Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Futuristic Vertical Farming Sprouts Up In Tennessee Greenhouses

Vertical farming is like growing vegetables in a greenhouse on steroids. The industry includes methods like aquaponics, aeroponics and hydroponics. And it's predicted to reach almost $6 billion in revenues within the next five years.

June 26, 2017 | Caroline Leland, Nashville Public Radio

Vertical farming is like growing vegetables in a greenhouse on steroids. The industry includes methods like aquaponics, aeroponics and hydroponics. And it's predicted to reach almost $6 billion in revenues within the next five years.

One of the centers of vertical farming is Tennessee, where the technique is providing locally grown vegetables year-round. Caroline Leland (@CarolineLeland) reports from Here & Now contributor Nashville Public Radio.

This segment aired on June 26, 2017.

Related:

Vertical Growth

Vertical Growth

Vertical farming outfit Intelligent Growth Solutions is looking to complete the construction of its first indoor growth facility James Hutton Institute in Scotland in the next few months. The company then plans to launch a full-scale trial to deliver the UK’s first commercially viable vertical growing environment together with global automation firm Omron.

IGS says it aims to demonstrate that vertical farming is commercially viable by significantly reducing power and labour costs. The initiative is also looking to gain a better understanding of the plant science and types of crops which can be grown best in an indoor farming environment.

“By adopting the principles of Total Controlled Environment Agriculture [a technology-based approach toward food production], a system in which all aspects of the growing environment can be controlled, it is possible to eliminate variations in the growing environment, enabling the grower to produce consistent, high quality crops with minimal wastage, in any location, all year round,” says Henry Aykroyd, CEO of IGS.

Image: Intelligent Growth Solutions

Vertical Funding

Vertical Funding

Image: Bright Agrotech

US-based Newbean Capital has launched an alternative finance arm, Contain, with a focus on providing funding for vertical farmers. The new unit will deliver lease financing for those practising vertical farming and indoor agriculture using hydroponic aquaponic and aeroponic techniques.

Contain recently arranged a five-year lease agreement for Bright Agrotech’s ZipFarm equipment for MyChoice Programs, an East Coast non-profit supporting individuals with developmental disabilities. MyChoice Programs is transforming one of its buildings into a vertical farm that could feed both the residents of its homes and the local community.

Bright Agrotech has just been acquired by vertical farming company Plenty as part of the latter’s efforts to build field-scale indoor farms around the world. Plenty farms combine machine learning, IoT, Big Data, sophisticated environmental controls and heirloom seed stock, and the company reckons it can grow fruits and vegetables, using 1% of the water, less than 1% of the land, and none of the pesticides, synthetic fertilisers or GMOs of conventional agriculture.

St. Paul-Based Urban Organics Aims To Provide Local Greens All Year Long

St. Paul-Based Urban Organics Aims To Provide Local Greens All Year Long

June 24, 2017 12:37 PM By Rachel Slavik

Filed Under: Dave Haider, Rachel Slavik, St. Paul, Urban Organics

MINNEAPOLIS (WCCO) — Minnesota winters aren’t exactly ideal growing conditions for fresh local produce. One St. Paul company is working to bring local, organic greens to store shelves all year long.

Urban Organics is among the first to begin mass producing several varieties of lettuce within city limits prompting an agricultural evolution, of sorts.

Outdoor farming is moving inside because of people like Dave Haider.

“It’s absolutely perfect growing conditions 365 days a year,” Haider said.

Dave is the co-owner of Urban Organics, which produces locally-grown, organic leafy greens.

“I think people are starting to have a deeper focus on where their food comes from,” Haider said.

That interest has led to incredible growth since the company’s launch four years ago. Haider started with a smaller operation in the Hamm’s brewery but recently expanded to a new 90,000 square facility in the old Schmidt Brewery.

“I don’t think we anticipated such a high demand so quickly,” Haider said.

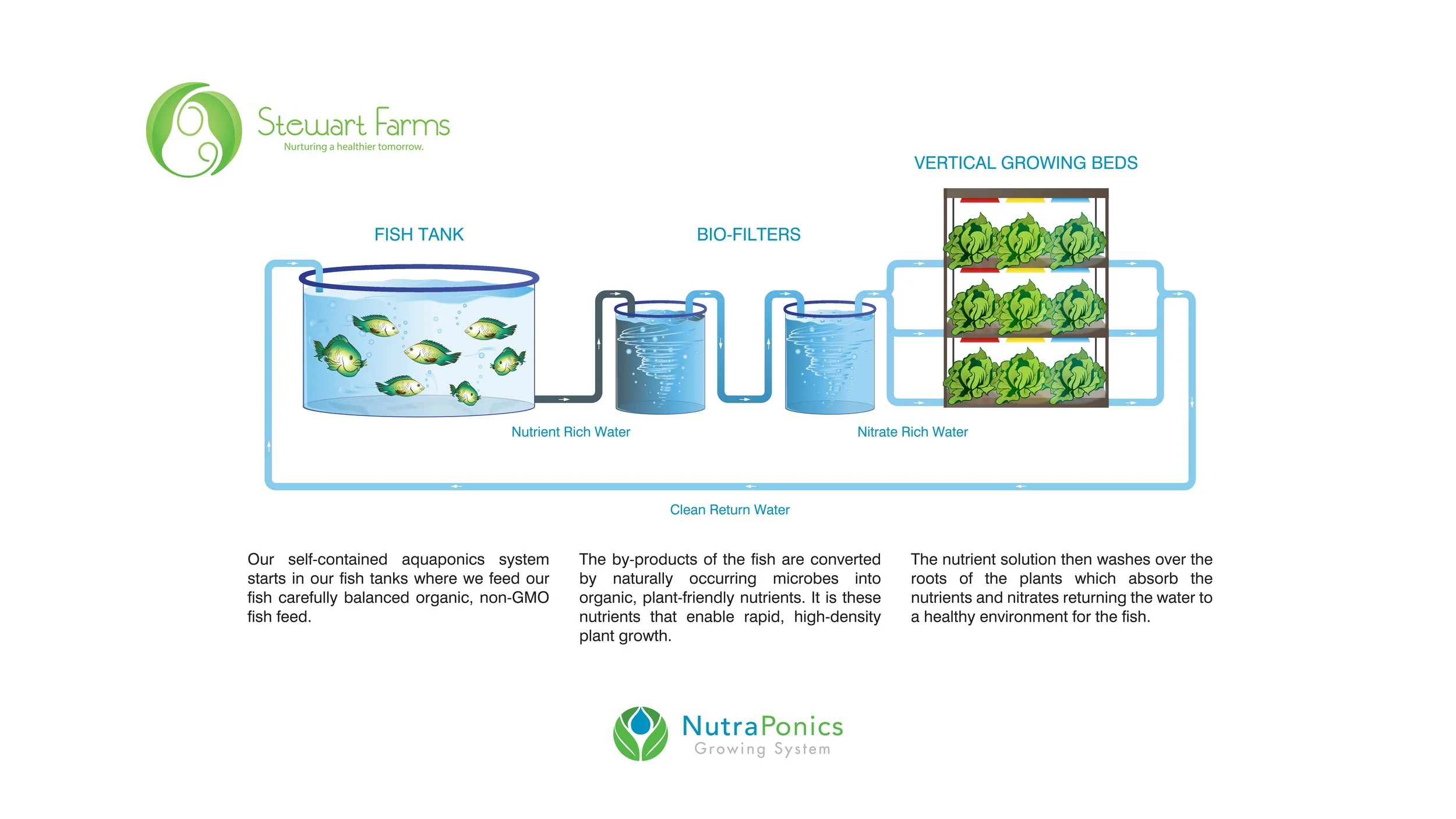

Urban Organics has found success using aquaponics and hydroponics, a process where fish and water are combined to help plants grow.

Each leafy green sprouts in nutrient filled water funneled from onsite tanks containing salmon and char.

“We capture the waste, remove the solid waste and ammonia in the water. It’s converted to nitrates through a biological filter and it’s that nitrate rich water that provides all the nutrients, all the nitrogen for the plants,” Haider said.

Dave said the end result is a growing system that uses less than five percent of water compared to conventional agriculture and ultimately allows fresh greens to reach store shelves within a day and a half.

“Very low impact on the environment,” Haider said.

The products are in most co-ops around the Twin Cities and three Lunds/Byerly’s stores. For more on where and what lettuce varieties are available, go here.

A Google-Backed Warehouse Farm Just Raised $20 Million to Build in Cities Across The US

A Google-Backed Warehouse Farm Just Raised $20 Million to Build in Cities Across The US

Bowery

Indoor agriculture startup Bowery says it's creating the farm of the future.

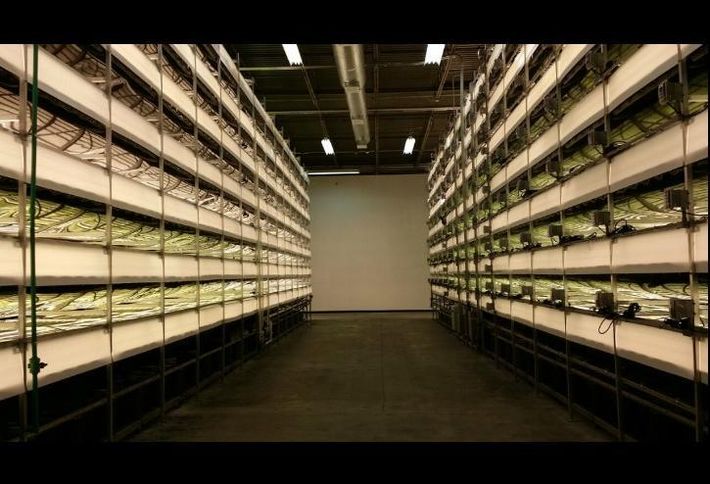

Unlike traditional outdoor farms, Bowery grows greens under LEDs (which mimic natural sunlight) inside a giant warehouse in New Jersey. Instead of soil, crops sprout in nutrient-rich water beds on trays stacked from the floor to the ceiling. Throughout the growing process, sensors in the trays track the growing process.

The company just raised $20 million in Series A funding, co-led by General Catalyst and GGV Capital ith participatio from GV (formerly Google Ventures). With the new funding, it will build more farms (first in the tri-state area and later in other cities across the US), move beyond greens to other crops, and hire more people.

When Bowery launched earlier in 2017, co-founder Irving Fain told Business Insider the farm has the capacity to grow 100 times more greens per square foot than the average industrial farm. The startup's operational costs stay low because it automates traditional farm labor and uses a proprietary piece of software, called FarmOS, to optimize its growing process.

Bowery is currently testing over 80 different varieties of greens, including baby kale, mustard greens, and arugula.

Bowery

Out of those 80, Bowery is selling six types for about the cost of most organic greens. Available at select Whole Foods and Foragers stores in the tri-state area, a five-ounce package of greens costs $3.99.

Bowery is one of many urban farming startups that have emerged in recent years. Also in New Jersey, AeroFarms started commercial production inside a 69,000-square-foot warehouse in 2016. Brooklyn's Square Roots, which made its first harvest in early 2017, is growing its produce inside ten 320-square-foot shipping containers.

Unlike Bowery, which says it will now experiment with other crops besides greens, these companies solely produce leafy greens. Compared to other vegetables and fruits, greens usually make more financial sense for vertical farms — They can sell greens at a higher price per pound that most other types of produce.

Bowery Farm is now ramping up for large-scale production (Fain would not disclose the farm's size or growing capacity), and is already working on its next farm in the tri-state area. In the future, Fain hopes to expand internationally.

Pentair Aquatic Eco-Systems Launches Australia-Focused Website

A brand new website directed at Australian aquaculture professionals, PentairAES.com.au, is now live. Pentair Aquatic Eco-Systems’ regionally-focused website is well-timed, as the Australian aquaculture industry continues to grow.

Pentair Aquatic Eco-Systems Launches Australia-Focused Website

A brand new website directed at Australian aquaculture professionals, PentairAES.com.au, is now live. Pentair Aquatic Eco-Systems’ regionally-focused website is well-timed, as the Australian aquaculture industry continues to grow. In order to meet demand, the industry needs a reliable supplier. With an office in Melbourne, and a local stock of products, Pentair Aquatic Eco-Systems (PAES) offers convenient and comprehensive service to customers, with a wide array of technologies and solutions.

With species like barramundi on the rise, expertise is at a premium. Pentair Aquatic Eco-Systems has the equipment and expertise to offer solutions for a variety of species; Atlantic salmon, rainbow trout, barramundi and more. Our offering addresses the entire life cycle of these species. Pentair’s Melbourne office features a full range of aquaculture technology and equipment that is ready to ship. Their dedicated sales staff is prepared to answer any questions and provide solutions to new and existing farms.

Pentair Aquatic Eco-Systems’ Sales Manager for Australia and New Zealand is Brendan Lee. With a great passion for the industry, prior to Pentair, Brendan has held positions at a leading Rainbow Trout producer in Victoria, after which, he moved on to a research and development role, working with fresh and salt water algae species and live feed production – all of which has built valuable experience in all aspects of aquaculture, which benefits his customers greatly. When asked for comment on Pentair’s focus on the Australian market, Lee stated, “I look forward to assisting current and future customers with any of their project, design, service and equipment needs, as we continue to build the Australian and New Zealand aquaculture sector together!”

Pentair Aquatic Eco-Systems is committed to excellence in all aspects of business. Whether a client is seeking assistance with equipment selection, consultation, technical support, system design, redesign/retrofitting services, maintenance or service contracts— Pentair AES is the single-source industry leader to count on. Pentair provides what’s needed to make any system operate more efficiently and effectively to help you maximize profit in every facet of your operation.

Their main focus is excellence, and they strive to be the best in the three key areas of supporting commercial facilities: Design ● Service ● Equipment. A go-to motto for Pentair AES employees is, “If you are ready to get your aquaculture project started… ASK US!”

For additional information on Pentair Aquatic Eco-Systems, visit their Australian-focused website, PentairAES.com.au

Sales Contact: Brendan Lee

Pentair Aquatic Eco-Systems, Inc. (Melbourne)

1300-137-344

Vertical Farming Using LED lights – Interview With Céline Nicole, Philips Lighting Research

Vertical Farming Using LED lights – Interview With Céline Nicole, Philips Lighting Research

Posted on 20/06/2017 by Diana Macovei

Vertical Farming using LED lights – Interview with Céline Nicole, Philips Lighting Research

Céline Nicole, from Philips Lighting Research will present her vision on the developments of Vertical Farming using LED lights on the 28th of June, at the Vertical Farming Conference in Venlo, The Netherlands.

Plant scientist and researcher Céline Nicole worked at Philips Horticulture LEDs solutions for 8 years and at the Philips Lighting Research for 16 years.

Since the year 2000, vertical farms have been introduced to grow vegetables and soft fruits. As LED lights became increasingly efficient they have become the light source of choice for commercial scale vertical farming.

How has vertical farming become so efficient?

“With the growing population, living in cities more and more, we need a solution to feed the world. Vertical farming represents a contribution to meeting that challenge. With this technology, growing conditions can be controlled including the climate, the water, nutrition and the light. Philips Lighting uses different light combinations which we call light recipes. These are a combination of different LED colours (spectrum), intensity and lighting hours per day. In vertical farming, water is re-used making this system very sustainable for water usage (more than 90% on water savings). No pesticides or other chemicals are used because there are no external influences getting inside the farm and everything used inside the farm is sterile. Accurate control of the climate allows crop growth in the best conditions. And because there are no seasons inside the farm, the yield per year is the highest of what can be achieved compared to other ways of growing crops.,” according to Nicole.

In addition, vertical farms can be built close to or in cities, allowing the shortest time from farm to fork. That increases useful shelf-life of the fresh produce and improves logistics, and therefore also contributes to reduced food waste.

You create an indoor climate, but is that good for the vegetables, as nature has its reasons for varying conditions.

Nature and climate varies much on the surface of the globe. For plant growth, tropical regions are rather mild in temperature and humidity, while continental or temperate climates have colder and warmer months with variations in humidity. Vegetables are originating from all over the world and have therefore evolved for different climate and light conditions. In a vertical farm it is possible to create a climate close to the optimal growing conditions for each variety.

For example, spinach likes it cold, especially at the start of growth and we can adjust the climate in order to optimize its growth and quality. In contrast, Basil likes it warm because it is a tropical plant, but it is grown in Europe as an annual crop. This is changing with vertical farming as we can now grow Basil at any time of the year, regardless of the season, and of a very high quality.

“Optimizing growing conditions for plants doesn’t always necessarily mean that it is good for the plant, sometimes it is done to achieve benefits for the consumer. For example, growing red oak lettuce in a climate and with light settings that is good for plant biomass production will not always create a good red colour like it would when grown outside in the summer. This is in fact a ‘stress response’ due to the UV component in sunlight. With the knowledge that we are gathering at Grow Wise centre and with our customers, we are developing and fine-tuning growth recipes for different crops. With vertical farming we can create climates and light conditions that mimic the natural environmental changes, in order to trigger the plant to produce those photo protective pigments (anthocyanin) and make them identical to when grown outside,” says Nicole.

Can you elaborate on Nitrates and health?

For decades there has been a controversy about assessing the possible negative health effects of nitrates ingested from vegetables. Over the past 5-10 years, more and more articles have appeared claiming the opposite, that nitrate consumption is healthy. It was shown to have an antimicrobial activity and also to enable the body to produce nitric oxide which is believed to have an important physiological role in vascoregulation and therefore beneficial for cardiovascular patients. The vascoregulation has been proved and is used by high level sportive people who need to perform in a short time frame. Still, the association of high nitrate levels has a negative impact on consumer minds. The Dutch food authorities’ recommendation has recently changed the advice on spinach and high nitrate vegetables. The limitation of daily uptake in grams has vanished in the Netherlands and some other countries. This is probably due to recent research showing that people eating on average more vegetables per day are more likely to be healthy. However, since there is no scientific consensus, it is wise to know how to limit the amount of nitrate when growing leafy vegetables, especially for those vegetables containing a lot (like spinach or rucola).

“With vertical farming we can provide both, low or high nitrate vegetables. Some of our customers desire to have a very low nitrate level in leafy vegetables, and we can help them by providing this. We can also provide a ‘runners’ lettuce with an ultra-high nitrate content if anyone asks. For sure, with vertical farming we are preventing pollution of the environment from overusing nitrogen fertilizers as the irrigation circuit is closed and water is recycled.” Concludes Nicole

For more information and registration to the Vertical Farming Conference, we invite you to visit https://www.verticalfarmingconference.com/

The interview was made by Jakajima, the organiser of the conference. For more interviews with speakers at Jakajima conferences, we invite you to visit Jakajima’s website

Newbean Capital Launches Finance Arm To Support Indoor AG

Contain Inc Partners With AmHydro, Bright Agrotech & CropKing:

Newbean Capital Launches Finance Arm To Support Indoor AG

Newbean Capital, a registered investment advisor and organizer behind the Indoor Ag-Con events, has launched an alternate finance arm, Contain Inc.. “Our goal is to become the alternate finance provider of choice to indoor farmers”, said Nicola Kerslake, co-founder of Contain Inc.

The venture has partnered with three indoor agriculture technology providers to provide lease financing to their customers. For longstanding industry consultant AmHydro, it will offer lease financing for the company’s Get Growing! greenhouse bundle packages. AmHydro has been designing and building innovative, hydroponic systems for over 30 years. It manufactures and helps to install food-grade growing systems for both small and large commercial operations. AmHydro offers systems for the small business entrepreneur up to the large multi-acre commercial suppliers of companies such as Whole Foods and Costco.

Contain Inc has recently arranged a five-year lease agreement for Bright Agrotech’s ZipFarm equipment at a 6.5% rate for MyChoice Programs, an East coast nonprofit that supports individuals with developmental disabilities to participate in their communities. As one of its innovative programs, it decided to transform a building into a vertical farm that could feed both the residents of its homes and the local community using Bright Agrotech equipment.

Its newest partner - CropKing - a manufacturer and distributor of commercial greenhouse structures, hydroponic growing equipment, and supplies. Known for working with family farms, it has specialized in the business of controlled environment agriculture and hydroponic growing since 1982. It offers both bucket and NFT systems for indoor grows.

See also :

contain.ag

amhydro.com/financing

brightagrotech.com

cropking.com

mychoiceprograms.com

Publication date: 6/20/2017

Vertical Farming Conference

Vertical Farming Conference

Herman van Bekkem will discuss the Greenpeace vision for ecological farming and especially Vertical Farming in Europe’s main cities, on the 28 June 2017, at the Vertical Farming Conference in Venlo, The Netherlands. Herman van Bekkem is an agricultural expert with Greenpeace and tries to educate the agricultural sector for ecological farming on the seven principles set up by Greenpeace. (The report on the Greenpeace vision for ecological farming, and the seven principles, can be downloaded freely from their website)

“There are many pros and cons regarding Vertical Farming, but this development offers the possibility to use far less pesticides and fungicides, which are no longer needed. This way the impact on the environment is reduced as well which is a great benefit. But the question is if Vertical farming is the solution to many of the agricultural challenges, as we know them today,” says Van Bekkem.

Culture

“The present use of large numbers of greenhouses for instance in the Netherlands has its pros, but also a larger number of cons. By planting huge amounts of the same crop in one greenhouse creates a good feeding ground for fungi and plagues. Simply the uniformity makes it very vulnerable to any diseases which may be in the greenhouse. That is why we encourage farmers to grow different kinds of crops in one greenhouse so as to build in some resistance and use far less pesticides and fungicides.

“A monoculture in a greenhouse has many weaknesses and this way you can turn it around. This new way of farming is also important for Vertical Farming as it is close to a greenhouse culture,” according to Van Bekkem.

He is reserved on the success of Vertical Farming especially in Western Europe. He explains his view:

“There are not that many vertical farms in cities, look at the Netherlands, there are only very few of them. Only in Asia you see them now coming up in cities. But the biggest problem is that a handful of large corporations control large parts of our food system right this moment, which is in fact not working in a positive way for Vertical Farming. Corporations and food policy makers are stubbornly sticking to an increase in yields as the global goal. This obscures the real challenge; we need to rethink how we use the food we are producing, right now and in the future. In a better food system, ecological livestock systems would make use of the agricultural land and resources not required for human food needs and at the same time drastically reduce the amount of animal products we produce and consume globally.”

Use of insects

Van Bekkem is also very positive about the use of insects to battle crop illnesses.

“At a micro and macro level it is most useful to use insects, to counter insects that attack the crop or otherwise destroy it. Instead of pesticides you can use for instance the parasitic wasp or the predatory mite, two useful weapons in the battle against the insect pests. Not only do they take care of each other but also the soil improves where the crop is grown. Even flowers will bloom and with the right seasonable change of crop the soil improves a lot. But on top of that the crop gets stronger and more resistant towards any enemies. This way the circle is round again and the environment has much improved.“

Sustainable

“It is possible to increase soil fertility without the use of chemicals. Ecological Farming also protects soils from erosion, pollution and acidification. By increasing soil organic matter where necessary, we can enhance water retention and prevent land degradation. Something which we can do on the small scale vertical farms very directly, so as to improve the quality of food directly as well as the enclosed environment,” concludes Van Bekkem.

For more information and registration to the Vertical Farming Conference, go to: https://www.verticalfarmingconference.com/

The interview was made by Jakajima, the organiser of the conference.

Scotland’s First Indoor Vertical Farm To Start Up In Autumn

Scotland’s First Indoor Vertical Farm To Start Up In Autumn

Scotland's first full-scale indoor vertical farm is being built at the James Hutton Institute near Dundee

ILONA AMOS - 15:25Wednesday 21 June 2017

Scotland’s first indoor vertical farm is due to be up and running later this year.

The purpose-built facility, which is currently under construction on the outskirts of Dundee, will be the first full-scale scheme of its type in the country.

The initial crops to be grown at the experimental unit will be herbs and salad plants, which will be cultivated in vertically stacked layers with hi-tech LED lighting and special hydroponic systems supplying nourishment.

Tomatoes, cucumbers and strawberries will be trialled at a later stage.

It’s hoped vertical farming can help solve the problem of feeding the expanding world population and minimise damage to the planet from increased agriculture.

Growing in this way can offer a number of benefits over traditional outdoor methods, such as reducing the amount of space required and cutting the need for pesticides.

Controlled conditions allow crops to be grown all year round, with success not dependent on seasons or weather conditions.

Their compact nature also means the farms can be sited in built-up areas, making produce more local and therefore reducing transportation.

However, maintaining an optimum artificial environment is costly.

The Dundee project is the brainchild of Scottish-based vertical farming business Intelligent Growth Solutions (IGS) and is being carried out in collaboration with the James Hutton Institute for crop research and global automation business Omron.

Its aim is to deliver the first commercially viable operation in the UK – and possibly worldwide – by cutting labour and power costs.

It is hoped new insights into the varieties of crops best suited to cultivation in an indoor farming environment will also be revealed.

“Vertical farming allows us to provide the exact environmental conditions necessary for optimal plant growth,” said Henry Aykroyd, chief executive of IGS.

“By growing closer to the market in controlled vertical farming conditions, it is possible to accurately predict and grow to market demand, thereby reducing food waste.

“It is locally produced, therefore there is a reduction in food miles, and through the controlled environment there is a greater capacity to control quality, taste and flavour.

“The products are fresher, have a longer shelf life, and crop losses due to weather, disease, drought or pests are effectively eliminated.

“We believe that as populations grow and market demand increases there will be a far greater demand for indoor growing, closer to the consumer and produced as needed, to improve efficiency and reduce food waste.”

He added: “A highly integrated automation strategy, patented energy-reduction technology and the most advanced biological research available will be the three key pillars to success in this project.

“Partnering with two leading experts, Omron and the James Hutton Institute, to deliver this provides the very best opportunity for a new approach to vertical farming.”

Professor Colin Campbell, chief executive of the James Hutton Institute, said: “We are delighted to see how well the work on IGS’s indoor growth facility at our Dundee site is progressing.

“This initiative combines our world-leading knowledge of plant science at the James Hutton Institute and IGS’s entrepreneurship to develop efficient ways of growing plants on a small footprint with low energy and water input.”

Omron field sales engineer Kassim Okera added: “Omron’s guiding principles drive us to be a pioneer in creating and supporting the development of inspired solutions for the future.

“I can’t think of a better example than this one, which uses the most advanced technology to solve a humanitarian need.”

Scottish Trial Site To Test Commercial Viability and Increase Understanding of Vertical Farming

A collaboration with Omron, a global provider of automation and control systems, the purpose-built facility will enable a full-scale trial of a vertical growing environment.

Scottish Trial Site To Test Commercial Viability and Increase Understanding of Vertical Farming

21 June 2017, by Gavin McEwan, Be the first to comment

Dundee-based vertical farming business Intelligent Growth Solutions (IGS) will complete construction of its first indoor growth facility, at the James Hutton Institute (JHI), "in the next few months".

Image: IGS

A collaboration with Omron, a global provider of automation and control systems, the purpose-built facility will enable a full-scale trial of a vertical growing environment.

As well as assessing the format's commercial viability through lower power and labour costs, it aims to yield a better understanding of the plant science involved and types of crops which can be grown best in an indoor farming environment.

IGS chief executive Henry Aykroyd said: "By adopting the principles of Total Controlled Environment Agriculture (TCEA), a system in which all aspects of the growing environment can be controlled, it is possible to eliminate variations in the growing environment, enabling the grower to produce consistent, high quality crops with minimal wastage, in any location, all year round."

Automation will initially control and monitor the stacking system, the LED lighting and hydroponics systems, and will ultimately control every feature in the facility.

JHI chief executive Professor Colin Campbell added: "This initiative combines our world-leading knowledge of plant science and IGS' entrepreneurship to develop efficient ways of growing plants on a small footprint with low energy and water input."

New "Lego-Like" Vertical Growing System Offers Flexibility And Small Footprint

New "Lego-Like" Vertical Growing System Offers Flexibility And Small Footprint

16 June 2017, by Gavin McEwan, Be the first to comment

A German firm has launched the latest format in high-density soil-less urban growing.

Image: Aponix

The modular Aponix Vertical Barrel uses an NFT hydroponic system and is designed particularly for urban farming facilities operating on limited space.

"There are no fixed structures necessary for the set-up, like tables or racks, so the barrels can be positioned and moved easily to provide flexibility," explained its inventor Marco Tidona.

The units are constructed out of a single "Lego-like" part that forms 1/6th of a ring segment, any number of which can then be stacked vertically, topped with a lid that incorporates irrigation using a simple sprinkler or spray nozzle, he added.

The entire barrel can sit ona stand or even be hung from above, and rapidly dismantled after use for washing and re-planting.

"Many barrels can be connected in line and be powered by a central reservoir with organic or mineral liquid nutrient solution and a pump for irrigation," Tidona said, and suggested herbs, lettuce or strawberries as candidate crops.

He added: "Aponix is expanding and is currently looking for sales and manufacturing partners."

Jason Wargent Sees Crop Farming Going Vertical And Joining The Urban Landscape. A flood of Innovation is About To Be Unleashed

Jason Wargent Sees Crop Farming Going Vertical And Joining The Urban Landscape. A flood of Innovation is About To Be Unleashed

Posted in Rural News June 21, 2017 - 08:08am, Guest

By Jason Wargent*

The past 50 years have seen huge change in agriculture and food production. Rapid increases in the use of farmable land and intensification of the use of agricultural inputs have both contributed to the significant yield improvements achieved for staple crops since the 1960s. Now we are in a new phase where the magnitude and diversification of agricultural innovation must be maximised to meet the growing challenges of the 21st century. Not only have we reached the peak of ‘simple’ agricultural intensification, but we also face significant climatic uncertainty, combined with a rapidly growing global middle class.

Taken together, the demands of modern and future agriculture are arguably very different to those at the start of the Green Revolution. An expanding middle class has obvious implications for demands on food quality and safety; in New Zealand, numerous horticultural players have developed strong market positions by supplying premium products at a premium price, e.g. novel kiwifruit varieties and wine possessing characteristic properties. The New Zealand farming experience highlights that there is ample opportunity to produce high-value food that tells a story about food quality, sustainability, geography, tradition or nutrition.

As land availability decreases in many parts of the world, and land costs increase, pressure for the pace of agricultural evolution to accelerate is mounting. That said, new paradigms for premium agricultural production are emerging.

Despite the fact that indoor farming has been part of the agricultural landscape for nearly 200 years, we arguably sit at the front end of a next great ag-revolution, where food is grown within a highly diverse, ultra-technological, indoor ecosystem of cropping environments. Indoor farming now has wide interpretations of meaning; the most historical incarnation is that of glasshouse production, used for hothouse tomato cultivation. Protected cultivation can also be equally applied to the use of tunnel or ‘hoop’ houses, usually clad in plastic materials or netting.

Both environments have seen huge innovation growth in the last 30 years, from the introduction of sodium-based artificial-lighting sources into glasshouses to increase crop productivity to the development of ‘smart’ polymer-incorporated claddings for tunnel houses, which can regulate the lighting or temperature environment for crops within. However, both types of crop system still rely on ambient local climatic conditions to greater and lesser extents, e.g. sunlight (therefore day length) and temperature.

The quest to optimise every aspect of a crop’s production cycle led innovators in the 1980s to conceive the first prototype ‘plant factories’, where crops were grown completely indoors, using artificial lighting and environmental-control systems. Some of this innovation was driven by the space race, and the desire of agencies such as NASA to develop food production systems which were fully closed loops, in which food crops could be grown from seed to harvest using artificial light and circulating nutrient processes, such as those exploited in hydroponic systems. Those early enclosed systems have subsequently inspired a generation of entrepreneurs and technologists in the present, where a range of indoor farming categories are flourishing.

One of the most talked-about categories is ‘vertical farming’, the practice of incorporating vertically stacked layers or shelves of crops, often to maximise space-use efficiency in limited-footprint buildings, e.g. converted or purpose-built warehouses in urban areas. Vertical crops are farmed in their entirety under isolated, controlled conditions, thus creating an exciting vacuum of opportunity for agri-tech. Vertical farming has begun to capture imaginations, with visions of former industrial spaces glowing with floor-to-ceiling LED lighting. There are now likely as many physical manifestations of vertical farming as there are opportunities or motivations associated with adoption of the practice.

Controlling the environment

As discussed earlier, full control over a crop is a clear advantage of fully-indoor production: it means complete mitigation of climatic influence, and therefore the potential to extend or manipulate cropping seasons. Climatic isolation also means buffering food supply (and arguably food quality) from turbulent, one-off events, such as exceptionally dry or wet weather periods, or from pest and disease pressures. Equally, there is the opportunity for control and enhancement of food quality and nutrition.

Plants are composed of highly complex, responsive signalling networks, capable of acclimating to an environment on the basis of different cues or stimuli. As many as 200,000 secondary metabolite compounds have been identified in plants, many of which are associated with implications for produce taste or nutritional qualities. As our understanding of the associated plant biology grows alongside advances in agricultural technology, those stimuli required to nudge plants into a particular taste or nutritional profile can be deduced, and then deployed in a controlled environment.

Related Topics - Rural NewsMassey UniversityinnovationfoodJason Wargent

An oft-mentioned advantage of vertical farming is the strong potential for localising produce-to-purchaser dynamics. In urban environments, shipping times from vertical farm to customer have been quoted in minutes, as opposed to hours or days. The potential to fully integrate food production into what is a typical consumer lifestyle — an urban one — is a tantalising proposition for many food retailers and marketers. The reality of nutritious herbs being grown one block away from a major city food market could be a food marketer’s dream. That said, there are still a very limited number of published life-cycle analysis studies focused on vertical farming. Understanding the cradle-to-grave impacts of vertical farming from a sustainability perspective will allow for greater consumer understanding, and for tech advances to underpin exploitation of the related opportunities, e.g. energy efficiencies, nutrient re-use, co-location with larger-scale customers, packaging and storage. The question as to how a consumer comprehends the very nature of an indoor farm, set against the ‘locally grown’ perspective, will be an interesting value proposition to unravel over time. Does a local indoor farm carry the same cachet as an outdoor, sunshine-bathed farm?

As well as the attraction of isolating seasonal downsides or exploiting urban co-location, arguably one of the most exciting and valuable opportunities for vertical farming is the pure potential to foster agri-innovation of all kinds. Certainly, vertical farming would not exist now without the already-substantial innovation leaps that have taken place to date, for which there can be broader applications beyond full-indoor farming itself. Growing crop plants to full yield in an isolated environment requires an understanding of the very essence of agriculture: nutrients, water and light must all be understood and calibrated to a crop’s needs, and in a cost-effective manner. An obvious reality with full-indoor farming is that there is a capital expenditure that would dwarf many agriculture operations on a per-unit area basis. So the challenges are twofold: ensure cost-efficiency following the associated capex, and employ a substantial amount of cutting-edge, ‘grow-how’ to produce products that meet a premium price point.

Light could be the hottest topic in indoor farming: plants require light for autotrophic nutrition, and fully-indoor spaces lack it. The rise of LED lighting for crop growth has been exponential in the last five years, following not just the expanding interest in light for unlit indoor spaces but also as a replacement for more historical, heavy-duty supplementary lighting sources. LEDs offer the ability to control the light environment (or spectrum) to a far greater extent than has previously been possible.

One exciting challenge with LEDs revolves around the aim to blueprint the lighting requirements for different crops. Getting the light right for increased crop productivity or quality indoors requires innovation and experimentation — for instance, an appropriate mix and intensity of, say, red and blue light will be different for tomatoes versus capsicums. Similarly, ensuring that higher-value herbs that are grown indoors maintain aromatic or taste compositions that meet (or exceed) consumer expectations will require careful tuning of the light environment.

Urban co-location

The win-win for agriculture in general is that the pressure to innovate for fully-indoor farming will very likely lead to new knowledge or IP, which could be exploited in the future for all manner of farming. From the development of soilless plant production techniques to advances in energy efficiency and automation, not only must indoor farming deliver food that meets a premium price point, but also practitioners must maximise crop yields per unit area of production space — aims that sit at the very heart of agriculture challenges and opportunities this century. Given the current economics of establishing and maintaining a fully-indoor space, this maximisation of quality and yield is arguably vital for indoor farming to grow.

The US has been one of the most active parts of the world (as well as Asia) in nurturing fully-indoor farming projects. At present, however, the scale of full-indoor (vertical) farming operations is still a very small proportion of all farming space by volume. The types of crops which currently sit within a feasibility range for vertical farming also have certain limits at present. For example, shorter-rotation, higher‑value products such as herbs or baby greens are particularly amenable to vertical farming, whereas row/field crops such as corn or soy are largely untouched to date, although some micro-pasture full-indoor container systems have been developed for grasses. However, there have been few limits to date regarding the innovation endeavours of indoor farming entrepreneurs: for example, the farming of vaccines for the pharmaceutical industry. We are likely sitting at the narrow end of the funnel right now, with greater innovation leaps yet to come.

Indoor farming cannot (and arguably does not aim to) replace field-based farming. Significant scale will take a number of years to achieve, and there is a strong case for indoor farming to differentiate in terms of the categories of crops produced, the price-points and the geographical locations. While such a complementation-style model is the likely norm right now, it is hard to predict where indoor farming will reach to in the future given the opportunities and the entrepreneurial nature of the sector at present. The potential for hybrid-exchanges of agri-tech in and out of indoor farming to drive advances in other farming forms is strong.

In addition to production and innovation, one other vital outcome from the advent of indoor farming can be education. With urban co-location, and the intersection of multi-disciplines (science, engineering and marketing, to name a few), one weighty additional responsibility for indoor farmers is the translation and communication of the realities and opportunities of farming to a younger generation of future innovators. Using tools such as container/urban food gardens in schools, site visits and educational partnerships, further integration of farming into large urban areas is a necessary path for our farming needs and traditions to build and evolve over the next 50 years.

Jason Wargent is an associate professor at the Institute of Agriculture and Environment, Massey University. This article is an essay in Massey University's 2017 New Zealand Land & Food Annual - No free lunch. It is reposted here with permission. The New Zealand Land & Food Annual 2017, Edited by Claire Massey, published by Massey University Press, RRP: $39.99, available in bookshops nationwide.

The Vertical Farming Summit

The Vertical Farming Summit

The future of food is being developed in tech hubs and cities around the world. If you’re not currently in one of those places, going to live events is a great way to learn more about vertical farming and urban agriculture.

If you haven’t been able to make it to any in person AgTech events, Chris created this online event for you.

Check out: The Vertical Farming Summit!

Chris Powers recently had the honor and the opportunity to interview a lot of innovators who are working hard to build the future of food

The Vertical Farming Summit will be live June 16-25th with a number of additional sessions and live trainings happening that week.

Here’s what you’ll learn during the summit:

- A methodology for developing your vertical farming business and planning for success.

Lessons on building a mission driven, venture backed startup around fresh food.

Creative new forms of distribution for gourmet plants and mushrooms.

How to use crop data to unlock higher profits.

How to turn waste into opportunity and using organics in hydroponic systems

The Power of a Plant: A Teacher's Odyssey to Grow Healthy Minds and Schools

How to turn your positive environmental impact into a competitive advantage in the new economy.

How to build your network and land exciting new opportunities in urban agriculture.

Farm Marketing -- How to boost sales and profits using automation and customer research.

The 12 steps to becoming an urban or vertical farmer.

Legal considerations when setting up a farm / agtech business.

Why sunlight isn’t free and other insights from AeroFarms.

Closed loop technology and how to start growing your own food at home.

AVA, Urban futurism and the impacts of digitization on agriculture.

Insights from successful agricultural businesses.

Projects that you should be paying attention to and following.

Top resources and recommendations for learning about urban agriculture and vertical farming.

How to pitch your vertical farming business to investors.

How to start small and scale up intentionally.

… and many more sessions to be announced.

This summit will be 100% online, which means you can learn about these exciting topics and connect with the speakers from anywhere you can get a connection.

The Vertical Farming Summit will be streaming for free from June 16-25th to reach as many people as possible.

If you can’t make all the sessions you can grab an All-Access Pass.

Chris Powers is excited to share all of these expert interviews with you and is looking forward to seeing you in the summit!

About the author: Chris Powers is an entrepreneur and urban agriculture advocate who is using digital marketing to share knowledge about emerging technologies in food.

Sign Up For The Virtual Summit and The Blog to Learn More

Going Indoors To Grow Local

Going Indoors To Grow Local

Alberta company wants to license its hydroponics-aquaponics system to others

Posted Jun. 15th, 2017 by Barbara Duckworth

Nutraponics employees include aquaculturalist Geoff Harrison, left, plant specialist Stephanie Bach and CEO Tanner Stewart. The company grows fresh produce at its facility near Sherwood Park, Alta. | Barbara Duckworth photo

SHERWOOD PARK, Alta. — Providing fresh local produce to Canadians year round could be achieved with a new farming concept that combines horticulture with aquaculture.

NutraPonics, which opened in 2015 near Sherwood Park, is dedicated to supplying the local produce market and supporting local suppliers.

Since last December, it has been selling fresh romaine lettuce, kale, Swiss chard, basil and arugula every week.

The produce is marketed through the Organic Box, a privately owned company in Edmonton that supplies its customers with individually selected orders of locally grown food through online sales and from a store front.

“Everything is marketed as local. We are 32 kilometres from the Organic Box, so that is as local as you can get,” said Stephanie Bach, a plant scientist with the company.

Added chief executive officer Tanner Stewart: “We are hoping to provide less need for products from very far away.”

Stewart, who invested in the company three years ago, is among about 50 private shareholders in the company, which plans to franchise the concept of growing produce indoors in a controlled environment.

“Our model is to not build our own farms and create a massive amount of in-house production,” Stewart said.

“Our business model is to build and license these facilities.”

Former CEO Rick Purdy and a company owner started the system. Purdy researched hydroponics to grow food in water and added aquaponics to use byproducts from fish to create a new growing system.

This farm is considered a demonstration facility, where staff can research the best use of the fish, water and plant development.

There are three tanks full of tilapia fish. The nutrient-enriched water from the tanks is delivered to the plants, which are grown in five layers in a controlled atmosphere.

About 1000 sq. metres of growing space are available, where plants are under red and blue LED lights and fed hydroponically.

Under Bach’s supervision, seeds are planted in a special volcanic rock growing medium from Ontario. They sprout within a week and are then transplanted to the main growing rooms. The plants can be harvested within four weeks for same day pickup by clients.

The company employs about 10 people and while each person might have an official job description, the reality is everyone helps with the fish as well as planting and harvesting.

There is no plan at this time to sell the fish.

“The economics of land-based fish farms is fairly fixed,” said Stewart.

“In order to do business, you really have to look at 200 tonnes of production per year to reach economies of scale. This is two tonnes a year.”

This farm sits on 19 acres, but Stewart envisions any empty urban warehouse as a viable growing operation.

NutraPonics is an agriculture company which sells proprietary growing technologies. These technologies utilize symbiotic relationships between plants and fish known as aquaponics to grow nutrient-rich herbs, vegetables and fish in an enclosed, controlled environment. For more information please visit http://www.nutraponics.ca/home

Whitehorse, Yukon, will be the location of the next farm. The goal in the northern community is to grow and sell produce year round at a competitive price with less freight and a longer shelf life.

Stewart also hopes to develop a facility near his hometown in New Brunswick.

The produce is sold at a competitive price. For example, a bundle of romaine lettuce is offered at $6.25 in a 284 gram package.

“You have to be careful in an emerging industry like ours.” Stewart said.

“You really have to make sure you are focused on this as a business, you need to grow your produce at a certain price and you need to make sure your consumers are going to be happy to buy it at that price.”

He estimated that start-up costs are comparable to any new farm and considers this a stable business model with a decent rate of return on investment.

The difference could be a faster turnaround time from construction to the time saleable product is ready.

“Once we get up and running and all the capital costs are done, then we can produce on a consistent basis, week after week, in fairly short order after we turn the building on,” he said.

5 Repurposed Warehouses Turned Indoor Farms That Need No Land Or Sun To Grow Crops

5 Repurposed Warehouses Turned Indoor Farms That Need No Land Or Sun To Grow Crops

June 15, 2017 Chuck Sudo, Bisnow, Chicago

Earth's population is expected to reach 8.5 billion people by 2030. That is 8.5 billion mouths to feed. With dwindling land resources and soaring farming costs across the country, vertical indoor farms may be a solution to feeding the world. Often repurposed from former warehouses, the indoor farms need no sunlight or pesticides and require less water to grow produce.

Following are five indoor farms leading the pack.

1. AeroFarms

AeroFarms, Newark, N.J.

Location: Newark, New Jersey

Produce Grown: Baby greens and herbs

Company/Owner: AeroFarms At 70K SF, the world's largest indoor vertical farm cost $39M to build, and uses LED lights and computer controls to tailor the lighting for each plant. A closed-loop aeroponic system mists the roots of the greens and reduces water usage by 95%. Constant monitoring of nutrients allows AeroFarms to grow a plant from seed to harvest in half the time of a traditional farm. AeroFarms produces 2 million pounds of produce a year.

2. Gotham Greens

Courtesy of Gotham Greens rooftop greenhouse in Chicago

Location: Gotham Greens operates greenhouses in Brookln, Queens and Chicago's Pullman neighborhood.

Produce Grown: Eight types of lettuce, tomatoes, arugula, basil and bok choy Company/Owner: Gotham Greens A pioneer in the indoor farming industry, Gotham Greens built its first rooftop greenhouse in Greenpoint, Brooklyn, and installed solar panels, LED lighting, thermal curtains and a recirculating irrigation system to offset electrical use and reduce water usage. Gotham Green's newest greenhouse in Chicago is located on top of the Method home products plant and cost $8M to build. At 75K SF (or two acres), it produces a crop yield equal to that of a 50-acre farm.

3. Green Sense Farms

Green Sense Farms, Portage, Indiana

Location: Portage, Indiana

Produce Grown: Micro and baby greens, lettuce and herbs Company/Owner: Green Sense Farms Green Sense's 30K SF farm is capable of growing produce for up to 20 million people within a 100-mile radius. The farm is equipped with customized LED lights from Dutch technology firm Royal Philips and grows its produce in automated carousels, while computerized controls provide perfect conditions for year-round farming. Green Sense CEO Robert Colangelo believes his model is scalable and last year raised over $400K in equity crowdfunding to help build a nationwide network of similar indoor farms.

4. Bowery Bowery

Bowery Farming, Kearny, N.J.

Location: Kearny, New Jersey

Produce Grown: Baby kale, arugula, butterhead lettuce and basil. Company/Owner: Bowery Dubbing itself the world's "first post-organic greens" grower, Bowery uses LED lights to mimic sunlight, grows its greens in nutrient-rich water trays stacked from floor to ceiling, uses data analysis to monitor plantings from seed to harvest and robotics to harvest the crops. Investors love what Bowery is doing so much that the company announced Wednesday that it raised $20M to expand its operations in the U.S. and overseas. Bowery raised $7.5M in February from a pool of investors including "Top Chef" judge and chef Tom Colicchio.

5. Local Roots Farms

A shipping container farm from Local Roots Farms

Location: Vernon, California

Produce Grown: Baby and micro greens Company/Owner: Local Roots Farms Local Roots Farms is innovating urban farming design and building indoor farms from 40-foot-long shipping containers. These portable indoor farms are capable of producing the equivalent of a five-acre farm. Local Roots believes this model will disrupt food deserts around the world by setting up the container farms where they are needed most.

FreshTEC Achievement Award for Peter Quiring

NatureFresh Farms' TOMZ Best New Vegetable Finalist

FreshTEC Achievement Award for Peter Quiring

Thousands of produce industry executives are arriving in Chicago this week to attend the United Fresh Produce Association’s Annual FreshMKT & FreshTEC Expos & Convention June 13-15. During the festivities on Tuesday, June 13, greenhouse vegetable grower and NatureFresh Farms owner & president Peter Quiring will be receiving the FreshTEC Achievement Award for his contributions to the produce industry over the last 20 years.

“Peter’s contributions to greenhouse technology have advanced the industry significantly,” said United Fresh President & CEO Tom Stenzel. “His competitive drive and commitment to invest in technology advancements in controlled growing environments are what set him apart. We’re proud to honor Peter with this FreshTEC Achievement Award.”

“It is a great honor to be recognized by your peers,” said Peter Quiring. “Innovation in the way we build our greenhouses and how we grow our vegetables is what has driven my companies for many years. Implementing the latest in technology has allowed us to be a more efficient operation from start to finish”, stated Quiring.

In addition to receiving the FreshTEC Award for Achievement, NatureFresh™ Farms has been named a Finalist for the Best New Vegetable Award for its TOMZ® Snacking Tomato Program.

“We saw a need in the market place to create a category wide program that would give consumers consistent quality, regardless of the season”, said Chris Veillon, Director of Marketing. The TOMZ® Program is unique in that it provides consumers up to 7 different types of specialty tomatoes under one brand: Red/Yellow/Orange Grape, Red Cherry, Mixed Snacking, Mixed Grape, and Sweet Red Cocktail Tomatoes. Grown in NatureFresh™’s new state of the art greenhouse in Delta, OH from October to July and in NatureFresh™’s high tech greenhouses in Leamington, ON March to November, the company is ensuring that locally grown snacking tomatoes are available year-round.

“Consumers want summer-like flavor in July, November, and February and the TOMZ® Program does just that!”, commented Veillon.

The TOMZ® Program is built on the following principles:

- TOMZ® is promoting the category as a whole, not just one item

- Driven by Flavor; 7 unique products under one brand

- Reduced food miles creates extended shelf life

- Creating a consumer connection with multiple flavors

- Same seed | same grower | same farms = consistency

- High impact packaging colors to brighten the produce aisle

- Geo-targeted consumer facing digital content to raise awareness

- Available year-round: Delta, OH & Leamington, ON

“We believe that the TOMZ® Program can strengthen the snacking category as a whole. It is not just about one tomato with flavor, it is a complete line of fresh tomatoes with flavor”, said Ray Wowryk, Director of Business Development.

NatureFresh™ Farms continues to sample its TOMZ® Tomatoes at all #GreenInTheCity tour stops this year with the company’s mobile Greenhouse Education Center.

NatureFresh™ Farms will have its complete line of greenhouse grown tomatoes, bell peppers, and cucumbers on display at the FreshMKT Trade show during the United Fresh Convention in Chicago, June 14-15. Attendees are invited to visit Booth 3231.

To learn more about NatureFresh™ Farms, visit naturefresh.ca.

Going Vertical to Increase your Yields? Let’s Look at the Realities… You Might be Surprised!

Author | Joe Swartz

Going Vertical to Increase your Yields? Let’s Look at the Realities… You Might be Surprised!

We are certainly living in a time of unparalleled technological advancement in general but certainly in the agricultural field.

We’re constantly looking for that latest and greatest “thing” to make our lives easier or to solve one of our existing problems. In controlled environment agriculture, we’ve sought to improve our overall yields and quality by altering the growing environment. We’ve made tremendous improvements to that end by providing more optimum levels of temperature, light, C02, nutrients, dissolved oxygen and more. For the most part, I would consider this all highly successful.

We have also modified our growing systems to effectively manage our plant populations – our greenhouse “real estate,” if you will.

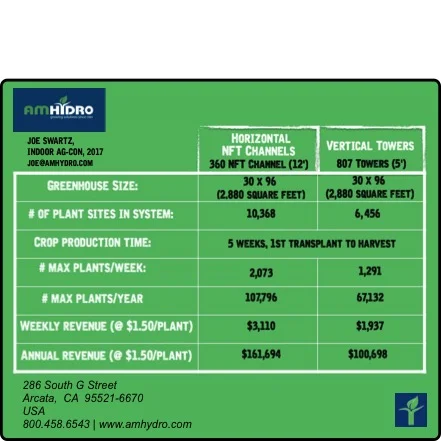

To this end, one of the latest and most heralded “cool, flashy, and sexy” technologies attempting to increase production is to hang NFT channels vertically—- essentially stacking production UP, instead of OUT. We’ve seen quite a bit of this “vertical revolution” these past few years.

Initially, these “towers” were promoted for use in greenhouses. Despite significant issues with inconsistent growth (due to insufficient light reaching the plants toward the bottom), we began to see this technology proliferate and it began to move indoors as well. At the present time, these towers are a staple in many of the major “shipping container” farms, as well as some indoor growing applications.

Over the past 30 years, we’ve seen them all. This recent “farming revolution” has certainly received a lion’s share of publicity and accolades from the media and others. The claim is that these vertical tower systems are “revolutionary technology” and are to be the “future of food.” However, many questions have been raised about the actual effectiveness, sustainability or productivity of trying to install growing systems and crops into a metal box or stacking them up inside a building that was not designed for horticultural production. Despite the “cool factor” of making such a choice, wouldn’t it make more sense to put our production into a properly designed growing environment, such as a greenhouse? This is certainly a very valid question, one that I will be addressing in depth in an upcoming article. In the meantime, let’s look at the effectiveness (?) of hanging our plants vertically.

NFT vs Towers

So why DO we see so many shipping containers and indoor farms promoting the use of vertical towers?

The practice is based on the concept that hanging NFT growing channels vertically, up and down, utilizes more growing space and achieves higher plant populations. “Look!” they say, “When we plant the crops on a vertical plane, we achieve higher production than those horizontal NFT systems!”

It makes sense, doesn’t it, that growing plants vertically would allow more plants per square foot. I mean, a vertical tower would provide more plants and thus higher production, right?

Actually, the answer is no.

When you look closer and break it down, the numbers tell a very different story.

Here are two similar growing systems. One is a horizontal NFT system, demonstrating proper real estate management, and the other is a system of vertical hanging NFT towers-utilizing vertical height in an attempt to get more plants in a given footprint.

When we look at these two systems, we can see that we actually get MORE plants and HIGHER overall production with horizontal NFT in EXACTLY the same footprint.

So how do we do this? By properly utilizing our technologies and real estate management.

It’s really as simple as that.

I know this appears to fly in the face of logic and common sense, but when you examine the data, you see that it’s true.

Despite outward appearances, the horizontal NFT system actually contains almost 4 thousand more plant sites than the vertical towers, all while still maintaining the proper parameters for crop growth.

Given the same crop growth rates in both systems, the horizontal system yields over 40 thousand MORE harvestable crop plants per year than the vertical tower system.

40 thousand more.

If we’re selling lettuce for example, at $1.50 per head, we are looking at more than $60,000 per year in additional revenue……all with essentially the same production costs.

Do I want a simple technology that yields $60,000 more in revenue per year?

You bet I do.

High Quality – High Yields – Consistent Production. Every day, all the time.

This is why you MUST look closely at ALL technologies……….what they CAN do for you…….as well as what happens when you fail to evaluate them properly.

Failure to correctly analyze just his one technology can mean the difference in over $60,000 PER YEAR in additional revenue in the same amount of growing area, with the same basic financial inputs. That’s a STAGGERING difference!

Proper “real estate management” at correct growth parameters = good crops! You can’t replicate this with a vertical system!

With the technological explosion going on around us, it is easy to see the “flash” of a particular technology but miss the substance. Don’t make this mistake. When looking at those “cool” or “sexy” technologies, did deeper.

Take a good look at the crops.

Are they of appropriate market size? What is the quality like? Are the plants all consistent throughout the crop?

Look beyond the wall of green. Look at the individual crops.

Could you sell these on the open market at a price point that is economically sustainable?

If you don’t know the answers to these and other questions, I strongly suggest that you look a little deeper. We can all TELL you about our technologies, and what’s effective. But, if we can’t also SHOW you, then none of what we say is credible. Evaluating with this critical eye will serve you well as you decide on the technologies to best serve your needs.

Indoor Farming Plus Made In USA LED Grow Lights: Profile 1.3

Indoor Farming Plus Made In USA LED Grow Lights: Profile 1.3

GREENandSAVE Staff

This is one of the profiles in an ongoing series covering next generation agriculture. We are seeing an increased trend for indoor farming across the United States and around the world. This is a positive trend given that local farming reduces adverse CO2 emissions from moving food long distances. If you would like us to review and profile your company, just let us know! Contact Us.

Company Profile: Farmbox Greens

Farmbox Greens is Seattle's first indoor vertical farm.

Here is some of the “About Us” content: At Farmbox Greens we approach agriculture in an innovative way. We grow in square feet, not acres. We use energy efficient LEDs and a fully climate controlled environment to produce the freshest produce that can be on your plate within hours of harvest.

Since planting the first seeds of our urban farm in 2011 we’ve set out to change where and how great produce is grown. We’ve created a sustainable farm where the harvest cycle is days not months. Our farm uses 90 percent less water than traditional farming, is pesticide and herbicide free and is fresh year round.

Seattle’s first indoor vertical farm to grow produce, we make fresh local greens more accessible. We use a small amount of space (just a few hundred square feet) to grow thousands of pounds of greens annually. We work hard to grow local produce because we think it tastes better. Go ahead and taste it, we think you’ll agree!

Here is the link to learn more: http://www.farmboxgreens.com/.

To date, the cost of man made lighting has been a barrier for indoor agriculture. A new generation of LED lighting provides cost effective opportunities for farmers to deliver local produce. Warehouses and greenhouses are both viable structures for next generation agriculture. Here is one example of next generation made in USA LED grow light technology to help farmers: Commercial LED Grow Lights.