Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Startup That Grows Crops in Shipping Containers Unveils Sleek, New Design

At first glance, the tall metal box on the Greenway looks somewhat innocuous. But open the doors and there’s a salad disco happening inside

At first glance, the tall metal box on the Greenway looks somewhat innocuous. But open the doors and there’s a salad disco happening inside.

The large white container, which will be situated in the park all day Friday at the corner of High and Purchase streets, is the latest product from Freight Farms, the local startup that enables would-be farmers to grow produce anywhere using its tricked-out shipping containers.

The company, which has raised nearly $5 million in funding, has become somewhat of a darling to the startup set. Google is using one of its hydroponic containers to feed its 20,000 employees in Palo Alto, and last month Freight Farms partnered with Elon Musk’s chef brother, Kimbal, to help launch his urban farming accelerator, Square Roots.

Since launching in 2010, the company has sold 100 of its signature device, the Leafy Green Machine, said its president, Jon Friedman.

The prototype is a slightly smaller version of the modular growing system. He dubbed it the Leafy Green C (the C stands for community, or compact ... they haven’t decided yet). It’s about one quarter the size of a typical shipping container, clocking in at about 10 feet long, 9 feet high, and 8 feet wide. And it can grow 200 heads of lettuce each week.

Inside is where the fun starts.

Farmers plug their seedlings into six-foot tall, gutter-like “towers” that act as a growing medium for the young shoots. Each tower is then hung from the ceiling and lit with blue and red LED lights, which can be tweaked to emulate the sun as it cycles through the day.

Imagine dozens of vertical spinning towers of lettuce. The entire system gives off a very disco-like feel.

The original containers, which each cost $85,000, are now in nine countries, six islands, 25 states, and 12 schools. But Friedman said the system’s new design has a different customer in mind. It will be half as expensive as the original model (the exact price is not yet set, he said). He’s hoping to attract restaurants, communities and perhaps even individuals who are excited about the idea of container farming but don’t necessarily need nearly an acres worth of produce a week. The company will begin taking preorders in November.

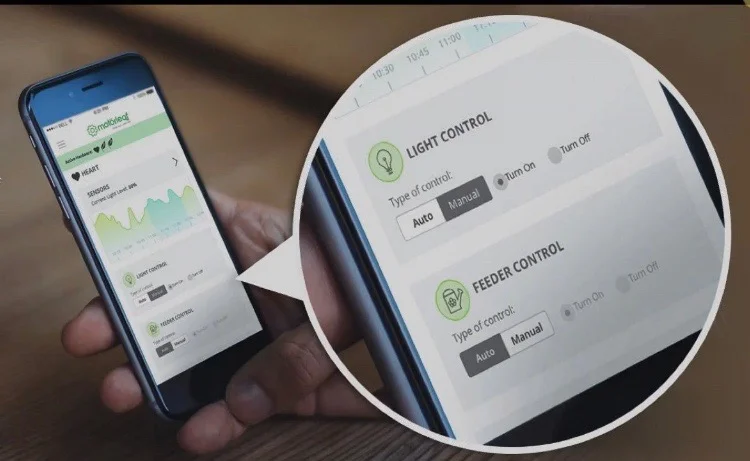

Part of the draw, said Kyle Seaman, the company’s farm technology director, is the newly-designed app called Farmhand that allows the owner of the unit to control all aspects of the container from a smartphone, adjusting the light, heat, nutrients, and water.

“The app informs the farmer if something goes wrong,” said Seamen.

Should their lettuce need some love, they’ll get a ping on their phone. Now, if they can just make it connect to Spotify, they’ll be in business.

Janelle Nanos can be reached at janelle.nanos@globe.com. Follow her on Twitter @janellenanos.

The Growroom is a spherical farm pod that brings agriculture to city streets

With a rapidly increasing population, food demands are skyrocketing, but current factory farming methods are hardly sustainable. Space10 wants to address that problem with brilliant solutions like The Growroom.

Space10 and Danish architects Mads-Ulrik Husum & Sine Lindholm created an innovative, beautiful urban farm dome that shows how we can bring nature and food farming back to our cities. With a rapidly increasing population, food demands are skyrocketing, but current factory farming methods are hardly sustainable. Space10 wants to address that problem with brilliant solutions like The Growroom.

The Growroom was exhibited first at the CHART ART FAIR in Copenhagen, a fair that exhibits exceptional design from the Nordic region. According to Space10, the Growroom is meant to “spark conversations about how we can bring nature back into our cities, grow our own food and tackle the rapidly increasing demand for significantly more food in the future.”

The Growroom is filled from floor to ceiling, end to end, with vegetables, herbs and other edible plants, with a cozy space in the center to reflect and relax. It is a beautiful way to explore how we can bring more food to our cities in a self-sustaining eco system that can supply hyper-local food that is seasonal, fresh and high quality. Growroom gives us “food that tastes better, is healthier for us, more nutritional and doesn’t put massive pressure on our dwindling supplies of fresh water nor our environment,” says Space10.

Earlier this month, people were able to step into the “farm” and experience the Growroom with every sense – from the smell of the plants to the light filtering in between the garden spaces. It’s easy to imagine how such a space could become a feature of every neighborhood, providing a green escape from city life that also provides nourishment. “We’re inviting [people] to step inside the growing green haven, smell and taste the abundance of herbs and plants, and hopefully it will spark passion about growing your own food in the future,” said Carla Cammilla Hjort, Director of Space10.

Space10 co-created ‘The Growroom’ together with architects Mads-Ulrik Husum & Sine Lindholm, interaction designer Thomas Sandahl Christensen and gardener Sebastian Dragelykke, Tradium and Raaschou. Hjort says, “At Space10, we envision a future where we grow much more food inside our cities. Food producing architecture could enable us to do so.”

By Kristine Lofgren

Modular Farms Newsletter #3

Toronto & Modular Farm!

Now that the dog days of summer have passed, we figured it was once again time to get you all formally updated on our whereabouts. Amidst the record-breaking heatwave that has been plaguing Toronto for the last few weeks, we have managed to keep cool by doing what we do best - working away in our climate-controlled Modular Farm!

The moment we have all been anticipating has finally arrived. The technicians have finished their work, our initial run of Modular Farm raised Kale has been harvested, and our first sets of Collard and Lettuce seedlings have been transplanted. Also, as you can see from the above photo, we've begun experimenting with the various colourful spectrums our Intravision Spectra Blade LED lights have to offer. If all proceeds as planned, expect to receive a formal invitation to our official unveiling very soon.

On the R&D side, our team has been very busy designing the new line of secondary modules. With the Primary Module almost complete, we've turned our attention to developing the Vestibule, Off-Grid and Macro Farm modules next, as we consider them to be the most vital secondary modules. Once completed, those who have already purchased a Primary Module will be able to easily scale up their production capabilities, have an active climate and pest barrier, and have the ability to power their farms even in the most remote locations.

Every Thursday afternoon for the past month and a half we've had the pleasure of being a part of the #FarmFreshTO pop-up farmer's market at the Bay Adelaide Centre. Unlike other farmers markets around the city, which tend to be more focused on simply buying and selling produce, the main mission of #FarmFreshTO has been to raise awareness of urban vertical farming practices and sustainable living.

We've greatly enjoyed engaging with, and educating, the public on the benefits and applications of our technology; we can't thank Usful enough for giving us such an amazing opportunity. If you're in the area we highly recommend coming down to Arnell Plaza on a Thursday to say hi, treat yourself to some samples, and get a hands-on look at our technology. Just be sure to do it soon, as the final day of the market is September 15th.

Ending the food insecurity issue in Canada has always been, and will always be, the main reason for our existence. While this may seem like a daunting task, we've already seen great strides being made across the country by passionate, like-minded people who have been utilizing ZipGrow technology to feed themselves, their families, and communities in a sustainable fashion. We currently have Modular Farms scheduled for delivery from coast to coast in the next 12 months, however, there are so many Canadians still in desperate need of our help, and we need your help to get them properly fed. Contact us today to find out if a Modular Farm is a good fit for your family and community.

Stay tuned for the next installment of our newsletter!

IES Launched Full Range Of LED Horticulture Grow Lighting Products

IES is one of the leading global developers of greenhouse and indoor farming and gardening LED lights solution.

IES is one of the leading global developers of greenhouse and indoor farming and gardening LED lights solution. With an international team of agriculture experts and researchers, IES focuses on driving innovation and development in their industry which has earned them the status of being a global leading light in the field of supplemental lighting. Recently,

Technological advancements have paved the way to more unconventional methods of cultivating plants, growing and caring for them which include indoor farming and gardening. IES is directed by their desire to generate and cultivate innovative and hi-tech LED Horticulture Lighting technology. Their main point of focus is to satisfy their customers through their high standards of quality in both their products and their customer services. The company spokesperson said: Our Horticulture LED Solutions develops light systems to condition any crop in growth. We do not only provide mere lighting, but we provide the best possible care to increase profit for the grower, we call this custom made plan a ‘light recipe’.”

The range of products has been created to cater to the needs of contemporary indoor and greenhouse farming and gardening lighting needs, the comprehensive range of products includes LED lights specially designed for a greenhouse, hydroponics, aeroponics, home garden, farm, vegetable shed, botanic garden, flower exhibitions, horticulture, hydroponics, hemp cultivations, medical plants cultivations, etc. the spokesperson continued: “Our light recipes are suitable for different segments within horticulture, e.g. vegetable production, tissue culture and young plant production, cut flowers, seedlings and nurseries. Horticulture LED Solutions is offering knowledge of LED Plant lighting around the world to you.”

Consistent global standards of quality and various certifications are the testament to the company's commitment towards maintaining the highest levels of superiority. The company takes a lot of pride in the fact that they maintain a large worldwide customer based with clients in every part of the world including Europe, America, the Middle East and Southeast Asia, their product are available for sale on all major online marketplaces and the complete details of each product is available on the IES horticulture lighting website.

The company looks forward to expanding their global customer base to become a major LED grow lighting manufacturer globally and continue serving their esteemed clients with top of the range products.

About:

IES Lighting Co., Ltd is a horticulture and agriculture LED light producer based in China.

For more information please visit: http://www.grow-lighting.com/

Contact: Jessie

info@grow-lighting.com

Shenzhen,China

Media Contact

Company Name: IES Lighting Co., Ltd

Contact Person: Jessie

Email: info@grow-lighting.com

Country: China

Website: http://www.grow-lighting.com/

Green Sense Farm Crowdfunding Offer Quickly Hits Goal on StartEngine

Green Sense Farm, raising capital under Reg CF on StartEngine, quickly hit its goal within the first 24 hours of listing.

Green Sense Farm, raising capital under Reg CF on StartEngine, quickly hit its goal within the first 24 hours of listing.

Green Sense Farms is a “vertical farm”. The company has established a vision of building a network of indoor vertical farms, and locate them at perishable food distribution centers owned by large grocery stores. The company also intends on creating locations at institutional campuses or wherever large volumes of food are served. If you think about it, a vertical farm makes sense. Grow the food close to where it is going to be consumed and you save on transportation (no lettuce from 3000 miles away), minimize associated pollution and harvest only when ripe. Green Sense says it is the market leader in the emerging indoor vertical farming market. The company first launched in Portage, Indiana in a 20,000 square foot facility. They now have ten development farms in their pipeline in the US, China, Canada and Scandinavia. They formed a Hong Kong company to help build out China operations. The first farm opened in China last month.

The concept is easy the practice is hard.

Green Sense Farm says it can harvest year round using the fraction of resources necessary in a traditional farm. No pesticides, herbicides, GMO seeds necessary.

Watch the video below published last year about the company.

Have a crowdfunding offering you'd like to share? Submit an offering for consideration using our Submit a Tip form and we may share it on our site!

By JD Alois

Green Sense Farms Reaches Crowdfunding Goal on Day 1

Green Sense Farms, an indoor farm company based in Portage, has raised more than $120,000 in a crowdfunding campaign.

Green Sense Farms, an indoor farm company based in Portage, has raised more than $120,000 in a crowdfunding campaign on startengine.com.

The market-leading company, which raked in $788,000 in revenue last year and just opened its first farm in China, reached its minimum goal of $100,000 on the first day but hopes to raise up to $1 million to build a network of indoor vertical farms. These would be built at perishable food distribution centers owned by large grocery stores and institutional campuses that serve a lot of food daily, such as at hospital cafeterias.

“We’re not subject to rain or drought," Founder and CEO of Green Sense Farms Robert Colangelo said. "We precisely control the indoor environment, to create the perfect conditions for our plants to grow year-round, every single day.”

Last year, the U.S. Securities and Exchange Commission adopted rules that allow companies to sell securities through crowdfunding, which SEC Chairwoman Mary Jo White said would give smaller companies a more innovative way to raise capital while protecting investors.

Companies can go online to raise up to $1 million through crowdfunding over a 12-month period. They're required to disclose independently audited financial information, including from tax returns, and the crowdfunding platforms have to provide investors with disclosures and educational materials.

Green Sense Farms, which reports having $2.6 million in assets, grows GMO-free leafy green vegetables indoors, using less water and land than traditional agriculture. The company says more sustainable farming practices are needed because climate change is reducing the amount of arable land and the world's population is projected to reach 9.7 billion by 2050.

"Green Sense Farms has been the fortunate recipient of numerous stories about our exciting innovative indoor vertical farming technology," Colangelo said. "All this press has generated many inquiries from individuals asking how they can invest in our sustainable farm. We’re pleased to announce that the recently released crowdfunding regulations now allow for individuals to make direct equity investments in growth companies like ours."

The company, which started with a 20,000-square-foot farm in Portage, is seeking investments of at least $100 to fund R&D for new farm designs and to expand its network. It's eyeing indoor farms near colleges, hospitals, military bases and corporate campuses, including abroad in Canada, Scandinavia and China.

"Just as Green Sense Farms has disrupted produce distribution and cut out the middleman, the new crowdfunding regulations have democratized the capital markets, allowing individuals the opportunity to take advantage of public offerings without the use of traditional stock brokers," Colangelo said.

For more information, visit www.startengine.com/startup/green-sense-farms-llc.

Spanish Pharmaceutical Giant Puts Growtainer into Operation

After installing the first international Growtainer in the UK last year, GreenTech Agro is expanding its presence in Europe with the recent installation of another Growtainer at Spanish biotechnological giant Bioibérica.

The Growtainer is the brainchild of Glenn Behrman, founder of GreenTech Agro and CEA Advisors. Two years after introducing his first Growtainers for sale in 2014, Behrman has now installed another EU Growtainer at the factory of leading Spanish pharmaceutical company Bioibérica in Pallafols, outside of Barcelona. Their enthusiasm for the Growtainer and vertical production has been driven by their interest in new, modern and sustainable indoor farming practices. They will use the Growtainer to produce leafy greens, herbs and vegetables for their canteen at the factory site, in order to gain more hands on experience with indoor growing.

"Bioibérica is a forward thinking company that is committed to discovering new technologies and industries", said Behrman. "They are open to new innovations and other industry angles that have a potential for capitalization.”

For the Bioibérica project, Behrman collaborated with Dutch horticultural installer Stolze, whose team transformed the used shipping container, outfitted by RCC Container Trading, into a vertical farm. After the installation at the Port of Rotterdam, the Growtainer was shipped to Spain where Behrman and an expert crew from Stolze completed the delivery with a final installation last week.

Proprietary technology

Inside Bioibérica's Growtainer there are a total of 12 Growracks divided into two separate production chambers. Ten of the Growracks have 4 layers and will be used for regular cultivation, and two racks with 5 layers each will be used for propagation.

Besides having a dedicated proprietary technology for ebb and flow irrigation installed, the Growracks are equipped with Philips GreenPower LED Generation 2 production modules, which are specifically designed for multilayer cultivation in conditioned environments with no daylight. The LED modules ensure a uniform light distribution across the shelves, which means that every plant receives the same level and quality of light.

The irrigation in the Growtainer is divided into six separate zones in order to provide flexibility and allow a wide variety of production of crops at various growth stages. Behrman worked closely with Stolze's engineers to design a sophisticated control system to manage the irrigation, climate, humidity and CO2 levels inside the Growtainer. The entire climate and crop control can be managed remotely via a computer or mobile phone.

Canteen & Research

Bioibérica will grow several crops inside the Growtainer, in the first place to supply their nearby canteen with everyday fresh and safely grown veggies. "They will use it to feed their employees first and gain indoor farming experience with it. While this is an important objective of the installation, Bioiberica is laser focused on the potential advances in their Bio stimulant products. They are excited to incorporate the Growtainer’s state of the art technology based production capacity for further research within their existing business models."

Behrman, who has a long term background in horticulture, has gained a lot of experience with technology based production and container farms over the past few years. "Thanks to the close cooperation with Stolze, VK Pro and RCC Containers, the Holland built Growtainers have become a real state of the art, completely proprietary system. While there are currently many other individuals in the US that offer shipping container farm systems, none of them is as flexible or sophisticated as this one, because this Growtainer version has focused on and tried to improve everything everybody else is trying to do."

Financing and substantial support

At the moment Behrman is continuing to improve the Growracks and building more Growtainers for clients in the United States. "But we have many other exciting plans to announce soon", said Behrman, not only referring to the several new installations in process. "We are almost ready to announce a more manageable crop specific Growtainer for the beginning farmer, with financing and a substantial support system in place, an onsite production initiative with a major US Supermarket Chain and other projects which focus on the highest and best economic use for this exciting and evolving technology.”

For more information:

CEA Advisors - GreenTech Agro

Glenn Behrman (e-mail)

www.growtainers.com

Publication date: 9/7/2016

Author: Boy de Nijs

Copyright: www.hortidaily.com

Motorleaf Is Nest Meets Lego For Next-Gen Agriculture

The world of agricultural technology, or Agtech, is rapidly evolving.

Motorleaf Is Nest Meets Lego For Next-Gen Agriculture

The world of agricultural technology, or Agtech, is rapidly evolving.

It’s automating laborious tasks and providing farmers and growers with greater knowledge and insight into their crops than ever before. As technology evolves so does the needs of the farmer and the growing environment. Around 20% of the world’s food production is grown within cities rather rural areas and inherent in this is the multi-billion dollar industry of indoor growing and hydroponics.

The industry includes $5 billion in urban farming in the US and $5.7 billion for legal cannabis production.

Agtech company motorleaf have released the world’s first wireless monitoring, motion detection and automated growing system for hobby and industrial growers. I spoke to CEO and co-founder Ally Monk to learn more.

According to Monk, the idea originated when as a keen indoor hobby gardener, motorleaf’s co-founder and CTO Ramen Dutta wanted to go on holidays and needed a system to take care of his plants in his absence:

“Ramen was going on vacation, but he had the problem of what would happen to his plants in his absence. He looked at the market and assumed there would be something like a smart home system akin to google Nest but there was nothing. So he started making a HUB that could monitor what was going on and automate a range of appliances such as the water chiller and water level, air temperature, webcam, heating, and cooling. He soon realized that other indoor farmers were interested."

How motorleaf works

The Heart

Motorleaf has created a system that can automate and monitor an indoor growth area with up to 5 acre coverage. Their hardware, described by some as “Nest meets Lego for agriculture” is designed to be plug-and-play, and the grower decides which part of their plant operation they control/monitor and automate. It consists of four modular units:

- The Heart collects Air Temp, Humidity, & Light Level data. Users can connect any lighting hardware, and feeder pump- and start automating their operation in seconds.

- The Power Leaf connects wirelessly to the Heart which tells them when to turn on and off, based upon pre-set times or sensor readings from the Heart and Droplet.

- The Droplet monitors everything that’s connected to a grower’s water reservoir. Every 4 seconds The Droplet wirelessly sends data to The Heart, information on water level, temperature, PH level, and nutrient levels.

- The Driplet allows growers to automate the delivery of PH and Nutrients, again based upon timer setting or actual live grow conditions.

The system is agnostic, retails for about $1,500 and contains free software which facilitates custom settings, so the motorleaf hardware will automate the grower’s equipment and adjust to their crop’s needs. It’s available online and offline as many growers do not have WiFi in their crop space. It also alerts the grower to any problems that need attending to.

More importantly, it also involves intuitive efforts in predicting and anticipating the needs of the plants. Monk says:

“We’ve never been able to speak to plants but now through technology we can listen to them through their data, we can then understand what they need and feedback instructions to the equipment that’s looking after them so we can best serve their crops.

He also notes the many people’s depiction of the farmer outdoor engaged in manual labour as not entirely actually noting “The farmer of the future looks after his farm through his mobile phone and tablet.”1 He adds that indoor growers in particular have needs which can be more complex than traditional farming:

“When you start growing indoors you have to mimic nature, they have worry bout all the things they have to control indoors such as PH; nutrients, humidity, light, air temperature. How are they controlling it? Switches, controllers, some software and in many cases people are still using pen and paper. Urban farming is on the rise but the technology that looks after this is really lagging behind.”

Motorleaf is well-timed to respond to an emerging market. They receive receives 40,000 data points per customer per week and therefore can start predicting a crop’s needs, solving potential problems before they exist. Also, the start-up plans to use its network of data and growers to connect users to each other – on an opt-in basis – to share data, plant recipes and knowledge.

With the growth in indoor agriculture, hobby farmers and small to medium enterprises will soon benefit from effective IoT technology that enables smart crops and smart farming.

By Cate Lawrence

SAPS: Using LED lighting for growing puts crops in best possible light

Food: It’s what makes the world go ‘round. This, and air and water, you know, the essentials or fundamentals.

Number 5 in the Sustainable Agricultural Practices Series.

Food: It’s what makes the world go ‘round. This, and air and water, you know, the essentials or fundamentals.

Efficiency, meanwhile, is responsible for practices, such as growing foods, to be improved; streamlined in some cases. And, innovation is what allows efficiency to take place.

Hydroponic growing technique

One innovation in agricultural practices is the application of light. Outside, light is provided by the sun. Inside growing, on the other hand, is another matter entirely. What we’re talking about here is specialized lighting application inside greenhouses, for example, of light-emitting diode (LED) lighting as a way to improve inside growing conditions for crops and plants grown in this manner.

It’s becoming a more viable way of growing food indoors. It’s also much more efficient.

“Hidden inside the prominent Philips lighting building in Eindhoven, the Netherlands, is the state-of-the-art GrowWise Center,” writes Vegetable Growers News correspondent Melanie Epp in: “Lighting the way: LED lighting solutions create a recipe for optimum plant growth,” the Sept. 2016 VGN cover story. “Here, researchers work to provide tailor-made LED light growth recipes for producers who wish to grow healthy, quality food indoors year round. The facility is concentrating its research on optimizing recipes for leafy vegetables, strawberries and herbs. Other areas of research are looking at growing wheat and potatoes indoors.”

Global director of city farming for Philips is Gus van der Feltz, who emphasizes that through its research production of food grown on the local level (and this could include urban settings) can be enabled around the world. The result is conservation of land and water, less waste and reduced need for shipping produce to distant markets, Epp brought to bear in the “Lighting the way” piece.

More LED lighting benefits

But LED lighting for indoor growing goes beyond even this. “LED lighting has improved the taste, quality and health of vegetables; reduced losses due to pests, disease and weed pressure; and reduced overall energy costs, said Robert Colangelo of Green Sense Farms in Illinois,” related Epp. All of these pluses surely mean one thing: air-quality improvement. Additionally, there is no dust being kicked up on account of farm tractor disking (tilling) and plowing of land that are common in field-farming practices. Shipping local also cuts down on pollution entering the air.

Unique to growing crops in LED lighting conditions is that, with the correct combination of LED lighting colors, things like “plant height, width, color and taste,” can be controlled, added Epp. “Red light, for instance, affects height, and blue affects width.”

Because LEDs are low power devices, lighting using this technology just lasts longer, compared to, say, fluorescents, and they also give off less heat.

“‘Having lights that produce less heat and PAR (higher photosynthetic active radiation) and use less electricity are much more sustainable, better for the environment and better for our business because they’re more economical,’ he said,” Epp wrote in citing Colangelo.

Application of LED lighting in facilitating crop growth proves beyond a shadow of a doubt that the science of growing crops has indeed come a long, long way.

Image above: NASA, Kennedy Space Center

By Alan Kandel

This Indoor Farm Can Bring Fresh Produce to Food Deserts

This Indoor Farm Can Bring Fresh Produce to Food Deserts!

Almonds got the brunt of the bad press, but they hardly deserve all the blame for California’s water woes. Sure, it’s worth considering how to minimize your water footprint, and forgoing your daily handful of almonds in solidarity with the parched earth couldn’t hurt. But considering how widespread the water crisis is, and the fact that agriculture is responsible for 80 percent of the country’s water consumption, the more crucial question to be asking now—particularly on Earth Day—is what can be done to fundamentally change the way our food gets made?

Mattias Lepp says at least part of the answer involves making it easier for anyone—even city dwellers—to farm their own food. That’s why Lepp, founder of the Estonian startup Click & Grow, has developed what he calls a Smart Farm, an indoor farming system that requires 95 percent less water than traditional agriculture.

You may remember Click & Grow from their uber-successful Smart Herb Garden Kickstarter campaign a few years back. That product let people easily grow herbs in their homes with minimal maintenance. The Smart Farm is similar, but on a much larger scale. The system, which Lepp spent years developing in partnership with universities across Estonia, France, and Russia, can hold 50 to 250 plants at a time, making it a viable option for urban areas that don’t have access to fresh produce—areas the US government calls food deserts. Ideally, a shift to urban farming could drastically reduce the distance between where food is grown and where it is consumed.

The market for these indoor farms, or so-called vertical farms, is already fast-growing, driven by the growing realization that the current water-chugging agricultural system is unsustainable. On one end of the spectrum, countless DIY indoor farming enthusiasts are growing small gardens in their homes. On the other are professional outfits like Green Sense Farms out of Chicago, which grows leafy greens indoors and sells them at local stores. Even tech giants like Panasonic and Toshiba have begun developing gigantic de facto farms of their own in Asia, where there is a severe shortage of agricultural land.

And yet, the majority of these larger farms use hydroponic farming, a process that involves growing plants in mineral solutions instead of soil. They save anywhere from 70 to 80 percent of the water required for traditional agriculture, but they’re complex and can cost tens of thousands of dollars. For most of us, it wouldn’t be economically practical for you or me to grow a full-scale farm at home.

With the Smart Farm, which costs just $1,500, Lepp says it can be. “People all over the world have worked intensively the last 10 or 20 years on bringing food production closer to cities and finding ways to grow it more efficiently,” he says. “But today they all are using hydroponics, and that is unfortunately expensive and messy. We see how we can change this.”

Rather than relying on hydroponics, the Smart Farm uses a new type of soil called Smart Soil, which Lepp developed in partnership with academic advisors. The soil itself is spongey, allowing air and nutrients to flow through. Meanwhile, the nutrients are covered in a special coating that responds to soil moisture. The hardware, which looks like a glass refrigerator, consists of trays for each plant equipped with LED lights and sensors that detect when the moisture levels are off balance. The “farmer” can use an app to adjust the water levels in the system, which triggers more nutrients to be released.

This process cuts down on the amount of water required to grow the plants, Lepp says, because no wastewater is produced. At the same time, the time people have to spend actually tending to the plants is minimized.

“Click & Grow can give the plant the perfect conditions to grow, because air, water, and nutrients are dosed perfectly without any obstacles,” says Uno Mäeorg, a professor at the University of Tartu in Estonia, who worked with Lepp on the development of Smart Soil “And since those conditions are perfect for the plant, it provides us healthier plants.”

Be that as it may, the Smart Farm is still a long way from accomplishing Lepp’s eventual dream of putting a full-scale farm in every urban neighborhood. For starters, the system only supports a limited number of plants today, including strawberries, tomatoes, lettuce, and other herbs, though Lepp says that will change with time. Also, for now the Smart Farm is only available on a built-to-order basis. While the company already has orders coming in and pilot projects with universities, it won’t begin full-scale retail distribution until 2016.

Then there’s the simple fact that we’re all just plain used to buying food from a store. The dream of distributed farming may always be limited to the number of consumers who care enough to try it out.

Still, according to Dr. Dickson Despommier, a professor of public health and microbiology at Columbia University and author of the book The Vertical Farm, that number is growing steadily. And as more people become willing to give indoor farming a try, he says it’s critically important that they have tools, like the Smart Farm, to ease the effort.

“I think it could make a dent in the commercial side of things,” Despommier says of indoor farming’s potential to impact mainstream agriculture. “And if you look at what’s happening in California, there may not be a commercial side of things for much longer.”

Issie Lapowski

Indoor Farm Boxes Promise Little Work and Lots of Fresh Produce

In a dark apartment corner, a head of lettuce glows—and grows.

For many city-dwelling apartment renters, securing a home with a sprig of green space is a tall order, let alone a place that gets enough sunshine or rain to cultivate a fresh vegetable garden. A pair of designers have found a way to bring farms to homes—no outdoor space required.

(Photo: Courtesy Replantable)

“There’s a lot of people who have tried to start a garden to have fresh-picked food at home,” Ruwan Subasinghe, lead product designer of the start-up Replantable, wrote in an email to TakePart. “But their garden never lived longer than a single season, because the soil was poor, or the plants didn’t get enough light, or they didn’t have a green thumb, or most often because they just didn’t have the time to keep up with it.”

Enter the nanofarm, a roughly 18-by-14-inch wooden box that uses LEDs in place of the sun to nourish greens. Subasinghe has also created specially designed plant pads for the boxes. The fabric pads are woven to trap moisture and nurture the crops—including lettuce, arugula, beets, and bok choy—all without the use of pesticides.

“Instead of trying to modify the crop through genetic modification or pesticides, indoor agriculture modifies the environment that the crop grows in,” Subasinghe explained.

Subasinghe and business partner Alex Weiss have turned to Kickstarter to fund their indoor farming project. The nanofarms cost $350, along with $25 for a set of five plant pads, which contain 16–25 plants each. With more than a month to go, the two have raised more than a quarter of their $50,000 goal.

A plethora of urban- and indoor-farming projects have cropped up in recent years, but most require daily care. Subasinghe said that people would be able to forget about their nanofarms until the time came to pick the produce. “We already have too many things to keep track of in our busy lives,” he said.

The no-muss, no-fuss farm boxes simply require users to add water, turn on a timer, and wait for a notification light, which signals that the plants are ready for picking. So far, the nanofarm has been delivered to a handful of test users, all of whom report hands-off farming and plentiful harvests.

(Photo: Courtesy Replantable)

Subasinghe expects that his effort will help cut down on food waste—an environmental hazard that accounts for 8 percent of global greenhouse gas emissions. Antihunger advocates estimate that Americans waste about 40 percent of all food produced, most of which gets tossed out at home.

“When [consumers] buy a bag of salad greens at the grocery store, they rarely get to eat the whole thing before it gets forgotten in the fridge,” Subasinghe wrote. “The nanofarm lets people harvest minutes before eating, and only pick what they’re about to eat. The rest stays alive and growing rather than decomposing and shrinking. Our customers have shown us that they’re able to harvest every last bit of produce from the nanofarm.”

Subasinghe acknowledges that shelling out $350 for a nanofarm can be daunting for some buyers compared with a few dollars for a head of lettuce. But he hopes people will see the boxes as an investment. The nanofarm lasts for up to five years and only adds about $1 a month to utility bills. Replantable aims to have the first units out to buyers by August 2017.

Correction: Aug. 29, 2016

An earlier version of this article misstated the cost of the plants. A set of five plant pads costs $25, with each pad containing 16–25 plants.

By Gwendolyn Wu

What the Heck Is… Vertical Farming?

Radical solutions are needed to keep up with our fast-growing world population.

Our weekly series What The Heck Is… sheds light on the strange unexplained acronyms and unfamiliar buzzwords that creep into our everyday lives.

Farming, something humans have been doing for thousands of years, is struggling to adapt to our modern world. Radical solutions are needed to keep up with our fast-growing world population.

What’s wrong with regular farming?

Firstly it’s expensive, both in financial cost and the cost of land required to grow food at scale.

It’s environmentally unfriendly, not just with chemicals and pesticides being poured into the ground, but also the fact that farms only generate a few harvests a year. During winter most of the world’s farmland is simply being wasted.

Plus farming is creating food in the places that we don’t really need it.

More than 50% of the world’s population lives in cities, and this will rise to 80% by 2050, but all the food is being created in rural areas because of the land required to grow at scale.

The result is that transport costs, the environmental impact of transporting this food, and the fact that 30% of all farmed food is wasted because it spoils before it can be eaten, make traditional farming a costly exercise.

So is there a better way?

What the heck is vertical farming?

As its name suggests, vertical farming is a new way of growing of food can be stacked vertically, rather than horizontally, and uses technology to solve the problems with traditional farming.

Think trays of crops stacked in warehouses, with their water, pesticides and even sunlight controlled by a computer, giving them exactly what they need to grow and dramatically boosting the quantity of food produced.

The theory suggests that these vertical farms could even be built inside skyscrapers or existing buildings, creating food where it is needed and reducing the environmental impact of farming.

We say theory, because at the moment that’s exactly what vertical farming is.

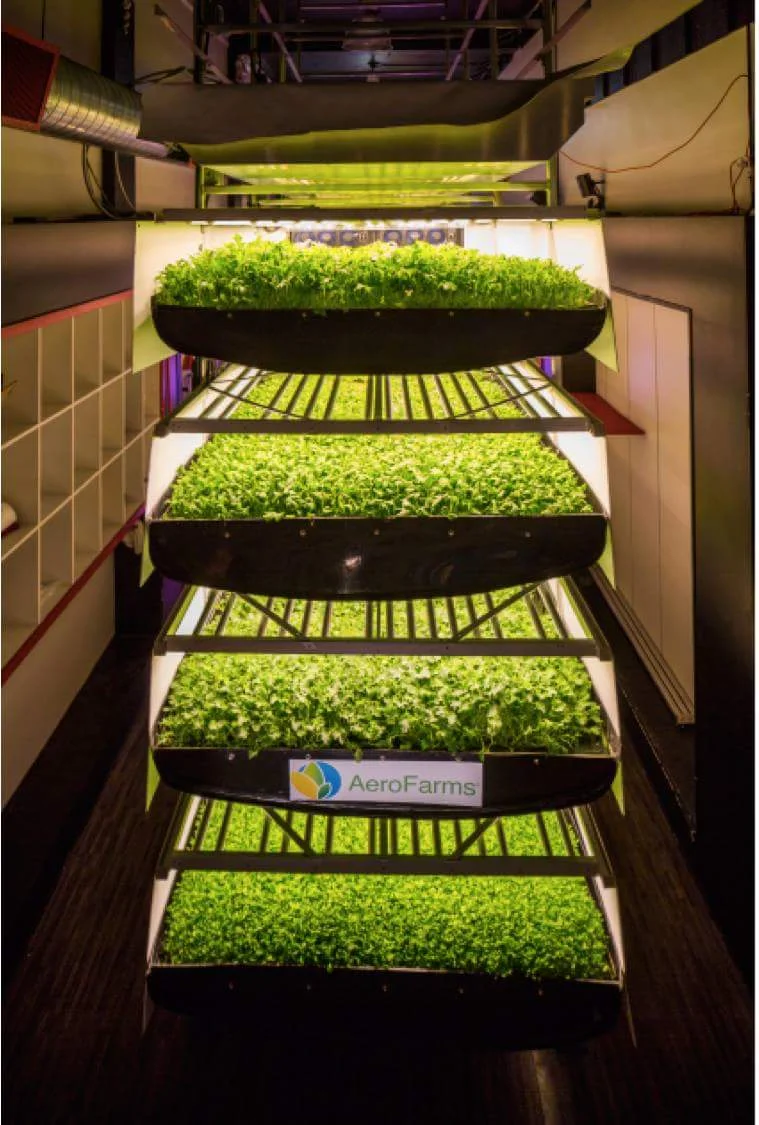

AeroFarm hasn't started vertically farming on an industrial scale, yet.

Putting theory into practice

Today there are several vertical farms in the early stages of construction.

In the US, Vertical Harvest based in Jackson, Wyoming, is up-and-running planning to vertically grow 100,000 pounds of vegetables every year.

If they achieve that goal it will offset 3% of the produce currently being shipped into the town.

But it’s early days and they have yet to prove that they can vertical farm this amount of food at such a scale.

AeroFarms in Newark, New Jersey, has even grander goals. The company plans to harvest 2m pounds of veg a year from their 69,000 sq ft warehouse, using 95% less water and 50% less fertiliser than a traditional farm… once production starts in September 2016.

The projects share two things in common:

Neither has proved that they can yet produce the quantity of food they promise, at an acceptable price and with a sustainable business model.

And both are supported by millions of dollars in venture capital investments and government subsidies.

What does it mean for your food shop?

If vertical farming works, the price you pay for food could fall – as transport costs disappear and farming becomes less wasteful – as we enter a new era of locally-sourced food.

Or, the price of your food could skyrocket – if the cost of the technology is passed onto shoppers, or if the efficiencies of vertical farming are never realised.

With millions being spent on vertical farming and dozens of vertical farms coming online over the next few months and years, it won’t be long until we discover if the food of the future will be grown in a warehouse.

Our weekly series What The Heck Is… exists to shed light on the strange unexplained acronyms and unfamiliar buzzwords that creep into our everyday lives.

By Oliver Smith

Farms Grow Up: Why Vertical Farming May Be Our Future

This is the dream of vertical farming.

The towering structures that fill urban skylines across the world could soon be filled with people and farm equipment. This is the dream of vertical farming.

Vertical farms can take a wide range of forms. The connecting feature of these innovative agriculture centers is their ability to grow food without using a lot of land. They accomplish this generally by growing food in stackable trays or on various growing levels within a vertical structure. While these growing centers can be built almost anywhere, many enthusiasts imagine them sprouting up in urban centers as either self-contained structures or even integrated into office and residential buildings.

Advanced vertical farm designs combine greenhouse agriculture, renewable energy, and hydroponics to provide cities locally based agriculture centers.

Elements of this futuristic vision are already a reality in the United States, the Middle East, Asia and Europe.

The birth of modern vertical farms

Ecologist and Columbia University Professor Dickson Despommier is most often credited with creating the modern vertical farm movement. After working on the concept for years, Despommier’s ideas entered the mainstream when he published The Vertical Farm Feeding the World in the 21st Century in 2011. This book helped fuel interest and development in vertical farms, but, as he explains in the video below, practical vertical farms are going to look more like complex greenhouses than the fantastical designs put forward by young innovators.

The argument for vertical farming

“The human population is expected to rise to at least 8.6 billion, requiring an additional 109 hectares to feed them using current technologies, or roughly the size of Brazil, Despommier said in an essay on vertical farming. “That quantity of additional arable land is simply not available.”

Despommier believes building up is the only solution.

Read More: Ugly Fruits and Vegetable Might Be the Answer to Zero Food Waste

Other advocates of vertical farming cite a broader set of benefits, ranging from year-round production, to reduced pesticide use, to less pollution from shorter distribution lines when growing centers are located within the populations they feed.

It’s important to note that there are skeptics who refute Despommier’s claims that the planet is running out of usable farmland as well as the sustainability of vertical farms. Despite these objections, a global industry has developed around vertical farming.

How it works

Vertical farming must get creative to duplicate traditional agriculture in non-traditional spaces.

Companies use a wide range of solutions from rotating crops to face the sun (like the Sky Greens approach mentioned below), to reflecting sunlight onto each level of the farm, to special LED lighting systems that replace sunlight.

Vertical farming can actually create more food than traditional farming by growing food hydroponically. This method uses substantially less water and, because it’s enclosed, is less vulnerable to bugs and disease. And soil alternatives like pumicemake the growing environment much more flexible and efficient, as well as less ecologically damaging to set up.

Read More: 7 Myths About GMOs That Actually Aren’t True

Does it work?

Vertical farms are already in use in a wide variety of places like the US, Oman, and Singapore. Current examples are more in the “advanced greenhouse” variety that Despommier referenced in his video, but there are a few companies putting more futuristic designs into practice.

Here’s a look at a few of the vertical farms already changing agriculture.

Podponics, (USA, Dubai, Oman)

The advanced greenhouse company, Podponics, started in Atlanta, Georgia, in the United States. Their system uses recycled shipping containers to create stackable, modular greenhouses. The company estimates each shipping container produces the same yield as an acre of traditional farmland. The company has raised millions in startup capital and runs projects in Atlanta, Dubai, and Oman.

Aerofarms (USA)

Image: Aerofarms

The world’s largest vertical farm is now located in Newark, NJ, in the United States. Startup Aerofarms converted a steel factory into a 69,000-square foot agriculture center that opened earlier this year.

The urban farm produces as much as 2-million pounds of leafy greens a year through a new growing system called “aeroponics,” which does not use direct sunlight or soil to deliver nutrients. It nourishes the plants with special LED lighting and delivers nutrients to plant roots through a liquid mist. The trays can be seen in the image below.

Their lettuces are already available in stores across New Jersey.

Plantagon (Sweden)

Image: Plantagon Mockup

A Swedish company, Plantagon, is one of the leaders in bringing agriculture into urban settings. The company sells conversion kits for existing buildings interested in adding greenhouse growing pods to their interior or exterior spaces. Next, the company intends to create the world’s first true “mixed use” building with both offices and agriculture centers in the same structure.

Read More: Don't Buy These 6 Foods If You Care About Humanity

The company currently runs a geodesic dome known as the “Plantscraper” in Linkoping, Sweden (pictured above). The dome has allowed the company to experiment with different technologies as they design their full mixed-use building also intended to be in Linkoping. In the video below, Plantagon outlines the vision for this first-of-its-kind space.

Sky Greens (Singapore)

Built by Sky Urban Solutions, the Sky Greens vertical farm is the “world’s first low-carbon, hydraulic-driven vertical farm,” according to its website. The farm’s major innovation is a system that rotates hydroponic trays so each is regularly exposed to natural sunlight, reducing the need for costly lighting systems.

Sky Urban Solutions is planning a much larger urban agricultural initiative for the small island nation it calls home. The company wants to build the SG100 Agripolis, a farm and research center that could provide 30% of Singapore’s green leafy vegetable needs. The proposed project has the backing of Singapore’s government because it would promote national food security and resiliency. The video below provides an overview of the venture.

The future of farming

It’s not clear if vertical farming will save the planet, but the early international experiments do seem to show it will be part of the world’s agricultural systems.

By Brandon Blackburn-Dwyer

Futuristic Japanese Indoor Vertical Farm Produces 12,000 Heads of Lettuce a Day with LED Lighting

Philips Lighting has launched the latest in its indoor vertical farming experiments, with trials at two Japanese facilities.

Philips Lighting has launched the latest in its indoor vertical farming experiments, with trials at two Japanese facilities—with one growing 12,000 heads of lettuce a day under horticultural LED lighting technology. Indoor farming is a growing trend in urban centers, where farmland is not prevalent. A wide variety of herbs and greens can be cultivated in climate-controlled environments under LED lighting, for an energy efficient food production method that connects local folks to freshly grown produce.

The two trial farms in Japan demonstrate the awesome potential of indoor urban farming efforts.

Innovatus’ Fuji Farm in Shizuoka Prefecture is an almost 20,000 square foot facility where farmers have spent the past 14 months growing five different varieties of lettuce. Now, the farm harvests 12,000 heads a day that are mainly frilled lettuce, green leaf, and romaine. The efficient vertical farm setup saves not only land and energy, but also water, and Fuji Farm’s harvests can be picked, packaged, and on store shelves in under two hours.

At Delicious Cook’s urban farm in Narashino City in the Chiba Prefecture, an enticing selection of edible herbs are grown under Philips LED lighting. There, farmers have been experimenting with less common varieties of herbs, including edible chrysanthemums and coriander, with great success. In a space smaller than many urban apartments (around 860 square feet), the farm recently completed a 10-month trial in which these unusual herbs were grown under Philips GreenPower LED system. The resulting crops will be used in the company’s processed food products.

One of the key advantages of Philips Lighting horticultural LED systems is the “recipes” used to cultivate specific crops. Farmers are able to set the precise combinations of light, temperature, and humidity level for optimal production of each type of plant. Philips makes the job of urban farmers even easier by developing specific light recipes for various crops, which dictate light spectrum, intensity, illumination moment, uniformity, and positioning. Using this approach, crop yields skyrocket, with consistent quality and flavor, all without daylight.

Images via Philips Lighting

By Cat DiStasio

Farming on the moon and meat grown in a lab. Six thoughts on the future of food.

As a technologist turned restaurateur, Kimbal Musk thinks daily about the future of food.

As a technologist turned restaurateur, Kimbal Musk thinks daily about the future of food.

Kimbal Musk (Courtesy of The Kitchen)

His own collection of restaurants, named The Kitchen and Next Door, aim to shake up food distribution by sourcing ingredients locally and providing fresh, natural food at sensible prices. His company, also called The Kitchen, builds hundreds of school gardens to teach children in low-income communities about healthy eating.

“No one wins in the industrial food system,” Musk said. “It’s awful at the individual level, and at the economic and community level.”

Musk’s last name should sound familiar. His older brother, Elon Musk, is the founder and chief executive behind technology firms Tesla and SpaceX. Musk sits on the boards of both of his brother’s companies, as well as the board of Mexican fast-casual chain, Chipotle. His career, in many ways, straddles the line between food and technology. (He and Elon originally made their fortune founding Zip2, a company that Compaq acquired in 1999.)

Musk spoke about his business ventures and restoring trust in the food industry last month at the World Future Society’s annual summit. Innovations caught up with him after the conference to pick his brain further. Here are six of Musk’s bold thoughts on the future of our food.

1. Vertical farming is poised for prime time — and outer space.

There is no question that Musk is a strong proponent of vertical farming, by which crops are grown in tall stacks under LED lights inside massive indoor facilities. The practice is being driven in large part by a desire to grow produce locally and thereby eliminate the need to ship items long distances. It would allow major urban centers, such as New York City or Chicago, to eat local fruits and vegetables during all four seasons. Musk said that 2015 marked the first year when vertical farming companies could sell produce at a profit, meaning the declining cost of the technology makes the practice feasible for the mass market. And when future generations eventually inhabit the moon, vertical farming may be how people eat fruits and veggies there. At least that’s what Musk told the audience of futurists late last month.

Lettuce farming in a modern hydroponic vertical farm, which uses only 1 percent of water a normal soil based farm would require.

2. Farming could soon be cool again.

Young Americans have not been bullish on careers in farming since roughly the Great Depression. Family farms have declined precipitously and corporate farms have been on the rise in the last 80 years, as The Washington Post previously reported. Musk sees an opportunity for that to change. The U.S. Department of Agriculture will offer $20 million each year in grants for new farmers until at least 2018. And thanks to aforementioned vertical farming, budding green thumbs need not move to rural communities to break into the agriculture business. For those who do desire the great outdoors, however, there may soon be ample land up for grabs. The average age of farm owners continues to increase, and more farmland will become available as those individuals lay down their shovels. “There will be an avalanche of supply of farmland over the next 5 to 10 years, or maybe at the latest 15 years,” Musk said. “It’s going to be a very exciting time in farming.”

3. The next million-dollar ideas will come from disrupting the food industry.

Of course, farming is just one end of the global food supply chain. Musk believes the industry is ripe for disruption all along the pipeline, from those who process ingredients into products to those who distribute them to restaurants that serve them. He compared it to the Internet in the 1990s. “You don’t know exactly what opportunity is in front of you, but you want to be in that industry. You want to be at the start of that wave,” Musk said. “My advice for any entrepreneur or innovator is to get into the food industry in some form so you have a front-row seat to what’s going on.” Successful entrepreneurs in the food business are also more likely to hail from Minneapolis or Memphis than Silicon Valley or New York, Musk added. America’s heartland and its food consumption habits more accurately reflect the country at large. “If you’re a vegan fast food joint in LA, you just don’t speak the same language as the heartland,” Musk said.

4. Trust in the food system requires greater transparency.

Musk focused much of his World Future Summit speech on trust and the idea that we no longer have much in our food. Whether it’s genetically modified produce or hard-to-pronounce chemical ingredients, Musk said that people often aren’t aware of what they’re eating or how it was made. In a world where vegetables are grown in warehouses and meat is made of plants (more on this in a minute), Musk said that building trust through transparency is absolutely crucial. “The problem with industrial food is zero transparency. The system thrives on the fact that there is no transparency,” Musk said. He hopes the next generation of food growers and manufacturers take a different approach. “If I were these guys, I would be thinking very much about transparency. What is the true impact of their product? What is the true nutrition of their product? Even if they have to use some futuristic ingredient, for lack of a better word, they’re very clear about what it is rather than hiding it from the consumer.”

5. Community impact requires entrepreneurs to go deep, not broad.

You don’t often meet entrepreneurs who think local. Take Musk’s older brother, who is trying to send people into space and eliminate their need to drive cars here on Earth. Musk said he, too, had a mind for global domination as a tech entrepreneur, but the same broad approach does not work in food. Shopping for groceries and dining at restaurants are still inherently local, and having an impact on the food people choose to consume has to be local as well. That’s why when Musk builds school gardens in a city, he constructs dozens of them at a time. He’s slated to open 50 in Pittsburgh and 100 in Indianapolis, for example. “When I look at a community and think about how we can bring this community to a real-food culture and get them thriving again, you have to go deep,” he said.

6. Our taste for meat will force us to look beyond animals.

Can a burger made from pea protein replace meat?

The beyond burger from Beyond Meat aims to replicate the texture, color and taste of a beef burger. (Jayne Orenstein, Joe Yonan/The Washington Post)

Successful efforts have been made to engineer meat in a laboratory or replicate it using plant-based ingredients. These aren’t frozen veggie burgers; we’re talking about an innovation beyond that. “Meat” that doesn’t come from cows, pigs and chickens could one day be more widely eaten, a shift that both animal welfare advocates and environmentalists would likely celebrate. After all, the increasing number of livestock that is necessary to sate the world population’s meat consumption has had a well-documented, negative impact on the environment. For his part, Musk is much more enthusiastic about plant-based meat products, questioning whether the lab-grown variety is something consumers will ever trust. He also says simply eating less meat is one path forward. “I am a fan of less and better meat rather than replacing meat,” he said. “That’s just me personally.”

Read more from The Washington Post’s Innovations section.

By Steven Overly

UK’s First Vertical Farm To Be Built In Scotland

They have the ability to grow crops in quick time, without the need for vast amounts of land, water or sunshine

UK’s First Vertical Farm To Be Built In Scotland

ALISON CAMPSIE

They have the ability to grow crops in quick time, without the need for vast amounts of land, water or sunshine.

Now the first vertical farm of its type in the UK is to be built in Scotland following a £2.5 million investment from the James Hutton Institute and Intelligent Growth Solutions (IGS).

Lettuce, baby leaf vegetables and microgreens are to be planted in the high-tech growing house near Invergowrie as part of a research project into how vertical farms can best produce crops for Scotland and beyond.

The method is being championed around the world –particularly in urban centres in the US as a way to grow food in small spaces without the need to transport the produce over long distances.

Crops are typically grown under LED lights with hydroponic systems using minimum water and no soil.

IGS predicts costs – such as those generated by lighting –will fall quickly to allow crops such as strawberries and tomatoes to be grown.

Henry Aykroyd, chief executive of IGS with 30 years experience in large-scale farming in the UK, Eastern Europe and California, said: “Our mission is to enable our customers to be the lowest cost producers by growing local globally, with better quality and saving natural resources. The process uses little water, no pesticides, can enhance taste and is consistent all year round.”

The Invergowrie farm will be the first in the UK to be built using automated towers which can respond to peaks and troughs of energy use.

Mr Aykroyd said: “Our real-time software can ‘grab’ power when the grid has surplus power and ‘shut down’ at peak times.

“Our automated growth towers are fully programmable to suit many diverse crops, and provide smart solutions to automation, power management and lighting issues,” he added.

Perth and Kinross Council has granted approval for the project with a 10-year lease now signed by the James Hutton Institute and IGS.

Professor Colin Campbell, Chief Executive of the James Hutton Institute, said: “We are doing more research with such innovative companies in the private sector and this example combines our knowledge of plant science and specialised infrastructure to work with others whose vision is aligned to help solve the challenges around long-term food security.”

How Motorleaf Is Helping Automate Indoor Farming

The motorleaf system can be used in any type of indoor farming operation from greenhouses through to warehouses and at any size

How Motorleaf Is Helping Automate Indoor Farming

Editor’s Note: motorleaf is raising $750k in seed funding on AgFunder.

If you walk into the produce aisle at Price Chopper’s Market Bistro store in Latham, New York, you will be greeted with one of the first hydroponic tomato growing operations inside a grocery store.

Installed in the store when it was built in 2014, the hydroponic display has developed quite a following from local consumers who keenly report back on the progress of the tomato plants to the operator, Vermont Hydroponic Produce.

What they don’t realize is that Vermont Hydroponic Produce has a clear view of this operation without having to step foot into the store, because the operation is being monitored, and automated, by a technology platform developed by Canadian startup motorleaf.

Motorleaf has built a smart and automated indoor farming operating system, consisting of hardware devices and software analytics, to enable growers to capture data about their crops, learn what the crops need, and instruct existing equipment to answer those needs.

Price Chopper is using motorleaf’s HEART device, which collects air temperature, humidity, and lighting level data, and feeds into motorleaf’s intuitive software. The HEART device then connects to an operation’s lighting hardware and feeder pumps to start automating their use. Growers can receive custom alerts to any mobile device to find out about the changing conditions of their farm and can even connect webcams into the HEART so they can view the farm in real-time.

The HEART, one of 4 hardware units. Plug it in and it starts collecting Air Temp, Humidity, & Light Level data. Connect any lighting hardware, and feeder pump and start automating their operation in seconds.

The HEART is the central hub of the motorleaf system, and can connect with up to 250 pieces of equipment. motorleaf has also developed another three pieces of hardware that can connect into the system and perform other tasks. The DROPLET connects to an operation’s water reservoir and collects essential information about water, PH, and nutrient levels, as well as temperature in the reservoir, and sends that data to the HEART. The DRIPLET enables growers to automate the delivery of PH and nutrients into the water supply based on a timer or conditions on the farm. Lastly, the POWERLEAF unit can control other equipment such as air conditioners and heaters, and can be instructed by the HEART to turn them off based on timers or sensor readings from the HEART and the DROPLET.

Motorleaf has the added benefit of continuing to collect data and automate operations even if an internet connection is lost, because the HEART acts as the main controller and router, sending out a signal to anything in range — about 90 meters — using low-frequency radio.

This 99% of guaranteed uptime is just one of the things setting motorleaf apart from other indoor grow solutions on the market. It also uses industrial quality sensors and probes, both local and cloud-stored data, multiple log-in and access profiles with a view only feature, motion detection with any webcam, and machine learning algorithms.

The motorleaf system can be used in any type of indoor farming operation from greenhouses through to warehouses and at any size. IBISWorld estimates that hydroponic growing equipment purchased in stores is already valued at $645 million, and with global hydroponic produce valued at $17.7 billion by Manifest Mind, and US legal cannabis at $5.7 billion, motorleaf has plenty of potential customers.

Motorleaf receives 40,000 data points per customer per week and therefore can start predicting a crop’s needs, solving potential problems before they exist. Also, the startup plans to use its network of data and growers to connect users to each other – on an opt-in basis – to share data, plant recipes and knowledge.

Ramen Dutta, the inventor of motorleaf, started building the first prototype after trying to find a solution flexible enough to control and automate his own gardens.

Dutta graduated from McGill University with a degree in agriculture engineering. Instead of pursuing a career in agriculture, he went into IT and launched his own company, RamComputing Services, but continued to pursue his passion for agriculture by running a small indoor hobby farm.

After several months of hacking and improving his prototype and realizing that other growers in his area also wanted such a solution, he joined forces with Ally Monk, now CEO of motorleaf. Monk has a background in business and product development for technology, including roles at eFundraising.com, which was sold to Readers Digest for $27 million, OneBigPlanet, where he helped to raise $3 million in venture capital, and MemberBenefits Inc, which was acquired by Brook Ventures.

“The demands of Ramen’s IT business meant that he didn’t want to constantly go back and forth to his operation to test PH and nutrient levels, so he looked for an off-the-shelf solution that could turn his garden into a smart garden — like a ‘Nest’ for ag — and he couldn’t find anything on the market,” says Monk. “So he started hacking together what we eventually called the HUB — for Huge Ugly Box — which was giant but started to offer the solutions he wanted.” The company has since reduced the size of this box significantly in an elegant and functional design.

Local growers instantly showed interest in the system, pushing Dutta and Monk to focus full-time on the business and they won a place in the Founders Fuel accelerator program, one of Canada’s leading accelerators, where the theme was artificial intelligence. This accelerator is funded by Real Ventures, which has now invested in motorleaf.

Now the technology is market ready and without any cash spent on marketing, motorleaf has over 200 units on order from a range of customers including OEM manufacturers, supermarkets, high schools and licensed cannabis farmers. motorleaf is now raising $750k in seed funding on AgFunder to manufacture and market its technology at scale and build out the motorleaf team.

View the profile here and email motorleaf@agfunder.com to connect with the company.

Vertical Farms On The Rise In Land Scarce Singapore

Vertical farming is growing in Singapore. From just one in 2012, there are now seven licensed vertical farms producing vegetables, fish and crab

Vertical farms on the rise in land scarce Singapore

There are seven licensed vertical farms in Singapore producing vegetables, fish and crab

Published: Jul 10, 2016, 5:00 am SGT

Vertical farming is growing in Singapore. From just one in 2012, there are now seven licensed vertical farms producing vegetables, fish and crab.

These farms use high-tech and high-yield methods to overcome the limitations of traditional farming and transform their work into lucrative businesses.

Vertical farming is also gaining popularity because the farms optimise land use in land-scarce Singapore and can operate on minimal manpower.

Packet Greens, for instance, is an indoor vertical vegetable farm that sits on 1,500 sq ft of space - about the size of two three-room HDB flats - in a unit in an industrial building in Boon Lay Way. Only three people are needed to harvest the 30kg daily yield of vegetables.

For those with larger premises, the numbers are more impressive.

Sky Greens, Singapore's first vertical farm, produces up to 1,000kg of vegetables a day. About 10 farmhands are needed to harvest that amount. When the farm reaches full capacity early next year, it can produce 5,000 to 10,000kg a day.

Vertical farms have high yields because they are high-tech. At Sky Greens in Lim Chu Kang, vegetables grow on 9m-tall towers made of tiers of planting troughs rotating around an aluminium frame. Each tower produces five to 10 times more vegetables than conventional methods in the same land area.

Apollo Aquaculture Group, which has a vertical fish farm and a crab farm, uses high-tech water treatment, which circulates water in self-contained systems that clean it more efficiently. An optimal environment for the fish protects them from disease, lowers death rates and allows more fish to be reared in a single tank.

Owners say the most challenging - and expensive - part of setting up a vertical farm is sorting out the technology. Most took about two years to design and develop their systems.

The founders of indoor vertical farm Sustenir Agriculture in Admiralty, which began operations in 2014, spent 11/2 years speaking to consultants and professors, so they could understand the possibilities and limitations of growing vegetables in a controlled indoor environment.

Today, co-founders Benjamin Swan, 35, and Martin Lavoo, 29, who have invested $3 million in their farm to date, have a global patent on their infrastructure design. They say their technology allows them to produce vegetables that have no exposure to chemicals, pesticides, pollutants and even dirt.

Vertical crab farm Gills 'N' Claws in Kranji was born after 21/2 years of research and development. The farm fattens up Sri Lankan mud crabs that are bred in a hatchery in Sri Lanka and then sells them to crab dealers and restaurants here.

Vertical crab farm Gills ‘N’ Claws, run by chief executive Steven Suresh, fattens up mud crabs that are bred in Sri Lanka and then sells them to crab dealers and restaurants here.

Once things are up and running at these farms, the gains are significant. Gills 'N' Claws chief executive Steven Suresh, 46, says about 1,000 mud crabs can be raised in 100 sq m, compared with 30 in open farming.

Because of the high quality of Sustenir Agriculture's produce, the company counts among its clients restaurants from top food and beverage groups such as Tung Lok, Les Amis and Da Paolo.

Mr Swan says Sustenir will soon be selling its vegetables at major supermarket chain Cold Storage and upscale chain Jasons.

In spite of the high set-up cost, the farmers say their products are reasonably priced. Apollo Aquaculture chief executive Eric Ng, 43, who has spent about $4 million on his farms, says his hybrid grouper retails at about $28 a kg, which is comparable with the market rate.

In some cases, the produce is cheaper than the market rate.

The farmers' efforts have taken them beyond Singapore.

Sky Greens has been actively expanding overseas in markets such as China and Thailand and is exploring Malaysia and Hawaii.

Mr Suresh, too, is in talks with investors from countries including Australia and Germany.

The Agri-Food & Veterinary Authority of Singapore says it is supportive of vertical farming as it makes use of technology and production systems that optimise land use and boosts the capability and productivity of local farms.

Vertical farmers such as Mr Swan hope their efforts will draw younger ones. He says: "The sector needs young talent to find new and creative ways of farming, so that we can make a difference to people's lives and the environment."

Mr Eric Ng, chief executive of home-grown fish farm Apollo Aquaculture Group, runs a high- tech vertical farm that was built up from scratch.

His 10m-high, three-storey vertical fish farm is the only one of its kind licensed by the Agri-Food & Veterinary Authority of Singapore (AVA). Everything can be remotely controlled and is carefully programmed, right down to the amount of fish feed dispensed via automatic feeders.

Mr Ng, 43, says of the precision involved in running the farm in Lim Chu Kang: "This operates more like an engineering plant."

His father set up the farm in 1969. It employed traditional fish farming methods until Mr Ng took over the reins when his father died in 2009.

"My father was pro-technology," he says. "He told me to transform things if I saw the need for technology to move the business forward."

In 2009, with help from a Spring Singapore technology improvement grant, he built a $600,000 tank quarantine and filtration system for the farm's ornamental fish, which reduced water usage dramatically.

The system, which he calls the Aquadeck, comprises rows of tanks stacked three levels high. They allow for high-density stocking of fish while maintaining high water quality.

In 2012, he built a $1-million land- based fish farm. The 12-tank experimental system could rear 300 to 400kg of fish in each tank, using high-tech water treatment.

After that took off, Mr Ng says he started thinking multi-tier. With a land area of 20,000 sq m in Lim Chu Kang, he is not lacking space. However, he believes developing vertically is the way to go.

"We can intensively farm our products in a single unit and with a smaller footprint."

The yield from a vertical farm is eight to 10 times more than what he can get from open farming.

The three-storey structure was completed last November, following two years of design and development. It comes with six ponds - two on each level. Each pond is 135 sq m and can hold about 22,000 fish fry.

Mr Ng, who is married to a housewife and has three children, has reared seabass, giant trevally, several types of grouper and shrimp.

"It's all in the water," he says of the successful rearing method, which he adds is parasite-free and does not have fin rot or gut problems.

He supplies the fish to restaurants, including Majestic Bay Seafood Restaurant at Gardens by the Bay and Kai Garden at Marina Square.

He also runs a vertical crab farm, which he started experimenting with in 2011 and went full scale in 2013. He began with 200 crabs and can now farm 4,000.

The soft-shelled mud crabs are housed individually in vertically stacked, toolbox-shaped containers and fed fresh fish scraps. He gets the Sri Lankan and Philippine mud crabs from suppliers in Singapore when they weigh 80 to 100g and readies them for sale when they are 300 to 500g.

With the business going swimmingly, he has his sights set on bigger things. He intends to build another similar vertical farm at his Lim Chu Kang premises and will be helping a fish farmer in Sungei Tengah construct a multi-tiered structure.

He will have to relocate the farms next year when the lease expires, but he says that does not mean his efforts would be wasted. Because of their modular design, he can "strip down" the farms and build them up again.

He hopes to boost home-grown production with his vertical farms. In 2014, only 8 per cent of all fish consumed here - about 4.2 million kilogrammes - came from local sources, well short of the AVA's 15 per cent target.

Mr Ng hopes to produce 7 to 8 per cent of Singapore's fish intake in three years' time. It is a bold vision, considering his farm is producing just 0.2 per cent of the fish consumed here at the moment.

"I've only just begun," he says.

More than 50 types of pesticide-free vegetables

Do not underestimate the small premises that vertical vegetable farm Packet Greens occupies.

It operates out of a single, 1,500 sq ft unit in industrial building TradeHub21 in Boon Lay Way and can grow 20 to 30 varieties of vegetables at a time.

In the two years that it has been in operation, it has succeeded in growing more than 50 types of vegetables, herbs and edible greens. These include lettuce, rocket, celery, kale, basil, thyme, mint and dill, and exotic varieties such as shiso, ice plant and the swollen- stemmed kohlrabi.

The farm was started in 2014 by entrepreneur Phuan Pui Jong and his wife, Madam Tio Siew Geok, 64. He died of a heart attack in November last year at age 70.

The farm is now run by Madam Tio and their children, Frank, 40, and Praise, 37.

Before the farm, Mr Phuan and his son founded home-grown solar panel-maker Sunseap Enterprises in 2000.With a slowdown in the manufacturing sector, the older Mr Phuan decided to look at other business opportunities.

The farm is a product of his interest - he used to grow herbs and flowers at home. In 2014, he and his wife went to Taiwan to see how indoor vertical farms there were run.

Impressed by how these could grow pesticide-free vegetables that could be eaten safely without first being washed, he paid a six-figure sum to import the technology from one of the farms in Taiwan to Singapore.