Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Vertical Farming Startup Oishii Raises $50m In Series A Funding

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone.”

By Sian Yates

03/11/2021

Oishii, a vertical farming startup based in New Jersey, has raised $50 million during a Series A funding round led by Sparx Group’s Mirai Creation Fund II.

The funds will enable Oishii to open vertical strawberry farms in new markets, expand its flagship farm outside of Manhattan, and accelerate its investment in R&D.

“Our mission is to change the way we grow food. We set out to deliver exceptionally delicious and sustainable produce,” said Oishii CEO Hiroki Koga. “We started with the strawberry – a fruit that routinely tops the dirty dozen of most pesticide-riddled crops – as it has long been considered the ‘holy grail’ of vertical farming.”

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone. From there, we’ll quickly expand into new fruits and produce,” he added.

Oishii is already known for its innovative farming techniques that have enabled the company to “perfect the strawberry,” while its proprietary and first-of-its-kind pollination method is conducted naturally with bees.

The company’s vertical farms feature zero pesticides and produce ripe fruit all year round, using less water and land than traditional agricultural methods.

“Oishii is the farm of the future,” said Sparx Group president and Group CEO Shuhei Abe. “The cultivation and pollination techniques the company has developed set them well apart from the industry, positioning Oishii to quickly revolutionise agriculture as we know it.”

The company has raised a total of $55 million since its founding in 2016.

The Stock Market Discovers Indoor Ag In A Big Way

Special purpose acquisition companies are a faster cheaper way to raise company funds than the traditional IPO process. What role may they play in our ever growing vertical farming industry?

Robinhood antics aside, there’s no hotter topic in finance right now than SPACs (special purpose acquisition companies), and even indoor agriculture has become caught up in the buzz.

SPACs, or special purpose acquisition corporations, are a shell company that lists itself on a stock exchange and then uses the listing proceeds to acquire or merge with another company. It’s an attractive route to raising funds for companies looking for a faster and cheaper way to list than the rigours of the traditional IPO process.

Though SPACs have been around since the 1990s, they have had a reputation for being “the buyer of last resort”, primarily owing to a spate of failures in the early 2000s. The approach has once more taken off in recent years. There was nearly 8x as much raised in 2020 as in 2018, and 2021’s total has already surpassed last year’s[1]. The approach has become so hot that even Goldman Sachs junior investment bankers recently complained that they were burned out by the sheer volume of SPACs they’re working on[2].

This newfound enthusiasm is generally traced to a combination of tighter SEC regulations, efforts by cash-rich private equity companies to exit portfolio companies and fewer traditional IPO listings. Higher quality sponsors, such as 40-year old private equity firm Thoma Bravo, lead some to believe that things are different this time around. The lustre of famous SPAC participants – such as baseball player A-Rod and basketball legend Shaquille O’Neal – has helped things along.

Detractors point to post-listing underperformance by SPACs, high fees to sponsors and opaqueness around the acquisition of companies. SPAC rules mean that institutional investors sometimes get to see information on potential acquisitions ahead of retail investors.[3] On a recent Clubhouse chat, one investor compared SPACs to the risky no-revenue internet listings of the late 1990s. Another questioned whether retail investors’ appetite for such vehicles would cause greater market volatility[4].

Dan Bienvenue, the interim CEO of mega public pension fund CALPERs, recently described SPACs as “fraught with potential misalignment, potential governance issues”.[5] That said, similar dire warnings have accompanied the rise of many a new approach in finance, most recently equity crowdfunding, and have proven wrong as often as right.

As is so often the case in indoor agriculture, cannabis companies have led the way when it comes to SPACs, generally listing in Canada owing to the US federal prohibition on the crop. One example is Choice Consolidation Corp, which raised $150mm in February, and says that it plans to acquire “existing strong single-state operators”[6].

Historically, food-focused indoor agriculture companies have sourced little of their capital from public markets, preferring instead to work with private equity and strategic investors. To be sure, there is a small cadre of listed CEA firms, such as Canadian greenhouse operator Village Farms (TSE: VFF) and Canadian grow system tech company CubicFarm Systems Corp (TSXV: CUB) are exceptions to this rule.

All of that changed last month when Kentucky-based greenhouse company AppHarvest raised $475mm through NASDAQ listed SPAC Novus Capital. The funds will fuel the expansion of up to a dozen new farms through 2025.

Naturally, the move has led to speculation that vertical farms and greenhouses will follow suit, though it’s worth noting that the rules that govern SPACs aren’t necessarily friendly to CEA companies. They favour large, highly valued companies that easily capture the attention of retail investors, and those are not plentiful in CEA.

Regardless of whether the SPAC trend becomes a permanent feature of the indoor farm fundraising landscape, one more method of accessing capital for CEA can only be a good thing. For the moment at least.

For more information:

Contain

www.contain.ag

Note: None of the above constitutes investment advice.

Sources:

[1] SPACInsider figures

[2] “Goldman’s junior bankers complain of crushing workload amid SPAC-fueled boom in Wall Street deals”, CNBC, March 18, 2021

[3] For instance, where a PIPE is being considered by the SPAC

[4] “SPACS: IPO 2.0 & Agrifoodtech Exits”, March 4, 2021

[5] “CalPERS’ Bienvenue: SPACs are fraught with potential misalignment”, Private Equity International, March 16, 2021

[6] “New cannabis SPAC raises $150 million in IPO for US acquisitions”, Marijuana Business Daily, February 19, 2021

Publication date: Wed 24 Mar 2021

Author: Rebekka Boekhout

© VerticalFarmDaily.com

CALS Researchers Imagine Future of Urban Farming

Making the case for urban agriculture, Cornell researchers have presented a vision for greener cities and a more equitable future for farmers

March 26, 2021

By Rory Sheppard

Making the case for urban agriculture, Cornell researchers have presented a vision for greener cities and a more equitable future for farmers.

The Cornell Small Farms Program, housed in the College of Agriculture and Life Sciences, is responsible for a body of research that advocates for the development of viable small farms throughout New York State.

Cornell Small Farms continues to advocate for urban agriculture through emerging projects such as Urban Ag, which focuses on highlighting the considerations farmers need to make to farms in urban environments and cites examples of successful urban farming.

As part of the program’s mission to ensure a future of rural and urban agriculture through research and educational opportunities, Director of the Cornell Small Farms Program, Dr. Anusuya Rangarajan and Urban Agriculture Specialist of the Cornell Small Farms Program, Molly Riordan published “The Promise of Urban Agriculture” in 2019.

The authors argue in the report that urban farms have the potential to become commercially viable, adding that up to now, much of the existing research has focused on the impact of urban agriculture on social indicators, such as community development and educational attainment.

According to Riordan, the make of a viable urban farm depends on factors such as the laws and regulations of a municipality, the availability and affordability of land, and opportunities available for season extension.

To produce a more comprehensive picture of the future of urban agriculture, Rangarajan and Riordan started by collecting data, speaking to an active network of growers.

“Every time we spoke with someone, we asked, ‘Who else should we speak with about commercial farming in cities?’” Riordan said in an email. “Inevitably that led us to more conversations that broadened and deepened our understanding. We spoke with over 160 individuals in the course of the study.”

Since publication, the multiple findings and recommendations of the report have started to take effect. Partnering with Rooted, an urban agriculture training organization, Cornell Small Farms has been working to introduce training for urban farmers to help improve commercial viability.

Riordan said that the farms, specifically those in controlled environments, have been known to generate considerable finances and interest from venture capital, alongside the development of more technology-focused urban farms. Likewise, technical assistance, research, and training will be essential in increasing the number of urban farms in the coming years.

As the researchers envisioned the future of urban agriculture, they were acutely aware of the concerns that still impact the field. One of the major challenges for urban farmers is, despite the typically smaller nature of the farms, urban land access.

“Knowing that urban growers struggle for access to land, especially Black, Indigenous, immigrant and other farmers of color, institutions can do more to lift up their voices and put the weight and the funding of the

Lead photo: Ben Parker/Sun Senior Photographer -

Housed in CALS, the Cornell Small Farms Program seeks to build more diverse, equitable, and sustainable food systems.

Eastern Kentucky Company Growing Local Economy By Growing Vegetables Year-Round

AppHarvest has created 300 jobs in Appalachia, an area not really known for growing tomatoes.

by GIL MCCLANAHAN

MOREHEAD, Ky. (WCHS) — Imagine growing fresh local tomatoes in the dead of winter. A company in Eastern Kentucky is using high-tech agriculture to grow vegetables indoors.

To View The Video, Please Click Here.

AppHarvest checks tomatoes growing inside the company's 60-acre indoor greenhouse.

(AppHarvest ) Courtesy Photo

AppHarvest opened in Rowan County, Ky. last October. They are growing more than just vegetables. They are growing the economy in an area that sorely needs it.

What's growing inside AppHarvest's 2.8-million square foot facility is capable of producing more food with less resources.

"For our first harvest to be on a day where there was a snowy mountainside could not have been any more timely. The fact that we are able to grow a great juicy flavorful tomato in the middle of January and February is what we have been working to accomplish," AppHarvest Founder and CEO Jonathan Webb said.

Webb said five months after opening its Morehead indoor farm facility, the company shipped more than a million beefsteak tomatoes to several major supermarket chains, including Kroger, Walmart and Publix. Those large bushels and bushels of tomatoes are grown using using the latest technology, no pesticides and with recycled water in a controlled environment using 90% less water than water used in open-field agriculture.

"We're just trying to get that plant a consistent environment year round with the right amount of light and the right amount of humidity and the right temperature just to grow, and the vines of our crops the tomato plant end up being 45 feet and we grow them vertically so that is how we can get so much more production," Webb said.

One of the company's more well-known investors is Martha Stewart.

"I said Martha, can I get five minutes and I told her what we are doing. She was like, look we need good healthy fruits and vegetables available at an affordable price. I love the region you are working in," Webb said.

A couple of weeks later, Webb met with Stewart at her New York office, and she decided to become an investor in the company. Some local restaurants are looking forward to the day when they can buy their vegetables locally from AppHarvest. Tim Kochendoerfer, Operating Partner with Reno's Roadhouse in Morehead, buys his vegetables from a company in Louisville.

"It will be another selling point to show that we are a local restaurant," Kochendoerfer said.

Webb points out AppHarvest is not trying to replace traditional family farming. "Absolutely not. We want to work hard with local farmers," he said.

Webb said by partnering with local farmers, more local produce can get on grocery store shelves, because last year 4 billion pounds of tomatoes were imported from Mexico.

"What we are working to replace is the imports from Mexico where you got children working for $5 a day using illegal chemical pesticides in the produce is sitting on a truck for 2-3000 miles," Webb said.

AppHarvest has already started influencing the next generation of farmers by donating high tech container farms to local schools. Students learn to grow crops, not in the traditional way, but inside recycled shipping containers. The containers can produce what is typically grown on 4 acres of land. Rowan County Senior High School was the second school to receive one. It arrived last fall.

"We sell that lettuce to our food service department and it's served in all of our cafeterias in the district," said Brandy Carver, Principal at Rowan County Senior High School.

"When we talk about food insecurity and young people going home hungry, what better way can we solve these problems by putting technology in the classroom. let kids learn, then let the kids take the food home with them and get healthy food in the cafeterias," Webb said.

AppHarvest has created 300 jobs in Appalachia, an area not really known for growing tomatoes. Local leaders believe the company will attract more business to the area.

"I fully expect in time we'll see more and more activity along that line like we do in all sectors," said Jason Slone, Executive Director of the Morehead-Rowan County Chamber of Commerce.

"We will eventually be at the top 25 grocers. Name a grocer. We've been getting phone calls from all of them," Webb said.

AppHarvest has two more indoor farming facilities under construction in Madison County, Ky., with a goal of building 10 more facilities like the one in Rowan County by the year 2025.

To find out more about AppHarvest click here.

Vertical Farms vs Greenhouses – The First Consideration: Location

When and where to use a vertical farm versus a greenhouse, and what factors – both economic and environmental – make the difference.

In just the past decade or so, sustainable farming has seen a high-tech makeover in the form of Controlled Environment Agriculture, or CEA, which consists of two main technologies: Vertical farms and greenhouses.

When it comes to feeding the world, it’s not a choice between vertical farms or greenhouses. We’ll need both to feed our growing global population with healthy, sustainable food, and we need to understand the ideal situation for each.

But as a business decision, it often is a choice between the two – and that’s what we hope to explain in this five-part series of articles: When and where to use a vertical farm versus a greenhouse, and what factors – both economic and environmental – make the difference.

In this first post, we’ll cover the basic differences between vertical farms and greenhouses, and why location matters so much when deciding between the two. Then stay tuned because, in the next articles, we’ll dive deeper into energy and lighting costs, automation and other expenses, environmental and crop considerations, and finally, the future of farming.

Vertical Farms vs Greenhouses: The Basics

The two technologies are often confused, but there are significant differences between them in resource use, cost, output, and, perhaps most importantly, the ideal locations for each.

Greenhouses are the more traditional technology that you’re probably familiar with: A single layer of crops, planted inside an enclosed space with walls and a ceiling made of glass or plastic to allow natural light in. They’re semi-controlled environments.

Vertical farms, on the other hand, are a much more recent invention using trays of usually hydroponic plants, stacked in floor-to-ceiling towers, with LED lights illuminating each layer, and climate control constantly adjusting the temperature, humidity and more.

In the upcoming articles in this series, we’ll dive into each part of these differences in more detail. But for now, let’s start with the first question entrepreneurs always need answering: The price tag.

Henry Gordon-Smith is the CEO of Agritecture, an independent consultancy and software creator that helps clients decide between the two technologies. As he puts it, “Vertical farming represents the most expensive, most controlled form of agriculture.”

At first blush, vertical farms are, in fact, shockingly more expensive than greenhouses – six to 10 times as costly. Gordon-Smith says vertical farming costs 2,200 to 2,600 Euro per square meter of cultivation bed space, while high-tech greenhouses cost 250 to 350 Euro per square meter of cultivation space.

Both offer a year-round source of fresh, pesticide-free, locally-grown produce, which provides better nutrition than the same foods that arrive from far away.

But what else do farmers, entrepreneurs, and investors get for all the added expense of vertical farming?

The answer is pretty simple: A more compact farm with more production per square meter, less water use, and more control over both quantity and quality. (With iFarm, this predictability is part of the package, in the form of a guaranteed yield within a precise time frame.)

For some entrepreneurs or municipalities, the cachet of implementing a high-tech farming technique that’s only been in use for less than a decade is also a factor in favour of vertical farming. But most often, the choice comes down to location.

The Ideal Location for a Vertical Farm versus a Greenhouse

The first step in determining the feasibility of building a vertical farm or greenhouse is to look at the drivers and constraints – many of which are simply location-based.

Places with limited space, such as dense urban areas, and limited access to fresh water are ideal for vertical farms. Doubly so if they have access to low-cost, renewable energy, and if they’re near a market with high demand for the crops vertical farms excel at producing: Leafy-greens, micro-greens, herbs and berries grown locally, without pesticides.

But in areas with unlimited space, lots of natural sunlight, and high-cost and/or high-carbon electricity, greenhouses may be the better option and the extra expenses of vertical farming might not make sense.

How these considerations apply in broad regions of the world is illustrated below:

Hydroponics Farming: Why Hydroponic Farms Are Trending In India?

As per reports, India’s hydroponics market is expected to grow at a compound annual growth rate of 13.53% between 2020 and 2027.

Hydroponics is slowly gaining popularity in India and attracting more and more farmers. Basically, hydroponics is a type of horticulture and a subset of hydroculture, which is a method of growing plants, usually crops, without soil, by using mineral nutrient solutions in an aqueous solvent.

Hydroponic farming can be done in a small space also like a balcony which is a soil-less, water-based farming process. Rather than using soil for plant nutrition, crops are fed nutrient-rich water, negating a lot of the baggage that comes with soil-based methods.

Hydroponics is the practice of growing plants in a nutrient-rich solution, skipping the soil. “It has been practised for centuries, so it is not a new technology," points out Akhila Vijayaraghavan, the founder-director of Coimbatore’s Parna Farms, adding the Hanging Gardens of Babylon are believed to have been hydroponically grown. “The Aztecs created vast hydroponic systems using rafts called chinampas," she says.

The film piqued Gopal’s interest, and he began reading about the method to grow plants without soil. “We started working with hydroponics as a project in 2012. At that time, we didn’t know much about the plight of farmers and how a technology like this could add value," said Gopal. The idea was to create awareness among the right audience and sell “through prototypes and hobby kits."

Urban farmers are taking to hydroponics, a water-smart solution to grow pesticide-free produce on rooftops and terraces. As per reports, India’s hydroponics market is expected to grow at a compound annual growth rate of 13.53% between 2020 and 2027.

What is Hydroponics

Hydroponics is a branch of hydroculture, in which plants are grown without soil by using water solvent which consists of minerals nutrient solution. Terrestrial plants may be grown with their roots only, roots are exposed to the nutritious liquid, or roots may be supported physically by a medium like gravel.

Plants are also grown through a process called photosynthesis, in which plants use sunlight and a chemical inside their leaves called chlorophyll to convert carbon dioxide and water into glucose and oxygen, as shown in reaction.

6CO2 + 6H2O → C6H12O6(Glucose)+ 6O2

The nutrients we use in hydroponic systems may come from different sources, such as fish excrement, duck manure, or chemical fertilisers.

1Advantages of Hydroponics

Plantation without soil

We can grow plants in places where the land is limited, doesn't exist, or is contaminated. In the early time period, Hydroponics was a successful technique used to supply fresh vegetables for troops in Wake Island. It has been considered as the future farming to grow foods for astronauts in space by NASA.

Better use of space and location

All those plants need are provided and maintained in a system, you can grow plants in a small apartment, bedrooms or kitchen as long as you have some spaces.

Roots of plants usually expand and spread out in search of foods, and oxygen in the soil but in the case of Hydroponics, roots are sunk in a tank full of oxygenated nutrient solution and are directly in contact with vital minerals. This means that you can grow your plants closer, and consequently huge space savings.

Climate control

Hydroponic growers can have total control over climate, temperature, humidity, light, the composition of the air. This means you can grow foods all year, regardless of the season. Farmers can produce foods at the right time to maximize their profits.

Water-saving

Plants grown by the process of hydroponically can use 10% of water, as compared to one grown on the field because water is recirculated, in this method. Plants will take up the water they need, while run-off water will be captured and return to the system. Water loss in this system will only occur in two forms - evaporation and leaks from the system.

Use of nutrients

You can have 100% control of the nutrients (foods) that plants need in this method. Before planting, growers can check what are plants requirement and what amounts of nutrients needed at particular stages and at what percentage they should be mixed with water.

Better growth rate

Do hydroponic plants grow faster than in soil? Yes, because you can set conditions favourable to the plant’s growth like temperature, lights, moisture, and especially nutrients. As plants are placed in favourable conditions, nutrients are provided in sufficient amounts and come into direct contacts with the root systems. Therefore, plants do not waste valuable energy in the search for diluted nutrients in the soil and put their complete focus on growth.

A Fully Automated Three-Dimensional Vertical Farm Comes Into Operation

Eponic Agriculture Co. Ltd is a supplier of indoor farming equipment. Alice, the company's director, introduced the recently fully automated production system of a stereochemical vertical farm

Eponic Agriculture Co. Ltd is a supplier of indoor farming equipment. Alice, the company's director, introduced the recently fully automated production system of a stereochemical vertical farm.

"The current three-dimensional indoor farms on the market are based on semi-automated workflow, with some links requiring additional equipment configuration and no continuity in the whole planting system. In order to solve this problem, we developed and designed a complete automated planting system, including the processes from sowing to planting, full-spectrum planting light control, fertilization, harvesting, and cleaning. Which are all done by automated equipment. Whereas all procedures can be controlled by intelligent software with real-time monitoring, data collection, and many other functions."

Benefits of an automated farm

When talking about the advantages of the automated equipment, Alice said, "Take our recently built 20-layer vertical farm as an example. First of all, the mechanical sowing time is 10 times-30 times faster than manual sowing. And on top of that, the use of automated equipment can realize precise planting and efficient communication of multi-layer planting surfaces. The 20-layer vegetable trays are automatically transferred to the ground for uniform watering, harvesting, and cleaning. This greatly improves productivity.

Secondly, the use of lift trucks is required when handling high-level crops. There are certain safety hazards in using lift trucks in a small space. While operating the automated equipment, only a tablet computer is needed to control the whole planting process, which is much safer and more convenient."

Although automated vertical farm systems have many advantages, their application in China is not yet popular. "In terms of production design, we have gone through countless experiments to design the most suitable software program. As well as hardware equipment for practical planting applications. Luckily after a long period of research, we finally chose the most cost-effective and suitable materials. The R&D investment is large and time-consuming.”

From a cost point of view, according to Alice, a fully automatic system is 2-3 times higher in costs than the semi-automatic system which is currently used more often. Most traditional agricultural companies find it difficult to accept such high initial costs. Thirdly, the automated system requires high technical requirements for farm managers. Managers need to have an understanding of both planting technology and software. Alice adds: “It is for these three reasons that the application of fully automated stereoscopic systems is not very common in China and other countries."

Automated planting

"Although the application is not yet widespread, I think fully automated stereoscopic planting is a trend. Urbanization has led to a reduction in arable land and soil pollution has triggered problems with pests and pesticide residues in fruits and vegetables, and the development of three-dimensional agriculture is the only way to maximize and optimize output in a limited area. Currently, stereoscopic planting plants still require a lot of manual labor to operate. As labor costs rise and planting techniques require more precision, the use of automated equipment will be a future trend," Alice notes.

"Automated systems are a trend, not only in China but also globally. Urbanization has been moving forward, in the face of soil pollution, pesticides and pests, etc. The planting area is gradually reduced and three-dimensional agriculture must be developed in order to quantify planting. Three-dimensional agriculture can be located near the city, and reduce the transport distance, people can eat the freshest vegetables, to achieve local supply. Therefore it is necessary to promote automated, intelligent planting systems in order to achieve efficient planting and sustainable development." Alice said.

Industry experience

Eponic Agriculture Co. Ltd's head office, Dahua Intelligent Electronics, has a twenty-five-year history division. The team has been focusing on the development and production of intelligent control systems and industrial lighting. Alice said that based on years of technical foundation, we developed full-spectrum LED planting lights which have been approved and applied by the USDA. Over the years, we have received technical support and affirmation from several agricultural doctors from Europe and the United States, focusing on the development and production of automated stereoscopic planting equipment.

According to Alice, the company has laboratories and showrooms in the US, Australia and Africa. This year, the company is planning on opening new showrooms and laboratories in Europe. “We are expanding our global reach and continue to optimize our growing systems to be a better supplier of fully automated growing equipment."

For more information:

Eponic Agriculture Co. Ltd

Alice Ou, Director

aliceou@eponicagriculture.com

www.eponicagriculture.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

7 New HDB Carpark Rooftop Sites Offered For Rental For Urban Farming In Public Tender

More local produce. Part of Singapore's efforts to strengthen its food security is increasing its capability to produce food locally

Part of Singapore's efforts to strengthen its food security is increasing its capability to produce food locally.

To do this, more sites for urban rooftop farms atop multi-storey Housing Development Board (HDB) carparks are being offered for rental, via a public tender process that was launched today (Feb. 23).

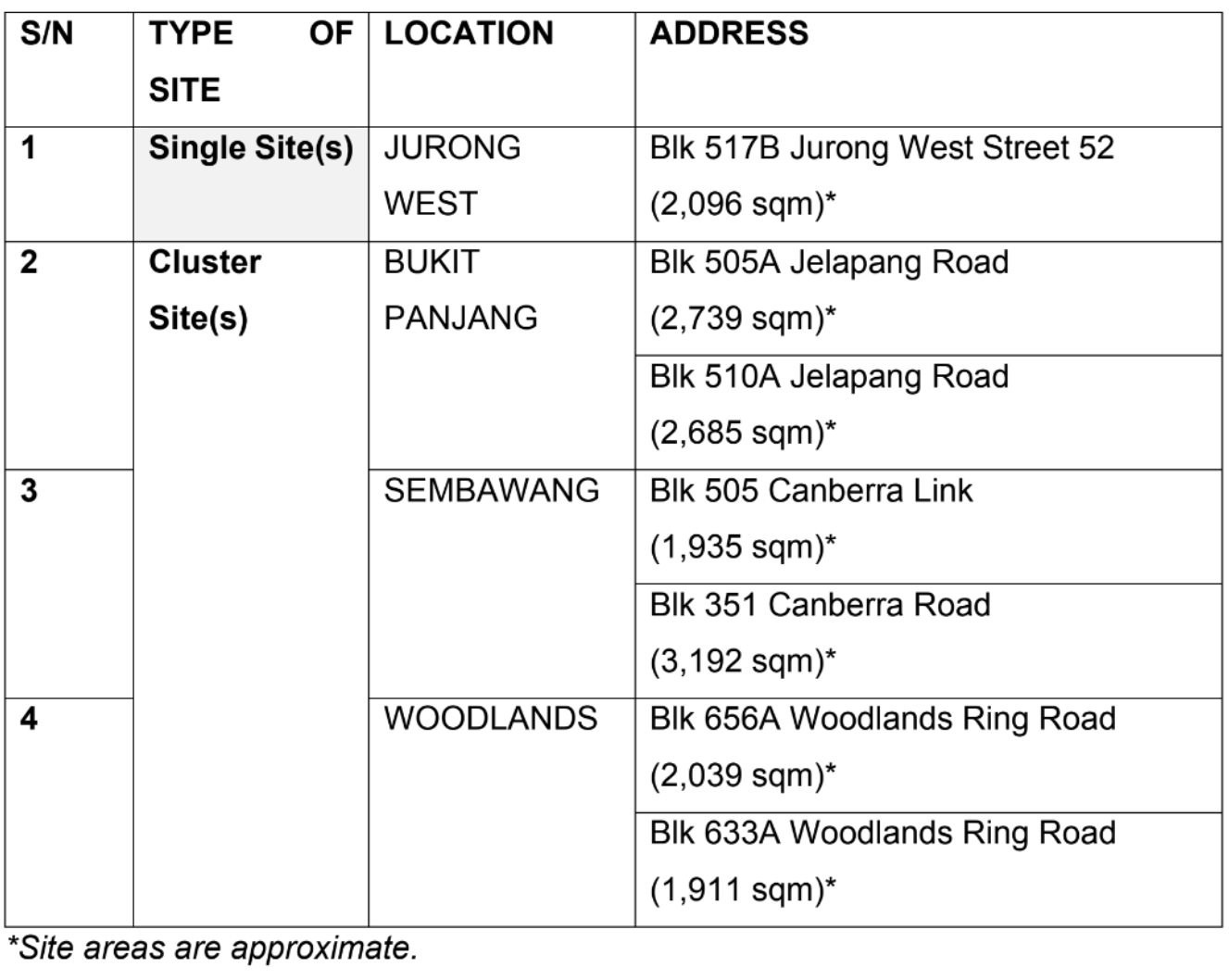

Seven new sites

Seven sites have been identified in Jurong West, Bukit Panjang, Sembawang and Woodlands, according to the Singapore Food Agency (SFA) and HDB.

The sites will be used to farm vegetables and other food crops, and will also be used to pack and store produce.

They will be tendered out as a single site (in Jurong West) and three cluster sites (in Bukit Panjang, Sembawang and Woodlands).

Screenshot from SFA and HDB

Tenderers who successfully bid for cluster sites will be awarded all sites within the cluster, to allow them to cut costs through production at scale.

Single-site farms, on the other hand, provide opportunities to "testbed innovative ideas".

Tenderers must submit their proposals via GeBiz before the tender closes on Mar. 23, 4pm.

Proposals will be assessed on their bid price, production output, design and site layout, as well as their business and marketing plans.

More information can be found on SFA's website here.

Producing food locally

This is the second time tenders were launched for rooftop urban farms on carparks here — the first took place in Sep. 2020, with nine sites being awarded.

Collectively, the nine farming systems can potentially produce around 1,600 tonnes (1,600,000kg) of vegetables per year.

Having more space for commercial farming in land-constrained Singapore is one of SFA's strategies to achieve its "30 by 30" goal — which is to produce 30 percent of Singapore's food locally by 2030.

The move is also in line with HDB’s Green Towns Programme to intensify greening in HDB estates.

“Besides contributing to our food security, Multi-Storey Car Park (MSCP) rooftop farms help to bring the community closer to local produce, thereby raising awareness and support for local produce," said Melvin Chow, Senior Director of SFA’s Food Supply Resilience Division.

Aquaponics In The Heart of Zurich

Umami creates microgreens in the city centre

They produce greens, but they travel to work by streetcar and don't need to put on weatherproof clothing. That's because Umami employees will harvest vegetables and herbs already in the early growth stages, as so-called microgreens. And they do so in a largely self-built facility, on the 4th floor of an office building in Zurich's Kreis 4 district.

Full-time producers instead of restaurant operators

In the beginning, the three friends Manuel Vock, Robin Bertschinger and Denis Weinberg wanted to open a restaurant. They wanted to produce half of the products themselves. At the same time, Manuel Vock was researching aquaponics systems for his bachelor's thesis. He introduced the principle to his friends, and the team began building a prototype set-up in a former archive in 2016.

That was the end of their restaurant plan and at the same time the beginning of completely self-produced food. The guys grew several varieties of microgreens and sold them to restaurateurs who were excited to have a regional product. "Up to that point, microgreens from the Netherlands were the only alternative," says Luca Grandjean, who joined the team of Umamigos (as Umami employees call themselves) in 2019.

The aquapinic facility / Image: Umami

Microgreens

Microgreens, unlike sprouts, grow on a substrate or in soil, require light and nutrients, and are consumed without roots. They are vegetables or spice plants that are harvested immediately after their cotyledons develop. As a result, microgreens contain a high concentration of vitamins and trace elements. The small plants are used as nutritional supplements and can add sweetness and spice to different dishes.

Fish excrement as fertilizer

Regionality is not the only plus of the little plants. Umami grows the microgreens in a cycle based on nature; the only input is fish feed. But even this is actually food waste and, additionally, insects that Umami produces via scraps.

African cichlids (tilapias) and other fish species swim in various tanks, and their excretions enrich the water with nitrogen and other micronutrients. The enriched water flows into the system to the tray on which the microgreens thrive.

These are sown on a hemp-based substrate and positioned in hard trays so that their roots can touch the water, absorbing the nutrients. The water, now purified by the plants, flows back to the fish, who recharge it. Thanks to this recirculation system, only about 1% of the water needs to be replaced with fresh drinking water each month. "That's about two bathtubs full of water. Just what is lost to evaporation," Grandjean says.

Aquaponics

Aquaponics refers to a process in food production that combines raising fish in aquaculture and cultivating crops in hydroponics. There are various combinations, such as the cultivation of tomatoes and the production of tilapias, as described in this article.

Not just fish and microgreens are part of the 'ecosystem', as the Umamigos like to call their jungle. Mussels, shrimp, snails, algae and many other plants also contribute to the Umami ecosystem. "We are copying nature. Yet we have learnt that the more players there are in the cycle, the better the system works," says Luca Grandjean. This might seem to be a contradiction, but he explains: "If there are just two actors in the system and something happens to one of them, the system is quickly unbalanced."

Nomen est omen

Their most important element, he says, is Zurich's tap water; it sets the pace. "We have no soil percolation, 95% less water loss than conventional agricultural systems," Grandjean says.

Environmentally-friendly production, free of chemicals, strikes a chord with consumers. Above all, however, the products have to taste right, says Luca Grandjean. It's no coincidence that the three friends named their startup Umami when they founded it in 2015. The Japanese word means tasty or spicy, and is one of the five basic tastes, alongside sweet, sour, bitter and salty.

"The glutamate found in meat, for example, tastes umami," Grandjean explains. He adds: "The microgreens are very palatable and don't contain glutamate, but our fish do." He is referring to the license to sell fish that the Umamigos recently obtained.

For more information: https://www.eat-umami.ch/

How This Vertical Farm Grows 80,000 Pounds of Produce per Week

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process”

Bowery Farming uses technology to prioritize accessibility and sustainability in their produce growing operations

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process” says chief science officer Henry Sztul. “Our goal is actually to have as few people walking around our plants as possible.”

Bowery Farming is a network of vertical farms working to reengineer the growing process. Using a system of light and watering technology, Bowery is able to use 95 percent less water than a traditional outdoor farm, zero pesticides and chemicals, and grow food that tastes as good as anyone else’s.

Bowery Farming uses vertical farm-specific seeds that are optimized for flavor instead of insect resistance and durability. Seeds are mechanically pressed into trays of soil, and sent out into growing positions, or racks within the building that have their own lighting and watering systems. Each tray gets its own QR code so that they can be monitored and assigned a customized plan for water and light until they’re ready to be harvested.

Irving Fain, Bowery Farming’s founder and CEO contemplates the prediction from the United Nations that 70 to 80 percent of the world’s population will be living in and around cities in the next 30 years. “Figuring out ‘how do you feed and how do you provide fresh food to urban environments both more efficiently as well as more sustainably?’ is a very important question today, and an even more important question in the years to come.”

Bringing The Future To life In Abu Dhabi

A cluster of shipping containers in a city centre is about the last place you’d expect to find salad growing. Yet for the past year, vertical farming startup Madar Farms has been using this site in Masdar City, Abu Dhabi, to grow leafy green vegetables using 95 per cent less water than traditional agriculture

Amid the deserts of Abu Dhabi, a new wave of entrepreneurs and innovators are sowing the seeds of a more sustainable future.

Image from: Wired

A cluster of shipping containers in a city centre is about the last place you’d expect to find salad growing. Yet for the past year, vertical farming startup Madar Farms has been using this site in Masdar City, Abu Dhabi, to grow leafy green vegetables using 95 per cent less water than traditional agriculture.

Madar Farms is one of a number of agtech startups benefitting from a package of incentives from the Abu Dhabi Investment Office (ADIO) aimed at spurring the development of innovative solutions for sustainable desert farming. The partnership is part of ADIO’s $545 million Innovation Programme dedicated to supporting companies in high-growth areas.

“Abu Dhabi is pressing ahead with our mission to ‘turn the desert green’,” explained H.E. Dr. Tariq Bin Hendi, Director General of ADIO, in November 2020. “We have created an environment where innovative ideas can flourish and the companies we partnered with earlier this year are already propelling the growth of Abu Dhabi’s 24,000 farms.”

The pandemic has made food supply a critical concern across the entire world, combined with the effects of population growth and climate change, which are stretching the capacity of less efficient traditional farming methods. Abu Dhabi’s pioneering efforts to drive agricultural innovation have been gathering pace and look set to produce cutting-edge solutions addressing food security challenges.

Beyond work supporting the application of novel agricultural technologies, Abu Dhabi is also investing in foundational research and development to tackle this growing problem.

In December, the emirate’s recently created Advanced Technology Research Council [ATRC], responsible for defining Abu Dhabi’s R&D strategy and establishing the emirate and the wider UAE as a desired home for advanced technology talent, announced a four-year competition with a $15 million prize for food security research. Launched through ATRC’s project management arm, ASPIRE, in partnership with the XPRIZE Foundation, the award will support the development of environmentally-friendly protein alternatives with the aim to "feed the next billion".

Image from: Madar Farms

Global Challenges, Local Solutions

Food security is far from the only global challenge on the emirate’s R&D menu. In November 2020, the ATRC announced the launch of the Technology Innovation Institute (TII), created to support applied research on the key priorities of quantum research, autonomous robotics, cryptography, advanced materials, digital security, directed energy and secure systems.

“The technologies under development at TII are not randomly selected,” explains the centre’s secretary general Faisal Al Bannai. “This research will complement fields that are of national importance. Quantum technologies and cryptography are crucial for protecting critical infrastructure, for example, while directed energy research has use-cases in healthcare. But beyond this, the technologies and research of TII will have global impact.”

Future research directions will be developed by the ATRC’s ASPIRE pillar, in collaboration with stakeholders from across a diverse range of industry sectors.

“ASPIRE defines the problem, sets milestones, and monitors the progress of the projects,” Al Bannai says. “It will also make impactful decisions related to the selection of research partners and the allocation of funding, to ensure that their R&D priorities align with Abu Dhabi and the UAE's broader development goals.”

Image from: Agritecture

Nurturing Next-Generation Talent

To address these challenges, ATRC’s first initiative is a talent development programme, NexTech, which has begun the recruitment of 125 local researchers, who will work across 31 projects in collaboration with 23 world-leading research centres.

Alongside universities and research institutes from across the US, the UK, Europe and South America, these partners include Abu Dhabi’s own Khalifa University, and Mohamed bin Zayed University of Artificial Intelligence, the world’s first graduate-level institute focused on artificial intelligence.

“Our aim is to up skill the researchers by allowing them to work across various disciplines in collaboration with world-renowned experts,” Al Bannai says.

Beyond academic collaborators, TII is also working with a number of industry partners, such as hyperloop technology company, Virgin Hyperloop. Such industry collaborations, Al Bannai points out, are essential to ensuring that TII research directly tackles relevant problems and has a smooth path to commercial impact in order to fuel job creation across the UAE.

“By engaging with top global talent, universities and research institutions and industry players, TII connects an intellectual community,” he says. “This reinforces Abu Dhabi and the UAE’s status as a global hub for innovation and contributes to the broader development of the knowledge-based economy.”

Forget Politics, Danny Ayalon Wants to Effect Change on The Ground

Having transitioned from politics to agriculture, Danny Ayalon shares how vertical farming, which provides fresh fruits and vegetables all year round, and lab-grown meat can rehabilitate the environment and dramatically reduce household expenditures

Having transitioned from politics to agriculture, Danny Ayalon shares how vertical farming, which provides fresh fruits and vegetables all year round, and lab-grown meat can rehabilitate the environment and dramatically reduce household expenditures.

Image from: Yehoshua Yosef

The coronavirus pandemic has drawn attention to humankind's carbon footprint. More than ever before we ask ourselves, how can we become more sustainable? Can we prevent pollution? How can we minimize waste? What about lowering emission levels? Will there be enough food for everyone in the future?

Danny Ayalon, a former ambassador and foreign policy adviser to three prime ministers-turned entrepreneur, believes that the answer to many of the world's problems lies in modern agriculture.

Having transitioned from politics to agriculture, he works with Future Crops, an Amsterdam-based company focused on vertical farming – the practice of growing crops in vertically stacked layers that often incorporates controlled-environment agriculture, which aims to optimize plant growth – and MeaTech, a company that creates lab-grown meat.

"Ever since the coronavirus came into our lives, we realized that man is not in charge of the universe," Ayalon told Israel Hayom.

"Our control over the forces of nature, of Earth, of our future is more limited than we had thought. And when we are no longer in charge of the world, only three things guarantee our lives here: food, water, and energy security. Food, water, and energy are three resources that can be depleted and therefore literally cast a cloud on our world.

"Experts have come to a conclusion that one of the most important fields to focus on is agriculture, and indeed we are currently witnessing the most significant agricultural revolution ever since the first agricultural revolution that took place about 10,00 years ago."

Q: Back then, in the first agricultural revolution, there was a need for a lot of land.

"But today we have technology. The name of the game is to reach maximum output with minimum input in the smallest space possible. This is the holy grail of the new revolution. And that is how technology enters the picture. To grow fruits, vegetables and spices today requires lots of space. The technology we developed at Future Crops allows us to minimize the space, increase production and redefine the food supply chain."

Q: How exactly?

"We have a nine-story hangar in Amsterdam to grow crops like coriander, basil, dill, and parsley. It has LED lights, and each plant gets exactly the amount of light it needs. We are the plant psychologists, [we] listen to all its needs and do everything to make sure the plant grows in the most optimal way.

Image from: Future Crops

"If it lacks something, it immediately receives water. Everything is done without a human's touch. We use algorithms and big data in collaboration with world-class researchers from the Weizmann Institute. It is essentially the application of vertical farming, growing various crops in vertically stacked layers, in enclosed structures, on soil platforms.

"For example, if it takes a month to grow lettuce in an open field, in a vertical farm, it takes two weeks, half that time. There's also a significant reduction in water consumption, and no pesticides or sprays are used at all. Also, the produce is available in all seasons; it does not depend on the temperature. Whoever likes mangos and strawberries, for example, will be able to enjoy them all year round."

Q: So if produce is grown faster and within a smaller space, is it going to cost less?

"The prices might be a bit higher today because this technology and the various infrastructures require an economic return of the initial investment in them. With time, the process will become more efficient, and the investments will be repaid, so in the end, the prices that the consumer will need to pay will be lower than today.

"Let me give you a simple example. Do you know how much a kilogram [2.2 pounds] of basil costs in Europe today? €90 ($108). In Israel, the price is €20 ($24). In the [United Arab] Emirates, where almost everything connected to food is imported – the prices go accordingly as well. Once you have more innovative vertical farms, consumers will pay much less."

Q: Should we expect vertical farm skyscrapers to pop up all over?

"I'm not sure that we will need skyscrapers, as with time the facilities will become smaller. Imagine that in every supermarket there will be a vertical produce stand with all the vegetables and spices, and later also fruits which you pick on the spot, without the need to move the produce from place to place. That is why vertical farming is also called urban farming, meaning there is no need for fields; you can grow [produce] on the rooftop. No resource limits you."

Q: What about the taste?

"Ours is a fresher and tastier product. I ought to give credit to the Weizmann Institute here. The challenge for them wasn't the quality of the vitamins but the taste, and they managed to achieve a great taste. In the Netherlands, Future Crops already sells parsley, and it tastes outstanding."

Q: Regular parsley lasts for about two weeks in the fridge. What about Future Crops parsley?

"Our parsley has a two-month shelf life, and it does not oxidize within a week or two."

Q: If every country will be self-reliant in terms of agriculture, do you think it will affect relations between countries?

"Economies will become self-sufficient eventually, which will ensure security with far fewer conflicts. There is less and less water in the Middle East, which might someday lead to tensions. We hope technology will reduce the tensions between countries, and territory will be less critical. Our world faces crucial challenges. Food and water security have the potential to either divide or bring us together and ensure our long-term existence.

"By the way, in every developed Western country, like the United States, Australia, and also in Europe, issues of food security, climate, and greenhouse emissions are on the top of the political agenda. We are not talking about it [in Israel,] as security and foreign affairs take the central stage, but Israel does have a lot to offer here."

Q: Do we have the potential to become the Silicon Valley of advanced agriculture?

"Israel takes tremendous pride in its actions that help save the world. Will we become the Silicon Valley of agriculture? There is no doubt about it. We can already see foreign investors who come here to look for opportunities, including my business partner Lior Maimon, co-founder and CEO of Silver Road Capital, and Steven Levin, one of the leaders of the US food industry. Silver Road Capital is a holdings and financial advisory firm with a broad portfolio of high-tech companies, as well as agricultural and food technologies, and represents international companies and funds in investments in Israel and the world.

"Future Crops's goal is to raise 35 million shekels on the Israeli stock exchange to invest in enlarging the existing facilities and [set up] other production lines and facilities in Europe and other continents. We cooperate with the Albert Heijn supermarket chain [in the Netherlands] and a leading food chain in France."

Q: Vertical farming is estimated at $3 billion. Google and Amazon have invested hundreds of millions in the field as well. What is their goal?

"A simple answer would be profit. A longer answer is that they [large corporations] understand that food has the highest demand. People cannot live without food and water, and Google and Amazon understand that potential."

Q: US President Joe Biden took office with the largest team of climate experts ever. That ought to give the field momentum.

"Green energy and vertical farming will get a considerable boost. Climate change and green energy are well-rooted in the Democratic Party's ideology.

"It is also possible that large companies entered the agriculture fields precisely because of the Biden administration; they are worried about their future. They are afraid of a certain dismantling, so focusing on secondary fields is part of a security scenario for them."

Q: Biden also wants to address greenhouse emissions, which are the result of the food production industry, mainly meat. Are Amazon and Google's food counterparts - McDonald's and Burger King - looking for meat substitutes?

"Firstly, cultured [lab-grown] meat does not require grazing land, cows do not need to be fed, and so much land can instead be turned into forests that support the environment. This is an optimistic industry that leaves us with a better world.

"As for the meat alternatives market, there are two major companies in the US that produce plant-based protein, Beyond Meat, and Impossible Foods.

"Impossible's burgers are already at Burger King, McDonald's has partnered up with Beyond Meat, and last November, it announced that it would create its own plant-based burger.

"The problem is that pea protein [used in plant-based burgers,] does not have all the amino acids that animal protein contains. Also, they need to add additives to supplement for taste and smell.

"At MeaTech, where I'm a director, we are on our way to producing animal meat, cultured meat, real stakes: we take a cow's own stem cell from which meat can be produced in almost unlimited quantities. We also use 3D digital printing technology. And we also created a thin layer of meat, carpaccio. Needless to say, no cow was harmed in the process."

Image from: MeaTech

Q: Why do you use 3D printers?

"Because there is no need for a human being's involvement. It is relevant now during the coronavirus pandemic when the food supply chain is disrupted. With such printers, your production can continue without delays, whenever you want.

Also, it is theoretically possible to provide food for space flights. Astronauts who go out into space will not have to take food with them; rather, they will be able to produce it on the spot.

"People understand that crises like the coronavirus can disrupt the supply chain and are looking for alternatives. A 3D printer allows restaurants, supermarkets, and butcher shops to have meat without relying on the supply chain."

Q: The death rate from obesity is higher than the death rate from hunger. How will cultured meat affect these statistics?

"It is possible to create meat with much less fat and more protein in each portion and add various nutrients in the future to strengthen the immune system and prevent disease. This, of course, requires a lot of research and approvals. Just like there's talk about customized medicine, so it will be possible to produce food that suits a person's genetic structure and body in the most optimal way."

Q: Will the cost of this meat also be optimal?

"They will cost more in the beginning compared to regular meat because there are initial costs that have to be repaid. When it becomes a mass production, prices will drop over time."

Q: With your vast experience in politics, what do you think of Israeli politics these days? Do you ever consider a political comeback?

"No election campaign goes by without someone making me an offer [to return to politics] but I'm not interested. Unfortunately, the Israeli government, and all governments in the Western world, have not been able to run their countries properly in recent years.

"For example, more of the government's national taks are transitioning to the private market or the third sector. We see that associations [are the ones] who take care of the needy, establish settlements in the Negev and in the Galilee, bring immigrants to Israel and provide Israelis with information. All these things should be done by the government.

"The Israeli government lacks vision, ideologies, every matter is personal and is charged with negative sentiments. If I do return one day, it will only happen after we change the government system which will take its power from small [political] parties.

"In my opinion, we need to transition to a regional choice, by district. This will result in higher quality politicians. How so? Because whoever wants to be elected will need to run and convince the people who live in his area and district, and they are the ones who know his activities best. Also, closed primaries should be avoided because they make all kinds of deals possible. That needs to change."

Warehouse Becoming Vertical Farms — And They’re Feeding New Jersey

New Jersey's vertical farms are transforming agriculture by helping farmers meet growing food demand. New Jersey Agriculture Secretary Doug Fisher said that while conventional farming in outdoor fields remains critical, vertical farming has its advantages because of its efficiency and resistance to pests and thus less need for chemicals

Image from: New Jersey 101.5

New Jersey's vertical farms are transforming agriculture by helping farmers meet growing food demand.

New Jersey Agriculture Secretary Doug Fisher said that while conventional farming in outdoor fields remains critical, vertical farming has its advantages because of its efficiency and resistance to pests and thus less need for chemicals.

Vertical farming is the process of growing food vertically in stacked layers indoors under artificial light and temperature, mainly in buildings. These plants receive the same nutrients and all the elements needed to grow plants for food.

Vertical farms are also versatile. Plants may be growing in containers, in old warehouses, in shipping containers, in abandoned buildings.

"That's one of the great advantages — that we can put agriculture in the midst of many landscapes that have lost their vitality," said Fisher.

ResearchandMarkets.com says the U.S. vertical farming market is projected to reach values of around $3 billion by the year 2024.

The one drawback is that its operational and labor costs make it expensive to get up and running.

Image from: AeroFarms

In the past decade, however, vertical farming has become more popular, creating significant crop yields all over the state.

AeroFarms in Newark is the world's largest indoor vertical farm. The farm converted a 75-year-old 70,000-square-foot steel mill into a vertical farming operation. AeroFarms' key products include Dream Greens, its retail brand of baby and micro-greens, available year-round in several ShopRite supermarkets.

Kula Urban Farm in Asbury Park opened in 2014. Vacant lots are transformed into urban farms and there's a hydroponic greenhouse on site. That produce is sold to local restaurants.

Beyond Organic Growers in Freehold uses no pesticides and all seeds and nutrients are organic. There's a minimum of 12,000 plants growing on 144 vertical towers. On its website, it says the greenhouse utilizes a new growing technique called aeroponics, which involves vertical towers where the plant roots hang in the air while a nutrient solution is delivered with a fine mist. It also boasts that by using this method, plants can grow with less land and water while yielding up to 30% more three times faster than traditional soil farming.

Vertical farms in New Jersey help feed local communities. Many are in urban areas and are a form of urban farming.

Fisher predicts that vertical farms will be operational in stores and supermarkets around the state.

"It's continued to expand. There's going to be many, many ways and almost any area in the state has the opportunity to have a vertical farm," Fisher said.

Vertical Farming: Ugandan Company Develops Solution for Urban Agriculture

We speak to Lilian Nakigozi, founder of Women Smiles Uganda, a company that manufactures and sells vertical farms used to grow crops in areas where there is limited space

We speak to Lilian Nakigozi, founder of Women Smiles Uganda, a company that manufactures and sells vertical farms used to grow crops in areas where there is limited space.

Image from: How We Made It in Africa

1. How Did You Come Up with the Idea to Start Women Smiles Uganda?

Women Smiles Uganda is a social enterprise formed out of passion and personal experience. I grew up with a single mother and eight siblings in Katanga, one of the biggest slums in Kampala, Uganda. I experienced hunger and poverty where we lived. There was no land for us to grow crops and we didn’t have money to buy food. Life was hard; we would often go to sleep on empty stomachs and our baby sister starved to death.

Growing up like that, I pledged to use my knowledge and skills to come up with an idea that could solve hunger and, at the same time, improve people’s livelihoods, particularly women and young girls living in the urban slums. In 2017, while studying business at Makerere University, I had the idea of developing a vertical farm. This came amid so many challenges: a lack of finance and moral support. I would use the money provided to me for lunch as a government student to save for the initial capital of my venture.

I managed to accumulate $300 and used this to buy materials to manufacture the first 20 vertical farms. I gave these to 20 families and, in 2018, we fully started operations in different urban slums.

2. Tell Us About Your Vertical Farms and How They Work.

Women Smiles vertical farms are made out of wood and recycled plastic materials. Each unit is capable of growing up to 200 plants. The product also has an internal bearing system which turns 360° to guarantee optimal use of the sunlight and is fitted with an inbuilt drip irrigation system and greenhouse material to address any agro-climatic challenges.

The farms can be positioned on a rooftop, veranda, walkway, office building or a desk. This allows the growth of crops throughout the year, season after season, unaffected by climatic changes like drought.

In addition, we train our customers on how to make compost manure using vermicomposting and also provide them with a market for their fresh produce.

Image from: How We Made It in Africa

3. Explain Your Revenue Model.

Women Smiles Uganda generates revenue by selling affordable, reliable and modern vertical farms at $35, making a profit margin of $10 on each unit. The women groups are recruited into our training schemes and we teach them how to use vertical farming to grow crops and make compost manure by vermicomposting. Women groups become our outgrowers of fruits and vegetables. We buy the fresh produce from our outgrowers and resell to restaurants, schools and hotels.

We also make money through partnering with NGOs and other small private organisations to provide training in urban farming concepts to the beneficiaries of their projects.

4. What Are Some of the Major Challenges of Running This Business?

The major challenge we face is limited funds by the smallholder farmers to purchase the vertical farms. However, we mitigate this by putting some of them into our outgrower scheme which helps them to generate income from the fresh produce we buy. We have also linked some of them to financial institutions to access finance.

5. How Do You Generate Sales?

We reach our customers directly via our marketing team which moves door to door, identifying organised women groups and educating them about the benefits of vertical farming for improved food security. Most of our customers are low-income earners and very few of them have access to the internet.

However, we do also make use of social media platforms like Facebook to reach out to our customers, especially the youth.

In addition, we organise talk shows and community gatherings with the assistance of local leaders with whom we work hand in hand to provide educational and inspirational materials to people, teaching them about smart agriculture techniques.

6. Who Are Your Main Competitors?

Just like any business, we have got competitors; our major competitors include Camp Green and Spark Agro-Initiatives.

Image from: The Conversation

7. What Mistakes Have You Made in Business and What Did You Learn From Them?

As a victim of hunger and poverty, my dream was for every family in slums to have a vertical farm. I ended up giving some vertical farms on credit. Unfortunately, most of them failed to pay and we ended up with huge losses.

This taught me to shift the risk of payment default to a third party. Every customer who may need our farms on credit is now linked to our partner micro-finance bank. By doing this, it is the responsibility of the bank to recover the funds from our customers and it has worked well.

8. Apart from This Industry, Name an Untapped Business Opportunity in Uganda.

Manufacturing of cooler sheds for the storage of perishable agricultural produce is one untapped opportunity. Currently, Ugandan smallholder farmers lose up to 40% of their fresh produce because of a lack of reliable cold storage systems.

Providing a cheap and reliable 24/7 cold storage system would dramatically reduce post-harvest losses for these farmers.

Is AppHarvest the Future of Farming?

In this video from Motley Fool Live, recorded on Jan. 28, Industry Focus host Nick Sciple and Motley Fool contributor Lou Whiteman discuss AppHarvest, one such SPAC that is looking to disrupt the agriculture industry. Here are the details on what AppHarvest wants to do, and a look at whether the company represents the future of farming.

Special purpose acquisition companies, or SPACs, are red-hot right now, with investors clamoring to get into promising young companies.

In this video from Motley Fool Live, recorded on Jan. 28, Industry Focus host Nick Sciple and Motley Fool contributor Lou Whiteman discuss AppHarvest, one such SPAC that is looking to disrupt the agriculture industry. Here are the details on what AppHarvest wants to do, and a look at whether the company represents the future of farming.

Nick Sciple: One last company I wanted to talk about, Lou, and this is one I think it's -- you pay attention to, but not one I'm super excited to run in and buy. It was a company called AppHarvest. It's coming public via a [SPAC] this year. This vertical farming space. We talked about Gladstone Land buying traditional farmland. AppHarvest is taking a very different approach, trying to lean into some of the ESG-type movements.

Lou Whiteman: Yeah. Let's look at this. It probably wouldn't surprise you that the U.S. is the biggest global farm exporter as we said, but it might surprise you that the Netherlands, the tiny little country, is No. 2. The way they do that is tech: Greenhouse farm structure. AppHarvest has taken that model and brought it to the U.S. They have, I believe, three farms in Appalachia. The pitches can produce 30x the yields using 90% less water. Right now, it's mostly tomatoes and it is early-stage. I don't own this stock either. I love this idea. There's some reasons that I'm not buying in right now that we can get into. But this is fascinating to me. We talked about making the world a better place. This is the company that we need to be successful to make the world a better place. The warning on it is that it is a SPAC. So it's not public yet. Right now, I believe N-O-V-S. That deal should close soon. [Editor's note: The deal has since closed.] I'm not the only one excited about it. I tend not to like to buy IPOs and new companies anyway. I think the caution around buying into the excitement applies here. There is a Martha Stewart video on their website talking up the company, which I love Martha Stewart, but that's a hype level that makes me want to just watch and see what they produce. This is just three little farms in Appalachia right now and a great idea. This was all over my watchlist. I would imagine I would love to hold it at some point, but just be careful because this is, as we saw SPACs last year in other areas, people are very excited about this.

Sciple: Yeah. I think, like we've said, for a lot of these companies, the prospects are great. I think when you look at the reduced water usage, better, environmentally friendly, all those sorts of things. I like that they are in Appalachia. As someone who is from the South, I like it when more rural areas get some people actually investing money there. But again, there's a lot of execution between now and really getting to a place where this is the future of farming and they're going to reach scale and all those sorts of things. But this is a company I'm definitely going to have my radar on and pay attention to as they continue to report earnings. Because you can tell yourself a story about how this type of vertical farming, indoor farming disrupts this traditional model, can be more efficient, cleaner, etc. Something to continue paying attention to as we have more information, because this company, like you said, Lou, isn't all the way public yet. We still got to have this SPAC deal finalized and then we get all our fun SEC filings and quarterly calls and all those sorts of things. Once we have that, I will be very much looking forward to seeing what the company has to say.

Whiteman: Right. Just to finish up along too, the interesting thing here is that it is a proven concept because it has worked elsewhere. The downside of that is that it needed to work there. Netherlands just doesn't have -- and this is an expensive proposition to get started, to get going. There's potential there, but in a country blessed with almost seemingly unlimited farmland for now, for long term it makes sense. But in the short term, it could be a hard thing to really get up and running. I think you're right, just one to watch.

No Dirt? No Farm? No Problem. The Potential For Soil-Less Agriculture Is Huge

It’s a growing industry — $9.5 billion in sales is expected to nearly double in the next five years — that stems, in part, from concerns about growing enough food to feed a worldwide population expected to hit 10 billion in the next 30 years.

At Plenty’s South San Francisco hydroponics growing facility, a million plants produce leafy greens that are sold through area grocery stores. The company plans to open a farm in Compton this year.

(Plenty)

Imagine kale that doesn’t taste like a punishment for something you did in a previous life. Envision leafy greens that aren’t limp from their journey to your plate. Anticipate the intense flavor of just-picked herbs that kick up your latest culinary creation a notch or three.

Then consider the possibility that such advancements will play a role in altering the face of agriculture, becoming sources of flavorful, fresh produce in “food deserts” and making farm-to-table restaurant cuisine possible because produce is grown on the premises, even in urban areas.

This is the potential and the promise of hydroponics (a term that also includes aeroponics and aquaponics systems), the soil-less cultivation of crops in controlled environments. It’s a growing industry — $9.5 billion in sales is expected to nearly double in the next five years — that stems, in part, from concerns about growing enough food to feed a worldwide population expected to hit 10 billion in the next 30 years.

The growing method isn’t new. The Hanging Gardens of Babylon, dating to the 6th century B.C., maybe a precursor to today’s hydroponics, if they existed. (Historians disagree on that as well as where the gardens were.) Then, as now, technology is a key to giving growers, not Mother Nature, more control overproduction.

The size of today’s systems varies. They might be as simple and compact as an in-home system that’s about the size of a couple of loaves of bread stacked on top of each other. Some of the growing popularity of those units may be connected to the pandemic, according to Paul Rabaut, director of marketing for AeroGarden, which produces systems for in-home crop production.

“As soon as the pandemic was declared in mid-March and the quarantine took effect, we saw immediate growth spikes, unlike anything we’d ever seen before,” he said. Those spikes resulted, he said, from the need for entertainment beyond Netflix and jigsaw puzzles, a desire to minimize trips to the grocery store and the promise of teachable moments for kids now schooled at home.

At the other end of the spectrum are large urban farms. Plenty, for instance, has a South San Francisco hydroponics growing facility where a million plant sites produce crops, some of which are sold through area grocery stores. The company hopes to open a farm in Compton this year that’s expected to be about the size of a big-box store and will grow the equivalent of 700 acres of food.

Plenty scientists, engineers and growers at work in their South San Francisco hydroponics growing facility.

(Plenty)

“It’s a super vibrant community with a rich agricultural history,” Nate Storey, a cofounder of the vertical farming company, said of the Compton facility. “It also happens to be a food desert.

“Americans eat only about 30% of what they should be eating as far as fresh foods,” he said. “We started this company because we realized the world needed more fresh fruits and vegetables.”

As different as hydroponics growing systems are, most have this in common: The plants thrive because of the nutrients they receive and the consistency of the environment and can produce crops of fresh leafy greens and other vegetables, various herbs and sometimes fruits.

Such controlled-environment agriculture is part of the larger trend of urban farms, recognized last year by the May opening of the U.S. Department of Agriculture’s Office of Urban Agriculture and Innovative Production. The farms’ proximity to larger markets means produce can be delivered quickly to consumers, whether they’re grocery shoppers, airline passengers, students or communities in need or restaurants, an industry that has been devastated in the last year.

Today’s micro-and mega-farms have taken on increased importance, partly because of world hunger, which will increase as the population grows.

Add increasing urbanization that is gobbling available agricultural land in many countries, mix in climate change and the scramble for water to grow crops — as much as 70% of the world’s water is used for agriculture — and the planet may be at a tipping point.

No single change in the approach to feeding the world will shift the balance by itself.

Hydroponic farming is “a solution,” said Alexander Olesen, a cofounder of Babylon Micro farms in Virginia, which uses its small growing units to help corporate cafeterias, senior living centres, hotels and resorts provide fresh produce, “but they are not the solution.”

Babylon Micro farms in Virginia provides fresh produce for corporate cafeterias, senior living centers, hotels and resorts.

(Babylon Micro-Farms Inc.)

For one thing, not all crops are viable. Nearly everything can be grown using hydroponics but some crops, such as wheat, some root vegetables (including carrots, beets and onions), and melons and vining crops, are impractical. The easiest crops to grow: leafy greens, including spinach and lettuce; microgreens; herbs such as basil, cilantro, oregano and marjoram; some vegetables, such as green peppers and cucumbers; and certain fruits, including tomatoes and strawberries.

Although hydroponic farming means crops grow faster — thus increasing output — the process comes with a significant carbon footprint, according to “The Promise of Urban Agriculture,” a report by the Department of Agriculture/Agricultural Marketing Service and Cornell University Small Farms Program. Lights generate heat, which then must be removed by cooling. Lettuce grown in traditional greenhouses is far cheaper, the report says.

If these crops can be grown traditionally — in a garden or in a commercial field — why bother with growing systems that are less intuitive than planting seeds, watering and harvesting? Among the reasons:

Climate control: Such indoor agriculture generally means consistent light, temperatures, nutrients and moisture for crops no longer held hostage by nature’s cycles of drought, storms and seasons.

Environmental friendliness: Pesticides generally aren’t used and thus create no harmful runoff, unlike field-grown crops.

Productivity: Leafy greens tend to be cool-season crops, but in a controlled environment, it’s an any-time-of-year crop without the worry of depleting the soil because of overuse because, of course, there is no soil.

Use of space: AeroFarms, a former steel mill in Newark, N.J., boasts that it can produce 2 million pounds of food each year in its 70,000 square feet, or about 1.3 acres. California’s Monterey County, by contrast, uses nearly 59,000 acres — out of 24.3 million acres statewide of ranches and farms — to grow its No. 1 crop, which is leaf lettuce valued at $840.6 million, its 2019 crop report showed.

AeroFarms in Newark, N.J. boasts it can produce 2 million pounds of food each year at its 70,000-square-foot facility in Newark, N.J.

(AeroFarms)

Food safety: In E. coli outbreaks in late October and early November of last year, fingers pointed to romaine lettuce that sickened consumers in 19 states, including California. In November and December of 2019, three other outbreaks of the bacterial illness were traced to California’s Salinas Valley. A Food and Drug Administration study, released in May with results from that trio of outbreaks, “suggest(s) that a potential contributing factor has been the proximity of cattle,” whose faeces often contain the bacteria and can find its way into water systems.

That’s less of an issue with crops in controlled-environment agriculture, said Alex Tyink, president of Fork Farms of Green Bay, Wis., which produces growing systems suitable for homes and schools.

“In the field, you can’t control what goes where,” he said, including wildlife, livestock or even birds that may find their way into an open growing area.

And as for workers, “The human safety approaches that we take [with] people in our farm make it hard for them to contaminate even if they wanted to,” he said.

“Before people walk in, they gown up, put their hair in nets, beards in nets, put on eye covering and bootie covers for their shoes, then walk through a water bath.”