Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

VIDEO: Indoor Farming Biz AppHarvest Delivered Sales In First Earnings As Public Company

AppHarvest, the tech-forward indoor vertical farming company that went public in February, released its first earnings report showing Q1 net sales of $2.3 million for its tomato harvest

May 17, 2021

AppHarvest, the tech-forward indoor vertical farming company that went public in February, released its first earnings report showing Q1 net sales of $2.3 million for its tomato harvest. The stock ($APPH) was up on the news, rising to more than $13 a share in morning trading, but still well short of its closing high of $38.

Founder and CEO Jonathan Webb spoke to Cheddar about the company's challenges in building a facility and harvesting its product amid a pandemic and pointed to expanding in the future. "Our thesis is that controlled-environment agriculture will be growing almost all fruit and vegetable production at scale indoors," Webb said.

Vertical Farming Startup Oishii Raises $50m In Series A Funding

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone.”

By Sian Yates

03/11/2021

Oishii, a vertical farming startup based in New Jersey, has raised $50 million during a Series A funding round led by Sparx Group’s Mirai Creation Fund II.

The funds will enable Oishii to open vertical strawberry farms in new markets, expand its flagship farm outside of Manhattan, and accelerate its investment in R&D.

“Our mission is to change the way we grow food. We set out to deliver exceptionally delicious and sustainable produce,” said Oishii CEO Hiroki Koga. “We started with the strawberry – a fruit that routinely tops the dirty dozen of most pesticide-riddled crops – as it has long been considered the ‘holy grail’ of vertical farming.”

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone. From there, we’ll quickly expand into new fruits and produce,” he added.

Oishii is already known for its innovative farming techniques that have enabled the company to “perfect the strawberry,” while its proprietary and first-of-its-kind pollination method is conducted naturally with bees.

The company’s vertical farms feature zero pesticides and produce ripe fruit all year round, using less water and land than traditional agricultural methods.

“Oishii is the farm of the future,” said Sparx Group president and Group CEO Shuhei Abe. “The cultivation and pollination techniques the company has developed set them well apart from the industry, positioning Oishii to quickly revolutionise agriculture as we know it.”

The company has raised a total of $55 million since its founding in 2016.

Local Vertical Farm Startup Joins Growing Global Market

Ortaliza Urban Farms is a dream that has been sprouting for some time now.

What if there was a more sustainable way to provide fresh, truly local greens to our communities? And what if there was a way to do it while bringing diverse flavors to the table year-round?

It sounds like an ambitious goal. But it is one that Carina Biacchi and her partner, Alvaro Fernandes, are set to meet.

Ortaliza Urban Farms is a dream that has been sprouting for some time now.

Carina Biacchi is no stranger to business. With a bachelor’s and postgrads in business administration, she has worked in several different sectors, from NGOs to massive corporations. “I’ve mostly worked in sales and marketing” Carina states. “And I have entrepreneurship in my DNA. My parents were entrepreneurs long before I was born.”

And as formidable as Carina is, she is among good company. Alvaro Fernandes, her partner, is an Agronomist Engineer. “He’s a passionate specialist in controlled environment agriculture” Carina explains.

When the two met they quickly started dreaming about their own indoor farm. Years passed, and the two immigrated to Canada and started a family. But those entrepreneurial sparks continued to fly.

“It took us a while to build our lives in Canada,” Carina states. “But we continued to research the idea we had. We kept visiting other businesses in the industry and we even traveled to New York and other areas to see what they had to offer in terms of vertical farms.”

But what is vertical farming? Vertical farming is a growing worldwide phenomenon set to add significant value to the food system. Food security and sustainability continue to be some of the top concerns for city planners, and venture capital firms are investing big into vertical farm operations.

And what is an urban farm? Simply put, urban farming is growing food in urban areas. “We’re located right on Main Street,” Carina states. “In a commercial zoning area. That is pretty unique by itself, and the town of Kingsville has proven to be the perfect partner to help us launch our dream.”

A hyper-local farm-to-plate experience

And while Ortaliza is not the first micro green seller in the region, they are the first to create a storefront, creating an exciting farm-to-plate experience, loaded with flavor and freshness.

“We are truly local!” Carina stresses. “Sometimes, when you see that something is “local” on your grocery shelves, it’s actually from another part of the Province. That might be fine for large vegetables, but greens are special. Think of all the nutrients you would get from a full vegetable but concentrated to deliver all that deliciousness in every single bite. Microgreens require just-picked freshness, so we are super, hyper-local. We’re only growing and selling here in our County.”

This business model, Carina explains, also allows them to reduce food mileage and consequently, food waste. “Leafy greens in Canada can sometimes travel thousands of miles before reaching their destination” Carina reports. “And it can take up to two weeks for the produce to get there. We have a commitment to sustainability, and we will always be local, no matter where we spread our roots to in the future.”

One of Ortaliza’s business Advisors, Adam Castle of WEtech Alliance says the launch of this business in Kingsville represents a unique opportunity for the Startup. “Here we are in the very heart of greenhouse agriculture, not just for Canada but seconded only to Holland from a global perspective,” says Castle. “So you’re planting yourself in a community that lives and breathes agriculture, who knows the value of being able to see where your food comes from and how it’s grown, at a time when the average consumer is more engaged than ever in providing the freshest, most sustainably grown food they can for themselves and their family. I applaud Kingsville for making room at their table for new kinds of agriculture, and being a business-friendly partner that our clients can count on.

“…it certainly fits hand-in-hand with the innovation and the diversification that we’re trying to identify with.”

One enthusiastic supporter of this innovative new business is Nelson Santos, the Mayor of Kingsville and the Deputy Warden of Essex.

“This isn’t your typical business, but it certainly fits in with the entrepreneurial spirit that we have in our community,” Nelson explains. “And it certainly fits hand-in-hand with the innovation and the diversification that we’re trying to identify with. They are touching on all the different aspects of what the community is looking for. Their business is one that is certainly going to turn quite a few heads. It’s very exciting, both in regards to the food aspect and the extension of agriculture.”

Ortaliza is now taking pre-orders for their home delivery service at www.Ortaliza.ca, which promises to deliver a lot more than leafy goodness.

“We want to be more than a farm-to-table service,” says Carina. “We want our customers to think of us as their weekly dose of living, natural vitamins that add easy nutrition to just about every recipe they can think of!”

To learn more and become a friend of the farm, head to www.ortaliza.ca or find them on social media at @OrtalizaFarms

US-VIRGINIA: Arlington’s Only Commercial Farm To Expand, Double Production

Virginia Gov. Ralph Northam announced this afternoon that Fresh Impact Farms will be getting a $30,000 grant — half from the state, half from the county — that will help it double production and create six jobs.

Believe it or not, Arlington County has a working commercial farm.

The farm, which is located in a commercial building along Lee Highway, uses hydroponic technology to grow a variety of edible plants indoors. And it’s about to expand.

Virginia Gov. Ralph Northam announced this afternoon that Fresh Impact Farms will be getting a $30,000 grant — half from the state, half from the county — that will help it double production and create six jobs.

Fresh Impact, Arlington County’s only commercial farm, is banking on its restaurant customers ramping up purchases as vaccinated customers flock back to the indoor dining. It also launched a direct-to-consumer Community Supported Agriculture program last year.

County Board Chair Matt de Ferranti hailed the business and its expansion.

“Governor Northam’s award to Fresh Impact Farms, Arlington’s only commercial farm, is an innovative way to celebrate unique uses of technology to help a small business pivot during the pandemic,” de Ferranti said in a statement. “I am thrilled that Fresh Impact Farms is growing and looking to the future of a sustainable food supply.”

More on the company’s expansion, below, from a press release issued by the governor’s office.

Governor Ralph Northam today announced that Fresh Impact Farms will invest $137,500, create six new jobs, and more than double production at its Arlington County indoor facility. Operating since 2018 as Arlington’s only commercial farm, Fresh Impact Farms uses proprietary hydroponic technology to grow a variety of specialty herbs, leafy greens, and edible flowers for sale to customers in the Greater Washington, D.C. metro area.

Like many companies, Fresh Impact Farms has pivoted its business model amid the COVID-19 pandemic. Seizing the opportunity created by more people cooking at home, the company initiated a Community Supported Agriculture (CSA) program targeting area residents. The CSA program, which focuses on leafy greens and home kitchen-friendly herbs, has grown steadily since its establishment in April 2020 and now includes smaller wholesale clients. Now, with vaccinations underway and the restaurant industry poised to rebound, Fresh Impact Farms is expanding, which will allow the company to resume supplying their restaurant customers, while also meeting new demand through their CSA program.

“Agriculture continues to be a key driver of our economic recovery in both rural and urban areas of our Commonwealth,” said Governor Northam. “Innovative, dynamic businesses like Fresh Impact Farms are demonstrating how exciting new opportunities can grow out of pandemic-related challenges. I congratulate the company on their success and am thrilled to award the first-ever AFID grant to Arlington County to support this expansion.”

This expansion by Fresh Impact Farms will include a second grow room, larger production facility, and an educational hub where, post-pandemic, customers will be able to see how their food is harvested. Over the next three years, the company expects to grow an additional 10,500 pounds of Virginia-grown leafy greens, herbs, and edible flowers for restaurant and CSA customers.

“Agriculture is Virginia’s largest private sector industry and the Commonwealth continues to be on the forefront of emerging agriculture technologies,” said Secretary of Agriculture and Forestry Bettina Ring. “I am inspired by Fresh Impact Farms’ commitment to not only bringing fresh, local produce to Virginians, but also for its commitment to educate our community about how local food is grown.”

“2020 was undoubtedly one of the hardest years in recent memory for many people and businesses, but I’m heartened by the strength and flexibility the entire Fresh Impact Farms team has shown in our deep pivot to consumers and a CSA model to help us get to the point where we are ready to expand our business,” said Fresh Impact Farms Founder Ryan Pierce. “The support and generosity from the Commonwealth and Arlington County will be valuable as we expand our production and move towards a hybrid model of serving both the needs of restaurants and consumers. As the owner of a local food business, nothing gets me more excited than seeing the community come together in support of local food. The future is bright for urban agriculture and this grant will help us make an even greater impact in our community.”

The Commonwealth is partnering with Arlington County and the Arlington County Industrial Development Authority (IDA) on this project through the Governor’s Agriculture and Forestry Industries Development (AFID) Fund, which is administered by the Virginia Department of Agriculture and Consumer Services (VDACS). Governor Northam approved a $15,000 grant from the AFID Fund to secure the project for Virginia, which Arlington County will match with local funds.

“The Arlington County IDA’s match of the Governor’s AFID grant to Fresh Impact Farms represents an important investment in urban agriculture, sustainability, and technology,” said Arlington County IDA Chair Edwin Fountain. “This project will advance the County’s innovative and forward-thinking approach to developing new sectors of economic activity in Arlington.” […]

“Congratulations to Fresh Impact Farms,” said Senator Janet Howell. “This expansion not only supports our local economy, but also has a significant impact promoting healthy families and vibrant communities as a whole.”

“I am delighted Governor Northam has approved a grant from the AFID Fund to deliver this project for the Commonwealth and Arlington County,” said Delegate Richard Sullivan. “Fresh Impact Farms has been a pivotal resource for providing fresh food to the community. This expansion shows a commitment not only to homegrown produce, but to a healthier community and local economy in Arlington.”

"We’re Retrofitting With The Variables We Have In Place"

Planted Detroit introduces new 20.000 sq. ft. growing facility

“The Square Room is a big block of pink lights with eight levels, where all our growing is done. Everything after germination is done in the same room, both harvesting of our baby greens and microgreens. Because we’re almost done with our PARS (Planted Automated Racking System), which is the big automation,” says Megan Burritt, Managing partner at Planted Detroit.

From a mix-fused downtown neighborhood in Detroit, daily deliveries of ready-to-eat salads and fresh greens are transported to local retailers and restaurants. Planted Detroit makes a large contribution to the city’s share of fresh produce.

New facility

Planted Detroit has been in the middle of the construction of its new 20.000 sq. ft growing facility. The growing space has been a massive update to the company compared to its previous 6-level growing facility which was between 1500-2000 sq. ft. The same room was used for processing, packaging, harvesting, and so on. “It was rather crowded, says Megan, but the main goal was to keep everything tight for the construction to continue in the near surrounding. We’re very serious about biosecurity and we have a daily procedure for everyone who sets foot in our grow room to go through. Making sure our greens don’t come into contact with pathogens is our top priority.

The new growing room

The Square Room, one of our growing rooms, is highly automated, including an automatic harvester to ensure work-efficiency. Once everything is big enough to be transplanted out of their plug trays, PARS (Planted Automated Racking System) will be transplanted with gutters and then go into harvesting. On the other side of PARS, the gutters are taken down and harvested through Planted’s new automatic harvester.

Delivering directly to consumers

The company wants to reach a higher volume of customers as it’s aiming to obtain a consumer brand status. Next to that, the company is always on the lookout for finding more customers through other venues. “We want to go directly to consumers via our web-store to shorten food miles as much as possible, delivering the freshest and most delicious greens,” Megan says. In order to do that the company needed to have a bit more scale, trying to maximize the space they already had.

She adds: “Our farm maybe isn’t the square footage which we could have built from scratch, but we’re retrofitting with the variables we have in place. That is why we have done a combination of a microgreen vertical nursery and PARS for baby greens. Our direct customers wanted meal solutions and we’ve been able to deliver them that. We’ve been doing everything from seed to plate basically.”

Megan Burritt, Managing partner

New projects coming up

On the same campus, 10 meters away, a new farm will be constructed, under the company's office space. In this farm herbs and edible flowers will be grown in response to different customers' demands. Megan says that Planted Detroit’s wholesale customers got them to this point as they were very interested in herbs and edible flowers. “However we weren’t able to perfect these as well in the systems that our baby greens were in perfectly. That’s why we’ve been leaning into R&D lately because once finishing the construction of Farm 2 it will have excellent growing conditions that are better than they have been for those crops.”

Edible flowers are an interesting thing, says Megan, but the company has gotten so much interest in it. According to Megan there aren’t many farms in the US that are growing them. “They’re high priced at this point. It sort of sticks to our original innovation, namely what exists here in the food system and what does not. Where can we fill the ‘does not exist niche’ and satisfy the needs of our customers.”

The company is rolling out a subscription program sometime this year and figuring out where it fits into the fresh food subscription system and how they can partner with other parties in order to get produce closer to society. “It’s great to have this ag job, applied science to be able to do. In all the things we’ve been doing is hiring these Detroiters and showing that we can really create a really great culture of work. It’s really great to see we’re contributing to a better Detroit and a better tomorrow,” Megan states.

Team expansion

During 2020 most of the team stayed on by moving around working hours, so the farm could come back in full force. By the time all equipment was in place, 10 to 12 people were added to the team to have them fully trained before the system would be functioning. “It has been really wonderful to expand the team to see what our capacity is,” says Megan.

“Luckily we’ve been able to develop systems that have been resilient. We’ve seen so many different patterns in consumer behavior but they seem to have fallen in our favor. People are eating more at home, shopping for groceries more, and that triggered our pivot focusing on direct consumers. But now, it’s perfectly in line with our strategy on how we go to market. As long as we can supply our customer needs we’ll be on the right path. Nothing but bright hopes for the future right now,” Megan affirms.

For more information:

Planted Detroit

Megan Burritt, Managing partner

megan@planteddetroit.com

www.planteddetroit.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

New York’s Gotham Greens Plans Solano County Indoor Produce Farm

It will be located on 33.6 acres of agricultural land purchased from the university adjacent to Interstate 80.

GARY QUACKENBUSH

FOR THE NORTH BAY BUSINESS JOURNAL

Example of the greenhouse operated by Gotham Greens which announced plans to open in Solano County (Photo courtesy of Gotham Greens)

Gotham Greens Holdings LLC, a firm with indoor agriculture operations across the U.S., Tuesday, announced plans to build a facility next to the University of California, Davis.

The first phase of this 10-acre Solano County facility is expected to open later this year. It will be located on 33.6 acres of agricultural land purchased from the university adjacent to Interstate 80.

The company stated its plans will provide it with the ability to deliver fresh leafy greens, herbs, plant-based dressings, dips and cooking sauces to more retailers, foodservice operators and consumers on the West Coast.

“… We are partnering with one of the highest-ranked agricultural research centers in the world to advance the entire agriculture system,” said Viraj Puri, co-founder and CEO of Gotham Greens. “California is responsible for growing one-third of the country’s vegetables and two-thirds of the nation’s fruit, yet in recent years, issues surrounding drought, food safety and worker welfare have demonstrated the need for continued innovation.”

The greenhouse will generate 60 full-time jobs and provide UC students with the opportunity to learn first-hand how to sustainably grow produce year-round in a safe, clean, climate-controlled environment. The company stated its facilities use 95% less water and 97% less land than conventional farming. Nationwide, Gotham Greens has 500,000 square feet of greenhouse space at five locations staffed by 400 employees.

The UC Division of Agriculture and National Resources and the UC Davis College of Agriculture and Environmental Sciences has entered into a partnership with Gotham Greens to advance research and innovation in the areas of indoor agriculture, greenhouse technology, and urban agriculture to help advance the science, workforce technology, and profitability of indoor agriculture globally.

“We are building a Controlled Environment Agriculture Consortium to support and advance the indoor farming industry, grow more fresh produce on less land and create new jobs for Californians,” said Gabriel Youtsey, the division’s chief innovation officer. “Gotham Greens is an anchoring partner of this research and industry collaboration that we hope will spur innovation, create a new indoor farming workforce and support industry growth.”

Helene Dillard, dean of the college, said, “This partnership will offer our students the chance to learn best practices from leading experts in indoor farming.”

Gotham Greens recently raised $87 million in new equity and debt capital bringing the company’s total financing to $130 million to fuel the next phase of growth.

Founded in 2009 in Brooklyn, New York, Gotham Greens (gothamgreens.com) owns and operates greenhouses in New York, Illinois, Rhode Island, Maryland and Colorado. Its produce is available in more than 40 states and 2,000 retail stores, including Albertsons Companies (Safeway, Jewel-Osco, and Shaw’s), Whole Foods Market, Target, King Soopers, Harris Teeter, and Sprouts.

The company’s products can also be purchased through e-commerce sites including AmazonFresh, FreshDirect and Peapod.

Lead Photo: Gotham Greens

Vertical Farms Nailed Tiny Salads. Now They Need To Feed The World

Vertical farming is finally growing up. But can it move from salad garnishes for the wealthy to sustainable produce for the masses?

Gartenfeld Island, in Berlin’s western suburb of Spandau, was once the bellows of Germany’s industrial revolution. It hosted Europe’s first high-rise factory and, until World War II, helped make Berlin, behind London and New York, the third-largest city on Earth.

Today’s Berlin is still a shell of its former self (there are over a hundred cities more populous), and the browbeaten brick buildings that now occupy Gartenfeld Island offer little in the way of grandeur. Flapping in the gloom of a grey November morning in 2020 is a sign which reads, in German, “The Last Days of Humanity”.

Yet inside one of these buildings is a company perched at agriculture’s avant-garde, part of the startup scene dragging Berlin back to its pioneering roots. In under eight years, Infarm has become a leader in vertical farming, an industry proponents say could help feed the world and address some of the environmental issues associated with traditional agriculture. Its staff wear not the plaid or twill of the field but the black, baggy uniform of the city’s hipsters.

Infarm has shipped over a thousand of its “farms” to shops and chefs across Europe (and a few in the US). These units, which look like jumbo vending machines, grow fresh greens and herbs in rows of trays fed by nutrient-rich water and lit by banks of tiny LEDs, each of which is more than ten times brighter than the regular bulb you’d find in your dining room. Shoppers pick the plants straight from the shelf where they’re growing.

Infarm crop science director, Pavlos Kalaitzoglou, in his Berlin lab

Credit Ériver Hijano

Gartenfeld Island, however, is home to something more spectacular. Here, in a former Siemens washing machine factory, stand four white, 18-metre-high “grow chambers”, controlled by software and served by robots. These are the company’s next generation of vertical farms: fully-automated, modular high-rises it hopes will scale the business to the next level. According to Infarm, each one of these new units uses 95 per cent less water, 99 per cent less space and 75 per cent less fertilizer than conventional land-based farming. This means higher yields, fresher produce and a smaller carbon footprint.

Agriculture is a £6 trillion global industry that has altered the face and lungs of the Earth for 12,000 years. But, unless we change our food systems, we’ll be in trouble. By 2050, the global population will be 9.7 billion, two billion more than today. Fifty-six per cent of us live in cities; by 2050 it will be 70 per cent. If the prosperity of megastates like India and China continues to soar, and our diets remain the same, we will need to double food production without razing the Amazon to do it. That sign on Gartenfeld Island might not be so alarmist.

Vertical farmers believe they are a part of the solution. Connected, precision systems have grown crops at hundreds of times the efficiency of soil-based agriculture. Located in or close to urban centres, they slash the farm-to-table time and eliminate logistics. New tech is allowing growers to tamper with light spectra and manipulate plant biology. Critics, however, question the role of vertical farms in our food future. They are towering lunchboxes for late capitalism, they argue – producing garnishes for the rich when it is the plates of the poor we must fill. Vertical farms already make money, and heavyweights including Amazon and SoftBank are investing in various companies in the hopes of cornering a market expected to be worth almost £10 billion in the next five to ten years. Infarm is leading that race in Europe. It has partnered with European retailers including Aldi, Carrefour and Marks & Spencer. In 2019 it penned a deal with Kroger, America’s largest supermarket chain. Venture capitalists have handed the firm a total of £228 million.

Not bad for a hare-brained experiment that started in a Berlin apartment.

An Infarm employee tends to a batch of seedlings in a special incubator

Credit Ériver Hijano

In 2011, a year before he moved to Berlin, Erez Galonska went off-grid. He grew up in a village in his native Israel, but the young nation was growing too, and farms made way for buildings. Soon the village was a town, and its inhabitants ever more disconnected from their natural surroundings.

Galonska’s father had studied agriculture, and the son had dreamed of recovering a connection with nature he felt he had lost. The search took him to the mountains of the Canary Islands, where he found a plot of land and got to work. He drank water from springs, drew energy from solar panels, and spent long hours farming produce he then sold or bartered at local markets.

When he met his now-wife Osnat Michaeli, “I traded it for love,” he says. “Love is stronger than anything.” In 2012, the couple, alongside Galonska’s brother Guy, who had studied Chinese medicine, moved to Berlin to work on a friend’s social media project. But the hunger for self-sufficiency remained. It was “a personal quest,” Michaeli says. “How we can be self-sufficient, live off the grid. Food is a big part of that journey.”

We meet at a Jewish restaurant in Berlin’s historic Gropius Bau art museum. It is mid-morning, and Covid-19 has cleared the tables. But a row of Infarm units whirs away quietly along one wall, producing basil, mint, wasabi rocket (a type of rocket leaf with the punchy flavour of wasabi), and other, more exotic herbs. Such produce was a pipedream for the three Infarm co-founders eight years ago. Growing crops when living on a tropical island was one thing. Doing it in a small apartment, located in the tumbledown Berlin neighbourhood of Neukölln, was quite another. Soon after moving from the Canaries, Erez Galonska typed “can you grow without soil” into Google.

Japan had taken to indoor farming in the 1970s, and this bore some helpful information on its techniques. The same was true of illegal cannabis growers, who swapped tips about hydroponics – growing with nutrient-packed water rather than soil – across subreddits.

Several trips to a DIY store later, the trio had what resembled a hydroponic farm. It was a big, chaotic Rube Goldberg machine, and it leaked everywhere. Growing wasn’t simply a case of switching on the lights and waiting. Brightness, nutrients, humidity, temperature – every tweaked metric resulted in an entirely different plant. One experiment yielded lettuce so fibrous it was like eating plastic. “We failed thousands of times,” Erez Galonska says.

Two of Infarm’s co-founders, Osnat Michaeli and Erez Galonska

Credit Ériver Hijano

Eventually, the team grew some tasty greens. They imagined future restaurant menus boasting of food grown “in-farm”, rather than simply made in-house, and founded Infarm in 2013. But there was a hitch: indoor-grown cannabis sells for around £1,000 per kilo. Lettuce for £1.20. Most of the early vertical farms required heaps of manual work and operated in the red. “It simply wasn’t a sustainable business model,” Erez Galonska says.

By 2014, they decided to roadshow their idea and shipped a 1955 Airstream trailer – a brushed-aluminium American icon – to Berlin. The trailer belonged to a former FBI agent, but it was conspicuous in a city of Volkswagens, caravans and Plattenbau buildings. Michaeli and the Galonska brothers transformed it into a mobile vertical farm, then pitched up at an urban garden collective in Berlin’s trendy Kreuzberg district. There they proselytised indoor farming to urban planners, food activists, architects and hackers, handing out salads and running workshops. Fresh, local food – even if it cost a little more – would entice a growing number of foodies who were interested in where their meals came from. The trailer cost nothing but petrol money to move, and emissions from the growing process itself were almost nil.

When the designer of a swanky hotel across town came by trailer, he asked if the team could install something similar in his restaurant. “That was really the trigger,” says Guy Galonska. “We rented a workshop and we got to develop a system for them.”

When they installed their first “farm” in a Berlin supermarket, VCs took notice and visited Infarm’s young founders at their Kreuzberg office-cum-kitchen, where they hosted dinner parties featuring Infarm crops. But a return on investment still seemed distant: some investors thought the farms were an art project. Maintaining locations manually was exhausting, and the team almost went bankrupt “two or three times,” Guy Galonska says. “I think all of us got a lot of white hair during that time,” he adds. “It was a very challenging thing to do.”

A €2 million grant from the European Union in 2016 helped. With it came deals to place Infarm units in supermarkets and restaurants across Germany. Managing them all would require something precise, connected and efficient. To become a sustainable business, Infarm would have to behave less like a farm, and more like a tech startup.

An Infarm kiosk in the Edeka Supermarket E Center in Berlin

Credit Ériver Hijano

For around 2,500 years after King Nebuchadnezzar II of Babylon gifted his wife some hanging gardens, little changed in the world of hydroponic farming. Asian farmers grew rice on giant, terraced paddies, and Aztecs built “chinampa” rigs that floated along the swamps of southern Mexico.

Life magazine published a drawing of stacked homes, each growing its own produce, in 1909, and the term “vertical farming” appeared six years later. The US Air Force fed hydroponically-grown veggies to its troops during World War II, and Nasa explored the tech as a solution for life off-planet. But vertical farming didn’t really capture public imagination until 1999, when Dickson Despommier, a Columbia University professor, devised a 30-storey skyscraper filled with farms. In 2010, Despommier published The Vertical Farm: Feeding the World in the 21st Century, which has become the industry’s utopian testament.

“I had no expectations whatsoever that this would turn commercial,” Despommier says. “We just thought it was a good idea, because we didn’t see any other way out of stopping deforestation in favour of farming, and keeping the carbon dioxide content of the atmosphere at a reasonable level. It turned out to be a crazy idea whose time has come.”

The vertical farming concept is simple: growing produce on vertically-stacked levels, rather than side by side in a field. Instead of the Sun, the vertical farm uses artificial light, and where there is ordinarily soil, growers use nutritious water or, in the case of “aeroponic” farms, an evenly-dispersed mist.

Vertical farms take up a vanishing amount of land compared to their conventional cousins. They use almost no water, don’t flush contaminating pesticides into the ecosystem, and can be built where people actually live. But, by and large, they have not functioned as businesses. Only the black-market margins of weed, and Japan’s high-income, high-import food ecosystem, have catered to profit. It costs hundreds of thousands of pounds to erect a mid-sized vertical farm, and energy use is prohibitively high.

Advances in technology are changing this. By bolting automation, machine learning and cloud-connected software on to vertical farms, firms can trim physical labour, increase capacity and maintain a dizzying range of cultivation variables. Infarm staff at a separate office to the new Berlin farm, located some 23km southeast of Spandau in the Tempelhof district, keep track of “plant recipe” settings at any one of the startup’s 1,220 in-store units, including CO2 levels, pH and growth cycles, via the company’s Farm Control Cloud Platform, a bit like a giant CCTV room. Machine learning finesses recipes, and keeps each plant as uniform as possible.

Inside the new vertical farm, trays of produce are tended by automated systems

Credit Ériver Hijano

Gartenfeld Island’s employees – mechanical and electrical engineers, software developers, crop scientists and biologists – get closer to the produce, but only just. They monitor via an iPad and feed crops into the building’s four massive grow chambers, or farms, each one about the height and width of two London buses, with ventilation systems that whoosh like a subdued turbine hall.

From there on in, robots do the hard work. Inside the farms, a robotic “plant retrieval system” – basically a tricked-out teddy picker – scoots up and down a perpendicular beam, plucking trays of plants in various stages of growth and shuffling them closer, or further, from LED lights at the summit. The firm claims this reduces service time by 88 per cent. A sliver of the window is the only way to see the device in-person: everything is hermetically sealed to keep out pests. “With automation, you invest once and then that price goes down over time,” says Orie Sofer, Infarm’s hardware lab lead. “With human labour, unfortunately, over time the price goes up.”

The number of crop plants varies depending on the produce, but there are usually just under 300 in a “farm” at any one time. Each farm yields the equivalent of 10,000 square metres of land and uses just five litres of water per kilo of food (traditional vegetable farming uses around 322 litres per kg).

Infarm is not alone in this revolution. AeroFarms, a Newark, New Jersey-based startup, feeds an aeroponic mist to roots that are separated from their leaves by a cloth. It’s most recent funding round was led by Ingka Group, the parent of Swedish furniture giant IKEA. New York’s Bowery Farming, like Infarm, focuses on automation and a proprietary dashboard called BoweryOS that, among other things, takes photos of crops in real-time for analysis. It’s £123 million in backing comes from investors including Singapore’s sovereign fund Temasek. Bowery CEO and founder Irving Fain believe his addressable market “is about a hundred billion dollars a year, just in the US, of crops that we think are good candidates for us to grow.”

Leading the vertical farming VC race is Plenty, a San Francisco-headquartered brand that has raised almost half a billion pounds in the capital since it was founded in 2013, including a 2020 Series D round led by Masayoshi Son’s $100 billion SoftBank Vision Fund. Plenty feeds its greens with water that trickles down six-metre-tall poles; infrared sensors pour data into an algorithm that nudges the plant’s growth recipe accordingly.

Plenty co-founder and chief science officer Nate Storey, who works at the company’s test farm in Wyoming, likens these deep-tech solutions to the tools that powered agriculture’s most recent revolution: “The tractor allowed farmers to be freed from constraints. Half of their land was dedicated to raising draft animals, and the tractor came along and freed them from a life where they were basically managing animals just so they could plough their land.”

For them, he says, automation is similar. “It allows us to get rid of the hardest work – the work that is unpleasant, the work [growers] don’t like to do – and focus on the work that really matters.”

Infarm kiosks inside the Beba restaurant in the Gropius Bau museum

Credit Ériver Hijano

Infarm differs from the competition on two fronts. The first is its focus on modular design: each component is compatible and scalable, like a giant, noisy LEGO set. Modularity makes it possible to install Infarm units anywhere in the world in a matter of weeks, no matter the size. That enables the company’s second USP: its business model. Infarm has no stores, selling produce instead via its remote units.

Clients tell Infarm which produce they want, and “create a schedule,” says Michaeli. “You buy the plants. Everything on the farm is controlled by Tempelhof. Everything that’s grown belongs to the client.” A chef may demand pesto that’s made from particular three-day-aged Greek and Italian basil, for example. Infarm can do that (Tim Raue, Berlin’s most famous chef, is a customer). “Everyone stops and asks about the farm,” one Berlin store manager says. “It’s great to have innovation here.”

Infarm has “two big advantages,” says Nicola Kerslake, founder of Contain Inc, a Nevada-based agtech financier. “One is that they’ve figured out how to do product onsite, which is really not very easy. And the other is that they have these great relationships with big purchasers like Marks & Spencer.”

“When you look at where the arms race is in this industry,” she continues, “it’s really been in two areas: How do I get hold of as much capital as possible, and how do I sign up the right partners? Having Marks & Spencer in your back pocket is really useful.”

It has helped encourage investors to open their chequebooks. Hiro Tamura, a partner at London VC firm Atomico, first met Infarm’s founding trio in 2018. A year later he led its £75 million Series B round. “They could roll these things out,” he says. “They worked, and they didn’t need some industrial-sized warehouse to do it. I didn’t lean in, I fell into the rabbit hole. And it was incredible. I was like, wow, these guys are thinking about time and speed to market modularity.”

Infarm ploughs a chunk of its revenue back into research. In a mezzanine-level lab sitting above the farms at Gartenfeld Island, a dozen white-coated analysts conduct tests on herbs to a soundtrack of Ariana Grande, measuring crop sugar levels, acidity, vitamins, toxicity, antioxidants and more. Via a process of phenotyping – the study of organisms’ characteristics relative to their environment – they hope to create more flavourful plants, or new tastes altogether.

“It’s not just about the hardware,” Kerslake explains. “It’s about how the hardware interacts with the rest of your farm system. And we’re starting to see a lot more sophistication on that front because the AI programs these companies started three or four years ago are now starting to bear fruit.”

Infarm’s results are high-quality: juicy lettuce, wasabi rocket that kicks, and basil that’s far more fragrant than the budget variety. “The end goal with almost everything that we’re doing is developing some sort of playbook, some sort of modular and standardised system, that we can then copy-paste to wherever we go,” says Pavlos Kalaitzoglou, Infarm’s director of plant science. Across from the lab, tomatoes and shiitake mushrooms grow in wine cellar-size chambers. They are living proof of how the firm is looking to diversify from herbs and leafy greens, whose low energy and water requirements make them the staple crop of every vertical farming startup today.

Rows of LED-illuminated produce inside one of Infarm’s four massive new grow chambers

Credit Ériver Hijano

We are in danger of farming the planet to death. Agriculture already occupies 40 per cent of all liveable land on Earth, and food production causes a quarter of all greenhouse gases. An area the size of Scotland disappears from tropical rainforests, responsible for up to a quarter of land photosynthesis, each year. Clearing more trees to feed our spiralling population will not help.

“We need to go back to the drawing board and rethink which avenues we can environmentally afford to pursue,” says Nicola Cannon, a professor at the Royal Agricultural University in Cirencester. Nitrogen fertiliser is particularly harmful to the environment, Cannon adds, “and has led us to adopt systems which have grossly exceeded the planetary boundaries.”

Current food systems are wildly inefficient: waste accounts for 25 per cent of all calories. And yet, almost a billion people suffer from hunger worldwide. These are not issues vertical farming will solve, critics, argue. Going local does little beyond satisfying consumers.

Energy is another tricky issue. Ninety per cent of Infarm’s electricity today is renewable, and it wants to reach zero emissions in the next few years. But this doesn’t factor in the environmental cost of building a steel-and-cement facility.

“Vertical farms are a round-off error to the round-off error in terms of contributing to the big levers out there,” Jonathan Foley, an environmental scientist based in Minneapolis, says. “Like most technologies that are getting a lot of venture capital and which come from Silicon Valley kind of thinking, it’s being massively overhyped at the cost of real solutions. There’s an opportunity cost to put all this technology, money and renewable energy – that could be used for other things that we need energy for – into growing arugula for rich people at $10 an ounce.”

More than half the world’s food energy comes from its three “mega-crops”: wheat, corn and rice. They require wind, seasons and micronutrients that vertical farms are unable to replicate today. These are the crops that can prevent famine in Somalia, Bangladesh or Bolivia – not lettuce. “Vertical farms are growing the edge of the plate, not the centre of the plate,” Foley says.

But Despommier says it’s too soon to criticise the young industry for not addressing issues such as crop diversity. “What you’re really seeing is a rush towards profitability to get their feet wet, and to get their ledgers in the black and to pay off their investors, before they start diversifying,” he says.

“In a world where you think that land is unlimited and that resources are unlimited, indoor farming would be nonsensical,” Plenty co-founder Storey says. “As crazy as it seems to replace the Sun with electricity, it makes sense today. And it really makes more and more sense as time goes on.”

Much of the hope vested in vertical farms rests on the light-emitting diode. This tiny bead of light is the industry’s packhorse: it is a farm’s biggest financial layout and the nucleus of its most exciting advances. Modern LEDs are nothing like the ones that powered your childhood TV. They’ve progressed at such a rate, in fact, that they’ve developed their own law to adhere to: “Haitz’s Law”. Each decade, their cost drops by a factor of ten, while the light they generate leaps by a factor of 20.

That curve will eventually plateau, experts say. But not before LEDs improve enough to allow vertical farms to profit from food closer to the middle of the plate. Infarm’s current smart LED set-up is over 50 per cent more efficient than the one that lit its first farms. Haitz’s Law has helped some companies experiment in growing potatoes, which require far more energy and water than leafy greens. Turning profit from a crop that delivers the highest calories per acre would be momentous for the industry.

The cutting edge of LED technology today is smart sensors that can regulate the brightness and spectrum of light to replicate growing outdoors – or enhance it. Much of the planet’s first flora grew only in the ocean, which looks blue because it absorbs blue light at least.

Photosynthesis, therefore, occurs best between the blue and red light spectra. By tailoring LEDs to emit only these colours, or by dimming at intervals meant to mirror a plant’s natural cycle, vertical farmers can further reduce their energy burden – like stripping a road car to its bare bones so it can drive faster.

Recent discoveries have been more surprising. Strawberries, for example, react particularly well to green light. Some spectra can increase vitamin C in concentrated fruits like kiwis, while others extend shelf-lives by almost a week. In the future, says Fei Jia, of LED firm Heliospectra, growers “can get feedback from the lighting and the plants themselves on how the lighting should be applied… to further improve the consistency of the crop quality.”

“If you judge it from what you have today, you understand what [critics] are saying,” Guy Galonska says. “How can you grow rice and wheat and save the world? And they are right. But they can’t see ten years ahead: they can’t see all the different trends that are going to support that revolution.”

Other technological advances are helping agriculture in different ways. Drones and sensors help map and streamline growing. Drip irrigation dramatically reduces the burden on dwindling water supplies. Circular production – where waste products from one process contribute to fuelling another – is becoming more commonplace, especially in livestock farming. Cell-grown or insect-based meat (or vegetarianism) will reduce our reliance on livestock, which consume 45 per cent of the planet’s crops. Infarm, and the broader vertical farm cohort, may not be saving the world today. But it wants to build taller farms, place them in public buildings like schools, and teach people the value of fresh, healthy vegetables. If 70 per cent of us are to live in cities, then cities “can become these communities of growing,” says Erez Galonska.

Ultimately, Infarm wants to build a network of tens of thousands of automated farms, each one pumping streams of data back into a giant AI system in Berlin. This “brain”, as Galonska calls it, will pour that information into algorithms to generate better food at lower costs, each new yield shaving fractions from the water, energy and nutrients required. Then, Infarm could become something closer to the dream Galonska left behind in the Canaries: truly self-sufficient.

It’s a long way from the leaky, DIY gadget he and his co-founders built in their front room. “The way the world is going now, it’s very clear to everyone it’s running in the wrong direction,” Galonska says. “We definitely believe in the power of collaboration: bringing those outside-the-box thoughts to create a new system that will generate more food, better food, much more sustainably, and help to heal the planet – because that’s the main issue on the table.”

7 New HDB Carpark Rooftop Sites Offered For Rental For Urban Farming In Public Tender

More local produce. Part of Singapore's efforts to strengthen its food security is increasing its capability to produce food locally

Part of Singapore's efforts to strengthen its food security is increasing its capability to produce food locally.

To do this, more sites for urban rooftop farms atop multi-storey Housing Development Board (HDB) carparks are being offered for rental, via a public tender process that was launched today (Feb. 23).

Seven new sites

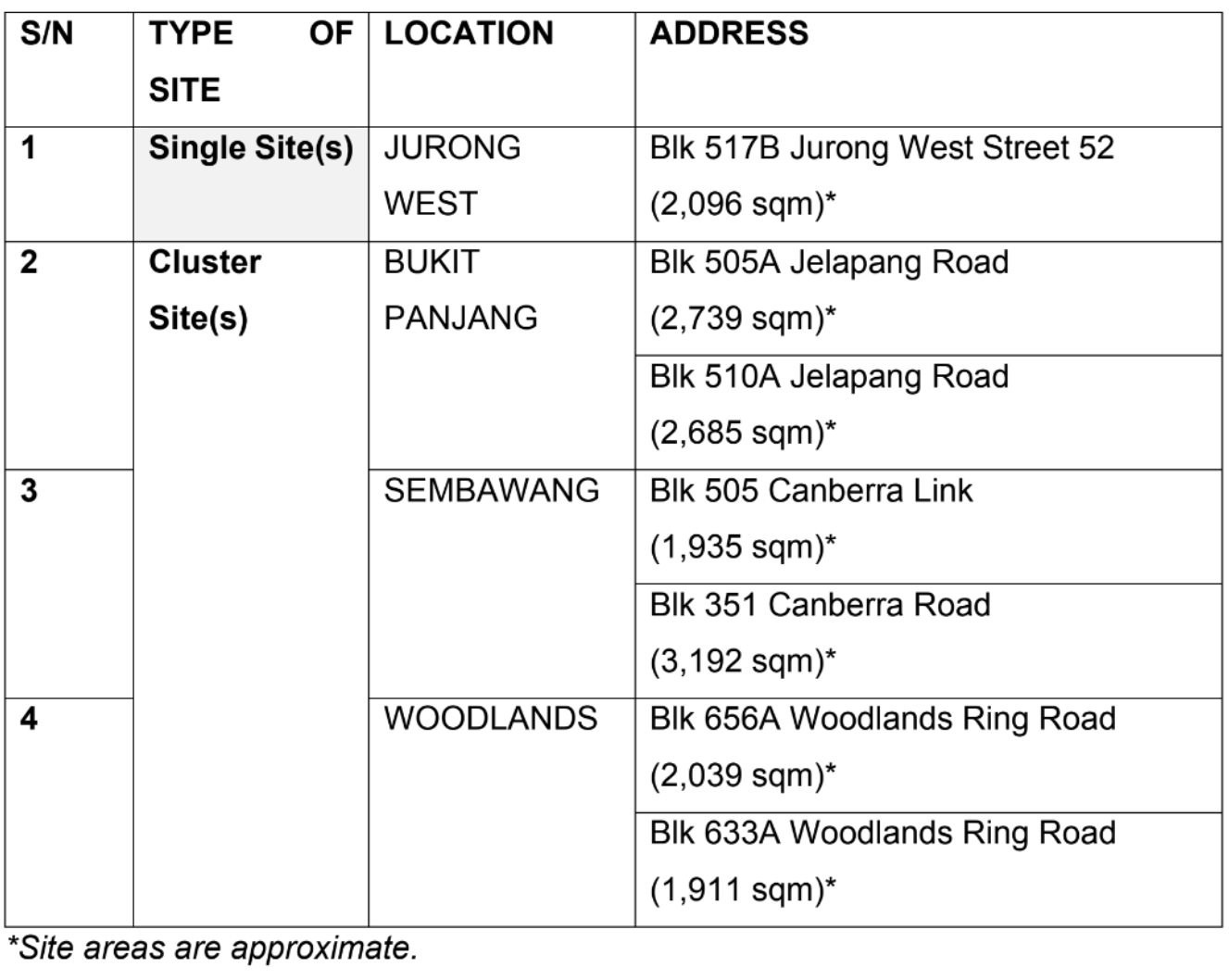

Seven sites have been identified in Jurong West, Bukit Panjang, Sembawang and Woodlands, according to the Singapore Food Agency (SFA) and HDB.

The sites will be used to farm vegetables and other food crops, and will also be used to pack and store produce.

They will be tendered out as a single site (in Jurong West) and three cluster sites (in Bukit Panjang, Sembawang and Woodlands).

Screenshot from SFA and HDB

Tenderers who successfully bid for cluster sites will be awarded all sites within the cluster, to allow them to cut costs through production at scale.

Single-site farms, on the other hand, provide opportunities to "testbed innovative ideas".

Tenderers must submit their proposals via GeBiz before the tender closes on Mar. 23, 4pm.

Proposals will be assessed on their bid price, production output, design and site layout, as well as their business and marketing plans.

More information can be found on SFA's website here.

Producing food locally

This is the second time tenders were launched for rooftop urban farms on carparks here — the first took place in Sep. 2020, with nine sites being awarded.

Collectively, the nine farming systems can potentially produce around 1,600 tonnes (1,600,000kg) of vegetables per year.

Having more space for commercial farming in land-constrained Singapore is one of SFA's strategies to achieve its "30 by 30" goal — which is to produce 30 percent of Singapore's food locally by 2030.

The move is also in line with HDB’s Green Towns Programme to intensify greening in HDB estates.

“Besides contributing to our food security, Multi-Storey Car Park (MSCP) rooftop farms help to bring the community closer to local produce, thereby raising awareness and support for local produce," said Melvin Chow, Senior Director of SFA’s Food Supply Resilience Division.

GoodLeaf Farms Launches Aggressive Expansion Plans

GoodLeaf will bring its innovative and proprietary controlled-environment agriculture technology to more Canadian markets over the coming year

NEWS PROVIDED BY

McCain invests in a national network of vertical farms to bring tasty, local food to Canadians

GUELPH, ON, - With the closure of a successful new funding round, GoodLeaf Farms is embarking on an aggressive growth and expansion plan to build a national network of vertical farms that will bring fresh, delicious, nutritious and locally grown leafy greens to Canadians across the country.

Backed by a sizeable investment from McCain Foods Limited — which has increased its total investment in GoodLeaf to more than $65 million — GoodLeaf will bring its innovative and proprietary controlled-environment agriculture technology to more Canadian markets over the coming year, providing more Canadian consumers with year-round local food that is typically imported from the Southern United States or Mexico.

"From our start in Truro to our first commercial farm in Guelph, GoodLeaf has built a strong foundation for future growth," says Barry Murchie, Chief Executive Officer of GoodLeaf. "We want to be a global leader in vertical farming. Our first step to accomplishing that is ensuring we have a strong footprint in Canada, giving Canadians access to top quality, nutrient-dense, sustainably grown and pesticide-free leafy greens 365 days a year."

GoodLeaf opened its first commercial vertical farm in Guelph, Ont., in the fall of 2019. By the end of 2021, GoodLeaf is planning two more indoor vertical farms — one to serve the grocery and foodservice networks in Eastern Canada, and one for Western Canada.

The exact locations will be announced shortly.

"It is our intention to build farms that support the Canadian grocery store network, foodservice industry and consumers," says Mr Murchie. "We want to change what people are eating by providing a fresh, healthy and local alternative that, until now, hasn't been available in Canada. We are driving a new way to grow food, with disruptive technology that brings consumers leafy greens from their own backyard. This is a fundamental game-changer."

GoodLeaf's vertical farm grows to produce on hydroponic trays stacked in multiple horizontal levels. A proprietary system of specialized LED lights is engineered to emulate the spring sun, giving plants the light they crave to maximize photosynthesis. The indoor controlled environment is almost clinical, meaning there are no pesticides, herbicides or fungicides used. It is also immune to weather extremes, such as summer droughts or late spring frosts that can be lethal to crops.

Furthermore, having a local source of year-round food is vital to Canada's food security and sovereignty, concerns that were in the spotlight at the height of the COVID-19 pandemic as shoppers were faced with rapidly dwindling supplies on grocery store shelves.

At its 45,000-square-foot Guelph farm, every day GoodLeaf is harvesting microgreens (Spicy Mustard Medley, Asian Blend, Micro Arugula, Micro Radish and Pea Shoots) and baby greens (Ontario Baby Kale, Ontario Baby Arugula and Ontario Spring Mix) for Ontario grocery stores, ensuring a local supply of fresh, nutrient-dense leafy greens all year long.

GoodLeaf produce is exceptional in a salad, as a topping for burgers and sandwiches, as a kick of nutrients in a smoothie or as an ingredient to elevate your favourite dish.

Follow GoodLeaf Farms on Instagram @goodleaffarms and Like it on Facebook at /GoodLeafFarms.

About GoodLeaf Farms:

With a passion for delicious, nutrient-rich greens, GoodLeaf was founded in Truro, NS, in 2011. Using innovative technology and leveraging multi-level vertical farming, GoodLeaf has created a controlled and efficient indoor farm that can grow fresh produce anywhere in the world, 365 days of the year. The system combines innovations in LED lighting with leading-edge hydroponic techniques to produce sustainable, safe, pesticide-free, nutrient-dense leafy greens. GoodLeaf has ongoing R&D Programs in collaboration with the University of Guelph, Dalhousie University and Acadia University.

Learn more at goodleaffarms.com.

About McCain Foods (Canada)

McCain Foods (Canada) is the Canadian division of McCain Foods Limited, an international leader in the frozen food industry. McCain Foods is the world's largest manufacturer of frozen potato specialities, and also produces other quality products such as appetizers, vegetables and desserts that can be found in restaurants and retail stores in more than 160 countries around the world. In Canada, the company has eight production facilities with approximately 2,400 employees and, in addition to its famous French fries and potato specialities, makes frozen desserts, snacks and appetizers.

SOURCE GoodLeaf Farms

For further information: Michelle Hann, Senior Consultant, Digital and Communications, Enterprise Canada, mhann@enterprisecanada.com, 613-716-2118

CGTN Conversations: Chinese Firms Add Strength To Dubai's Future Tech Ecosystem

CGTN Digital's International Editor Abhishek G. Bhaya spoke with Faisal Al Hawi, the head of Accelerator and Incubators at the Dubai Future Foundation, and Stuart Oda, the founder and CEO of Alesca Life.

Over the decades, the Gulf city of Dubai has emerged as a land of innovation and a place where the future could be felt right now in the present. The city is actively encouraging global collaborations to drive innovation and future technology in the United Arab Emirates and internationally through its Dubai Future Accelerators (DFA) initiative that was launched in 2016 under the aegis of Dubai Future Foundation.

In recent years, many Chinese tech firms and start-ups – which are known for their technological prowess – have partnered with DFA to contribute to their mission of imagining, designing and co-creating solutions for future challenges.

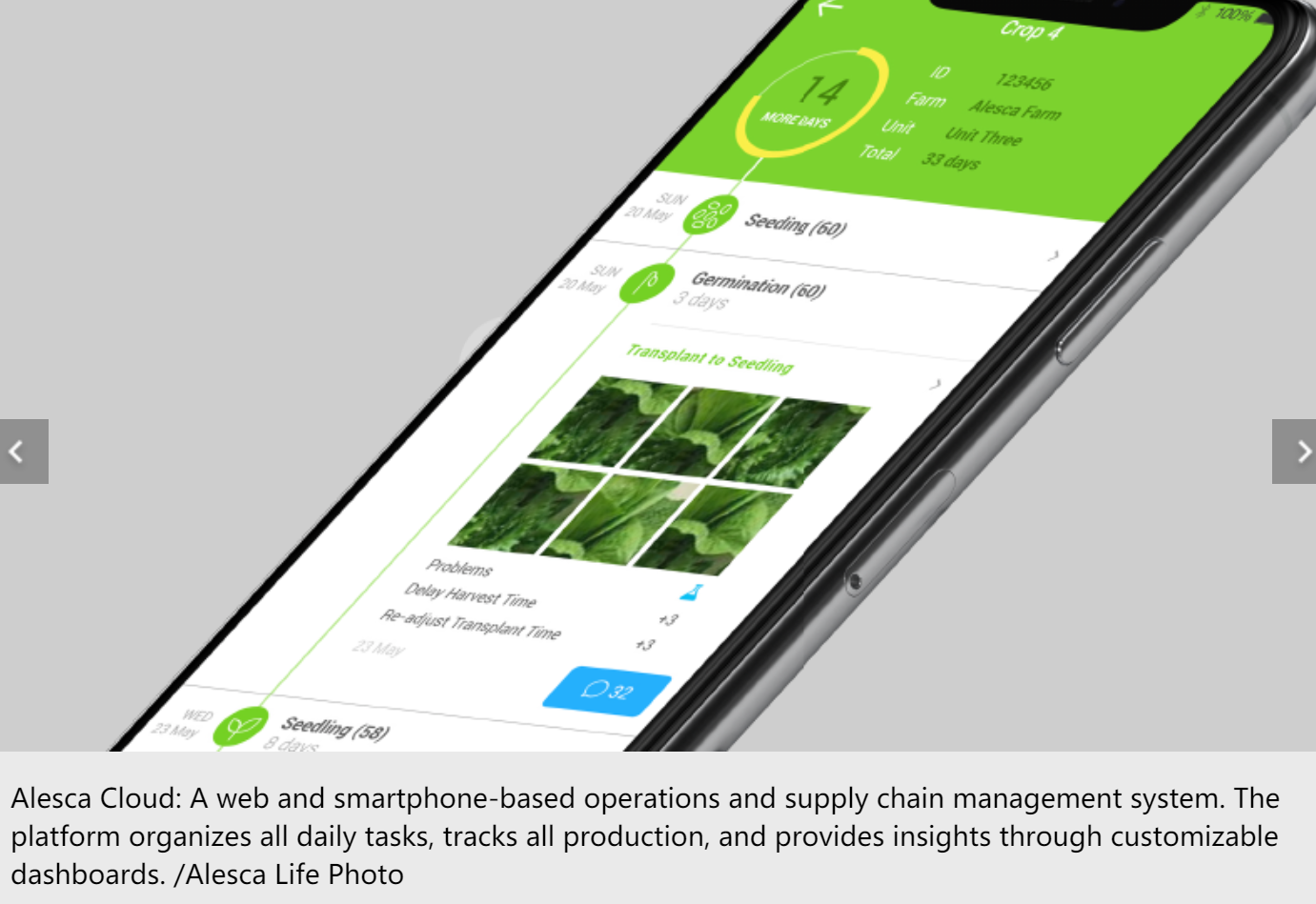

One such successful initiative has come from Beijing-headquartered Alesca Life, an agro-tech company that is creating next-generation urban farming solutions that consume five per cent water and 30 per cent energy vis-à-vis conventional farming.

To get an overview of DFA's future innovation agenda and how Chinese firms are contributing in making that vision a reality, CGTN Digital's International Editor Abhishek G. Bhaya spoke with Faisal Al Hawi, the head of Accelerator and Incubators at the Dubai Future Foundation, and Stuart Oda, the founder and CEO of Alesca Life.

Al Hawi is responsible for creating a myriad of programs that connect different stakeholders, government and private, with innovative startups and companies from around the world to experiment with and making Dubai the testbed for future ideas.

Oda is an investment banker-turned- urban farmer with a passion for innovation and sustainability. He founded Alesca Life in 2013 with an aim to make food production more localized and data-driven.

Edited excerpts:

Bhaya: Faisal, please tell us a bit about the vision of the DFA initiative and what it aims to achieve and also some of the main areas and technologies it has tasted success in the past four years?

Al Hawi: Dubai Future Accelerators is an initiative that was born four years ago under the Dubai Future Foundation. The vision was pretty much straightforward – to put Dubai as a leading city of the world when it comes to technology innovation. Our mission is to turn Dubai into a global testbed for innovations and technologies. The DFA looks around for all the start-ups in the global scene, trying to understand the technology needs, the partner needs, the local ecosystem needs, and trying to bridge the gap between these two players of the market.

We do this in what we call the Area 2071, which is like the heart of our ecosystem in Dubai and we've had tremendous success. Throughout the four years, we've run eight cohorts, the eighth cohort is ongoing as we speak. We've engaged with more than 300 start-ups and over 60 pilot projects were produced out of DFA and more than 150 memoranda of understanding or commercial agreements were signed with different government entities and private sector partners.

Dubai Future Accelerators is positioned in a way that basically bridges the gap between the big players, be it government or private sector, and the start-up innovators from around the world.

Bhaya: How many Chinese firms and start-ups have availed the DFA program so far? Please name some of the major projects the Chinese entities have undertaken in the UAE as part of the DFA initiative.

Al Hawi: We've worked with Chinese companies ever since Cohort 1 back in 2016. So, Alesca Life is one of them. Shellpay, which was a fintech company working with the General Directorate of Immigration in Dubai, was another company. There was another company called Future Trends, working with Dubai Health Authority on medical imaging, and utilizing the technologies of AI and machine learning to optimize the diagnosis of late-stage cancers.

Yitu Technology is another Chinese AI-based company which worked very closely with [UAE's largest telecom service provider] Etisalat on solving some of their telecom related issues. So these are just to name a few companies that worked with us.

We really understand the strength Chinese ecosystem brings to our ecosystem. And I think we complement each other in a lot of areas.

Another example, broader than just Dubai Future Accelerators, is within Area 2071, where SenseTime actually has an office here, and they work very closely with the AI office, in a couple of strategic projects.

So, the partnership is growing stronger and stronger, year after year. And we definitely believe that there are areas specifically in the fourth industrial revolution technologies, blockchain, AI and IoT and the likes that we will definitely materialize more and more outcomes and success moving forward.

Bhaya: Stuart, what is the story behind Alesca Life?

Oda: Seven years ago, I started Alesca Life here in Beijing. The vision of the company is to democratize access to fresh and nutritious food by democratizing the means and the knowledge of production.

And the more research that I was doing, it became very clear that one of the most pressing challenges over the next decades wasn't so much actually related to connectivity, as these things were becoming easier with the proliferation of smartphones and computers, but access to fresh and nutritious food. And so, my team and I wanted to find a way in which we can make this access a lot easier. And wherever it made sense to localize that fresh food production, and wherever food production currently existed to make it more data driven.

So we set on this journey seven years ago, and we currently have our teams and offices across Japan, China, and the United Arab Emirates and we have partnerships across many more countries. We're developing precision farming tools to accomplish, to increase the productivity, the profitability, and the predictability of food production by up to 10 times.

Bhaya: The urban farming technologies including vertical farms and data-driven food production are certainly relevant for an arid region like the Arabian Peninsula. How did your partnership with DFA come about and what has been the journey like in the UAE for Alesca Life?

Oda: In 2016, our team was selected into the DFA program as part of Cohort 1. It was actually our first entry into the Gulf region. We knew that the technology had huge promise and potential in the region, and we wanted to make a serious commitment to the region. The DFA program was kind enough to offer us a spot in Cohort 1.

It has been hugely transformational in two ways. You know, the way in which business is done in the Middle East is very different. And to be able to have an organization like DFA, both providing the meaningful introductions, reducing some of the barriers related to the company's formation, and then also just the credibility that is bestowed on some of the companies that get to go through the program. All three of these things contributed enormously to our success in the region.

Through this program we've also been able to find meaningful strategic partnerships to mitigate some of the challenges related to concentration of supply chain, for example, even being in a place like China, to have manufacturing bases and other places in other countries, is beneficial for us.

So, right after the DFA program, we had an opportunity to localize the manufacturing of our container farm in the Emirates of Ajman in the UAE, so that we can serve our customers and our base in the GCC (Gulf Cooperation Council) and also to showcase our commitment to the region that we're not just there to sell our systems, but that we are there for the long term.

Bhaya: The year 2020 has been a watershed in many ways for the world due to the COVID-19 pandemic, reinforcing our increasing reliance on digital and AI technologies without which we can't imagine a future. How did the global crisis impact the long-term vision of DFA?

Al Hawi: The pandemic has definitely affected everyone. At DFA, we realized that innovation is the way to be resilient for the future, prepared for the future and understanding exactly the problems of today that potentially, and unfortunately, led us into the pandemic. We had just a very short drop-in time in which everybody had to just realign ourselves, and that was around March. But we immediately resumed back in October.

Not just the DFA, I think all the government entities, as well as start-ups, realized how important a role they play in this ecosystem. And Cohort 8, that is currently ongoing and will last until the end of March, is specifically looking at challenges that will basically be more specific around life after COVID.

I'll share a couple of examples. The Dubai Roads and Transport Authority (RTA) is looking into new solutions of shared mobility. We are very much accustomed to the ride-hailing apps and public transport systems. But that has changed forever. So they (RTA) are really being proactive in trying to foresight what new models of public transport and shared mobility will be out there. And we're really excited to see what comes out as solutions in a couple of weeks' time.

Another entity which is really looking at how things might evolve in the health care sector is the Dubai Health Authority. They are focusing on preventive health care measures, solutions and products, but not only from a sense of being preventive or proactive but in a sense of also democratizing access to that device.

Bhaya: Food security is already a global concern and going to be a top challenge in the future. It did aggravate last year due to the supply-chain disruption caused by the pandemic. What are some of the innovative solutions that Alesca Life offers to meet this challenge and has COVID-19 triggered a sense of greater urgency?

Oda: This is a great point. Pre-pandemic, in 2018-19, a lot of the interest and investment from governments, companies and investors was in food tech, which was related to food delivery and meal kits at home. And it was really focused on one thing, which was consumer convenience. What has happened in 2020, with the pandemic and now that we're in 2021, is that the focus has shifted materially from food tech to agtech - agricultural technology, which is focused on resilience. It's about community resilience, as opposed to consumer convenience.

So, one of the solutions, the benefits or the outcomes of the pandemic, was a renewed interest in agtech. And by that, I mean, local food production is in control of your own supply chain for fresh and nutritious food. So, since the pandemic has happened, since the lockdowns have begun, I've probably spoken to individuals and government entities from over 30 countries that are interested in finding ways in which they can secure a minimum supply of local fresh food production in their own countries, in their own communities.

The shift has accelerated towards this localization, towards this decentralized form of food production that can happen almost anywhere. And one of the solutions that we're providing for this is to bundle all of our precision farming tools – our monitoring equipment, our automation systems, our farm management and software tools, and even our latest computer vision AI cameras – and bundle all these products together to create an incredibly capital efficient indoor farm. And this allows both governments, at large scale, and even community, at a smaller scale, to be able to be in control of their local food production needs.

Interviewer and script: Abhishek G Bhaya

Video editors: Meiyi Yan & Wu Chutian

Cover image: Du Chenxin

Infographics: Jia Jieqiong

Director: Mei Yan

Vertical Farming: Ugandan Company Develops Solution for Urban Agriculture

We speak to Lilian Nakigozi, founder of Women Smiles Uganda, a company that manufactures and sells vertical farms used to grow crops in areas where there is limited space

We speak to Lilian Nakigozi, founder of Women Smiles Uganda, a company that manufactures and sells vertical farms used to grow crops in areas where there is limited space.

Image from: How We Made It in Africa

1. How Did You Come Up with the Idea to Start Women Smiles Uganda?

Women Smiles Uganda is a social enterprise formed out of passion and personal experience. I grew up with a single mother and eight siblings in Katanga, one of the biggest slums in Kampala, Uganda. I experienced hunger and poverty where we lived. There was no land for us to grow crops and we didn’t have money to buy food. Life was hard; we would often go to sleep on empty stomachs and our baby sister starved to death.

Growing up like that, I pledged to use my knowledge and skills to come up with an idea that could solve hunger and, at the same time, improve people’s livelihoods, particularly women and young girls living in the urban slums. In 2017, while studying business at Makerere University, I had the idea of developing a vertical farm. This came amid so many challenges: a lack of finance and moral support. I would use the money provided to me for lunch as a government student to save for the initial capital of my venture.

I managed to accumulate $300 and used this to buy materials to manufacture the first 20 vertical farms. I gave these to 20 families and, in 2018, we fully started operations in different urban slums.

2. Tell Us About Your Vertical Farms and How They Work.

Women Smiles vertical farms are made out of wood and recycled plastic materials. Each unit is capable of growing up to 200 plants. The product also has an internal bearing system which turns 360° to guarantee optimal use of the sunlight and is fitted with an inbuilt drip irrigation system and greenhouse material to address any agro-climatic challenges.

The farms can be positioned on a rooftop, veranda, walkway, office building or a desk. This allows the growth of crops throughout the year, season after season, unaffected by climatic changes like drought.

In addition, we train our customers on how to make compost manure using vermicomposting and also provide them with a market for their fresh produce.

Image from: How We Made It in Africa

3. Explain Your Revenue Model.

Women Smiles Uganda generates revenue by selling affordable, reliable and modern vertical farms at $35, making a profit margin of $10 on each unit. The women groups are recruited into our training schemes and we teach them how to use vertical farming to grow crops and make compost manure by vermicomposting. Women groups become our outgrowers of fruits and vegetables. We buy the fresh produce from our outgrowers and resell to restaurants, schools and hotels.

We also make money through partnering with NGOs and other small private organisations to provide training in urban farming concepts to the beneficiaries of their projects.

4. What Are Some of the Major Challenges of Running This Business?

The major challenge we face is limited funds by the smallholder farmers to purchase the vertical farms. However, we mitigate this by putting some of them into our outgrower scheme which helps them to generate income from the fresh produce we buy. We have also linked some of them to financial institutions to access finance.

5. How Do You Generate Sales?

We reach our customers directly via our marketing team which moves door to door, identifying organised women groups and educating them about the benefits of vertical farming for improved food security. Most of our customers are low-income earners and very few of them have access to the internet.

However, we do also make use of social media platforms like Facebook to reach out to our customers, especially the youth.

In addition, we organise talk shows and community gatherings with the assistance of local leaders with whom we work hand in hand to provide educational and inspirational materials to people, teaching them about smart agriculture techniques.

6. Who Are Your Main Competitors?

Just like any business, we have got competitors; our major competitors include Camp Green and Spark Agro-Initiatives.

Image from: The Conversation

7. What Mistakes Have You Made in Business and What Did You Learn From Them?

As a victim of hunger and poverty, my dream was for every family in slums to have a vertical farm. I ended up giving some vertical farms on credit. Unfortunately, most of them failed to pay and we ended up with huge losses.

This taught me to shift the risk of payment default to a third party. Every customer who may need our farms on credit is now linked to our partner micro-finance bank. By doing this, it is the responsibility of the bank to recover the funds from our customers and it has worked well.

8. Apart from This Industry, Name an Untapped Business Opportunity in Uganda.

Manufacturing of cooler sheds for the storage of perishable agricultural produce is one untapped opportunity. Currently, Ugandan smallholder farmers lose up to 40% of their fresh produce because of a lack of reliable cold storage systems.

Providing a cheap and reliable 24/7 cold storage system would dramatically reduce post-harvest losses for these farmers.

Is AppHarvest the Future of Farming?

In this video from Motley Fool Live, recorded on Jan. 28, Industry Focus host Nick Sciple and Motley Fool contributor Lou Whiteman discuss AppHarvest, one such SPAC that is looking to disrupt the agriculture industry. Here are the details on what AppHarvest wants to do, and a look at whether the company represents the future of farming.

Special purpose acquisition companies, or SPACs, are red-hot right now, with investors clamoring to get into promising young companies.

In this video from Motley Fool Live, recorded on Jan. 28, Industry Focus host Nick Sciple and Motley Fool contributor Lou Whiteman discuss AppHarvest, one such SPAC that is looking to disrupt the agriculture industry. Here are the details on what AppHarvest wants to do, and a look at whether the company represents the future of farming.

Nick Sciple: One last company I wanted to talk about, Lou, and this is one I think it's -- you pay attention to, but not one I'm super excited to run in and buy. It was a company called AppHarvest. It's coming public via a [SPAC] this year. This vertical farming space. We talked about Gladstone Land buying traditional farmland. AppHarvest is taking a very different approach, trying to lean into some of the ESG-type movements.

Lou Whiteman: Yeah. Let's look at this. It probably wouldn't surprise you that the U.S. is the biggest global farm exporter as we said, but it might surprise you that the Netherlands, the tiny little country, is No. 2. The way they do that is tech: Greenhouse farm structure. AppHarvest has taken that model and brought it to the U.S. They have, I believe, three farms in Appalachia. The pitches can produce 30x the yields using 90% less water. Right now, it's mostly tomatoes and it is early-stage. I don't own this stock either. I love this idea. There's some reasons that I'm not buying in right now that we can get into. But this is fascinating to me. We talked about making the world a better place. This is the company that we need to be successful to make the world a better place. The warning on it is that it is a SPAC. So it's not public yet. Right now, I believe N-O-V-S. That deal should close soon. [Editor's note: The deal has since closed.] I'm not the only one excited about it. I tend not to like to buy IPOs and new companies anyway. I think the caution around buying into the excitement applies here. There is a Martha Stewart video on their website talking up the company, which I love Martha Stewart, but that's a hype level that makes me want to just watch and see what they produce. This is just three little farms in Appalachia right now and a great idea. This was all over my watchlist. I would imagine I would love to hold it at some point, but just be careful because this is, as we saw SPACs last year in other areas, people are very excited about this.

Sciple: Yeah. I think, like we've said, for a lot of these companies, the prospects are great. I think when you look at the reduced water usage, better, environmentally friendly, all those sorts of things. I like that they are in Appalachia. As someone who is from the South, I like it when more rural areas get some people actually investing money there. But again, there's a lot of execution between now and really getting to a place where this is the future of farming and they're going to reach scale and all those sorts of things. But this is a company I'm definitely going to have my radar on and pay attention to as they continue to report earnings. Because you can tell yourself a story about how this type of vertical farming, indoor farming disrupts this traditional model, can be more efficient, cleaner, etc. Something to continue paying attention to as we have more information, because this company, like you said, Lou, isn't all the way public yet. We still got to have this SPAC deal finalized and then we get all our fun SEC filings and quarterly calls and all those sorts of things. Once we have that, I will be very much looking forward to seeing what the company has to say.

Whiteman: Right. Just to finish up along too, the interesting thing here is that it is a proven concept because it has worked elsewhere. The downside of that is that it needed to work there. Netherlands just doesn't have -- and this is an expensive proposition to get started, to get going. There's potential there, but in a country blessed with almost seemingly unlimited farmland for now, for long term it makes sense. But in the short term, it could be a hard thing to really get up and running. I think you're right, just one to watch.

London Food Bank Is Going Greener With Greenhouse

CTV's Nick Paparella check in on the progress as the food bank aims to grow some of its own fresh produce for use during the winter months.

Nick Paparella CTV News London Reporter