of ICT infrastructure,” said Heng. “You’ve got to find the radio connectivity like Lora, subscribe to a service provider, and connect your sensors to a sensor collector.

“We make it easy by investing in a platform and because we are a service provider with edge hub assets for deploying radio connectivity, all AbyFarm needs to do is to bring their sensors onboard.”

Going forward, Heng said SPTel is looking to support next-generation video analytics capabilities through edge cloud services that can be used to crunch workloads closer to where they reside, reducing latency.

AbyFarm was one of six companies to win contracts from the Singapore Food Agency last year to build urban farms at nine rooftop carparks in public housing estates across Singapore.

The goal is to collectively produce about 1,600 tonnes of vegetables a year in a bid by the city-state – where less than 1% of the land is used for agriculture – to become more self-sufficient in meeting the nutritional needs of its people.

That could well be achievable with technology that makes farming more efficient, scalable, and less labor-intensive than before. “We are willing to train and educate the next generation in agrotechnology because now you don’t need 10 farmers to take care of one farm,” said Xie. “It’s just looking at the dashboard and, with the alerts, doing what is required.”

Vertical Farming: Growing Up After The Pandemic

As COVID-19 restrictions are easing around the globe, one of the things we have learned from the pandemic is that it is time to redesign and reengineer the food supply chain. Vertical farming may be the answer.

July 29, 2021

The Top 5 Benefits of Vertical Farming for Building a Sustainable and Resilient Fresh Food Supply Chain

“The COVID-19 crisis has really shown the cracks in the system. And I think that it was a test by Mother Nature to say, ‘Humanity, get your act together because your food systems are pretty fragile.’" This was an observation made by Dr. Nate Storey, co-founder and Chief Science Officer at Plenty, one of America’s leading indoor farming companies. Dr. Storey participated in a recent vertical farming webinar, co-presented by Heliospectra and the Association for Vertical Farming (AVF). Its purpose was to discuss the road ahead for vertical farming and building a sustainable blueprint to supply food to the world.

The global response to the pandemic had an impact on all industries, and the food supply chain was not exempt:

Laborers were unable to tend to the crops.

Farmers were unable to get their produce to market.

Restaurants, schools, and independent stores were shuttered.

Consumers had to adapt to different ways to source their food.

As COVID-19 restrictions are easing around the globe, one of the things we have learned from the pandemic is that it is time to redesign and reengineer the food supply chain. Vertical farming may be the answer. Here are the top 5 benefits of vertical farming for building a sustainable and resilient fresh food supply chain:

1.) Proximity to Markets Results in Efficient Distribution

Transportation channels were disrupted as governments responded to the pandemic, which made it difficult for rural farmers to get their fresh produce to market. Vertical farms have a much smaller footprint compared to traditional field farms, which means they can be established inside, or closer to, urban areas. Heliospectra’s CEO, Ali Ahmadian, remarked during the webinar that “Urbanization is increasing, and by 2050 we're going to have close to 70% of the world’s population concentrated in urban areas. The population is growing, and COVID-19 has shown us that current food supply logistics are not sustainable when under stress. Going forward, we need to find ways to produce more food locally, where the population lives.” Proximity to market should also help reduce transportation costs and CO2 emissions, while time to market and produce freshness should improve.

2.) Innovative Technology Boosts a Growing Industry

Vertical farming is still in its infancy, but Dr. Storey noted, “We’re on the cusp of huge growth and expansion as an industry. In the next 10 to 15 years, vertical farming will rise as one of the dominant forms of agriculture.” He continued, “Technology has caught up with the vertical farming vision, and we're going to start to see tremendous growth over the next decade. I'm pretty excited about that.”

Some of the fundamental technologies available to vertical farmers today include the ability to control and monitor:

Lighting

Irrigation

Nutrients, PH, and CO2 levels

Air temperature and humidity

AI, big data, and intelligent controls

Vertical farms address many of the shortcomings of traditional field farms. Dr. Joel Cuello, a Professor of Bio-Systems Engineering at the University of Arizona, noted that “Vertical Farming is where artificial intelligence (AI) really has a big role to play. A lot of folks have already done optimizations in terms of lighting, temperature, relative humidity, but they are really done in a very limited scale. With big data and then applying AI, that is really a breakthrough waiting to happen in terms of vertical farming.”

LED grow lights and recent advances in AI and intelligent control technology have been catalysts for sustainable year-round growing, enabling vertical farmers to maximize crop yields, refine crop quality, and standardize production with no seasonal downtime. By providing the light spectra that plants need and a controlled growing environment in which they flourish year-round, commercial vertical farming equipment can provide a sustainable and resilient way to feed the ever-changing world.

3.) Modern LED Systems Increase Energy Efficiency and High-Quality Crop Yields

The quantity, quality, duration, and distribution of light that each plant receives can be optimized. Innovative lighting technology developments have enabled vertical farmers to produce more quality food with less. Dr. Storey commented, “At Plenty, the primary tech inputs are LEDs and semiconductor technologies. As the cost of LEDs goes down and the efficiencies go up, we reap the benefits with very little investment on our part.” He continued, “We have created our own technology cost curve around indoor agriculture, which shows costs going down and quality going up. An illustration of that would be yield at Plenty has gone up 12X in the last 18 months. We have improved yield to the same unit of energy by 12X.”

4.) Labor Profile Shift Reduces Operational Overheads

There has been more recognition since COVID-19 of the inherent benefits of indoor/vertical farming, which can produce more with fewer hands. Lack of labor, particularly in times of global crisis, is a big contributor to food insecurity. The promise of vertical farms is that they could become a factor for resilience in any food supply chain. Dr. Storey commented, “With vertical farming, the supply chain is less complicated. It changes the shape of the labor profile of the business, from employing many workers in the field, which is a source of instability for field production, to employing much smaller numbers of very highly trained people that are operating robotics and managing production lines.”

5.) Modular and Scalable Design to Meet Changing Market Demands

Another benefit of vertical farming is its ability to quickly respond to food demand. Vertical farms can be modularized, and the modules can be shipped on pallets and quickly set up where the demand lies. They can also be added to and scaled to accommodate the rotation of crops according to market needs. This scalability enables farmers to establish vertical farms quickly and anywhere there is a need for food. It can also help farmers meet latent market demands. Storey commented, “When we look at the market, we see a world that consumes only 30% of what it should in terms of fresh fruits and vegetables. So, as we talk about scaling farms, we also have to talk about latent demand, like how much demand is out there that isn't being accessed because of low quality or just the lack of access to fresh food.” The potential for scalable, modular farms to fill this market need is enormous.

The COVID-19 crisis revealed weaknesses in the food supply chain. Storey commented, “We already had a system under stress that was beleaguered by rising labor prices, by the extended supply chains, and the fact that most of the consumers have been separated from the producers.” He continued, “The places where we produce the food and the places where we consume the food have been stretching out further and further and further. In many cases, it's a global supply chain now. We've been pushing the field to its max.”

Want to know more? Watch the entire webinar: The Road Ahead for Vertical Farming Building Tomorrow's Industry Blueprint Today. WATCH NOW

The Philippines: Simple Is The best

Our investment is returned to us TEN TIMES PLUS in increased local participation in our FREE training programs and peaceful sleep knowing people are NOT going to bed hungry

I was motivated to develop our farm, Kitakitz Natural Farm, when I saw local children were suffering development issues. Kids of the same age in my hometown of Bloomsburg Pennsylvania are Significantly healthier. When we first retired to the Philippines in 2010 I was shocked when I discovered kids that were of similar ages to our 9-year-old were actually several years OLDER! They were short, lightweight, boney, and had numerous development issues including poor skin, hair, and dental health.

So I decided growing food for my own use was NOT ENOUGH!

Everything we do is 100% Organic and we do NOT use Chemical pesticides or fertilizers. Our Vegetables, Fruit, Flowers, Various Plants, Bamboo, trees & scrubs, cuttings & Seeds are grown in compost and vermiculture created soil.

We are also developing HYDROPONIC SYSTEMS USING HANGING VERTICLE BAMBOO POLES.

Throughout the farm, we apply NO TILL agriculture and permaculture food forest techniques similar to the Cuban Urban ORGANOPONICO & CONSULTORIO. We also provide FREE training to those who want to duplicate our programs and provide fresh produce, seeds, & Tools in ADDITION to wages for those who work on the farm. We also SELL fruits and Vegetables through our vendors at BELOW market prices. Our goal is NOT to make $$ but to help people to become 100% food Self Sufficient.

We have friends in the USA who help us sponsor families here. Our programs create Long term solutions for food Security. We are totally Unlike Government Give-away programs. State-sponsored programs are weak at best and only provide short-term solutions with minimal disbursement amounts of rice and processed food sufficient for only a few meals.

In nearly 100% of our cases, our PLAN is providing long-term solutions. For less than $100 per family, we set them up with over 150 lbs of food like Rice, Oats, Flour, Fruit juices, peanut butter, canned meat & fish, and of course SEEDS. Plus we provide EDUCATION on Nutrition & Meal planning, how to save seed, and growing sprouts and vegetables in limited space and sunlight. When they follow the PLAN within a few days our recipients are growing and eating their own FRESH food. Additionally, within a few weeks they can also be harvesting fast-growing crops like 50 DAY Radish, & 30 to 40 DAY Pakchoi, Spinach & lettuce. (See photos below of our standard Seed, Food & Sprouts Family plan)

Our investment is returned to us TEN TIMES PLUS in increased local participation in our FREE training programs and peaceful sleep knowing people are NOT going to bed hungry.

VIDEO: Foundation Farms, Corp., Reports A Second Harvest Is Currently Underway

Following an overwhelmingly positive response from customers who purchased the first crop last month, the word is spreading throughout the surrounding communities and this second crop is already sold even before harvesting has been completed

NEW YORK, NY / ACCESSWIRE / July 15, 2021 / Foundation Farms, Corp., ('Foundation Farms') a subsidiary of GME Innotainment, Inc. (OTC PINK:GMEV) today reported that the second harvest is currently underway at the company's E-ROOTS CENTRE located in the Red Deer, Alberta area.

Following an overwhelmingly positive response from customers who purchased the first crop last month, the word is spreading throughout the surrounding communities and this second crop is already sold even before harvesting has been completed. Consumers have been delighted with the "no blemishes" produce and we have had numerous reports that the flavors and palatability of the vegetable greens are, "much better than anything that we have ever purchased at local supermarkets."

In response to the market demand, the company has expanded from an assortment of six basic leafy greens and herbs in the first crop to a total of 14 leafy greens and herbs, two fruits (strawberries and cayenne peppers), and four varieties of edible flowers in this second crop. Management and on-site staff also report the very successful functioning of the E-ROOTS system with minimal labor input.

When asked about these results, Ed Kroeker, CEO of Foundation Farms stated "I am pleased to report that, if anything, we may have under-estimated the expectations we have held until now. There is a lot of attention paid to tangible benefits of vertical farming including environmental sustainability, low water usage, ability to convert urban waste spaces to food production, and reduction of food transportation logistics. Our E-ROOTS CENTRES are demonstrating that we can produce plant-based food products whose culinary qualities supersede anything currently available in conventional food markets. We plan to have the same impact on the plant-based food market as Angus-beef branding has had on the red meat market. This will soon become even more evident as we are getting ready to announce several new joint ventures."

Yves R. Michel, CEO of GMEV further added, "In just a few short months of production at the Red Deer area vertical farm, Foundation Farms is demonstrating an ability to set a new standard of excellence in this industry and the demand for the products supports profitability projections. With product demand this high for smaller population centers, I am excited to see what happens once some of the larger population centers get hold of this technology.

CONTACT:

Yves R. Michel

Chief Executive Officer and Director

208 East 51st St., Suite 170

New York, NY 10022

www.srcorpgroup.com

OTCPink: GMEV

Forward-Looking Statements

Certain statements in this press release constitute forward-looking statements. These forward-looking statements are based on current expectations and assumptions that involve risks and uncertainties and on information available to the Company as of the date hereof. The Company's actual results could differ materially from those stated or implied, due to risks and uncertainties associated with its business, which include the risk factors disclosed in its latest Annual Report on OTCMarkets.com, it’s Regulation A+ Offering Statement, and other filings with the Securities and Exchange Commission, including the sections entitled "Risk Factors" and "Management's Discussion and Analysis of Financial Condition and Results of Operations" contained therein. Forward-looking statements include statements regarding the Company's expectations, beliefs, intentions or strategies regarding the future, and can be identified by forward-looking words such as "plans," "anticipate," "believe," "could," "continue," "estimate," "expect," "intend," "may," "should," "will" and "would" or similar words. The Company expressly disclaims any obligation or undertaking to disseminate any updates or revisions to any forward-looking statement contained herein to reflect any change in the Company's expectations with regard thereto or any change in events, conditions or circumstances on which any such statement is based.

SOURCE: GME Innotainment, Inc.

VIDEO: Is the Future of Agriculture Micro-Farms?

Is the future of agriculture micro-farms? When the pandemic hit, the retail food landscape changed dramatically. With “big food” supplying most restaurants and grocery stores, they faced numerous challenges— from labor shortages, redistribution challenges to distribution sites with long travel times— causing many individuals to turn to smaller, local farms.

July 2, 2021

Is the future of agriculture micro-farms? When the pandemic hit, the retail food landscape changed dramatically. With “big food” supplying most restaurants and grocery stores, they faced numerous challenges— from labor shortages, redistribution challenges to distribution sites with long travel times— causing many individuals to turn to smaller, local farms.

In this week’s episode of TheSquare Podcast, we have a curious conversation with Jeff Bednar, Owner and founder of Profound Microfarms and Profound Foods. The Profound family business started as a 2.6-acre farm in Texas growing leafy greens, edible flowers, culinary herbs, and microgreens in 17,000 sq ft of hydroponic greenhouses.

Source: Vertical Farm Daily

"Central And Eastern Europe Can Be The Powerhouse of Global Food Security"

"Closed-system farming helps tackle the biggest challenges in global food supply security", says Tungsram president & CEO Joerg Bauer

July 6, 2021

"Closed-system farming helps tackle the biggest challenges in global food supply security", says Tungsram president & CEO Joerg Bauer.

Climate change causing extreme weather conditions in certain areas, overpopulation, soil contamination, the depletion of areas suitable for agricultural production, urbanization, and growing demand for quality food all point toward the increasing importance of local indoor farming and urban vertical farms. The world’s population is predicted to reach 9.7 billion by 2050 (2 billion more than today), with most of the growth set to take place in Africa and developing countries where climate change hits the hardest. Moreover, in just 10 years, humanity will need 50% more food than today (calculating with a current annual growth rate of 5%).

"We are convinced that outdoor farming alone will not be able to meet these challenges. The much-needed technological advances of precision agriculture, improved seeds, and irrigation will be needed to counterbalance the adverse impact of climate change alone: innovative solutions designed to ensure food security must complement this huge undertaking. Indoor farming stands out as one of the best-suited solutions," he explains.

"Indoor farms are highly water-efficient installations that take up considerably less space, and are independent from weather conditions and the change of seasons. Paired with other technology-driven solutions, these farms can be the guarantees of basic human wellbeing for billions of people, where basic wellbeing is defined by 2,200 calories of healthy, balanced food intake and 10 liters of water (for drinking, basic hygiene and cooking) per person a day."

Joerg Bauer with Tungsram

The company supplies LED / Vertical Farming solutions

Innovation and investment

However, for this exciting disruptive technology that balances on the thin line between agriculture, industry 4.0, and digital technology to provide real global solutions and be able to produce staple food for the masses, including integrated ecosystems that can also feed animals in a sustainable way, a lot of innovation and investment is necessary. "Humanity will have to embrace sources of food that go beyond the traditional approach, such as algae, bacteria, or insects, which often have a much higher conversion rate of feed intake to edible food. By cleverly combining different elements such as vertical farms, animal husbandry, insects, and fish, we can get very close to a zero-waste cluster with optimal productivity – allowing strategic autonomy even in countries with adverse climatic conditions."

Although Central and Eastern Europe do not typically bear the brunt of the most severe consequences of climate change and food scarcity, an increasing number of European initiatives focus, for example, on the impact of the 24% decline in water sources on the continent in the last few years.

"However, the CEE region could play a much bigger role than simply making the necessary investments to solve its own looming climate problems. I have always looked at the CEE region as a historically well-established bridge connecting Europe with developing countries in need and working closely with North Africa and the Middle East. It is up to the nations of this region, to us, to understand what happens to geopolitical stability if we fail to help these developing countries to deal with all the negative, sometimes catastrophic consequences of climate change and fast population growth. In addition to being our basic social responsibility and humanitarian obligation to offset these effects, it is also in our very own interest to act. Innovation is needed to propel sustainable food production forward and end hunger in the world," Joerg adds.

"Central and Eastern Europe’s commitment therefore should be to become a global food security powerhouse that develops and starts scaling the solutions, which will allow the citizens of developing countries to live a sustainable and worthwhile life in their home regions."

What should governments and businesses in the region do to achieve this?

"They should acknowledge that the CEE region could potentially play a significant role in these solutions and provide funding for research and innovation to scale food security. By doing so, we would all be working to make the world more livable and we would physically be sowing the seeds of human happiness."

Written by Joerg Bauer President & CEO of Tungsram, originally published in Globsec Disruptive Tech Trends in CEE

For more information:

Tungsram

Keith Thomas, Commercial Leader

keith.thomas2@tungsram.com

agritech.tungsram.com

VIDEO: Signify Expands LED Installation At Walters Gardens With Philips GreenPower LED Toplighting Compact

“It was a really easy decision to go with the Philips LED toplighting compact”, says Aren Philips, finishing lead grower at Walters Gardens. “The tops are fuller, the roots are more active, we are able to finish our hostas product 1 to 2 weeks ahead of schedule.”

July 6, 2021

Eindhoven, the Netherlands – Signify (Euronext: LIGHT), the world leader in lighting, is supplying Walters Gardens with the Philips GreenPower LED toplighting compact to expand their existing lighting installation. Walters Gardens is a market leader in the ornamental industry from Zeeland, Michigan, in the United States.

They first trialed Philips GreenPower LED toplighting in 2014 - one of the first growers in North America to install Philips horticulture LED grow lights over ornamental crops, with the aim to jump-start their spring perennial production.

As a result of the trial’s success, Walter’s Gardens partnered with Signify again, when expanding their lighted growing areas in 2019 - 2020, with the Philips GreenPower toplighting compact.

“It was a really easy decision to go with the Philips LED toplighting compact”, says Aren Philips, finishing lead grower at Walters Gardens. “The tops are fuller, the roots are more active, we are able to finish our hostas product 1 to 2 weeks ahead of schedule.”

Together with the high efficacy of the toplighting compact, and the easy 1:1 replacement of the HPS, leading to a great ROI, Walters Gardens knew the expansion would pay off.

Learn more about the Philips LED grow lights for floriculture here.

--- END ---

For more information:

Global Marcom Manager Horticulture at Signify

Daniela Damoiseaux

Tel: +31 6 31 65 29 69

Email: daniela.damoiseaux@signify.com

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings, and public spaces. With 2020 sales of EUR 6.5 billion, we have approximately 37,000 employees and are present in over 70 countries. We unlock the extraordinary potential of light for brighter lives and a better world. We achieved carbon neutrality in 2020, have been in the Dow Jones Sustainability World Index since our IPO for four consecutive years and were named Industry Leader in 2017, 2018 and 2019. News from Signify is located at the Newsroom, Twitter, LinkedIn, and Instagram. Information for investors can be found on the Investor Relations page.

FRANCE: In The Jungle Vertical Farm, The Aromatic Herbs See Life In Pink

Founded in 2016 by former financier Gilles Dreyfuss and a founder Nicholas Segui, this young growth launched the first site in chateau-theory. It plans to open two more by the end of 2022 and become the number one vertical vegetable farm in the country

June 26, 2021

Pascal Mollard-Chenebenoit

France Media Agency

Founded in 2016 by former financier Gilles Dreyfuss and a founder Nicholas Segui, this young growth launched the first site in chateau-theory. It plans to open two more by the end of 2022 and become the number one vertical vegetable farm in the country.

This agriculture works on hydroponics, i.e. without soil, the plants grow on a surface and receive water rich in nutrients. In all warm and humid weather, the garden is lit by LEDs.

Two production “towers” operate with platforms ten meters high. “By the end of this year, we will have nineteen,” Jungle president Gilles Dreyfus told AFP.

A tower can produce 400,000 plants a year. When all is said and done, the 38-year-old former financier explained that the annual production would be 8 million plants.

Taste

Jungle grows aromatic herbs (basil, parsley, cilantro, chives), microgreens (mustard, ple da radish, red shiso, wasabi) and salads (lettuce, arugula).

Playing in Ultra-Fresh its products are intended for mass distribution and its herbs are already available in some Parisian stores.

“Keeping the power of industrial innovation in the service of plant life”: this is the motto of the Jungle. “With pesticide-free plants we meet consumer uses and new needs, they taste, they are alive, they are recognizable and most of all they are produced very close to where they are sold and eaten,” says Gilles Dreyfus.

In the warehouse, the seed course, mounted on a tray, begins on an automated belt. Sow them accurately in a small container filled with surface.

Then to the germination rooms, with tropical climates, the plants stay for a few days. Before joining cultivation tours to thrive and reach maturity.

In the tower, a computer controls all the parameters (water, nutrients, lighting, temperature, humidity, CO2, Ventilation) and constantly adjusts them according to the desired target.

“By playing with the light spectrum and different color ratios, we can make a plant flower faster, more compact, have larger leaves, and change its morphology,” explained Michael Mittrand, agronomist and research and culture administrator.

Robot

A robot has the maneuver to manipulate the trays set up at fifteen levels and control their health condition.

“We have a lot more productivity because we optimize all the parameters,” Gilles Dreyfus stressed. “On earth, you will have a maximum of 3 to 5 crops of basil a year. We have 14 ”.

It aims for profitability by the end of 2022, with the second site at half its capacity.

Jungle also relies on plant production for perfume manufacturers and cosmetic brands. This activity already represents 30% of its turnover, but the company is silent on the flowers produced.

Product area is hidden from visitors. It grows there “rare flower”, which enters into the recipe for perfume, Gilles Dreyfus has the content to say.

After ten years in finance, he decided to change his life in 2015 after reading an article about vertical farming and went to New York to meet the “Father of Concept”, Professor Emeritus Dixon Despomier at Columbia University. He goes to a world conference on vertical agriculture in California.

“When I got back to Paris, I quit my job. I went all over the world to see what was already there ”. On the way, he meets Nicholas Dupuy, who has become his partner.

The Jungle raised just 42 million euros for takeoff.

Logan Leo

Experienced Media Personality skilled in Breaking News, Television, Intelligence Gathering, News Analysis, and Social Media. Strong media and communication professional with a Master of Science (MSc) focused in Economics from Harward University.

VIDEO: Sweden: Growing Food In Umeå In A Freight Farms Shipping Container

Ellen Bergström and Daniel Remes are growing food in Umeå, Sweden to create a resilient and sustainable local food system

Ellen Bergström And Daniel Remes Are Growing

Food in Umeå, Sweden To Create A Resilient

And Sustainable Local Food System.

Although they had little agriculture experience, the realization that their community needed a dependable food supply chain that offered fresh, quality produce even through the long, dark winter months, led them to start their Freight Farming business, MY Harvest.

Click on the video below to watch their story.

For more information:

Freight Farms

info@freightfarms.com

www.freightfarms.com

24 Jun 2021

VIDEO: Ohio Company Redefines Farming By Going Indoors

Farm Manager Noah Zelkind was working on Wall Street before making the switch to 80 Acres, which houses 20 different growing rooms

The Hamilton company 80 Acres Farm will now have produce in Kroger stores across the state.

BY OLIVIA WILE

June 24, 2021

CINCINNATI — The future of farming is right here in Ohio, and it’s happening indoors.

What You Need To Know

The company 80 Acres Farms has the ability to control and change the environment of each of the rooms where produce is growing

The farm doesn't see itself as competition with other conventional farms, but instead aims to help feed a growing population

Its produce is now being sold in Kroger locations in Ohio

The company 80 Acres Farms in Hamilton, 20 miles north of Cincinnati, is one of just a handful of “vertical farms” in the world. Farm Manager Noah Zelkind was working on Wall Street before making the switch to 80 Acres, which houses 20 different growing rooms.

“We have 10 levels stacked on top of each other, 10 rows long, and 10 tables inside of each row,” said Zelkind.

The company is able to control and change the environment of each of the rooms where produce is growing. It’s technology that’s years in the making.

“We went through and tried to study nature and replicate everything that’s important about it and really make sure we’re giving the plant exactly what it needs but in the most efficient way possible.”

It's a method Zelkind said gives the company ultimate control.

"This really is the next generation of farming," he said. "We have a completely different level over the control of the entire process of growing than anything anyone has done before.”

“You're going to get the same healthy fresh lettuce whether you're in the middle of winter and it's snowing outside or you’re in the middle of the summer.”

But he said the company is not trying to compete with conventional farmers.

"We don’t see ourselves competing with farmers at all,” said Zelkind. “If you look, we’re supposed to have 10 billion people in the world in the next 20 to 30 years, and in order to feed the population, we’re going to need 70% more arable land.”

The farm's produce is now available in Kroger stores across the state.

USA - FLORIDA: Finn Farms Begins Production At Babcock Ranch

The goal is to naturally grow produce year-round without fighting Florida’s humidity, and one company did it with 95% less water than traditional agriculture

Reporter: Erika Jackson

Writer: Jackie Winchester

June 21, 2021

From Seeds To Your Table,

There’s A One-Of-A-Kind Prototype

Greenhouse In Southwest Florida

The goal is to naturally grow produce year-round without fighting Florida’s humidity, and one company did it with 95% less water than traditional agriculture.

“This is controlled environment agriculture at its best,” said Oskari Kariste, founder and CEO of Finn Farms at Babcock Ranch.

What exactly does that mean? To break it down, the greenhouse is about the size of a soccer field. It can seed 60,000 plants a day and produce 1.5 million pounds of greens a year. That’s the same as 60 acres of open-field farming.

“This is totally the future of farming,” Kariste said.

He brought Finnish farming to Southwest Florida, dropping it in the heart of Babcock Ranch.

“What better way to do it than when you’re thinking about sustainability and innovation all at the same time,” said Syd Kitson, CEO, and chairman of Kitson & Partners.

The $13 million greenhouse uses recycled rainwater and condensation from the plants. It takes 95% less water to keep these plants thriving compared to traditional farming.

The plants grow on 300-foot-long tables. Most are harvested in less than 30 days.

“You have to see taste and feel the production in your hands and we are able to show how premium our quality is,” Kariste said.

“It’s always local and fresh, I think that’s the key component.”

Finn Farms is negotiating with buyers to start selling its produce. Phase two of the project is expected to be double the size and include vertical farming.

USA: WASHINGTON STATE - Ummah Sustained Agroecology Center - Long Time! We Have Been Getting Things Started Here On The West Coast. We Opened!

Ummah Sustained AgroEcology Center - U.S.A.C. features Washington States 1st Certified Jr Master Gardener, Youth Agroecology, and Discover through Hydroponic K8 Farm School programs

Ummah Sustained Agroecology Center, a unique opportunity for your K-8 child to be creative, and confident while building lasting friendships. Our youth development program nurtures a child’s instinctive curiosity through informal exploration learning experiences

Ummah Sustained AgroEcology Center - U.S.A.C. features Washington States 1st Certified Jr Master Gardener, Youth Agroecology, and Discover through Hydroponic K8 Farm School programs.

Our Certified Urban Permaculture center houses three hydroponic systems including Freight Farm, a greenhouse, raised beds, community garden, small session classroom, and Afrocentric resource library.

We offer volunteer opportunities through WSU Extension Snohomish County 4-H and AmeriCorp.

VIDEO: Can An Indoor Smart Garden Beat Outdoor Gardening? We Tested It

Can smart gardens really grow delicious vegetables inside your apartment? WSJ asked Timothy Hammond, an urban gardener, and educator in Houston, to test out Rise Gardens

Can smart gardens really grow delicious vegetables inside your apartment? WSJ asked Timothy Hammond, an urban gardener, and educator in Houston, to test out Rise Gardens hydroponic smart garden to see how the vegetables compare with his own outdoor garden.

Photo: Ben Hallock for The Wall Street Journal

Vertical Roots Expands To Atlanta, Partners With Two Wholesalers

The company partnered with two of the leading Southeastern produce suppliers, Collins Brothers Produce BB #:128652 and Phoenix Wholesale Foodservice BB #:134241, to place the farm directly at their facilities

June 11, 2021

CHARLESTON, S.C., June 10, 2021 /PRNewswire/ — Vertical Roots, the largest hydroponic container farm in the U.S. sustainably growing fresh leafy greens year-round, opened its third indoor farm in Atlanta, Georgia this June.

The company partnered with two of the leading Southeastern produce suppliers, Collins Brothers Produce BB #:128652 and Phoenix Wholesale Foodservice BB #:134241, to place the farm directly at their facilities.

The new Atlanta farm site will eliminate the need for produce transportation to the distributor and allow Vertical Roots lettuce to be delivered to local customers the same day it’s harvested.

Located within the Atlanta State Farmers Market, this is phase one of the company’s Atlanta expansion. With farm production underway, Vertical Roots Georgia Grown™ lettuce will be available in grocery stores in July 2021.

Crisp, sweet, tender, or buttery, Vertical Roots lettuces are nutritious, pesticide-free, and come in a wide variety of flavors, colors, and textures for culinary masterpieces and everyday meals. With long lasting freshness, produce is in the hands of consumers within one to three days of being harvested and has up to a 21-day shelf life.

Vertical Roots’ mission is to revolutionize the ways communities grow, distribute, and consume food. Farming directly at distribution hubs is a part of Vertical Roots’ distinctive strategy to eliminate a massive leg of produce transportation in order to reduce emissions and provide communities with fresh, locally-grown produce.

The new Atlanta farmsite will reduce produce transportation by an estimated 300 miles per delivery and will help meet the company’s retail demand that services thousands of grocery stores across the Southeast and Mid-Atlantic, as well as restaurants, universities, and schools.

“A large part of our mission is to grow food as close to the point of consumption as possible, and this farmsite accomplishes just that,” said Andrew Hare, co-founder, and general manager of Vertical Roots. “The Collins family are esteemed produce industry leaders for three generations, and we’re ecstatic about the unique grower-supplier partnership that we’ve cultivated.”

David Collins, President of Collins Brothers & Phoenix Wholesale Foodservice, said, “At Collins Brothers and Phoenix Wholesale, we’ve had the privilege to work with dedicated farmers across the country for decades. We’re thrilled to partner with Vertical Roots as they bring an innovative way of farming to the agriculture industry. We look forward to this relationship as we share a like-minded mission in providing our customers with high quality, fresh, local produce.”

Vertical Roots’ state-of-the-art indoor farms are manufactured from upcycled shipping containers at the company’s headquarters in Charleston, SC. The farm containers made their way to Atlanta on June 8, where farmers started seeding and transplanting to produce Vertical Roots lettuce within weeks.

A small footprint with a large output, the new farm will produce half a million heads of lettuce this year. Each 320-square-foot container maximizes the growing space with 3,400 plants per harvest, and up to 17 harvests per year.

Vertical Roots farms operate with the highest globally recognized food safety standards, eliminating the need for pesticides of any kind.

An AmplifiedAg, Inc.® company, Vertical Roots operates farms with proprietary software and technology. The farms don’t rely on soil, use up to 95% less water and grow crops 25% faster, compared to traditional farming methods.

About Vertical Roots:

An AmplifiedAg, Inc. company, Vertical Roots is the country’s largest hydroponic container farm and is revolutionizing the ways communities grow, distribute and consume food. Sustainably-grown indoors and pesticide-free, Vertical Roots leafy greens are fresh, clean, nutritious, and delivered to your local grocery store within one to three days of being harvested. Vertical Roots produce is available at thousands of leading grocery stores in 12 Southeastern states, educational institutions, restaurants, and other food service organizations. Vertical Roots operates farms in Charleston, S.C., Columbia, S.C. and Atlanta, Ga.

Tagged greenhouse, lettuce, vertical farming

USA - ALABAMA: Auburn College of Agriculture Using High-Tech Shipping Containers To Grow Produce For Campus Dining

Unique ‘Vertical’ Farms part of Planned 16-Acre Transformation Garden On Campus

High-tech Horticulture

Unique ‘Vertical’ Farms part of Planned 16-Acre Transformation Garden On Campus

June 10, 2021

Josh Woods | College of Agriculture

Recycled shipping containers have gained popularity in recent years, being converted into everything from houses to small stores—but the Auburn University College of Agriculture, in partnership with Campus Dining, is using them as self-contained “vertical” farms to grow produce to serve to students.

In April, the college acquired two Freight Farms shipping containers that have been converted into technologically advanced hydroponic growing stations in which plants grow vertically indoors without soil, getting their nutrition from water and light energy from powerful LEDs.

Now, the farms are producing the first crop of lettuce.

“This is state of the art,” said Desmond Layne, head of the Department of Horticulture. “We're talking growing from seed to fork in four to six weeks, depending on whether it is lettuce, arugula or another vegetable crop that can grow in there. And we can produce 15 times as much per year as we could outside in the same exact spot.”

Associate Professor of Horticulture Daniel Wells taught a vertical farming course this spring and leads operations of the vertical farms.

Wells said the containers are outfitted with a complete climate control system, which includes air conditioning and humidity control. Because they are highly insulated, the system ensures the same climate 365 days a year.

The converted containers also have an elaborate lighting system, giving all the light the plants need from two color LEDs.

“We can do any number of colors of lights,” he said. “But it turns out for photosynthesis, plants use mostly red and blue light. What’s neat about that is you can cut out a lot of the other color spectrum, creating far less heat energy. That's very efficient. It means more of the energy used is turned into light than heat.”

The containers also allow for controlled carbon dioxide levels, which accelerates plant growth.

“Ambient CO2, what you and I are exposed to every day, is about 400 ppm [parts per million],” he said. “And that’s fine, plants can grow there. But if we boost the CO2 to 1,000 ppm, they’ll grow faster. And because we’re containing the CO2, the plants can really use it. And it’s not dangerous for humans at all.”

Wells and Director of Dining and Concessions Glenn Loughridge first initiated a partnership between the College of Agriculture and Campus Dining five years ago through the Auburn Aquaponics Project, which uses hydroponics and aquaculture technologies to provide a system in which nutrient-laden wastewater from fish production is used as a food source for plant growth. Today, fish from this effort are served in dining facilities on the Auburn campus.

The new vertical farms build on that effort.

“We're in the process of finishing a $26 million dining hall in the center of campus,” Loughridge said. “It has always been foremost in my mind that we would have the opportunity to feature produce grown here on campus in that dining hall. In our biggest location, our biggest asset, we want to bring our A-game.

“This is hyper-local, on-campus sourcing,” he added. “Can you imagine being a potential student coming to tour, seeing where these products are grown, and then going to eat there? It’s incredible. We truly believe this elevates our dining experience.”

The converted shipping containers were manufactured by Freight Farms, a Boston-based company operating in 45 states and 28 countries.

“There are a few different companies out there doing this,” Layne said. “But Freight Farms is the most sophisticated. They’re the ones who have both the best product on the market and the largest production of these containers. It’s really a best-case scenario.”

Adam Lenhard, a rising senior majoring in biological agricultural technology management, said Wells’ course has been one of the most influential courses he’s taken at Auburn.

“It has been very helpful, not just in preparation for the arrival of the freights, but also in learning all about new hydroponic technologies and growing techniques,” Lenhard said. “Post-graduation, I plan to continue to work with these types of indoor, LED hydroponic systems. My primary goal after college is to normalize urban hydroponic farming, provide large, consistent yields of fresh vegetables and provide food to those in need who do not have as much access to fresh produce.”

Transformation Garden

The vertical farms are located on the College of Agriculture’s planned 16-acre Transformation Garden on the south end of the university’s campus, near the intersection of Lem Morrison Drive and Duncan Drive. The goal of the garden is to encompass every aspect of plant-based agriculture, including everything from fruits and vegetables to ornamentals to grow crops and more.

The Transformation Garden will showcase new technology and the history of agriculture, as it envelops Auburn’s Old Rotation, a single-acre research plot created in 1896. Continuously since that year, the historic landmark has been the site for testing and advancing transformative ideas that are now commonplace—ideas like crop rotation, cover crops, and low- and no-till farming.

(Written by: Kristen Bowman)

HELP DEVELOP THE TRANSFORMATION GARDEN

To help develop the new Transformation Garden, you can give online or contact Phillip Cowart, College of Agriculture director of development, at poc0001@auburn.edu or 334-844-1198.

Auburn University is a nationally ranked land grant institution recognized for its commitment to world-class scholarship, interdisciplinary research with an elite, top-tier Carnegie R1 classification, life-changing outreach with Carnegie’s Community Engagement designation and an undergraduate education experience second to none. Auburn is home to more than 30,000 students, and its faculty and research partners collaborate to develop and deliver meaningful scholarship, science and technology-based advancements that meet pressing regional, national and global needs. Auburn’s commitment to active student engagement, professional success and public/private partnership drives a growing reputation for outreach and extension that delivers broad economic, health and societal impact.

Latest Newsroom Articles

Natalie Portman, Other Celebs, Invest In Vertical Farming Startup Bowery

The sustainable agriculture startup, the largest vertical farming firm in the U.S., secured over $300 million from both individuals and investment groups to help expand its operations across the U.S.

$300M Investment Round Will Help

The Company Expand Its

Indoor Farms Across The U.S.

June 4, 2021

Natalie Portman | Roy Rochlin / Getty Images

Natalie Portman, an actor as well-known for her film roles as her dedication to causes ranging from the environment to animal welfare, has thrown her financial support behind a new investment round for Bowery Farming. The sustainable agriculture startup, the largest vertical farming firm in the U.S., secured over $300 million from both individuals and investment groups to help expand its operations across the U.S.

"At Bowery, we're reinventing a new supply chain that's simpler, safer, more sustainable and ultimately provides vibrantly flavorful produce unlike what's available today," Irving Fain, CEO, and Founder of Bowery Farming, said in a press release. "This infusion of new capital from Fidelity, other new investors, and the additional support of our long-term investor partners is an acknowledgment of the critical need for new solutions to our current agricultural system, and the enormous economic opportunity that comes with supporting our mission.

Portman’s investment is the latest in a series of big moves by the vegan activist to help grow companies that provide healthy, sustainable, and animal-friendly products to millions around the globe. In July of 2020, she joined others such as Oprah Winfrey and Starbucks CEO Howard Schultz in investing in milk-alternative startup Oatly. In November, she teamed with music artist John Legend in backing MycoWorks, a company creating vegan leather from fungus, to help raise more than $45 million.

“So now lots of people make fun of vegans, right? Lots of people make fun of anybody who cares about anything deeply, right?,” Portman said during a youth activism speech in 2019. “But I’m here to say, it is always a great thing to care…whether it’s environmental issues, animal rights, women’s rights, equality, never be afraid to show how much you care.”

Joining Portman in the latest investment round for Bowery, which has raised more than $465 million since its founding in 2014, were well-known plant-based eating advocates Lewis Hamilton and Chris Paul, as well as world-renowned chef and hunger advocate José Andrés and singer-songwriter Justin Timberlake.

Growth of vertical farming reaches new heights

So why is everyone from celebrities to investment groups throwing money at Bowery? Simply put, the skepticism around vertical farming that stunted early growth has been replaced with blooming enthusiasm in the wake of its success.

In the last year, Bowery has gone from selling produce in under 100 retail locations across the U.S. to nearly 800. According to Fain, these include such giants as Whole Foods Market, Giant Food, Stop & Shop, Walmart, and Weis Markets.

“It’s definitely bigger than the pandemic,” Fain told The Spoon. “What you’re seeing is a food system that’s evolving and [people have a desire] to see transparency and traceability in the food system.”

Bowery presently has two vertical farming sites in New Jersey and Maryland, with a third slated to open in Bethlehem, PA later this year. Each industrial space features various greens and herbs (butter lettuce, cilantro, arugula, etc.) stacked vertically in trays and grown hydroponically using a state-of-the-art computer control system and LED lights. An average of 80,000 pounds of produce is generated each week using 95% less water than traditional farms and with zero pesticides or chemicals. And because these vertical farms can be built within cities, transport costs and their associated environmental impacts are drastically reduced.

While the focus for vertical farming remains firmly planted on greens, Bowery is testing new crops like tomatoes, peppers, and strawberries. They are also making constant improvements to the artificial intelligence system that monitors the plants at all times. At any moment, the computer can make changes to improve the yield or alter the flavor of a particular crop.

“We achieve a plant vision system and that vision system takes photos of our crops in real-time and runs them through our machine learning algorithms,” Fain said in an interview with Tech at Bloomberg. “We know what’s happening with a crop right now and whether it’s healthy, but then also predict what we will see with this crop based on what we’ve seen in the past and what tweaks and changes we want to make.”

Yes, we know that sounds like some slice of a dystopian future, but vertical farming is quickly proving itself a necessary technology to help feed and sustain humanity. For Fain, he believes the ability to do all of this with fewer resources, chemicals, and independent changing climate conditions or unexpected global crises is something that should be celebrated and not feared.

“I actually view it as this incredibly optimistic opportunity to say, ‘Wow, like, isn't it amazing that technology has taken us to a point where something that we've done in a certain way for hundreds and hundreds of years with iteration and optimization can really be rethought and re-imagined in totality because of human creativity and human ingenuity?", he told MyClimateJourney. “And I think that's actually exciting and that's something that we should be happy about and optimistic about. And that to me is really the message in what we're building at Bowery.”

News Environment Business & Policy Science Animals Home & Design Current Events