Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Plenty Vertical Farm CEO Matt Barnard: “We Have a Lot of Work to Do” [Podcast]

In this week’s podcast, I’m excited to be speaking to Matt Barnard, the CEO of Plenty, a vertical farming group on the West Coast of the US. If you’re in the agrifood tech space, you will have had to have been living under a rock not to have heard of the record-breaking $200 million investment that Japan’s SoftBank made into Plenty over the summer along with other investors.

Plenty Vertical Farm CEO Matt Barnard: “We Have a Lot of Work to Do” [Podcast]

DECEMBER 20, 2017 LOUISA BURWOOD-TAYLOR

In this week’s podcast, I’m excited to be speaking to Matt Barnard, the CEO of Plenty, a vertical farming group on the West Coast of the US. If you’re in the agrifood tech space, you will have had to have been living under a rock not to have heard of the record-breaking $200 million investment that Japan’s SoftBank made into Plenty over the summer along with other investors. It was actually the first time that Plenty really came out of stealth to tell the world who they were and what they were up to.

I speak to Matt today to find out a little bit more about the last few years and how they’ve been building the company. I hope you enjoy our conversation – there’s an abridged transcription below too.

B-T: Matt, we first met a couple of years ago at the Indoor Ag-Con in New York back when you were called See Jane Farm, and I didn’t really know much about you other than having seen your name on a few investor presentations, but you were in stealth. We did talk about doing an interview at some point, but the timing sort of was never right. The next thing happens, and you’ve raised the largest ever farm tech funding round with SoftBank. That was quite the entrance into the public domain! Maybe you can start by telling us, why was it important for you to be in stealth until that point?

Matt Barnard: Well, I don’t know that it was important for us to be in stealth so much as it was to make sure that we didn’t take up air time when we weren’t yet ready with something to talk about. What we try to do is we try to be ahead of the story if you will, and try not to talk about ourselves too much because no one likes to sit in a room with someone who talks about themselves!

Louisa B-T: Right! I think there are quite a few companies in agtech and indoor ag that actually do speak very early about plans and things. You’re saying that your idea is you wanted to have something of substance to talk about before you told everyone who you were?

Matt Barnard: Right. We also, at that point in time, though we were growing amazing produce and getting it into the lives of a lot of people here in Silicon Valley, we weren’t really ready to capitalize on anything that would come from talking about ourselves. We didn’t want to give the impression to people that we were ready to execute on something that we weren’t really ready for. We just decided to wait.

Louisa B-T: What was with the name change from See Jane Farm to Plenty?

Matt Barnard: We are a company that has global ambitions. We see a lot of problems and a lot of demand to serve around the world. As we thought about having a name that was appropriate for a global, multicultural company, we wanted to make sure that we did that. When you step outside of the US borders, people haven’t seen those reading primaries that were popular in the ’50s, ’60s, ’70s, and a little bit in the ’80s here in the United States that involved Dick and Jane, Spot the Dog, and Puff the Cat. They didn’t know that we were referring to a simpler time with better food that was more nutritious. What we decided to move to the name “Plenty”, which was better able to communicate to cultures around the world and set us up more for success that way.

Louisa B-T: Fair enough. Now, before we talk about the business, I just want to talk a little bit about your background. LinkedIn tells me, and correct me if I’m wrong, that you’ve been a private equity and debt investor, and you’ve built at least one business. Is that right? How would you sum up your resume?

Matt Barnard: Yeah, I’ve built several. A big portion of my career was in the wireless telecommunications industry. I was in that industry for about a decade and helped to build and, ultimately, ran a company that engineered, designed, and deployed the networks for the world’s largest telecommunications companies; so Verizon, AT&T, Sirius XM, Comcast, Rogers in Canada. We designed their networks; we engineered them, we deployed them. They relied on us to make their networks better quality and to cover evermore things, if you will, add capacity, add quality, add coverage. I spent 10 years doing that and helping to build amazing teams of people that were the top in the industry.

After that, I was in the private equity industry for a bit, mainly looking for ways to invest in water technology because a driving passion of mine is to help to fix the water industry, the water system rather.

Louisa B-T: Where does that passion come from?

Matt Barnard: Well, there are a few things essential in life. I don’t know if there’s anything more essential than water. We need water, we need energy, we need food, we need caring human relationships. That’s about it. The water system is severely stressed, and it is one where due to some societal choices a century or two ago, we hide the cost of acquiring cleaning and delivering water to people. The cost isn’t associated with the price, or the price isn’t associated with the cost and, therefore, we’re kind of over consuming. I liken it to a batter that’s draining, where if you have a remote control car or any device powered by a battery, the battery is draining in the background, you don’t necessary know how fast it’s draining and how low it is because the car is still performing exactly as you would expect it to. Ultimately, at some point, it crosses a threshold, and it stops performing. Our water battery, the battery of our water system is severely drained, and we are in danger of crossing that threshold with the largest aquifer in North America slated to be dry in a couple of decades.

Louisa, it takes 1,000 years to replenish that aquifer. It’s under the Great Plains states, which are responsible for much of our cereal production; Texas, Oklahoma, Colorado, Nebraska, Kansas. It covers a massive area. There are now entire areas of Nebraska who can no longer access the Ogallala Aquifer to feed their wheat fields. We have some sirens going off, and I’m motivated to help them fight that.

Louisa B-T: Yeah, those are terrifying stats, but not statistics that everyone necessarily knows in the U.S or globally. Was there any particular reason that you kind of delved into looking at that. Did you have any personal experience with water shortages?

Matt Barnard: I started looking at what was happening in the water systems around the world, in part because of my interest because I grew up on a farm in Wisconsin. I was aware of what had happened on that farm going back a generation when people knew less about how their actions affected the quality and quantity of the water supply. I was already a bit aware of it. I started to look into it in my early 20’s. As I read more and more about it, first in publications like The Economist and then in grabbing books about it, whether the Cadillac Desert or there are now many books and documentaries on it understanding more and more of what’s happening around the world.

Louisa B-T: Yeah. I guess that sort of segues nicely into how and why, my next question is, why indoor ag? Bearing in mind your previous experience, but I presume that that passion for solving the water crisis played a role there?

Matt Barnard: Yes. After I spent that time looking for ways to help alleviate stress in the water systems, I then went back into large-scale technology systems around resources. I was brought in to help scale a company that did cellular smart grids, so these are large technology systems to help electrical, water, and gas utilities damp down and spread demand. After that is when I worked to found Plenty because it is a way for me to pursue my desire to help fix the water systems. Growing up on the farm in Wisconsin, I became keenly aware of the fact that I loved the food that we grew on our farm. I did not enjoy the food that we bought at the grocery store, particularly fresh produce. I loved fresh produce on the farm and not the stuff we bought at the store.

In fact, in Wisconsin, there are a lot of crops you can’t grow. The crops we couldn’t grow on the farm, I didn’t even understand why people liked them. I couldn’t figure it out. It wasn’t until I moved to California that I learned that a couple of thousand miles and a week in a truck has a way of destroying, what is otherwise, some amazing fresh produce. That, and then I’ve had a couple of health incidents in my life, and the life of my family that has caused me to really delve deep into how we eat affects how healthy we are and increases or decreases our risk for various terminal diseases. All of those things together; my experience with food on the farm, my desire to help fix the stresses of the water systems, and family experiences that caused me to dive into what we know about our diet and how it affects our health are all what led me here to Plenty.

Louisa B-T: Fast forwarding to today or to this year and the big $200 million round that you raised with SoftBank and others, can you maybe tell me a little about what drew SoftBank to you compared to other indoor ag groups? How do you think you differentiate yourselves? At this point, a lot of the focus is around growing leafy greens. I know that you guys are growing cucumbers and strawberries too. What’s the Plenty difference that has enabled you to attract these big investors with these global ambitions?

Matt Barnard: Well, there are a lot of large global investors around the world, many of whom are now invested in Plenty, that have been looking for ways to invest in this industry for a number of years. They had been looking at, “Hey, what are the economics of this business? What does it take to succeed? What does a team need to look like if we want to build a global brand?” They saw in us the foundation of a technology system that could grow amazing food that fits into the budgets of people around the world. They saw a great balanced team across a lot of areas of domain expertise and are very excited the vision of being able to solve for what they knew to be the secular trend that got them in the industry in the first place.

They were already aware that the agricultural capacity is declining both absolutely and on a per person basis around the world. They knew that four percent of the world’s population is consuming roughly 30 percent of the fruits and vegetables of the world, which means that 96 percent of the world’s population did not have access to fruits and vegetables in the way that they would like. They were aware of all those secular trends; persistently rising in labor and land costs. They were looking to find ways to solve for it. Those were some of the things that got us to this place.

Louisa B-T: It seems to me that the big challenge ahead for indoor agriculture is scaling and is your business model. As I mentioned, leafy greens seem to be the main area of focus, and that’s not going to provide the nutritional needs of the world. Can you talk a bit about how you’re going to get into other food products that can answer those urgent issues that you’ve mentioned? At this point, it still seems like it’s a lot of potential; when is the reality that you’re going to be getting this nutritional food into the hands of those people globally?

Matt Barnard: We have a lot of work to do. Building both a business and farms around the world does take a little bit of time. We are working on it quickly, but I think people at the end of the day, as they look back three, five, 10 years from now, they’re going to be stunned at the rate that which more and more people around the world have access to fresh fruits and vegetables and a nutrient-rich diet in a way that they do not in 2017. We are developing multiple farms, we have literally dozens of farms in different stages of development in different parts of the world right now. Several of those will open in 2018 and then the rest are slated for 2019 and beyond. We’re going to be working to get these farms out so that we can get food into the homes and hands and mouths of people as quickly as possible.

Louisa B-T: Just thinking about, you mentioned about the technology piece was something that was very appealing to investors and potentially a differentiator for you. You’re building some exciting stuff inside your vertical farms. I think I read somewhere that you have tiny seeding robots. Is that right? Is that technology that you’re actually developing in-house, or you’re working with other people on that?

Matt Barnard: We do seed in an automated way. That is technology that we have applied kind of wrapper that adapts it to what we do. The core of that is technology that was developed outside of Plenty. We are doing some very groundbreaking work in robotics to help get more food in the homes of more people. Not in seeding, it’s in other parts of the farming process.

Louisa B-T: How important is robotics and automation for indoor agriculture? Is it about a labor issue? I know it can be tough to find people to work in indoor farms that have the right expertise or is it about the precision aspect of it and avoiding any …

Matt Barnard: This isn’t actually an indoor agriculture problem, it’s a challenge for all of agriculture. As we look around the world, what we see is we see a global fruit and vegetable market of about 500 billion dollars. We think that if these crops were to be available to 7.3 billion people around the world, this would be a 2.5 trillion or three trillion dollar industry. We believe this to be an industry with a tremendous amount of suppressed demands. We view our job as getting more fresh fruits and vegetables into more people’s budgets, and automation is key to that because we actually have a better ability to do it inside than outside. It’s just much harder to make those processes automated when you’re outside.

Louisa B-T: That automation, I assume, is pretty essential for the business models to work? It sounds to me that there are some indoor farming groups that have really struggled with that cost component. That relates not just to labor, but also to electricity costs for lighting and so on. For making the business models work, that automation is pretty essential, is that right?

Matt Barnard: That’s right. Just like growing these crops outside, it’s essential to drive labor costs out and just as labor costs caused California strawberry industry out in the field to lose about 15% of its acreage last year because of labor costs, we deal with the same thing. We are working to find ways to get more of this into people’s homes.

Louisa B-T: Another challenge that we see, and I actually asked our CIO Michael Dean what he thought, he said that he had learned that fresh produce supply is very relationship driven with many relationships developed over decades and strong distribution networks in many markets between the producer and the retailer adds another level of complexity and a cost base for what is a low cost/high volume product for many of these crops. How do you plan to get over those challenges? If you have global plans to be in various different markets, it’s obviously going to be very different in each place that you go.

Matt Barnard: That’s right. It is. Growing a global business is very, very difficult. We’re very aware of that. It’s one of the reasons why we raised the financing we did so we could build the team necessary to do it. In order to feed the need of the people of Japan, and the people of China, and the people of Saudi Arabia, and the people of the UK and Ireland, and Canada, and all the people of the United States that we’re working to serve, you’re right, it absolutely requires a large team to be able to get this food out to as many people as possible. It’s one of the things that drove us to put that financing together.

Louisa B-T: Thinking about the venture capital investors from your earlier rounds, I’m wondering, if you’re raising $200 million at Series B, perhaps a Series C is going to be even bigger, how are those original VCs going to keep up with some of those larger, more mature investors? My question kind of feeds into how suitable is VC money for indoor agriculture, which is pretty infrastructural in its nature?

Matt Barnard: Sure. The answer to that question could stretch an hour, but I’m going to try to condense it into something that’s shorter because no one wants to listen to me talk for an hour. First of all, relative to our earlier stage investors and keeping up, they don’t necessarily expect to, they know that when a business that they invest in succeeds, that ultimately it’s going to move past them. Really, they want it to because what they know is that their capital is some of the most expensive investment funds on the Earth. For a company to keep using that means that really the company isn’t succeeding. The companies need to graduate out of that type of capital at some point in time. That’s one.

With respect to, “is venture capital appropriate”, it really just depends on the stage of the business. We expect in a few years to no longer be accessing that type of capital either. As you look at how infrastructure is built out around the world, once it is mature and proven over the course of years, people tend to use debt to finance the building of infrastructure in the financing of businesses. Just like field farmers raise a lot of financing from year to year from their banks in the form of debt, Plenty plans to finance the built out of its global finance network, or excuse me, global farm network. It all just depends on the size of the business, the stage of the business, and what’s the most appropriate of capital at each given point of the business. That answer changes over time, and if we’re successful, we absolutely won’t be accessing venture capital at some point in the future.

Louisa B-T: What is your ultimate route? What is the potential exit for your investors?

Matt Barnard: We’re focused not so much on that as we are in getting people the most amazing food that they have ever had, the best produce they’ve ever had, produce that’s better than ice cream, produce that’s better than chocolate, strawberries that are so amazing that people eat them before they get home from the grocery store and have to go back for a second trip. We’re focused on that, getting the people of the world more nutrient-rich food, fresh fruits and vegetables, and being able to live happier, healthier, longer lives. We’re working to build, to delight customers in that way as we work to build an amazing brand around lifestyle, health, food, and sustainability. Everything else will follow from that.

Louisa B-T: The focus is on building a stand-alone business at this point?

Matt Barnard: That’s right.

Louisa B-T: Looking ahead to next year, what can you tell us about what plans you have on the horizon? You mentioned that you have various different locations in development. The only ones we know about are obviously in California and in Seattle. Can you tell us, are they going to be based globally in Japan perhaps?

Matt Barnard: You will see us around the globe. We are not quite ready to talk about the specific market that we’re launching in. I’m going to be excited to talk to you about that very soon for a few of them, but we’re not releasing those yet. We do that in a very coordinated way. A farm launch [inaudible 00:22:43] is almost like a product launch, so we coordinate that with everyone involved there at launch. It ends up involving other companies and partners. We will be letting you know and there will be more farms in 2018. We will be an international company very soon.

Louisa B-T: Yeah, that’s great. Will you be opening up the farms to give us more of a sense of what technologies you’re building in-house or is that always going to be a little bit secretive?

Matt Barnard: You’ll find us not talking a lot about it in the next year or so, but as the years pass, we’re going to talk more and more about it. We’re actually at looking at building … We’re looking at some ways that we can bring the public in and show them how it is that we grow this food that’s so amazing that they can’t wait to have more of it.

What’s fun about working here at Plenty is that we have all of these different areas of domain expertise where we have people that are deep experts in computer science, and machine learning, and plant science, and farm operations, and mechanical engineering. It’s quite an exciting place to work just because of the richness of our team.

Louisa B-T: Yeah. It just seems to me that you’re going to have a lot of these indoor ag groups all building several systems from scratch when there’s probably a lot of knowledge out there that could be shared for the benefit of the industry overall. I’m just wondering when that kind of point will be that it will be more democratized some of this.

Matt Barnard: Yeah, we actually are already working on a plan to do this. I don’t expect it’s going to be in 2018, but I do expect it’s going to be sooner than people think.

Louisa B-T: Fabulous. What is your favorite fruit and vegetable? Just to finish off!

Matt Barnard: Out of a Plenty farm, I have to say our kale is stunning. One of my favorite quotes, and I’ve heard it in multiple ways because everybody has their own way of saying it, but people have our kale, and they say, “Gosh, you shouldn’t even call it kale because all I know is that I hate kale, but I love this.” It’s totally different, and there’s a little bit of sweetness to balance it out too, so it just has a much more balanced taste. It’s not tough and chewy; it’s velvety and soft. That’s a pretty exciting crop to me because we can make that super nutritious food. Instead of the food, you should eat, it’s the food that you can’t wait to eat.

We have kale. I love our strawberries. People are just going to be addicted to our strawberries. They’re going to have a hard time getting home from the grocery store without eating them all.

Louisa B-T: I can’t wait to try them. When will I be able to have my first taste?

Matt Barnard: You can come out to San Francisco and try them now, try the kale. We can probably arrange a tasting for you out of our Wyoming farm on the strawberries here in the next few months. In Seattle, you’ll be able to try some of these crops in Q2 of 2018. It’s happening soon.

Fluence Bioengineering Launches New Vertical Farming Lighting Solutions

Fluence Bioengineering Launches New Vertical Farming Lighting Solutions

Versatile, easy-to-deploy LED systems designed to increase plant density, yield, and quality while reducing installation and operating costs

Fluence RAZR4 LED Grow Light

The Fluence RAZR system not only creates an environment for improved growth and development of our microgreens, but allows us to run a commercial-scale vertical farm at a lower operating cost.

AUSTIN, TEXAS (PRWEB) NOVEMBER 30, 2017

Fluence Bioengineering, Inc. (“Fluence”) today launched three new horticulture lighting solutions designed for the world’s largest vertical farms. With a sleek form-factor, broad-spectrum, optimized light intensity, and world-class energy efficiency, the new Fluence RAZR Series is built for a wide range of vertical farming applications from full-cycle cultivation of leafy greens and microgreens, to young plant propagation of vegetable, ornamental and cannabis crops.

“The new Fluence RAZR solutions are purpose-built to address the unique challenges and opportunities associated with vertical farming,” said Randy Johnson, Co-Founder, and CTO at Fluence Bioengineering. “Every design consideration that went into the new RAZR Series, from the thin form-factor to modular daisy-chain configuration, is predicated on increasing our vertical farming customers’ outputs while reducing their inputs.”

Dense Vertical Farming

With a 1.5-inch thin form-factor, and a mounting height as close as five inches from the plant canopy, the Fluence RAZR Series delivers uniform photosynthetic photon flux density (PPFD) for maximum space-use efficiency and yield per square foot. With the ability to stack vertically in carts and shelving, or daisy-chain horizontally across racks and rolling tables, the new Fluence RAZR Series is built for quick and easy deployment to reduce installation time and material costs thanks to a one-to-many design which connects up to ten lighting modules to one power supply.

The RAZR4 Array is ideal for full-cycle leafy green, basil, strawberry and culinary herb production as well as early-stage vegetative growth for vegetables, ornamentals and cannabis cultivation with an average PPFD up to 375 µmol/m2/s over a 2-foot by 4-foot canopy with a 5-inch mounting height above the plant canopy. The RAZR4 Array includes five lighting modules, and covers 40 square-feet of the canopy.

The RAZR3 Array is ideal for full-cycle leafy green and microgreen production as well as

propagation of vegetable, ornamental and cannabis crops with an average PPFD up to 260 µmol/m2/s over a 2-foot by 4-foot area with an 8-inch mounting height above canopy. The RAZR3 Array includes seven lighting modules, and covers 56 square-feet of canopy.

The RAZR2 Array is ideal for tissue culture, seedlings and cutting/cloning propagation as well as ornamental plugs and starter pots with an average PPFD up to 160 µmol/m2/s over a 2-foot by 4-foot area with a 12-inch mounting height above canopy. The RAZR2 Array includes 10 lighting modules, and covers 80 square-feet of canopy.

Each RAZR lighting system is designed and built in Austin, Texas, USA with an anodized, extruded aluminum alloy chassis and integrated passive heatsink for natural convective thermal management (zero moving parts), and is ETL wet location rated to withstand the harshest of growing environments.

The new RAZR Series is available now. To learn more, visit http://fluence.science/razr

Proven Results in Vertical Farms

Edenworks is moving leafy green and microgreen production closer to consumption with their Brooklyn-based aquaponics vertical farm. Edenworks conducted a trial of several LED vendors, ultimately installing the latest Fluence RAZR3 system which enables Edenworks to add more layers of production per square foot while increasing plant quality and decreasing operating costs. To learn more, visit http://fluence.science/edenworks

“Vertical farming allows us to deliver the highest quality product possible at the lowest cost possible,” said Ben Silverman, Co-Founder and Chief Design Officer at Edenworks. “The Fluence RAZR system not only creates an environment for improved growth and development of our microgreens, but allows us to run a commercial-scale vertical farm at a lower operating cost.”

Farm.One grows hundreds of rare crop varieties for New York City’s finest restaurants out of their downtown Manhattan vertical farm. With a continual focus on improving plant flavor, texture and color, Farm.One tested numerous LED lights culminating in their decision to deploy Fluence RAZR solutions after seeing higher quality and yields. To learn more, visit http://fluence.science/farm-one

“We are constantly evaluating new forms of ag-tech to improve the production and bottom-line of our vertical farm,” said Robert Laing, CEO at Farm.One. “The Fluence RAZR system achieves both with a thin, easy-to-install form-factor which allows us to grow more product per square inch, and optimal light intensity, uniformity and spectrum to cultivate a high-quality crop that exceeds our customers’ expectations.”

About Fluence Bioengineering

Fluence Bioengineering is a photobiology design company exploring physiological plant development under various levels of photosynthetically active radiation and custom spectra. The company partners with leading research institutions to engineer the most powerful and efficient horticulture lighting solutions for both science and commercial applications. All Fluence systems are designed and built in Austin, TX. https://fluence.science/

How To Build A Successful Vertical Farm

How To Build A Successful Vertical Farm

The interest in growing plants indoors in vertical farms keeps increasing. But many investors who thought they could simply buy an empty warehouse, plug in some grow lights and turn out perfect heads of lettuce to make money have been disappointed. Here are a few key lessons learned from city farming expert Roel Janssen on successful vertical farm projects.

Part 1: Getting the climate, lighting and spacing right

The most crucial part when starting an indoor farm is to have a grower that understands how to grow plants indoors. New (sensor) technologies and the internet of things offer great opportunities for indoor farming, but if you don’t have a grower you will not get out the most of your operation. You can have great packaging and attractive marketing tools, but the product itself will determine your success. That being said; these are some of the most important factors that can determine the success or failure of your vertical farm investment:

- Crop selection

- Lighting selection and design-in

- Airflow design and climate control

- Spacing strategies for plants

- Crop logistics and automation

- Irrigation and nutrition

- Data, sensors, control and software

- Substrate choice

- Target audience and sales channel

When we look at how to get the highest return on an investment for a vertical farm, we focus a lot of attention on creating a facility that allows you to produce the highest yield of crops (measured in grams) using the most ideal amount of light (measured in moles or mol). That’s because your LED grow lights are amongst the highest expenses in terms of the city farming infrastructure and operation. Keeping that in mind, here are a few of our most valuable tips for increasing your grams per mol. The information is gathered from research done at the Philips GrowWise Center as well as commercial projects ranging from US, Japan to Europe.

Step 1: Get the climate right

One aspect that many new vertical farm growers overlook when they are creating an indoor farming environment is maintaining the best climate conditions. If we assume 50% of the electrical input power is converted into light, the remaining 50% is converted directly into heat. A proper airflow can remove this direct heat, but also the light that will be absorbed by the crop will indirectly be converted into heat. Typically the crop evaporates water into the air to get rid of this heat, therefore this process will result in a higher humidity of the air. To keep increasing humidity and temperature under control, you must start with a good ventilation and air handling system in your vertical farm. Not installing a proper climate control and air handling system will decrease your yields, resulting in additional costs and hassle after installation to fix inefficiencies.

Step 2: Get the lighting right

Once you have a good climate, how can you get the highest yields from it? We have done hundreds of research projects on growing plants indoor focusing on yield and the most optimal light intensity for a certain crop or variety. Yield however is not always the most crucial and single most important part. Let’s take red oak lettuce as an example. When this lettuce is grown outside in a field, it turns red because it is stressed by the sun or large temperature changes and it typically yields less compared to its’ green version. When the same variety is grown indoors, it remains mostly green because there is no UV light, but it does develop fast and shows comparable or sometimes even better growth than a green version. At Philips Lighting’s GrowWise Center, we have four full-time plant specialists who develop so-called light and growth recipes for specific crops. Based on their research, we developed a coloration light recipe for red oak lettuce that turns a mostly green head of red oak lettuce into a dark red lettuce in just three days. Growers can grow a large head of lettuce in their regular growth cycle, apply this light recipe as a pre-harvest treatment, and get a great quality crop with much higher yields and the proper appearance. Together with breeding companies we screen and help them develop varieties that could support growers to help them differentiate even more based on taste, quality or color.

Step 3: Get the spacing right

The spacing strategy you use when growing plants indoors is another way to improve your grams/ mol. You want to space plants so that each one gets an optimal amount of light and you are lighting the plants instead of the shelves they are on. Knowing the ideal spacing strategy can avoid you having to invest in spacing robots because you can check the extra yield spacing plants delivers compared to the investment needed for automation of this strategy. For our vertical farm projects, we can contribute to your business calculations with advice on the best spacing and light recipe to use for each crop. Based on that information you can decide if manual spacing or spacing robots are the most cost-efficient choice for your facility. Next to that our cooperation with the leading breeders in the industry will enable you to pick the right variety for your crop specific requirements.

In the next blog, we will discuss more crucial starting points to boost your chance of success in a vertical farm.

Roel Janssen is the Global Director City Farming at Philips Lighting. With a background in business administration, Roel has 8 years of experience in vertical farming. Roel has led the implementation of two Philips City Farming facilities – GrowWise and BrightBox and currently oversees all activities in the City Farming group. Next to his work at Philips Lighting, Roel is a guest lecturer for courses on vertical farms and growing without daylight at universities and other organizations.

Plenty Farms: Our Mission Explained And Explored

Plenty’s mission began in 2014 when its founders conducted an in-depth study of industrial agriculture. Their conclusion: While traditional agriculture has the ability to feed lots of people, producing large volumes of food cheaply comes at quite a cost.

Plenty is a new kind of farm for a new kind of world. We’re an indoor farming company comprised of passionate people determined to solve systemic problems in our food system.

At Plenty, we’re on a mission to transform produce from a bland commodity to a delicious movement.

But what does that mean? And why are we so deeply invested in bringing this mission to life in local communities around the world?

From a bland commodity

Plenty’s mission began in 2014 when its founders conducted an in-depth study of industrial agriculture. Their conclusion: While traditional agriculture has the ability to feed lots of people, producing large volumes of food cheaply comes at quite a cost.

Most produce is involved in a long, inefficient distribution dance. This journey results in waste, countless miles of transportation, and has changed the very makeup of the food we eat.

Crops are bred, grown, and packaged to increase the shelf life – not to create great flavor and better nutrition. Think: tasteless iceberg lettuce, watery beefsteak tomatoes, or mealy apples.

Agriculture has developed to solve for year-round produce availability, but it’s come at the expense of loss in variety, nutritional value, and perhaps most importantly, taste and freshness.

Plenty’s founders decided to envision a different food system, one optimized for unparalleled taste and experience rather than anything else. And that’s what we’re bringing to life in every farm we build.

To a delicious movement

We know that produce can be so much more than a bland commodity, and that’s why we are committed to expanding the availability of quality, delicious produce.

We also know that solving for the deficits in the current food supply and distribution systems is a complex undertaking.

The good news is that millions of people want what we want and together, we can can build a better system. In three steps, here’s how we plan to do it:

1. Remove waste from almost every step in the supply chain to grow produce that is more flavorful and fresher than it has been in years. This will result in deeper enjoyment and satisfaction in every bite.

2. Build farms near you. We’re bringing back local farming that meets communities where they are, so you don’t have to settle for underwhelming produce that’s traveled hundreds, or even thousands, of miles.

3. Use 1% of the water, a fraction of the land, and zero pesticides, synthetic fertilizers, or GMOs. This allows us to grow produce as a force for responsibility and enjoyment so that you can feel confident that your mouth watering meals are driven by responsible farming practices.

Plenty is produce with purpose and we’re reimagining farming for a more responsible, better-tasting future.

Why this mission matters

In the last 125 years, we’ve added six billion people to the planet and are currently running out of land where it’s economical to grow crops. Simply put, we need innovative ways to meet the ever-growing demand for fresh fruit and vegetables.

Just like the world needed the steel plow and the tractor, new and sophisticated agricultural systems are what we need if we want to continue to feed the 7 billion people currently on the planet (8.5 billion by 2030).

Our goal is to give people more delicious produce, while at the same time building a future of farming that can produce food that’s healthier and more convenient.

Join us to create a better food system

Plenty is committed to helping people living healthier, happier, and more abundant lives. We know that food can inspire joy.

We also believe in doing what’s best for the planet and promise to offer the most enjoyable produce specifically grown to delight and inspire you. But we can’t do this alone.

Will you join us in helping to transform produce from a bland commodity into a delicious movement?

If you’re down for the cause, please follow us. With your help and support, we will bring this real food revolution to life!

Pure Harvest Rakes In $4.5 Million

Pure Harvest Rakes In $4.5 Million

- November 16, 2017 | ABU DHABI

- By Iris Dorbian

Abu Dhabi-based Pure Harvest Smart Farms, an arid climate agribusiness, has raised $4.5 million in funding. Shorooq Investments was the lead investor.

Pure Harvest Smart Farms (Pure Harvest or the Company), a tech-enabled arid climate agribusiness based in Abu Dhabi in the United Arab Emirates, announced today a historic Seed investment of USD $4.5 million in a financing round that was significantly oversubscribed. This follows an earlier USD $1.1 million pre-Seed round led by Abu Dhabi-based Shorooq Investments. Venture financing was provided by a leading federal government-backed fund, the Company’s technology partners, and a consortium of angel investors from around the world, all of whom were strongly aligned with the Company’s mission—to offer a true & tangible food security solution to the region by deploying advanced and sustainable controlled-environment agriculture technologies in order to grow premium quality local fresh fruits & vegetables year-round; overcoming the region’s harsh, arid climate and increasingly scarce freshwater resources.

Proceeds from the financing will be used to fund the construction of Pure Harvest’s inaugural high-tech, fully climate controlled greenhouse facility in Nahel, United Arab Emirates. The Company expects to complete the facility by mid-year and to begin selling its products in the second half of 2018. Following the demonstration of its technology and its ability to serve the fast-growing demand for fresh local produce, Pure Harvest intends to quickly expand in the region, recognizing that other GCC countries are facing the same challenges that the UAE faces with regards to import-dependence, water shortages, and climate-driven production constraints.

Pure Harvest also announced the appointment of a new Advisor and Kingdom of Saudi Arabia (KSA) Local Partner, Sultan bin Khalid Al Saud. “Sultan is a fellow Stanford Graduate School of Business alumnus and is a trusted advisor who brings a wealth of experience to the Company, having worked for Saudi Aramco, McKinsey, and Passport Capital. He will be working closely with the Company to enable near-term expansion into the attractive Saudi market,” said Sky Kurtz, Co-Founder & CEO of Pure Harvest. “We are extremely pleased to welcome Sultan to our family.”

A member of the Pure Harvest board and a participant in both the pre-Seed and Seed rounds, David Scott, who is also a well-known economic and strategy advisor to regional governments and state-owned enterprises, emphasized the impact that Pure Harvest could have on several pressing regional challenges. “Pure Harvest’s tech-enabled approach to arid climate agriculture and its strong project team offer a realistic and much-needed solution for improving food security across the Gulf, as well as a means not just to maintain domestic agriculture, but to profitably expand it – all while preserving the region’s precious remaining fresh water aquifers. Ultimately, I see this kind of sustainable domestic agriculture as a critical component of any successful post-oil diversification strategy and I’m excited to be a part of this effort,” said Mr. Scott.

Commenting on the successful conclusion of the Seed round, Mr. Kurtz said: “This financing is an important milestone for the Company. We now have sufficient capital to deploy our solution on a commercial scale and to demonstrate to our many stakeholders a future where high quality, sustainably grown, fresh local produce can be abundantly available every single day… and at a lower cost & environmental impact than current imports. We are humbled that such an esteemed group of investors, advisors & partners share our vision and are willing to back us to transform food production in the Middle East.”

“Shorooq Investments is thrilled to see Pure Harvest closing the largest Seed financing to-date in the MENA region. When evaluating investment opportunities, we try to think from a broader regional & macro perspective and to create a positive social impact,” said Mahmoud Adi, Co-Founder at Pure Harvest and the Founding Partner of Shorooq Investments. “With Pure Harvest, we hope to address food security concerns and to take a giant step forward to be less dependent on international imports for fresh produce, which will directly contribute to the UAE’s long-term sustainability. We are proud to have backed this important venture since its inception and to support the strong founding team whom we believe has the right capabilities and core values to succeed”.

In addition to receiving investment from Shorooq Investments, Mr. Scott and Sultan bin Khalid, Pure Harvest is backed by the following (non-exhaustive) list of visionary Angel investors: Magnus Olsson, Founder and Managing Director of Careem; Hazem Abu Khalaf, CFA, Director at The Abraaj Group; Jim Finnigan, Co-Founder of SoFi; Peter Satow, Founder & CEO of PESA Advanced Hydroponics; Abdulrahman Kaki; Anmol Budhraja, Founder and CEO and Arnab Chatterjee, Managing Director of Three Comma Financial Consultancy; Charles Anderson, Founder & CEO of Currency; Florian Weidinger, Fund Manager at NESTOR Far East Fund; Douglas Kelbaugh FAIA, Professor and former dean at the University of Michigan’s Taubman College of Architecture and Urban Planning; Mohammed Khudairi, Managing Partner of Khudairi Group; Troels Andersen, CEO of Mondo Ride; Husam and Muhammed Al Zubair of The Zubair Corporation; Bina Khan and James Joy, Co-Founders and Managing Partners of Summit Venture Partners; Edmund Ang, CFA, Vice President at First Energy Bank; and Theodore Cleary, Director at Crito Capital, among others.

About Pure Harvest

Pure Harvest Smart Farms (“Pure Harvest” or the “Company”) is a regional innovator in sustainable agriculture focused on the production of premium quality fruits & vegetables in the extreme climates of the Arab Gulf region, using world-leading high-tech, climate controlled greenhouse production technology to deliver vine crops (tomatoes, capsicum, strawberries, cucumbers, eggplants, etc.). The Company will soon deploy a wider portfolio of best-in-class controlled-environment agriculture technologies (e.g. vertical farms, container-based growing solutions) to deliver a wide variety of fresh produce. Pure Harvest seeks to leverage innovative technology solutions to pioneer year-round production of affordable, premium quality fresh produce. In recognition of regional vulnerabilities associated with water scarcity, food import dependence, and sustainability, Pure Harvest is committed to resource efficiency and overcoming climate challenges to deliver European standards to customers with always-available, high quality, farm-to-fork products.

US Businesses Making Farming Technologies for Cities

Cam MacKugler waters a seedsheet at the Food Loves Tech event in Brooklyn, Nov. 3, 2017. (T. Trinh/VOA)

US Businesses Making Farming Technologies for Cities

November 25, 2017

How do you get the freshest, locally grown fruits and vegetables in a big city?

For an increasing number of Americans, the answer is to grow the fruits and vegetables themselves.

Businessman Cam MacKugler can help. He is the founder and chief executive officer of Seedsheet.

MacKugler was at the Food Loves Tech event in Brooklyn, New York, earlier this month. He was showing off Seedsheet products, which are for people who live in high-rise buildings or other homes with little space for growing plants.

Seedsheet products come with fabric sheets and small pods, each filled with a mix of seeds and soil. The fabric is placed on top of dirt in a home planter or in the ground. When watered, the pods soften and eventually break up as the plants start to grow.

The seed groupings on any given Seedsheet provide vegetables or herbs for salads and other meals. Pricing starts at $15 for the factory-made sheets. But you can spend up to $100 for a larger, made-to-order outdoor covering measuring 1.2 by 2.4 meters.

Efforts like Seedsheet come as Americans increasingly want to know where their food comes from. Many are looking for socially and environmentally responsible growing methods.

MacKugler told VOA that most of the company’s sales come from young people living in cities.

American consumers are not giving up on the low cost and ease of packaged and prepared foods. But new products and technologies are playing a part in helping Americans understand where their food comes from.

“Consumer education is really progressing,” said Nicole Baum of Gotham Greens, a grower of hydroponically grown produce.

Baum said consumers were less familiar with the term “hydroponics” -- growing plants in water instead of soil -- when Gotham Greens first started in 2011. But more and more Americans have since heard about this form of agriculture.

Baum said she has also seen an increase in competing companies.

“We’re definitely seeing a lot more people within the space from when we first started, which is awesome,” she said. “I think it’s really great that other people are coming into the space and looking for ways to use technology to have more productive, efficient growth.”

Gotham Greens provides leafy greens and herbs grown on buildings to supermarkets and top-rated New York restaurants like Gramercy Tavern.

Companies like Smallhold also advertised their services at the Food Loves Tech event. Smallhold manufactures mini-farms – small, self-contained structures -- for growing mushrooms. The mushroom mini-farms are meant to be used in restaurants, not homes.

Smallhold sets up the devices and services them at restaurants, with restaurant workers harvesting mushrooms when they are ready. Hannah Shufro, operations lead at Smallhold, said the mini-farms help cut down on pollution that comes with transporting and shipping produce.

Shufro also noted that produce begins to lose its nutritional value right from the time it is harvested.

"When you’re harvesting food right out of a system that’s growing onsite, it does not get fresher than that, she said.”

I’m Susan Shand

Tina Trinh reported this story for VOANews.com. George Grow adapted her report for Learning English. Ashley Thompson was the editor.

A Beginner’s Guide to Vertical Farming

Also known as indoor farming, vertical farming has in recent years gained recognition as a solid method of sustainability. The system was born out of the challenges affecting the 21st century, specifically issues like food shortage, resource depletion, and overpopulation.

A Beginner’s Guide to Vertical Farming

November 28, 2017

Written by Claudia Beck

Also known as indoor farming, vertical farming has in recent years gained recognition as a solid method of sustainability. The system was born out of the challenges affecting the 21st century, specifically issues like food shortage, resource depletion, and overpopulation.

Feeding the future: vertical farming

Vertical farming is the practice of food production that takes the form of vertically stacked layers and vertically inclined surfaces. The method is executed inside a controlled environment building, usually without soil or natural light.

The method of growing the crops in a vertical farm involves the following elements.

• Temperature control

• Humidity control

• Artificial lighting

• Control and monitoring of nutrients and fertiliser

When undertaking vertical agriculture as a small to medium business, planning is essential. You need to ensure that you can sell what you grow, and that your production costs are not too high. The first step to ensuring this, therefore, is picking the right crops.

The aspiring vertical farmer needs to conduct a feasibility study and come up with a profitable and sustainable plan. This is because each species you plan to grow will have a growing method tailored to its needs. Determining the daily nutrient and light uptake each crop requires is crucial.

Animated GIF credit: Lizzie Lomax

The indoor farm represents significant benefits to the consumer as it increases food accessibility. Because farms can be located anywhere, more people can start growing their own crops. Production then moves closer to the consumer, and farms are able to produce consistent value and volume year-wide. Currently, building-based and shipping container vertical farms are the most common.

How does indoor farming work?

There are several key factors that determine the viability of a vertical farm.

1. Physical layout

The objective of indoor farming is to maximise volume. This is achieved by maximising the output efficiency per square meter, which is where the vertical tower structure comes from.

2. Lighting

Image credit: Business Wire

Optimising light for crop growth in vertical agriculture usually involves a mixture of grow lights and natural light. Specialised technologies like rotating beds increase the efficiency of the light sources and can fulfil different crop requirements.

3. Growing medium

There are three different models for the indoor agriculture system.

A. Hydroponics

In hydroponics, crops grow in the nutrient-rich water basin and water is recirculated, creating better efficiency and lower water consumption. Scalable in size and cost, hydroponic farming is highly adaptable to its farmers’ production goals and needs. It includes methods like Drip Irrigation, Deep Water Culture, Ebb and Flow, Nutrient Film Technique, and the Wick System.

B. Aeroponics

Image credit: Foundation Far

Aeroponic farming involves frequently spraying crops with a nutrient-based mist, using a periodic timer (no soil, sunlight, or water). Aeroponics delivers nutrients directly to the plant roots to conserve water and reduce intensive labour. Scalability is another massive benefit with this method, and crops are easily harvested without soil.

C. Aquaponics

A closed-loop food production system, aquaponics is the practice of cultivating both fish and plants. The fish provide nutrients and beneficial bacteria to the plants,which in turn filter the water for the fish. Aquaponic farming creates a highly productive and balanced ecosystem with many benefits, including its water-conservative approach.

4. Sustainability features

Image credit: Cleanroom News

Many built-in sustainable features like rainwater tanks, wind turbines, and multipurpose spaces can offset energy costs in a vertical farm. Indoor farminguses less water than conventional farming practices and is not season-dependent for seed growth, which maximises revenue year-round.

What can you grow in your vertical farm?

With the right hydroponic, aeroponic, or aquaponic farm set-up, you can grow almost anything. Just because you can do so, however, doesn’t mean you should. Consider the following aspects when choosing the best crops for your vertical farm.

1. Economic viability

Especially if you’re growing for profit, study the economics of the species you have shortlisted for your indoor farm.

A. Demand

What is the demand for this crop within your area or within the market you choose to serve? You may decide that your project will provide for your family as well as for your local community.

B. Growing technique

Though vertical farming methods mean lower overheads on average, the size and particular system you use dictates your short and long-term production costs. You’ll want to keep these figures as minimal as possible.

C. Climate

Different systems have climate requirements (heating, cooling, and lighting) that may necessitate another sectioned-off space. Consider if you have the room and operations budget for your chosen system design.

As a grower, striking a balance between these elements ensures maximum yield and value out of your indoor farm.

2. Timing and liability

All good things take time—patience is a necessary element of indoor agriculture. This truth is embodied in what is called in farming as a ‘turn.’ A turn is the total amount of time it takes to introduce a seed or seedling into the farm system, grow it, and harvest it as a mature plant, for sale at the market or serving on your plate.

There are two types of crops you can choose to grow: fast turn crops and slow turn crops. Dependent on your growing reason, needs, and requirements, you can pick either one or both for your vertical farm.

Image credit: Forbes

Fast turn crops include lettuce, cabbage, chard, collard greens, mustard greens, parsley, cilantro, mint, chives, basil, and various microgreens. They usually take up to six weeks to produce.

Slow turn crops are typically harder to grow, but have a higher revenue margin compared to leafy greens. This includes ‘woody’ herbs like oregano and rosemary, and fruiting crops like strawberry and tomato. A good guide to follow for a beginner grower is to plant 80 percent greens, and 20 percent herbs.

Vertical agriculture: from farm to fork, all under one roof

Vertical farming can be as small or as large in scale—it all depends on the farmer’s goals and requirements! A vertical farm can benefit both your home and business, providing your community with reliable access to fresh produce.

While the traditional block of land enabled families to grow their own food, block sizes have gotten increasingly smaller throughout the decades.

Luckily, indoor farming lets us grow crops with a fraction of the space, sun, soil, and water conventional farming uses. What’s more, vertical farms are protected from the harsh weather brought about by climate change. The result? Robust and resilient crops turning up whenever needed, grown in soil and water-conservative, stable crop systems.

Title image courtesy of Digital Trends

Why LED Lighting is Ideal For Indoor Farming

According to data from National Geographic, the sun radiates enough energy in 15 minutes to equal energy consumption of the entire world for ONE YEAR.

Why LED Lighting is Ideal For Indoor Farming

According to data from National Geographic, the sun radiates enough energy in 15 minutes to equal energy consumption of the entire world for ONE YEAR.

The sun is so powerful that it was worshiped by ancient cultures.

So how is it possible to have lighting for growing plants indoor that is actually more efficient than the sun?

And why is it often a shade of purple???

Why is LED lighting is ideal for indoor growing?

Ancient cultures worshiped the sun due to its life giving power (source)

The idea that plants need exposure to daylight for perfect growing conditions has persisted during the sustained growth of indoor farming in the past several decades.

But, as numerous researchers (and an increasingly large amount of growers) have realized, the concept of sunlight as a necessity is, in fact, a flat out myth.

Why?

Read on to find the step-by-step explanation for how LED lighting is revolutionizing indoor growing, and more!

In the rest of the article we will discuss:

1) Why Purple (a.k.a. blue-red LEDs?

2) LED Lighting vs Daylight

3) PROS and CONS of LED Grow Lights

Ready?

Let's get started!

Why Purple (a.k.a. blue-red) LEDs?

The technical answer, in a nutshell, is related to the spectrum of color present in different types of light. While good 'ol sunlight contains a variety of color spectra (think rainbows), it turns out that plants only need specific color spectra to grow properly.

What colors work best?

According to urban farming research on the way plants respond to light, the blue-red spectra is ideal for plant growth.

The reason for this is because chlorophyll, which plays a central role in plant growth and photosynthesis, responds primarily to "peak" spectra in the blue and red ranges, or 450 nanometer and 650 nanometer wave lengths respectively.

Some research has also experimented with using other forms of light in urban agriculture growing settings, often yellow LED spectra, to alter plant traits such as color, texture, and increased shelf life.

With a consumer base increasingly enamored by rare and interesting varieties of common fruits and vegetables, concepts such as red or yellow carrots can be marked up as exotic items or at the very least add some extra zest for small-scale urban farmer.

Plant growth does not require the full spectra present in daylight (via Illumitex)

LED Lighting vs Daylight

Sunlight, in fact, is inefficient in many ways when it comes to optimizing small-scale, urban agriculture.

For one, the heat generated by the sun can be damaging to plants and can have an adverse effect on shelf life immediately post harvest.

This "heat effect" caused by sunlight is even further amplified when the plants are closely packed, as is often the case in urban farming.

In contrast to sunlight, LED lights are known for transferring nearly undetectable amounts of heat onto plants, and the bulbs themselves are even often cool to the touch. The result?

Urban farms with LED lighting can have more closely packed arrangements for maximum efficiency. These arrangements would not be possible in normal agricultural environments without compromising the health of the plants.

Besides the decreased heat transfer, LED lighting is a cheaper alternative to traditional lighting sources that emulate daylight conditions.

Although there is often a higher upfront cost with LED lighting, the best way to view the cost-savings of LED lighting for urban farming is as a long-term investment.

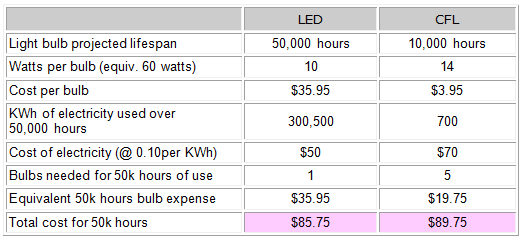

This is because LED lighting has a much higher energy efficiency over time compared to other urban farming lighting technologies such as halogen or compact fluorescent (CFL).

As a quantitative example, average CFL lighting options on the market will have approximately 1/3 the lifespan of LED lighting options, with similar lighting strengths (Look for 12-16 W / 800-1000 Lumens)

Plants, due to the presence of chlorophyll necessary for photosynthesis, respond mainly to red and blue color spectra (via NPR)

Pros and Cons of LED Grow Lights

PROS

1) LED's use WAY less electricity:

Most LED grow lights use 40% - 50% of the wattage of other lighting sources, like high pressure sodium lights or fluorescent.

2) Less airflow needed

It is a simple fact that for indoor growing, proper ventilation is required.

According to this post from Epic Gardening, ventilation for indoor growing helps prevent at least:

- Excess Moisture

- Proliferation of Pests

- Weakening of Plant Stems

Now, can you guess the #1 cause of heat in an indoor growing environment?

That's right: Grow lights.

But here's the catch:

LEDs generate far less heat than all other types of grow lights. As a result, less ventilation is needed to prevent excess moisture, pest problems, and other ventilation related issues.

From an economic perspective, smaller fans cost less than larger fans, so your ventilation investment requirement with LED grow lights will typically be lower than with other types of grow lights.

Additionally, the on-going electricity cost of powering fans is also eliminated.

3) Less Heat

As we have already discussed above (#2), LEDs generate far less heat than other grow lights.

Now, the reason why LED's generate less heat is because they emit far less infrared heat as output.

Other types of grow lights like high pressure sodium and metal halide grow lights emit enormous amounts of infrared heat - over half of the wattage that powers an HPS or MH light is instantly lost as heat.

Bottom line?

LEDs are far more efficient and produce far less heat.

4) EXTREMELY long life

LED's grow lights are as close to immortal as grow lights get:

They typically have at least 50,000 hours of usable life, which is nearly 6 years of continuous use.

If you are utilizing the lights on a 50% on /50% off schedule (common benchmark), this is over 11 years of shelf life.

5) No need to purchase reflector equipment to improve efficiency

HPS/MH systems often require use reflectors to help re-capture light that was not directed toward plants and instead illuminates walls and ceiling.

LED's have superb directional focus and therefore reflectors are not necessary.

6) Stackability

Because LED's have so much lower heat emission, they can be placed closer to the plants.

The result of this is that the ability to "stack" plants in a growing space is possible.

This is potentially the most exciting benefit of using LEDs: the potential to double the production output (or triple, or 4x, etc) without changing the area of the growing space.

Now, one consideration to remember is that the height of the growing space is a factor.

However, this type of stacking functionality is just not doable with other types of grow lights.

Cons

1) Upfront Cost

LED's will commonly be at least 2x more expensive then many other types of grow lights.

The return on investment may pay off over time with less energy use, replacement cost, and less investment in other previously needed equipment like fans and reflectors.

See how the economics compare with the case study from Diffen above.

2) Heavy

The component of an LED grow light that makes it heavy is the heat sink, which helps absorb excess generated heat.

As a rule of thumb, a quality LED grow light will have 10 square inches of heat sink space per LED watt.

If you do the math, you will see that this heat sink space adds up VERY quickly and adds a lot of weight.

The result of this is that investment to support the weight of LED grow lights is often a good idea, *especially* if you are stacking layers into a vertical farming stylesystem.

3) Technology Still Developing

As far as commercial indoor growing, LED technologies have not been around for very long (less than 10 years).

Previously lighting methods have included High Pressure Sodium and Metal Halidelighting.

One risk with LED lights is that they are understood less thoroughly than other types of grow lights, which have been studied for several decades.

What does this mean?

Essentially, the support and knowledge base for LED grow lights is far more limited than other types of grow lights.

However, where there is a knowledge gap, there is also opportunity...

4) "Purple" Color

The purplish color that most LED grow lights will generate can be problematic beyond just being annoying:

How?

This color of lighting presents a couple real challenges that can become huge problems:

- Pest damage is harder to identify with LED grow lights

- Nutritional deficiencies, such as yellow under-nourishment and black rot, are more difficult to identify

- Potential danger to YOUR eyes without proper protection. As detailed in this article from Electronics Weekly, the potential to damage your vision with LED lights is very real, and protective eyeware is best practice

Solution: Inspecting plants being grown with LED grow lights is best done using an alternate source of light, such as a fluorescent bar. Most commercial LED operations will inspect plants with fluorescent lights at least once every 10 days.

In Summary

So, why does all of this information matter? In an urban farming environment where space and resources may be limited, optimizing lighting will often be a winning strategy for best urban farming results.

- Red and Blue light (purple when combined) are optimal for plant growth in tightly packed, urban farming style conditions

- LED lighting has several advantages over daylight or other lighting alternatives, such as cheaper pricing over time and reduced heat transferred onto plants

- Experimentation with other color spectra with LEDs such as Yellow LEDs can cause changes in urban farming crop flavor, color, and other aesthetic characteristics.

- There are many pros and cons to using LED grow lights. In general, LEDs are far more efficient than other types of grow lights in many aspects, however they are more expensive and still relatively new as far as large scale commercial use goes.

Questions, comments, feedback? Follow us @urbanvineco

This Small Pennsylvania Region Produces Half The Mushroom Crop in The U.S.

A small Pennsylvania region is the largest producer in the world of fresh mushrooms. Photo by Flickr user Chris Goldberg

This Small Pennsylvania Region Produces Half The Mushroom Crop in The U.S.

Nation | Nov 11, 2017

In a small section of Pennsylvania, indoor farms are producing more than a million pounds of mushrooms every day.

Farmers in Chester County, Pennsylvania, have been producing mushrooms since the late 1800s when several local Quakers decided to grow them in the space underneath their flowerbeds, NPR reported in 2012, citing local lore.

Today, the industry generates hundreds of millions of dollars in sales each year for Chester County, which has also held a yearly mushroom festival for more than 30 years. The area’s commercial mushroom farms grow them indoors, which allows them to carefully control the environment and maximize production.

Recently, indoor farming — a model that commercial mushroom producers have used for decades — has drawn more attention as an approach to sustainable food production. Michael Guttman, director of the sustainable development office for Kennett Township, Pennsylvania, spoke with the PBS NewsHour Weekend about the area’s mushroom heritage and the lessons that mushroom production offers for other farmers.

Tell me about Kennett Township. How many people live and work here, and what do they produce?

Kennett Township is one of several municipalities in the immediate area that’s in the mushroom industry. We have about 9,000 people. Kennett Square, which is closely aligned with us, has about another 6,000.

We’re the largest producer in the world of fresh mushrooms. And we not only produce but pack and ship all across North America, with delivery typically within 48 hours. That’s about a half a billion pounds of mushrooms a year. And that represents about 50 percent of the U.S. mushroom crop.

So is all of that produce grown indoors?

All mushrooms grown commercially are grown indoors. It’s not possible to produce mushrooms in commercial quantities without completely controlling the environment.

How has indoor mushroom farming changed over the years? Has there been any advancements in technology that have impacted the way you grow?

Of course. So in the beginning, it wasn’t possible to grow mushrooms in the summer, because it was too hot. Mushrooms generate a lot of heat. And so if you’re growing them indoors, you have to keep them cool. So — advancements — first, it was cooled with ice. And then of course refrigeration came in. So that was a major change.

Another, probably more fundamental change was that originally, mushrooms were grown and canned. And there were some canning operations that continued until even into the 21st century. But by and large, we switched over to fresh mushrooms probably by the 1970s or ’80s. Because the canned mushroom market became very competitive. You can can mushrooms anywhere in the world and distribute them. But if you want to deliver them fresh to the U.S. market, you have to deliver them immediately, and obviously quickly.

What are you doing to attract new farming ventures to Kennett Township?

We already control about 50 percent of the production in the United States, and another 15 percent are nearby. So there’s not a lot of growth in that market for us. We’re the top producer in part because we have the lowest cost. But there’s a limit to how much more of the market we can take that way.

So it’s very attractive to us to consider bringing in other crops. But until recently, that just wasn’t economically feasible. So the new developments in what we call green indoor agriculture, mainly new forms of lighting, new forms of computer control, and irrigation and so forth — those make it possible now to grow competitive green products. And that would be very interesting to us, because they would use much of the same infrastructure that we have.

How is that a benefit to an incoming producer?

Well, one of the problems that people have in the green indoor agriculture industry today is reaching the levels of production that allow them to have the price point to be competitive with field-grown crops from areas like California, Mexico, Chile, etc.

In order to get to those costs, they have to ramp their production up to a level where their next problem is distribution. So if they come into a community like us, we can solve two classes of problems for them. One is, when they come to construct their facilities, we know that game and we play that very well. So our utilities understand it. Our rules and regulations are organized around that. And we have services here to help construct those facilities.

But particularly when they wanna distribute, we’re already distributing to exactly the same market, the same produce market, that they wanna get into. We’ve been doing it for a hundred years, and certainly in the fresh market for the last 50 or 60. We have all of those relationships, and we have all the facilities to handle that produce and get it to market within 48 hours.

Chester County in Pennsylvania controls about 50 percent of the country’s mushroom production. The Photo by Flickr user Adam Fagan.

What do you see as some of the challenges facing indoor growers that newcomers to the field might not be aware of?

I think that the biggest emphasis in green indoor agriculture as it’s developed over the last decade or so has been coming up with economical growing techniques to reach the price point where they can compete with field crops. So for the last decade or so, the green indoor agriculture industry has been working on developing efficient techniques of growing that can compete with field crops. But they haven’t given a lot of thought to what happens when they actually produce those things in quantities.

So I think their biggest challenge is to be able to both produce in large quantities and get that distributed. So several companies I’ve talked to have actually cancelled projects because they couldn’t figure out if they grew that much, how they would distribute it.

Are there any newer innovations that have changed the way indoor mushroom farming looks like here in Kennett?

There’s a lot of technology, most of it developed in Europe, to better automate or semi-automate production. So here in Kennett, because we have such a long history, we’ve been building facilities. For example, we build the frames for the vertical farms with wood. That’s the classic way to do it, and it’s still done that way and it’s still economically feasible to do it. But the newer facilities, they now employ aluminum shelving that has tracks, so that you can run different types of equipment up and down. And that makes a big difference.

The other of course is computer-controlled climate. So these systems are just getting more and more sophisticated. And not only do they do a good job of controlling the environment, but they collect a lot of data that can be used for analysis. One of the things that we’re interested in in the longer term is how that could become big data, where we could analyze — at a much larger scale — the impact of anything from climates to nutrients to agricultural pests, whatever, based on a larger base of data.

Corinne is the Senior Multimedia Web Editor for NewsHour Weekend. She serves on the advisory board for VIDA: Women in Literary Arts, and graduated from Tufts University, where she studied English literature.

A Look Beyond the Glass at NatureFresh™ Farms

The company operates on a mantra that was coined by Peter Quiring “We don’t just grow produce, we grow people”.

A Look Beyond the Glass at NatureFresh™ Farms

Delta, Ohio | November 20th, 2017

On Wednesday, November 15th & Thursday, November 16th NatureFresh™ Farms opened their doors to the community for their first ever Open House.

“The Ohio community has been extremely supportive throughout the entire build and we have continuously received many inquiries from our neighbors wanting a chance to take a look behind the glass” explained John Ketler, General Manager. “Education is a key component of who we are and we wanted to ensure that our neighbors had a chance to see exactly how we grow; from seedling to harvest.”

The response to the NatureFresh™ Open House was both stunning and humbling. Within days of the registration going live, there was more interest than hours available in the day as well over 1000 people registered to tour the facility. The team had originally planned on the event lasting one day, however, had to extend the tour to two days in order to accommodate all those interested.

“For us, it’s more than just existing in Delta. We want to be an active partner in the community. It is important for us to show our neighbors how we grow and provide total transparency,” commented Peter Quiring, President, and CEO. “We had school groups, senior homes, care facilities, farming clubs, and many families come out. It was great to be able to show everyone exactly where the produce they have sitting on their kitchen table comes from”. With interactive sessions, the team was able to give individuals a firsthand understanding of greenhouse growing techniques such as the Integrated Pest Management (IPM) system & the growing medium.

The company operates on a mantra that was coined by Peter Quiring “We don’t just grow produce, we grow people”. In that spirit, NatureFresh™ partnered with JJ Safe House and Open Doors Delta to raise awareness and funds for the local charities. With produce being sold for $2 an item, approximately $2000 was raised in addition to over 3000 lbs of produce being donated to the charities to help support local families having a healthier and happier Thanksgiving.

“The feedback we received after the event was phenomenal,” said Ketler. “The community was amazed by everything from the scope and technology incorporated in the facility to the flavor of the tomatoes. Overall, we couldn’t have asked for a better event.”

To learn more about NatureFresh™ Farms, visit naturefresh.ca

Kara Badder

Marketing Project Manager

kara@naturefresh.ca

Phone: 519.326.1111;3215

Mobile: 226.936.2358

IPM Essen Show Preview - New Look For Top Trade Fair

IPM Essen Show Preview - New Look For Top Trade Fair

15 December 2017, by Gavin McEwan,

Venue modernization will mean better display space for exhibitors at Europe's largest trade fair for the horticulture industry, says Gavin McEwan.

IPM Essen: Denmark will be in the limelight with umbrella trade body Floradania bringing almost 100 exhibitors to the event

Show Details IPM Essen

When 23-26 January

Where Messe Essen, Norbertstraße 2, 45131 Essen, Germany

Website http://www.messe-essen.de/

Tel +49 (0) 201 3101 430

Regular visitors to IPM Essen, Europe’s largest horticulture trade fair, will notice a few changes when the event opens its doors later this month. Modernisation of the event site has brought in a new Glass Foyer East, while Fair Hall 9 is being replaced by a new space that organizers describe as "flooded with light" and will be partially open for the show.

National pavilions will again be a major feature and, after a major French push at the show last year, the 2018 show will put Denmark in the limelight, with umbrella trade body Floradania bringing almost 100 exhibitors to the temporary Hall 14 and the foyer of the Grugahalle.