Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

How Vertical Farms Are Revolutionizing Agribusiness

What is vertical farming and why does it matter?

William Ramstein ・ 1 March 2021 ・ Vertical Farming

Urban planners are tasked with answering some pressing inquiries: how can farming be brought closer to consumers; is digital agriculture an essential ingredient for making cities smarter; and can vertical farming improve socio-economic disparities?

Key Takeaways:

Vertical farming uses LED, Robotics and AI to bring vegetables closer to city dwellers.

The total addressable market for vertical farming is estimated at around $700 billion.

Spread, a Japanese vertical farm is profitable but most firms fail.

Vertical farming is a great way to produce controlled supplies of a customized plant.

Vertical farming struggles with electricity costs despite reducing carbon emissions.

What is vertical farming and why does it matter?

The bedrock characteristic of cryptocurrency technology is called decentralization, a sovereign and flexible organizational system led by a commune, and today other industries like farming are catching the bug. Farming needs to change its practices in order to meet ecological objectives set up by governments and decentralization could open the door to increasing food access and reducing carbon emissions from food transportation. Smart decentralized vertical farming implies using technology like digital platforms, robotics and artificial intelligence to bring food closer to the growing demand seen in cities.

Despite the difficulty of competing against the cost structure of traditional farming, vertical farming offers numerous advantages. It grants more yield per square meter and reduces waste in both carbon and water usage. The production of vegetables is made in large and often times un-used warehouses close to city centers thus cutting transportation costs and middlemen expenses. The supply is more easily controlled, protected, and priced regardless of global weather and plants are customized to local consumer preferences. Consumers are already paying a premium on farmer’s market products, so why not vertical farm products too?

Cases of vertical farming: Nigeria is one of the most promising African nations because of its age pyramid. But with a large young population comes questions around food and water access and today, more than 170 million Nigerians need prolonged and sustainable access to these resources. Nigeria currently imports $3.5 billion worth of food products while exporting only 1/7 of that figure. Fresh Direct is Nigeria’s first Hydroponics Company (growing crops without standard soil) that combines vertical farming to its business model to reduce the distance between cities and rural farming regions.

The firm is able to produce seven to 10 times the yields because of its stackable shipping containers, which use technologies such as drip irrigation, and cold storage. Direct Farming operates with a community mindset, with the goal to inspire more young farmers to set up shop in urban centers and become urban farmers. The company also trains and finances low-skilled workers into urban farmers and increases economic productivity in unemployed youth groups.

In Japan, a company called Spread is one of the world’s most sophisticated examples of vertical farming. Their factory mainly produces lettuce. Large robotic arms transplant lettuce seedlings into pots where they are left to grow under LED lights. Believe it or not, but the factory can produce 30,000 lettuce heads a day. CEO Shinji Inada boasts of being the only large-scale vertical farm that is profitable and hopes that more widespread adoption continues growing.

However, companies like Spread and A-Plus (another similar farm in Fukushima) struggle to lower unit economics because of their low-scale operations, and they find it hard to penetrate the traditional downstream sellers. When producing high-priced lettuce by the tonne, trucking goods to the local wholesaler does not work partly because vertical farming offers customized products for specific local needs, not necessarily for broad demand. These players have thus geared their focus towards international buyers like UAE to export their goods.

Is vertical farming there yet?

Most vertical farms have failed because of the high initial costs and high operational expenses of running robotic equipment. While sunlight is free, the energy cost of running LEDs is not. The solution could be to install renewable energies like solar panels and wind turbines. However, the fixed cost of that installation would inevitably factor into the end-product, or at least on the balance sheet as a liability assuming they keep prices reasonable for consumers.

While Mr. Inada can rightly boast of turning profits, most firms toss lettuce at a loss. The industry should see more growth ahead, however, with research group IDTechEx forecasting that annual sales of $700 million could more than double to $1.5 billion in 2030. There remain technological challenges though. While many competitors boast of successfully leveraging AI and robotics and filtration, new entrants have seen problems with watering automation systems, mold, and infestations (most players do not use pesticides).

Some analysts suggest that while the excitement around vertical farms makes sense, the farming style might just end up becoming just another way of farming amongst greenhouse and open sky farms. More specifically, vertical farming will focus on high-margin crops rather than commodities like bulk grains.

While the challenges of vertical farming are clear, every country has different needs and constraints. There is a large interest from smaller island countries like Singapore or Iceland, rich economies, and countries that have a higher propensity to import due to less arable lands. Britain is a good example of a country that meets the criteria and in the context of Brexit, it makes all the more sense because of import costs and independence constraints. A potential labor crisis could soon loom too assuming seasonal workers are denied entry into the country. Vertical farms only require one-third of the manpower to run and could therefore alleviate the industry.

The market opportunity…According to research by Barclays Investment Bank, the market opportunity for vertical farms is large. Analysts estimate the size of the global fruit and vegetable market to be $1.2 trillion and the total addressable market for vertical farms to be $700 billion. The purchased energy use to produce 1kg of lettuce is 247-kilowatt hours far exceeding Netherland greenhouses’ 70-kilowatt hours consumption. With retailers being asked to meet more carbon-neutral objectives, some vertical farms believe they will be able to overcome their expense through increased demand and scale.

The pandemic has imposed many supply chains disruptions and labor shortages threatening food security in regions around the world relying heavily on imports. Vertical farming is recognized lately and since 2014, has seen a flow of funds equal to $1.8 billion according to data group Dealroom. SoftBank fundraised $140 million into Plenty, a start-up, and countries like Abu Dhabi want to build farms in deserts.

Some of the top players in the global farming market include Vertical Farm Systems (Australia), American Hydroponics (US), Agrilution (Germany), Green Sense Farms (US), Everlight Electronics (Taiwan), Koninklijke Philips (Netherlands), Sky Greens (Singapore), Illumitex (US), Urban Crop (Belgium), Aerofarms (US) and InFarm (Germany).

Fresh Impact Farms Awarded Arlington's First Agriculture Grant

Arlington County received its first-ever agriculture fund grant from the state, money that will go to county-based Fresh Impact Farms.

Operating since 2018, Fresh Impact Farms uses hydroponic technology to grow a variety of speciality herbs, leafy greens, and edible flowers indoors. (Mark Hand/Patch)

ARLINGTON, VA — Arlington County received its first-ever agriculture fund grant from the state, money that will go to Fresh Impact Farms, an Arlington-based company that plans to double production at its indoor growing facility.

Virginia Gov. Ralph Northam announced Monday that he had awarded an Agriculture and Forestry Industries Development, or AFID, Fund grant to Arlington totalling $15,000 to be given to Fresh Impact Farms. The company will receive a total of $30,000 from the government, with Arlington County matching the state grant with local funds.

"Agriculture continues to be a key driver of our economic recovery in both rural and urban areas of our commonwealth," Northam said Monday in a statement. "Innovative, dynamic businesses like Fresh Impact Farms are demonstrating how exciting new opportunities can grow out of pandemic-related challenges."

"I congratulate the company on their success and am thrilled to award the first-ever AFID grant to Arlington County to support this expansion," the governor said.

In recent decades, Arlington County has grown into one of the most densely populated counties in the nation. Up until World War II, Arlington still had plenty of farmland. But over the past 60-plus years, the only farming in the county has been of the backyard and patio variety or in the community gardens in the Four Mile Run area.

Operating since 2018, Fresh Impact Farms uses proprietary hydroponic technology to grow a variety of specialty herbs, leafy greens, and edible flowers indoors.

"Governor Northam's award to Fresh Impact Farms, Arlington's only commercial farm, is an innovative way to celebrate unique uses of technology to help a small business pivot during the pandemic," Arlington County Board of Supervisors Chairman Matt de Ferranti said. "I am thrilled that Fresh Impact Farms is growing and looking to the future of a sustainable food supply."

The company will invest a total of $137,500 as part of the expansion, which will include a second grow room, a larger production facility, and an educational hub where customers, after the pandemic, will be able to see how their food is harvested.

Fresh Impact Farms' community-supported agriculture or CSA, program focuses on leafy greens and home kitchen-friendly herbs and has grown them steadily since the program's creation last April. Along with residential customers, the company now has smaller wholesale clients in the Washington, D.C., area.

The future is bright for urban agriculture, said Ryan Pierce, founder of Fresh Impact Farms, located in the back of a Lee Highway strip mall. (Mark Hand/Patch)

After the start of the pandemic, Fresh Impact Farms decided to shift its business model to a CSA delivery service in order to continue generating revenue.

"Seizing the opportunity created by more people cooking at home, the company initiated a Community Supported Agriculture program targeting area residents," the governor's office said.

"Now, with vaccinations underway and the restaurant industry poised to rebound, Fresh Impact Farms is expanding, which will allow the company to resume supplying their restaurant customers, while also meeting new demand through their CSA program," the governor's office said.

Over the next three years, the company expects to grow an additional 10,500 pounds of Virginia-grown leafy greens, herbs, and edible flowers for restaurant and CSA customers.

The future is bright for urban agriculture, said Ryan Pierce, founder of Fresh Impact Farms, located in the back of a Lee Highway strip mall.

"The support and generosity from the Commonwealth and Arlington County will be valuable as we expand our production and move towards a hybrid model of serving both the needs of restaurants and consumers," Pierce said in a statement. "As the owner of a local food business, nothing gets me more excited than seeing the community come together in support of local food."

The funds from the Arlington County Industrial Development Authority, together with the state grant, represent "an important investment in urban agriculture, sustainability, and technology," Arlington County IDA Chair Edwin Fountain said in a statement. "This project will advance the County's innovative and forward-thinking approach to developing new sectors of economic activity in Arlington."

7 New HDB Carpark Rooftop Sites Offered For Rental For Urban Farming In Public Tender

More local produce. Part of Singapore's efforts to strengthen its food security is increasing its capability to produce food locally

Part of Singapore's efforts to strengthen its food security is increasing its capability to produce food locally.

To do this, more sites for urban rooftop farms atop multi-storey Housing Development Board (HDB) carparks are being offered for rental, via a public tender process that was launched today (Feb. 23).

Seven new sites

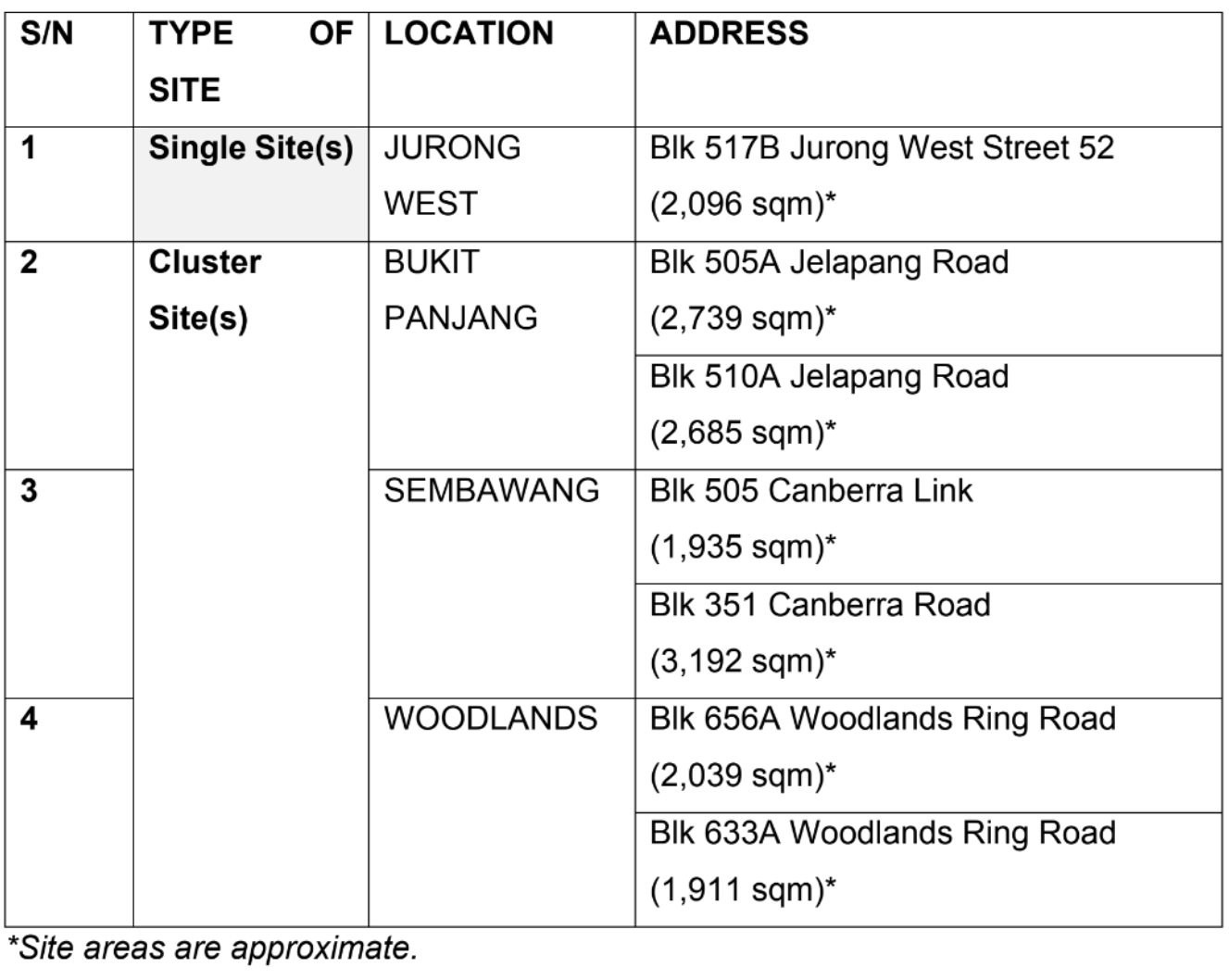

Seven sites have been identified in Jurong West, Bukit Panjang, Sembawang and Woodlands, according to the Singapore Food Agency (SFA) and HDB.

The sites will be used to farm vegetables and other food crops, and will also be used to pack and store produce.

They will be tendered out as a single site (in Jurong West) and three cluster sites (in Bukit Panjang, Sembawang and Woodlands).

Screenshot from SFA and HDB

Tenderers who successfully bid for cluster sites will be awarded all sites within the cluster, to allow them to cut costs through production at scale.

Single-site farms, on the other hand, provide opportunities to "testbed innovative ideas".

Tenderers must submit their proposals via GeBiz before the tender closes on Mar. 23, 4pm.

Proposals will be assessed on their bid price, production output, design and site layout, as well as their business and marketing plans.

More information can be found on SFA's website here.

Producing food locally

This is the second time tenders were launched for rooftop urban farms on carparks here — the first took place in Sep. 2020, with nine sites being awarded.

Collectively, the nine farming systems can potentially produce around 1,600 tonnes (1,600,000kg) of vegetables per year.

Having more space for commercial farming in land-constrained Singapore is one of SFA's strategies to achieve its "30 by 30" goal — which is to produce 30 percent of Singapore's food locally by 2030.

The move is also in line with HDB’s Green Towns Programme to intensify greening in HDB estates.

“Besides contributing to our food security, Multi-Storey Car Park (MSCP) rooftop farms help to bring the community closer to local produce, thereby raising awareness and support for local produce," said Melvin Chow, Senior Director of SFA’s Food Supply Resilience Division.

Agritech: Precision Farming With AI, IoT and 5G

For a company that grows and delivers vegetables, Boomgrow Productions Sdn Bhd’s office is nothing like a farm, or even a vertical farm. Where farms are bedecked with wheelbarrows, spades and hoes, Boomgrow’s floor plan is akin to a co-working space with a communal island table, several cubicles, comfortable armchairs, a cosy hanging rattan chair and a glass-walled conference room in the middle

Image from: Photo by Mohd Izwan Mohd Nazam/The Edge

For a company that grows and delivers vegetables, Boomgrow Productions Sdn Bhd’s office is nothing like a farm, or even a vertical farm.

Where farms are bedecked with wheelbarrows, spades and hoes, Boomgrow’s floor plan is akin to a co-working space with a communal island table, several cubicles, comfortable armchairs, a cosy hanging rattan chair and a glass-walled conference room in the middle.

At a corner, propped up along a walkway leading to a rectangular chamber fitted with grow lights, are rows of support stilts with hydroponic planters developed in-house and an agricultural technologist perched on a chair, perusing data. “This is where some of the R&D work happens,” says Jay Dasen, co-founder of the agritech start-up.

But there is a larger farm where most of the work behind this high-tech initiative is executed. Located a stone’s throw from the city centre in Ampang is a 40ft repurposed shipping container outfitted with perception technologies and artificial intelligence (AI) capabilities that mimic the ideal environment to produce more than 50,000kg of vegetables a year.

Stacked in vertical layers, Boomgrow’s vegetables are grown under artificial lights with Internet of Things (IoT) sensors to detect everything from leaf discolouration to nitrate composition. This is coupled with AI and machine learning algorithms.

Boomgrow is the country’s first 5G-connected vertical farm. With the low latency and larger bandwidth technology, the start-up is able to monitor production in real time as well as maintain key parameters, such as temperature and humidity, to ensure optimal growth conditions.

When Jay and her co-founders, K Muralidesan and Shan Palani, embarked on this initiative six years ago, Boomgrow was nowhere near what it is today.

The three founders got together hoping to do their part in building a more sustainable future. “I’ve spent years advising small and large companies on sustainability, environmental and social governance disclosures. I even embarked on a doctorate in sustainability disclosure and governance,” says Jay.

“But I felt a deep sense of disconnect because while I saw companies evolving in terms of policies, processes and procedures towards sustainability, the people in those organisations were not transforming. Sustainability is almost like this white noise in the background. We know it’s important and we know it needs to be done, but we don’t really know how to integrate it into our lives.

“That disconnect really troubled me. When we started Boomgrow, it wasn’t a linear journey. Boomgrow is something that came out of meaningful conversations and many years of research.”

Shan, on the other hand, was an architect who developed a taste for sustainable designs when he was designing modular structures with minimal impact on their surroundings between regular projects. “It was great doing that kind of work. But I was getting very dissatisfied because the projects were customer-driven, which meant I would end up having debates about trivial stuff such as the colour of wall tiles,” he says.

As for Murali, the impetus to start Boomgrow came from having lived overseas — while working in capital markets and financial services — where quality and nutritious produce was easily available.

Ultimately, they concluded that the best way to work towards their shared sustainability goals was to address the imminent problem of food shortage.

“By 2050, the world’s population is expected to grow to 9.7 billion people, two-thirds of whom will be in Asia-Pacific. Feeding all those people will definitely be a huge challenge,” says Jay.

“The current agricultural practice is not built for resilience, but efficiency. So, when you think of farming, you think of vast tracts of land located far away from where you live or shop.

“The only way we could reimagine or rethink that was to make sure the food is located closer to consumers, with a hyperlocal strategy that is traceable and transparent, and also free of pesticides.”

Having little experience in growing anything, it took them a while to figure out the best mechanism to achieve their goal. “After we started working on prototypes, we realised that the tropics are not designed for certain types of farming,” says Jay.

“And then, there is the problem of harmful chemicals and pesticides everywhere, which has become a necessity for farmers to protect their crops because of the unpredictable climate. We went through many iterations … when we started, we used to farm in little boxes, but that didn’t quite work out.”

They explored different methodologies, from hydroponics to aquaponics, and even started growing outdoors. But they lost a lot of crops when a heat wave struck.

That was when they started exploring more effective ways to farm. “How can we protect the farm from terrible torrential rains, plant 365 days a year and keep prices affordable? It took us five years to answer these questions,” says Jay.

Even though farmers all over the world currently produce more than enough food to feed everyone, 820 million people — roughly 11% of the global population — did not have enough to eat in 2018, according to the World Health Organization. Concurrently, food safety and quality concerns are rising, with more consumers opting for organically produced food as well as safe foods, out of fear of harmful synthetic fertilisers, pesticides, herbicides and fungicides.

According to ResearchAndMarkets.com, consumer demand for global organic fruit and vegetables was valued at US$19.16 billion in 2019 and is anticipated to expand at a compound annual growth rate (CAGR) of 6.5% by 2026.

Meanwhile, the precision farming market was estimated to be US$7 billion in 2020 and is projected to reach US$12.8 billion by 2025, at a CAGR of 12.7% between 2020 and 2025, states MarketsandMarkets Research Pte Ltd.

Malaysia currently imports RM1 billion worth of leafy vegetables from countries such as Australia, China and Japan. Sourcing good and safe food from local suppliers not only benefits the country from a food security standpoint but also improves Malaysia’s competitive advantage, says Jay.

Unlike organic farming — which is still a soil-based method — tech-enabled precision farming has the advantage of catering for increasing demand and optimum crop production with the limited resources available. Moreover, changing weather patterns due to global warming encourage the adoption of advanced farming technologies to enhance farm productivity and crop yield.

Boomgrow’s model does not require the acres of land that traditional farms need, Jay emphasises. With indoor farms, the company promises a year-round harvest, undisturbed by climate and which uses 95% less water, land and fuel to operate.

Traditional farming is back-breaking labour. But with precision technology, farmers can spend less time on the farm and more on doing other things to develop their business, she says.

Boomgrow has secured more than RM300,000 in funding via technology and innovation grants from SME Corporation Malaysia, PlaTCOM Ventures and Malaysia Digital Economy Corporation, and is on track to build the country’s largest indoor farms.

Image from: Boomgrow

The company got its chance to showcase the strength of its smart technology when Telekom Malaysia Bhd (TM) approached it to be a part of the telco’s Smart Agriculture cluster in Langkawi last October.

“5G makes it faster for us to process the multiple data streams that we need because we collect data for machine learning, and then AI helps us to make decisions faster,” Jay explains.

“We manage the farm using machines to study inputs like water and electricity and even measure humidity. All the farm’s produce is lab-tested and we can keep our promise that there are no pesticides, herbicides or any preserving chemicals. We follow the food safety standards set by the EU, where nitrate accumulation in plant tissues is a big issue.”

With TM’s 5G technology and Boomgrow’s patent-pending technology, the latter is able to grow vegetables like the staple Asian greens and highland crops such as butterhead and romaine lettuce as well as kale and mint. While the company is able to grow more than 30 varieties of leafy greens, it has decided to stick to a selection of crops that is most in demand to reduce waste, says Jay.

As it stands, shipping containers are the best fit for the company’s current endeavour as containerised modular farms are the simplest means of bringing better food to local communities. However, it is also developing a blueprint to house farms in buildings, she says.

Since the showcase, Boomgrow has started to supply its crops to various hotels in Langkawi. It rolled out its e-commerce platform last year after the Movement Control Order was imposed.

“On our website, we promise to deliver the greens within six hours of harvest. But actually, you could get them way earlier. We harvest the morning after the orders come in and the vegetables are delivered on the same day,” says Jay.

Being mindful of Boomgrow’s carbon footprint, orders are organised and scheduled according to consumers’ localities, she points out. “We don’t want our delivery partners zipping everywhere, so we stagger the orders based on where consumers live.

“For example, all deliveries to Petaling Jaya happen on Thursdays, but the vegetables are harvested that morning. They are not harvested a week before, three days before or the night before. This is what it means to be hyperlocal. We want to deliver produce at its freshest and most nutritious state.”

Plans to expand regionally are also underway, once Boomgrow’s fundraising exercise is complete, says Jay. “Most probably, this will only happen when the Covid-19 pandemic ends.”

To gain the knowledge they have today, the team had to “unlearn” everything they knew and take up new skills to figure what would work best for their business, says Jay. “All this wouldn’t have been possible if we had not experimented with smart cameras to monitor the condition of our produce,” she laughs.

Vertical Farming ‘At a Crossroads’

Although growing crops all year round with Controlled Environment Agriculture (CEA) has been proposed as a method to localize food production and increase resilience against extreme climate events, the efficiency and limitations of this strategy need to be evaluated for each location

Building the right business model to balance resource usage with socio-economic conditions is crucial to capturing new markets, say speakers ahead of Agri-TechE event

Image from: Fruitnet

Although growing crops all year round with Controlled Environment Agriculture (CEA) has been proposed as a method to localize food production and increase resilience against extreme climate events, the efficiency and limitations of this strategy need to be evaluated for each location.

That is the conclusion of research by Luuk Graamans of Wageningen University & Research, a speaker at the upcoming Agri-TechE event on CEA, which takes place on 25 February.

His research shows that integration with urban energy infrastructure can make vertical farms more viable. Graamans’ research around the modelling of vertical farms shows that these systems are able to achieve higher resource use efficiencies, compared to more traditional food production, except when it comes to electricity.

Vertical farms, therefore, need to offer additional benefits to offset this increased energy use, Graamans said. One example his team has investigated is whether vertical farms could also provide heat.

“We investigated if vertical farms could provide not just food for people living in densely populated areas and also heat their homes using waste heat. We found that CEA can contribute to stabilizing the increasingly complex energy grid.”

Diversification

This balance between complex factors both within the growing environment and wider socio-economic conditions means that the rapidly growing CEA industry is beginning to diversify with different business models emerging.

Jack Farmer is CSO at vertical producer LettUs Grow, which recently launched its Drop & Grow growing units, offering a complete farming solution in a shipping container.

He believes everyone in the vertical farming space is going to hit a crossroads. “Vertical farming, with its focus on higher value and higher density crops, is effectively a subset of the broader horticultural sector,” he said.

"All the players in the vertical farming space are facing a choice – to scale vertically and try to capture as much value in that specific space, or to diversify and take their technology expertise broader.”

LettUs Grow is focussed on being the leading technology provider in containerised farming, and its smaller ‘Drop & Grow: 24’ container is mainly focussed on people entering the horticultural space.

Opportunities in retail

“This year is looking really exciting,” he said. “Supermarkets are investing to ensure a sustainable source of food production in the UK, which is what CEA provides. We’re also seeing a growth in ‘experiential’ food and retail and that’s also where we see our Drop & Grow container farm fitting in.”

Kate Hofman, CEO, GrowUp agrees. The company launched the UK’s first commercial-scale vertical farm in 2014.

“It will be really interesting to see how the foodservice world recovers after lockdown – the rough numbers are that supermarket trade was up at least 11 per cent in the last year – so retail still looks like a really good direction to go in.

“If we want to have an impact on the food system in the UK and change it for the better, we’re committed to partnering with those big retailers to help them deliver on their sustainability and values-driven goals.

“Our focus is very much as a salad grower that grows a fantastic product that everyone will want to buy. And we’re focussed on bringing down the cost of sustainable food, which means doing it at a big enough scale to gain the economies of production that are needed to be able to sell at everyday prices.”

Making the Numbers Add Up

The economics are an important part of the discussion. Recent investment in the sector has come from the Middle East, and other locations, where abundant solar power and scarce resources are driving interest in CEA. Graamans’ research has revealed a number of scenarios where CEA has a strong business case.

For the UK, CEA should be seen as a continuum from glasshouses to vertical farming, he believes. “Greenhouses can incorporate the technologies from vertical farms to increase climate control and to enhance their performance under specific climates."

It is this aspect that is grabbing the attention of conventional fresh produce growers in open field and covered crop production.

A Blended Approach

James Green, director of agriculture at G’s, thinks combining different growing methods is the way forward. “There’s a balance in all of these systems between energy costs for lighting, energy costs for cooling, costs of nutrient supply, and then transportation and the supply and demand. At the end of the day, sunshine is pretty cheap and it comes up every day.

“I think a blended approach, where you’re getting as much benefit as you can from nature but you’re supplementing it and controlling the growth conditions, is what we are aiming for, rather than the fully artificially lit ‘vertical farming’.”

Graamans, Farmer and Hofman will join a discussion with conventional vegetable producers, vertical farmers and technology providers at the Agri-TechE event ‘Controlled Environment Agriculture is growing up’ on 25 February 2021.

Bringing The Future To life In Abu Dhabi

A cluster of shipping containers in a city centre is about the last place you’d expect to find salad growing. Yet for the past year, vertical farming startup Madar Farms has been using this site in Masdar City, Abu Dhabi, to grow leafy green vegetables using 95 per cent less water than traditional agriculture

Amid the deserts of Abu Dhabi, a new wave of entrepreneurs and innovators are sowing the seeds of a more sustainable future.

Image from: Wired

A cluster of shipping containers in a city centre is about the last place you’d expect to find salad growing. Yet for the past year, vertical farming startup Madar Farms has been using this site in Masdar City, Abu Dhabi, to grow leafy green vegetables using 95 per cent less water than traditional agriculture.

Madar Farms is one of a number of agtech startups benefitting from a package of incentives from the Abu Dhabi Investment Office (ADIO) aimed at spurring the development of innovative solutions for sustainable desert farming. The partnership is part of ADIO’s $545 million Innovation Programme dedicated to supporting companies in high-growth areas.

“Abu Dhabi is pressing ahead with our mission to ‘turn the desert green’,” explained H.E. Dr. Tariq Bin Hendi, Director General of ADIO, in November 2020. “We have created an environment where innovative ideas can flourish and the companies we partnered with earlier this year are already propelling the growth of Abu Dhabi’s 24,000 farms.”

The pandemic has made food supply a critical concern across the entire world, combined with the effects of population growth and climate change, which are stretching the capacity of less efficient traditional farming methods. Abu Dhabi’s pioneering efforts to drive agricultural innovation have been gathering pace and look set to produce cutting-edge solutions addressing food security challenges.

Beyond work supporting the application of novel agricultural technologies, Abu Dhabi is also investing in foundational research and development to tackle this growing problem.

In December, the emirate’s recently created Advanced Technology Research Council [ATRC], responsible for defining Abu Dhabi’s R&D strategy and establishing the emirate and the wider UAE as a desired home for advanced technology talent, announced a four-year competition with a $15 million prize for food security research. Launched through ATRC’s project management arm, ASPIRE, in partnership with the XPRIZE Foundation, the award will support the development of environmentally-friendly protein alternatives with the aim to "feed the next billion".

Image from: Madar Farms

Global Challenges, Local Solutions

Food security is far from the only global challenge on the emirate’s R&D menu. In November 2020, the ATRC announced the launch of the Technology Innovation Institute (TII), created to support applied research on the key priorities of quantum research, autonomous robotics, cryptography, advanced materials, digital security, directed energy and secure systems.

“The technologies under development at TII are not randomly selected,” explains the centre’s secretary general Faisal Al Bannai. “This research will complement fields that are of national importance. Quantum technologies and cryptography are crucial for protecting critical infrastructure, for example, while directed energy research has use-cases in healthcare. But beyond this, the technologies and research of TII will have global impact.”

Future research directions will be developed by the ATRC’s ASPIRE pillar, in collaboration with stakeholders from across a diverse range of industry sectors.

“ASPIRE defines the problem, sets milestones, and monitors the progress of the projects,” Al Bannai says. “It will also make impactful decisions related to the selection of research partners and the allocation of funding, to ensure that their R&D priorities align with Abu Dhabi and the UAE's broader development goals.”

Image from: Agritecture

Nurturing Next-Generation Talent

To address these challenges, ATRC’s first initiative is a talent development programme, NexTech, which has begun the recruitment of 125 local researchers, who will work across 31 projects in collaboration with 23 world-leading research centres.

Alongside universities and research institutes from across the US, the UK, Europe and South America, these partners include Abu Dhabi’s own Khalifa University, and Mohamed bin Zayed University of Artificial Intelligence, the world’s first graduate-level institute focused on artificial intelligence.

“Our aim is to up skill the researchers by allowing them to work across various disciplines in collaboration with world-renowned experts,” Al Bannai says.

Beyond academic collaborators, TII is also working with a number of industry partners, such as hyperloop technology company, Virgin Hyperloop. Such industry collaborations, Al Bannai points out, are essential to ensuring that TII research directly tackles relevant problems and has a smooth path to commercial impact in order to fuel job creation across the UAE.

“By engaging with top global talent, universities and research institutions and industry players, TII connects an intellectual community,” he says. “This reinforces Abu Dhabi and the UAE’s status as a global hub for innovation and contributes to the broader development of the knowledge-based economy.”

Recycling Solar Energy for Indoor Farming Use

New patented technology that recycles renewable energy is ready to revolutionize CEA (Controlled Environment Agriculture) and make indoor farming both more profitable and more attainable in remote rural areas. This upgrade in solar technology offers benefits for farmers, consumers, businesses, environmentalists and local governments

New patented technology that recycles renewable energy is ready to revolutionize CEA (Controlled Environment Agriculture) and make indoor farming both more profitable and more attainable in remote rural areas. This upgrade in solar technology offers benefits for farmers, consumers, businesses, environmentalists and local governments.

Two businesses are building a prototype of the vertical farm of the future in Marquette, Kansas (pop. 620.) The indoor farm will recycle its own solar energy at night and during storms by absorbing LED light energy when it’s used to illuminate the interior growing spaces. The 60-unit, 11-acre prototype development will function independently of the local power grid using technology designed and built by Kansas native David Hinson, CTO of TSO Greenhouses.

Image from: Hortidaily

This technology will reduce burdensome costs of power, water, financing, real estate acquisitions, and property taxes. Such hurdles have often been the downfall of previous vertical farms, especially in urban areas. The forward-thinking pair’s plan addresses and solves all of these challenges.

The duo’s “ag tech campus” model includes accelerated growing of all-natural, clean food and protein fodder as well as reliable 5G internet for rural farmers, citizens and businesses. The entire system will be powered by renewable energy and make digital telecom deployment more practical.

Image from: Hortidaily

Hinson’s technology enables roof-mounted “solar trackers” to capture LED energy at night from the light reflected inside the structures that house hydroponic crops growing inside. These trackers rotate East to West when the sun is shining and then flip inward at night and during bad weather.

As a result, farmers can harness the energy generated “off-hours” to grow a variety of crops 24 hours a day in multiple vertical “stacks” based on bespoke microclimates. Growing by “zones” inside a multi-level structure boosts crop production and horticulture flexibility. Traditional indoor farms and rudimentary greenhouses usually grow only 1-2 crops for local distribution.

In contrast, these new farms will be able to produce 10-15 different plant species simultaneously. Increased agility and production speed will also improve vertical farmers' ability to react to sudden demand shifts.

Image from: Hortidaily

5G Adds Lucrative Tech Payoff to Growth Cycle

Since the new 24/7/365 solar energy recycling technology only needs 33 percent to 40 percent of the harnessed energy, developers and farmers can sell excess energy for additional revenue. The local clean energy will power wireless 5G with the help of small rotating solar trackers with batteries. These trackers can be placed on community buildings, water towers, grain elevators, farm silos, bridge spans, existing cell towers and other permanent objects to ensure uptime and reliability.

This new source of 5G will create emerging markets for renewable energy, boosting rural economies. In the past, 5G telecom has been difficult to install and deploy in remote areas.

Path Diversity will be a game-changer

The pair plan to locate data centers near 100GB digital fiber trunks to further reduce the cost and time required to deploy 5G wireless. High-end data processing groups pay premium rates for 5G, which is rated as Tier 5 (aka T5 or always-on) based on its reliability. T5 is far less subject to outages and service disruptions.

Such state-of-the-art data centers are expected to attract the largest data processing groups in the world based on their enhanced functionality and amenities. This market also provides another lucrative revenue stream for farmers and tax-equity entrepreneurs interested in sustainability.

Investors Can Support Sustainability with “free money”

Freedom Farms CEO Geist and TSO Greenhouses Hinson have already raised nearly half a million dollars for Phase One, which will be the prototype of the vertical farming headquarters. They’re seeking an additional $2.5 million to finish the prototype by summer 2021.

Phase Two will be devoted to building 12 larger campuses that will fan out statewide from the headquarters in McPherson, Kansas. The entire $2 billion hub-and-spoke sustainability system is targeted for completion by 2030. Yields are expected to feed nearly 3 million residents statewide including many school lunch programs. Local hospitals, restaurants, colleges, universities, assisted living centers and public agencies are expected to become customers of the same-day harvests.

Investors will be able to reap these profits without ever risking their own money. Thanks to little-known U.S tax credit programs and clean-energy incentives, these projects don’t require a cash infusion. VC firms can "pool" their tax obligations, converting them to credits. This structure sets the project apart from previous urban farms or sluggish VC-funded startups.

Solar panels rotate with the sun so direct sunlight can reach inside the CEA facility and stimulate photosynthesis. Software allows the indoor farmer to create direct sun exposure on certain plants while creating shade for others, all based on each plant’s DNA preference.

The solar panels (modules) can be fully closed facing outward to create 100% shade inside if desired for any length of time controlled by the grower. By using TSO Greenhouses’ technology, vertical farmers and greenhouse growers can control and optimize sun and shade exposure simultaneously. This allows different crops to grow in zones inside the structure tailored precisely to receive the ideal light and shade to maximize plant life and production.

This 11-acre greenhouse will eventually serve as a headquarters to 12 smaller greenhouse hubs across Kansas. What makes this greenhouse unique is its ability to recycle solar energy to grow crops 24 hours a day while powering lucrative 5G data centers.

Warehouse Becoming Vertical Farms — And They’re Feeding New Jersey

New Jersey's vertical farms are transforming agriculture by helping farmers meet growing food demand. New Jersey Agriculture Secretary Doug Fisher said that while conventional farming in outdoor fields remains critical, vertical farming has its advantages because of its efficiency and resistance to pests and thus less need for chemicals

Image from: New Jersey 101.5

New Jersey's vertical farms are transforming agriculture by helping farmers meet growing food demand.

New Jersey Agriculture Secretary Doug Fisher said that while conventional farming in outdoor fields remains critical, vertical farming has its advantages because of its efficiency and resistance to pests and thus less need for chemicals.

Vertical farming is the process of growing food vertically in stacked layers indoors under artificial light and temperature, mainly in buildings. These plants receive the same nutrients and all the elements needed to grow plants for food.

Vertical farms are also versatile. Plants may be growing in containers, in old warehouses, in shipping containers, in abandoned buildings.

"That's one of the great advantages — that we can put agriculture in the midst of many landscapes that have lost their vitality," said Fisher.

ResearchandMarkets.com says the U.S. vertical farming market is projected to reach values of around $3 billion by the year 2024.

The one drawback is that its operational and labor costs make it expensive to get up and running.

Image from: AeroFarms

In the past decade, however, vertical farming has become more popular, creating significant crop yields all over the state.

AeroFarms in Newark is the world's largest indoor vertical farm. The farm converted a 75-year-old 70,000-square-foot steel mill into a vertical farming operation. AeroFarms' key products include Dream Greens, its retail brand of baby and micro-greens, available year-round in several ShopRite supermarkets.

Kula Urban Farm in Asbury Park opened in 2014. Vacant lots are transformed into urban farms and there's a hydroponic greenhouse on site. That produce is sold to local restaurants.

Beyond Organic Growers in Freehold uses no pesticides and all seeds and nutrients are organic. There's a minimum of 12,000 plants growing on 144 vertical towers. On its website, it says the greenhouse utilizes a new growing technique called aeroponics, which involves vertical towers where the plant roots hang in the air while a nutrient solution is delivered with a fine mist. It also boasts that by using this method, plants can grow with less land and water while yielding up to 30% more three times faster than traditional soil farming.

Vertical farms in New Jersey help feed local communities. Many are in urban areas and are a form of urban farming.

Fisher predicts that vertical farms will be operational in stores and supermarkets around the state.

"It's continued to expand. There's going to be many, many ways and almost any area in the state has the opportunity to have a vertical farm," Fisher said.

Advice For New Vertical Farmers: Grower Spotlight on Andrew Worrall

Andrew is LettUs Grow’s Farm Manager, he manages two of our sites across Bristol and has brought a wealth of knowledge into the company through his previous experience in indoor farming roles across the UK including at Grow Up, Raynor Foods & RootLabs. In this three part interview, we explore what it’s been like to move from animal husbandry to indoor farming, the lessons he’s learned along the way, what it’s like working at LettUs Grow and his advice for those new to indoor growing.

Last week we spoke about running a farm at LettUs Grow. What excites you about vertical farming?

It’s the future of the industry. Also, the amount of salad that these farms can produce for their local community. We want to be able to eat salad all year round and we import to make that happen. However, just a small farm can easily provide for its local community, very efficiently and all year round. The sustainability element is also exciting: with our salad there’s no food miles, it’s very minimalistic. You could use an electric van or bike to distribute this crop if you wanted to. It’s a step forward in terms of what we need to do to take care of our planet.

What do you think are the biggest downsides to vertical farming?

It’s still a new technology and it can be expensive. The biggest roadblock facing the industry is that we need more people and companies to collaborate together to make sure we can build these farms at a sensible rate, so we can provide farms to anyone. We want to be able to provide farms to people, communities and countries that don’t have a lot of money, so that they can provide affordable fresh produce to local people.

How has vertical farming impacted your life?

Massively! I wanted to find my passion, a job that I loved - that was very important to me. It’s satisfying to be in a position now where I’m very happy to be doing what I do and I look forward to going into work. I was happy to make the move from London to Bristol. I would have moved even further if it meant being able to continue working within this industry.

Image from: LettUs Grow

How do you see vertical farming playing a part in the future?

When indoor farming first came about, it had a reputation of being competition for outdoor farming, which just isn’t the case. There’s so much we can’t grow that outdoor farming can provide, such as cereal crops. I’m glad we’re at a stage where indoor and outdoor farms can start to work together to optimise both methods. With these new relationships, there should be a good increase in the amount of indoor farms you’ll be seeing. What LettUs Grow offers with DROP & GROW™ is an exciting project because that’s a 40ft shipping container which can be placed pretty much anywhere. It’s not that big - it could go in a car park or behind a restaurant, but actually provide quite a lot of salad to that area.

How much of our food should be grown this way?

Good question. If you had asked me a while back I would have just said salad, but now I’ve changed my mind. Indoor farming can have a massive impact on propagation, especially aeroponics, because of how we aerate and nourish our roots. We could start lettuce for greenhouse projects and we can also propagate tomatoes, strawberries and tree whips. Propagating trees in this way could potentially be hugely beneficial and it’s something we want to do more of.

We can also quickly grow large amounts of microgreens, baby leafs, herbs and we can grow fruiting crops like strawberries. We are slowly chipping away and it’s really exciting. I’m waiting to see if I can ever say I’ve grown or propagated every crop that can be grown in these farms!

What do you think are the biggest benefits of vertical farming?

How fast these crops can grow! The turnover can be as short as 5 days from seed, depending on the crop. Also how clean it can be - I’m very dedicated to making sure these farms are built to ensure they are easy to be maintained and clean. The most exciting part is the crop growth rate though - it’s incredible how fast our crop grows from seed to plate. In a very well maintained growing calendar, which Ostara® is great for supporting, you can optimise your beds so that the day you harvest can also be the day you germinate onto that same bed. Your farms can be forever providing salad at very fast rates.

Image from: LettUs Grow

What was the biggest change you encountered during your years indoor farming?

Moving from being a production grower to an R&D grower. It has been a great change! As a production grower I knew what I needed to know about growing the plant safely and getting it onto a plate so it was good for the consumer. Now I’m fully optimising, learning and understanding the plants completely, so that I can help the grower that I used to be. We spend a lot of time on crop recipes to make sure that whoever we sell our farms to can start up very quickly and they won’t have to spend months developing their crops. If they have the customers and clients behind them, they can buy DROP & GROW and start producing salad as soon as it's been commissioned.

What was the biggest change you encountered in the industry?

More and more people are speaking about what’s going on in the industry and getting involved. I get so many messages on LinkedIn with people who want to get into this career. It’s exciting to see that indoor growing is a career people can access now. When I was developing my skills I didn’t know I would end up in indoor farming. There are more opportunities than ever before. For example, our Crop Technician is doing a placement here for 2 years. The aim is that they can gain the skill sets and knowledge they need to then go off and do the same practice in any farm they want.

What advice do you have for people who are looking to start a career in growing?

Reach out to companies who are already out there. You could start off part-time or as an assistant. If you are patient and dedicated then it’s a journey I promise you won’t regret. It takes a lot of work, but the outcome is amazing - you’ll be learning so much about this new technology. You’ll also build great relationships: there are so many amazing people in this industry who are so interesting, with different backgrounds, who are willing to share their knowledge. You can always learn more and other people are a great source of that.

What about for those looking to start a vertical farming business?

Do your homework. There are people out there who you can reach out to and it’s very easy to get information. It’s very easy to get excited about the idea and jump straight into it, because it is exciting and can be very rewarding, but it’s really important to do it step by step. Know how to scale properly, learning the differences between a small and larger farm. Understand how many people you’ll need and the logistics. I’d also advise people to get some practical work experience before you buy. You want to start the company knowing the tricks of the trade.

Image from: LettUs Grow

LettUs Grow Blog: www.lettusgrow.com/blog/advice-for-vertical-farmers

US: Growing Up: Vertical Farming Makes the Most of Limited Space

To increase agricultural yields, a CALS horticultural scientist and his students are literally looking up. They want to know if growing plants indoors in vertically stacked layers could be part of the solution to feeding a fast-growing world population as farmland becomes scarcer

Horticultural scientist Ricardo Hernandez and Mark Watson work with lettuce plants inside the vertical farm near the JC Raulston Arboretum. (2019)

October 26, 2020 | Dee Shore

To increase agricultural yields, a CALS horticultural scientist and his students are literally looking up. They want to know if growing plants indoors in vertically stacked layers could be part of the solution to feeding a fast-growing world population as farmland becomes scarcer.

Ricardo Hernandez, a leading expert on growing plants in controlled environments, is exploring ways to make vertical farming profitable and sustainable. He and his students have modified a donated shipping container to grow produce and herbs on campus.

Mark Watson, who graduated in May, says that indoor vertical farming has several advantages. It allows for year-round production, and it’s less susceptible to weather extremes. It can also be used in urban settings, potentially reducing food losses that occur in getting crops from rural farms to tables.

Still, substantial challenges remain. Indoor production requires significant energy, which pushes farmers’ costs up.

Watson hadn’t heard of vertical farming before he took Hernandez’s controlled-environment horticulture class in 2019. He went on to win a national award for independent research on the best temperature and humidity to allow tomato plants to heal indoors after being grafted onto the rootstocks of other plants.

He also served as president of NC State’s Vertical Farms Club, which is testing leafy greens and other food crops in the shipping container and exploring marketing opportunities. The club includes students in horticulture, plant and microbial biology, crop and soil sciences, electrical and computer engineering, and mechanical and aerospace engineering.

Hernandez sees possibilities for farmers to raise high-value seedlings in vertical farms. As he explains, “Using a controlled environment can be key, because we can grow plants in high density and manipulate the environment—the lighting, the temperature, air movements and carbon dioxide concentrations—to produce the best seedlings possible.”

Little Wild Things City Farm

Little Wild Things City Farm produces soil-grown microgreens, shoots, and edible flowers on less than one-quarter acre in the heart of Washington, D.C.

Little Wild Things City Farm produces soil-grown microgreens, shoots, and edible flowers on less than one-quarter acre in the heart of Washington, D.C.

We believe that environmentally sustainable, commercially viable farming is possible in urban landscapes—and we're proving it.

As a first generation farm, we combine the best of time-honored sustainable growing techniques with new innovations and a disciplined business focus to achieve high yields from our very small growing spaces.

We aim to demonstrate that farming is a desirable career for the best and brightest of the next generation, and seek to develop relationships with customers who share our values to create a transformative impact on our local food system.

WHAT ARE MICROGREENS?

Our microgreens are tiny edible greens that provide exceptional flavor, nutritional value, texture, and color to salads, sandwiches, wraps, tacos, pizza, smoothies, soup and more. Smaller than “baby greens,” and harvested later than “sprouts,” microgreens provide a variety of leaf flavors, such as sweet and spicy, and come in many vibrant colors. Fine dining chefs use microgreens to enhance the beauty, taste and freshness of their dishes with their delicate textures and distinctive flavors.

Researchers at the USDA Agricultural Research Service and the University of Maryland began studying the nutritional content of microgreens in 2012. They looked at four groups of vitamins and other phytochemicals – including vitamin C, vitamin E, and beta carotene — in 25 varieties of microgreens. The researchers found that leaves from nearly all of the microgreens had four to six times more nutrients than the mature leaves of the same plant, with variation among the varieties – red cabbage was highest in vitamin C, while the green daikon radish microgreens had the most vitamin E [i]

[i] Xiao, Z.; Lester, G. E.; Luo, Y.; Wang, Q. (2012). "Assessment of Vitamin and Carotenoid Concentrations of Emerging Food Products: Edible Microgreens". Journal of Agricultural and Food Chemistry 60 (31): 7644-7651

Village Farms Spreads The Word About Healthy Eating

The Transformer Bumblebee even got in on the action to create some buzz about eating healthy!

Press Release – Village Farms recently sponsored and participated in “Cars for the Cure”, a car show benefitting the American Lung Association. This event showcased an array of the most distinctive and unforgettable cars from around the world during a daylong, family-friendly festival.

A team of volunteers from Village Farms spent the day giving away almost 2000 pounds of their authentic Heavenly Villagio Marzano® tomatoes to participants, attendees, and volunteers. The Transformer Bumblebee even got in on the action to create some buzz about eating healthy!

“Village Farms was proud to be a sponsor and support Cars for the Cure in its 15th year,” said Helen Aquino, Director of Brand Marketing and Communications. “Participating in an event like this for such a good cause was especially rewarding. We truly enjoyed getting out in our community to promote health and wellness and we loved hearing time and time again how much people enjoy the Garden Fresh Flavor® of our tomatoes!”

Now in its second century, the American Lung Association is the oldest voluntary health organization in the United States and the leading organization working to save lives by improving lung health and preventing lung disease. Founded in 1904 to fight tuberculosis, the American Lung Association today fights lung disease in all its forms, with special emphasis on asthma, tobacco control and environmental health.

About Village Farms

Village Farms is one of the largest producers, marketers, and distributors of premium-quality, greenhouse-grown fruits and vegetables in North America. The food our farmers grow, along with other greenhouse farmers under exclusive arrangements are all grown in environmentally friendly, soil-less, glass greenhouses. The Village Farms® brand of fruits and vegetables is marketed and distributed primarily to local retail grocers and dedicated fresh food distributors throughout the United States and Canada. Since its inception, Village Farms has been guided by sustainability principles that enable us to grow food 365 days a year that not only feeds the growing population but is healthier for people and the planet. Village Farms is Good for the Earth® and good for you.

Earth Notes: Urban Agriculture

Vertically stacked growing shelves, closely spaced plantings, and covered beds are helping farms fit in where space is often restricted.

By DIANE HOPE • FEB 13, 2019

In backyards and vacant lots, urban farming is on the rise in towns and cities across the Colorado Plateau. Vertically stacked growing shelves, closely spaced plantings, and covered beds are helping farms fit in where space is often restricted.

Roots Micro Farm

CREDIT MADELYN CHANCE

Listen

Listening...

2:00

Warehouse farming operations grow crops in sterile atmospheres that need costly nutrient inputs and energy for lighting. But small-scale urban farms offer lots of sustainable advantages.

These farms use natural sunlight and moisture, and make great use of local food waste, says Josh Chance. He and his wife Maddy established Roots Micro Farm on a neighborhood lot in downtown Flagstaff two and half years ago.

They mix organic waste from Northern Arizona University and local breweries with horse manure from nearby barns, creating deep fertile growing beds. Hoop houses let them extend the growing season from late April through December. They raise everything from kale to kohlrabi and tomatoes to edible flowers.

Such small urban farms can’t achieve the economies of scale that massive modern farming can – so their produce may cost a bit more than at large grocery chains. But, since they’re often located just a mile or two from consumers, local growers deliver fresh, healthy produce requiring little or no energy for transportation.

There are some extra benefits too--these farms provide pleasant green spaces within a city. And they can give young people the chance to see where food comes from, and how it’s grown. Some even provide training workshops for locals to learn - and trade - skills.

All in all, urban agriculture appears to be an idea ripe for the picking.

Farming On The Roofs of Shopping Malls In Singapore

Agriculture, takes up only about 1% of its land area.

Amidst the luxurious commercial setting of Singapore's Orchard Road, filled with fancy malls, department stores and food courts, there is a farm.

Reuters reports that the 6,450 sq ft Comcrop farm utilises vertical racks and hydroponics to grow leafy greens and herbs such as basil and perppermint, which are sold to nearby bars, restaurants and stores.

Allan Lim set up the rooftop farm five years ago, and recently opened a 4,000-square-metre farm with a greenhouse on the edge of the city.

The goal, in Singapore where land is at a premium, is to tackle food security.

“Agriculture is not seen as a key sector in Singapore. But we import most of our food, so we are very vulnerable to sudden disruptions in supply,” Lim said.

“Land, natural resources and low-cost labor used to be the predominant way that countries achieved food security. But we can use technology to solve any deficiencies,” he said.

In the country where 5.6 million people are densely packed in, land reclamation, moving transport utilities and storage underground, and clearing cemeteries for homes and highways have been undertaken.

Agriculture, takes up only about 1% of its land area.

Last year, Singapore topped the Economist Intelligence Unit’s (EIU) Global Food Security Index of 113 countries for the first time, scoring high on affordability, availability and safety.

However, importing more than 90% of its food, food security is susceptible to climate change and natural resource risks.

As climate change makes its impact felt across the world, the scarcity of water, shifting weather, and population growth will require better ways to feed the people.

A study published last year, cited by Reuters notes that urban agriculture currently produces as much as 180 million metric tonnes of food a year - up to 10% of the global output of pulses and vegetables.

From what was once an agrarian economy that produced nearly all of its own food, from pig farms, vegetable gardens and durian orchards and chicken in the kampongs, to government is now pushing to relocate over 60 farms in the countryside by 2021, to reclaim land for the military.

Speaking to the publication, Chelsea Wan, a second-generation farmer who runs Jurong Frog Farm said: “It’s getting tougher because leases are shorter, it’s harder to hire workers, and it’s expensive to invest in new technologies.

“We support the government’s effort to increase productivity through technology, but we feel sidelined,” she said.

Urban Farms Could be Incredibly Efficient—But Aren’t Yet

Casual farmers overwork, buy fertilizer, and use municipal water.

JOHN TIMMER - 12/28/2018, 3:45 AM

The green revolution that transformed modern agriculture has generally increased its scale. There's tremendous potential for efficiencies in the large-scale application of mechanization, fertilization, and pesticide use. But operating at that level requires large tracts of land, which means sources of food have grown increasingly distant from the people in urban centers who will ultimately eat most of it.

In some ways, hyper-local food is a counterculture movement, focused on growing herbs and vegetables in the same dense urban environments where they will be eaten. It trades the huge efficiencies of modern agriculture for large savings in transportation and storage costs. But is urban farming environmentally friendly?

According to researchers at Australia's University of New England, the answer is pretty complex. Within their somewhat limited group of gardeners, urban agriculture is far more productive for the amount of land used but isn't especially efficient with labor and materials use. But the materials issue could be solved, and the labor inefficiency may be a product of the fact that most urban farmers are hobbyists and are doing it for fun.

Urban ag

The researchers—Robert McDougalla, Paul Kristiansena, and Romina Rader—defined urban agriculture as taking place within a kilometer of a densely built environment. Working in the Sydney area, they were able to find 13 urban farmers who were willing to keep detailed logs of their activity for an entire year. Labor and materials costs were tracked, as was the value of the produce it helped create. The energetic costs of the materials and labor were also calculated in order to assess the sustainability of urban farming.

The plots cultivated by these farmers were quite small, with the median only a bit over 10 square meters. Yet they were extremely productive, with a mean of just under six kilograms of produce for each of those square meters. That's about twice as productive as a typical Australian vegetable farm, although the output range of the urban farms was huge—everything from slightly below large farm productivity to five times as productive.

For the vast majority of crops, however, the urban farms weren't especially effective. They required far more labor than traditional farms, and, as a result, the total value of the inputs into the crop exceeded the income from selling it. In other words, the urban farmers were losing money, at least by traditional accounting measures. And the farms weren't especially sustainable, with only about 10 percent of all the inputs coming from renewable resources. Again, labor was a major culprit, as it's not considered very renewable, and urban farming is very labor-intensive.

So that all sounds like a bit of a disaster, really. But as mentioned above, things quickly get complex. The urban farmers, as it turned out, bought compost and fertilizer and used the municipal water supply. Cities, as the authors note, produce large quantities of organic waste that could be used to make compost. While it would require additional labor and land space, it would be easy to make the care of the crops far more sustainable. Combined with the use of collected rainwater, these could get the percentage of renewable contributions up to roughly 40 percent.

Laborious

Then there's the issue of the time spent on labor. The urban farmers don't seem to be especially efficient compared to regular farm laborers, and by all indications they don't necessarily want to be. For many of them, it's more a hobby than career; they put in more labor because they enjoy it or find it relaxing. If you start reducing the labor costs to reflect this, things start changing dramatically. If only the material costs of urban farming are considered (meaning labor was set to $0), then the apparent efficiency improves dramatically.

Not surprisingly, ignoring labor costs also makes a big difference financially, with the profit-to-cost ratio going from a mean of 0.62 up to 2.8, indicating that these urban farms would generally be quite profitable.

Labor also makes a big difference in terms of energy use. As they're now operating, these urban farms aren't very different from rural farms, which means they're not sustainable. Shifting to local sources of materials, like rainwater and compost, would drop the energy use dramatically, shifting the farms into territory that's typically considered sustainable. Eliminating labor considerations on top of that would make urban agriculture among the most efficient means of growing vegetables presently studied.

There are two obvious caveats to this work: the small number of farms sampled and the fact that they were all in a single urban area. This sort of study will obviously need to be replicated in other locations before we can start generalizing about hyper-local produce. But the role of labor in this sort of analysis makes conclusions difficult to generalize. Is it reasonable to discount some fraction of the labor costs when people are doing the farming for pleasure? Do we start considering a tomato plant on a balcony part of an urban farm?

While many of the details are unclear, the overall conclusion seems solid: while urban farms aren't yet there in terms of sustainability and energy use, the potential for them to outpace their larger rural cousins is definitely there. But it will take an entire sustainable support infrastructure for them to truly arrive.

With Farms Atop Malls, Singapore Gets Serious About Food Security

The farm's small size belies its big ambition: to help improve the city's food security.

January 09, 2019 5:11 PM

SINGAPORE —

Visitors to Singapore's Orchard Road, the city's main shopping belt, will find fancy malls, trendy department stores, abundant food courts — and a small farm.

Comcrop's 600-square-meter (6,450-square-foot) farm on the roof of one of the malls uses vertical racks and hydroponics to grow leafy greens and herbs such as basil and peppermint that it sells to nearby bars, restaurants and stores.

The farm's small size belies its big ambition: to help improve the city's food security.

Comcrop's Allan Lim, who set up the rooftop farm five years ago, recently opened a 4,000-square-meter farm with a greenhouse on the edge of the city.

He believes high-tech urban farms are the way ahead for the city, where more land cannot be cultivated.

"Agriculture is not seen as a key sector in Singapore. But we import most of our food, so we are very vulnerable to sudden disruptions in supply," Lim said.

"Land, natural resources and low-cost labor used to be the predominant way that countries achieved food security. But we can use technology to solve any deficiencies," he said.

Singapore last year topped the Economist Intelligence Unit's (EIU) Global Food Security Index of 113 countries for the first time, scoring high on measures such as affordability, availability and safety.

Yet, as the country imports more than 90 percent of its food, its food security is susceptible to climate change and natural resource risks, the EIU noted.

With 5.6 million people in an area three-fifths the size of New York City — and with the population estimated to grow to 6.9 million by 2030 — land is at a premium in Singapore.

The country has long reclaimed land from the sea, and plans to move more of its transport, utilities and storage underground to free up space for housing, offices and greenery.

It has also cleared dozens of cemeteries for homes and highways.

An aerial view shows Citiponics' urban farm located on the rooftop of a multi-story garage in a public housing estate in western Singapore, April 17, 2018.

Agriculture makes up only about 1 percent of its land area, so better use of space is key, said Samina Raja, a professor of urban and regional planning at the University at Buffalo in New York.

"Urban agriculture is increasingly being recognized as a legitimate land use in cities," she said. "It offers a multitude of benefits, from increased food security and improved nutrition to greening of spaces. But food is seldom a part of urban planning."

Supply shocks

Countries across the world are battling the worsening impacts of climate change, water scarcity and population growth to find better ways to feed their people.

Scientists are working on innovations — from gene editing of crops and lab-grown meat to robots and drones — to fundamentally change how food is grown, distributed and eaten.

With more than two-thirds of the world's population forecast to live in cities by 2050, urban agriculture is critical, a study published last year stated.

Urban agriculture currently produces as much as 180 million metric tons of food a year — up to 10 percent of the global output of pulses and vegetables, the study noted.

Additional benefits, such as reduction of the urban heat-island effect, avoided stormwater runoff, nitrogen fixation and energy savings could be worth $160 billion annually, it said.

Countries including China, India, Brazil and Indonesia could benefit significantly from urban agriculture, it said.

"Urban agriculture should not be expected to eliminate food insecurity, but that should not be the only metric," said study co-author Matei Georgescu, a professor of urban planning at Arizona State University.

"It can build social cohesion among residents, improve economic prospects for growers, and have nutritional benefits. In addition, greening cities can help to transition away from traditional concrete jungles," he said.

Singapore was once an agrarian economy that produced nearly all its own food. There were pig farms and durian orchards, and vegetable gardens and chickens in the kampongs, or villages.

But in its push for rapid economic growth after independence in 1965, industrialization took precedence, and most farms were phased out, said Kenny Eng, president of the Kranji Countryside Association, which represents local farmers.

Organic cilantro seedlings sprout from growing towers that are primarily made out of polyvinyl chloride pipes at Citiponics' urban farm on the rooftop of a multi-story garage in a public housing estate in western Singapore, April 17, 2018.

The global food crisis of 2007-08, when prices spiked, causing widespread economic instability and social unrest, may have led the government to rethink its food security strategy to guard against such shocks, Eng said.

"In an age of climate uncertainty and rapid urbanization, there are merits to protecting indigenous agriculture and farmers' livelihoods," he said.

Local production is a core component of the food security road map, according to the Agri-Food and Veterinary Authority (AVA) of Singapore, a state agency that helps farmers upgrade with technical know-how, research and overseas study tours.

Given its land constraints, AVA has also been looking to unlock more spaces, including underutilized or alternative spaces, and harness technological innovations to "grow more with less," a spokeswoman said by email.

Intrinsic value

A visit to the Kranji countryside, just a 45-minute drive from the city's bustling downtown, and where dozens of farms are located, offers a view of the old and the new.

Livestock farms and organic vegetable plots sit alongside vertical farms and climate-controlled greenhouses.

Yet many longtime farmers are fearful of the future, as the government pushes for upgrades and plans to relocate more than 60 farms by 2021 to return land to the military.

Many farms might be forced to shut down, said Chelsea Wan, a second-generation farmer who runs Jurong Frog Farm.

"It's getting tougher because leases are shorter, it's harder to hire workers, and it's expensive to invest in new technologies," she told the Thomson Reuters Foundation.

"We support the government's effort to increase productivity through technology, but we feel sidelined," she said.

Wan is a member of the Kranji Countryside Association, which has tried to spur local interest in farming by welcoming farmers' markets, study tours, homestays and weddings.

Small peri-urban farms at the edge of the city, like those in Kranji, are not just necessary for food security, Eng said.

"The countryside is an inalienable part of our heritage and nation-building, and the farms have an intrinsic value for education, conservation, the community and tourism," he said.

At the rooftop farm on Orchard Road, Lim looks on as brisk, elderly Singaporeans, whom he has hired to get around the worker shortage, harvest, sort and pack the day's output.

"It's not a competition between urban farms and landed farms; it's a question of relevance," he said. "You have to ask: What works best in a city like Singapore?"

Urban Farmer Turns to Crowdfunding to Support Growing Business

A loan would take too long to help, and when someone suggested crowdfunding, the urban farmer saw how much further that small business support could go.

By Sean Evans | January 10, 2019 at 5:04 PM EST - Updated January 10 at 6:50 PM

SAVANNAH, GA (WTOC) - Just blocks from busy Pennsylvania Avenue and not far from the heart of downtown Savannah, there’s a business venture you might not know about, or think could be that close to downtown. In fact, it’s growing so much that its loyal customers and folks who support them are chipping in to help them grow.

“I am the owner and sole employee of Vertu Farm," said Chris Molander.

Molander started Vertu Farm on Savannah’s east side about three years ago after cultivating a passion for farming in high school and college.

“When an opportunity opened up out here at the old dairy farm, I just jumped on it," Molander said, as he picked some of his crops from the ground.