Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

The Advantages of Local Food Production

There is a growing movement worldwide, including in our tri-county area, to encourage local farming. This is a rich agricultural region, but most of what is produced is exported, while more than 90 percent of what we consume is imported

By Dennis Allen

August 5, 2021

My last article focused on creating food security in Brazil with the accompanying benefit of strengthening community. There is a growing movement worldwide, including in our tri-county area, to encourage local farming. This is a rich agricultural region, but most of what is produced is exported, while more than 90 percent of what we consume is imported.

A similar situation existed in Rosario, Argentina, when the economy collapsed in 2001. A quarter of the work force was unemployed, half the population dropped below the poverty line, and food shortages became common. To address this crisis, the municipal government started its Urban Agriculture Program to create employment and counter hunger. The city partnered with 700 families and made available unused land for farming. Two decades later, the program is still vital and has expanded to the surrounding region. Within the city limits, there are 2,000 acres of gardens and orchards. Gardens are in every corner of the city, including abandoned factories, old dumps, and empty lots. Rosario has just been awarded the World Resource Institute’s coveted Prize for Cities, the global award recognizing transformative urban change.

Cities around the planet are incentivizing local farming, returning to an old pattern linking food production and consumption, and often small scale. There are community farms, rooftop gardens and greenhouses, vertical hydroponic farms, aquaculture ponds, orchards, animal husbandry, front-yard and backyard gardens, beehives, and herb gardens.

Locally grown food is less expensive, in part because there is minimal or no transportation involved. It is fresher and more nutritious, features which diminish the farther away the food is produced. Several studies have documented that small-scale, family farms use less energy and less water. Often, rainwater is harvested to grow these fruits and vegetables, and sometimes wastewater can even be used.

The Community Environmental Council (CEC) is working with farmers, researchers, educators, and policy makers to develop a comprehensive food program locally. Our many farmers’ markets and network of family and community gardens provide a strong component for what is envisioned. The underlying principle of CEC’s approach is tackling climate change — reducing carbon emissions, turning food waste into resources, shifting to renewable energy, and building up soils to hold more water, nutrients, and carbon.

One of the biggest hurdles in our area is the cost of land. Many small farmers are forced to lease fields with an attendant precariousness. Some activists are starting to work toward greater permanence and ownership. Local municipalities and our three counties need to give priority to lands they control for permanent food use, including curb strips, degraded lands, and even parts of parks and school yards.

CEC, with its 50-year history of approaching challenges through theory, policy, and practice, is uniquely positioned to develop partners and alliances to transform our food sector to be more resilient and climate friendly.

Lead Photo: Localizing Our Food Will Produce Health, Economic, and Climate-Offset Benefits

Eat Local, Think Global

Regardless of how large or small their community is, 70 percent of people recognize the importance of purchases that support their local economy, and about 60 percent value locally grown products when they go food shopping.

August 2, 2021

Confronted with so much uncertainty last year, many people took comfort in the simple act of supporting their neighborhood retailers. And when it comes to food shopping in particular, research suggests that Americans’ desire to buy from local and regional growers won’t be fading anytime soon. Regardless of how large or small their community is, 70 percent of people recognize the importance of purchases that support their local economy, and about 60 percent value locally grown products when they go food shopping.

It doesn’t hurt that local food is more readily available, even in the midst of a crisis, according to the majority of shoppers. But the benefits of filling grocery carts with locally sourced items, especially produce, extend well beyond convenience alone. For starters, purchases from local growers can generate income for other local businesses. Additionally, produce that has traveled shorter distances to reach grocery store shelves tastes fresher and retains more of its nutrients. Moreover—and perhaps most important for today’s environmentally conscious consumers—shopping from local and regional growers can help curb carbon emissions, waste and pesticide use.

A harvest crew manager transports fresh kale to the Consalo Family Farms central warehouse in Vineland, N.J.

“It's about building relationships. We grow our business together, so we’re both in it together.”

Ricardo Dimarzio, Mid-Atlantic Produce Sales Manager for Safeway

A harvest crew manager transports fresh kale to the Consalo Family Farms central warehouse in Vineland, N.J.

Some grocery stores are helping lead the way forward for a local food movement that benefits the environment. Safeway, for example, has been working with sustainable local and regional farmers for generations, and more recently began sourcing vegetables and herbs from low-impact vertical farms in the D.C. area. These efforts are reducing negative effects on the planet, while also ensuring that shoppers get the freshest blueberries and crispest salad greens. What’s more, Safeway’s approach is helping support a network of family growers and modern farming companies alike.

“It's about building relationships. We grow our business together, so we’re both in it together,” said Ricardo Dimarzio, Mid-Atlantic Produce Sales Manager for Safeway.

How local farming provides a foundation for a sustainable food system

Over the past two years, half of consumers have adjusted their eating habits in an effort to live more sustainably, whether that has meant cutting down on food waste, paying more attention to food companies’ environmental impacts, or adding more fresh and local foods to their diets. But the pandemic showed people just how important those habits can be to their health and survival, according to food industry experts. Eating certain fruits and vegetables can boost immunity, for example, especially if they are picked fresh.

“Locally grown crops are being harvested at their peak. That's when they're dense in nutrients,” said Chelsea Consalo, who represents the fourth generation of New Jersey-based Consalo Farms, which began doing business with Safeway in the 1960s. After they’re picked, local fruits and vegetables spend less time in transit, ultimately reaching grocery stores and consumers more quickly and with nutrients intact. On the other hand, when produce is shipped across long distances, factors such as air quality, artificial lighting and temperature changes during transport can lower foods’ nutritional value, according to Consalo. Her family farm specializes in growing, packing and shipping blueberries, citrus fruits, cooking greens, herbs, salad items and hard squash, all of which can be found at Safeway stores in the Mid-Atlantic region.

Peppers grow at Consalo Family Farms.

Workers harvest beets at Consalo Family Farms.

A worker harvests blueberries.

Blueberries at Consalo Family Farms.

Chelsea Consalo, vice president of produce operations for Consalo Family Farms (left), and her sister Sarah, the finance manager.

Consalo Farms also exemplifies how growers can contribute to a more sustainable food system. For starters, shorter shipping distances mean less fuel consumption and air pollution. Consalo Farms also has a local recycling program and is working to reduce waste by using top-seal packaging that contains 35 percent less plastic than conventional packaging materials. Another big priority for the farm is water conservation, which the family achieves through an app-controlled drip irrigation system that sends just enough water to crops at specific time intervals. Soil health also contributes to the farm’s overall sustainability and helps cut down on water use, according to Consalo.

“Something as simple as mulching increases moisture retention in the soil, and it can regulate the soil temperature,” she said.

How a local food supply chain works

Local produce can benefit our health, our planet and our taste buds.

The environmental benefits of choosing local food at the grocery store

The basis of Safeway’s relationship with Consalo Farms—high quality products, delivered consistently—is still there. What has changed is how both sides approach sustainability. For the Consalo family, new technologies are making it possible to boost water conservation and soil health and cut back on packaging waste. For Safeway, efforts to work with more regional and local growers have only intensified. The company has stopped shipping California produce to its East Coast stores, for instance, in favor of stocking its produce sections with seasonal, regional specialties, whether it’s blueberries from New Jersey in June, honeycrisp apples from Pennsylvania in the fall, or corn and watermelon from Maryland during the summer.

“They grow it right there and they ship it right there, and it's in our warehouse within two hours. That's what's going to be the future.”

Ricardo Dimarzio, Mid-Atlantic Produce Sales Manager for Safeway

Harvested rainbow chard at Consalo Family Farms.

Fostering relationships with local growers has been crucial for Safeway, according to Dimarzio. By giving local and regional farmers regular business, Safeway can be among the first to know when new products come available. To that end, Safeway has also branched out beyond traditional agriculture to work with a new integrated farming company called Bowery Farming, which grows a variety of salad greens and herbs at its vertical greenhouse in Baltimore. The company is also experimenting with growing strawberries and cucumbers, according to Dimarzio. Safeway is able to specify which products they want to buy, how much they need and when they need it, reducing food waste and ensuring a fresher product. Lettuce, microgreens, and basil, for instance, are all cut to order.

“They grow it right there and they ship it right there, and it's in our warehouse within two hours,” Dimarzio said. “That's what's going to be the future.”

These kinds of efforts ultimately help ensure that shoppers can access the freshest possible products, get the most nutritional benefits, and know that they’re doing their part to help reduce waste and carbon emissions. And they’ll be supporting people like Consalo, who is paying it forward by donating blueberry plants to a local school and speaking to students about local agriculture and sustainability. In turn, she said, “the community can support the farms.”

Lead Photo: Driven by the pandemic and the growing environmental movement, grocery shoppers and stores alike have a renewed appreciation for locally grown products

How Do We Build Sustainable Local Food Systems?

Food Tank, in partnership with the Danone Institute North America, is hosting a very special virtual event, "One Planet. One Health," to discuss solutions to build more sustainable local food systems on Thursday, May 6, 2021, at 12 p.m. ET

Let's Work Together to Build Sustainable,

Local Food Systems With a Global Impact

Food Tank, in partnership with the Danone Institute North America, is hosting a very special virtual event, "One Planet. One Health," to discuss solutions to build more sustainable local food systems on Thursday, May 6, 2021, at 12 p.m. ET.

We’ve curated a terrific lineup of speakers, including luminaries like N. Diane Moss (Project New Village), Dariush Mozaffarian (Friedman School of Nutrition Science & Policy, Tufts University), Jose Oliva (HEAL Food Alliance), A-dae Romero-Briones (Cochiti/Kiowa, First Nations Development Institute), Tambra Raye Stevenson (WANDA), and more.

I’ll be moderating. You can register here.

Also, I strongly urge eligible nonprofits to apply for the Danone Institute North America grant program to help local communities live the "One Planet. One Health" vision.

Danone Institute North America will award a total of up to $160,000 for this initiative. Individual team grants of $30,000 plus a $10,000 incremental award for the team with the strongest communications plan will be awarded for work to be conducted over a two-year period. The call for entries is open now through June 6, 2021. For information and to submit an application, visit Danone Institute North America here.

Danone Institute North America launched the "One Planet. One Health" Initiative grant program in 2019 to support local projects that strengthen food systems, reflecting Danone’s belief that the health of people and the health of the planet are interconnected.

"The pandemic has not only sparked a health crisis but also has emerged as one of the most destructive economic and societal challenges of our time," says Leslie Lytle, President of Danone Institute North America and professor at the Gillings School of Global Public Health at the University of North Carolina, Chapel Hill.

Please let me know if you apply for the grant, and join me for free on May 6 by registering HERE.

All the very best,

Dani

Eastern Kentucky Company Growing Local Economy By Growing Vegetables Year-Round

AppHarvest has created 300 jobs in Appalachia, an area not really known for growing tomatoes.

by GIL MCCLANAHAN

MOREHEAD, Ky. (WCHS) — Imagine growing fresh local tomatoes in the dead of winter. A company in Eastern Kentucky is using high-tech agriculture to grow vegetables indoors.

To View The Video, Please Click Here.

AppHarvest checks tomatoes growing inside the company's 60-acre indoor greenhouse.

(AppHarvest ) Courtesy Photo

AppHarvest opened in Rowan County, Ky. last October. They are growing more than just vegetables. They are growing the economy in an area that sorely needs it.

What's growing inside AppHarvest's 2.8-million square foot facility is capable of producing more food with less resources.

"For our first harvest to be on a day where there was a snowy mountainside could not have been any more timely. The fact that we are able to grow a great juicy flavorful tomato in the middle of January and February is what we have been working to accomplish," AppHarvest Founder and CEO Jonathan Webb said.

Webb said five months after opening its Morehead indoor farm facility, the company shipped more than a million beefsteak tomatoes to several major supermarket chains, including Kroger, Walmart and Publix. Those large bushels and bushels of tomatoes are grown using using the latest technology, no pesticides and with recycled water in a controlled environment using 90% less water than water used in open-field agriculture.

"We're just trying to get that plant a consistent environment year round with the right amount of light and the right amount of humidity and the right temperature just to grow, and the vines of our crops the tomato plant end up being 45 feet and we grow them vertically so that is how we can get so much more production," Webb said.

One of the company's more well-known investors is Martha Stewart.

"I said Martha, can I get five minutes and I told her what we are doing. She was like, look we need good healthy fruits and vegetables available at an affordable price. I love the region you are working in," Webb said.

A couple of weeks later, Webb met with Stewart at her New York office, and she decided to become an investor in the company. Some local restaurants are looking forward to the day when they can buy their vegetables locally from AppHarvest. Tim Kochendoerfer, Operating Partner with Reno's Roadhouse in Morehead, buys his vegetables from a company in Louisville.

"It will be another selling point to show that we are a local restaurant," Kochendoerfer said.

Webb points out AppHarvest is not trying to replace traditional family farming. "Absolutely not. We want to work hard with local farmers," he said.

Webb said by partnering with local farmers, more local produce can get on grocery store shelves, because last year 4 billion pounds of tomatoes were imported from Mexico.

"What we are working to replace is the imports from Mexico where you got children working for $5 a day using illegal chemical pesticides in the produce is sitting on a truck for 2-3000 miles," Webb said.

AppHarvest has already started influencing the next generation of farmers by donating high tech container farms to local schools. Students learn to grow crops, not in the traditional way, but inside recycled shipping containers. The containers can produce what is typically grown on 4 acres of land. Rowan County Senior High School was the second school to receive one. It arrived last fall.

"We sell that lettuce to our food service department and it's served in all of our cafeterias in the district," said Brandy Carver, Principal at Rowan County Senior High School.

"When we talk about food insecurity and young people going home hungry, what better way can we solve these problems by putting technology in the classroom. let kids learn, then let the kids take the food home with them and get healthy food in the cafeterias," Webb said.

AppHarvest has created 300 jobs in Appalachia, an area not really known for growing tomatoes. Local leaders believe the company will attract more business to the area.

"I fully expect in time we'll see more and more activity along that line like we do in all sectors," said Jason Slone, Executive Director of the Morehead-Rowan County Chamber of Commerce.

"We will eventually be at the top 25 grocers. Name a grocer. We've been getting phone calls from all of them," Webb said.

AppHarvest has two more indoor farming facilities under construction in Madison County, Ky., with a goal of building 10 more facilities like the one in Rowan County by the year 2025.

To find out more about AppHarvest click here.

Hydroponics Greenhouse Provides Hands-On Learning At Hudson High School

A $20,000 grant was given by The Kiwanis Club of Hudson to support the project, and this money was used to purchase greenhouse equipment.

Yeji Kim

Special to the Hudson Hub-Times

A Jan. 15 tour led by HHS AP Environmental Science teacher Matthew Kearns offered members of The Kiwanis Club of Hudson insight into the hydroponic greenhouse. The club donated a $20,000 grant to help fund the project. Submitted Photo

Project-based learning is a learning model where students work together to engage in real-world questions and problems, and the Hudson High School hydroponics greenhouse centres around this approach to education.

The hydroponics greenhouse started roughly two years ago, and Phillip Herman, Superintendent of the Hudson City School District, and Christina Wooley, HCSD Curriculum Coordinator, are credited with most of the original idea.

Herman first learned about hydroponics gardening and greenhouses from a community member and thought there may be a way to better utilize the HHS greenhouse space to create learning opportunities for students. He began by discussing the idea with teachers, visiting an operating hydroponics greenhouse and exploring areas of the curriculum that could be enhanced.

The first year consisted largely of planning, strategizing and raising money, and this past year was when equipment started to come in and crops began to grow.

A hydroponics greenhouse differs from a traditional greenhouse in that no soil is required. Instead, the plants draw up nutrient-rich water. Less water is used since the water is recycled, and because of the absence of soil, hydroponics greenhouses take up less space — the plants can be stacked vertically. The HHS hydroponics greenhouse also includes a monitoring computer system that measures what is currently in the water and what will be needed.

A $20,000 grant was given by The Kiwanis Club of Hudson to support the project, and this money was used to purchase greenhouse equipment.

CropKing, an Ohio-based hydroponics equipment company, was the supplier for the equipment, seeds and fertilizer, and the firm also aided in setting up the equipment and trained those involved with the greenhouse.

Two other grants, an ADAR grant and a grant from the Hudson Parent-Teacher Organization supplemented the Kiwanis grant money. The greenhouse itself is located off of HHS biology classes and has been there before the hydroponics greenhouse was started.

Students are faced with real-world questions, such as how to sustain crops in regions without sufficient access to water, ways to use the land effectively and properly, impacts on the environment and how to grow sustainably and locally.

Science teacher Matthew Kearns said students have been seeing the benefit of this project, which includes those in the AP Environmental Science class he teaches, special education students who work with Intervention Specialist Kristin Stonestreet and biology classes taught by Ron Wright. Students visit at least once a week to monitor the crops.

Currently, the greenhouse is growing its first round of crops, which includes lettuce, tomatoes and cucumbers.

Stonestreet and Kearns are considering adding cilantro, basil and peppers as well. The diversification would enhance the project-based learning aspect, as students will need to work together to figure out how much additional lighting and heat every crop needs.

The long term goal is to get involved with the community; through connecting with the business department and forming a club, students plan to sell produce from the greenhouse at the Hudson Farmers Market in the summertime and sell to HCSD faculty and staff when school is in session, engaging aspects of science, business and team-work. Several potential products for sale in the future include a salsa kit, tomato sauce and fresh herbs.

Herman notes how this greenhouse works to enhance classroom activity and curriculum.

“Over recent years, we have continued to learn more about and explore opportunities for project-based learning. Project-based learning enables students to learn course content and develop other essential success skills by beginning with a challenging problem or question and conducting a sustained inquiry to explore solutions to the problem and answers to their questions. Together, Christina Wooley, Mr Kearns and Mrs Stonestreet dug in and worked collaboratively to do the hard work to bring an idea to implementation.”

Climate Corps America: The Urban Farms Transforming How America’s Most Vulnerable Communities Eat

Urban farms not only promote healthy eating but have the ability to transform industrial cities.

Louise Boyle

The microwave plays a significantly more important role to urban farming in Baltimore than you might first imagine.

“Our butternut squash comes from a seed which makes it little and easily microwaveable,” Gwen Kokes, food and farm programme director at Civic Works, told The Independent. “For our [customers] this is really important as it might be too expensive to turn on the gas to cook or the oven might not be working.”

The squash, along with a range of produce, is grown at Real Food Farm, one branch of Civic Works urban service corps program in Maryland’s largest city.

The farm started about a decade ago and spans eight acres in northeast Baltimore with four fields, more than 100 fruit trees, a greenhouse for seedlings, and eight “hoop houses” which, for the uninitiated, are a sort of passive greenhouse with crops planted directly in the soil but sheltered by heavy-duty plastic sheets stretched over frames.

The farm produces 5,000 pounds of fruit and vegetables each year to be sold for reduced cost at farmers’ markets in low-income neighbourhoods across Baltimore. A mobile market, operating out of a box truck, also visits all 12 senior centres in the city.

“In total, we distribute about 100,000 pounds of food every year,” says Ms Kokes. “We buy from other urban farms in a 50-mile radius, prioritising Black-owned farms. Sometimes we have donations from Hungry Harvest, a programme to reduce food waste from grocery stores, and we’ve been adding pantry and hygiene items so that it’s more of a one-stop shop.”

Civic Works is part of AmeriCorps, the federal agency for service and volunteering programmes in the US. To tackle the climate crisis, President Biden has called for “reinvigorating and repurposing” the agency into a so-called “Civilian Climate Corps” to provide jobs while ramping up clean energy and sustainability to “heal our public lands and make us less vulnerable to wildfires and floods”.

“Biden’s plan could be huge for us,” Ms Kokes said. “I think it can grow exponentially. There’s plenty of demand for these jobs.”

The non-profit also runs programmes to mentor students, fix up abandoned houses and makes homes safer for seniors by doing minor DIY like adding handrails and ramps.

AmeriCorps estimates that its existing network – 25,000 participants in about 130 programmes – could be scaled up to 500,000 young people and veterans over the next five years.

Around 19 million people in the US live in “food deserts”. The term is believed to have been coined in Scotland in the early 1990s by a public housing resident, referring to areas where healthy, fresh options are scarce and packaged and fast food has proliferated.

The term is now seen as having negative connotations, implying that “low healthy food access is a naturally occurring phenomenon, rather than the result of underlying structural inequities”, according to a 2018 study by John Hopkins. (Baltimore residents told researchers they preferred the term “Healthy Food Priority Areas”.)

Researchers also point to the systemic racism at the heart of Americans’ access to food. It’s difficult to improve diet and health, for example, if prices for nutritious food are far beyond your budget, and there’s no public transport to take you stores.

“The fact that predominantly black neighbourhoods, on average, have fewer stores and poorer quality [food] compared to their white counterparts means something,” Ashanté M. Reese, professor of sociology and anthropology at Spelman College who studies race and food inequity, told HuffPost .

Baltimore is one of America’s poorest cities. In 22 of the city’s 668 Census tracts, at least 40 per cent of residents live below the poverty line. Even before Covid, the unemployment rate in the poorest neighbourhoods hovered above 15 per cent, triple that of wealthier areas.

Lack of access to healthy food in Baltimore is one layer of racial inequality that has plagued the city since the early 20th century, when deliberate policies were put in place to separate the city’s white and Black residents.

In the city’s Greenmount East neighbourhood the average life expectancy is around 66 years while four miles away in the wealthier Roland Park, the average life expectancy is 84 years, according to Kaiser Health News.

That’s where organisations like Real Food Farm step in. Those who are unemployed or on low-incomes and using government nutrition assistance programmes get double the value for their dollar if it’s spent at the farmers’ market, for example.

Urban farms not only promote healthy eating but have the ability to transform industrial cities.

“Motor City” Detroit, once the backbone of the car industry, has suffered a well-documented decline since its mid-20th century heyday. But its industrial wastelands have been transformed by urban farming with at least 1,400 farms and gardens in the city. In Pittsburgh, Hilltop Urban Farm is set to become the largest urban farm in the country. Baltimore has around 17 urban farms and upwards of 75 community gardens that grow food, according to Baltimore magazine.

Civic Works’ role on the frontline of food insecurity meant that its teams were well-positioned to adapt during the Covid pandemic, delivering boxes of fresh produce and basic necessities to the most vulnerable at no cost. They also worked with public bodies and local charities to deliver donations.

“During lockdown, Baltimore City public school system had to get rid of those little cartons of milk really fast. We have thousands of customers so we focused on getting those out to them,” Ms Kokes said.

From March through the end of July, the programme’s teams ran a free programme delivering boxes of produce, meals and hygiene kits to about 1,000 households a week. They went on to launch a discounted local produce programme, delivering boxes with about $15-$20 of food for $5 with free delivery, mostly to seniors.

Urban farms will play a role in mitigating how climate change impacts urban areas. Cities are often several degrees hotter than rural areas due to the “urban heat island effect” caused by dark-coloured roads and buildings. Increasing vegetation cover can help curb rising temperatures.

Urban farms can also lower the risk of flooding during heavy downpours and help retain water in dry areas, according to a paper in the journal Earth’s Future.

Research in 2018 from Arizona State University and Google found that urban agriculture could save the energy equivalent of 9 million home air conditioning units and produce up to 180m tonnes of food globally. Along with supplying almost the entire recommended consumption of vegetables for city dwellers, it would cut food waste and reduce emissions from transportation of produce, the study found.

Maryland is among the states most vulnerable to climate change, facing both rising sea levels and heightened storm intensity. Government data predicts that Maryland’s sizeable farming community could suffer costly losses during extreme droughts and heat waves.

Ms Kokes says that more extreme and unpredictable weather has impacted their operations in recent years.

“With day-to-day farming, we have to get ‘swamp ready’,” she said. “2018 was the worst for Maryland farmers as the rain was astronomical. We took a huge hit. It was very humbling because we had to reckon with our limitations, and partner with others to be a reliable source of food.

“Irregular weather patterns especially in the spring make it really difficult to know when to plant. We’ve [also] had early frost in October. Our farmer Stewart is a very smart, science-oriented guy and thankfully, there’s resources that we can lean on to translate this unpredictability into clear language.”

Around 3,000 students from kindergarten to high school have visited Real Food Farm over the years to learn about agriculture. Separately, programmes like Future Harvest are preparing the farmers of the future. But it’s important that Real Food Farm’s mission stays relevant to the communities they are in, Ms Kokes said.

“Environmentalism, from our perspective and our work, has to be people-focused,” she said. “We’re not talking about weather patterns when people are hungry and just want affordable produce in their neighbourhood.”

Little Leaf Farms Raises $90M to Grow Its Greenhouse Network

Massachusetts-based Little Leaf Farms has raised $90 million in a debt and equity financing round to expand its network of hydroponic greenhouses on the East Coast. The round was led by Equilibrium Capital as well as founding investors Bill Helman and Pilot House Associates. Bank of America also participated.

by Jennifer Marston

Image from: Little Leaf Farms

Massachusetts-based Little Leaf Farms has raised $90 million in a debt and equity financing round to expand its network of hydroponic greenhouses on the East Coast. The round was led by Equilibrium Capital as well as founding investors Bill Helman and Pilot House Associates. Bank of America also participated.

Little Leaf Farms says the capital is “earmarked” to build new greenhouse sites along the East Coast, where its lettuce is currently available in about 2,500 stores.

The company already operates one 10-acre greenhouse in Devins, Massachusetts. Its facility grows leafy greens using hydroponics and a mixture of sunlight supplemented by LED-powered grow lights. Rainwater captured from the facility’s roof provides most of the water used on the farm.

According to a press release, Little Leaf Farms has doubled its retail sales to $38 million since 2019. And last year, the company bought180 acres of land in Pennsylvania on which to build an additional facility. Still another greenhouse, slated for North Carolina, will serve the Southeast region of the U.S.

Little Leaf Farms joins the likes of Revol Greens, Gotham Greens, AppHarvest, and others in bringing local(ish) greens to a greater percentage of the population. These facilities generally pack and ship their greens on the day of or day after harvesting, and only supply retailers within a certain radius. Little Leaf Farms, for example, currently servers only parts of Massachusetts, Pennsylvania, New York, and New Jersey.

The list of regions the company serves will no doubt lengthen as the company builds up its greenhouse network in the coming months.

Investors Seed Indoor Farms As Pandemic Disrupts Food Supplies

Proponents, including the U.S. Department of Agriculture (USDA), say urban farming increases food security at a time of rising inflation and limited global supplies. North American produce output is concentrated in Mexico and the U.S. Southwest, including California, which is prone to wildfires and other severe weather

Wausau, WI, USA Stevens Point

Feb 18, 2021

By Rod Nickel

(Reuters) - Investors used to brush off Amin Jadavji's pitch to buy Elevate Farms’ vertical growing technology and produce stacks of leafy greens indoors with artificial light.

"They would say, 'This is great, but it sounds like a science experiment,'" said Jadavji, CEO of Toronto-based Elevate.

Now, indoor farms are positioning themselves as one of the solutions to pandemic-induced disruptions to the harvesting, shipping, and sale of food.

"It's helped us change the narrative," said Jadavji, whose company runs a vertical farm in Ontario, and is building others in New York and New Zealand.

Proponents, including the U.S. Department of Agriculture (USDA), say urban farming increases food security at a time of rising inflation and limited global supplies. North American produce output is concentrated in Mexico and the U.S. Southwest, including California, which is prone to wildfires and other severe weather.

Climate-change concerns are also accelerating investments, including by agribusiness giant Bayer AG, into multi-storey vertical farms or greenhouses the size of 50 football fields.

They are enabling small North American companies like BrightFarms, AppHarvest and Elevate to bolster indoor production and compete with established players AeroFarms and Plenty, backed by Amazon.com Inc founder Jeff Bezos.

But critics question the environmental cost of indoor farms' high power requirements.

Vertical farms grow leafy greens indoors in stacked layers or on walls of foliage inside of warehouses or shipping containers. They rely on artificial light, temperature control and growing systems with minimal soil that involve water or mist, instead of the vast tracts of land in traditional agriculture.

Greenhouses can harness the sun's rays and have lower power requirements. Well-established in Asia and Europe, greenhouses are expanding in North America, using greater automation.

Investments in global indoor farms totaled $394 million in 2020, AgFunder research head Louisa Burwood-Taylor said.

The average investment last year doubled in size, as large players including BrightFarms and Plenty raised fresh capital, she said.

A big funding acceleration lies ahead, after pandemic food disruptions - such as infections among migrant workers that harvest North American produce - raised concerns about supply disruptions, said Joe Crotty, director of corporate finance at investment bank KPMG, which advises vertical farms.

"The real ramp-up is the next three to five years," Crotty said.

Vegetables grown in vertical farms or greenhouses are still just a fraction of overall production. U.S. sales of food crops grown under cover, including tomatoes, cucumbers and lettuce, amounted to 790 million pounds in 2019, up 50% from 2014, according to the USDA.

California's outdoor head lettuce production alone was nearly four times larger, at 2.9 billion pounds.

USDA is seeking members for a new urban agriculture advisory committee to encourage indoor and other emerging farm practices.

PLANT BREEDING MOVES INDOORS

Bayer, one of the world's biggest seed developers, aims to provide the plant technology to expand vertical agriculture. In August, it teamed with Singapore sovereign fund Temasek to create Unfold, a California-based company, with $30 million in seed money.

Unfold says it is the first company focused on designing seeds for indoor lettuce, tomatoes, peppers, spinach and cucumbers, using Bayer germplasm, a plant's genetic material, said Chief Executive John Purcell.

Their advances may include, for example, more compact plants and an increased breeding focus on quality, Purcell said.

Unfold hopes to make its first sales by early 2022, targeting existing farms, and start-ups in Singapore and the United Kingdom.

Greenhouses are also expanding, touting higher yields than open-field farming.

AppHarvest, which grows tomatoes in a 60-acre greenhouse in Morehead, Kentucky, broke ground on two more in the state last year. The company aims to operate 12 facilities by 2025.

Its greenhouses are positioned to reach 70% of the U.S. population within a day's drive, giving them a transportation edge over the southwest produce industry, said Chief Executive Jonathan Webb.

"We're looking to rip the produce industry out of California and Mexico and bring it over here," Webb said.

Projected global population growth will require a large increase in food production, a tough proposition outdoors given frequent disasters and severe weather, he said.

New York-based BrightFarms, which runs four greenhouses, positions them near major U.S. cities, said Chief Executive Steve Platt. The company, whose customers include grocers Kroger and Walmart, plans to open its two largest farms this year, in North Carolina and Massachusetts.

Platt expects that within a decade, half of all leafy greens in the United States will come from indoor farms, up from less than 10% currently.

"It's a whole wave moving in this direction because the system we have today isn’t set up to feed people across the country," he said.

'CRAZY, CRAZY THINGS'

But Stan Cox, research scholar for non-profit The Land Institute, is skeptical of vertical farms. They depend on grocery store premiums to offset higher electricity costs for lighting and temperature control, he said.

"The whole reason we have agriculture is to harvest sunlight that’s hitting the earth every day," he said. "We can get it for free."

Bruce Bugbee, a professor of environmental plant physiology at Utah State University, has studied space farming for NASA. But he finds power-intensive vertical farming on Earth far-fetched.

"Venture capital goes into all kinds of crazy, crazy things and this is another thing on the list."

Bugbee estimates that vertical farms use 10 times the energy to produce food as outdoor farms, even factoring in the fuel to truck conventional produce across country from California.

AeroFarms, operator of one of the world's largest vertical farms, a former New Jersey steel mill, says comparing energy use with outdoor agriculture is not straightforward. Produce that ships long distances has a higher spoilage rate and many outdoor produce farms use irrigated water and pesticides, said Chief Executive Officer David Rosenberg.

Vertical farms tout other environmental benefits.

Elevate uses a closed loop system to water plants automatically, collect moisture plants emit and then re-water them with it. Such a system requires 2% of the water used on an outdoor romaine lettuce operation, Jadavji said. The company uses no pesticides.

"I think we're solving a problem," he said.

(Reporting by Rod Nickel in Winnipeg, Manitoba; additional reporting by Karl Plume in Chicago; Editing by Caroline Stauffer and Lisa Shumaker)

How This Vertical Farm Grows 80,000 Pounds of Produce per Week

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process”

Bowery Farming uses technology to prioritize accessibility and sustainability in their produce growing operations

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process” says chief science officer Henry Sztul. “Our goal is actually to have as few people walking around our plants as possible.”

Bowery Farming is a network of vertical farms working to reengineer the growing process. Using a system of light and watering technology, Bowery is able to use 95 percent less water than a traditional outdoor farm, zero pesticides and chemicals, and grow food that tastes as good as anyone else’s.

Bowery Farming uses vertical farm-specific seeds that are optimized for flavor instead of insect resistance and durability. Seeds are mechanically pressed into trays of soil, and sent out into growing positions, or racks within the building that have their own lighting and watering systems. Each tray gets its own QR code so that they can be monitored and assigned a customized plan for water and light until they’re ready to be harvested.

Irving Fain, Bowery Farming’s founder and CEO contemplates the prediction from the United Nations that 70 to 80 percent of the world’s population will be living in and around cities in the next 30 years. “Figuring out ‘how do you feed and how do you provide fresh food to urban environments both more efficiently as well as more sustainably?’ is a very important question today, and an even more important question in the years to come.”

CGTN Conversations: Chinese Firms Add Strength To Dubai's Future Tech Ecosystem

CGTN Digital's International Editor Abhishek G. Bhaya spoke with Faisal Al Hawi, the head of Accelerator and Incubators at the Dubai Future Foundation, and Stuart Oda, the founder and CEO of Alesca Life.

Over the decades, the Gulf city of Dubai has emerged as a land of innovation and a place where the future could be felt right now in the present. The city is actively encouraging global collaborations to drive innovation and future technology in the United Arab Emirates and internationally through its Dubai Future Accelerators (DFA) initiative that was launched in 2016 under the aegis of Dubai Future Foundation.

In recent years, many Chinese tech firms and start-ups – which are known for their technological prowess – have partnered with DFA to contribute to their mission of imagining, designing and co-creating solutions for future challenges.

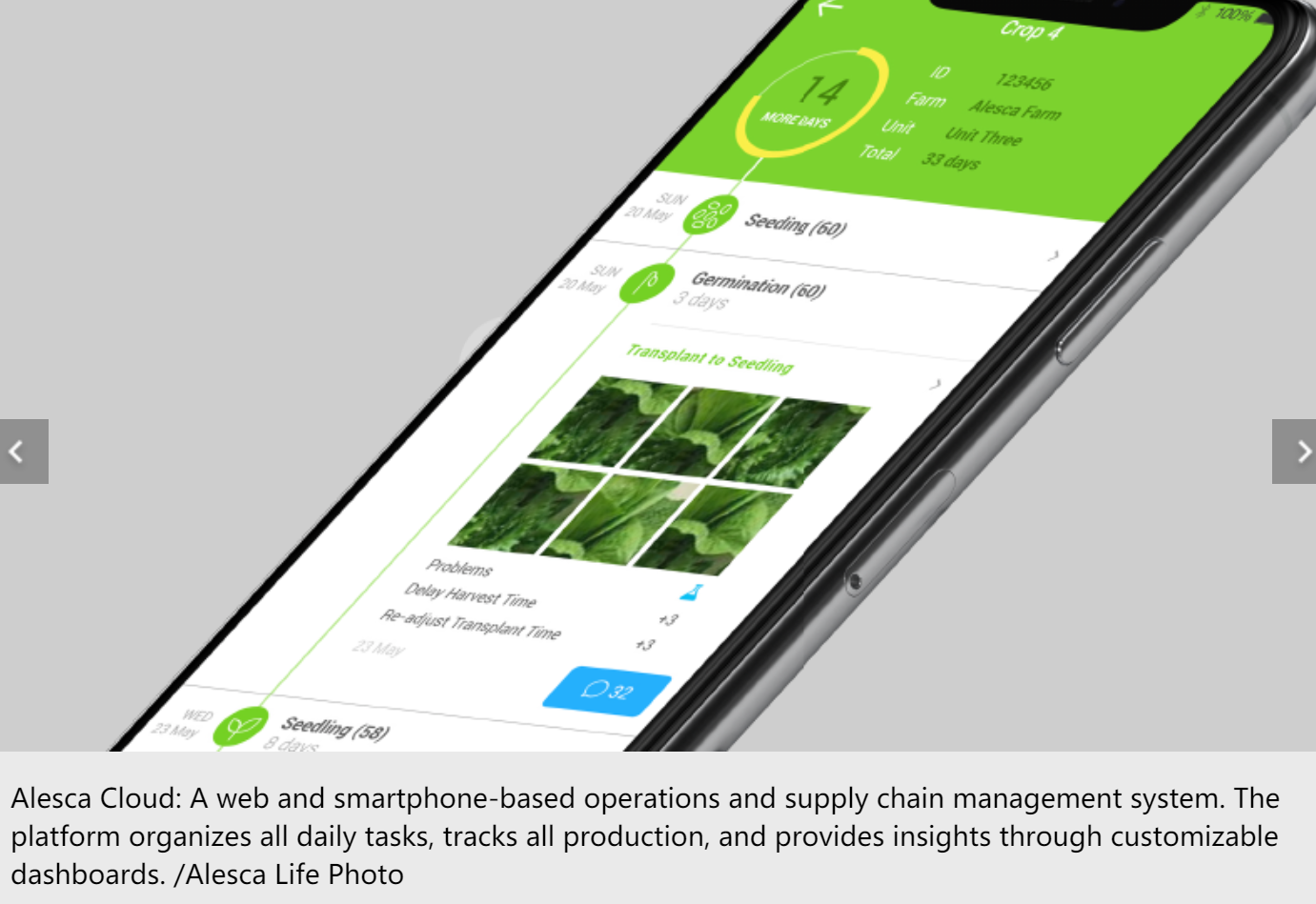

One such successful initiative has come from Beijing-headquartered Alesca Life, an agro-tech company that is creating next-generation urban farming solutions that consume five per cent water and 30 per cent energy vis-à-vis conventional farming.

To get an overview of DFA's future innovation agenda and how Chinese firms are contributing in making that vision a reality, CGTN Digital's International Editor Abhishek G. Bhaya spoke with Faisal Al Hawi, the head of Accelerator and Incubators at the Dubai Future Foundation, and Stuart Oda, the founder and CEO of Alesca Life.

Al Hawi is responsible for creating a myriad of programs that connect different stakeholders, government and private, with innovative startups and companies from around the world to experiment with and making Dubai the testbed for future ideas.

Oda is an investment banker-turned- urban farmer with a passion for innovation and sustainability. He founded Alesca Life in 2013 with an aim to make food production more localized and data-driven.

Edited excerpts:

Bhaya: Faisal, please tell us a bit about the vision of the DFA initiative and what it aims to achieve and also some of the main areas and technologies it has tasted success in the past four years?

Al Hawi: Dubai Future Accelerators is an initiative that was born four years ago under the Dubai Future Foundation. The vision was pretty much straightforward – to put Dubai as a leading city of the world when it comes to technology innovation. Our mission is to turn Dubai into a global testbed for innovations and technologies. The DFA looks around for all the start-ups in the global scene, trying to understand the technology needs, the partner needs, the local ecosystem needs, and trying to bridge the gap between these two players of the market.

We do this in what we call the Area 2071, which is like the heart of our ecosystem in Dubai and we've had tremendous success. Throughout the four years, we've run eight cohorts, the eighth cohort is ongoing as we speak. We've engaged with more than 300 start-ups and over 60 pilot projects were produced out of DFA and more than 150 memoranda of understanding or commercial agreements were signed with different government entities and private sector partners.

Dubai Future Accelerators is positioned in a way that basically bridges the gap between the big players, be it government or private sector, and the start-up innovators from around the world.

Bhaya: How many Chinese firms and start-ups have availed the DFA program so far? Please name some of the major projects the Chinese entities have undertaken in the UAE as part of the DFA initiative.

Al Hawi: We've worked with Chinese companies ever since Cohort 1 back in 2016. So, Alesca Life is one of them. Shellpay, which was a fintech company working with the General Directorate of Immigration in Dubai, was another company. There was another company called Future Trends, working with Dubai Health Authority on medical imaging, and utilizing the technologies of AI and machine learning to optimize the diagnosis of late-stage cancers.

Yitu Technology is another Chinese AI-based company which worked very closely with [UAE's largest telecom service provider] Etisalat on solving some of their telecom related issues. So these are just to name a few companies that worked with us.

We really understand the strength Chinese ecosystem brings to our ecosystem. And I think we complement each other in a lot of areas.

Another example, broader than just Dubai Future Accelerators, is within Area 2071, where SenseTime actually has an office here, and they work very closely with the AI office, in a couple of strategic projects.

So, the partnership is growing stronger and stronger, year after year. And we definitely believe that there are areas specifically in the fourth industrial revolution technologies, blockchain, AI and IoT and the likes that we will definitely materialize more and more outcomes and success moving forward.

Bhaya: Stuart, what is the story behind Alesca Life?

Oda: Seven years ago, I started Alesca Life here in Beijing. The vision of the company is to democratize access to fresh and nutritious food by democratizing the means and the knowledge of production.

And the more research that I was doing, it became very clear that one of the most pressing challenges over the next decades wasn't so much actually related to connectivity, as these things were becoming easier with the proliferation of smartphones and computers, but access to fresh and nutritious food. And so, my team and I wanted to find a way in which we can make this access a lot easier. And wherever it made sense to localize that fresh food production, and wherever food production currently existed to make it more data driven.

So we set on this journey seven years ago, and we currently have our teams and offices across Japan, China, and the United Arab Emirates and we have partnerships across many more countries. We're developing precision farming tools to accomplish, to increase the productivity, the profitability, and the predictability of food production by up to 10 times.

Bhaya: The urban farming technologies including vertical farms and data-driven food production are certainly relevant for an arid region like the Arabian Peninsula. How did your partnership with DFA come about and what has been the journey like in the UAE for Alesca Life?

Oda: In 2016, our team was selected into the DFA program as part of Cohort 1. It was actually our first entry into the Gulf region. We knew that the technology had huge promise and potential in the region, and we wanted to make a serious commitment to the region. The DFA program was kind enough to offer us a spot in Cohort 1.

It has been hugely transformational in two ways. You know, the way in which business is done in the Middle East is very different. And to be able to have an organization like DFA, both providing the meaningful introductions, reducing some of the barriers related to the company's formation, and then also just the credibility that is bestowed on some of the companies that get to go through the program. All three of these things contributed enormously to our success in the region.

Through this program we've also been able to find meaningful strategic partnerships to mitigate some of the challenges related to concentration of supply chain, for example, even being in a place like China, to have manufacturing bases and other places in other countries, is beneficial for us.

So, right after the DFA program, we had an opportunity to localize the manufacturing of our container farm in the Emirates of Ajman in the UAE, so that we can serve our customers and our base in the GCC (Gulf Cooperation Council) and also to showcase our commitment to the region that we're not just there to sell our systems, but that we are there for the long term.

Bhaya: The year 2020 has been a watershed in many ways for the world due to the COVID-19 pandemic, reinforcing our increasing reliance on digital and AI technologies without which we can't imagine a future. How did the global crisis impact the long-term vision of DFA?

Al Hawi: The pandemic has definitely affected everyone. At DFA, we realized that innovation is the way to be resilient for the future, prepared for the future and understanding exactly the problems of today that potentially, and unfortunately, led us into the pandemic. We had just a very short drop-in time in which everybody had to just realign ourselves, and that was around March. But we immediately resumed back in October.

Not just the DFA, I think all the government entities, as well as start-ups, realized how important a role they play in this ecosystem. And Cohort 8, that is currently ongoing and will last until the end of March, is specifically looking at challenges that will basically be more specific around life after COVID.

I'll share a couple of examples. The Dubai Roads and Transport Authority (RTA) is looking into new solutions of shared mobility. We are very much accustomed to the ride-hailing apps and public transport systems. But that has changed forever. So they (RTA) are really being proactive in trying to foresight what new models of public transport and shared mobility will be out there. And we're really excited to see what comes out as solutions in a couple of weeks' time.

Another entity which is really looking at how things might evolve in the health care sector is the Dubai Health Authority. They are focusing on preventive health care measures, solutions and products, but not only from a sense of being preventive or proactive but in a sense of also democratizing access to that device.

Bhaya: Food security is already a global concern and going to be a top challenge in the future. It did aggravate last year due to the supply-chain disruption caused by the pandemic. What are some of the innovative solutions that Alesca Life offers to meet this challenge and has COVID-19 triggered a sense of greater urgency?

Oda: This is a great point. Pre-pandemic, in 2018-19, a lot of the interest and investment from governments, companies and investors was in food tech, which was related to food delivery and meal kits at home. And it was really focused on one thing, which was consumer convenience. What has happened in 2020, with the pandemic and now that we're in 2021, is that the focus has shifted materially from food tech to agtech - agricultural technology, which is focused on resilience. It's about community resilience, as opposed to consumer convenience.

So, one of the solutions, the benefits or the outcomes of the pandemic, was a renewed interest in agtech. And by that, I mean, local food production is in control of your own supply chain for fresh and nutritious food. So, since the pandemic has happened, since the lockdowns have begun, I've probably spoken to individuals and government entities from over 30 countries that are interested in finding ways in which they can secure a minimum supply of local fresh food production in their own countries, in their own communities.

The shift has accelerated towards this localization, towards this decentralized form of food production that can happen almost anywhere. And one of the solutions that we're providing for this is to bundle all of our precision farming tools – our monitoring equipment, our automation systems, our farm management and software tools, and even our latest computer vision AI cameras – and bundle all these products together to create an incredibly capital efficient indoor farm. And this allows both governments, at large scale, and even community, at a smaller scale, to be able to be in control of their local food production needs.

Interviewer and script: Abhishek G Bhaya

Video editors: Meiyi Yan & Wu Chutian

Cover image: Du Chenxin

Infographics: Jia Jieqiong

Director: Mei Yan

Fifth Season Takes Vertical Farming to a Whole New Level

Fifth Season’s verdant baby spinach screams farm fresh even though it’s grown nowhere near traditional farmland. The sweet and slightly crunchy greens are grown in a Braddock warehouse on racks stacked 30 feet high. Located just a stone’s throw from U.S. Steel’s Mon Valley Works Edgar Thomson Plant, it is urban farming at its core

Image from: Pittsburgh Post-Gazzette

Fifth Season’s verdant baby spinach screams farm fresh even though it’s grown nowhere near traditional farmland. The sweet and slightly crunchy greens are grown in a Braddock warehouse on racks stacked 30 feet high. Located just a stone’s throw from U.S. Steel’s Mon Valley Works Edgar Thomson Plant, it is urban farming at its core.

What makes the vertical farming operation especially unique is that it is automated and robots call the shots. About 40 to 60 machines are involved in every step of the life of the spinach and other leafy greens, from planting the seed to providing nutrients to the final packing.

Fifth Season does employ local “farm workers” to assist the robots in seeding, harvesting, packaging, quality assurance and control using computer software, but there is no human touch involved through it all.

“The first time someone ever touches the spinach leaf with a finger is when the package is opened,” says Grant Vandenbussche, chief category officer.

Co-founded by brothers Austin and Brac Webb and Austin Lawrence, Fifth Season started a year ago. Within months it was rolling out its baby spinach, leafy greens and salad kits.

“We wanted a name that represents what we are doing,” says Austin Webb, 32, who also is the CEO. “It is a call to the fact we have created an entirely new season. It is 24/7, 365 with the technology we have built.”

None of them planned to become modern farmers, says the Carnegie Mellon University grad, but they turned to vertical farming because it was an efficient, economically sustainable way to solve land and water woes.

Image from: thespoon.tech

‘Fields’ of Greens

Fifth Season grows an equivalent production of 200 acres in 25,000 square feet of grow space. Its “fields” are stacked on top of one another in vertical shelves. When you add up all that surface area of grow space, it is more like 126,000 square feet.

“We also quickly turn crops at the farm,” Mr. Vandenbussche says.

While spinach takes about 40 days to grow outdoors and can be harvested only twice during its peak season, it takes the crop only three or four weeks to grow in the controlled environment and is harvested 19 times. Once the plants are harvested, a new cycle of reseeding begins with fresh media, seeds and nutrients.

“That’s why we get so much more productivity,” he says. “We are immediately reseeding our ‘land.’”

This controlled environment yields quality produce because it is always peak season at Fifth Season, says Chris Cerveny, who heads the Grow R&D division. Greens are grown in the same conditions year-round, getting the exact amount of nutrients and water they need. Because pests and airborne toxins also are kept at bay, crops can be produced without pesticides.

All that TLC comes through in the slightly curled baby spinach, which is sweet and not grassy. The leaf doesn’t wilt or get slimy or lose its slight crunch even after two weeks of refrigeration.

A lot of thought was given even for the curl, which gives the spinach a stronger volume, making it look full and bountiful. The curl also makes the spinach more forkable unlike its flat-leaf counterpart that is hard to stab on a plate.

Other leafy greens such as kale, mustard, Chinese cabbage, green tatsoi and purple pac choi are featured in two blends — Bridge City and Three Rivers. Fifth Season plans to roll out its Romaine lettuce in spring.

The greens also are found in four types of salad kits — Sweet Grains (blended greens, quinoa, chickpeas, corn, feta and poppy seed dressing), Crunchy Sesame (blended greens, farro, sesame sticks, dried cranberries and ginger-mandarin dressing), Toasted Tuscan (spinach, lentils, sun-dried tomatoes, bagel chips and vinaigrette), and Spiced Southwest (blended greens, black beans, pepitas, cotija cheese, corn-salsa sticks and chipotle ranch dressing) — which are available online and in Giant Eagle stores. A fifth salad kit is in the works and is being called “a shakeup of one of the most classic salads.”

While machines are a big part of what Fifth Season does, it seeks to keep human connection alive. It recently launched a recipe blog for those who have an appetite for cooking and writing, The Green Room is devoted to cataloging personal memories, dream meals and recipes via short stories.

Fifth Season also has partnered with the Penguins and is providing greens for the team’s pregame meals for the 2020-21 season.

“We want people in Pittsburgh to be able to eat the exact same delicious blend of greens that Sidney Crosby and company are eating,” Mr. Webb says. “We want people to know that there’s a new way to grow food and to eat and experience it.”

Image from: Next Pittsburgh

It’s All Under Control

Everything from seeding to packaging is done in four rooms. The process starts in the seeding and processing room, where seeds and growing media are placed inside black planter-like boxes called inserts. Each has a unique code that’s traced by a software system. The inserts go on white trays that pass through a photo station, feeding information to the computer system, and then glide into the bio dome.

There are two rooms in the bio dome, each with a grow space of 12,500 square feet. They’re lit up with a pinkish-purplish glow from high-efficiency LED light bulbs that mimic the different seasons of the year.

“They are positioned over the plants at different heights depending on stage of growth,” Mr. Cerveny says. “This is partly how we can provide consistently ideal growing conditions.”

As the plants grow, they are moved by a robot to optimize their growth cycle. Full-grown crops are transferred to the harvesting room by another robot.

“Harvesting is where it becomes like a Willy Wonka factory,” Mr. Vandenbussche says.

Long rows of trays filled with tiny plants are sent on a conveyor system to a station where workers inspect them for quality with surgical tools. After inspection, the plants are harvested by a robot and then immediately ride up a tall conveyor to be packaged and sealed in a 34- to 36-degree room so they remain fresh.

“Every crop we grow gets evaluated for maximum flavor, volume, crunch and color,” he says.

The plants’ intense, dark color is controlled by LED light bulbs, which are dialed up or down to get the correct hue. Although they never see the sun, the greens don’t get into a funk as humans might.

“What humans see in terms of light and how chlorophyll responds during photosynthesis are two different things,” Mr. Cerveny says. “Plants really only need red and blue light to grow effectively. We include some additional colors to help bring out other quality aspects of our crops, but providing the full sunlight spectrum is effectively a waste of energy, especially indoors.

“To the human eye, it looks like the plants live in a land of purple and pink lights, but they are perfectly happy there.”

Even though the environment is controlled and the software system is constantly updated, no two plants are exactly the same. Some fight for light more than others. Some might fail the quality control test and end up in a compost waste facility if their flavor is off or their color is not right.

“That is what is so amazing. We have more control than any other farmer, and yet we have limitations. Every seed is different,” Mr. Vandenbussche says. “They are plants. They are real living organisms.”

Is AppHarvest the Future of Farming?

In this video from Motley Fool Live, recorded on Jan. 28, Industry Focus host Nick Sciple and Motley Fool contributor Lou Whiteman discuss AppHarvest, one such SPAC that is looking to disrupt the agriculture industry. Here are the details on what AppHarvest wants to do, and a look at whether the company represents the future of farming.

Special purpose acquisition companies, or SPACs, are red-hot right now, with investors clamoring to get into promising young companies.

In this video from Motley Fool Live, recorded on Jan. 28, Industry Focus host Nick Sciple and Motley Fool contributor Lou Whiteman discuss AppHarvest, one such SPAC that is looking to disrupt the agriculture industry. Here are the details on what AppHarvest wants to do, and a look at whether the company represents the future of farming.

Nick Sciple: One last company I wanted to talk about, Lou, and this is one I think it's -- you pay attention to, but not one I'm super excited to run in and buy. It was a company called AppHarvest. It's coming public via a [SPAC] this year. This vertical farming space. We talked about Gladstone Land buying traditional farmland. AppHarvest is taking a very different approach, trying to lean into some of the ESG-type movements.

Lou Whiteman: Yeah. Let's look at this. It probably wouldn't surprise you that the U.S. is the biggest global farm exporter as we said, but it might surprise you that the Netherlands, the tiny little country, is No. 2. The way they do that is tech: Greenhouse farm structure. AppHarvest has taken that model and brought it to the U.S. They have, I believe, three farms in Appalachia. The pitches can produce 30x the yields using 90% less water. Right now, it's mostly tomatoes and it is early-stage. I don't own this stock either. I love this idea. There's some reasons that I'm not buying in right now that we can get into. But this is fascinating to me. We talked about making the world a better place. This is the company that we need to be successful to make the world a better place. The warning on it is that it is a SPAC. So it's not public yet. Right now, I believe N-O-V-S. That deal should close soon. [Editor's note: The deal has since closed.] I'm not the only one excited about it. I tend not to like to buy IPOs and new companies anyway. I think the caution around buying into the excitement applies here. There is a Martha Stewart video on their website talking up the company, which I love Martha Stewart, but that's a hype level that makes me want to just watch and see what they produce. This is just three little farms in Appalachia right now and a great idea. This was all over my watchlist. I would imagine I would love to hold it at some point, but just be careful because this is, as we saw SPACs last year in other areas, people are very excited about this.

Sciple: Yeah. I think, like we've said, for a lot of these companies, the prospects are great. I think when you look at the reduced water usage, better, environmentally friendly, all those sorts of things. I like that they are in Appalachia. As someone who is from the South, I like it when more rural areas get some people actually investing money there. But again, there's a lot of execution between now and really getting to a place where this is the future of farming and they're going to reach scale and all those sorts of things. But this is a company I'm definitely going to have my radar on and pay attention to as they continue to report earnings. Because you can tell yourself a story about how this type of vertical farming, indoor farming disrupts this traditional model, can be more efficient, cleaner, etc. Something to continue paying attention to as we have more information, because this company, like you said, Lou, isn't all the way public yet. We still got to have this SPAC deal finalized and then we get all our fun SEC filings and quarterly calls and all those sorts of things. Once we have that, I will be very much looking forward to seeing what the company has to say.

Whiteman: Right. Just to finish up along too, the interesting thing here is that it is a proven concept because it has worked elsewhere. The downside of that is that it needed to work there. Netherlands just doesn't have -- and this is an expensive proposition to get started, to get going. There's potential there, but in a country blessed with almost seemingly unlimited farmland for now, for long term it makes sense. But in the short term, it could be a hard thing to really get up and running. I think you're right, just one to watch.

VIDEO: This Company Is Solving America's Food Issues One Backyard At A Time

Love & Carrots lowers our carbon footprint by making sustainable food sources very, very local

Love & Carrots lowers our carbon footprint by making sustainable food sources very, very local

By Richie Hertzberg | January 6, 2021

The average American has an annual carbon footprint of 16 tons, which ranks among the highest in the world. In fact, it's about quadruple the global average. One of the most significant contributing factors to our elevated carbon emissions is where we get out food, which is often shipped from far away, especially for those of us who live in cities.

A plucky business called Love & Carrots, which began a decade ago with one woman and a truck, is addressing this national issue by installing produce gardens across the Washington D.C. area. They’ve installed more than 1000 gardens in almost a decade of business.

Natalie Carver, director of horticulture said, “Our founder Meredith Sheperd saw so many sunny yards not being used for food. And saw the opportunity to start a business and start building gardens in all these sunny pockets across the city."

Unlike most businesses, as Love & Carrots scales, it reduces the overall carbon footprint by bringing city residents as close as possible to their food sources…their own backyards.

Nearly 30% of our food-related carbon emissions comes from transportation. Whether we’re importing bananas from Guatemala, or trucking carrots across the country from the main producer in Bakersfield, California, there is a tremendous amount of energy wasted by shipping perishable food long distances in short amounts of time.

The cost of convenience is not just environmental—you can taste it in the quality and freshness of the fruits and vegetables you eat. “When I first started harvesting in my garden, I realized that the food that I buy in local stores is not really what it tastes like,” says Yong Lee, a Love & Carrots garden owner. “So my palate had to get used to the fact that 'carrot' actually tastes like a stronger version of the carrot you get at a store.

Love & Carrots offers a full-service, turn-key operation. People interested in a garden receive a consultation on the optimal place for their garden as well as a top to bottom installation. If they want it, they can receive garden coaching to help them manage their produce and even have Love and Carrots staff manage the garden in its entirety.

The company's goal, however, stretches from Washington DC all the way back to America's biggest carrot patch in Bakersfield, California. It aims to be a national model, creating a ripple effect across the country. "Our goal is to expose as many people as possible to sustainable practices and smart growing," the company says, "so they can use that knowledge themselves and continue to share it with others."

Vertical Farming Takes Root In Taiwan

Taiwan is uniquely placed to benefit from the application of information technology to agriculture, enabling it to help provide food for an expanding global population.

Exposed root system for hydroponically grown plants at YesHealth's iFarm in Taoyuan. Photo: Jules Quartly

After becoming a world leader in semiconductors and other electronic products, Taiwan is now looking to smart agriculture as its next vine to climb. The island aims to supply much of the world’s fruit and vegetables within the next 30 years.

This might seem rather unlikely until you consider that the future of farming is not land and labor but factories and robots. Furthermore, Taiwan already possesses in abundance the tools that tomorrow’s smart farmers will use, including solar and advanced light technology, chemicals, gene editing, drones, smart sensors, software, algorithms, data mining, and big data.

Many of these technologies are being put to use in a glittering new 14-story vertical farm at Copenhagen Markets in Denmark’s capital. The first phase of construction of the 7,000-square-meter facility finished in early December. It is one of Europe’s biggest and most efficient vertical farms and was built using a blueprint of patented technologies from Taiwan’s YesHealth Group.

The result of a partnership between YesHealth and Danish agritech startup Nordic Harvest, the farm looks like a fancy warehouse from the outside. The interior is fitted with rows upon rows and columns upon columns of trays containing leafy greens, growing under an intense battery of more than 20,000 smart LED lights. The plants are tended by engineers in lab coats and guided by software that processes over 5,000 individual data points to optimize plant health.

Rows of fresh produce grown under batteries of LED lights at iFarm. Photo: Jules Quartly

The LEDs provide variable spectrum light for 100 different kinds of plants, nanobubble hydroponics oxygenate the roots and inhibit bacterial growth, and liquid microbial fertilizers derived from oyster shells, brown sugar, and soy milk provide essential nutrients for plants and soil. Even the music played to the plants is science-infused, with classical or light jazz music ranging between 115 and 250 Hertz seeming to work best.

Production at the new vertical farm is set to begin in the new year and will scale up to around 3,000 kilograms of leafy vegetables per day by the end of 2021, equating to approximately 1,000 tons of greens annually. Crucially, unlike most farms, these figures are close to guaranteed since production is not at the mercy of climate, the weather, pests and disease, pesticide residue, nitrate levels, or hundreds of other variables that affect traditional farming.

According to Jesper Hansen, YesHealth Group’s Chief Communications Officer, the partnership with Nordic Harvest has been a productive one so far. It took just five months to install the farm and all the produce is pre-sold to ensure the operation is profitable by Q3 of 2021.

“This collaboration is just the start of a long-term journey together,” Hansen said in an email from Denmark. He notes that the two partners plan to expand to other Scandinavian countries over the next several years.

Hansen credits Taiwan for its efficient development of the technology and know-how to reproduce vertical farms all over the world and calls the Danish development “a crucial milestone in our international expansion.” He adds that the company is eyeing new partners in Europe, Asia, and the MENA (the Middle East and North Africa) region.

YesHealth is the brainchild of serial tech entrepreneur Winston Tsai, who started an LCD screen company at age 21. His “eureka moment” came after being diagnosed with liver cancer and partly linking his illness to pollution in foods. After recovering, he made it his mission to produce affordable, pesticide-free produce by harnessing the power of technology.

He founded YesHealth Agri-Biotechnology Co. Ltd. in 2011 and six years later established YesHealth iFarm in Taoyuan’s Luzhu District. The iFarm cultivates an ever-expanding range of leafy vegetables and herbs in a 2,500-square-meter warehouse factory. It produces 1,500 kilograms of leafy greens per day, a yield which the company says is 100 times more efficient than a traditional farm using the same space and requires only 10% as much water. In addition, YesHealth has a farm in China’s Shenzhen, which harvests up to 2,500 kilograms per day.

A tour of iFarm is well worth a visit and introduces the wide variety of plants grown there. Photo: Jules Quartly

YesHealth’s products are sold to major retailers both in Taiwan and abroad, including restaurants, hotels, and airports. Its stated aim is to supply a total of 7,000 kilograms of leafy greens per day worldwide in 2021.

Diners enjoy a meal at iFarm’s restaurant, which overlooks the vertical farm. Photo: Jules Quartly

Having sampled the produce at the iFarm, I can confirm the arugula grown there is as tasty as any I have tried, while the lettuce and leguminous alfalfa is a perfectly clean, green, and crunchy eating experience – the result, I was informed, of an optimal growing environment and harvesting at exactly the right time.

A plate of salad featuring leafy greens grown at the iFarm site. Photo: Jules Quartly

In a sense, it’s back to the future for Taiwan, which had a largely agricultural economy up until the 1950s. Agriculture was one of the pillars supporting the nation’s economic miracle after World War II. With the help of mechanization and productivity gains, agricultural production at that time contributed around a third of Taiwan’s GDP.

In more recent times it has accounted for just 1.8-1.9% of GDP. That greatly reduced figure, which includes animal husbandry, fishing, and forestry, is not due to a decline in agricultural output per se, so much as the growth in manufacturing and the emergence of a pervasive service sector.

Taiwan has a wide range of rich, often volcanic soils that are exceptionally fertile, along with a subtropical climate that provides plentiful sun and rain. It is known as the “Fruit Kingdom” because of the quality of its fruit, with dozens of varieties ranging from bananas and papayas to wax apples and guavas. More than 100 kinds of vegetables grow all year round.

On the other hand, Taiwan’s mainly mountainous geography means just 25% of the land is suitable for farming. Meanwhile, climate change is affecting agricultural production by increasing summer temperatures and making rainfall more unpredictable. At the same time, considerable soil erosion, acidification, contamination by chemicals and heavy metals, and strong pesticide use have diminished soil quality over the last 50 years.

Furthermore, the proportion of Taiwanese involved in farming has rapidly declined, from 37% of the population in the early 1970s to the current 15% or less, according to the Yearbook of the Republic of China. Not only is the farming population declining, but it’s also ageing as well.

Those factors may not pose as much of an issue, however, since the old model of agriculture is being disrupted so dramatically that even economies of scale are being upended. Given the large size and advanced technology of the U.S., it may come as no surprise that it is the world’s biggest exporter of food as measured by value. Second on the list, however, is the Netherlands, which has just 0.045% the area of the U.S.

According to a National Geographic report in September 2017, the Netherlands’ achievement can be attributed to the work coming out of Wageningen University & Research, 80 kilometres from Amsterdam in the heart of Food Valley – the world’s agricultural equivalent of Silicon Valley in California. The university strives to come up with ways to increase yields and sustainability, and then to disseminate that knowledge.

New generation

With its strong background in information technology, Taiwan is in a good position to follow that example. The island manufactures everything required for what is known as precision agriculture, a farming management concept that uses IT to collect data from multiple sources as a means of increasing crop yields and boosting profitability. Taiwan is thus the ideal place for putting together prototypes relatively quickly and cheaply.