Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Horticulture Lighting Calculator Speeds Grow Light Development

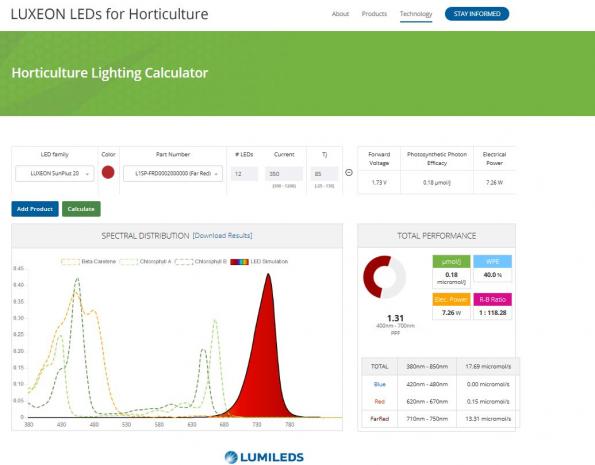

Designers of grow lights for greenhouses, vertical farms and other horticulture applications can speed up their time to market by using an online calculator freely accessible online Lumileds' website

Horticulture Lighting Calculator Speeds Grow Light Development

January 18, 2017 // By Julien Happich

Designers of grow lights for greenhouses, vertical farms and other horticulture applications can speed up their time to market by using an online calculator freely accessible online Lumileds' website.

The calculator allows the user to input various LED combinations and operating conditions to generate the spectral power distribution, photosynthetic photon flux (PPF), and power usage of a fixture using Lumileds LUXEON SunPlus Series LEDs.

Designed to allow easy modifications of LEDs and operating conditions, the calculator facilitates fixture design by generating real-time feedback on spectral power distribution.

“With the Horticulture Lighting Calculator, fixture manufacturers can test many lighting scenarios in a short period of time, so that their optimum designs can be brought to market much more quickly and efficiently than if each potential fixture were built and tested individually,” explains Jennifer Holland, Product Manager of the LUXEON SunPlus Series LEDs and Horticulture Lighting Calculator.

Try out the Horticulture Lighting Calculator atwww.lumileds.com/horticulture/calculator

Empowering Indoor Farming

EMPOWERING INDOOR FARMING

With integrated, intuitive and intelligent solutions to achieve maximum efficiency, quality, and profitability.

CoolFarm came up in this new context where our dominant food paradigm is breaking down: climate change, increasing droughts, soil depletion and disease, excess fertilization, phosphorus scarcity, water pollution, chemical overloads, pollinator destruction, and biodiversity loss, threaten our business-as-usual approach to food production. Consumers and retailers are increasingly demanding safer, high-quality foods with less unpaid burden on our shared environment and public health. It’s forecasted that by 2050 we will need to feed more than 10 billion people, requiring a 70% increase in global food production.

CoolFarm brings a disruptive technology that helps to solve this problem. No matter if we are talking about greenhouses or warehouses (urban farming, indoor farming inside the cities), crop production is optimized, resulting in more efficient management of human resources, maximum water, nutrients, acid, and energy savings. The technology combines artificial intelligence and machine learning, aiming at growing crops in the most efficient way, giving to them what they need and when they need it. All data is managed in the cloud and can be assessed online or offline, through mobile phones, tablets or laptops. For this CoolFarm also developed an innovative optical sensor called CoolFarm Eye that sees and feels the plants behaviors regarding all the actions that are being taken over the crops, allowing plant awareness.

COOLFARM SOLUTIONS

CoolFarm Eye

The Eye is a smart camera that uses NDVI (Normalized Difference Vegetation Index) technology combined with advanced computer vision algorithms to measure plant size (Leaf Area Index), growth rate and health index. All data is pushed to the cloud and displayed on your CoolFarm dashboard. It comes equipped with an anti-fog fisheye lens, allowing it to be installed in vertical farming warehouses or normal greenhouses. The Eye uses a single PoE (Power over Ethernet) connection for a cleaner installation, using a single cable for both power and communication. It is equipped with a Web server that allows an easy setup of the sensor, as well as direct access to all images used during the image processing algorithm (raw, LAI and NDVI), for an easier calibration process.

CoolFarm in/cloud

in/coud is made for growers that want to keep their current control systems but also want to manage their farms at once, anywhere and anytime, integrating all relevant data in a unique and easy to use dashboard. The software features are: recipes module to control any relevant variable such as the light cycle, water cycle, nutrients tanks, air specifications and water conditions; integrated data in real time; notifications; powerful analytics; activity log; complete administrative panel to create and manage all users and farms at once.

CoolFarm in/control

in/control is the all-in-one control system easily adapted to all indoor typologies and growing techniques. It ́s the most integrated, intuitive and intelligent control system available in the market. It includes all in/cloud features and all CoolFarm sensors: Air temperature, Humidity, and CO2; CoolFarm Eye; pH; EC; DO; ORP; Ammonia; Nitrate; Nitrite; Water Flow; Level Sensor and Pressure Sensor.

CoolFarm in/store

To be unveiled to the world in March 2017 at EuroShop (http://www.euroshop-tradefair.com/ ) retail trade fair, in/store is the ultimate turnkey solution to grow indoor! It is a closed climatized and vertical space that works with hydroponics, LED lights, growing beds managed by lifts (that work both vertically and horizontally) and with all CoolFarm Technology inside (meaning that it is intelligent and can be controlled remotely).

The goal is to bring fresh crops into different commercial places, close to people and all year round, with the capability to manage crops cycles in time, meaning more production, no costs in transportation, less environmental pollution and zero waste.

The system is built in a way that there is no need for the operator to enter inside the module to harvest or monitor the crops, since the machine provides to him what he needs and when he needs, eliminating all contamination risks.

If a client wants to grow a large scale production, the client just needs to buy several modules (flexible in height and width). The modules work together like a puzzle, meaning that the client just needs to have one unique feed of water and nutrients for all of them (for example).

It was designed not only to grow plants but also to germinate them.

The Next Generation Of Farmers Is Being Trained In New York City High Schools

The Next Generation Of Farmers Is Being Trained In New York City High Schools

January 5, 2017 - 11:40 AM ET

LELA NARGI

Natalie Arroyo is a senior "Aggie," one of 600 New York City public school students enrolled in a specialized, four-year agriculture program at John Bowne High School in Queens. She plans to become an agriculture educator after college.

It's Monday, 8:00 a.m., and these teens have already mucked stalls in the barn and fed the goats, alpacas and miniature cows. They've rounded up eggs in the henhouse, harvested cabbages and a few green-tinged tomatoes, and arranged them in tidy tiers to sell in the Agriculture Store. And now, they're ready to put in a full day of classes.

These are the Aggies. They're the first kids to arrive at John Bowne High School in Flushing, Queens, in the morning, and the last to leave on the New York City buses and subways that shuttle them home in the evening.

Some 600 of the city's public school students are enrolled in Bowne's specialized, four-year agriculture program. Like most of their schoolmates, the Aggies follow an ordinary curriculum of English, math and social studies. But they also learn the building blocks of diverse careers in the booming industry of agriculture, which sees almost 60,000 new jobs open up in the U.S. every year, according to the USDA. The Aggies grow crops, care for livestock, and learn the rudiments of floriculture, viticulture, aquaculture, biotechnology and entrepreneurship.

While high schools in rural farming areas have long prepared students for these sorts of jobs, they can't come close to meeting the demand. So some urban public high schools are stepping in to fill the void.

Since 2007, students at the Food and Finance High School in midtown Manhattan have grown tilapia and lettuces in interconnected, water-based labs built by a Cornell University agriculturist. The city's Harbor School on Governor's Island has so far graduated three classes of aquaculture students, who have hatched trout and worked on oyster farms that supply restaurants.

Bowne's program is much older — it harks back to World War I, when city boys were recruited to fill in for upstate farmers serving overseas. Today, it attracts a diverse array of students – including many girls. Many are low income; some have parents who hail from Central America and the Caribbean, where more than a few once grew their own subsistence crops.

"We're trying to give these kids as many career opportunities as possible," says Steve Perry, who's headed Bowne's program for 20 years, and also graduated from it. "But for a lot of them, we're also home base."

Forty percent of Aggies go on to ag-degree programs at colleges like SUNY Cobleskill and Cornell, studying everything from animal sciences to food safety and farm management.

"It's so annoying that everyone thinks we're just farmers," says Aggie senior Erika Jerez with a roll of her eyes. She's sporting a sweatshirt from Rutgers University, where she hopes to study food processing next fall. "But there's so much more to ag than farming!"

Erika Jerez, a senior Aggie at John Bowne, hopes to study food processing at Rutgers University next fall. "There's so much more to ag than farming!" she says.

Fellow Aggie senior Jailene Cajilina says her parents farmed a piece of land back in Ecuador. Despite that, she admits that before starting at Bowne, she had a poor idea of how food was grown.

"Being in a city, you lose touch that someone out there is breaking their back growing these plants, having to slug it out with animals and the weather," she says.

Caijilina spent four years doing everything from weeding broccoli beds to interning at an upstate organic dairy, gaining first-hand knowledge of the physical and financial struggles of farmers. That's not a life she's eager to replicate. Instead, she plans to become a large-animal veterinarian.

"A lot of these kids are focused on supporting their families," explains Rebecca Cossa, a Bowne plant science teacher. And with so many farms starting up within city limits, she sees potential for future generations of Aggies to find farm-centric careers close to home.

There's also demand for ag teachers. The New York State Education Department got requests to help set up 65 ag-ed programs statewide last year, some of which require certified ag teachers. It's a number administrators expect to keep growing over the next decade.

Natalie Arroyo already knows that education is the direction she'll be heading when she graduates from Bowne this June. After an internship last summer in which she taught children about animals at a Fresh Air Fund camp, she says, "To see someone who wants to learn what you know, and choose their career based on something you taught them, that's really inspiring."

Says Mayorga, "The kids in the STEM program at Bowne know about science and technology." But the Aggies, she says, can grow their own food.

"That's right," says fellow Aggie Dayana Panora. "The Aggies are ready for the zombie apocalypse!"

Lela Nargi is a Brooklyn-based journalist and cookbook author. Her writing has appeared in publications including Gastronomica, Civil Eats and Roads & Kingdoms.

UAE Innovators Invited to Present Game-Changing Solutions at Global Forum for Innovations in Agriculture

UAE Innovators Invited to Present Game-Changing Solutions at Global Forum for Innovations in Agriculture

Open call for innovations to join fight in feeding growing population, improve agricultural productivity in MENA

Cutting edge businesses, start-ups, researchers, scientists and entrepreneurs of the UAE are being encouraged to present their game-changing agricultural innovations to an influential audience who have the ability to take their solutions to the next level and help tackle food security.

The Global Forum for Innovations in Agriculture (GFIA) is the world’s influential event for the future of sustainable agriculture. The two-day event returns to Abu Dhabi in March 2017 and the Call for Innovations is now open for anyone who believes they can help make a difference to the way in which farmers and growers work and produce food in the MENA region.

From pioneering entrepreneurs to established businesses, more than 300 innovators have presented their solutions and technologies on stage in front of thousands of investors, food producers, retailers, government delegations, scientists and NGOs since the launch of GFIA in 2014.

Facing water scarcity supply and limited availability of fertile land, the Middle East heavily relies on food imported from abroad and the UAE, Egypt as well as Saudi Arabia are among the top fifteen global importers of food, according to a 2015 World Trade Organisation report.

While The Global Food Security Index, developed by the Economist Intelligence Unit (EIU) in partnership with DuPont, indicates that the MENA region made improvements in food affordability, availability, quality and safety between 2014 and 2015, the progressing impacts of climate change will pose new challenges to the region with its soaring population.

According to Alpen Capital's 2013 GCC Food Industry Report, the region will require 49.1 million tonnes of food per year by the end of 2017 with the UAE leading as the largest consumer at 1,486kg per capita annually.

To address this demand, the private sector in partnership with governments should be actively seeking innovative solutions that tackle food security, nutrition and distribution challenges.

“We’re seeking applications from budding entrepreneurs, innovators and practically anyone who has an idea they think can challenge conventional methods of agricultural farming,” said Nicola Davison, GFIA Event Director.

“We’re especially encouraging those from Abu Dhabi and the wider UAE community to come forward. Now is the time to share your ideas and innovations that can help farmers improve productivity in our region in a sustainable way and help to counter global hunger through pioneering developments in sustainable agriculture.”

All entries should be made online at www.innovationsinagriculture.com before the 31August 2016 deadline, and will be judged by a network of international partners including Anterra Capital, McKinsey, the University of Wageningen, CGIAR and the University of Arizona.

The programme for next year’s event will cover the entire agricultural spectrum, with a particularly strong focus on themes most relevant to the MENA region including climate-smart agriculture, disease and pest management, salt water agriculture, water management, ICT solutions and organic agriculture.

New features to the show include an expanded livestock area, a start-up pavilion to help emerging ag-tech companies meet potential investors, an AgriFood Leaders Forum and a Demo Zone where exhibitors will give live and practical demonstrations of their products and systems.

Speakers from the 2016 edition included His Excellency Dr Thani bin Ahmed Al Zeyoudi, Minister of Climate Change and Environment, His Excellency Rashed Mohammed Khalfan Al Shariqi from Abu Dhabi Food Control Authority, Aidan Cotter from the Irish Food Board, Mamadou Biteye from the Rockefeller Foundation in Kenya, and Haydar Alsahtout from the Arabian Shrimp Company in Saudi Arabia.

“Earlier this year, more than 6,000 visitors from 96 countries descended upon Abu Dhabi to take part in dozens of presentations and panel discussions uniquely designed to tackle world hunger and food security in the face of climate change and resource scarcity,” added Davison.

“We saw more than 80 game-changing innovations for agriculture presented on stage and many of these innovators have met investors, science partners and technology buyers to take their innovations to the next level.

“This year, we plan to present even more solutions and technologies that have the ability to influence the way in which food is produced. We have to collaborate if we are to feed 9 billion people by 2050 while facing the challenges caused by changing climate.”

Indoor Harvest Corp and Alamo CBD Enter Into Discussions to Combine and Ultimately Create Medical Cannabinoids Pharmaceutical Group

Indoor Harvest Corp and Alamo CBD Enter Into Discussions to Combine and Ultimately Create Medical Cannabinoids Pharmaceutical Group

January 03, 2017 13:39 ET | Source: Indoor Harvest Corp

HOUSTON, Jan. 03, 2017 (GLOBE NEWSWIRE) -- Indoor Harvest Corp (OTCQB:INQD), through its brand name Indoor Harvest®, is a full service, state of the art design-build engineering firm for the indoor and vertical farming industry. The Company provides production platforms, mechanical systems and complete custom designed build outs for both greenhouse and building integrated agriculture grows.

The Company is pleased to announce it has entered into discussions to acquire 100% of the member interests in Alamo CBD, LLC. (“Alamo”), a Texas Limited Liability Company. Upon closing of the acquisition, it is intended that Indoor Harvest shareholders would retain 40% and Alamo shareholders would retain 60%, of the total issued and outstanding common stock of Indoor Harvest. It is contemplated that at or subsequent to the acquisition of Alamo by Indoor Harvest, Indoor Harvest will spin-off its vertical farming operations including its produce and engineering, procurement and construction related operations to Indoor Harvest shareholders at the closing of the acquisition. The Company’s remaining cannabis related assets, agreements, intellectual property and operations will remain with Indoor Harvest/Alamo.

Alamo has signed an agreement with Vyripharm Enterprises, LLC. ("Vyripharm"), a Delaware limited liability company, to form a Joint Venture for pharmaceutical cannabinoids research (“Joint Venture”). Under the proposed joint venture with Vyripharm, Alamo will provide pure medical cannabis oil/product to Vyripharm in order to provide specific chemical profiles needed for Vyripharm’s research and patient treatments. It is planned that Alamo will, as a result of the acquisition by Indoor Harvest described above, have the right to Indoor Harvest’s patent pending biomanufacturing platform which it will then use in connection with the planned Joint Venture. The Joint Venture’s business plan is to develop specific process IP to achieve specific chemical profiles to treat various medical conditions such as epilepsy or PTSD, custom tailored to each patient.

It is anticipated that a condition precedent to the closing of the acquisition will be that Indoor Harvest must raise sufficient capital to repay all existing Company debt and pay for the expenses necessary to complete the spin-off of its vertical farming operations and to complete the proposed acquisition, currently anticipated to be approximately $1,000,000 in the aggregate. John Choo, Chief Executive Officer of Indoor Harvest noted, “The acquisition and spin-off transaction currently contemplated would, if all aspects of the transaction are effected as currently planned, complete Indoor Harvest’s previously announced plan to separate our cannabis and produce related operations.”

Chad Sykes, founder and Chief Innovation Officer of Indoor Harvest, added, “It will be the aspiration of our Company after acquisition of Alamo and thus becoming a joint venture partner with Vyripharm Biopharmaceuticals, to become a leader in the medical cannabinoids pharmaceutical space. Our aeroponic biomanufacturing platform allows for very precise control of plant expression, which allows a producer to create repeatable, consistent chemical profiles. We believe that unlike the small number of pharmaceutical groups operating in cannabis today, which use less precise cultivation methods and isolate certain chemical compounds, we can harness the benefits of the full entourage effect through the actual cultivation process. The planned Joint Venture that we’ll become part of our acquisition of Alamo has the potential to leverage our individual entities’ IP, agreements and relationships and would position us to become a major part of a serious player in the pharmaceutical space and medical cannabis research.”

Alamo’s current business plan is to use ten (10) acres of land, to include water rights, in La Vernia, Wilson County, Texas, to construct a 17,500 square foot cannabidiol pharmaceutical production facility. Alamo plans to seek a license to operate their facility under the Texas Compassionate Use Act. The Texas Compassionate Use Act (Senate Bill 339) was signed by Gov. Greg Abbott and became effective June 1, 2015. The bill requires the Department of Public Saftey (“DPS”) to create a secure registry of physicians who treat epilepsy for the purpose of prescribing low-THC cannabis to patients who have been diagnosed with intractable epilepsy. In addition, the bill requires DPS to license at least three dispensing organizations by Sept. 1, 2017. In addition to plans to file an application to operate under the Texas Compassionate Use Act, Alamo also plans to file an application with the DEA and register to become an authorized producer of medical cannabis and medical cannabis extracts for pharmaceutical research and clinical trials within the United States.

Vyripharm has advised us as follows: It is a biopharmaceutical company with a goal of improving clinical management through diagnosis and treatment with botanicals, synthetic pharmaceuticals and drug delivery systems. Vyripharm is reformulating its patented In-Situ Hydrogel, N4 Technology and Oligosaccharide (Dual Agent) Technology to develop applications in combination with medical cannabinoids for nuclear imaging and treatment for neurologic disorders including, but not limited to, post-traumatic stress disorder, epilepsy, acute/chronic disorders, cancers, metabolic disorders, and microbiome. Vyripharm is working diligently to prepare and file a range of new patent applications covering what it has described to us as being breakthrough work on medical cannabinoids (synthetic/natural).

Dr. Elias Jackson, Vyripharm’s Director of Scientific Public Relations said, “Early studies have shown a positive impact on certain resistant forms of cancer. We are carefully analyzing these results before we formally release this data. Based on the strength of these early studies, we believe that medical cannabis will play a vital role in the treatment regimen addressing a range of cancers, and that Texas and the Texas Medical Center could become a focal point for this important research.” Vyripharm has entered into sponsored research agreements for its core platforms with the University of Texas Medical Branch Galveston, The University of Texas Health Science Center at Houston – Institute of Molecular Medicine Sponsored Research and The University of Texas M.D. Anderson Cancer Center. There is also an agreement with the National Institute of Drug Abuse and has pending agreements with Baylor College of Medicine and the VA Hospital in Houston, TX.

Cynthia Cortez, Alamo’s Marketing Director said “Alamo together with Indoor Harvest after the planned acquisition transaction and through the Joint Venture will have complete control over the entire grow process to ensure consistent high quality medical cannabis. Utilizing Indoor Harvest’s state-of-the-art cultivation process will maintain a clean product for patients. In addition, Alamo looks forward to working with Vyripharm to provide what is intended to be high-quality medical cannabis for their research and development studies. We believe that Vyripharm, Indoor Harvest and Alamo share the same goal of becoming recognized as the global leaders in comprehensive cannabis product testing, certified pure cannabis oil, and evaluating the efficacy of certified pure cannabis in humans.”

Alamo and Indoor Harvest are currently completing customary due diligence and it is expected a definitive acquisition agreement will be agreed upon on or before February 15, 2017. We understand that Alamo and Vyripharm are also completing customary due diligence regarding the proposed Joint Venture which the parties expect to complete a definitive agreement prior to the closing of our acquisition of Alamo.

Consistent with the SEC’s April 2013 guidance on using social media outlets like Facebook and Twitter to make corporate disclosures and announce key information in compliance with Regulation FD, Indoor Harvest is alerting investors and other members of the general public that Indoor Harvest will provide weekly updates on operations and progress through its social media on Facebook, Twitter and YouTube. Investors, potential investors and individuals interested in our company are encouraged to keep informed by following us on Twitter, YouTube or Facebook.

ABOUT ALAMO CBD

Alamo CBD, LLC is dedicated to producing high quality CBD products in service to the patients of South Texas. The company is based in the San Antonio metropolitan area and was founded by a qualified team consisting of a pharmacist, a neuropsychologist, a microbiologist, a horticulturalist, and a dietitian. For more information, please visit http://www.alamocbd.com.

ABOUT VYRIPHARM BIOPHARMACEUTICALS

Vyripharm is a biopharmaceutical firm focused on natural products, regulatory testing, pharmaceutical drug development, data storage, monitoring technology, development of imaging agents, and drug delivery systems. The aim of Vyripharm is to improve clinical management through diagnosis and treatment with botanicals, synthetic pharmaceuticals, and drug delivery systems.

ABOUT INDOOR HARVEST CORP

Indoor Harvest Corp, through its brand name Indoor Harvest®, is a full service, state of the art design-build engineering firm for the indoor farming industry. Providing production platforms and complete custom designed build outs for both greenhouse and building integrated agriculture (BIA) grows, tailored to the specific needs of virtually any cultivar. Our patent pending aeroponic fixtures are based upon a modular concept in which primary components are interchangeable. Visit our website at http://www.indoorharvest.com for more information about our Company.

FORWARD LOOKING STATEMENTS

This release contains certain “forward-looking statements” relating to the business of Indoor Harvest and its subsidiary companies, which can be identified by the use of forward-looking terminology such as “estimates,” “believes,” “anticipates,” “intends,” expects” and similar expressions. Such forward-looking statements involve known and unknown risks and uncertainties that may cause actual results to be materially different from those described herein as anticipated, believed, estimated or expected. Certain of these risks and uncertainties are or will be described in greater detail in our filings with the Securities and Exchange Commission. These forward-looking statements are based on Indoor Harvest’s current expectations and beliefs concerning future developments and their potential effects on Indoor Harvest. There can be no assurance that future developments affecting Indoor Harvest will be those anticipated by Indoor Harvest. These forward-looking statements involve a number of risks, uncertainties (some of which are beyond the control of the Company) or other assumptions that may cause actual results or performance to be materially different from those expressed or implied by such forward-looking statements. Indoor Harvest undertakes no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as may be required under applicable securities laws.

Contacts: Indoor Harvest Corp CINO, Mr. Chad Sykes 713-410-7903 ccsykes@indoorharvest.com

The Aquaculture Industry, Other Than For Shellfish, Is Completely Dependent On The Animal Feed Industry That Sustains It

Grass Fed Fish

The Aquaculture Industry, Other Than For Shellfish, Is Completely Dependent On The Animal Feed Industry That Sustains It.

By John Reid*

This sounds almost silly to say because it is so obvious, but few fully understand where their feed comes from, and the changes that are accelerating amongst all animal feeds as well as for aquaculture diets. This is kind of like the old adage that most people think that “food comes from the supermarket”, forgetting about the role of farms that produce our food. With aquaculture, many people forget that (excluding fish meal) the source of all of our aquaculture feeds is not from our feed suppliers, but our farms, and in particular our soil, water resources, and climate.

There are four key global trends that are colliding to create a great opportunity and challenge for animal protein production and especially the aquaculture industry. The success of surmounting these will depend entirely on our feed sources. These four are: the growing global demand for more meat protein, skyrocketing population growth, soil erosion, and climate change factors like declining water availability, rising temperatures, and ocean acidification.

Immediately you may be beginning to think this is an article about some doomsday scenario; it is not, but only because I will be so bold as to say, because we will have addressed a major shift in the kinds of fish we grow and the feeds we feed them. This article is not necessarily a unique description of our challenges, but possibly a unique solution.

Macro Environment Challenges

The world’s population now stands above seven billion people and all estimates have it growing to about ten and a half billion by 2050. This is a growth increase of 35% or 1.5 million new people per week. We are adding (and need to feed) the equivalent of one additional New York City metropolitan area every two months!

A 35% growth in population means we need to increase the global food supply by at least 35%. This in itself is a daunting challenge to accomplish, but due to changing eating preferences towards higher meat consumption, it is expected that world food production will need to increase by nearly 100%. This is due to the additional feed needed to produce an increasing percent of animal protein.

In the next 35 years this 35% to 100% increase in food production needs to be created in as much as 30% less land than is available for today’s population. This is due to declining soil fertility, and soil erosion. In the US, an area the size of the state of Rhode Island is lost every year to soil erosion. Between 1840 and 1917 when the first soil surveys of the US were done, there was over eight feet of topsoil depth (or tilth) across the US. The average today is approximately eight inches. By some estimates soil loss in the US is greater now than it was during the ‘dust-bowl’ days of the 1930’s. (We have consumed our fossil soils in similar ways as our fossil fuels). The US has lost nearly 87% of its topsoil resources since the mid 1800’s. The loss of topsoil costs the US USD$36 billion every year in productivity losses.

Around the world soil is being lost 10 to 40 times faster than it is being replenished. Worldwide, cropland is shrinking by more than 10 million ha a year due to soil erosion (about the size of the state of Indiana every year). This implies that farming techniques used today are not sustainable, and production on much of the US and global soils needs to be changed to less soil intensive techniques. Next to (and irrespective of) Global Warming, soil loss is considered the greatest challenge to sustaining US and global food supplies. It is questionable that soils of US and the world can maintain their current output let alone sustain the massive increase in agriculture that will be needed to sustain population growth.

Compounding the dearth of soil tilth is diminishing water availability. Even if more land were pressed into agricultural production (at great cost to forests and biodiversity), there is not the water needed to support additional cultivation using existing practices. Some 70% of the planet is covered by water, but only 2% is fresh water, and of that 2%, 1.6% is (currently) contained in frozen ice caps, leaving only .4% available for the existing population of 7 Billion people. By 2025, the World Bank predicts that 66% of the world will run short of fresh drinking water and 80% of the world will be fresh water limited by 2050.

The water shortages for agriculture will be immense. Meeting crop demands in the next ten years, for 2025, when the world´s population will be ‘just’ 8 billion, will require a new volume of water equivalent to the entire flow of the Nile river, times ten! There just simply will not be enough water to increase current agricultural output by 100% using current practices. There may not even be enough to supply the base of 35% needed to feed the world as we do today.

Multiplying the negative impacts on food production, beyond the trends of soil loss and water shortages, are the effects of climate change or global warming. There are many impacts of global warming on agriculture that are too numerous to note here, but probably the largest will be the impact of excessive heat. With many crops already growing near their maximum heat tolerance, most crop yields will fall with any further rise in temperatures. Corn fails to form seed heads when average growing temperatures are above 95°F and soybean above 102°F. Crop yields are predicted to fall by much as 10% in the US and as much as 50% in Pakistan, or about a 30% global reduction in output due just to heat, not counting lost soil or limited water resources. There are many compounding factors like ethanol production but heat is one of the key factors for price spikes and long term increase in grain prices.

The impact of global warming on food supplies does not stop on land, but continues deep into the oceans. Not counting aquaculture, currently 16% to 20% of the world’s protein comes from ocean fisheries. Including the 5% of the world’s protein produced from fisheries products that are fed to animals, the oceans’ percent of global protein production is near 25%. Given that it takes 2 to 15 pounds of grain or fodder to grow a pound of protein on land, the 16% to 25% of global protein that comes from the oceans is reducing the load that terrestrial agriculture needs to produce protein by as much as 50% (assuming a good food conversion ratio or FCR of 2). Ocean yields in many areas are falling due to overfishing, but global warming will exacerbate declining ocean harvests. Even if ocean harvests remain constant, the 100% new food production needed will not have the ~25% subsidy that is currently provided by the oceans. This means we are likely faced with producing as much as 150% more food to maintain expected market preferences.

Marine or ocean-based aquaculture cannot be counted as a true increase in ocean yields because it relies from 50% to 90% on terrestrially produced feeds. Aquaculture can create protein more efficiently but is not a true substitute for lost ocean harvests because even ocean aquaculture is dependent on land based soil and water resources to grow feed. Feeding terrestrial-based feeds to an ocean environment is also a form of soil erosion, a concept discussed more below.

Like the terrestrial impacts of global warming, impacts on fisheries yield are also too numerous to note here. Currently the largest impact is projected to come from changes in the pH of seawater, or ocean acidification. The dissolving of CO2 into seawater, forming carbonic acid, causes ocean acidification. Predictions on the decline in ocean fisheries yield due to ocean acidification are still preliminary but range from 10% to a 50% drop in all ocean yields by the end of this century. Calcium based shelled animals, like shrimp, crabs and mollusks are the most at risk. They represent 21% of all ocean harvests and their loss could be from 30% to a complete collapse of all production. In 2008, shellfish aquaculture producers in the US Pacific Northwest experienced an 80% drop in shellfish stocks due to drops in ocean pH. Regional stocks have since recovered to 70% of their previous total, but this one event is indicative of how sensitive ocean species are to pH changes. Based on the decline of calcareous algae, which are one of the key supports of the entire marine food system, many fish species may also be at risk.

The net impact of current trends of population growth, soil loss, water shortages, temperature rise, and ocean acidification, (and other factors not noted here) add up to a very challenging time to sustain existing production let alone provide the minimum need of 35% to 150% more food for the world.

The US food system is not likely to collapse but the price pressures put on US supply due to domestic and international demand for exports of protein and grain stock will push US food and especially US protein prices to rise much higher than the normal rates experienced over the last 50 years. This is a large opportunity for aquaculture markets to provide a competitive protein source but a huge challenge regarding the food supplies for aquaculture.

Grains As Our Food Base

The sustainability of aquaculture feed sources is directly related to the sustainability and to the very viability of the aquaculture industry itself. There has been a lot of attention paid to replacing fishmeal in diets given the well-discussed limitations of fishmeal supply, overfishing of fishmeal, as well as price limitations. Concurrent with reductions in use, or a complete shift away from fishmeal, have been innovations in other protein boosters, like insect diets, algae and other protein sources. But these are all added to a base of grains. Even though we are still developing effective all-grain diets, grains have become the backbone of the aquaculture industry, just like they are for Chicken, Pork and Beef.

However as noted above, it is highly likely that grains cannot carry the load of increased production in a sustainable way. Grains are delicious on their own, and provide a cornucopia of other uses, but they simply cannot be looked at as the base that will continue to supply the animal feed industry sustainably.

If soil tilth alone is used as an indication of sustainability we have been “deficit-spending”, draining the bank account of our soil tilth for a long time. Some could argue this goes back to the reasons humans migrated out of Mesopotamia to northern Europe, but that is another article. If one really does the math, the “global stoichiometry,” it simply does not add up to depend on grains for the long-term future of protein production or aquaculture’s food supply. I will be so bold again as to say: it is an inevitability that we must reduce our dependence on grains for all animal feeds, or reduce our dependence on animal protein.

Grass Based Feeds

Rather than everyone going on vegetarian diets, one proposed solution that would work could be grass-based feeds. Everything about grass production is nearly the opposite of grain production. Grasses use a fraction of the water and fertilizer of grains, are more heat-tolerant than grains, have equivalent, sometimes larger biomass yields and many types are high protein. Because grasses are mowed, and not tilled, they protect and grow soil tilth, not consume it. Grasses can be pelleted and processed in similar ways as grains, with many similar mineral and vitamin mixes added. But most importantly, grasses produced in sustainable ways, sequester carbon in huge quantities.

Some claim that a large percentage of carbon emissions causing global warming has come from our lost soils. Not just burning of oil, but soil volatizing back to gaseous carbon that was once sequestered in our deep soils. Even more dramatic is the possibility that converting a large portion of our grain base to grass could recapture this carbon and reduce annual carbon emissions by 25% or more. This is a large controversial topic, but some have powerful and well-grounded arguments that this could be a larger factor in slowing climate change than all the wind, solar or even nuclear production installed to date.

All current terrestrial species could grow well on grass-based diets since most evolved to eat grasses in the first place. Aquaculture has the ability to take the best advantage of grass diets, due to overall lower food conversion ratios, the fact that many fish species are efficient low protein consumers, and other well-known factors.

So how do grass based feeds get the world more production, not just the same equivalent yields in a more sustainable way? A large percentage of grass production will need to replace grain fields, and this is not likely to create any net-new production, but it helps reduce soil erosion and the yield killing impacts of global warming. Gains come when grasses are produced on lands that are now currently too poor to grow grains, land set-asides for soil-conservation purposes become moot, and a net increase in cultivable area is realized. The 60% to 70% lower water requirements of grasses can allow irrigated areas to double or triple their effective acreage. When greater net yields are combined with the greater efficiencies of aquaculture achieving the 35% increase in food production seems likely, and gives us a strong shot at supplying the expanding market for higher protein foods such as fish.

Grasses Are Not A Panacea (Yet)

As with any new approach to production, grass-based feeds need to undergo a lot of development to be commercially viable on the mass-scale that is needed. The first challenge is that commonly grown grasses are not as energy dense, nor protein rich as most grains. This author has worked with diets that were effectively 40% grasses, and 60% grains to boost protein to a minimal level of 28% that was fed to tilapia. Growth was about 90% that of the 32% protein diets used as a control. A good start but not a viable solution for most tilapia growers, and certainly not for other species requiring higher protein diets. Real progress will be made when the ratio can be flipped to 70% grass and just 30% grains or other additives, with equivalent or better growth rates.

This initial formula was based primarily on substituting alfalfa, since that was all that was commercially available at the time. But there are literally thousands of different types of grasses to work with. When these are combined with the new protein boosting compounds coming on the market, based on insects, a wide range of digestive enzymes, and a host of others, perfecting high protein diets in the 35% range seems very likely.

The other side of the coin to raising the protein level of feeds is lowering the protein requirements of fish. Chickens do very well on a 20% protein diet, and this is one reason they dominate the market as a low-cost protein. High chicken growth on low protein feed was not luck, this represents as much as 100 years of development from early modern chicken breeds like the Rhode Island Red to Arbor Acer’s (Avigen’s) breeding stock. Tilapia, grass carp and many others are good aquaculture options, but they are nearly wild-stock species. The genetic potential for fish species is so much greater than poultry, given their lower overhead as cold-blooded animals and many other reasons. We are just scratching the surface at breeding better strains of the existing species we have, or developing new low-protein eating species.

One other challenge for grass-based diets that must be considered is the recycling of aquaculture wastes back to farmland. The soil-regenerative capacity of grasses is large, but if the manure of aquaculture is thrown into rivers, or the ocean, it is a form of soil erosion. Manure is still the biomass of the soil and too much loss can out-strip the soil growth rate, and we are back again at the negative soil production rates we have currently. Applying aquaculture manure to farmland, to a substantial degree will preclude the use of saltwater production. Not to be a ‘soil-fascist’, there is of course some room to feed marine species with terrestrially sourced diets, but it must be kept at a minimum because saltwater manure cannot be applied to terrestrial fields. This places interesting constraints on the kind of aquaculture systems that can be used. Of course RAS comes to mind, but the use of irrigation reservoirs as ponds, or culture cages in large reservoirs where the manure wastes can be cycled back to farmland, also become preferable methods of production.

A large advantage of grass-based feeds as a whole production program combining diets, genetics and production systems, is it is likely to be much more profitable than current aquaculture techniques. All the attributes that make grass-based feeds sustainable, also make it a less expensive production system. The opportunity exists to lower costs sufficiently to rival chicken as the low cost protein in the world, and the massive sales volumes that would come with that.

A Long-Term Program That Must Be Developed Quickly

Given all of the social and environmental issues noted here that are literally growing exponentially, there is a lot to do. To develop grass based feeds, a multidisciplinary approach is needed between farmers, feed mills, additive producers, livestock and aquaculture producers, and universities as well as governments to modify some laws, provide research funding and create some initial market incentives.

Options other than grass-diets may evolve, but whatever they are they will have to meet the basic tenants discussed here. I will be bold again to say that if these are not met, we will not be able to avoid huge calamities in food production, and all the societal issues that can spin out of food shortages. We categorically cannot continue as we are now for much more than 20 to a maximum of 30 years.

The good news is we have solutions. They will involve a large investment, but can generate huge opportunities. The opportunity is to generate a new low cost protein that can feed the world, upgrade protein levels for many, be sustainable, and possibly stop or even reverse global warming. Now this is a recipe worth pursuing. There was a Green Revolution, and a Blue Revolution – but this is the Teal Revolution, blending fish and fields, Green and Blue for Grass Fed Fish!

*John Reid Is the CEO of Waterfield Farms, Inc. He has over thirty years of experience in the design, finance and operations of food and energy companies. He has built and run multiple aquaculture and hydroponic systems as well as worked with co-generation and bio-fuels around the world.

Watch Interviews With experts. View All The Materials From The Seventh International Forum on Food and Nutrition

Watch Interviews With experts. View All The Materials From The Seventh International Forum on Food and Nutrition

Following the 7th International Forum on Food and Nutrition, the BCFN Foundation has published interviews with the event’s experts. Watch online to learn about their reflections and analyses on the work completed and the challenges ahead to create new spaces for discussion and detailed study.

BCFN would also like to take this opportunity to wish you the best in the New Year and invite you to discover the Foundation’s projects for a 2017 full of initiatives aimed at promoting sustainability for food and the environment.

View all the materials from the seventh International Forum on Food and Nutrition: videos of presentations, in-depth explorations and documentation.

Artificial Trees and Vertical Farms Helping Turn Europe’s Cities Green

Artificial Trees and Vertical Farms Helping Turn Europe’s Cities Green

20 December 2016

KEY THEME: OPEN INNOVATION

Moss-covered boards that absorb city pollution and warehouses where fish and LED-lit lettuce grow side-by-side are helping to reshape the way that urban Europeans live their lives.

People in Europe are increasingly living in dense urban spaces where pollution is worsened by the exhaust fumes of lorries that must haul fresh food from the remote countryside, and where overwork means people rush in and out of their homes and can leave their central heating systems burning through gas.

It’s problems such as these that today’s entrepreneurs have turned their attention to. The result is companies like Germany-based Tado, that has developed a thermostat that taps into the weather forecast, Green City Solutions, that is creating an artificial tree to mop up particulate pollution, and GrowUp Urban Farms, that runs a so-called vertical farm in a warehouse in London.

‘We use 90 % less water than traditional agriculture,’ explained Tom Webster, co-founder of GrowUp Urban Farms.

The company received its initial funding from the EU’s European Institute for Innovation and Technology (EIT). The EIT distributed the funding through Climate-KIC, a so-called Knowledge and Innovation Community set up to help businesses develop and to train entrepreneurs.

The Issue

More Europeans live in cities than suburbs, towns and villages, yet one in five city dwellers are directly affected by pollution, according to Eurostat, the EU’s statistical arm.

As Europe moves to cut back on greenhouse gas emissions, technology that can improve the lives of city dwellers sustainably will become increasingly important.

In a vertical farm, crops are stacked on plastic benches up to 10 levels high and illuminated by LED lighting. They are irrigated by the run-off from fish farms.

The idea is to place them in industrial warehouses close to where people live.

‘Agriculture is an industrial process the way that it is carried out globally, and the reality of it is that the current industrial process is not climate-change resilient,’ said Webster. ‘What we’re offering is a new solution which is more energy efficient and more resilient to climate change.’

It also means salad from an urban farm is fresher than salad grown in remote fields as it can be chilled immediately after being harvested, while on rural farms it has to be transported to a packing facility first.

‘By reducing the supply chain, the time it takes to get to consumers, you’re giving them more nutritious food,’ said Webster, who is also in the process of planning a site 10 times bigger than his current 600-square-metre site on the eastern edge of London.

New economy

It’s the kind of growth story that can be heard throughout this new economy of high-tech companies creating businesses that can help Europe rein back greenhouse gas emissions and improve the lives of city dwellers.

‘In Germany we have 45 % market share,’ explained Christian Deilmann, the founder and chief executive of Climate-KIC-funded Tado, a maker of a home thermostat that connects to the internet for weather updates and tracks your movements using your smartphone so it can turn on the radiators when you’re on your way home.

Heating accounts for around two-thirds of the energy used in a typical home in northern Europe, and the company claims that by using its intelligent thermostat, people can cut these costs by up to 31 % by ensuring that the boiler is only running when necessary.

‘In the future we are 100 % convinced that every home but also every building … will be heated and cooled in an intelligent way,’ said Deilmann.

Their objective is to get around 30 % of this increased market across Europe, and Deilmann hopes this will mean significant growth for the company.

‘What we’re offering is a new solution which is more energy efficient and more resilient to climate change.’

Tom Webster, Co-founder, GrowUp Urban Farms

‘Hopefully we will bring the company to the stock market,’ he said. ‘What E.ON and EDF are today, we want to become in the future.’

While they are at an earlier stage, Germany-based Green City Solutions is also getting ready for a growth phase as it develops its CITYTREE technology to filter pollution from the air on city streets.

With the help of Climate-KIC, the company has teamed up with the north Italian city of Modena to run a pilot project next year to put six CITYTREEs onto a city street.

The vertical flat-panelled device combines moss and wireless technology. It controls the humidity around the moss, which then acts as a filter, taking pollution particles out of the air.

After developing the CITYTREE, the company plans to improve the technology so that it is scaled back to just the plant and the equipment needed to supply it with the right nutrients and the correct amount of water. Once this work is complete, then it will be able to be used on existing surfaces around cities to clean the air.

‘You could apply that to every surface, every pre-existing installation, every infrastructure,’ said co-founder Zhengliang Wu. ‘You maybe even could mount it to public transportation.’

This Software Engineer Sold His Company to Start a Vertical Hydroponic Farm in Goa

“You are what you eat,” they say. And that’s what Ajay Naik, a Goa-based hydroponic farmer, believes in. After quitting his job and giving up his company, this software engineer decided to help farmers across India learn about hydroponics and the use of technology in agriculture.

This Software Engineer Sold His Company to Start a Vertical Hydroponic Farm in Goa

December 20, 2016

“You are what you eat,” they say. And that’s what Ajay Naik, a Goa-based hydroponic farmer, believes in. After quitting his job and giving up his company, this software engineer decided to help farmers across India learn about hydroponics and the use of technology in agriculture.

“For several years I have been noticing that many farmers’ children prefer to go for an MBA or engineering degree these days instead of taking up farming. This is because agriculture is not always lucrative. But then, not many of us are focusing on the root of the system we live in – that is good quality food. Only when you have healthy food can you have a healthy country,” says Ajay Naik, a Goa-based software engineer-turned hydroponic farmer. In times like these when the younger generation of farmers choose to opt for anything but agriculture, the case of Ajay would seem to be a paradox of sorts. The 32-year-old has turned to hydroponic farming in an attempt to grow quality food because a lot of vegetables and fruits supplied to markets today are grown using harmful chemicals that are detrimental to health.

He believes that the right use of technology can improve a field’s produce but the problem is that Indian farmers are already struggling with finances and are reluctant to take risks “They fear that if their investment in technology does not work out, it may lead to huge losses,” he says. Ajay wants to change the equation by taking technology to as many farmers as he can. And that is where hydroponics comes into the picture.

Hydroponics is the process of growing plants in water with added nutrients without the use of soil.

What attracted Ajay towards this form of agriculture is that it limits the use of chemicals. After initial research he came to know about a person in Pune who has a doctorate in plant nutrition and manages a hydroponic farm. Ajay met him, saw his farms and learned as much as he could.

You may also like: Home Gardens That Require Very Little Space & Time – All You Need to Know About Vertical Gardening!

“It was inspiring and motivated me to start a farm of my own as well. The fact that hydroponics involves technology, like developing a system for automatic circulation of water, controlling the parameters of temperature, humidity, etc. made me like it even more. I have been working in the IT industry for the past 10 years and I understand these things. In fact, it would have been difficult for me to understand traditional forms of agriculture,” he says.

Fully equipped with the required knowledge, Ajay started his farm two months ago in Karaswada, Goa. With a team of six people, he now grows exotic vegetables like lettuce and salad greens using the Nutrient Film Technique (NFT). This is a hydroponic technique in which a shallow stream of water containing nutrients for plant growth circulates past the bare roots of plants in watertight cylindrical tubes also called channels. The water flows from one end and is re-circulated into the system from the other end, thus reducing water consumption by 80% when compared to traditional farming.

Since there is no soil involved in the process, there is no need for pesticides. Ajay has set up his system in a vertical farming model with racks that have seven levels to save space.

He claims that this is Goa’s first vertical hydroponics farm, which occupies an area of 150 square metres. “I grow three tonnes of lettuce every month. The farm is set up in a controlled environment that enables me to grow exotic vegetables all-year-round without being dependent on the weather,” he says. In addition, he is now trying to convince other farmers to adopt this technology. “I have already started showing the technique to farmers in vegetable expositions conducted by the agriculture department in different places in Goa. The department is also keen on collaborating with me so they can take it to more farmers,” he says. Other than this, he sells his produce to local vendors and also in supermarkets. “I am planning to grow bell pepper, cucumber and strawberries too. In the future, I would also like to shift to other hydroponics techniques and increase the produce,” he adds.

Originally from Karnataka, Ajay came to Goa to work with a software company, which he quit in 2011 to start his own enterprise to develop mobile applications.

He then sold his company this year and used his savings to start this farm. He also received help from two investors. While the initial cost of setting up the farm is high, Ajay feels that he will be able to recover it over a period of time with hydroponics farming because of the high turnover.

“Producing food nowadays is becoming a real challenge. With the increasing population, water scarcity, and the ecological impact of transportation, hydroponics is the best choice for commercial as well as home-based farming. Among many advantages, hydroponics allows you to produce more (20 to 30%) high-quality vegetables and fruits, save on water and nutrient consumption, and grow fresh food everywhere – including sterile and unproductive lands, or in big cities and capitals. It helps cutting down on expensive intermediaries and shipping costs,” he concludes.

You can contact Ajay by writing to him at ajay20naik@gmail.com

Farm Tour and the First Farmer's Market 🌱🎅

THIS EVENT WILL BE THEIR FIRST FARMERS MARKET THIS COMING WEDNESDAY (12/21) AND WE WOULD LOVE YOU TO COME

Farm Tour and the First Farmer's Market 🌱🎅

Wednesday, December 21, 2016

5:00 PM to 8:00 PMSquare Roots Urban Farming Campus

630 Flushing Avenue, Brooklyn, 11206, New York, NY (map)

Tour the Square Roots farms, meet the farmers, and buy a bundle of fresh, tasty, locally-grown greens - just in time for cooking up a holiday feast!

Our indoor, modular, vertical farms squeeze the equivalent of 2 acres of outdoor farmland into a climate-controlled shipping container. So our farmers can grow non-GMO, fresh, tasty greens all year round. Like, now!

This should be a fun event - so bring a friend :)

Square Roots’ mission is to empower the next generation to become leaders in the "real food" revolution. This means coaching young, passionate people to grow real food, sell locally and build sustainable businesses.

The first cohort of farmer-entrepreneurs are just about to harvest their first crop. They will be growing a wide variety of leafy greens and herbs - from lettuce and basil to chard and kale to specialty items like shiso.

THIS EVENT WILL BE THEIR FIRST FARMERS MARKET THIS COMING WEDNESDAY (12/21) AND WE WOULD LOVE YOU TO COME.

We know, we know, it's a busy time of year. There are holiday parties and year end deadlines, and all sorts of legitimate excuses that could be made. But if you are buying food from the grocery store this week in time for holiday feasts, then why not buy fresh, locally-grown produce from Square Roots - and support a local farmer!

We are located at 630 Flushing Ave, Brooklyn. We have a community space is inside a crazy old Pfizer Pharmaceutical factory (that alone is worth seeing!), and our farm is in the parking lot (yes, really). It's right off the J, M and G trains - 10 mins max across the Williamsburg Bridge if you are coming from Manhattan.

The event kicks off at 5pm. We will do a farm tour at 5:30pm and again 6:30pm - where you will get to see the farms and talk about the tech. Meanwhile you can sample and buy freshly harvest, tasty greens - while hanging out with the farmers - in the comfort of our indoor space.

Thanks for reading this far down. See you there! 🌱

IoT and Agriculture: A Natural Combination

IoT and Agriculture: A Natural Combination

Solid examples of IoT applicability are sometimes hard to articulate. But agriculture provides a use case that is quite concrete, even if in rural environments.

By Andrew Brust for Big on Data | December 16, 2016 -- 20:14 GMT (20:14 GMT) | Topic: Big Data Analytics

We all know that the Internet of Things (IoT) represents game-changing transformation in the industrial application of technology...or at least we think we do. Perhaps more accurately, we sense that denying IoT's significance would be foolishly contrarian. And while we might have an innate sense of why IoT is so important, we also might come up short when pressed to describe specific applications of IoT technology.

That's why I love learning about real use cases, especially ones that veer off the path of domains like preventive maintenance, which are almost cliché. Recently, I had the chance to learn of one such IoT application. It's rich, complex and it satisfyingly broadened how I think about IoT. Specifically, I spoke with the Daniel Koppel, Co-Founder and CEO of Israeli company Prospera, which focuses on the application of IoT in agriculture.

The use case

Prospera, a company founded about 2 years ago by a team of computer scientists and agronomists, has built some very interesting technology that centers around monitoring crop growth, in order to optimize it. While farmers have long had some data -- like weather readings and low-resolution satellite images -- available to them, it turns out not to be enough. And even if it were, weather data from a government weather station -- which might be 30km away from the actual growing area -- doesn't deliver the "hyper-local" climate data that is crucial.

When you grow in volume, though, the geographic dispersal of your farmland makes it difficult to go around and collect that data manually -- and the rural settings for that farmland make the electrical and network connectivity, that had been necessary to collect that data, hard to come by.

It's different now

But now low-cost sensors can obtain temperature and humidity data; and low-cost cameras can measure light/radiation and gather valuable images. The devices can communicate over WiFi or 3G mobile data technology and can often run on solar power. This approach has been making technology with great efficacy in indoor agriculture, increasingly applicable in outdoor settings too.

Prospera does not view itself as a sensor company though, but rather as a data company. And not just one that helps customers collect data and act on it, but one that builds data intelligence and thus domain expertise.

In other words, there is an element of crowd-sourcing here: although granular data is kept private, all data (which, in aggregate, amounts to hundreds of thousands of readings per day) benefits the construction, testing and accuracy of predictive models. These models help track the correlation between specific values in the collected data, crop growth and output. Understanding those correlations, and making predictions based upon them, is where Prospera hits its value proposition sweet spot.

The vision thing

Beyond predictive applications, there are prescriptive applications too. Computer vision/imaging has serious applicability in this domain, as the capture of images combined with pattern recognition technology can help detect crop disease and, on an automated basis, dispatch personnel to address it. It can also help alert farmers to where they need to prune and harvest. So not only is the data collection made more economical, but the methodical analysis of the collected data, and the dispatch of responsive action, is made more feasible and economical as well.

While expense was once an issue, Prospera's Koppel says that "sensors are commodities" now. In fact, the company says that three conditions in the market have combined to make its technology so effective and efficacious: the neural network technology behind the machine learning has become much better; the sensor hardware has become much cheaper and, because of greater mainstream appreciation for Big Data and machine learning, market readiness has crossed the chasm too.

Why Israel?

Israel is a high-tech country, well-populated with venture-funded tech startups. Top-notch technical universities like Technion and Hebrew University (Koppel's alma mater), as well as byproducts of, and veterans from, tech research in the country's defense forces, provide much of the raw material for such commercial, entrepreneurial activity.

Israel also has a history as an agricultural society, centered around Kibbutzim and Moshavs, both of which are collective agricultural settlements, the former sometimes likened to communes. Further, because much of Israel is desert, irrigation techniques and other technological optimizations have been part of its agricultural approach since the country's founding.

Put all of this together and you have a place that, industrially and culturally, is predisposed to growing its crops in a scientifically-influenced fashion.

How far beyond?

While kibbutzim and moshavs in Israel have served as test labs for Prospera's technology, the company has customers who have deployed the technology in Europe and Mexico. The US is next -- and for some customers there, Prospera expects to collect data not just from stationary sensors over terrestrial wireless data connections, but via drone and over Satellite data links as well.

Some current customers implement Prospera's technology in parts of their farms, to compare data-driven farming with those of more traditional methods, and results have been good. Prospera says that customers have used the company's technology to discover problems in irrigation, ward off disease and reduce yield volatility.

Prospera's technology has even allowed farmers to make course corrections in their growing techniques, in order to maximize output in the current growing cycle, and not just apply lessons learned to the next cycle.

All roads lead to analytics

As fascinating and as far-flung as Prospera's IoT use case may seem to some of us, it ultimately comes back to the mainstream of BI and Big Data: collecting data and analyzing it. In fact, Prospera's software delivers rather familiar-looking dashboards on computers and mobile devices, just like the technology with which we may be more familiar.

Ultimately, that may be the most valuable lesson of all. The stuff we already know -- the OLAP cubes, the MapReduce jobs, the streaming data processing and the D3 visualizations -- can be thought of and implemented in very specific and very impressive industrial use cases. The technologies needn't be relegated to isolated discussions of their own rigors. In fact, when we think of the technology in applied capacities, we provide a lot more value, and we help Big Data and IoT move past their hype cycle quasi-paralysis.

We need more companies like Prospera, that combine tech with domain expertise, cultural idiosyncrasies and a lot of imagination. That's how this field will get to the next level. The value of vision goes beyond data captured from image sensors.

The Square Roots Urban Farming Community, NYC

Farm Tour and the First Farmer's Market 🌱🎅Wednesday, December 21, 2016

- 5:00 PM to 8:00 PM

Square Roots Urban Farming Campus

630 Flushing Avenue, Brooklyn, 11206, New York, NY (map)

Tour the Square Roots farms, meet the farmers, and buy a bundle of fresh, tasty, locally-grown greens - just in time for cooking up a holiday feast!

Our indoor, modular, vertical farms squeeze the equivalent of 2 acres of outdoor farmland into a climate-controlled shipping container. So our farmers can grow non-GMO, fresh, tasty greens all year round. Like, now!

This should be a fun event - so bring a friend :)

Square Roots’ mission is to empower the next generation to become leaders in the "real food" revolution. This means coaching young, passionate people to grow real food, sell locally and build sustainable businesses.

The first cohort of farmer-entrepreneurs are just about to harvest their first crop. They will be growing a wide variety of leafy greens and herbs - from lettuce and basil to chard and kale to specialty items like shiso.

THIS EVENT WILL BE THEIR FIRST FARMERS MARKET THIS COMING WEDNESDAY (12/21) AND WE WOULD LOVE YOU TO COME.

We know, we know, it's a busy time of year. There are holiday parties and year end deadlines, and all sorts of legitimate excuses that could be made. But if you are buying food from the grocery store this week in time for holiday feasts, then why not buy fresh, locally-grown produce from Square Roots - and support a local farmer!

We are located at 630 Flushing Ave, Brooklyn. We have a community space is inside a crazy old Pfizer Pharmaceutical factory (that alone is worth seeing!), and our farm is in the parking lot (yes, really). It's right off the J, M and G trains - 10 mins max across the Williamsburg Bridge if you are coming from Manhattan.

The event kicks off at 5pm. We will do a farm tour at 5:30pm and again 6:30pm - where you will get to see the farms and talk about the tech. Meanwhile you can sample and buy freshly harvest, tasty greens - while hanging out with the farmers - in the comfort of our indoor space.

Thanks for reading this far down. See you there! 🌱

Agrilyst Founder Up For Vertical Farming Award

“Farms have a vast amount of production data, and, unfortunately, the information exists in fragmented, independent systems,” Kopf wrote this year.

Agrilyst Founder Up For Vertical Farming Award

Allison Kopf at TechCrunch Disrupt NY.

Brooklyn’s own Allison Kopf is up for Changemaker of the Year for 2016 from the Association for Vertical Farming, a leading industry group.

It’s been quite a year for the young founder, who raised over $1 million in seed funding and headlined TechCrunch Disrupt New York 2016 after winning 2015’s San Francisco iteration. Her company, Agrilyst, makes data analytics software for farmers, with a focus on indoor farmers.

“Farms have a vast amount of production data, and, unfortunately, the information exists in fragmented, independent systems,” Kopf wrote this year. “As a result, growers are spending time and money creating optimization plans while still performing in a sub-optimal state. Farms are leaving revenue on the table. Our goal with the Agrilyst platform is to turn a burden for growers, data management, into their most useful tool.”

The Seedstock 'Future of Food - Urban Ag Field Trip'

Urban agriculture ventures of all different stripes - from commercial hydroponic enterprises and rooftop aeroponic farms to community gardens planted atop formerly vacant lots - are not only disrupting the food system, but also generating community and economic capital

The Seedstock 'Future of Food - Urban Ag Field Trip'

DESCRIPTION

Urban agriculture ventures of all different stripes - from commercial hydroponic enterprises and rooftop aeroponic farms to community gardens planted atop formerly vacant lots - are not only disrupting the food system, but also generating community and economic capital.

To give you an up close and personal look at a series of innovative urban farming operations that have emerged to tackle challenges to food access, meet marketplace demand for local food, and increase food security, Seedstock, a social venture that seeks to foster the development of sustainable local food systems, has put together the 'Future of Food - Urban Ag Field Trip'.

Slated for Friday, January 27, 2017, the field trip will look at the impact of urban farming in Los Angeles County, the most populous county in the United States, and include lectures on such topics as the past, present, and future of urban agriculture, vertical farming, and sourcing local food from urban farms.

Spots on the 'Future of Food - Urban Ag Field Trip' are limited, and it will sell out. So grab your tickets before it's too late!

Scheduled Field Trips Stops include:

The USC Teaching Garden is utilizing aeroponics to challenge the food systems status quo on campus. The University of Southern California (USC) Teaching Garden was established this spring to supply fresh produce to the university’s on-campus restaurants, dining halls, catering services, and hotel, while also teaching students and staff about flavor and sustainability. The garden utilizes aeroponic towers to produce chemical-free fruit, vegetables, herbs, and edible flowers without traditional soil growing media.

Local Roots Farms is an indoor vertical farming company based in Los Angeles that designs, builds, deploys, and operates controlled environment farms. Situated in shipping containers, the farms (called TerraFarms) grow with up to 99% less water, 365 days a year, pesticide and herbicide free, and with absolute consistency in production. Their plug and play form provides an innovative solution to the retail and foodservice sectors by greatly reducing supply-chain risks such as price volatility and food safety exposure.

The Growing Experience is a seven-acre urban farm in North Long Beach that is located on a previously vacant lot. The Growing Experience urban farm is unique in that it is owned and operated by the Housing Authority of the County of Los Angeles (HACoLA), which manages 3,229 units of public and other affordable housing for the county’s Public Housing program. “The North Long Beach community has been historically under-served and classified as a food desert,” says Holly Carpenter, program manager with the Housing Authority of the County of Los Angeles. “The Growing Experience was designed to help meet the needs of the community by increas[ing] access to healthy foods.”

Confirmed Speakers include:

Rachel Surls - Sustainable Food Systems Advisor for UC Cooperative Extension and co-author of the book 'From Cows to Concrete: The Rise and Fall of Farming in Los Angeles'. From the book jacket: "From the earliest pueblo cornfields to the struggles of farm workers to the rise of the environmental movement, From Cows to Concrete tells the epic tale of how agriculture forged Los Angeles into an urban metropolis, and how, ultimately, the Los Angeles farm empire spurred the very growth that paved it over, as sprawling suburbs swallowed up thousands of acres of prime farmland. More than 150 vintage images enhance and expand the fascinating, detailed history" An option to purchase the hardcover book at discount is available for purchase with your ticket for the field trip.

Erik Oberholtzer - Co-founder and CEO of Tender Greens

Chef Eric Ernest - Executive Chef of USC Hospitality

A farm-to-fork lunch hosted by Local Roots Farms featuring lettuce grown on site in the company's TerraFarms will be provided by sponsor:

Ticket Refund Policy: Please note that we do not offer refunds on tickets, but you are welcome to transfer your ticket to a friend or colleague at any time up until 2 days before the event. To do so, please email us at admin@seedstock.com and include your name, order number and the name of the person to whom you would like to transfer your ticket.

TAGS

Things To Do In Los Angeles, CA Tour Community

Lessons from Japan: What the Western Indoor Ag Industry Can Learn from the East

Lessons from Japan: What the Western Indoor Ag Industry Can Learn from the East

DECEMBER 13, 2016 PIETER DE SMEDT

Editor’s Note: Pieter De Smedt is the US country manager for Urban Crops, a global indoor farming group building fully robotized vertical plant factories. Urban Crops recently opened its regional headquarters in Miami, Florida, and is in the process of hiring new sales agents for the North American region. If you are interested in applying, email Pieter here.

It is well known in indoor agriculture circles that Japan has more experience with indoor farming than the US and Europe, and its plant factories are more advanced. Here De Smedt offers his key takeaways from an event bringing the industry from both sides of the world together.

The East Meets West: Joining Forces in Ag Tech & Controlled Environment Ag event took place in Salinas, California a couple of weeks ago. It offered a day of insightful presentations by a number of Japanese and US-based companies and organizations. The main goal was the exchange of information on the current state and future direction of the indoor agriculture industry in each geography. Equally insightful were the different networking opportunities in between sessions – it is not every day one gets the chance to exchange thoughts with people in your industry from the other side of the globe.

Here are my four key takeaways from the event:

1. Data trumps dreams

When looking back at the overall event and the presentations made by the Japanese companies and organizations, the most striking comparison between Japanese indoor agriculture operations and their US counterparts was their use of data. Japan’s indoor ag practitioners are much more data driven than the typically more visionary and – let us be honest – dreamy, story-telling tone of their US peers.