Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Vertical Gardening: A Modern Farming Method

Many of our communities are transforming into industrial and urban centres as the earth’s population increases. This growth, coupled with climate change, poses new challenges to the human populace to produce enough food as farmland acreage decreases and consumers’ demands increase.

July 25, 2021

Many of our communities are transforming into industrial and urban centres as the earth’s population increases. This growth, coupled with climate change, poses new challenges to the human populace to produce enough food as farmland acreage decreases and consumers’ demands increase.

Over the past decade, scientists and agronomists have been developing methods to produce double or triple the amount of food, using the same scale of land or less a farmer may cultivate. One of these approaches currently gaining much attention and adaptation is the vertical gardening or farming method.

NAREI staff harvesting and inspecting various crops planted in the vertical stack stand model, using PVC gutters

The notion of farming indoors is not strange to us, since greenhouse agricultural systems have been widely adopted for some time now. These houses have been used for years, providing conditions for numerous commercial crops (such as tomatoes, strawberries, peppers, and cucumbers) to thrive at its maximum production index. Cultivating under shaded facilities compared to outdoor farming fields can aid in year-round production, but few or none of these greenhouses have been constructed as multi-storey facilities.

Vertical farming is a method that uses vertically inclined surfaces to produce food, instead of the traditional method of growing vegetables on a single level in a greenhouse or open field. The National Agricultural Research and Extension Institute (NAREI) is currently evaluating the cost and productivity of various vertical-farming models. The experiment is being conducted at NAREI’s compound, Mon Repos, ECD.

NAREI staff harvesting and inspecting various crops planted in the vertical stack stand model, using PVC gutters

The vertical models installed under the tunnel house are: vertical stack stand using PVC gutters, vertical trellis made of nylon, barrel model using recycled plastic drums, and vertical wall using recycled plastic bottles.

Using vertical farming techniques have numerous advantages, such as: year-round production; reducing soil erosion and runoffs; maximising the use of abandoned structures or unused spaces; minimising crop failures due to harsh weather conditions and reduces the use of fossil fuels, since less farm mechanisation is needed. It also creates new urban employment openings; adds energy back to the grid via methane generation; returns farmlands to nature, aiding in restoring ecosystem functions; reduces pest and disease indices; reduces the need for abundant use of pesticides and herbicides, and offers the possibility of a sustainable food-production engine for our communities.

The experiment is being done to ascertain yields of a wide variety of crops needed to sustain large populations, without exhausting existing resources. With the success of this study, local households in Guyana can better utilise yard space to produce their foods at a cheaper cost and local farmers can increase productivity to reach consumer demand. In addition to that, this method can be utilised to combat major challenges faced due to climate variation in Guyana, such as flooding.

SINGAPORE - VIDEOS: How IoT And Machine Learning Are Automating Agriculture

A new generation of farmers is tapping the internet of things and machine learning to operate self-sustaining urban farms with minimal supervision

A New Generation of Farmers Is Tapping The internet of Things And Machine Learning To Operate Self-Sustaining Urban Farms With Minimal Supervision

By Aaron Tan, TechTarget

21 Jul 2021

A new generation of farmers is turning to technologies such as the internet of things (IoT) and machine learning to automate agricultural production, alleviating the need to toil on the land while keeping a watchful eye on their crops.

Joining their ranks is Phoebe Xie, director, and co-founder of Singapore-based agrotechnology startup AbyFarm. Teaming up with technology service provider SPTel, Xie is building a smart hydroponics farm in a greenhouse that uses a plethora of IoT sensors, including video cameras, to keep the farm humming around the clock.

“To run a self-regulating farm at the optimal temperature with optimal water and nutrient supply, and to control the quality and taste of vegetables and fruits, we need IoT sensors,” she said, adding that the farm and its sensors collect and monitor thousands of data points, including humidity and temperature.

With the data and in certain environmental conditions, processes and actions are automatically triggered to protect crops from the elements. For instance, if the temperature or humidity gets too high, fans, water curtains, and roof shades are activated in the greenhouse.

Xie said the smart farm, located at a rooftop carpark in Singapore, is also equipped with sensors that monitor the pH and electrical conductivity levels of water. Among the sensors, which are connected to a Lora low-power wide area network, is a dozer that automatically releases acidic or alkaline nutrients to maintain optimal pH levels.

Whereas the farmers of old had to physically inspect their crops, AbyFarm’s agronomists and farmers can do so remotely using video cameras and image recognition technology to identify crops that might be succumbing to disease.

“If the image recognition finds that a plant is likely to be sick, the farmer will be alerted to go onsite to check how the plant is right now,” said Xie, adding that agronomists will also advise farmers on taking corrective actions to prevent disease or restore the health of their crops.

Like any machine learning system, AbyFarm’s algorithms get smarter over time. Each time a crop is affected by disease, data about the occurrence and corrective action is fed into the system, enabling its algorithms to formulate solutions for other farmers with similar crop issues – without consulting an agronomist.

With that, said Xie, even those who are new to the field can use the system to guide them on treating diseased crops, which can be isolated from other crops to prevent cross-infections.

AbyFarm’s automated farming system, which is hosted on SPTel’s private cloud, can also advise farmers on the best time to transplant their crops after germination and harvest them later for sale, said Xie.

Heng Kwee Tong, vice-president for engineering and customer solutions at SPTel, said the company has built up a software-defined platform to help companies like AbyFarm overcome the challenges of deploying applications such as IoT.

“The common struggle that companies like AbyFarm face with building an IoT solution is that it is quite intensive in terms of ICT infrastructure,” said Heng. “You’ve got to find the radio connectivity like Lora, subscribe to a service provider, and connect your sensors to a sensor collector.

“We make it easy by investing in a platform and because we are a service provider with edge hub assets for deploying radio connectivity, all AbyFarm needs to do is to bring their sensors onboard.”

Going forward, Heng said SPTel is looking to support next-generation video analytics capabilities through edge cloud services that can be used to crunch workloads closer to where they reside, reducing latency.

AbyFarm was one of six companies to win contracts from the Singapore Food Agency last year to build urban farms at nine rooftop carparks in public housing estates across Singapore.

The goal is to collectively produce about 1,600 tonnes of vegetables a year in a bid by the city-state – where less than 1% of the land is used for agriculture – to become more self-sufficient in meeting the nutritional needs of its people.

That could well be achievable with technology that makes farming more efficient, scalable, and less labor-intensive than before. “We are willing to train and educate the next generation in agrotechnology because now you don’t need 10 farmers to take care of one farm,” said Xie. “It’s just looking at the dashboard and, with the alerts, doing what is required.”

Vertical Harvest Maine, Sodexo Pair For Local Produce On College Campuses

n August 2021, Vertical Harvest Maine (VHM) will break ground on a 70,000 square foot, four-story farm in downtown Westbrook. Developer TDB LLC says that the master plan integrates residential apartments, commercial space, and four stories of parking

Indoor Farming Partnership Will

Increase Local Produce Served

On Maine’s College Campuses

May 18, 202|

Source: Sodexo SA

Westbrook, Maine, May 18, 2021 (GLOBE NEWSWIRE) -- Sodexo, a global foodservice provider and one of Maine’s largest employers, today announced that it will source as much as 80-percent of its lettuce products from Vertical Harvest Maine, the State’s newest hydroponic urban farm, and the first vertical greenhouse in the United States. The produce will be served at all fourteen Sodexo partners, including collegiate campuses from Fort Kent to South Portland. Earlier this year, Sodexo pledged to spend at least $1M at local Maine farms and food producers in 2021.

“We are a global company that is committed to spending locally,” says Varun Avasthi, Director of Strategic Partnerships, Sodexo. “One challenge we face when sourcing local food is Maine’s short outdoor growing season. The partnership with Vertical Harvest will be a game-changer for Sodexo’s ability to buy fresh produce twelve months per year,” Avasthi added.

In August 2021, Vertical Harvest Maine (VHM) will break ground on a 70,000 square foot, four-story farm in downtown Westbrook. Developer TDB LLC says that the master plan integrates residential apartments, commercial space, and four stories of parking. The company plans to grow over 1-million pounds per year of local produce, create 50 jobs, and hire Mainers with physical and intellectual disabilities, in coordination with State and local agencies. This year, Fast Company recognized Vertical Harvest in their annual “World Changing Ideas” awards, which honors businesses that are innovating solutions to world problems.

“VHM’s output will displace out-of-state produce and will not compete with local, traditional farms,” says Nona Yehia, Vertical Harvest founder. With the majority of Maine’s produce imported, VHM founders say indoor farming will have a positive impact on Maine’s agricultural output. “VHM is extremely proud to grow local food, and to create meaningful jobs for Maine’s underemployed,” Yehia says. The Westbrook location is the second for Vertical Harvest, the first is in Jackson Hole, WY.

“This partnership illustrates how strategically the Maine business community works together,” says Glenn Cummings, President, University of Southern Maine. “The partnership between Sodexo and VHM enforces our commitment to serving Maine-grown food whenever possible – it is a win-win,” Cummings said.

“This project exemplifies the goals and vision of Maine’s 10-Year Economic Development Strategy,” said Heather Johnson, Commissioner of the Department of Economic and Community Development.

Sodexo is one of Maine’s largest employers, with 760 employees and a $21M payroll. It serves 13,000 meals daily at colleges and hospitals across Maine, including Central Maine Medical Center and Southern Maine Community College. In 2015, Sodexo founded The Maine Course, a local organization with a mission to increase the company’s local food spend annually. Sodexo and VHM will prepare for the first harvest, which is planned for the Fall 2022 academic year.

# # #

About Sodexo North America” Sodexo North America is part of a global, Fortune 500 company with a presence in 64 countries. Sodexo is a leading provider of integrated food, facilities management, and other services that enhance organizational performance, contribute to local communities and improve quality of life for millions of customers in corporate, education, healthcare, senior living, sports and leisure, government, and other environments daily. Sodexo is committed to supporting diversity and inclusion and safety while upholding the highest standards of corporate responsibility and ethical business conduct. In support of local communities across the U.S., in 2020, the Sodexo Stop Hunger Foundation mobilized 10,000 Sodexo volunteers to distribute 4.1 million meals to help 5.9 million children and adults meet their immediate food needs. Since 1996, the Stop Hunger Foundation has contributed $36.7 million to help feed children in America impacted by hunger. To learn more about Sodexo, visit us.sodexo.com, and connect with us on Facebook, Instagram, LinkedIn, Twitter and YouTube.

Photo Credit: Harriman and GYDE ArchitectsPhoto Credit: Harriman and GYDE Architects

Contact Data

Dasha Ross-Smith

Sodexo

Dasha.Ross-Smith@sodexo.comLife In 2050: A Look At The Homes of The Future

In an age where Climate Change and technological change will essentially be competing for control of our future, the challenge will be how to leverage one to address the other

Rapidly Accelerating Technology And The Need For

Sustainable Living Will Revolutionize

How People Live by 2050

May 15, 2021

Welcome back to the "Life in 2050" series! So far, we've looked at how ongoing developments in science, technology, and geopolitics will be reflected in terms of warfare and the economy. Today, we are shifting gears a little and looking at how the turbulence of this century will affect the way people live from day today.

As noted in the previous two installments, changes in the 21st century will be driven by two major factors. These include the disruption caused by rapidly accelerating technological progress, and the disruption caused by rising global temperatures, and the environmental impact this will have (aka. Climate Change).

These factors will be pulling the world in opposite directions, and simultaneously at that. Rising seas, hotter summers, wetter winters, increased flooding, drought, pandemics, desertification, and shrinking supplies of fresh water will likely lead to all kinds of scarcity, humanitarian crises, and increased levels of mortality.

Meanwhile, technological advances in terms of renewable energy, fusion power, materials science, blockchains, smart technology, additive manufacturing (3D printing), commercial space exploration, and biotechnology are set to lead to a new era of abundance in terms of energy, wealth, health, and new resources.

In an age where Climate Change and technological change will essentially be competing for control of our future, the challenge will be how to leverage one to address the other. All told, there are four areas where this will really come into play:

Growth of Urban Centers

Machine Learning and AI

Decentralization of Everything

Sustainable Cities

Rising Seas and Sinking Coastlines

The growth of cities

As we addressed in the second installment, the global population is projected to grow considerably by 2050. In fact, according to the "World Population Prospects 2019" report compiled by the United Nations Department of Economic and Social Affairs, the global census rolls will account for about 9.74 billion people by mid-century.

Furthermore, a 2020 report by the International Institute for Environment and Development estimates that by 2050, roughly 68% of the population will live in urban centers. That works out to 6.6 billion people, or an increase of 2.2 billion from today. You might say that almost all of the population growth between now and 2050 will happen in cities.

This will result in an increased demand for housing, electricity, water, food, basic services, education, transport, and medical services in these places. The infrastructure and resources needed to meet this demand will place added stress on the surrounding environments, which are already heavily stressed as it is.

Urban expansion means that more land needs to be cleared to build infrastructure, more water needs to be diverted for utilities, more electricity needs to be generated, and more agricultural land needs to be set aside for growing food.

Luckily, there's an upside to all this growth. While more people means more in the way of need, it also means more in the way of production. And if there is one thing cities are very good at, it's fostering innovation, the creation of new industries, and cultural expression - and all through the act of bringing people together.

As a result, cities in 2050 will be built (or rebuilt) to provide for the basic needs of their populations in ways that absolutely must be sustainable. This means finding ways to do more with less, not to mention eliminating waste as much as possible. All of this will be possible through the art of...

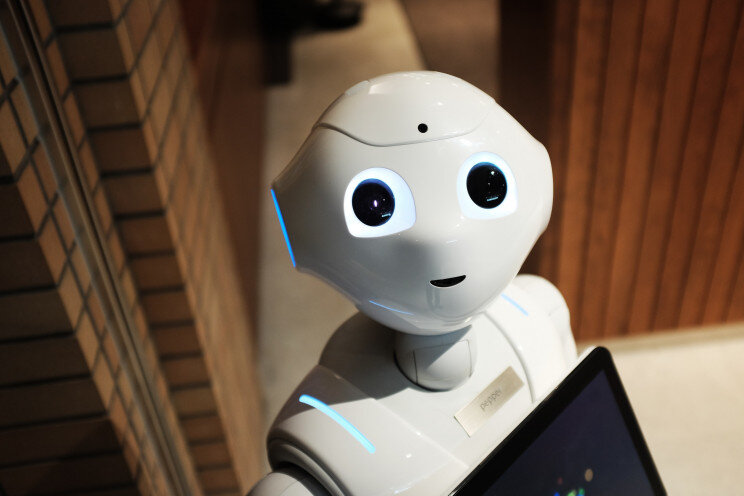

"Smart" living

The idea of "smart homes" is one that has really taken off in the past decade. The concept builds on the idea of "smartphones" and other such devices, which are accessible anywhere there is an internet connection. In the case of smart homes, a person will have access to everything in their home (appliances, devices, utilities, etc.) through Bluetooth and wireless internet.

In the future, this will extend to the point where the "Internet of Things" (IoT) becomes a reality. This concept refers to the way in which the digital world and real world will become intertwined like never before. On the one hand, this will be driven by the trillions of devices, sensors, and geotags that connect countless points in the real world to the internet.

On the other, people's experience of the real world will be increasingly mediated throug augment tedh reality, virtual reality (AR/VR), and the help of artificial intelligence. On top of that, the ability to connect with just about anyone and everything will revolutionize the way we live. And strangely enough, many of us have had a preview of this due to the recent pandemic.

Source: Alex Knight/Unsplash

For one thing, people in 2050 will be used to being able to have just about everything delivered to their doorstep. Door-to-door delivery services will likely become increasingly automated and involve smart cars, shuttle pods that drive around on their own tracks, and aerial drones.

Similarly, just about everything will be doable from the comfort of home, especially when it comes to working. Home offices with high-speed internet will become the norm, meetings will be virtual, and traveling for the sake of business or attending conferences will be largely unheard of.

Even education will take place in the home or within individual apartment blocks and tenements. Similar to distance education, children will log in to virtual classrooms where they are guided (with the help of a teacher or AI) through various lessons. Haptics will provide the sensation of "hands-on" education, eliminating the need to be physically in a classroom.

An explosion in the use of household robots is also projected to take place by 2050. These could take the form of mobile units or next-generation appliances that are integrated directly into a room. These robots will be able to handle everything from regular household maintenance, cleaning, preparing food, and other such tasks.

Moreover, the concept of the "smart home" will achieve literal proportions. Household AI 'managers' are sure to become a common feature of future homes, connected to all your devices, running your household robots and your appliances, and monitor your habits to ensure that you are remaining within your budget.

Distributed systems

Another interesting change is the way in which energy, money, goods and services, and even politics and administration will be distributed in the coming years. Whereas the industrial revolution brought about greater centralization of work and economics that is still in use to this day, the world of tomorrow will be almost entirely decentralized.

For example, in the previous installment, we looked at how increased reliance on renewable energy will affect the global economy. Given that the majority of demand for electricity will still be coming from urban centers, the shift will be visible in terms of how and where power is generated. In short, energy concerns of the future will be moving away from the centralized grids and become more localized.

Today, the infrastructure for providing electricity (aka. the electrical grid) consists of the following connected elements:

power stations located away from heavily populated areas, which are connected

electrical transmitters to carry power over long distances

electrical substations that transform voltage from high transmission to low distribution

distribution transformers to individual homes and buildings

The term "grid" is fitting because the electricity is generated in a central place, then routed through a gridlike network to where it is needed. In contrast, by 2050, cities will have distributed power stations that run on solar, wind, piezoelectric, geothermal, biomass, and other "green" sources of energy.

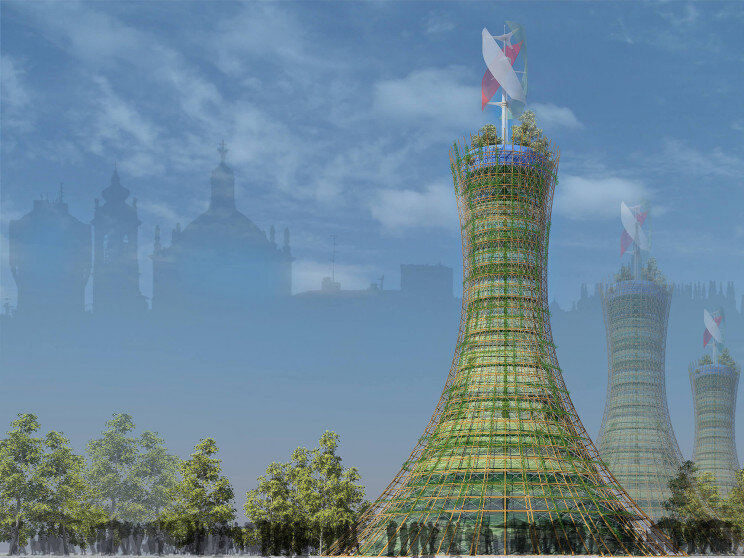

Source: Inhabitat

These localized centers will provide power for a specific area, and large buildings are likely to provide their own power using built-in solar arrays, turbines, and biofuel generators. However, power grids will not disappear, as the development of fusion power and Tokamak reactors will still require distribution centers and nodes.

The proliferation of wireless internet, satellite internet, and blockchain technology will also mean people can connect anywhere at any time. As a result, politics could look more like "town hall meetings" that will be virtual events that far more people will be able to participate in. In the same way that video conferencing will mean that most business is conducted virtually, local politics will also be affected.

Green megacities

Due to the ongoing loss of arable land, cities will also become greener spaces, where architecture and ecology come together for the sake of healthy living. This concept, known as "arcology," was coined in 1969 by architect Paolo Soleri, who proposed the concept as a means of addressing urban sprawl and the consequent destruction of green spaces.

In designs featuring arcology, agricultural operations and green spaces co-existed alongside residential and commercial centers, and space was to be used more creatively. Whereas most cities are two-dimensional, with individual highrises dotting the landscape (or clustered in the central business districts), arcologies are three-dimensional and built into the surrounding environment.

This thinking has become revitalized since the turn of the century, thanks to the escalating problem of climate change. Today, there are countless architectural firms and design studios that specialize in the creation of urban spaces that are reminiscent of the principles of arcology or similarly governed by the same principles of efficiency and sustainability.

Common features include urban farming, where local residents tend to community gardens, vertical farms, hydroponics, insect farms (high-protein!), and aquaponics (where plants and fish live symbiotically, and both are a source of nutrients). These operations will be helped along with the development of genetically modified organisms (GMOs) and microbial engineering.

To prevent stress on the existing water supply, most of what is needed for irrigation will come from rainwater capture, grey-water recycling, and water reclamation units. It's also a safe bet that by 2050, many homes and domiciles will have a 3D food printer dedicated to manufacturing nutritious meals tailored to specific tastes and dietary requirements.

Another recent innovation is carbon capture, which city planners are incorporating into modern urban development plans for the sake of combating climate change and urban pollution. While foliage has always been a means of cleaning city air, future cities may include large numbers of artificial trees, bioreactor facilities, and carbon-absorbing structures built right into their facades.

As an added bonus, carbon dioxide that is scrubbed from the air can be easily converted into biofuels using Bioenergy with carbon capture and storage (BECSS) technology. Buildings equipped with a carbon capture apparatus will therefore be able to create biofuel, perhaps as a backup power source, but also as a local supply of fuel for vehicles that still run on biodiesel.

Powering it all will be a number of renewable energy sources, such as the aforementioned solar arrays, vertical wind turbines, piezoelectric surfaces, and heat-exchange technology (for the sake of climate control). Each building that contains multiple dwellings is likely to be its own grow-op, power plant, and fuel station, providing the basic necessities of life locally.

Crystal Island: This arcology was proposed by Norman Foster, founder of the architecture firm Foster and Partners. True to its name, Crystal Island would be a tall, spire-like compression structure that would appear crystalline. The entire structure would be wrapped in a breathable "second skin" that would be sealed in winter to prevent heat loss and opened in summer to cool the interior.

The planned arcology was to be integrated into Nagatinskaya Poyma Park in central Moscow. Standing 1,476 ft (450 m) high and containing 27 million ft² (2.5 million m²) of floor space, it would have been the largest structure on Earth. Construction was postponed in 2009 due to the global economic crisis and has remained in limbo since.

Masdar City: Named after the design firm building it, Masdar City is a planned project for the city of Abu Dhabi in the United Arab Emirates. Also designed by Foster and Partners, the city will be a hub for clean energy companies as well as the location of the International Renewable Energy Agency's (IRENA) headquarters.

Based on the goal of a carbon-neutrality, Masdar is powered by a combination of solar energy, wind power, and all lighting and water are controlled by movement sensors to reduce consumption. Much of the city's water is rainwater or captured by condensers, and up to 80% of wastewater will be recycled and reused as many times as possible.

As of 2016, the city's official website reported that 2,000 people are employed in the city and that only 300 students reside there. However, expansion is expected to continue until it reaches its planned capacity of 50,000 residents, 1,500 businesses, and 60,000 workers making the daily commute.

Cities at sea

In an age of climate change, many designers have incorporated rising sea levels and the loss of coastlines into their arcological concepts. A number of designs have been proposed already, examples of which include:

Boston Arcology: Also known as BOA, this concept for a sustainable megastructure in Boston Harbor was conceived by Kevin Schopfer. Designed in the shape of a rectangle with crisscrossing structures in its interior, this city would house 15,000 people and include hotels, offices, retail spaces, museums, and a city hall.

Consistent with Leadership in Energy and Environmental Design (LEED) standards, it would draw its power from a combination of solar, wind, and other renewables and would serve as an expansion of the city without adding to the environmental impact of urban sprawl.

Harvest City: The Haiti earthquake of 2010 left 250,000 people dead, 300,000 people injured, and about 1.5 million people homeless. In response, Schopfer (in collaboration with Tangram 3DS) conceived Harvest City, a floating complex made up of tethered floating modules - 2 mi (3.2 km) in diameter - off the coast of Port-au-Prince, Haiti.

The city would be capable of housing 30,000 residents within four communities - dedicated 2/3 to agriculture, 1/3 to light industry - all of which would be interconnected by a linear canal system. The entire city would float and be anchored to the ocean floor, reducing its vulnerability to plate tectonics and earthquakes considerably.

Lilypad City: Otherwise known as just Lilypad, this concept for a floating city was proposed by Vincent Callebaut. Essentially, Callebaut anticipated that rising sea levels and disappearing coastlines would give rise to a new phenomenon known as "climate refugees." As coastal cities sink into the ocean in this century, people will need to be relocated to new facilities.

Hence the Lilypad concept, a completely self-sufficient floating city that could accommodate up to 50,000 people. Power would be provided through a combination of solar, wind, tidal, and biomass, while the entire structure is able to absorb CO2 from the atmosphere through a titanium dioxide outer skin.

New Orleans Arcology Habitat: Located off the coast of New Orleans, where the Mississippi River empties into the Gulf of Mexico, the NOAH concept was another design proposed by Kevin Schopfer (the same architect who thought up BOA). The design was largely inspired by Hurricane Katrina and the understanding that recurring storm activity in the region is only going to get more severe.

"The first challenge is to overcome both the physical and psychological damages of recurring severe weather patterns," they wrote. "Though re-population has begun, the need to provide a stabilized and safe environment is paramount to a long-term recovery and economic well-being of New Orleans."

This triangular city would be able to house as many as 50,000 New Orleans residents within its 20,000 residential units - each measuring 1100 ft² (100 m²). To ensure that it kept the tourism industry alive, it would also have up to three hotels (200 rooms each), 1500 time-share units, and three casinos.

Shimizu Mega-City Pyramid: This megastructure (aka. the TRY 2004 Pyramid) was proposed by Shimizu Corporation in 2004 as a solution to Tokyo's problem of overpopulation. Inspired by the Great Pyramid of Giza, the structure would be built in Tokyo Bay, measure 6,575 feet (over 2000 m) high, and house 1 million people.

However, the design relies entirely on the future availability of super-materials (such as carbon nanotubes). This is due to the weight of the pyramid, which would be the largest structure ever built and exceed the stress tolerances of existing building materials. While the original plan was to commence construction by 2030, Shimizu remained determined to complete it by 2110.

Summary

As the 21st century unfolds, the world will be forced to suffer through two major opposing phenomena. Technological development will continue to accelerate, with serious implications for the way we live, work, play, and even eat. At the same time, climate change will be ramping up, causing severe disruptions to the very natural systems humans are dependent on for their survival.

Luckily, there's an upside to this mess of contradictions. While rising tides and increased drought, storms, wildfires, etc., will be a humanitarian nightmare, they will also pressure us to find solutions. And while the rapid advance of technology will be a constant source of stress, it will also bring about innovation that addresses environmental problems.

It will be a strange time, where the entire world will be caught between surviving and thriving, scarcity and abundance, recession and growth. Nevertheless, the potential for positive change is there and could lead to a whole new era of better living and sustainability.

Lead photo: Stefano Boeri Architecture¨

VIDEO: Singapore’s Urban Farmers Seek High-Tech Solutions To Turn Waste Into Resources

With the challenges of climate change and a growing population, research and development have become critical in helping overcome threats to sustainability with the help of technology

MAY 11, 2021

KEY POINTS

Singapore’s first urban insect farm, Insectta, is a biotech start-up extracting valuable biomaterials from the black soldier fly.

With the challenges of climate change and a growing population, research and development have Nessa Anwar become critical in helping overcome threats to sustainability with the help of technology.

Farmers in typically traditional environments are also tapping into technology to bring added value to their fields of specialty, such as Singapore fish farm Eco-Ark.

Farmers are popping up in major cities - here’s why

SINGAPORE — Thousands of wriggling larvae won’t deter this self-declared “urban farmer.”

Chua Kai-Ning is one of the founders of Singapore’s first urban insect farm, Insectta — a high-tech farm that rears the black soldier fly to help turn food waste into biomaterials for industrial use.

“The black soldier fly is a way to contribute to what we call the circular economy, where we produce things without anything going to waste,” said the 26-year-old, who has a background in English linguistics.

Some in Singapore are turning to urban farming in this land-scarce city, as they look for high-tech ways to turn waste into useful resources.

Chua is one of them.

We are not only reimagining what we farm, but what we get out of the farming process.

Chua Kai-Ning

CO-FOUNDER, INSECTTA

“Their superpower is their ability to consume food waste,” she said of the black soldier fly, regularly scooping up a handful of writhing insects with her bare hands throughout the farm visit.

“A kilo of larvae can go through four kilograms of waste in just 24 hours,” she said, explaining that pre-consumer food waste — primarily soybean leftovers and spent grain from the beer-brewing industry — is fed to the larvae.

But the work doesn’t stop there.

Insectta’s co-founder and chief technology officer Phua Jun Wei demonstrating water-soluble melanin derived from their black soldier fly larvae.

From the insect farm, the trays of larvae are transported to a laboratory on the other side of the island state. There, biomaterials are extracted from the larvae and used to produce valuable substances for electronics, pharmaceuticals, and cosmetics, such as chitosan and melanin.

The future of urban agriculture, Chua maintained, is in deep technology. Deep tech companies are often start-ups founded on scientific and engineering breakthroughs, aimed at harnessing technology to address environmental or societal challenges.

“We are not only reimagining what we farm but what we get out of the farming process.”

Pioneers such as Insectta are not the only ones coming up with high-tech ways of farming to cater to a world with evolving needs. Farmers in typically traditional environments are also tapping into technology to bring added value to their fields of specialty.

Eco-Ark is one such example. The closed-containment floating fish farm located in the eastern side of Singapore uses seawater that has been optimally treated to farm fish.

The farm — an area slightly smaller than two basketball courts — also uses green energy tapped from its solar roof to power about 20% of its farming activities, the company said.

The Eco-Ark is a closed-containment floating fish farm located off a Singapore coast, yielding more than 160 tonnes of fish a year.

“We produce our own oxygen, we produce our own ozone,” said Leow Ban Tat, CEO of Aquaculture Centre of Excellence, which built Eco-Ark.

Open-net fish farms are vulnerable to environmental threats such as plankton blooms, oil spills and warmer waters due to climate change. Unlike these traditional farms, fish on the Eco-Ark are contained in seawater that is filtered and treated to kill pathogens.

“As fish grow, they produce a lot of ammonia and nitrates,” he explained, adding that water discharged back to the sea is treated and free of waste.

In addition to a water filtration system that improves the mortality of fish reared, the high-tech floating farm is the first in the country to have post-harvest facilities, said Leow.

After cleaning and preparing ready-made fish for consumption, the fish bones and fish heads left behind are turned into pellets that can be used as plant fertilizer, ensuring no unnecessary waste.

Singapore sets its sights on high-tech farming

Traditionally, urban farms are not known to be energy efficient. Critics say that growing food with the help of high-tech systems to boost artificial farming environments, such as in climate control, raises energy costs.

With the challenges of climate change and a growing population, research and development have become critical to overcoming threats to sustainability with the help of technology.

In its latest budget, Singapore set aside 60 million Singapore dollars (about $45.2 million) to encourage farmers to utilize technology. The Agri-Food Cluster Transformation Fund was established in February to help farmers better apply technology to local food production.

The goal of sustainability has drawn people like aquaculturist Nick Goh to fish farms like Eco-Ark.

“This is actually what I wanted to do. It is not sustainable if we keep on doing fish-netting outside, fishing, fish trawling,” he told CNBC. “So if we have aquaculture in the field, we can actually first sustain the ocean, and second, sustain ourselves in terms of food security-wise.”

Black soldier fly larvae eating through a tray of pre-consumer food waste.

Insectta’s Chua admits it’s not been easy.

“Pioneering anything, especially in a deep tech industry, is definitely scary,” Chua said. “But it’s also empowering because you know that you’re the first mover for change.”

“If we don’t go out there and look for new solutions to current problems such as the food waste crisis, dwindling natural resources, we’re never going to make any headway.”

Join Our Next Conversation - April 28, 2021 | 2:00 to 3:00 pm EDT

Join us for a fun “Fireside Chat” as Indoor Ag-Con’s Content Chair Jim Pantaleo sits down with Dan to discuss this great success story

In 2010, Dan Albert began laying the groundwork for what would become Farmbox Greens, a Seattle-based vertical farm growing specialty produce for retail and foodservice customers.

In 2016, Farmbox was acquired by a regional produce company and Dan went on to scale Farmbox to serve customers in the Northwest and beyond.

Join us for a fun “Fireside Chat” as Indoor Ag-Con’s Content Chair Jim Pantaleo sits down with Dan to discuss this great success story—from the farm’s early days to those first meetings with potential restaurant customers to making the connection with Charlie’s Produce.

Jim and Dan will also talk about Dan’s newest role as Vice President of Plant Performance with Unfold.

LEARN MORE & SAVE YOUR FREE SPOT!

PODCAST: Vertical Farming Podcast - Season 3 Episode 29 - Nicholas Dyner. Nick Is The CEO of Moleaer

In this episode, Harry and Nick discuss Nick’s extensive background working in the water treatment industry

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show Nicholas Dyner. Nick is the CEO of Moleaer, an organization that produces commercial nanobubble generators to deliver sustainable, chemical-free water quality improvement for agriculture, reservoirs, lakes, ponds, and more.

In this episode, Harry and Nick discuss Nick’s extensive background working in the water treatment industry. Nick expounds on nanobubble technology, what it is and how it can be used to improve vertical farming and the agricultural industry as a whole. Finally, Harry and Nick talk about the ongoing struggle for universal access to safe water and how advancements in technology can help restore and improve the quality of sea life.

Listen & Subscribe

Vertical Farming Startup Oishii Raises $50m In Series A Funding

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone.”

By Sian Yates

03/11/2021

Oishii, a vertical farming startup based in New Jersey, has raised $50 million during a Series A funding round led by Sparx Group’s Mirai Creation Fund II.

The funds will enable Oishii to open vertical strawberry farms in new markets, expand its flagship farm outside of Manhattan, and accelerate its investment in R&D.

“Our mission is to change the way we grow food. We set out to deliver exceptionally delicious and sustainable produce,” said Oishii CEO Hiroki Koga. “We started with the strawberry – a fruit that routinely tops the dirty dozen of most pesticide-riddled crops – as it has long been considered the ‘holy grail’ of vertical farming.”

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone. From there, we’ll quickly expand into new fruits and produce,” he added.

Oishii is already known for its innovative farming techniques that have enabled the company to “perfect the strawberry,” while its proprietary and first-of-its-kind pollination method is conducted naturally with bees.

The company’s vertical farms feature zero pesticides and produce ripe fruit all year round, using less water and land than traditional agricultural methods.

“Oishii is the farm of the future,” said Sparx Group president and Group CEO Shuhei Abe. “The cultivation and pollination techniques the company has developed set them well apart from the industry, positioning Oishii to quickly revolutionise agriculture as we know it.”

The company has raised a total of $55 million since its founding in 2016.

Little Leaf Farms Raises $90M to Grow Its Greenhouse Network

Massachusetts-based Little Leaf Farms has raised $90 million in a debt and equity financing round to expand its network of hydroponic greenhouses on the East Coast. The round was led by Equilibrium Capital as well as founding investors Bill Helman and Pilot House Associates. Bank of America also participated.

by Jennifer Marston

Image from: Little Leaf Farms

Massachusetts-based Little Leaf Farms has raised $90 million in a debt and equity financing round to expand its network of hydroponic greenhouses on the East Coast. The round was led by Equilibrium Capital as well as founding investors Bill Helman and Pilot House Associates. Bank of America also participated.

Little Leaf Farms says the capital is “earmarked” to build new greenhouse sites along the East Coast, where its lettuce is currently available in about 2,500 stores.

The company already operates one 10-acre greenhouse in Devins, Massachusetts. Its facility grows leafy greens using hydroponics and a mixture of sunlight supplemented by LED-powered grow lights. Rainwater captured from the facility’s roof provides most of the water used on the farm.

According to a press release, Little Leaf Farms has doubled its retail sales to $38 million since 2019. And last year, the company bought180 acres of land in Pennsylvania on which to build an additional facility. Still another greenhouse, slated for North Carolina, will serve the Southeast region of the U.S.

Little Leaf Farms joins the likes of Revol Greens, Gotham Greens, AppHarvest, and others in bringing local(ish) greens to a greater percentage of the population. These facilities generally pack and ship their greens on the day of or day after harvesting, and only supply retailers within a certain radius. Little Leaf Farms, for example, currently servers only parts of Massachusetts, Pennsylvania, New York, and New Jersey.

The list of regions the company serves will no doubt lengthen as the company builds up its greenhouse network in the coming months.

VIDEO: How This Vertical Farm Grows 80,000 Pounds of Produce Per Week

Bowery Farming is a network of vertical farms working to reengineer the growing process

Bowery Farming Uses Technology To Prioritize

Accessibility And Sustainability In Their Produce

Growing Operations

by Terri Ciccone and Eater Video Feb 20, 2021

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process,” says chief science officer Henry Sztul. “Our goal is actually to have as few people walking around our plants as possible.”

Bowery Farming is a network of vertical farms working to reengineer the growing process. Using a system of light and watering technology, Bowery is able to use 95 percent less water than a traditional outdoor farm, zero pesticides, and chemicals, and grow food that tastes as good as anyone else’s.

Bowery Farming uses vertical farm-specific seeds that are optimized for flavor instead of insect resistance and durability. Seeds are mechanically pressed into trays of soil and sent out into growing positions, or racks within the building that have their own lighting and watering systems. Each tray gets its own QR code so that they can be monitored and assigned a customized plan for water and light until they’re ready to be harvested.

Irving Fain, Bowery Farming’s founder, and CEO contemplates the prediction from the United Nations that 70 to 80 percent of the world’s population will be living in and around cities in the next 30 years. “Figuring out” how do you feed and how do you provide fresh food to urban environments both more efficiently as well as more sustainably?’ is a very important question today, and an even more important question in the years to come.”

Indoor Farming Gains Ground Amid Pandemic, Climate Challenges

Investors used to brush off Amin Jadavji’s pitch to buy Elevate Farms’ vertical growing technology and produce stacks of leafy greens indoors with artificial light. Now, indoor farms are positioning themselves as one of the solutions to coronavirus pandemic-induced disruptions to the harvesting, shipping, and sale of food

Investors say urban farming can boost food security despite rising inflation, trade tensions and global food shortages.

Image from: Reuters via AppHarvest

Investors used to brush off Amin Jadavji’s pitch to buy Elevate Farms’ vertical growing technology and produce stacks of leafy greens indoors with artificial light.

“They would say, ‘This is great, but it sounds like a science experiment,'” said Jadavji, CEO of Toronto, Canada-based Elevate.

Now, indoor farms are positioning themselves as one of the solutions to coronavirus pandemic-induced disruptions to the harvesting, shipping, and sale of food.

“It’s helped us change the narrative,” said Jadavji, whose company runs a vertical farm in Ontario, and is building others in New York and New Zealand.

Proponents, including the US Department of Agriculture (USDA), say urban farming increases food security at a time of rising inflation and limited global supplies. North American produce output is concentrated in Mexico and the US southwest, including California, which is prone to wildfires and other severe weather.

Climate-change concerns are also accelerating investments, including by agribusiness giant Bayer AG, into multi-storey vertical farms or greenhouses the size of 50 football fields.

They are enabling small North American companies like Elevate to bolster indoor production and compete with established players BrightFarms, AeroFarms and Plenty, backed by Amazon.com Inc founder Jeff Bezos.

But critics question the environmental cost of indoor farms’ high power requirements.

Vertical farms grow leafy greens indoors in stacked layers or on walls of foliage inside of warehouses or shipping containers. They rely on artificial light, temperature control and growing systems with minimal soil that involve water or mist, instead of the vast tracts of land in traditional agriculture.

Image from: Reuters via AppHarvest

Greenhouses can harness the sun’s rays and have lower power requirements. Well-established in Asia and Europe, greenhouses are expanding in North America, using greater automation.

Investments in global indoor farms totalled a record-high $500m in 2020, AgFunder research head Louisa Burwood-Taylor said.

The average investment last year rose sharply, as large players including BrightFarms and Plenty raised fresh capital, she said.

A big funding acceleration lies ahead, after pandemic food disruptions – such as infections among migrant workers that harvest North American produce – raised concerns about supply disruptions, said Joe Crotty, director of corporate finance at accounting firm KPMG, which advises vertical farms and provides investment banking services.

“The real ramp-up is the next three to five years,” Crotty said.

Vegetables grown in vertical farms or greenhouses are still just a fraction of overall production. US sales of food crops grown under cover, including tomatoes, cucumbers and lettuce, amounted to 358 million kilogrammes (790 million pounds) in 2019, up 50 percent from 2014, according to the USDA.

California’s outdoor head lettuce production alone was nearly four times larger, at 1.3 billion kg (2.9 billion pounds).

Image from: Reuters via AppHarvest

The USDA is seeking members for a new urban agriculture advisory committee to encourage indoor and other emerging farm practices.

Plant Breeding Moves Indoors

Bayer, one of the world’s biggest seed developers, aims to provide the plant technology to expand vertical agriculture. In August, it teamed with Singapore sovereign fund Temasek to create Unfold, a California-based company, with $30m in seed money.

Unfold says it is the first company focused on designing seeds for indoor lettuce, tomatoes, peppers, spinach and cucumbers, using Bayer germplasm, a plant’s genetic material, said Chief Executive John Purcell.

Their advances may include, for example, more compact plants and an increased breeding focus on quality, Purcell said.

Unfold hopes to make its first sales by early 2022, targeting existing farms, and startups in Singapore and the United Kingdom.

Greenhouses are also expanding, touting higher yields than open-field farming.

AppHarvest, which grows tomatoes in a 60-acre greenhouse in Morehead, Kentucky, broke ground on two more in the state last year. The company aims to operate 12 facilities by 2025.

Its greenhouses are positioned to reach 70 percent of the US population within a day’s drive, giving them a transportation edge over the southwest produce industry, said Chief Executive Jonathan Webb.

“We’re looking to rip the produce industry out of California and Mexico and bring it over here,” Webb said.

Projected global population growth will require a large increase in food production, a tough proposition outdoors given frequent disasters and severe weather, he said.

Image from: Reuters via AppHarvest

New York-based BrightFarms, which runs four greenhouses, positions them near major US cities, said Chief Executive Steve Platt. The company, whose customers include grocers Kroger and Walmart, plans to open its two largest farms this year, in North Carolina and Massachusetts.

Platt expects that within a decade, half of all leafy greens in the US will come from indoor farms, up from less than 10 percent currently.

“It’s a whole wave moving in this direction because the system we have today isn’t set up to feed people across the country,” he said.

‘Crazy, Crazy Things’

But Stan Cox, research scholar for non-profit The Land Institute, is sceptical of vertical farms. They depend on grocery store premiums to offset higher electricity costs for lighting and temperature control, he said.

“The whole reason we have agriculture is to harvest sunlight that’s hitting the earth every day,” he said. “We can get it for free.”

Bruce Bugbee, a professor of environmental plant physiology at Utah State University, has studied space farming for NASA. But he finds power-intensive vertical farming on Earth far-fetched.

“Venture capital goes into all kinds of crazy, crazy things and this is another thing on the list.”

Bugbee estimates that vertical farms use 10 times the energy to produce food as outdoor farms, even factoring in the fuel to truck conventional produce across the country from California.

AeroFarms, operator of one of the world’s largest vertical farms, based in a former New Jersey steel mill, says comparing energy use with outdoor agriculture is not straightforward. Produce that ships long distances has a higher spoilage rate and many outdoor produce farms use irrigated water and pesticides, said Chief Executive Officer David Rosenberg.

Vertical farmers tout other environmental benefits.

Elevate uses a closed-loop system to water plants automatically, collect moisture that plants emit and then re-water them with it. Such a system requires two percent of the water used on an outdoor romaine lettuce operation, Jadavji said. The company uses no pesticides.

“I think we’re solving a problem,” he said.

Agritech: Precision Farming With AI, IoT and 5G

For a company that grows and delivers vegetables, Boomgrow Productions Sdn Bhd’s office is nothing like a farm, or even a vertical farm. Where farms are bedecked with wheelbarrows, spades and hoes, Boomgrow’s floor plan is akin to a co-working space with a communal island table, several cubicles, comfortable armchairs, a cosy hanging rattan chair and a glass-walled conference room in the middle

Image from: Photo by Mohd Izwan Mohd Nazam/The Edge

For a company that grows and delivers vegetables, Boomgrow Productions Sdn Bhd’s office is nothing like a farm, or even a vertical farm.

Where farms are bedecked with wheelbarrows, spades and hoes, Boomgrow’s floor plan is akin to a co-working space with a communal island table, several cubicles, comfortable armchairs, a cosy hanging rattan chair and a glass-walled conference room in the middle.

At a corner, propped up along a walkway leading to a rectangular chamber fitted with grow lights, are rows of support stilts with hydroponic planters developed in-house and an agricultural technologist perched on a chair, perusing data. “This is where some of the R&D work happens,” says Jay Dasen, co-founder of the agritech start-up.

But there is a larger farm where most of the work behind this high-tech initiative is executed. Located a stone’s throw from the city centre in Ampang is a 40ft repurposed shipping container outfitted with perception technologies and artificial intelligence (AI) capabilities that mimic the ideal environment to produce more than 50,000kg of vegetables a year.

Stacked in vertical layers, Boomgrow’s vegetables are grown under artificial lights with Internet of Things (IoT) sensors to detect everything from leaf discolouration to nitrate composition. This is coupled with AI and machine learning algorithms.

Boomgrow is the country’s first 5G-connected vertical farm. With the low latency and larger bandwidth technology, the start-up is able to monitor production in real time as well as maintain key parameters, such as temperature and humidity, to ensure optimal growth conditions.

When Jay and her co-founders, K Muralidesan and Shan Palani, embarked on this initiative six years ago, Boomgrow was nowhere near what it is today.

The three founders got together hoping to do their part in building a more sustainable future. “I’ve spent years advising small and large companies on sustainability, environmental and social governance disclosures. I even embarked on a doctorate in sustainability disclosure and governance,” says Jay.

“But I felt a deep sense of disconnect because while I saw companies evolving in terms of policies, processes and procedures towards sustainability, the people in those organisations were not transforming. Sustainability is almost like this white noise in the background. We know it’s important and we know it needs to be done, but we don’t really know how to integrate it into our lives.

“That disconnect really troubled me. When we started Boomgrow, it wasn’t a linear journey. Boomgrow is something that came out of meaningful conversations and many years of research.”

Shan, on the other hand, was an architect who developed a taste for sustainable designs when he was designing modular structures with minimal impact on their surroundings between regular projects. “It was great doing that kind of work. But I was getting very dissatisfied because the projects were customer-driven, which meant I would end up having debates about trivial stuff such as the colour of wall tiles,” he says.

As for Murali, the impetus to start Boomgrow came from having lived overseas — while working in capital markets and financial services — where quality and nutritious produce was easily available.

Ultimately, they concluded that the best way to work towards their shared sustainability goals was to address the imminent problem of food shortage.

“By 2050, the world’s population is expected to grow to 9.7 billion people, two-thirds of whom will be in Asia-Pacific. Feeding all those people will definitely be a huge challenge,” says Jay.

“The current agricultural practice is not built for resilience, but efficiency. So, when you think of farming, you think of vast tracts of land located far away from where you live or shop.

“The only way we could reimagine or rethink that was to make sure the food is located closer to consumers, with a hyperlocal strategy that is traceable and transparent, and also free of pesticides.”

Having little experience in growing anything, it took them a while to figure out the best mechanism to achieve their goal. “After we started working on prototypes, we realised that the tropics are not designed for certain types of farming,” says Jay.

“And then, there is the problem of harmful chemicals and pesticides everywhere, which has become a necessity for farmers to protect their crops because of the unpredictable climate. We went through many iterations … when we started, we used to farm in little boxes, but that didn’t quite work out.”

They explored different methodologies, from hydroponics to aquaponics, and even started growing outdoors. But they lost a lot of crops when a heat wave struck.

That was when they started exploring more effective ways to farm. “How can we protect the farm from terrible torrential rains, plant 365 days a year and keep prices affordable? It took us five years to answer these questions,” says Jay.

Even though farmers all over the world currently produce more than enough food to feed everyone, 820 million people — roughly 11% of the global population — did not have enough to eat in 2018, according to the World Health Organization. Concurrently, food safety and quality concerns are rising, with more consumers opting for organically produced food as well as safe foods, out of fear of harmful synthetic fertilisers, pesticides, herbicides and fungicides.

According to ResearchAndMarkets.com, consumer demand for global organic fruit and vegetables was valued at US$19.16 billion in 2019 and is anticipated to expand at a compound annual growth rate (CAGR) of 6.5% by 2026.

Meanwhile, the precision farming market was estimated to be US$7 billion in 2020 and is projected to reach US$12.8 billion by 2025, at a CAGR of 12.7% between 2020 and 2025, states MarketsandMarkets Research Pte Ltd.

Malaysia currently imports RM1 billion worth of leafy vegetables from countries such as Australia, China and Japan. Sourcing good and safe food from local suppliers not only benefits the country from a food security standpoint but also improves Malaysia’s competitive advantage, says Jay.

Unlike organic farming — which is still a soil-based method — tech-enabled precision farming has the advantage of catering for increasing demand and optimum crop production with the limited resources available. Moreover, changing weather patterns due to global warming encourage the adoption of advanced farming technologies to enhance farm productivity and crop yield.

Boomgrow’s model does not require the acres of land that traditional farms need, Jay emphasises. With indoor farms, the company promises a year-round harvest, undisturbed by climate and which uses 95% less water, land and fuel to operate.

Traditional farming is back-breaking labour. But with precision technology, farmers can spend less time on the farm and more on doing other things to develop their business, she says.

Boomgrow has secured more than RM300,000 in funding via technology and innovation grants from SME Corporation Malaysia, PlaTCOM Ventures and Malaysia Digital Economy Corporation, and is on track to build the country’s largest indoor farms.

Image from: Boomgrow

The company got its chance to showcase the strength of its smart technology when Telekom Malaysia Bhd (TM) approached it to be a part of the telco’s Smart Agriculture cluster in Langkawi last October.

“5G makes it faster for us to process the multiple data streams that we need because we collect data for machine learning, and then AI helps us to make decisions faster,” Jay explains.

“We manage the farm using machines to study inputs like water and electricity and even measure humidity. All the farm’s produce is lab-tested and we can keep our promise that there are no pesticides, herbicides or any preserving chemicals. We follow the food safety standards set by the EU, where nitrate accumulation in plant tissues is a big issue.”

With TM’s 5G technology and Boomgrow’s patent-pending technology, the latter is able to grow vegetables like the staple Asian greens and highland crops such as butterhead and romaine lettuce as well as kale and mint. While the company is able to grow more than 30 varieties of leafy greens, it has decided to stick to a selection of crops that is most in demand to reduce waste, says Jay.

As it stands, shipping containers are the best fit for the company’s current endeavour as containerised modular farms are the simplest means of bringing better food to local communities. However, it is also developing a blueprint to house farms in buildings, she says.

Since the showcase, Boomgrow has started to supply its crops to various hotels in Langkawi. It rolled out its e-commerce platform last year after the Movement Control Order was imposed.

“On our website, we promise to deliver the greens within six hours of harvest. But actually, you could get them way earlier. We harvest the morning after the orders come in and the vegetables are delivered on the same day,” says Jay.

Being mindful of Boomgrow’s carbon footprint, orders are organised and scheduled according to consumers’ localities, she points out. “We don’t want our delivery partners zipping everywhere, so we stagger the orders based on where consumers live.

“For example, all deliveries to Petaling Jaya happen on Thursdays, but the vegetables are harvested that morning. They are not harvested a week before, three days before or the night before. This is what it means to be hyperlocal. We want to deliver produce at its freshest and most nutritious state.”

Plans to expand regionally are also underway, once Boomgrow’s fundraising exercise is complete, says Jay. “Most probably, this will only happen when the Covid-19 pandemic ends.”

To gain the knowledge they have today, the team had to “unlearn” everything they knew and take up new skills to figure what would work best for their business, says Jay. “All this wouldn’t have been possible if we had not experimented with smart cameras to monitor the condition of our produce,” she laughs.

WEBINAR: Learning Transfer From The Cannabis Industry To The Vertical Farming Industry

We are thrilled to organize a Webinar focusing on the technical aspects and experience of these experts

MARCH 3, 2021

AT 16:00 Central European Time

ONLINE

Register

Critical Lessons: Learning Transfer from the Cannabis Industry to the Vertical Farming Industry

We are thrilled to organize a Webinar focusing on the technical aspects and experience of these experts:

Our speaker Emil Breza is Co-Founder, President, and CEO of AgricUltra™ Advancements Inc. Bringing together his interdisciplinary technical expertise and many years of product development and innovation he introduced to AgricUltra a PlantFirst™ design approach to create one of the industries most advanced Turn-Key Vertical solutions for Controlled Environment Agriculture applications.

Prior to founding AgricUltra, Emil had years of experience in Process Engineering, the Automotive Industry, Professional consulting, and the Military where he honed his ability to identify the root cause of problems and develop solutions that are outside the box.

Our speaker Buck Young is co-founder and Executive Director at CannTx Life Sciences Inc, a Canadian LP focused on leveraging innovation and science to produce exceptional cannabis products and provide solutions to the industry. He is also the CEO of Saed Technologies Ltd, which develops and licenses technologies related to plant propagation, a Board member of Mary Agrotechnologies, and sits on the management committee for a cannabis botanical drug strategic alliance with Devonian Health Group. He is passionate about translating research findings into commercial outcomes, advancing the adoption of precision agriculture, and understanding nature’s pharmacopeia.

Emil Breza

Buck Young

Dr. Joel Cuello

Please register here, there is only a limited number of tickets available.

Register

TAGS: ADVANTAGES OF VERTICAL FARMING AFRICA AGRITECHNICA AGROSPACE AVF WORKSHOP BRAINSTORM THE ECOSYSTEM DESIGNING THE ECOSYSTEM DLG ECOLOGICALLY ECONOMICALLY EVENT FOOD SAFETY FOOD SECURITY FOOD SYSTEM FOODSYSTEM FOOD TRACEABILITY FRAUNHOFER FRAUNHOFER IME HOW VERTICAL FARMING WORKS HUNGER INFARM INFOGRAPHICS INSPIRATIONAL ITALY MOTIVATION OPPORTUNITIES OPPPORTUNITIES PARTNER EVENT REGIONAL DEVELOPMENT RETAIL ROME RZ SOCIALLY SOUTHAFRICA STORYTELLING SUBMISSION SUMMIT SUPERMARKET SUPPLYCHAIN SUSTAINABILITY THE SIX SESSIONS URBAN AG VERTICAL FARMING WORKSHOP WORKSHOP WARM UP

Where Vertical Farming and Affordable Housing Can Grow Together

Some vertical farms grow greens in old warehouses, former steel mills, or other sites set apart from the heart of cities. But a new series of projects will build multistory greenhouses directly inside affordable housing developments

Some vertical farms grow greens in old warehouses, former steel mills, or other sites set apart from the heart of cities. But a new series of projects will build multistory greenhouses directly inside affordable housing developments.

“Bringing the farm back to the city center can have a lot of benefits,” says Nona Yehia, CEO of Vertical Harvest, a company that will soon break ground on a new building in Westbrook, ME, that combines a vertical farm with affordable housing. Similar developments will follow in Chicago and in Philadelphia, where a farm-plus-housing will be built in the Tioga District, an opportunity zone.

Inside each building, the ground level will offer community access, while the greenhouse fills the second, third, and fourth floors, covering 70,000 square feet and growing around a million pounds of produce a year. (The amount of housing varies by site; in Maine, there will be only 15 units of housing, though the project will create 50 new jobs.)

In Chicago, there may be a community kitchen on the first level. In each location, residents will be able to buy fresh produce on-site; Vertical Harvest also plans to let others in the neighborhood buy greens directly from the farm. While it will sell to supermarkets, restaurants, hospitals, and other large customers, it also plans to subsidize 10% to 15% of its harvest for local food pantries and other community organizations.

“By creating a large-scale farm in a food desert, we are creating a large source of healthy, locally grown food 365 days a year,” Yehia says.

Vertical Farming ‘At a Crossroads’

Although growing crops all year round with Controlled Environment Agriculture (CEA) has been proposed as a method to localize food production and increase resilience against extreme climate events, the efficiency and limitations of this strategy need to be evaluated for each location

Building the right business model to balance resource usage with socio-economic conditions is crucial to capturing new markets, say speakers ahead of Agri-TechE event

Image from: Fruitnet

Although growing crops all year round with Controlled Environment Agriculture (CEA) has been proposed as a method to localize food production and increase resilience against extreme climate events, the efficiency and limitations of this strategy need to be evaluated for each location.

That is the conclusion of research by Luuk Graamans of Wageningen University & Research, a speaker at the upcoming Agri-TechE event on CEA, which takes place on 25 February.

His research shows that integration with urban energy infrastructure can make vertical farms more viable. Graamans’ research around the modelling of vertical farms shows that these systems are able to achieve higher resource use efficiencies, compared to more traditional food production, except when it comes to electricity.

Vertical farms, therefore, need to offer additional benefits to offset this increased energy use, Graamans said. One example his team has investigated is whether vertical farms could also provide heat.

“We investigated if vertical farms could provide not just food for people living in densely populated areas and also heat their homes using waste heat. We found that CEA can contribute to stabilizing the increasingly complex energy grid.”

Diversification

This balance between complex factors both within the growing environment and wider socio-economic conditions means that the rapidly growing CEA industry is beginning to diversify with different business models emerging.

Jack Farmer is CSO at vertical producer LettUs Grow, which recently launched its Drop & Grow growing units, offering a complete farming solution in a shipping container.

He believes everyone in the vertical farming space is going to hit a crossroads. “Vertical farming, with its focus on higher value and higher density crops, is effectively a subset of the broader horticultural sector,” he said.

"All the players in the vertical farming space are facing a choice – to scale vertically and try to capture as much value in that specific space, or to diversify and take their technology expertise broader.”

LettUs Grow is focussed on being the leading technology provider in containerised farming, and its smaller ‘Drop & Grow: 24’ container is mainly focussed on people entering the horticultural space.

Opportunities in retail

“This year is looking really exciting,” he said. “Supermarkets are investing to ensure a sustainable source of food production in the UK, which is what CEA provides. We’re also seeing a growth in ‘experiential’ food and retail and that’s also where we see our Drop & Grow container farm fitting in.”

Kate Hofman, CEO, GrowUp agrees. The company launched the UK’s first commercial-scale vertical farm in 2014.

“It will be really interesting to see how the foodservice world recovers after lockdown – the rough numbers are that supermarket trade was up at least 11 per cent in the last year – so retail still looks like a really good direction to go in.

“If we want to have an impact on the food system in the UK and change it for the better, we’re committed to partnering with those big retailers to help them deliver on their sustainability and values-driven goals.

“Our focus is very much as a salad grower that grows a fantastic product that everyone will want to buy. And we’re focussed on bringing down the cost of sustainable food, which means doing it at a big enough scale to gain the economies of production that are needed to be able to sell at everyday prices.”

Making the Numbers Add Up

The economics are an important part of the discussion. Recent investment in the sector has come from the Middle East, and other locations, where abundant solar power and scarce resources are driving interest in CEA. Graamans’ research has revealed a number of scenarios where CEA has a strong business case.

For the UK, CEA should be seen as a continuum from glasshouses to vertical farming, he believes. “Greenhouses can incorporate the technologies from vertical farms to increase climate control and to enhance their performance under specific climates."

It is this aspect that is grabbing the attention of conventional fresh produce growers in open field and covered crop production.

A Blended Approach

James Green, director of agriculture at G’s, thinks combining different growing methods is the way forward. “There’s a balance in all of these systems between energy costs for lighting, energy costs for cooling, costs of nutrient supply, and then transportation and the supply and demand. At the end of the day, sunshine is pretty cheap and it comes up every day.

“I think a blended approach, where you’re getting as much benefit as you can from nature but you’re supplementing it and controlling the growth conditions, is what we are aiming for, rather than the fully artificially lit ‘vertical farming’.”

Graamans, Farmer and Hofman will join a discussion with conventional vegetable producers, vertical farmers and technology providers at the Agri-TechE event ‘Controlled Environment Agriculture is growing up’ on 25 February 2021.

How This Vertical Farm Grows 80,000 Pounds of Produce per Week

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process”

Bowery Farming uses technology to prioritize accessibility and sustainability in their produce growing operations

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process” says chief science officer Henry Sztul. “Our goal is actually to have as few people walking around our plants as possible.”

Bowery Farming is a network of vertical farms working to reengineer the growing process. Using a system of light and watering technology, Bowery is able to use 95 percent less water than a traditional outdoor farm, zero pesticides and chemicals, and grow food that tastes as good as anyone else’s.

Bowery Farming uses vertical farm-specific seeds that are optimized for flavor instead of insect resistance and durability. Seeds are mechanically pressed into trays of soil, and sent out into growing positions, or racks within the building that have their own lighting and watering systems. Each tray gets its own QR code so that they can be monitored and assigned a customized plan for water and light until they’re ready to be harvested.

Irving Fain, Bowery Farming’s founder and CEO contemplates the prediction from the United Nations that 70 to 80 percent of the world’s population will be living in and around cities in the next 30 years. “Figuring out ‘how do you feed and how do you provide fresh food to urban environments both more efficiently as well as more sustainably?’ is a very important question today, and an even more important question in the years to come.”

Indoor Farming Company With Backing From Ubben Aims to Solve The Problems With America’s Produce

The agriculture technology company focuses on building an indoor farm in Appalachia. The company combines agricultural techniques with cutting-edge technology and including access for all to nutritious food, farming, and building a homegrown food supply. The company operates a 60-acre controlled environment, agriculture facility in Morehead, Kentucky, which grows juicy beefsteak tomatoes and tomatoes on the vine

Image from: AppHarvest

Company: AppHarvest Inc. (APPH)

The agriculture technology company focuses on building an indoor farm in Appalachia. The company combines agricultural techniques with cutting-edge technology and including access for all to nutritious food, farming, and building a homegrown food supply. The company operates a 60-acre controlled environment, agriculture facility in Morehead, Kentucky, which grows juicy beefsteak tomatoes and tomatoes on the vine. It also operates a 60-acre indoor farm, outside Richmond, Kentucky, where it cultivates fresh fruits and veggies.

The company’s technological systems monitor the pollination across all 68 bays and 684 rows of plants. AppHarvest is only the fourth U.S. public Certified B corporation. A B corporation is a company that has (1) achieved a high standard of social and environmental performance as measured by the B Impact Assessment, (2) verified their scores through transparency requirements, and (3) made a legal commitment to consider all stakeholders, not just shareholders. Any company can apply to be one.

Stock Market Value: $3.3 billion ($33.26 per share)

Image from: CNBC

Activist:

Inclusive Capital

Percentage Ownership:

12.05%

Average Cost:

n/a

Activist Commentary:

Inclusive Capital Partners was formed in 2020 by ValueAct founder Jeff Ubben, to leverage capitalism and governance in pursuit of a healthy planet and the health of its inhabitants. The firm seeks long-term shareholder value through active partnership with companies whose core businesses contribute solutions to this pursuit. Inclusive is a returns driven fund with a focus on environmental and social investing.

Their primary focus is on environmental and social value creation, which leads to shareholder value creation. It is the successor to the ValueAct Spring Fund, which was launched in January 2018 and merged into Inclusive in 2020.