Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Lettuce: Meet The Salad Kings of SA

Back home in East London in 1978, he made the decision to become a farmer, an option that was met with criticism from family and peers who did not have farming backgrounds.

By Glenneis Kriel

August 6, 2021

Not knowing what to do after finishing his military service back in the 1970s, Michael Kaplan set off to work on a kibbutz in Israel, where he was exposed to banana, dairy and chicken production.

From there, he backpacked through Europe, and was particularly impressed by the new technologies that farmers in the Netherlands were using to protect their crops and improve production efficiencies.

Back home in East London in 1978, he made the decision to become a farmer, an option that was met with criticism from family and peers who did not have farming backgrounds.

“My mother, Ethel, was a doctor and my father, Lewis, a lawyer, so they thought I was completely bonkers when I told them I wanted to farm,” recalls Kaplan.

In pursuit of his dream, he wanted to study agriculture at the Elsenburg Agricultural

Training Institute in the Western Cape, but entries had already closed by the time he applied. So he began working at what was then the English Trust Company farm in Stellenbosch, thanks to an introduction from his childhood friend, Bruce Glazer, who already worked there.

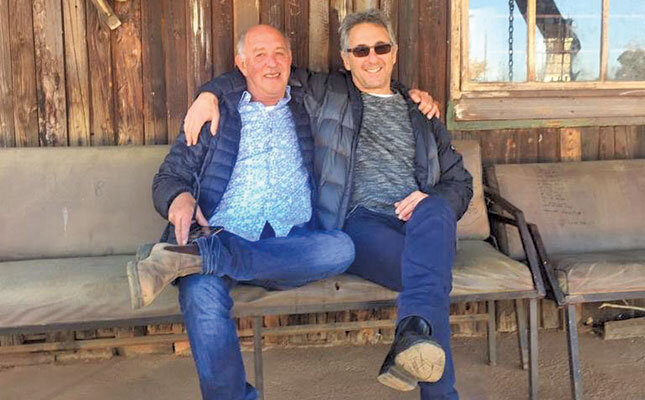

Dew Crisp was co-founded by childhood friends Michael Kaplan (left) and Bruce Glazer.

“It really was a case of being in the right place at the right time, as the English Trust Company was one of the first to introduce farming tunnels in South Africa.

“They produced tomatoes using the nutrient film technique [NFT] and experimented with the gravel flow technique [GFT] to grow butter lettuce and celery,” says Kaplan.

These hydroponic techniques, he explains, are similar in that both entail the circulation of a nutrient solution in a closed system. The difference is that with GFT, gravel is used as a growth medium, whereas, with NFT, plants are suspended and their roots exposed.

Early days

Kaplan worked at the English Trust Company for two years. He then learnt that the Joburg Market sold up to three times more vegetables than its Cape Town equivalent.

Deciding it was time to spread his wings, he drove up to Johannesburg, where he began looking for a business partner and land on which to grow his own produce.

“My mother lent me R10 000, which I used to rent land near Heidelberg [about 50km south-east of Johannesburg] and produce celery under 2 000m² of nets using GFT,” says Kaplan.

In 1981, Heidelberg was hit by a severe snowstorm. It destroyed almost all of Kaplan’s infrastructure, but he managed to save most of the crop and used the income from the sale to rebuild his operation.

“I kept costs low by doing almost everything myself, and using the income to grow the operation, reaching 8 000m² by the third year of production,” recalls Kaplan.

In his fourth year of operation, he started looking for land closer to the Joburg Market and with more favourable production conditions.

“These are actually two of the most important prerequisites for farming success; you need to be close to the market, and farm in a region where the climatic and production conditions are suited to the crop you want to grow. I learnt the hard way that the Highveld is unsuited to salad production in winter,” he says.

Financing

With a clearer idea of what he required, Kaplan bought land near Nooitgedacht and applied to the Land Bank for a loan.

Being unfamiliar with hydroponic production, the bank declined his application, but Kaplan managed to secure a loan from First National Bank at an interest rate of 26%. Fortunately, the market was far less competitive and demanding in those days, which enabled him to repay the loan quickly.

“It would be almost impossible to accomplish the same today; land, labour, infrastructure and production costs are exorbitant. And you buy everything in dollars and euros but get paid in rands,” he says.

Costs are driven up even further by international production standards and auditing programmes such as GlobalGAP and HACCP, which are required to supply most markets today, while market access is complicated by retailers and big buyers demanding huge supply volumes all year round.

An impressive growth path

In the intervening years, Glazer had studied agriculture at Elsenburg and thereafter also worked on a kibbutz in Israel. On his return in 1984 he bought a farm near Kaplan’s, and two years later the two decided to amalgamate their businesses to create better economies of scale.

The new company was called Dew Crisp. To add value to their produce, they sold ready-to-eat lettuce in pillow packs, a market they dominated for over six years.

Since then, Dew Crisp has grown into one of the largest value-added salad suppliers in South Africa, expanding their geographical footprint over time to lengthen their production season and mitigate climate and production risks.

Today, they have 10ha under production in Muldersdrift, 200ha near Bapsfontein and 140ha near Philippi, as well as processing plants in the West and East Rand of Gauteng and in Franschhoek in the Western Cape.

Dew Crisp also sources produce from between 15 and 20 selected farmers across geographically diverse regions, some of whom have been supplying the business for over 25 years.

The company’s empowerment arm, Rural Farms, supports and sources produce from five previously disadvantaged smallholder farmers.

In 2009, Agri-Vie, the Africa Food & Agribusiness Investment Fund, bought a 49% share in Dew Crisp, which enabled Kaplan and Glazer to grow the business and place greater emphasis on financial administration and corporate governance.

“We realised that it wasn’t enough to simply follow the market; we had to create our own destiny by becoming market leaders.

“To achieve this, we needed to be innovative and have a really good understanding of consumer trends. We’ve introduced many firsts on the market,” says Kaplan.

Glazer and Kaplan have also drastically diversified their market risks by supplying all the major retailers, various prepared-meal manufacturers such as the Rhodes Food Group, and food service companies such as KFC, McDonald’s, Nando’s and Burger King.

Production

Dew Crisp’s produce is grown under nets, in plastic tunnels and in open fields.

“Tomatoes, English cucumbers and peppers don’t like water or cold [air] on their leaves, so we generally produce them under plastic,” says Kaplan.

Shade nets are used in the production of salad vegetables, as these are sensitive to sunlight, heat and wind. The nets also protect against hail and bird damage while reducing the impact of rain by breaking up the droplets. In addition, they help to absorb heat and keep the production area cool.

Open-field production is highly seasonal and limited to hardier vegetables such as sweetcorn, onions and cabbage.

Most of the produce is grown in hydroponic systems, where the plants are supplied with nutrients via a nutrient solution. In most cases, Dew Crisp uses closed hydroponics (recycled water).

“Closed hydroponics is used for salad production in GFT, whereas open hydroponics is used in the production of tomatoes and cucumbers, as they are really sensitive to diseases that might spread with the water. For this reason, each of these plants has access to its own dripper,” explains Kaplan.

Sawdust and coco peat are used as growth mediums in the open hydroponic systems.

“Some farmers sterilise these mediums to reuse them, but I prefer using them only once to prevent disease outbreaks. We do, however, reuse the gravel in the open gravel system, after cleaning it with a chlorine solution at the end of each production cycle.”

In the same way, the crops that are planted in the soil are rotated to prevent a build-up of diseases.

Water quality largely determines the success of a hydroponic system, so a farmer should not even think of using it if the irrigation water is of poor quality or has high levels of chlorine or sodium. Water can be pretreated to rectify mineral imbalances, but this drives up costs. Water should, in any case, be filtered before use.

Dew Crisp has worked with scientists for years to refine its plant feeding programmes based on the nutritional requirements of various crops during different development phases.

“The trick is to supply exactly what the plant needs. An undersupply leads to plant deficiencies, while an oversupply is wasteful and might result in damage to the system and plants. To prevent this, we constantly monitor the recycled solution, plant growth and climatic conditions, and tweak the nutritional programme accordingly,” says Kaplan.

Achieving this with open-field crops is even more challenging due to soil differences. Soil, nonetheless, has a higher buffering capacity and is thus more forgiving.

The farm does not employ any climate-control technology because of its high capital and running costs. Instead, tunnel windows are opened and closed to augment ventilation and reduce the interior temperature.

Even without climate-control technology, production is energy-intensive, as the water has to be recycled continuously. Back-up generators are a necessity, as most of the salads will die within hours if water flow is interrupted.

Advice

Farming, and especially farming under protection, has become highly specialised over the years, with low profit margins leaving little room for error.

“In the past, when a buyer ordered a hundred frilly lettuces, we could plant 150 and it didn’t really have an impact on the bottom line. These days, production costs are so high that we plant to order and programme,” says Kaplan.

The shift has also made it increasingly important for farmers to make use of consultants to fill their knowledge gaps.

“If you want to be successful today, you need to surround yourself with people who are better skilled than you are in their respective jobs.”

Email Michael Kaplan at mkaplan@dewcrisp.com.

Lead Photo: Shade nets are used in the production of salad vegetables, as these are sensitive to sunlight, heat and wind. Photo: Dew Crisp

Farm Tech Investing Is Accelerating Faster Than Ever – New Report

‘Farm tech’ investing soared to $7.9 billion in 2020, topping 2019 investments by $2.3 trillion, or 41%, according to AgFunder’s latest Farm Tech Investment Report.

By Jessica Pothering & Louisa Burwood-Taylor

August 4, 2021

We’ve been watching the surge of investor interest in upstream, close-to-the-farm technologies since the Covid-19 pandemic started. We now have numbers that show just how significant that farm tech investor interest is.

‘Farm tech’ investing soared to $7.9 billion in 2020, topping 2019 investments by $2.3 trillion, or 41%, according to AgFunder’s latest Farm Tech Investment Report. [Disclosure: AgFunder is AFN‘s parent company.]

To put this in perspective, farm tech’s acceleration was about six percentage points greater than agrifoodtech overall — that’s foodtech and farm tech combined — and 37 percentage points higher than global VC’s year-over-year increase in 2020 (which Crunchbase pegged at just 4%.)

Much of the investment activity was led by two sectors: Ag Biotechnology and Novel Farming Systems (mostly the indoor farming of crops and insects). Investors pumped more than $1.5 billion into each category. Ag Biotech companies attracted particular interest from investors: 173 deals closed, representing 58% growth from 2019. Novel Farming Systems deal activity grew by 47% year-over-year.

As difficult as 2020 was globally (2021 hasn’t been pretty in many parts of the world), the pandemic seems to have buoyed farm tech because it “exposed cracks in the industrial agricultural system,” particularly the vulnerability of the food supply chain, Infarm’s CEO Erez Galonza told AFN in an interview featured in the report. The German hyper-local vertical farming venture, whose modular units can be found in grocery stores across Europe, secured $170 million from investors last year.

“[The pandemic] highlighted the need for resilient, localized solutions,” he added.

Farm tech funding 2012-2020

Yellow bar denotes projected total by end of 2021 as more 2020 data come to light. Credit: AgFunder

SPACs for best-funded farm tech categories

Perhaps the biggest winner, in that sense, was US-based high-tech greenhouse operator, AppHarvest. The company announced plans to go public last September via a special purpose acquisition company, or SPAC. It officially listed on the Nasdaq stock exchange in January, just weeks after shipping its first harvest.

AppHarvest recently purchased robotics leader and AgFunder portfolio company Root AI, making founder Josh Lessing the publicly listed company’s new CTO. Read more here.

AppHarvest kicked off a SPAC trend for Farm Tech companies, and Novel Farming ventures specifically. We’ve since seen four other agrifoodtech companies announce plans to go public through SPACs: agbiotech companies Benson Hill and Gingko Bioworks and novel farming ventures AeroFarms and Local Bounti. (Keep up to date with agrifoodtech SPAC news here.)

It is interesting to see public listing activity happening in the two agrifoodtech sectors that surged the most in terms of deal activity last year; it signals that there could be more to come if the process proves successful for these early case studies. For now, it’s certainly providing an exit opportunity to early agtech ventures that bet on deep technologies requiring significant amounts of time (and certainly hefty commitments of resources) to become revenue-generating, much less profitable.

That in and of itself is a significant milestone for a maturing agtech industry.

Pandemic pivots

It isn’t all about Ag Biotech and Novel Farming Systems; the biggest deals of 2020 were in the Agribusiness Marketplace sector. Boston-based Indigo Ag raised two investment rounds, totaling $535 million last year, and San Carlos, Calif.-based Farmers Business Network raised $250 million.

Indigo Ag’s executive team told AFN that because it deals directly with the food supply chain, the company confronted an immediate shock from the pandemic.

“The global pandemic was an external challenge that required our team, like many others, to quickly adapt to ensure that our customers and employees were supported,” they said in a special interview featured in the report. “While we were fortunate that our operations were not significantly impeded by the pandemic, we did have to quickly expand our support services and tap our creativity to enable our farmers, buyers and partners to manage their business with confidence during the early stages of Covid-19.”

The company launched a transport support hotline for grain growers, carriers and shippers to ensure the supply of grain could continue to move as efficiently as possible. It also focused on developing pricing tools, access to grain marketing advisors, and even a podcast to help growers grapple with pandemic-related market volatility.

Indigo Ag isn’t a stranger to unchartered business terrain. The company has put itself in the middle of the evolving but murky carbon markets. “With new players entering the carbon space nearly weekly – many taking less rigorous approaches to verification and measurement – Indigo has remained steadily focused on enabling farmers to make informed decisions about how, when and why to participate in the carbon market,” the Indigo Ag team told AFN.

They added: “By leveraging our scientific insight, technological capabilities, and use of industry-leading carbon accounting protocols, Indigo ensures farmers are supported with the right tools and information to take advantage of the opportunity to raise a new and increasingly valuable crop: carbon.”

Food’s sustainable future

Verification of carbon-capture accounting is indeed getting increased attention and scrutiny. It’s likely to be a key theme in the agriculture industry going forward, and it’s one of AgFunder’s key trends to watch in 2021, alongside overall food system sustainability.

“We can invent a new, sustainable food industry, feeding the planet all the while protecting its biodiversity, and combatting climate change,” the executive team behind French insect farming venture Ynsect told AFN. The company sees insects as a crucial component of food’s sustainable future.

“Insects can aid food security and be a part of the solution to food shortages, given their high nutritional value, low requirements for land and water, low emissions of greenhouse gases, and the high efficiency at which they can convert feed into food,” the Ynsect team argued in an interview featured in the report.

Investors seem to agree: Ynsect scored the largest amount of funding in the novel farming sector in 2020, raising $222 million in 2020, taking its Series C total to $372 million, to build an industrial-sized farm for its Molitor mealworms near the city of Amiens. Ynsect went on to acquire Dutch insect farming company Protifarm in April of this year.

Many of the world’s consumers may as yet be skeptical of insects as a protein source. But consumer consciousness and demand for high-quality, low-environmental impact foods is certainly a trend influencing the evolution of Farm Tech, as evidenced by the range of startups that attracted funding in 2020.

Ag Biotech ventures like Benson Hill, GreenLight Biosciences, and Pivot Bio secured investor backing for helping to diversify crop input technology away from environmentally-harmful synthetic chemicals.

Novel Farming ventures are developing highly efficient and resource-conservative approaches to growing fresh foods.

Farm Management Software, Sensing & IoT companies like ICEYE, Aclima and Cervest are illuminating climate change impacts and helping companies anticipate and forecast climate-related disruptions.

Food preservation technologies like Apeel Sciences’s are helping reduce food waste, as are e-grocery services like Misfits Market and Imperfect Foods, which sell “ugly produce” that would otherwise be wasted among their fresh foods and grocery offerings.

Companies like Celtic Renewables are turning farm waste into a resource through the production of biofuels.

“As companies increasingly make commitments to improve their environmental impact – and governments at all levels enact policies to encourage climate-smart agriculture,” said the Indigo Ag team, “the opportunity for agriculture to act as a climate solution will only become more apparent.”

The Art Of Growing Plants Without Soil – Aeroponics, And Hydroponic

Historically, humans have grown crops in soil and they could not think of growing them in the air or a liquid but the advent of modern science and technology has made it possible

Jenna Walter

July 12, 2021

The post-apocalyptic scenario depicted in Wall-E shows that the planet earth had turned into a barren wasteland, although the movie shows a seedling growing out of a shoe, a possible solution would have been the use of aeroponics and hydroponics. These processes of growing plants without soil as a medium are mind-boggling for many.

Historically, humans have grown crops in soil and they could not think of growing them in the air or a liquid but the advent of modern science and technology has made it possible.

Hydroponics:

Hydroponics requires an aqueous solvent to grow a plant. The hydroponic system will control the environmental conditions of the plant. These conditions include the temperature and the pH balance. Simultaneously it also maximizes plants’ exposure to nutrients and water.

Hydroponics has a simple philosophy that is to provide the exact things the plant needs to grow. The administration of nutrient solutions is tailored to the needs of the particular plant being grown. The system will let the researchers control the exact amount of sunlight needed and for how long it is needed. These conditions are customized and controlled to accelerate the growth of the plant. The controlling of these factors helps reduce the chances of diseases or stunted plant growth.

On the contrary, plants that are grown in conventional conditions are more susceptible to growth issues. The soil of these plants can have fungus which can spread to the plants. Conventional plantations are also vulnerable to wildlife. Locusts attacks are also common on crops. They are known to consume whole fields in a day.

The hydroponics system can end the uncertainty that comes with growing plants outdoors. The soil only acts as a barrier for the seed while a hydroponic system allows a plant to grow vigorously.

If you are into trying out hydroponics you can buy a hydroponic garden kit. It will help you grow your favorite plants within your home.

Aeroponics:

Aeroponic systems will use the nutrient-laden mist to provide the plant necessary nourishment. It is based on the above-mentioned hydroponics systems in which the roots are submerged in a soilless growing medium.

The aeroponic eliminates the growing medium, the roots are left mid-air hanging from the pieces of foam stuffed into tiny pots. The roots are sprayed with nutrient-rich mist from time to time using specially designed devices that let you control the amount of mist, its pressure, and direction.

The seeds are planted in the foam stuffed tiny pots. On one side of the seed is light and on the other side is the mist. The foam helps to hold the plant as it grows over time.

The Use Of This Technology In Future

In the future use of these technologies will only increase. Climate change and global warming are making it difficult to grow crops using conventional methods. The earth is becoming barren due to aggressive farming practices.

The only solution left would be to use hydroponics and aeroponics. They offer more control over the growth of the plant. They can help increase crop production and they are safer because they do not use pesticides or insecticides.

Sustainably Goals Urges Architect To Build A Greenhouse Around Former Fruit Farm

As decided by the municipality of Gooik, visitors can now see the refurbished agricultural buildings enclosed within a greenhouse-like structure, this way learning more about the countryside of Belgium

Is it a greenhouse, is it an educational center, is it a former fruit farm? It is all in one. A former fruit farm in Gooik, Belgium, is now functioning as an educational center. As decided by the municipality of Gooik, visitors can now see the refurbished agricultural buildings enclosed within a greenhouse-like structure, this way learning more about the countryside of Belgium. Architect Jo Taillieu: "We wanted a generous building that could provide the necessary comfort to all users of the center, even in bad weather, and provide an anchor point for exploring the Pajottenland.”

The old farmhouse had been used as an education center already for years, but the project became to big to be run by volunteers completely. That’s why the municipality bought it and realized further expansion plans.

Interwoven

"Paddenbroek is by no means inconspicuous. In the hilly Pajottenland region, landscape, nature, heritage, and culture have been closely interwoven for centuries. Maintaining that balance was one of the major goals," architect Jo Taillieu explains. "The farmstead and especially the outbuildings were in a bad state and unsuitable for achieving the intended objectives. The link with the context was almost non-existent. The first idea - a classic renovation - was discarded, as was a new building, because it was unrealistic and did not meet the task that could be expected of an educational and tourist center. We, therefore, opted for a roof that would cover the farmstead, the historic baking oven, and the space around it."

Photo courtesy Jo Tailleu

Sustainability was one of the main goals of the construction. The dilapidated outbuildings were dismantled and the farmstead and the baking oven incorporated, restored, and insulated with moisture-regulating wood-wool cement boards and loam. Only these rooms and the offices can be heated. Thus, heating costs are sustainably limited to a few cores in the building and not everything needs to be air-conditioned. Inside the unheated greenhouse, therefore, there is an intermediate climate. Visitors are sheltered from rain and wind and can still enjoy the magnificent view of the surroundings. Upstairs are two more multi-purpose rooms that can be used as meeting rooms.

According to Stefan De Clerq, one of the business managers of the greenhouse construction company, the challenge was mostly the size and complexity of the project, as the features of this construction did not allow for a basic model. We created a unique truss and steel construction where each step was carefully monitored. All steel components were produced in our own workshops. This challenge was brought to a successful conclusion by the close cooperation between our draftsmen, our production team, and the external architects. Our own typical aluminum profiles and glass, applied in the roof and wall, also contribute to the elegant appearance of this nevertheless quite robust realization."

The construction of a complex like that of Paddenbroek in a rural area is not obvious and initially met with the necessary reservations, as could be expected. The fact that the municipality was prepared to go along with the story of architect Jo Taillieu and project manager Dries Deleye, therefore, shows vision and insight. Now that the construction is complete, everyone agrees that Gooik has gained a valuable multipurpose center that responds to ecological sustainability and from which the residents can also derive maximum benefit.

Lead photo: Photo courtesy Jo Tailleu

Publication date: Thu 29 Apr 2021

© HortiDaily.com / Contact

Luci Faas Recognized For Her Industry Efforts As Women In Produce Honoree

The Canadian Produce Marketing Association, in partnership with Grocery Business Magazine, has developed the Women in Produce initiative to recognize the achievements of outstanding women in the produce industry

Leamington, ON (April 9th, 2021) – Nature Fresh Farms’ very own Product Development Specialist, Luci Faas, has been recognized for her excellence in the produce industry.

The Canadian Produce Marketing Association, in partnership with Grocery Business Magazine, has developed the Women in Produce initiative to recognize the achievements of outstanding women in the produce industry. Luci Faas, along with nine other women, were nominated by industry peers for their contributions to promoting produce in the industry. The ten honorees will be recognized during CPMA’s Fresh Summit virtual event on April 13th.

Last year Nature Fresh Farms launched their Compostable Cucumber wrap with Luci leading its development. The concept of a home Compostable Cucumber wrap was very new, with the initial investigation solely beginning with online research and making phone calls. After two years of trial and development, they were able to develop a film made from a starch-based material with a printed PLU in compostable ink and launched the product on the North American market.

“I have always been passionate about sustainable packaging and I am very honored by the nomination. However, I want to acknowledge the various others who worked on this film and their patience in making this innovative idea into a reality for us,” shared Luci. “I believe this will pave the way for more sustainable packaging options to grace the shelves of grocery stores across the continent.”

Luci Faas joined Nature Fresh Farms three years ago as Purchasing & Product Development, now as Product Development Specialist, Luci is responsible for sourcing innovative Nature Fresh Farms packaging and understanding its viability by initiating and monitoring shelf-life testing. She is on top of the latest industry developments in sustainable packaging and ensures all new packaging meets recognized criteria, in addition to maintaining memberships with industry associations including Sustainable Packaging Coalition and How2Recycle. Her dedication to the vigorous research, development, and implementation of industry-leading sustainable packaging solutions has been a great service for both the produce industry and the environment.

“We are extremely fortunate to have Luci’s passion, knowledge, and expertise behind our packaging development, which is why when the call for nominations came out for the Women in Produce initiative, we knew she deserved the recognition,” shared Vice President John Ketler. “We have a lot of strong women working at Nature Fresh Farms, and we feel that it is important to increase the profiles of women in this industry to engage and create awareness.”

Women play a critical role in the daily operations of farming and the agriculture industry, which is why it is important to continually support their advancement, leadership, and the diverse perspectives they bring to the industry. Nature Fresh Farms would like to acknowledge all the incredible women in the agriculture industry and congratulate the Women in Produce nominees for their accomplishments.

-30-

About Nature Fresh Farms -

Continuously expanding, Nature Fresh Farms has become one of the largest independent, vertically integrated greenhouse vegetable farms in North America. As a year-round grower with farms in Leamington, ON, Delta, OH, and Mexico, Nature Fresh Farms prides itself on consistently delivering exceptional flavor and quality to key retailers throughout North America, while continuing to innovate and introduce more viable and sustainable growing and packaging solutions.

SOURCE: Nature Fresh Farms | info@naturefresh.ca T: 519 326 1111 | www.naturefresh.ca

Vertical Farming Startup Oishii Raises $50m In Series A Funding

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone.”

By Sian Yates

03/11/2021

Oishii, a vertical farming startup based in New Jersey, has raised $50 million during a Series A funding round led by Sparx Group’s Mirai Creation Fund II.

The funds will enable Oishii to open vertical strawberry farms in new markets, expand its flagship farm outside of Manhattan, and accelerate its investment in R&D.

“Our mission is to change the way we grow food. We set out to deliver exceptionally delicious and sustainable produce,” said Oishii CEO Hiroki Koga. “We started with the strawberry – a fruit that routinely tops the dirty dozen of most pesticide-riddled crops – as it has long been considered the ‘holy grail’ of vertical farming.”

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone. From there, we’ll quickly expand into new fruits and produce,” he added.

Oishii is already known for its innovative farming techniques that have enabled the company to “perfect the strawberry,” while its proprietary and first-of-its-kind pollination method is conducted naturally with bees.

The company’s vertical farms feature zero pesticides and produce ripe fruit all year round, using less water and land than traditional agricultural methods.

“Oishii is the farm of the future,” said Sparx Group president and Group CEO Shuhei Abe. “The cultivation and pollination techniques the company has developed set them well apart from the industry, positioning Oishii to quickly revolutionise agriculture as we know it.”

The company has raised a total of $55 million since its founding in 2016.

Forget Politics, Danny Ayalon Wants to Effect Change on The Ground

Having transitioned from politics to agriculture, Danny Ayalon shares how vertical farming, which provides fresh fruits and vegetables all year round, and lab-grown meat can rehabilitate the environment and dramatically reduce household expenditures

Having transitioned from politics to agriculture, Danny Ayalon shares how vertical farming, which provides fresh fruits and vegetables all year round, and lab-grown meat can rehabilitate the environment and dramatically reduce household expenditures.

Image from: Yehoshua Yosef

The coronavirus pandemic has drawn attention to humankind's carbon footprint. More than ever before we ask ourselves, how can we become more sustainable? Can we prevent pollution? How can we minimize waste? What about lowering emission levels? Will there be enough food for everyone in the future?

Danny Ayalon, a former ambassador and foreign policy adviser to three prime ministers-turned entrepreneur, believes that the answer to many of the world's problems lies in modern agriculture.

Having transitioned from politics to agriculture, he works with Future Crops, an Amsterdam-based company focused on vertical farming – the practice of growing crops in vertically stacked layers that often incorporates controlled-environment agriculture, which aims to optimize plant growth – and MeaTech, a company that creates lab-grown meat.

"Ever since the coronavirus came into our lives, we realized that man is not in charge of the universe," Ayalon told Israel Hayom.

"Our control over the forces of nature, of Earth, of our future is more limited than we had thought. And when we are no longer in charge of the world, only three things guarantee our lives here: food, water, and energy security. Food, water, and energy are three resources that can be depleted and therefore literally cast a cloud on our world.

"Experts have come to a conclusion that one of the most important fields to focus on is agriculture, and indeed we are currently witnessing the most significant agricultural revolution ever since the first agricultural revolution that took place about 10,00 years ago."

Q: Back then, in the first agricultural revolution, there was a need for a lot of land.

"But today we have technology. The name of the game is to reach maximum output with minimum input in the smallest space possible. This is the holy grail of the new revolution. And that is how technology enters the picture. To grow fruits, vegetables and spices today requires lots of space. The technology we developed at Future Crops allows us to minimize the space, increase production and redefine the food supply chain."

Q: How exactly?

"We have a nine-story hangar in Amsterdam to grow crops like coriander, basil, dill, and parsley. It has LED lights, and each plant gets exactly the amount of light it needs. We are the plant psychologists, [we] listen to all its needs and do everything to make sure the plant grows in the most optimal way.

Image from: Future Crops

"If it lacks something, it immediately receives water. Everything is done without a human's touch. We use algorithms and big data in collaboration with world-class researchers from the Weizmann Institute. It is essentially the application of vertical farming, growing various crops in vertically stacked layers, in enclosed structures, on soil platforms.

"For example, if it takes a month to grow lettuce in an open field, in a vertical farm, it takes two weeks, half that time. There's also a significant reduction in water consumption, and no pesticides or sprays are used at all. Also, the produce is available in all seasons; it does not depend on the temperature. Whoever likes mangos and strawberries, for example, will be able to enjoy them all year round."

Q: So if produce is grown faster and within a smaller space, is it going to cost less?

"The prices might be a bit higher today because this technology and the various infrastructures require an economic return of the initial investment in them. With time, the process will become more efficient, and the investments will be repaid, so in the end, the prices that the consumer will need to pay will be lower than today.

"Let me give you a simple example. Do you know how much a kilogram [2.2 pounds] of basil costs in Europe today? €90 ($108). In Israel, the price is €20 ($24). In the [United Arab] Emirates, where almost everything connected to food is imported – the prices go accordingly as well. Once you have more innovative vertical farms, consumers will pay much less."

Q: Should we expect vertical farm skyscrapers to pop up all over?

"I'm not sure that we will need skyscrapers, as with time the facilities will become smaller. Imagine that in every supermarket there will be a vertical produce stand with all the vegetables and spices, and later also fruits which you pick on the spot, without the need to move the produce from place to place. That is why vertical farming is also called urban farming, meaning there is no need for fields; you can grow [produce] on the rooftop. No resource limits you."

Q: What about the taste?

"Ours is a fresher and tastier product. I ought to give credit to the Weizmann Institute here. The challenge for them wasn't the quality of the vitamins but the taste, and they managed to achieve a great taste. In the Netherlands, Future Crops already sells parsley, and it tastes outstanding."

Q: Regular parsley lasts for about two weeks in the fridge. What about Future Crops parsley?

"Our parsley has a two-month shelf life, and it does not oxidize within a week or two."

Q: If every country will be self-reliant in terms of agriculture, do you think it will affect relations between countries?

"Economies will become self-sufficient eventually, which will ensure security with far fewer conflicts. There is less and less water in the Middle East, which might someday lead to tensions. We hope technology will reduce the tensions between countries, and territory will be less critical. Our world faces crucial challenges. Food and water security have the potential to either divide or bring us together and ensure our long-term existence.

"By the way, in every developed Western country, like the United States, Australia, and also in Europe, issues of food security, climate, and greenhouse emissions are on the top of the political agenda. We are not talking about it [in Israel,] as security and foreign affairs take the central stage, but Israel does have a lot to offer here."

Q: Do we have the potential to become the Silicon Valley of advanced agriculture?

"Israel takes tremendous pride in its actions that help save the world. Will we become the Silicon Valley of agriculture? There is no doubt about it. We can already see foreign investors who come here to look for opportunities, including my business partner Lior Maimon, co-founder and CEO of Silver Road Capital, and Steven Levin, one of the leaders of the US food industry. Silver Road Capital is a holdings and financial advisory firm with a broad portfolio of high-tech companies, as well as agricultural and food technologies, and represents international companies and funds in investments in Israel and the world.

"Future Crops's goal is to raise 35 million shekels on the Israeli stock exchange to invest in enlarging the existing facilities and [set up] other production lines and facilities in Europe and other continents. We cooperate with the Albert Heijn supermarket chain [in the Netherlands] and a leading food chain in France."

Q: Vertical farming is estimated at $3 billion. Google and Amazon have invested hundreds of millions in the field as well. What is their goal?

"A simple answer would be profit. A longer answer is that they [large corporations] understand that food has the highest demand. People cannot live without food and water, and Google and Amazon understand that potential."

Q: US President Joe Biden took office with the largest team of climate experts ever. That ought to give the field momentum.

"Green energy and vertical farming will get a considerable boost. Climate change and green energy are well-rooted in the Democratic Party's ideology.

"It is also possible that large companies entered the agriculture fields precisely because of the Biden administration; they are worried about their future. They are afraid of a certain dismantling, so focusing on secondary fields is part of a security scenario for them."

Q: Biden also wants to address greenhouse emissions, which are the result of the food production industry, mainly meat. Are Amazon and Google's food counterparts - McDonald's and Burger King - looking for meat substitutes?

"Firstly, cultured [lab-grown] meat does not require grazing land, cows do not need to be fed, and so much land can instead be turned into forests that support the environment. This is an optimistic industry that leaves us with a better world.

"As for the meat alternatives market, there are two major companies in the US that produce plant-based protein, Beyond Meat, and Impossible Foods.

"Impossible's burgers are already at Burger King, McDonald's has partnered up with Beyond Meat, and last November, it announced that it would create its own plant-based burger.

"The problem is that pea protein [used in plant-based burgers,] does not have all the amino acids that animal protein contains. Also, they need to add additives to supplement for taste and smell.

"At MeaTech, where I'm a director, we are on our way to producing animal meat, cultured meat, real stakes: we take a cow's own stem cell from which meat can be produced in almost unlimited quantities. We also use 3D digital printing technology. And we also created a thin layer of meat, carpaccio. Needless to say, no cow was harmed in the process."

Image from: MeaTech

Q: Why do you use 3D printers?

"Because there is no need for a human being's involvement. It is relevant now during the coronavirus pandemic when the food supply chain is disrupted. With such printers, your production can continue without delays, whenever you want.

Also, it is theoretically possible to provide food for space flights. Astronauts who go out into space will not have to take food with them; rather, they will be able to produce it on the spot.

"People understand that crises like the coronavirus can disrupt the supply chain and are looking for alternatives. A 3D printer allows restaurants, supermarkets, and butcher shops to have meat without relying on the supply chain."

Q: The death rate from obesity is higher than the death rate from hunger. How will cultured meat affect these statistics?

"It is possible to create meat with much less fat and more protein in each portion and add various nutrients in the future to strengthen the immune system and prevent disease. This, of course, requires a lot of research and approvals. Just like there's talk about customized medicine, so it will be possible to produce food that suits a person's genetic structure and body in the most optimal way."

Q: Will the cost of this meat also be optimal?

"They will cost more in the beginning compared to regular meat because there are initial costs that have to be repaid. When it becomes a mass production, prices will drop over time."

Q: With your vast experience in politics, what do you think of Israeli politics these days? Do you ever consider a political comeback?

"No election campaign goes by without someone making me an offer [to return to politics] but I'm not interested. Unfortunately, the Israeli government, and all governments in the Western world, have not been able to run their countries properly in recent years.

"For example, more of the government's national taks are transitioning to the private market or the third sector. We see that associations [are the ones] who take care of the needy, establish settlements in the Negev and in the Galilee, bring immigrants to Israel and provide Israelis with information. All these things should be done by the government.

"The Israeli government lacks vision, ideologies, every matter is personal and is charged with negative sentiments. If I do return one day, it will only happen after we change the government system which will take its power from small [political] parties.

"In my opinion, we need to transition to a regional choice, by district. This will result in higher quality politicians. How so? Because whoever wants to be elected will need to run and convince the people who live in his area and district, and they are the ones who know his activities best. Also, closed primaries should be avoided because they make all kinds of deals possible. That needs to change."

The Philippines: Congress OKs Bill Promoting Urban Agriculture

Benitez headed the technical working group that produced the consolidated bill, which will mainstream vertical farms, indoor farms, and community gardens in cities and urbanizing areas

January 29, 2021

THE House of Representatives approved on second reading, Wednesday, January 27, 2021, House Bill No. 8385, consolidating several bills promoting urban agriculture authored by Third District Representative Francisco Benitez.

Benitez headed the technical working group that produced the consolidated bill, which will mainstream vertical farms, indoor farms, and community gardens in cities and urbanizing areas.

The bill stated that about 2.5-million Filipino families experienced involuntary hunger at least once in the past three months based on the 2019 second-quarter survey of Social Weather Station, of which the higher hunger incidence was recorded in Metro Manila, with 520,000 families experiencing hunger.

According to the Expanded National Nutrition conducted by the Food and Nutrition Research Institute, 53.9 percent of Filipino households are food insecure.

To address this, Benitez said it is imperative to introduce game-changing solutions, increasing production by maximizing available spaces and utilizing emerging agricultural technologies and methods, particularly in urban areas where hunger incidence is prevalent.

$1.8 Million Dollar Alaska Micro-Grant Opportunity

Both individuals and organizations can apply; the definition is very broad: all individuals, Indian Tribes or tribal organizations, non-profit organizations, and federally funded educational facilities in the State of Alaska

State of Alaska, Division of Agriculture

Micro-Grants For Food Security 2021

Important: February 15th Scoping Pre-Application Deadline

There is a two-step process to apply:

1) Submit a simple, two-page application by the February 15th deadline.

2) Applications meeting the criteria, will be notified to submit a full proposal.

More Details and Dates

The Department of Natural Resources Division of Agriculture has complete Micro-Grants for Food Security information.

February 15: The simple two-page Scoping Pre-Application is due.

Grant Award Scoping Applications and Full Applications are to be submitted to dnr.ag.grants@alaska.gov or by mail at Division of Agriculture, Attn: Grants Coordinator, 1801 S. Margaret Drive, Palmer, Alaska 99645.

March 1, 2021: Notification of selection for full proposal submissions. Qualified, unfunded applications will be given priority in 2022.

April (TBD), 2021 - Announcement of final awards

Overview

Alaskans have a huge opportunity to increase their food security and resilience through a $1.8 million dollar mini-grant offered through the State of Alaska Division of Agriculture in 2021.

VH Hydroponics is offering guidance and estimates for interested clients who would like to apply. Email iinfo@vhhydroponics.com or (907) 782-4420.

Who Can Apply?

Both individuals and organizations can apply; the definition is very broad: all individuals, Indian Tribes or tribal organizations, non-profit organizations, and federally funded educational facilities in the State of Alaska. Therefore, everyone in the State of Alaska who has a project which will meet the requirements of the program are eligible to participate.

How much?

$1.8 million dollars for 2021. There will be additional funding in 2022 and 2023.

Individuals

Individuals may apply for up to $5,000 per year for up to 3 years. The maximum of $15,000 over 3 years.

Organizations

Organizations may apply for up to $10,000 per year for up to 3 years. Maximum of $30,000 over 3 years.

Multiple Awards For The Same

Project Are Allowed | 10% Matching

Awards may be granted for two or more eligible entities to carry out the same project. 10% match is required; but for individual grants, a waiver may be requested which will be considered for approval.

Purpose And Use of Grant Funds

To engage in activities that will increase the quantity and quality of locally grown food for food insecure individuals, families, neighborhoods, and communities, including by:

Purchasing tools, equipment, soil, soil amendments, seeds, plants, animals, canning equipment, refrigeration, or other items necessary to grow and store food;

Expanding areas under cultivation to grow food or to qualify for an EQUIP high tunnel to extend the growing season;

Hydroponic and aeroponic farming;

Building, buying, erecting, or repairing fencing for livestock, poultry, or reindeer;

Purchasing and equipping a slaughter and processing facility;

Traveling to participate in agricultural education

Paying for shipping of items related to growing or raising food;

Creating or expanding avenues for the sale of local food, increasing the availability of local nutritious food, and engaging in other activities related to increasing food security (including subsistence)

Scoping Pre-Application Project Scoring

An independent Review Committee will evaluate the scoping pre-applications with the following criteria:

Eligibility of the proposal per the farm bill legislation

The ability of the proposed activity to increase the production and/or storage capacity in the local community

The level of food insecurity in the applicant’s region

Other relevant information as to the capacity and purpose of the applicants

VH Hydroponics is Here to Help

Contact VH Hydroponics to learn more about pricing and possibilities

Email: VH Hydroponics for More Information

VH Hydroponics | (907) 782-4420 | https://vhhydroponics.com

The Capital Expenses For Vertical Farms And Greenhouses

Here at Agritecture, we have performed side-by-side analyses of vertical farms and greenhouses. For most US markets, the greenhouse model comes out ahead on both capital and operational costs

28-01-202 | Agritecture

Written By: Djavid Amidi-Abraham

Breaking down the differences in CapEx between Vertical Farms and Greenhouses. If we peer into the portfolios of some venture capital investors with funds dedicated to agriculture investments, we see a hesitance to invest in vertical farms.

Here at Agritecture, we have performed side-by-side analyses of vertical farms and greenhouses. For most US markets, the greenhouse model comes out ahead on both capital and operational costs.

Let’s look at an example located in a New York Metropolitan market scenario with two similarly sized facilities having similar amounts of bed space (production capacity). The below tables indicate their differing costs per lb of leafy greens grown in the first year.

This analysis focuses on production systems and has thus excluded costs relating to installation and land acquisition, but includes an additional distribution cost for the greenhouse model, as this greenhouse is likely to be located outside of an urban area but still within the “local” range. In the interest of equating production conditions, the greenhouse model also includes additional capital and operational costs for the integration of supplemental lighting in order to bring the daily light integral to equal quantities provided by most vertical farms.

While we may see different scenarios in the future, this assessment draws on current prices and equipment performance.

Greenhouses draw a lot of their value from the fact that the production surfaces are mostly illuminated by the sun, a free resource. Vertical farms, on the other hand, have to pay for the light that their crops see, a significant added cost that often occupies high percentages of operational costs.

In addition, a specialized HVAC system must be designed and implemented to neutralize the heat emitted by the lights. Additional dehumidification capacity is also required with design setpoints relative to the transpiration rate of the crops being grown. HVAC is often the second-highest, non-labor expenditure for VF operations and when dehumidification is added into the mix, overall HVAC operational costs can even exceed lighting electricity costs.

As LEDs become more efficient, less power will be required to cool the space and the economic scenario for VFs becomes more attractive as two of the highest operational costs have been reduced.

To date, the introduction of LEDs to the agriculture industry has made VFs possible. In the future, the continued improvement of LEDs will make VFs more competitive against other modes of controlled environment crop production. It’s hard to say if VFs will outcompete greenhouses on their costs of production as greenhouses similarly benefit from lighting efficiency improvements that will enable them to serve more northern markets at lower operational costs.

While greenhouses outcompete vertical farms today, there may be a future where those tables are turned.

It should be considered that the efficacy of either of these approaches to CEA will be informed by local market conditions. In relation to both the revenue generated and the costs of operation, markets around the world provide differing contexts for the production of crops in protected agriculture scenarios, and these varying costs and opportunities create a unique scenario in every market.

Agritecture’s consultants have a deep understanding of these costs and opportunities and have provided these insights to over 100 clients in more than 20 countries. If any of our readers would like to explore the possibilities in their local region, reach out to Agritecture and we can assess this opportunity through our unique approach and assessment methodology.

This is the second of a two-part series on how vertical farming compares to other farming methods, from our Lead Systems Designer, Djavid Amidi-Abraham. To read Part 1, click here.

Source and Photo Courtesy of Agritecture

* New Deadlines * Center of Excellence Announces: Indoor Farming "Best in Class" Awards!

Companies that score the highest in each category will be nominated for an “Indoor Ag Center Best in Class Award” (TM)

Center of Excellence Announces

Indoor Farming

"Best in Class" Awards!

Who Can Enter

Indoor Vertical Farms

Plant Factories

Greenhouses

Grow System Solution Manufacturers

Lighting Companies

How to Enter

Go to: https://indooragcenter.org/awards/

New Deadlines for Submissions:

Manufacturers: Feb 1, 2021

Growers: Feb 15, 2021

There Is No Fee To Enter

Companies that score the highest

in each category

will be nominated for an

“Indoor Ag Center Best in Class Award” (TM).

Learn More

Our vision is to accelerate the growth of the indoor farming industry. We believe we can do that by recognizing excellence. Consequently, we have embarked upon an ambitious program to collect bench-marking data on indoor farm operations and equipment used to run vertical farms and greenhouses. Each year we will review the data and publicly recognize key stakeholders for their excellence in several categories.

What Are The Emerging Trends Affecting Indoor Farming? State of Indoor Farming Survey

Artemis Ag has opened its third annual State of Indoor Farming Survey, and is looking for your input

By Artemis Ag

January 9, 2021

Photo: Kalera

Artemis Ag has opened its third annual State of Indoor Farming Survey, and is looking for your input. The survey will provide insights on emerging trends and challenges in the greenhouse and vertical farming industries.

“We’re looking forward to learning how growers are facing new challenges such as COVID-19,” says Allison Kopf, CEO of Artemis Ag. “In the past, expansion was one of the prime goals for growers, and we’ve asked some new questions around the topic. We will be sharing even more information related to technology usage, the evolution of the industry, and how growers are working with lenders.”

In the past few years, more than 500 growers have participated in Artemis’ annual State of Indoor Farming Surveys. Past reports have been downloaded more than 2 million times and are one of the most widely circulated and respected sources of industry data.

More and better data collected means more insights for growers. Growers can participate in the 2020 State of Indoor Farming survey here.

The survey will be open for a few weeks and Artemis expects to launch the 2020 report immediately following.

Learn more here.

Bowery Farming Brings Indoor Vertical Farm To Bethlehem, PA - On Every Main Street

New York-based Bowery Farming is set to build its fourth and largest facility on the nearly 9-acre Lehigh Valley Industrial Park VII site in south Bethlehem

By GREG CAPOGNA • JAN 5, 2021

Lead Photo: Bowery Farming transforms industrial spaces into smart farms where crops are stacked vertically to maximize space. The design and year-round operation can yield 100 times more produce in the same space as traditional outdoor farms. BOWERY FARMING

Host Greg Capogna, in a Lehigh Valley exclusive, sits down with Irving Fain, CEO, and Founder of Bowery Farming, and Dennis Davin, Secretary of Pennsylvania's Department of Community and Economic Development, to discuss Bowery coming to Bethlehem, vertical farming, sustainable agriculture, the environment and jobs for the Lehigh Valley.

Listen

OEMS 1/4/21 Bowery Farming

New York-based Bowery Farming is set to build its fourth and largest facility on the nearly 9-acre Lehigh Valley Industrial Park VII site in south Bethlehem. The move is expected to create 70 new full-time jobs within the next three years. Bowery is the largest vertical farming company in the U.S..

Tune in to On Every Main Street Mondays from 6:30 to 7:00 PM following Lehigh Valley Arts Salon.

(Original air-date: 1/4/2020)

AVF Presents Advisory Board For 2021

The Advisory Board will support and advise AVF Board of Directors in all strategic developments, oversee the implementation of annual objectives and create a valuable ecosystem for the members to advance the Vertical Farming industry globally

AVF is honored to introduce our Advisory Board members for the year 2021, they are experts in their own fields and represent different sections of the indoor farming industry and academia.

The Advisory Board will support and advise AVF Board of Directors in all strategic developments, oversee the implementation of annual objectives and create a valuable ecosystem for the members to advance the Vertical Farming industry globally. AVF’s board and staff are pleased to have the support of this esteemed group going forward.

Ali Ahmadian is the CEO of Heliospectra and the chair of AVF’s Advisory Board for 2021.

Ali combines his passion for people and technology with 20 years of international business leadership experience to his position at the helm of Heliospectra.

Ali is globally recognized for his successful track record of developing new business and delivering profitable growth in a multitude of geographies. He has lived and worked in five different countries on three different continents over the course of his career. Highly skilled in integrating cultural and commercial experiences, he excels in establishing partnerships with different stakeholders and driving diverse teams to peak performance. Prior to joining Heliospectra, Ali was Vice President of Tetra Pak in Asia Pacific and served as a member of Tetra Pak’s global executive team.

Luis Trujillo is an Area Sales Manager at Hoogendoorn Growth Management.

He has more than 25 years of experience in markets with a strong focus on innovation and technology. He is currently with Hoogendoorn America.

Jasper den Besten is a professor at HAS University of Applied Sciences in the Netherlands.

He is researching new cultivation systems, with a focus on cultivation without daylight. Since 2009, HAS University has been involved in very applied LED-lit climate cell research.

Hemant Julka is the Co-founder and COO at Veggitech in the UAE, a professional with over 3 decades of experience in business and technology.

He is a social entrepreneur with a vision to make a positive impact in transforming communities at the grass-root level. The Agro-Tech startup company, VeggiTech, is disrupting the Agriculture industry with protected Hydroponics and grow light-based Hydroponics.

Max Loesel is the CEO of Agrilution and one of the Co-founders of the AVF.

He is a young entrepreneur and has been engaging with activists for sustainable living to preserve our planet for years. He has pioneered a fully automated Vertical Farming home system with Agrilution.

For more information:

Association for Vertical Farming

info@vertical-farming.net

www.vertical-farming.net

Publication date: Wed 6 Jan 2021

Nature Fresh Farms Hires New General Manager For Their Mexico Greenhouse

Nature Fresh Farms has expanded operations into Mexico to be close to growing partners and augment their existing North American supply chain. Central Mexico’s favorable climate reinforces their ability to provide fresh produce 365 days of the year

Leamington, ON (January 11, 2021) – Nature Fresh Farms welcomes Robert Van Der Geest as General Manager to their Mexico team.

Nature Fresh Farms has financially invested in the operation of a 15-acre greenhouse with an additional 15 acres under construction, located in Central Mexico. Robert Van Der Geest has been brought on to lead their greenhouse operations and take on the role as General Manager of Nature Fresh Farms Mexico.

Nature Fresh Farms has expanded operations into Mexico to be close to growing partners and augment their existing North American supply chain. Central Mexico’s favorable climate reinforces their ability to provide fresh produce 365 days of the year. By having full control over the operations in Mexico, Nature Fresh Farms can ensure the level of quality and flavor their customers expect.

Originally from Holland, Robert first began his agricultural career in the cut flower industry. For five years Robert ran a cut flower project in Mexico and following his return to Holland he shifted to produce greenhouse growing, then in 2016, he moved back to Mexico to continue the management of greenhouses in the region. Robert is excited to join the Nature Fresh Farms Mexico team and will be playing a key role in meeting the company’s growth goals as well as building on their commitment to providing fresh and consistent produce to their customers throughout the year.

“One of the first things I’ve noticed about this company is the real team environment, which is a fantastic achievement for a company this large,” shared Robert. “I’m looking forward to working with a team that is so innovative and constantly pursuing growth.”

Robert will be responsible for the initial set up of the facility and will take care of personnel and operational management to ensure the facility runs smoothly while helping to integrate the greenhouse with the rest of Nature Fresh Farms operations. He is thrilled about the new opportunities arising in Mexico and looks forward to acquiring more knowledge and applying it to growing.

“We welcome the addition of Robert to the Nature Fresh Farms teams,” announced Vice President, John Ketler. “With our new facilities in Mexico, we needed someone with an extensive understanding of the industry and familiarity of the region and Robert is a great fit.”

Nature Fresh Farms is thrilled with the growth and direction of the company along with the steady expansion of their team. As the business continues to grow, the company is excited to offer new opportunities for professional development.

About Nature Fresh Farms -

-30-

Continuously expanding, Nature Fresh Farms has become one of the largest independent, vertically integrated greenhouse vegetable farms in North America. As a year-round grower with farms in Leamington, ON, Delta, OH, and Mexico, Nature Fresh Farms prides itself on consistently delivering exceptional flavor and quality to key retailers throughout North America, while continuing to innovate and introduce more viable and sustainable growing and packaging solutions.

SOURCE: Nature Fresh Farms | info@naturefresh.ca T: 519 326 1111 | www.naturefresh.ca

Biological Innovation Is Key To The Economic & Environmental Sustainability of CEA

As the global population rapidly urbanizes, we need to move our agricultural production to within urban and peri-urban areas

January 6, 2021

Editor’s note: Leonard Lerer is founder and CEO at Back of the Yards Algae Sciences (BYAS), a Chicago, US-based biotech company developing sustainable novel ingredients derived from algae.

BYAS is a graduate of the GROW Impact Accelerator, which is affiliated with AFN’s parent company AgFunder.

As the global population rapidly urbanizes, we need to move our agricultural production to within urban and peri-urban areas. The environmental and social costs of large-scale, industrial farming are huge, and include the fallout from widespread pesticide and chemical use, the depletion of land resources, and the progressive depopulation of rural areas.

In regions where land is at a premium or climatic conditions are not favorable for outdoor farming, the only alternative is the controlled environment agriculture (CEA) ‘plant factory’ – whether an indoor, vertical, or greenhouse-based facility.

The advantage of CEA is clear: safer, standardized, pesticide-free produce with short delivery ‘circuits’ that are less polluting.

Invest with Impact. Click here.

The flipside is that the jury is still out as to whether indoor or vertically farmed produce can be considered especially sustainable given lighting energy costs in particular. If these energy input costs could be reduced, then the door opens to using vertical farming as a production system for food staples such as wheat, corn, and soy.

The current energy use reduction effort in CEA is largely focused on improving lighting technology with the goal of greater energy efficiency and ‘tuning’ light frequencies to the photosynthetic needs of plants. But perhaps there are other approaches to support the transition of indoor and vertical farming into an incontrovertible part of the urban food chain?

Recently published research from BYAS offers the exciting prospect of moving vertical farming past the economic and environmental sustainability barrier. This is the opportunity to transform indoor and vertical farming from simply a source of leafy greens, vegetables, and small fruits into a real, long-term pillar of urban food security.

At the heart of this promising approach is the application of an algae-based biostimulant to significantly reduce growing time, thereby saving energy and increasing profitability. After more than two years of intensive research, BYAS has developed a proprietary microalgae extract that shortens the time between planting and harvesting in leafy greens and vegetables. This phycocyanin-rich spirulina extract (PRSE) is part of the BYAS portfolio of alternative proteins, including food colorants and plant-based meat ingredients.

Published research shows that PRSE is effective as a biostimulant in hydroponics, improving growth, yield, and quality of lettuce while cutting maturation time by six days (about 21%.) PRSE-treated lettuce showed a 12.5% increase in yield, a 22% increase in photosynthetic efficiency, a mean increase of 2.6 cm in leaf length and 2.2cm in basal stem diameter. In a shelf-life test, wilting was seen two to three days after it was observed in control groups. The treated groups were a brighter green (specifically 17% brighter and 75% greener) and better tasting. They had firmer texture, stronger aroma, and more intense flavor than the untreated group, according to an independent certification agency.

Using high-performance liquid chromatography analysis, the BYAS team also examined nutrient content showing that PRSE-treated lettuce had 30% more of the flavonoid, quercetin.

Natural biostimulants offer vertical farmers a new avenue for reducing energy inputs, while the improvement in product quality will assist in improving profitability by ensuring better selling prices. The most exciting aspect of developing natural biostimulants specifically for vertical farming is the possibility to extend the indoor farming sector into row crops as food staples, ensuring not only better and more secure food supplies for urban populations, but also protecting the planet.

agfunder, algae, asia, Europe, Frankly Speaking, grow, microalgae, United States, vertical farming

JPFA Offering Online Training Course On Plant Factories

The Japan Plant Factory Association is starting a new online English-language training course on Plant Factories with Artificial Lighting (PFAL) in February and is receiving applications now

English Training Course on Artificial Lighting In February

The Japan Plant Factory Association is starting a new online English-language training course on Plant Factories with Artificial Lighting (PFAL) in February and is receiving applications now.

The JPFA 2021 online training course on PFALs scheduled for February 18 – March 11 comprises introductory classes and special content designed for participants to acquire practical knowledge and expertise. The learning event follows its first online English-language training course that was offered last year.

Click here to view the course brochure.

All interested parties in plant factories or vertical farms can seize this opportunity as the course is not only available for JPFA members but also for non-JPFA members. The JPFA is a nonprofit organization committed to advancing controlled-environment agriculture.

The lecturers include Toyoki Kozai, honorary president of the JPFA and former president and professor emeritus of Chiba University, who is known as the father of plant factories. Introductory classes will cover such topics as current PFALs and forthcoming technologies as well as environmental effects on plants. Special content will allow participants to learn practical methods.

The course will also provide participants with a virtual tour to a commercial, large-scale PFAL and exhibitions by companies in the PFAL and related businesses. Although participants cannot get together as in on-site courses, the course’s platform allows them to enjoy interacting with other attendees and representatives of exhibitors. Also, a live question-and-answer session is planned for participants to deepen their understanding.

“Thank you so much for the opportunity to look deeper into this ‘industry,’ which is likely to reshape our future soon,” a Romanian participant of the 2020 course said.

Because the course is online, it may be easier to attend it than an on-site one, especially for those who live outside Japan.

Click here to apply for the course.

VIDEO: Havecon Introduces Havelettuce Projects: Standardized Turn-Key Lettuce Greenhouses Make Entering Greenhouse Industry Easier

Havelettuce will not only take on the build of a greenhouse but the complete project realization, offering a plug and play concept for starting a lettuce greenhouse enterprise. With this new initiative, the door into the horticultural industry will open more easily, CEO Henk Verbakel explains

Havecon has been known as a turnkey greenhouse supplier for many years now, but as of now they'll take turnkey to a new level under the name of “Havelettuce Projects”. Havelettuce will not only take on the build of a greenhouse but the complete project realization, offering a plug and play concept for starting a lettuce greenhouse enterprise. With this new initiative, the door into the horticultural industry will open more easily, CEO Henk Verbakel explains.

Reduce food miles

"Growing hydroponic vegetables closer to consumers will reduce food miles and help reverse the trend of foreign produce imports. Together with our partners and suppliers we bring over 100 years of combined experience in developing large-scale hydroponic greenhouses for several kinds of fruit, vegetables and medicinal cannabis. With Havelettuce Projects, we're using this knowledge to offer 1-2 and 2-4 hectare standardized, turn-key hydroponic lettuce greenhouses," says Henk.

With this new concept, they're answering to the growing demand for local food production and helping investors and other newcomers to the industry find an easy entrance. "We'll manage the entire project from start to finish. This means you only deal with one company," says Jon Adams, Vice President North America. "Furthermore, we provide project anonymity to our customers to provide a competitive edge by being the face of the project until it goes live."

Investors

The horticultural industry has become of interest for many investors and according to the Havelettuce team, it's not difficult to see why. "It is a proven method of growing plants in a soilless environment by relying on a nutrient-rich water solution," Jon explains. "Hydroponics can rapidly help serve unmet demands for fresh vegetables by being grown close to their markets. And it's a sound investment: with investment sizes of 20-50 million dollars for a 1- 4 ha projects we can show a 10-year average EBIDTA of 30 – 45%."

Hydroponic advantages

He adds how growing produce in a hydroponic greenhouse has many advantages. "Greenhouse temperatures and inputs can be precisely controlled, allowing plants to grow faster and face fewer diseases than their outside soil counterparts. Furthermore, a closed-loop irrigation system results in major water savings and uses less fertilizers. This prevents pollutants from entering soil and groundwater as seen with open-field production."

And it's not just the existing industry players anymore that see these opportunities. Many new people are entering the industry. To make it easy for them to do so and to avoid reinventing the wheel, Havelettuce has been created. "Our team has built over 400 greenhouse facilities throughout the world from project as small as 0.1 to over 100 hectares. And now we combine our expertise in hydroponic farming with that of our partners. With the standards we created, Havelettuce Projects makes lettuce cultivation in greenhouses possible for everyone in any climate," he shows.

This means that location, climate, utility load studies, feasibility studies, and all other things you can think of like the community outreach and education, the permitting and incentive procurement will be taken on by our team and by doing so relieve the investors, just as of course the engineering and constructing, project management, crop and harvest advice, and grower consulting and training. "We will provide all of the necessary tools needed to succeed in this industry."

For more information:

Havelettuce

info@havelettuce.com

www.havelettuce.com

Linkedin

Twitter

Publication date: Mon 4 Jan 2021

Author: Arlette Sijmonsma

© FreshPlaza.com

Ready For The Green Revolution? Agrilution Brings The Herb Garden Into The House With The "Plantcube"

The “Plantcube” from Agrilution promises always spring in the kitchen - a fully automated grow cabinet that enables vertical farming even on a small scale

December 20, 2020

The “Plantcube” from Agrilution promises always spring in the kitchen - a fully automated grow cabinet that enables vertical farming even on a small scale. AD spoke with Maximilian Lössl, Co-Founder and CEO, about the first experiments in his parents' cellar, the new features of the 2nd generation “Plantcube” - and about why the basil must never run out in his personal mini-farm.

With your high-tech herb garden in the design closet, you create a closed ecosystem in which it is always spring. What does such a mini vertical farm bring us at home?

As the closed ecosystem mimics the perfect spring conditions every day, herbs, salads and micro-greens grow with a density of up to 30 percent higher nutrients; without any transport routes, cooling chains or plastic waste. The harvest also lands directly on the plate and thus retains the secondary plant substances, vitamins, and minerals that are so important. Thanks to the special light frequency, the controlled climate, and the hydroponic irrigation, optimal ripening conditions exist throughout the year - and without pesticides or seasonal dependencies! Technology and nature go hand in hand.

In 2013, Maximilian Lössl (right) and Philipp Wagner founded “Agrilution” together. (Photo: Agrilution)

You started with the farm-to-table experiments in your parents' basement. How did the idea come about?

The initial spark, the enthusiasm for vertical farming, came from a book by Dr. Dickson Despommier. On the recommendation of the author, I actually went to Den Bosch in the Netherlands to study. But the theory wasn't enough for me, I became impatient and wanted to act. So I took the concept of vertical farming further; the idea of a "mini vertical farm" for your own home was born. Philipp Wagner then came in for the technical implementation. Our friendship goes back to school days, when we played basketball together in a club. We started the experiments in my parents' garage and founded Agrilution together in 2013.

Which salads and herbs exactly grow in the “Plantcube”?