Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Bringing The Future To life In Abu Dhabi

A cluster of shipping containers in a city centre is about the last place you’d expect to find salad growing. Yet for the past year, vertical farming startup Madar Farms has been using this site in Masdar City, Abu Dhabi, to grow leafy green vegetables using 95 per cent less water than traditional agriculture

Amid the deserts of Abu Dhabi, a new wave of entrepreneurs and innovators are sowing the seeds of a more sustainable future.

Image from: Wired

A cluster of shipping containers in a city centre is about the last place you’d expect to find salad growing. Yet for the past year, vertical farming startup Madar Farms has been using this site in Masdar City, Abu Dhabi, to grow leafy green vegetables using 95 per cent less water than traditional agriculture.

Madar Farms is one of a number of agtech startups benefitting from a package of incentives from the Abu Dhabi Investment Office (ADIO) aimed at spurring the development of innovative solutions for sustainable desert farming. The partnership is part of ADIO’s $545 million Innovation Programme dedicated to supporting companies in high-growth areas.

“Abu Dhabi is pressing ahead with our mission to ‘turn the desert green’,” explained H.E. Dr. Tariq Bin Hendi, Director General of ADIO, in November 2020. “We have created an environment where innovative ideas can flourish and the companies we partnered with earlier this year are already propelling the growth of Abu Dhabi’s 24,000 farms.”

The pandemic has made food supply a critical concern across the entire world, combined with the effects of population growth and climate change, which are stretching the capacity of less efficient traditional farming methods. Abu Dhabi’s pioneering efforts to drive agricultural innovation have been gathering pace and look set to produce cutting-edge solutions addressing food security challenges.

Beyond work supporting the application of novel agricultural technologies, Abu Dhabi is also investing in foundational research and development to tackle this growing problem.

In December, the emirate’s recently created Advanced Technology Research Council [ATRC], responsible for defining Abu Dhabi’s R&D strategy and establishing the emirate and the wider UAE as a desired home for advanced technology talent, announced a four-year competition with a $15 million prize for food security research. Launched through ATRC’s project management arm, ASPIRE, in partnership with the XPRIZE Foundation, the award will support the development of environmentally-friendly protein alternatives with the aim to "feed the next billion".

Image from: Madar Farms

Global Challenges, Local Solutions

Food security is far from the only global challenge on the emirate’s R&D menu. In November 2020, the ATRC announced the launch of the Technology Innovation Institute (TII), created to support applied research on the key priorities of quantum research, autonomous robotics, cryptography, advanced materials, digital security, directed energy and secure systems.

“The technologies under development at TII are not randomly selected,” explains the centre’s secretary general Faisal Al Bannai. “This research will complement fields that are of national importance. Quantum technologies and cryptography are crucial for protecting critical infrastructure, for example, while directed energy research has use-cases in healthcare. But beyond this, the technologies and research of TII will have global impact.”

Future research directions will be developed by the ATRC’s ASPIRE pillar, in collaboration with stakeholders from across a diverse range of industry sectors.

“ASPIRE defines the problem, sets milestones, and monitors the progress of the projects,” Al Bannai says. “It will also make impactful decisions related to the selection of research partners and the allocation of funding, to ensure that their R&D priorities align with Abu Dhabi and the UAE's broader development goals.”

Image from: Agritecture

Nurturing Next-Generation Talent

To address these challenges, ATRC’s first initiative is a talent development programme, NexTech, which has begun the recruitment of 125 local researchers, who will work across 31 projects in collaboration with 23 world-leading research centres.

Alongside universities and research institutes from across the US, the UK, Europe and South America, these partners include Abu Dhabi’s own Khalifa University, and Mohamed bin Zayed University of Artificial Intelligence, the world’s first graduate-level institute focused on artificial intelligence.

“Our aim is to up skill the researchers by allowing them to work across various disciplines in collaboration with world-renowned experts,” Al Bannai says.

Beyond academic collaborators, TII is also working with a number of industry partners, such as hyperloop technology company, Virgin Hyperloop. Such industry collaborations, Al Bannai points out, are essential to ensuring that TII research directly tackles relevant problems and has a smooth path to commercial impact in order to fuel job creation across the UAE.

“By engaging with top global talent, universities and research institutions and industry players, TII connects an intellectual community,” he says. “This reinforces Abu Dhabi and the UAE’s status as a global hub for innovation and contributes to the broader development of the knowledge-based economy.”

Jellyfish Barge: The Floating, Modular Greenhouse

Studiomobile and Pnat came up with the Jellyfish Barge which is a floating, modular greenhouse designed especially for coastal communities and can help them cultivate crops without relying on soil, freshwater, and chemical energy consumption

By 2050, the global demand for food is expected to be 60-70% higher than today at the rate our population is increasing. There will be a scarcity of water and cultivable land and we need to solve this issue before we enter a global food crisis.

Agriculture is already being threatened by climate change where in some parts things like rising sea levels are causing floods in fertile land and the weather is making it more challenging to grow crops in other parts. To avoid a major food crisis, we need to come up with alternative solutions for agriculture like this floating greenhouse which can give nature time to recuperate and us some time to switch to more sustainable habits.

Studiomobile and Pnat came up with the Jellyfish Barge which is a floating, modular greenhouse designed especially for coastal communities and can help them cultivate crops without relying on soil, freshwater, and chemical energy consumption.

The innovative greenhouse uses solar energy to purify salt, brackish, or polluted water. There are 7 solar desalination units planted around the perimeter and are able to produce 150 liters (39.6 gallons) of clean freshwater every day from the existing water body the greenhouse is floating on.

The simple materials, easy self-construction, and low-cost technologies make it accessible to many communities who may not have a big fund. The module has a 70 square meter wooden base that floats on 96 recycled plastic drums and supports a glass greenhouse where the crops grow.

Read more at Yanko Design (Ruchi Thukral)

9 Novembert 2020

New Floating Farm Facility in NYC Designed To Withstand Storm Surge

The developer is building a 158,000 square foot floating farm structure located off the Hunts Point food distribution center in the Bronx

The indoor farming industry has been rapidly expanding. With that, we are seeing innovations in design, technology, and products. A principle of indoor farming is around how food can be grown while using land, space, and resources efficiently. In New York City, space is certainly limited and we’ve seen urban farms utilize space in innovative ways. Some examples include rooftop farms like Brooklyn Grange, indoor usage of small spaces like Farm One, and floating demonstration farms like Swale.

Cities that are surrounded by water have been constructing their coastal areas to build structures that are resilient to storm surge. Aqua Ark, an experienced developer for building commercial and residential water-borne structures, believes in the concept of floating cities. Aqua Ark’s most recent water-borne venture is constructing the largest farm in New York City. The developer is building a 158,000 square foot floating farm structure located off the Hunts Point food distribution center in the Bronx. The facility provides up to 4 acres of horizontal growing area, a scale otherwise unattainable in NYC. This is a unique opportunity for farm operators to grow food in such close proximity to the largest food distribution center in the world. The proximity to Hunts Point reduces the impact of transport costs and environmental costs for produce deliveries.

Being a coastal city, New York City is susceptible to flooding and stormwater surge. The city is still rebuilding from the aftermath of Hurricane Sandy in 2012. The storm brought to light the realities of climate change and rising sea levels for developers and urban planners. The hurricane highlighted Hunts Point distribution center's “vulnerability to rising flood waters and to power outages that could be caused by extreme heat waves or infrastructure failures.” Thus, Hunts Point has become a priority zone to invest in the area and protect it from multiple risk factors. The City of New York has made coastal protection the top priority for the Hunts Point resiliency project. The Waterborne Farm facility was designed to withstand the effects of storm surge. During extreme surges the facility rises, staying secured in place until the surge recedes ensuring no structural damage will occur.

The water environment also provides benefits for energy savings from reduced heating and cooling costs. Through water mass heat pumps and the possible use of extra heat from a nearby water treatment plant, savings of 30-70% on heating costs and 20-50% on cooling costs are feasible, as shown by data from the United States Environmental Protection Agency. The energy efficiency of the facility is specifically important for this region which suffers from the highest levels of air pollution in New York City. Additionally, because this site will be located on the water, there are minimal obstructions to natural light, a benefit that brings with it more potential cost savings.

Aqua Ark is seeking applicants from potential farming operators around the world wishing to lease the facility. The facility is a blank canvas where Aqua Ark is willing to work with the tenant to customize a design to accommodate any type of indoor farming operation, whether that’s a vertical farm, greenhouse, aquaponics or another growing system.

To be eligible, you must have experience opening and operating a large scale indoor farm and or qualifications of staff and supervision to manage and maintain a class A indoor farm proof of financial viability.

For more information:

Agritecture

Yara Nagi

yara@agritecture.com

www.agritecture.com

Publication date: Tue 21 Jan 2020

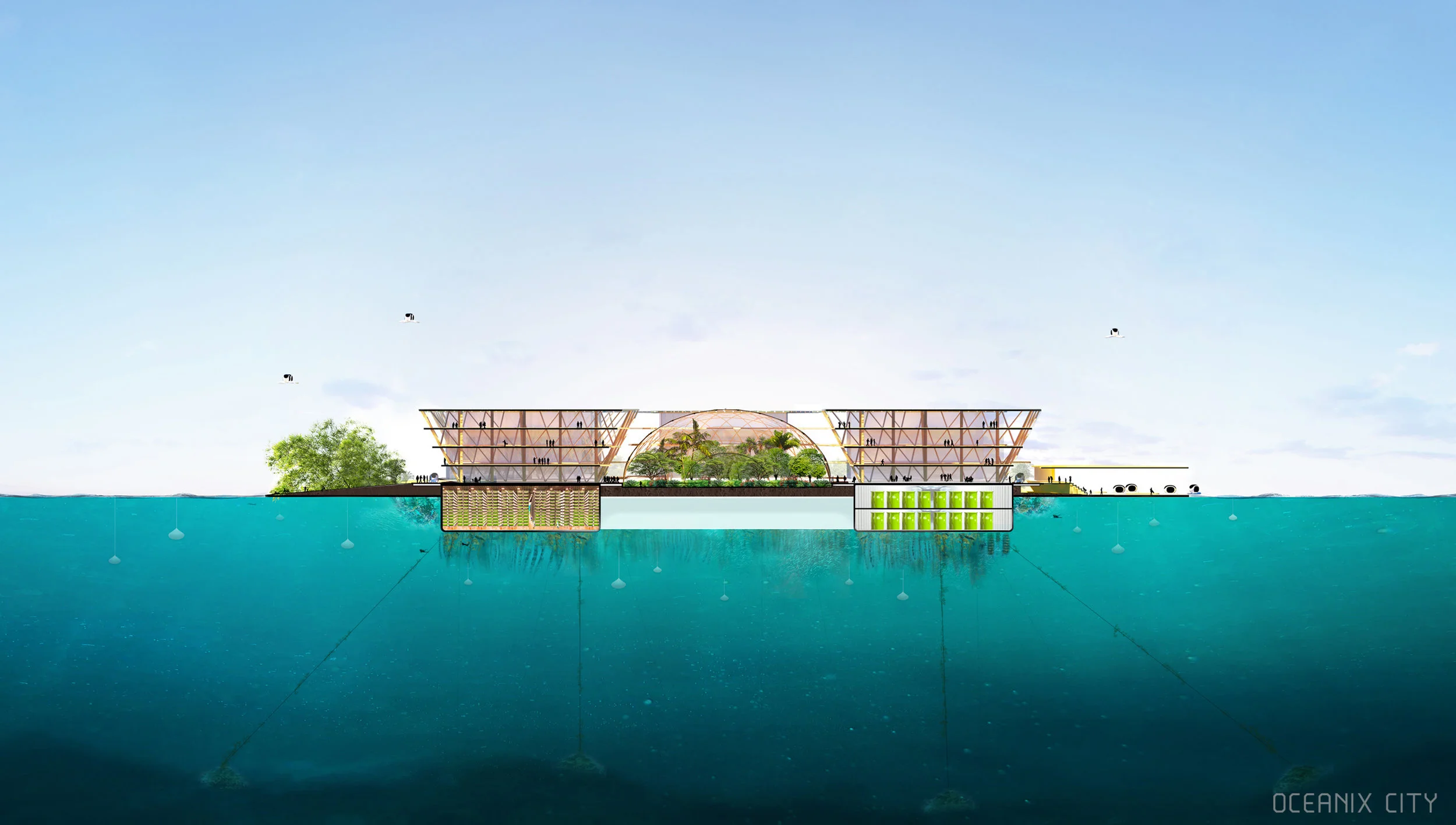

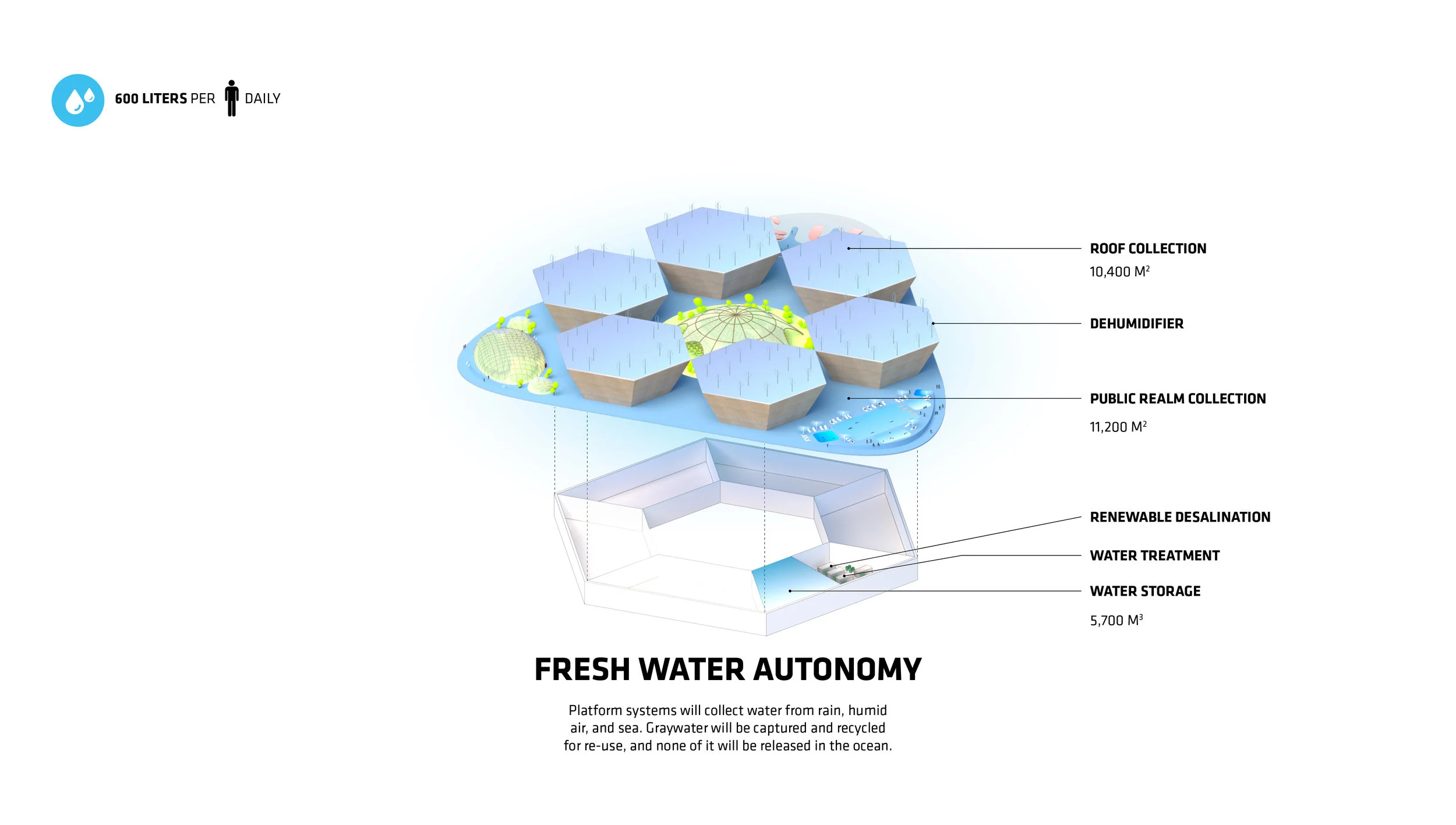

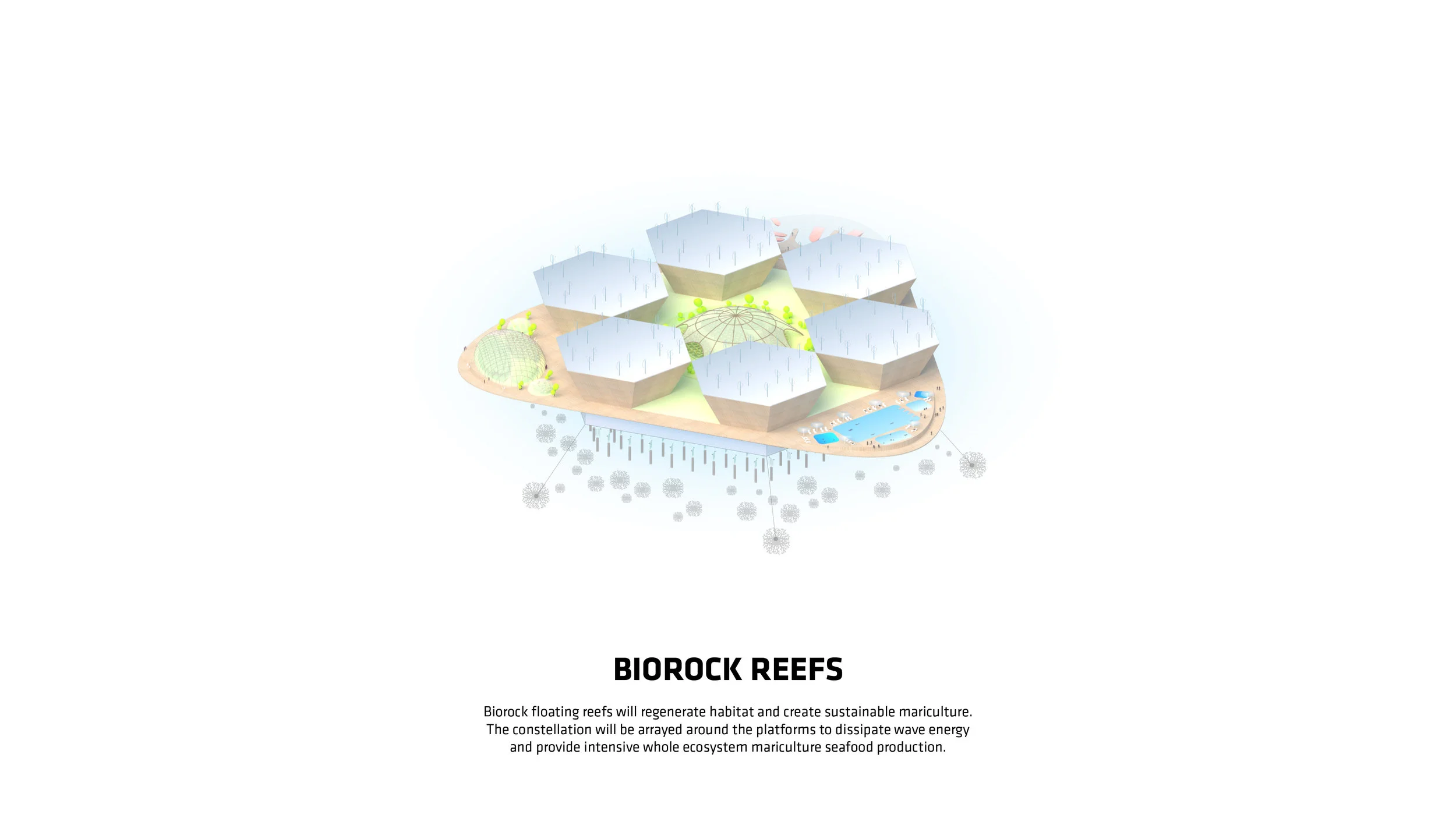

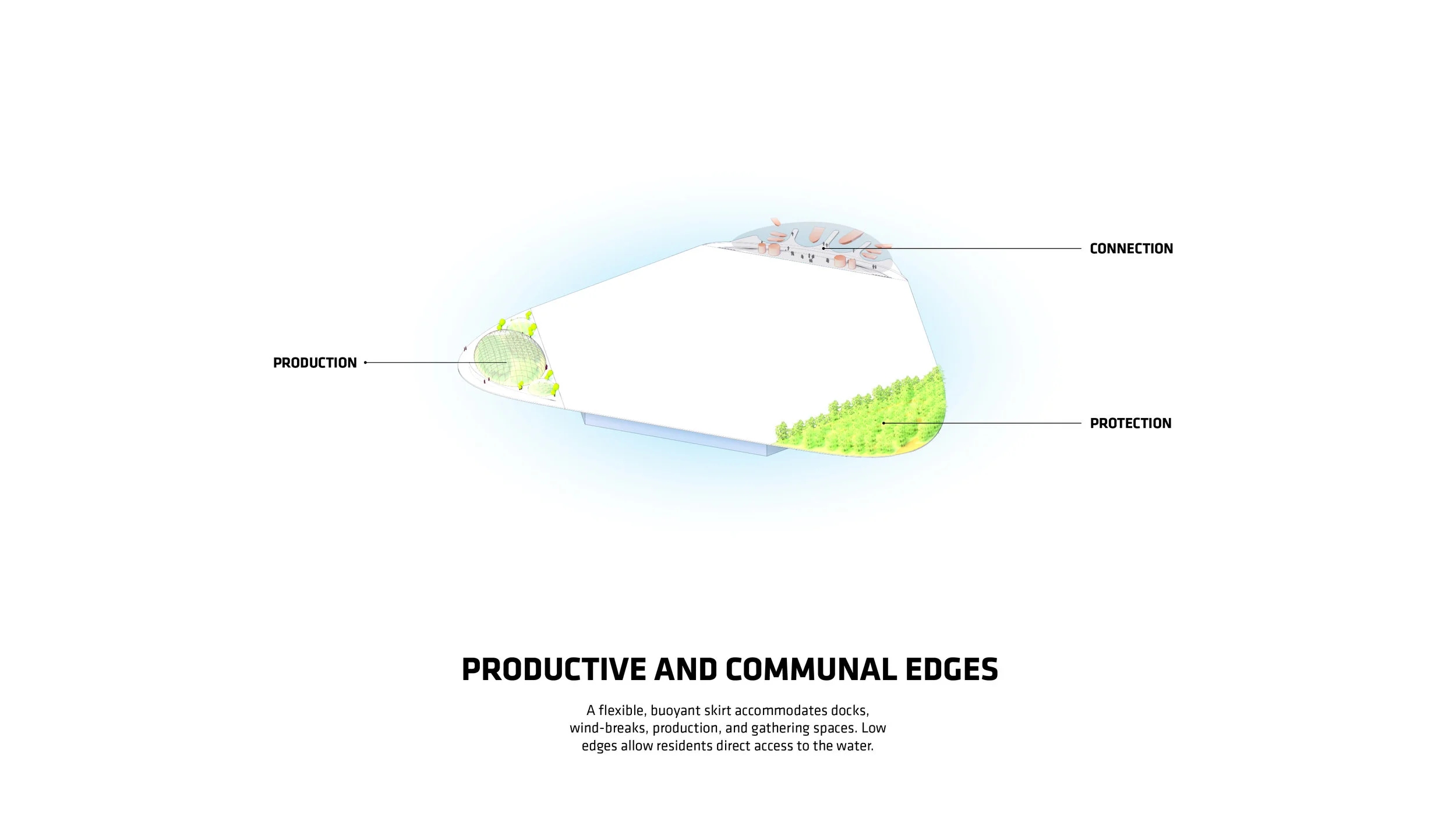

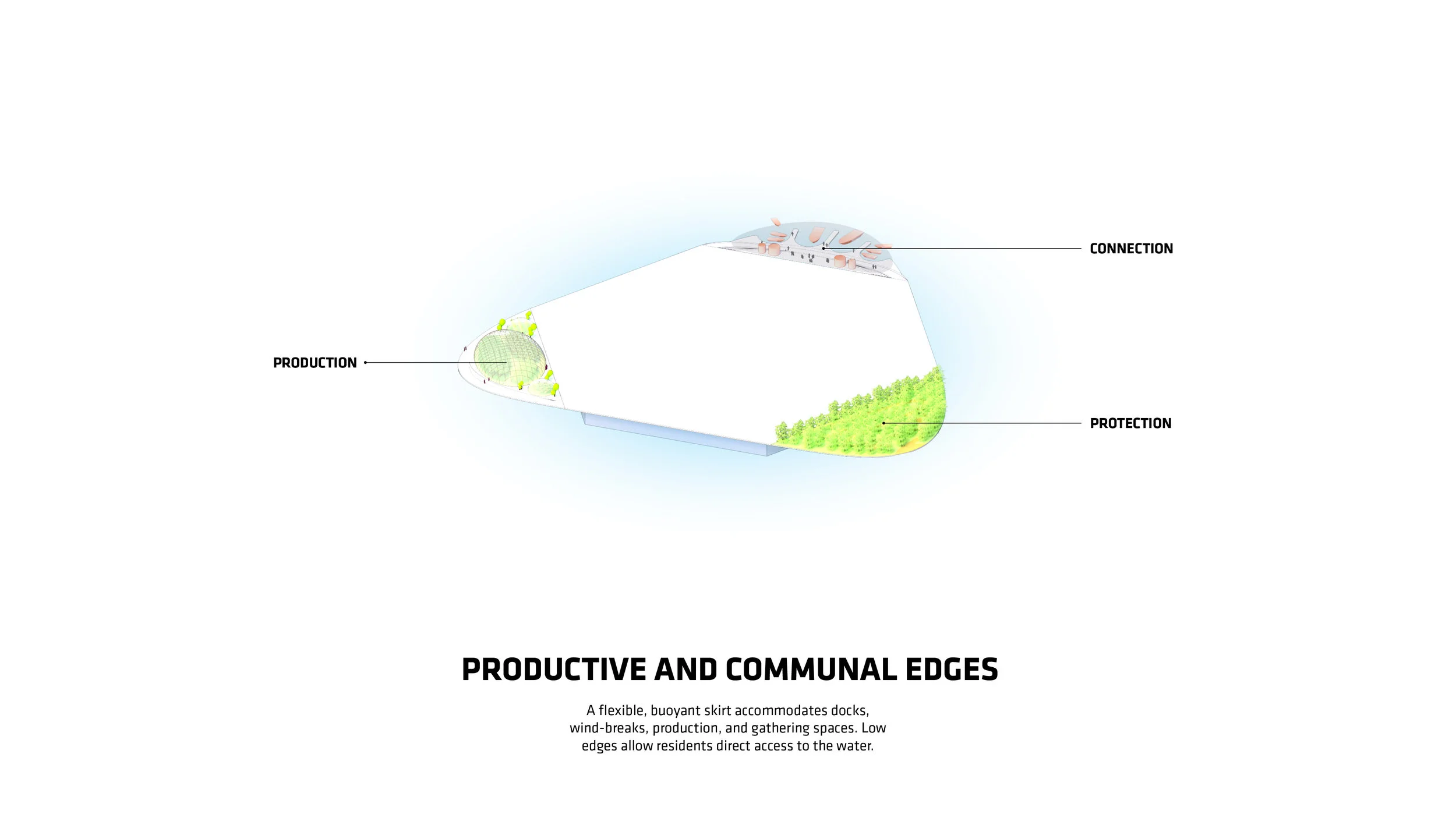

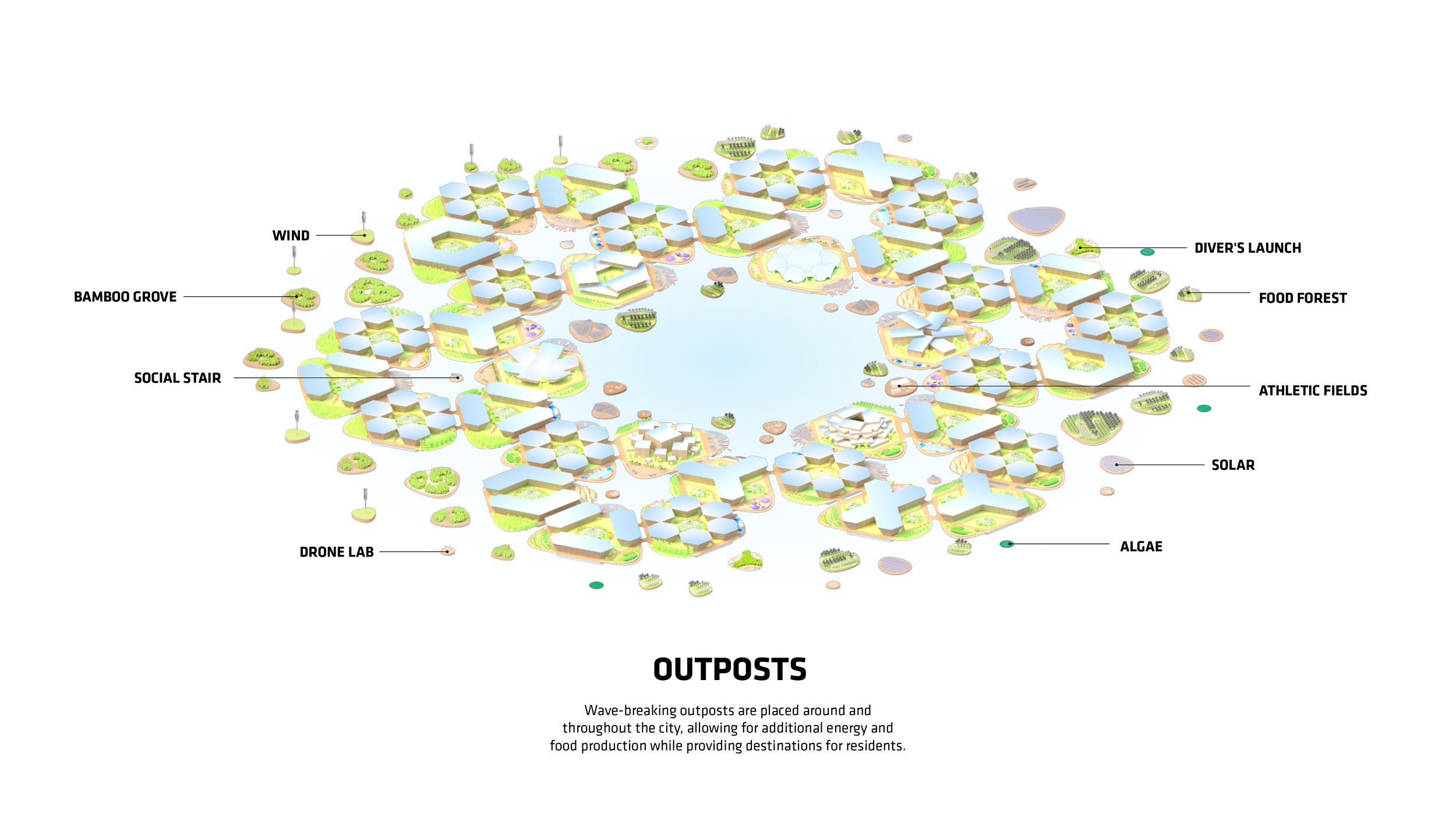

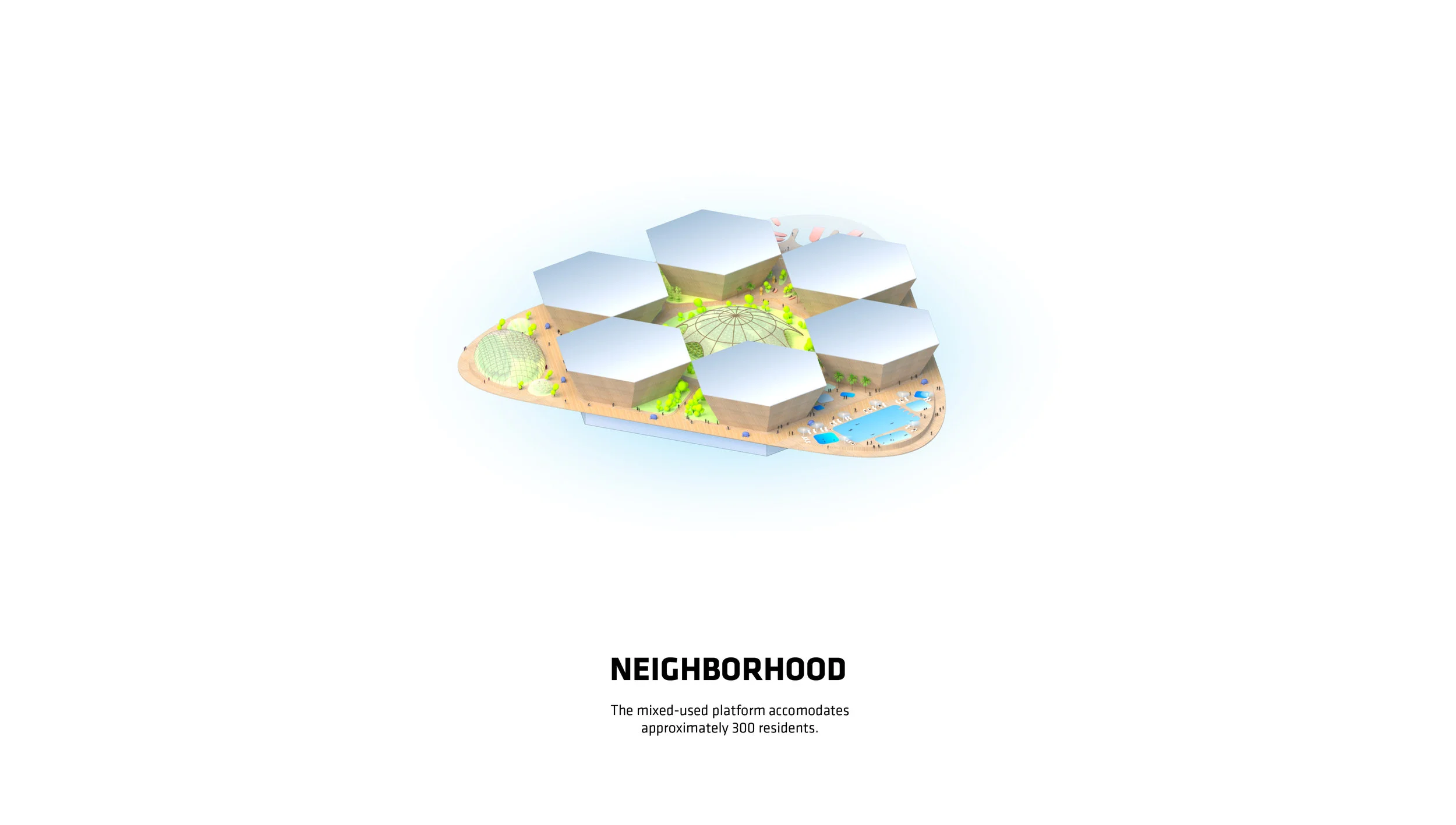

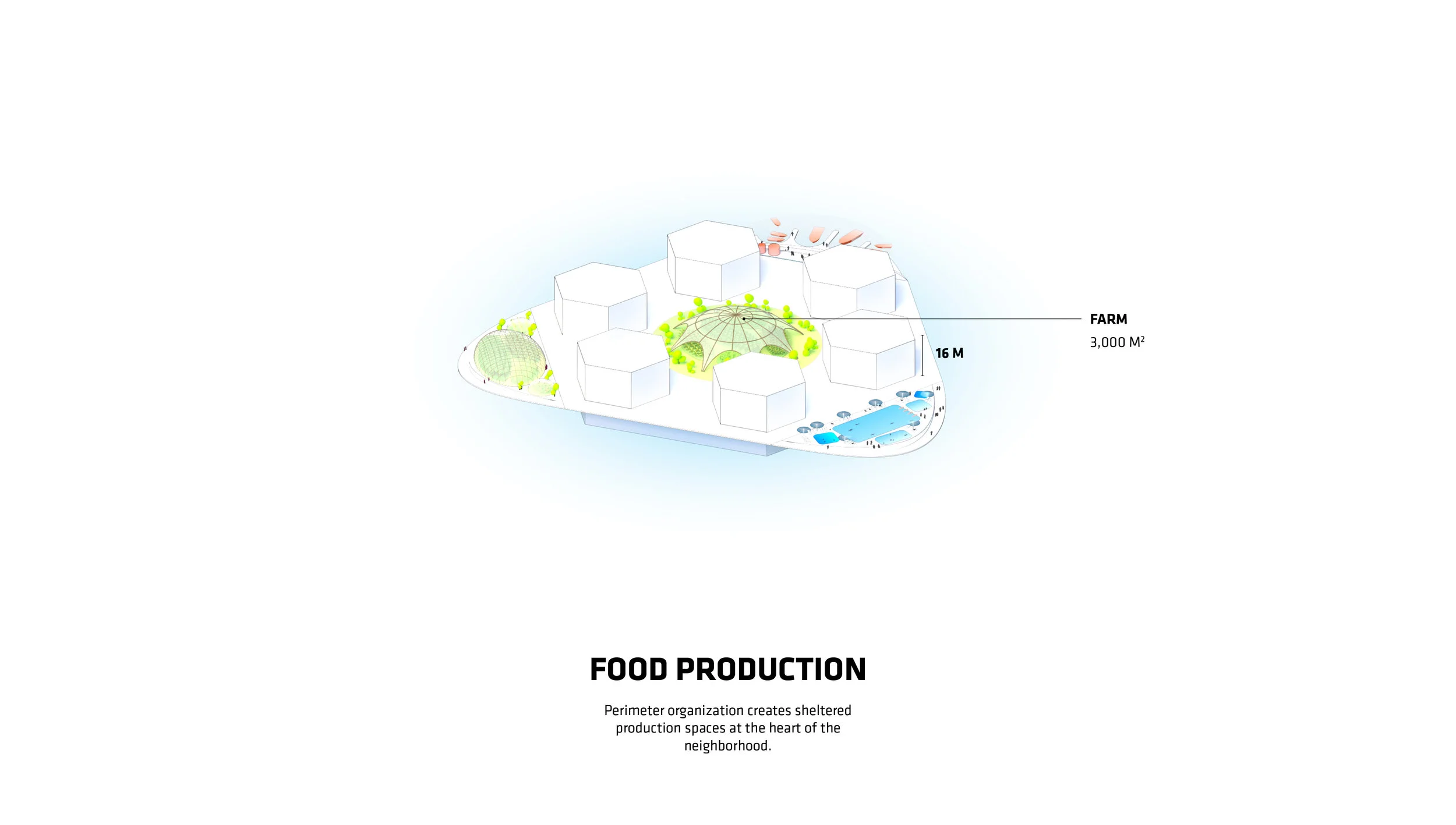

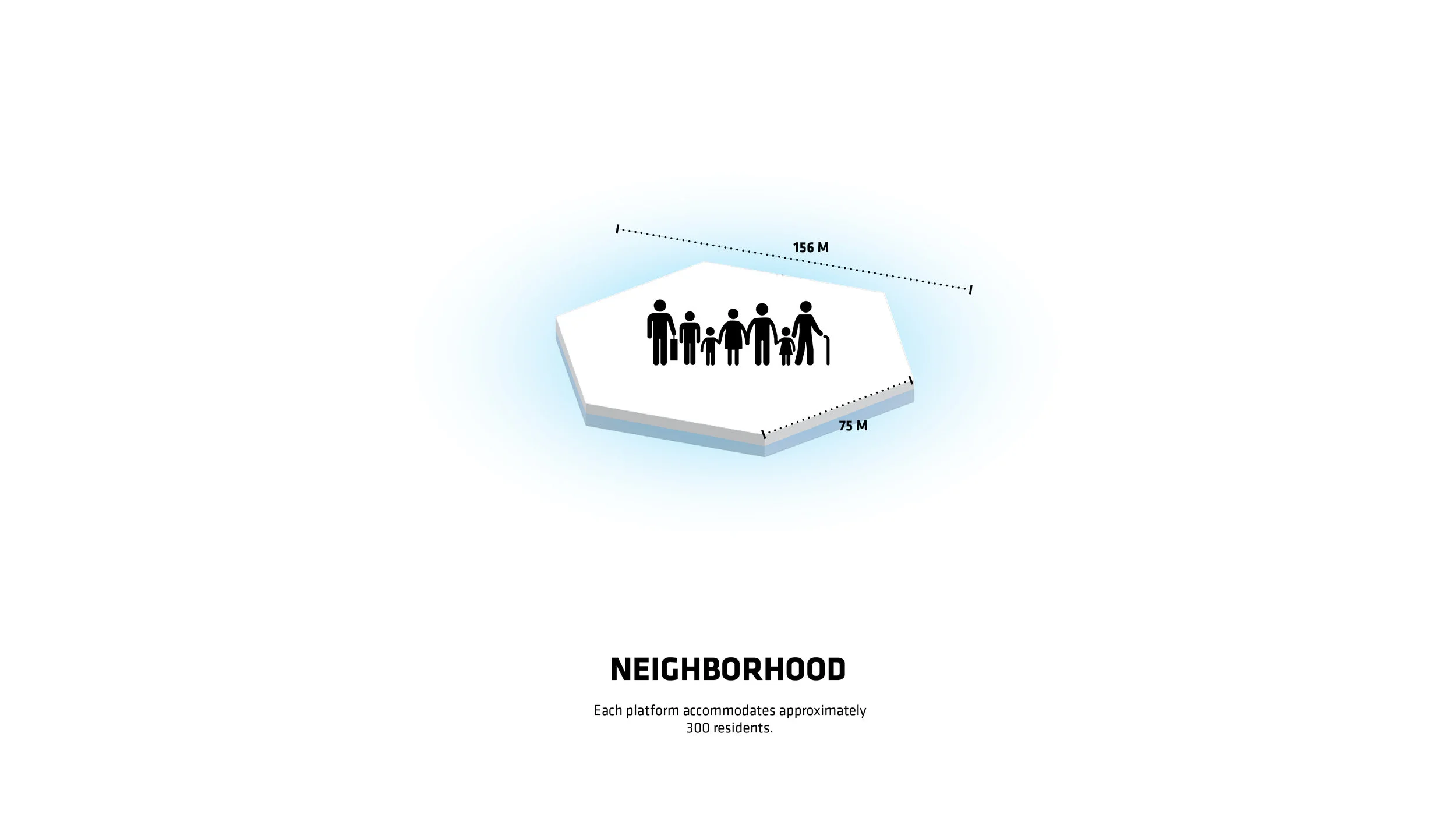

Oceanix City: This Concept Of Floating City Includes Food Production And Farming

Linked by Michael Levenston

“Every island has 3,000 square metres of outdoor agriculture that will also be designed so that it can be enjoyed as free space,” said Ingels.

By Katharine Schwab

Fast Company

Apr 4, 2019

Excerpt:

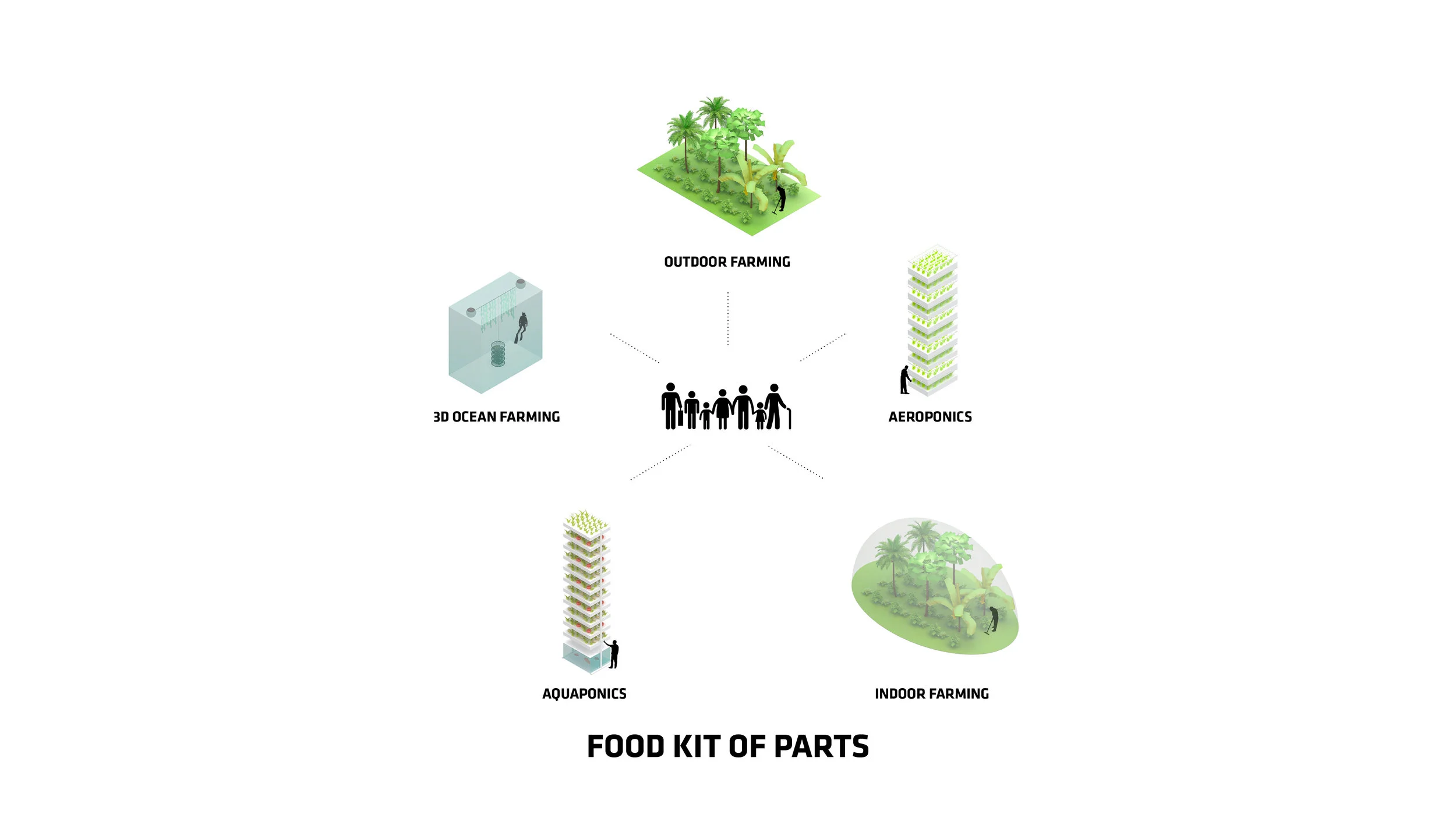

For Oceanix’s idea to work, all the food needed to feed every person living in the floating city would need to be grown there. What does that mean? There’s certainly no meat involved, mostly because beans are a far more efficient way of getting protein. Some crops would be grown outdoors–an estimated 32,000 square feet on each hexagon would be devoted to food cultivation. Much of that would be outdoors, since the sun uses the least amount of stored energy, and the crops would double as green space for residents.

But according to Clare Miflin, the cofounder of the Center for Zero Waste Design, a floating city would also need to experiment with other ways of growing food. One possibility: outdoor vertical farming for crops like lettuce. Then there’s hydroponics and aeroponics, the latter of which uses 10 times less water than traditional farming simply by spraying plant roots with mist. Aquaponics, in which plants grow hydroponically and are fertilized with fish waste, has a deep precedent–the Aztecs used aquaponic farming on their own floating agricultural islands many centuries ago.

With food comes food waste. Miflin wants to create a circular system where all food waste is turned into nutrients for the soil through composting. Food waste would go through a pneumatic system of pipes directly to an anaerobic digester to start the composting process. But there’s also the problem of packaging. Miflin believes that it would be crucial for the floating city to only use reusable food containers, with centrally located drop-off points for people to put their empty containers; from there, they could be cleaned centrally and reused.

Read the complete article here.

The World's First Floating Farm Making Waves In Rotterdam

By Simon Fry

Technology of Business Reporter

August 16, 2018

The floating farm will start with about 40 cows milked by robots | LELY

The world's first offshore dairy farm opens in the Port of Rotterdam this year, with the aim of helping the city produce more of its own food sustainably. But will such farms ever be able to produce enough to feed the world's growing urban populations?

A Dutch property company, Beladon, is launching the world's first "floating farm" in a city port.

It has built the offshore facility right in the middle of Rotterdam's Merwehaven harbour and will use it to farm 40 Meuse-Rhine-Issel cows milked by robots.

Built-up urban areas may not seem like the most sensible places to run farms, but reducing the distance food travels before it reaches consumers' plates makes environmental sense as it reduces transport pollution.

And if the global population grows to 9.8 billion by 2050 as expected, 70% are forecast to live in cities - up from 55% today.

An artist's impression of how Beladon's floating farm will look when finished

FLOATING FARM

So urban indoor farms, where produce is grown vertically on stacks of shelves under ultraviolet lights, are - literally - on the rise.

Beladon's farm, which is on three levels and is anchored to the ocean floor, is expected to open at the end of 2018 and produce about 800 litres of milk a day.

Peter van Wingerden, an engineer at Beladon, came up with the idea in 2012 when he was in New York working on a floating housing project on the Hudson river.

While there, Hurricane Sandy struck, flooding the city streets and crippling its transport networks. Deliveries struggled to get through and within two days it was hard to find fresh produce in shops.

"Seeing the devastation caused by Hurricane Sandy I was struck by the need for food to be produced as near as possible to consumers," says Mr van Wingerden.

Minke van Wingerden thinks floating farms have great potential for cities built near water | JAN VAN DER MEIJDE

"So the idea came up to produce fresh food in a climate-adaptive way on the water."

The concept would be resilient against hurricanes, too, he adds.

At first, people thought the idea was "weird, funny or unbelievable", he says, but they have started to come round.

"With increasing demand for healthy food, fast-growing urbanisation and climate change, we can't rely on the food production systems of the past any more," he says.

Later in 2012, his team began working on the design and talking to the Port Authority in Rotterdam. Despite its initial hesitations about the potential noise and smell, the port gave Beladon a space to build a prototype.

Since then the farm has taken shape, and earlier this summer its floating platform was moved by barge from Zaandam in the north of Holland, to Rotterdam.

Peter's wife and business partner, Minke van Wingerden, says the farm will start with 40 cows, enough for the venture to break even. But she says it is "easily scalable", with larger operations promising "obvious efficiencies".

The farm also aims to reuse and recycle as much as it can.

"At least 80% of what our cows eat will be waste products from Rotterdam's food industry," says the farm's general manager, Albert Boersen.

That might include grains discarded by local breweries, leftovers from restaurants and cafes, by-products from local wheat mills, and even grass clippings, all collected and delivered in electric trucks provided by local "green waste" firm GroenCollect.

"We will grow duckweed as an animal feed, too," says Ms van Wingerden. "It is high in protein, fast-growing and can be nurtured with cow urine. We will have an installation of four or five vertical platforms growing the plant under special LED lights."

Waste fodder for the cows will be collected from restaurants and breweries in electric vans | THE FLOATING FARM

The project will even generate some of its own energy - hydrogen produced through electrolysis powered by solar panels.

Once up and running, the farm will produce and pasteurize milk and yogurt on-site and sell it in Rotterdam. It will also process and sell its own cow manure.

Dr. Fenton Beed, a team leader at the UN's Food and Agriculture Organisation, thinks urban farms are useful because they tend to use less water, fertilizer, and pesticide than conventional production systems.

But he also acknowledges that space limitations may prevent enough food being produced to supply the world's burgeoning urban populations.

"Constraints to producing food in controlled environments include costs for initial investment, LED lighting and continuous energy supplies," says Dr Beed.

"That means that unless policies incentivize the engagement of smaller producers, this technology will be reserved for income-rich private and public entities."

Plenty grows its crops vertically indoors | PLENTY

But such concerns aren't stopping companies like Plenty from attracting significant investment.

The San Francisco-based start-up produces leafy greens in indoor farms and claims it can grow up to 350 times more per square metre than outdoor field farms.

Its crops are grown on six-metre vertical poles, using hydroponics - a water-only feeding system - and LED lights. No soil or pesticides are used. Infrared sensors monitor how the crops are faring so that the system can adjust light, heat and water flow accordingly.

Since it was founded in 2013, Plenty has raised $226m (£177m) from investors such as Amazon's Jeff Bezos, SoftBank's Vision Fund and Innovation Endeavors. This year it will expand its US operations and open its first farm in the Middle East.

Spread's Techno Farm concept is attracting investment | SPREAD

Japan's Spread is another firm developing automated vegetable-growing in vertical urban settings with its Techno Farm concept.

Back in the Netherlands, Peter and Minke van Wingerden are looking at opportunities to build more floating farms around the country, as well as in Asia.

"We hope to make many more floating farms, but also welcome others copying us or coming up with concepts contributing to these goals," says Mr van Wingerden.

"Healthy, sufficient food production is key to a better, cleaner, safer world."

Related Topics

The New Borders of Floating Farms

The New Borders of Floating Farms

The latest development in urban gardening comes from the Netherlands: here's a closer look at the Beladon project in Rotterdam.

By Monica Rossi on April 25, 2017

While there has been a lot of talk recently about vertical farming, which has made locally grown produce and earth friendliness into a movement as well as a business, the latest development in urban gardening comes from the Netherlands.

It all springs from a fact that is so obvious as to be almost banal: 71% of the earth's surface is covered with water and of this 97% is made up of oceans. So why not exploit these immense unutilised areas to build floating farms?

In Rotterdam, a project beyond the concept of “urban farm”

Imagine a specific area in one of the most important European port cities. Then imagine seeing a multi-story floating platform able to supply the city with local produce without occupying as much as a hectare of land.

What you see is the project created by Beladon, who specialise in floating constructions, in collaboration with the Dutch food farming institute Courage and the Uit Je Eigen Stad, which manages urban farms in Rotterdam.

But what makes this project different, for instance, from that of Singapore? "Our project is a further development of the urban farm concept," explains Minke van Wingerden, a company partner. "Here, we do not just grow vegetables: the farm can actually supply us with very fresh milk, cheese, butter and yogurt, all produced on the spot. Anyone can go along to the ‘field’ and buy whatever they need, seven days a week, and visit the farm at the same time.

"This project is able to satisfy the food requirements of big cities because it is modular and may easily be extended in height and width. We are convinced that it can provide an answer to an ever growing demand for food in a world whose population continues to increase, as well as being a winning formula for reducing pollution."

Floating Farm Rotterdam from Eline Wieland on Vimeo.

In practical terms, this means that not only are solar panels and wind turbines used to power the farm, but all rainwater will be reused and the cows’ urine will not be simply disposed of, but purified to irrigate the grass of the floating fields. Even manure will be recovered and used by farms in the city outskirts.

In brief, a perfect example of circular economy that is already paving the way for further initiatives – greenhouses for growing vegetables and breeding farmyard animals such as egg-laying hens, also in Rotterdam and with the same players. “Before that happens, though, we need to complete the pilot project which will be finished and handed over to the city in November 2017,” van Wingerden points out.

And where there is no water available?

"Our floating farm concept," the company executives explain, "is easy to replicate wherever there is water. On a lake, for instance or a river system. Even where water is scarce or the stretch of water is insufficient, we can build vertically on dry land to occupy less space, which can then be allocated to other activities.”

However, once conceived and planned, projects sych as these must be completed. Many projects in fact, despite the praise they receive, never go further than the drawing board stage. Such as the Smart Floating Farm by Barcelona's Forward Thinking Architecture.

"The Catalan project has not got off the ground yet," Minke tells us. "We are, however, in contact with its creators.” Beladon could in fact join forces with the Spanish designers, whose floating farm has been conceived for growing vegetables using hydroponic techniques (on intermediary floors), fish farming (on “ground” level), comprising fish egg nurseries and energy production by solar panels (roofing), where rainwater could also be collected.

Where, on the other hand, there is plenty of water and sheltered space

Have you ever heard of a project by a London-based student who suggests exploiting cargo ships for creating itinerant vegetable farms? According to Philippe Hohlfeld of London's Royal College of Art (RCA) over 70% of consumer goods are now transported by sea (from Asia to the rest of the world and back).

More often than not, the cargo ships are empty on their return voyage. “And so," the student poses the question to the press, "why not transform the empty containers into hydroponic vegetable farms?" This idea, dubbed Grow Frame suggests putting 13 million containers to good use, which otherwise would transport nothing but air.

And then we have the sea depths

While Hohlfeld is still seeking funds to get his prototype off the ground, in Italy’s bay of Noli (near Savona) the first underwater farm is already operational, housed in special glasshouses (looking like transparent vinyl bubbles) positioned at a depth of eight to 10 metres.

This initiative, based on an idea conceived by Sergio Gamberini of the Ocean Reef Group, a company specialising in the production of underwater equipment, located in California as well as Liguria, has made it possible to farm in the undersea space in front of the bay, thanks to eight biospheres. Nemo’s Garden, as the project is called, was implemented in 2012 and in late 2016 it was possible to taste the fruits of the first basil grown under the sea.

Incidentally, starred chef Davide Pezzuto (of the Heinz Beck school), has introduced it to the menu of the D.one ristorante diffuso in Montepagano (Teramo). Foodies and chefs agree that this basil has sublime aromatic properties. Without forgetting that it is 100% organic: parasites are unable to penetrate the sea depths and consequently there is no need for pesticides.

But you may be wondering how the glasshouses work. During the day, the temperature of the air contained in the biospheres increases by a few degrees and, since the sea water is colder, condensation forms inside the sphere and trickles down the walls in the form of freshwater.

Besides, since the daytime and night-time temperatures do not vary greatly, the temperature within the biospheres remains constantly around 25°C. The results have been so positive that Gamberini and partners have been induced to start growing thyme, oregano, strawberries, peas, garlic, lettuce and nasturtiums.