Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Introducing Our Earthbag - Biodegradable and Compostable!

It’s what eco-conscious consumers want

Columbia Vertical Farm Uses Technology To Cut Plastic Pollution And Boost Sustainability

The new packaging comes at no extra cost to the customer and will be cheaper in the long-run for Vertical Roots

Vertical Roots is the largest hydroponic container farm in the country. They grow and package lettuce varieties and have recently implemented a packaging process that reduces plastic with a resealable film. TRACY GLANTZ TGLANTZ@THESTATE.COM

With the use of agricultural technology, Vertical Roots farm in West Columbia created a packaging system for its leafy greens that cut down the company’s plastic usage by 30% and extends the shelf life of the lettuce.

In 2015, high school friends Andrew Hare and Matt Daniels created the idea for Vertical Roots, now the largest hydroponic container farm in the country. Hare is the general manager of the company and Daniels acts as the chief horticulturist.

The first Vertical Roots opened in Charleston and expanded with its second farm site in West Columbia in 2019. Vertical Roots parent company, AmplifiedAg, manufactures the container farms and farm technology of which Vertical Roots operates.

The farms are part of a growing industry called controlled environmental agriculture (CEA) that uses technology to ramp up nutrient-rich food production year around.

Hydroponics helps the farm uses 98% less water than traditional farming, according to Hare. Their technology creates an indoor environment to grow lettuce on the East Coast. Most lettuce in the U.S. comes from California and Arizona, where temperatures do not fluctuate much throughout the year, travelling 2,000 miles from farm to table. Vertical Roots offers a solution for local lettuce.

“Our mission is to revolutionize the way communities grow, distribute and consume food,” said Hare. As populations grow, Hare said the ability to produce enough food is a global concern.

VERTICAL ROOTS AGRICULTURAL INNOVATION

As a company committed to sustainability, Vertical Roots had to address its plastic usage and the consumer demand for environmentally friendly products.

“I think everyone can agree that the amount of plastic that’s consumed and used globally is a bit of a problem,” said Hare.

If Vertical Roots were to completely opt-out of using plastics, as much as 40% of the lettuce would be damaged in transportation to the retailers, Hare said. So the company decided to still use plastic containers in order to cut out food waste, but it changed the amount and type of plastic used.

By replacing the conventional “clamshell” plastic lids that you see on a container of lettuce at the grocery store, Vertical Roots cut down more than 30% of plastic usage by creating a resealable film lid. The new packaging comes at no extra cost to the customer and will be cheaper in the long-run for Vertical Roots, according to Hare.

The farm also uses recycled plastic that can also be recycled again after use. Tiny perforations in the film lid of the packaging allow air to leave the lettuce container and extends the product’s freshness, making Vertical Roots lettuce last around 14 days on the shelf.

“We tested respiration and condensation with each lettuce variety, and ultimately found that we could extend the freshness and shelf life of our salad mixes even more,” said Hare.

Vertical Roots, at the S.C. Farmer’s Market, is the largest hydroponic container farm in the country. They grow and package lettuce varieties. Tracy Glantz TGLANTZ@THESTATE.COM

GROWTH IN THE AGRICULTURAL TECHNOLOGY INDUSTRY

In the first three quarters of 2020, a record $754 million of venture capital was invested in the vertical farming industry, according to PitchBook data. This was a 34% increase from the entire previous year, Bloomberg reported in a January article.

A 2019 report from Global Market Insights showed that the vertical farming market size, or the number of potential customers or unit sales, surpassed $3 billion in 2018 and said it, “will exhibit a massive compound annual growth rate (CAGR) of over 27% from 2019 to 2026.”

In vertical farms, crops are harvested on several vertical layers indoors, where farmers can grow year-round by controlling light, temperature, water and other factors, according to the U.S. Department of Agriculture.

Vertical agriculture is also seen as a growing industry because it “could help increase food production and expand agricultural operations as the world’s population is projected to exceed 9 billion by 2050,” according to the USDA.

However, some are skeptical about the future of vertical farming for several reasons. The farms use LED light bulbs to grow crops, which require a lot of energy and money to operate.

Also, the farms mostly produce greens, which are low in calories because they take less water and light. The new farming technology is marketed as a way to combat world hunger, but in poorer countries, low-calorie greens are not as beneficial, according to Bloomberg.

THE FUTURE OF VERTICAL ROOTS

Despite a tough year due to COVID-19, Vertical Roots will open two more indoor, container farms in Georgia and Florida in 2021.

The company lost revenue from foodservice customers like restaurants, schools and universities during the pandemic, said Hare.

Those food service customers accounted for about half of Vertical Roots’ business, Hare said. Grocery store business stayed steady and even grew during the pandemic. As schools and restaurants are slowly reopening, Vertical Roots is gaining business back.

The West Columbia farm location produces about $1.5 million pounds of produce per year, said Hare. Vertical Roots lettuce is in 1,200 different grocery stores in 11 states, including Lowes Foods stores, Publix, Harris Teeter and Whole Foods Market chains.

Hare said the company is constantly working on sustainable initiatives, including figuring out a way to reduce light energy consumption by 20-25%, thinking about compostable packaging systems and finding ways to use less water at the farms.

In the future, Vertical Roots hopes to offer a larger variety of produce. The team is experimenting with growing foods like tomatoes, cucumbers, peppers, herbs and mushrooms to see if they could be viable products.

At 25,000 square feet, the world's first indoor vertical farm is also one of the largest farms. Located 120 miles south of Seoul, South Korea, fruits and vegetables grow without soil, bathed in light from pink LEDs. BY META VIERS

1 of 3

Vertical Roots, at the S.C. Farmer’s Market, is the largest hydroponic container farm in the country. They grow and package lettuce varieties. TRACY GLANTZ TGLANTZ@THESTATE.COM

Bottom of Fresh Herbs Bag Becomes Growing Pot

Bottom of Fresh Herbs Bag Becomes Growing Pot

Danish Company Launches New Package Solution

Danish-based growing company Grow Up FARM is launching a new product, named Eat-Grow-Repeat: Small pea plants that grow in hemp in a bag. Refrigerated and bagged, the pea sprouts keep fresh for a week. "Rip off the upper section of the bag, and the bottom of the bag is now the pot," they explain. "Place the bottom of the bag with pea plants on your windowsill and care for it with light, water, and a little love. The growth will continue, and after a few days you can cut completely fresh pea sprouts for your salad bowl."

"Usually, bean sprouts are packed in a tray and then flow wrapped, so the consumer would have to repack any sprouts that may be leftover. But now this is history," they explain.

The corner stone of the Greenow family business was laid back in 1966, when the first generation pioneered the professional cultivation of bean sprouts. It turned into a success and still is - who does not regularly add the crisp and healthy bean sprouts to the shopping cart? Sales of organic bean sprouts are growing steadily, and this has led Greenow to seek a more efficient packaging solution, also since their pea sprouts dependance Grow Up FARM is growing as well.

Fresh produce

Initially, the Schur®Star Packaging Machine they use for this new packaging was only planned for packing bean sprouts fully automatically into reclosable bags. "Often, one does not eat all the sprouts at once; but in a reclosable bag, the sprouts do not desiccate in the refrigerator, but will retain their crispness for up to eight days. Hereby, the consumer can make his contribution to reducing problematic food waste, which is today an issue in both the retail outlet and the home," they say.

Capacity for new project

With its large capacity, the Schur®Star Packaging Machine has given Greenow & Grow Up FARM the opportunity to realize the Eat-Grow-Repeat project. The pea plants are initially grown in an entirely new, vertical greenhouse – on five floors, in a 100% controlled climate, with recirculated water, under artificial light and completely without soil. And to match the 100% compostable contents, the bag is produced of PE, a single-layer material that does not require separation to be processed in a recycling system.

Convenient packing

”Bean sprouts are our core product, for which we chose the Schur®Star Concept,” says Lasse Vilmar, CEO and third generation in the company. ”But because of the versatility of the packaging machine and its high capacity, we decided to speed up the new Eat-Grow-Repeat project. When starting up a new project, flexibility is of the utmost importance, as you must be able to quickly adapt to market reactions”.

Lasse Vilmar continues: ”Now we can change from a fully automatic to a manual packing process in a few minutes – e.g. if we want to pack meal salads with different elements. Also in terms of bag constructions we are not at all limited to the two bag types that we started up with. We are excited about the new flexibility and the many options, and we feel convinced that the market will welcome our novelties: Healthy and tasty produce in convenient packaging.”

With its rectangular fill opening in the entire width of the bag, the Schur®Star Packaging Machine is ideal for filling of light and unevenly shaped products, such as a portion of bean sprouts or small pea plants. With more than 500 companies around the world, the concept packs all types of products – including a broad range of fresh produce, into a comprehensive range of bag constructions.

For more information:

Schur Star Systems GmbH

Tel:+49 (0) 461 99 750

Email: sfg@schur.com

www.schur.com/en/

11 Jan 2021

Grower To Flexible Packaging

Forward Greens' vertically farmed edible plants packaging was changed twice before finding the best metrics-based sustainable option, an OPP pillow pack

Forward Greens' vertically farmed edible plants packaging was changed twice before finding the best metrics-based sustainable option, an OPP pillow pack.

January 04, 2021

Sometimes the best of intentions doesn’t turn out as expected, which is why the phrase “if at first, you don’t succeed, try, try again” was crafted for those whose persistency pays off.

Taking that to heart was Forward Greens, an indoor “vertical farm” brand in Vancouver, WA, that went from PET clamshell packaging to tetrahedral-shaped oriented polypropylene bags to OPP pillow-pack bags. The final iteration was part of a major rebrand this year that centered on using the most sustainable packaging. Ken Kaneko, the company’s founder, and CEO provides answers regarding the packaging and decision-making process.

How did your sustainable journey begin?

Kaneko: Forward Greens’ process for developing a sustainable packaging solution for our greens started with researching waste stream management with local municipalities to understand how we could integrate with the existing infrastructure. Along with the Oregon Department of Environmental Quality and Portland Metro, we ran a Life Cycle Assessment (LCA) to understand the impact of production, logistics, and disposal for available packaging options. From this, we learned that material mass was the largest driver in carbon emissions and that most plastics, even compostable ones, are not accepted by the municipalities. After synthesizing all the information, we concluded that flexible plastic packaging demonstrated the lowest material mass and thus the lowest carbon emissions.

Forward Greens

It would be helpful to know more about your products and customers.

Kaneko: Forward Greens currently has 9 products across baby greens and microgreens, all delivered from farm to market within 48 hours of harvest. We’re unique in that it takes about 19 days from seed to market shelf for our baby greens and about 9 days from seed to market shelf for our microgreens.

Our target customer is anyone who is interested in locally grown, healthy greens — to use for salads, as ingredients, or toppings. We hope we attract those who are especially conscious of their impact on the environment, knowing that with our products, customers are not extraneously stressing the planet. That of course includes our packaging, but also in how we grow the plants themselves. Our sustainable indoor farming practices use 95% less water and 99% less land than outdoor agriculture. We skip the use of herbicides, pesticides and fungicides, and use only non-GMO seeds.

Why was the polymer choice made?

Kaneko: When we rebranded to Forward Greens this summer, we shifted from PET clamshell packaging to OPP flexible packaging to better reflect our mission. The OPP film uses 92% less plastic than traditional clamshells, 12 times less plastic, and produces eight times fewer carbon dioxide emissions compared to, for example, a recycled polypropylene tub.

Forward Greens

Comment on the tetrahedral design (seen above).

Kaneko: Forward Greens initially decided to adopt a tetrahedral shape for our packaging to help the product stand out, but also for two primary logistical reasons. First, the tetrahedral shape allows for more volumetric space for the greens with the same amount of plastic material. Second, the tetrahedral shape uniquely helps our greens stay safe and avoid getting crushed throughout the distribution process from farm customer’s plates.

Why didn’t that work and what was behind the change to the pillow pack?

Kaneko: There are a few reasons why Forward Greens decided to switch from the tetrahedral shape to the pillow pack. The primary reason is that retailers merchandise based on existing shelving units, which are often paid for by incumbent or slotted brands. Trying something new in that environment is very difficult, both for new brands and the retailers. Even though Forward Greens did receive initial buy-in from our retailers and staff, when it came time for the new packaging to rollout, it was more complicated to accommodate the new shape on the shelf than expected, so we adopted the pillow pack to streamline that process for everyone involved.

Forward Greens

Also, we used to be known as West Village Farms, but changed our brand to Forward Greens this summer to better reflect our dedication to sustainable practices and our hope to move the entire industry forward. The packaging change from our clamshells to the tetrahedral packaging shape was part of that brand launch. The most-recent package change from the tetrahedral shape to the pillow pack uses the same look that debuted this summer, but in the pillow-pack shape.

As an indoor farm, Forward Greens is constantly trying to improve yields and reduce production costs. Our recent switch from the tetrahedral packaging design to the pillow pack shape increased our content volume and net weight by 33%.

Talk about the timeframe for these changes.

Kaneko: The process for developing both our new packaging and rebrand as Forward Greens from West Village Farms was a huge undertaking. We began the initial planning and development for the new brand in late 2019. The new packaging and brand officially launched the summer of 2020 in the midst of the pandemic.

Switching from the tetrahedral shape to the pillow pack took about four months.

Can you credit the other companies involved?

Kaneko: We worked with Grady Britton, a Portland, OR-based marketing agency, to develop our new brand and packaging design. We wanted the new look to bring to life what we stand for, so the packaging reflects a love of community, food, and the planet while sparking joy. The new-look is vibrantly colorful, and part of that is because bagged greens is a crowded market. The new brand design stretches accepted notions of produce packaging design while ensuring the product still looks appetizing. The bag also offers a windowed look inside so customers can see how fresh the greens are.

What feedback have you received?

Kaneko: Forward Greens’ customers and retailers appreciated the effort and unique look of the new packaging shape. We may have just been a little bit ahead of the curve for the greens industry with the tetrahedral packaging shape.

What lessons did you learn in the past months?

Kaneko: Brands need to be selective about trying new things at retailer sites. There is a certain speed at which retailers move and it’s very different from the speed at which a company, like Forward Greens, moves. Regardless of the change back to the original pillow pack packaging shape, our fundamental goal is that our packaging has one of the lowest environmental impacts available, all while helping retailers merchandise our greens to the customers who want to buy our products.

TAGS: SUSTAINABLE PRACTICES SUSTAINABILITY EXTRUSION: FILM & SHEET

Nature Fresh Farms Pledges To Plant 25,000 Trees In Sustainability Campaign

After two years of research and development, Nature Fresh Farms has officially launched their 100 percent home compostable Cucumber wrap, a first for the North American marketplace

Leamington, ON | October 1, 2020

Nature Fresh Farms has launched its sustainability campaign following the release of their new home compostable Cucumber wrap.

After two years of research and development, Nature Fresh Farms has officially launched their 100 percent home compostable Cucumber wrap, a first for the North American marketplace. Made from a starch-based PLA that is derived from plant-based resources, the film is home compostable breaking down naturally into CO2 and water within 90 days.

To celebrate its release and promote to consumers and customers alike, Nature Fresh Farms has launched a unique marketing campaign and want their followers to join in their initiative to make a difference. Their campaign has kicked-off with high-impact social media posts going live on their Instagram, Facebook, and LinkedIn accounts. Every time someone shares these posts during the month of October, they will plant a tree. With one share equalling one tree, the company is pledging to plant up to 25,000 trees to help our forests thrive.

“We really wanted to grab the attention of our consumers and followers with this home compostable film,” said Luci Faas, Product Development Specialist. “Through this initiative, we hope to raise awareness of this packaging design that will make a lasting change on the environment but also go even further by planting trees to help our North American forests flourish.”

This campaign seeks to spotlight the progression of their sustainable packaging design while encouraging their followers to spread the word by sharing social media posts and help plant a tree. The initiative supports Nature Fresh Farms commitment to bettering the environment and their continued investment in searching for more sustainable packaging designs.

“Our customers are looking for more environmentally friendly packaging and we want to give them that,” shared Director of Sales, Matt Quiring. “With our continued goal of finding more viable packaging solutions we want to provide more options and make it easier for most people to make positive environmental choices.”

At Nature Fresh Farms they are driven to accelerate innovation through evidence-informed sustainable packaging solutions providing a better experience for their customers, while also helping to preserve the vitality of our planet.

About Nature Fresh Farms

Continuously expanding, Nature Fresh Farms has become one of the largest independent, vertically integrated greenhouse vegetable farms in North America. As a year-round grower with farms in Leamington, ON, Delta, OH, and Mexico, Nature Fresh Farms prides itself on consistently delivering exceptional flavor and quality to key retailers throughout North America, while continuing to innovate and introduce more viable and sustainable growing and packaging solutions.

SOURCE: Nature Fresh Farms | info@naturefresh.ca T: 519 326 1111 | www.naturefresh.ca

Complete Packaging Solutions For Leafy Greens

JASA has been in the automatic packaging market for sliced vegetables for 35 years; consequently, they gained all the knowledge and expertise to pack mixed lettuce varieties in various ways

JASA has been in the automatic packaging market for sliced vegetables for 35 years; consequently, they gained all the knowledge and expertise to pack mixed lettuce varieties in various ways.

Bags filled with leafy greens on a vertical packaging machine.

Packed in trays with a lid or top seal.

Salad bowls with various extra components such as proteins and dressings.

A sleeve around the packaging ensures the leafy greens will stand out on the shelf.

As a packager of leafy greens, JASA can put together a complete packaging solution to pack mixed lettuce at high speed. And as a system integrator, the company takes full accountability of the weighing and packaging process.

"To make the packaging process as easy as possible for the customer, we are a partner throughout the entire process," says Sandra Somford. "We listen to the customer's wishes during the building phase and contribute ideas to arrive at the best packaging solution." This total solution also looks at the best options for the production line in combination with the packaging and packaging materials; printed or clear film, labels, or action stickers. "Our complete packaging lines make it all possible."

The company uses highly accurate weighers, ideal for leafy greens. With distribution rights for weighers from various brands, JASA develops and produces multiple machines, such as vertical packaging machines, under its own brand and management. In addition, the complete packaging lines are both maintenance and user friendly. The production lines have a hygienic design and are made from stainless steel, ensuring they meet the highest hygienic and quality standards.

For more information:

Sandra Somford

JASA Packaging Solutions, Inc.

Tel: +1 (804) 290-3683

Email: sandra.somford@jasapackaging.com

www.jasa.nl

Publication date: Mon 28 Sep 2020

A Journey Through The World Supply Chain With IFCO Systems

Founded in 1992, IFCO was the first pioneer to reintroduce a reusable packaging system for the entire fresh product supply chain, from producer to retailer

Founded in 1992, IFCO was the first pioneer to reintroduce a reusable packaging system for the entire fresh product supply chain, from producer to retailer. They are now the clear market leader in the world, with operations in more than 50 countries across five continents and subsidiaries in 30 countries. Their services are used by 320 of the world’s largest retail companies and over 14,000 growers and food producers. How did they grow from niche service providers to global supply chain leaders? I sat down with CEO Wolfgang Orgeldinger at FruitLogistica in Berlin to find out.

It starts with a pool of 314 million plastic containers

These containers account for 1.7 billion roundtrips per year, from one end of the supply chain to the other and back. The system is simple: first, a newly cleaned and sanitized container is sent to a grower or packer; the product is then packed and shipped to a distribution center, where it is distributed to retail outlets; the product is then sold and the container is returned to a service center where it is cleaned. Round trip complete.

The prime products are fresh fruit and vegetables, but IFCO also transports significant volumes of meat, eggs, seafood, and bread. Most containers stay in a regional pool: for example, containers will complete roundtrips for transporting cabbage in Germany, oranges in Spain, or leafed salad in Holland. But they are also used for southern hemisphere imports, bringing kiwis from New Zealand, grapes and apples from South America, and oranges from Argentina. If you ever wondered where your bananas came from, there is a good chance they came from Central America in an IFCO container.

Regional pools are flexible and scalable: you could have a specific pool for continents like North America and Europe, or scale down to a country level for Japan, Argentina, or Chile; or you could hyper-localize the pool down to a city level, for integration with vertical farms in an urban food system. To give an example, Mr. Orgeldinger cited the city of Sao Paolo, where 90% of fresh produce is grown within 100km of the city center. IFCO’s pool of containers in this region only moves within that circumference.

The operation of these pools is much more sustainable than transporting fresh products with single-use packaging.

To begin with, the containers are designed to be sturdy: each container is used for up to 120 round trips before it reaches the end of its life cycle. Small damage is repaired at servicing centers; if the container is beyond repair, the material is ground down and turned into new packaging. IFCO is the only company directly recycling its own crates to make new ones; this is possible because their crates are made out of one material and can be ground directly into the production process. This cradle to cradle system helps IFCO reduce CO2 emissions by 60%, consume 80% less energy and use up to 80% less water in its operations when compared to using single-use packaging.

But why use plastic at all? The answer is to reduce food waste. When you transport fresh products, you have to account for humidity and plastic is the best material to reduce this problem. With IFCO’s containers, the damage and spoil rates of fresh products is 90% less compared to a single-use container. A further innovation in the IFCO system is that it is totally modular: they design containers in two footprint specifications: 60X40 cm and 30X40 cm. Each footprint stacks perfectly to maximize space and reduce the likelihood of a fall. Finally, each container includes a ventilation system that extends the lifespan of the food in transit and on the shelf.

Given all the advantages of their product versus single-use packaging, it’s no wonder that customers are flocking to IFCO’s sustainable solution. ‘Customers come because the system reduces costs,’ says Mr. Orgeldinger. If you look at the cost-saving across the entire supply chain, from field to retail store, and account for all packaging related costs, all handling costs, and product damage, IFCO can save up to 27% of the total cost. Given the growing momentum of environmental concerns among consumers and suppliers, IFCO is well primed to lead the supply chain into the future. Let’s take a look at how else IFCO is innovating to help growers, producers and businesses save money and save the environment: it starts with technology.

Innovation in packaging: Apps, AI, and integration with vertical farms.

You might wonder how much technology can be packed into a plastic box. But it’s more about the technology that surrounds the box itself. Remember that pool of 314 million plastic containers? They are tagged and the new generation is readable by your smartphone. IFCO is developing a new app that enables smartphone users to identify and count all containers on a pallet. The new technology will first be rolled out in service centers and trialed in order to improve the AI algorithm. They will then provide this service to customers, enabling all participants in a given pool to act more efficiently.

Another new app enables customers to do all transactions with IFCO via their smartphone. This is an industry first, enabling growers who rely on mobile technology to participate in the supply chain more efficiently. Other technical innovations that were mentioned by Mr. Orgeldinger included integrating IFD and GPS-based systems and blockchain solutions into their producer to retailer model. But I was most interested to find out about how IFCO could integrate with innovations in other fields, like the transition of fresh food production to hyper-local vertical farms.

Vertical farms offer IFCO containers a shorter roundtrip journey

Mr. Orgeldinger told me that vertical farming is the most interesting solution for feeding the growing population who live in large urban areas. Modular, reusable plastic containers are perfect for transporting fresh produce across short distances and there is significant scope for integrating IFCO’s packaging with the shorter supply chains that are enabled by vertical farming. This is scaling down from continent to country to city, creating a whole new set of container pools for IFCO to fill. Both IFCO and the vertical farms they choose to work with will play a significant role in the sustainability of urban areas going forward. We will be watching this space closely.

Find out more about IFCO at https://www.ifco.com/

KYLE BALDOCK

View All Posts

Innovative Aquaponics Company Achieves a Greener World’s First Non-GMO Certification For Salmon

Superior Fresh, an industry-leading aquaponics facility specializing in organic leafy greens and Atlantic salmon, is the first company to offer salmon Certified Non-GMO by A Greener World

HIXTON, WI –Superior Fresh, an industry-leading aquaponics facility specializing in organic leafy greens and Atlantic salmon, is the first company to offer salmon Certified Non-GMO by A Greener World. The company’s flagship facility is the largest of its kind, practicing ecologically sound water conservation and native prairie restoration in a closed-loop, zero-discharge system.

Developed at the request of farmers and consumers seeking a meaningful non-GMO label, Certified Non-GMO by AGW guarantees food is produced without the use of genetically modified feed, supplements or ingredients, and comes from animals raised according to higher animal welfare standards using sustainable agriculture methods. On salmon, the Certified Non-GMO by AGW label includes A Greener World’s Salmon Welfare Certified standards, incorporating the UK RSPCA’s respected higher welfare salmon standards. Certified Non-GMO by AGW has meaningful prohibitions on GMO contamination (see comparison chart here for more details), and ensures that at no point in the growing, processing or manufacturing of the product will GMOs enter the system.

Superior Fresh’s announcement follows FDA’s recent controversial approval of genetically modified salmon for human consumption–despite significant opposition from consumer advocates, fishing groups, public health officials and native communities. As public concern for the labeling of GMOs (genetically modified organisms, also known as GE, or genetically engineered) continues to grow, the market for non-GMO products is surging 17% annually and expected to reach 1.1 billion USD by 2023, according to industry analyst, Technavio. Consumers seek out non-GMO products for a variety of reasons, including environmental sustainability, health, corporate consolidation and transparency. A lack of clear labeling around GMOs means that consumers must actively seek out Certified Non-GMO products to avoid them.

Superior Fresh President Brandon Gottsacker says,

“The fish production systems at Superior Fresh are designed and managed using technology that maintains clean water, giving our salmon the opportunity to live in a stress-free environment. It is our duty to make sure our fish have great welfare, leading to the best quality fish for the consumer. In the absence of a USDA Organic standard for seafood, we chose to obtain the AGW certifications for Salmon Welfare and GMO-Free to assure our customers that we meet their standards.”

AGW Executive Director Andrew Gunther says,

“We work with some of the most forward-thinking food producers on the planet, and the team at Superior Fresh is no exception. Wild fisheries are under significant threat–through habitat destruction, industrially abusive production practices, and now genetically modified salmon. Stewardship-based approaches like that of Superior Fresh are essential solutions if we are to meet our current needs without impacting wild ecosystems while we work to rebuild them. This has been an inspiring project and we are thrilled to support the work of independent, sustainable aquaculturists in this sphere.”

ABOUT A GREENER WORLD

A Greener World (AGW) identifies, audits, certifies and promotes practical, sustainable farming systems by supporting farmers and ranchers and informing consumers. AGW’s growing family of trusted certifications includes Certified Animal Welfare Approved by AGW, Certified Grassfed by AGW and Certified Non-GMO by AGW. Each program is designed to have positive and measurable impacts on the environment, society and animals, and to encourage truly sustainable farming practices. AGW’s standards and procedures are robust and transparent and achievable.

A nonprofilt funded by public donations and membership, A Greener World offers a range of resources to help people make informed food choices, including an Online Directory of certified farms and products and Food Labels Exposed–a definitive guide to food label claims (available in print and online). For more information visit agreenerworld.org.

ABOUT SUPERIOR FRESH

Superior Fresh brings together a one-of-a kind sustainable ecosystem that combines the world’s most advanced aquaculture and hydroponic growing techniques. By using the cleanest water and mimicking the natural environment, we provide an ideal and safe growing environment for our fish. Our Atlantic salmon receive only the best care and animal husbandry–they never receive any hormones or antibiotics, and they’re fed a sustainable, organic diet. We’re delivering an unparalleled eating experience with the most premium fish. For more information and availability visit superiorfresh.com.

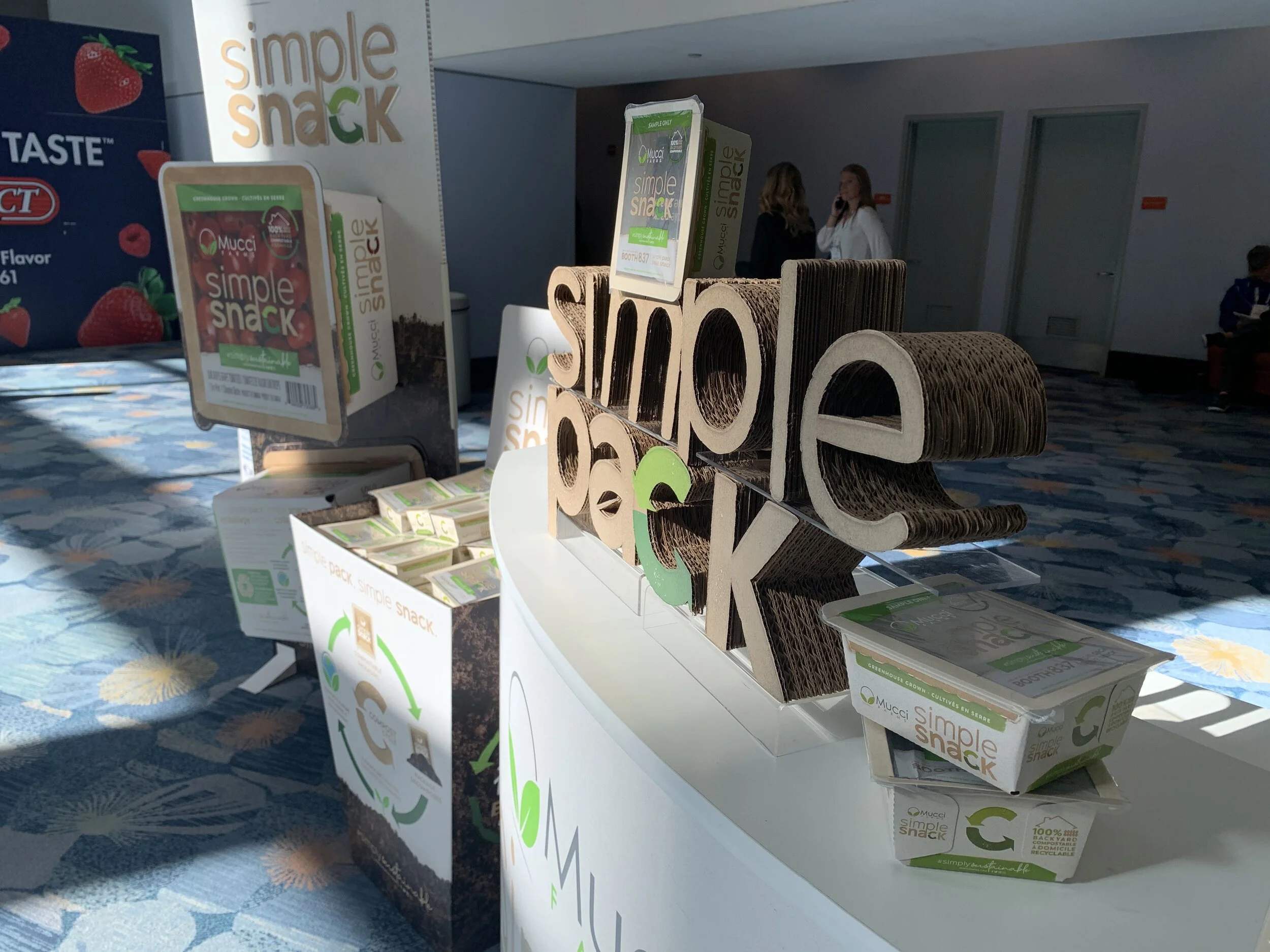

Mucci Farms Wins Best Sustainable Packaging Award At Fresh Summit 2019

“To win this category, in particular, is exciting because sustainability is by far the top of mind subject in the food industry today,” says Emily Murracas, Director of Marketing

October 21st, 2019 (Anaheim, California) – Mucci Farms announces that they have been awarded the top prize for Best Sustainable Packaging at the PMA’s Fresh Summit Conference and Expo for Simple Snack, a plastic-free, backyard compostable series of packaging. “To win this category, in particular, is exciting because sustainability is by far the top of mind subject in the food industry today,” says Emily Murracas, Director of Marketing.

“We’ve been recognized in the industry for flavour and innovation over the years, so we are ecstatic to be able to package those award-winning products in a package that helps to address a global concern. It’s also very special to win in a competitive category that included submissions from packaging suppliers and fellow marketers.”

A vertically integrated greenhouse grower extensively committed to sustainability at all ends of the business, Simple Snack adds to those commitments. The package is composed of a tray made from agricultural waste and the lidding film is made of sugar-cane and wood fibers using a process that emphasizes social and environmental responsibility.

“Consumer feedback over the last several months has been almost exclusively focused on the reduction of plastic, so we feel like we’ve addressed that concern by coming up with a truly plastic-free package,” said Fernanda Albuquerque, Packaging Development Manager. “We also saw the value of being able to add key messaging to the tray which gave our designers a larger canvas for branding, information, and education.”

A dedicated partner of the Produce Marketing Association, Mucci Farms also sponsored the annual Center for Growing Talent 5k race, which seamlessly fits with their company objectives to be a health and wellness conscious brand. Race participants were served refreshing smoothies made with the Award Winning SmucciesTM Sweet Strawberries. Additionally, the company had a sampling station at the show entrance where attendees could take home a sample of their very own Simple Snack package.

On the show floor, the Mucci Farms team welcomed buyers and attendees to their world of colours that included their entire lineup of offerings including their newest item, Zingers shishito peppers and the highly sought after CuteCumber Poppers. With chefs on hand putting together a variety of flavourful samples, the Mucci Farms booth has become a featured destination every year.

The Fresh Summit Conference & Expo took place from October 18-20 in Anaheim, California.

For Info:

Ajit Saxena

Public Relations & Digital Marketing Manager

519-326-8881 Ext 2253

asaxena@muccifarms.com

Paper Sleeves Added To Greensleeve Product Range

Earlier this year, Mediane launched their Greensleeve program including a variety of sustainable packaging sleeve alternatives to the herbal plant market. Next to Home Compostable Film, Industrial Compostable PLA and Recyclable Green PE, the Greensleeve program now also includes a paper variant.

Many existing and non-existing customers from different European countries have shown great interest already. First results are to be seen on the shelf at some leading supermarkets in the EU. Given the positive reactions from the market, the expectations are that more supermarkets will follow shortly.

‘’This clearly indicates that the use of plastics in the Agro and Horti-industry is under pressure’’, according to Mike Leistikow, sales manager at Mediane. ‘’The use of paper responds to the growing awareness of the consumer. Paper is seen as a more sustainable option. We are independent converter of packaging sleeves and for us we adjust ourselves to market demand. Obviously there is a lot to be said about the pros and cons of each sustainable alternative, however we are not forced to defend or push through either of these alternatives since we are in the position to produce and offer them all. This is the choice and decision of the retailer”.

For many countries, depending on local legislation on waste management, Home Compostable or bio-based recyclable materials are definitely the preferred option with a lower CO2 footprint. The advantage of the paper/paper variant is that it is produced out of recycled kraft and can be thrown away together with the old newspapers and can be considered to be 100% recyclable. Next to the 100% paper version, Mediane also offers the Paper/Film variant and the Paper/Partly (paper with bio-film).

Just like traditional sleeves, the Greensleeve paper sleeves are supplied on a block and can be packed in the same way.

For more information:

Mediane

P.O. Box 1623

3600 BP Maarssen

The Netherlands

+31 346 285029

info@mediane.nl

www.mediane-flexibles.com

www.greensleeve.green

Publication date: 5/7/2019

Inside The GMO Law: What Needs To Be Labeled And Why It Matters

The regulations state that manufacturers can voluntarily disclose GMOs if a product contains some of these highly refined ingredients or has a lower concentration of biologically engineered material, which GMO advocates cheer and consumer organizations caution

Highly refined ingredients and the "BE" acronym are out, according to regulations issued in December. The food industry and consumer groups are split on how effective the new measure will be.

AUTHOR Megan Poinski@meganpoinski

Now that the final GMO labeling regulations have been rolled out, what is going to bear the new seal that certifies a product is derived from bioengineering?

The answer: Not as many products as advocates for the labeling might have thought. It's been estimated that up to 75% of the products in a grocery store are made with ingredients derived from crops that were genetically modified. According to the regulations, items that contain highly refined ingredients don't have to be labeled.

Additionally, to require a label, a product needs to have at least 5% bioengineered material, which is a higher concentration amount than most other countries that have GMO labels.

The regulations state that manufacturers can voluntarily disclose GMOs if a product contains some of these highly refined ingredients or has a lower concentration of biologically engineered material, which GMO advocates cheer and consumer organizations caution.

The new labeling requirements, which most manufacturers must implement starting in 2020, were viewed by some analysts as fair.

"They balance consumers' request for more information with a labeling approach that is based on facts, practicality and common sense, rather than politics and fear," Sean McBride of DSM Strategic Communication told Food Dive in an email. "No one side got everything it wanted, and there will be special interest skirmishes in the 116th Congress and beyond over this, but for now, we have a clear flight path to providing consumers with the transparency they want and deserve.”

There are many other aspects of the regulations those in the industry appreciate and despise. But the time for changes has passed. Manufacturers now need to work on ensuring that their labels comply with the new guidelines. According to the regulations, manufacturers may put their labels to the test as soon as this month.

Credit: Okanagan Specialty Fruits

What needs to be labeled?

While the new regulations outlined the symbols and terms that will be used, what needs to be labeled did not change during the rulemaking process. Meat, poultry and egg products by themselves are not included in the disclosure, which is stated clearly in the law. Neither are multi-ingredient products that have these items as their first ingredients, such as a canned stew with beef broth.

The final rule lays out a much more nuanced — and consequential — point. Many crops that become food ingredients are GMO, but they go through a refining process to become useful ingredients. That process often destroys the genetic material in the ingredients. One of the largest questions for the final rulemaking was whether these ingredients needed to be labeled as GMOs.

Companies and trade organizations were split on the issue. In its comments on the rule, the Grocery Manufacturers Association said about 90% of the nation's corn, soybean and sugar beet crops are genetically modified. If the products using refined versions of those crops do not have to be labeled as GMO, it estimated 78% fewer products would have to be disclosed under federal law.

The U.S. Department of Agriculture decided not to require the disclosure because the initial law said GMO food needs to contain modified genetic material. If it cannot be detected, it is not there. And because the initial law also does not say anything about classifying some of these ingredients from GMO crops as "highly refined," the final rule does not take on this classification of definition.

Consumer advocates who oppose GMOs were strident in their disapproval of the ruling.

"The USDA has betrayed the public trust by denying Americans the right to know how their food is produce," Andrew Kimbrell, executive director at Center for Food Safety, said in a written statement. "Instead of providing clarity and transparency, they have created large scale confusion and uncertainty for consumers, food producers, and retailers."

The Consumer Federation of America said in a statement that exempting refined products from disclosure is "inadequate."

However, many major food manufacturers — including Campbell Soup, Mars, Danone, Kellogg, Coca-Cola and Unilever — have been voluntarily disclosing GMOs, heavily refined or not, since the mandatory labeling issue was first debated several years ago.

The USDA also will maintain a list of crops that are definitively GMO that are produced anywhere in the world. This list helps food manufacturers know which ingredients they need to disclose, but it is not exhaustive and will be updated periodically. The regulation gives manufacturers 18 months to update their labels after an ingredient is added to the list.

Currently, the following crops are defined as GMO: alfalfa, Arctic apple, canola, corn, cotton, Bt-Begun eggplant, ringspot virus-resistant varieties of papaya, pink pineapple, potato, AquAdvantage salmon, soybean, summer squash and sugarbeet.

The regulation also indicates where and how on-package disclosure is required. It needs to be seen under ordinary shopping conditions, and must be located near other information on the label that features the manufacturer's name and location. The disclosure can be through text, smartphone-scannable digital links, URLs, a telephone number, text messages or the "BE" symbol. If a digital link is used, it needs to have the words "scan here for more food information" next to it.

While there were several options for the BE symbol in the preliminary framework, the final rules set one that has a round picture of a plant growing in a sunny farm field. A green circle around the picture features the word "BIOENGINEERED" or "DERIVED FROM BIOENGINEERING." There is no BE acronym — the regulations say many consumers did not know what it stood for — and an earlier logo with a smiley face was abandoned.

Credit: Flickr, Dave Herholz

Will it be useful for consumers?

Since it's been known that scientists and food companies were working with ingredients from lab-modified plants, many consumers have wanted to know if they are eating them. While the predominant scientific consensus is GMO food is safe and items made with these ingredients are just as nutritious as their counterparts, consumers value transparency.

Are they getting it from this labeling law? Reactions are mixed.

"No one should be surprised that the most anti-consumer, anti-transparency administration in modern times is denying Americans basic information about what’s in their food and how it’s grown," the Environmental Working Group said in a written statement. The organization takes issue with several aspects of the law, mainly the ruling on not having to label highly refined ingredients as GMOs. EWG has added "Certrified GMO-free" — using verifications from the Non-GMO Project — as a category on its food information website.

The Grocery Manufacturers Association focused on the cohesiveness of the labeling regulations. The federal law requiring labeling was quickly passed — partially to preempt a Vermont state law requiring its own labeling scheme for GMO products sold there. With the regulations in place, consumers are closer to getting the information they seek on food products, the trade group said.

"Disclosure is imperative to increasing transparency, educating consumers and building trust of brands, the food industry and government," Karin Moore, GMA's senior vice president and general counsel, said in a written statement. "We are pleased that the USDA has now provided a structure for our companies to share this information voluntarily, building a foundation for government to more quickly respond to innovation in food and agriculture in the future."

Food Marketing Institute President and CEO Leslie Sarasin agreed, hailing the "more precise vocabulary into the public discourse regarding biotechnology in food production" represented by the new labeling requirements.

While there has been some voluntary disclosure of GMOs — and certification of non-GMO products — Thomas Gremillion, director of the CFA's Food Policy Institute, mentioned the issue of terminology. Consumers have been using "GMO" and "genetically modified" to talk about these food products — not "bioengineered," which will appear on the label. "Bioengineered" is the term in the law — the acronym "GMO" only appears twice in the text, and each time to say certain products cannot be labeled "non-GMO."

Regardless of terminology, some say that having the law in place doesn't correct fearmongering over GMOs. Transparency group Peel Back the Label said it may actually make it worse.

"While the USDA’s new disclosure rule provides additional clarity for consumers regarding what is and what is not a bioengineered food, it does nothing to reign in the growing use of misleading food labels and meaningless absence claims that are designed to capitalize on consumer fears and confusion in order to boost sales," the group said in a statement emailed to Food Dive. "Consumers deserve both truth and transparency in food labeling, and Peel Back the Label urges the USDA and Food and Drug Administration (FDA) to review current voluntary disclosure regulations to ensure food labeling is founded in science, not in fear.”

Follow Megan Poinski on Twitter

Filed Under: Ingredients Packaging / Labeling Policy

Top image credit: U.S. Department of Agriculture

Why It’s Critical For Food Companies To Choose Sustainable Packaging

Photo courtesy of Sustana

December 5, 2018

Every day, 2.2 million pounds of waste paper converge on Sustana recycling mills, where we sort and process it into more than 230,000 tons of post-consumer recycled fiber per year.

The U.S. is in the midst of an increasingly sophisticated and urgent conversation about environmental damage from single-use plastics and containers. Restaurant operators and food distributors, in particular, are thinking more about how sustainable packaging can help to address food-related social and environmental issues while delivering a positive brand impact.

While plastics and plastic packaging are an integral part of the global economy and provide it with many benefits, their typically linear value chains entail significant drawbacks that are becoming more apparent by the day. In a business-as-usual scenario, projected growth in plastics production could lead by 2050 to the oceans' containing more plastics than fish, and the entire plastics industry could consume 20 percent of total oil production and 15 percent of the annual carbon budget.

Sustainable food packaging and brand identity

Sustana aims to be a part of the solution. We promote and apply sustainable manufacturing and business practices to deliver premium, eco-friendly recycled fibers to customers across North America. One such product is EnviroLife, the only 100 percent post-consumer recycled fiber in North America that is FDA-compliant for use in direct food contact packaging under all conditions of use.

For restaurants looking to differentiate their brand and attract environmentally conscious consumers, packaging is an excellent way to demonstrate concern for the earth while materially reducing environmental impact. Sustana recognizes that food packaging is becoming another way to articulate a company’s values, and to show its commitment to the environment and to the communities in which it operates.

Projected growth in plastics production could lead by 2050 to the oceans' containing more plastics than fish.

As we dialogue with end users, we see how successful food and beverage companies know that customers develop a relationship with their product packaging. A customer will have half an hour with that coffee cup, for instance. It might have their name on it with logos and design. This provides a tangible way for a customer to look at that and feel good about the choice they made. They’ll notice that it’s not disposable, it’s reusable. This object transmits the company’s values in a very real way. The customer will feel good about having contributed.

McDonald’s recent announcement that it will source all packaging from recycled, renewable or certified sources by 2025 highlights the significant shift underway in the market. Starbucks’ announcement earlier this year that it aims to launch a fully recyclable and compostable coffee cup within three years further emphasizes the transition.

Packaging for a circular economy

According to a third-party Life Cycle Analysis, EnviroLife’s environmental impact is much lower than that of generic North American virgin fiber. Our patented manufacturing process eliminates optical brightening agents, resulting in a product that is suitable for food contact with no need for a barrier or coating. Because of this treatment, EnviroLife is free from contaminants that are present in most other post-consumer fibers.

Straight from production, EnviroLife is ready to be used in all food packaging applications, including takeaway containers, soup containers, coffee and tea cups, coffee bags, cheese-and-meat interleaving paper and bread bags. EnviroLife is also certified by the Forest Stewardship Council.

EnviroLife is free from contaminants that are present in most other post-consumer fibers.

Sustana’s Chairman and CEO, Fabian de Armas, speaks to EnviroLife’s unique environmental benefits: “EnviroLife is the only 100 percent recycled fiber in North America that provides a zero-fluorescence solution and meets FDA requirements for direct food contact without the need for a barrier. Sustana provides its clients with premium products and environmentally sustainable solutions whose impacts are measurable. We conduct a third-party-verified analysis of the impact of using our products on the environment in terms of overall carbon footprint; it’s an entire life cycle analysis for our products. Sustana is the only producer that does this, and we’re proud of that.”

Shrinking environmental footprint

Sustana transforms post-consumer waste paper into premium recycled fiber, with state-of-the-art recycling mills in De Pere, Wisconsin, and Lévis, Quebec. Every day, 2.2 million pounds of waste paper converge on Sustana recycling mills, where we sort and process it into more than 230,000 tons of post-consumer recycled fiber per year. By recycling waste paper, the mills save enough energy to power 85,000 average U.S. homes for one year.

EnviroLife’s low environmental impact helps food-serving brands meet their sustainability goals, and answer the growing consumer demand for environmentally friendly products. We recognize that when it comes to packaging, how it’s created and where it originates have become just as important as looks and function.

Topics:

Orange Packaging Goes Green!

12.6.18

One Hudson Valley company is leading the charge in making plastic more earth-friendly. Orange Packaging of Newburgh, New York, is now offering an innovative, proprietary compostable plastic. Made from 100 percent sustainable, renewable plant-based materials, this plastic can be thermoformed into a variety of shapes and packages and is guaranteed to start breaking down in a composting environment within 45-60 days.

“We’ve spent a long time perfecting the tooling and production process in preparation for this new, earth-friendly plastic offering and are we thrilled with the result,” says Michael Esposito, Vice President of Orange Packaging.

For manufacturers in search of earth-friendly packaging, this news is huge. “When you’re done with the product inside the package you can compost the container along with your other food scraps in your backyard compost pile or a local commercial facility,” said Esposito. “The plastic is designed to begin breaking down in under two months. It’s a win for the manufacturer, the customer and the planet.”

Orange Packaging’s proprietary compostable plastic meets food-grade standards and can withstand higher and lower temps than previous iterations of compostable plastics, making it ideal for any and all packaging—including food packaging. It can be refrigerated, frozen or microwaved without affecting the plastic package or its contents. In warehouse environments, this compostable plastic holds infinite shelf life, so there is no expiration date.

The R&D invested in this new process allowed Michael and his team at Orange Packaging to create a preferred, earth-friendly solution that won’t break the bank for commercial clients. For pricing and more information on Orange Packaging’s proprietary compostable plastic, email michael@orangepkg.com.

Have Your Food and Eat the Wrapper Too

Contributing Author: Alaina Spencer

According to the U.N. Food and Agricultural Organization (FAO), “approximately 8 million metric tons of plastic waste enters the ocean every year.” This plastic waste can take up to 400 years to break down in the landfill, harming animal life, polluting cities, or overwhelming landfills. To combat the harmful environmental effects of plastic, many companies are seeking to replace excess plastic packaging with edible materials. Using innovative technology and plant-based materials like seaweed, organizations have developed numerous packaging alternatives safe for human consumption.

To highlight these inspiring alternatives to plastic, Food Tanks brings you 18 innovations in edible packaging. These organizations are working to reduce plastic waste, support a healthy environment, and influence consumer behavior.

1. Apeel Sciences

Apeel, a translucent ‘peel’ that slows water loss and oxidation from Apeel Sciences, works to extend the freshness of fruits and vegetables and reduce the amount of rotten, wasted food. The California-based company, Apeel Sciences, used plant-derived materials found in peels and skins in creating Apeel to naturally lengthen the shelf life of perishable foods. The sheer coating keeps air out by acting like a second peel and is completely edible. Apeel is trying to reduce the amount of food lost for producers, suppliers, retailers, and consumers.

2. Bakeys

Bakeys, an edible cutlery company, was founded in India to try to provide a waste-free and chemical-free alternative to disposable plastic, wood, and bamboo cutlery. The founder, Narayana Peesapaty, created Bakeys out of concern for groundwater depletion and the danger of plastic toxins on human systems. The cutlery is made of a blend of sorghum, rice, and wheat flours, completely biodegradable, and vegan-friendly.

3. Coolhaus

Coolhaus is a Los Angeles-based ice cream sandwich company that offers their creations in an edible potato wafer paper wrapping. While not all of their products are packaged in edible packaging, Coolhaus offers this potato wrapping as an eco-friendly alternative to their other plastic-based wrappers. To reduce catering and event packaging waste, Coolhaus imprints the tasteless potato wrappers with specific logos or brands using edible ink for each event.

4. Do Eat

Belgium-based company, Do Eat, combines water and potato starch to create a gluten-free, vegetarian, edible package for sandwiches, bagels, cookies, and other individual foods. As an alternative to plastic food packaging, Do Eat packaging is completely edible, biodegradable, and home compostable. The neutral flavor allows the packaging to be paired with savory or sweet foods and can be grilled with its contents. Do Eat founders, Thibaut Gilquin and Hélèn Hoyois, are attempting to change consumer waste behavior without consumers noticing a difference.

5. Ecovative

Ecovative is a design and packaging company working to develop, produce, and market environmentally friendly products to work in conjunction with the Earth’s ecosystem. The New York-based company begins at the cellular level by using mycelium, the vegetative part of a fungus, to grow packaging for wine bottles, cold storage, or any product needing support. Ecovative uses various nutrients and environments to grow the mycelium packaging which creates differing strengths and flexibilities. While Eben Bayer, a co-founder, says the packaging is, in fact, edible, he encourages consumers to compost it to use as fertilizer.

6. E6PR

A Mexican-based start-up, Eco Six Pack Ring or E6PR, is trying to replace the plastic six-pack ring that holds beer cans by combining compostable matter and by-product waste to create an eco-friendly six-pack ring. Plastic six-pack rings often make their way to the ocean greatly harming sea life, which inspired E6PR to create an environmentally and animal friendly product. These biodegradable and compostable ‘ecorings’ completely break down if left in the wild or in water and do not harm animal’s digestive tracts. The ecorings are also 100 percent edible, but the company does not encourage human consumption due to possible contamination on the journey to the retail store.

7. Evoware

Evoware, a seaweed-based packaging company, works to reduce plastic waste by replacing plastic food packaging with edible, dissolvable, and biodegradable packaging. The tasteless, odorless packaging comes in various sizes to fit sandwiches, cereals, or coffee sachets and is customizable for specific colors and brand logos. Along with reducing plastic waste, the Indonesian-based company collaborates with local seaweed farmers to try to reduce carbon emissions, increase farmers’ incomes, and maintain clean shores. Evoware is trying to provide an eco-solution to plastic waste while improving the livelihoods of Indonesian seaweed farmers.

8. Loliware

Loliware is a biodegradable, edible cup company founded and designed by Parsons School of Design graduates, Chelsea Briganti and Leigh Ann Tucker. Loliware uses seaweed, organic sweeteners, and fruit and vegetable coloring to produce natural, non-toxic cups that are FDA approved to eat. According to Briganti and Tucker, Americans throw away 25 million plastic cups every year which inspired them to create Loliware. Loliware is trying to change the packaging industry by providing edible products as a solution to one-use plastic cups. The company is currently in the midst of launching an edible straw with the hope to expand their products and decrease the abundance of single-use plastics.

9. Monosol

Monosol, an Indiana-based packaging company, utilizes water-soluble film technology to create sustainable packaging that completely dissolves in water. A division of Japan-based parent company, Kuraray, Monosol partners with various businesses to provide an eco-friendly alternative to packaging of all sorts including detergents, personal care products, and food goods. Because the packaging is transparent, tasteless, and odorless, Monosol is trying to replace the wrapping for foods such as oatmeal and spices.

10. NVYRO

NVYRO, pronounced en-vi-ro, transforms Cassava plants, also called tapioca, into single-use biodegradable and edible packaging to offer an alternative to polystyrene and plastic food packaging. The Cassava plant is a sturdy raw material, which is then broken down and processed through thermal compression moulding making NVYRO’s products water-resistant for 75 minutes and oil resistant for several hours. Based in the United Kingdom, NVYRO offers a wide variety of products ranging from plates and cups to take-out containers in the hopes to replace current single-use plastic and paper goods.

11. Poppits

Florida-based startup, Poppits, is a toothpaste company using water-soluble pods to attempt to reduce the need for plastic toothpaste tubes and caps. In efforts to eliminate plastic pollution, Poppits use food-grade edible film to house single-use toothpaste pods that completely dissolve when brushing, which are packaged in sustainably sourced, biodegradable cardboard and recyclable aluminum. Poppits inventor, Wayne Solan, hopes to decrease bathroom mess while providing an edible and environmentally friendly toothpaste package.

12. Scoby

Polish design student, Roza Janusz, drew inspiration from vegetable cultivation to create Scoby: Living Packages, an edible, recyclable packaging, for her graduate project at the School of Form in Poznan, Poland. Scoby, short for Symbiotic Culture of Bacteria and Yeast, is a growing, living organism most known as the membrane found in kombucha. Janusz uses extracts from agricultural waste to feed Scoby which then grow into edible and compostable packaging. Janusz wants farmers to grow their own Scoby to limit wasteful packaging practices and instead create zero-waste packaging.

13. Skipping Rocks Lab

London-based start-up, Skipping Rocks Lab, uses seaweed and plant materials to create waste-free alternatives to plastic packaging. Their first product, Ooho, dubbed “water you can eat,” strives to provide the convenience of plastic water bottles without the environmental impact. Ooho is a spherical, flexible package made of seaweed that holds water and can be eaten like a grape. While Ooho is currently only sold at events, Skipping Rocks Lab is working on getting Ooho into stores to help reduce the amount of plastic water bottles ending up in the oceans and prevent millions of kilograms of CO2 from ever being emitted.

14. Taste No Waste Project

Montreal-based anthropological researcher and industrial designer, Diane Leclair Bisson, uses culture-specific research to inform sustainable food packaging innovations that seek to change consumer interaction with food containers through the Taste No Waste Project. The Taste No Waste Project replaces disposable food containers with edible ones made from tomatoes to offer a possible waste reduction solution and a new gastronomic experience. By creating an edible container, Diane hopes to generate a more meaningful interaction with food and its packaging, which she thinks can be an agent for cultural change.

15. TIPA

Inspired by the compostability of an orange peel, TIPA, an Israeli-based sustainable packaging company, creates packing material that looks and feels like plastic with one large difference: it’s completely home compostable. Daphna Nissenbaum and Tal Neuman founded TIPA as a potential solution to the world’s growing plastic waste problem. TIPA combines bio-materials and technology to create flexible, plastic-like packaging that is 100 percent biodegradable and leaves no toxic residue.

16. Tomorrow Machine

A Swedish design company, Tomorrow Machine, questions the lifespan of plastic food packaging through their own packaging series, This Too Shall Pass. The packages in the series have the same life-span of the contents they hold whether it’s juice, rice, or oil. The edible packaging for oil is made of wax-coated sugar, which cracks open like an egg then melts under water. The designers behind the food packaging series work to build a more sustainable world through research, technology, and new materials.

17. United States Department of Agriculture (USDA)

Two chemical engineers, Peggy Tomasula and Laetitia Bonnaillie, of the Agricultural Research Service (ARS) in the USDA, are trying to reduce food spoilage by using casein proteins found in milk to create an edible wrapping product similar to plastic wrap. The researchers recently combined an alkali compound to the casein wrapping, which they state keeps oxygen out of food 500 times better than petroleum-based wrappings and is resistant to humidity, temperature, and moisture. Because the wrapping is made of the casein protein, the researchers suggest use with other dairy products or provide an allergy warning.

18. WikiCells

Inspired by the methods of nature, WikiCells are edible skins that encase food or liquids to create a protective barrier from the outside world. Harvard Professor, David Edwards, came up with the idea to use various natural food particles held together by nutritive ions to construct a completely edible skin as an alternative to plastic packaging. With the help of designer François Azambourg, Edwards brought WikiCells to fruition with the hopes of WikiCells products being sold in bulk, similar to fruits or vegetables, which the consumer could later wash at home. Incredible Foods commercialized WikiCells and now sell the products in the United States as Perfectly Free bites.

Danielle Nierenberg

Danielle Nierenberg is President of Food Tank and an expert on sustainable agriculture and food issues. She has written extensively on gender and population, the spread of factory farming in the developing world and innovations in sustainable agriculture.

Mucci Farms Takes Home Best New Packaging Award from United Fresh

Mucci Farms Takes Home Best New Packaging Award from United Fresh

June 29, 2018

by Lillie Apostolos

CHICAGO, IL - With so many people looking for inspiration in produce aisles, Mucci Farms is stepping up as a company wanting to lasso in consumers’ interest in new and interesting ways. Mucci's very own CuteCucumber Poppers won the Best New Packaging for this year’s United Fresh Produce Innovation Award at 2018’s Chicago-based FreshMkt Expo. The awarded company was selected after exhibitors and attendees voted on their favorite from a list of seven nominated packages in the category.

Emily Murracas, Director of Marketing, Mucci Farms

“We are delighted to win the packaging award for CuteCumber Poppers because we really feel like we’re bringing something new to the greenhouse produce category by including a tasty dip inside each container,” Director of Marketing Emily Murracas said. “In addition, our focus was to create multiple convenient packages to accommodate a variety of customers in the rapidly growing snacking category.”

The Mucci Farms team posing with their award. The company won this year’s United Fresh Produce Innovation Award

The one-bite variety used in CuteCucumber Poppers are on a roll, having recently won the People’s Choice Award at the Leamington Greenhouse Competition. Offering incredible flavor paired with an irresistible crunchy texture, the product will be available in three pack styles to stay in tune with club stores, retailers, and foodservice.

Fernanda Albuquerque, New Product Development Manager, Mucci Farms

“With this product, we decided to create a lineup of new packages to give our partners multiple options based on their demographics and value proposition,” Fernanda Albuquerque, New Product Development Manager, shared in a press release. “The 1.5 lbs and 5 oz top-seal packages are custom thermoformed trays that securely hold the dip container in place. The 9 oz tray is a 3 x 3 oz format with EZ Snap convenience, allowing consumers to tear off each container for 3 individual snack size packs.”

Mucci Farms' award-winning Cutecumber Poppers packaging

Attendees had the opportunity to check in with the company at their booth. The greenhouse grower also co-sponsored the breakfast session, which announced recipients of the 2018 Retail Produce Manager Awards. This segment of the show celebrated produce and foodservice industry professionals from across the continent.

Joe Spano, Vice President of Sales and Marketing, Mucci Farms

“Sponsoring this event is important to us as it recognizes the front-line staff that bring our products to life through merchandising and recipes,” Vice President of Mucci International Marketing Joe Spano shared. “We’d like to congratulate all the award recipients and thank them for all they do to raise the profile of healthy eating.”

Congratulations to the Mucci Farms team! We look forward to seeing how your award-winning packaging pushes the category forward and inspires more consumers to fall in love with produce and the cute offerings our industry provides.

Mucci Farms

Cucumbers Cucumber Mucci Farms New packaging CutecumberTM Poppers Award United Fresh Best New Packaging CuteCumbers

Mucci Farms grows a variety of standard and specialty tomatoes, peppers, cucumbers, and eggplant. Fresh and delicious,...

Packaging Solutions For The Vertical Farmer

Vertical farming is on the rise in big cities around the globe and new growers and distributors are hustling to get into the market. In fact, by 2023, the vertical farming market is expected to reach 6.4 billion U.S. dollars around the world.

Packaging Solutions For The Vertical Farmer

Vertical farming is on the rise in big cities across the globe and new growers and distributors are hustling to get into the market. In fact, by 2023, the vertical farming market is expected to reach 6.4 billion U.S. dollars around the world. One company is poised to back this trend’s growth.

“More produce means more packaging—and that’s where we come in,” says Michael Esposito, Vice President of Orange Packaging, a fully integrated manufacturing facility in Newburgh, New York. With 150,000 square feet of manufacturing space and 10 production lines, the team at Orange Packaging is ready to assist vertical farmers with their packaging needs at a moment’s notice.

I’m so encouraged by the growth of vertical farming across our area,” says Esposito. “The fact that it allows farmers to produce more food using less resources makes it a win in my book. It sounds like a viable, long-term solution and we’d like to help it succeed.”

Orange Packaging’s facility is filled with a diverse array of tools and equipment to meet any packaging need. Their Thermoforming tools have created packaging for every type of grower—from the top produce companies sold at big box retailers to the smaller, local farms you’d find at a local grocery store or farmer’s market.

Orange Packaging also offers a variety of Thermoformed packaging materials like small herb clamshells, bulk lettuce containers, tubs and bins in several different materials like food-grade APET and rPET as well as corn-based PLA.

“Partnering with hard-working business owners is what we do best—and that includes local farmers and growers,” says Esposito. “Let us help you get your product to market. Whether that’s the farmer’s market or the supermarket—we’re here for you!”

Packaging isn’t the company’s only forte. The company also specializes in designing and engineering POP displays and custom molds. The team can even handle fulfillment and has the ability to drop ship anywhere in the world. Their expansive facility allows them to run high-volume orders quickly. They keep stock items on hand that can be purchased immediately, while custom orders can be produced in as little as 3-4 weeks.

For more information or to set up a quote, contact michael@orangepkg.com.