Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

AppHarvest Taps Amazon Veteran Mark Keller To Operationalize AI-Informed Farm Operating System

AgTech leader AppHarvest, a public benefit company and certified B Corporation focused on farming more sustainably using 90% less water than open-field agriculture and only recycled rainwater, has named Amazon veteran Mark Keller as its SVP, Software Applications Platform.

July 26, 2021

Keller joins the AppHarvest technology group as SVP, Software Applications Platform, with a proven track record of building AWS services and high-performing teams

AgTech leader AppHarvest (NASDAQ: APPH, APPHW), a public benefit company and certified B Corporation focused on farming more sustainably using 90% less water than open-field agriculture and only recycled rainwater, has named Amazon veteran Mark Keller as its SVP, Software Applications Platform. Keller joins the AppHarvest technology group as it works to operationalize its Project TalOS platform to make fresh fruit and vegetable production as reliable as consumer goods manufacturing.

To create the Farm of the Future, AppHarvest is investing in robotics, artificial intelligence, tele-operation, and proprietary seed genetics. With robots roving through the facility alongside the company’s human labor force, interacting with and caring for the crops, the company will be collecting data continuously on plant production to feed into AI and then using software to align facility operations with sales and logistics.

“We are massively expanding our team to build out our digital operating model for farming, which has AI at its core that can manage a global network of facilities and effortlessly execute complex supply chain strategies intelligently and autonomously,” said Josh Lessing, AppHarvest chief technology officer. “Adding an industry veteran like Mark will be a true game-changer for this growth phase of our business, and his strong, people-centric leadership skills will be a key enabler for the AppHarvest technology group.”

Keller has a proven record spanning more than 25 years of turning ideas into full-featured technology solutions, such as launching Amazon’s first four large-scale Kiva robotics sortable warehouses and the PrimeNow Warehouse Management Software used to run the company’s one-hour fulfillment centers.

“The Holy Grail in agriculture is predicting and managing yield and quality,” said AppHarvest founder and CEO Jonathan Webb. “Having Mark join will accelerate our efforts as we train our intelligent robot, Virgo, to harvest multiple crops—ranging from tomatoes and cucumbers to more delicate fruits such as strawberries—as we move toward more AI-informed growing. These insights collected and analyzed, then fed into AI, will be the true game-changer for us since every piece of fruit is an outcome that resulted from the many variables in the growing process.”

“Two of the most pressing global concerns are water scarcity and creating resilient food supply, and AppHarvest is solving for both,” said Keller. “As a father of four, I want to leave a strong legacy for my children and leverage technology for good. The foundation AppHarvest is building will give controlled environment agriculture the opportunity to restructure the food landscape to mirror the hyper-efficient e-commerce landscape.”

Keller is a Hispanic Gulf-War veteran who brings a unique perspective to employee engagement programs being an early driver of the Amazon Warriors veterans employee group and having participated in the Latinos @ Amazon employee group. Keller also was an early adopter of the Military Apprentice Software Development Engineer program to improve diversity hiring in technology, which he expects to continue at AppHarvest.

About AppHarvest

AppHarvest is an applied technology company in Appalachia developing and operating some of the world’s largest high-tech indoor farms, designed to grow non-GMO, chemical pesticide-free produce, using up to 90 percent less water than open-field agriculture and only recycled rainwater while producing yields up to 30 times that of traditional agriculture on the same amount of land without agricultural runoff. The company combines conventional agricultural techniques with cutting-edge technology including artificial intelligence and robotics to improve access for all to nutritious food, farming more sustainably, building a domestic food supply, and increasing investment in Appalachia. The company’s 60-acre Morehead, Ky. facility is among the largest indoor farms in the U.S. For more information, visit https://www.appharvest.com/.

Grōv Technologies Signs Definitive Agreement With Superior Farms

Agtech and indoor farming company, Grōv Technologies, today announced a definitive agreement with California-based Superior Farms for the purchase of 10 Olympus Tower Farms that will produce fresh year-round feed for Superior’s upcoming Sheep Discovery Center™ in Central Utah

July 12, 2021

Vineyard — Agtech and indoor farming company, Grōv Technologies, today announced a definitive agreement with California-based Superior Farms for the purchase of 10 Olympus Tower Farms that will produce fresh year-round feed for Superior’s upcoming Sheep Discovery Center™ in Central Utah. Grōv is part of Superior Farms’ efforts to dramatically improve the sustainability and growth of US lamb production.

The ten Olympus Tower Farms will produce 60,000 pounds of Grōv’s fresh High-Density Nutrient (HDN) Superfeed wheatgrass a day using less than 5 percent of the water needed for field-grown fodder, without the use of pesticides or herbicides.

The Sheep Discovery Center is a new venture of Superior Farms. The goal of the Discovery Center is to showcase how sustainably focused science and technology can help farmers increase their flocks and consistently produce high-quality lamb.

“Our collaboration with Superior showcases how Grōv indoor ag technology can benefit farmers who want to improve production and sustainability, and minimize risk, especially as it relates to drought conditions that plague regions across the world,” says Steve Lindsley, president of Grōv Technologies. “The innovative thinking of Superior Farms is right in line with our efforts to provide feed security for animals and food security for growing populations.”

Leveraging Grōv’s indoor Olympus Tower Farms to grow fresh HDN feed, Superior Farms intends to optimize nutrition and environmental conditions to help support animal health during the lambing cycle. Superior Farms will also implement Grōv’s seasonal lighting technology as part of Superior’s efforts to improve the productivity of their sheep and provide a more consistent lamb supply throughout the year.

“The current Western U.S. megadrought is pushing farmers to ration their natural resources and find innovative ways to give their animals a more sustainable and nutrient-rich environment,” says Rick Stott, CEO of Superior Farms. “Feeding sheep with Grōv HDN opens up new opportunities for sheep farmers and gives them a way to overcome the water issues affecting their flocks.”

During the Covid pandemic, more consumers tried lamb for the first time and continued to purchase it throughout the year. The US lamb industry expects demand to keep rising as the number of new consumers who are more familiar with lamb continues to grow.

For more information about Grōv Technologies please visit www.Grōvtech.com.

About Grōv Technologies, LLC

Grōv Technologies is pioneering next-generation indoor agriculture technology and science to help meet the demand for global food and animal feed security. The company has developed enterprise-scale, automated controlled environment agriculture (CEA) systems to grow high-density nutrient animal feed and other crops using significantly less water and resources than traditional farming. These systems utilize patented low-heat LED technology, seed-to-harvest robotics, and data-driven scientifically proven indoor growing protocols. Grōv also operates an LED lighting and power management subsidiary, Stellar Smart Energy Solutions, using proprietary Wave Power Transformation and power management networking technology for commercial and agricultural facilities. Grōv is wholly owned by Nu Skin Enterprises, Inc. (NYSE: NUS), which develops and distributes a comprehensive line of premium-quality beauty and wellness solutions through a global network of sales leaders.

About Superior Farms

Superior Farms, the leading purveyor of sustainably raised, ranch-to-table American lamb. Proudly providing the highest quality natural lamb for a variety of recipes from weeknight dinners to Sunday brunch, lunches, and more, Superior Farms offers a range of premium cuts. From the mountains of Utah, the brisk winters of Minnesota, and the shores of California, Superior Farms prides itself on working exclusively with family ranchers who raise lambs with the best care and commitment to quality wellbeing and stable environment. Respecting a nutrient-rich land, maintaining a sustainable footprint, and working with dedicated family ranchers who raise flocks with the highest level of care, all are core values that make Superior Farms the leader in American lamb. From the plant floor to the corner office, Superior Farms is also proud to be 100 percent owned by its dedicated and talented employees. For more information, visit www.superiorfarms.com, order home delivery at www.superior-farms.com, or follow the brand on Instagram (@SuperiorFarms) and Facebook (@SuperiorFarms).

HPNow And Kaneya Sign HPGen™ Distribution Agreement For Japanese High-Tech Horticulture Market

Agreement will provide Japan’s cutting-edge horticulture growers with access to HPGen™ benefits in autonomous, safe, and sustainable irrigation water treatment

COPENHAGEN, DENMARK, and MINAMICHITA, JAPAN (July 15, 2021) – HPNow, a global provider of HPGen™ Peroxide UltraPure™ on-site generation solutions, and Kaneya, Japan’s leading distributor of advanced horticulture inputs and solutions, are pleased to announce the signing of an HPGen™ distribution agreement for the Japanese market.

The Kaneya team with the HPGen™ system

Kaneya is a leader in the horticulture industry in Japan. The company has a large international network, and its mission as a distributor of high-end greenhouses and related equipment and inputs is to contribute to the future of advanced horticulture. The HPGen™ systems will play key role in supporting the company’s vision. Kaneya is active in 10 countries, and also operates its own high-tech greenhouse.

The distribution agreement will give Japan access to HPNow’s patented technology solution for autonomous, safe, and sustainable on-site generation of ultrapure hydrogen peroxide. HPGen has already proven strong effectiveness in agriculture operations around the world, providing for improved crop protection and reduced irrigation system maintenance across a wide range of crops, cultivation methods, and climates. Many HPGen customers further report increased crop yields.

“We’re very pleased to be working together with such an esteemed company as Kaneya,” comments Ziv Gottesfeld, CEO of HPNow. “Japan is at the forefront of controlled-environment agriculture, and this agreement is illustrative of the confidence the industry has in our products to support its cutting-edge cultivation methods.”

“We are looking forward to a strong collaboration with HPNow in the Japanese market,” adds Kazuta Aoyama, International Sales and Business Development Manager with Kaneya. “The HPGen technology offers exciting benefits to Japanese growers, which they will be eager to integrate into their operations.”

About Kaneya

Celebrating its golden anniversary, Kaneya is a leading horticultural and agricultural solution provider, selling and distributing products that range from its core, technologically advanced offering of plastic pots and trays, to a variety of other related products produced by leading horticulture companies around the world, including substrate, seeds, and plants, greenhouse equipment, fertilizer, etc. With more than 12,000 customers on record, and some 5,000 active, satisfied, and fiercely loyal active customers, Kaneya operates throughout Japan and exports its products to 10 countries, and has established itself as a global force in the horticulture industry.

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas, and Asia, they address their clients’ water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in on-site generation of hydrogen peroxide and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn and Facebook.

How AgriTech Is Playing A Key Role In Greenhouse Vegetable Production

In this exclusive interview with Greenhouse Grower, Gov. Beshear provides a closer look at the AgriTech Initiative and how companies like Kentucky Fresh Harvest are building a brighter future for the commonwealth

June 2, 2021

Editor’s Note: This is the last of a four-part series covering of growth of Kentucky Fresh Harvest as it prepares for its first crop. Check out the previous parts of the series here.

In support of Kentucky Gov. Andy Beshear’s vision of a diverse and resilient agricultural industry in Kentucky, one of the keys to the long-term growth plan of Kentucky Fresh Harvest is its involvement with the Kentucky AgriTech Initiative. This initiative is designed to highlight Kentucky’s unique position to offer an environment that can attract, develop, and sustain agritech-related enterprises.

In this exclusive interview with Greenhouse Grower, Gov. Beshear provides a closer look at the AgriTech Initiative and how companies like Kentucky Fresh Harvest are building a brighter future for the commonwealth.

Greenhouse Grower: Can you give an overview of the Kentucky AgriTech Initiative, why it was formed, and its goals?

Gov. Beshear: Last June, I took several steps, including creating an AgriTech Advisory Council, to keep my promise to build America’s AgriTech capital in Kentucky. The council includes representatives from farming, education, labor, civic life, and representatives from leading companies in the commonwealth such as Alltech, AppHarvest, Black Soil, and Kentucky Fresh Harvest.

Your readers are familiar with Kentucky Fresh Harvest, which cares about where our food comes from, how our food is grown, and who grows our food. These are all elements that align with the Kentucky AgriTech Initiative. Because of this, they have been able to revolutionize the protected agriculture industry and become an authority on vegetable production in Kentucky.

Kentucky Fresh Harvest already has been through the growing pains associated with building a greenhouse of this scale. So, it made sense for them to join the AgriTech Advisory Council nearly a year ago in our collective mission to highlight and develop Kentucky’s tremendous potential to help solve one of the greatest challenges of our generation: producing reliable, safe, and accessible food for the world. While that challenge is prevalent today, the expected global population surge in between now and 2050 will only amplify its severity. Team Kentucky is addressing this by combining three signature strengths: Kentucky’s prowess as a national leader in both manufacturing and logistics, along with our deep roots as an agricultural state.

The initiative will attract and cultivate good-paying, private-sector jobs and companies that create technologies, services and produce to help feed the world.

Our AgriTech Advisory Council’s goals for the initiative:

Create good jobs and strengthen Kentucky’s economy;

Attract local and global technologies and partners that support the development of innovative agriculture in the commonwealth;

Craft policies that spur the development of our agritech ecosystem;

Develop local supply and demand for technologies and agricultural products grown and manufactured here in Kentucky;

Develop and attract the necessary workforce to sustain the agritech ecosystem;

Help develop access to capital for new and innovative businesses in this sector; and

Build necessary cooperation channels between interested players.

Greenhouse Grower: What are the benefits of the initiative to both consumers and growing operations?

Gov. Beshear: By harnessing the assets in our backyard, the AgriTech Advisory Council seeks to develop an environment in which consumers gain better access to healthy food, obtain a more thorough understanding of where their food comes from, and realize the benefits of supporting local, sustainable farms. Relative to growing operations, the initiative focuses on helping them do what they do best – run their businesses while relying on Team Kentucky as a partner that shares their vision for a more sustainable, equitable, and resilient food system based right here in the Bluegrass State.

Greenhouse Grower: How can growers get involved?

Gov. Beshear: We want to hear from growers, no matter the size of their operations. We believe there are a number of opportunities for collaboration among growers and other innovators from all sectors – from greenhouse vegetable producers to our advanced manufacturing and logistic sectors. We even offer opportunities on all levels of the educational and workforce training system so that some of our youngest minds can look forward to becoming a part of the industry. If you are in a position to showcase your work or engage with Kentucky students, please contact us. Visit www.agritech.ky.gov.

Greenhouse Grower: What has been Kentucky’s experience of working with Kentucky Fresh Harvest?

Gov. Beshear: Kentucky Fresh Harvest has been a great partner of the commonwealth and true pioneers in the state’s high-tech greenhouse sector. Rocky Adkins, my Senior Advisor, and I visited the site in Lincoln County recently, and it was great to see the rich promise of agritech in Kentucky on display. The company’s scientific approach shows us that certain obstacles of large-scale agritech are no longer relevant. Kentucky Fresh Harvest’s dedication to education and inclusivity are great examples of excellent corporate citizenship and ambassadorship for the industry as a whole.

Source and Photo Courtesy of Greenhouse Grower

A Greenhouse In A Box For Small Farmers

Hyderabad-based startup Kheyti’s focus on small farmers has attracted the interest of US-based impact investment firm Acumen

Lush growth inside a low-cost Kheyti greenhouse in Telangana.

With one-tenth of the water and pesticides required and a manifold increase in yield, greenhouses can be transformative. The catch is that their upfront investment cost puts them beyond the reach of those who need them the most—small farmers dependent on rain or borewells. But what if a minimalistic greenhouse is designed from the outset, keeping in mind the needs and limitations of small farmers?

Hyderabad-based Kheyti has partnered with manufacturing and design companies to introduce such a concept. Its modular greenhouse kit, including a drip irrigation system, occupies just a tenth of an acre and costs less than ₹1 lakh. That’s much smaller and cheaper than normal greenhouses which only large farmers can afford. Around 500 farmers in Telangana are the early adopters of this “greenhouse in a box", which comes along with inputs like the appropriate seeds and fertilizers.

It began on a 1.8-acre farm in Narayanpur village, 60km north of Hyderabad, in 2017, recalls Kaushik K., co-founder, and CEO of Kheyti. “Venkatesh and his wife Lakshmi were growing rice along with some vegetables on the side. They worked hard, but their annual income of ₹30,000 barely sufficed for a family of five. The biggest challenge for them was that they could not fully utilize even their 1.8 acres of land because their borewells would run dry in the summer months," says Kaushik.

Model farm

Kheyti had set up an R&D farm on the outskirts of Hyderabad to demonstrate its greenhouse to small farmers. Venkatesh was among the first to visit the farm. “We showed him he could grow high-quality vegetables with so much more yields. But he had only one question: How much water would it need? When we explained that for the greenhouse he would run his borewell pump for only five minutes compared to an hour’s running time for his open field, he was ready to sign up," says Kaushik.

There was a hitch. The ₹5 lakh cost of the greenhouse was relatively low but still too much to raise for the likes of Venkatesh. So, why not make it even smaller and more affordable? It’s from such interactions that Kheyti’s greenhouse designs evolved.

“Venkatesh was the first one and after getting his greenhouse, he continued to give us feedback on what we should do for the next version," recounts Kaushik.

Today, Kheyti offers a 400 sq. m greenhouse for ₹80,000, with insect netting, shade netting, and polyethylene sheets to protect crops from pests, heat and excessive rain. That compares favourably with the ₹25 lakh that a one-acre (4,047 sq. m) greenhouse of this type would cost.

Local Vertical Farm Startup Joins Growing Global Market

Ortaliza Urban Farms is a dream that has been sprouting for some time now.

What if there was a more sustainable way to provide fresh, truly local greens to our communities? And what if there was a way to do it while bringing diverse flavors to the table year-round?

It sounds like an ambitious goal. But it is one that Carina Biacchi and her partner, Alvaro Fernandes, are set to meet.

Ortaliza Urban Farms is a dream that has been sprouting for some time now.

Carina Biacchi is no stranger to business. With a bachelor’s and postgrads in business administration, she has worked in several different sectors, from NGOs to massive corporations. “I’ve mostly worked in sales and marketing” Carina states. “And I have entrepreneurship in my DNA. My parents were entrepreneurs long before I was born.”

And as formidable as Carina is, she is among good company. Alvaro Fernandes, her partner, is an Agronomist Engineer. “He’s a passionate specialist in controlled environment agriculture” Carina explains.

When the two met they quickly started dreaming about their own indoor farm. Years passed, and the two immigrated to Canada and started a family. But those entrepreneurial sparks continued to fly.

“It took us a while to build our lives in Canada,” Carina states. “But we continued to research the idea we had. We kept visiting other businesses in the industry and we even traveled to New York and other areas to see what they had to offer in terms of vertical farms.”

But what is vertical farming? Vertical farming is a growing worldwide phenomenon set to add significant value to the food system. Food security and sustainability continue to be some of the top concerns for city planners, and venture capital firms are investing big into vertical farm operations.

And what is an urban farm? Simply put, urban farming is growing food in urban areas. “We’re located right on Main Street,” Carina states. “In a commercial zoning area. That is pretty unique by itself, and the town of Kingsville has proven to be the perfect partner to help us launch our dream.”

A hyper-local farm-to-plate experience

And while Ortaliza is not the first micro green seller in the region, they are the first to create a storefront, creating an exciting farm-to-plate experience, loaded with flavor and freshness.

“We are truly local!” Carina stresses. “Sometimes, when you see that something is “local” on your grocery shelves, it’s actually from another part of the Province. That might be fine for large vegetables, but greens are special. Think of all the nutrients you would get from a full vegetable but concentrated to deliver all that deliciousness in every single bite. Microgreens require just-picked freshness, so we are super, hyper-local. We’re only growing and selling here in our County.”

This business model, Carina explains, also allows them to reduce food mileage and consequently, food waste. “Leafy greens in Canada can sometimes travel thousands of miles before reaching their destination” Carina reports. “And it can take up to two weeks for the produce to get there. We have a commitment to sustainability, and we will always be local, no matter where we spread our roots to in the future.”

One of Ortaliza’s business Advisors, Adam Castle of WEtech Alliance says the launch of this business in Kingsville represents a unique opportunity for the Startup. “Here we are in the very heart of greenhouse agriculture, not just for Canada but seconded only to Holland from a global perspective,” says Castle. “So you’re planting yourself in a community that lives and breathes agriculture, who knows the value of being able to see where your food comes from and how it’s grown, at a time when the average consumer is more engaged than ever in providing the freshest, most sustainably grown food they can for themselves and their family. I applaud Kingsville for making room at their table for new kinds of agriculture, and being a business-friendly partner that our clients can count on.

“…it certainly fits hand-in-hand with the innovation and the diversification that we’re trying to identify with.”

One enthusiastic supporter of this innovative new business is Nelson Santos, the Mayor of Kingsville and the Deputy Warden of Essex.

“This isn’t your typical business, but it certainly fits in with the entrepreneurial spirit that we have in our community,” Nelson explains. “And it certainly fits hand-in-hand with the innovation and the diversification that we’re trying to identify with. They are touching on all the different aspects of what the community is looking for. Their business is one that is certainly going to turn quite a few heads. It’s very exciting, both in regards to the food aspect and the extension of agriculture.”

Ortaliza is now taking pre-orders for their home delivery service at www.Ortaliza.ca, which promises to deliver a lot more than leafy goodness.

“We want to be more than a farm-to-table service,” says Carina. “We want our customers to think of us as their weekly dose of living, natural vitamins that add easy nutrition to just about every recipe they can think of!”

To learn more and become a friend of the farm, head to www.ortaliza.ca or find them on social media at @OrtalizaFarms

A New FEZ "Karakalpak-Agro" Established In Uzbekistan

“….increasing the production of agricultural products, expanding its deep processing and increasing exports, effectively using the production potential of the region…”

Tashkent, Uzbekistan (UzDaily.com) - The Cabinet of Ministers adopted a resolution”On measures to organize the activities of the free economic zone “Karakalpak-Agro”.

In accordance with the decree of the President “On measures for the comprehensive socio-economic development of the Republic of Karakalpakstan in 2020–2023” on an area of 875.4 hectares in Amu Darya, Buzatausky, Kegeili, Konlikul, Kushgirot, Muynak, Nukus , Takhiatash, Turtkul, Khodjeyli, Shumanai and Ellikala districts, the SEZ "Karakalpak-agro" was created.

The functions of managing the activities of the FEZ "Karakalpak-Agro" are assigned to the State Unitary Enterprise "Directorate of the free economic zone" Nukus ".

The main tasks and directions of the SEZ "Karakalpak-Agro":

- attracting direct foreign and domestic investments for organizing modern greenhouses on a cluster basis, including hydroponic ones, as well as organizing the production of structures, equipment and other components for the construction of modern energy-efficient greenhouses;

- increasing the production of agricultural products, expanding its deep processing and increasing exports, effectively using the production potential of the region;

- encouraging the organization of the complete process of agricultural production from seeds to delivery to the market;

- introduction of effective mechanisms for providing greenhouses with seeds and seedlings of high-yielding crops demanded by the market, by creating conditions for organizing nurseries, as well as seed production;

- formation of a modern infrastructure for the provision of logistics services, assistance to agricultural producers in organizing the export of their products;

- widespread introduction of modern resource-saving technologies, the use of alternative sources of thermal energy in the organization of greenhouses;

- creation of research and production centers to assess the compliance of products with international standards.

The Council of Ministers of Karakalpakstan, together with the Ministry of Investments and Foreign Trade, the Chamber of Commerce and Industry and commercial banks, was instructed to develop a targeted program of facilities for the production of structures for greenhouses on the territory of Karakalpak-Agro within two months, with the allocation of vacant non-agricultural land.

US-VIRGINIA: Arlington’s Only Commercial Farm To Expand, Double Production

Virginia Gov. Ralph Northam announced this afternoon that Fresh Impact Farms will be getting a $30,000 grant — half from the state, half from the county — that will help it double production and create six jobs.

Believe it or not, Arlington County has a working commercial farm.

The farm, which is located in a commercial building along Lee Highway, uses hydroponic technology to grow a variety of edible plants indoors. And it’s about to expand.

Virginia Gov. Ralph Northam announced this afternoon that Fresh Impact Farms will be getting a $30,000 grant — half from the state, half from the county — that will help it double production and create six jobs.

Fresh Impact, Arlington County’s only commercial farm, is banking on its restaurant customers ramping up purchases as vaccinated customers flock back to the indoor dining. It also launched a direct-to-consumer Community Supported Agriculture program last year.

County Board Chair Matt de Ferranti hailed the business and its expansion.

“Governor Northam’s award to Fresh Impact Farms, Arlington’s only commercial farm, is an innovative way to celebrate unique uses of technology to help a small business pivot during the pandemic,” de Ferranti said in a statement. “I am thrilled that Fresh Impact Farms is growing and looking to the future of a sustainable food supply.”

More on the company’s expansion, below, from a press release issued by the governor’s office.

Governor Ralph Northam today announced that Fresh Impact Farms will invest $137,500, create six new jobs, and more than double production at its Arlington County indoor facility. Operating since 2018 as Arlington’s only commercial farm, Fresh Impact Farms uses proprietary hydroponic technology to grow a variety of specialty herbs, leafy greens, and edible flowers for sale to customers in the Greater Washington, D.C. metro area.

Like many companies, Fresh Impact Farms has pivoted its business model amid the COVID-19 pandemic. Seizing the opportunity created by more people cooking at home, the company initiated a Community Supported Agriculture (CSA) program targeting area residents. The CSA program, which focuses on leafy greens and home kitchen-friendly herbs, has grown steadily since its establishment in April 2020 and now includes smaller wholesale clients. Now, with vaccinations underway and the restaurant industry poised to rebound, Fresh Impact Farms is expanding, which will allow the company to resume supplying their restaurant customers, while also meeting new demand through their CSA program.

“Agriculture continues to be a key driver of our economic recovery in both rural and urban areas of our Commonwealth,” said Governor Northam. “Innovative, dynamic businesses like Fresh Impact Farms are demonstrating how exciting new opportunities can grow out of pandemic-related challenges. I congratulate the company on their success and am thrilled to award the first-ever AFID grant to Arlington County to support this expansion.”

This expansion by Fresh Impact Farms will include a second grow room, larger production facility, and an educational hub where, post-pandemic, customers will be able to see how their food is harvested. Over the next three years, the company expects to grow an additional 10,500 pounds of Virginia-grown leafy greens, herbs, and edible flowers for restaurant and CSA customers.

“Agriculture is Virginia’s largest private sector industry and the Commonwealth continues to be on the forefront of emerging agriculture technologies,” said Secretary of Agriculture and Forestry Bettina Ring. “I am inspired by Fresh Impact Farms’ commitment to not only bringing fresh, local produce to Virginians, but also for its commitment to educate our community about how local food is grown.”

“2020 was undoubtedly one of the hardest years in recent memory for many people and businesses, but I’m heartened by the strength and flexibility the entire Fresh Impact Farms team has shown in our deep pivot to consumers and a CSA model to help us get to the point where we are ready to expand our business,” said Fresh Impact Farms Founder Ryan Pierce. “The support and generosity from the Commonwealth and Arlington County will be valuable as we expand our production and move towards a hybrid model of serving both the needs of restaurants and consumers. As the owner of a local food business, nothing gets me more excited than seeing the community come together in support of local food. The future is bright for urban agriculture and this grant will help us make an even greater impact in our community.”

The Commonwealth is partnering with Arlington County and the Arlington County Industrial Development Authority (IDA) on this project through the Governor’s Agriculture and Forestry Industries Development (AFID) Fund, which is administered by the Virginia Department of Agriculture and Consumer Services (VDACS). Governor Northam approved a $15,000 grant from the AFID Fund to secure the project for Virginia, which Arlington County will match with local funds.

“The Arlington County IDA’s match of the Governor’s AFID grant to Fresh Impact Farms represents an important investment in urban agriculture, sustainability, and technology,” said Arlington County IDA Chair Edwin Fountain. “This project will advance the County’s innovative and forward-thinking approach to developing new sectors of economic activity in Arlington.” […]

“Congratulations to Fresh Impact Farms,” said Senator Janet Howell. “This expansion not only supports our local economy, but also has a significant impact promoting healthy families and vibrant communities as a whole.”

“I am delighted Governor Northam has approved a grant from the AFID Fund to deliver this project for the Commonwealth and Arlington County,” said Delegate Richard Sullivan. “Fresh Impact Farms has been a pivotal resource for providing fresh food to the community. This expansion shows a commitment not only to homegrown produce, but to a healthier community and local economy in Arlington.”

How Vertical Farms Are Revolutionizing Agribusiness

What is vertical farming and why does it matter?

William Ramstein ・ 1 March 2021 ・ Vertical Farming

Urban planners are tasked with answering some pressing inquiries: how can farming be brought closer to consumers; is digital agriculture an essential ingredient for making cities smarter; and can vertical farming improve socio-economic disparities?

Key Takeaways:

Vertical farming uses LED, Robotics and AI to bring vegetables closer to city dwellers.

The total addressable market for vertical farming is estimated at around $700 billion.

Spread, a Japanese vertical farm is profitable but most firms fail.

Vertical farming is a great way to produce controlled supplies of a customized plant.

Vertical farming struggles with electricity costs despite reducing carbon emissions.

What is vertical farming and why does it matter?

The bedrock characteristic of cryptocurrency technology is called decentralization, a sovereign and flexible organizational system led by a commune, and today other industries like farming are catching the bug. Farming needs to change its practices in order to meet ecological objectives set up by governments and decentralization could open the door to increasing food access and reducing carbon emissions from food transportation. Smart decentralized vertical farming implies using technology like digital platforms, robotics and artificial intelligence to bring food closer to the growing demand seen in cities.

Despite the difficulty of competing against the cost structure of traditional farming, vertical farming offers numerous advantages. It grants more yield per square meter and reduces waste in both carbon and water usage. The production of vegetables is made in large and often times un-used warehouses close to city centers thus cutting transportation costs and middlemen expenses. The supply is more easily controlled, protected, and priced regardless of global weather and plants are customized to local consumer preferences. Consumers are already paying a premium on farmer’s market products, so why not vertical farm products too?

Cases of vertical farming: Nigeria is one of the most promising African nations because of its age pyramid. But with a large young population comes questions around food and water access and today, more than 170 million Nigerians need prolonged and sustainable access to these resources. Nigeria currently imports $3.5 billion worth of food products while exporting only 1/7 of that figure. Fresh Direct is Nigeria’s first Hydroponics Company (growing crops without standard soil) that combines vertical farming to its business model to reduce the distance between cities and rural farming regions.

The firm is able to produce seven to 10 times the yields because of its stackable shipping containers, which use technologies such as drip irrigation, and cold storage. Direct Farming operates with a community mindset, with the goal to inspire more young farmers to set up shop in urban centers and become urban farmers. The company also trains and finances low-skilled workers into urban farmers and increases economic productivity in unemployed youth groups.

In Japan, a company called Spread is one of the world’s most sophisticated examples of vertical farming. Their factory mainly produces lettuce. Large robotic arms transplant lettuce seedlings into pots where they are left to grow under LED lights. Believe it or not, but the factory can produce 30,000 lettuce heads a day. CEO Shinji Inada boasts of being the only large-scale vertical farm that is profitable and hopes that more widespread adoption continues growing.

However, companies like Spread and A-Plus (another similar farm in Fukushima) struggle to lower unit economics because of their low-scale operations, and they find it hard to penetrate the traditional downstream sellers. When producing high-priced lettuce by the tonne, trucking goods to the local wholesaler does not work partly because vertical farming offers customized products for specific local needs, not necessarily for broad demand. These players have thus geared their focus towards international buyers like UAE to export their goods.

Is vertical farming there yet?

Most vertical farms have failed because of the high initial costs and high operational expenses of running robotic equipment. While sunlight is free, the energy cost of running LEDs is not. The solution could be to install renewable energies like solar panels and wind turbines. However, the fixed cost of that installation would inevitably factor into the end-product, or at least on the balance sheet as a liability assuming they keep prices reasonable for consumers.

While Mr. Inada can rightly boast of turning profits, most firms toss lettuce at a loss. The industry should see more growth ahead, however, with research group IDTechEx forecasting that annual sales of $700 million could more than double to $1.5 billion in 2030. There remain technological challenges though. While many competitors boast of successfully leveraging AI and robotics and filtration, new entrants have seen problems with watering automation systems, mold, and infestations (most players do not use pesticides).

Some analysts suggest that while the excitement around vertical farms makes sense, the farming style might just end up becoming just another way of farming amongst greenhouse and open sky farms. More specifically, vertical farming will focus on high-margin crops rather than commodities like bulk grains.

While the challenges of vertical farming are clear, every country has different needs and constraints. There is a large interest from smaller island countries like Singapore or Iceland, rich economies, and countries that have a higher propensity to import due to less arable lands. Britain is a good example of a country that meets the criteria and in the context of Brexit, it makes all the more sense because of import costs and independence constraints. A potential labor crisis could soon loom too assuming seasonal workers are denied entry into the country. Vertical farms only require one-third of the manpower to run and could therefore alleviate the industry.

The market opportunity…According to research by Barclays Investment Bank, the market opportunity for vertical farms is large. Analysts estimate the size of the global fruit and vegetable market to be $1.2 trillion and the total addressable market for vertical farms to be $700 billion. The purchased energy use to produce 1kg of lettuce is 247-kilowatt hours far exceeding Netherland greenhouses’ 70-kilowatt hours consumption. With retailers being asked to meet more carbon-neutral objectives, some vertical farms believe they will be able to overcome their expense through increased demand and scale.

The pandemic has imposed many supply chains disruptions and labor shortages threatening food security in regions around the world relying heavily on imports. Vertical farming is recognized lately and since 2014, has seen a flow of funds equal to $1.8 billion according to data group Dealroom. SoftBank fundraised $140 million into Plenty, a start-up, and countries like Abu Dhabi want to build farms in deserts.

Some of the top players in the global farming market include Vertical Farm Systems (Australia), American Hydroponics (US), Agrilution (Germany), Green Sense Farms (US), Everlight Electronics (Taiwan), Koninklijke Philips (Netherlands), Sky Greens (Singapore), Illumitex (US), Urban Crop (Belgium), Aerofarms (US) and InFarm (Germany).

"We’re Retrofitting With The Variables We Have In Place"

Planted Detroit introduces new 20.000 sq. ft. growing facility

“The Square Room is a big block of pink lights with eight levels, where all our growing is done. Everything after germination is done in the same room, both harvesting of our baby greens and microgreens. Because we’re almost done with our PARS (Planted Automated Racking System), which is the big automation,” says Megan Burritt, Managing partner at Planted Detroit.

From a mix-fused downtown neighborhood in Detroit, daily deliveries of ready-to-eat salads and fresh greens are transported to local retailers and restaurants. Planted Detroit makes a large contribution to the city’s share of fresh produce.

New facility

Planted Detroit has been in the middle of the construction of its new 20.000 sq. ft growing facility. The growing space has been a massive update to the company compared to its previous 6-level growing facility which was between 1500-2000 sq. ft. The same room was used for processing, packaging, harvesting, and so on. “It was rather crowded, says Megan, but the main goal was to keep everything tight for the construction to continue in the near surrounding. We’re very serious about biosecurity and we have a daily procedure for everyone who sets foot in our grow room to go through. Making sure our greens don’t come into contact with pathogens is our top priority.

The new growing room

The Square Room, one of our growing rooms, is highly automated, including an automatic harvester to ensure work-efficiency. Once everything is big enough to be transplanted out of their plug trays, PARS (Planted Automated Racking System) will be transplanted with gutters and then go into harvesting. On the other side of PARS, the gutters are taken down and harvested through Planted’s new automatic harvester.

Delivering directly to consumers

The company wants to reach a higher volume of customers as it’s aiming to obtain a consumer brand status. Next to that, the company is always on the lookout for finding more customers through other venues. “We want to go directly to consumers via our web-store to shorten food miles as much as possible, delivering the freshest and most delicious greens,” Megan says. In order to do that the company needed to have a bit more scale, trying to maximize the space they already had.

She adds: “Our farm maybe isn’t the square footage which we could have built from scratch, but we’re retrofitting with the variables we have in place. That is why we have done a combination of a microgreen vertical nursery and PARS for baby greens. Our direct customers wanted meal solutions and we’ve been able to deliver them that. We’ve been doing everything from seed to plate basically.”

Megan Burritt, Managing partner

New projects coming up

On the same campus, 10 meters away, a new farm will be constructed, under the company's office space. In this farm herbs and edible flowers will be grown in response to different customers' demands. Megan says that Planted Detroit’s wholesale customers got them to this point as they were very interested in herbs and edible flowers. “However we weren’t able to perfect these as well in the systems that our baby greens were in perfectly. That’s why we’ve been leaning into R&D lately because once finishing the construction of Farm 2 it will have excellent growing conditions that are better than they have been for those crops.”

Edible flowers are an interesting thing, says Megan, but the company has gotten so much interest in it. According to Megan there aren’t many farms in the US that are growing them. “They’re high priced at this point. It sort of sticks to our original innovation, namely what exists here in the food system and what does not. Where can we fill the ‘does not exist niche’ and satisfy the needs of our customers.”

The company is rolling out a subscription program sometime this year and figuring out where it fits into the fresh food subscription system and how they can partner with other parties in order to get produce closer to society. “It’s great to have this ag job, applied science to be able to do. In all the things we’ve been doing is hiring these Detroiters and showing that we can really create a really great culture of work. It’s really great to see we’re contributing to a better Detroit and a better tomorrow,” Megan states.

Team expansion

During 2020 most of the team stayed on by moving around working hours, so the farm could come back in full force. By the time all equipment was in place, 10 to 12 people were added to the team to have them fully trained before the system would be functioning. “It has been really wonderful to expand the team to see what our capacity is,” says Megan.

“Luckily we’ve been able to develop systems that have been resilient. We’ve seen so many different patterns in consumer behavior but they seem to have fallen in our favor. People are eating more at home, shopping for groceries more, and that triggered our pivot focusing on direct consumers. But now, it’s perfectly in line with our strategy on how we go to market. As long as we can supply our customer needs we’ll be on the right path. Nothing but bright hopes for the future right now,” Megan affirms.

For more information:

Planted Detroit

Megan Burritt, Managing partner

megan@planteddetroit.com

www.planteddetroit.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

Eastern Kentucky Company Growing Local Economy By Growing Vegetables Year-Round

AppHarvest has created 300 jobs in Appalachia, an area not really known for growing tomatoes.

by GIL MCCLANAHAN

MOREHEAD, Ky. (WCHS) — Imagine growing fresh local tomatoes in the dead of winter. A company in Eastern Kentucky is using high-tech agriculture to grow vegetables indoors.

To View The Video, Please Click Here.

AppHarvest checks tomatoes growing inside the company's 60-acre indoor greenhouse.

(AppHarvest ) Courtesy Photo

AppHarvest opened in Rowan County, Ky. last October. They are growing more than just vegetables. They are growing the economy in an area that sorely needs it.

What's growing inside AppHarvest's 2.8-million square foot facility is capable of producing more food with less resources.

"For our first harvest to be on a day where there was a snowy mountainside could not have been any more timely. The fact that we are able to grow a great juicy flavorful tomato in the middle of January and February is what we have been working to accomplish," AppHarvest Founder and CEO Jonathan Webb said.

Webb said five months after opening its Morehead indoor farm facility, the company shipped more than a million beefsteak tomatoes to several major supermarket chains, including Kroger, Walmart and Publix. Those large bushels and bushels of tomatoes are grown using using the latest technology, no pesticides and with recycled water in a controlled environment using 90% less water than water used in open-field agriculture.

"We're just trying to get that plant a consistent environment year round with the right amount of light and the right amount of humidity and the right temperature just to grow, and the vines of our crops the tomato plant end up being 45 feet and we grow them vertically so that is how we can get so much more production," Webb said.

One of the company's more well-known investors is Martha Stewart.

"I said Martha, can I get five minutes and I told her what we are doing. She was like, look we need good healthy fruits and vegetables available at an affordable price. I love the region you are working in," Webb said.

A couple of weeks later, Webb met with Stewart at her New York office, and she decided to become an investor in the company. Some local restaurants are looking forward to the day when they can buy their vegetables locally from AppHarvest. Tim Kochendoerfer, Operating Partner with Reno's Roadhouse in Morehead, buys his vegetables from a company in Louisville.

"It will be another selling point to show that we are a local restaurant," Kochendoerfer said.

Webb points out AppHarvest is not trying to replace traditional family farming. "Absolutely not. We want to work hard with local farmers," he said.

Webb said by partnering with local farmers, more local produce can get on grocery store shelves, because last year 4 billion pounds of tomatoes were imported from Mexico.

"What we are working to replace is the imports from Mexico where you got children working for $5 a day using illegal chemical pesticides in the produce is sitting on a truck for 2-3000 miles," Webb said.

AppHarvest has already started influencing the next generation of farmers by donating high tech container farms to local schools. Students learn to grow crops, not in the traditional way, but inside recycled shipping containers. The containers can produce what is typically grown on 4 acres of land. Rowan County Senior High School was the second school to receive one. It arrived last fall.

"We sell that lettuce to our food service department and it's served in all of our cafeterias in the district," said Brandy Carver, Principal at Rowan County Senior High School.

"When we talk about food insecurity and young people going home hungry, what better way can we solve these problems by putting technology in the classroom. let kids learn, then let the kids take the food home with them and get healthy food in the cafeterias," Webb said.

AppHarvest has created 300 jobs in Appalachia, an area not really known for growing tomatoes. Local leaders believe the company will attract more business to the area.

"I fully expect in time we'll see more and more activity along that line like we do in all sectors," said Jason Slone, Executive Director of the Morehead-Rowan County Chamber of Commerce.

"We will eventually be at the top 25 grocers. Name a grocer. We've been getting phone calls from all of them," Webb said.

AppHarvest has two more indoor farming facilities under construction in Madison County, Ky., with a goal of building 10 more facilities like the one in Rowan County by the year 2025.

To find out more about AppHarvest click here.

New York’s Gotham Greens Plans Solano County Indoor Produce Farm

It will be located on 33.6 acres of agricultural land purchased from the university adjacent to Interstate 80.

GARY QUACKENBUSH

FOR THE NORTH BAY BUSINESS JOURNAL

Example of the greenhouse operated by Gotham Greens which announced plans to open in Solano County (Photo courtesy of Gotham Greens)

Gotham Greens Holdings LLC, a firm with indoor agriculture operations across the U.S., Tuesday, announced plans to build a facility next to the University of California, Davis.

The first phase of this 10-acre Solano County facility is expected to open later this year. It will be located on 33.6 acres of agricultural land purchased from the university adjacent to Interstate 80.

The company stated its plans will provide it with the ability to deliver fresh leafy greens, herbs, plant-based dressings, dips and cooking sauces to more retailers, foodservice operators and consumers on the West Coast.

“… We are partnering with one of the highest-ranked agricultural research centers in the world to advance the entire agriculture system,” said Viraj Puri, co-founder and CEO of Gotham Greens. “California is responsible for growing one-third of the country’s vegetables and two-thirds of the nation’s fruit, yet in recent years, issues surrounding drought, food safety and worker welfare have demonstrated the need for continued innovation.”

The greenhouse will generate 60 full-time jobs and provide UC students with the opportunity to learn first-hand how to sustainably grow produce year-round in a safe, clean, climate-controlled environment. The company stated its facilities use 95% less water and 97% less land than conventional farming. Nationwide, Gotham Greens has 500,000 square feet of greenhouse space at five locations staffed by 400 employees.

The UC Division of Agriculture and National Resources and the UC Davis College of Agriculture and Environmental Sciences has entered into a partnership with Gotham Greens to advance research and innovation in the areas of indoor agriculture, greenhouse technology, and urban agriculture to help advance the science, workforce technology, and profitability of indoor agriculture globally.

“We are building a Controlled Environment Agriculture Consortium to support and advance the indoor farming industry, grow more fresh produce on less land and create new jobs for Californians,” said Gabriel Youtsey, the division’s chief innovation officer. “Gotham Greens is an anchoring partner of this research and industry collaboration that we hope will spur innovation, create a new indoor farming workforce and support industry growth.”

Helene Dillard, dean of the college, said, “This partnership will offer our students the chance to learn best practices from leading experts in indoor farming.”

Gotham Greens recently raised $87 million in new equity and debt capital bringing the company’s total financing to $130 million to fuel the next phase of growth.

Founded in 2009 in Brooklyn, New York, Gotham Greens (gothamgreens.com) owns and operates greenhouses in New York, Illinois, Rhode Island, Maryland and Colorado. Its produce is available in more than 40 states and 2,000 retail stores, including Albertsons Companies (Safeway, Jewel-Osco, and Shaw’s), Whole Foods Market, Target, King Soopers, Harris Teeter, and Sprouts.

The company’s products can also be purchased through e-commerce sites including AmazonFresh, FreshDirect and Peapod.

Lead Photo: Gotham Greens

Vertical Farms vs Greenhouses – The First Consideration: Location

When and where to use a vertical farm versus a greenhouse, and what factors – both economic and environmental – make the difference.

In just the past decade or so, sustainable farming has seen a high-tech makeover in the form of Controlled Environment Agriculture, or CEA, which consists of two main technologies: Vertical farms and greenhouses.

When it comes to feeding the world, it’s not a choice between vertical farms or greenhouses. We’ll need both to feed our growing global population with healthy, sustainable food, and we need to understand the ideal situation for each.

But as a business decision, it often is a choice between the two – and that’s what we hope to explain in this five-part series of articles: When and where to use a vertical farm versus a greenhouse, and what factors – both economic and environmental – make the difference.

In this first post, we’ll cover the basic differences between vertical farms and greenhouses, and why location matters so much when deciding between the two. Then stay tuned because, in the next articles, we’ll dive deeper into energy and lighting costs, automation and other expenses, environmental and crop considerations, and finally, the future of farming.

Vertical Farms vs Greenhouses: The Basics

The two technologies are often confused, but there are significant differences between them in resource use, cost, output, and, perhaps most importantly, the ideal locations for each.

Greenhouses are the more traditional technology that you’re probably familiar with: A single layer of crops, planted inside an enclosed space with walls and a ceiling made of glass or plastic to allow natural light in. They’re semi-controlled environments.

Vertical farms, on the other hand, are a much more recent invention using trays of usually hydroponic plants, stacked in floor-to-ceiling towers, with LED lights illuminating each layer, and climate control constantly adjusting the temperature, humidity and more.

In the upcoming articles in this series, we’ll dive into each part of these differences in more detail. But for now, let’s start with the first question entrepreneurs always need answering: The price tag.

Henry Gordon-Smith is the CEO of Agritecture, an independent consultancy and software creator that helps clients decide between the two technologies. As he puts it, “Vertical farming represents the most expensive, most controlled form of agriculture.”

At first blush, vertical farms are, in fact, shockingly more expensive than greenhouses – six to 10 times as costly. Gordon-Smith says vertical farming costs 2,200 to 2,600 Euro per square meter of cultivation bed space, while high-tech greenhouses cost 250 to 350 Euro per square meter of cultivation space.

Both offer a year-round source of fresh, pesticide-free, locally-grown produce, which provides better nutrition than the same foods that arrive from far away.

But what else do farmers, entrepreneurs, and investors get for all the added expense of vertical farming?

The answer is pretty simple: A more compact farm with more production per square meter, less water use, and more control over both quantity and quality. (With iFarm, this predictability is part of the package, in the form of a guaranteed yield within a precise time frame.)

For some entrepreneurs or municipalities, the cachet of implementing a high-tech farming technique that’s only been in use for less than a decade is also a factor in favour of vertical farming. But most often, the choice comes down to location.

The Ideal Location for a Vertical Farm versus a Greenhouse

The first step in determining the feasibility of building a vertical farm or greenhouse is to look at the drivers and constraints – many of which are simply location-based.

Places with limited space, such as dense urban areas, and limited access to fresh water are ideal for vertical farms. Doubly so if they have access to low-cost, renewable energy, and if they’re near a market with high demand for the crops vertical farms excel at producing: Leafy-greens, micro-greens, herbs and berries grown locally, without pesticides.

But in areas with unlimited space, lots of natural sunlight, and high-cost and/or high-carbon electricity, greenhouses may be the better option and the extra expenses of vertical farming might not make sense.

How these considerations apply in broad regions of the world is illustrated below:

BONAFIDE Will Continue To Develop It's Concept On Decentralized Agriculture And Food Supply Systems

The trend for decentralization is growing all the time and we trust that agricultural policies will follow suit to support local farmers and a new generation of young entrepreneurs that find their ideology in creating new markets

Over the last 6 years, we have seen technology advance to facilitate urban vertical farming embracing entrepreneurial opportunities, the supply of fresh food daily, and secure cultural kitchens requirements for raw materials anytime anywhere.

At the same time conflicts, natural resource competition, and climate change have had adverse effects on food security that local production using new technology can alleviate.

The trend for decentralization is growing all the time and we trust that agricultural policies will follow suit to support local farmers and a new generation of young entrepreneurs that find their ideology in creating new markets.

thomas.tapio@gmail.com

Thomas Tapio (LION) • Consultant (retired)

Strasbourg 27th February 2021, 🇫🇷🇪🇺

7 New HDB Carpark Rooftop Sites Offered For Rental For Urban Farming In Public Tender

More local produce. Part of Singapore's efforts to strengthen its food security is increasing its capability to produce food locally

Part of Singapore's efforts to strengthen its food security is increasing its capability to produce food locally.

To do this, more sites for urban rooftop farms atop multi-storey Housing Development Board (HDB) carparks are being offered for rental, via a public tender process that was launched today (Feb. 23).

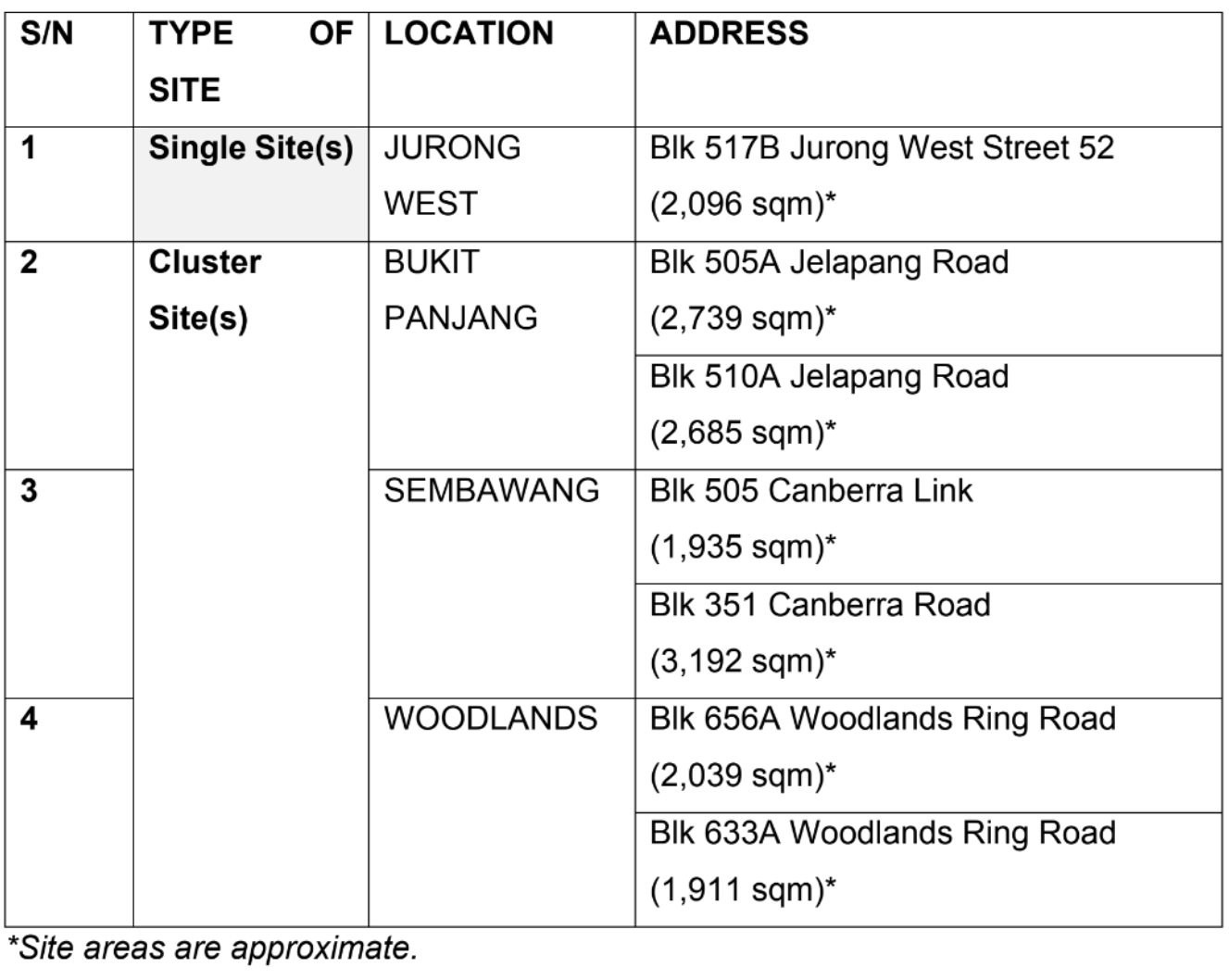

Seven new sites

Seven sites have been identified in Jurong West, Bukit Panjang, Sembawang and Woodlands, according to the Singapore Food Agency (SFA) and HDB.

The sites will be used to farm vegetables and other food crops, and will also be used to pack and store produce.

They will be tendered out as a single site (in Jurong West) and three cluster sites (in Bukit Panjang, Sembawang and Woodlands).

Screenshot from SFA and HDB

Tenderers who successfully bid for cluster sites will be awarded all sites within the cluster, to allow them to cut costs through production at scale.

Single-site farms, on the other hand, provide opportunities to "testbed innovative ideas".

Tenderers must submit their proposals via GeBiz before the tender closes on Mar. 23, 4pm.

Proposals will be assessed on their bid price, production output, design and site layout, as well as their business and marketing plans.

More information can be found on SFA's website here.

Producing food locally

This is the second time tenders were launched for rooftop urban farms on carparks here — the first took place in Sep. 2020, with nine sites being awarded.

Collectively, the nine farming systems can potentially produce around 1,600 tonnes (1,600,000kg) of vegetables per year.

Having more space for commercial farming in land-constrained Singapore is one of SFA's strategies to achieve its "30 by 30" goal — which is to produce 30 percent of Singapore's food locally by 2030.

The move is also in line with HDB’s Green Towns Programme to intensify greening in HDB estates.

“Besides contributing to our food security, Multi-Storey Car Park (MSCP) rooftop farms help to bring the community closer to local produce, thereby raising awareness and support for local produce," said Melvin Chow, Senior Director of SFA’s Food Supply Resilience Division.

Aquaponics In The Heart of Zurich

Umami creates microgreens in the city centre

They produce greens, but they travel to work by streetcar and don't need to put on weatherproof clothing. That's because Umami employees will harvest vegetables and herbs already in the early growth stages, as so-called microgreens. And they do so in a largely self-built facility, on the 4th floor of an office building in Zurich's Kreis 4 district.

Full-time producers instead of restaurant operators

In the beginning, the three friends Manuel Vock, Robin Bertschinger and Denis Weinberg wanted to open a restaurant. They wanted to produce half of the products themselves. At the same time, Manuel Vock was researching aquaponics systems for his bachelor's thesis. He introduced the principle to his friends, and the team began building a prototype set-up in a former archive in 2016.

That was the end of their restaurant plan and at the same time the beginning of completely self-produced food. The guys grew several varieties of microgreens and sold them to restaurateurs who were excited to have a regional product. "Up to that point, microgreens from the Netherlands were the only alternative," says Luca Grandjean, who joined the team of Umamigos (as Umami employees call themselves) in 2019.

The aquapinic facility / Image: Umami

Microgreens

Microgreens, unlike sprouts, grow on a substrate or in soil, require light and nutrients, and are consumed without roots. They are vegetables or spice plants that are harvested immediately after their cotyledons develop. As a result, microgreens contain a high concentration of vitamins and trace elements. The small plants are used as nutritional supplements and can add sweetness and spice to different dishes.

Fish excrement as fertilizer

Regionality is not the only plus of the little plants. Umami grows the microgreens in a cycle based on nature; the only input is fish feed. But even this is actually food waste and, additionally, insects that Umami produces via scraps.

African cichlids (tilapias) and other fish species swim in various tanks, and their excretions enrich the water with nitrogen and other micronutrients. The enriched water flows into the system to the tray on which the microgreens thrive.

These are sown on a hemp-based substrate and positioned in hard trays so that their roots can touch the water, absorbing the nutrients. The water, now purified by the plants, flows back to the fish, who recharge it. Thanks to this recirculation system, only about 1% of the water needs to be replaced with fresh drinking water each month. "That's about two bathtubs full of water. Just what is lost to evaporation," Grandjean says.

Aquaponics

Aquaponics refers to a process in food production that combines raising fish in aquaculture and cultivating crops in hydroponics. There are various combinations, such as the cultivation of tomatoes and the production of tilapias, as described in this article.

Not just fish and microgreens are part of the 'ecosystem', as the Umamigos like to call their jungle. Mussels, shrimp, snails, algae and many other plants also contribute to the Umami ecosystem. "We are copying nature. Yet we have learnt that the more players there are in the cycle, the better the system works," says Luca Grandjean. This might seem to be a contradiction, but he explains: "If there are just two actors in the system and something happens to one of them, the system is quickly unbalanced."

Nomen est omen

Their most important element, he says, is Zurich's tap water; it sets the pace. "We have no soil percolation, 95% less water loss than conventional agricultural systems," Grandjean says.

Environmentally-friendly production, free of chemicals, strikes a chord with consumers. Above all, however, the products have to taste right, says Luca Grandjean. It's no coincidence that the three friends named their startup Umami when they founded it in 2015. The Japanese word means tasty or spicy, and is one of the five basic tastes, alongside sweet, sour, bitter and salty.

"The glutamate found in meat, for example, tastes umami," Grandjean explains. He adds: "The microgreens are very palatable and don't contain glutamate, but our fish do." He is referring to the license to sell fish that the Umamigos recently obtained.

For more information: https://www.eat-umami.ch/

Climate Corps America: The Urban Farms Transforming How America’s Most Vulnerable Communities Eat

Urban farms not only promote healthy eating but have the ability to transform industrial cities.

Louise Boyle

The microwave plays a significantly more important role to urban farming in Baltimore than you might first imagine.

“Our butternut squash comes from a seed which makes it little and easily microwaveable,” Gwen Kokes, food and farm programme director at Civic Works, told The Independent. “For our [customers] this is really important as it might be too expensive to turn on the gas to cook or the oven might not be working.”

The squash, along with a range of produce, is grown at Real Food Farm, one branch of Civic Works urban service corps program in Maryland’s largest city.

The farm started about a decade ago and spans eight acres in northeast Baltimore with four fields, more than 100 fruit trees, a greenhouse for seedlings, and eight “hoop houses” which, for the uninitiated, are a sort of passive greenhouse with crops planted directly in the soil but sheltered by heavy-duty plastic sheets stretched over frames.

The farm produces 5,000 pounds of fruit and vegetables each year to be sold for reduced cost at farmers’ markets in low-income neighbourhoods across Baltimore. A mobile market, operating out of a box truck, also visits all 12 senior centres in the city.

“In total, we distribute about 100,000 pounds of food every year,” says Ms Kokes. “We buy from other urban farms in a 50-mile radius, prioritising Black-owned farms. Sometimes we have donations from Hungry Harvest, a programme to reduce food waste from grocery stores, and we’ve been adding pantry and hygiene items so that it’s more of a one-stop shop.”

Civic Works is part of AmeriCorps, the federal agency for service and volunteering programmes in the US. To tackle the climate crisis, President Biden has called for “reinvigorating and repurposing” the agency into a so-called “Civilian Climate Corps” to provide jobs while ramping up clean energy and sustainability to “heal our public lands and make us less vulnerable to wildfires and floods”.

“Biden’s plan could be huge for us,” Ms Kokes said. “I think it can grow exponentially. There’s plenty of demand for these jobs.”

The non-profit also runs programmes to mentor students, fix up abandoned houses and makes homes safer for seniors by doing minor DIY like adding handrails and ramps.

AmeriCorps estimates that its existing network – 25,000 participants in about 130 programmes – could be scaled up to 500,000 young people and veterans over the next five years.

Around 19 million people in the US live in “food deserts”. The term is believed to have been coined in Scotland in the early 1990s by a public housing resident, referring to areas where healthy, fresh options are scarce and packaged and fast food has proliferated.

The term is now seen as having negative connotations, implying that “low healthy food access is a naturally occurring phenomenon, rather than the result of underlying structural inequities”, according to a 2018 study by John Hopkins. (Baltimore residents told researchers they preferred the term “Healthy Food Priority Areas”.)

Researchers also point to the systemic racism at the heart of Americans’ access to food. It’s difficult to improve diet and health, for example, if prices for nutritious food are far beyond your budget, and there’s no public transport to take you stores.

“The fact that predominantly black neighbourhoods, on average, have fewer stores and poorer quality [food] compared to their white counterparts means something,” Ashanté M. Reese, professor of sociology and anthropology at Spelman College who studies race and food inequity, told HuffPost .

Baltimore is one of America’s poorest cities. In 22 of the city’s 668 Census tracts, at least 40 per cent of residents live below the poverty line. Even before Covid, the unemployment rate in the poorest neighbourhoods hovered above 15 per cent, triple that of wealthier areas.

Lack of access to healthy food in Baltimore is one layer of racial inequality that has plagued the city since the early 20th century, when deliberate policies were put in place to separate the city’s white and Black residents.

In the city’s Greenmount East neighbourhood the average life expectancy is around 66 years while four miles away in the wealthier Roland Park, the average life expectancy is 84 years, according to Kaiser Health News.

That’s where organisations like Real Food Farm step in. Those who are unemployed or on low-incomes and using government nutrition assistance programmes get double the value for their dollar if it’s spent at the farmers’ market, for example.

Urban farms not only promote healthy eating but have the ability to transform industrial cities.

“Motor City” Detroit, once the backbone of the car industry, has suffered a well-documented decline since its mid-20th century heyday. But its industrial wastelands have been transformed by urban farming with at least 1,400 farms and gardens in the city. In Pittsburgh, Hilltop Urban Farm is set to become the largest urban farm in the country. Baltimore has around 17 urban farms and upwards of 75 community gardens that grow food, according to Baltimore magazine.

Civic Works’ role on the frontline of food insecurity meant that its teams were well-positioned to adapt during the Covid pandemic, delivering boxes of fresh produce and basic necessities to the most vulnerable at no cost. They also worked with public bodies and local charities to deliver donations.

“During lockdown, Baltimore City public school system had to get rid of those little cartons of milk really fast. We have thousands of customers so we focused on getting those out to them,” Ms Kokes said.

From March through the end of July, the programme’s teams ran a free programme delivering boxes of produce, meals and hygiene kits to about 1,000 households a week. They went on to launch a discounted local produce programme, delivering boxes with about $15-$20 of food for $5 with free delivery, mostly to seniors.

Urban farms will play a role in mitigating how climate change impacts urban areas. Cities are often several degrees hotter than rural areas due to the “urban heat island effect” caused by dark-coloured roads and buildings. Increasing vegetation cover can help curb rising temperatures.

Urban farms can also lower the risk of flooding during heavy downpours and help retain water in dry areas, according to a paper in the journal Earth’s Future.

Research in 2018 from Arizona State University and Google found that urban agriculture could save the energy equivalent of 9 million home air conditioning units and produce up to 180m tonnes of food globally. Along with supplying almost the entire recommended consumption of vegetables for city dwellers, it would cut food waste and reduce emissions from transportation of produce, the study found.

Maryland is among the states most vulnerable to climate change, facing both rising sea levels and heightened storm intensity. Government data predicts that Maryland’s sizeable farming community could suffer costly losses during extreme droughts and heat waves.

Ms Kokes says that more extreme and unpredictable weather has impacted their operations in recent years.

“With day-to-day farming, we have to get ‘swamp ready’,” she said. “2018 was the worst for Maryland farmers as the rain was astronomical. We took a huge hit. It was very humbling because we had to reckon with our limitations, and partner with others to be a reliable source of food.

“Irregular weather patterns especially in the spring make it really difficult to know when to plant. We’ve [also] had early frost in October. Our farmer Stewart is a very smart, science-oriented guy and thankfully, there’s resources that we can lean on to translate this unpredictability into clear language.”

Around 3,000 students from kindergarten to high school have visited Real Food Farm over the years to learn about agriculture. Separately, programmes like Future Harvest are preparing the farmers of the future. But it’s important that Real Food Farm’s mission stays relevant to the communities they are in, Ms Kokes said.

“Environmentalism, from our perspective and our work, has to be people-focused,” she said. “We’re not talking about weather patterns when people are hungry and just want affordable produce in their neighbourhood.”

Belgian Bio-Planet Now Sells Vertically-Farmed Coriander Too

For us, the story didn't end with sustainable basil.

Just under a year ago, Bio-Planet first introduced its basil to the market. This came from this Belgian store's self-developed vertical farm. "This cultivation method differs from conventional farming. It requires less water and space and fewer nutrients. That results in herbs with tiny ecological footprints. For us, the story didn't end with sustainable basil. We now have the technique down for coriander. We've been selling this second vertically-farmed herb since 19 February. That's in the Bio-Planet webshop and 31 stores", says a representative from this supermarket chain.

"Consistent, year-round quality"