Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

NatureFresh™ Farms Receives Top Honors For TOMZ®, OntarioRed™, and Yellow Bell Peppers at Greenhouse Vegetable Awards

NatureFresh™ Farms Receives Top Honors For TOMZ®, OntarioRed™, and Yellow Bell Peppers at Greenhouse Vegetable Awards

Leamington, ON (June 19th, 2017) – Long known as the Tomato Capital of Canada, Leamington, Ontario once again hosted its annual Greenhouse Vegetable Awards this past weekend. Showcasing the best greenhouse vegetables from leading North American growers, family owned NatureFresh™ Farms took home many top honors including the coveted ‘Best Overall Tomato’.

“Receiving these awards is more than just about showcasing the best that we grow, it is about our commitment to pushing the category in the right direction in delivering consistent flavor across the category”, commented Peter Quiring, Owner & President. “The TOMZ® Red Cherry Tomato is a game changer; super sweet, bite-sized, crunchy, with the perfect balance of acidity, the real winners are the consumers who can enjoy this premium snacking tomato year-round, it’s hands down our grower’s choice”, said Quiring.

NatureFresh™ Farms took top honors in the following categories:

- Best Overall Tomato; TOMZ® Red Cherry Tomato

- Best Bite Sized Tomatoes; TOMZ® Red Cherry Tomato

- Best Cocktail Tomato; TOMZ® Sweet Red Cocktail Tomato

- Best Beefsteak Tomato; OntarioRed™ Red Beefsteak Tomato

- Best Yellow Bell Pepper

This is the second year in a row that NatureFresh™ Farms has won the Best Cocktail Tomato Award as well as the Best Yellow Bell Pepper Award, which is a fantastic accomplishment considering strong competition from other varieties in the market place.

“Our retail customers love our TOMZ® Snacking Tomato program because of the unique and flavorful varieties we grow,” said Matt Quiring, Executive Retail Accounts Manager. “It’s not just about selecting the right seed to grow, it is about the growing environment, the plant nutrition, and the grow to market strategy we employ year-round from our farms to ensure we deliver the best we grow, regardless of the season. Our TOMZ® Red Cherry is the best snacking tomato available on the market, hence why it won the Best Overall Tomato Award”, said Quiring.

NatureFresh™’s TOMZ® Snacking Tomatoes were a finalist for Best New Vegetable Award at the United Fresh Convention in Chicago recently.

“We trial more than 300+ different varieties each year to ensure we are always delivering the most flavorful varieties available worldwide”, said Benny Teichroeb, Trial Program Coordinator. NatureFresh™ Farms conducts its product research & development in its 2.5 acre Trial Greenhouse & Discovery Center in Leamington.

All funds raised from the Greenhouse Competitions go to R.E.A.CH. International. This local charity has raised hundreds of thousands of dollars to build schools & clinics, drill water wells, and sponsor and care for impoverished children in Uganda, Africa.

To learn more about NatureFresh™ Farms, visit NatureFresh.ca.

-30-

About NatureFresh Farms™ -

NatureFresh Farms™ has grown to become one of the largest independent, vertically integrated greenhouse vegetable growers in North America. Growing in Leamington, ON and Delta, OH, NatureFresh™ Farms prides itself on exceptional flavor & quality. Family owned NatureFresh Farms™ ships Non-GMO greenhouse grown produce year-round to key retailers throughout North America.

SOURCE: Chris Veillon | chris@naturefresh.ca

Director of Marketing | NatureFresh™ Farms

Going Indoors To Grow Local

Going Indoors To Grow Local

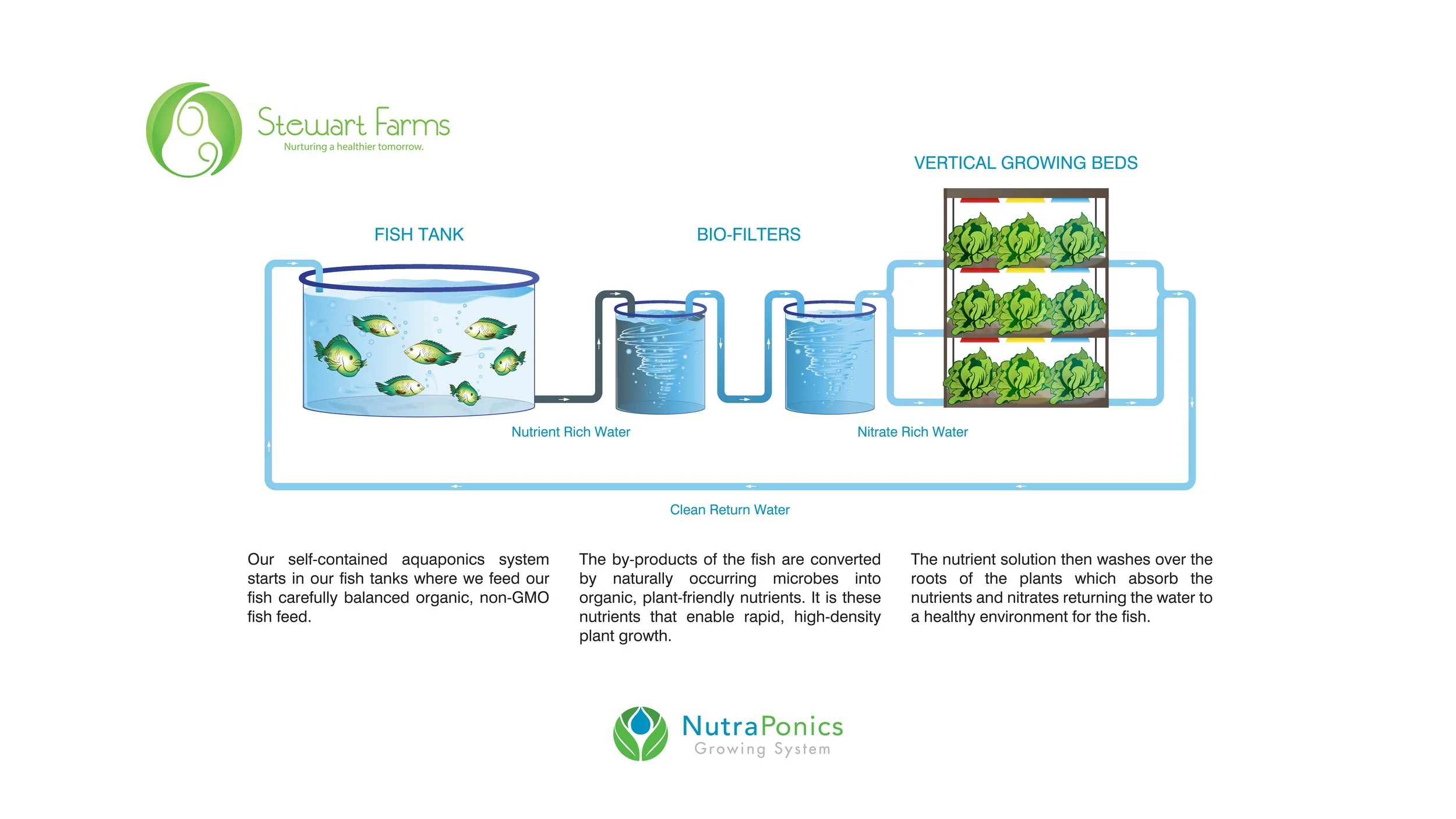

Alberta company wants to license its hydroponics-aquaponics system to others

Posted Jun. 15th, 2017 by Barbara Duckworth

Nutraponics employees include aquaculturalist Geoff Harrison, left, plant specialist Stephanie Bach and CEO Tanner Stewart. The company grows fresh produce at its facility near Sherwood Park, Alta. | Barbara Duckworth photo

SHERWOOD PARK, Alta. — Providing fresh local produce to Canadians year round could be achieved with a new farming concept that combines horticulture with aquaculture.

NutraPonics, which opened in 2015 near Sherwood Park, is dedicated to supplying the local produce market and supporting local suppliers.

Since last December, it has been selling fresh romaine lettuce, kale, Swiss chard, basil and arugula every week.

The produce is marketed through the Organic Box, a privately owned company in Edmonton that supplies its customers with individually selected orders of locally grown food through online sales and from a store front.

“Everything is marketed as local. We are 32 kilometres from the Organic Box, so that is as local as you can get,” said Stephanie Bach, a plant scientist with the company.

Added chief executive officer Tanner Stewart: “We are hoping to provide less need for products from very far away.”

Stewart, who invested in the company three years ago, is among about 50 private shareholders in the company, which plans to franchise the concept of growing produce indoors in a controlled environment.

“Our model is to not build our own farms and create a massive amount of in-house production,” Stewart said.

“Our business model is to build and license these facilities.”

Former CEO Rick Purdy and a company owner started the system. Purdy researched hydroponics to grow food in water and added aquaponics to use byproducts from fish to create a new growing system.

This farm is considered a demonstration facility, where staff can research the best use of the fish, water and plant development.

There are three tanks full of tilapia fish. The nutrient-enriched water from the tanks is delivered to the plants, which are grown in five layers in a controlled atmosphere.

About 1000 sq. metres of growing space are available, where plants are under red and blue LED lights and fed hydroponically.

Under Bach’s supervision, seeds are planted in a special volcanic rock growing medium from Ontario. They sprout within a week and are then transplanted to the main growing rooms. The plants can be harvested within four weeks for same day pickup by clients.

The company employs about 10 people and while each person might have an official job description, the reality is everyone helps with the fish as well as planting and harvesting.

There is no plan at this time to sell the fish.

“The economics of land-based fish farms is fairly fixed,” said Stewart.

“In order to do business, you really have to look at 200 tonnes of production per year to reach economies of scale. This is two tonnes a year.”

This farm sits on 19 acres, but Stewart envisions any empty urban warehouse as a viable growing operation.

NutraPonics is an agriculture company which sells proprietary growing technologies. These technologies utilize symbiotic relationships between plants and fish known as aquaponics to grow nutrient-rich herbs, vegetables and fish in an enclosed, controlled environment. For more information please visit http://www.nutraponics.ca/home

Whitehorse, Yukon, will be the location of the next farm. The goal in the northern community is to grow and sell produce year round at a competitive price with less freight and a longer shelf life.

Stewart also hopes to develop a facility near his hometown in New Brunswick.

The produce is sold at a competitive price. For example, a bundle of romaine lettuce is offered at $6.25 in a 284 gram package.

“You have to be careful in an emerging industry like ours.” Stewart said.

“You really have to make sure you are focused on this as a business, you need to grow your produce at a certain price and you need to make sure your consumers are going to be happy to buy it at that price.”

He estimated that start-up costs are comparable to any new farm and considers this a stable business model with a decent rate of return on investment.

The difference could be a faster turnaround time from construction to the time saleable product is ready.

“Once we get up and running and all the capital costs are done, then we can produce on a consistent basis, week after week, in fairly short order after we turn the building on,” he said.

Innovative Thinking and Technology: The Key to Solving Global Problems

Innovative Thinking and Technology: The Key to Solving Global Problems

Austin Belisle - June 1, 2017

This blog was guest-written by Brandi DeCarli, Founding Partner of Farm from a Box. She’ll be guest-speaking during the “Global Problem Solvers Who are Guardians of Our Planet” session of the Women Rock-IT series on June 15th.

Every aspect of our modern-day lives has been impacted by technology. From cloud and robotics to digital currency and drones, our lives are inextricably tied to the technology that surrounds us. While farming may not be the first thing that comes to mind when thinking of technology, it has played a key role in changing the face of agriculture and our global food system.

In the past 50 years, the Green Revolution has pushed to increase crop yields through large-scale intensification of single crops. Advances in mechanized farming allowed for larger and larger acreage to be farmed. By focusing on the large-scale intensification of a single crop, the natural checks and balances that diverse ecosystems provide were no longer in place.

To maintain production, it required heavy use of fertilizers and pesticides, which has directly impacted soil fertility and ecosystems around the globe. Now, with 40% of our agricultural soil degraded and 70% of our freshwater resources being gulped up by agriculture, it is clear that our current approach is not sustainable.

While advances in technology have enabled global agricultural production to increase with our growing population, those gains came at an unprecedented environmental cost. As we work to feed a growing global population, the environmental pressures will continue to increase.

By 2050, the world’s population is expected to grow by more than two billion people. Half will be born in Sub-Saharan Africa, and another 30 percent in South and Southeast Asia. Those regions are also where the effects of climate change are expected to hit hardest.

So, how can make sure that the growing need for food worldwide is met in an ecologically sustainable way? And what role can technology play? The opportunity may be in shifting our focus from mass production to production by the masses.

An estimated 70% of the world’s food comes from small, rural farms that are no bigger, on average, than two acres. And despite the increase in large-scale industrialized farms, small, rural farms are still the backbone of our global food supply. But these rural areas are often the most vulnerable to the effects of climate change.

The challenges of drought, degraded soil, and inefficient and labor-intensive methods contribute to and exacerbate low and unreliable crop production. Without access to the infrastructure or technologies that can support a productive farm, farmers will either struggle with low yields, depend on chemical inputs that further deplete the soil, or rely on outside aid.

This is where Farm from a Box comes in.

Farm from a Box works to bridge the “access” gap by providing a complete, off-grid toolkit for sustainable, tech-powered agriculture. Built from a modified shipping container, each unit contains a complete ecosystem of smart farm technologies to enhance agricultural productivity; from renewable power and micro-drip irrigation to Information and Communications Technology equipment.

Designed as the “Swiss-Army knife” of farming, this mobile infrastructure provides all the tools needed to support a two-acre farm. By empowering farmers to grow and sustain food production at the community level, we build greater resilience to climate shocks, boost livelihoods, and help bridge the access gap by making healthy food locally available.

With its own off-grid power, Farm from a Box can act as its own micro-grid in remote locations; drip irrigation helps save water and stabilize crops through drought conditions while also extending the growing season; internal cold-storage helps keep crops fresher longer, reducing post-harvest loss by 80%; Wi-Fi connectivity improves information access and exchange; and a cloud-based IoT system helps monitor production and efficiencies.

By introducing micro-irrigation, we can extend the growing season and better support a wide variety of crops throughout the year, while lowering the amount the water used by applying it directly to the plant. The off-grid power array and storage provide a reliable energy source to power the pump, move the water through the irrigation lines, cool the internal cold storage area, and support the charging of auxiliary needs.

We have also connected each unit with Wi-Fi capabilities and a complete IoT system to improve operational efficiency, optimize water and energy use, and provide guidance on farm management and market information. Because we have integrated sensors on all of the primary systems, we can monitor and control the performance of the system, and also set alerts for when a component dips below or exceeds certain levels.

Let me give you an example of how this applies in a real-world situation. We recently teamed up with the United Nations World Food Programme Tanzania and WFP’s Innovation Accelerator to support food and nutrition security for refugee and host communities. Our Farm from a Box system will be used to increase the availability of nutritious crops, provide low-cost agricultural commodities and, through increased production, boost the income levels for both refugees and the surrounding host communities.

Because the farm is operating in a remote location in eastern Tanzania, information becomes a vital component to ensuring the system is working as it should be, and the farmers have the data they need to know what is happening and why. Through our cloud-based IoT system, both the community and the WFP has open access to see how much energy the solar panels are producing, how much water is being used, and if the overall system is functioning properly.

Now, technology for the sake of technology isn’t a standalone solution; how it is utilized in overall value creation is where we find the real impact. By marrying technology with small-scale regenerative farming practices, we can improve soil quality, reduce dependence on outside inputs, conserve water, and build up nutrients.

Techniques like composting, crop rotation and diversification, cover cropping, and no-till practices nurture the soil’s fertility and help produce a healthier crop. By shifting our focus from industrialized agriculture to local organic agriculture, we can potentially convert carbon from a greenhouse gas into a food-producing asset.

Farm from a Box is just one of many innovations that are working to empower smallholder farmers with sustainable solutions; there are vertical farm systems, small farm robots that automate field work, drones that use near-infrared and thermal sensors to “see” how plants are doing. Technological innovations like these can help us achieve better health, well-being, and equity throughout our planetary system as a whole.

But we need creative solutions, and sometimes that requires thinking outside of the box. I don’t come from a technological background, nor does my business partner, but we saw a problem and thought, “There must be a better way.” We all have the power to change our world for the better. Food is something that connects us all and has a direct impact on our everyday lives and environment.

When we first set out to start Farm from a Box, our intention was to create a mobile infrastructure that could provide people with the tools they need to grow their own nutritious food. Over time, that idea has grown; we now see Farm from a Box as a tool that could transform local production and nutritional security globally.

Whether it is a local school, community group, or remote village in an underdeveloped country, smallholder farmers are the ecological gatekeepers to building a more sustainable and equitable food supply. Technology has the potential to help solve the intractable problems facing humanity and will continue to play an increasingly vital role in global food security and planetary health. But it will require innovative thinking from all of us to achieve it.

Why High-Tech Urban Farms Won't Displace Community Gardens

Why High-Tech Urban Farms Won't Displace Community Gardens

Jody Allard/May 16, 2017

To serve neighborhoods, they need to work together.

High-tech innovations can help urban farmers grow anywhere. (Open Agriculture Initiative, MIT Media Lab)

Urban farmers are increasingly leveraging technologies like machine learning and smartphone integration to build high-yield farms in small urban spaces. And while it may seem that those innovations upend the “slow food” idea of working together in the dirt to grow organic zucchini or lettuce, sharing time and crops with neighbors, the success of these higher-tech projects may hinge on the support of local community gardeners.

In theory, a commitment to building a local food system that meets the needs of urban dwellers without relying on long-distance transportation methods—which can leave a substantial carbon footprint—is great. Many contemporary urban farms are cropping up in direct opposition to large-scale agricultural operations that are perceived as harmful to people and the environment. But in practice, urban farmers have struggled with limited real estate, high-priced infrastructure, and other challenges unique to the city environment. (Chicago’s green rooftop initiatives, for instance, were successful in revitalizing interest in urban farming, but even the 3.5 million square feet of urban farmland on 500-plus rooftops has failed to make a real dent in the city’s food demands.) Those are constraints that high-tech innovations aim to solve.

HIGH-TECH HELP FOR URBAN FARMERS

Housed on only one-eighth of an acre, Urban Produce in Irvine, California, harvests the volume of crops typical of a 16-acre facility. The indoor vertical farming operation specializes in growing organic microgreens, herbs, and leafy greens in a controlled environment. While Urban Produce has only one location today, they have big aspirations. "In five years, we hope to build 25 urban farms worldwide. Imagine cities, corporate campuses, master-planned communities, cruise ships, and military bases growing their own local, organic produce," says Urban Produce CEO Ed Horton. "In 20 years, I expect we’ll be growing organic produce on the International Space Station."

Space farming aside, high-yield urban farms that produce thousands of pounds of food are only one piece of the tech-enabled urban farming puzzle. Other initiatives are focusing on bringing families back into the fold with self-contained farms that are designed for use in small city apartments. Grove Garden combines an aquarium with a garden to create a closed-loop ecosystem: you feed the fish, their water is cycled to water the plants, and the plants grow to feed you. Grove Garden uses one-tenth of the water of traditional farming methods, and it's all remotely manageable by a smartphone app.

Still in the fundraising stage, Lyfbox is another permaculture garden option that can produce 40 different crops in a few feet of growing space. But Lyfbox goes one step further with an app that leads urban farmers from planting to cooking, reducing food waste by providing recipe suggestions when a crop is ready to harvest. The app even connects farmers with their community to help them buy or sell their crops from their smartphones.

The most productive urban farms have one thing in common: they rely on tightly controlled environments in order to maximize crops year-round, regardless of local growing conditions. In these environments, growing conditions are automated based on a combination of farming wisdom, trial-and-error, and growing models. But until recently, there was no such thing as an ideal "recipe" for growing conditions—making each smart farming environment only as good as the data it has available.

MIT's OpenAg initiative, in partnership with Sentient, hopes to change that. Using the power of 2 million computers located in 4,000 sites worldwide, researchers set out to discover whether advanced artificial intelligence could offer farmers insight into the optimal way to grow crops. Researchers began by testing basil in growing chambers called "Food Computers," which are similar to the type of closed-loop environments used by many urban farmers. Soon, the AI made a surprising discovery: basil grows best when exposed to continuous sunlight. By the end of the 18-week experiment, researchers had collected three million points of data, per plant, per growth cycle. This data is publicly available to anyone who wants to work with it, and in the future, researchers hope to program the AI to adapt its growing conditions based on what it learns throughout the growth cycle.

MIT’s food computer information is open data, so any farmer can build one. (Open Agriculture Initiative, MIT Media Lab)

"Farmers know a lot about the conditions in their own environment, but not even the best farmer knows how to grow the plants optimally when you can control all these environmental factors at will," says Risto Miikkulainen, vice president of research at Sentient. "We believe these recipes will help farmers grow the best crops, with the most yield, in the places that need [them] most. This would not only reduce the cost of exporting food across the world, but also reduce the amount of energy required to grow plants. We might even see food being grown directly in grocery stores."

If grocery stores doubling as farms sounds outlandish, consider how unlikely growing meat in a laboratory would've sounded a decade ago. The technology exists to make these goals a reality, but it will take more than technology to revolutionize urban farming. Their success relies on a community that's interested in and educated about sustainability, and is willing to invest in it—and that's where small community gardens can make a big impact.

COMMUNITY GARDENS HAVE DEEP ROOTS

With increasingly divergent technologies and resources, you might expect community gardeners to be at odds with the new generation of high-tech urban farmers. As urban farms continue to adopt new technologies to enhance their crop yields, space constraints could eventually pit the two against each other. Are community gardeners excited by the prospect or afraid they'll lose the community that made their gardens so successful?

In many cases, today's community gardens exist to solve a problem very different from the one they were aiming at in the 1890s, when Detroit and other cities looked to them to offer residents a place to raise a homegrown solution to an economic recession that left laborers unemployed and hungry. Now, many gardens are an antidote to isolation from nature and neighbors. While some gardeners enjoy the financial benefits of selling food, most community gardens aren't intended to feed their communities entirely. Unlike large-scale urban farming operations, their primary focus is on teaching sustainable farming principles and connecting with members of their communities.

Higher-tech innovations won’t necessarily compete with community gardens that are deeply rooted in their communities. (Carlos Jasso/Reuters)

Karin La Greca is on the board of the Fresh Roots Farm, a two-acre nonprofit organic educational farm in Mahweh, New Jersey. While each volunteer receives some of the food the farm produces, she says it's the community, not the food, that attract volunteers to the farm. "Community gardens give a sense of place to the residents of the community," she says.

Sable Bender used to work for an organic farm that relied on draft horses to plow the fields. Now, she works for the largest greenhouse manufacturer in the country and does her own farming on a smaller scale, helping out at a local school garden. She sees larger urban farms and community gardens as essential to each other's existence. "As people learn about urban farms, it encourages them to get involved with a community garden and it creates a desire to know more and try growing something for themselves," she says. "On the other hand, you have people who have been involved with a community garden taking on larger urban agriculture projects."

La Greca agrees. Far from being afraid of the impacts of urban farms on her own small community garden, she welcomes the opportunity to teach sustainable farming principles to a larger audience. "Community gardens allow residents to connect with nature, something that has been lost along the way," she says. "As community gardens move forward both in municipalities and schools, I believe farmers will get the respect they deserve and the community will support the farmers and collaborate together to change our food system for a better future."

Artificial intelligence and smartphone-integrated farms might seem like strange bedfellows for a movement that prides itself on returning to a more "natural" state. Talking casually about machine learning and closed-loop ecosystems, these aren't your grandparents' farmers—and they may be exactly what's needed to make their vision of sustainable urban farming a reality.

Kiss the Ground Releases The Compost Story With a Celebrity Cast

Created in collaboration with Elevate Films, Kiss the Ground has released The Compost Story, a 6-minute video about why compost is a regenerative solution for depleted lands

Kiss the Ground Releases The Compost Story With a Celebrity Cast

Created in collaboration with Elevate Films, Kiss the Ground has released The Compost Story, a 6-minute video about why compost is a regenerative solution for depleted lands. Kiss the Ground wants to educate people how to turn biodegradable waste into healthy soils. This process also works to reduce the effects of climate change. Combining a celebrity cast of Rosario Dawson, Amy Smart, Adrian Grenier, Paul Blackthorne, and Kendrick Sampson, this video invites people everywhere to see compost in a completely new light.

Kiss the Ground believes that compost is a regenerating, probiotic solution for depleted land. Compost could also play a major role in rebalancing the world’s carbon cycle. Turning polluting waste streams into a valuable resource is a win-win proposition, says Kiss the Ground.

This message is a follow-up to The Soil Story, a 5-minute video on how soil can sequester carbon from the atmosphere to balance the climate.

The Urban Farmer: Interview With João Igor of CoolFarm

The Urban Farmer: Interview With João Igor of CoolFarm

In Future trends Posted on May 25, 2017

Created out of necessity, CoolFarm now offers smart farming solutions that allow you to plug, play, and produce fresh food all year round. Get the inside scoop on how co-founder João Igor has discovered a novel way to make agriculture an integral part of urban life.

If you haven’t heard about urban farming, you must have been living under a rock for the past few years! City-based agriculture offers the opportunity to have healthy food in abundance, at a fraction of the cost, by growing only what we need, close to home.

Urban ag startups have boomed in the last few years, offering everything from unorthodox growing setups to soil sensors, hydroponics and all manner of crop data analytics. We’ve recently spoke to João Igor of CoolFarm, a Portuguese startup operating in the smarter food and in the greenhouse sustainable agriculture area. Here’s their take on the potential for urban farming.

“I found myself suffering from health problems due to the fast food that we consume inside cities, I’ve also seen my friends and family suffering from the same issues. I wanted to do something to fight this, and I ended up in finding the right team of co-founders for this project.”

Together, we started building the CoolFarm technology in order to make farming easier and to bring fresh and nutritious food to cities, close to the people.

New Sustainable Model

CoolFarm offers indoor farming solutions for production of high quality food. Their solutions provide maximum efficiency and profitability. Their control system, called CoolFarm in/control is plant-centred. Using an intuitive dashboard, growers are able to monitor and contnrol all their farms at once, anywhere, anytime. Artificial intelligence and machine learning algorithms ensure optimized crop production, as well as efficient management of resources.

“We also offer to the market the CoolFarm Eye, an innovative cloud based optical sensor made to capture plants’ area and plant greenness, monitoring crops through time,” explains João. “Using the Eye, growers can make wiser and straight forward decisions to achieve the best results.”

2017 marks the launch of CoolFarm in/store, a closed and vertical system with a clean and climatized environment inside, perfect to grow premium seedlings, microgreens, leafy greens, herbs and flowers. Reportedly, it uses 90% less water than common agriculture and it does not need pesticides or herbicides. It is modular, with each module covering nearly 100 square meters of the production area.

Intelligent and highly intuitive, the system is aimed at growers, food distributors, grocery and supermarket chains, research centers, medical centers, and communities.

The system is equipped with two columns of movable hydroponic growing beds, one vertical lift, a fertigation system, topnotch sensors to measure all the variables concerning the plants, LED grow lights, CoolFarm in/control system and an antechamber.

Cities Turning Green

Throughout the world, urban farming is becoming an integral part of the urban landscape. CoolFarm is part of the booming trend. However, in order to emerge into a viable industry solution, CoolFarm needs agents and distributors worldwide, as well as adequate support from governments.

“Stakeholders must jointly address food and sustainability issues, and promote novel technologies and solutions for better farming,” says João. Although there is an urgent need for producing health, tasty, environmentally sustainable food, redesigning the agricultural system would not be straightforward.

As a creative person and as a designer my job is to build new and intuitive solutions, as well as to communicate them in the best way; as a tech guy I need to bring top notch technology, like robotics, for fields in need.

Sprouting Imaginative Solutions

The European startup ecosystem has bred numerous success stories, and CoolFarm is one of them. “We’ve gained a lot of attention, especially from the media, which is essential for any startup business trying to create brand awareness.” They also learned a lot about marketing, business, and securing funding and capital.

However, the biggest lesson, by far, is avoiding money from people that don’t understand complex markets such as agriculture.

“In general, European incubators and accelerators are good. We have excellent people behind the scene, and Europe doesn’t lack experience or knowledge.”

Apparently, launching a startup in Europe was the right decision: the team now counts nearly 20 people creating indoor farming solutions, from horticulturists and biologists, software and hardware engineers, web, mobile and product designers, marketing and business experts.

If you want a sustainable business in agriculture, avoid money from people who don’t understand such a complex market.

Early product is strong, but their roadmap is much more exciting. “We want to install the in/store solution at universities, hospitals, supermarkets, cruises, buildings,” says João, adding that they want to grasp a significant portion of the market with their new product. “The next 18 months are going to be game changing for CoolFarm. Watch and see!”

Kimbal Musk Says Food Is The New Internet

Kimbal Musk Says Food Is The New Internet

Former tech entrepreneur Kimbal Musk’s ambitions for innovation in sustainable farming are as grand as his brother Elon’s for space travel and electric cars

URBAN COWBOY | Kimbal Musk at Koberstein Ranch in Colorado. “He’s got good judgment overall and has been put through the ringer a few times,” says his brother, Elon. PHOTO: MORGAN RACHEL LEVY FOR WSJ. MAGAZINE

By Jay Cheshes

May 25, 2017 10:52 a.m. ET

ON A BRISK WINTER morning, Kimbal Musk is an incongruous sight in his signature cowboy hat and monogrammed silver K belt buckle—his folksy uniform of the past few years—as he addresses a crowd outside a cluster of shipping containers in a Brooklyn parking lot. Inside each container, pink grow lights and fire hydrant irrigation feed vertical stacks of edible crops—arugula, shiso, basil and chard, among others—the equivalent of two acres of cultivated land inside a climate-controlled 320-square-foot shell. “This is basically a business in a box,” Kimbal says, presenting his latest venture to its investors, friends and curious neighbors.

Square Roots, his new incubator for urban farming, aims to empower a generation of indoor agriculturalists, offering 10 young entrepreneurs this year (chosen from 500 applicants) the tools to build a business selling the food they grow. It will take on and mentor a new group annually, with more container campuses following across the country. “Within a few years, we will have an army of Square Roots entrepreneurs in the food ecosystem,” he says of the enterprise, launched last November with co-founder and CEO Tobias Peggs—a British expat with a Ph.D. in artificial intelligence—across from the Marcy Houses, in Bedford-Stuyvesant (where Jay Z, famously, sold crack cocaine in the 1980s).

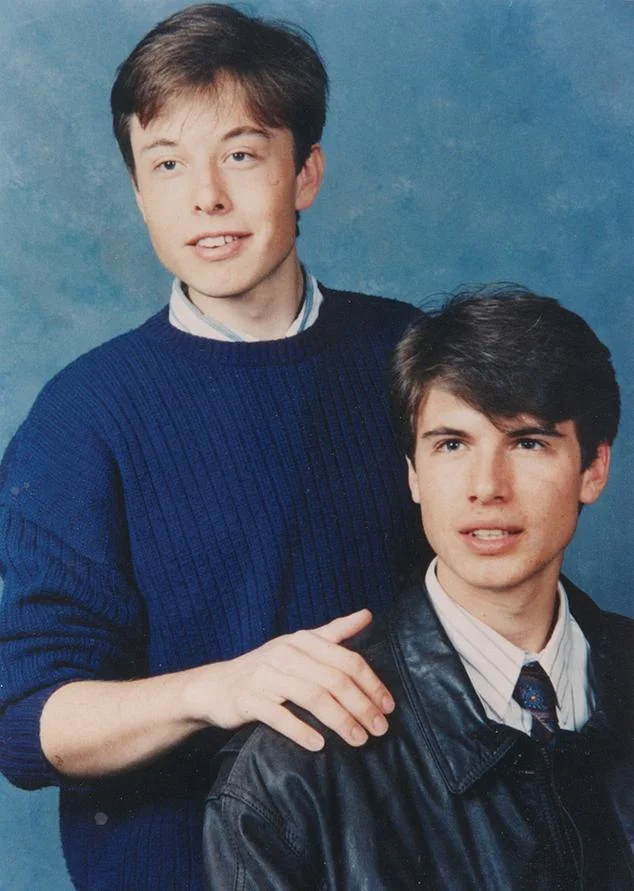

Clockwise from far left: Elon (left) and Kimbal, at 17 and 16. PHOTO: COURTESY OF KIMBAL MUSK

Entrepreneurial drive runs in the family for Kimbal, 44, a close confidante of his brother, Elon, and a board member (and major shareholder) at Tesla and SpaceX. “If something happens to me, he can represent my interests,” says Elon of his kid brother (one year younger) and worst-case-scenario proxy. “He knows me better than pretty much anyone else. He’s got good judgment overall and has been put through the ringer a few times.”

Kimbal, a veteran of the tech world, has in recent years shifted his focus to food—or the “new internet,” as he called it in a 2015 TEDx Talk. With the missionary zeal his brother brings to electric sports cars and private space travel, Kimbal has launched a series of companies designed to make a lasting impact on food culture, through restaurants, school gardens and urban farms.

‘‘I want to reach a lot of people. We’ve put too much emphasis on preciousness with food.’’

—Kimbal Musk

Since 2010, a nonprofit venture supported by the Musk Foundation has built hundreds of Learning Gardens in American schools, installing self-watering polyethylene planters where kids learn to grow what they eat. Meanwhile, his Kitchen family of restaurants—promising local, sustainable, affordable food—is rapidly expanding across the American heartland, with five locations opening this year, including new outposts in Memphis and Indianapolis. Kimbal hopes to have 50 “urban-casual” Next Door restaurants, 1,000 Learning Gardens and a battalion of container farms by 2020. “I want to be able to reach a lot of people,” he says. “I think we’ve put too much emphasis on preciousness with food—and the result is a real split between the haves and have nots.”

The Musk brothers grew up in South Africa during the last gasp of the apartheid era. Kimbal, the more gregarious sibling, got his start selling chocolate Easter eggs at a steep markup door-to-door in their Pretoria suburb. “When people would balk at the price, I’d say, ‘You’re supporting a young capitalist,’ ” he recalls. While Elon spent hours programming on his Commodore VIC-20, Kimbal tinkered in the kitchen. “If the maid cooked, people would pick at the food and watch TV,” he says. “If I cooked, my dad would make us all sit down and eat ‘Kimbal’s meal.’ ”

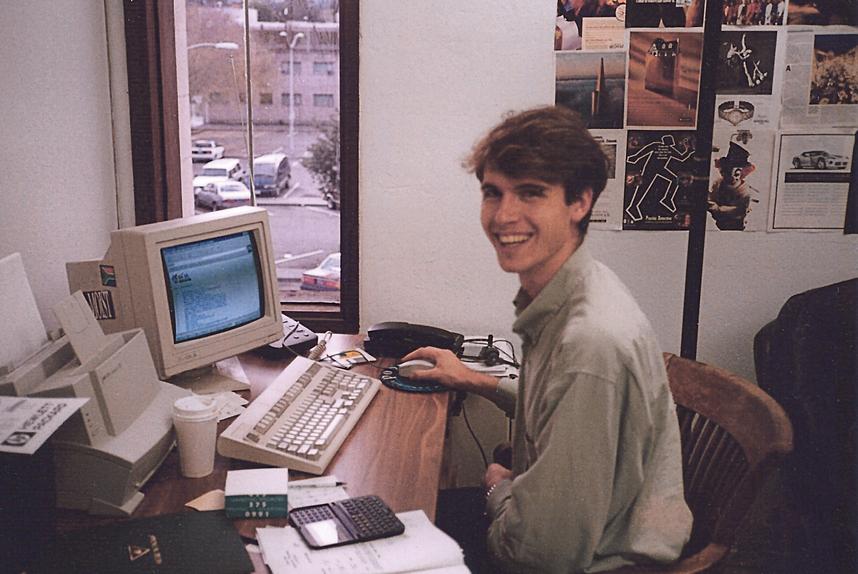

Kimbal in the kitchen, 2002. PHOTO: COURTESY OF KIMBAL MUSK

After high school, the brothers moved to Canada, both enrolling, for a time, in Queen’s University in Kingston, Ontario (Kimbal studied business, Elon physics). In 1995, they founded a company together in Palo Alto, California, the online business directory Zip2. “I had come over as an illegal immigrant,” Kimbal says of the move. “We slept in the office, showered at the YMCA.”

The brothers were close but also intensely competitive. Sometimes work disputes would get physical. “In a start-up, you’re just trying to survive,” says Elon. “Tensions are high.” Once they could afford it, Kimbal cooked for the whole Zip2 team in the apartment complex they shared. In 1999, the Musks sold their business to Compaq for $300 million. Though they remain investors and advisers in each other’s companies, their official partnership ended there.

HOME FRONT | Kimbal’s mother, Maye (right), with her parents at the family farm near Pretoria, South Africa, 1978. PHOTO: COURTESY OF KIMBAL MUSK

After Elon launched the payment site that would later become PayPal , Kimbal, on a lark, enrolled in cooking school. He finished his studies at the French Culinary Institute in New York in late summer 2001 with no intention of pursuing a career in food. A few weeks later, after two planes flew into the Twin Towers, he spent the next six weeks as a volunteer cook, feeding firefighters out of the kitchen at Bouley. At the end of it he wanted nothing more than to open his own restaurant. “After that visceral experience, I just had to do it,” he says.

Searching for a dramatic change in scenery, post-9/11, Kimbal and his new wife at the time, lighting artist Jen Lewin, set out on a cross-country road trip looking for a place to put down roots and raise a family. They settled on Boulder, Colorado, “a walkable town, a great restaurant town,” says Kimbal at the 140-year-old Victorian home they bought there in 2002 (they have two sons and have since divorced).

The house he now shares with food-policy activist Christiana Wyly—with a cherry-red Tesla parked out back—is a few blocks from the original Kitchen, an American bistro he launched in 2004 with chef-partner Hugo Matheson, a veteran of London’s River Cafe. The Kitchen sourced ingredients from local farmers, composted food waste, ran on wind power and used recycled materials in its décor. For its first two years, the two partners worked full-time as co-chefs, taking turns composing the menu, which changed every day. Eventually, the daily grind became too much for Kimbal. “I got a little bored with the business,” he says.

Kimbal in his Zip2 office, 1996. PHOTO: COURTESY OF KIMBAL MUSK

By 2006, he was back working in tech, as CEO of a social-media-analytics start-up. The Kitchen might have remained a sideline if not for a series of unlikely events. On February 10, 2010, at a TED conference in California, he listened to Jamie Oliver admonish America for its childhood obesity problem. Four days later, while barreling down a slope in Jackson Hole, Wyoming, Kimbal flipped his inner tube and broke his neck. In the hospital, wondering if he’d ever walk again, he began to reconsider his life, with Oliver’s comments rattling around in his head. “The message I heard was: The people who have no excuse should be doing something about this—and I was one of those people,” says Kimbal. “I told myself, If I get through this I’m going to focus on food and doing things at scale.” Apart from losing some feeling in his fingers, he made a full recovery.

Since then Kimbal has become a cheerful crusader for “real food,” as he calls it, sharing his message on the lecture circuit. “He’s a compelling speaker,” says food writer and activist Michael Pollan. “Particularly in his passion for kids, his recognition that if we’re going to change our approach to eating in this country, it’s about showing kids where food comes from, how to grow it, how to prepare it.”

“In 2004, there were very few local farmers that would work with us,” says Kimbal. “We opened the Kitchen before farm-to-table was a term. We showed that you could be busy and profitable while creating a new supply chain. Now there’s a huge backlash against processed food, industrial food. Real food is simply food you trust to nourish your body, nourish the farmer and nourish the planet.”

The Future of Farming: Japan Goes Vertical And Moves Indoors

The Future of Farming: Japan Goes Vertical And Moves Indoors

Spread, Fujitsu and AeroFarms are growing vegetables hydroponically, with successful yields

BY MELINDA JOE

21 MAY 2017

Spread, Fujitsu and AeroFarms are growing vegetables hydroponically, with successful yields

Indoor agriculture is on the rise all over the world – particularly in Asia, where concerns over food safety and pesticide use in recent years have fuelled a boom in so-called plant factories. Spread, Japan’s largest vertical farm, produces more than 20,000 heads of lettuce a day in its 3000-square-metre facility outside of Kyoto.

Spread Co's vertical farms

The vegetables are cultivated hydroponically – without soil, in beds of constantly circulating nutrient solution – under LED lights in a sterile, climate-controlled environment. Later this year, the company plans to open a second facility that will use robot technology to automate tasks such as harvesting and boost total production to a whopping 50,000 heads per day.

Electronics giant Fujitsu is among a number of Japanese technology firms to embrace horticulture, converting factories that had formerly been used to manufacture semiconductors into tightly sealed indoor plantations manned by engineers in white cleanroom suits.

Fujitsu’s cloud-based software allows workers to easily monitor sensors that track the growth of the plants. Nutrient and light levels can be adjusted to develop varieties of lettuce with, for example, low potassium content for people with kidney disease.

AeroFarms

Last year, AeroFarms, located in New Jersey, made headlines for becoming the world’s biggest vertical farm, with the capacity to harvest roughly 1,000 tonnes of greens per year.

The company employs aeroponic technology, a more efficient form of hydroponics, where plants are grown in a mist environment. The company relies on big data to oversee the cultivation of 250 varieties of organically grown herbs and leafy vegetables.

From Moscow: A ‘City Farm’ Home Appliance

From Moscow: A ‘City Farm’ Home Appliance

The body is completely leak-tight, made of sound eight-layered composite aluminum. You can select out of 9 coloring options.

Regulated «smart» tinting coating of a farm’s glass door enables to turn down the glaring light RainbowSpectrum ™. Tinting coating is controlled with the use of the INTELLIGENT EXPERT application.

Module body is made of Softtouch plastic due to which it is highly wear-resistance and possesses elegant appearance.

Innovative module structure with in-built drip watering system enables to

control the level of the nutrients and minerals supply to the plants as well as enables to easily change the glasses for growing.

Rainbow Spectrum ensures efficient process of plant photosynthesis at the expense of using solely the blue and red spectrum colors. Innovative light-emitting diode unit is automatically adjusted to the croppings grown in the city farm creating the most favorable conditions for their growth and fruiting.

Automatic climate control system ensures favorable air temperature and humidity for the croppings development inside a city farm. Measurements by all parameters are displayed in the INTELLIGENTEXPERT application.

China Focus: Factory Farms The Future For Chinese Scientists

Factory Farms The Future For Chinese Scientists

Source: Xinhua| 2017-04-30 09:06:29|Editor: Yamei

XIAMEN, Fujian Province, April 30 (Xinhua) -- In a factory in eastern China, farming is becoming like scientific endeavor, with leafy vegetables embedded neatly on stacked layers, and workers in laboratory suits tending the plants in cleanrooms.

The factory, with an area of 10,000 square meters, is in Quanzhou, Fujian Province. Built in June 2016, the land is designed to be a "plant factory," where all environmental factors, including light, humidity, temperature and gases, can be controlled to produce quality vegetables.

The method is pursued by Sananbio, a joint venture between the Institute of Botany under the Chinese Academy of Sciences (IBCAS) and Sanan Group, a Chinese optoelectronics giant. The company is attempting to produce more crops in less space while minimizing environmental damage.

Sananbio said it would invest 7 billion yuan (about 1.02 billion U.S. dollars) to bring the new breed of agriculture to reality.

NEW FARMING

Plant factories, also known as a vertical farms, are part of a new global industry.

China now has about 80 plant factories, and Sananbio has touted its Quanzhou facility as the world's largest plant factory.

In the factory, leafy greens grow in six stacked layers with two lines of blue and red LED lights hung above each layer. The plants are grown using hydroponics, a method that uses mineral nutrient solutions in a water solvent instead of soil.

"Unlike traditional farming, we can control the duration of lighting and the component of mineral solutions to bring a higher yield," said Pei Kequan, a researcher with IBCAS and director of R&D in Sanabio. "The new method yields ten-times more crops per square meter than traditional farming."

From seedling to harvesting, vegetables in the farm usually take 35 days, about 10 days shorter than greenhouse plants.

To achieve a higher yield, scientists have developed an algorithm which automates the color and duration of light best for plant growth, as well as different mineral solutions suitable for different growth stages.

The plant factory produces 1.5 tonnes of vegetables every day, most of which are sold to supermarkets and restaurants in Quanzhou and nearby cities.

The world's population will bloat to 9.7 billion by 2050, when 70 percent of people will reside in urban areas, according to the World Health Organization.

Pei said he believes the plant factory can be part of a solution for potential future food crises.

In the factory, he has even brought vertical farming into a deserted shipping container.

"Even if we had to move underground someday, the plant factory could help ensure a steady supply of vegetables," he said.

HEALTHIER FUTURE

Before entering the factory, Sananbio staff have to go through strict cleanroom procedures: putting on face masks, gloves, boots, and overalls, taking air showers, and putting personal belongings through an ultraviolet sterilizer.

The company aims to prevent any external hazards that could threaten the plants, which receive no fertilizers or pesticides.

By adjusting the mineral solution, scientists are able to produce vegetables rich or low in certain nutrients.

The factory has already been churning out low-potassium lettuces, which are good for people with kidney problems.

Adding to the 20 types of leafy greens already grown in the factory, the scientists are experimenting on growing herbs used in traditional Chinese medicine and other healthcare products.

Zheng Yanhai, a researcher at Sananbio, studies anoectohilus formosanus, a rare herb in eastern China with many health benefits.

"In the plant factory, we can produce the plants with almost the same nutrients as wild anoectohilus," Zheng said. "We tested different light, humidity, temperature, gases and mineral solutions to form a perfect recipe for the plant."

The factory will start with rare herbs first and then focus on other health care products, Zheng said.

GROWING PAINS

Currently, most of the products in the plant factory are short-stemmed leafy greens.

"Work is in progress to bring more varieties to the factory," said Li Dongfang, an IBCAS researcher and Sananbio employee.

Some are concerned about the energy consumed with LED lights and air-conditioning.

"Currently, it takes about 10 kwh of electricity to produce one kilogram of vegetables," said Pei, who added that the number is expected to drop in three to five years, with higher LED luminous efficiency.

In a Yonghui superstore in neighboring Xiamen city, the vegetables from the plant factory have a specially designated area, and are sold at about a 30 percent premium, slightly higher than organic and locally produced food.

"Lettuce from the plant factory is a bit expensive, at least for now, there are many other healthy options," said Wang Yuefeng, a consumer browsing through the products, which are next to the counter for locally produced food.

Sananbio said it plans to expand the factory further to drive down the cost in the next six months. "The price will not be a problem in the future, with people's improving living standards," Li said.

The Startup That Will Change The Way China Feeds Its Cities

The Startup That Will Change The Way China Feeds Its Cities

Beijing-based startup Alesca Life is democratizing access to fresh food by creating solutions that enable anyone anywhere to grow the safest, healthiest, and freshest produce in the most efficient way possible. Their automated indoor food production system is currently growing nutrient-dense produce using no pesticides, no soil, no sunlight, 20-25 times less water, fertilizer, and land compared to traditional farming practices.

CEO Stuart Oda shares his thoughts on the necessity of evolving the modern agriculture framework to feed the globe’s ever-growing population.

What experiences inspired you to start this company?

I’ve traveled to over 40 countries and one of the most common challenges faced by emerging market countries was the access to highly nutritious, safe, fresh foods. The unpredictability of weather due to climate change and lack of access to critical resources and education makes food production and distribution and the stable supply of nutrition through fresh foods an enormous challenge.

Also, fresh food logistics is essentially the movement of water and nutrition in a perishable, damageable form: incredibly energy intense and wasteful with both food and packaging. Many of the problems of the agricultural supply chain can be overcome by removing the key variables of present day agriculture: weather, logistics, and land.

Finally, the environmental degradation associated with agriculture is quite alarming. When I was an investment banker in Tokyo, someone I greatly respected always reused printouts until the white on the paper was almost gone. Her explanation was simple, “I don’t want my grandchildren to have to visit a museum to see what a tree looks like.”

Agriculture must become a more environmentally friendly practice to ensure that future generations do not inherit a heavily polluted planet. Alesca Life was born out of the frustration of an archaic method of food production to create a more sustainable alternative to feed our current and future population.

Why solve the issues you’re trying to solve?

The world will face a number of significant challenges in the coming decades, including rapid population growth and urbanization, higher food distribution inequality and waste, environmental degradation, and natural resource depletion. In developing countries, there is the additional problem of poor food quality and safety.

Also, as the sharing economy and automation grows, the most basic of urban infrastructure and human capital will become idle or underutilized. A solution to these challenges will be critical for global social, economic, and environmental development.

Why is your solution unique?

Alesca Life designs and builds turn-key farming solutions that enable anyone in any environment to produce safe and healthy produce locally. We have several hardware form factors that enable pesticide-free food production at any scale, and we coupled it with a cloud-based operational management system that enables complete production data transparency and supply chain traceability.

The agricultural industry has traditionally been additive: more chemicals, more water, more logistics, more land. Alesca Life’s philosophy is the exact opposite: food production utilizing minimal inputs on virtually no land.

Also, our solution is looking to integrate an IT infrastructure that allows for supply chain transparency to end the production of “anonymous food” and by growing in a more consistent environment we want to end the concept of “ugly vegetables” which are some of the biggest contributors to poor food quality and high food waste.

What has been your company’s proudest moment been to date?

For the founders, completing our hand-built shipping container farm and commencing fresh vegetable production was a moment of incredible pride.

For the team, installing our first indoor food production system into Swire Hotels for the onsite production of fresh wheatgrass was one of our collective highlights.

My personal proudest moment was when, following a visit to our urban container farm, a young child told us that he wanted to be an urban farmer when he grew up.

What do you hope the world will look like as a result of your work?

Our team hopes that the integration of food production as one of the core functions of urban environments will help to create more resilient, sustainable, and beautiful cities for urban citizens. Also, if the extension of our technology can impact food production in space (outer space), it would be an incredibly exciting future.

AeroFarms: The Farm of the Future

“Doesn’t it feel like we’re walking into the first scene of a sci-fi thriller?” I whispered to the woman in the white lab coat and hairnet (the same getup I was required to wear) as we approached the glowing towers in the distance. I made sure that one chick was way out in front, see her? It’s the same tactic I use in the ocean. Farthest one out gets devoured and gives you time to swim to shore. Take notes, kids.

Anyway, thankfully we weren’t headed into any crazy, sci-fi danger. (Sorry to put you out there, chick in the front.) We were actually taking part in a tour of AeroFarms’ temporary facility located in an abandoned indoor paintball arena in Newark. They left behind the really cool wall art which made the whole experience feel like the weirdest party I’d ever been to.

The aforementioned glowing towers were actually the vertical LED illuminated stacks of baby leafy greens thriving under perfect conditions, getting ready to be harvested and sent off to local grocery stores.

AeroFarms’ noble and awe-inspiring mission is to combat our global food crisis and bring farming and fresh, nutritious, leafy greens into our world’s food deserts. I’m pretty sure we can all get behind that.

The facility we toured was soon to be shut down and all growing moved to their new facility which is an abandoned steel mill on Rome Street in Newark, where their estimated annual output will be up to 2 million pounds. Currently, the Newark location employs a staff of 126, 60% from the surrounding area, 40% from Newark. Growing food and jobs: well played my friends. Well played.

AeroFarms has projects in development on four continents, with plans to open sustainable vertical farms all over the world in the coming years. The Garden State got lucky when the company chose New Jersey as the site for its beta farms in 2004.

The company claims to use “95% less water than field-farmed food, with yields of 130 times higher per square foot annually.” Those are some pretty impressive stats. And they take out the middle distribution man by growing right where the population for consumption is. It’s crazy clever.

The latest development under the AeroFarms brand is the new line of fresh greens “Dream Greens,” for retail. We were lucky enough to enjoy a brief chew-through of the varying taste profiles of a few of the more than 250 varieties of baby greens and herbs. On the menu for the day was their baby kale, baby arugula, baby ruby streaks (which had a surprising baked potato flavor), baby watercress, and baby bok choy.

Our guide for the day, Alina Zolotareva, explained the flavors we were discovering and talked about how AeroFarms greens are bred to be more flavorful and more nutritious than your typical fresh greens at the supermarket, which are raised with one goal in mind: shelf life.

With the AeroFarms model, pests are not an issue. Climate is not an issue. Lack of water is not an issue. The seeds are sewn on clothes made out of recycled plastic bottles and are used over and over again for germinating seeds. Plants grow faster in this environment which means the farm can yield more harvests per year than the traditional farm. I told you, it’s the farm of the future. There’s so much more I could go into, but it’s all on the website for if you’re looking for a deeper dive.

If you are looking to buy Dream Greens, which I highly recommend, check out the store locator here. AeroFarms currently supplies the NY-Metro area via brick-and-mortar retail partners including Whole Foods and ShopRite, as well as via FreshDirect to Connecticut, Washington, D.C., and Philadelphia.

I plan on keeping a close eye on this company and the company’s progress. Rumor alert: Next stop, Camden!

South Jersey Startup Alfrea Has Platform to Match People to Land They Can Farm

South Jersey Startup Alfrea Has Platform to Match People to Land They Can Farm

By Esther Surden, March 7, 2017, 10 p.m.

And to match farmers and gardeners to people who want to work their land

Alfrea, a Galloway-based startup, has developed a platform to help individuals move towards growing and consuming local, sustainable food.

According to founder David Wagstaff, the idea for Alfrea came from his family. “My father is 92 and my mother is 86, and they own a farm and live in a house near it. I live in New Jersey and they live in Maryland. As time went on, they needed more help managing and working the farm. I needed to hire more people to help. Over the years, we put signs on the road and used Craigslist. Neither of those methods seemed like the right way to match people to land to me.”

Also, Wagstaff was thinking about his own health and longevity. While he has good genes, with grandparents living past 100, he wanted to make those years quality years. “Food is really the cornerstone for quality longevity,” he said. “It really made some sense to create an application that makes it easier for people to connect with the land, makes it easier for people to find farm and garden help and services, and easier for people to eat well.”

Additionally, Wagstaff and his father both had another problem this platform could fix. They both wanted to grow a vegetable garden near their homes, for their own use. Wagstaff wondered how he could get people to keep up the garden while he went on vacation. “It wasn’t easy to find someone. There are landscapers, but they aren’t necessarily the right avenue to take, especially if you want to grow sustainable foods.”

So Alfrea was born.

Wagstaff began ideating the startup in August 2015, and launched a minimal viable product (MVP) 10 months later. “Simply put, we connect supply with demand,” much like Airbnb, he said. The first task Alfrea took on was to connect people with their neighbors for the purpose of farming or growing food. For now, the startup is focusing on New Jersey, Pennsylvania and Maryland. Wagstaff is working with two additional full-time employees, Lindsey Ricker, customer engagement manager, and John Dynak, who is called “chief everything else officer.”

The MVP was developed as a hybrid open-source platform with some custom development. The startup used offshore developers to achieve its goal. Wagstaff noted that the MVP is fully functional: People can go onto the website and find land or services. And they can use their credit cards, so they don’t have to give cash to anyone. There is a geographic search capability and a way for customers to rate their experiences.

“We are on track to get 7,000 subscribers by the end of the year,” Wagstaff said. He added that the MVP, while not fully featured, is highly scalable, so it wouldn’t be a problem if 100,000 subscribers signed up.

Wagstaff is excited about the social impact his startup could have as it continues to grow. “One of the things I find exciting about Alfrea is that, not only does it have the potential to be a big, scalable business, it has the potential to have a big impact.”

For example, he said, it is a very cost-effective solution to give people who don’t have access to locally grown food access to the platform. He cited Camden as an example, which is a “food desert,” with no supermarket. “If we had one person once a week in Camden to provide food delivery, it will provide employment for them and access to food for the community,” Wagstaff said.

Also, locally grown food cuts back significantly on carbon emissions, as trucks are no longer driving long distances to deliver food to a community. “Industrial agriculture is one of the problems leading to climate change,” said Wagstaff. “When people grow sustainably and locally, there is the potential to put carbon back in the ground.”

While Alfrea is aimed at individuals, one of the ways the company is going to market itself is to encourage apartment complex managers to offer the sustainable-food-matching service as a perk to folks who live in their communities. “There are over 56 million people living in apartments, and some of those would like to grow their own food, but they don’t have a space to do it. So we can connect them with a community plot or a farm nearby,” Wagstaff said.

Wagstaff is also going after the health and wellness market, attempting have the platform adopted as part of the healthier-eating services offered by company health plans.

Alfrea offers its platform on a freemium basis to buyers. “If you are looking for someone to work in your garden, you don’t have to pay for that. However, the person who is earning income thorough the services Alfrea provides, whether land, services or food, pays a nominal monthly fee.” Right now the fee is $4.50 for individuals and $15 for business customers, although the fees have been temporarily waived to build up the customer base. The startup also charges transaction-processing fees, as well as fees for marketing. And it’s considering exclusive advertising deals as well.

Wagstaff says that the overall market for his platform is large. “Some 42 million Americans are growing some part of their food supply today. I’ve seen studies that say that as many as 82 percent of Americans would like to grow their own food if they had that option.” Those folks are grocery store shoppers, he said. But the problem with grocery stores is that they are hit or miss. Sometimes they have local sustainable food and other times they don’t. Also, they may define “local” a bit more liberally than most foodies would, he said.

The startup isn’t alone trying to help individuals grow their own food. Shared Earth (Fairfield, Conn.) and Urban Garden Share (Seattle, Wash.) focus on people sharing their backyards, Wagstaff said. On the services side, there are a million landscapers; and on the land side, a million farmers. They can be seen as competitors, said Wagstaff, but also as folks who could use Alfrea’s platform.

David Wagstaff, founder of Alfrea | Courtesy Alfrea

A farm stand, | Courtesy Alfrea

Why Yardfarm?

Why Yardfarm?

America’s future depends on cultivating the next generation to be yardfarmers.

The global climate is changing fast. This will require a radical shift in America’s economy, either proactively to limit carbon emissions, or in response to disruptions in global trade, and in food and energy supplies caused by runaway climate change. In turn, the consumer economy that provides the majority of the country’s jobs will inevitably contract.

Young people are often the first pushed out of a shrinking economy (as can be seen in Spain and Greece, both with youth unemployment rates of over 50 percent). Even today in the U.S.—in a relatively strong economic position globally—unemployment for 20-29 year olds with a college degree is at 11 percent, with many more ‘underemployed.’ Economists from the University of British Columbia and York University found that “Having a B.A. is less about obtaining access to high-paying managerial and technology jobs and more about beating less-educated workers for the barista or clerical job.” About 60 percent of 20-29 year olds still rely on parents for money, and 20 percent have moved back in with them—typically a source of great shame in the individualist American culture.

Meanwhile, the fifth largest crop in America is the turf-grass lawn with 40 million acres under cultivation, just after corn, soy, hay and wheat. These lawns are significant emitters of carbon dioxide (thanks to lawn mowing), major users of water (including in drought-prone areas), and considerable polluters as they absorb three million tons of chemical fertilizers and 30,000 tons of pesticides each year.

But imagine turning this upside down. What if adult children could proudly move back in with their parents—filling underutilized housing stock, reviving multigenerational living, and converting the ecologically problematic lawns around the neighborhood into a major source of sustainable food, household security and community resilience?

While yardfarming isn’t easy, it can be highly productive. Just a quarter acre of yard can produce more than 2,000 pounds of fruits and vegetables and provide a six-fold return on every dollar invested. The Victory Garden movement during World War II reveals the potential of this type of small-scale farming mobilization, with 18-20 million Victory Gardens producing 40 percent of household vegetable needs by the war’s end.

Imagine if suburban, exurban and even small urban plots around the country were converted to yardfarms. This land could create new livelihoods, food security, community resilience, and more biodiverse lands that would absorb water runoff, attract local wildlife, and sequester carbon (in the form of richer soils). Moreover it would reduce demand for lawn chemicals, and over time reduce demand for industrial food and farming—in turn making it possible for those lands to be rewilded.

And perhaps best of all, it would start rebuilding the norm around multigenerational living. In 2013, average home size in the U.S. hit a new record of 2,598 square feet, with an average of just 2.54 people living in the average American household. Having young people move back in to family homes would rebuild family ties and increase family interdependence, shrink household living costs, and reduce housing impacts on the environment and demand for new housing, all of which is a far more resilient, more sustainable way to design households and communities in the disrupted future that’s on our doorstep.

The Growing Trend of Vertical Farming

CBS NEWS

March 27, 2017, 11:46 AM

The Growing Trend of Vertical Farming

The world’s population will climb from around seven billion people to nearly 10 billion by 2050. That will make it even more challenging to feed everyone on the planet.

Companies like AeroFarms are rethinking how we grow fresh and affordable produce through vertical farming -- growing vegetables like kale, arugula and watercress indoors on shelves stacked seven levels high. When all is said and done, AeroFarms hopes to produce 1.7 million pounds of greens a year.

A 70,000-square foot facility, housed in a former Newark, N.J., steel plant, is AeroFarms CEO David Rosenberg’s green machine. It grows 130 times more produce than the average American field farm of the same size per year.

But to fully understand this large-scale operation, you’ve got to go back to its roots, where it all began seven years ago, inside Philip’s Academy Charter School.

AeroFarms’ prototype was planted in the school’s cafeteria as a teaching tool for students to learn the basics of biology, chemistry, and nutrition.

“I think growing food every day and seeing it, I understand and have a better taste for it, and understanding for it,” said student Susannah Love. “I appreciate it a lot more.”

The technology is called aeroponics, which grows plants on a re-usable fabric -- proprietary information.

But as Love explained it to CBS News correspondent Michelle Miller, this process needs no soil, no sunlight, and uses less water than conventional farming.

“We’re misting it from underneath, so the water comes up through the sheet and it hits the seedlings.”

Hits them with a nutrient-rich solution that allows the plant to take root. LED lights substitute for the sun.

Rosenberg says vertical farming offers higher yields with less land, less time, and no pesticides. They can farm indoors in any city, anywhere around the world: “From seed to harvest in 16 days, what otherwise takes 30 days in the field,” he told Miller. “And then we’re able to do that 22 times a year versus, in the field, three times a year, because of seasonality.”

Still, not everyone is sold.

“Early adopting is not necessarily bad,” said Cornell University researcher Kale Harbick. But he says his studies found indoor farms that rely solely on artificial light are not energy-efficient or sustainable.

“Just because it’s possible to grow inside a warehouse doesn’t mean it’s a good idea, doesn’t mean it’s cost effective,” said Harbick. “If you do the math, the energy costs just aren’t what they should be.”

Harbick warns these companies struggle once their seed money runs dry. Case in point: One Chicago-based company recently shut down its growing operations.

Rosenberg says AeroFarms LEDs that run 24/7 have been tweaked to save energy. He didn’t share just how much.

Investors believe in it. AeroFarms has raised more than $50 million from the likes of Goldman Sachs and Prudential, and received more than $9 million in state and local grants.

Miller asked, “Why would someone want to buy from you as opposed to a field farmer or a greenhouse farmer?”

“Here, we’re growing in the local community,” he replied. “That’s the supply chain difference. But it turns out that we’re able to compete on taste and texture.”

By adjusting the lights and nutrients, Rosenberg says they can also make their arugula more peppery, their kale a little sweeter.

Which for many of us, parents in particular, might be the biggest selling point of all, to get their kids to enjoy their greens.

AeroFarms’ product is available in area grocery stores and supermarkets for about $3.99 a package.

For more info:

Aerofarms' 70,000-square foot facility, a former Newark, N.J., steel plant, grows 130 times more produce than the average American field farm of the same size per year.

CBS NEWS

Seedlings being grown by students at Philip's Academy Charter school. The students grow some of the greens for their cafeteria's salad bar.

CBS NEWS

CEO David Rosenberg gives correspondent Michelle Miller a tour of Aerofarms' vertical farming facility.

CBS NEWS

How A Rooftop Farm Feeds A City

How A Rooftop Farm Feeds A City

You all probably know my love for greenhouses, local food and educating city folk on where their food comes from.

Last night, I just put on another ted talk to watch whilst I cooked dinner, and decided to simply click on one of the ‘recommended’ videos that popped up on Youtube. My mood went from average to incredibly happy, in a matter of seconds. THANKS Youtube, you have impressed me once again.

This Ted talk video merged all these passions of mine, into one.

Greenhouses formed the major part of my first job as a graduate. I loved observing how the crops were growing in a protected environment, and how different growing techniques influenced the quality and yield gained. My Australian boss was Dutch, so understandably I learned a lot on the processes involved with growing a good greenhouse crop, from this expert.

Local food, as outlined in the video, is something that ‘is not new’ but something we miss in urban populations. I love growing my own veg at home, and consider myself to know quite a bit about agriculture, however, I cringe a bit, every time I visit a farm to see waste, or hear of food getting wasted. In the Montreal rooftop greenhouse outlined in the video, there is very little food waste, as produce is eaten very soon after production, with minimal transportation. Incredible.

Educating city folk on where food comes from, my final passion, really needn’t even be an issue. Hearing towards the end of the video, that urbanites were picking their own food and reducing the need for not only food miles, but resources, whilst seeding sustainability by knowing their food, just gave me so many warm fuzzies- we definitely need more of this.

So in this Ted Talk, Mohamed Hage, a Lebanese born Montreal-dweller, educates us on the disconnect I observe daily, and how to address it, by utilizing the ‘underwear’ of the building- the roof.

Sustainable agriculture means recycling water, optimizing energy use and growing without any synthetic pesticides, herbicides or fungicides. It doesn’t just stop at the farm.

- Water conservation: Recirculation of irrigation water and capturing rain water

- Pest control: Biocontrols take care of harmful pests

- Saving energy: Using half the energy to heat

- Compost: Composting organic waste on-site

- Freshness: Delivering the same day produce is harvested

Here is his business if you’d like to read more: http://lufa.com/en/ Please do- it’s an amazing website and concept.

Here we go, Canadians, once again, bawse.

Who else is up for greenhouses on supermarket/community centre rooves? Who would like to help me instigate this technology in Australia’s largest cities of Sydney and Melbourne?

HELP SPREAD THESE LITTLE SEEDS OF SUSTAINABILITY FOR ME!

Peace,

Jess

Meet Alfrea, The Social Enterprise That’s Like Airbnb For Community Gardening

Mar. 22, 2017 4:49 pm

Meet Alfrea, The Social Enterprise That’s Like Airbnb For Community Gardening

The online platform connects aspiring gardeners to open garden space as well as locally grown food in their communities.

By Julie Zeglen / STAFF

If you belong to one of the 40+ million households in the United States that gardens for food, you should probably know about Alfrea.

The year-old social enterprise based out of New Jersey connects aspiring gardeners to open garden space as well as locally grown food in their communities.

The online platform also connects people with excess resources to those seeking resources. Have a big ol’ backyard that would be perfect for someone else’s herb garden? Looking to sell that surplus of tomatoes your crop yielded last season? Alfrea can help you out.

“What Airbnb did for the bedroom, we’re trying to do for land,” Lindsey Ricker, Alfrea’s customer engagement manager, told us during her “Around the Corner” interview. Learn more below.

Modular Farms Newsletter #6

January has undoubtedly been the busiest month in the history of our young company. For each calendar day that passed we were introduced to more and more people that are driven to reshape the agricultural landscape, both domestically and abroad, via the use of ZipGrow technology, Modular Farms and other sustainable farming practices

Modular Farms Newsletter #6

January has undoubtedly been the busiest month in the history of our young company. For each calendar day that passed we were introduced to more and more people that are driven to reshape the agricultural landscape, both domestically and abroad, via the use of ZipGrow technology, Modular Farms and other sustainable farming practices. At this rate, 2017 is poised to be a huge year for the indoor farming industry as a whole, and we are honored to be amongst the cohort of businesses that are helping to educate and empower the next generation of hydroponic farmers to make a difference in their communities.

Recently, we had the privilege of taking some of our FarmWalls out of our office and showcasing them at various places throughout our community. The first stop on tour was at an event hosted by 4Life Natural Foods in Kensington Market - an urban Toronto grocery store focused on selling locally sourced, sustainable organic produce. We partnered with 4Life to assist in the development and construction of a 5000 square foot indoor ZipFarm that will be located on the roof of their downtown location.

The FarmWall we showcased at the event gave the grocer's patrons a chance to get a first-hand look, feel and taste of the produce that will be available to them year-round once construction of the rooftop farm is complete. Needless to say, a lot of excitement ensued from those who bravely trekked through the hideous snowstorm to attend that evening.

The second, and more permanent, stop on the FarmWall tour was at the Institute of Management and Innovation, located at the University of Toronto's Mississauga campus. Under the guidance of our Plant Health Technician, Kevin, the Sustainability Management grad students have been eagerly putting their studies into practice by utilizing the 2-tower system as a part of their Capstone project. We are overjoyed with the amount of interest that the students are having with the project, and are excited to see and taste the fruits of their labour!