Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Polygreens Podcast Episode: 34 Vijay Rapaka - Oasis Company

Skilled in Research and New Product Development, Strategic Planning, and Research Management. Successfully developed and launched several groundbreaking technologies

In this episode, Joe and Nick interview Vijay Rapaka, an experienced technical professional, passionate and motivated to deliver commercial value through research and innovation. Skilled in Research and New Product Development, Strategic Planning, and Research Management. Successfully developed and launched several groundbreaking technologies.

Latest Episode

Feds To Spend $4.95M On Vertical Farming Project, Research In Northern Manitoba

The funding will see the University of Manitoba partner with Opaskwayak Cree Nation to develop a smart vertical farming initiative for the First Nation

By Marissa Turton

July 6, 2021

The federal government says it will spend nearly $5 million on a partnership that will see food growing smarter in several communities.

The funding will see the University of Manitoba partner with Opaskwayak Cree Nation to develop a smart vertical farming initiative for the First Nation.

The $4.95 million, to be doled out over the next six years, will support programs at the U of M, the University of Guelph, and McGill University, as well as seven additional institutions.

As part of her project, U of M professor Miyoung Suh will collaborate with Glenn Ross, executive director of OCN Health Authority, on developing real-world solutions to food and nutrition security in the community, according to the U of M.

This project began when Ross introduced a vertical smart farm concept, complete with real-time automation, to the community. From there, he began working with Suh and others in the faculty of agricultural and food sciences at the U of M.

The first step of the project was successful, and now the pair will collaborate with other communities in the area that struggle with easily accessible fresh food, especially in the winter.

Click to View Video: Fighting Food Insecurity

“Of particular concern is the high incidences of gestational diabetes and spontaneous abortions in pregnant mothers” in areas where there is little fresh food, said the U of M.

“The researchers will test if fresh vegetables from the vertical farms, eaten during pregnancy, decreases these incidences.”

“Food is a basic entry point for building healthy communities,” Suh said in a press release. “The availability of fresh produce up north is limited, but smart technology involving local food production could be a simple solution in transforming those communities.”

Ross added that the “SMART cities project and concept is the way of the future.”

“The world is now changing faster than we have ever seen and we are just starting to see how bad climate change can be and the threat it has on our grandchildren.

“The high quality of foods from the smart farm program will eliminate many diseases and help make health care sustainable in Canada. It will also help us sustain the earth for many generations to come without destroying our planet. This is our ultimate goal.”

The funding announced Monday comes from the Canadian Institutes of Health Research, the Natural Sciences and Engineering Research Council and the Social Sciences and Humanities Research Council.

Lead photo: Miyoung Suh's new project will continue to research food insecurity in northern Manitoba. ST. BONIFACE HOSPITAL RESEARCH MEDIA SERVICES

Agrify Enters Into Multi-Year Vertical Farming Research And Development Partnership With Curaleaf

Agrify Corporation (NasdaqCM:AGFY) (“Agrify” or the “Company”), a developer of highly advanced and proprietary precision hardware and software cultivation solutions for the indoor agriculture marketplace, today announced that it has signed a definitive Collaboration Agreement (“the Agreement”) forming a long-term research and development (“R&D”) partnership with Curaleaf Holdings, Inc

Partnership To Study Impact

of Cultivation Environment on

Plant Health And Harvest Yields

July 06, 2021

BILLERICA, Mass

Agrify Corporation (NasdaqCM:AGFY) (“Agrify” or the “Company”), a developer of highly advanced and proprietary precision hardware and software cultivation solutions for the indoor agriculture marketplace, today announced that it has signed a definitive Collaboration Agreement (“the Agreement”) forming a long-term research and development (“R&D”) partnership with Curaleaf Holdings, Inc. (“Curaleaf”). Curaleaf is one of the largest multi-state operators (“MSOs”) in the United States and the largest vertically integrated cannabis company in Europe as Curaleaf International.

The research will be focused on evaluating the impact of certain environmental conditions created and controlled by Agrify’s Vertical Farming Units (“VFUs”) and Agrify Insights™ software platform on harvest yields, plant terpene profiles, and flavonoid concentrations. It will also explore and analyze techniques to enhance the aesthetic appeal, aroma, and overall chemical profile of cannabis flower. In addition, the joint research team plans to study the effect of regulated environments on the overall health and longevity of cannabis plants, including research on the maturation of the chemical profile of the plants over their lifecycle.

“We are thrilled to announce our first MSO collaboration and honored to partner with Curaleaf to advance this important research,” said Raymond Chang, Chief Executive Officer of Agrify. “Curaleaf is a cannabis industry leader, and our shared research will demonstrate the critical importance that an optimally controlled environment can play on the cultivator's ability to consistently produce high-quality flower. I am proud to showcase our cutting-edge indoor vertical farming grow cultivation technology and assist Curaleaf in growing the high-quality, consistent cannabis they are known for in the most cost-effective manner possible.”

“Since our inception, we have been committed to providing our customers with premier and innovative cannabis products and experiences, with a relentless drive for quality,” said Joseph Bayern, Chief Executive Officer of Curaleaf. “The cultivation environment plays a critical role in the plant’s chemical composition, and we believe this research will help to further increase understanding of the conditions required to optimize a plant's genetic potential.”

Under the terms of the Agreement, Agrify will supply its VFUs and provide use of the Company’s Agrify Insights™ software platform for a period of three years at Curaleaf's primary R&D facility located in Massachusetts, with an option to extend another three years. The collaboration combines Agrify’s technology and expertise in creating optimized cultivation environments with Agrify Insights™-based data and Curaleaf’s expertise in cultivation and production of quality cannabis products. All test data collected by Agrify Insights™ will be jointly owned.

About Curaleaf Holdings, Inc.

Curaleaf Holdings, Inc. (CSE: CURA) (OTCQX: CURLF) ("Curaleaf") is a leading international provider of consumer products in cannabis with a mission to improve lives by providing clarity around cannabis and confidence around consumption. As a high-growth cannabis company known for quality, expertise and reliability, the company and its brands, including Curaleaf and Select, provide industry-leading service, product selection and accessibility across the medical and adult-use markets. In the United States, Curaleaf currently operates in 23 states with 107 dispensaries, 22 cultivation sites and over 30 processing sites, and employs over 5,000 team members. Curaleaf International is the largest vertically integrated cannabis company in Europe with a unique supply and distribution network throughout the European market, bringing together pioneering science and research with cutting-edge cultivation, extraction and production. Curaleaf is listed on the Canadian Securities Exchange under the symbol CURA and trades on the OTCQX market under the symbol CURLF. For more information, please visit https://ir.curaleaf.com.

About Agrify (NasdaqCM:AGFY)

Agrify is a developer of premium grow solutions for the indoor agriculture marketplace. The Company uses data, science, and technology to empower its customers to be more efficient, more productive, and more intelligent about how they run their businesses. Agrify’s highly advanced and proprietary hardware and software solutions have been designed to help its customers achieve the highest quality, consistency, and yield, all at the lowest possible cost. For more information, please visit Agrify’s website at www.agrify.com.

Forward-Looking Statements

This press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995 concerning Agrify and other matters. All statements contained in this press release that do not relate to matters of historical fact should be considered forward-looking statements, including, without limitation, statements regarding the research to be performed under the Agreement. In some cases, you can identify forward-looking statements by terms such as "may," "will," "should," "expects," "plans," "anticipates," "could," "intends," "targets," "projects," "contemplates," "believes," "estimates," "predicts," "potential" or "continue" or the negative of these terms or other similar expressions. The forward-looking statements in this press release are only predictions. We have based these forward-looking statements largely on our current expectations and projections about future events that we believe may affect our business, financial condition and results of operations. Forward-looking statements involve known and unknown risks, uncertainties and other important factors that may cause our actual results, performance or achievements to be materially different from any future results, performance or achievements expressed or implied by the forward-looking statements. You should carefully consider the risks and uncertainties that affect our business, including those described in our filings with the Securities and Exchange Commission (“SEC”), including under the caption “Risk Factors” in our Annual Report on Form 10-K for the year ended December 31, 2020 with the SEC, which can be obtained on the SEC website at www.sec.gov. These forward-looking statements speak only as of the date of this communication. Except as required by applicable law, we do not plan to publicly update or revise any forward-looking statements, whether as a result of any new information, future events or otherwise. You are advised, however, to consult any further disclosures we make on related subjects in our public announcements and filings with the SEC.

Agrify

Niv Krikov

Chief Financial Officer

niv.krikov@agrify.com

(617) 896-5240

Investor Relations

Rob Kelly

ir@mattio.com

(416) 992-4539

Media Contact

Renee Cotsis

renee@mattio.com

August 20th - 2nd Annual OptimIA Research Collaborative Update

Plan to join our annual stakeholder meeting online to learn our collaborative research update

Registration is now open!

2021 OptimIA Research Collaborative Update

August 20th, 2021

10 AM - 3 PM Eastern

Plan to join our annual

stakeholder meeting online to

learn our collaborative research update!

Meeting Information & Agenda

OptimIA (Optimizing Indoor Agriculture) is a USDA-funded Specialty Crop Research Initiative project to support indoor farming industry through critical research and extension activities.

Register

Affordable, Image-Based Crop Monitoring Using Smartphones and Microcontrollers

Dr. Krishna Nemali and his research group at Purdue University are tackling crop-monitoring challenges facing hydroponic and flower growers. Of the group’s many research foci, image-based crop monitoring using smartphones and microcontrollers has been at the forefront of Purdue’s technological advancements for the CEA industry.

Smart Sensors From Purdue University

With a mission to deliver easy-to-use, rapid and affordable technologies to the controlled environment agriculture (CEA) industry, Dr. Krishna Nemali and his research group at Purdue University are tackling crop-monitoring challenges facing hydroponic and flower growers. Of the group’s many research foci, image-based crop monitoring using smartphones and microcontrollers has been at the forefront of Purdue’s technological advancements for the CEA industry.

Image-based crop monitoring made practical and affordable

Image analysis is being used for monitoring plants in conventional, field-based agriculture through satellites, drones, and camera-mounted vehicles. However, these technologies are not practical for greenhouses and indoor farms due to the architecture of these facilities, which limits the movement of drones or camera-mounted vehicles over plants. Dr. Nemali and his research group are working to bring image-based crop monitoring on smartphones as handheld sensors. For installations where using cameras fixed to the growing systems is preferred (e.g. vertical farms with multi-tiered racking) or applications where continuous monitoring is useful, the research team is also building a system with a Raspberry Pi microcontroller and high-resolution camera, which sends the images to a central computer for processing and interpretation.

Left: Dr. Krishna Nemali. Right: smartphone sensor

Compared image-based monitoring to human evaluation

To test the efficacy of image-based crop monitoring, the research team grew lettuce and tomatoes under optimal and suboptimal conditions. In a blind trial, crop growth was visually evaluated daily by people (using a rating system) and by image-based sensors. As Dr. Nemali explains, the image-based system recorded statistically significant differences in crop growth between optimal and sub-optimal conditions 3-4 days before the human eye could detect differences.

“When you regularly take these photos and develop growth curves, you can monitor how your crop is measuring up against expected optimal growth. If these images indicate an issue, growers can resolve this before it is too late,” says Dr. Nemali.

The images can also be used to assess nitrogen status, germination percentage, and rate, and color progression, allowing the grower to monitor crop health, planting material, and estimate the time to harvest. Plant nitrogen status is usually measured in a laboratory, which is expensive and time-consuming or using expensive chlorophyll meters. Dr. Nemali’s research developed accurate algorithms using images captured by smartphones and microcontrollers to rapidly estimate plant nitrogen status.

Different plant measurements can be measured using images collected by a smartphone or microcontroller

Instantaneously assessing plant nitrogen

“Imaging the benefits of instantaneously assessing plant nitrogen status in CEA industry. Growers can supply fertilizers based on plant needs and avoid over or under application rates,” says Dr. Nemali

As these technologies are being developed at Purdue University, they will be made available to growers at a low cost, with any generated funds being poured back into further research and development. The smartphone app should be available in the spring of 2022, with a low purchase price and yearly license.

With photo-quality varying according to the camera, ambient light conditions, and distance from the crop, normalization processes have been incorporated into algorithms to ensure high-quality analyses. To account for differences in distance from the crop between imaging sessions, each photo is taken with a standard, measured object in the frame.

“Let’s say we have a red square with a known area of 25 cm2 and we place it beside the crop in each image. The computer will recognize that object, uses its area to determine the right pixel-area conversion and apply it to the plant. This creates a relative scale and eliminates height/distance altogether,” says Dr. Nemali.

To normalize for different light conditions, the technology considers different reflected wavelengths, both of which are affected by light intensity. By taking the ratio of two wavelengths, the setup can eliminate the effects of light intensity on the images altogether.

A demonstration of smartphone-based image technology can be viewed on Dr. Nemali’s website at this link.

Additional areas of research

Aside from image-based crop monitoring, Dr. Nemali’s research group is conducting extensive research on nitrogen management in hydroponically grown organic lettuce production.

“The yields of organic lettuce is usually lower compared to conventional production, because of challenges with nitrogen availability to plants in organic production. While organic lettuce does command a higher price, we still need to increase these yields to make it sustainable and organic produce more available to consumers,” explains Dr. Nemali.

Other areas of research include the use of ultraviolet radiation and ozone to reduce the risk of E. coli contamination in lettuce, and the optimization of production techniques to improve the nutritional density of leafy greens.

For more information on ongoing research in Dr. Nemali’s research group:

Dr. Krishna Nemali

Assistant Professor in Controlled Environment Agriculture

Purdue University

https://www.purdue.edu/hla/sites/cea/

24 June 2021

Author: Rose Seguin

© HortiDaily.com

AeroFarms Commences Construction On AgX Research Center

AgX will bring innovative research and development to the UAE and the Middle East to advance sustainable controlled environment agriculture (CEA) and vertical farming and help address broader global agriculture supply chain issues

AeroFarms Wholly-Owned Subsidiary AeroFarms AgX LTD Has Started

Construction Focused On Some Recent Developments

03 Jul 2021

AeroFarms, a certified B Corporation, and specialist in indoor vertical farming announced that AeroFarms AgX LTD, its wholly-owned subsidiary in the UAE, has started construction in Abu Dhabi on the company’s Research Center focused on the latest developments for indoor vertical farming, innovation, and AgTech.

AgX will bring innovative research and development to the UAE and the Middle East to advance sustainable controlled environment agriculture (CEA) and vertical farming and help address broader global agriculture supply chain issues.

Last year, ADIO announced that it is providing $150m in incentives to bring global AgTech pioneers to Abu Dhabi, including its partnership with AeroFarms to build a vertical farming facility dedicated to developing next-generation agriculture in arid and desert climates.

The transformational R&D conducted at AeroFarms AgX is expected to enable new business lines, technologies, and growth of the AeroFarms platform while serving as a hub for regional expansion. AeroFarms AgX is expected to be completed and operational in the first quarter of 2022.

HE Dr Tariq Bin Hendi, Director General of ADIO, said: “This important milestone for AeroFarms AgX is another step in the realization of Abu Dhabi’s mission to ‘turn the desert green’. In line with this goal, ADIO is supporting innovative technology that has the potential to impact farming practices across the globe and improve the food production value chain worldwide. AeroFarms AgX will add to the growing capabilities of Abu Dhabi’s agriculture ecosystem while benefiting from the emirate’s plentiful land, natural heat, competitive energy prices, access to research universities, and skilled talent.”

AeroFarms AgX will be the largest indoor vertical farm of its kind for research and development in the world, leading the way in breakthrough innovation to solve some of the world’s most pressing agriculture challenges.

AeroFarms AgX will employ a projected 60 highly skilled engineers, horticulturists, and scientists and will have high-tech laboratories conducting organoleptic research and precision phenotyping, phytochemical analysis, advanced speed breeding, as well as next-generation machine vision, machine learning, robotics, and automation. AeroFarms AgX will also play a key role in Abu Dhabi’s AgTech ecosystem by working with local universities on research projects to tackle problems of agriculture within desert and arid climates.

David Rosenberg, Co-Founder, and CEO of AeroFarms commented: “This is an important development for AeroFarms as we expand globally and leverage our R&D and growing expertise. AeroFarms has been the global leader for controlled environment agriculture since 2004, and we will utilize this cutting-edge R&D Center to conduct the latest research in plant science, vertical farming, and automation, accelerating innovation cycles and commercializing products.

Our vision has always been to leverage our expertise in plant biology and build on our successful history of collaborating with government, universities, industry and major international companies. We are pleased to take this step forward and proud to be a catalyst for helping to establish the Emirate of Abu Dhabi as a global hub for AgTech innovation.”

Lead photo: AeroFarms to build world's largest indoor vertical farm in Abu Dhabi. AeroFarms

BrightFarms Forms Research And Development Innovation Hub BrightLabs; Steve Platt And Matt Lingard Comment

BrightLabs places a key focus on developing proprietary and patented ecosystems for plants to thrive, increasing their flavor, yields, and texture in the process

June 24th, 2021

by Jenna Plasterer

IRVINGTON, NY - A new launch and a new leader? Tell me more! These are just a couple of the titillating details included in BrightFarms’ most recent announcement. The indoor greens grower has formed a new research and development (R&D) hub called BrightLabs at its Ohio growing facility. Matt Lingard, PhD, a former Bayer plant scientist with over 15 years of experience in biotechnology and greenhouse science, will be leading the BrightLabs team as Vice President of Agriculture and Science.

Steve Platt, Chief Executive Officer, BrightFarms“

The indoor farming industry is at an inflection point as local, indoor-farmed produce becomes a priority for retailers and consumers. Among competitors, we’ve developed the most profitable model for the production of indoor leafy greens, but it’s essential that we maintain our market advantage to stay ahead of the curve,” said Steve Platt, Chief Executive Officer. “We’ve built up a team of the best minds in indoor agriculture to officially launch BrightLabs, where we’ll develop the next phase of game-changing products and technology solutions for our operations.”

BrightLabs places a key focus on developing proprietary and patented ecosystems for plants to thrive, increasing their flavor, yields, and texture in the process. The team will bring together experts in technology, microbiology, and plant science to deliver breakthrough innovations in the salad category and beyond.

BrightFarms has formed a new research and development (R&D) hub called BrightLabs at its Ohio growing facility

This multi-million dollar R&D investment is launching as part of the company’s $100 million Series E Fundraise led by Cox Enterprises and represents a significant increase in the company’s research capabilities. Ten percent of the company is now dedicated to developing complex, patented growing solutions to be applied to BrightFarms’ burgeoning network of greenhouses.

Matt Lingard, PhD, Vice President of Agriculture and Science, BrightFarms“

No other indoor farming company is studying a plant’s microbiome, the naturally occurring bacteria that help determine its health, to the same degree that we are,” said Lingard. “Instead of pouring dollars into artificial lighting research, we’re developing cutting-edge biotechnology solutions to out-maneuver our competition with the most productive indoor farms in the industry. There’s no question that high-tech greenhouses that leverage natural sunshine have emerged as the most promising new generation of agriculture technologies, and optimizing the microbiome will allow us to unlock even more of a plant’s natural potential in our indoor farms.”

BrightLabs aims to double its production of its hydroponically grown spinach, and will build on the success of its best-selling Sunny Crunch variety with a new, antioxidant-rich lettuce, NutriGreens, set for release this June.

BrightLabs places a key focus on developing proprietary and patented ecosystems for plants to thrive, increasing their flavor, yields, and texture in the process

BrightOS, the company’s award-winning proprietary data system, will help the BrightLabs team accelerate their research with machine learning and advanced data analysis.

Stay tuned as we wait to see the incredible innovations to come.

Indoor Farming Indoor Ag BrightFarms Research Development Research and Development R&D Innovation Innovates Innovation Hub BrightLabs Launch New Launch BrightOS Steve Platt Matt Lingard

COMPANIES IN THIS STORY

BrightFarms

BrightFarms finances, designs, builds and operates greenhouse farms at or near supermarkets, cutting time, distance, and...

Singapore: Mega-Farm, Research Center To Open By December 2021

&ever is currently building a mega-farm in Singapore with support from the Singapore Food Agency, SFA, and the Economic Development Board, EDB, and will be launched by the end of 2021. The mega-farm will be 15m high and have an annual production capacity of up to 500,000 kg of leafy greens.

&ever

“We’re really happy to have launched in Munich and consumers really like our harvest-on-demand concept,” says Franz Drack, Chief Marketing Officer at &ever. "We just need to see how to increase the accessibility of our solutions. I’d love to see 200 vertical farms in Europe with this technology in the next five years."

Although it all started in Hamburg, &ever is currently headquartered in Munich which is also where the grow tower showroom is located. In 2020, &ever opened its first commercial farm in Kuwait, spanning 3,400 m2 and with a daily output capacity of 550 kg. The farm provides its leafy greens to Kuwaiti restaurants and retailers. The company also recently launched a grow tower in an EDEKA Stadler+Honner “Die Frisch-Nachbarn” supermarket in Unterfôhring near Munich.

Mega-farm and research center

&ever is currently building a mega-farm in Singapore with support from the Singapore Food Agency, SFA, and the Economic Development Board, EDB, and will be launched by the end of 2021. The mega-farm will be 15m high and have an annual production capacity of up to 500,000 kg of leafy greens.

In addition to the mega-farm, &ever will be establishing Singapore as its global R&D center to accelerate knowledge development and transfer to the mega-farm. The R&D center will focus on improving energy use efficiency through optimized lighting strategies and improving crop quality by evaluating different seed and substrate combinations. Moreover, &ever will be working to develop non-invasive crop monitoring processes through vision systems.

“We’re getting tremendous support from our local partners EDB, SFA and A*Star; everyone is keen to get this farm online. This farm is what we are most excited about this year,” Franz notes. To better address consumer demand, &ever conducted market research in Singapore by speaking with potential consumers and foodservice providers. This research has allowed &ever to explore the balance between western and eastern leafy green species to be grown in the mega-farm.

“Our team under the lead of our country manager, Kerstin Köhler, have worked with food service providers who are very good at telling us what products are needed and wanted. Some products are very interesting for certain segments of the value chain, so we try to talk to a lot of different people,” says Franz.

&ever is continuing to focus on leafy greens, microgreens and herbs for the time being. While there is a lot of interest in fruits (like strawberries), Franz explains that the company is focused on keeping its product range simple to perfect the growing process.

&ever's growing tower

Rebranding efforts

In recent months, the vertical farming industry has seen major players taking a new approach to product branding by using brightly colored packaging. &ever is also focused on bright, enticing packaging designed to represent the company’s values and production process.

“We will start using colors that represent what we’re actually doing. Yellow for the light, blue for the water and green for our greens. It allows the brand to stand out and visually signals to consumers that things are changing. This shows that we are a new type of agricultural company. Stay tuned for that in the second half of 2021.” explains Franz.

Franz also notes that &ever’s products are also sold living, whereas many indoor farms sell cut greens, packaged in clamshells or other packaging materials. Moreover, &ever is also looking into direct-to-consumer sales of leafy greens.

In building its mega-farm, putting its products on European shelves and rebranding, &ever is eager to continue growing by getting consumers excited and developing more farm projects across the world.

&ever is a German agtech company offering three growing solutions, each addressing a different level of production. The &ever grow box is a small-scale system that allows growers to produce 15-30 kg of leafy greens per day in a small footprint. The company’s medium-sized solution is the &ever grow tower which is a small room containing a circular cultivation module.

Young plants are first transplanted in the inner circle and are gradually pushed further to the outer circles as new plants are introduced to the system. In pushing the plants further, the older plants receive more available space to continue growing without crowding neighboring plants. The grow towers provide a customizable output of 20-50 kg of leafy greens per day. Finally, &ever also develops large-scaled production system which it calls mega-farms.

For more information:

Franz Drack, CMO

&ever

local@andever.de

www.and-ever.com

Publication date: Tue 8 Jun 2021

Author: Rebekka Boekhout

© VerticalFarmDaily.com

A Primer On Vertical Farming As The Industry Gains Steam

The modern concept of vertical farming was put forth in 1999 by Columbia University microbiologist Dickson Despommier, who along with his students, came up with a design of a skyscraper farm that could feed 50,000 people

MAY 28, 2021

The modern concept of vertical farming was put forth in 1999 by Columbia University microbiologist Dickson Despommier, who along with his students, came up with a design of a skyscraper farm that could feed 50,000 people.

Since then, vertical farming has become a multi-billion-dollar industry. And it’s growing rapidly.

According to PitchBook data, nearly $1.9 billion of global venture capital was invested in indoor farming in 2020, nearly tripling investment in 2019. And just this week, New York-based vertical farming startup Bowery Farming raised $300 million in its latest funding round, valuing the company at $2.3 billion.

Vertical farming growth may be accelerating at the ideal time, as concerns about population growth and climate change push the food industry to innovate to meet tomorrow’s challenges.

By 2050, around 68% of the world population is expected to live in urban areas, and this growth will lead to an increased demand for food. The use of vertical farming could play a role in preparing for such a challenge. At the same time, it could help restore forests depleted by commercialized agriculture and curb planet-warming emissions caused by farming and transportation. Agriculture and forestry alone account for about a quarter of the world’s greenhouse gases.

What is it?

Vertical farming is the practice of growing crops in vertically stacked layers as opposed to a single level, like a field or greenhouse.

Through the artificial control of temperature, light, humidity, and gases, food can be produced indoors in a way that optimizes plant growth and soilless farming techniques such as hydroponics, aquaponics, and aeroponics. The benefits of which are reliable, environmentally friendly, year-round crop production, significantly reduced water usage (by some estimates up to 95% less), efficient land use, and less exposure to chemicals and disease.

Among its downsides, vertical farms are costly to set up and operate and are too dependent on technologies that have yet to reach full maturity. Further, with its heavy reliance on electricity for lighting and climate control, it uses more energy than traditional farming methods and contributes to greenhouse gas emissions.

With that, the sector continues to innovate. And with vertical farming merely in its infancy, it’s reasonable to expect big things in the coming decades.

Investors certainly think so.

In fact, the global vertical farming market is projected to reach $12.77 billion by 2026, growing at a CAGR of 24.6%, according to Allied Market Research.

OnePointOne And Sakata Seed America Aim To Accelerate The Quality And Variety In Vertical Farming

OnePointOne’s system consists of advanced aeroponics and a fleet of robotic growers to perform most of the day-to-day production functions – from planting, to watering, to harvesting

Industry-Leading Partnership Will Drive Data, Growth, and Consumer Options

SAN JOSE, CA — OnePointOne and Sakata Seed America announced today a game-changing collaboration in the acceleration of vertical farming. Together, the two leading entities will share intelligence and analysis focused on maximizing plant outputs while minimizing environmental impact.

The large-scale research program begins today at OnePointOne’s facility in San Jose, CA. Their 25-foot vertical structure uses LED lights to supplant the sun, a nutrient-rich mist to replace the soils, and a clean-room environment, akin to a computer lab, as the production field.

OnePointOne’s system consists of advanced aeroponics and a fleet of robotic growers to perform most of the day-to-day production functions – from planting, to watering, to harvesting.

Sakata’s wide array of state-of-the-art genetics coupled with OnePointOne’s industry-leading, proprietary tech promises to drive further innovations and discovery.

Dave Armstrong, President/CEO of Sakata adds, “We are taking the Controlled Environment Agriculture arena very seriously. By working with OnePointOne on product research and development, we aim to push the segment’s development in a real-world vertical production environment. Working together directly and fully sharing information enables both sides to capture data that might otherwise take years to generate.”

“Working with OnePointOne gives us the opportunity to test many of our varieties in a true vertical system and highly precise indoor environment. The performance data we’ll collect will help us continue to refine our varieties and fine-tune our breeding programs for the CEA space,” said Tracy Lee, Sakata’s Controlled Environment Agriculture (CEA) Lead.

“We are on a mission to unleash the power of plants to feed, fuel and heal the world,” explains Sam Bertram, CEO, and Co-Founder of OnePointOne. “As we launch Willo, the world’s first personalized vertical farming experience, this Sakata partnership will help amplify our ability to bring an exciting list of cultivars to our members. Furthermore, it will drive the innovations and advances needed to bring a more sustainable growth platform to the market at scale.”

About Sakata Seed America, Inc.: Headquartered in Morgan Hill, CA, Sakata Seed America is a major research, seed production, and marketing-distribution subsidiary of Sakata Seed Corporation, established in 1913. Sakata Seed America, which recently celebrated its 40th anniversary, serves as the headquarters for the North American/Central American operations. Their mission is to quickly and efficiently meet industry expectations for quality seed, innovative genetics, and excellent greenhouse and field performance.

About OnePointOne: Founded in Silicon Valley, OnePointOne is revolutionizing vertical farming by building the most technologically advanced plant cultivation platform on the planet through innovations in automation, AI, and plant science. In 2020, OnePointOne launched Willo (www.willo.farm) the world’s first personalized vertical farming program designed to amplify human health.

Bowery Farming Unveils Research And Breeding Hub, Farm X

Farm X is one of the largest and most sophisticated vertical farming R&D facilities in the world, and will further accelerate the commercialization of products specifically designed for Bowery’s indoor system

May 18, 2021

NEW YORK, May 18, 2021 /PRNewswire/ — Bowery Farming, the largest vertical farming company in the United States, today announced the opening of Farm X, its newest state-of-the-art innovation hub for plant science in Kearny, N.J., adjacent to Bowery’s original R&D Center of Excellence and first commercial farm.

Farm X is one of the largest and most sophisticated vertical farming R&D facilities in the world, and will further accelerate the commercialization of products specifically designed for Bowery’s indoor system.

From the cultivation of strawberries, root vegetables, tomatoes, peppers and beyond, to the discovery of the next generation of wildly flavorful leafy greens, Farm X expands Bowery’s R&D capacity by nearly 300%.

“We’re proud to be the largest vertical farming company in the United States that is consistently and reliably delivering our customers a wide variety of high quality, flavorful produce that’s local, safe and sustainable,” said Irving Fain, founder, and CEO of Bowery Farming.

“From day one, our R&D team has been working tirelessly to unlock the next frontier in agriculture, and Farm X enables us to expedite the discovery of new vibrant crops and pioneering technological advancements that will further accelerate our momentum as the category leader.”

Bowery’s world-class team of plant breeders, plant physiologists, biochemists, and more, are constantly innovating from seed-to-shelf. At Farm X, they will be able to test more, faster—ultimately accelerating the discovery of new crops, growing recipes, and efficiency improvements that can be replicated at scale across the company’s network of commercial farms.

Featuring proprietary, highly customizable, modular growing environments managed and monitored by new technology developed in-house, Farm X will further unlock the next phase of Bowery’s growth.

Farm X also features a sensory lab where Bowery will continue its quest for the perfect cultivars for indoor growing, as well as launch the first-ever on-site breeding program at a vertical farming company.

Under the new breeding program, Bowery’s team will be able to develop varieties that thrive in its unique growing conditions and evaluate each one for optimal taste, quality and yield, rather than to survive outdoors, pest-resistance, and long-haul transportation. While a traditional breeding program takes up to ten years, Bowery’s controlled indoor environment and 24/7 monitoring of crops will enable the company to bring new groundbreaking products to market at scale in a fraction of the time.

Bowery’s R&D team works year-round to uncover flavor-packed produce and bring new and exciting culinary experiences to consumers. Beyond the cultivation of new fruits and vegetables at Farm X, they are also developing the next generation of greens.

The Farmer’s Selection category, which launched in January 2021, emerged as a way to let consumers in on the process, bringing the thrill of discovering a new ingredient at your local farm stand to the grocery store. Bowery is launching a new small-batch green every four months under this new category.

The first greens released, Bowery Mustard Frills — hearty mustard greens with a tingly start and a fiery, wasabi-style finish — were available through April 2021. Green Sorrel, bright, tart baby greens with a zing and the next release in the series, is now available from May through August 2021.

Farm X also serves as an experimental space for innovation in farm design, data science, computer vision, autonomous robotics, hardware, and software that can be deployed in Bowery’s growing network of commercial farms.

As Bowery continues to advance the integration of proprietary smart farming technology, it recently announced Injong Rhee (formerly VP at Google and CTO of Samsung Mobile) as its Chief Technology Officer. Rhee will ensure that every farm continues to benefit from the collective intelligence of the BoweryOS, the company’s proprietary operating system which integrates software, hardware, sensors, computer vision systems, machine learning models and robotics to orchestrate and automate the entirety of operations.

Rhee’s team is ensuring the advanced technological learnings discovered at Farm X will be seamlessly integrated and applied at scale across Bowery’s network.

Bowery has experienced more than 750% brick-and-mortar sales growth, and more than quadrupled sales with e-commerce partners, including Amazon, since early 2020. Bowery’s newest commercial farm in Bethlehem, Pennsylvania, will bring local, pesticide-free produce, harvested year-round at peak freshness, to a surrounding population of 50 million people within a 200-mile radius, and will be its largest and most technologically-advanced commercial farm yet, further automating the growing process from seed to store.

About Bowery Farming

Bowery Farming, the Modern Farming Company, was founded in 2015 with the belief that technology and human ingenuity can grow better food for a better future. Propelled by its proprietary software system, the BoweryOS, Bowery builds smart indoor vertical farms that deliver a wide variety of Protected Produce — in little time, near cities they serve, for a truly local approach.

Bowery’s farms are growing the next generation of vibrant and flavorful produce. With BoweryOS, farms are 100 times more productive on the same footprint of land than traditional agriculture and grow traceable pesticide-free produce with a fraction of the water and land.

The largest vertical farming company in the U.S., Bowery’s produce is available in more than 850 grocery stores and via e-commerce platforms serving the Tri-state and Mid-Atlantic region, including Amazon Fresh, Giant Food, Walmart, Weis, Whole Foods Market, Albertsons Companies and specialty grocers.

Based in New York City, Bowery has raised more than $172.5 million from leading investors, including Temasek and GV (formerly Google Ventures), General Catalyst, GGV Capital, First Round Capital, Henry Kravis, Jeff Wilke, and Dara Khosrowshahi, as well as some of the foremost thought leaders in food, including Tom Colicchio, José Andres, and David Barber of Blue Hill.

Tagged greenhouse, research, technology, vertical farming

RUSSIA: A Unique Vertical Farm Can Produce 10 Times More Seed Potatoes A Year

Less than a year after the opening of the World-class Scientific Center "Agrotechnologies for the Future", Russian scientists had a breakthrough: the first-ever vertical farm with dynamic LED lighting

Less than a year after the opening of the World-class Scientific Center "Agrotechnologies for the Future", Russian scientists had a breakthrough: the first-ever vertical farm with dynamic LED lighting.

FEDERAL RESEARCH CENTRE «FUNDAMENTALS OF BIOTECHNOLOGY» OF THE RUSSIAN ACADEMY OF SCIENCE

The pandemic has interfered with technological production chains in many areas of agriculture, making the restoration of the Russian seed bank a priority of national food safety. Furthermore, pests and weather conditions prevent the production of standardized raw materials in needed quantities every year. It is only economically efficient to grow high-value crops such as berries or herbs in automated greenhouses. Potatoes, peppers, tomatoes, and oilseeds which are needed much more do not fall into this group.

A team from the Federal Research Center for Biotechnology of the Russian Academy of Sciences rose to the challenge and presented the first pre-production prototype of a vertical farm. The prototype was developed in the framework of the "Smart City Farm" project initiated by the World-class Scientific Center "Agrotechnologies for the Future" that was opened in 2020. Scientists have grown healthy potato for further multiplication in the field.

The crop rapid seed reproduction facility combines state-of-the-art digital technology with organic farming techniques. The vertical City Farm has controlled conditions: dynamic lighting, an automatic irrigation system, pathogen-free air, and nutrients supplied to the plant from a special substrate. A unique feature of the innovative farm is the individually adjustable LED lighting with different spectral composition preferred for specific varieties and for different periods of plant growth.

The complex makes it possible to grow products with specified properties under controlled conditions on an industrial scale with more than ten times the productivity from 1 m2 per year. It has also managed to achieve six harvests a year on the City Farm. This is because of unlocking the natural potential of varieties under controlled vertical farm conditions that do not depend on climate, weather or seed contamination risks.

"Our goal was to develop a universal multifunctional tool that would tap into the natural potential of different varieties, increase their productivity, and improve quantitative parameters. We used nature-like technologies and adjustable LED lighting without adding any genetic modifications. Our complex is based on the extensive researches of the RAS Biotechnology Research Centre. It is economically viable for industrial cultivation of the crops in demand. In addition, it is completely environmentally friendly and waste-free," said Vasiliy Zotov, a Candidate of Biological Sciences, and the head of the project.

The vertical farm consists of module stands with automated watering and multichannel LED lighting systems, as well as a set of microclimate and substrate sensors. Currently, the team is developing databases and analyzes the effect of adjustable lighting on various crops at different stages: from in vitro to nursery plants and final products. In particular, the team studies the influence of adjustable lighting on the morphogenesis and production process (including the biosynthesis of secondary metabolites) in different varieties of plants, including future generations.

"Another important feature of the vertical farm and the controlled vegetation technology developed for it is their flexibility and universal nature. The system can be easily changed to fit a particular task. For example, lighting can be chosen and automatically adjusted to secure the growth of other plants: flowers, berries, potatoes, beetroots, or even wheat", said Dmitry Kravchenko, a Candidate of Agricultural Sciences, a senior researcher at the Federal Research Center for Biotechnology of the Russian Academy of Sciences, and a development and agricultural support specialist in the project.

The team has already received the first commercial orders from major agricultural producers and potato processing companies. In the future, the scientists plan to develop a technology for controlled vegetation of essential-oil-bearing plants and vegetables, such as tomatoes and peppers.

Lead Image: IMAGE: THE MODULE STAND WITH AUTOMATED WATERING AND MULTICHANNEL LED LIGHTING SYSTEMS. view more

CREDIT: FEDERAL RESEARCH CENTER FOR BIOTECHNOLOGY OF THE RUSSIAN ACADEMY OF SCIENCES

###

Disclaimer: AAAS and EurekAlert! are not responsible for the accuracy of news releases posted to EurekAlert! by contributing institutions or for the use of any information through the EurekAlert system.

Latest Research On Indoor Farming Now Just A Click Away

OptimIA is a website featuring research results from six horticulture, engineering, and agricultural economics professors and Extension specialists

By Brian Sparks

May 19, 2021

Greenhouse growers now have access to a new online resource to help make their indoor farming businesses more productive and profitable. OptimIA is a website featuring research results from six horticulture, engineering, and agricultural economics professors and Extension specialists, and their graduate students and technicians, at Michigan State University, The Ohio State University, Purdue University, and the University of Arizona. Born from a four-year, USDA grant-funded project, the website is one tool researchers are making available to anyone interested in overcoming the technological, environmental, and financial challenges common to indoor farming.

In addition to the latest published research, the website offers trade articles authored by OptimIA project scientists, indoor production research highlights, recorded webinars presented by top national and international indoor farming experts, upcoming events related to indoor farming and the OptimIA project, and FAQs.

The OptimIA project’s ultimate goal is to define the environmental parameters within which leafy greens such as lettuce perform best in indoor vertical farms. While the work of each project researcher is unique, it all centers around the effects of light, carbon dioxide, humidity, temperature, air movement, and economics (operating, labor, equipment, etc.) on the sustainability and profitability of using indoor farms to produce leafy greens and microgreens.

The site will be frequently updated with new research results, as they become available.

To access the OptimIA project website, click here.

OptimIA is funded by the USDA‘s Specialty Crop Research Initiative.

NYC’s Bowery Farming Unveils Farm X - A Science, Breeding Hub

Farm X will accelerate the commercialization of products specifically designed for Bowery’s indoor system. The hub will expand the company’s research and development capacity by almost 300%, including cultivation of strawberries, root vegetables, tomatoes, and peppers

By AMY SOWDER

May 18, 2021

(Photos courtesy Bowery Farming)

New York City-based vertical grower Bowery Farming has opened Farm X, an innovation hub for plant science in Kearny, N.J., next to Bowery’s original R&D Center of Excellence and first commercial farm.

Farm X will accelerate the commercialization of products specifically designed for Bowery’s indoor system, according to a news release. The hub will expand the company’s research and development capacity by almost 300%, including cultivation of strawberries, root vegetables, tomatoes, and peppers.

“From day one, our R&D team has been working tirelessly to unlock the next frontier in agriculture, and Farm X enables us to expedite the discovery of new vibrant crops and pioneering technological advancements that will further accelerate our momentum as the category leader,” founder and CEO Irving Fain said in the release.

At Farm X, Bowery’s plant breeders, plant physiologists, biochemists, and others will be able to test more, faster—ultimately accelerating the discovery of new crops, growing recipes, and efficiency improvements that can be replicated at scale across the company’s network of commercial farms.

Farm X also features a sensory lab where Bowery will seek ideal cultivars for indoor growing, as well as launch an onsite breeding program. In that program, Bowery’s team will develop varieties that thrive in its unique growing conditions and evaluate each one for optimal taste, quality and yield. Bowery’s controlled indoor environment and around-the-clock crop monitoring should increase the speed and efficiency of these goals.

Researchers are also developing new greens, such as the Farmer’s Selection category, which launched in January. Bowery plans to release a new, small-batch green every four months under this new category. The first, Bowery Mustard Frills — “hearty mustard greens with a tingly start and a fiery, wasabi-style finish,” according to the release — was available through April 2021. Green Sorrel, bright, tart baby greens with a zing and the next release in the series, is now available from May through August.

Farm X also serves as an experimental space for innovation in farm design, data science, computer vision, autonomous robotics, hardware, and software that can be deployed in Bowery’s growing network of commercial farms.

To further that mission, Bowery hired Injong Rhee, formerly vice president at Google and chief technology officer of Samsung Mobile, as its chief technology officer. Rhee will work on ensuring that every farm continues to benefit from the collective intelligence of the BoweryOS, the company’s proprietary operating system which integrates software, hardware, sensors, computer vision systems, machine learning models and robotics to orchestrate and automate the entirety of operations. The technological learnings discovered at Farm X will be integrated and applied at scale across Bowery’s network.

Bowery has experienced more than 750% brick-and-mortar sales growth, and more than quadrupled sales with e-commerce partners, including Amazon, since early 2020, according to the release. Bowery’s newest commercial farm in Bethlehem, Pa., will bring local produce year-round to a surrounding population of 50 million people within a 200-mile radius.

Vertical Farming On The Rise: Arkansas Agricultural Experiment Station And 80 Acres Farms Enter Research Agreement

Utilizing world-class technology and analytics to offer customers a wide variety of pesticide-free food with a longer shelf-life that exceeds the highest food safety standards

80 Acres Farms enters into a master research agreement with the Experiment Station at The University of Arkansas with scientists to propose collaborative vertical farming research projects aimed to advance the science of vertical farming

NEWS PROVIDED BY 80 Acres Farms

HAMILTON, Ohio, April 26, 2021 /PRNewswire/ -- Vertical farming business 80 Acres Farms has entered into a collaborative research agreement with the Arkansas Agricultural Experiment Station to advance the science of vertical farming.

Scientists with the experiment station, the research arm of the University of Arkansas System Division of Agriculture, will coordinate with 80 Acres Farms researchers to pursue a variety of vertical farming research topics, said Bryan Renk, director of commercialization for the division's Technology Commercialization Office.

Utilizing world-class technology and analytics to offer customers a wide variety of pesticide-free food with a longer shelf-life that exceeds the highest food safety standards.

"Vertical farming is growing and trending," Renk said. "There are multiple companies forming across the U.S. that are trying to take advantage of that trend."

Jean-François Meullenet, senior associate vice president for agriculture research and director of the experiment station, said the agreement provides a unique opportunity for research.

"We are very excited about this new research partnership with 80 Acres Farms," Meullenet said. "Protected farming is a strategic research direction for the Arkansas Agricultural Experiment Station, and 80 Acres Farm is a leader in this area."

Renk said that the initial round of proposed and current research includes a project analyzing the chemical components of 80 Acres produce, an exploration into new protocols for vertical farming, and evaluation of novel blackberry variety selections that are suited for the vertical farming environment.

"We have a great multidisciplinary team of faculty that can make great contributions to the development of vertical farming technology," Meullenet said. "I look forward to seeing the impact we can have through this research."

"80 Acres is expanding its vertical farming R&D facility in Springdale, Arkansas to develop the growing recipes for multiple leafy and fruiting produce crops," said Victor Verlage, senior vice president for operations, agronomy, and research and development at 80 Acres Farms. "We are calibrating and aligning all the growing conditions, incorporating several proprietary AgTech capabilities that were not available until recently, to bring hyper-fresh fruits and vegetables loaded with taste and nutrition so our consumers can indulge in healthy diets," he said.

Margaret Worthington, assistant professor of fruit breeding and genetics in the horticulture department for the experiment station and Dale Bumpers College of Agricultural, Food and Life Sciences at the University of Arkansas, is evaluating blackberry varieties that may perform well in these novel growing conditions.

"We hope to identify blackberry breeding selections that perform well in fully-controlled indoor environments and vertical farms," Worthington said.

"Fruit breeding is a long-term effort," she said. "We need to be forward-thinking and consider how the potential varieties moving through our breeding pipeline are going to fit into new markets and productions systems that are just beginning to develop.

"The Arkansas Fruit Breeding Program has a history of mutually beneficial public-private research collaborations and I am looking forward to working with this new partner," she said.

In addition to collaborating on research, 80 Acres Farms also plans to create internship opportunities for Bumpers college students.

"80 Acres Farms is eager to provide opportunities for the next generation of farmers where they will have access to best-in-class vertical farming technology," said Verlage. "The students will have immersive training right here in Northwest Arkansas, minutes from the university campus."

To learn more about the Division of Agriculture research, visit the Arkansas Agricultural Experiment Station website: https://aaes.uark.edu. Follow us on Twitter at @ArkAgResearch and Instagram at ArkAgResearch.

About the Division of Agriculture

The University of Arkansas System Division of Agriculture's mission is to strengthen agriculture, communities, and families by connecting trusted research to the adoption of best practices. Through the Agricultural Experiment Station and the Cooperative Extension Service, the Division of Agriculture conducts research and extension work within the nation's historic land grant education system.

The Division of Agriculture is one of 20 entities within the University of Arkansas System. It has offices in all 75 counties in Arkansas and faculty on five system campuses.

The University of Arkansas System Division of Agriculture offers all its Extension and Research programs and services without regard to race, color, sex, gender identity, sexual orientation, national origin, religion, age, disability, marital or veteran status, genetic information, or any other legally protected status, and is an Affirmative Action/Equal Opportunity Employer.

About 80 Acres Farms

80 Acres Farms is a vertical farming leader providing customers with the freshest and most nutritious fruits and vegetables at affordable prices. Utilizing world-class technology and analytics, the Company offers customers a wide variety of pesticide-free food with a longer shelf-life that exceeds the highest food safety standards.

For further information, please contact us at:

Rebecca Haders / rebecca.haders@eafarms.com / +1 513-910-9089

Related Files

Related Images

80-acres-farms-vertical-farming.jpg

80 Acres Farms' Vertical Farming Technology

Utilizing world-class technology and analytics to offer customers a wide variety of pesticide-free food with a longer shelf-life that exceeds the highest food safety standards.

SOURCE 80 Acres Farms

Unfold Expands, Adds Research Facility For Vertical Farming

Unfold, a company that combines leading seed genetics with crop growing and agronomic expertise to advance the vertical farming industry welcomes Minos Athanassiadis as a company advisor and breaks ground on its new state-of-the-art R&D vertical farm facility in Davis, California

April 15, 2021

Unfold, a company that combines leading seed genetics with crop growing and agronomic expertise to advance the vertical farming industry welcomes Minos Athanassiadis as a company advisor and breaks ground on its new state-of-the-art R&D vertical farm facility in Davis, California.

Minos Athanassiadis, one of the foremost leaders in the produce space, working at brands such as Dole Fresh Vegetables, Underwood Ranches, and Fresh Link Group, will leverage his expertise to help Unfold develop products of value to produce retailers and consumers.

“Consumer demands are propelling changes in the food supply that are safe, transparent, personalized, and sustainable,” said Athanassiadis. “As an advisor to Unfold, I look forward to working with their fast-growing team to help them discover and develop products that will meet this criteria for retailers and consumers alike.”

Since launching, Unfold has doubled in size, bringing on diverse talent expertise from software engineers who will build digital agronomic services for vertical farm operators to the computational biology experts that will breed tomorrow’s seeds.

For vertical farms to have an impact on our food system, production can't begin and end with leafy greens. The industry’s success will require new products to be brought to market to supplement what can be produced by traditional farms and greenhouses. With the opening of their new R&D facility, Unfold will leverage expertise in AI, machine learning, and plant biology to test new varieties of fruits and vegetables faster and to develop the digital tools that will speed up plant optimization for Unfold’s customers.

“As we look to bring seeds to market in the next year, Minos’ rich history in the produce industry will be invaluable,” said John Purcell, Ph.D., President, and CEO of Unfold. “Another variable to this equation is finally being able to open the doors to our R&D facility in Davis where we’ll be able to push the boundaries of our plant breeding in controlled environments that leverage state-of-the-art digital tools.”

For additional information about Unfold or to hear about potential career opportunities, please visit our website at https://unfold.ag/.

Lead photo and logo courtesy Unfold

New York’s Gotham Greens Plans Solano County Indoor Produce Farm

It will be located on 33.6 acres of agricultural land purchased from the university adjacent to Interstate 80.

GARY QUACKENBUSH

FOR THE NORTH BAY BUSINESS JOURNAL

Example of the greenhouse operated by Gotham Greens which announced plans to open in Solano County (Photo courtesy of Gotham Greens)

Gotham Greens Holdings LLC, a firm with indoor agriculture operations across the U.S., Tuesday, announced plans to build a facility next to the University of California, Davis.

The first phase of this 10-acre Solano County facility is expected to open later this year. It will be located on 33.6 acres of agricultural land purchased from the university adjacent to Interstate 80.

The company stated its plans will provide it with the ability to deliver fresh leafy greens, herbs, plant-based dressings, dips and cooking sauces to more retailers, foodservice operators and consumers on the West Coast.

“… We are partnering with one of the highest-ranked agricultural research centers in the world to advance the entire agriculture system,” said Viraj Puri, co-founder and CEO of Gotham Greens. “California is responsible for growing one-third of the country’s vegetables and two-thirds of the nation’s fruit, yet in recent years, issues surrounding drought, food safety and worker welfare have demonstrated the need for continued innovation.”

The greenhouse will generate 60 full-time jobs and provide UC students with the opportunity to learn first-hand how to sustainably grow produce year-round in a safe, clean, climate-controlled environment. The company stated its facilities use 95% less water and 97% less land than conventional farming. Nationwide, Gotham Greens has 500,000 square feet of greenhouse space at five locations staffed by 400 employees.

The UC Division of Agriculture and National Resources and the UC Davis College of Agriculture and Environmental Sciences has entered into a partnership with Gotham Greens to advance research and innovation in the areas of indoor agriculture, greenhouse technology, and urban agriculture to help advance the science, workforce technology, and profitability of indoor agriculture globally.

“We are building a Controlled Environment Agriculture Consortium to support and advance the indoor farming industry, grow more fresh produce on less land and create new jobs for Californians,” said Gabriel Youtsey, the division’s chief innovation officer. “Gotham Greens is an anchoring partner of this research and industry collaboration that we hope will spur innovation, create a new indoor farming workforce and support industry growth.”

Helene Dillard, dean of the college, said, “This partnership will offer our students the chance to learn best practices from leading experts in indoor farming.”

Gotham Greens recently raised $87 million in new equity and debt capital bringing the company’s total financing to $130 million to fuel the next phase of growth.

Founded in 2009 in Brooklyn, New York, Gotham Greens (gothamgreens.com) owns and operates greenhouses in New York, Illinois, Rhode Island, Maryland and Colorado. Its produce is available in more than 40 states and 2,000 retail stores, including Albertsons Companies (Safeway, Jewel-Osco, and Shaw’s), Whole Foods Market, Target, King Soopers, Harris Teeter, and Sprouts.

The company’s products can also be purchased through e-commerce sites including AmazonFresh, FreshDirect and Peapod.

Lead Photo: Gotham Greens

Vertical Barrels Components "Ready For Vertical Farming Integration"

The aponix vertical barrel system is an alternative vertical NFT solution from Germany that can be used instead of rack systems to use vertical space more efficiently in hydroponic setups and at the same time use natural sunlight better

The aponix vertical barrel system is an alternative vertical NFT solution from Germany that can be used instead of rack systems to use vertical space more efficiently in hydroponic setups and at the same time use natural sunlight better. The system aims to maximize the number of possible grow spaces per level arranged in a given 3D room by increasing the diameter from a ‘Tower’ to a ‘Barrel’.

The whole system is based on lego-like ring segment pieces that serve either as spacers or provide differently organized inserts for standard 2-inch netpots. Assembling multiple of these ring segment pieces will result in stackable ring segments or barrel levels to assemble one or multiple such vertical cylinders. With more ring segments stacked, the height and the number of grow spaces are increased.

By the end of 2020 aponix will have developed the new ‘Version 3’ that will incorporate all collected improvements from the existing global user base from the last 3 years and adding a few more features:

Liquid will be guided more precisely inside. It will also have a new more robust and tight connection mechanism and air traps to keep liquid inside also on high flow rates.

There will be a backwards-compatible and reusable grow plug insert, that is supposed to replace 2-inch one-time use plastic netpots also in other systems. It will also have an optional plant trellis insert to grow larger flowers and fruiting dwarf varieties.

There will be a new lid-base that speeds up setup of lines of vertical barrels and enable rotation of the units if needed.

There will also be a dedicated sprinkler dome lid enabling different sprinkler options including own solutions and also the own existing pressure-less irrigation option using the waterbuffer.

Vertical barrels will be more stable and can be built higher unsing the new V3 part.

There will only be a single ring segment piece in ‘Version 3’ with 2 grow pod inserts that only allow 2 stacking positions instead of 4 in V2. If spaces are unused they can be capped with a nice green cover plug.

As of 2020 aponix also changed their market strategy from looking for distributors to starting to work only with product partners who bring in own engineering and create more specific and distinguishable solutions based on aponix components. Aponix parts are now defined as being mere infrastructure parts that always need to be integrated into a greater individual context involving more or less horticulture engineering depending on the application. Which means product partners create their own unique solutions based on aponix components adding other external even competitive pieces, logic and/or service and market them independently under their own brand and own product name.

For more information:

Aponix

hello@aponix.eu

www.aponix.eu

18 Feb 2021

Delivering The Optimal Growing Parameters

“Especially in the pharmaceutical or supplemental industry, you need an extremely strict batch control that leaves no room for variation,” says Dr Alexis Moschopoulos, Managing Director at Grobotic Systems.

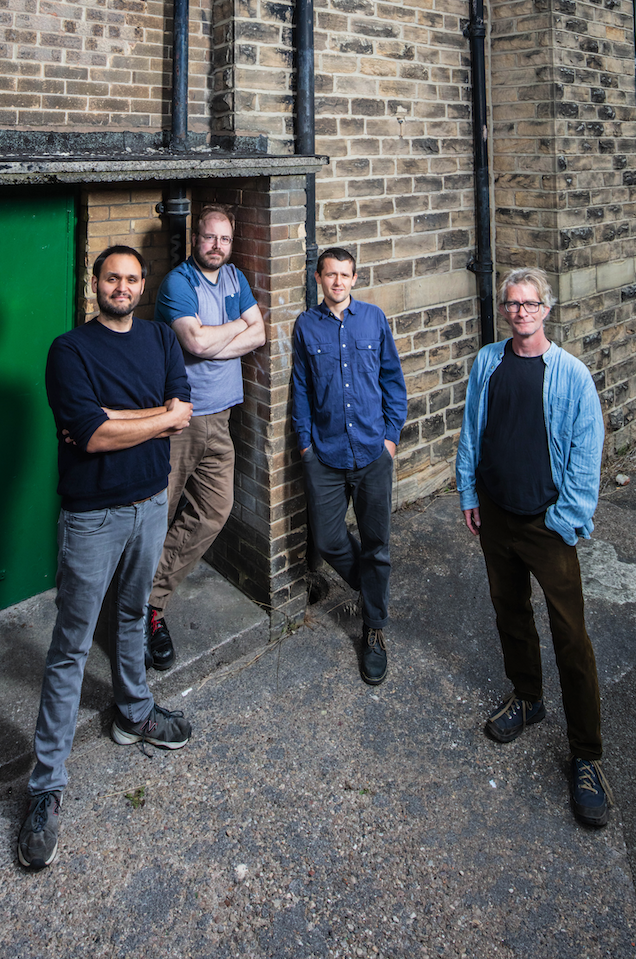

The Grobotic Systems team shows off an early prototype Grobotic chamber. From left to right: Gareth Coleman (Software Developer), Richard Banks (Chief Technology Officer), Dr Alexis Moschopoulos (Managing Director), and Andrew Merson (Mechanical Engineer). Credit: UKRI.

Growing a new variety

Indoor farming has numerous growing parameters to take into account. Particularly when growing a new variety, all variables should be perfected in order to reach an optimum yield. In an indoor space, experimenting with these environmental parameters might, however, seem tricky. But what about trying out this environment in a smaller setting, such as an experimental growth chamber?

Alexis is fully aware of the challenges that vertical farmers face. The environmental control needs to be as precise as possible, as the effect of different light spectra or nutrients may have a significant impact on crop yield and quality. With this challenge in mind, Grobotic Systems brings a new solution to the market: a compact and highly instrumented growth chamber. “It’s an experimental chamber rather than a farming chamber. Therefore, you won’t use it to grow vegetables, but you can use it to identify which growing parameters are best suited to your crops,” Alexis says.

The Grobotic Systems team outside their workshop in Sheffield, England. From left to right: Dr Alexis Moschopoulos, Richard Banks, Andrew Merson, and Gareth Coleman. Credit: UKRI.

On your desk or under your bench

According to Alexis, the chamber fits on your desk or under your bench. It can apply any environmental condition preferred, including light spectra and temperature. Internet connection via the growth chambers allows users to monitor plants on their cellphones via integrated cameras and other sensors inside the chamber.

Another advantage of the chambers’ size is that they can be stacked in an array, adjusting variables in each chamber. In this way, a multi-variable experiment can help users identify which environment works most optimally for their intended crop. “When using a large cultivation room, it is hard to split the room into different temperatures. A smaller cultivation space, such as our growth chambers, can be placed anywhere, just like a personal computer. Moving away from the large expensive capital equipment and machinery to small and stackable experimental chambers saves a lot of space and money.”

Alexis first came up with the concept of the growth chamber during his PhD and postdoctoral work in plant genetics. Several prototypes are currently being used at research institutes and start-up companies. Grobotic Systems is working on a more advanced growth chamber that will be launched in the summer of 2021: “We are integrating feedback from the deployed prototypes into the design of the advanced chamber, and we will start marketing the advanced chamber later this year.”

Richard Banks designs a control system circuit board for an early prototype Grobotic chamber. Credit: UKRI.

Large-scale farms

Not only new farmers can benefit from running small-scale experiments in a growth chamber, but also large-scale, established farms, since the chamber allows them to experiment with new varieties, creating the optimal yield. This will in turn enable them to upscale their production. “Not all farmers like to invest their time in carrying out experiments, as some trust that the vertical farming technologies they buy will always work for them. However, in the end it could save them a lot of money. No one needs to use productive farm space to do the experiments, just a few manageable boxes can suffice.”

Gareth Coleman works on the chamber imaging and control systems. Credit: UKRI.

For more information:

Grobotic Systems

Dr Alexis Moschopoulos, Managing Director alexis@groboticsystems.com

www.groboticsystems.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

(Assistant) Professor Crop Modelling In Greenhouses And Vertical Farms (Tenure Track)

Are you keen to contribute to the sustainable production of healthy fresh vegetables? We have a vacancy for an Assistant professor of Crop modelling in Greenhouses and vertical farms. Do you like to supervise students? Do you want to combine modelling and data analytics with plant experimentations? Then this position could be a perfect fit for you!

The chair group Horticulture and Product Physiology of Wageningen University & Research (WUR) is keen to hire an Assistant Professor (0.7-1.0 ft). As an Assistant Professor, you will take a leading role in developing research and education and the opportunity to establish your own research and education in crop modeling in greenhouses and vertical farms.

This position also involves experimental physiological work at the plant organ, whole plant or whole crop level, which is necessary to build, calibrate and validate models.

In this challenging career trajectory:

You will perform research on modeling, combined with experimentation, of growth, development, and quality of horticultural crops and products (vegetables, fruits, cut flowers, and/or pot plants).

You acquire, lead and implement together with the chair holder and other staff members innovative and creative (inter-)national research projects for our group. Once acquired you also implement and lead these projects.

You supervise Ph.D., MSc, and BSc students, and you will develop and teach courses (lectures, practicals) on the modeling of key plant processes in greenhouses and vertical farms.

Your work will focus on the development of models, which are a combination of multiscale Spatio-temporal data-driven, as well as knowledge-based models. Model applications may include predictions of yield, plant development and growth, quality, post-harvest behavior, resource use and running costs for crops grown in greenhouses and vertical farms

You collaborate with colleagues and establish a personal research portfolio that is embedded in the Horticulture and Product Physiology group

You undertake research on modeling and data analytics, combined with experimentation, that leads to high-quality research output.

You will perform research on modeling, combined with experimentation, of growth, development, and quality of horticultural crops and products (vegetables, fruits, cut flowers, and/or pot plants).

Tenure Track is a career path for scientists who pursue to excel in education and research. We seek to attract scientific talent and to stimulate and support their development.

Requirements:

You hold a Ph.D. degree in plant science, mathematical science, biological science, data science, or similar.

You have experience in modeling and data analytics, as well as a keen interest in combining these activities with experimentation with plants.

You have published research in high-quality journals and are willing to develop your skills in teaching and grant proposal acquisition.

You are strong in stakeholder management because you need to communicate the importance and significance of your research.

This position requires excellent English language proficiency (a minimum of CEFR C2 level). For more information about this proficiency level, please visit our special language page.

The chair group Horticulture & Product Physiology

The chair group Horticulture and Product Physiology conduct high impact research and educate students providing the scientific basis required to answer questions that are of utmost importance for sustainable crop production and product quality in horticulture.

The research focus is on how physiological processes in crops, plants, and plant organs interact with the abiotic environment and how this affects crop production and product quality. Questions arising from horticultural practice are translated into fundamental research topics, aiming to explain mechanisms. The research and education contribute to sustainably feeding the World with healthy high-quality products.

The chair group is an international team consisting of 15 permanent staff members, about 25 Ph.D. candidates and postdocs, and a number of guest researchers. Each year about 40 MSc students conduct their thesis study (6-month research) at our group. We organize and participate in a variety of courses for BSc and MSc students to transfer knowledge on horticulture (pre-and post-harvest), environmental physiology, and product quality.

More info about the chair group can be found at www.hpp.wur.nl or see the video below:

Salary Benefits:

Wageningen University & Research offers excellent terms of employment. A few highlights from our Collective Labour Agreement:

sabbatical leave, study leave, and paid parental leave;