Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

80 Acres Farms Secures $160 Million In Series B Led by General Atlantic To Accelerate Global Farm Expansion & Product Development

80 Acres Farms' vertical farm systems grow the widest variety of produce commercially sold at scale by any vertical farm to-date, including leafy greens, herbs, tomatoes, cucumbers, and microgreens

August 9, 2021

HAMILTON, OH / ACCESSWIRE / 80 Acres Farms, the industry-leading vertical farming company, has secured $160 million in additional funding in a round led by General Atlantic and joined by Siemens Financial Services, Inc. (the U.S. financing arm of global technology company Siemens). The company intends to utilize the capital for continued expansion and product development, building from its current footprint of vertical farms that yield a diverse offering of high-quality produce.

The funding round also included Blue Earth (formerly PG Impact Investments) and General Atlantic's Beyond Net Zero team, in addition to participation from existing investors including Barclays and Taurus.

80 Acres Farms' vertical farm systems grow the widest variety of produce commercially sold at scale by any vertical farm to-date, including leafy greens, herbs, tomatoes, cucumbers, and microgreens. The company's breakthrough growing technologies and advanced data analytics capabilities have enabled this industry-leading product breadth, driving over 450% revenue growth since the end of 2020. 80 Acres Farms now services over 600 retail and food service locations, including its recent expansion with Kroger, announced earlier this year to 316 stores in the U.S. Midwest and to the e-commerce channel powered by Kroger - Ocado Solutions' partnership. With farms co-located near customers, 80 Acres Farms' produce travels significantly fewer food miles, shortening the farm-to-table footprint and reducing overall food waste. Growing methods at 80 Acres Farms use 97% less water than traditional farming practices and are powered by renewable energy.

- ADVERTISEMENT -

To date, 80 Acres Farms operates eight indoor farms and is committed to supporting and building high-tech production facilities close to regions where fresh produce is consumed. The company has transformed a former factory in Hamilton, Ohio, to a world-class tomato indoor farm, and in 2020, 80 Acres Farms completed construction on a new, 64,000-square-foot, state-of-the art farm with 10 levels of cultivating space. 80 Acres Farms is currently engaged in identifying new farm locations for additional commercial farms to operate at similar scale.

Shaw Joseph, Managing Director of General Atlantic, said: "80 Acres Farms is building an incredibly exciting vertical farming business that provides high-quality produce through innovative practices. With global food consumption increasing and growing threats impacting supply chains and food security, there is a pressing need for healthy, fresh and local foods that are grown in more sustainable and cost-effective ways. We look forward to working closely with Mike, Tisha and the broader 80 Acres Farms' team as they scale."

Jason Thompson, Vice President of Sustainability and Growth Equity at Siemens Financial Services, said, "We are committed to help scale sustainable vertical farming technology. 80 Acres has demonstrated their ability to build and operate profitable farms, and Siemens is enthusiastic about the opportunity to support its global expansion with both our capital and technical know-how, including our recently established Center of Competence dedicated to supporting companies in realizing their digital transformation."

Kayode Akinola, Head of Private Equity Directs at Blue Earth Capital, said, "We are excited to be partnering with General Atlantic and Siemens to provide growth capital and support to Mike, Tisha and the entire 80 Acres team to help scale their operations within existing and new markets."

Mike Zelkind, CEO of 80 Acres Farms, said: "We are proud of what our team has been able to accomplish and enthusiastic about the road ahead. We are also honored to be supported by such a high caliber group of strategic investors who are enabling us to continue to lead this evolving and fast-growing industry. The investment is a quantum leap for the business to build more farms both nationally and globally.

Tisha Livingston, CEO of Infinite Acres, and Co-founder of 80 Acres Farms, said: "The new investment positions the company as the leading proven and profitable technology provider prepared for rapid expansion. In addition, this enables 80 Acres to focus on their operational expertise and deep research and development capabilities beyond leafy greens."

As part of this funding round, Shaw Joseph will join the 80 Acres Farms board. Eli Aheto, former 80 Acres Farms board member, led BeyondNetZero's contributions to this round. "I am pleased to be able to continue and grow my support of 80 Acres with this contribution from the BeyondNetZero team. 80 Acres has proven a farm design that is poised to reduce food miles, food waste and the resulting negative carbon emissions that exist within our food supply chain," said Eli Aheto.

Barclays acted as sole placement agent to 80 Acres on the capital raise.

About 80 Acres Farms

80 Acres Farms is a vertical farming leader providing customers with the freshest, and most nutritious fruits and vegetables at affordable prices. Utilizing world-class technology and analytics, the Company offers customers a wide variety of pesticide-free food with a longer shelf-life that exceeds the highest standards in food safety. Consumers can find 80 Acres' products of just-picked salads, tomatoes, cucumbers, herbs, and microgreens at Kroger, Whole Foods, The Fresh Market, Dorothy Lane Markets, Jungle Jim's Markets, and key National Foodservice Distributors including Sysco and US Foods.

Media Contact

Rebecca Haders / rebecca.haders@eafarms.com / +1 513-910-9089

About General Atlantic

General Atlantic is a leading global growth equity firm with more than four decades of experience providing capital and strategic support for over 400 growth companies throughout its history. Established in 1980 to partner with visionary entrepreneurs and deliver lasting impact, the firm combines a collaborative global approach, sector specific expertise, a long-term investment horizon and a deep understanding of growth drivers to partner with great entrepreneurs and management teams to scale innovative businesses around the world. General Atlantic currently has over $65 billion in assets under management and more than 175 investment professionals based in New York, Amsterdam, Beijing, Hong Kong, Jakarta, London, Mexico City, Mumbai, Munich, Palo Alto, São Paulo, Shanghai, Singapore and Stamford. For more information on General Atlantic, please visit the website: www.generalatlantic.com

General Atlantic also recently formed its BeyondNetZero (BnZ) team to seek out growth companies delivering innovative climate solutions. BnZ looks to identify entrepreneurs with technologies that enable companies to meet and exceed Net Zero emissions targets, with a focus on de-carbonization, energy efficiency, resource conservation and emissions management.

Media Contacts

Mary Armstrong & Emily Japlon / General Atlantic media@generalatlantic.com

Faustine Rohr-Lacoste / Spendesk faustine@spendesk.com

About Siemens Financial Services

Siemens Financial Services (SFS) - the financing arm of Siemens - provides business-to-business financial solutions. A unique combination of financial expertise, risk management and industry know-how enable SFS to create tailored innovative financial solutions. With these, SFS facilitates growth, creates value, enhances competitiveness and helps customers access new technologies. SFS supports investments with equipment and technology financing and leasing, corporate lending, equity investments and project and structured financing. Trade and receivable financing solutions complete the SFS portfolio. With an international network, SFS is well adapted to country-specific legal requirements and able to provide financial solutions globally. Within Siemens, SFS is an expert adviser for financial risks. Siemens Financial Services has its global headquarters in Munich, Germany, and has around 2,800 employees worldwide. www.siemens.com/finance.

About Blue Earth Capital

Blue Earth Capital is a global investment firm focused on sustainability and impact investing. Headquartered in Zug, Switzerland, with operations in New York, London, Singapore, Luxembourg and Guernsey, Blue Earth Capital seeks to invest in businesses that address pressing environmental and social challenges, whilst generating market-rate financial returns. Initiated in 2015 by Urs Wietlisbach, one of the founders of Partners Group, and backed by the Wietlisbach Foundation, Blue Earth Capital was incubated and built up with the support of Partners Group.

Media Contacts

Urs Baumann / CEO Blue Earth Capital urs.baumann@blueearth.capital

Geoponica Greens, Indoor Vertical Farm, To Open Facility In Hamilton Twp.

Geoponica Greens, an indoor hydroponics vertical farm business based in Chesilhurst, is expanding its existing operations to the historic Mill One warehouse in Hamilton Township this fall, the company announced.

August 4, 2021

Geoponica Greens, an indoor hydroponics vertical farm business based in Chesilhurst, is expanding its existing operations to the historic Mill One warehouse in Hamilton Township this fall, the company announced.

Desmond Hayes, founder and owner of Geoponica Greens, said the company utilizes hydroponics, an agricultural practice of growing plants without soil, using only water and nutrients — while avoiding the use of pesticides or insecticides.

By delivering the nutrients straight to the plants’ roots, this grow method is also able to shorten crop cycles, produce the best flavors and level of nutrition and increase the lifespan of the crop, he said.

“Geoponica Greens is dedicated to changing the way food is both grown and realized through our low-waste model and our hyperlocal interaction within nearby areas,” Hayes said.

“New Jersey is strategically located between New York City and Philadelphia, making it the perfect place to reimagine farming. We are especially excited to reach minority communities, Opportunity Zones and food deserts, and introduce our sustainable methods of agriculture to new areas.”

The new warehouse space will support Geoponica Greens’ efforts to provide fresh microgreens, leafy greens and herbs to the local communities, with plans to hire three to five employees and interns in the first year.

Because the produce will be grown in an indoor farm, it is not subjected to the effects of climate seasonality, so the facility will be able to harvest 2-3 tons of greens per year at full capacity, Hayes said.

Geoponica Greens also plans to create a local Community Supported Agriculture program aimed at bringing a subscription-based model to customers.

A minority business owner, Hayes founded Geoponica Greens in 2014.

Choose New Jersey provided Geoponica Greens with state resources information, economic development connections and site selection assistance and will continue to support the company’s success in New Jersey.

Choose New Jersey CEO Jose Lozano said his group was happy to keep such an innovative company within the state.

“True to our nickname as the Garden State and the most densely populated state in the country, it is no surprise that New Jersey is on the forefront of the urban farm movement,” he said.

“Geoponica Greens is an integral part of that movement, and Choose New Jersey is proud to support their continued growth in our state as they bring agricultural innovation to Hamilton and its surrounding communities.”

Geoponica Greens, an indoor hydroponics vertical farm business based in Chesilhurst, is expanding its existing operations to the historic Mill One warehouse in Hamilton Township this fall, the company announced.

Desmond Hayes, founder and owner of Geoponica Greens, said the company utilizes hydroponics, an agricultural practice of growing plants without soil, using only water and nutrients — while avoiding the use of pesticides or insecticides.

By delivering the nutrients straight to the plants’ roots, this grow method is also able to shorten crop cycles, produce the best flavors and level of nutrition and increase the lifespan of the crop, he said.

“Geoponica Greens is dedicated to changing the way food is both grown and realized through our low-waste model and our hyperlocal interaction within nearby areas,” Hayes said.

“New Jersey is strategically located between New York City and Philadelphia, making it the perfect place to reimagine farming. We are especially excited to reach minority communities, Opportunity Zones and food deserts, and introduce our sustainable methods of agriculture to new areas.”

The new warehouse space will support Geoponica Greens’ efforts to provide fresh microgreens, leafy greens and herbs to the local communities, with plans to hire three to five employees and interns in the first year.

Because the produce will be grown in an indoor farm, it is not subjected to the effects of climate seasonality, so the facility will be able to harvest 2-3 tons of greens per year at full capacity, Hayes said.

Geoponica Greens also plans to create a local Community Supported Agriculture program aimed at bringing a subscription-based model to customers.

About Mill One and Geoponica Greens

The historic Mill One warehouse was once home to notable Atlantic Products Corp. during the World War II era in the Trenton area. The 2,000-square-foot warehouse was selected because of its important features that will support Geoponica Greens’ hydroponics operations. With high ceilings, skylights and exposed brick walls, the impressive existing warehouse is being renovated to become a modern, sustainable space.

A minority business owner, Hayes founded Geoponica Greens in 2014.

Choose New Jersey provided Geoponica Greens with state resources information, economic development connections and site selection assistance and will continue to support the company’s success in New Jersey.

Choose New Jersey CEO Jose Lozano said his group was happy to keep such an innovative company within the state.

“True to our nickname as the Garden State and the most densely populated state in the country, it is no surprise that New Jersey is on the forefront of the urban farm movement,” he said.

“Geoponica Greens is an integral part of that movement, and Choose New Jersey is proud to support their continued growth in our state as they bring agricultural innovation to Hamilton and its surrounding communities.”

Lead Photo: Geoponica greens uses hydroponic techniques to grow produce. - Geoponica Greens

AeroFarms and Nokia Unveil Partnership for Next Generation AI-Enabled Plant Vision Technology

AeroFarms and Nokia Bell Labs today unveiled a groundbreaking multi-year partnership to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels.

August 5, 2021

NEWARK, N.J.--(BUSINESS WIRE)--AeroFarms and Nokia Bell Labs today unveiled a groundbreaking multi-year partnership to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels.

As part of this partnership, AeroFarms, a Certified B Corporation and global leader in indoor vertical farming, contributes its commercial growing expertise, comprehensive environmental controls, an agriculture-focused data platform, and machine vision core foundation. Nokia Bell Labs, the world-renowned industrial research arm of Nokia, contributes its groundbreaking autonomous drone control and orchestration systems, private wireless networks, robust image and sensor data pipelines, and innovative artificial intelligence (AI) enabled mobile sensor technologies. This combination of innovative technologies allows AeroFarms to reach the next level of imaging insights that further enhance its capabilities as an industry leading operator of world-class, fully-connected smart vertical farms that grow the highest quality plants all year round.

AeroFarms and Nokia Bell Labs have been working together since 2020 and have reached an important milestone of achieving a proof of concept for this state-of-the-art integrated system and testing the technologies with AeroFarms’ current commercial crop varieties. Together, they are now ready to scale this system to all of AeroFarms’ crops and future indoor vertical farms, including the next ones in Danville, Virginia and Abu Dhabi, UAE.

The integration of Nokia Bell Labs’ AI-enabled drone-based sensors and advanced machine learning, computer vision and data analytics technologies with AeroFarms’ existing machine vision tools enhances and elevates AeroFarms’ position as an agriculture platform and capabilities organization dedicated to solving food and agriculture supply chain challenges.

David Rosenberg, CEO at AeroFarms, said: “With Nokia Bell Labs, we have developed the next-generation system that can image every plant every day in a cost-effective way at scale. This level of detailed imaging and insights helps us be better farmers by monitoring our plant biology dynamically and allowing us to course correct as needed to ensure the highest level of quality all year round. When I watch the drones autonomously imaging our plants, I am blown away by how this truly represents the power of harnessing leading-edge technologies and bringing brilliant problem solvers together from diverse groups to grow the best plants possible.”

Roger Buelow, CTO at AeroFarms, said: “AeroFarms’ expert team of plant scientists and engineers have been working together for two years with Nokia Bell Labs’ top researchers and engineers to train these complex learning systems with a nuanced understanding of plant biology. We have created a cross-disciplinary understanding at an industrial scale to develop the latest imaging technology to help accelerate our ability to introduce new crops and ensure the highest quality for our commercial operations.”

Nokia Bell Labs’ machine vision technology has enabled the most precise data capture yet, down to the level of individual plants, using leaf size segmentation, quantification, and pixel-based scanning to identify consistency and variation. Going beyond what even the human eye can perceive, this state-of-the art imaging technology enables the gathering of immense insights about a plant including its leaf size, stem length, coloration, curvature, spotting, and tearing. The end-to-end system is flexible and robust, built to take advantage of Nokia’s industry-leading 5G private wireless network with cloud processing technology, designed for low latency and high privacy in an on-premises network. It also provides intelligent industrial analytics capabilities as an integrated service that can be deployed quickly and efficiently anywhere.

Thierry Klein, VP, Integrated Solutions and Experiences Research Lab at Nokia, said: “Nokia Bell Labs is driven to solve hard and impactful problems, and together with AeroFarms, we are building the ability to see and identify plant interactions at unprecedented levels. The fundamental technologies of this partnership are our strength, and vertical farming is just the beginning. With the AeroFarms platform, we are exploring the power of network driven intelligence for industrial outcomes. These capabilities can expand into a multitude of indoor industrial operations, including logistics, warehousing, distribution hubs, and manufacturing.”

The multi-year partnership between AeroFarms and Nokia is anchored on shared values as mission-driven companies with the vision to scale technologies for the greater good. AeroFarms’ vertical farming platform is more sustainable than traditional farming with up to 390 times greater productivity per square foot annually, while using up to 95% less water and zero pesticides. In addition, vertical farming provides local food options for communities, reducing the environmental impact of trucking and shipping produce long distances and helping combat food waste.

Additional resources

AeroFarms website

Nokia Bell Labs website

About Nokia

At Nokia, we create technology that helps the world act together. As a trusted partner for critical networks, we are committed to innovation and technology leadership across mobile, fixed and cloud networks. We create value with intellectual property and long-term research, led by the award-winning Nokia Bell Labs. Adhering to the highest standards of integrity and security, we help build the capabilities needed for a more productive, sustainable and inclusive world.

About AeroFarms

Since 2004, AeroFarms has been leading the way for indoor vertical farming and championing transformational innovation for agriculture. On a mission to grow the best plants possible for the betterment of humanity, AeroFarms is a Certified B Corporation with global headquarters in Newark, New Jersey. Named one of the World’s Most Innovative Companies by Fast Company two years in a row and one of TIME’s Best Inventions in Food, AeroFarms patented, award-winning indoor vertical farming technology provides the perfect conditions for healthy plants to thrive, taking agriculture to a new level of precision, food safety, and productivity while using up to 95% less water and no pesticides ever versus traditional field farming. AeroFarms enables local production to safely grow all year round, using vertical farming for elevated flavor. In addition, through its proprietary growing technology platform, AeroFarms has grown over 550 varieties and has developed multi-year strategic partnerships ranging from government to major Fortune 500 companies to help uniquely solve agriculture supply chain needs. For additional information, visit: https://aerofarms.com/.

On March 26, 2021, AeroFarms announced a definitive business combination agreement with Spring Valley Acquisition Corp. (Nasdaq: SV). Upon the closing of the business combination, AeroFarms will become publicly traded on Nasdaq under the new ticker symbol "ARFM". Additional information about the transaction can be viewed here: https://aerofarms.com/investors/.

No Offer or Solicitation

This press release does not constitute an offer to sell or a solicitation of an offer to buy, or the solicitation of any vote or approval in any jurisdiction in connection with a proposed potential business combination among Spring Valley and AeroFarms or any related transactions, nor shall there be any sale, issuance or transfer of securities in any jurisdiction where, or to any person to whom, such offer, solicitation or sale may be unlawful. Any offering of securities or solicitation of votes regarding the proposed transaction will be made only by means of a proxy statement/prospectus that complies with applicable rules and regulations promulgated under the Securities Act of 1933, as amended (the “Securities Act”), and Securities Exchange Act of 1934, as amended, or pursuant to an exemption from the Securities Act or in a transaction not subject to the registration requirements of the Securities Act.

Forward Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “might,” “will,” “estimate,” “continue,” “contemplate,” “anticipate,” “intend,” “expect,” “should,” “would,” “could,” “plan,” “predict,” “project,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this press release, including those regarding the expected benefits of the partnership, improvement of plant yields and quality and Spring Valley’s proposed acquisition of AeroFarms are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of the respective management of AeroFarms and Spring Valley and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AeroFarms and Spring Valley. These forward-looking statements are subject to a number of risks and uncertainties, including changes in domestic and foreign business, market, financial, political, and legal conditions; the inability of the parties to successfully or timely consummate the proposed transaction, including the risk that any regulatory approvals are not obtained, are delayed or are subject to unanticipated conditions that could adversely affect the combined company or the expected benefits of the proposed transaction or that the approval of the stockholders of Spring Valley or AeroFarms is not obtained; failure to realize the anticipated benefits of the proposed transaction; risks related to the expansion of AeroFarms’ business and the timing of expected business milestones; the effects of competition on AeroFarms’ business; the ability of Spring Valley or AeroFarms to issue equity or equity-linked securities or obtain debt financing in connection with the proposed transaction or in the future, and those factors discussed in Spring Valley’s Annual Report on Form 10-K, Quarterly Report on Form 10-Q, final prospectus dated November 25, 2020 and definitive proxy statement/prospectus dated July 26, 2021 under the heading “Risk Factors,” and other documents Spring Valley has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that neither Spring Valley nor AeroFarms presently know, or that Spring Valley nor AeroFarms currently believe are immaterial, that could also cause actual results to differ from those contained in the forward-looking statements. In addition, forward-looking statements reflect Spring Valley’s and AeroFarms’ expectations, plans, or forecasts of future events and views as of the date of this press release. Spring Valley and AeroFarms anticipate that subsequent events and developments will cause Spring Valley’s and AeroFarms’ assessments to change. However, while Spring Valley and AeroFarms may elect to update these forward-looking statements at some point in the future, Spring Valley and AeroFarms specifically disclaim any obligation to do so. These forward-looking statements should not be relied upon as representing Spring Valley’s and AeroFarms’ assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Contacts

AeroFarms Contacts

Investor Relations:

Jeff Sonnek

ICR

Jeff.Sonnek@icrinc.com

1-646-277-1263

Media Relations:

Marc Oshima

AeroFarms

MarcOshima@AeroFarms.com

1-917-673-4602

What’s Real And What’s Hype With Controlled Environment Agriculture?

The flourishing development of Controlled Environment Agriculture and how retailers and consumers view this emerging segment of fresh produce production will be the topic of an educational session at Organic Produce Summit 2021.

July 27, 2021

The flourishing development of Controlled Environment Agriculture and how retailers and consumers view this emerging segment of fresh produce production will be the topic of an educational session at Organic Produce Summit 2021. The Growth of CEA—What’s Real and What’s Hype from a Retail and Consumer Perspective will feature leadership from a pair of recognized retailers and one of the fresh produce industry’s most progressive grower-shippers, offering their insight on how indoor-grown fresh produce items come to market, pricing and marketing challenges, and how consumers are reacting to them.

Moderated by Walter Robb, former CEO of Whole Foods, the session is the second of a two-part educational series at OPS offering a retailer and consumer perspective on the growth of indoor growing. Among the topics to be discussed in the session are the impact of indoor-grown products on the supply chain, the messaging and labeling of these various items, and the ramifications of what CEA production means for the organic fresh produce industry.

Panelists for the session include Frances Dillard, vice president of brand and product marketing at Driscoll’s; Victor Savanello, vice president produce and floral at Spartan Nash; and Shawn Peery, vice president produce and floral at Albertsons.

Production of fresh produce in CEA has become a $100 billion-plus industry, showcasing how growing indoors uses less water and no pesticides, while incorporating innovative and efficient technologies to provide fresher produce to consumers. “CEA is changing the landscape of food production and providing consumers a variety of new items that will continue to evolve in the years ahead,” said Susan Canales, president of Organic Produce Summit. “OPS attendees will have the chance to hear from retail leadership on how these products are marketed and learn about the challenges and opportunities these new items offer consumers.”

This second educational workshop follows a session exploring the growth of CEA from leaders actively involved in the production of indoor growing. The panelists for the first session include Philip Karp, president of Shenandoah Growers; Marc Oshima, co-founder of AeroFarms; and Caitlin Tierney, director of business development for Mastronardi Produce.

“Indoor agriculture is increasingly playing a more meaningful role in our fresh produce supply, in terms of volume, variety, and geographical footprint,” said Robb. “The ability of indoor ag to provide predictability and resiliency for supply, coupled with its lower impact on both the environment and resource use, is drawing substantial interest from both investors and consumers. Clearly, the future will be a hybrid one and our panels will explore how quickly and responsibly this will happen.”

Organic Produce Summit 2021 is a live and in-person two-day event specifically designed to bring together organic fresh produce growers, shippers, and processors with retailer and buying organizations from across North America. Over 1,000 attendees will meet Sept. 15-16 in Monterey, CA, to exchange ideas, information and insights into the organic fresh produce industry.

In addition to the educational sessions focused on CEA, a session looking at the organic industry in a post-COVID-19 environment and a keynote presentation by Jim Donald, co-chairman of Albertsons, have also been announced. OPS 2021 also includes a selection of field tours for retailers and buyers, a gala opening night reception, and a sold-out trade show floor featuring over 150 producers and processors of organic fresh produce from across North America and the globe.

Converting Urban Areas Into Indoor Pesticide-Free Farms For Year-Round Food

Indoor farming addresses the concern of limited arable land and water wastage. In vertical farming, the need for land can be reduced by a hundred-fold, and by recirculating and reusing water, an average of 95% less water is required for growing the same crops when compared to outdoor farming

By Li Yap

July 14, 2021

Concerns With Traditional Farming

Traditional farms typically rely on herbicides, pesticides and fertilizers to grow crops, which can pollute the environment if used in excess. Up to 98% of a chemical spray will bounce off a crop instead of staying on the plant, resulting in chemicals accumulating in the soil and, eventually, waterways.

Biodiversity loss is another concern of conventional farming as the conversion of wild spaces to farmland has resulted in less space for wild plants and animals to live in. With the global population predicted to reach 9.7 billion by 2050, the agriculture industry is under pressure to scale up to meet these demands, which could potentially affect the natural environment further if nothing is done to rethink current farming practices.

With 40% of available global land already occupied by fields of crops and pastures for animals, it would be difficult to completely eliminate the impact that farms have on the natural environment. However, part of the answer could lie in indoor farming where growing conditions can be better managed, reducing the environmental impact of growing produce.

Indoor Farming Technology Market

The indoor farming technology market was valued at $14.5 billion in 2020 and is projected to reach $24.8 billion by 2026.

The contained facilities used in indoor farming allow farmers to better control and optimize growing conditions. This results in higher yields compared to traditional farming methods whilst using less land area. For example, the average yield of tomatoes grown using traditional methods was reported in 2016 to be 1.85 pounds per square foot, while the average yield of tomatoes grown from greenhouse hydroponics was 10.59 pounds per square foot. By increasing the growing area by stacking additional planting layers, the overall crop yield can be increased.

Indoor farming addresses the concern of limited arable land and water wastage. In vertical farming, the need for land can be reduced by a hundred-fold, and by recirculating and reusing water, an average of 95% less water is required for growing the same crops when compared to outdoor farming.

Vertical farming is one of the techniques used to grow crops within indoor environments. By using artificial light and vertical growing systems such as aeroponics, aquaponics and hydroponics, crops such as kale, lettuce, strawberries and herbs can be grown within a clinically clean indoor system without the need for soil, sunlight and pesticides. This technology allows vertical farms to be set up close to populous areas or urban hubs, where harvests can be distributed locally.

80 Acres Farms

80 Acres Farms operates vertical farms in eight locations across four states. Its farms produce crops using zero pesticides and consume 97% less water compared to traditional farms.

Using 100% renewable energy and being completely indoors, 80 Acres’ operation is capable of producing various crop varieties all year without the need to rely on favorable weather.

Sophisticated technologies, including AI sensors, are incorporated into its operation to ensure that growth environments are optimized according to the plants’ genetics and that harvests are at the peak of ripeness. By relying on a smaller delivery radius, customers are able to access the produce within a day of picking.

“80 Acres' farms are, on average, 300 to 400 times more productive than field farming”, says co-founder Mike Zelkind. This is due to the vertical structures used for growing produce, which allows room for more crops in less space as well as faster-growing produce.

Current Limitations of Indoor Farming

Apart from the high energy costs associated with operating vertical farms, there are also high investment costs for urban land and for the technologies and devices needed to carefully control and monitor the growing environment – these include aspects such as temperature, lighting, and pollination.

The high initial investment compared with traditional farming is a drawback for indoor farms, but this also invites the opportunity for innovation and the development of more cost-effective technologies.

Transforming Agriculture for the Future

Transforming farming in a way that does not affect the natural environment will be no small task, given the sheer scale of the world’s agriculture. With a growing demand for food, there is an ever-increasing pressure for high-yielding and sustainable farming techniques.

In addition to being a great use of spaces not traditionally utilized for agriculture, the high yields of pesticide-free indoor farms show great promise. Although indoor farming is unlikely to completely replace traditional field farming right now, it still has the potential to answer, at least in part, the question about food security in the years to come.

Lead Photo: With the ever-growing demand for food placing increased pressure on the Earth’s resources, innovators are re-examining the fundamentals of farming to create a new and sustainable food system. With the hopes of potentially transforming global food systems, many emerging start-ups have identified urban indoor farming as a viable alternative to conventional farming.

mage Credit: Nikolay_E/Shutterstock.com

Video Credit: 80 Acres Farms/YouTube.com

RotoGro (ASX:RGI) Updates Market On Vertical Farming Tech

The RotoGro Garden System is the core of the company's technology with the ability to maximize plant surface growing area by situating a spherical garden around a centrally placed lighting system

Source: RotoGro

RotoGro (RGI) provides an update of its vertical farming technology with encouraging results from recent trials

The company says recent data indicates its garden systems produce more yield per square meter when compared to other indoor vertical farming methods

Further, trials of RotoGro 710 are said to be progressing well and the team is trialing how to further reduce water and energy usage

RGI is also encouraged by its studies and customer feedback for its RotoGro 420 system which it says validates commercial-scale cultivation of lawful cannabis

Shares were trading 2.3 percent higher at 4.4 cents apiece

RotoGro designs and manufactures cultivation solutions for indoor vertical farming, operating in perishable foods and lawful cannabis.

The RotoGro Garden System is the core of the company's technology with the ability to maximize plant surface growing area by situating a spherical garden around a centrally placed lighting system.

The systems can be stacked, maximizing the yields per square meter when compared to the ground space occupied.

RGI said data collected from recent crop trials conducted in collaboration with agriculture company Verity Greens and herb grower and distributor Fresh Leaf indicates its garden systems produce more yield per square meter when compared to other indoor vertical farming methods.

Specifically, RotoGro projects yields 3.8 to 15.3 times the yield per square meter compared to industry-leading farming producers and greater in contrast to greenhouse and conventional farming.

CEO Michael Di Tommaso said ventures like the ones with Verity Greens and Fresh Leaf will "strengthen RotoGro’s market presence by successfully penetrating the burgeoning indoor vertical farming industry with its technology offerings".

Further, internal trials of the company's most recently developed garden system, the RotoGro 710, are said to be progressing well with cultivation of 48 kilograms of basil and 26.5 kilograms of cilantro in a single harvest cycle.

After multiple trials cultivating leafy greens, the agronomy team repeatedly achieved yields of 124 kilograms in a fully planted RotoGro 710, indicating single harvest yields of 372 kilograms could be achieved when the technology is at full capacity, stacked three-high.

The team is trialing shorter full crop cycle lengths while maintaining yields and aims to refine the plant irrigation schedules to further minimize water usage and refine the environmental controls to ensure enhanced energy efficiencies.

In other news, RotoGro has enabled full automation of its lawful cannabis cultivator, RotoGro 420.

The company's software controls the wheel revolution speed, lighting cycles, and spectrum variations, direct CO2 injection as well as the plant irrigation processes and environmental controls including temperature, air conditioning, and humidification.

Notably, the 420-garden system has been able to consistently produce 10.2 kilograms of dried cannabis flower in a single 56-day crop cycle when stacked three-high.

RGI said its studies in combination with its customer’s data validates the commercial viability of RotoGro 420 in the commercial-scale cultivation of lawful

cannabis.

Mr Di Tommaso said RotoGro is continuing to develop relationships globally to expand its presence in both the perishable foods and lawful cannabis markets.

Shares were trading 2.3 percent higher at 4.4 cents apiece at 1:31 pm AEST.

Natural Gas Liquids Drive Geothermal Tech

A Canada-based firm has developed geothermal technology that removes water from the equation

A Canada-based firm has developed geothermal technology that removes water from the equation.

Commonly associated with water via hot springs, geysers, or plumes of steam, geothermal energy relies on underground heat. A Canada-based firm has developed geothermal technology that removes water from the equation, potentially expanding where the renewable resource can be tapped.

“Geothermal, derived from its Greek roots, means ‘earth’ and ‘hot’ and quite literally means that we bring heat up from the ground,” Chris Cheng, a senior development engineer with Eavor, told Rigzone. “This heat can then be used directly or converted to electricity with a power generation unit.”

Unlike conventional approaches to harness geothermal energy, Eavor’s technology uses a closed-loop energy system that eliminates the need to find hot water or steam resources, Cheng continued.

“Since there is heat under the ground everywhere, Eavor technology is applicable in many more places than traditional geothermal, places where that hot water or steam resource may not exist,” he said.

Cheng explained that his company’s technology generates electricity by bringing heat up to the earth’s surface with a working fluid inside the “Eavor-Loop” system, exchanging heat with the working fluid – often one of two natural gas liquids – used by the power-generating unit.

“For an Organic Rankine Cycle application, this working fluid is usually butane or pentane, shown in the red loop and is chosen for its lower-than-water boiling temperature,” Cheng said, referencing the diagram below that illustrates Eavor’s closed-loop technology. “The working fluid is allowed to vaporize and expand in the power turbine which turns this into rotational energy, making electricity. The working fluid is cooled and condensed back to a liquid and is ready to collect heat from the Eavor-Loop once again.”

This diagram outlines how Eavor's closed-loop geothermal technology works. IMAGE SOURCE: Eavor

“While the power generation unit is not unique to Eavor, Eavor’s novelty in its closed-loop design reduces exploration risk – no need for hot aquifers – and allows for more predictability and operational control, including dispatchability,” Cheng said.

The geothermal technology’s novelty evidently appeals to two major oil and gas players, which have steered investment dollars to Eavor. Find out which companies are supporting the technology developer in the following excerpts from Rigzone’s conversation with Cheng.

Rigzone: Where in North America is there sufficient geothermal potential to sustainably diversify the energy mix?

Chris Cheng: The average geothermal gradient around the world is about 30 degrees Celsius (86 degrees Fahrenheit) per kilometer (0.6 miles), which means that, on average, the temperature increases by 30 degrees for every kilometer you drill into the earth.

It all comes down to price, and Eavor believes there is geothermal potential in most places in the world, including all of North America, for both heat and electricity. For now, while the technology is new and costs are high, Eavor is targeting locales where the price for heat and electricity is also high, such as in Germany, the Netherlands, or Japan. These countries have what we call feed-in tariffs in place to help support the transition to renewables.

Eavor is working hard to reduce the cost of its technology so that it can be economic anywhere, comparable to the prices we see now for wind and solar but with the added benefit of dispatchability and small footprint.

Rigzone: What makes geothermal stand out as a renewable resource?

Cheng: Compared to wind and solar, geothermal has a relatively small surface footprint which is important in jurisdictions where surface space may be at a premium.

Secondly, as previously mentioned, Eavor’s closed-loop design allows for improved operational control, making the Eavor-Loop both load following and dispatchable. The heat in the ground is always present, while the wind and the sun may not always be there.

Rigzone: Where do you see geothermal contributing to the energy transition, particularly in North America?

Cheng: Eavor sees itself fitting into the energy mix alongside other renewables. It can fill in the gaps where wind, solar and traditional geothermal are less effective, such as during the night, when the weather is unfavorable, or where the geology doesn’t support traditional geothermal.

Rigzone: What are the biggest misconceptions you hear about geothermal energy, perhaps from the oil and gas community? How do you overcome them?

Cheng: We get a lot of questions about induced seismicity or fracing, which can be a non-starter in some places. With Eavor’s closed-loop system, there is no fracing and a very, very low probability of induced seismicity, so it’s important that we educate potential clients and partners about what separates our technology from the incumbents.

While we are adopting technology from oil and gas, Eavor’s technology eliminates some of the perceived negative aspects that may be associated with enhanced geothermal systems or hydrocarbon extraction, such as fracing.

In the grand scheme of things, the misconceptions are not that major – something that a few technical meetings can overcome – and the overall reception has been positive. Our latest round of investment back in February of 2021, which included bp (NYSE: BP) and Chevron (NYSE: CVX), are a good indicator that we have been embraced by at least some major players in the oil and gas industry as a viable solution.

Rigzone: Where do you see geothermal market opportunities for oil and gas industry players such as operating companies, drilling companies, service and equipment providers, etc.?

Cheng: One of the reasons Eavor is based in Calgary is because of the vast amount of geoscience and engineering expertise that exists due to the oil and gas roots of this city. There is a lot of opportunity for technical staff, service and equipment providers to pivot into geothermal due to the amount of overlap between the two industries.

For example, as a development engineer, the work that I do is remarkably similar to oil and gas. We have to select a good place to drill an Eavor-Loop, which begins with good geological and geophysical work, then we have to design the well and spend capital to drill the well and construct the facility, and finally sell a commodity for a forecasted price over many years.

Sound familiar? For geothermal, instead of oil and gas, the commodity is heat and power, but the development process and the financial modeling is very similar!

To contact the author, email mveazey@rigzone.com. Find out more about geothermal energy in recent Rigzone articles discussing orphaned oil and gas wells, market opportunities and collaboration, and ultra-deep drilling technology.

USA - VIDEO: President David Lee Recap Business Update

AppHarvest president and board member David Lee joined Yahoo! Finance to discuss the company’s mission, a business update, and the ways AgTech helps impact food security and sustainability

DAVID LEE:

‘OUR FOCUS IS CREATING VALUE

FOR OUR SHAREHOLDERS

OVER THE LONG-TERM'

AppHarvest president and board member David Lee joined Yahoo! Finance to discuss the company’s mission, a business update, and the ways AgTech helps impact food security and sustainability.

“It's about using technology at AppHarvest, creating a consumer movement, being radically transparent, and – trying to build a better food company, very similar to where we started back when we launched the business at Impossible Foods,” Lee said. These are two companies that are different, but they share a common approach. Do well for investors, do well for the planet, and demonstrate that you can do both.”

Watch Here

Vertical Harvest Maine, Sodexo Pair For Local Produce On College Campuses

n August 2021, Vertical Harvest Maine (VHM) will break ground on a 70,000 square foot, four-story farm in downtown Westbrook. Developer TDB LLC says that the master plan integrates residential apartments, commercial space, and four stories of parking

Indoor Farming Partnership Will

Increase Local Produce Served

On Maine’s College Campuses

May 18, 202|

Source: Sodexo SA

Westbrook, Maine, May 18, 2021 (GLOBE NEWSWIRE) -- Sodexo, a global foodservice provider and one of Maine’s largest employers, today announced that it will source as much as 80-percent of its lettuce products from Vertical Harvest Maine, the State’s newest hydroponic urban farm, and the first vertical greenhouse in the United States. The produce will be served at all fourteen Sodexo partners, including collegiate campuses from Fort Kent to South Portland. Earlier this year, Sodexo pledged to spend at least $1M at local Maine farms and food producers in 2021.

“We are a global company that is committed to spending locally,” says Varun Avasthi, Director of Strategic Partnerships, Sodexo. “One challenge we face when sourcing local food is Maine’s short outdoor growing season. The partnership with Vertical Harvest will be a game-changer for Sodexo’s ability to buy fresh produce twelve months per year,” Avasthi added.

In August 2021, Vertical Harvest Maine (VHM) will break ground on a 70,000 square foot, four-story farm in downtown Westbrook. Developer TDB LLC says that the master plan integrates residential apartments, commercial space, and four stories of parking. The company plans to grow over 1-million pounds per year of local produce, create 50 jobs, and hire Mainers with physical and intellectual disabilities, in coordination with State and local agencies. This year, Fast Company recognized Vertical Harvest in their annual “World Changing Ideas” awards, which honors businesses that are innovating solutions to world problems.

“VHM’s output will displace out-of-state produce and will not compete with local, traditional farms,” says Nona Yehia, Vertical Harvest founder. With the majority of Maine’s produce imported, VHM founders say indoor farming will have a positive impact on Maine’s agricultural output. “VHM is extremely proud to grow local food, and to create meaningful jobs for Maine’s underemployed,” Yehia says. The Westbrook location is the second for Vertical Harvest, the first is in Jackson Hole, WY.

“This partnership illustrates how strategically the Maine business community works together,” says Glenn Cummings, President, University of Southern Maine. “The partnership between Sodexo and VHM enforces our commitment to serving Maine-grown food whenever possible – it is a win-win,” Cummings said.

“This project exemplifies the goals and vision of Maine’s 10-Year Economic Development Strategy,” said Heather Johnson, Commissioner of the Department of Economic and Community Development.

Sodexo is one of Maine’s largest employers, with 760 employees and a $21M payroll. It serves 13,000 meals daily at colleges and hospitals across Maine, including Central Maine Medical Center and Southern Maine Community College. In 2015, Sodexo founded The Maine Course, a local organization with a mission to increase the company’s local food spend annually. Sodexo and VHM will prepare for the first harvest, which is planned for the Fall 2022 academic year.

# # #

About Sodexo North America” Sodexo North America is part of a global, Fortune 500 company with a presence in 64 countries. Sodexo is a leading provider of integrated food, facilities management, and other services that enhance organizational performance, contribute to local communities and improve quality of life for millions of customers in corporate, education, healthcare, senior living, sports and leisure, government, and other environments daily. Sodexo is committed to supporting diversity and inclusion and safety while upholding the highest standards of corporate responsibility and ethical business conduct. In support of local communities across the U.S., in 2020, the Sodexo Stop Hunger Foundation mobilized 10,000 Sodexo volunteers to distribute 4.1 million meals to help 5.9 million children and adults meet their immediate food needs. Since 1996, the Stop Hunger Foundation has contributed $36.7 million to help feed children in America impacted by hunger. To learn more about Sodexo, visit us.sodexo.com, and connect with us on Facebook, Instagram, LinkedIn, Twitter and YouTube.

Photo Credit: Harriman and GYDE ArchitectsPhoto Credit: Harriman and GYDE Architects

Contact Data

Dasha Ross-Smith

Sodexo

Dasha.Ross-Smith@sodexo.comUSA: INDIANA - CASS Housing Is Growing, In More Ways Than One

A local organization keeps growing, in more ways than one. CASS Housing is adding CASS Gardens, an opportunity for residents to grow produce and create jobs

FORT WAYNE, Ind. (WANE) – A local organization keeps growing, in more ways than one. CASS Housing is adding CASS Gardens, an opportunity for residents to grow produce and create jobs.

The mission of CASS Housing is to create and maintain customizable, affordable, sustainable, and safe living arrangements for individuals with developmental and/or intellectual disabilities that promote independent living skills.

These residents will now have the opportunity to work in shipping containers transformed into a garden. Each container will grow 2.5 acres of leafy greens and herbs. The idea was grown from a parent of a future resident and the partnership with Freight Farms was developed. The containers can grow produce year-round and only use 5 gallons of water a day, saving 95% over traditional farming. The LED technology grows the plants on panels inside the containers.

Currently, CASS Housing has two containers and has plans to add 15 in the future. Each container will supply two part-time jobs that residents with CASS Housing are able to walk to.

Planting begins Thursday. The produce will be harvested, processed and sold or distributed to customers individually or through wholesale.

“We believe that this employment program could change the national discussion for people with disabilities, starting here in Fort Wayne,” Executive Director David Buuck says.

This is the second Freight Farm in the state of Indiana.

To find out more or to donate, visit casshousing.org.

Join Our Next Conversation - April 28, 2021 | 2:00 to 3:00 pm EDT

Join us for a fun “Fireside Chat” as Indoor Ag-Con’s Content Chair Jim Pantaleo sits down with Dan to discuss this great success story

In 2010, Dan Albert began laying the groundwork for what would become Farmbox Greens, a Seattle-based vertical farm growing specialty produce for retail and foodservice customers.

In 2016, Farmbox was acquired by a regional produce company and Dan went on to scale Farmbox to serve customers in the Northwest and beyond.

Join us for a fun “Fireside Chat” as Indoor Ag-Con’s Content Chair Jim Pantaleo sits down with Dan to discuss this great success story—from the farm’s early days to those first meetings with potential restaurant customers to making the connection with Charlie’s Produce.

Jim and Dan will also talk about Dan’s newest role as Vice President of Plant Performance with Unfold.

LEARN MORE & SAVE YOUR FREE SPOT!

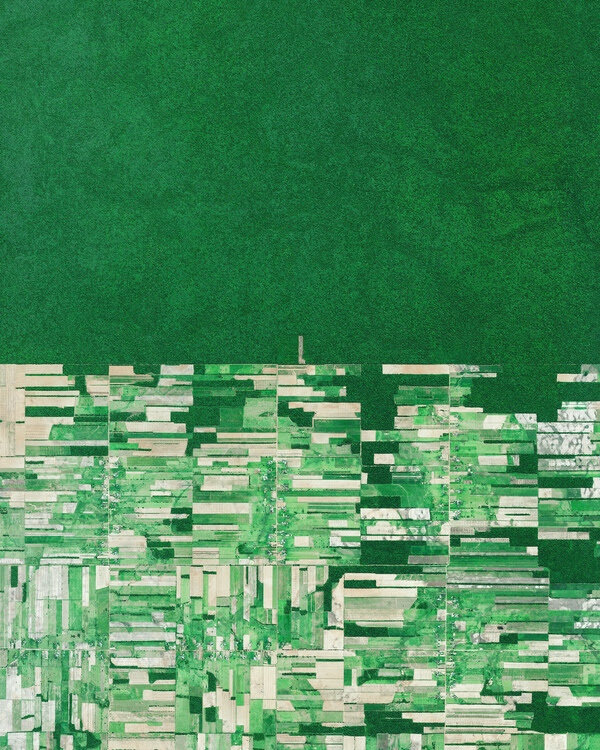

Bolivian Deforestation

Deforestation in the country has primarily been driven by the expansion of mechanized agriculture and cattle ranching.

April 9, 2021

Deforestation of The Rainforest Is Visible In Santa Cruz, Bolivia.

Deforestation in the country has primarily been driven by the expansion of mechanized agriculture and cattle ranching.

This Overview highlights the country’s struggle to expand food production in order to meet the needs of its growing population, and the sacrificial destruction of its forests that has taken place to do so.

-17.387750°, -60.562131°

Source imagery: Maxar

Your Quick Guide To Grow Room Controllers

A grow room controller brings together all the moving parts of your cultivation facility and allows you to automate your operation

March 5, 2021

What is a Grow Room Controller?

A grow room controller brings together all the moving parts of your cultivation facility and allows you to automate your operation. With a grow room controller, you can monitor and control your climate, lighting, irrigation, fertigation, and track your crop’s success to adjust and improve each cycle. These control systems can connect to existing equipment or come with their own set of sensors to track your environment, and adjust according to your set parameters, ultimately saving you time and money.

Grow room controllers integrate with existing systems, or can be purchased with sensors and equipment for larger operations. Some systems need only a few sensors and an application for your phone or computer, while others require larger computing and monitoring devices. Which option you choose will largely depend on the size of your greenhouse or indoor growing operation.

Being able to monitor and control your indoor or greenhouse facility is crucial for consistent and desired results. These systems are a huge benefit to all crop types, including cannabis, and can be adjusted to fit your cultivation style and desired outcomes. Not only will you be able to more accurately track and monitor your crop’s progress, but you can then take that learning and replicate it or improve upon it for your next growth cycle.

The Benefits

Grow room controllers offer you complete control and oversight of your crop. Any environmental aspect that you wish to control can be monitored and adjusted with a grow room control system. More advanced systems offer automation for your whole system, allowing you to pull yourself out of the weeds (pun intended) of trying to control everything manually. Grow room controllers are also scalable, especially if you purchase a setup with that in mind, allowing you to expand your facility but keep the same environmental parameters and automation.

All greenhouse and indoor growers know that having control over your environment is crucial to achieving desired results. This means monitoring and adjusting your lighting, climate, irrigation, and fertigation to ensure consistency, which can be time-consuming. A greenhouse control system does the monitoring and adjusting for you, ensuring all of the environmental controls work together and are adjusted accurately.

With advanced control systems, you can program light preferences for your greenhouse, so if light falls below a certain threshold your lights will adjust and will turn off if it exceeds that threshold. Indoor growing can also benefit from lighting such as timers and spectrum controls. Hydroponic sensors in your medium can tell you if you need to increase or decrease water durations. Ultimately being as efficient as possible with water and electricity, which is both environmentally and economically beneficial.

This monitoring and automation are incredibly cost-effective in the long run for your greenhouse or indoor facility. The more automation you have, the less labor you need to support your cultivation, and labor is one of the most, if not the most costly aspect of a cultivation facility. Grow room and greenhouse control systems can also schedule timers and alarms for preventative maintenance so that your equipment can receive proper downtime, preventing blowouts and loss of productivity.

How to Select a Grow Room Controller

Figure 1 from GroAdvisor Webinar

The above worksheet is an example of how you can select the right grow room controller for your needs. While many focus on cost, it’s also important to take into account which system will integrate with and enhance your facility the most. Take stock of your equipment and current manual system to ensure that your new grow room controller will add value to your operation.

Finding a grow room controller that is right for your facility will help you realize your fullest growth potential. Once you have compared and found a system that can accommodate the environmental controls you’d like to track and automate, all that’s left is the installation. Once the grow room controller is installed and your parameters are set you will no longer have to manually adjust your elements, saving time and labor, which ultimately saves money.

Vertical Farming Startup Oishii Raises $50m In Series A Funding

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone.”

By Sian Yates

03/11/2021

Oishii, a vertical farming startup based in New Jersey, has raised $50 million during a Series A funding round led by Sparx Group’s Mirai Creation Fund II.

The funds will enable Oishii to open vertical strawberry farms in new markets, expand its flagship farm outside of Manhattan, and accelerate its investment in R&D.

“Our mission is to change the way we grow food. We set out to deliver exceptionally delicious and sustainable produce,” said Oishii CEO Hiroki Koga. “We started with the strawberry – a fruit that routinely tops the dirty dozen of most pesticide-riddled crops – as it has long been considered the ‘holy grail’ of vertical farming.”

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone. From there, we’ll quickly expand into new fruits and produce,” he added.

Oishii is already known for its innovative farming techniques that have enabled the company to “perfect the strawberry,” while its proprietary and first-of-its-kind pollination method is conducted naturally with bees.

The company’s vertical farms feature zero pesticides and produce ripe fruit all year round, using less water and land than traditional agricultural methods.

“Oishii is the farm of the future,” said Sparx Group president and Group CEO Shuhei Abe. “The cultivation and pollination techniques the company has developed set them well apart from the industry, positioning Oishii to quickly revolutionise agriculture as we know it.”

The company has raised a total of $55 million since its founding in 2016.

VIDEOS: AppHarvest CEO On Building The Third Wave of Sustainable Infrastructure

AppHarvest founder and CEO Jonathan Webb broke down what goals the agriculture technology is seeking to achieve by building a homegrown food supply in the U.S.

AppHarvest founder and CEO Jonathan Webb broke down what goals the agriculture technology is seeking to achieve by building a homegrown food supply in the U.S.

Babylon Micro-Farms Establishes New Corporate Headquarters In Richmond, Virginia

The company has developed disruptive technology - a cloud-based platform that operates vertical farms through a mobile phone app that controls all aspects of farming at the touch of a button

Richmond, VA (February 2021) Babylon Micro-Farms has chosen Richmond, Virginia as the site for their corporate headquarters, opening a new office and R & D space in historic Scott’s Addition. The move from Charlottesville was driven by the company’s growth and need for a larger talent pool - they had been courted by California and Arizona as an up-and-coming tech company in the indoor ag-tech space.

The company has developed disruptive technology - a cloud-based platform that operates vertical farms through a mobile phone app that controls all aspects of farming at the touch of a button. The indoor ag-tech industry is projected to grow globally from USD $121.26 billion in 2019 to USD $167.42 billion by 2025, a compound annual growth rate of 5.4% according to the latest report released by Market Data Forecast last week.

Babylon’s CEO and Co-Founder, Alexander Olesen, commented on the move. “Richmond is the perfect launchpad for our next phase of growth. It has a dynamic business eco-system and gives Babylon the chance to build an even stronger foundation for the future with everything it has to offer.”

Babylon began hiring locally in Richmond prior to the move, scaling up their operations in preparation for the anticipated increase in sales in 2021. Graham Smith, CTO and Co-Founder of Babylon, said “Our growth has been based on significant R & D we were able to accomplish because of support from The Center for Innovative Technology, the National Science Foundation and investors that understood early on the potential for this technology. Richmond offers a hub where innovation and industry intersect and having our headquarters here will fuel our expansion.”

The company expects to triple its workforce in the next three years, adding jobs in every department, from assembly to engineering. For more information visit www.babylonmicrofarms.com or contact janet@babymicrofarms.com for interview requests.

Babylon Micro-Farms team, from left to right: Alexander Olesen, CEO and co-founder; Marc Oosterhuis, COO; and Graham Smith, CTO, and co-founder. Courtesy of Babylon Micro Farms

ABOUT BABYLON MICRO-FARMS

At the touch of a button, Babylon Micro-Farms delivers a simple, yet engaging indoor growing experience. Babylon helps senior living communities, hospitals, schools, and hospitality companies showcase their commitment to providing fresh, nutritious produce and sustainability to their residents, employees, and customers.

They have designed a complete on-site farming service that makes growing simple for anyone, thanks to their plug-and-play Micro-Farms and Guided Growing App. Babylon offers the most affordable, efficient, and advanced vertical farming platform available, remotely managed through the cloud with unparalleled customer service. Since their humble beginnings as a social entrepreneur student project, Babylon have attracted investors from Silicon Valley, been awarded a grant from the National Science Foundation to support their research, patented a groundbreaking technology, and received recognition by Virginia's Governor Northam for their contribution as a technology innovator following their successful application for funding from the Center for Innovative Technology.

Babylon has designed a software platform to reclaim the decentralized food system of the 21st Century - using modular vertical farms that enables anyone to grow local produce on-site, all year round, indoors. They launched their first products focusing on the health care and senior living markets where our vertical farms provide access to food-as-medicine quality food and a variety of therapeutic activities.

Website:

https://www.babylonmicrofarms.com/

Press Contact:

Sharon Rettinger

Little Leaf Farms Raises $90M to Grow Its Greenhouse Network

Massachusetts-based Little Leaf Farms has raised $90 million in a debt and equity financing round to expand its network of hydroponic greenhouses on the East Coast. The round was led by Equilibrium Capital as well as founding investors Bill Helman and Pilot House Associates. Bank of America also participated.

by Jennifer Marston

Image from: Little Leaf Farms

Massachusetts-based Little Leaf Farms has raised $90 million in a debt and equity financing round to expand its network of hydroponic greenhouses on the East Coast. The round was led by Equilibrium Capital as well as founding investors Bill Helman and Pilot House Associates. Bank of America also participated.

Little Leaf Farms says the capital is “earmarked” to build new greenhouse sites along the East Coast, where its lettuce is currently available in about 2,500 stores.

The company already operates one 10-acre greenhouse in Devins, Massachusetts. Its facility grows leafy greens using hydroponics and a mixture of sunlight supplemented by LED-powered grow lights. Rainwater captured from the facility’s roof provides most of the water used on the farm.

According to a press release, Little Leaf Farms has doubled its retail sales to $38 million since 2019. And last year, the company bought180 acres of land in Pennsylvania on which to build an additional facility. Still another greenhouse, slated for North Carolina, will serve the Southeast region of the U.S.

Little Leaf Farms joins the likes of Revol Greens, Gotham Greens, AppHarvest, and others in bringing local(ish) greens to a greater percentage of the population. These facilities generally pack and ship their greens on the day of or day after harvesting, and only supply retailers within a certain radius. Little Leaf Farms, for example, currently servers only parts of Massachusetts, Pennsylvania, New York, and New Jersey.

The list of regions the company serves will no doubt lengthen as the company builds up its greenhouse network in the coming months.

VIDEO: How This Vertical Farm Grows 80,000 Pounds of Produce Per Week

Bowery Farming is a network of vertical farms working to reengineer the growing process

Bowery Farming Uses Technology To Prioritize

Accessibility And Sustainability In Their Produce

Growing Operations

by Terri Ciccone and Eater Video Feb 20, 2021

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process,” says chief science officer Henry Sztul. “Our goal is actually to have as few people walking around our plants as possible.”

Bowery Farming is a network of vertical farms working to reengineer the growing process. Using a system of light and watering technology, Bowery is able to use 95 percent less water than a traditional outdoor farm, zero pesticides, and chemicals, and grow food that tastes as good as anyone else’s.

Bowery Farming uses vertical farm-specific seeds that are optimized for flavor instead of insect resistance and durability. Seeds are mechanically pressed into trays of soil and sent out into growing positions, or racks within the building that have their own lighting and watering systems. Each tray gets its own QR code so that they can be monitored and assigned a customized plan for water and light until they’re ready to be harvested.

Irving Fain, Bowery Farming’s founder, and CEO contemplates the prediction from the United Nations that 70 to 80 percent of the world’s population will be living in and around cities in the next 30 years. “Figuring out” how do you feed and how do you provide fresh food to urban environments both more efficiently as well as more sustainably?’ is a very important question today, and an even more important question in the years to come.”

Indoor Farming Gains Ground Amid Pandemic, Climate Challenges

Investors used to brush off Amin Jadavji’s pitch to buy Elevate Farms’ vertical growing technology and produce stacks of leafy greens indoors with artificial light. Now, indoor farms are positioning themselves as one of the solutions to coronavirus pandemic-induced disruptions to the harvesting, shipping, and sale of food

Investors say urban farming can boost food security despite rising inflation, trade tensions and global food shortages.

Image from: Reuters via AppHarvest

Investors used to brush off Amin Jadavji’s pitch to buy Elevate Farms’ vertical growing technology and produce stacks of leafy greens indoors with artificial light.

“They would say, ‘This is great, but it sounds like a science experiment,'” said Jadavji, CEO of Toronto, Canada-based Elevate.

Now, indoor farms are positioning themselves as one of the solutions to coronavirus pandemic-induced disruptions to the harvesting, shipping, and sale of food.

“It’s helped us change the narrative,” said Jadavji, whose company runs a vertical farm in Ontario, and is building others in New York and New Zealand.

Proponents, including the US Department of Agriculture (USDA), say urban farming increases food security at a time of rising inflation and limited global supplies. North American produce output is concentrated in Mexico and the US southwest, including California, which is prone to wildfires and other severe weather.

Climate-change concerns are also accelerating investments, including by agribusiness giant Bayer AG, into multi-storey vertical farms or greenhouses the size of 50 football fields.

They are enabling small North American companies like Elevate to bolster indoor production and compete with established players BrightFarms, AeroFarms and Plenty, backed by Amazon.com Inc founder Jeff Bezos.

But critics question the environmental cost of indoor farms’ high power requirements.

Vertical farms grow leafy greens indoors in stacked layers or on walls of foliage inside of warehouses or shipping containers. They rely on artificial light, temperature control and growing systems with minimal soil that involve water or mist, instead of the vast tracts of land in traditional agriculture.

Image from: Reuters via AppHarvest

Greenhouses can harness the sun’s rays and have lower power requirements. Well-established in Asia and Europe, greenhouses are expanding in North America, using greater automation.

Investments in global indoor farms totalled a record-high $500m in 2020, AgFunder research head Louisa Burwood-Taylor said.

The average investment last year rose sharply, as large players including BrightFarms and Plenty raised fresh capital, she said.

A big funding acceleration lies ahead, after pandemic food disruptions – such as infections among migrant workers that harvest North American produce – raised concerns about supply disruptions, said Joe Crotty, director of corporate finance at accounting firm KPMG, which advises vertical farms and provides investment banking services.

“The real ramp-up is the next three to five years,” Crotty said.

Vegetables grown in vertical farms or greenhouses are still just a fraction of overall production. US sales of food crops grown under cover, including tomatoes, cucumbers and lettuce, amounted to 358 million kilogrammes (790 million pounds) in 2019, up 50 percent from 2014, according to the USDA.

California’s outdoor head lettuce production alone was nearly four times larger, at 1.3 billion kg (2.9 billion pounds).

Image from: Reuters via AppHarvest

The USDA is seeking members for a new urban agriculture advisory committee to encourage indoor and other emerging farm practices.

Plant Breeding Moves Indoors

Bayer, one of the world’s biggest seed developers, aims to provide the plant technology to expand vertical agriculture. In August, it teamed with Singapore sovereign fund Temasek to create Unfold, a California-based company, with $30m in seed money.

Unfold says it is the first company focused on designing seeds for indoor lettuce, tomatoes, peppers, spinach and cucumbers, using Bayer germplasm, a plant’s genetic material, said Chief Executive John Purcell.

Their advances may include, for example, more compact plants and an increased breeding focus on quality, Purcell said.

Unfold hopes to make its first sales by early 2022, targeting existing farms, and startups in Singapore and the United Kingdom.

Greenhouses are also expanding, touting higher yields than open-field farming.

AppHarvest, which grows tomatoes in a 60-acre greenhouse in Morehead, Kentucky, broke ground on two more in the state last year. The company aims to operate 12 facilities by 2025.

Its greenhouses are positioned to reach 70 percent of the US population within a day’s drive, giving them a transportation edge over the southwest produce industry, said Chief Executive Jonathan Webb.

“We’re looking to rip the produce industry out of California and Mexico and bring it over here,” Webb said.

Projected global population growth will require a large increase in food production, a tough proposition outdoors given frequent disasters and severe weather, he said.

Image from: Reuters via AppHarvest

New York-based BrightFarms, which runs four greenhouses, positions them near major US cities, said Chief Executive Steve Platt. The company, whose customers include grocers Kroger and Walmart, plans to open its two largest farms this year, in North Carolina and Massachusetts.

Platt expects that within a decade, half of all leafy greens in the US will come from indoor farms, up from less than 10 percent currently.

“It’s a whole wave moving in this direction because the system we have today isn’t set up to feed people across the country,” he said.

‘Crazy, Crazy Things’

But Stan Cox, research scholar for non-profit The Land Institute, is sceptical of vertical farms. They depend on grocery store premiums to offset higher electricity costs for lighting and temperature control, he said.

“The whole reason we have agriculture is to harvest sunlight that’s hitting the earth every day,” he said. “We can get it for free.”

Bruce Bugbee, a professor of environmental plant physiology at Utah State University, has studied space farming for NASA. But he finds power-intensive vertical farming on Earth far-fetched.