Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Grow Pod Solutions Develops New Vertical Farm Technology That Needs No Sun or Soil

Grow Pod Solutions Develops New Vertical Farm Technology That Needs No Sun or Soil

New system also uses significantly less water than conventional farms

Feb 28, 2017, 11:10 ET

CORONA, Calif., Feb. 28, 2017 /PRNewswire/ -- Grow Pod Solutions (www.growpodsolutions.com), the premier developer of technology-enriched automated indoor farms, announced the development of their new Hydrologic Technology (HLT), which grows crops with no sunlight or soil, and uses about 90% less water than a conventional outdoor farm.

"This is the world's most sophisticated indoor farm," said George Natzic, President of Grow Pod Solutions. "Our new technologies will not only improve the way food is grown and distributed, but will literally change the world."

The system uses an offshoot of hydroponics to grow plants without soil. The process differs from conventional soil methods, and uses water and a nutrient solution flowing through the growing medium, producing significantly better results.

Grow Pod Solutions' Hydrologic Technology (HLT), utilizes special hydroponics that delivers more oxygen to plant roots, stimulating growth and preventing disease. With Grow Pod's disease-free environment, plants grow at higher density compared to other forms of cultivation.

Inside the GrowPod HLT Container, all elements of the environment, including light, humidity, and temperature, are controlled. There is no need for artificial chemical additives or fertilizers because the system uses no soil. There are never any pesticides because there are no bugs inside the pod.

"This goes beyond organic," Natzic said. "We can produce the cleanest food in the world."

Grow Pod Solutions' portable farms are customized to grow specific varieties of fruits, vegetables, herbs and cash-crops, and can be placed virtually anywhere in the world. The entire environment is controlled remotely from any computer or smart phone utilizing the Grow Pod Solutions Management App. GrowPods can utilize alternative energy, thereby operating entirely "Off the Grid."

For more information, call: (951) 549-9490 or visit: www.growpodsolutions.com

About Grow Pod Solutions:

Grow Pod Solutions develops transportable growing environments, utilizing new technologies that produce superior quality crops and higher yields, in a completely secure, remotely managed and monitored environment.

Grow Pod Solutions provides non-profit organizations, restaurants, cash-crop entrepreneurs, and urban farmers, the ability to grow fresh, organic produce year-round. As a sealed system, water needs are minimal; and with on-board water and air filtration systems, plants, vegetables and crops are grown to their fullest potential.

Connect:

Call: (951) 549-9490

Email: info@growpodsolutions.com

Visit: www.growpodsolutions.com

Facebook: facebook.com/GrowPod-Solutions-1660511410944495

Twitter:@GrowPodSolution

Media Contact:

Innovation Agency

310-571-5592

www.inov8.us

info(at)inov8.us

SOURCE Grow Pod Solutions

Related Links

http://www.growpodsolutions.com

Preview: Grow Pod Solutions Acquires Mobile Farming Systems

Also from this source

JAN 27, 2017, 12:42 ETGrow Pod Solutions Acquires Mobile Farming Systems

JAN 23, 2017, 12:43 ETAgricultural Tech Investment Rises to Record $25 Billion

Philips Lighting and Ecobain Gardens Transform First Commercial Vertical Farm Operation in Canada

Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting, today announced the completed installation of Philips GreenPower LED Production Modules at Ecobain Gardens, the largest commercial vertical farm operation in Canada

hilips Lighting and Ecobain Gardens Transform First Commercial Vertical Farm Operation in Canada

Business Wire February 28, 2017

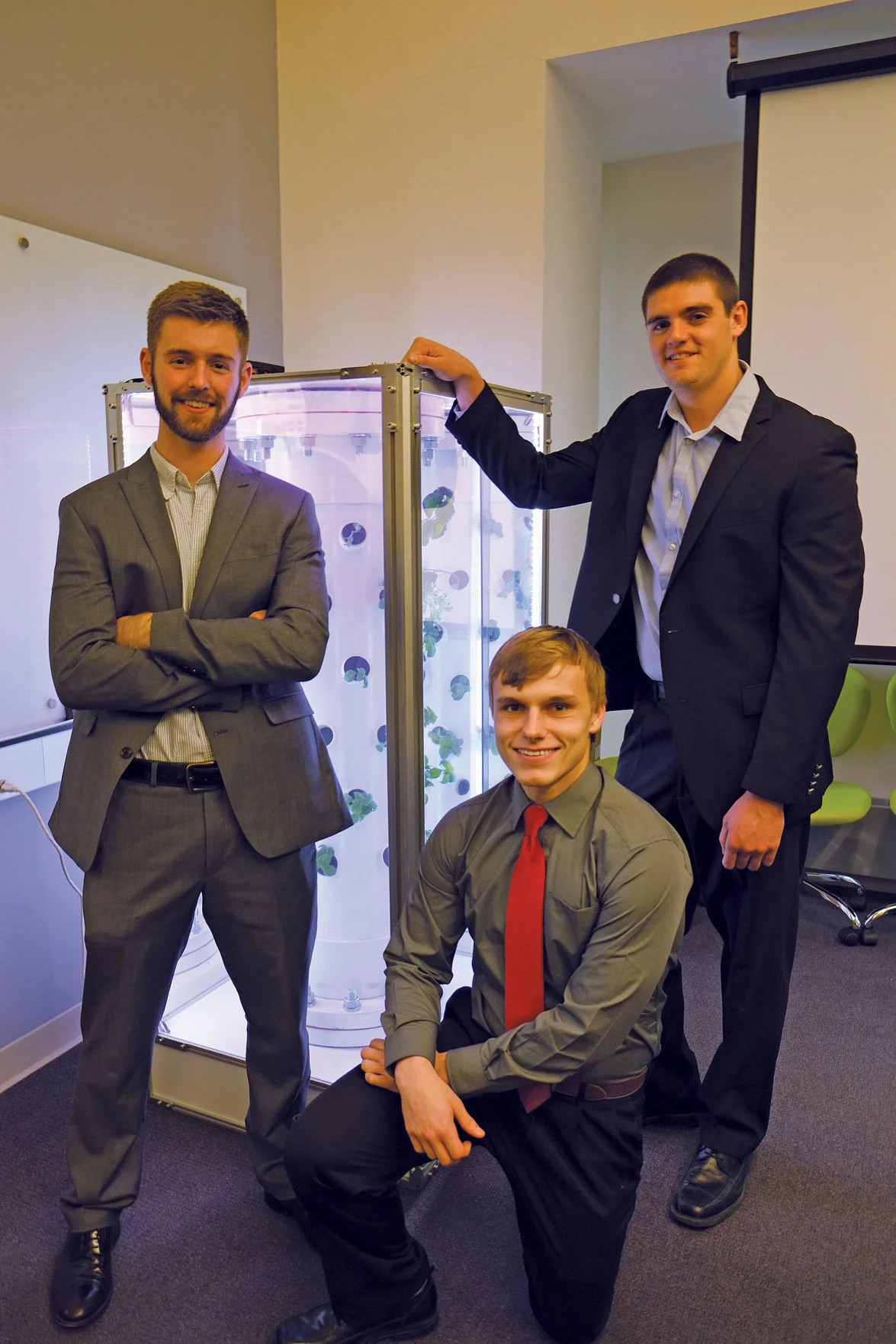

Philips Lighting and Ecobain Gardens Transform First Commercial Vertical Farm Operation in Canada. (Photo: Business Wire) Multimedia Gallery URL

Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting, today announced the completed installation of Philips GreenPower LED Production Modules at Ecobain Gardens, the largest commercial vertical farm operation in Canada. By upgrading the fluorescent lighting previously used in the facility to LED, Philips Lighting is helping the vertical farming pioneer to produce at commercial scale, accelerate growing cycles and grow healthier, more consistent plants, while saving up to $30,000 Canadian in energy costs per year.

This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20170228005329/en/

Producing both organic and non-organic, nutrient-rich herbs and microgreens in a fully controlled indoor facility, Ecobain Gardens was established in 2013 and is the first commercial vertical farming operation in Saskatchewan, Canada. The facility produces 18,000 pounds of produce each year in less than 1,400 square feet. Its farming method uses up to 98 percent less water, zero harmful chemicals or pesticides and the newest energy-efficient LED lighting available from Philips Lighting. The vertical growing technology and local distribution systems reduce energy use, travel time and proximity of the crop, spoilage rates and overall operating costs.

Ecobain Gardens has partnered with food distributor Star Produce to distribute its produce throughout Canada to retailers such as Loblaws, Federated Co-op, Safeway, Sobeys, and other local grocery stores.

“Our goal is to grow our operation to a scale where we can make a difference to the people of our community who need quality nutrition, no matter their economic standing or geographical location,” said Brian Bain, Cofounder and CEO of Ecobain Gardens “The innovative LED products provided by Philips Lighting are helping us build cost effective, smart, productive farms to safely service this massive void we have in our food system. Our passion for growing plants and providing the best possible product, in unique and alternative ways, has helped shape our business and perspective on farming.”

After evaluating several LED lighting suppliers, Ecobain Gardens selected Philips GreenPower LED Production Modules to replace its original fluorescent lights in order to improve plant growth and quality, as well as significantly reduce energy consumption. Once the more energy efficient system was installed, Ecobain achieved dramatic changes in its crops. Growing cycles are considerably shorter and it is now producing more than 10,000 basil plants a week, which is at commercial scale. The low heat output of the Philips LED lights produces healthier, more consistent plant growth by reducing the heat stress on the plant canopy and root zone and by providing more uniform lighting. Plants also have a better dry weight compared to fluorescent lighting or LED lighting systems from other manufacturers.

In addition, the LED lighting system helped to reduce Ecobain’s HVAC system costs by almost 50 percent while providing Ecobain with increased space efficiency due to the minimal heat radiated by the modules. These benefits enable tighter placement of crop rows and therefore more yield from the same growing area.

Paul Boers Ltd, the Philips Horticulture Partner supporting the Ecobain project, worked with Philips Lighting and the local power provider, SaskPower to define an electric rebate structure, which resulted in a rebate of more than $70,000 Canadian dollars for Ecobain Gardens.

“We collaborate closely with our partners and customers to achieve vertical farms that deliver superior produce quality as well as economic performance, resulting in an attractive return on investment,” said Udo van Slooten, Managing Director for Philips Lighting Horticulture LED Solutions. “In partnership with Ecobain Gardens, we are taking vertical farming to the next level by demonstrating the potential of their investment as well as guiding them and their investors through the analysis and decision making process.”

For more information on Philips Horticulture products, click here: http://www.usa.lighting.philips.com/products/horticulture.html

About Philips Lighting

Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting products, systems and services, delivers innovations that unlock business value, providing rich user experiences that help improve lives. Serving professional and consumer markets, we lead the industry in leveraging the Internet of Things to transform homes, buildings and urban spaces. With 2016 sales of EUR 7.1 billion, we have approximately 34,000 employees in over 70 countries. News from Philips Lighting is located at http://www.newsroom.lighting.philips.com

View source version on businesswire.com: http://www.businesswire.com/news/home/20170228005329/en/

MULTIMEDIA AVAILABLE:http://www.businesswire.com/news/home/20170228005329/en/

Technology Hits The Fields

During a recent blizzard in Massachusetts, Sonia Lo, CEO of FreshBox Farms, was in a grocery store suggesting to skeptical patrons that they sample her leafy greens. “They were picked yesterday,” is what she told tasters

FEB 27, 2017 @ 09:12 AM

Mike Montgomery, CONTRIBUTOR

Technology Hits The Fields

Opinions expressed by Forbes Contributors are their own.

During a recent blizzard in Massachusetts, Sonia Lo, CEO of FreshBox Farms, was in a grocery store suggesting to skeptical patrons that they sample her leafy greens. “They were picked yesterday,” is what she told tasters. She also told them no, they weren’t picked elsewhere and flown in that morning. Lo’s greens — over 30 different types — grow year-round in an airtight modular box in Millis, Massachusetts. Every plant’s tray is attached to a sensor to determine just the right amount of water, nutrients and LED lighting the plant needs.

“We have an algorithm for every plant variety,” says Lo. They measure around 10,000 data points per plant for factors such as environment, nutrients, plant stress and LED light. “We have our own software intended to identify if the plants are unhappy. We don’t use chemical controls — we rely on these digital points to pre-empt plant stress and allow for extraordinary things like faster grow times.”

As corporate investors start putting their money into agriculture technology (ag tech) startups, shoppers might just start seeing a lot more fresh crops at their local stores, even in the dead of winter.

Ag tech — from hobbyist to huge commercial farms — is taking off. CB Insights defines ag tech as “technology that increases the efficiency of farms (in the form of software), sensors, aerial-based data, internet-based distribution channels (marketplaces) and tools for technology-enabled farming.”

A recent report from Boston Consulting Group says that “new technologies are revolutionizing agriculture.” In fact, according to this report, venture capital firms have upped their ag tech investments by 80% since 2012 — even though commodity prices remain volatile.

Cleveland Justis, the executive director of the Mike and Renee Child Institute for Innovation and Entrepreneurship at University of California, Davis says his campus is seeing a lot of traffic from venture capitalists as well as big industry companies who are looking for fresh agricultural technologies. Researchers at UC Davis are working on food growth technologies such as gut microbiome innovations, precision farming and drought-friendly cultivation.

“Companies are seeing this as a hub of science around how we feed people and make more resilient crops with less,” Justis says. “How are we going to feed 9 billion people in the future? Not with a simple software program. We’re going to have to use really deep, cutting-edge research to inform these processes.”

The software market for precision farming (such as yield monitoring, field mapping, crop scouting and weather forecasting) is expected to grow 14% between 2016 and 2022 in the United States. Dale Jefferson, president and COO of CropZilla Software Inc., says that in less than two years, his precision farming startup’s software has been installed in farms across the U.S. and Canada, and it is even being tested in Italy. His software takes into account every aspect of a farm, from the types of seeds planted to the number of workers and combines in use.

“We create a digital model,” he says. Farmers can use the software to play with variables and see how potential changes — such as an expensive combine purchase or hiring 10 new field hands — can affect their forecast. For instance, a Midwestern farmer recently used CropZilla to see what would happen if he took his soybean planting schedule from one 12-hour shift to two 10-hour shifts. “The numbers worked out to a five bushel-per-acre increase,” Jefferson says. The farmer made an additional $170,000 from his soybean yield after making this change.

“With corn and bean prices down, farmers are turning to technology to help them survive,” Jefferson says.

Motorleaf Launches Kickstarter Campaign To Debut The HEART, A Wireless, Automated Indoor Growing System

Motorleaf Launches Kickstarter Campaign To Debut The HEART, A Wireless, Automated Indoor Growing System

otorleaf helps growers monitor, automate and control their indoor gardens with intuitive, full-featured software and modular hardware

MONTREAL, CANADA (PRWEB) FEBRUARY 24, 2017

The Motorleaf team launched their Kickstarter campaign today and is looking to raise a total of CA$5,000 to put their products into production. Their latest product, the HEART, is one of four hardware units that connects wirelessly to control indoor gardens ranging from the size of a closet to a five-acre field. The HEART collects air temperature, humidity and light level data. With the HEART, growers can connect any lighting hardware or feeder pumps to start automating their operation within seconds.

With all Motorleaf products, users can monitor all major aspects of their grow room environment directly from their laptop, desktop, tablet or smartphone. Motorleaf products make it easy to monitor water temperature, PH levels, water levels, air temperature, humidity levels, nutrient levels and light levels. Users can connect their HEART to Motorleaf’s Droplet hardware to monitor their water reservoir tank, the Powerleaf(s) to automate their overall growing environment and/or to the Driplet to wirelessly automate the delivery of pH and nutrients to their water reservoir. Motorleaf’s Artificial Intelligence-equipped hardware components help take the guesswork out of growing.

“As a team, we share a clear understanding of what our technology enables people all over the world to achieve,” said CEO and Co-Founder Ally Monk. “With our products, people will be able to grow more produce within their communities with less waste and better yields. We work to connect growers to their plants, and to each other.”

In addition, motion detection and 24/7 video monitoring can be enabled, as well as custom alerts to notify the user of any unexpected changes within the garden. Growers have the option of operating HEART as its own unit or connecting it to any of Motorleaf’s additional Artificial Intelligence and Machine Learning-enabled hardware to gain additional automation.

Early supporters can pre-order Motorleaf’s HEART for CA$589, which is 30% less than the future retail price. Additional products from Motorleaf’s collection will also be available in addition to the HEART. For more information about the Heart and other Motorleaf products, visit http://bit.ly/MotorleafKS.

ABOUT MOTORLEAF

With offices in Montreal and Sutton, Quebec, Canada; the Motorleaf co-founders shared a passion for indoor farming and technology. The otorleaf team consists of gardeners, coders and new product specialists. For more information, visit http://www.motorleaf.com.

Urban Farming Insider: Indoor Urban Farming Tips from Ally Monk, CEO and Co-Founder of Motorleaf

Ally Monk and Ramen Dutta co-founded Motorleaf, an indoor hydroponic and greenhouse automation startup in 2015, when Ramen made the first working prototype (image of a current product below). CEO Ally shared with us the history of Motorleaf, the role of Artificial Intelligence in Urban Farming, and tips for indoor urban farming beginners

Urban Farming Insider: Indoor Urban Farming Tips from Ally Monk, CEO and Co-Founder of Motorleaf

Ally Monk and Ramen Dutta co-founded Motorleaf, an indoor hydroponic and greenhouse automation startup in 2015, when Ramen made the first working prototype (image of a current product below). CEO Ally shared with us the history of Motorleaf, the role of Artificial Intelligence in Urban Farming, and tips for indoor urban farming beginners.

Most importantly, Motorleaf is now live on Kickstarter! If you find this article interesting, check out their kickstarter page!

Sections Covered:

- The Role of Artificial Intelligence (AI) in Urban Farming

- The typical scale of indoor farmers in acreage

- How the components of the Motorleaf system help indoor urban farmers

- Tips to Improve Indoor Growing: Conclusions from the Motorleaf Data

- How to design a "blueprint" for your urban farming system

- Rapid Fire Questions

Introduction

UV:Can you talk about, for people who don't know the background of Motorleaf and how it started, the cofounders, kind of what the founding principles were, that kind of thing?

Ally: Well the background to how Motorleaf started really starts with my co-founder Ramen Dutta, and he had an education at McGill university in agricultural engineering, so he always had an interest and a passion for agriculture, and he's been growing indoors since he was a kid basically.

He left university and for the better part of 15 years he was at an IT company, he was still growing indoors, but one of the recurring problems whenever he wanted to go away (from his indoor growing operation), he'd either have to find somebody who really knew his system to look after it while he was gone or he had to basically expect is crops to do really badly while he was away or die.

So that had a pretty big impact, because if he would go on vacation for as long as he wanted, all of his crops would die.

So Ramen went online and thought there should be some sort of solution, like one on a smart phone, like Google, Nest, for example, something like that, but for his (indoor growing) system, but he couldn't find one.

So he basically started hacking together the first version of Motorleaf back in 2015, and shortly thereafter, we started working in the same co-working space, and started showing it to some other people, and they said "Wow, build me one!", and at that point we decided to try to bring it to market, and our ambition wasn't particularly grand, it was, "can we bring it to market and make enough money to just sort of supplement our income" was really as much as we wanted to do.

Then we went to the Indoor AgCon conference in Las Vegas, in late 2015, and we spoke to Mike Betts, who is the director of investment for AgFunder, and he said he liked what we were building and encouraged us to not just try to reach market but start a proper business and get going.

Then next, by luck almost, we applied to the Founder Fuel accelerator program in Montreal, and unbeknownst to us, the theme of the cohort that they were starting was Artificial Intelligence, and they were really one of the first groups of people to start speaking to us, really it was the first moment when a 3rd party looked at what we were building and really started to look into the size of the market, and said "Hey guys, what you're building has bigger applications than what you were first thinking about", and we finished founder fuel in July of 2016.

From that point forward we decided we would really need some funding to accelerate the business, and that's what we've been doing since then.

UV: It's just you two co-founders right?

Ally: Yep, Ramen and myself are the co-founders and and including some of the part time people that work with us we're at 10 or 12 people right now.

The Role of Artificial Intelligence (AI) in Urban Farming

UV: Why does agriculture need AI? Are there more simple solutions that can get most of the problem solved? What's the key difference here?

Ally:

There's a few really key differences.

When Ramen was looking online for a system he really wanted something that was wireless and scalable so that he could access his data, looking at his growth.

He wanted a true online and offline system that could talk to the AI side of things, even if you set things on a timer, or as an example, you set things to keep your pH at a certain level, that doesn't take into any consideration data that your plants might be emitting that you could capture that could tell you that they actually need something to change immediately.

Maybe that data will tell you, based on all kinds of different variants, if you set or change something now, something bad will happen if you continue as you are.

Really, In a way, one of the definitions of AI is that it's able to do something that no human can do manually, so a very simple example would be that with our system, every four seconds you're testing your pH level.

Now, you could say that a human could do that every four seconds, do that test every four seconds, but through machine learning, could a human predict a very complex algorithm based on thousands and thousands of data points every single day?

Probably not. People need indoor agriculture to start getting smart because it's not a place with (this type of) technology, we're giving them shortcuts and answers that otherwise would take a hell of a long time to figure out.

The typical scale of indoor farmers in acreage

UV: For the people you're working with the actual customers, can you talk about their scale? For someone who is just starting out and thinking about starting a system like this themselves, what are the square meters or square feet that their working with and what is the range there?

Ally: One of the best things that Ramen did in the early days is that we had this one prototype that was the first big unit, it had everything, it was the first prototype, and it was very expensive to produce.

But he, by design, opted to include all the components, and by connecting them wirelessly by the radio, it enabled you to add on more and more (components), it enabled anyone to grow and use our system from the size of a closet up to 5 acres, and that's simply using one, main control, which is the "heart" unit, and from there you can add on other pieces and start monitoring and controlling everything else that you might need.

How the components of the Motorleaf system help indoor urban farmers

UV: Is that as simple as sticking a sensor in the soil or growing medium? What does the hardware look like?

Ally: The four units that we currently have on the market (The "Droplet", "Driplet" , "Powerleaf", and "Heart") (we have more coming out soon), cover the different aspects.

If you want to break it down into 2 categories, they are:

1) monitoring, and

2) automation.

So on the monitoring side of things, the "heart" has the hard drive inside of it, it allows for the alerts and communicators with the web tool, you can have a view of your indoor growing, you can also monitor motion for security, and every 4 seconds it's monitoring your air temperature, your humidity, and things like that, so that's the first unit.

The second unit is called the droplet, and every 3 or 4 seconds it is monitoring your water level, water temperature, your pH level, and your nutrient level, so that's four different things being monitored every four seconds near your reservoir tank (compatible with both soil and hydroponic style growing).

The next unit we have is the driplet. The driplet can deliver pH up, pH down, nutrient A, nutrient B, depending what the grower has determined to be the optimal one, the optimal application of nutrients that it needs. '

UV: I'm assuming the load the nutrients physically at the growing site? They can add the actual physical nutrient or buffer or whatever they're doing right?

Ally: Yes the driplet basically sucks up, pH up pH down, Nutrient A, Nutrient B, from whatever containers they want to use and then it pumps it into the reservoir tank and that allows the readings that the droplet gets.

The last unit does a lot of things, and it is the "Power Leaf", and with the Powerleaf you can connect any 2 pieces of crop equipment, as an example, a humidifier or a de-humidifier, but based on what the sensors from either the heart or the droplet are telling you, you can turn things on or off automatically, so for example, using data from the water reservoir tank could be "hey my tank is down to the last 20%, I'm going to have to turn on my reservoir".

UV: You can customize solutions using the (4th) Powerleaf component, and make your own custom whatever it is that you want to do?

Ally: Exactly, you might just want to buy one powerleaf you may want to buy 100 of them.

Tips to Improve Indoor Growing: Conclusions from the Motorleaf Data

UV: Getting to the conclusions that you can draw from getting access to this data, based off of the data that you're collecting, if you had to summarize a couple ways that people using your system or people not using your system to really quickly improve how they're growing, what would those, say, three things be?

Ally: People don't know, and perhaps don't even record how much time they spend manually doing anything, if you're talking about a commercial grower, they're running a business.

So there's the growing aspect and the running the business aspect, so what we've found is that you can 70% of the time that someone is likely being paid by using our system. That includes adjusting the pH and all the rest of it.

The data is allowing people to understand what has happened, during their grow. So we also, have time lapse video, you see your whole grow as like a movie, but instead of seeing just eventually what happened, you can see, on this day, this happened, on that day what happened that made my plants droop, my pH suddenly collapsed, did my lights not come on properly?

Imagine being able to go back in time and look in detail at everything that happened during that grow that's a really useful tool.

Not only just looking back, imagine if you had a fantastic grow that you want to replicate, look back, see exactly what your settings were, then replicate that for the next grow.

UV: So to make sure I understand correctly, one of the things that you've noticed or one of the mistakes you think people make is not properly accounting for the time they spend manually working and also they don't pay enough attention to past results that have been good or bad, and trying to avoid or replicate those results.

Ally: Yes. Also just the manner in which they record those good results. How many people do you know who literally write things down on scraps of paper and then say "I just lost it that was three months ago where did I put it?".

Imagine having one place where all of your data is clean. It's data that is very accurate as well it's not like "oh I had a quick look at the temperature gauge it looked around 20 degrees Celsius" but now you actually have hard data that is indisputable.

How to design a "blueprint" for your urban farming system

UV: A lot of people ask us about a word, it comes up a lot, that is "blueprint". The essential components for a system, can you talk about the core components and what a blueprint might look like (for indoor urban farming)?

Ally: We've designed everything to be system agnostic, anybody that's using anything in any manner can use us.

But what we've found that comes up again and again when we're being asked, "Is it going to work with X", "Is it going to work with Y", is are they soil based or are they using a hydroponic type of system or aeroponics.

The most important thing I think is are people using a water reservoir tank with the pH and nutrients directly (hydroponic) versus someone who is (growing in soil).

Lighting is also incredibly important, we're talking with many manufacturers who are very interested in knowing how effective their lights are and capturing data while the grow is happening.

Having enough light and the right kind of light is really important more and more for people.

The grow medium, we know that people want to test, as an example clay pellets for one grow and coco for the next one, so understanding what is the grow medium for the crop you're using.

Everything is a recipe. If you're making a cake (for example), your ingredients (can be different), using one type of flour vs another type of flour, tastes completely different.

Some people need to figure out, "What is my ideal set of ingredients for my set up", and then stick to it if they're happy with it.

That's where comparing the data really helps, because if you have a record of exactly what you're doing and have been doing you know what works and what doesn't work and what exactly changed, and know, "what we're the things that worked?".

Rapid Fire Questions

UV: Rapid fire questions: What's your favorite fruit or vegetable?

Ally: Strawberries because they should be grown in every land and we hope to do that. Favorite vegetable would probably be...probably a carrot.

UV: What's the most common crop you see your customers growing?

Ally: We don't ask, based off the information that we do have, I would say that it is probably a split between micro greens and leafy greens.

UV: What's a good book that you've read, about agriculture or urban farming that you would suggest to somebody who is just starting out? It doesn't have to be about urban Ag it can be any kind of book.

Ally: I would say the one that resonates with me, because everyone in agriculture has to be patient and philosophical about things, is a book of quotes from Winnie the Pooh. Winnie the Pooh has a good outlook on life.

UV: What's the biggest or moist surprising things you've learned in your Motorleaf journey?

Ally: How hard it is to build hardware, it is not a joke. It's like you have to start 2 different companies at the same time. Most people don't appreciate how big of a challenge it is to get hardware to market.

UV: How many times harder is the hardware than the software?

Ally: I would say it's probably 10x as hard. If we start talking about artificial intelligence and making that work, which is a whole other part, that is 20x harder.

UV: Last one I have is what can you tell us about your launch, what are the details, what's the website people go to, what's the pricing, any other relevant information?

Ally: We've been in beta since the summer of 2016, publically launch on Kickstarter Feb 21st, and the best place to find that information is Motorleaf.com, you'll find links to the Kickstarter on that page, also if you sign up for our newsletter on our website, under the contact box area, you will automatically get emailed the early bird special!

UV: What is your policy on data ownership?

Ally: I want to be clear that people don't have to share data with us, there's always a question around who owns the data, so we have an offline and an online mode that people can use that will (provide the option of private data).

Thanks Ally!

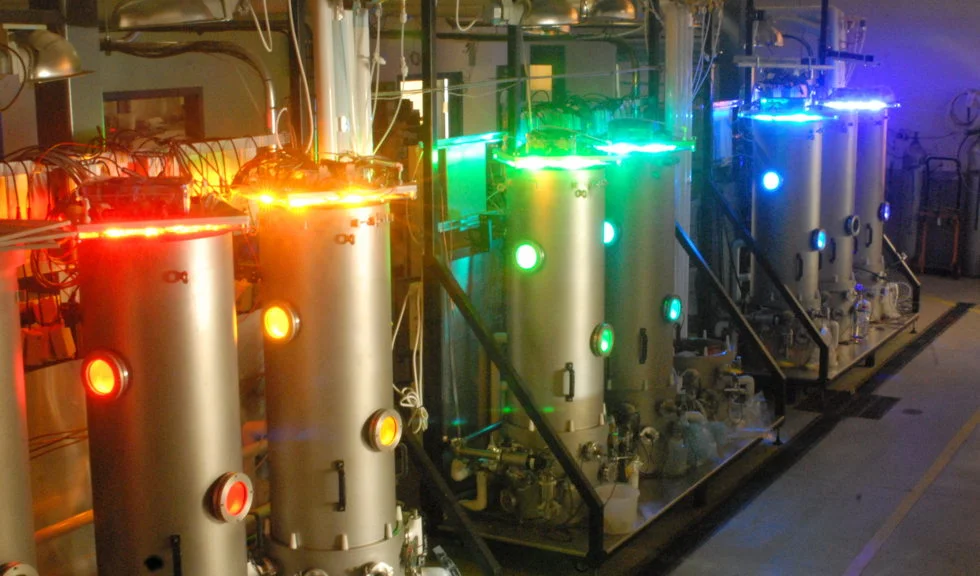

The Powerleaf by Motorleaf, one of 4 product components currently available to indoor urban farmers. Courtesy of Motorleaf

Farming Meets High Tech When Natural History Museum Kicks Off Food Lecture Series

FEB 19, 2017

Become a Member | Ad-Free Login

Farming Meets High Tech When Natural History Museum Kicks Off Food Lecture Series

By KATHY STEPHENSON | The Salt Lake Tribune

First Published Feb 18 2017 12:24PM • Last Updated Feb 18 2017 10:19 pm

They say you can't fool nature, but hundreds of "nerd farmers" around the globe are tapping technology to control climate and create the perfect conditions for growing food.

They are doing it with a personal food computer created by Caleb Harper and his team in the Open Agriculture Initiative at the Massachusetts Institute of Technology. Harper, the principal investigator and director of the lab, leads a diverse group of engineers, architects and scientists in the development of future food systems.

Their climate-controlled box, which can sit on a tabletop, has a computer brain and sensors that allow users to manipulate temperature, carbon-dioxide levels, humidity, light and pH. The plants are grown in minimal amount of water — no soil — using hydroponics.

Anyone, in any part of the world, can grow food, no matter the season, said Harper. Imagine growing water-loving tropical fruits in the middle of the Utah desert or sun-loving summer berries in the midst of a harsh winter.

Harper will talk about this blending of agriculture and technology Tuesday, when he kicks off the Natural History Museum of Utah's annual lecture series. Food is the theme of the five presentations, which include a keynote address by TV personality, chef and author Andrew Zimmern. Tickets for his talk go on sale Wednesday. (See box for details.)

Harper's lecture is free but requires a reservation.

There are nearly 400 "nerd farmers" around the globe who have built personal food computers — using Open Ag's open-source technology — collecting and sharing data with other users, Harper said.

"Every food computer that comes online, whatever they grow is recorded and in the future can be replayed as many times as we want," he said.

Farmers create their own growing "recipe" such as programming in more light or less humidity to see what happens. "As people explore, we are decoding that plant and getting a clearer map of a plant's ability to express itself," he said. "It's pretty phenomenal."

Eventually, Harper hopes the data can be used to create economically viable farms — possibly in shipping containers — that can be placed anywhere to create "hyperlocal food production."

"We need better food-supply chains, which are notoriously complex," he said. "This technology could be a new tool in the chain."

Interest in the personal food computers has grown beyond just the research stage, so Harper recently formed the nonprofit Open Agriculture Foundation, which will protect the open-source data and intellectual property and foster the growing community of farmers.

Harper and Utah entrepreneur Daniel Blake also have started Fenome, a small business that has begun assembling kits the community can buy that have everything needed to build a personal food computer.

The Fenome lab in West Valley City also houses large indoor growing tents, where Blake and the staff experiment with varieties of plants, learning which ones grow best in the personal food computer environments.

The personal food computers have other applications, as well. Many schools are using them to teach about biology, botany and climate change as well as coding, computer programming and engineering.

And Blake recently returned from Jordan, where he visited Azraq, a camp for refugees of the Syrian civil war. He said the United Nations World Food Organization is interested in food computer systems that could help supply at least a portion of the food to those living in the camps. Currently, all food and water are shipped.

"We are in the beginning stages of the process," Blake said, "but food computers could be deployed anywhere, especially harsh environments where food security is a problem."

Ikea Releases Open Source Designs For A Garden Sphere That Feeds A Whole Neighborhood

If you’ve already constructed Ikea desks and chairs, then it’s time to take your skills to the next level.

This week Space10, an Ikea lab for futuristic, solutions-oriented designs, released open source plans for The Growroom, a large, multi-tiered spherical garden designed to sustainably grow enough food for an entire neighborhood. Hoping to help spur local growing and sourcing, Space10 made the plans available for free on Thursday.

02/17/2017 01:20 pm ET

Ikea Releases Open Source Designs For A Garden Sphere That Feeds A Whole Neighborhood

It doesn’t even require nails.

If you’ve already constructed Ikea desks and chairs, then it’s time to take your skills to the next level.

This week the company released open source plans for The Growroom, a large, multi-tiered spherical garden designed to sustainably grow enough food for an entire neighborhood. Hoping to help spur local growing and sourcing, Ikea made the plans available for free on Thursday.

All it takes to complete the 17-step, architect-designed DIY garden of your dreams is plywood, a visit to your local community workshop, rubber hammers, metal screws and some patience:

The garden’s “slices” are designed so that water and light reaches each level.

The Growroom is a brainchild of Space10, Ikea’s lab for futuristic, solutions-oriented designs. Though it’s intended mainly for use as a neighborhood garden in cities, you could also build one for your own backyard, a spokesman told HuffPost.

The Growroom doesn’t come in a flat pack like most Ikea products. Rather, users download the files needed to create perfectly-sized plywood pieces, using a local fab lab workshop for professional cutting. Then, they can assemble them using the free instructions online.

There are already plans to build Growrooms in Helsinki, Taipei, Rio de Janeiro and San Francisco, according to a press release. And if you’re up to the challenge, it could bring more locally-sourced food right to your hometown, Space10 writes:

Local food represents a serious alternative to the global food model. It reduces food miles, our pressure on the environment, and educates our children of where food actually comes from. ... The challenge is that traditional farming takes up a lot of space and space is a scarce resource in our urban environments.

The Growroom ...is designed to support our everyday sense of well being in the cities by creating a small oasis or ‘pause’ architecture in our high paced societal scenery, and enables people to connect with nature as we smell and taste the abundance of herbs and plants. The pavilion, built as a sphere, can stand freely in any context and points in a direction of expanding contemporary and shared architecture.

Why We Need Technology As The Key Ingredient In Our Food

When asked how food security and production can be improved in Africa, former Rwandan minister and current president of the Alliance for a Green Revolution in Africa (AGRA) Agnes Kaliba, had one simple answer: “Access to technologies.”

Peter Diamandis, ContributorChairman XPRIZE

Why We Need Technology As The Key Ingredient In Our Food

02/17/2017 01:54 pm ET | Updated 15 hours ago

hen asked how food security and production can be improved in Africa, former Rwandan minister and current president of the Alliance for a Green Revolution in Africa (AGRA) Agnes Kaliba, had one simple answer: “Access to technologies.”

Ms. Kaliba is exactly right. We are sitting at the cusp of an explosion in exponential technologies, which can be the most critically important ingredients to improve the health and quality of life for all humanity.

The World Food Programme (WFP), the largest humanitarian organization in the world, estimates that some 795 million people do not have enough to eat to maintain their health. Additionally, we have faced an unprecedented number of large-scale emergencies — Syria, Iraq and the El Niño weather phenomenon in Southern Africa. Just last month, WFP stepped up support for tens of thousands of displaced Syrians returning home to the ruins of eastern Aleppo City, providing hot meals, ready-to-eat canned food and staple food items such as rice, beans, vegetable oil and lentils. Like Agnes Kaliba in Nairobi, WFP has resolved that technology will help most rapidly in providing better assistance in emergencies and achieve a world without hunger.

Singularity University (SU), which I co-founded with Ray Kurzweil in 2008, is a benefit organization focused on using exponential technologies to solve our Global Grand Challenges. At the World Economic Forum in Davos, Ertharin Cousin, the Executive Director of WFP, announced a new partnership with SU for a Global Impact Challenge for food.

Our Challenge is soliciting bold ideas from innovators around the world on how to create a sustainable supply of food after the onset of a crisis. In this way, we can help vulnerable families support their own households and reduce their dependence on external assistance. Entries can range from concepts to implemented innovations. Shortlisted winners will be invited to a bootcamp at the WFP Innovation Accelerator in Munich to flesh out their ideas with WFP innovators. One team will be selected to attend an all-expenses-paid, nine-week Global Solutions Program at Singularity University at NASA Research Park in Silicon Valley.

Here are some examples of moonshot thinking – and how converging exponential technologies are already reinventing food:

- Vertical Farming: If 80% of our planet’s arable land is already in use, then let’s look up. The impact of technology in vertical farming is powerful. In addition to maximizing the use of land, we can use AI to control the exact frequency and duration of light and pH and nutrient levels of the water supply. Vertical farms using clean-room technologies avoid pesticides and herbicides, and the fossil fuels used for plowing, fertilizing, harvesting and food delivery. Vertical farms are immune to weather, with crops grown year-round. One acre of a vertical farm can produce 10x to 20x that of a traditional farm. And if roughly one-quarter of world’s food calories are lost or wasted in transportation, then let’s think local. The average American meal travels 1,500 miles before being consumed. Moreover, 70 percent of a food’s final retail price is the cost of transportation, storage and handling. These miles add up quickly. The vertical farming market was $1.1 billion in 2015, and projected to exceed $6 billion by 2022.

- Hydroponics and Aeroponics: Traditional agriculture uses 70 percent of the water on this planet. Hydroponics is 70 percent more efficient than traditional agriculture, and aeroponics is 70 percent more efficient than hydroponics. In times of war and natural disaster, there are no readily available food sources, so let’s think creatively on how we can grow food from — and in — the air.

- Bioprinting Meat: In 2016, it took 63 billion land animals to feed 7 billion humans. It’s a HUGE business. Land animals occupy one-third of the non-ice landmass, use 8% of our water supply and generate 18% of all greenhouse gases — more than all the cars in the world. Work is progressing on bioprinting (tissue engineering and 3D printing) to grow meat (beef, chicken and pork) and leathers in a lab. By bio-printing meat, we would be able to feed the world with 99% less land, 96% less water, 96% fewer greenhouse gases and 45% less energy.

- Shifting diets: Optimal health requires 10-20 percent of calories to come from protein. One example of innovative thinking comes from Africa, where farmers are installing fish ponds in home gardens, as the mud from the bottom of the pond also makes a great mineral-rich fertilizer. In the lab, scientists are investigating new biocrops.

This is just the beginning. If we are really serious about creating a vibrant ecosystem of sustainable food production, we need to be thinking exponentially and using technology to help create cost-efficient innovative solutions that can feed the world.

GE Lighting Horticultural LED Lights Are Specifically Designed for Controlled Environment Agriculture

GE Lighting Horticultural LED Lights Are Specifically Designed for Controlled Environment Agriculture

GE Lighting has introduced LED grow lights for use in greenhouses, vertical farms, tissue culture labs and growth chambers.

BEDFORD, TX (PRWEB) FEBRUARY 15, 2017

GE Lighting has been offering horticultural LED lights to the North American market since 2011.

“GE had been marketing horticultural LED lights in Japan prior to introducing them to the United States,” said Sharee Thornton, Product Manager at GE Lighting. “The reason for not introducing them sooner was the U.S. horticulture market was just starting to work with LEDs and GE was still developing the products specific to this market. We currently have three LED products that we are actively selling in the North American market and have additional products that are expected to come out during 2017. These would include interlighting and toplighting products.

“We have customers who operate vertical farms that are asking for a toplighting product. We are developing toplighting products for both vertical farms and for greenhouses.”

Horticultural LED grow lights

GE Arize Life

The primary application of the GE Arize Life LED light fixture is as a replacement for fluorescent lights typically found in tissue culture labs, growth chambers and testing labs. The fixture is available as a 2-, 4- and 8-foot light bar.

“This fixture has an integrated power supply, is IP66 rated and UL wet rated, which means it’s splash proof and easy to clean,” Thornton said. “If the fixture is used in a high moisture environment, it is easy to wipe clean. The operating temperature can be from 0ºC-40ºC (32ºF-104ºF). The fixtures can be daisy-chained from end to end or they can be daisy-chained with a jumper cable.”

Thornton said the Life fixture, which has a 5-year limited warranty, previously had a L80 of 36,000 hours. She stated GE has updated the fixture to a L90 of 36,000 hours.

“This means at 36,000 hours a grower will still have 90 percent of the fixture light intensity available,” she said. “Other fixtures on the market are at L70 at 35,000 or 25,000 hours. That means at either 35,000 or 25,000 hours a grower is going to get 70 percent of the light intensity. A grower would have to replace the fixture if he loses 25-30 percent of the light intensity. Within that time period at 90 percent a grower may not have to replace the GE light fixture depending on what he is growing.”

Thornton said replacement of the fixtures will depend on where they are used.

“If the fixtures are used in a vertical farm where they account for 100 percent of the supplemental light the plants are receiving, those are usually operated 16-18 hours per day,” she said. “The lights won’t be operating 24 hours because the plants have to have some time to rest. At a rate of 16 hours of light, seven days a week, the fixtures would run approximately 5,000 hours per year. The life expectancy of the fixtures would be around seven years.

“This is what we typically see with some of our other applications. That is why we are able to offer a longer life expectancy. GE has been doing this with its other products. We know how to mechanically and electronically put the products together and run them at a higher efficiency in order to get a longer life. For growers who are using the lights for propagation rather than for a vertical farm, the life expectancy could be even longer if the lights aren’t run as often or as long.”

GE Arize Lynk

Side-by-side the Lynk and Life light bar fixtures look identical. The GE Arize Lynk fixture is available as a 4- and 8-foot light bar with plans to release a 2-foot bar in 2017.

“The biggest difference between the two fixtures is the light intensity,” Thornton said. “The Lynk fixture can be used with vertical farms, in greenhouses, and growth chambers. Like the Life fixture, Lynk is IP66 rated and UL wet rated so it can be cleaned very easily. The Lynk fixtures can also be daisy chained from end-to-end. It has an independent driver so there is no additional driver required. There is also a plug so that it can be hot wired or it can be plugged in.”

Thornton said because the Lynk and Life fixtures are lightweight, weighing less than 5 pounds, they are easy to install with mounting clips.

“The mounting clips are attached with fasteners and then the fixtures are attached to the clips,” she said. “It is a very easy and fast installation. Hort Americas has done a video showing how easy the fixtures are to install.”

Thornton said GE offers similar light spectrums for both the Lynk and Life fixtures.

“We have a reproductive spectrum, a vegetative and a balance. It depends on the goals of the growers,” she said. “The purple light is the ideal light for photosynthesis. Some growers want all purple and then they will move the crop out to harvest it. Others want white light so that they don’t have to move the product around. A grower can have a balanced pink, a balanced purple and a balanced white.

“The reproductive spectrum with a higher red content is for the grower who wants to promote flowering and fruiting. The light spectrum for vegetative growth, which has a higher blue content, is for the grower looking at size or selling the product by the pound. If a grower really doesn’t know what light spectrum he wants or wants a spectrum for both reproductive and vegetative, he can choose the balanced spectrum of red and blue. The balance is the more common spectrum chosen because growers want both or don’t know and want to see what happens with the balanced spectrum. If the balanced spectrum doesn’t produce a beefy enough plant then the grower will look at the vegetative spectrum. Or if the plant didn’t flower or fruit as well as expected, then the grower would use the reproductive spectrum.”

Thornton said the Lynk fixture puts out about twice as much light as the Life fixture.

“A 4-foot reproductive Life fixture produces about 43.2 micromoles per second (μmol/s),” she said. “A 4-foot Lynk fixture produces 82.9 μmol/s. So it’s almost double. There would be a similar difference for the 8-foot fixtures too. An 8-foot reproductive Life fixture produces about 86.3 μmol/s and an 8-foot Lynk fixture is around 181.5 μmol/s.

“We have seen a lot of the 8-foot fixtures used in vertical farms. Because of the insulation and they are so easy to clean, it is a lot easier to install the 8-foot fixtures. A lot of the vertical racks have five 8-foot sections so it works out perfect for the 8-foot light fixtures.”

GE Arize™ Greenhouse Pro LED Flowering Lamp

The GE Arize Greenhouse Pro is for photoperiodic control. It is set up on a BR30 platform.

“This bulb’s main application is to primarily control photoperiod and flowering in greenhouses,” Thornton said. “The light intensity of this bulb is 17.8 μmol/s. It is not as intense as the Arize light bar fixtures, but for its application it is very competitive with similar bulbs on the market. Its life expectancy is L90 at 10,000 hours. It is 90 percent at 10,000 hours.

“We have some trials going on at Michigan State University and expect to have some results coming out this year so that we can help growers use this bulb efficiently.”

Indoor Growing System Earns Innovation Award

West Midlands-based urban growing specialist Hydrogarden has taken the Innovation Award at the EEF Future Manufacturing Awards

Indoor Growing System Earns Innovation Award

14 February 2017, by Gavin McEwan

West Midlands-based urban growing specialist Hydrogarden has taken the Innovation Award at the EEF Future Manufacturing Awards.

Judges noted the company's drive to achieve sustainability and its ambition to become carbon-neutral through its vertical farming solution, V-Farm, and praised its innovative approach to engaging with a variety of customers.

V-farm is a fully controllable vertical farming concept, bespoke to the needs of the end user, whether growing on an urban rooftop, warehouse or even in space.

HydroGarden managing director Jonathan Aldridge said: "Manufacturers are amongst the most prolific and successful innovators in the UK, so to win this award is a great accomplishment and compliment to our team."

The company reported last year that interest in urban and enclosed growing systems was growing "even among old-school growers, some of whom are already seeing huge savings."

The company has helped equip recent high-profile London urban agriculture ventures GrowUp, an aquaponics complex in a warehouse in Beckton; and Growing Underground, a subterranean hydroponic salad farm in Clapham.

The company has already equipped two farms in Singapore and one in Australia, growing micro-greens, herbs and salads and has developed growing protocols for around 20 crops including strawberries, pak choi and even rhubarb.

Key to this has been its own experimental Project Urban Grow facility at its base in Coventry. This trial version of the VydroFarm system occupies just 24sq m but has a growing area of 55sq m thanks to its five-storey NFT hydroponic growing system on three mobile racks, which can produce nearly 2,000 lettuces in 28 days.

It uses Valoya LED lighting including the Finnish manufacturer's full-spectrum model.

Formerly the Engineering Employers Federation, EEF works to champion manufacturing and engineering in the UK and the EU.

RELATED ARTICLES

Crofters, A Startup Helping You Grow Completely Organic Food Right Inside A Living Room

Crofters, A Startup Helping You Grow Completely Organic Food Right Inside A Living Room

“Fear kills more dreams than failure ever will.”

This belief brought Deepak Srinivasan a long way who now finds himself on the entrepreneurial path.

According to Deepak, “The industrialized farming methods based on fossil fuels are putting a huge amount of pressure on our planet. To come up with technically advanced systems that can enable farming in urban areas in a sustainable manner is the need of the hour. The food we eat is engineered to travel long distances and 50 percent of our food is wasted even before it reaches us. We need ways to produce healthy local food."

Deepak, with his co-founder Ashish Khan, started Crofters in March 2016, and they have come up with devices that will help people farm their fresh, healthy food in a sustainable manner. Crofters have developed India's first fully automatic indoor home farm.

They have built an intelligent, self-cleaning, indoor aquaponics ecosystem that helps grow completely organic food right inside a living room. It is for passionate gardeners living in crowded apartments without a backyard space or a terrace of their own.

A combo of nature and technology

They have built an intelligent WiFi-enabled mobile app and sensor unit which helps control and monitor all ecosystem parameters remotely. All this comes with zero maintenance. Users can use the system to grow vegetables, herbs, or small fruits. They are looking to gather data from its users to replicate the model on a large, commercial scale in the future.

How do they implement this?

They create hardware and software that enable people to grow their own fresh food. They have a series of products and solutions that will enable farming in places previously considered unsuitable for it. Their LED grow light technology will help in the indoor farming area to convert huge spaces in urban areas into farms. They claim that their technology will reduce water consumption by 80 percent and pave the way for vertical farming that will make more use of available space.

How did they choose the name of their company and what does it mean?

According to Ashish, “Crofter refers to someone who farms on a small piece of land, so we named our company Crofters as we are on a mission to make farming accessible to everyone on this planet."

Core service/product

They develop IoT-based indoor and outdoor farms based on the science of aquaponics.

Monetization strategy

They have an online-only model for selling their products with doorstep delivery and service. They are into consumables model with income from the sales of accessories to the users through the marketplace. They are working towards setting up experience centres for experiencing the Crofters ecosystem in Bengaluru and Chennai. They will work with ed tech companies on a partnership basis by licensing of their product with a curriculum.

Funding status

They are bootstrapped and want to achieve some tangible traction before looking for funding.

Panasonic's First Indoor Farm Grows Over 80 Tons of Greens Per Year — Take A Look Inside

Panasonic may be known for its consumer electronics, but the Japanese company is also venturing into indoor agriculture

Panasonic's First Indoor Farm Grows Over 80 Tons of Greens Per Year — Take A Look Inside

Panasonic may be known for its consumer electronics, but the Japanese company is also venturing into indoor agriculture.

In 2014, Panasonic started growing leafy greens inside a warehouse in Singapore and selling them to local grocers and restaurants. At the time, the 2,670-square-foot farm produced just 3.6 tons of produce per year. The farm's square footage and output have both more than quadrupled since then, Alfred Tham, the assistant manager of Panasonic's Agriculture Business Division, tells Business Insider.

Panasonic's greens are all grown indoors year-round, with LEDs replacing sunlight. The growing beds are stacked to the ceiling in order to achieve a higher yield in the limited space.

Take a look inside.

Women In CEA Startups

Interest in furthering the development of controlled environment agriculture (CEA) is propelled forward by the idea that we can create real solutions to some of humanity’s basic needs: like growing nutritious food. By bringing farming under cover, be that in a hoophouse, greenhouse or vertical farm, we have found ways to closely monitor and manipulate growing conditions

Women In CEA Startups

Meet 4 female trailblazers raising the bar in controlled environment agriculture through entrepreneurship.

January 25, 2017

Cassie Neiden

Interest in furthering the development of controlled environment agriculture (CEA) is propelled forward by the idea that we can create real solutions to some of humanity’s basic needs: like growing nutritious food. By bringing farming under cover, be that in a hoophouse, greenhouse or vertical farm, we have found ways to closely monitor and manipulate growing conditions. These efforts have resulted in extended growing seasons — all while improving food access, flavor and local economies.

But CEA’s improvements do not stop there. As this dynamic, ever-changing industry continues to adapt and evolve, new ideas coming to the forefront aim to solve challenges and streamline systems. Unsurprisingly, many of them are coming from women, who asking the simple question: Why not?

Why not integrate greenhouse data into a user-friendly platform? Why not ask if an abandoned garden needs a revamp? Why not grow clean, healthy greens in the comfort of a home? Why not make a greenhouse three stories tall?

On the following pages, we feature determined, inspiring women who are finding CEA success through their innovations and leadership.

Allison Kopf, Founder & CEO, Agrilyst

DATA-DRIVEN: Kopf put together a team of highly skilled data scientists and engineers to form Agrilyst, an intelligence software platform for indoor farmers, in 2015. Agrilyst utilizes algorithms to track and record data from sensors throughout the greenhouse to help growers better understand their operation’s metrics to improve plant quality and output.

Since the company’s conception, Kopf and her 10-member team have nabbed first place in TechCrunch Disrupt’s prestigious technology startup competition, raised more than $1 million in investments for development, secured customers in five countries, and in January, launched Agrilyst Reporting, which helps growers curate their own customized data sets.

“We’re helping [growers] visualize data like never before,” Kopf says. “Big data is just a [phrase], but having insights and having meaningful visualizations is important to growers, so we’ve spent a lot of time focused on that.”

BRIGHT IDEA: Based in the startup central, NYC, Kopf has experience in helping to build companies. Before founding Agrilyst, she spent four years as the Real Estate and Government Relations Manager at BrightFarms, a hydroponic grower and greenhouse builder in New York. She was one of the first employees at the company back in 2011.

“It was a really easy jump for me to say, ‘I want to be in this startup world, and I want to do something that I believe in and work alongside a team on something that’s a big problem that’s solvable by us,’” she says.

In fact, much of the idea for Agrilyst came from her time at BrightFarms. “When I was on the operating side, my job was to essentially solve problems as they came up. And that was really challenging to do because we had fragmented data systems,” she says.

Essentially, climate control systems and other technological advances provided data to the growers — but they had no comprehensive way of gathering and analyzing it. “I said, ‘That’s it. We can’t do this anymore. We have to find a way to log this data somehow,’” Kopf says. “I can build this platform to integrate this data and build a team of people smarter than me to get [growers] insights into that data.” And Agrilyst was born.

Kopf's startup advice is to make yourself an expert in your field, but don't go it alone. "It wastes time and money, especially in this space," she says.

LEVELED OUT: Part of Kopf’s success in the male-dominated technology space is due to her mindset. She was the only woman in her physics class in college; she’s spearheaded a legislative campaign; and also fearlessly pitched her business model to venture capitalists. No matter the space she’s in, she refuses to be intimidated based on her gender because she simply doesn’t factor it in.

“The way that I approach it is that I’m there because I’m the person to do this,” Kopf says. “I presented the company that I had built because I was the right person to build this company. This [is] the thing I was put on this earth to solve. That’s the way I operate … I’ve made myself the expert in the thing I’m doing, and that’s the only [way] you can have confidence standing up there and presenting something that’s yours, in my opinion.”

BORN LEADER: While Agrilyst takes up much of Kopf’s time, she hasn’t shied away from additional professional leadership opportunities. She’s an advisor for a nonprofit to promote young women’s involvement in tech called #BUILTBYGIRLS, as well as a mentor for Square Roots Urban Growers, a hydroponic vertical farm builder. Kopf was also named Entrepreneur of the Year by Technical.ly Brooklyn, and Changemaker of the Year by the Association for Vertical Farming earlier this year.

So it’s no surprise that her favorite part of starting a business is building a team.

“I get to work with people who are tremendously brilliant and interesting, especially in our space,” she says. “And we have not yet hired from a job posting. We’ve consistently hired through our team’s network. But what we’ve done a very good job at is expanding our network broad enough to find [those] people … and make sure we incentivize them to put them on our team.”

Kopf’s also a huge proponent of hiring people of diversity. Agrilyst’s small team is made up of employees from many different backgrounds, and an even split of men and women. “It makes your company and product better, too, by having diversity and by having people who don’t look and think and speak like you do. By nature, you end up building a product that’s more inclusive for a broader set of customers,” she says. “Not ignoring colorblind people when you are building the colors of your platform; not ignoring left-handed folks when you’re building an iPad that doesn’t switch the right way … All of those things can be included earlier by broadening your community.”

BIGGEST CHALLENGE: Opportunities abound with any startup as it morphs into its own identity. So Kopf’s biggest challenge is keeping the company focused. “There are so many areas of agriculture that have a data problem,” she says. “This is why you see so many data companies sprouting up in the outdoor space — or cash commodities crops … It’s one of our biggest industries.

“But as a startup, and as 10 people,” she continues, “you can’t tackle every problem.” She says she’s proud of the way Agrilyst communicates with indoor growers, listening to them and building on what they want to see.

THE BOTTOM LINE: The most rewarding aspect of Kopf’s job is realizing results from what she and her team have created. “Seeing something physically change, or seeing operational management methods change based on using our platform and how that makes a grower able to reach profitability, or expand operations, or open a new facility, or expand into new crops — that, to me, is probably the most successful thing that we could possibly do,” she says.

Vanessa Hanel, Owner & Operator, Micro YY

TINY PRODUCT, BIG OPPORTUNITY: After working on the administrative side of the Calgary Farmers Market for about a year and a half, Hanel decided she wanted to be the grower, not the one sitting behind the desk. So in the basement of her home in Calgary, Alberta, Hanel launched Micro YYC and began to grow a plethora of microgreens varieties and other leafy greens for multiple clients, including a large local farmers market, a CSA-inspired subscription service, and local restaurants and specialty grocers. Hanel’s offerings include pea shoots, broccoli, kale, kohlrabi, arugula and other microgreen blends. “I’m super passionate about quality, delicious food,” Hanel says. “So it makes me happy every day to be growing these happy little sprouts.”

COMMUNITY COLLABORATION: One of Hanel’s biggest accounts is a cooperative with other local growers called YYC Growers’ Harvest Box. On a bi-weekly basis, customers can pick up a “harvest box” that includes a selection of seasonal produce from several different farms in the area. Hanel says not only does this bring her a good amount of business — the collective has grown exponentially from 80 shares in 2015 to more than 500 in 2016 — it also gives her a sense of belonging. The farmers frequently get together for meetings and potlucks and lean on each other for advice and moral support. “It makes you realize you’re not the only one doing something weird for a job,” she jokes.

SOCIAL STANDING: As a one-woman operation, Hanel says she hasn’t had much time to craft a website, but she’s acquired plenty of customers and mentors through social media marketing to keep her going. Every restaurant she’s worked with has found her either on Twitter or Instagram, and she’s acquired some helpful growing advice along the way.

Hanel's microgreens are sold to YYC restaurants and farmers markets.

Photo: Kevin Daines, courtesy of Hop Compost

“Instagram is amazing because it’s so easy to post good pictures on there,” Hanel says. “There’s a great community — it’s so easy to find other people in Calgary doing small local businesses, and food business, and other urban farms in other cities and countries. I connect with a lot of other microgreen growers on Instagram, just asking each other questions, like, ‘What trays are those?’”

PLUS ONE: While Hanel doesn’t necessarily need a large working area to bring in her produce-growing profits, she says her biggest challenge is keeping up with the daily workflow. Because her crop can turn over as quickly as nine days, Hanel plants every week. “I plant on Mondays, and I start harvesting last week’s planting and by the end of the week I clean everything up and I start again on Monday,” she says. It doesn’t leave her much time to strategically grow her business, which she says is her biggest challenge, and so she’s looking to bring on a part-time employee in the near future.

ENTREPRENEUR TIP: Since being featured in Modern Farmer in December 2015, Hanel says she receives many calls from people asking how to get started and where to go to acquire resources. She suggests hitting up local food events and being willing to network, listening to others and being willing to learn. “You can’t expect it to happen overnight,” she says. “But those things will end up counting in the long run.”

Mary Ackley, Founder, Little Wild Things City Farm

Photo: Amber Breitenberg

DREAM JOB: Ackley began her career in a different field, working as an engineer in the United States Agency for International Development (USAID) environmental sector for about seven years, but she aspired to own her own farming business while she was working and hobby gardening overseas in Sri Lanka. When she moved home to Washington, D.C. in 2013, she decided to pursue her love of farming. In 2014, Ackley established Little Wild Things City Farm, a microgreen and edible flower producer specializing in more than 50 different varieties. The produce is sold at local restaurants, grocery stores and farmers markets in the D.C. area. The farm also sells value-added products, like wedding cakes with edible garnishes and ready-made salads.

LAND HUNT: When it came time to find a space to grow, it was a bit difficult, as it can be in any highly populated urban area. Then she realized the only places where there was available land was at institutions, such as schools and churches, so she thought it might be best to ask to use an abandoned plot on another property, instead of purchasing one outright.

On a jog one afternoon, she came across a monastery with an abandoned garden, so she inquired about it. A monk had maintained the space for many years, but when he passed on, no one else had the know-how or passion to take it over — so Ackley offered to help. “To have someone young and ambitious come in to help grow something productive there and also maintain the space — and then [receive] produce — is great,” Ackley says. So in 2014, she started the business with edible flowers and leafy greens.

But that’s not the only location Little Wild Things is currently inhabiting. When a new restaurant, The Pub and the People, came to the area, Ackley did the same thing. But this time, she moved into the restaurant’s basement to grow microgreens under sole-source lighting.

Ackley has also found success in value-added products such as ready-made salads.

MODEL FOR SUCCESS: Ackley wanted to grow something that had the shortest phase to maturity as possible, so she could have more crop turns in a smaller space. Microgreens fit her business plan well. “I was really attracted to the idea that farming in the most environmentally sustainable way would also be the most productive way of farming, and the most profitable way of farming, in theory,” she says. The shorter-term crops have also allowed her to improve growing techniques along the way. “With microgreens, you grow them every 10 days, so you’re learning everything about all these different varieties,” she adds. “Within two years you’re a total expert.”

TECH SAVVY: She and her four-member team have moved to online-only ordering, which has helped her streamline and organize the business. It’s also allowed for on-demand deliveries Monday through Friday. “A chef can log onto our website and place an order, and we’ll actually harvest it right then and there on the spot,” she says. Then a courier service delivers it to the customers. The process can be as quick as 45 minutes, or a maximum of about four hours. “It allows us to compete with farms that are farther outside the city that can’t provide that type of quick service,” she adds.

Photo: Amber Breitenberg

WORDS OF WISDOM: Ackley says jump in, even if your roadmap isn’t complete yet. “People spend a lot of time planning,” she says. “But sometimes you need to just give it a try, and get past the barrier of doing something ... You [won’t] know what the challenges are going to be until you actually are doing whatever it is you want to do.”

Nona Yehia, CEO & Co-Founder, Vertical Harves

PROFESSIONAL PIVOT: An architect by trade, Yehia, and her co-founder Penny McBride, set out for an endeavor to create a sustainable business operation in the city of Jackson Hole, Wyo. in 2008. Providing local food through greenhouse growing was top of mind because of the city’s short four-month growing season. But the duo’s biggest challenge was to find an available construction site in Jackson Hole, a city whose proximity to a national park makes land extremely costly. A town councilman showed them a piece of property owned by the city in the heart of downtown, essentially left over from a parking garage construction. The land was 30 feet wide by 150 feet long and owned by Jackson Hole. “I’m sure, knowing him quite well, that he thought we would put [up] a hoophouse and extend the growing season by a few months,” Yehia says. “But we had bigger aspirations. We wanted to create a consistent source of local food that served the community year-round, and provided employment for people year-round at a substantial level.”

So up they went.

ONE-OF-A-KIND: Vertical Harvest opened a greenhouse that expands in height rather than square footage. The structure opened in March 2016. The entire building works as a complete ecosystem, Yehia says, but each of the three floors has a different microclimate.

The first floor is public-facing. There is an on-site market, as well as a small public atrium that allows people to “experience the verticality of the greenhouse,” Yehia says. It boasts a three-story living wall, as well as a living classroom where basil is grown and educational sessions will soon take place.

The second floor is used for lettuce and microgreen production, where the product is placed on vertically and horizontally rotating carousels. “Not only do we take advantage of as much natural light as we can give to those plants, but it balances out with supplemental artificial lights as plants rotate back into the depth of the building. It brings the plant to the farmer for harvesting and transplanting,” Yehia says.

On the third floor is tomato production, which looks very similar to a standard tomato greenhouse. “It’s really hot up there because we get the solar gain from not only the south but the roof, and it creates the perfect environment,” she says.

The tomato house at Vertical Harvest sits on the top floor of the structure to take advantage of its natural light and heat benefits.

HELPING HANDS: Vertical Harvest employs persons with developmental disabilities, which resonates with Yehia because she has a brother with developmental disabilities. “That was important to my involvement with the project because growing up, I was acutely aware of our ability as a society to really nurture this population during education, but when it comes to employment, there are still a lot of challenges out there.”

Employee positions vary widely, from market associates, to spokespersons and marketing personnel, to IPM assistants, production associates and even an assistant greenhouse manager. “One of the big models that we use to make this whole thing work is something that’s just recently been adopted in the disability world,” Yehia says. “So some people work three hours, some people work 40 hours, depending on skill and ability, and we have a customized plan for each employee.”

STARTUP TAKEAWAYS: Yehia advises aspiring startup owners to let others challenge your ideas. “Listen to your skeptics and critics and value them just as much as your supporters because they will ask you the hard questions,” she says. “And if you can answer them, then you know you’ve got a dream that’s

Hundred-Story Food-Growing Tower Is Dream of Weed Entrepreneur

Hundred-Story Food-Growing Tower Is Dream of Weed Entrepreneu

According to Rick Byrd, the future of farming is tall, dirtless and local.

Byrd's vision of skyscraper farms to feed city dwellers begins with a much different kind of crop: marijuana.

The 45-year-old is chief executive officer and founder of Pure Agrobusiness Inc., a company that sells equipment to grow legal cannabis, a market worth $6 billion in 2016 and expected to reach $50 billion by 2026, according to Cowen & Co.

Because cannabis has higher profit margins than food, and pot is mostly grown inside, Byrd said he hopes the innovations perfected by PureAgro, with the help of customer feedback, could one day revolutionize food production. It's just a question of how much it costs.

Pot is "the perfect catalyst to bring in what I think really needs to change in farming," Byrd said in an interview. "You can't have the average produce truck going 1,500 miles to get to your plate. And there's no way, obviously, to farm the amount of acres that we would need to feed New York City unless we go vertical."

Byrd imagines a 100-story glass skyscraper filled with floors of stacked beds of fruits, vegetables and grain. The same technology that currently enables vertical indoor farms to raise primo weed can one day produce perfect tomatoes or succulent lettuce, Byrd said. Paper or mesh holds up the plants, substituting for soil. Powerful lights do the work now done by the sun, but better. Data calibrate the exact light spectrum and nutrients for the plants to thrive, and machines drip just enough water. Harvests are frequent -- four or five a year, compared with one outdoor.

Making urban farms vertical instead of horizontal could cut agriculture's reliance on fossil fuels and diminish risks from pests, pesticides and an increasingly haywire environment, Byrd said.

Because price is less of a problem with cannabis, pot growers are better able to adapt to new, more expensive technology. An ounce of kale, for instance, costs 49 cents at Whole Foods Market. An ounce of cannabis can run $150 to $200, according to data from BDS Analytics, a research firm. When technology expenses fall low enough, a tipping point arrives, and food farmers can take advantage of what the pot producers already use. With legal weed pushing down pot costs, even marijuana growers will need cheaper technology, Byrd said.

"Who do you think is going to implement technology? Obviously the cannabis guys," Byrd said.