Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Kimbal Musk Says Food Is The New Internet

Kimbal Musk Says Food Is The New Internet

Former tech entrepreneur Kimbal Musk’s ambitions for innovation in sustainable farming are as grand as his brother Elon’s for space travel and electric cars

URBAN COWBOY | Kimbal Musk at Koberstein Ranch in Colorado. “He’s got good judgment overall and has been put through the ringer a few times,” says his brother, Elon. PHOTO: MORGAN RACHEL LEVY FOR WSJ. MAGAZINE

By Jay Cheshes

May 25, 2017 10:52 a.m. ET

ON A BRISK WINTER morning, Kimbal Musk is an incongruous sight in his signature cowboy hat and monogrammed silver K belt buckle—his folksy uniform of the past few years—as he addresses a crowd outside a cluster of shipping containers in a Brooklyn parking lot. Inside each container, pink grow lights and fire hydrant irrigation feed vertical stacks of edible crops—arugula, shiso, basil and chard, among others—the equivalent of two acres of cultivated land inside a climate-controlled 320-square-foot shell. “This is basically a business in a box,” Kimbal says, presenting his latest venture to its investors, friends and curious neighbors.

Square Roots, his new incubator for urban farming, aims to empower a generation of indoor agriculturalists, offering 10 young entrepreneurs this year (chosen from 500 applicants) the tools to build a business selling the food they grow. It will take on and mentor a new group annually, with more container campuses following across the country. “Within a few years, we will have an army of Square Roots entrepreneurs in the food ecosystem,” he says of the enterprise, launched last November with co-founder and CEO Tobias Peggs—a British expat with a Ph.D. in artificial intelligence—across from the Marcy Houses, in Bedford-Stuyvesant (where Jay Z, famously, sold crack cocaine in the 1980s).

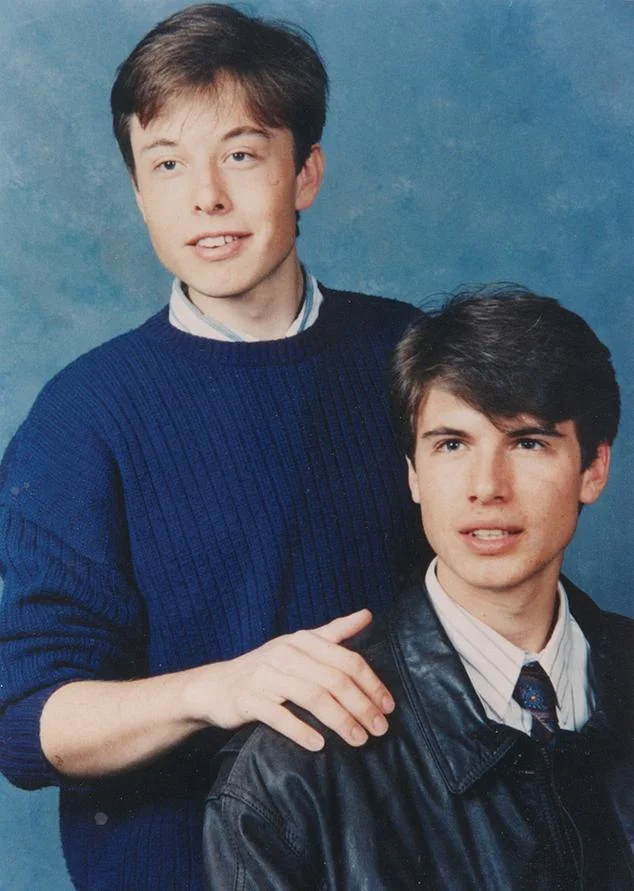

Clockwise from far left: Elon (left) and Kimbal, at 17 and 16. PHOTO: COURTESY OF KIMBAL MUSK

Entrepreneurial drive runs in the family for Kimbal, 44, a close confidante of his brother, Elon, and a board member (and major shareholder) at Tesla and SpaceX. “If something happens to me, he can represent my interests,” says Elon of his kid brother (one year younger) and worst-case-scenario proxy. “He knows me better than pretty much anyone else. He’s got good judgment overall and has been put through the ringer a few times.”

Kimbal, a veteran of the tech world, has in recent years shifted his focus to food—or the “new internet,” as he called it in a 2015 TEDx Talk. With the missionary zeal his brother brings to electric sports cars and private space travel, Kimbal has launched a series of companies designed to make a lasting impact on food culture, through restaurants, school gardens and urban farms.

‘‘I want to reach a lot of people. We’ve put too much emphasis on preciousness with food.’’

—Kimbal Musk

Since 2010, a nonprofit venture supported by the Musk Foundation has built hundreds of Learning Gardens in American schools, installing self-watering polyethylene planters where kids learn to grow what they eat. Meanwhile, his Kitchen family of restaurants—promising local, sustainable, affordable food—is rapidly expanding across the American heartland, with five locations opening this year, including new outposts in Memphis and Indianapolis. Kimbal hopes to have 50 “urban-casual” Next Door restaurants, 1,000 Learning Gardens and a battalion of container farms by 2020. “I want to be able to reach a lot of people,” he says. “I think we’ve put too much emphasis on preciousness with food—and the result is a real split between the haves and have nots.”

The Musk brothers grew up in South Africa during the last gasp of the apartheid era. Kimbal, the more gregarious sibling, got his start selling chocolate Easter eggs at a steep markup door-to-door in their Pretoria suburb. “When people would balk at the price, I’d say, ‘You’re supporting a young capitalist,’ ” he recalls. While Elon spent hours programming on his Commodore VIC-20, Kimbal tinkered in the kitchen. “If the maid cooked, people would pick at the food and watch TV,” he says. “If I cooked, my dad would make us all sit down and eat ‘Kimbal’s meal.’ ”

Kimbal in the kitchen, 2002. PHOTO: COURTESY OF KIMBAL MUSK

After high school, the brothers moved to Canada, both enrolling, for a time, in Queen’s University in Kingston, Ontario (Kimbal studied business, Elon physics). In 1995, they founded a company together in Palo Alto, California, the online business directory Zip2. “I had come over as an illegal immigrant,” Kimbal says of the move. “We slept in the office, showered at the YMCA.”

The brothers were close but also intensely competitive. Sometimes work disputes would get physical. “In a start-up, you’re just trying to survive,” says Elon. “Tensions are high.” Once they could afford it, Kimbal cooked for the whole Zip2 team in the apartment complex they shared. In 1999, the Musks sold their business to Compaq for $300 million. Though they remain investors and advisers in each other’s companies, their official partnership ended there.

HOME FRONT | Kimbal’s mother, Maye (right), with her parents at the family farm near Pretoria, South Africa, 1978. PHOTO: COURTESY OF KIMBAL MUSK

After Elon launched the payment site that would later become PayPal , Kimbal, on a lark, enrolled in cooking school. He finished his studies at the French Culinary Institute in New York in late summer 2001 with no intention of pursuing a career in food. A few weeks later, after two planes flew into the Twin Towers, he spent the next six weeks as a volunteer cook, feeding firefighters out of the kitchen at Bouley. At the end of it he wanted nothing more than to open his own restaurant. “After that visceral experience, I just had to do it,” he says.

Searching for a dramatic change in scenery, post-9/11, Kimbal and his new wife at the time, lighting artist Jen Lewin, set out on a cross-country road trip looking for a place to put down roots and raise a family. They settled on Boulder, Colorado, “a walkable town, a great restaurant town,” says Kimbal at the 140-year-old Victorian home they bought there in 2002 (they have two sons and have since divorced).

The house he now shares with food-policy activist Christiana Wyly—with a cherry-red Tesla parked out back—is a few blocks from the original Kitchen, an American bistro he launched in 2004 with chef-partner Hugo Matheson, a veteran of London’s River Cafe. The Kitchen sourced ingredients from local farmers, composted food waste, ran on wind power and used recycled materials in its décor. For its first two years, the two partners worked full-time as co-chefs, taking turns composing the menu, which changed every day. Eventually, the daily grind became too much for Kimbal. “I got a little bored with the business,” he says.

Kimbal in his Zip2 office, 1996. PHOTO: COURTESY OF KIMBAL MUSK

By 2006, he was back working in tech, as CEO of a social-media-analytics start-up. The Kitchen might have remained a sideline if not for a series of unlikely events. On February 10, 2010, at a TED conference in California, he listened to Jamie Oliver admonish America for its childhood obesity problem. Four days later, while barreling down a slope in Jackson Hole, Wyoming, Kimbal flipped his inner tube and broke his neck. In the hospital, wondering if he’d ever walk again, he began to reconsider his life, with Oliver’s comments rattling around in his head. “The message I heard was: The people who have no excuse should be doing something about this—and I was one of those people,” says Kimbal. “I told myself, If I get through this I’m going to focus on food and doing things at scale.” Apart from losing some feeling in his fingers, he made a full recovery.

Since then Kimbal has become a cheerful crusader for “real food,” as he calls it, sharing his message on the lecture circuit. “He’s a compelling speaker,” says food writer and activist Michael Pollan. “Particularly in his passion for kids, his recognition that if we’re going to change our approach to eating in this country, it’s about showing kids where food comes from, how to grow it, how to prepare it.”

“In 2004, there were very few local farmers that would work with us,” says Kimbal. “We opened the Kitchen before farm-to-table was a term. We showed that you could be busy and profitable while creating a new supply chain. Now there’s a huge backlash against processed food, industrial food. Real food is simply food you trust to nourish your body, nourish the farmer and nourish the planet.”

Bowery Reinvents Farming for Urban Landscapes

Bowery Reinvents Farming for Urban Landscapes

May 26, 2017 by Annie Pilon In Green Business

Agriculture is one of the oldest industries out there. But businesses are still finding new ways to update this industry in order to get fresh produce to the people who need it most.

Bowery Indoor Farming

Bowery is one such business. The farming startup made its goal to get fresh produce to consumers in big cities in a sustainable way. To achieve that goal, the company uses hardware and proprietary software to set up vertically stacked gardens that operate indoors year-round.

This solves a couple of different problems. First, many city dwellers live in food deserts, or places where there isn’t a whole lot of fresh produce available. Secondly, traditional agriculture uses massive amounts of water and other resources. And Bowery’s high tech approach allows the business to function in a way that’s both sustainable and not reliant on outdoor weather.

A Great Example of Innovation

What this business shows is that you can put a new spin on almost any industry, as long as you’re willing to get a little creative. Throughout the years, people have come up with plenty of new tools to update agriculture or make certain processes more efficient. But if you’re willing to look at things in a new way, and innovate based on your observations, you can still find ways to update almost any business model.

Image: Bowery

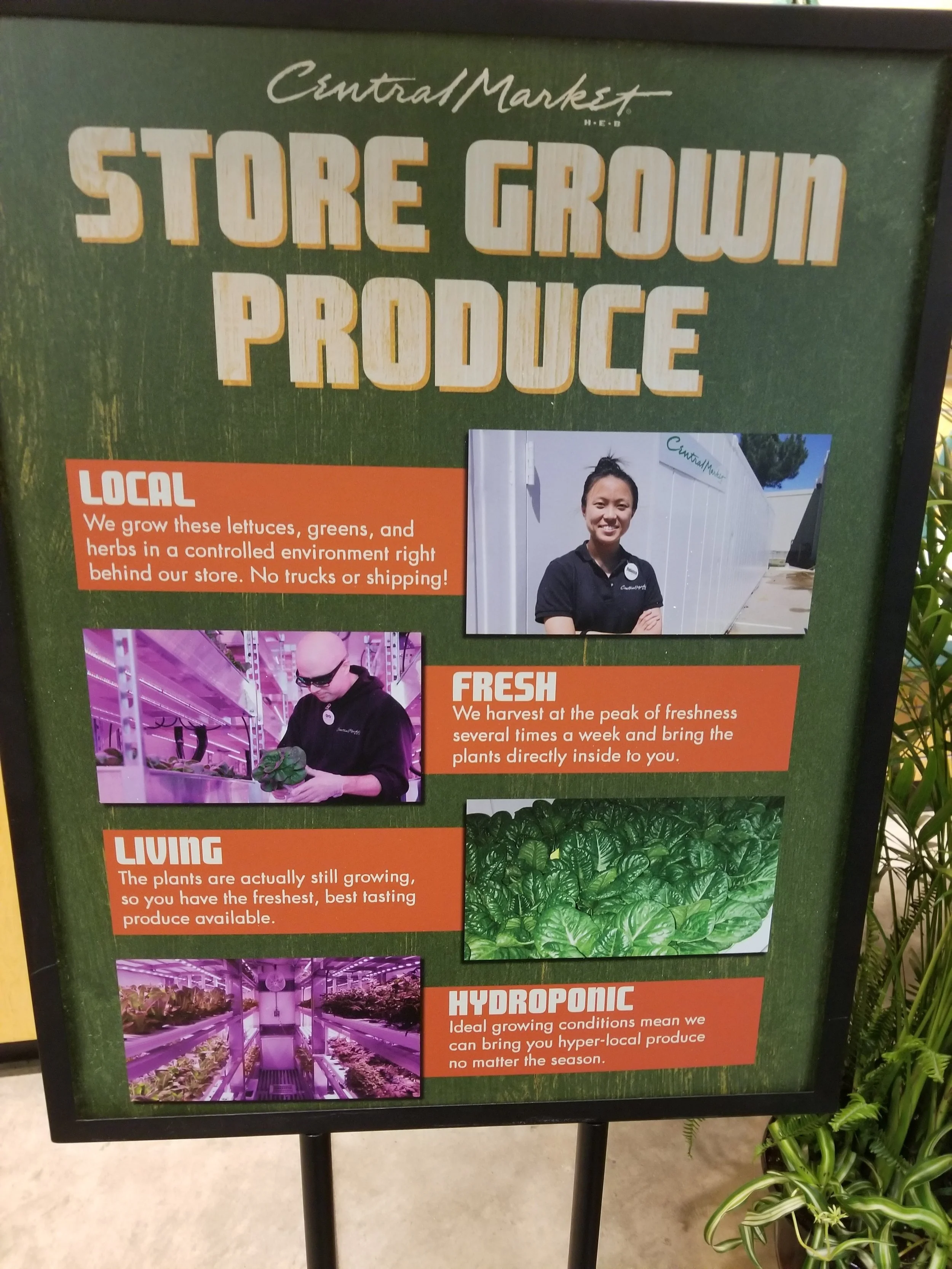

H-E-B-Owned Central Market Partners With CEA Advisors and Growtainer® For Store Grown Initiative

H-E-B-Owned Central Market Partners With CEA Advisors and Growtainer® For Store Grown Initiative

Friday, May. 19th, 2017

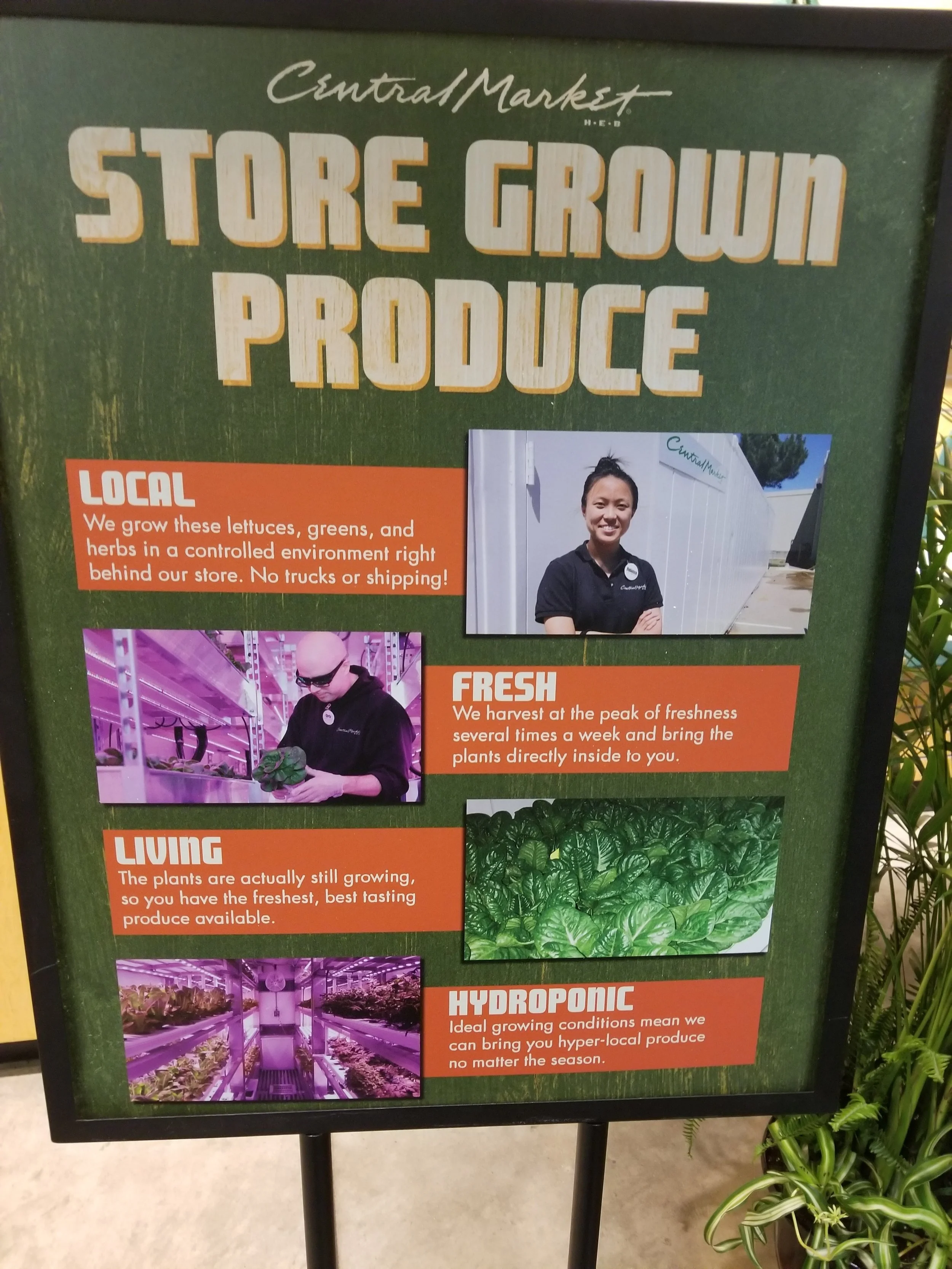

DALLAS, TX – After more than a year of planning between Central Market’s Produce Marketing team and CEA Advisors, the two companies have announced the completing of the first custom built onsite production Growtainer®. Central Market’s new Store Grown Produce program is in effect and turning out fresh leafy greens, herbs, and spices for Central Market customers in Dallas.

Glenn Behrman, Founder, Greentech Agro LLC and CEA Advisors LLC.

“We spent over a year discussing [Central Market’s] concerns and objectives, and when I was sure we were all on the same page, we began the design and manufacturing process” said Glenn Behrman, Founder of Greentech Agro LLC and CEA Advisors LLC.

The state-of-the-art 53-foot custom-built Growtainer provides 480-square-feet of climate-controlled vertical production space designed for maximum efficiency and food safety compliance. The miniature production facility features a dedicated proprietary technology for ebb and flow irrigation and a state-of-the-art water monitoring system, and its Growracks® are equipped with energy efficient LED production modules specifically designed for multilayer cultivation.

Growtainer

According to a press release, Central Market—the Texas-based upscale grocery banner owned by H-E-B—is currently using its Growtainer setup in an effort to “produce the freshest, unique, gourmet leafy greens and herbs for Central Market customers at the retail level.” The release noted that Central Market and CEA Advisors have worked closely with Chris Higgins and Tyler Baras of premier horticultural supplier Hort Americas to train the Central Market associates to operate a food safety compliant, climate controlled, LED-lit, multi-layer vertical indoor production environment.

Central Market storefront

“CEA Advisors is proud to be working with the Produce Team at Central Market, all committed to innovation and focused on food safety, unique products, and the customer experience” said Behrman.

GreenGro Technologies, Inc. (GRNH: OTC Pink Current) | Greengro Technologies, Inc. Retains Investor Relations Partners to Support Company's Strategic IR Program

GreenGro Technologies, Inc. (GRNH: OTC Pink Current) | Greengro Technologies, Inc. Retains Investor Relations Partners to Support Company's Strategic IR Program

May 25, 2017

OTC Disclosure & News Service

ANAHEIM, Calif., May 25, 2017 (GLOBE NEWSWIRE) — Greengro Technologies, Inc. (OTC:GRNH), a leader in the indoor agriculture technology market, today announced that it has retained Investor Relations Partners (IRP), one of the fastest growth investor and public relations firms in the nation, to expand the Company’s strategic investor relations program.

“GreenGro Technologies is at the forefront of the burgeoning indoor agriculture technology market. Our business units cover the entire indoor agriculture supply chain from developing growing technology to growing structures, plant processing, distribution and sales,” said Jim Haas, Chief Executive Officer of GreenGro Technologies, Inc. “In the past few months we have made a number of strategic acquisitions and partnerships and built what we believe is a solid pipeline of significant deals. However, the market has yet to grasp our unique strategy and the enormous role we expect to play in the indoor agriculture market. We have retained IRP to help communicate the series of expected positive developments to the investment community in an effort to significantly increase our exposure as well as support our overriding goal of building shareholder value,” concluded Mr. Haas.

To be added to the Company’s investor lists, please contact Bill Miller at Investor Relations Partners at 844-565-5665 or via email at bmiller@irpartnersinc.com.

About Greengro Technologies

Greengro Technologies (OTC:GRNH) is a world class provider of eco-friendly green technologies with specific domain expertise in indoor and outdoor agricultural science systems serving both the consumer and commercial farming markets. It brings together community and commerce through the growth and distribution of healthy, nutritious foods and vital medicines backed by science and technology. Customers include restaurants, community gardens, small and large scale commercial clients. Greengro Technologies also provides design, construction and maintenance services to large grow and cultivation operations and collectives in the medical and recreational marijuana sectors.

The company’s websites: www.greengrotech.com, offer regular updates including educational videos, projects updates, recipes and nutritional information, and where to find the company’s products. https://www.facebook.com/GreengroTechnologiesInc.

About Investor Relations Partners

Investor Relations Partners, Inc. (IRP) is a full-service investor relations firm serving a global client base. The principals of IRP have received top industry awards for their investor relations programs for a number of high-profile companies, including, but not limited to, Starwood Hotels & Resorts Worldwide, ValueVision Media, Taro Pharmaceuticals, and LJ International. The firm’s principals have executed effective investor relations programs for dozens of public companies, ranging from emerging micro-cap companies to multinational corporations with market capitalizations in excess of $15 billion. For further information on IRP, please visit the firm’s Website at www.irpartnersinc.com.

Forward Looking Statements

This release may contain forward-looking statements. Actual results may differ from those projected due to a number of risks and uncertainties, including, but not limited to, the possibility that some or all of the matters and transactions considered by the Company may not proceed as contemplated, and by all other matters specified in the Company’s filings with the Securities and Exchange Commission. These statements are made based upon current expectations that are subject to risk and uncertainty. The Company does not undertake to update forward-looking statements in this news release to reflect actual results, changes in assumptions or changes in other factors affecting such forward-looking information. Assumptions and other information that could cause results to differ from those set forth in the forward-looking information can be found in the Company’s filings with the Securities and Exchange Commission (www.sec.gov), including its recent periodic reports.

Investor/Media Contact: Bill Miller Investor Relations Partners Phone: 844-565-5665 bmiller@irpartnersinc.com

Copyright © 2017 GlobeNewswire. All Rights Reserved

This Texas Supermarket Is Growing Its Own Veggies In A Shipping Container Farm

This Texas Supermarket Is Growing Its Own Veggies In A Shipping Container Farm

Agriculture, Carousel Showcase, News, Sustainable Food, Urban Farming

A Texas chain of supermarkets isn’t just in the business of selling vegetables; it’s growing them, too. Based in Dallas, the H-E-B-owned Central Market has joined forces with Controlled Environment Agriculture Advisors, a self-described “horticulture disrupting” firm, to raise some of its produce in a custom-built onsite shipping container—a first for an American food retailer.

The 53-foot-long “Growtainer” features 480 square feet of climate-controlled and food-compliant vertical space designed to achieve a higher yield in a shorter time than conventional methods, according to GreenTech Agro, the system’s manufacturer.

Related: Belgian supermarket unveils plan to sell food grown on their own rooftop garden

“We spent over a year discussing [Central Market’s] concerns and objectives, and when I was sure we were all on the same page, we began the design and manufacturing process,” said Glenn Behrman, founder of GreenTech Agro and CEA Advisors, in a statement.

The miniature farm comes with a modular, self-contained series of LED-lit aluminum “GrowRacks” that supports any number of cultivation levels.

Related: Pop-up shipping container farm puts a full acre of lettuce in your backyard

It also offers an intelligent water-monitoring system, as well a zoned irrigation system that meets the needs of different varieties of produce at different stages of growth.

The Growtainer is part of Central Market’s efforts to “produce the freshest, unique, gourmet leafy greens and herbs for Central Market customers at the retail level,” the supermarket said. The hyper-local vegetables are marketed under the label “Store-Grown Produce.”

Related: Freight Farms are super efficient hydroponic farms built inside shipping containers

“CEA Advisors is proud to be working with the Produce Team at Central Market, all committed to innovation and focused on food safety, unique products, and the customer experience,” Behrman added.

Sustainable Indoor Farm Aims To Grow The Most Delicious Produce

Sustainable Indoor Farm Aims To Grow The Most Delicious Produce

A San Francisco startup is creating an indoor vertical farm that aspires to produce crops more efficiently and sustainably than traditional farms

- 25 MAY 2017

Indoor vertical farming startup Plenty wants to transform the way greens are produced. The company, headquartered in San Francisco, has created 20-foot towers of rare herbs and greens—including special kinds of basil, chives, mizuna, red leaf lettuce and Siberian kale—that are not frequently available at the average grocery store because of their high production costs.

“When you’re not outside and you’re no longer constrained by the sun, you can do things that make it easier for humans to do work and work faster, and for machines to work faster,” Plenty CEO and co-founder Matt Barnard told Fast Company. The company claims it can grow crops up to 350 times more effectively than conventional farms in a given area. Indoor vertical farms are more energy- and space-efficient, Barnard says, producing the same output as fairly large farms in a far smaller space. He believes that the indoor farming process, once perfected, may become more sustainable than traditional farms.

Plenty is attempting to put ever-improving technology toward its success and plans to build farms near large cities so it can fit into existing supply chains that deliver to city limits. Faster delivery means better food, preserving both flavor and nutrients. Indoor farming also has the potential to be more sustainable by using solar energy and cutting down on the costs and pollutants of traditional supply chains.

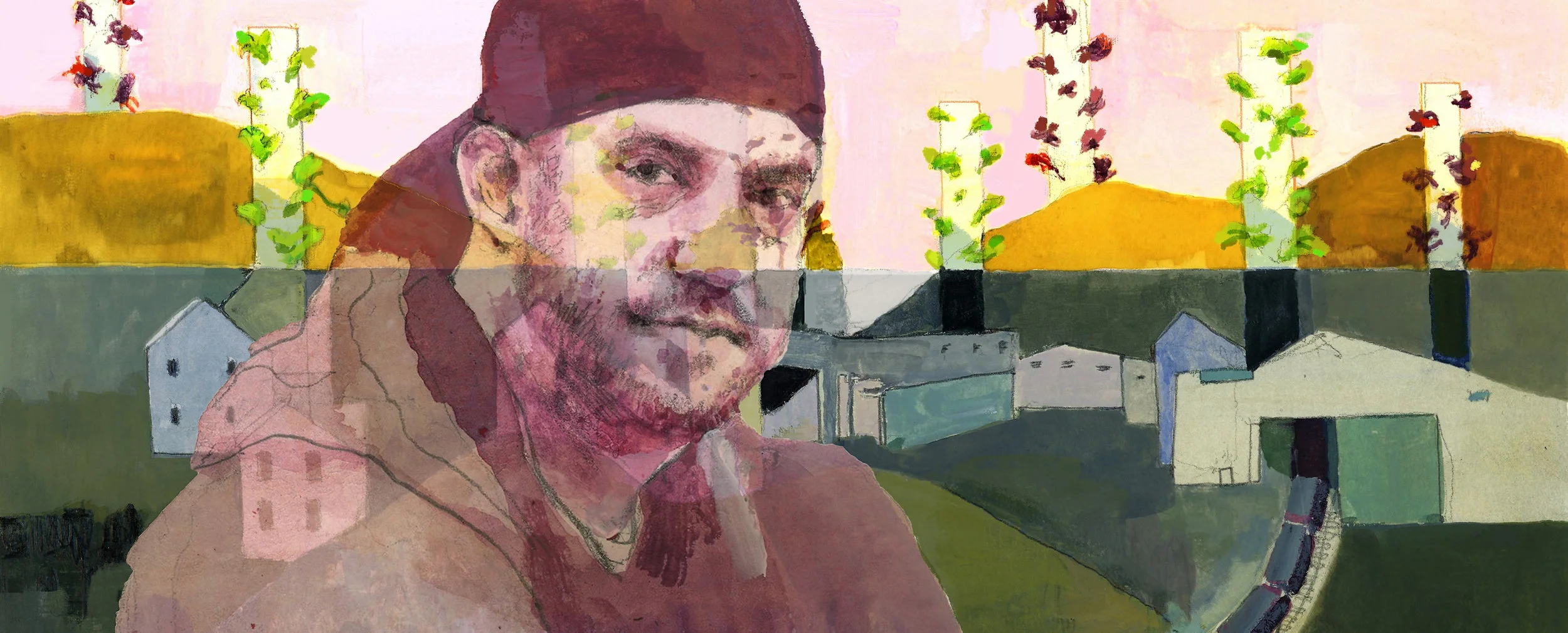

Can Hydroponic Lettuce Save Coal Country?

Story by Otis Gray

Illustration by Jia Sung

5.3.17

Can Hydroponic Lettuce Save Coal Country?

Young people tend to talk about “getting out” of McDowell County, West Virginia. But one radical farmer is bringing life back to his struggling hometown.

This story is a collaboration between Narratively and Hungry, a podcast about the food we eat, the people who make it, and the inspiring stories surrounding food you don’t usuall

* * *

Joel McKinney, 33, is thick and tall, with tattooed arms and a backward baseball cap. There’s a restless demeanor exuding from beneath the militaristic dude-ness he must have picked up during his time in the Navy. He slides open the greenhouse door and a warm draft washes out.

On the north side of the greenhouse are two long rows of eight-foot-tall bright white PVC towers standing at attention. From each PVC pipe explodes scores of violently purple and green heads of lettuce growing vertically up the tube. Each plant sits askew in a little cup fitted into its respective hole in the tower. A steady trickle of electricity and water reverberate in the warm tunnel. These are McKinney’s hydroponic lettuce towers.

“People are so stuck on traditional agriculture, and that’s fine, it’s all great. But I’m not growing out, I’m growing up,” he says. “What I’m doin’ with the towers, it’s not just about hydroponics to me. It’s not just about growing food. To me, this thing embraces change.”

A scene off the main road going through McDowell.

The vibrant, futuristic setup is entirely unexpected in a place like McDowell, and that’s kinda the point for McKinney. McDowell is a remote coal county tucked away in rural West Virginia. Back in the late fifties when coal was booming, McDowell’s population was over 100,000. In 2017 that number has dropped below twenty thousand. It has made headlines over the last decade for its daunting economic hardships, rampant opioid use, and most recently, its overwhelming support for Donald Trump in the 2016 presidential election. But these headlines fail to cover creative people like McKinney who are responding to those circumstances.

McKinney cradles a deep green head of lettuce between his fingers. The towers each sit atop big black buckets with neat tubes running in between, making the greenhouse look like a room full of computer servers as curated by an obsessive farmer. Each bucket is filled with a nutrient-rich solution – water loaded with natural stuff the plants need to grow. A pump system carries the solution to the top of the tower, where it trickles down inside and is directed to the roots of each plant. The roots dangle into the passing solution and soak it all up. The solution then falls back to the bucket, and is cyclically pumped up to the top again. While the physics of it are simple, McKinney has taken extreme care to make these towers as efficient as possible.

McKinney served in the Navy as a machinist mate, and was honorably discharged after spending 2003 to 2007 aboard the USS Trenton. He went in as an engineer, devouring any manuals he could find and ravenously learning the technology of the ship’s systems. The old-school tech used on the ships – the steam-powered stuff, the electronics – captivated McKinney. He excelled among his peers and became the first E-3 Seaman with the title of qualified firearm supervisor in the 35-year history of the USS Trenton. He deployed to Lebanon, Beirut, facilitated an Israeli evacuation, traveled up and down Latin America, and has seen most of the United States.

Joel McKinney with his hydroponic towers.

Something you’d notice driving through McDowell is that there aren’t a whole lot of people McKinney’s age. You generally see children, and then people who look to be at least forty. This is in large part due to the dramatic decline of jobs over the last fifty years, which has forced adults to flee to urban areas in West Virginia, Ohio, and Kentucky, often sending money back to kids they left in McDowell to be raised by grandparents. The younger generation has seen the county rocked by floods, a recession, and an epidemic of opioid addiction that has deterred those who leave from ever coming back.

“I was forced to adapt,” McKinney says. After the Navy, McKinney went to work for the railroad. During the next seven years, he honed his skills in electrical engineering and operating machinery, but quickly plateaued and wound up unchallenged by the job. He got bored and started drinking heavily – “I have a really addictive personality,” he explains – and got a DUI. The DUI led to a suspension from his railroad job, during which time he wound up back in McDowell helping his mom Linda at their food bank. She had one of these towers lying around so, he did what he does best: He started tinkering.

As the coal industry declined, many people here turned to traditional farming for food and profit, but the runoff from the mines made it tough to grow anything, much less anything healthy. Byproducts like arsenic, selenium, mercury, and compaction often ravage otherwise fertile soil in coal-heavy towns. Even if you do produce enough crop to sell, McDowell is secluded enough that the time and money spent on transportation to a viable market would eat up any profits. Hydroponics provided McKinney a way to farm without using the contaminated water, and the cost is so low that folks in McDowell can afford to buy the resulting produce themselves, cutting out the need for costly transportation.

McKinney calculates that the 440 heads of lettuce he has growing in this roughly twenty-by-five-foot area take up less than one-eighth of the space it would take to grow in the ground and uses ninety percent less water. This means that farmers using McKinney’s systems could bypass tainted water, produce year-round, and multiply their crop by ten times each harvest. All without using pesticides, GMOs, or growth chemicals.

The local public school has become one of McKinney’s accounts and buys lettuce for their lunches. As part of the deal, he gets to teach a raucous group of six-year-olds about hydroponics by installing a tower in one of the classrooms. “Man, working on the railroad is a lot like working with kindergartners. But I’m a structured guy, I work with bullet points – so when you go from the military to working with kids. . .”

He fiddles with a tube feeding into one of the buckets and laughs. “I learn a lot from them. I can’t go in with kids and teach like, tropism and nitrogen cycles and covalent bonding, but you go in with kindergartners and you say, ‘okay well, this is lettuce. This is what lettuce should taste like.’”

“Oh my gosh, he thinks he’s horrible with the kids and he’s fantastic. I tell him he needs to be a teacher,” Kimball Elementary school teacher Sarah Diaz says. “Many of our kids are not exposed to varieties of food,” she adds. “So even simple things like a salad with homegrown vegetables and a homemade dressing, that’s a big deal. They love the flavor. We had so many kids coming away saying ‘I really like vegetables!’ Whereas before, they wouldn’t touch it!”

Diaz says the learning doesn’t stop after kindergarten, it has to become embedded in McDowell’s culture. “If we can get people like Joel to plant a fire in these kids and develop a program that allows them to grow with these systems and grow into it, I can see huge potential for change in the next couple generations.”

The question is whether people in McDowell will embrace the new system. McKinney admits that people in McDowell can be a tough bunch to work with because of their deep traditions and weathered attitudes. Folks in McDowell even describe themselves as “good people, but defensive.” This has a lot to do with decades of their livelihood (coal and other big industries) being outsourced, broken promises from the government, and media outlets that portray their home as a hellish wasteland waiting for politicians to come save them.

McKinney says the people of McDowell constantly surprise him with how on board they are with the hydroponics. “People can be pretty close-minded, but hey, man, I’ve been all over the world, these are very good people here in Appalachia.”

Hydroponic Lettuce Towers in Joel McKinney’s greenhouse.

Hydroponic projects in big cities get most of the media attention, focusing on people growing indoors without a lot of space. But it’s wildly useful in rural areas too. “This is absolutely sustainable here,” McKinney says. “It’s something anybody can do and now I’m training people of all ages how to pick this thing up and run with it.”

“The hydroponics is kinda’ a visual for the concept of change. I wanna bring some change into a rural poverty situation,” McKinney says, nodding his head and looking at a crop. “People will say opportunities don’t exist here. And I say, ‘you’re absolutely right. Create it.’ And that’s what we’re doin’, we’re creating a market.”

His operation is applicable to countless rural economies throughout Appalachia and the rest of the U.S. that are primed with mechanically-minded industry families who are in need of better food and sustainable incomes. Coal will not come back permanently. McKinney knows this, and the folks of McDowell know this too. Transitioning into simple yet futuristic agriculture could revolutionize their narrative.

McKinney shuts the door to the greenhouse. “Look,” he says frankly as he walks back across the cold lot. “I don’t believe that lettuce and strawberries are gonna save McDowell.”

Hydroponics are a beginning. An example that there is more. “Kids here, especially once they hit the junior high age, they just feel like there’s no hope, there’s no chance for change. So as soon as they can they say ‘let’s get out of McDowell.’

“I’m really trying to change that logic as best I can. I don’t think it’ll happen in my generation, but I’m hopin’ to kinda be the spark that initiated some change in this place ’cause I believe it can happen. It’s just gonna take a long time.”

Listen to the extended audio version of this story – featuring Senator Bernie Sanders – on the Hungry podcast. You can subscribe to Hungry on iTunes, Stitcher, your podcast app, or via www.hungryradio.org.

Urban Agriculture: Growing Network Wants to Make City Farming Easier

Urban Agriculture: Growing Network Wants to Make City Farming Easier

Courtesy photo This photo from Grow Pittsburgh shows an urban agriculture area in the city.

MAY 24, 2017

CHERIE HICKS - Staff Writer - chicks@altoonamirror.com

Living in the city doesn’t mean you can’t raise a wide variety of your own food. And a growing network of urban agricultural interests in Blair County is trying to make it easier.

Kick-started by a grant last year and joining a nationwide movement, the Blair County Urban Ag Program already has pulled together more than 100 members from different groups — schools, churches, governmental organizations, nonprofit agencies, homeowners, farming interests and more. They are sharing how-to information from raising backyard chickens to gardening with organic practices, and they’re taking lessons from Pittsburgh.

“We’re surrounded by all these big farms, but people living in the city of Altoona are going hungry … because they live in a food desert,” said Beth Futrick, an ombudsman with the Blair County Conservation District and recipient of a $46,000 grant last year to start the urban ag program.

“Food deserts” are large pockets of residences at least a mile from a supermarket or large grocery store where fresh food can be purchased, she said.

“Too many poor people lack transportation to get to Weis so they walk to the closest convenience store” and purchase prepared, processed food, according to Futrick.

Last year, she enlisted the Healthy Blair County Coalition and organized the network’s first event, a tour of a community garden in State College. More than 30 people in the medical field, schools, WIC and other social programs showed up, Futrick said, with one common goal: How to get healthier foods to their customers, their clients, their patients, their students.

“We are trying to reach out to as many people as we can and build a network.”

The grant helps pay for her salary, as well as a consultant, speakers and other education programs, especially to get the word out about the programs, she said.

Tyrone Milling, for example, held a seminar on how to raise backyard chickens, and the network promoted the idea. It is legal to raise chickens in your backyard in Altoona, said Planning Director Lee Slusser, who noted that goats, chickens and rabbits are “great urban animals.”

The City of Altoona mulled an animal husbandry ordinance similar to Pittsburgh’s, but there haven’t been very many complaints so it got shelved for the time being, said Slusser, who is an active member of the urban ag network.

But it still would be unwise, Futrick said, for city residents to have a rooster.

“My dad had a rooster that at 3 o’clock in the morning would go ‘cockadoodle doo’,” she said. “Don’t make your neighbors upset.”

Futrick noted that Pennsylvania has a right-to-farm law that prevents municipalities from getting too strict, though.

“We can regulate how many animals you can own,” such as one cow per acre, Slusser said. “But we can’t ban it outright.”

Another major component of the urban ag network is the Society of St. Vincent DePaul, which has operated the nonprofit Monastery Community Gardens south of Hollidaysburg since 2008. In addition to growing produce for local food banks, the society rents out garden plots and a few are still available this season for $25 or $40. (Contact Kathy Saller at ksaller@netzero.com).

It also sponsors regular gardening classes in conjunction with the urban ag network.

The next education event, a workshop sponsored by the National Association of Conservation Districts, will discuss indoor farming techniques from 9 a.m. to 2:30 p.m. on June 12 at the Logan Valley Mall Community Room. The deadline to register is June 1. Area experts will discuss hydroponics (growing plants without soil); aquaponics (dealing with the relationship between aquaculture, or farming fish, and hydroponics); Bokashi composting (an anaerobic composting method for kitchen scraps, including dairy and meat); and growing microgreens, the immature shoots of edible plants. A $15 fee to attend includes lunch and education credits are available.

A bus trip to Pittsburgh on June 28 ($30 per person) will include visits to several programs of the Grow Pittsburgh program, which formally organized in 2008 and today has 18 full-time staff members.

“We really think about growing food across the city, among all different ages and in all different kinds of communities,” said Jake Seltman, executive director.

Its programs include urban gardens and school gardens, and it provides resources for community gardens throughout Pittsburgh, having started more than 60 of them before turning over their sustainable operations to the communities in which they’re located, he said.

“We provide a lot of resources,” Seltman continued. “We share best practices and make it easier for people to grow their own food.”

Its website (www .GrowPittsburgh.org) is full of resources for urban dwellers.

The Blair urban ag program specifically will visit the Grow Pittsburgh’s Braddock Urban Farm, as well as the Allegheny County Courthouse’s rooftop garden, the Phipps Conserva-tory and Botanical Gardens’ Center for Sustainable Landscapes and the Phipps’ Homegrown program at the Homewood YMCA.

Among the lessons Futrick said she hopes the network can teach to consumers is an understanding of growing seasons and which crops are available here and when.

“They want corn in April,” she said. “We just need to do some customer education. We shouldn’t buy so much from California. There it’s picked to travel, not for good taste.

“We can grow really nice stuff here in Pennsylvania.”

Mirror Staff Writer Cherie Hicks is at 949-7030.

The World’s Smallest Garden is Created in New York City

The World’s Smallest Garden is Created in New York City

Nate Littlewood and Rob Elliott have created The World’s Smallest Garden, a device which turns an empty bottle into a hydroponic garden.

After meeting at Columbia University in early 2016, the co-founders combined their skills in business and food growing systems to launch this first product, which is intended for beginning growers to use in their home. Setup for the product should only take about 60 seconds, by placing the small, biodegradable plastic device into the top of a bottle—such as a whiskey or wine bottle.

With UrbanLeaf, Littlewood and Elliott hope to create an experience which helps people reconnect with their food. Food Tank had a chance to speak with Nate Littlewood about the inspiration behind UrbanLeaf and challenges he and his partner have faced along the way.

Food Tank (FT): What was the inspiration that led to creating the UrbanLeaf product?

Nathan Littlewood (NL): We wanted to show people that growing food at home could be fun, easy, and accessible. Through over 200 customer interviews, we feel we’ve developed a pretty good handle on the sorts of challenges and obstacles that amateur urban farmers face.

Nine times out of ten, home gardens fail because people forget to water them. The World’s Smallest Garden solves this problem in the simplest, most elegant, and cost-effective way we could imagine. It provides a way for plants to water themselves. We also like that it repurposes something that is available locally (an empty bottle) to create the hydroponic reservoir. In doing so, we eliminate the need to make an injection molded plastic reservoir and import it from overseas. The small amount of plastic we do use in our product is biodegradable. It costs us a bit more, but we feel this is money well spent.

FT: What has been your biggest challenge in developing UrbanLeaf?

NL: It’s been really hard finding hardware know-how and expertise here in New York. There’s a ton of people that understand tech and services based businesses, but widget producers are few and far between! We were recently accepted into FutureWorks, which is a hardware-specific Incubator Program. It seems like an amazing community and we’re looking forward to getting more involved!

FT: How do hydroponics contribute to a more sustainable food system?

NL: Hydroponics opens up new possibilities for food-system design. It doesn’t rely on clearing land, soil quality, large open spaces, and the right season. Hydroponics is very well suited to growing food in urban environments. It’s stackable, it can go vertical, and it can be modular. It allows us to conceive food system designs that involve shorter supply chains, fewer food miles, less weather vulnerability, less wastage, and less packaging.

UrbanLeaf co-founders Nate Littlewood and Rob Elliott. | Photo courtesy of UrbanLeaf

FT: What piece of advice would you give to early entrepreneurs trying to make an impact in the food system?

NL: Emily, you’d know better than most about the level of interest growing around food and sustainability—and I’m sure you’ll agree that this is a good thing. Whilst it’s encouraging to see so many bright, talented, and motivated people entering this space, coming from a business background, I do worry that food businesses generally have low barriers to entry. I fear that a lot of people are going to burn a lot of capital over the next 5 to 10 years learning hard lessons about the importance of competitive advantage. As a producer of consumer hydroponics products, this is something I worry about more than most! My advice is to remember that you can’t pay your rent with passion—most landlords require dollars.

FT: What inspires you to keep working towards food system change every day?

NL: When I’m an old man, and I tell my grandchildren what I’ve done with my life, I want them to be so excited about the answer that they go to school the next day and tell all their friends about it. I’m only in my 30s, so the grandkids are some way off, but the quality of the environmental legacy that I leave behind for them is why I’m doing this. I want them to be able to enjoy the great outdoors in the same way I have. I’m also 100-percent confident that we can improve the quality of thousands of peoples’ lives along the way by providing an experience that helps them reconnect with food.

FT: You’ve mentioned that The World’s Smallest Garden is only a first step towards building a future where food is fresh, local, and personal. What is your vision for UrbanLeaf down the road?

NL: Our goal is to make our customers happy, and to show people that growing their own food can be fun, easy, and accessible. The World’s Smallest Garden is the perfect product to start with both for us as a company and for consumers who are new to this space. Ultimately we want to grow with our customers, and we have a really exciting pipeline of new products that we’ll be releasing over the next few years. I’ll tell you more about that in our next interview!

What is Urban Agriculture?

Welcome!

Are you interested in starting an urban farm? Seeking details on how to raise backyard chickens and bees? Looking for information on laws, zoning and regulations that relate to urban agriculture? We offer resources on small-scale production, including soil, planting, irrigation, pest management, and harvesting, as well as information on the business of farming, such as how to market urban farm products.

After you explore the site, please complete our survey! We’d like to know if you found what you were looking for and hear your suggestions.

Benefits of Urban Agriculture

Urban agriculture can positively impact communities in many ways. It can improve access to healthy food, promote community development, and create jobs. A number of cities in California, including San Francisco, Los Angeles, and San Diego have recently updated municipal policies to facilitate urban agriculture, due to strong community interest. If you’d like to learn more about some documented impacts of urban agriculture, see Research.

Challenges of Urban Agriculture

Despite the benefits associated with urban agriculture, there are many challenges. Urban farmers routinely face issues related to zoning, soil, water access, and profitability, as a few examples. At the community level, noise and nuisance issues can come into play. This site is intended to share the research on both benefits and challenges, and best practices on how to address those as a farmer or local decision maker.

Who We Are

UC ANR is part of the nation’s land grant university system, with more than a century of experience providing research-based knowledge to California farmers. This site offers resources that we’ve identified as most useful for urban farmers and local decision makers and stakeholders. Additionally, we are identifying gaps where resources need to be developed. Our team includes more than 15 experts, ranging from UC farm advisors, to agricultural economists, to urban planners and policy makers.

Rice University Students Create Indoor Farming Device

A group of mechanical engineering students at Rice University have come up with a way to cultivate vegetables without needing a large plot of land outdoors.

Rice University Students Create Indoor Farming Device

By Rebecca Hazen, rebecca.hazen@chron.com

Photo: Lettuce Turnip The Beet

Published 4:11 pm, Tuesday, May 23, 2017

A group of mechanical engineering students at Rice University, called the Lettuce Turnip the Beet team, have come up with a way to cultivate vegetables indoors.

A group of mechanical engineering students at Rice University have come up with a way to cultivate vegetables without needing a large plot of land outdoors.

The Senior Capstone Design project, made up of students Jared Broadman, George Dawson, Sanjiv Gopalkrishnan and Dominique Schaefer Pipps, aptly named their group "Lettuce Turnip the Beet." (LTTB)

According to group member Gopalkrishnan, the mechanical engineering department pitched different projects to the senior students, including a vegetable cultivation machine, and the four choose to work on that particular project.

The main goal of team LTTB, through the vegetable cultivation machine, was to produce one salad per week, for a year.

"Other goals were to make the project sustainable, easy to build and operate, and able to be used in an apartment setting. We have achieved all of our goals - our most recent harvest yielded eleven salads after four weeks of growth," Gopalkrishnan said.

The team has been working on the project since August, and created two versions, both with vegetables growing hydroponically - without soil. The first prototype is in an enclosed area outside. It is based on a triangular frame, has three circular grow tubes, and two pumps with inputs into each of the tubes. It is about 6 feet tall. The second prototype is inside. It is eight feet tall, hosts six square grow tubes, and one pump with an input to the top of the tube arrangement.

"The wooden frame of the second prototype is modular, in that it is composed of four two foot tall sections of two-by-fours, held together by dowel rods. The frame was designed this way to facilitate customization and easy transport. The pipes are square because they are easier to fit into the framework, and have a larger bottom area for the roots to lay upon as the nutrient solution flows across them," Golpalkrishnan explained. "The one input was chosen for ease of operation, as the pipes are all connected in a gravity fed cascade. It is vertical for easy user access. The triangular shape of the first prototype made it hard to access plants at the top. We use a Platinum P900 LED to feed plants at the top of the device, with two smaller fluorescent lights to supplement the bottom plants. The entire device draws about the same amount of power as a microwave."

Golpalkrishnan continued, "We learned quite a bit from the first iteration that we implemented into the second, final prototype. We built the first prototype in November 2016 and the second prototype in February 2017."

It may seem complicated, but the reality is that growing plants is straightforward. They just need light, water, nutrients and a place to grow.

"If the system is set up properly (which is easy to do, and takes about an hour per week to maintain), the plants grow on their own. The biggest key to being able to grow indoors is a good grow light. Plants will grow without light, but one cannot harvest a salad per week without a good light. As far as anyone being able to do this - the answer is yes. Three of the four of our team had no gardening experience, and we have learned as we go," Golpalkrishnan said.

Tomatoes are currently being grown in the outdoor prototype, because there is easy access to pollinators. The LTTB team found that it was easy to grow leafy greens indoors because they do not require pollination. The indoor prototype is currently growing lettuce, kale, Swiss chard and spinach. There are also herbs like basil and parsley, and the team even managed to grow a carrot and radish.

"It is amazing to see the whole plant cycle, from seedling, to adolescent plant, to being able to harvest them. The device has made it easy for us to grow our own vegetables, and our hope is that the device can combat the negative practices utilized by industrial agriculture," Golpalkrishnan said.

Recently, the team showed off their work at the Engineering Design Showcase, which is an event for all Rice engineering teams. Lettuce Turnip the Beet won the Best Environment and Sustainability Design Award.

As the last part of the project, the team will travel to Gothenburg, Sweden, at the end of this month. There, the device will be implanted at the HSB Living Lab at Chalmers University.

"That trip will be the culmination of our efforts as a team, as we are going our separate ways after graduation. However, at least two of us will be building our own versions of the device for personal use," Gopalkrishnan said.

How Millennials Will Forever Change America’s Farmlands

How Millennials Will Forever Change America’s Farmlands

[This article originally appeared in Fortune on March 21, 2017]

Square Roots co-founders Kimbal Musk and Tobias Peggs with the first cohort of urban farmer entrepreneurs on the Brooklyn- based Square Roots vertical farming campus.

As Americans increasingly reject cheap, processed food and embrace high-quality, responsibly-sourced nutrition, hyper-local farming is having a moment.

Tiny plots on rooftops and small backyards are popping up all across America, particularly in urban areas that have never been associated with food production. These micro-farms aren’t meant to earn a profit or feed vast numbers of people, but they reflect the Millennial generation’s desire to forge a direct connection with the food they consume.

These efforts are an admirable manifestation of the mantra to think globally and act locally, but they miss the opportunity that is going on right now: the economics of branded local farms have changed, and technology in agriculture has led to a renaissance of independent American farming. Whether this means farming the traditional acreage of the Heartland or adapting to cutting-edge indoor farming methods, the result is the same: demand for real food is far outstripping supply. Highly-educated, entrepreneurial, and socially conscious young people have a great opportunity to think seriously about agriculture as a career.

On the surface, this advice sounds dubious, given the well-documented, decades-long decline of independent farming in America. Between 2007 and 2012, the number of active farmers in America dropped by 100,000 and the number of new farmers fell by more than 20%. Ironically, however, the titanic, faceless factory farms are barely eking out a profit. That often means that an independent 100-acre farm growing high-demand crops can be far more profitable than a 10,000-acre commodity farm growing corn that may end up getting wasted as ethanol.

The key to reviving America’s agricultural economy is casting aside the sentimental images we associate with farming — starting with what a farmer looks like. In recent years, many of the same technologies that have revolutionized the consumer world have fundamentally altered and improved the way we farm. Drones, satellites, autonomous tractors and robotics are now all at home on farms. As a result, tomorrow’s farms won’t just be part of the agricultural sector, they’ll also be part of the tech sector — and tomorrow’s farmers will look a whole lot like the coders who populate Silicon Valley…except with better tans.

The next assumption about farming we need to cast aside is what a farm looks like and where it will be found. The vast planting fields of America’s heartland are going to change by adjusting to grow real food with 21st century technology, but tomorrow’s farms will also be vertical and in or near our urban centers. By 2050, 70 percent of the global population will live in cities. As both a social imperative and a practical matter, it makes sense to grow food near these cities, rather than to waste time and resources delivering products from hundreds or even thousands of miles away.

Square Roots urban farming campus in Brooklyn, NY.

This will require innovative new technology that will create even more flexibility in the way we farm. With this in mind, I recently co-founded Square Roots, a social enterprise that aims to accelerate urban farming by empowering thousands of young Americans to become real food entrepreneurs. We create campuses of climate-controlled, indoor hydroponic farms in the heart of our biggest cities and train entrepreneurs how to grow and sell their food year-round. After their training, these young entrepreneurial farmers, in partnership with the U.S. Department of Agriculture, can qualify for larger loan programs as a next step to owning their own farm — either soil-based or indoor. Whether they move on to their own farm or another business, they are prepared to build forward-thinking companies that will become profitable and create good jobs.

Greens growing vertically with a Square Roots farmer entrepreneur in the background. Photo Courtesy Square Roots

We are investing in this initiative not only because it’s the right thing to do, but also because we are confident that agriculture is poised for explosive growth, and that technology and the power of locally branded farms will be the keystone to success. Just ask self-described “AgTech nerds” like Sarah Mock, who is a leader in the growing movement of Millennial entrepreneurs who see an opportunity in farming to achieve the double bottom line — value and values — that is key to solving our planet’s toughest challenges.

Private enterprise will lead this revolution, but the federal government must help fuel its growth. The 2018 farm bill is a critical opportunity. This massive legislation, renegotiated by Congress every five years, establishes the blueprint and funding priorities across America’s agricultural sector. Last year, Democratic U.S. Senator Debbie Stabenow of Michigan introduced forward-looking legislation called the Urban Agriculture Act that would offer protections and loan options that are currently available only to traditional rural farmers. Ideas like these are essential.

A future in which our food is safer, healthier and environmentally sustainable can exist alongside one in which our agricultural economy grows and creates good jobs for millions of American workers. The technologies and business practices of modern farming is spreading rapidly. The opportunity for a young farmer has never been better — and it’s a future we can all get behind.

Confusion Over Hydroponics Grows at National Organic Standards Board Meeting

Proponents of organic certification being exclusive to soil-based agriculture, as opposed to hydroponics and aquaponics, were left frustrated by the National Organic Standard Board (NOSB) meeting in Denver last week when the board decided not to vote on the eligibility of hydroponic farming for at least another six months

Confusion Over Hydroponics Grows at National Organic Standards Board Meeting

APRIL 25, 2017 by JILL ETTINGER

Proponents of organic certification being exclusive to soil-based agriculture, as opposed to hydroponics and aquaponics, were left frustrated by the National Organic Standard Board (NOSB) meeting in Denver last week when the board decided not to vote on the eligibility of hydroponic farming for at least another six months.

“The NOSB decided this was something so fundamental to the organics industry, they want everyone participating in the policy developing process for how to handle container and hydroponic growing systems,” Lee Frankel, executive director for the Coalition for Sustainable Organics told the Packer.

Currently, hydroponic and aquaponic farming methods are eligible for the USDA organic certification despite using no soil—a point many members of the organic industry say is significant because soil plays a huge part of the process of becoming an organic producer. Not only is cleaning up soil and ensuring that it’s free from agricultural runoff, banned pesticides, herbicides, fungicides, and fertilizers, critical to the quality of the food, but it’s also vital to the environment and ecosystems connected to it.

“Soilless, hydroponic/container growing is not necessarily ‘bad,’ it simply isn’t organic, by law,” says The Cornucopia Institute, the organic industry’s leading watchdog group. “Allowing year-round imports from countries where hydroponic/container growing is illegal, then labeling and selling them as organic in this country, undercuts legitimate US organic farmers. It is dead wrong—and patently illegal under the Organic Foods Production Act and the current regulations.”

Much of the confusion lies in the National Organic Program’s definitions of organic, and more specifically, the definitions of both hydroponic and aquaponics farming methods that don’t involve soil. While some water-based growing methods rely on liquid fertilizers and rocks, soil is otherwise absent from the process. Hydroponics and aquaponics have been certified through the program since the USDA developed the standards in 2002. They make growing in soil-less environments possible, such as urban areas. The water-based growing methods also reduce the risk of pests and weeds, common issues with soil-based growing methods that increase the needs of pesticides and herbicides.

But there are so many types of aquaponic and hydroponic growing that the NOSB is requesting more information on the specific growing mechanisms of these systems in order to determine whether or not the methods can continue to qualify as organic.

“The NOP should adopt the European standard that requires that organic crops be grown in the soil in the ground, except for edible sprouts, aquatic plants growing outdoors in their native ecosystems, and transplants sold in their containers,” The Cornucopia Institute noted in its public comments to the NOSB.

“Soilless systems are not organic systems,” Cornucopia explains, “because they are removed from the regenerative organic practices that capture carbon and nitrogen from the atmosphere into the soil.”

“[O]rganics should be about more than soil,” Marianne Cufone, executive director of the Recirculating Farms Coalition and proponent of soil-less farming, told FoodNavigator-USA. “It should be about the whole picture. We should be looking to improve our planet and these types of farms at their very core are eco-efficient.”

Frankel says the organic industry shouldn’t expect a decision in October, either, citing significant turnover in the board earlier this year adding to the decision-making processes.

“NOSB has not yet achieved consensus among its members regarding definitions, and without definitions a vote on prohibition cannot occur,” he said.

iStock/LouisHiemstra

This Uptown Urban Farm Is Growing Career Opportunities for Kids Throughout the City | Edible Manhattan

This Uptown Urban Farm Is Growing Career Opportunities for Kids Throughout the City | Edible Manhattan

By Sarah McColl

Photos by Corinne Singer

“We want to capture whatever spark the children have and try to nurture it, even if it’s well outside the realm of agriculture,” Vincent says.

Up the street from the Apollo Theater, a lot on West 134th Street was once home to prowling neighborhood cats, abandoned engine parts and men playing dominos. With the vision of founder Tony Hillery, the kids of Harlem Grown’s youth farm, a truckload of soil from Home Depot and 400 strawberry plants, the makeshift junkyard has been a blooming Eden since 2011. Now, an arbor casts a low ceiling of leafy shade and a sign warns with a wink that, “Trespassers will be composted.”

The mission of this urban youth farm has never been rootbound. While lessons in nutrition and agriculture happen over hydroponics, and conversations about economic, social and food justice unfold between the garden rows, Harlem Grown is also connecting schoolchildren with professional mentors, internships and career connections.

“We’re trying to use the farms and food as a vehicle to inspire change beyond the plate,” says development director Vanessa Vincent. “We’ve been able to connect our youth to opportunities beyond their wildest dreams.”

Related:

Five Questions with Tony Hillery, Founder of Harlem Grown | Food Tank

Edible Manhattan: A Self-Guided Dominican Food Tour of Washington Heights & Inwood

At Harlem Shambles, The Meat is Worth the Trip | Edible Manhattan

Under the Tracks and Off the Grid, Urban Garden Center Rises Up | Edible Manhattan

Uptown, a Dominican Confection Makes Life Three Times Sweeter | Edible Manhattan

We invite you to subscribe to the weekly Uptown Love newsletter, like our Facebook page and follow us on Twitter & Instagram or e-mail us at UptownCollective@gmail.com.

Has This Silicon Valley Startup Finally Nailed The Indoor Farming Model?

Has This Silicon Valley Startup Finally Nailed The Indoor Farming Model?

Indoor farming is a trendy startup space, but many of those ventures have recently failed. Plenty thinks its technology, model, and timing mean it’s the place that will finally turn greens into green.

“We’re working to ensure that all of our food gets to the store within hours, and not days or weeks.” [Photo: courtesy Plenty]

“I like to call this the cathedral.” So says Matt Barnard, CEO and cofounder of the vertical farming startup Plenty. We’re standing in a room at the company’s headquarters in a former electronics distribution center in South San Francisco, staring up at glowing, 20-foot high towers filled with perfectly formed kale and herbs.

The company isn’t the first to build an indoor urban farm in a warehouse. Aerofarms, for example, grows greens in a 70,000-square foot former steel factory in Newark, New Jersey. Nearby, Bowery, another tech-filled indoor farm, grows what it calls “post-organic,” pesticide-free produce. But Plenty, which has received $26 million in funding to date from investors such as Bezos Expeditions and Innovation Endeavors, believes that it has the technology to grow food more efficiently–at the same cost or less than crops grown in the field–so it can more easily scale up to supply supermarkets around the world.

Inside another gleaming white room, wearing a food processing uniform and gloves, Barnard reaches up and picks rare varieties of basil, chives, a mustard green called mizuna, red leaf lettuce, sorrel, and Siberian kale, eating each and handing me samples as he talks. None of these are available in the average grocery store, because they wouldn’t survive the supply chain. Most produce available now has been bred or engineered to last through rough handling in distribution centers and long distances in trucks–not for taste. The heirloom seeds that Plenty uses, which were bred for taste, are more delicate.

“When you’re not outside and you’re no longer constrained by the sun, you can do things that make it easier for humans to do work and work faster, and for machines to work faster.” [Photo: courtesy Plenty]

“What the technology that we’ve developed enables us to do is essentially grow varietals that are just better than what’s in the store today,” he says. “What’s in the store today is the best that we can grow with a 3,000-mile supply chain. But the best that we can grow with a 50-mile supply chain is stunningly better. That’s why we’re working to ensure that all of our food gets to the store within hours, and not days or weeks.”

Unlike most other indoor farming companies, which typically grow food in rows on shelves, Plenty grows food vertically–each plant popping out of the side of a tall, skinny tower. Lights are also arranged vertically rather than pointing down from above. (BetterLife Growers, which plans to open in Atlanta this fall and provide jobs for underserved communities, is another example of a company that uses a vertical growing system; on a smaller scale, Tender Greens is using vertical systems to grow salad ingredients at some of its restaurants).

“When you’re not outside and you’re no longer constrained by the sun, you can do things that make it easier for humans to do work and work faster, and for machines to work faster,” says Barnard. “You can do things like use gravity to feed the water and the nutrients rather than having to use pumps, so you can be more energy efficient.” The farms are less expensive to build than other configurations. They also grow more food in less space than competitors like Aerofarms or Bowery. While Aerofarms claims to grow 130 times more produce than conventional farming in a given area, Plenty claims to grow 350 times more than conventional farming.

“Growing at a small scale, you can’t get to the labor efficiencies that you need. It requires, in essence, too many people.” [Photo: courtesy Plenty]

“Shifting to the vertical plane makes us usually four to six times more efficient spatially than a stacked system–[like] someone like Aerofarms or someone like Bowery,” says cofounder and chief science officer Nate Storey, who previously founded another vertical farming company called Bright Agrotech. “Ultimately, we’re able to have a much higher space-use efficiency than we could if we were trying to stack our equipment. So everything in the system serves that end, which is how can we pack more plant production into the space without sacrificing plant health.”

The design allows for what the company calls “field-scale architecture”–rooms that can produce the same output as a fairly large farm field in a tiny space. Some early companies in the urban farming industry were constrained by smaller production.

“Small-scale growing in 2017 is not a profitable enterprise, and there are a lot of systemic reasons for that that aren’t going to change,” says Barnard. “Growing at a small scale, you can’t get to the labor efficiencies that you need. It requires, in essence, too many people.”

Early indoor farming companies–like Chicago’s FarmedHere, which was once the largest indoor farm in the country and had hopes of national expansion but shut down in January 2017–also struggled with the cost of components like LED lights, which have dramatically fallen in the last several years. Podponics, an Atlanta indoor farming startup, raised $15 million from investors, but went bankrupt in 2016 after struggling with the economics of its system, particularly the cost of labor. Local Garden, a greenhouse in Vancouver, went bankrupt in 2014 after issues with productivity and access to capital. Others, like BrightFarms, had to rework their initial strategy because of the high cost and challenges of working on urban land. But as technology has improved, other indoor farming companies are growing. AeroFarms, with $61.5 million in investment, has projects in development on four continents, including a farm in Camden, New Jersey, near its first location, and is on track for its plans to build at least 25 more farms by 2020. Urban Produce, a vertical indoor farm in Irvine, California, hopes to expand to 25 locations in five years.

“There’s a timing aspect to this,” Barnard says. “Our technology is necessary to get to the right set of economics. But it’s also not fully sufficient. In other words, it enables us to capitalize on what’s happening in the commoditization in other areas. Utility computing, IoT, machine intelligence, wasn’t effective enough five years ago, much less affordable. Seven years ago . . . you would have spent 64 times more to buy the same amount of LED lights. So we’ve built into our design the ability to take advantage of advances in that field.”

The company continually iterates on the design, tweaking the placement of lights or plumbing or how the towers are moved in and out of a room in order to improve cost or productivity or flavor. A custom designed “growth medium” made from recycled plastic bottles takes the place of soil, holding roots in place, delivering nutrients, and hosting microbes.

The system makes it economic to grow crops other than leafy greens, which have been the mainstay of most indoor farms to date. Strawberries may come next, and perhaps tomatoes and cucumbers, all grown in varieties that naturally have more flavor than standard offerings in stores, and preserve that flavor because of the short supply chain.

“The promise that we’re making to customers is that it’s literally days faster.” [Photo: courtesy Plenty]

The company plans to build its farms next to large cities, but not directly inside, to best fit in existing supply chains that have distribution centers on city limits. “If you want to be delivering a large amount of super-amazing tasting produce to a large grocery store in the middle of a city, you want to be in the distribution center that feeds that grocery store,” Barnard says. “Because otherwise, it’s going to go back out of the city to the distribution center and then back to the store. And now you’ve cost [yourself] hours and maybe even a day or two. The promise that we’re making to customers is that it’s literally days faster.”

The taste is noticeably different. Rick Bayless, the Frontera chef, tried the produce at Google, where the founders started testing their core technology in a demonstration farm in 2014 (that farm is still supplying greens to Google’s cafeteria, though Plenty is not running it). “When I visited Plenty’s pilot farm, I was skeptical,” he says. “I’d had produce before that was grown under lights. And it always disappointed: weak in flavor and texture, like a shadow of the original. But that day at Google, I tasted something different. True and vibrant flavors, textures like I’m used to in field-raised greens and fruits, unusual varieties I’d only expect from really savvy growers. I knew these guys were onto something.”

By delivering food to customers more quickly, the process preserves both flavor and nutrients (after a week in the supply chain, produce can lose as much as 55% of nutrients like vitamin C). Like other indoor farming, the technology also saves arable land; Plenty says it can grow up to 350 times more produce in the same amount of space as conventional farming, with 1% of the water. In a sealed environment, there are so few pests that the company can use ladybugs to deal with them rather than pesticides. The process also cuts the cost and pollution associated with a typical supply chain.

Barnard says that “30% to 45% of the value [of produce] at shelf is trucks and distribution centers.” He adds, “And that to us doesn’t make any sense when we can be getting people better food that tastes better, is more nutritious, with less pesticides. I like to call it food for people, not trucks.”

While early indoor farming was much more energy-intensive, the improving efficiency of LED lights means that the new system can actually have a smaller carbon footprint than farming in the field, at least for certain crops. (This calculation takes other impacts into account, including the carbon footprint of transportation and distribution in traditional farming and the impact of food waste in the supply chain.) The production facilities could potentially also run at least in part on on-site renewable energy like solar power.

“The fact that we can compete with the field on cost is great, but what is, of course, more exciting is that we’re not just competing on real costs, we’re competing on carbon cost,” says Storey. Eventually, he believes that many varieties of food will be more sustainable to grow indoors than out.

The company envisions building farms in every major metropolitan area around the world. After the launch in San Francisco in 2017, other major markets will follow in 2018. “People are going to see that the nutrient-rich food in their diet–fruit and vegetable–is going to start tasting better, and it’s going to be grown in farms like this,” says Barnard. “And it’s going to happen with stunning swiftness, because we’re now at the point where we can get this into everyone’s budget.”

The Future of Farming: Japan Goes Vertical And Moves Indoors

The Future of Farming: Japan Goes Vertical And Moves Indoors

Spread, Fujitsu and AeroFarms are growing vegetables hydroponically, with successful yields

BY MELINDA JOE

21 MAY 2017

Spread, Fujitsu and AeroFarms are growing vegetables hydroponically, with successful yields

Indoor agriculture is on the rise all over the world – particularly in Asia, where concerns over food safety and pesticide use in recent years have fuelled a boom in so-called plant factories. Spread, Japan’s largest vertical farm, produces more than 20,000 heads of lettuce a day in its 3000-square-metre facility outside of Kyoto.

Spread Co's vertical farms

The vegetables are cultivated hydroponically – without soil, in beds of constantly circulating nutrient solution – under LED lights in a sterile, climate-controlled environment. Later this year, the company plans to open a second facility that will use robot technology to automate tasks such as harvesting and boost total production to a whopping 50,000 heads per day.

Electronics giant Fujitsu is among a number of Japanese technology firms to embrace horticulture, converting factories that had formerly been used to manufacture semiconductors into tightly sealed indoor plantations manned by engineers in white cleanroom suits.

Fujitsu’s cloud-based software allows workers to easily monitor sensors that track the growth of the plants. Nutrient and light levels can be adjusted to develop varieties of lettuce with, for example, low potassium content for people with kidney disease.

AeroFarms

Last year, AeroFarms, located in New Jersey, made headlines for becoming the world’s biggest vertical farm, with the capacity to harvest roughly 1,000 tonnes of greens per year.

The company employs aeroponic technology, a more efficient form of hydroponics, where plants are grown in a mist environment. The company relies on big data to oversee the cultivation of 250 varieties of organically grown herbs and leafy vegetables.

Packaged Produce Sold At Some Giant Stores Recalled Due to Possibility of Metal In Product

Packaged Produce Sold At Some Giant Stores Recalled Due to Possibility of Metal In Product

- MEAGEN FINNERTY | Website Producer

- May 19, 2017

packaged produce company is recalling its products sold at some Giant stores and Martin's Food Markets.

BrightFarms, which sells spinach, spring mix, kale and other similar products issued the voluntary recall because of potential contamination of metal pieces in the produce.

The metal may have made its way into packaging during construction at the company's Elkwood, Virginia, greenhouse, according to the recall.

The salad products have best-by dates between May 22 and 26. They are:

- BrightFarms Baby Spinach (4 oz. package)

- BrightFarms Spring Mix (4 oz. and 8 oz. package)

- BrightFarms Spinach Blend (4 oz. package)

- BrightFarms Baby Kale (3 oz. package)

- BrightFarms Arugula (4 oz. and 8 oz. package)

- BrightFarms Mixed Greens (4 oz. package)

- BrightFarms Baby Romaine (4 oz. and 8 oz. package)

Affected basil products, best-by dates ranging from May 18 to 23, are:

- BrightFarms Basil (.75 oz. package)

- BrightFarms Thai Basil (.75 oz. package)

- BrightFarms Lemon Basil (.75 oz. package)

Products from other greenhouses aren't affected by the recall. Consumers are encouraged to throw away products or return their purchases for a refund.

Affected stores are: Giant Landover, Giant Carlisle, Peapod and Martin’s Food Markets in Pennsylvania, Maryland, Virginia, Delaware, West Virginia and Washington, D.C., and possibly Capital Area Food Bank.

$3.5M Indoor Farming Facility Could Break Ground In June

$3.5M Indoor Farming Facility Could Break Ground In June

By Mark Peterson | Posted: Tue 5:58 PM, May 16, 2017 | Updated: Tue 6:41 PM, May 16, 2017

The construction of an indoor farming operation in inner-city South Bend could begin next month.

City officials expressed a willingness Tuesday to buy into the proposed $3.5 million dollar project—but not sight unseen.

“We’d like to at least get a visual on what those look like before we put our dollars and investment. We hope it will enhance the neighborhood. We don’t want it to be a detriment to the neighborhood,” said Jeff Rea, Chairman of the South Bend Industrial Revolving Loan Fund Board.

While there are plenty of pictures that show what the inside of a vertical farming operation in South Bend would look like, there’s not a single depiction of what it would look like on the outside.

“So, from what we’ve been told is that the building would be more like a tent structure, not, made out of fabric, not a solid,” said Tim Corcoran with South Bend’s Community Investment Department. “I don’t know of any other fabric buildings in our community.”

The proposed indoor growing facility would stand a story and a half tall and be window-less. “So it's a temporary facility if you will, it's a tent-like facility, so tent conjures up a different images for a lot of different people,” said Jeff Rea.

It was the impact on the overall image of the neighborhood off Sample Street, north of the Ivy Tech campus that had some worried. Every neighboring building near the vacant lot where the farm would be built is made of brick.

Members of South Bend’s Industrial Revolving Loan Fund Board today tentatively approved a $700,000 loan for the project. Final approval will come only if the ‘ayes’ still have it—after pictures of the proposed facility are provided and perused.

“Ultimately we're in support of the loans, we approved the loan today contingent on the visual, us approving the visual piece of that too, so we're going to ask the owner to give us some pictures and help us understand what this operation is going to look like,” said Jeff Rea.

After getting a peek at the pictures, members of the loan board plan to hook up by conference call to consider giving final approval. Officials say the developer, Green Sense Farms, wants to break ground on the South Bend project in June.

The vertical farming facility would be a place where green leafy vegetables would be grown year-round, under artificial light, and carefully controlled conditions. The facility would also be a place where Ivy Tech students could earn a degree.