Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

The Future of Food: Inside The World's Largest Urban Farm – Built on a Rooftop

On top of a striking new exhibition hall in the southern 15th arrondissement of Paris, the world’s largest urban rooftop farm has started to bear fruit. Strawberries, to be precise: small, intensely flavoured and resplendently red

In Paris, urban farmers are trying a soil-free approach to agriculture that uses less space and fewer resources. Could it help cities face the threats to our food supplies?

Urban farming on a Parisian rooftop. Photograph: Stéphane de Sakutin/AFP/Getty Images

08 Jul 2020

On top of a striking new exhibition hall in the southern 15th arrondissement of Paris, the world’s largest urban rooftop farm has started to bear fruit. Strawberries, to be precise: small, intensely flavoured and resplendently red.

They sprout abundantly from cream-coloured plastic columns. Pluck one out to peer inside and you see the columns are completely hollow, the roots of dozens of strawberry plants dangling into thin air.

From identical vertical columns nearby burst row upon row of lettuces; near those are aromatic basil, sage, and peppermint. Opposite, in narrow, horizontal trays packed not with soil but coco coir (coconut fibre), grow heirloom and cherry tomatoes, shiny aubergines, and brightly coloured chards.

“It is,” says Pascal Hardy, surveying his domain, “a clean, productive and sustainable model of agriculture that can in time make a real contribution to the resilience – social, economic and also environmental – of the kind of big cities where most of humanity now lives.

And look: it really works.”Hardy, an engineer, and sustainable development consultant, began experimenting with vertical farming and aeroponic growing towers – as those soil-free plastic columns are known – on his Paris apartment block roof five years ago.

This space is somewhat bigger: 14,000 sq metres, the size (almost exactly) of two football pitches. Coronavirus delayed its opening by a couple of months, but Nature Urbaine, as the operation is called, is now up and running, and has planted roughly a third of the available space.

Already, the team of young urban farmers who tend it have picked, in one day, 3,000 lettuces and 150 punnets of strawberries. When the remaining two-thirds of the vast rooftop of Paris Expo’s Pavillon 6 are in production, 20 staff will harvest up to 1,000kg of perhaps 35 different varieties of fruit and vegetables, every day.“

We’re not ever, obviously, going to feed the whole city this way,” cautions Hardy. “In the urban environment you’re working with very significant practical constraints, clearly, on what you can do and where. But if enough unused space – rooftops, walls, small patches of land – can be developed like this, there’s no reason why you shouldn’t eventually target maybe between 5% and 10% of consumption.”

Nature Urbaine is already supplying local residents, who can order fruit and veg boxes online; a clutch of nearby hotels; a private catering firm that operates 30 company canteens in and around Paris; and an airy bar and restaurant, Le Perchoir, which occupies one extremity of the Pavillon 6 rooftop.

Nature Urbaine. Photograph: Magali Delporte/The Guardian

Perhaps most significantly, however, this is a real-life showcase for the work of Hardy’s flourishing urban agriculture consultancy, Agripolis, which is currently fielding inquiries from around the world – including in the UK, the US, and Germany – to design, build and equip a new breed of soil-free inner-city farm.“The method’s advantages are many,” he says. “First, I don’t know about you, but I don’t much like the fact that most of the fruit and vegetables we eat have been treated with something like 17 different pesticides, or that the intensive farming techniques that produced them are such huge generators of greenhouse gases.“I don’t much like the fact, either, that they’ve travelled an average of 2,000 refrigerated kilometres to my plate, that their quality is so poor, because the varieties are selected for their capacity to withstand that journey, or that 80% of the price I pay goes to wholesalers and transport companies, not the producers.”

Produce grown using this soil-free method, on the other hand – which relies solely on a small quantity of water, enriched with organic nutrients, minerals and bacteria, pumped around a closed circuit of pipes, towers and trays – is “produced up here, and sold locally, just down there. It barely travels at all,” Hardy says.“It uses less space. An ordinary intensive farm can grow nine salads per square metre of soil; I can grow 50 in a single tower. You can select crop varieties for their flavour, not their resistance to the transport and storage chain, and you can pick them when they’re really at their best, and not before.”

No pesticides or fungicides are needed, no soil is exhausted, and the water that gently showers the plants’ roots every 12 minutes is recycled, so the method uses 90% less water than a classic intensive farm for the same yield. The whole automated process can be monitored and controlled, on site or remotely, with a tablet computer.

Urban farming is not, of course, a new phenomenon. The mayor of Paris, Anne Hidalgo, aims eventually to have at least 100 hectares of rooftops, walls and facades covered with greenery – including 30 hectares producing fruit and vegetables.

A programme called Les Parisculteurs invites local groups to come up with suitable projects for up to a dozen new sites every year.Inner-city agriculture is booming from Shanghai to Detroit and Tokyo to Bangkok. Strawberries are being grown in disused shipping containers; mushrooms in underground carparks. Not all techniques, however, are environmentally friendly: ultra-intensive, 10-storey indoor farms that have sprung up in the US rely on banks of LED lighting and are major consumers of energy, Hardy says.

Aeroponic farming, he says, is “virtuous”. The equipment weighs little, can be installed on almost any flat surface, and is cheap to buy: roughly €100 to €150 per sq metre. It is cheap to run, too, consuming a tiny fraction of the electricity used by some techniques.

Aeroponic farming is ‘virtuous’, says Pascal Hardy. Photograph: Magali Delporte/The Guardian

Produce grown this way typically sells at prices that, while generally higher than those of classic intensive agriculture, are lower than soil-based organic growers. In Paris, Nature Urbaine should break even, Hardy estimates, some time next year – a few months later than planned because of the pandemic

.There are limits to what farmers can grow this way, of course, and much of the produce is suited to the summer months. “Root vegetables we cannot do, at least not yet,” he says. “Radishes are OK, but carrots, potatoes, that kind of thing – the roots are simply too long. Fruit trees are obviously not an option. And beans tend to take up a lot of space for not much return.”

But Agripolis runs a smaller test farm, on top of a gym and swimming pool complex in the 11th arrondissement, where it experiments with new varieties and trials new techniques. A couple of promising varieties of raspberries are soon to make the transition to commercial production.

Urban agriculture is not the only development changing the face of farming. As with almost every other sector of the economy, digitisation and new technologies are transforming the way we grow food.

Artificial intelligence (AI) and the internet of things are beginning to revolutionise farming, from driverless, fully automated farm machinery that can sow seeds and fertilise and water soil with maximum precision to systems that monitor exactly how healthy individual animals are and how much they are producing (a concept known as the “connected cow”).

Other AI systems analyse satellite and remote ground sensor data, for example, to monitor plant health, soil condition, temperature and humidity and even to spot potential crop diseases.

Drones, too, have multiple potential uses on farms. With the world’s bee population in steep decline due to global heating, pesticides, and other factors, drones are increasingly being used to pollinate crops fields and fruit orchards. To avoid wasting pollen by wafting it randomly at crops, or the damage to individual flowers caused by drones rubbing against them, scientists in Japan have developed a system in which a drone uses what can only be described as a bubble gun to blow balls of specially formulated liquid containing pollen at individual blossoms.

With global food production estimated to need to increase by as much as 70% over the coming decades, many scientists believe genetic editing, which has already been used to create crops that produce higher yields or need less water to grow, will also have to play a bigger role.

The technique could help build plant and animal resistance to disease, and reduce waste. For example, with methane known to be a stronger greenhouse gas than carbon dioxide, research is under way into the stomach bacteria of cows in the hope that tweaking animals’ gut microbes may eventually allow them to produce not just more meat, but also less gas.

Seating at Le Perchoir. Photograph: Magali Delporte/The Guardian

Urban farming of the kind being practised in Paris is one part of a bigger and fast-changing picture. “Here, we’re really talking about about building resilience, on several levels – a word whose meaning I have come to understand personally,” says Hardy, pointing to the wheelchair he has been forced to use since being injured by a falling tree.

“That resilience can be economic: urban farming, hyper-local food production, can plainly provide a measure of relief in an economic crisis. But it is also environmental: boosting the amount of vegetation in our cities will help combat some of the effects of global heating, particularly urban ‘heat islands’.”

Done respectfully, and over time, inner-city agriculture can prompt us to think differently both about cities, by breaking down their traditional geography of different zones for working, living and playing, and about agriculture, by bringing food production closer into our lives. “It’s changing paradigms,” says Hardy.

US - VIRGINIA - What Does Governor Northam Have to Say About Babylon?

“Congratulations to Babylon Micro-Farms, an inspiring up and coming Virginia business, on its CRCF award. Babylon first received seed capital funding from CIT GAP Funds in August 2019

June 30, 2020

We are very excited to share the news that Governor Northam announced last week that Babylon has been awarded matching funds from the Center for Innovative Technology (CIT) for the Small Business Innovation Research (SBIR) grant we received from the National Science Foundation. The funding from the NSF made Babylon eligible for a highly competitive application process that CIT holds annually through the Commonwealth Research Commercialization Fund which provides additional support for SBIR recipients to foster ongoing innovation by Virginia-based companies.

“Congratulations to Babylon Micro-Farms, an inspiring up and coming Virginia business, on its CRCF award. Babylon first received seed capital funding from CIT GAP Funds in August 2019. I had the pleasure to get to know the team and learn about the vital work they are doing for indoor farming,” said Ed Albrigo, President and CEO of CIT. “They continue to move forward on research and development of their disruptive platform for hydroponic farming, which has now earned them funding support through CIT CRCF. The Babylon CRCF award, along with CIT GAP funding, is a prime example of how our programs work together to help sustain companies through the difficult first stages of the commercialization process. Sustainable urban agriculture technologies are among the most critical emerging technologies in the nation today, and thanks to Babylon, Virginia will play an essential role in the future of farming."

Babylon added Lansdowne Resort in Leesburg, VA to our portfolio of high-end resorts and we are happy to welcome them to the Babylon family. Lansdowne is very focused on the connection between food and health and has a history of being at the forefront of hospitality trends that incorporate wellness and mindfulness-based activity options. They offer their guests a carefully curated offering of dietary choices based on their commitment to providing them the highest possible quality available in every aspect of their experience. Babylon is proud to be part of that commitment.

The recently installed farm at Champion Brewing Company Pub is the first partnership between Babylon and our hometown pioneer of the rapidly growing craft beer movement. When founder Hunter Smith envisioned the Pub, he wanted to create a fun community space that was hip and cool, but truly more than that – a place for people to connect. Mission accomplished and since Babylon is all about connecting people to their food by growing it right in front of them, it was a natural fit. The synergy of two local startups working together to bring the best of local food and drink to the table is a winning combination. Stop by and have a cold beer, it's hot outside!

VIDEO: Dubai’s Badia is GCC’s First Commercial Vertical Indoor Farm

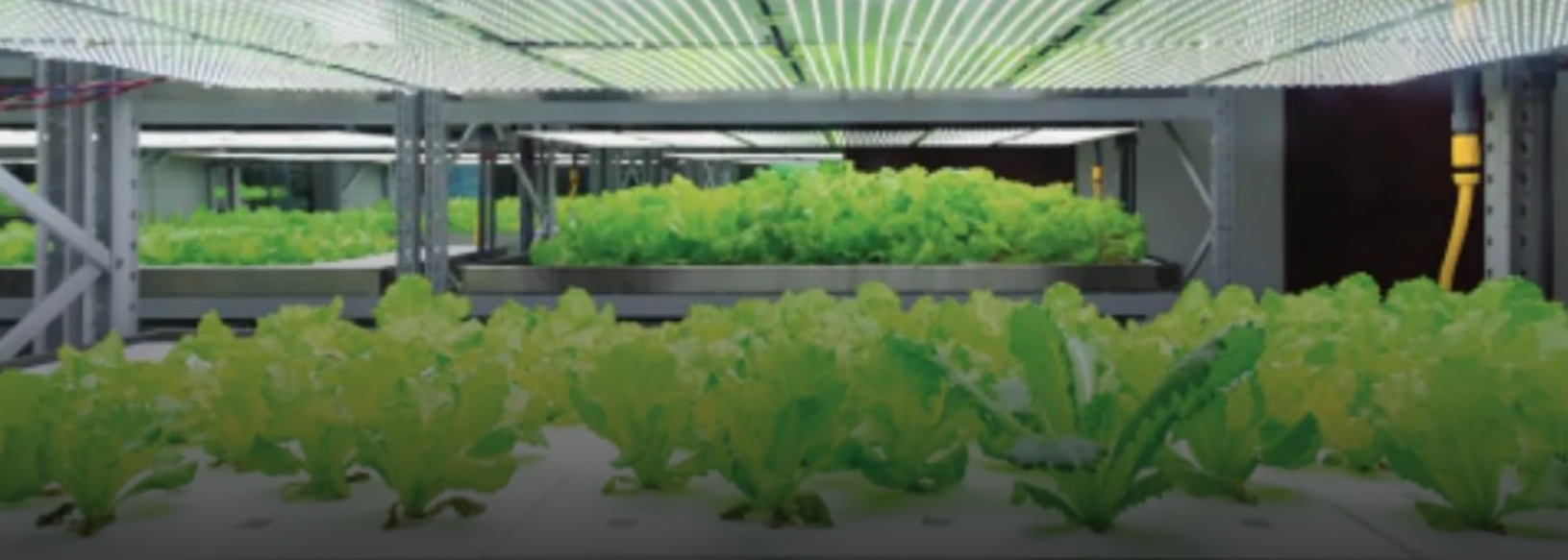

Badia Farms in Al Quoz Industrial area in Dubai is the GCC’s first commercial vertical indoor farm that supports Dubai’s agricultural sustainability

June 26, 2020

An expert takes notes on the health of vegetables.

Gulf Today, Staff Reporter

Badia Farms in Al Quoz Industrial area in Dubai is the GCC’s first commercial vertical indoor farm that supports Dubai’s agricultural sustainability.

The large-scale high-tech vertical farm produces 3,500kg of chemical, pesticide, and herbicide-free fruits and vegetables per year.

Badia Farms said, “We have a growing reputation for supplying the finest micro-greens and herbs to Dubai’s top restaurants, caterers and chefs.”

Vertical farming is the practice of producing food vertically in stacked layers, vertically inclined surfaces, and/or integrated in other structures.

It uses a combination of indoor farming techniques and controlled-environment agriculture (CEA) technology.

Experts examine a produce.

Vertical farms can grow non-native produce in locations where traditional agricultural methods are impossible. Also, there’s no exposure to the hazards of traditional farming, such as bugs, diseases, pesticides and weather.

In some ways, it’s as simple as it sounds: a vertical farm is a multi-story greenhouse where fruit and vegetables are grown in stacked up towers. There’s obviously a lot more to it than that – and here’s where we’ll try not to blind you with science.

The techy term for it all is hydroponics, which is a technique for growing produce without soil. Seeds are planted in a sterile, soil-less growing environment and then grown in nutrient-rich water. Water is recycled, and everything from air and water temperature through to humidity and lighting are controlled to create the perfect growing environment.

Badia Farms Vertical Farming Agriculture Dubai UAE InnovationTechnology

Vertical Farming In LatAm: AgroUrbana Closes $1m Seed Funding

Access to vertical farming technologies is deepening and widening across the world, bringing down the costs and hassle of locally producing anything from Singapore strawberries to Arctic tomatoes

July 2, 2020

Access to vertical farming technologies is deepening and widening across the world, bringing down the costs and hassle of locally producing anything from Singapore strawberries to Arctic tomatoes.

In Latin America, however, indoor vertical farms are still largely written off on a continent known for its abundant fertile soil and plentiful sunlight. Why need of artificial light or indoor automation when the sun is free and labor is cheap?

That said, there are early signs of a LatAm vertical farming awakening in Chile, where AgroUrbana has just raised a $1 million seed round, bringing its total capital raised to $1.5 million. AgroUrbana is South America’s first vertical farm, according to the Association for Vertical Farming.

Leading the round by contributing 33% of the cash was the CLIN Private Investment Fund administered by Chile Global Ventures, the venture capital arm of Fundación Chile, a public-private initiative for innovation and sustainability in the country. Support financing also came from CORFO (Chile’s Development Agency) and private investors like company builder and VC Engie Factory, the country’s largest telecommunications company Entel, and sustainability investor Zoma Capital.

In a video call with AFN, AgroUrbana f0unders Cristián Sjögren and Pablo Bunster described how the funds would be put to work at their 3,000 square feet pilot facility in the suburbs of Santiago, where testing is ongoing on layered stacks of hydroponically grown, LED-lit, renewable energy powered leafy greens and fruits. AgroUrbana’s first big offtake deal had just been inked with a major Chilean grocery retailer, they said.

A pre-planned switch from restaurant to retail

“It’s been run, run, run,” recalled Bunster, describing the political turmoil in Chile that brought curfews and shuttered restaurants months before Covid-19 locked down the country. That earlier disruption, he added, had actually had its upsides, as it got them thinking more about e-commerce and direct-to-consumer sales — so when the team’s restaurant deals dried up during the Covid-19 pandemic, the switch to retail was already scoped out.

As to scaling up further, Sjögren envisioned an eventual 30,000 square foot facility that would be bankrolled by a Series A that they plan to work towards later this year; the design and output would depend on the results of their pilot trials.

This size of farm sets the team somewhere in the middle of the two dominant visions of vertical farming: centralized versus distributed. Proponents of centralized systems argue that large-scale production—and financial viability—depend on ever-bigger and higher farms. These farms, or plant factories as they are sometimes called, are proliferating, aided by huge sums of capital. Plenty scooped up a whopping $200 million in Series B funding back in 2017. US-based AeroFarms raised $100 million in late-stage funding in 2019 while Fifth Season secured $50 million last year.

Although centralized facilities have generally dominated the vertical farming venture capital domain, distributed and decentralized business models are gaining pace, according to AgFunder’s 2019 industry report. One in particular—Germany’s Infarm—nabbed $100 million last year to deploy its connected growing cabinets in supermarkets. The theatricality of these cabinets harmoniously glowing in office buildings or hospitals in a post-corona world also holds sway in the popular and corporate imagination of 2020, with companies like Square Mile Farms recently crowdfunding over $300,000 on the promise of re-kitting office spaces like those of Microsoft’s London premises with fresh produce. In New York, Farmshelf has its own grow cabinets deployed in WeWork FoodLabs.

Learning from cash-heavy first movers

Mention of giants like Plenty or InFarm could be daunting for newer companies like Square Mile Farms or AgroUrbana and their hitherto modest sums raised. But there is perhaps an advantage in starting late — so long as the team learns from the costly mistakes and hubris of earlier endeavors. Here, both Bunster and Sjögren see parallels with the renewable industry, where they worked previously, and see the arrival of cheaper, more sustainable energy and capital in Chile as crucial to making vertical farming competitive.

AgroUrbana is exploring three options for solar going forward: either establish a PPA, in which they buy renewable energy from an existing plant; to finance a power plant which will sell to them later; or build their own solar farm. But they acknowledge that the larger the facility, the less feasible it is to have solar onsite.

The pair described how some Chilean outdoor farming is already lean and competitive, yet much of it has been geared towards high-value crops like avocados — and that stuff is primed for export. For the urbanizing local market, they see gaps for hyper-local fresh produce, where the competition would actually be with low-tech smallholder farmers with less traceable supply chains. In the context of Covid-19 and an ensuing consumer embrace of e-commerce options, better nutrition, less water use, and fewer pesticides, the pair reckon there is much to gain from providing produce that is consistently fresh 365 days a year.

Any chance of the world’s first vertically-farmed avocados any time soon? Unlikely, replied Bunster. As for gene editing, where Latin America is known to have more lax regulations than North America, Bunster said the plan was to work with what nature already provides, and just give them “the conditions of spring every day of the year.”

VIEDO: Vertical Farming Conference: 8 October 2020, Online or Offline At High Tech Campus Eindhoven, The Netherlands

A JakajimaTV talk with Jasper den Besten, HAS University of Applied Sciences about the importance of the variety choice for vertical farming

Basil, Exploring genetics for Vertical Farming

A JakajimaTV talk with Jasper den Besten, HAS University of Applied Sciences about the importance of the variety choice for vertical farming. Choosing the correct variety is often underexposed in vertical farming. However, the differences between varieties are huge.

Jasper den Besten will also be speaking at the Vertical Farming Conference, see the program here.

Source: Vertical Farming Conference.

#VerticalFarm #AgriFoodC #phapps

VIDEO: Home Hydroponics: Tech Trend Or The New Victory Garden?

Home gardening is experiencing a renaissance spurred by the Covid-19 pandemic. Facing anxiety surrounding food security and the need for hobbies during quarantine, close to 20% of Americans have reported taking up gardening as a result of the pandemic. Seed sales have soared to unprecedented level

Jun 30, 2020

Rob Girling Contributor

Co-Founder of Artefact, a purpose-driven strategy, and design company dedicated to responsible design. I am a designer passionate about mitigating the negative impact of technology and maximizing the positive.

Home gardening is experiencing a renaissance spurred by the Covid-19 pandemic. Facing anxiety surrounding food security and the need for hobbies during quarantine, close to 20% of Americans have reported taking up gardening as a result of the pandemic. Seed sales have soared to unprecedented levels.

An indoor vertical hydroponic system by Gardyn. COURTESY OF GARDYN.

As Covid-19 highlights, the precarious supply chain that supports our modern lifestyles and the benefit of more self-sufficiency, hydroponics – a method of growing plants without traditional soil, using water-based, nutrient-dense solutions – is emerging as the latest trend in smart home devices. Advances in hydroponic food-growing technology and LED lighting have reached a point where smart devices can take some of the labor, land, and expertise of traditional gardening out of the equation. Make no mistake that “real” gardening requires deep knowledge and effort to yield nutritional and emotional benefits; however, technology can now help laypeople experiment with growing fresh, nutritious food in their homes.

While home hydroponic systems are more effective, easy to use, and aesthetically pleasing than ever, there is a long way to go before the promise of sustainable, accessible food for all comes to fruition. Who wins and who loses in the smart food ecosystem and just how sustainable are these services? Let’s look at the design of three leading home hydroponics systems and the broader impact of such “smart growing”.

Home Hydroponics Leading the Pack

Gardyn, Rotofarm and Click & Grow are three of the leading “smart growing” entrants that promise attractive, no-hassle, indoor hydroponic systems.

The Gardyn system consists of three vertical artificial “stems” where up to 30 plants can grow at once. These stems are rooted in a sturdy, oval-shaped base reservoir where water, pumps and electronics are discretely hidden under a wooden lid. Two vertical aluminum bars hide the latest-generation LED lights that focus their attention on the plants and dissipate heat effectively. Gardyn comes with an AI assistant app that monitors and manages temperature, humidity, and light.

The most sculptural of the leading home hydroponic systems, the Bace Rotofarm is a jaw-droppingly gorgeous object with a supporting app component. Using a rotating circular drum, it slowly turns up to eight plants around an LED hub, compressing 5.5 feet of growing space into just 15 inches and eliminating gravitational penalty to help plants grow faster. Despite winning several design awards for its science-fiction-turned-reality aspiration, the Rotofarm will not launch until 2021 and its price remains a mystery.

A more economical home hydroponics system comes in the form of the Click & Grow Smart Garden. With three- and nine-plant growing options, the Click & Grow design concept looks vaguely like a carrying basket with an end-to-end handle that cleverly hides LED lights. Click & Grow is unique in its scaled design, allowing customers to stack Smart Gardens together to create a compact food growing system. Like the others, the system has a companion app to track growing schedules and help troubleshoot.

Improving Access to Produce, at a Cost

There is great opportunity for home hydroponics to improve education and access to healthy produce for those who live in food deserts or do not have access to nutritious food. Yet, so far, smart growing systems target tech-savvy, mostly affluent people living in high-density urban communities.

No matter the brand, existing home hydroponics systems command a hefty price tag. The Click & Grow system ranges from $99 for three plants to $599 for a 27-plant system, while the Gardyn kit starts at $799 with a monthly fee of $69 for 240 seed plants. Each plant might produce up to five yields before it needs replacing – that’s a lot of money for leafy greens, fresh herbs, and a handful of fruit.

These products make big claims about sustainability, healthy living, and a reliable food ecosystem, but don’t provide sufficient practical value for communities who could benefit the most from home hydroponics. One hopes that the pricing of these new systems reflects the enormous startup costs of building their business. Perhaps subsequent generations and scale can reduce the unit costs, like what has occurred in the electric vehicles market.

Lowering Environmental Impact

Dirt, when combined with growing chemicals, is responsible for significant water pollution in traditional farming. Rather than using soil, most home hydroponics systems call for compostable refill cubes similar to espresso pods. Each cube includes seeds planted in the company’s patented “growing medium” – in other words, artificial soil consisting of natural materials designed to hold water and nutrients more efficiently than regular dirt. Unlike espresso pods, these cubes are made from compostable corn-based plastic that can be thrown in the yard waste.

Gardyn's compostable "yCubes" are made up of rockwool and corn. COURTESY OF GARDYN.

The essential trade-off with indoor hydroponics is foregoing the free light-bulb in the sky: the sun. Depending on the amount of natural light available in a home, an LED hydroponic system uses significant electricity that adds to energy consumption and utility bills.

Nevertheless, growing food through hydroponics reduces reliance on industrial agro-farming with its heavy reliance on chemicals, fresh water, and the transportation infrastructure needed to get from production to table.

A Victory Garden Redux

Smart growing and home hydroponics is an exciting new trend in consumer hardware. While early entrants to the market feel more proof-of-concept than robust products or services, I predict that this category of products will improve quickly and become commonplace in homes of all types, expanding into other types of gardening and food production beyond leafy greens alone.

Although smart gardens may not yet be as impactful as the victory gardens that produced nearly 40% of vegetables in the US during World War II, there is significant opportunity for home hydroponics reduce dependence on an easily disrupted global food infrastructure while also easing individual environmental impact and increasing access to fresh, healthy produce.

I am a designer passionate about mitigating the negative impact of technology and maximizing the positive. I co-founded Artefact, a purpose-driven strategy and design company dedicated to responsible design. I have worked across the tech industry in various leadership roles at IDEO, Apple, Sony, and Microsoft. I also co-founded the SAAS resource management software 10000ft, acquired by Smartsheet in 2019

I am a designer passionate about mitigating the negative impact of technology and maximizing the positive. I co-founded Artefact, a purpose-driven strategy and design company dedicated to responsible design. I have worked across the tech industry in various leadership roles at IDEO, Apple, Sony, and Microsoft. I also co-founded the SAAS resource management software 10000ft, acquired by Smartsheet in 2019

Rob Girling

4 Facts You Need to Know About Vertical Farming LED Lighting

One of the main components that make vertical farming possible is the evolution of light-emitting diodes (LEDs)

One of the main components that make vertical farming possible is the evolution of light emitting diodes (LEDs). As LEDs become more and more accessible and affordable, the futuristic idea of vertical farming becomes more realistic for cities all over the globe. In this article, we’re going to share four important facts regarding vertical farming led lighting and how these systems are important to the future of farming.

LEDs are the best lighting system for vertical farming

With their ability to be highly energy efficient, LEDs produce light at optimal power while being able to last a long time. These effective light solutions are able to last for nearly six years, which is quite longer than other lighting solutions. What makes LEDs perfect for vertical farming is that they’re able to be confined in tight spaces with vertical layered crops, and they don’t emit too much heat. Other lighting solutions such as HPS or MH lights will damage vertical farming systems because they release too much heat, which is harmful to the crops.

LEDs are a cost-effective, energy saving solution

HPS lighting systems consume too much power in order to emit the same light levels as LEDs, which is why LED lighting systems are paving the way toward an affordable indoor growing environment. One of the significant benefits of using LED lights is that these advanced lighting systems do not consume as much power, which leads to reduced energy costs and higher productivity.

They use a visible spectrum to match the plant’s grow cycle

The innovative uses behind vertical farming LED lighting is that these systems use wavelengths on a visible spectrum to promote plant growth. When you see those pink colored lighting systems, this means that the LED lighting system is using a minuscule wavelength between the red and blue spectra to produce the pink glow. Plants depend on blue lightwaves to enhance the leaf’s color and prevent stretching, and the red light waves optimize photosynthesis. LED lights are able to emit the wavelengths needed to grow healthy, bountiful plants by mimicking their required natural environment.

LEDs are sustainable solutions to growing foods

Farmers are learning to work with LED lights because of their sustainable, efficient solutions. These vertical farming LED lighting systems are able to provide controlled lighting all-year-round, which allows for optimal plant growth. Also, by having a controlled indoor LED lighting environment, crops are saved from yearly harsh environmental conditions such as flooding, drought, hurricanes, and more. By being able to mimic sunlight, LEDs are a cost-effective solution to growing sustainable and healthy foods all year round indoors.

We at the Nick Greens Grow team are always learning and sharing our advanced farming knowledge with our subscribers. If you want to always stay up-to-date with the newest innovative farming technology subscribe to our YouTube channel for weekly videos or subscribe to our blog to get the latest farming information sent straight to your inbox!

#LEDlighting #verticalfarming #growlights #growfoodwithleds #verticalfarminggrowlights #ledlights #ledgrowlights #verticalfarmingLEDlighting #leds #indoorfarming

Ground Broken on New Hydroponic Facility To Serve The Marginalized Communities in Torrington CT.

The mission of the farm is to provide entry-level, safe, clean “green jobs” to members of the community

Published on July 6, 2020

Joe Swartz

Vice President/Lead Horticulturalist at AmHydro - 36 years as Controlled Environment Ag Consultant and Commercial Grower

June 30, 2020, was an exciting day for the local Connecticut organization, New Opportunities. http://www.newoppinc.org/ After years of planning, the ground was broken on a new hydroponic farm project called "CT Food4Thought" that is going to bring fresh, nutritious, pesticide-free food to local food banks, shelters, soup kitchens, and schools to communities throughout Connecticut. In addition to that, the farm will also supply retail grocery stores and co-ops with fresh produce as a way to generate income for programs through selling the produce grown. New Opportunities partnered with industry-leading Controlled Environment Agriculture Technology company AmHydro of Arcata, CA. (https://amhydro.com/ )

The groundbreaking marked the start of three greenhouses, containing AmHydro’s soilless hydroponic growing systems, being constructed in partner with Borghesi Engineering with plans to expand up to 12 greenhouses in the future. AmHydro VP Joe Swartz and the Commercial Growing Team at AmHydro will provide on-going support and grower training to ensure a successful project and economic sustainability.

New Opportunities is a social service organization that serves marginalized and low-income communities throughout Connecticut. The mission of the farm is to provide entry-level, safe, clean “green jobs” to members of the community. Specifically, CT Food4Thought wants to offer these job opportunities to those with developmental disabilities, those who have been previously incarcerated, and those who are unemployed as a way to provide a path to higher-level employment opportunities in both this industry and others, such as: the field of nutrition, food safety, environmental management, and horticulture.

Dr. James H. Gatling, Ph.D., CEO of New Opportunities, speaks prior to breaking ground.

New Opportunities Foundation had a vision and worked directly with hydroponic industry leader AmHydro to develop the most optimum growing system and production methods available. This hydroponic farm will use 90% less water than conventional field agriculture and will be able to produce more than 10 times the amount of produce that traditional growing methods yield. The farm will also be able to operate year-round due to the environmental controls inside the greenhouse that can simulate the perfect growing conditions for plants even in the dead of winter. This will allow people in Connecticut to have access to fresh, local produce all year in comparison to the normal outdoor growing season in the area that lasts approximately 120 days.

Bill Rybczyk, New Opportunities, Joe Swartz, AmHydro, Jon Jensen, the Corporate Advisory at the project site this Spring.

AmHydro is proud to partner with New Opportunities on their new project CT Food4Thought and is excited to continue to be a part of and support the project through providing training to members of New Opportunities and members of the community.

Quote, from Bill Rybczyk, Director of Research, Planning, and Development for New Opportunities Inc : “We’re planting seeds for lettuce and other herbs, but we’re also planting seeds into people’s lives, and they can then take that, and they begin to grow….and that impacts not only their lives but their children’s lives and their grandchildren’s lives into the future…..and that’s what this project is all about."

For more information, please contact Joe Swartz, VP, AmHydro at Joe@AmHydro.com

Published by

Vice President/Lead Horticulturalist at AmHydro - 36 years as Controlled Environment Ag Consultant and Commercial Grower

Please check out this amazing project that American Hydroponics is proud to be a part of. New Opportunities will be producing fresh, pesticide-free food, local "green jobs," and economic empowerment to marginalized communities.

Truly wonderful. hashtag#LocalFood hashtag#LocalFarms hashtag#WeGotThis hashtag#HelpingOthers hashtag#SustainableFarming

How To Start Growing With Hydroponics For Beginners

If you’d like to know how to build your own hydroponic garden and get started with indoor growing then this article will show you how!

If you’d like to know how to build your own hydroponic garden and get started with indoor growing then this article will show you how!

Think of this as the “ultimate” hydroponics guide for beginners because we’re not going to bog you down with too many details or confuse you with a ton of jargon …

On this page you’ll just find the simple, 30,000ft view of how it all works and how you can get started as quickly as possible growing your own hydroponic plants!

What Is Hydroponics?

Before we get started, let’s actually define what we are talking about here …

What is hydroponic farming anyways?

Wikipedia actually has the perfect definition because it’s so simple:

“Hydroponics is a subset of hydroculture and is a method of growing plants using mineral nutrient solutions, in water, without soil. Terrestrial plants may be grown with their roots in the mineral solution only, or in an inert medium, such as perlite or gravel. The nutrients in hydroponics can be from fish waste, normal nutrients, or duck manure.”

So basically, we’re looking to grow plants without actually having to plant them in the ground. That means we can grow them indoors if we choose!

Eljay from the YouTube series “How To Hydro” has a great explanation for why we want to do indoor gardening. He says, “Indoor growing is all about creating perfect Sundays, every day, for all your plants”:

Why Would You Want To Start Growing With Hydroponics?

A hydroponics vs. soil comparison for Holland Hybrid tomatoes showing taller plants from hydroponics.

There are many reasons why people want to get into hydro plant growing, but we’ll cover some of the most important and popular reasons here…

Faster Growth! Plants grow faster with hydroponics because it’s a more efficient way to grow them. For example, most experts agree that plants will grow at least 20% faster with hydroponics vs soil. That’s a huge time saver!

Bigger Yields! Scientists have lots of theories as to why this is the case, but the fact of the matter is that experts also agree you can expect at least 20-25% more yields with hydro as compared to growing in soil. That truly adds up!

No soil! This can be a benefit because you may live in an area where there is no good soil to grow plants outside. Or perhaps you don’t have any outside area because you live in an urban area. With a hydro grow you can still grow plants, even if you don’t have soil!

Space Saving! Because your plants don’t need to spread their roots out into lots of soil to get the nutrients they need (because they’re surrounded by oxygenated nutrient-rich water solution)–you can pack more plants closer together. This saves a TON of space and one of the amazing features about indoor grows is how many plants can be put together and grown in a small space. Again, this is perfect for urban dwellers who want to grow a lot of plants with little space.

Water Saving! Because you are using reservoirs that are covered (to prevent evaporation) and no water seeps out of the bottom (because they’re sealed)–the plants take up the exact amount of water they need at any one time and the rest remains in the reservoir to be used later. Compare this to soil gardening where you have to water your plants daily and most of the water is wasted. It’s easy to see how the same amount of water used to water a plant in soil for a day can water a plant in a simple hydroponic system for multiple days or even a week at a time! In short, you can save about 90% of your water by switching to hydro growing.

No Weeds! One of the most tedious, time-consuming and frustrating activities for many gardeners is cleaning their gardens and pulling out weeds. With hydroponics growing there are no weeds to pull!

Less Diseases & Pests! Because you’re not using soil, you also get rid of a lot of soil-borne diseases and pests that can normally wreak havoc on your plants and make gardening a pain.

A graph showing bigger circumference (size) plants from hydroponics. From A hydroponics vs. soil comparison for Holland Hybrid tomatoes.

Why NOW Is A Great Time To Start Your Own Hydro Farm

The truth is that Hydroponics gardening has never been more popular than right now!

The Different Types of Hydroponics and How They Are Different

When it comes to hydroponics systems, there are six main types to choose from. These are:

Deep Water Culture (DWC)

Ebb and Flow (Flood and Drain)

Wicking

Drip

Aeroponic

Nutrient Film Technique (NFT)

Now, there are actually multiple variations of each of these different types of hydro systems, but these are the “high level” overviews and categories of basic designs.

Here’s the important thing to remember:

ALL these systems are hydroponics because they don’t use soil, and because you’re feeding the plants a nutrient-rich water solution instead of planting them in soil. The only difference between each type is HOW they deliver the water, oxygen and nutrients that you’re feeding the plants.

The EASIEST Type of Hydroponics System To Setup

Without a doubt, most hydroponics experts would agree that a Deep Water Culture (DWC) hydroponics system is the easiest type of hydro system to use for indoor growing because it requires the LEAST amount of materials, supplies, and know-how to get started:

The Deep Water Culture (DWC) hydro system is the easiest for beginners to use.

In a DWC hydro system, you simply fill up a reservoir with your nutrient solution. You then suspend your plant’s roots in that solution so they receive the steady, continuous supply of water, oxygen, and nutrients.

Then a continuous oxygen supply is added to the water. The most common way that growers oxygenate the nutrient solution reservoir is with an air pump and airstone to pump bubbles into it. This keeps your plant’s roots from “drowning” which — while it sounds weird — is a real concern because your plants will suck the oxygen they need out of the water.

Using the DWC system, you’ll find it’s extremely simple to setup (once you understand how it all works) and extremely low-maintenance (again, once you understand how it works) making it perfect for hydroponics beginners.

What About Lighting For Your Plants?

The fact is that your plants need light to grow.

The simple answer is that if you can locate your hydroponics system where your plants can get at least 6 hours of sunlight per day, that is the best. Sunlight provides all the lighting that your plants need to grow correctly.

If you can’t locate your plants in direct sunlight, then you will have to provide artificial lighting using your own indoor grow lights. The truth is that a complete discussion of the proper indoor grow lights is beyond the scope of this article, but you will need to select the proper lighting system with the correct spectrum of light, intensity, power and that covers enough “footprint” to work with your garden. For more information on choosing the right hydroponic grow lights, click here.

Big Tip: Start Your Plants From Clones

If you’re just getting started growing hydroponically, you want to make it easier on yourself. The best way to do that is to eliminate all the things that might go wrong.

That’s why we recommend starting from a live plant instead of trying to use seeds for your first grow. This is called “cloning” and more tips on how to do this can be found here.

To use herbs as an example, simply acquire an herb seedling and gently remove it from the soil and potting container it came in and wash away all the dirt from the roots of the plant. You don’t want to contaminate your water.

Once you have rinsed the plant’s roots with water, then you can simply add it into your net pot in the lid of your bucket. If the seedling already has roots that you can pull through the net pot into the water, that’s even better and going to make your job easier. Then you simply cover the root system with your growing media and let the system do the rest of the work!

How To Make Sure Your Water Doesn’t KILL Your Plants!

If possible, you want to use Reverse Osmosis (RO) water for your nutrient solution because if you don’t you could seriously harm your plants. See our article “Why all hydroponics growers should use reverse osmosis water systems” for complete details.

Also, if you are using RO water and especially if you are using tap water, you need to know that pH is an important factor. Most tap water is in the 7.0-8.0 pH range. The recommended herbs in this guide thrive in water that’s a little lower pH than this, around the “sweet spot” of 5.5-6.3

How do you know? You’ll need to buy a pH testing kit to test your water. And if your pH is off then you will need to add pH-Up or pH-Down to adjust your pH levels.

Why is this so important? Because when the pH of your hydroponic system gets out of balance—which can happen quickly if some kind of stabilizing agent or mechanism is not put in place—the ability of your plants to absorb macro, secondary, and micronutrients, as well as vitamins, carbohydrates, and other beneficial sources, is limited.

The truth is that dealing with pH issues can be a real hassle. That’s the bad news. The good news is that, if you use the right products, you can completely eliminate all your pH issues and you will never have to worry about this!

The Best Nutrients For Beginners Are From Advanced Nutrients

The fact of the matter is that, no matter what you’re growing, the nutrients from Advanced Nutrients are the best nutrients for beginners (They’re also the best nutrients for professional growers too, but for different reasons that are beyond the scope of this article!).

How can we make such a bold statement?

Quite simply, it’s because all of Advanced Nutrients products are specifically designed for hydroponics growing. And they are the only nutrients to utilize scientific breakthroughs like pH Perfect Technology.

The fact is that Advanced Nutrients has spent many thousands of man-hours developing a technology that automatically balances your pH for you — putting it in the “sweet spot” and holds it there for weeks.

You can see more about pH Perfect Technology when you click here but the point is that for a beginner, again, the less variables the better. And utilizing the best nutrients in the world will only make your job easier.

Specifically, for the types of herbs we’re recommending on this page for beginners, we recommend using pH Perfect Sensi Grow A & B because you don’t actually want the herbs to bloom (because that could make them bitter).

By Advanced Nutrients | December 15, 2016

Farm Box Foods - Digital Farming Entrepreneurs

In 2017, an unlikely group of friends—a real estate agent, a solar energy entrepreneur, and a fabricator, decided to take action. From the drive to decentralize food supply chains and assist communities to produce more locally grown, healthy food, FarmBox Foods was born

OUR MISSION

We want to empower communities to produce their own locally grown produce year-round.

We strive to change the way people farm by merging technology and agriculture into a system that greatly reduces water usage and transportation costs while maximizing space.

We see a future where communities have achieved food independence by producing their own healthy food and distributing it locally – no longer relying on centralized food systems.

Our Story

Our planet is in trouble, and we need to find new, innovative approaches to food production.

In 2017, an unlikely group of friends—a real estate agent, a solar energy entrepreneur, and a fabricator, decided to take action. From the drive to decentralize food supply chains and assist communities to produce more locally grown healthy food, FarmBox Foods was born.

Our founders knew they had to search for agricultural innovations. At the heart of this new approach lies the shipping container. Our goal was to develop the most efficient, high-yielding container farm on the market. Early in our research and development, we saw the appeal of vertical farming—this design principle would allow us to maximize limited space. Bringing all these ideas together, FarmBox Foods created a hydroponic farm with an elegant and user-friendly design.

With our hydroponic farm on the market, FarmBox Foods is now looking for new ways to bring more healthy food options to communities. Enter mushrooms. With their myriad health benefits and culinary versatility, mushrooms are the perfect crop for sustainable food systems. Our first-of-its-kind gourmet mushroom farm will debut in 2020 and boost access to this superfood.

FarmBox Foods is changing the way we think about growing food, one shipping container at a time.

It comes down to what’s inside, the “Plant Force One” is built inside of a recycled 40-foot container. Helping the environment and help you change the way you farm

Aquaponic Growers Eligible For Coronavirus Assistance

Multiple USDA representatives assured the Aquaponics Association that aquaponics operations producing qualified crops are eligible for financial support through the Coronavirus Food Assistance Program (CFAP). The Deadline to apply is August 28, 2020. Growers are also eligible for Small Business Administration Programs

Multiple USDA representatives assured the Aquaponics Association that aquaponics operations producing qualified crops are eligible for financial support through the Coronavirus Food Assistance Program (CFAP). The Deadline to apply is August 28, 2020. Growers are also eligible for Small Business Administration Programs.

By Thomas Wheet and Brian Filipowich

The COVID-19 pandemic has negatively impacted the American agricultural industry in unprecedented ways. Farmers have watched harvests spoil, been forced to destroy crops, and have euthanized livestock due to the shifts in consumer behavior.

The USDA created the Coronavirus Food Assistance Program (CFAP) to assist farms that have suffered economically due to the outbreak.

We reached out to the USDA to inquire about aquaponic growers’ eligibility for CFAP and received encouraging, yet somewhat inconclusive, responses. While aquaponics is not explicitly highlighted as an eligible growing method for CFAP, numerous USDA representatives assured our policy team that aquaponic operations producing qualified crops could receive financial support through the program. Because funding decisions will ultimately be conducted at the county level, both the Aquaponics Association and USDA personnel strongly encourage any aquaponics organization to reach out to its county’s Farm Service Agency (FSA) to confirm that the organization meets all criteria required to receive support before completing the application process.

Deadline to apply: The USDA is accepting applications until August 28, 2020. Make sure to check with your FSA at your local USDA Service Center for any questions regarding the application process.

Who can apply for CFAP:

Producers of eligible commodities who have experienced a 5% or greater price decline due to COVID-19.

Individuals and/or legal entities that average an adjusted gross income of less than $900,000 in 2016, 2017, 2018. Make sure to check the CFAP website for additional eligibility guidelines.

Eligible crops: Non-specialty crops, wool, dairy, livestock, and specialty crops are all eligible for CFAP. For a complete list, make sure to take a look at the CFAP website.

General Business Assistance Programs

In addition to agriculture-specific economic assistance, the Federal Government has augmented general economic relief programs so that they also apply to agricultural. The U.S. Small Business Administration’s (SBA) Economic Injury Disaster Loan Program offers $10,000 loan advances for businesses experiencing a temporary loss in revenue and have less than 500 employees. The loan advances do not need to be repaid.

The USDA website notes: “For the first time, agricultural enterprises are now eligible for the disaster assistance from EIDL. As a result of the unprecedented legislation, American farmers, ranchers, and other agricultural businesses will now have access to emergency working capital.” The website also specifically notes that “aquaculture” businesses are eligible. Eligibility for CFAP is unaffected by participation in the PPP or EIDL.

Also from the SBA, the Payroll Protection Program offers guaranteed loans to support the payroll of businesses with less than 500 employees during the coronavirus pandemic. Unfortunately, the PPP deadline is June 30, 2020 (the day of this posting).

What is the Economic Effect of COVID on Aquaponics?

Surveys have indicated that COVID19 has hurt commercial aquaponic growers.

See:

1) Survey Results; COVID’s Effect on U.S. Aquaponics; and

2) Commercial Growers Hit Hard by Coronavirus.

We must do more to support commercial aquaponic growers during the pandemic so that we don’t set back our most efficient, sustainable form of agriculture.

Are you a grower that receives, has applied, or plans to apply for economic assistance through these government programs? Please complete this quick survey to let us know your experience, and if you have any questions or comments on the process.

Please Click Here To Access

The COVID Government Assistance Questionnaire

Jersey City May Have The U.S.'s First Municipal Vertical Farm. Experts Share How it Can Thrive

The city has signed a three-year contract with the Newark-based vertical farming company AeroFarms and plans to begin growing leafy greens in 10 locations including senior centers, schools, public housing complexes and municipal buildings later this year

Rebecca King | NorthJersey.com

June 26, 2020

Jersey City is on track to implement the country’s first municipal vertical farming program.

The city has signed a three-year contract with the Newark-based vertical farming company AeroFarms and plans to begin growing leafy greens in 10 locations including senior centers, schools, public housing complexes, and municipal buildings later this year.

“A lot of people don’t go for regular physicals,” said Jersey City Mayor Steven Fulop. “They’re not checking their sugar levels, blood pressure or cholesterol. Having people be more diligent about their diet will hopefully increase their lifespan, long-term.”

Once the microgreens start sprouting, members of the community will be able to sign up to receive free produce. They’ll be encouraged to attend seminars about healthy eating and get regular health tests done through Quest Diagnostics, which has also partnered with the city.

Because crops are stacked at this AeroFarms facility, the company says it can produce 390 times the crops from a traditional farm.~Courtesy of AeroFarms

“It’s important to be doing this prior to people getting diseases or sicknesses,” said Fulop. “A lot of what we’re doing is based on education. Many people aren’t aware of the bad foods they’re putting in their bodies on a regular basis.”

Vertical farming is one method of hydroponic controlled environment agriculture. Instead of being grown outside in soil, plants in vertical farms are stacked on shelves inside, misted with nutrients and lit with LED lights in lieu of sunlight.

Garrett Broad, an assistant professor at Fordham University whose research focuses on new food technology, food justice, and community-based organizing, says vertical farming has many sustainability boons.

Because the environment is completely controlled, the weather cannot destroy or affect crops. Vertical farming saves water. It reduces runoff. There’s no need for pesticides. And any kind of crop can be grown year-round. Fulop predicts Jersey City’s program will produce 19,000 pounds of food annually.

“The idea is that by doing vertical stacking, you can get a lot of productivity out of a very small area,” Broad said.

Farmers tend plants at AeroFarms with the help of platforms that can rise and fall.~Courtesy of AeroFarms

But, there are downsides. Vertical farming is extremely energy-intensive. Even energy-saving LED lights require a huge amount of power to shine on the crops. According to Fulop, Jersey City has no way to offset the impact of this energy use yet. Many of the farms are housed in decades-old buildings that have not been updated to include solar panels or other energy-saving technologies.

“It’s something we need to consider in the future,” said Fulop.

The other issue with vertical farming is that leafy greens are essentially the only plants worth growing, said Broad. Larger, heavier fruits and vegetables have too much biomass and require too much artificial light and nutrients to grow in a cost-effective way.

Indeed, Fulop confirmed that greens are the “easiest base material” to grow and will be the focus of Jersey City’s vertical farms.

That said, vertical farms do have the ability to create change in a community when done right, said Broad.

“Vertical gardens are similar to other urban farming projects we see,” he said. “They exist on a sort of spectrum. Some are total failures, some are a fun project and some are actually part of a social change.”

Projects that don’t receive enough funding or attention rank as “total failures.” Small community gardens rank in the “fun project” category -- “They provide small scale change. People get to know their food a bit more, they learn some horticultural skills, but it doesn’t drastically change the community,” said Broad.

According to Broad, Jersey City will have to do extensive community outreach to make vertical farming a long-term success – which means reaching out to faith leaders, schools and groups that are trusted by the community and getting them involved with the distribution of produce.

It means talking to residents about what vegetables they actually eat; planning cooking classes at times when people aren’t working; making dishes at those classes that the attendees will actually cook in their own homes.

As technology continues to improve, the company expects vertical farming to become even more cost-effective. | Courtesy of AeroFarms

“Did we ask to see if the people who are actually the target of this project have working kitchens? Are we making sure they have pots and pans? Are we growing food that’s culturally relevant to them? If we don’t ask these questions, a lot of times vertical farming projects stay in the ‘nice and fun’ category,” Broad said.

Jersey City has launched a few food initiatives in past years. The city gave grants to bodegas and corner stores to redesign display cases, putting fruits and vegetables next to their counters instead of snacks and candy to encourage healthy eating. Another program involved walking senior citizens around a supermarket and teaching them to read the labels on the back of packaged foods. At the end of the tour, they were given money and encouraged to purchase healthy meals.

Areas in which there is an extreme lack of nutritious, affordable food have been called “food deserts.” But, those who study farming technology have been moving away from that term, which brings up images of scarcity and used-up land. Instead, “food swamp” is now used to describe cities and towns that have food available, but few healthy options. Others use the term “food apartheid” to draw attention to food inequality. Poorer neighborhoods are usually the places that lack fresh, affordable food.

Jersey City is one such place, said Broad. If given the right attention, he added, a vertical farming initiative could be a step toward addressing poverty and food inequality.

“This is the kind of thing that can be fun and flashy and get media attention,” he said. “But, it’s up to us to apply pressure to the government and say, ‘OK, show us how this is part of something bigger.’”

Rebecca King is a food writer for NorthJersey.com. For more on where to dine and drink, please subscribe today and sign up for our North Jersey Eats newsletter.

Email: kingr@northjersey.com Twitter: @rebeccakingnj Instagram: @northjerseyeats

June 26, 2020

Former Pilot Grounded With Urban Farming

URBAN farming is fast catching on in Malaysia with many young people taking it up to grow vegetables in the backyards of their city dwellings

BY JENIFER LAENG ON JUNE 14, 2020

Chuo’s hydroponic lettuces are grown in the backyard of his parents’ home.

URBAN farming is fast catching on in Malaysia with many young people taking it up to grow vegetables in the backyards of their city dwellings.

There are many types of urban farming but one that is popular with many city folk is hydroponics.

Former pilot Eric Chuo Chuan Jin of Miri said he developed his interest in urban farming, particularly hydroponics, when he changed his diet last year.

“It all started when I became concerned about my health. I began working out and making changes to my eating habits, basically looking for clean and nutritious food.

“But eating healthy isn’t easy, especially here, and to get around this, I started thinking about how I could grow clean food in the backyard,” the 31-year-old recalled.

Chuo regularly checks on the lettuces he grows in his parents’ backyard.

Chuo said he researched the subject online and attended a hydroponics course in Kuala Lumpur.

“Thankfully, we have the Internet where we can pick up a lot of things. That was how I learned about hydroponic techniques.”

Of the many hydroponically grown vegetables, Chuo chose lettuces such as green coral, butterhead, and red leaf.

It took him some two months — from November last year — to plan and set up his small soil-less farm in his parents’ backyard (about 1,500 square feet) at Taman Tunku.

Chuo admitted starting the project wasn’t smooth sailing and it took him some time to get things right. But with all the trials and errors behind him, he has been reaping the fruits of his labour with good lettuce harvests since January.

New batches of lettuce are continuously planted to ensure consistent supply.

Before going into hydroponic farming, Chuo was a pilot, then a service engineer in Brunei, before moving back to Miri for good.

Opportunities

As he started to harvest more and knowing the difficulty in obtaining fresh and pesticide-free vegetables locally, Chuo realized the huge potential in commercializing his organic greens.

Subsequently, he set up a company to supply fresh, quality, and affordable vegetables to the people in Miri.

Chuo and his mum stand beside the stands of his hydroponic greens.

With his parents’ help, he has so far managed to sell to a few fruit stores, restaurants, and supermarkets.

“I supply about 5kg of lettuces daily to these places. Sometimes, I get surprise purchases from walk-in customers as well,” he said.

Chua said while he was able to do business under the Movement Control Order (MCO) and the Conditional MCO from March 18 till June 9, he couldn’t supply to restaurants which had been closed due to the lockdowns.

A few days before these lettuces are harvested.

“As you know, lettuces are widely used in restaurants for western food. So when they stopped operating, I was forced to look for other options.

“That was when I approached and negotiated with the supermarkets and stalls, selling fresh fruits, to include my vegetables on their racks. Thankfully, I managed to find these much-needed outlets,” he said.

Now, with the lifting of restrictions, Chuo said he couldn’t wait to resume business with the restaurants he had previously supplied

Challenges

While enjoying good business with his homegrown lettuces, he also faces the challenge of maintaining the amount he produces — on top of vouching for their quality — to ensure consistent supply to meet demand.

According to Chuo, one of the main concerns is the weather as lettuces need cool weather and slight shading to grow.

Fresh lettuces ready for delivery to the supermarket.

He needs to check the water level regularly to produce quality vegetables. The ventilation uses a timer, so it’s easy to control the moisture.

Another consideration is the high electricity bill.

“The ventilation, including the watering system, is automated, so electricity consumption is relatively high. But this is not a big issue,” he said.

Chuo pointed out that due to the limited growing space and the lengthy period between harvests, he had to keep planting in batches to ensure uninterrupted supply.

“It takes 45 days for each head of lettuce to be ready for harvest. So I have to plant continuously to avoid running out of stock. The challenge is I have limited growing space.”

Because of the huge market potential for his products in Miri, Chuo said he would be starting another project soon.

“I’m trying to plant other vegetables as well — tomatoes and herbs such as parsley.

“I’ll be using the same hydroponic and pesticide-free techniques to keep the taste, freshness, and quality of the vegetables,” he said.

New VIDEO by Food Retailer Freson Bros. Highlights Fresh Lettuce From Swiss Leaf Farms, Grown Inside a CubicFarms System

Shoppers at Freson Bros. now have access to locally grown lettuce that helps support Alberta jobs, increase food security, lower food miles, and use significantly less water

Alberta-based Freson Bros., a food retailer supplied by our customer Swiss Leaf Farms, produced a video to show how beautiful, fresh, and tasty lettuce is grown inside a CubicFarms system. Shoppers at Freson Bros. now have access to locally grown lettuce that helps support Alberta jobs, increase food security, lower food miles, and use significantly less water.

The Origins of Hydroponics

If one of you went to your grandfather and told him that people are growing plants and crops solely using water and have eliminated the soil use, he would've probably sighed and thought "Is this why we spend money on this nalayak's education?

Adhyayan Panwar | 22 Jun 2020

If one of you went to your grandfather and told him that people are growing plants and crops solely using water and have eliminated the soil use, he would've probably sighed and thought "Is this why we spend money on this nalayak's education?".

However, this is actually a practice. Plants can be and have been grown (for a while now) using almost no soil and “hydroponics” is the name given to this practice. Plants' roots are submerged in a water-based liquid, with extra nutrients and minerals added which are essential for the growth of the plants. In some cases, a medium is used so that the roots can hold the plants' weight and keep them upright. This medium is porous so that it can hold moisture and oxygen that the plants will require. The most popular media are clay, coir, brick shards, etc.

The solution contains all important nutrients present in appropriate proportions which ensure optimal growth. The main constituents are Nitrogen (N), Potassium (K), Calcium (Ca), Magnesium (Mg), etc. These are just some of the sixteen elements that are required by plants. Growing systems that don't use a medium are called liquid hydroponic systems which includes NFT (nutrient film technique, in which plants are put in slits in a tube through which nutrient solution is pumped), floating hydroponics, etc. When a medium is used, it's called aggregate hydroponics system which is further divided into open and closed systems. Rockwool is the most widely used medium in open system hydroponics.

Hydroponics is not, by any means, a new technology. Let's trace this practice right back to its origins.

THE ORIGINS:

The origins of hydroponics can be traced back to the ancient city of Babylon, where present-day Iraq is located. The Hanging Gardens of Babylon, one of the Seven Wonders of the Ancient World, is the first known example of soil-less growth of plants. This was around 600 BC. Later on, around 1100 BC, the Aztec Indians got creative with their growing techniques and created gardens that seemed to be floating. These “floating gardens” were called 'chinampas', which had a strong combination of roots and lashes, laden with sediment from lake-bottoms, providing nutrients to the crops and plantations.

Similar floating plantations were discovered by Marco Polo on his visit to China, which left him bewildered as he hadn't seen anything like this ever before. The first scientific perspective towards this soil-less technique is attributed to the Italian genius, Leonardo da Vinci, who observed that plants and crops needed to absorb minerals to survive. His findings were published after his death, that implied his famous branching rule: "all the branches of a tree at every stage of its height when put together are equal in thickness to the trunk".

THE JOURNEY:

In 1627, Sylva Sylvarum was published. Written by Francis Bacon, Sylva Sylvarum contained the earliest work on growing terrestrial plants with soil-less techniques. Major discoveries were made in the 17th century. Jean Baptista van Helmont, a Belgian chemist, discovered and proved that plants obtain the necessary minerals and nutrients (he called them "substances") from water. He performed the willow tree experiment, where the tree gained 164 pounds or 74.4 kg but the soil amount remained the same throughout the experiment. John Woodward performed the spear-mint experiment, which showed that plants grow better in impure water than to distilled water. The first standardized nutrient solution was created in the 18th century by Julius von Schaps and Wilhelm Knop which laid the foundations of hydroponics as we know it today. This solution made it possible to grow roots without any medium. Knop went on to create yet another solution, which is still in use today.

The word “hydroponic” was first used in 1937, coined by Dr. William Frederick Gericke, aptly known as the “father of hydroponics” (he made news when he was able to grow tomato vines more than 7-meters long just using mineral-nutrients solutions, right in his backyard!). The word is a combination of the Greek words “hydro” (meaning water) and “ponos” ( meaning labour). This means water-work, literally. After leaving his University position, Gericke wrote and published ‘Complete Guide to Soil-less Gardening’ in 1940. Then came into the picture Dennis R. Hoagland, who created a nutrient formula that provided the plants with all the nutrients essential for growth and catered to a large diversity of plant species. The Hoagland solution still serves as the basis for most of the nutrient solutions that are being utilised even today. Alongside Daniel I. Aaron, Hoagland published ‘The Water Culture Method for Growing Plants without Soil’, which is considered the most important text in hydroponics culture. There are accounts of the US Army using hydroponics to grow fresh food for the troops stationed in the infertile Pacific Islands, during World War II.

As the hydroponics technology picked up the attention across the world and the usage grew, it’s inevitable commercialisation took place. Lawrence Brooks founded ‘General Hydroponics’ in 1976. Now, even after 40 years, GH remains one of the leaders of continuously expanding the market of hydroponic mineral-nutrient solutions. In 1982, a new area called ‘The Land Pavilion’ was opened in Disneyworld’s EPCOT Center, where a ride goes through “gardens of tomorrow”, which are grown using hydroponic technology.

When you think about hydroponics, aside from the typical applications of the practice, you may also think about its applications in space and space travel. NASA is actually quite heavily invested in the practice of hydroponics. A research department completely dedicated to hydroponics and bio-farming was developed by NASA where they researched the growing of plants in extreme environments and hydroponic technology was a big player in the research.

THE PRESENT:

There’s no other way to put it, hydroponics is thriving. As per a recent Hydroponics Market Research Report, it is projected that the hydroponics market will be worth $27.29 billion by the year 2022. Currently, almost 90 percent of lettuce and tomatoes that are being grown in the US and Canada are being grown using hydroponics. As the population of the world keeps growing, hydroponics becomes a more viable substitute for traditional farming. Hydroponically grown crops take only 25 percent of the area used by traditional soil growing, for the same amount of crops. We all know the harrowing threat of water scarcity in the coming years. With hydroponics, water usage can be cut down by 90 percent. This is just another reason why hydroponics is booming. Zero pesticides and herbicide involvement, growth rate twice as fast as traditional agriculture, nutrient solutions with perfect pH eliminating soil worries, and the list is never-ending, which is why hydroponics is need for the present.

Countries have already started dedicating acres of lands for commercial hydroponics, including 10,000 acres in Holland, Israel reserving 30,000 acres, Australia and New Zealand having 8,00 acres between them and Canada with hundreds of acres of land for large-scale commercial greenhouses, mainly growing tomatoes, peppers, and cucumber. In India, hydroponics is still a pretty new technology but initiatives are being taken. Many startups have taken it upon them to make hydroponics more popular, affordable and accessible. These startups use new technologies like IoT (Internet of Things), data analysis, etc to perfect the procedure and make it as efficient as possible.

THE UNKNOWN:

While we don’t know what the future holds exactly, we can make a couple of calculated predictions as a society. Statistics and reports already indicate that hydroponics will have a special place in the coming years. As the concept of space travel and exploration becomes closer to reality with each passing day, hydroponics will find a place in long flights across space, where agriculture is restricted due to area and soil-weight limits. Similarly, when Mars colonisation does become a reality (Elon, we are looking at you) we won’t have to suffer the infertile and barren lands of unexplored planets since hydroponics will allow basic levels of agriculture, which is said to be the foundational step of every human civilization. Several companies across the globe have also begun providing ways to grow vegetables at home as well. As technological advances are being made, it won’t be surprising to see people growing their own assortments of vegetables in their own houses. There are already plenty of homes today that have home hydroponic installations.

With the drastic need for more and more land for the ever increasing urban sprawl, which reduces the land available for agriculture, hydroponics will eventually creep into our daily lives and get infused with our culture. Startups, commercial giants and space agencies have already begun traversing into this field. So, don't be surprised, when in the coming years every edible thing you see has hydroponic origins and your neighbor in a high-rise skyscraper is a successful farmer.

Adhyayan Pan

Shipping Container Farms Come to London as Growers Ditch Soil

In the era of climate change and Brexit, British farming is facing unprecedented challenges. How to supply environmentally friendly, locally sourced, and competitively priced food?

Vegetables Are Grown Vertically Supplied With Nutrient-Rich Water

20 June 2020

Racks of vegetables grown in a shipping container in London CREDIT: Fiona Hanson

In the era of climate change and Brexit, British farming is facing unprecedented challenges. How to supply environmentally friendly, locally sourced, and competitively priced food?

One part of the answer could lie in a shipping container in an east London car park, just moment’s away from the capital’s business district. Inside are racks of leafy green vegetables, grown vertically using hydroponic technology. Instead of being planted in soil, the vegetables are plugged into a system of nutrient-rich water and kept at the optimal temperature, under specially designed lighting.

The result is flavorsome lettuces, kale, basil, and other leaves, free of pesticides and using up to 95 percent less water than traditional agriculture over a fraction of the space. The shipping containers, which are custom made, mean the produce can be located virtually on the doorstep of its market, effectively eliminating food miles.“

Traditional organic farming is not sustainable if we're going to feed a population,” says Sebastian Sainsbury, the founder of Crate to Plate, which has just had its first harvest.

Not only does Crate to Plate use otherwise wasted space - these three shipping containers can grow the equivalent of an acre’s soil - but the proximity to customers keeps the produce fresh.“ When you harvest the lettuce from the soil, within 48 hours, you've lost 40 percent of the nutritional value. And it goes down every day,”