Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

"New York Is Ideally Suited For Greenhouse Production"

Intergrow Greenhouses is excited to announce the opening of its newest expansion in Upstate, NY. The 10-acre project will produce over 3 million pounds of fresh produce a year, feeding millions across the Northeast and Mid-Atlantic all of the way down to the Southeast.

August 10, 2021

Intergrow Greenhouses is excited to announce the opening of its newest expansion in Upstate, NY. The 10-acre project will produce over 3 million pounds of fresh produce a year, feeding millions across the Northeast and Mid-Atlantic all of the way down to the Southeast.

“We’ve been operating in the US since 1998, and always in New York State.” says Dirk Biemans, president of Intergrow Greenhouses. “Our European partners saw the opportunity for greenhouse-grown produce here in the US back in the 90s and we quickly set up shop. The climate here in New York is ideally suited for our greenhouse production, resulting in the best flavor, quality, and consistency for our retail partners all year. We are primed for successful growth here in NY. With nearly 60% of the US population only 24 hours from us, and growing consumer demand for local and domestically grown produce, we’ve got to be ready."

And a local company they truly are. Biemans reports over 70% of the 350 employees at Intergrow are permeant residents of New York State and that number is growing. “Labor is an extremely important part of our business model, if we can recruit, train, and retain local labor it can yield huge advantages for us.”

The new facility will be outfitted with HPS grow lights, adding to Intergrow’s ever-increasing winter offerings. It also boasts diffused glass for better light distribution and heating and fertigation systems. However, Biemans reports there were several challenges and delays that threatened the project finishing on time.

“Ocean freight is crazy right now, not only have prices increased but there’s been a huge problem with on-time arrivals and customs issues. The majority of this project came in prefabricated from Europe, which offers a lot of benefits but our team and chosen suppliers were not quite ready for the logistical challenges in 2021. However, we were able to pull through, overcoming those challenges, and working with the cards we were dealt. This project was successfully completed on time putting us at a total of 105 acres under glass.”

For more information:

Intergrow Greenhouses

www.intergrowgreenhouses.com

Lead Photo: Propagated tomato plants await their final placement in Intergrow’s Newest 10-acre greenhouse.

Common Farms (Hong Kong): “It's A Marathon And Not A Sprint For Us”

The product demand keeps growing. Inevitably, the pandemic has accelerated this demand for food quality and availability in Hong Kong.

By Rebekka Boekhout

July 23, 2021

The product demand keeps growing. Inevitably, the pandemic has accelerated this demand for food quality and availability in Hong Kong. “I think it’s because of the following reasons. One being that Common Farms can deliver with consistency, speed, and quality. Secondly, as people aren’t traveling they have disposable income to spend locally. The customers we serve are booked out for months. Lastly, pricing for imported produce fluctuates, which over time has a great impact on our customers.”

Lead Photo: Jessica Fong

Read the rest of the article here!

1-in-3 Agree This Grocery Store Has The Worst Quality Produce

Mashed had these big-box shoppers in mind when we conducted a recent survey of 593 U.S. residents. We asked, "Which grocery store has the worst-quality produce?"

By Ralph Schwartz

July 26, 2021

Some people prefer to grow their own garden or pick up their produce at the farmers market, straight from the person who grew it. On the other hand, a lot of us like to get our apples and lettuce at the same store where we buy our toilet paper and home furnishings. Mashed had these big-box shoppers in mind when we conducted a recent survey of 593 U.S. residents. We asked, "Which grocery store has the worst-quality produce?" We gave our survey participants eight options: Aldi, Costco, H.E.B., Kroger, Meijer, Publix, Target, and Walmart.

Before we reveal which of these retail chains our respondents considered the worst, let's take a look at who didn't get a lot of votes. Like golf, low scores are good in this survey, and three grocers each got less than 7% of the total vote. Faring best was Publix, with 6.41% of the votes. Publix might have been off the radar for most respondents, as the chain only has locations in seven Southeast states, according to the Publix website. Publix doesn't necessarily have a sterling reputation for produce. If it's known for anything, it's the fried chicken and sub sandwiches, per The Kitchn.

Costco and Kroger tied for second-lowest vote total, at 6.91%. This is more impressive, as both are truly national chains. The only real knock on Costco's produce is that a lot of it is sold in bulk, and normal-sized families might not use it all before it spoils, per CNBC.

Our survey says Walmart has the worst produce, despite a recent upgrade.

Now for the bad news in the Mashed survey that asked people which grocery store has the worst produce. The runner-up for worst produce was Target, which drew 16.53% of the vote. But Target was no competition for Walmart in the produce-quality race to the bottom. Walmart was our clear, er ... winner, with 33.39% of the total vote. Our survey respondents seem to know low-quality produce when they see it. Their answers matched a 2019 survey by Consumer Reports, which also ranked Target and Walmart's produce among the worst.

Target had planned to install vertical farms inside its stores beginning in 2017 (via Business Insider), but it's not clear whether this plan for getting the freshest possible produce in their stores ever got off the ground. Whatever the case, it has done little to improve Target's poor reputation for produce.

Meanwhile, Walmart made major improvements to its produce departments in 2020, according to Supermarket News. But the changes were more about the department's layout than the quality of the food. Wider aisles and lower displays were intended to reduce crowding and make it easier for shoppers to see the produce. But if you don't like what you see, then a redesign may not be much of a game-changer. Walmart may need to do more to lose its image as the worst grocery store for produce.

AeroFarms Expands Its Award-Winning Leafy Greens Product Assortment

AeroFarms, a Certified B Corporation and leader in indoor vertical farming, today announced that it is expanding its line of leafy greens to include 5 new items: Baby Bok Choy-The New SpinachTM, Micro Arugula, Micro Broccoli, Micro Kale, and Micro Rainbow Mix

July 13, 2021

NEWARK, N.J.–AeroFarms, a Certified B Corporation and leader in indoor vertical farming, today announced that it is expanding its line of leafy greens to include 5 new items: Baby Bok Choy-The New SpinachTM, Micro Arugula, Micro Broccoli, Micro Kale, and Micro Rainbow Mix.

AeroFarms® award-winning retail brand of leafy greens is prized for its elevated flavor and is grown using proprietary aeroponics and indoor vertical farming technologies, which yield annual productivity up to 390 times greater than traditional field farming while using up to 95% less water and zero pesticides.

There has been increased consumer interest in Asian greens and Future Fusebiquity – as outlined in Datassential’s Food Bytes 2021 Food Trends – that takes new generation products and combines them with well-known dishes. AeroFarms Baby Bok Choy-The New SpinachTM is reimagining how to create a better spinach experience that is juicier, more flavorful, and even more nutrient-dense with an ANDI (Aggregate Nutrient Density Index) score of 865 vs. spinach at 707, and it can be enjoyed in just about any spinach recipe for an updated new take on the dish.

Microgreens were recognized by The Today Show as one of the top health trends for 2021, and AeroFarms has been expanding this category at retail since 2019. Responding to consumer demand, AeroFarms has added Micro Arugula, Micro Broccoli, Micro Kale, and Micro Rainbow Mix to its core line of Micro Spicy Mix and Micro Super Mix. Produced year-round at the highest quality, AeroFarms microgreens offer great visual and flavor excitement, elevating the home cook into a chef. In addition, AeroFarms microgreens provide higher nutrient density than their mature green counterparts, offering a powerful way to provide a potent boost of vitamins, minerals, and phytonutrients.

AeroFarms starts by selecting the most flavorful varietals of microgreens and baby greens, then perfects them in its proprietary indoor vertical farms for optimal quality, yield, color, nutrition, texture, and taste. In fact, AeroFarms has trademarked Vertical Farming, Elevated Flavor™ to highlight to consumers not only where and how their food is grown, but also more importantly, the key growing benefits that AeroFarms uniquely brings to the market, setting a new culinary standard with millions of data points to prove it.

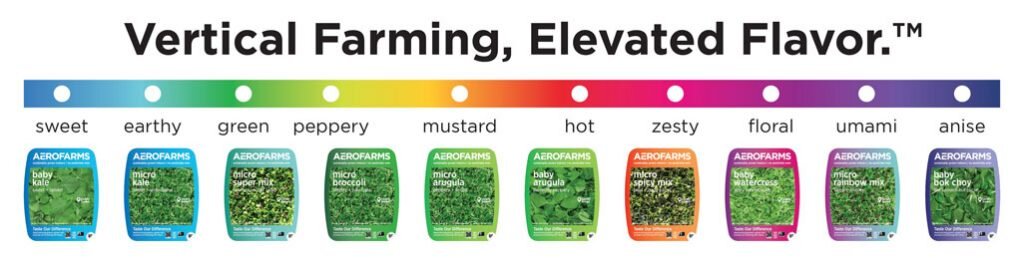

AeroFarms is able to grow its kale to be sweeter and its arugula to be perfectly peppery, and the Company has developed its signature FlavorSpectrum™ to represent the breadth of flavors and hundreds of varieties of leafy greens that it is able to grow. AeroFarms’ team of experts from horticulturists to engineers to data scientists to nutritionists paired each specific tasting note with a representative color to bring the FlavorSpectrum™ philosophy to life. Across its leafy greens packaging line, the cool blue tones represent sweet and mellow notes, while the intense reds represent bold and zesty flavors.

All AeroFarms leafy greens are safely grown indoors in New Jersey at one of AeroFarms’ state-of-the art commercial indoor vertical farms that is certified for USDA Good Agricultural Practices, SQF Level 2 Good Manufacturing Practices, Non-GMO Project Verification, and OU Kosher. AeroFarms leafy greens are completely pesticide free, and ready-to-eat without any need to wash, providing a major benefit to consumers looking for safety and convenience. AeroFarms leafy greens are available at major customers such as Amazon Fresh, Baldor Specialty Foods, FreshDirect, Morton Williams, ShopRite, Walmart, and Whole Foods.

“Our Company is committed to partnering with our retail partners to expand the entire category of leafy greens and drive consumption with our sustainably grown produce that is winning on taste,” said David Rosenberg, Co-Founder and Chief Executive Officer of AeroFarms. “We are excited to expand our line of microgreens, which we believe can move from just a garnish to center of the plate given their exceptional taste — microgreens can be enjoyed all of the time!”

About AeroFarms

Since 2004, AeroFarms has been leading the way for indoor vertical farming and championing transformational innovation for agriculture. On a mission to grow the best plants possible for the betterment of humanity, AeroFarms is a Certified B Corporation with global headquarters in Newark, New Jersey. Named one of the World’s Most Innovative Companies by Fast Company two years in a row and one of TIME’s Best Inventions in Food, AeroFarms patented, award-winning indoor vertical farming technology provides the perfect conditions for healthy plants to thrive, taking agriculture to a new level of precision, food safety, and productivity while using up to 95% less water and no pesticides ever versus traditional field farming. AeroFarms enables local production to safely grow all year round, using vertical farming for elevated flavor. In addition, through its proprietary growing technology platform, AeroFarms has developed multi-year strategic partnerships ranging from government to major Fortune 500 companies to help uniquely solve agriculture supply chain needs. For additional information, visit: https://aerofarms.com/.

On March 26, 2021, AeroFarms announced a definitive business combination agreement with Spring Valley Acquisition Corp. (Nasdaq: SV). Upon the closing of the business combination, AeroFarms will become publicly traded on Nasdaq under the new ticker symbol “ARFM”. Additional information about the transaction can be viewed here: https://aerofarms.com/investors/

No Offer or Solicitation

This press release does not constitute an offer to sell or a solicitation of an offer to buy, or the solicitation of any vote or approval in any jurisdiction in connection with a proposed potential business combination among Spring Valley and AeroFarms or any related transactions, nor shall there be any sale, issuance or transfer of securities in any jurisdiction where, or to any person to whom, such offer, solicitation or sale may be unlawful. Any offering of securities or solicitation of votes regarding the proposed transaction will be made only by means of a proxy statement/prospectus that complies with applicable rules and regulations promulgated under the Securities Act of 1933, as amended (the “Securities Act”), and Securities Exchange Act of 1934, as amended, or pursuant to an exemption from the Securities Act or in a transaction not subject to the registration requirements of the Securities Act.

Forward Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “might,” “will,” “estimate,” “continue,” “contemplate,” “anticipate,” “intend,” “expect,” “should,” “would,” “could,” “plan,” “predict,” “project,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this presentation, regarding Spring Valley’s proposed acquisition of AeroFarms, Spring Valley’s ability to consummate the transaction, the benefits of the transaction and the combined company’s future financial performance, as well as the combined company’s strategy, future operations, estimated financial position, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of the respective management of AeroFarms and Spring Valley and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AeroFarms and Spring Valley. These forward-looking statements are subject to a number of risks and uncertainties, including changes in domestic and foreign business, market, financial, political, and legal conditions; the inability of the parties to successfully or timely consummate the proposed transaction, including the risk that any regulatory approvals are not obtained, are delayed or are subject to unanticipated conditions that could adversely affect the combined company or the expected benefits of the proposed transaction or that the approval of the stockholders of Spring Valley or AeroFarms is not obtained; failure to realize the anticipated benefits of the proposed transaction; risks relating to the uncertainty of the projected financial information with respect to AeroFarms; risks related to the expansion of AeroFarms’ business and the timing of expected business milestones; the effects of competition on AeroFarms’ business; the ability of Spring Valley or AeroFarms to issue equity or equity-linked securities or obtain debt financing in connection with the proposed transaction or in the future, and those factors discussed in Spring Valley’s Annual Report on Form 10-K, Quarterly Report on Form 10-Q, final prospectus dated November 25, 2020 and preliminary proxy statement/prospectus dated May 10, 2021 under the heading “Risk Factors,” and other documents Spring Valley has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that neither Spring Valley nor AeroFarms presently know, or that Spring Valley nor AeroFarms currently believe are immaterial, that could also cause actual results to differ from those contained in the forward-looking statements. In addition, forward-looking statements reflect Spring Valley’s and AeroFarms’ expectations, plans, or forecasts of future events and views as of the date of this press release. Spring Valley and AeroFarms anticipate that subsequent events and developments will cause Spring Valley’s and AeroFarms’ assessments to change. However, while Spring Valley and AeroFarms may elect to update these forward-looking statements at some point in the future, Spring Valley and AeroFarms specifically disclaim any obligation to do so. These forward-looking statements should not be relied upon as representing Spring Valley’s and AeroFarms’ assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

1200% Increase In Production At ENOGROW In Times of A Pandemic!

One step closer to food sovereignty in New Brunswick Canada. 1200% increase in production at ENOGROW in times of a pandemic!

July 11, 2021

One step closer to food sovereignty in New Brunswick Canada. 1200% increase in production at ENOGROW in times of a pandemic!

Thanks to an equipment investment upgrade valued at nearly $250,000. ENOGROW, an indoor vertical hydroponic farm, located in Saint-Léolin NB, will see a production increase of leafy vegetables from 7,500 to

nearly 100,000 heads grown per year by the end of 2021. Due to the owners Chantal and Daniel Ratté hard work, perseverance and imagination, this amazing production surge occurs after less than 18 months of operation and in the midst of a worldwide pandemic.

Cultivation in a controlled environment takes place inside the former Le Maillon school, a 2280sqm building on 4 acres of land 12 month a year! ENOGROW currently offers their products to grocery stores, restaurants and on-site to the local population. With the above upgrades, along with a new refrigerated truck, the company will expand its customer’s network to Miramichi and Campbellton areas, and soon to southern New Brunswick as well.

Due to climate change, supply issues and the ever-growing demand for fresh local produce, this indoor hydroponic farm takes NB residents one step closer to food sovereignty year long!

This innovative indoor hydroponic farm grows nearly 20 different products year round, including 4 kinds of lettuce, various herbs and microgreens from organic seeds. All of this healthy produce is grown without soil, pesticides, herbicides or chemical residue, using 90% less water in only 10% of the space required by conventional cultivation.

The company is already working on their new goal for 2022, with expectations of 200,000 heads produced, a step closer to the final goal of 750,000 heads annually by 2025. This would create nearly 20 permanent jobs and serve New Brunswick, Prince Edward Island, Nova Scotia and Newfoundland with fresh and local leafy vegetables 12 months per year.

This is quite a challenge for Chantal and Daniel, whose company began their operations in November 2019, less than 3 months before the start of the pandemic. They work almost 80 hours a week. “We never thought

we had the ability to work this hard, especially me at 62 years old, says Dan. Advice to anyone thinking of beginning this kind of agricultural that request a high production volume to be profitable. This is real farm work, and it is year round, Dan explains!

The final commissioning of the new equipment is scheduled for end of July.

Daniel Ratté Pres.

Enogrow Inc.

916 Boul. Saint-Joseph,

Saint-Léolin, NB E8N 2P8

danielr@enogrow.com

Off: 506-604-4400 Cell:506-720-2007 FB: Enogrow

FRANÇAIS

06 Juillet 2021

Plus près de la souveraineté alimentaire au NB. Augmentation de 1200% de la production de légumes à feuilles chez Enogrow en temps de pandémie!

Grace à un investissement en équipements d’une valeur de près de $250,000, la ferme hydroponique verticale intérieure ENOGROW de Saint-Léolin verra sa production de légumes à feuilles passer de 7500

à près de 100,000 têtes cultivées par année d’ici la fin de 2021. C’est grâce au travail acharné, persévérance et imagination, des deux propriétaires Chantal et Daniel Ratté que cette incroyable augmentation de production se produit après moins de 18 mois d'exploitation et au milieu d'une pandémie mondiale.

Dû au changement climatique, problèmes en approvisionnement et ses coûts, ainsi qu’à la forte demande en produits frais local sans cesse grandissante, cette ferme hydroponique intérieure permet aux résidents du NB de franchir un pas de plus vers la souveraineté alimentaire.

La culture sous environnement contrôlée, se fait à l’intérieur de l’ancienne école Le Maillon, un bâtiment de 2280mc sur 4 acres. Ils offrent présentement leurs produits aux marchés d'alimentation, restaurants et sur place pour la population locale. Par cet ajout d’équipement et d’un camion réfrigéré, l’entreprise peux maintenant étendre son réseau de clients vers Miramichi et Campbellton et bientôt le sud du nouveau Brunswick.

La ferme hydroponique intérieure d’avant garde cultive près de 20 produits différents, dont 4 sortes de laitue incluant la romaine, fines herbes et micro-pousses à partir de graine graines organiques, sans terre, insecticides, herbicides ou résidus de produits chimique, en utilisant 90% moins d'eau en utilisant seulement 10% de l’espace requis par la culture conventionnelle et ce 12 mois par année!.

L'entreprise travaille déjà sur leur nouvel objectif pour 2022 qui devrait être près des 200,000 têtes produites en route vers son but final de 750,000 produites annuellement d'ici 2025. Ceci créera près de 20 emploies permanents et pourra servir le Nouveau Brunswick, Ile du Prince Edward, la Nouvelle-Écosse et Terre neuve en légumes à feuilles frais et local.

C’est tout un défi à relever pour Chantal et Daniel dont l’entreprise a démarré ses opérations en novembre 2019, soit moins de 3 moins de mois avant le début de la pandémie. Ils y travaillent près de 80 heures par semaine. ‘’ On ne pensait jamais avoir à travailler autant spécialement moi à 62 ans. C’est un pensez y bien avant, pour ceux et celles qui désirent se lancer dans ce genre d’agriculture qui demande un haut volume pour atteindre la rentabilité. C’est un travail de ferme mais à longueur d’année explique t-il!

La mise en service des nouveaux équipements est prévue fin juillet.

Daniel Ratté Prés.

Enogrow Inc.

916 Boul. Saint-Joseph,

Saint-Léolin, NB E8N 2P8

danielr@enogrow.com

Off: 506-604-4400 Cell:506-720-2007 FB: Enogrow

Vertical Farming Method To Produce UK Strawberries ‘Nine Months A Year’

Direct Produce Supplies (DPS) is stacking up 1,000 tonnes of strawberries and will be supplying Tesco using the method, which should guarantee supplies whatever the weather during the British summer

By Ben Mitchell

July 4, 2021

Strawberries grown in Britain could be on supermarket shelves nine months of the year using a new vertical-growing technique that is also better for the environment.

The system, which is being pioneered by a fruit-grower in Arundel, West Sussex, England, uses 50% less water and has a 90% lower carbon footprint but has yields five times higher than normal production methods.

Staff at Wickes Farm in Ford, West Sussex, UK, harvest strawberries at the state-of-the-art farm (Ben Stevens/Parsons Media/PA)

Direct Produce Supplies (DPS) is stacking up 1,000 tonnes of strawberries and will be supplying Tesco using the method, which should guarantee supplies whatever the weather during the British summer.

The strawberries are produced in vertically stacked beds under fully controlled conditions, with plants watered using a hydroponic feed instead of in the soil, which DPS says helps improve the nutrition value of the fruit.

Chief executive Paul Beynon said: “Vertical farming offers growers a protected environment that requires significantly less land, water and energy to produce excellent quality crops.

“We chose our farm location near Chichester on the south coast because this region gives the highest natural levels of light and heat in the UK and so maximises the potential.

“We are still at a relatively early stage in vertical growing and in the future we believe that we can make even further advances in sustainable strawberry production and that other fruit crops could take to the system in a similar way.”

Tesco fruit technical manager Sabina Wyant said: “Vertical crop production is a giant step for fresh produce growers in helping reduce their carbon footprint and use less water, at the same time boosting their yields.

“For shoppers there is also a clear benefit, with consistent quality fruit and availability for up to nine months of the year, regardless of the weather conditions.

“By example, right now during Wimbledon fortnight, the UK sees the highest demand of the year for strawberries but sometimes adverse weather conditions can challenge production at this time, leaving retailers with a shortfall.

“Vertical farming will put an end to that uncertainty and ensure perfect growing conditions during an extended nine-month season.”

Lead Photo: The strawberries are produced in vertically stacked beds under fully controlled conditions, with plants watered using a hydroponic feed instead of in the soil.

Startup Raises Millions for Vertical Green Production

Now the Danish startup Nabo Farm has received DKK 3 million. from investors to expand their version of an "urban agriculture" and will open farm number two in the capital, rather on Amager, it says in a press release.

By Torben Salomonsen

June 25, 2021

The production of vegetables in vertical farms is gaining ground all over the globe and in Denmark, indoor agriculture with coastal light has also found a market.

Now the Danish startup Nabo Farm has received DKK 3 million from investors to expand their version of an "urban agriculture" and will open farm number two in the capital, rather on Amager, it says in a press release.

Since 2018, Nabo Farm has had production of green from a disused car workshop in northwestern Copenhagen, but will now expand with another farm, which will simply be the first in a series of several, according to the founders Sebastian Dragelykke and Jens Juul Krogshede.

"For us as a start-up company, it is a great thing that we have succeeded in raising such a significant amount, because it means that we can now focus on scaling the Neighbor Farm concept further by opening another farm. At the same time, The investment from Danban and Vækstfonden also means that we can, at a societal level, help to spread the knowledge of sustainable food production," says Sebastian Dragelykke.

The 3 mio. As mentioned, this comes from the business angel network DanBan and Vækstfonden, and Nabo Farm currently sells green on a subscription to a clientele that includes canteens, catering companies and restaurants such as Compass Group, Aamanns, Meyers and Alchemist.

The goal of the company is to attract "more and larger investors" to fold the ambitions to produce even more food via LED lamps and a self-developed automatic irrigation system.

Lead Photo: The company Nabo Farm has raised capital to build a new indoor green production in Copenhagen.

Crowdfunding Developers of Herb Tower Succeed

In recent weeks, the entrepreneurs of Local Indoor Farming (LIF) ran a crowdfunding campaign to bring their innovative herb tower to the market. Successfully so, because thanks to the support of 88 investors, the herb tower can now be taken into production

July 6, 2021

In recent weeks, the entrepreneurs of Local Indoor Farming (LIF) ran a crowdfunding campaign to bring their innovative herb tower to the market. Successfully so, because thanks to the support of 88 investors, the herb tower can now be taken into production. The first specimens are expected in September.

The entrepreneurs, Harm, Marnix, and Ard-Jan from LIF, want to make high-quality fresh herbs available to everyone. They developed a herbal tower based on the principle of 'Local Indoor Farming'. This tower ensures that herbs can grow under ideal conditions. Because of the flexible design, the tower fits in any interior.

Minimum start-up capital exceeded

The required start capital to take the herbal tower into production was raised through a crowdfunding campaign. A total of 108,000 Euro was raised from 88 investors. The minimum amount of 80,000 Euro has thus been amply exceeded.

Even more important than the initial capital, according to the entrepreneurs, was the attention that they could draw to the herbal tower in this way. Quite a few towers have already been sold and there is also a great deal of interest from the catering and business sectors. This ensures a flying start for the young company.

First units

In the coming weeks, the finishing touches will be added to the production of the first units. They will be delivered from September onwards. The herb tower is offered in combination with a subscription for fresh herbs, so that the customer always has sufficient choice from a diverse range of herbs.

The entrepreneurs have developed a care package for the hotel and catering industry, so that companies do not have to worry about the maintenance of the tower. Customers can also order individual herbs and accessories via their webshop www.lifkruiden.nl.

The entrepreneurs want to stimulate the use of fresh herbs and combat waste. They inform about the use and maintenance of herbs by means of a herbal information package, which can be requested for free via www.lifgroup.nl/kruideninfopakket.

For more information:

Harm Keurhorst

LIF Group

hkeurhorst@lifgroup.nl

www.lifgroup.nl

UNFI Picks Up Living Greens Farm Products in Midwest Expansion

Living Greens Farm (LGF), the largest vertical, indoor aeroponic farm in the US that provides year-round fresh salads, salad kits, microgreens and herbs, announced the addition of significant new retail distribution of its products in the upper Midwest to independent, specialty, and co-op retailers

I|mage from: Living Green Farms

Living Greens Farm (LGF), the largest vertical, indoor aeroponic farm in the US that provides year-round fresh salads, salad kits, microgreens and herbs, announced the addition of significant new retail distribution of its products in the upper Midwest to independent, specialty, and co-op retailers.

Starting February 2021, LGF’s full line of products featuring ready-to-eat bagged salad products (Caesar Salad Kit, Southwest Salad Kit, Harvest Salad Kit, Chopped Romaine, and Chopped Butter Lettuce) will be carried by UNFI Produce Prescott (formerly Alberts Fresh Produce). UNFI Produce Prescott is a division of UNFI, which distributes food products to thousands of stores nationwide. Their focus is on independent, specialty and co-op retailers.

UNFI has eight warehouses nationwide. LGF’s products will be carried by their upper Midwest location, located just across the river from the Twin Cities in Prescott, WI. This distribution center services hundreds of retailers throughout Minnesota, Wisconsin, Illinois, North Dakota, South Dakota, Missouri, Iowa and Nebraska. UNFI is the first national Certified Organic distributor, something they take a lot of pride in. Their produce and floral businesses are rooted in local farms and seasonal import growers.

LGF’s proprietary vertical indoor farming method yields the highest quality and freshest produce available. This is because there are no pesticides or chemicals used in the growing process. And because LGF’s growing, cleaning and bagging process significantly reduces handling and time to the retail shelf, consumers enjoy the freshest product on the market. These benefits continue to attract new users and new retail distribution as UNFI Produce Prescott is the second UNFI location to carry LGF. In December, UNFI’s Hopkins, MN location began offering LGF products.

For more information on why Living Greens Farm products are the cleanest, freshest and healthiest farm salads and greens available, go to www.livinggreensfarm.com.

Warehouse Becoming Vertical Farms — And They’re Feeding New Jersey

New Jersey's vertical farms are transforming agriculture by helping farmers meet growing food demand. New Jersey Agriculture Secretary Doug Fisher said that while conventional farming in outdoor fields remains critical, vertical farming has its advantages because of its efficiency and resistance to pests and thus less need for chemicals

Image from: New Jersey 101.5

New Jersey's vertical farms are transforming agriculture by helping farmers meet growing food demand.

New Jersey Agriculture Secretary Doug Fisher said that while conventional farming in outdoor fields remains critical, vertical farming has its advantages because of its efficiency and resistance to pests and thus less need for chemicals.

Vertical farming is the process of growing food vertically in stacked layers indoors under artificial light and temperature, mainly in buildings. These plants receive the same nutrients and all the elements needed to grow plants for food.

Vertical farms are also versatile. Plants may be growing in containers, in old warehouses, in shipping containers, in abandoned buildings.

"That's one of the great advantages — that we can put agriculture in the midst of many landscapes that have lost their vitality," said Fisher.

ResearchandMarkets.com says the U.S. vertical farming market is projected to reach values of around $3 billion by the year 2024.

The one drawback is that its operational and labor costs make it expensive to get up and running.

Image from: AeroFarms

In the past decade, however, vertical farming has become more popular, creating significant crop yields all over the state.

AeroFarms in Newark is the world's largest indoor vertical farm. The farm converted a 75-year-old 70,000-square-foot steel mill into a vertical farming operation. AeroFarms' key products include Dream Greens, its retail brand of baby and micro-greens, available year-round in several ShopRite supermarkets.

Kula Urban Farm in Asbury Park opened in 2014. Vacant lots are transformed into urban farms and there's a hydroponic greenhouse on site. That produce is sold to local restaurants.

Beyond Organic Growers in Freehold uses no pesticides and all seeds and nutrients are organic. There's a minimum of 12,000 plants growing on 144 vertical towers. On its website, it says the greenhouse utilizes a new growing technique called aeroponics, which involves vertical towers where the plant roots hang in the air while a nutrient solution is delivered with a fine mist. It also boasts that by using this method, plants can grow with less land and water while yielding up to 30% more three times faster than traditional soil farming.

Vertical farms in New Jersey help feed local communities. Many are in urban areas and are a form of urban farming.

Fisher predicts that vertical farms will be operational in stores and supermarkets around the state.

"It's continued to expand. There's going to be many, many ways and almost any area in the state has the opportunity to have a vertical farm," Fisher said.

Feeding Leeds: A Fair and Self-Sustaining Food System for the City

A bold vision for feeding the population of Leeds would transform the city into a far more food secure, fair and sustainable place to live. Analysts from the University of Leeds’ Global Food and Environment Institute studied the city’s food system to assess its resilience in the face of supply chain and delivery disruptions caused by severe weather, climate change and events such as the COVID-19 pandemic and Brexit

Image from: University of Leeds

A bold vision for feeding the population of Leeds would transform the city into a far more food secure, fair and sustainable place to live.

Analysts from the University of Leeds’ Global Food and Environment Institute studied the city’s food system to assess its resilience in the face of supply chain and delivery disruptions caused by severe weather, climate change and events such as the COVID-19 pandemic and Brexit.

The urban food system includes all the activities involved in the production, distribution and consumption of food within a city.

They mapped and analysed publicly available data relating to agricultural production and human health in the metropolitan district and discovered that 48.4% of the city’s total calorific demand can be met by current commercial food production activities.

This is relatively high for such an urbanised space, but there is little diversity in what is being produced. Three cereal crops (wheat, barley, oats) dominate the Leeds production system, reflecting a post-war food system that focused on energy supply. This means that most of the fruits and vegetables consumed in the city are transported in from elsewhere.

The researchers’ findings also show that the most deprived areas of the district, which have higher rates of obesity, diabetes, and cardiovascular disease, are also likely to be the first to be impacted by supply disruptions. The resulting food shortages can increase prices, and people on low incomes may not have the option to travel to larger supermarkets or afford to bulk buy.

The researchers say there are no quick and easy options for significantly increasing the security, fairness, or sustainability of the food system supplying Leeds.

But they say the metropolitan district’s sizeable number of farmers, manufacturers, suppliers, and food services could all contribute to improving its food resilience by creating a system which provides easy access to healthy foods, shares energy, reuses water and nutrients and repurposes local infrastructure and resources.

Caroline Orfila, who led the study, published today in the journal Food Security, is Professor of Plant Biochemistry and Nutrition in the School of Food Science and Nutrition. She said: “Our work demonstrates the inequalities in food production and dietary health.

“The local food production system can only provide around 50% of the calories needed by the population, highlighting that ‘eating local’ is not currently possible for everyone. In particular, the local food system would not provide sufficient protein or fats. The lack of food diversity suggests current food production is also unlikely to meet vitamin and mineral requirements.

“Any disruptions to food production, distribution or retail, from flooding, longer term climate change, COVID-19 or Brexit, is likely to impact those in deprived areas the most.

“Disruptions tend to cause shortages in some food categories, which then increase food prices. People on low incomes spend more of their income on food; any increases in food prices will limit what they can afford to buy.

“People in deprived areas have limited choice of where to buy foods, they may not have private transport to access larger supermarkets or access to online shopping. They may also not have the cash flow or storage space to buy items in bulk, relying on what is available.

“Interventions are needed to level up those areas.”

Researchers identified more than 1,000km2 of warehousing, derelict land, and unused floor space in abandoned buildings, with direct or possible connections to renewable energy and water.

Half of this land lay near food banks, community centres and numerous food processors and outlets.

The land could potentially be used for no waste innovative farming techniques, including vertical food farms, where crops are grown in vertically stacked layers; green walls, where plants grow on vertical surfaces, and rooftop agriculture, where fresh produce is grown on top of buildings.

The study found that within the metropolitan district of Leeds there is substantial food activity with more than 5,500 businesses and charities supplying fresh and prepared food, including fast food providers, restaurants, and supermarkets. Some 23 food banks are located within the inner-city area.

There are almost 100 hectares of allotment controlled by Leeds City Council, and approximately 39 hectares of private allotment and community growing areas in the Leeds Metropolitan District.

Lead author Dr Paul Jensen, also from Leeds' School of Food Science and Nutrition at the University of Leeds, said: “We found there are numerous underutilised city assets that could be incorporated into a resource efficient urban food ecosystem, which could include a mix of vertical farming, hydroponics, or more conventional growing methods.

“Most notably, many of these areas are within those suffering most from food poverty, diet related health issues and a limited intake of fruit and vegetables - those who are usually the first to suffer during a crisis situation.”

The research identified locations for ‘food hubs’ that connect producers to consumers and discuss the need for a coordinated approach between producers, government, charitable groups and consumers in creating a more sustainable food system.

The research was carried out with FoodWise Leeds, a not-for-profit campaign by Leeds City Council, the University of Leeds, businesses and charities to address food health and sustainability issues.

FoodWise Leeds co-ordinator Sonja Woodcock, said: “This past year has highlighted how vulnerable the local food system is. Taking a coordinated approach and implementing available policy levers, such as including local food within public procurement contracts, increasing access to land for both commercial and community food growing, as well as investing in cooking and food skills will help to create a more resilient and fair local food system.”

Professor Orfila added: “These findings are significant because it shows the vulnerability and inequality of UK cities and urban food systems. The situation in Leeds mirrors the situation in many other cities worldwide.”

Professor Steve Banwart, Global Food and Environment Institute Director said: “The results of this study provide essential evidence to guide access to nutrition for the entire population. The project dramatically changes our view of what is a city and what is a farm and catalyses our partnerships to build a more resilient community.”

Further Information

‘Mapping the Production-Consumption Gap of an Urban Food System: An Empirical Case Study of Food Security and Resilience’ and is published on 8 February in the journal Food Security. It is available online here:https://link.springer.com/article/10.1007/s12571-021-01142-2.

For media enquiries, contact University of Leeds press office via pressoffice@leeds.ac.uk.

Is AppHarvest the Future of Farming?

In this video from Motley Fool Live, recorded on Jan. 28, Industry Focus host Nick Sciple and Motley Fool contributor Lou Whiteman discuss AppHarvest, one such SPAC that is looking to disrupt the agriculture industry. Here are the details on what AppHarvest wants to do, and a look at whether the company represents the future of farming.

Special purpose acquisition companies, or SPACs, are red-hot right now, with investors clamoring to get into promising young companies.

In this video from Motley Fool Live, recorded on Jan. 28, Industry Focus host Nick Sciple and Motley Fool contributor Lou Whiteman discuss AppHarvest, one such SPAC that is looking to disrupt the agriculture industry. Here are the details on what AppHarvest wants to do, and a look at whether the company represents the future of farming.

Nick Sciple: One last company I wanted to talk about, Lou, and this is one I think it's -- you pay attention to, but not one I'm super excited to run in and buy. It was a company called AppHarvest. It's coming public via a [SPAC] this year. This vertical farming space. We talked about Gladstone Land buying traditional farmland. AppHarvest is taking a very different approach, trying to lean into some of the ESG-type movements.

Lou Whiteman: Yeah. Let's look at this. It probably wouldn't surprise you that the U.S. is the biggest global farm exporter as we said, but it might surprise you that the Netherlands, the tiny little country, is No. 2. The way they do that is tech: Greenhouse farm structure. AppHarvest has taken that model and brought it to the U.S. They have, I believe, three farms in Appalachia. The pitches can produce 30x the yields using 90% less water. Right now, it's mostly tomatoes and it is early-stage. I don't own this stock either. I love this idea. There's some reasons that I'm not buying in right now that we can get into. But this is fascinating to me. We talked about making the world a better place. This is the company that we need to be successful to make the world a better place. The warning on it is that it is a SPAC. So it's not public yet. Right now, I believe N-O-V-S. That deal should close soon. [Editor's note: The deal has since closed.] I'm not the only one excited about it. I tend not to like to buy IPOs and new companies anyway. I think the caution around buying into the excitement applies here. There is a Martha Stewart video on their website talking up the company, which I love Martha Stewart, but that's a hype level that makes me want to just watch and see what they produce. This is just three little farms in Appalachia right now and a great idea. This was all over my watchlist. I would imagine I would love to hold it at some point, but just be careful because this is, as we saw SPACs last year in other areas, people are very excited about this.

Sciple: Yeah. I think, like we've said, for a lot of these companies, the prospects are great. I think when you look at the reduced water usage, better, environmentally friendly, all those sorts of things. I like that they are in Appalachia. As someone who is from the South, I like it when more rural areas get some people actually investing money there. But again, there's a lot of execution between now and really getting to a place where this is the future of farming and they're going to reach scale and all those sorts of things. But this is a company I'm definitely going to have my radar on and pay attention to as they continue to report earnings. Because you can tell yourself a story about how this type of vertical farming, indoor farming disrupts this traditional model, can be more efficient, cleaner, etc. Something to continue paying attention to as we have more information, because this company, like you said, Lou, isn't all the way public yet. We still got to have this SPAC deal finalized and then we get all our fun SEC filings and quarterly calls and all those sorts of things. Once we have that, I will be very much looking forward to seeing what the company has to say.

Whiteman: Right. Just to finish up along too, the interesting thing here is that it is a proven concept because it has worked elsewhere. The downside of that is that it needed to work there. Netherlands just doesn't have -- and this is an expensive proposition to get started, to get going. There's potential there, but in a country blessed with almost seemingly unlimited farmland for now, for long term it makes sense. But in the short term, it could be a hard thing to really get up and running. I think you're right, just one to watch.

Colruyt Grows Basil In Self-Developed Vertical Farm

The basil plants are grown in a sustainable way but are not organic. The problem is that they are not grown in the open air, nor on biological substrate, which is why they do not receive an organic certificate

On Tuesday, March 3rd, Colruyt Group introduced home-grown basil from a vertical farm. The fresh basil from the private label Boni Selection can be purchased from today in all 31 stores of Bio-Planet. Bio-Planet will also market-fresh coriander within months.

Fabrice Gabbato

According to Fabrice Gobbato, director of Bio-Planet and Okay; sustainability is in Colruyt's DNA and they were looking for a way to make the range more sustainable. "The system is sustainable and local. We do not use plant protection products and the product travels a distance up to five times less. The plants also need less space, water, and nutrients, which means that the footprint of this product is very small."

No organic label

"Although growing basil is quite difficult, we have opted for basil because there is a lot of demand for it," says Fabrice. "The basil plants are grown in a sustainable way but are not organic. The problem is that they are not grown in the open air, nor on biological substrate, which is why they do not receive an organic certificate.

The price that consumers pay for the fresh basil in the Bio-Planet stores is € 1.89, the normal market price."

Capacity: 250,000 plants

In the Colruyt distribution center, near the head office in the Netherlands, the retailer grows basil plants under violet light. "We have developed the entire installation, from ventilation to lamps, in collaboration with KU Leuven and UGent. We opted for our own installation because we mainly wanted to focus on energy efficiency, "says Wannes Voorend, R&D coordinator of Colruyt Group. "We are currently growing the plants on two layers of 450 square meters, with a capacity of 250,000 plants."

High technology

In the vertical farm, it is moist and the temperature is 30 ° C. "We use state-of-the-art technology whereby the plants receive a different mix of light, water, and air every day. This makes the plants stronger so that they can be kept longer. The right mix of red and blue light ensures that the plants contain more aroma and grow twice as fast, the R&D coordinator continues. We recycle all the water that the plants do not absorb or that evaporates. All the energy used by the vertical farm is green."

Future plans

Colruyt is in charge of the entire cultivation process, from growing the seeds to packaging the mature plants. "We started this project about three years ago in a small aquarium with lamps and currently we can supply 31 stores. In the future we want to grow at more levels and also supply the other chains, but this is a step in the right direction. Currently, all operations in the vertical farm are still done manually. We intend to automate the entire process, but that is the future, "says Wannes.

Sales of Organic Products In The US Continue To Grow

Retail sales of organic fruits and vegetables in the US continue to grow, but the way each store assumes their sale and the presentation strategies they use to do so may differ considerably

Retail sales of organic fruits and vegetables in the US continue to grow, but the way each store assumes their sale and the presentation strategies they use to do so may differ considerably.

The five stores of Sunset Foods Inc. in Highland Park, Illinois, usually offer more than 200 green items, said Vince Mastromauro, the stores' product director, who highlighted that the organic product category accounts for 8% to 10% of their product offer.

The main vegetable sales are of bagged salads, romaine lettuce, red and green leaves, kale, and spinach. In fruits, apples, summer fruits, and citrus fruits stand out. Mastromauro stressed that sales of organic berries, grapes, and lettuce had increased in recent years, possibly due to concerns about product safety.

Another example is the Apple Valley stores in Berrien Springs, Michigan, which have 40-50 units of organic produce in the fresh produce department, according to Brandon Easton, Apple Valley's product and supermarket manager. That accounts for at least 10% of the store's products.

The best-selling fruits, the professional stressed, are the bananas, the Gala apples, and the avocados. Meanwhile, the best selling vegetables in the store are the salad mixes. The Apple Valley Market presents one to five organic items in their ads each week.

Another example is Felton's Meat & Produce, from Plant City, Florida. This store's ecological program, however, is still not as advanced as that of other supermarkets.

The store only has three or four organic products, and they rarely have more than a dozen of them, according to their production manager, Ron Marshall. The organic products that have the highest demand there are the bananas, a couple of apple varieties, ripe tomatoes, and peppers packages.

Announcing the ecological offer is key

Positioning organic products in the retail sector is one of the key factors to increase sales of these products.

Sunset Foods stores display the refrigerated organic products in a 16-foot section, and their fresh organic produce is in a 12-foot section with a sign to differentiate it.

The Apple Valley Market of Easton markets most organic products together, but they also place some organic products that are clearly differentiated from their conventional counterparts next to the latter. For example, they can exhibit 2-pound bags of conventional lemons next to the organic versions, as the organic bags are clearly labeled as organic.

Organic avocados, on the other hand, are displayed separately from the conventional ones, as it is difficult to distinguish between the two types. The store uses colored signs so that consumers can distinguish between several items.

In the same way, the organic products at Felton's, Marshall, are marketed together in a 6-foot section and they are identified as organic via a large sign.

QFCs In Bellevue And Kirkland To Begin Growing Produce In-Store

QFCs in Kirkland and Bellevue appear to be taking the whole farm to table concept to a new level, since the grocer will now be growing some of their own food as well. It’ll probably require a new aisle

BY MYNORTHWEST STAFF

DECEMBER 1, 2019

QFCs in Kirkland and Bellevue appear to be taking the whole farm to table concept to a new level, since the grocer will now be growing some of their own food as well. It’ll probably require a new aisle.

The Kroger Company has teamed up with urban farming network Infarm that would bring modular living produce farms to a few of their stores. This doesn’t mean there will be vast fields in the QFC parking lot; rather, they will allow some of their produce to grow onsite using hydroponic technology, potentially producing items like kale, cilantro, and lettuce, among others.

QFC’s new self-checkout cameras may send you back to human checkouts

“Kroger believes that everyone deserves to have access to fresh, affordable and delicious food, no matter who you are, how you shop or what you like to eat,” said Suzy Monford, Kroger’s group vice president of fresh. “Our partnership with Infarm allows us to innovate by combining ground-breaking in-store farming technology with our passion for fresh, local produce and ecological sourcing. Kroger is excited to be first to market and offer the best of the season, and we’re proud to lead the U.S. on this journey.”

Infarms are stackable and controlled through a cloud-based farming platform that adjusts lighting and temperature remotely. In addition to freshness, the idea is also intended to eliminate unnecessary transportation and storage.

Believe it or not, some people actually call QFC ‘The Q’

The two QFCs in Kirkland and Bellevue will be the first in the county to undertake such a partnership with Infarm, with the company planning to expand to 15 QFCs in Washington and Oregon by April, reports The Seattle Times. The new greens are expected to be ready within weeks at the two Washington locations.

We Mapped How Food Gets From Farms To Your Home

Our map is a comprehensive snapshot of all food flows between counties in the U.S. – grains, fruits and vegetables, animal feed, and processed food items

2019

My team at the University of Illinois just developed the first high-resolution map of the U.S. food supply chain.

Our map is a comprehensive snapshot of all food flows between counties in the U.S. – grains, fruits and vegetables, animal feed, and processed food items.

To build the map, we brought together information from eight databases, including the Freight Analysis Framework from Oak Ridge National Laboratory, which tracks where items are shipped around the country, and Port Trade data from the U.S. Census Bureau, which shows the international ports through which goods are traded.

We also released this information in a publicly available database.

This map shows how food flows between counties in the U.S. Each line represents the transportation of all food commodities, along transit routes, like roads or railways. Environmental Research Letters (2019), CC BY-SA

What does this map reveal?

1. Where your food comes from

Now, residents in each county can see how they are connected to all other counties in the country via food transfers. Overall, there are 9.5 million links between counties on our map.

All Americans, from urban to rural are connected through the food system. Consumers all rely on distant producers; agricultural processing plants; food storage like grain silos and grocery stores; and food transportation systems.

For example, the map shows how a shipment of corn starts at a farm in Illinois, travels to a grain elevator in Iowa before heading to a feedlot in Kansas, and then travels in animal products being sent to grocery stores in Chicago.

2. Where the food hubs are

At over 17 million tons of food, Los Angeles County received more food than any other county in 2012, our study year. It shipped out even more: 22 million tons.

California’s Fresno County and Stanislaus County are the next largest, respectively. In fact, many of the counties that shipped and received the most food were located in California. This is due to the several large urban centers, such as Los Angeles and San Francisco, as well as the productive Central Valley in California.

Who ships and receives the most food, kilograms per year

In 2012, Los Angeles County both shipped (outflows) and received (inflows) more kilograms of food than any other U.S. county. Other California counties ranked highly in both categories.

We also looked for the core counties – the places that are most central to the overall structure of the food supply network. A disruption to any of these counties may have ripple effects for the food supply chain of the entire country.

We did this by looking for counties with the largest number of connections to others, as well as those that score highly in a factor called “betweenness centrality,” a measurement of the places with the largest fraction of the shortest paths.

San Bernardino County led the list, followed again by a number of other California transit hubs. Also on the list are Maricopa County, Arizona; Shelby County, Tennessee; and Harris County, Texas.

Core counties for the US food supply

A study showed that these nine counties -- mostly in California -- are most central to the overall structure of the food supply network. A disruption to any of these counties may have ripple effects for the food supply chain of the entire country.

However, our estimates are for 2012, an extreme drought year in the Cornbelt. So, in another year, the network may look different. It’s possible that counties within the Cornbelt would show up as more critical in non-drought years. This is something that we hope to dig into in future work.

3. How food travels from place to place

We also looked at how much food is transported between one county and another.

Many of the largest food transport links were within California. This indicates that there is a lot of internal food movement within the state.

One of the largest links is from Niagara County to Erie County in New York. That’s due to the flow of food through an important international overland port with Canada.

Some of the other largest links were inside the counties themselves. This is because of moving food items around for manufacturing within a county – for example, milk gets off a truck at a large depot and is then shipped to a yogurt facility, then the yogurt is moved to a grocery distribution warehouse, all within the same county.

The food supply chain relies on a complex web of interconnected infrastructure. For example, a lot of grain produced throughout the Midwest is transported to the Port of New Orleans for export. This primarily occurs via the waterways of the Ohio and Mississippi Rivers.

The infrastructure along these waterways – such as locks 52 and 53 – are critical, but have not been overhauled since their construction in 1929. They represent a serious bottleneck, slowing down innumerable supply chains nationwide, including that of grain. If they were to fail entirely, then commodity transport and supply chains would be completely disrupted.

Railroads are also important for moving grain. Fresh produce, on the other hand, is often moved around the country by refrigerated truck. This is due to the need to keep fresh fruits and vegetables – relatively high-value agricultural products – cool until they reach the consumer.

In future work, we hope to evaluate the specific infrastructure that is critical to the U.S. food supply chain.

[ You’re smart and curious about the world. So are The Conversation’s authors and editors. You can read us daily by subscribing to our newsletter. ]

Before you go...

It is easier than ever for special interests to spread disinformation on vital issues. To inform the public about what’s really going on, we help experts drill down into the facts. We can’t do this work without your help. Please support us – even a donation of $5 a week helps keep the lights on and our important operation running.

Donate now

Beth Daley

Editor and General Manager

Lettuce Prices Soar After Heatwave Wilted Salinas Crop

The prices of both romaine and iceberg lettuce have tripled in many stores around Northern California after crops grown in the Salinas Valley were destroyed by the mid-June heatwave

2 JULY 2019 / SF NEWS / JAY BARMANN

The prices of both romaine and iceberg lettuce have tripled in many stores around Northern California after crops grown in the Salinas Valley were destroyed by the mid-June heatwave.

Heads of lettuce wilted significantly in the extended heatwave the week of June 9, with some parts of the Salinas region hitting triple-digit temperatures. As KSBW reports after talking with local farmers, the heat left 20 to 30 percent of the lettuce crop unusable, which has meant that many big-name buyers from the farms are getting far less than they've ordered — and leading to higher prices.

Leaf lettuce is the number-one crop in Monterey County, as the county's Farm Bureau reported in both 2017 and 2018. Romaine lettuce crops actually decreased around 12 percent between the two years due to the well publicized E. coli outbreak, but 2018's lettuce production still accounted for $733 million in value for farmers. Strawberries are the county's second biggest crop, with a value of $698 million.

The coastal climate around Salinas typically makes it ideal for lettuce production, but some years and some planting periods get surprises from the weather. Jason Lathros of Churches Brothers Farms tells KSBW, "There's nothing you can do. That's Mother Nature. We play in an outdoor arena."

Lettuce production was also impacted by a particularly rainy May, which slowed down picking by about half, says Lathros. And picking all over the county has been impacted in the short term by President Trump's threats of ICE raids— one field supervisor reported that 15 fieldworkers failed to show up last week due to fears of a raid, according to Monterey County Weekly.

U.S. Organic Sales Break $50 Billion Mark

May 20, 2019

Organic sales are climbing across the board, and so are organic sales of fresh produce.

( File Photo )

U.S. organic sales hit a record $52.5 billion in 2018, up 6.3% from the previous year.

Organic food sales accounted for $47.9 billion, an increase of 5.9% from 2017, according to the Organic Trade Association.

More than one-third of organic food sales come from fruits and vegetables. Produce sales — including all forms, not just fresh — were $17.4 billion in 2018, up 5.6%.

“Organic is now considered mainstream, but the attitudes surrounding organic are anything but status quo,” OTA executive director and CEO Laura Batcha said in a news release. “In 2018, there was a notable shift in the mindset of those working in organic toward collaboration and activism to move the needle on the role organic can play in sustainability and tackling environmental initiatives.

“Activism is a natural reaction from an industry that is really close to the consumer,” Batcha said. “When we are in an environment where government is not moving fast enough, the industry is choosing to move to meet the consumer rather than get stalled.”

Fresh perspective

The United Fresh Produce Association, in its FreshFacts on Retail report about 2018, provided some context on the growth of organic fresh produce in particular.

Organic sales of fresh produce in 2018 were $5.6 billion, up 8.7%. Organic fresh vegetable sales were up 7.1%, organic fresh fruit sales were up 10.7%, and organic fresh herbs/spices sales were up 7.9%.

Packaged salads are far and away the top organic fresh produce item in terms of dollars, while organic bananas top the list for volume. Other big-ticket fresh items for organic are apples, carrots and strawberries

US (AZ): Farming Sustainably With Aquaponic Produce

It began years ago with a pledge from Chef Ken Harvey to provide his guests at Loews Ventana Canyon with food made from the freshest possible ingredients, and Harvey hasn’t cut any corners in sourcing his meats, cheeses, breads and produce from sustainable purveyors.

But it was his first meeting with the founders of Merchant’s Garden, a local aquaponics farm, which put his nearly pathological commitment to the principle of sustainability on an exciting new path. This ultimately resulted in his vow to grow and harvest onsite enough lettuce to serve his tens of thousands of guests per month, year-round, with only one percent of the water that’s used in conventional farming.

Occupying a climate-controlled storage space that wasn’t being fully utilized, the new hydroponic garden is the last stop on the lettuce’s journey before it lands on a guest’s plate. That journey begins aquaponically at Merchant’s Garden, where the lettuce spends its newborn month being fed through its young root system by water enriched by nutrients from biofiltered tilapia waste. It’s then transported live to Loews Ventana Canyon, 7000 N. Resort Drive, in floating containers, with its roots still submersed in the nutrient-rich water, for a subsequent cycle of hydroponic growing prior to harvest.

Harvey is currently growing Bibb and Red Cherokee lettuces, as well as three varieties of Romaine. His garden system’s capacity is nearly 300 heads per harvest, with multiple harvests per month, which equates to a full acre of farming if the lettuce was grown in the ground. And he tells me that he’s only using 200 gallons of water per month in a recirculating system that only loses water through evaporation and transpiration.

Publication date: 5/9/2019

Paper Sleeves Added To Greensleeve Product Range

Earlier this year, Mediane launched their Greensleeve program including a variety of sustainable packaging sleeve alternatives to the herbal plant market. Next to Home Compostable Film, Industrial Compostable PLA and Recyclable Green PE, the Greensleeve program now also includes a paper variant.

Many existing and non-existing customers from different European countries have shown great interest already. First results are to be seen on the shelf at some leading supermarkets in the EU. Given the positive reactions from the market, the expectations are that more supermarkets will follow shortly.

‘’This clearly indicates that the use of plastics in the Agro and Horti-industry is under pressure’’, according to Mike Leistikow, sales manager at Mediane. ‘’The use of paper responds to the growing awareness of the consumer. Paper is seen as a more sustainable option. We are independent converter of packaging sleeves and for us we adjust ourselves to market demand. Obviously there is a lot to be said about the pros and cons of each sustainable alternative, however we are not forced to defend or push through either of these alternatives since we are in the position to produce and offer them all. This is the choice and decision of the retailer”.

For many countries, depending on local legislation on waste management, Home Compostable or bio-based recyclable materials are definitely the preferred option with a lower CO2 footprint. The advantage of the paper/paper variant is that it is produced out of recycled kraft and can be thrown away together with the old newspapers and can be considered to be 100% recyclable. Next to the 100% paper version, Mediane also offers the Paper/Film variant and the Paper/Partly (paper with bio-film).

Just like traditional sleeves, the Greensleeve paper sleeves are supplied on a block and can be packed in the same way.

For more information:

Mediane

P.O. Box 1623

3600 BP Maarssen

The Netherlands

+31 346 285029

info@mediane.nl

www.mediane-flexibles.com

www.greensleeve.green

Publication date: 5/7/2019