Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

3 Of The Most Inspiring Farm Startups of 2016

3 Of The Most Inspiring Farm Startups of 2016

Posted by Amy Storey on December 30, 2016

Starting a farm isn't easy. And yet we've seen hundreds overcome the challenges of starting a farm and do it. Now they're providing fresh, nutritious food to their communities in ways that we truly admire.

But we haven't forgotten what it took to get there.

As we look forward on a new year of farming, we wanted to bring you some great examples and other resources to help you start your journey!

Each of these businesses launched a farm this year or helped feed their communities in other ways. Learn about how they did it, what kept them going, and follow them for current updates on their farms.

Triple Threat's The Farm - Aurora, Illinois

Nearly a year ago, Nick Marasco with Triple Threat Mentoring installed a ZipFarm in a Chicago warehouse with the dream of using it to enrich the community and train under-resourced youth.

After 12 months, we're glad to say that the farm is doing just that!

The ZipFarm is an indoor hydroponic farm used as a turnkey solution to problems like climate constraints, construction difficulty, and inconsistent yield. Nick chose the ZipFarm because in addition to these, the equipment allows him to work and train others in the farm. You can read more about the mentoring program here.

The example to follow: Like every farmer, Nick went through a learning curve during the first months of growing. Rather than see an insurmountable challenge, Nick saw new ways to teach and learn, and embraced it. This has made him a better farmer! Nick advises other farmers to do the same.

Follow Triple Threat Mentoring on Twitter or Instagram for more info.

American Heartland Acres - Stem, North Carolina

Matt Marsh and his family started American Heartland Acres with a strong belief that farming had to change and with the confidence that he could help do it.

Many farmers around the Marsh's were ill equipped for changing markets, and suffering from issues like rising prices of inputs. They had slipped into a way of life that was sacrificial rather than passion-driven. Matt knew this had to change. The cost of farming couldn't be greater than the benefits.

Using space- and labor-efficient technology and by approaching his craft pragmatically, Matt has crafted a farming model that allows him to feed his family and enjoy his profession as a basil farmer. He's known as the "basil guy" in the North Carolina towns of Stem and Durham.

The example to follow: "Due diligence" is a term thrown around a lot when planning a business, but it sometimes gets diluted with overuse. Matt is a great example of what due diligence ought to look like. He researched (and researches) his methods, hustles to form connections to potential clients, and constantly looks for ways to improve his farm.

Follow AH Acres on Instagram or Facebook for more info.

Green Wolf Vertical Farm - Panhandle, Texas

Marre Seleska started Green Wolf Vertical Farm in Panhandle, Texas after discovering that an indoor ZipGrow farm could not only trump the capricious Texas weather, but offer fresh food to a high-demand community.

Now Marre can hardly keep up with demand from her clientele, which consists mostly of farmer's market folks, chefs (who Marre sees as food artists hungry for quality supplies), and a soon-to-be CSA group.

The example to follow: When Marre saw opportunity ripe in her community, she took it. She has the ambition necessary for a small farmer and the hustle to back it up!

Growlife Inc Updates On Contract Extension

Growlife Inc one of the country’s most renowned indoor farming service providers, reported that the Board of Directors have given its nod to extend Marco Hegyi’s employment for another two years after discussions

DECEMBER 30, 2016

Growlife Inc Updates On Contract Extension

Growlife Inc (OTCMKTS:PHOT) one of the country’s most renowned indoor farming service providers, reported that the Board of Directors have given its nod to extend Marco Hegyi’s employment for another two years after discussions.

Hegyi has led Growlife back to active trading platform from the Gray Sheet, effectively maintained strong and constructive associations with customers, shareholders and suppliers, and helped company to continue operating through its most challenging times. Therefore, with this extended contract, the company will maintain management stability for the following two years under Hegyi’s leadership.

Mr. Hegyi joined Growlife back in 2013 as the firm’s President. In April 2014, the U.S. SEC temporarily suspended the firm’s stock from trading for 10 days. The suspension reason was given as questions that have been asked about the accuracy and acceptability of information in the market and possibly manipulative transactions in PHOT’s shares.

Later that year, the Commission detained and indicted four outside folks for mismanagement of PHOT stock. However, the commission didn’t file any charges against PHOT. As the CEO, Hegyi secured the necessary funding to maintain businesses, worked through the Commission procedure and closed a 22-month journey to start active trading.

Hegyi mentioned that Growlife is a great company, everything from its staff to its clients and investors, with a thrilling future that merits to benefit from the mounting demand for indoor farming. The upcoming vote is just one factor that can noticeably increase company’s market size and product demand.

There are numerous expansion opportunities for company, from serving large viable cultivation clients and caregivers to the developing home indoor cultivators, all who want the equipment, provisions and expertise that Growlife delivers. Also, strong and dependable financing partners, purchases, up-listing to OTCQB, service plans and increased associations, can boost greater growth. They are still lagging from closing what was planned.

The Indoor Harvest

The Indoor Harvest

Posted Dec. 29th, 2016 by Robert Arnason

For Randy King, the argument for indoor farming in Canada is just common sense.

For one, Canada is a northern country with long winters.

Two, during those long winters almost all fruit and vegetables in Canadian grocery stores are imported from Central America, Mexico or California.

Three, wouldn’t it be better if Canadians grew their own fruits and veggies?

“I think this is the way of the future for growing produce in northern regions,” said King, co-owner of West Grow Farms, a company with plans to build an indoor farm near Edmonton.

“In order to gain food sovereignty, we need to step out of the box and revolutionize how we approach growing produce…. Relying on other countries to feed us in the winter time, I’m not certain that’s going to be sustainable.”

In 2016, King and his business partner, Jim Philpott, signed a licensing deal with Indoor Farms of America, a company from the United States, to its technology.

Indoor Farms of America has developed a proprietary method to grow fruits and vegetables inside based on a technique called aeroponics.

Plants are grown without soil in aeroponics. The suspended roots are misted with nutrient-rich water.

Proponents of aeroponics say it can grow greens such as kale and spinach, or herbs like basil and sage, without the use of pesticides.

Large scale indoor farms, or vertical farms, are already growing produce in cities across North America.

- This year AeroFarms of Newark, New Jersey, built a 70,000 sq. foot vertical farm in a former steel mill. When fully operational, it will likely be the largest vertical farm in the world.

- The word “vertical” is used to describe indoor farms because trays of plants are typically stacked inside the building, reaching toward the ceiling.

- Chicago may have the most vertical farms of any major city in North America. It’s sometimes described as America’s urban farming capital.

- In Canada, dozens of companies are planning to construct or are building indoor farms, but it’s difficult to know how many are in operation.

King, who operates a couple of construction companies, became aware of the concept when a client asked him to design an indoor farm.

The project may have stalled, but it sparked King’s interest.

“You look at the nutritional value of a head of lettuce that’s been in transit for a couple of weeks, it’s probably diminished to the (point) where we’re eating straw,” said King, who grew up on a farm near Edmonton.

Supporters say vertical farms may revolutionize agriculture because plants grown indoors mature more quickly and can be harvested 10, 15 or 20 times annually, rather than two or three times a year for outdoor crops.

True believers go further. They say indoor agriculture will save the world.

“If vertical farming in urban centres becomes the norm, then one anticipated long-term benefit would be the gradual repair of many of the world’s damaged ecosystems through the systematic abandonment of farmland,” said Dickson Despommier, author of The Vertical Farm and host of the Urban Agriculture podcast. “The re-growth of hardwood forests could play a significant role in carbon sequestration and may help reverse current trends in global climate change.”

But environmental groups say vertical farms use an incredible amount of energy on artificial lights.

“Producing America’s annual vegetable crop (not counting potatoes) in vertical systems under lights would require well over half of the electricity this country generates every year,” wrote Stan Cox of The Land Institute, a group that supports sustainable agriculture, in Salon magazine.

King confirmed that lights are the biggest cost and challenge of indoor farming. Optimizing lighting for maximum growth is complex and the cost of LED lights can run into the millions.

But if growers get the lighting right, indoor farming can produce a huge quantity of leafy greens and other vegetables.

“We can get 157,000 plant sites in 3,200 sq. feet,” King said.

Based on West Grow’s trials, plants can reach maturity in about 22 days. Which means 15 growing cycles per year.

Once he has a handle on the lighting, King hopes to begin construction of the indoor farm early next year, in a warehouse in the Edmonton area. The 12,000 sq. foot facility will also have a store, so customers can buy produce at the site.

The plan is to start out with leafy greens and herbs. Then, expand into tomatoes, cucumbers and other veggies.

King is convinced that Albertans want to buy locally grown veggies year round.

“Talking to our potential customers … the grocers, they’re extremely excited,” King said. “They’re more than committed to buying local, fresh produce, 365 days of the year.”

King hopes the indoor farm will be producing greens and herbs by June of 2017.

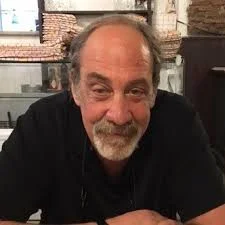

About Glenn Behrman

About - Glenn Behrman

Glenn is a native of New York City and has been involved in the horticulture industry for over 45 years. From a small retail store in New Haven, over the next 20 years Glenn built the business into a regional success, a high volume chain of retail stores and wholesale foliage distribution centers, including a lawn and garden import division. Glenn owned and operated garden centers from New York City to Philadelphia, foliage nurseries in Florida, orchid nurseries in Thailand and tree farms and nurseries in Vietnam. After selling his U.S. based business interests to devote more time to his Asian ventures, Glenn relocated to Bangkok, Thailand in 1994. Glenn has acted as a grower, broker and exporter of young plants and orchids and has introduced new ornamental plant varieties from Asia to growers worldwide. In addition to years of senior level day to day business management and operations, his experience further extends to designing and constructing thousands of square feet of nurseries and greenhouses.

During his time in Asia, in addition to his horticulture business, he has been involved in other ventures including an internet start-up which he founded and then sold to a Singapore investment group (www.theglobalgrocer.com) and the production of postage stamps for the Lao government (SEA Philatelic Group, Inc). He has also served as a Special Advisor to H.E. Sar Sambath, former Cambodian Ambassador to the United Nations. In 2011 he left his position as Landscape Project Manager for the $4.5 billion Ho Tram Strip project, consisting of 5 five star resorts and two Las Vegas style casinos in Vung Tau, Vietnam, to return to the United States to devote his full time and energy as co-founder and President of GreenTech Agro LLC. Glenn and his wife currently reside in Dallas where he manages the day to day operations of GreenTech Agro LLC and CEA Advisors LLC. Based at Texas A & M University Agrilife Research Center, Glenn works full time on the design, development and fabrication of the Growtainer™ containers, Growrack™ rack systems, Growtroller™ control systems and provides Consulting services to international clients on the development of innovative investment grade indoor farming projects

Premier Indoor Agriculture Conference Returns to Singapore For An Expanded Indoor Ag-Con Asia On January 24-25, 2017

Premier Indoor Agriculture Conference Returns to Singapore For An Expanded Indoor Ag-Con Asia On January 24-25, 2017

Indoor Ag-Con Asia features plant factory & vertical farming leaders such as Prof. Kozai of Chiba University, 808FACTORY, Autogrow, Kajima Corporation, MIRAI & Pegasus Agriculture.

SINGAPORE, SG (PRWEB) DECEMBER 29, 2016

Indoor agriculture is one of the fastest-growing industries in Asia as consumer demand for “clean food” benefits this form of farming that uses few pesticides and shields crops from environmental pollution. Indoor Ag-Con – the premier industry conference – will be returning to Singapore for the second year on January 24-25, 2017 to discuss the prospects for this increasingly important contributor to the global food supply chain.

The two-day seminar will be hosted at the Marina Bay Sands, Singapore, and is tailored toward corporate executives from the technology, investment, vertical farming, greenhouse growing, and food and beverage industries, along with hydroponic, aquaponic and aeroponic startups and urban farmers.

The event will consist of keynotes from industry leaders and extended networking breaks, along with an exhibition hall. More than 20 confirmed speakers include Professor Kozai of Chiba University, author of ‘The Plant Factory’, and executives from 808FACTORY, Autogrow, Intravision, Kajima Corporation, MIRAI, Pegasus Agriculture, and Urban Crops. “Our speakers will cover topics as diverse as automation for plant factories and financing an indoor agriculture startup” commented Nicola Kerslake, founder of Newbean Capital, the event’s host. Participants will receive an exclusive hard copy of the newest edition in our popular white paper series, which is sponsored by Pegasus Agriculture and will be the first published on global indoor agriculture policy. Agriculture technology companies, suppliers and automation companies will have the chance to meet and mingle with leading vertical farmers and commercial greenhouse operators at a drinks party on the first evening of the event. The platinum sponsor for the event is Lighting Science Group, and other sponsors include Autogrow, Kennett Township, Microsoft BizSpark, Pegasus Agriculture, Upgrown Farming and Urban Crops.

Beginning farmers, chefs and entrepreneurs can win passes to the event through the Nextbean program, which awards a limited number of complimentary passes to the event to those who have been industry participants for less than two years. Applications are open through December 31, 2016 at Indoor Ag-Con’s website. The program is supported by Newbean Capital, the host of Indoor Ag-Con, and Kennett Township, a leading indoor agriculture hub that produces half of the US’s mushrooms.

In the lead up to the main event, Indoor Ag-Con has partnered with Startup Weekend Singapore to add an indoor agriculture theme to a Startup Weekend on January 20-22, 2017, and will host a VIP reception with local fresh salad restaurant chain SaladStop!.

Indoor Ag-Con has also hosted events in Las Vegas, NV and New York, NY in the past year, and will host its first event in Dubai – in partnership with greenhouse major Pegasus Agriculture – in November 2017. Since it was founded in 2013, Indoor Ag-Con has captured an international audience and attracted some of the top names in the business. Events have welcomed over 1,500 participants from more than 20 countries.

Newbean Capital, the host of the conference, is a registered investment advisor; some of its clients or potential clients may participate in the conference. The Company is ably assisted in the event’s production by Rachelle Razon, Sarah Smith and Michael Nelson of Origin Event Planning, and by Michele Premone of Brede Allied.

2nd Annual Indoor Ag-Con Asia

Date – January 24-25, 2017

Place – Marina Bay Sands, Singapore

Exhibition Booths – available from US$1,599 at indoor.ag

Registration – available from US$349 at indoor.ag

Features – Two-day seminar, with keynote speakers, an exhibition hall, an after-party, and VIP reception

For more information, please visit http://www.indoor.ag/asia or call +1.775.623.7116 in the US and +65.3159.1305 in Singapore

No Sunlight, No Soil, No Problem: Vertical Farms Take Growing Indoors

No Sunlight, No Soil, No Problem: Vertical Farms Take Growing Indoors

New Jersey company seeks to build world's largest vertical farm inside old steel mill near the airport

By Steven D'Souza, CBC News

Posted: Dec 28, 2016 5:00 AM ET

Steven D'Souza

CBC News New York

Steven D'Souza is a Gemini-nominated journalist based in New York City. He has reported internationally from the papal conclave in Rome and the World Cup in Brazil, and he spent eight years in Toronto covering stories like the G20 protests and the Rob Ford crack video scandal.

Related Stories

- Food of the future: Bugs, seaweed and vertical farms

- St. Stephen possible home for country's largest aquaponics vertical farm

- Farming in the city: aquaponics farm comes to Montreal

- Stuck-in-the-mud Koreans help Manitoba First Nation grow fresh veggies

- Innovator wants to test fish aquaponics facility in Yukon

Inside a windowless warehouse once used for paintball, with planes heading to nearby Newark airport overhead, an industrial park in New Jersey seems an unlikely place to find fresh locally grown produce.

With LED lights standing in for the sun, and cloth replacing soil, the plants grown at AeroFarms are not your typical greens.

"This is fully controlled agriculture and allows us to understand plant biology in ways that, as humans, we've never achieved," said AeroFarms CEO and co-founder David Rosenberg, standing in front of rows of kale, arugula, lettuce and other leafy greens.

This is a vertical farm — a facility that looks like it jumped off the page of a science-fiction novel instead of an agriculture textbook.

Here seeds are woven into a mesh cloth made of recycled materials. Trays of plants are stacked one on top of the other in long rows. LED lamps provide the light, while water and nutrients are sprayed in a mist to the roots as they dangle below — a process called aeroponics.

"We give the plants what they want, when they want it, how they want it," Rosenberg said.

World's largest vertical farm

The company is currently building what's been described as the world's largest industrial vertical farm, with food grown 12 levels high inside a two-million-square-foot space, which the company says will produce two million pounds of food a year. It's set to open next year.

An AeroFarms' worker waters seeds freshly planted in a special cloth used to grow the plants. In vertical farming, the cloth replaces traditional soil and LED lights replace sunlight. (CBC News)

The pitch is enticing: locally grown food in any climate, year-round. In AeroFarms' case, they say they use 95 per cent less water, no pesticides and don't produce any of the waste that comes with industrial agriculture.

"We can take the exact same seeds that are out in the field that may take 30 to 45 days to grow, [and] we can grow it in 12 to 16 days by creating the perfect environment," said Marc Oshima, AeroFarms' chief marketing officer.

Problems with power

Indoor farming isn't a new concept. Farms across Canada are attempting similar concepts, trying to extend growing seasons and bringing fresher produce to colder climates.

But critics like Bruce Bugbee, a professor of crop physiology at Utah State University, say using artificial light to replace sunlight is still the biggest problem.

"I know how much electricity goes into the electric lights," he said, adding the cost doesn't include carbon emissions created from generating the power.

Then there's the problem of the light quality.

"To me, sunlight is still the gold standard for nutritional quality and they're aspiring to get it as good as the crops grown in sunlight," Bugbee said.

Big-ticket investors

Rosenberg says the company is using energy-efficient lighting and only grows the most cost-effective vegetables, focusing on micro-greens, instead of other vegetables like tomatoes, cucumbers or other larger produce.

Their efforts have won the support of big-name investors, like Goldman Sachs and Prudential, which have provided funding for the more than $30 million US project. One estimate projects that the vertical farming industry will grow to be worth as much as $6 billion US by 2022.

With computer models, data points and mechanical engineers working beside plant scientists and crop physiologists, Oshima says the operation is less farm, more tech startup.

"We like to think of ourselves as the Apple of farming, so the growing towers are really the hardware, the growing recipes for each of the variety is really the software."

A matter of taste

Another knock against indoor and vertical farms is the question of taste. Can plants grown in unnatural environments replicate the taste and texture of outdoor- and soil-grown plants?

To answer that, the company invited Marion Nestle — a professor of nutrition, food studies and public health at New York University — to tour their facility. Nestle was a skeptic.

"I rolled my eyes," she said, describing the initial invitation. "Why are we doing this when you can grow vegetables really beautifully in soil? What's the problem all of this technology is trying to solve?"

AeroFarms says it treats its plants with specific types of light, which allows for more efficient photosynthesis. But critics say the excessive use of electricity makes the operation less green than it appears. (Steven D'Souza/CBC News)

But Nestle says she's now a convert, after tasting samples of the produce AeroFarms sells to local grocery stores, making it available to nearby schools and the community.

"They taste a lot better than the microgreens we get in New York that have sometimes been on the road for a week."

Whether AeroFarms' crops are as nutritious as traditional produce, Nestle can't say; the nutrients the company feeds its plants is a closely kept secret.

While AeroFarms pitches its methods as a way to disrupt traditional farming, save water and provide access to fresh produce in urban areas underserved by grocery stores, Bugbee says vertical farming — and the more expensive produce it grows — won't solve the world's food problems.

"It will provide terrific food for people that can afford it, but they shouldn't be saying they'll save the planet."

Concrete Farms

Concrete Farms

What if you could pluck lettuce, cucumber and tomato from the rooftop farm in your residential building to prepare a salad that is fresh and pesticide free? And that, too, from plants grown without the use of soil?

Well, it could be a common sight in the near future. The Food and Agriculture Organization (FAO) of the United Nations estimates that by 2050, agriculture production must increase by 70 per cent to feed the ever-increasing population. India will be one of the world's top food importers if we do not try out every futuristic technology that can increase productivity by using less water and less or no soil, apart from reducing health risks to near zero.

Rising demand for fresh and pesticide-free horticultural produce for perennially-swelling urban population all over the world is resulting in the introduction of new farming techniques. These include soil-less techniques such as Hydroponics, Aeroponics and Aquaponics that will redefine commercial agriculture.

Vijay S Yelmalle, who runs a Mumbai-based start-up, Center for Research in Alternative Farming Technologies, says as greenhouse technology has had limited success in India, farming without soil is the best way to use our fast-expanding urban spaces. The best part is that mass adoption of this new technology is easier than we think

Soil plays a key role in growth of plants. It supports the plant, provides it nutrients, and holds moisture, organic matter and bacteria. Well-ploughed land means good oxygen circulation to the root zone. The new techniques provide all these things to the plants without using soil as the medium.

The word Hydroponics is derived from two Greek words, 'Hydro' (water) and 'Ponics' (to labour); so, it means putting water to work. In this, the roots of the plant are either submerged in water or in sterile and inert material. The nutrient salts are provided by dissolving them in the water. These salts are natural substances purified by fractional crystallisation, making them technically inorganic. There are different methods that suit specific plant varieties. While Nutrient Film Technology and Deep Water Culture are commonly used for green vegetables, Substrate-Based Hydroponics is often deployed to grow vines of tomato, cucumber, etc.

Commercial Hydroponics farms are usually set up over more than one hectare for optimum use of resources. The Hydroponics technology ensures consistent taste, shape and colour of the produce. The yield is high and predictable and free from soil-borne diseases. Besides, unlike the traditional open farms, commercial soil-less farms are immune from environmental changes. They also use almost 90 per cent less water. Further advancements in artificial lighting, ways to provide nutrients, pest management and building the systems vertically could multiply the yield of Hydroponics farms to tens of times the traditional farming yield.

In Aeroponics, plant roots are suspended in the air, and moisture and nutrients are provided through foggers. This provides most oxygen to the roots, making the plants grow faster and produce more. Aquaponics, on the other hand, involves replacement of nutrient salts with water from aquaculture, a method of growing a lot of fish in a small area. In other words, it finds a solution to the biggest challenge of aquaculture - the generation of ammonia from fish excreta, whose high concentration can be toxic - by allowing bacteria strains to convert ammonia into nitrites (also toxic to the fish) and to nitrates (less toxic to the fish). Nitrates, a major nutrient for the plants, are taken up by the plant roots. The water so cleaned is used for aquaculture.

Vertical/Urban Farming

Vertical farms are located in the centre of cities where space is available at a premium. These are built over a smaller carpet area but designed to grow vegetables in multiple layers. These farms generally employ the Aeroponics technique but Hydroponics and Aquaponics are used as well. Reduction in carbon footprint (vegetables are transported over hundreds of kilometres, adding carbon to the environment), conservation of water (sometimes condensed water from air-conditioning units is used), freshness/safety of the produce, and premium prices are the common considerations behind vertical farming. Worldwide many enthusiasts and agripreneurs are running successful vertical farms with more and more innovative ideas. There is no limit to these farms. They can go as high as you can pump water and access the place, either yourself or through a robot. The Association for Vertical Farming (AVF), an international NGO, is working with many farms to spread the technology. From Middle East to South-East Asia to Japan to USA to Europe, commercial soilless farms are producing quality and insecticide- and chemical-free produce. South Asia, however, has been slow in adopting these new technologies.

Scenario in India

India's protected cultivation (soil-based greenhouse) farming has had limited success due to wrong adaption of technology. Soilless farming being more advanced, most investors are reluctant to try it at a commercial scale. A few successful greenhouse farmers are trying the substrate-based Hydroponics to grow tomato, capsicum and cucumber and becoming successful. The major hurdle in the success of soil-based greenhouse farming, and even in soilless farming, is experience, knowledge and skills. But the scenario is changing fast. Under the initiative of the government of India, universities have started skill-based degree programmes for urban and rural youths. One such course, a degree in Greenhouse Management, is being offered by Ramnarain Ruia College in the heart of Mumbai. Much of the workforce trained in greenhouses is ready to venture into commercial soilless farms. Many agriculturists who are looking after huge commercial soilless farms are also ready to relocate to India if appropriate opportunity is provided

In Kakaako, A Growing Urban Farm Reaches New Heights

"Between the high rise buildings and industrial warehouses, a farm is the last thing you’d expect to find in urban Kaka‘ako. But one business is creating a space for growing food in an unexpected"

In Kakaako, A Growing Urban Farm Reaches New Heights

Between the high rise buildings and industrial warehouses, a farm is the last thing you’d expect to find in urban Kaka‘ako. But one business is creating a space for growing food in an unexpected

From the outside, this looks like just another building in Honolulu’s developing neighborhood of Kaka‘ako. But step inside a door on the second floor and you’re greeted with stacks of red and green lettuce glowing under rows of LED lights. This is Hawai‘i’s first indoor vertical farm.

“This is an ice plant, or crystal lettuce,” said Kerry Kakazu, the owner and operator of MetroGrow Hawai‘i. “It gives a little bit of a salty taste, nice as a garnish with poke or oysters.”

His love of technology and plants led him to research the growing field of vertical farming.

“Vertical farming just means it’s grown indoors and in multiple levels,” said Kakazu. “People have done vertical farming that’s soil based, but most of it is hydroponics.”

Kakazu uses a method he calls aeroponics, where the roots are suspended in air and bathed in a nutrient-rich mist, instead of soaking in water or planted in soil. This environment gives Kakazu more control of his crops. And since it’s indoors, he doesn’t have to worry about weather, pests and other agricultural challenges.

“This shows that you can do this kind of farming,” he said. “I don’t know if this would ever be enough to supply a large amount of food, like a more traditional farm. But for specialty crops or to grow things that are hard to grow outdoors, I think this is an ideal setup.”

Kakazu started MetroGrow Hawai‘i in 2014. He produces about 100 heads of lettuce a week and a couple dozen containers of microgreens. His clients range from high end restaurants in Chinatown to an herbology store that buys medicinal plants grown by Kakazu.

He’s looking to expand out of his 800 square foot space, but has run into challenge other urban dwellers are familiar with: high rents.

“That’s the one thing with urban food. There’s so much competition for the space, so costs can be high,” Kakazu explained. “Whether it can continue to survive this way, or if it has to be subsidized, somebody’s going to have to want food grown in the urban core. So we’ll have to see.”

Kakazu said eventually he’d like to be able to grow enough produce to feed the flow of residents who are moving into his neighborhood.

Space Age Farm: Chef Grows Hydroponic Greens In Upcycled Shipping Container In Bonner, Montana

Space Age Farm: Chef Grows Hydroponic Greens In Bonner, Montana

Jennifer Stackpole’s indoor farm looks like something out of a sci-fi movie.

Using a pre-assembled hydroponic vertical growing system inside a converted freight container at the Bonner mill site, Stackpole is growing tender crisp greens for local restaurants, stores and markets even as the temperature dips well below freezing throughout the dark Montana winter months.

Requiring only 10 gallons of water a day, red and blue LED lights, and a complex nutrient delivery and cooling system, Stackpole can produce the same amount of lettuce, kale, wasabi arugula and other leafy greens that ordinarily would take up two acres of farmland.

There is no need for soil, as each seed is inserted into a pre-made plug. Once they sprout, they're put into 256 hanging towers where nutrients and water drip down into a growing medium made from recycled polyethylene terephthalate (PET) bottles.

Stackpole calls her startup Wicked Good Greens, and she plans to purchase a second upcycled shipping container farm – nicknamed the Leafy Green Machine – from the same company where she got her first one, Freight Farms out of Boston. She paid to have it shipped here, but all it needs is to be hooked up to electricity and a garden hose, and she can grow more than 5,000 heads of lettuce at one time.

She also will be able to supply restaurants with a huge array of specialty herbs and crops such as tatsoi, basil, short French radishes and edible flowers.

“You’ve never seen anything like it,” Stackpole says as she demonstrates how she works the computer console that controls everything. “This is space age stuff.”

Because the air temperature and nutrients are regulated, and the plants get an even amount of light for 18 hours a day, the greens grow incredibly fast and without flaws.

“There’s no stress to the plants at all,” she said. “There’s no bugs or weather issues that affect most things that grow in the dirt. It produces these big, beautiful heads of lettuce. Everything’s dialed in.”

As a chef herself who operates Balsamroot Catering Co., Stackpole said that she understands what kitchen managers want. The unblemished greens don’t have to be heavily cleaned or processed, and there’s no brown spots or ridges. That saves time in the kitchen. As more and more customers demand farm-to-table, locally sourced food options, Stackpole is betting on an eager market.

“So we don’t have to eat stuff from Mexico or California that’s been sprayed and gassed and is all withered by the time it gets here,” she said. “When the chef receives these greens, they’ll still be alive so they have a very long shelf life, over two weeks. Timing can be everything to a chef because freshness delivers flavor, texture and aesthetics.” She said they will also appreciate the predictability and variety that her operation will offer.

Stackpole lives in Potomac and once ran the kitchen at the Montana Island Lodge on Salmon Lake. She took a two-day course in Boston to learn how to operate the machine.

There’s a constant workflow process she goes through to keep things moving so that the Leafy Green Machine is constantly producing. Certified organic seeds are planted in the seedling bay using tweezers and a chef’s funnel. After a week on the germination shelf, they get moved to the seedling trough for two weeks until being transferred to the towers for harvest.

A new crop will be ready each week, and she already has a list of customers lined up. Stackpole admits that many people ask her if the machine would be good for growing another type of green – marijuana – but she says that plant doesn’t grow well vertically and she’s not interested.

The US Government Is Loaning Millions Of Dollars To Jumpstart Urban Farming

The US Government Is Loaning Millions Of Dollars To Jumpstart Urban Farming

Electra Jarvis, a 27-year-old urban farming entrepreneur who is part of the Square Roots program in Brooklyn, New York. Mary Wetherill

Every year, the US Department of Agriculture devotes millions of dollars to farmers in rural areas.

The government is increasingly starting to offer assistance to urban farms, too.

In 2016, the USDA funded a dozen urban farms, the highest number in history, Val Dolicini, the administrator for the USDA Farm Services Agency, tells Business Insider.

In 2017, he expects the USDA to funnel even more money toward farms on rooftops, in greenhouses, and in warehouses.

USDA Microloans, a program that offers funding up to $50,000, is specifically geared toward urban farmers. Established in 2013, the program has awarded 23,000 loans worth $518 million to farms in California, Connecticut, and Massachusetts. Though it is open to all farmers, urban farmers often apply for it because it offers the money on a smaller scale than other programs. Seventy percent (or about 16,100 of those loans) have gone to new farmers, many of them in cities.

"Urban farmers are not looking to form 10,000 acres in Missouri, but perhaps in an indoor container on a parking lot next to old factory," Dolcini says.

In 2016, nine young farmers participating in a vertical farming accelerator program called Square Roots, founded by entrepreneurs Kimbal Musk (Elon's brother) and Tobias Peggs, became the first urban farmers to receive microloans in New York.

Farmers selected for Square Roots grow their crops inside climate-controlled, LED-lit shipping containers. The Square Roots farmers used their loans to cover the costs of seeds and operating expenses before their first harvests, Peggs says.

Entrepreneur Tobias Peggs outside Square Roots, a vertical farming startup accelerator in Brooklyn, New York.Sarah Jacobs

Peggs and Musk worked with the USDA to streamline the 2016 microloan application, which will make it even easier for urban farmers to gain funding in the future.

Dolcini says the agency wants to take advantage of people's experiences in other fields, or those who might be making an industry change (One of the Square Roots farmers used to be an accountant, and others are recent university graduates). The program also now allows grantees to use the loan for non-traditional farm equipment (think LEDs instead of tractors), which is beneficial for urban farmers.

Earlier in 2016, the USDA also published an "Urban Agriculture Toolkit," which includes advice about how to launch a greenhouse or rooftop farm, and how to apply for loans.

"The funding process made it impossible, or certainly extremely difficult, to complete if you were an urban farmer," Peggs says. "'Question 1: how big is your field?' is hard to answer if you don't have one."

The majority of USDA grants and loans still go to rural farms, but the agency is making an active effort to give urban farmers equal opportunities. Dolcini says these efforts were highlighted under the Obama administration, with the launch of the Know Your Farmer, Know Your Food campaign in 2009. It's easier to meet your farmer, he adds, when they grow in your own city.

"We've d one a lot of work in the Obama administration to open doors wider to urban farmers," Dolcini says. "The Square Roots farmers represent the tip of the iceberg into our foray into regional foods and giving folks greater access to the USDA who previously haven't had access."

Though Dolcini is leaving his position in January, he is optimistic that the USDA will still support urban farming under the Trump administration.

"We have demonstrated to the nation that our investments in microloans and conservation grants have really paid off, and we have made business case for them," he says. "It will be hard to un-do the success we've had."

Agriculture was not a significant part of Trump's platform. But his agricultural advisors and potential picks for the Secretary of Agriculture may hint at what his presidency could mean for the future of urban farming. A number have emphasized rural farming in their work. Some have also have advocated for industrial farming, a process in which food is produced on a huge scale in rural areas.

The USDA currently has 2,200 offices, the majority of which are located in rural states, like Missouri, Iowa, and Texas. In winter 2016 , Dolcini says the USDA hired NYC's first urban agriculture specialist, who will coordinate farm efforts in Brooklyn.

These initiatives underscore a growing movement within the USDA to support local food systems and look beyond rural agriculture.

"The global population is expected to be 9 billion by 2050. We really need to pull every farm into finding solutions for that — not just folks out in the Midwest who grow the lion's share of food but also those in urban agriculture," he says.

Though the modern local agriculture movement sprouted up in the late '90s, it has grown rapidly in cities in recent years. Today, urban farmers are not just growing a few tomatoes on rooftops, they're moving toward commercial production.

In 2016, the world's largest vertical farm, Aerofarms, launched inside a 70,000-square-foot warehouse in Newark, New Jersey. Brooklyn-based urban farming company Gotham Greens opened the world's largest rooftop farm in Chicago in late 2015.

"It seems like there's a new innovation every day in agriculture," Dolcini says.

Modular Farms Newsletter #5

2016 has been an incredible year of growth for Zipgrow, Modular Farms,

Upstart Farmers and the entire hydroponic food industry

Modular Farms Newsletter #5

This year in Brampton the ugly head of winter has reared itself a little earlier than we hoped. On the bright side, it's given us extra motivation to spend more time working within the heavily insulated walls of our Modular Farm. And for good reason, as we have begun donating our weekly harvests to the Daily Bread Food Bank in Etobicoke.

Since November 23rd, the Daily Bread team has been working tirelessly to ensure that this year's holiday food drive feeds as many hungry Canadians as possible. To date, they have amassed over 200,000 pounds of food, but they still have a long way to go. Their goal this season is 1.5 million pounds and if we all pitch in a little extra food we have no doubt that they'll get there!

We'd like to sincerely thank everyone who made the trip to our office last month to participate in our inaugural open house event. It was a pleasure to see such an intelligent and curious group of like-minded individuals interacting and sharing ideas; we hope that you all had as much fun attending the event as we did hosting it. We also made sure to videotape a portion of the event for those who couldn't be there physically, which you can watch by clicking here.

Back inside the office things are more exciting than ever. For starters, we recently added a new member to our team - Kamil - who has given us a much-needed boost in our engineering efforts. Under his guidance, our first round of Primary Modules will be making their way off the assembly line and into the hands of our customers in early 2017, followed by our Macro and Vestibule Module prototypes. Also, as you can see from the above gif, our Master Farmer Kevin has been skillfully pollinating and nurturing our first generation of office-grown Strawberry and Cherry Tomato plants, which we are excited to announce are getting close to being harvestable!

In addition to hosting clients and friends, we also had the pleasure of welcoming in a class of inquisitive young pupils and teachers from the St. Joan of Arc Secondary School in Mississauga. The students had already been operating their own classroom hydroponic and aquaponic system for a while and we were blown away by their level of understanding and appreciation for Zipgrow technology and our Modular Farm. When the students left that day, our team breathed a sigh of relief knowing that the next generation of Canadian hydroponic farmers are already blossoming, and will be well equipped to face the food scarcity challenges that the future holds for both our country and the rest of the world.

2016 has been an incredible year of growth for Zipgrow, Modular Farms, Upstart Farmers and the entire hydroponic food industry. More than ever, people have become conscious of the need for sustainable farming practices that are close to home. More importantly, these same people have begun taking it upon themselves to act as a force for change in their own communities. We are proud and grateful to be in a position to empower, educate and support people like you, and we can't wait to see what we can all accomplish together in 2017.

Happy holidays from all of us here at Modular Farms. We wish you nothing but health, happiness, and success in the new year!

Green Wolf Vertical Farm: Bringing Freshness To The Texas Panhandle

Green Wolf Vertical Farm: Bringing Freshness to the Texas Panhandle

Posted by Amy Storey on December 23, 2016Find me on:

Hundreds of years ago, the Texas panhandle was home to thousands of buffalo. After a few centuries of buffalo stomping on the ground, the soil was compacted and dense, leaving a challenge to future farmers.

Now, the land cattle country and home to thousands of acres of corn, wheat, milo, cotton, and other commodity crops grown by large farmers who have to amend the soil to make a living.

Although commodity growers (think wheat, soybeans, etc.) have established themselves and adapted their practices to grow in the hard Texas soil, small farmers have not.

The dramatic amendments that would have to be made to grow sensitive crops in the area are cost prohibitive, and other factors make growing too challenging to be profitable.

But to some, the lack of fresh produce is an opportunity, not an obstacle.

Marre Seleska currently runs Green Wolf Vertical Farm in Amarillo, Texas. She's a great example of someone who saw the challenges, and raised them a vertical farm.

According to Marre:

"The Texas Panhandle has long been known for its capricious weather. Soaking rains with the occasional crazy hail storms in the spring, hot dry winds in the summer, hot then cold fall and the occasional blizzard and then heat wave in the winter and of course drought. All of this weather craziness makes it our greenhouse and microgreen production so valuable in this area."

Marre is one of the only growers in her area, and certainly the only that can offer fresh leafy greens. Others that grow mostly grow okra, squash, tomato, beans, and peas. Fresh chard and kale, lettuce, and other greens are nearly impossible to find.

Marre, like many small farmers, didn't start out with plans for a large farm. In fact, she first started growing in a 15 by 20 foot sunroom to test the idea. She knew she would have to do three things with the space:

- Control the environment to balance the harsh Texas weather.

- Use unique growing methods to get the most out of the 300 square foot space.

Marre began growing in a ZipGrow hydroponic system with a relatively small goal.

"After much research into different ways of growing produce that DIDN’T involve traditional farming due to the poor soil, the unavailability of small plots of land and crazy weather, we found that the ZipGrow Towers combined all of the best parts of hydroponic systems in a much smaller space . . . It really just started out as an experiment for providing for family. I come from a line of women who did that for their families."

But as she began to test the growing techniques, the potential of the operation dawned on her.

"I began to see that this could turn into a commercial venture quite easily. Because it was nothing like those around [me]."

Marre saw the potential to scale and start selling produce. So she did it. She polished a crop list, added microgreens to the system, and started selling at farmer's markets. Market-goers loved them.

"We had repeat customers at the farmers market who came specifically for that. They're learning that they can bump up their nutrition without having to eat bushel baskets of lettuce and kale and broccoli. . . they can get microgreens and add it to their salad and bump up their nutritional intake by anywhere from 4-40%."

In comparison to the trucked-in greens, Marre's have higher quality and a much longer shelf life because they are younger when the customers get them.

"With the microgreens, nobody sells them live here. They're all cut. And they don't last very long. Where with mine, they last seven to ten days. Its fresher, it tastes better. I had one [customer] tell me that 'I never knew lettuce had a flavor until I bought yours.' "

This shared experience is part of what powers Marre and Green Wolf. "Being able to tell someone, 'here taste this' and watch their eyes light up... oh, that just gets me."

Green Wolf's produce certainly makes an impression. Consumers and chefs began to take notice and soon farmers market sales grew into restaurant sales.

Marre's farm - named Green Wolf Vertical Farm - represented a whole new palette of flavor and color for chefs, who Marre sees as food artists.

Where grocery stores might have alfalfa sprouts and sunflower shoots, Marre tests15-16 different varieties of microgreens alone.

Marre also has an advantage because as a small, personal farm she is able to customize orders and try out crops for customers.

If chefs are the artists, Green Wolf Vertical Farm is the ultimate art depot.

"They can talk to us and ask 'can you grow this' and 'I want to try something different'. I do a lot of consulting with chefs with their menu. I've had catering chefs what would go with a greek dinner. I do a lot of research on that also."

As Green Wolf Vertical Farm becomes a more valuable resource for chefs in the area, Marre is thinking about how to expand that resource to others in the community.

"I see it expanding to a lot more than just local chefs. Because we started out at a farmer's market, we had a lot of people who were able to try them out who had never heard of them before, who had no idea that they could even buy them."

Now, Marre is finishing up a greenhouse where she can expand the crop selection to her community to include crops like eggplant, gourmet bell peppers, salad tomatoes, and peas.

"We have a medium sized high hoop greenhouse that we will have half in the ZipGrow Towers and half in grow bags (for fruiting crops). In that space, not only can we grow year round, we can grow more than if we were using a traditional farming model with less loss."

Vertical Farming Market Worth US$ 6 Billion by 2022

12-21-2016 01:07 PM CET - Business, Economy, Finances, Banking & Insurance

Vertical Farming Market Worth US$ 6 Billion by 2022

Press release from: (MRE) Market Research Engine

Florida, December 20: Market Research Engine has published a new report titled “Vertical Farming Market by Growth Mechanism, Functional Mechanism and by Geography - Global Forecast to 2022”.

Vertical Farming is the future of modern day agriculture which is completely done in indoor agriculture labs. The vertical Farming market is expected to cross USD 6 Billion by 2022.

Browse full report here - www.marketresearchengine.com/reportdetails/vertical-farmi...

Vertical farming is an urban farming method where plant cultivation is carried out in multi storied building greenhouses using hydroponics or acquaponics growth mechanism. The vertical farming market will include those companies which are engaged in providing food by using vertical farming method and also the companies which provide various infrastructural services and equipment required for vertical farming. One of the main points is providing quality food with minimum use of pesticides is that these food products can be consumed by critically ill patients and by people having dermatological problems.

The report segments the global vertical farming market on the basis of functional device, growth mechanism and geography. The report also gives the detail vertical farming market by crop types with more emphasis on key vegetables and fruits produced in vertical farms.

How Vertical Farming is basically done?

Here plants are grown hydroponically, or without soil, nourished instead by the recycling of a nutrient-rich water solution. Some such farms rely on aeroponics, where the water solution is misted onto the plants' roots. The farms are typically several stories tall, allowing for crops to be stacked in an enclosed space. Photosynthesis is brought about by artificial light, and sometimes augmented by natural light, like in a greenhouse.

The primary reason of adoption of vertical farming technology as it will help to increase the crop production without increasing additional land area. This method will not use traditional farming methods rather new cultivation methods are used like hydroponics or acquaponics.

Hydroponics is most widely used for vertical farming.

The main driving factors for vertical farming are high quality of food with no use of pesticides and also no crop failures due to changing weather conditions.

The main players in the vertical farming are Green Sense Farms, Sky Greens, Indore Harvest Corporation, MoFlo Aeroponics and Everlight Electronics.

Download Free Sample Report: www.marketresearchengine.com/requestsample/vertical-farmi...

Who Should Buy this Report?

• Technology Providers

• Technology Investors

• Technology Standards Organizations

• Modern Agricultural Forums, Alliances, and Associations

• Government Agencies

• Venture Capitalists/Investors

• Private Firms

• Analysts and strategic business planners, and others.

Segmentation of this Report:

By Growth Mechanism

• Aeroponics

• Hydroponics

• Others

By Functional Mechanism

• Photosynthesis Process/Lighting

• Hydroponic Components

• Climate Control

• Sensors

By Geography

• North America

• Europe

• Asia-Pacific

• Rest of the World (ROW)

About MarketResearchEngine.com

Market Research Engine is a global market research and consulting organization. We provide market intelligence in emerging healthcare technologies, niche technologies and markets. Our market analysis powered by rigorous methodology and quality metrics provide information and forecasts across emerging markets, emerging technologies and emerging business models. Our deep focus on industry verticals and country reports help our clients to identify opportunities and develop business strategies.

Media Contact

Company Name: Market Research Engine

Contact Person: John Bay

Email: john@marketresearchengine.com

Phone: +1-855-984-1862, +91-860-565-7204

Country: United States

Website: www.marketresearchengine.com/

Address: 3422 SW 15 Street, Suite #8942, Deerfield Beach, FL 33442, United States

Here's What Happened at Freight Farms in 2016

Here's What Happened at Freight Farms in 2016

December 20, 2016

It's been another momentous year at Freight Farms, and we want to take a moment to celebrate just how far we've all come. If you’ll recall, at the end of last year we pledged to empower even more farmers across the globe, expand our own capabilities as a team and bring to light the power of farmhand. We've tallied up some numbers to see where we stand at the end of 2016...

We're thrilled to have over 100 Leafy Green Machines operating all across the world, by farmers with incredibly diverse backgrounds and motivations. As this network of freight farmers takes shape across the globe, we are excited to witness just how influential they are on the food movement as a whole.

With so many farmers joining the movement, we needed to scale up our own capabilities to ensure we were able to support them all! This year we added 11 new faces to the Freight Farms team, almost doubling our size! What departments grew the most? The Customer Success Team, the Farm Team and the Software Development Team.

The reasons for the growth of the Customer Success and Farm Team are pretty obvious, but why Software Development? One reason: to expand the capabilities of farmhand. Farmhand is what connects us and our farmers to the LGM, and it is an incredibly powerful tool. In 2016 we launched and improved numerous features to gather over 2.6 billion data points from all the LGMs.

That’s just a glimpse into what happened this year...take a look below at the rest of the highlights from 2016.

Affinor Growers Updates on License Holders, Quebec Property, and THC BioMed Equipment Shipment

Affinor is pleased to announce the license holder, Vertical Designs Ltd, located in Abbotsford BC has purchased 10 acres of agriculture land, received permits to build from the city, broke ground this month and has recently signed an agreement with Discovery Organics to purchase and distribute all strawberries produced by the facility.

Affinor Growers Updates on License Holders, Quebec Property, and THC BioMed Equipment Shipment

VANCOUVER, BRITISH COLUMBIA--(Marketwired - Dec. 20, 2016) - Affinor Growers (CSE:AFI)(CSE:AFI.CN)(FRANKFURT:1AF)(OTCQB:RSSFF) ("Affinor" or the "Corporation), a diversified agriculture and biotechnology company with proprietary vertical farming systems, would like to update shareholders on the progress with several license holders, the THC BioMed equipment shipment and property in Quebec.

License Holders Making Progress

Affinor is pleased to announce the license holder, Vertical Designs Ltd, located in Abbotsford BC has purchased 10 acres of agriculture land, received permits to build from the city, broke ground this month and has recently signed an agreement with Discovery Organics to purchase and distribute all strawberries produced by the facility. Vertical Designs Ltd. is planning to increase the total amount of towers to 36 in the initial build out, increasing Affinor's revenue on equipment sales and royalties. An additional 60,000 square feet of greenhouse over several phases is also being planned to ramp up production when needed to meet local demand roughly, adding another 200 towers when complete. Affinor is a 10% shareholder of Vertical Designs BC Ltd., and will benefit from profits, equipment sales, royalties and have a showcase facility available to sell additional license agreements.

Affinor is also pleased to announce that the license holder in Springfield Tennessee has recently closed on a property to build a greenhouse vertical farming facility. Affinor is working closely with them on planning, design and concepts to help with the next stage of permitting.

THC BioMed Equipment Shipment

Affinor is pleased to announce the equipment to grow and trial cannabis with THC BioMed located in Kelowna BC has been fabricated, finished and ready to be shipped. THC BioMed has requested to delay the shipment until January 2017 in order to complete various ongoing projects. The agreement between the companies, as outlined in Affinor's news release dated April 4 2016, is in good standing and they remain excited to use the technology in early 2017.

Quebec Property

Affinor would like to announce that it has sold the property in Quebec. Proceeds will be used to help further the company development and general administration.

About Affinor Growers Inc.

Affinor Growers is a publicly traded company on the Canadian Securities Exchange under the symbol ("AFI"). Affinor is focused on growing high quality crops such as romaine lettuce, spinach, strawberries using its vertical farming techniques. Affinor is committed to becoming a pre-eminent supplier and grower, using exclusive vertical farming techniques.

On Behalf of the Board of Directors

AFFINOR GROWERS INC.

- Jarrett Malnarick, President & CEO

The CSE has not reviewed and does not accept responsibility for the adequacy or accuracy of this release.

FORWARD LOOKING INFORMATION

This News Release contains forward-looking statements. The use of any of the words "anticipate", "continue", "estimate", "expect", "may", "will", "project", "should", "believe" and similar expressions are intended to identify forward-looking statements. Although the Company believes that the expectations and assumptions on which the forward-looking statements are based are reasonable, undue reliance should not be placed on the forward-looking statements because the Company can give no assurance that they will prove to be correct. Since forward-looking statements address future events and conditions, by their very nature they involve inherent risks and uncertainties. These statements speak only as of the date of this News Release. Actual results could differ materially from those currently anticipated due to a number of factors and risks including various risk factors discussed in the Company's disclosure documents which can be found under the Company's profile on www.sedar.com. This News Release contains "forward-looking statements" within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E the Securities Exchange Act of 1934, as amended and such forward-looking statements are made pursuant to the safe harbor provisions of the Private Securities Litigation Reform Act of 1995.

The View From Inside Square Roots’ Urban Shipping Container Farms

The View From Inside Square Roots’ Urban Shipping Container Farms

By April Joyner / CONTRIBUTOR

Square Roots, the urban farming accelerator launched by Kimbal Musk and Tobias Peggs, began its yearlong program in the Pfizer Building on the border of Williamsburg and Bed-Stuy. Due in part to the boldface name behind it, and also to the growing popularity of urban farming, the program got lots of buzz right off the bat. So how’s Square Roots’ bid to kick off a “real food” revolution going?

Last Wednesday, Peggs opened up Square Roots’ doors to the public for a tour of its shipping-container farms and a first taste of its 10 participants’ greens.

The program, as he pointed out, emphasizes the “urban” in urban farming: the container farms are just across the street from the Marcy Houses, and they connect to the city’s water supply through a fire hydrant. And there’s a good reason the farms have a pink-purplish glow. Red and blue are the colors most actively involved in photosynthesis, Peggs said, so to maximize resources the farms use those colors for lighting. Electricity is the farms’ greatest expense.

As for the tasting, Technical.ly was able to sample some mustard greens, at $5 a bag, grown by participant Sylvia Channing. Upon the urging of another participant, this reporter ate them raw, straight out the bag (which she would’ve never done otherwise — not Southern tradition), and they were surprisingly enjoyable: crisp and tangy.

But the real challenge ahead isn’t how the greens taste; it’s whether the participants can make viable businesses out of them. The program has hit the five-week mark, and the participants’ crops are set to reach their first harvest, which means they will finally have tangible goods to sell. Next Wednesday, Dec. 21, Square Roots will host its first farmers market.

The farmer-entrepreneurs have been given free rein to develop farming and business strategies of their own choosing. The challenge, both Peggs and the program’s participants stressed, is figuring out how to make the economics work. The modular farms, which use technology from Boston-based Freight Farms and Laramie, Wyo.–based Bright Agrotech, cost about $3,000 a month to run, according to participant Jonathan Bernard. But they also produce a relatively high yield, given the space: one farm, for instance, could yield 55,000 mini-heads of lettuce per year, Peggs said. The farming system Square Roots uses allows the participants to yield a weekly harvest once their first crop matures.

In addition to learning how to operate their farms, the participants are also getting advice on sales and marketing, including the basics of pricing: enough to meet their expenses, but not so much that customers will balk. For instance, Bernard plans to charge no more than $3 each for his mini-heads of lettuce in order to keep his prices competitive.

While Square Roots paid for the cost of the farm and the initial expenses to run them, the participants will be responsible for meeting expenses thereafter. The farming system itself is quite reliable, Bernard said, but without a real product just yet, none of the farmers has a customer base. Whether enough people will come to shop is an open question.

“I’m fine with that risk,” Bernard said. “Maybe I was chosen because I’m one of the people who’s crazy enough to consider it.”

Jonathan Bernard, one of Square Roots’ participants, in the accelerator’s office. (Photo by April Joyner)

As it turns out, even their choice of crops involves marketing strategy. For now, all of them are focusing on herbs and leafy greens, because they offer the most bang for the buck — the majority of the plant is eaten, as opposed to, say, a strawberry plant, from which only the fruit would be sold. In the beginning, Bernard said, they were given starter crops by lottery — each person drew a particular choice of plant — and then traded amongst each other for their preferred crop. Since then, they’ve had the opportunity to pick crops that appeal to their desired market.

And yes, as this reporter learned, there is a specific market segment for certain vegetables. Some of the participants have chosen specialty crops, such as Japanese shiso, to sell to high-end restaurants, while others are focusing on selling more common greens such as lettuce at farmers markets.

Another participant we spoke with, Electra Jarvis, chose kale and cilantro in order to appeal to vegetarians and vegans. Kale, of course, has been a trendy green (almost to the point of punchline) for some time, in part because it is known for being rich in nutrients. Jarvis chose cilantro, she said, because it’s versatile as a seasoning and as a garnish for many types of dishes.

She’s applied to several farmers markets, including New York City’s greenmarket program. Jarvis said she hopes to sell at the farmers market in Greenpoint’s McCarren Park, both for its relative proximity to her farm and its enthusiastic customer base. In addition, Jarvis, who is vegetarian and in the process of transitioning to a vegan diet, plans to attend meetups that cater to vegetarians and vegans in order to familiarize herself to her target customers.

“I want them to feel supported by somebody’s who looking out for that cause, to be a farmer that they can relate to,” she said.

On the farming side, the participants are beginning to experiment as well. At the launch of the program, they received general guidelines for the appropriate temperature, light and humidity settings for their farms, as well as a standard nutrient mix — potassium, nitrogen and phosphorus — for their plants. But as Peggs explained, the containers enable farmers to create custom environments, or “recipes,” for their crops — even to mimic particular climes in hopes of, say, reproducing the best kale out of Tuscany. Many of those “recipes,” which are usually tailored to specific plants, are proprietary, Jarvis told Technical.ly, so it’s been up to the farmers to figure out what works best for their specific crops.

So what drew Square Roots’ participants to the program in the first place?

As Peggs noted in our previous interview with him, they are indeed passionate about changing how people think about the food they consume. Bernard, for instance, is an avid cook interested in having high-quality ingredients available to the average person. He lives in Huntington, on Long Island, where he’s currently testing out his lettuce with members of a local CrossFit gym. His eventual dream, he told Technical.ly, is to see Square Roots’ urban farming system shrunk down into a module that could fit into a home kitchen.

“Once people start doing this at home, then they’re changing habits,” he said. “They’re not just paying more at the restaurant or at the grocery store, but they’re actually taking part in it. I think the consumer is the end goal.”

Jarvis also came to the program with a keen interest in the food industry. She is a student in Pratt’s masters program in sustainable environment systems, from which she’s on track to graduate this spring. Jarvis told Technical.ly that’s she particularly interested in helping to promote a plant-based diet as well as exploring whether vertical farms such as those used in Square Roots’ systems could be a path toward food justice — in other words, making fresh vegetables more accessible to everyone.

“I don’t know if this is the answer, but that’s what I’m here to find out,” she said.

-30-

April Joyner is a journalist who covers business, tech and finance. As a freelance writer, she has contributed to OZY, NewYorker.com and FastCompany.com. Joyner's writing has also appeared on Business Insider and USAToday.com.

Farm In The City

Farm In The City

BY ZULIANTIE DZUL - 17 DECEMBER 2016

Malaysia ventures into indoor farming to inspire more urbanites to grow their own food, writes Zuliantie Dzul

“I AM a city farmer,” read the words in black and striking green on the black T-shirt worn by the youth who greets me at the door of the second-floor office in Sri Kembangan, Selangor.

Walking in, I spot brown boxes of fertilizers neatly placed on the shelf across the door. Stacks of PVC pipes are on the concrete floor next to the shelf. The air inside is a little stuffy as the office had just recently opened for business.

The young man introduces himself as Jayden Koay, one of the founders of CityFarm Malaysia, a newly-founded organisation with the objective to inspire more people to become city farmers with the ability to grow locally from anywhere for a more sustainable future of food production. CityFarm Malaysia serves as a one-stop-centre to kick start your farming journey, supplying parts such as piping and products such as fertiliser and germination sponge. The sight of vegetables behind a closed wooden door and a glass panel catches my eyes. The affable

The sight of vegetables behind a closed wooden door and a glass panel catches my eyes. The affable Koay takes me inside the room, a vertical farm of lettuce, where slabs of leafy greens of different stages — from seedlings to ready-to-harvest — take up most of the 42sq m space. After a quick tour of the “farm”, we return to the office where we’re soon joined by Looi Choon Beng and Johanson Chew, the other co-founders of CityFarm Malaysia.

CityFarm Malaysia ventures into indoor farming to inspire more urbanites to grow their own food. Pix by Owee Ah Chun

HYDROPONIC IS BACK

The United Nation predicts that the world’s population will grow to 9.6 billion by 2050. 70 per cent of people will live in the cities and 70 per cent more food will be required to feed them. Yet, 80 per cent of cultivated land is already in use. Moreover, extreme weather patterns and devastated crops will create higher food prices, and consumers will become more conscious of how their foods are produced.

As the population rises, more cities will be developed. In the long run, we can no longer depend on food supplies from outside. And it is this very knowledge that drives the team of five to venture into indoor farming to cater to the rapid growth in consumer demand for affordable, high-quality, locally produced crop in any climate.

“We need sustainable supply. There won’t be enough land,” begins Koay.

Hydroponic is one of the basic farming methods which took the country by storm decades ago. Progression of hydroponic technology makes soilless farming possible within the urban household and this is the key to address food supply issue, where everyone can be a city farmer and part of the food supply process. “Soon after that, many other methods were engineered,” adds Koay.

For example, the farmers in Cameron Highlands are using the nutrient film technique, wherein a very shallow stream of water containing all the dissolved nutrients required for plant growth is re-circulated past the bare roots of plants in a watertight gully, also known as channels. There’s also the technology to replace sunlight with LED lights so your farm can be cultivated indoors.

Farming within the city can help reduce carbon foot print where transportation can be optimised. “The vegetables we buy from the markets travel about 300km to reach consumers in the city. The travelling produces carbon dioxide and petrol is needed to transport the fresh produces. What we do here is indoors and in the city. It’s already close to consumers,” explains Koay.

CITY FARM MADE POSSIBLE

Urban farming isn’t really an alien concept. It’s fast growing in popularity around the world. Across the Causeway, our neighbour Singapore has its own campaign. The scarcity of land in the city has prompted the Edible Garden City to promote the Grow Your Own Food movement. The hope is that — as stated in their website — people would grow edibles on all the under-utilised spaces such as rooftops and sidewalks.

“We do foodscaping. Our gardens work doubly hard to be both productive and pretty. We use herbs, vegetables and fruit trees to create a landscape that you can munch on.”

In addition, Edible Garden City supplies fresh produce and conducts workshops on farming-related topics. While focusing on the community, the company also seeds the knowledge of food growing in schools. “We believe that children are more likely to eat the greens that they grow,” it states.

The awareness of urban farming in the country, however, remains relatively low. This is why CityFarm Malaysia aims to play a part in the movement by creating simple and affordable farming system in cities.

“Our farming method is suitable for high rise buildings, with small balconies. We can customise the design for you, whether you want it on your balcony or mount it on your wall,” shares Koay.

The City Balcony Hydroponic set with a dimension of 1.5m by 60cm by 60cm is a simple and easy to use PVC system which includes 20 or 30 plants capacity, nutrient tank, nutrient pump, fittings and net pots. It’s suitable for city growers as it doesn’t require frequent supervision. It’s also affordable.

“Based on our climate, you can breed local vegetables and will have no problem growing them here. You can have lettuce, kale, choy sum, pak choy and herbs,” says Koay.

If you live in a small apartment with just one window, the City Window Farm is the best setup for growing vegetables.

Koay says: “City Window Farm is a basic hydroponic starter pack, all in one box. You can master that first. Just put near your window.” “Don’t worry, it comes with a manual,” Looi chips in.

Besides providing farming equipment, the team also organises classes, training, exhibitions and talks in public and in schools. So far, they have visited three schools in the Klang Valley. “We want to teach students about urban farming so when they go home, they can share their knowledge with their parents,” explains Koay.

THE A-TEAM The self-taught trio and two others behind the set-up are graduates of the Multimedia University in Cyberjaya. It was through clubs and student activities that they met as they were all on different programmes.

“It all started as a hobby about two years ago,” shares 28-year-old Chew, who’s a freelance software engineer. “I saw this urban farming concept on TV. It’s big in the US and Europe, and I was interested. So I bought a plant and put it in a small corner in Malaysian Global Innovation & Creativity Centre, where he worked. Soon after that, Koay decided to join as well.”

Discussions followed soon after and eventually, the idea became a reality and CityFarm Malaysia was born.

IT management consultant Looi says: “I want to be able to do something impactful but also something that can still feed my family.”

Koay, 27, from Terengganu, concurs: “Yes, we need to do something influential and make a difference. I was in the Oil & Gas industry before but I resigned to do this. But I still have a few other businesses.”

Their green hearts don’t just stop at CityFarm. They also practice green living as well. Looi and Koay confide that they use less plastic bags and polystyrene now while Chew plans to get an electric car for himself.

So what’s next?

Education. According to the team, they want to train the next generation on the importance of farming and how we can play a part to make the world a better place by growing food that is healthy, clean and fresh.

Koay concludes: “We want to start ahead and now it’s the time. There are only five of us and we can’t possibly reach the whole country by ourselves. Everyone should play a part for this kind of effort.”

Details at cityfarm.my and www.facebook.com/CityFarmMalaysia

Read More : http://www.nst.com.my/news/2016/12/197593/farm-city

The Square Roots Urban Farming Community, NYC

Farm Tour and the First Farmer's Market 🌱🎅Wednesday, December 21, 2016

- 5:00 PM to 8:00 PM

Square Roots Urban Farming Campus

630 Flushing Avenue, Brooklyn, 11206, New York, NY (map)

Tour the Square Roots farms, meet the farmers, and buy a bundle of fresh, tasty, locally-grown greens - just in time for cooking up a holiday feast!

Our indoor, modular, vertical farms squeeze the equivalent of 2 acres of outdoor farmland into a climate-controlled shipping container. So our farmers can grow non-GMO, fresh, tasty greens all year round. Like, now!

This should be a fun event - so bring a friend :)

Square Roots’ mission is to empower the next generation to become leaders in the "real food" revolution. This means coaching young, passionate people to grow real food, sell locally and build sustainable businesses.