Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

AgTech Investing Report - 2016

Agtech funding figures dipped to $3.2 billion in 2016 from $4.6 billion in 2015. This reflected the broader pullback in global venture markets, though deal activity in agtech was the strongest to date with 580 deals closed

AgTech Investing Report - 2016

Agtech funding figures dipped to $3.2 billion in 2016 from $4.6 billion in 2015. This reflected the broader pullback in global venture markets, though deal activity in agtech was the strongest to date with 580 deals closed.

The year 2016 was full of contrasts. While global VC investment fell 10%, total investment in agtech fell to $3.2 billion - a 30% drop from 2015, but well ahead of 2014. Interestingly, global VC deal activity declined 24%, but it was agtech’s busiest year to date with a 10% increase in the number of deals closed year-over-year. This was largely the result of new support from the growing number of accelerators and other early stage resources dedicated to food and agtech startups.

The dip in dollar funding in 2016 was due in part to a cooling off in investor interest in drones, food delivery, and bioenergy, and also because of a few large financings in 2015 that drove numbers. However, four of our nine sectors showed an uptick in activity, and Seed and Series B investment came in particularly strong.

Exits remained a talking point among VCs as M&A activity from the large agribusinesses remained far too low. 2017 is already looking a lot brighter for global VC, however, and we expect growth in agtech driven by investor interest in supporting the future of food and agriculture.

Global Vertical Farming Market 2017- AeroFarms, Gotham Greens , Bright Farms, Vertical Harvest

Worldwide Vertical Farming Market 2017 Research report is an in-depth analysis of 2017 global Vertical Farming market on the current state

Global Vertical Farming Market 2017- AeroFarms, Gotham Greens , Bright Farms, Vertical Harvest

by John Coates | @ | February 2, 2017 10:41 am

Worldwide Vertical Farming Market 2017 Research report is an in-depth analysis of 2017 global Vertical Farming market on the current state.

First of all, the report (2017 Vertical Farming Market) provides a basic overview of the Vertical Farming industry 2017 including – definitions, classifications, Vertical Farming market by applications and Vertical Farming industry chain structure. The 2017’s report on Vertical Farming Industry analysis is provided for the international Vertical Farming market including development history, Vertical Farming industry competitive landscape analysis, and major regions development status on Vertical Farming scenario.

After that, 2017 Worldwide Vertical Farming Market report includes development policies and plans are discussed. Vertical Farming market 2017 report also covers manufacturing processes and cost structures on Vertical Farming Scenario. This report also states Vertical Farming import/export, supply, Vertical Farming consumption figures as well as cost, price, Vertical Farming industry revenue and gross margin by regions (United States, EU, China, and Japan).

Then, the report focuses on global major leading Vertical Farming industry players with information such as company profiles, product picture and specification, capacity, Vertical Farming production, price, cost, Vertical Farming Market revenue and contact information.

Top Manufacturers Analysis in Vertical Farming market 2017:-

1 AeroFarms

2 Gotham Greens

3 Bright Farms

4 Vertical Harvest

5 Home Town Farms

6 Infinite Harvest

7 Lufa Farms

8 Beijing IEDA Protected Horticulture

9 FarmedHere

10 Garden Fresh Farms

11 Metro Farms

12 Green Sense Farms

Click Here for Report Sample: https://market.biz/report/global-vertical-farming-market-2017/41119/#requestforsample

Global Vertical Farming Market 2017 Analysis: By Product

1 Aeroponics

2 Hydroponics

3 Others

2017 global Vertical Farming market report also covers – Upstream raw materials, equipment and Vertical Farming downstream consumers analysis. Furthermore, the 2017 Vertical Farming market development trends, and marketing channels are analyzed on Vertical Farming scenario.

Finally, The Report (2017 Worldwide Vertical Farming Industry)- Feasibility of new investment projects is assessed, and overall Vertical Farming market research conclusions are offered.

Underground Greens Grower Secures Online Retail Deal

Underground Greens Grower Secures Online Retail Deal

1 February 2017, by Gavin McEwan, Be the first to comment

London urban farming pioneer Growing Underground launches its first retail range of international-themed salad mixes via Ocado.com from today (1 February).

Its five-strong series of salad mixes consists of:

- English – English mustard leaves, broccoli shoots and pea shoots;

- Italian – salad rocket, garlic chives and pea shoots;

- Indian – fennel, coriander and pea shoots;

- Asian – purple radish, coriander and pea shoots;

- Japanese – wasabi mustard, pink stem radish and pea shoots.

Based in a World War II bomb shelter 30m beneath Clapham High Street, Growing Underground was founded five years ago by entrepreneurs Steven Dring, Richard Ballard and Chris Nelson, and is backed by chef Michel Roux Jr.

So far the business has been supplying micro-herbs and salads to London wholesalers, farmers' markets and Michelin-starred restaurants. Growing in a fully controlled, pest-free environment enables it to provide crops of consistent quality year-round, it says.

New produce trials are ongoing, and the farm has the capacity to quadruple its growing space as demand increases.

Co-founder Steven Dring said: "We've been working for years to perfect what we do and we're so excited about this retail range. Sustainable, low-energy growing of exceptional produce is a central part of our ethos and we're delighted that through this partnership with the UK's leading online supermarket we can now share our amazing micro-herbs with consumers.

"We're so pleased that Ocado have put their faith in a small start-up that is working hard to promote innovation and sustainability in British farming, and are very encouraged by what this could mean for the future of the industry."

We Proudly Announce

We Proudly Announce

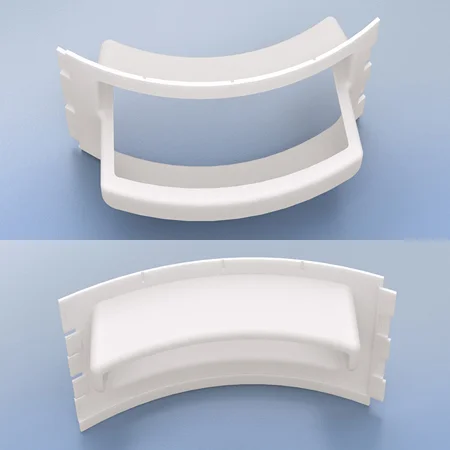

The series production of the 2. generation of our barrel parts is now up and running and we are ready to ship! This includes the standing base, the new lids and the two 2-inch net pot adapter parts to grow lettuce and herbs

All parts incorporate the improvements of the last two years of development and support from professional growers:

- An inside wing structure, directing the liquid to the root areas of your plants, also allowing for much higher barrels.

- A new connection mechanism between the adapter parts ensuring a tight more exact fit, easier assembly, facilitating to stack and handle barrel ring segments.

- A new irrigation option - an inverted sprinkler, and a new lid.

- Materials used: ASA as the main material for the 1/6th parts being the most robust and uv-resistant option and PVC for lids and stands.

If you are interested in running or testing the barrel concept please get in touch now. Here you can find pricing and shipping information and more detailed images of the parts and how it looks in production (scroll down).

In 2017 we plan to extend the barrel concept further into new soil-less adapter parts, that can be used for bigger plants and more versatile grow space set-ups. And we will even extend into a nifty movable soil-based wickerbed version. Click here for more information.

PCT Announcement

In the meantime the PCT announcement of our patent has been published (WO2016/156334) extending the priority phase to localize IP internationally. This is a major milestone to protect new partnerships.

We are currently looking for strong partners to manufacture and/or set up sales channels outside Germany/Europe! For more information please get in touch with us!

Trade shows and events 2016/2017

- GreenTech June 2016 in Amsterdam

- AgTech Week NYC September 2016 in New York City with demo of the aponix vertical barrel.

- CropWorld October 2016 in Amsterdam

- Upcoming 9-10 May 2017, meet us at the Global Forum for Innovations in Agriculture in Utrecht.

Latest mentions

- Read about Marco's and other opinions on the upcoming agri-food revolution.

- UrbanAg News: Aponix extended the NFT idea into the 3rd dimension with their vertical barrel

- National television visiting the aponix underground testing farm (5min video, German).

- Aponix winner at Green Product Award, category freestyle

- Staatliche Lehr- und Versuchsanstalt für Gartenbau Heidelberg (LVG) testing barrels in parallel to NFTs.

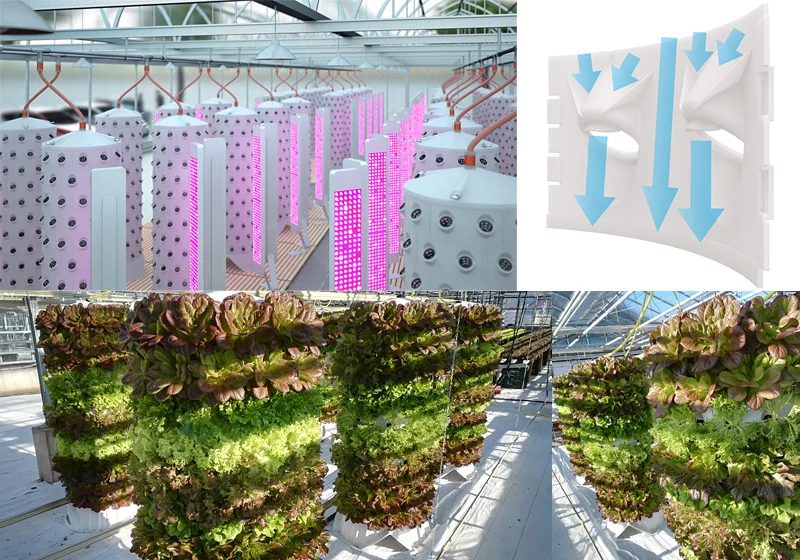

The Aponix Vertical Barrel

The aponix vertical barrel can be used as growing component like an NFT in an existing liquid nutrient cycle for high density growing.

Barrels can be build using simple and compact plant adapter parts, being assembled into barrel ring segments. By stacking ring segments you set up your grow spaces without the need for additional fixed table- or rack structures. The available cubic growing space determines the number of grow spaces you can run. Of course multiple barrels can be connected inside your production facility providing >60 grow spaces per sqm. Please check this page for some integration examples.

Barrels can be rotated. Hanging and standing versions are available. Currently each barrel is powered by one top sprinkler or a spray nozzle. Nutrient solution is running down the inside from the top lid being directed by an internal wing structure towards each root area of your plants, practically turning the barrel into a giant vertical 3D-NFT. For more details please check our FAQs.

Modular Farms Newsletter #6

January has undoubtedly been the busiest month in the history of our young company. For each calendar day that passed we were introduced to more and more people that are driven to reshape the agricultural landscape, both domestically and abroad, via the use of ZipGrow technology, Modular Farms and other sustainable farming practices

Modular Farms Newsletter #6

January has undoubtedly been the busiest month in the history of our young company. For each calendar day that passed we were introduced to more and more people that are driven to reshape the agricultural landscape, both domestically and abroad, via the use of ZipGrow technology, Modular Farms and other sustainable farming practices. At this rate, 2017 is poised to be a huge year for the indoor farming industry as a whole, and we are honored to be amongst the cohort of businesses that are helping to educate and empower the next generation of hydroponic farmers to make a difference in their communities.

Recently, we had the privilege of taking some of our FarmWalls out of our office and showcasing them at various places throughout our community. The first stop on tour was at an event hosted by 4Life Natural Foods in Kensington Market - an urban Toronto grocery store focused on selling locally sourced, sustainable organic produce. We partnered with 4Life to assist in the development and construction of a 5000 square foot indoor ZipFarm that will be located on the roof of their downtown location.

The FarmWall we showcased at the event gave the grocer's patrons a chance to get a first-hand look, feel and taste of the produce that will be available to them year-round once construction of the rooftop farm is complete. Needless to say, a lot of excitement ensued from those who bravely trekked through the hideous snowstorm to attend that evening.

The second, and more permanent, stop on the FarmWall tour was at the Institute of Management and Innovation, located at the University of Toronto's Mississauga campus. Under the guidance of our Plant Health Technician, Kevin, the Sustainability Management grad students have been eagerly putting their studies into practice by utilizing the 2-tower system as a part of their Capstone project. We are overjoyed with the amount of interest that the students are having with the project, and are excited to see and taste the fruits of their labour!

This month marked the end of an era for Modular Farms, as we watched our beloved beta farm get unplugged, decommissioned and whisked away from our office on the back of a truck. On the bright side, we took solace in the fact that it was on its way to Cornwall, where the Smart Greens team will be using it to educate and train the first generation of Canadian Modular Farmers. As much as our team will miss working and growing in the ol' girl, the farm's departure from our Brampton office signifies our official transition from farmers to manufacturers, as we begin getting the first set of Modular Farms off the production line and into the eager hands of our customers.

As most of you already know, unlike other containerized indoor farming providers, who simply re-purpose used shipping containers, we custom build our farms from the ground up. Aside from the extra room allotted to farmers for working, the fact that our farms are made in-house allows us to meticulously observe and scrutinize the entire manufacturing process. This ensures that the farms our customers are receiving meet all of our stringent quality control requirements; and, as you can see from the above video, it also ensures that we will have a steady stream of memorizing time-lapses of the farms being assembled for years to come!

This month also featured our CEO's yearly overseas pilgrimage out east to the annual Indoor Ag-Con event in Singapore, where he was once again honoured as a featured speaker. The event this year was mainly focused on the accelerating innovation in the industry, from plant biology to innovative farm designs and new business models. Once the event concluded, Eric also had the pleasure of venturing slightly south for the official ribbon-cutting of Modular Farms' new office and manufacturing facility in Australia!

Stay tuned for the next installment of our newsletter!

Hundred-Story Food-Growing Tower Is Dream of Weed Entrepreneur

Hundred-Story Food-Growing Tower Is Dream of Weed Entrepreneu

According to Rick Byrd, the future of farming is tall, dirtless and local.

Byrd's vision of skyscraper farms to feed city dwellers begins with a much different kind of crop: marijuana.

The 45-year-old is chief executive officer and founder of Pure Agrobusiness Inc., a company that sells equipment to grow legal cannabis, a market worth $6 billion in 2016 and expected to reach $50 billion by 2026, according to Cowen & Co.

Because cannabis has higher profit margins than food, and pot is mostly grown inside, Byrd said he hopes the innovations perfected by PureAgro, with the help of customer feedback, could one day revolutionize food production. It's just a question of how much it costs.

Pot is "the perfect catalyst to bring in what I think really needs to change in farming," Byrd said in an interview. "You can't have the average produce truck going 1,500 miles to get to your plate. And there's no way, obviously, to farm the amount of acres that we would need to feed New York City unless we go vertical."

Byrd imagines a 100-story glass skyscraper filled with floors of stacked beds of fruits, vegetables and grain. The same technology that currently enables vertical indoor farms to raise primo weed can one day produce perfect tomatoes or succulent lettuce, Byrd said. Paper or mesh holds up the plants, substituting for soil. Powerful lights do the work now done by the sun, but better. Data calibrate the exact light spectrum and nutrients for the plants to thrive, and machines drip just enough water. Harvests are frequent -- four or five a year, compared with one outdoor.

Making urban farms vertical instead of horizontal could cut agriculture's reliance on fossil fuels and diminish risks from pests, pesticides and an increasingly haywire environment, Byrd said.

Because price is less of a problem with cannabis, pot growers are better able to adapt to new, more expensive technology. An ounce of kale, for instance, costs 49 cents at Whole Foods Market. An ounce of cannabis can run $150 to $200, according to data from BDS Analytics, a research firm. When technology expenses fall low enough, a tipping point arrives, and food farmers can take advantage of what the pot producers already use. With legal weed pushing down pot costs, even marijuana growers will need cheaper technology, Byrd said.

"Who do you think is going to implement technology? Obviously the cannabis guys," Byrd said.

In some places, Byrd's dream of vertical food production is already happening. Specialty items -- basil leaves, for example -- are raised in air farms in places like Brooklyn, New York. Sky Greens, in Singapore, began operating in 2012 to reduce reliance on food imports. Plants are grown using hydroponics -- without soil -- in an aluminum frame. In the offices of Tokyo-based human-resources company Pasona Group Inc., 20 percent of the space is used to grow vegetables. Ten thousand square feet of growing beds and lights share space with conference rooms and offices. The building produces 100 different kinds of fruits and vegetables.

When Byrd first came across plans for farm-filled buildings nearly a decade ago, he thought they were far-fetched, he said. That was around 2008, as Byrd completed building the first LEED platinum certified home with actor Adrian Grenier, of "Entourage" fame, in a project that was featured on Discovery's Planet Green channel. Due to the show's exposure, Byrd received architectural plans for eco-friendly buildings from all over the world, including farms in 100-story high-rises.

"It didn't pencil out then," he said. "Then came the cannabis boom."

The problem with growing indoor food, or pot, is missing out on free resources like rain and sun.

"Why would you ever block a non-carbon-emitting source of photosynthetic active radiation that grows plants at no cost?" said Paul Sellew, CEO of Little Leaf Farms, a greenhouse that cultivates produce in Devens, Massachusetts. "It's a fad, and it will pass."

But climate change is making outdoor conditions less predictable, said Christiana Wyly, operating partner at Satori Capital, a private equity firm.

Byrd, who likes to wear blue and black Armani and said he doesn't smoke marijuana, said PureAgro, based in Denver and Los Angeles, recently began working with an investment bank. That's unusual for a business working with marijuana, which is legal in some form in 28 states but taboo with the federal government. Shares of publicly traded Scotts Miracle-Gro Co., an agricultural supply company and PureAgro's competitor, rose 48 percent last year. Now comes the uncertainty of the Trump administration, and a attorney general nominee in Alabama Sen. Jeff Sessions, who's expressed hostility to legal weed in the past, over how they plan to deal with federal drug law.

Given that the majority of the world's population lives in urban centers, it will eventually be necessary to grow food nearby, said Al Shay, an instructor in the Department of Horticulture at Oregon State University in Corvallis.

But the strength of the land-based farm lobby has kept the indoor industry from spreading more, he said. The cannabis industry could be the spark, he said.

"People toyed around with batteries in cars for a long time," Shay said. "It wasn't until Elon Musk came along with Tesla and made it highly efficient and super sexy."

The Ag Tech Market Map: 80+ Startups Powering The Future Of Farming And Agribusiness

JANUARY 30, 2017

The Ag Tech Market Map: 80+ Startups Powering The Future Of Farming And Agribusiness

Corporate investors such as Mitsui, Monsanto, and Syngenta have backed startups improving irrigation, crop spraying, harvesting, and more.

As population growth increases the need to ramp up food production, tech startups are creating a range of agricultural software, services, farming techniques, and more aimed at bringing more data and efficiency to the sector.

We used CB Insights data to identify more than 80 private companies in agriculture tech and categorized them into eight main categories.

We define ag tech as technology that increases the efficiency of farms (in the form of software), sensors, aerial-based data, internet-based distribution channels (marketplaces), and tools for technology-enabled farming. We only include companies that primarily target the agricultural sector.

Farming & Ag Tech Webinar

Tech companies are gradually changing farms and making agriculture more efficient. Register now to see trends, investment data, and more on this growing industry.

The breakdown is as follows:

- Farm Management Software: This includes software like that produced by Andreessen Horowitz-backed Granular that allows farmers to more efficiently manage their resources, crop production, farm animals, etc.

- Precision Agriculture and Predictive Data Analytics: These startups include those that focus on using big data and predictive analytics to address farm-related issues and make better farm-related decisions in order to save energy, increase efficiency, optimize herbicide and pesticide application (such as Prospera, which uses machine vision and artificial intelligence), and manage risk, among other uses.

- Sensors: Startups in the sensor category include Arable, which offers smart sensors that collect data and help farmers monitor crop health, weather, and soil quality.

- Animal Data: These companies provide software and hardware specifically aimed at better understanding livestock, from breeding patterns (Connecterra) to genomics (TL Biolabs).

- Robotics and Drones: This category includes drone companies and related drone services that cater to agricultural needs (such as TerrAvion), as well as robots or intelligent farm machines that perform various farm functions more efficiently (such as Blue River Technology, backed by Monsanto Growth Ventures, Syngenta Ventures, and Khosla Ventures, among others).

- Smart Irrigation: These startups, including Hortau, provide systems that help monitor and automate water usage for farms using various data exhausts.

- Next Gen Farms: A growing category of companies that utilize technology to provide alternative farming methods to enable farming in locations and settings that cannot support traditional farming. Examples include AeroFarms for vertical farming and BrightFarms for new greenhouses.

- Marketplaces: These startups offer marketplaces relevant to agriculture by connecting farmers directly to suppliers or consumers without any middlemen. While some are e-commerce platforms, others use tech to facilitate physical marketplaces (La Ruche Qui Dit Oui).

Some companies may overlap with different categories and are grouped according to their main use case.

Track all the Ag Tech startups in this brief and many more on our platform

Startups are working to change how our farms work. Sign up for a free trial and look for Ag Tech Startups in the Collections tab.

By 2030 Megacities May Devour More Than 86 Million Acres of Prime Farmland

By 2030 Megacities May Devour More Than 86 Million Acres of Prime Farmland

By Andrew Amelinckx on January 27, 2017

A recent study by a group of scientists from around the world finds that by 2030, sprawling mega-cities will squeeze out productive farmland, especially in Asia and Africa, putting a burden on what will be an already overtaxed food system.

The study, “Future urban land expansion and implications for global croplands,” published last month in the Proceedings of the National Academy of Sciences, finds that by 2030, as much as 86.5 million acres of productive farmland worldwide—between two and four percent of total farmland—will be lost as the world’s so called mega-cities, generally defined as being more than ten million residents, and the adjoining areas, called “mega urban regions,” take over prime agricultural croplands to make room for a growing population and their activities.

The group of scientists from Yale, Texas A&M, the University of Maryland, and research institutions in Germany, New Zealand, Sweden, and Austria, found that the world’s most productive cropland—that which is irrigated—is the most at risk. That’s because 60 percent of it is on the the outskirts of large cities. As these cities expand, cropland is lost. According to the study, this irrigated land tends to be twice as productive as the other 40 percent.

“The loss of these critical farmlands puts even more pressure on food producing systems and shows that we must produce strategies to cope with this global problem,” Burak Güneralp, one of the study’s authors and a research assistant professor in the Department of Geography at Texas A & M told Texas A & M Today.

Urban agriculture, the expansion of farming into areas farther from urban centers, and farming intensification practices (such as the heavy use of fertilizers), will offset some of the loss of farmland, say the scientists. Even so, some arid regions, like North Africa and the Middle East, are already pushing the outer limits of land use and don’t have the luxury of expanding farming into new areas away from large cities.

“The loss of cropland can be compensated by the global food system, but the effects will not be distributed equally,” the scientists write in the study. “Many less developed and emerging countries will face acute losses, both in absolute and relative terms.”

Egypt and and Vietnam would be among the hardest hit, with the former expected to lose more than 34 percent of its total farmland; the latter, more than 10 percent. Relatively speaking, the United States, isn’t at a huge risk; 7.3 million acres (.08 percent of total farmland) could be lost as large cities and mega urban areas expand into agricultural lands.

This trend is likely to result in a shift in global agricultural markets and trade, which will be bad for some countries—Egypt for example—which could become more reliant on food imports and “more susceptible to international food supply shocks” since it won’t be able to produce enough on its own. A good example of what can happen when countries are heavily dependent on imported agricultural products is illustrated by the 2010 food riots in Mozambique, which left a dozen people dead and more than 400 injured.

The study’s authors say that meeting the goals of creating enough housing for the urban population and preserving prime cropland requires “good governance” and urban planning. One big problem is that the countries most likely to be affected by cropland loss tend to have problems with corruption, ineffective governance, and a lack of regulatory control that makes planning for the future tough.

“The results suggest that strategies and policies to effectively steer patterns of urban expansion will be critical for preserving cropland,” say the authors. “In an increasingly interconnected world, the sustainability of urban areas cannot be considered in isolation from the sustainability of resources and livelihoods elsewhere.”

Norwegian Photobiology, Led Lights Company at Ag-Con Asia

Norwegian Photobiology, Led Lights Company at Ag-Con Asia

by Joakim Persson, Managing Editor ScandAsia

January 22, 2017

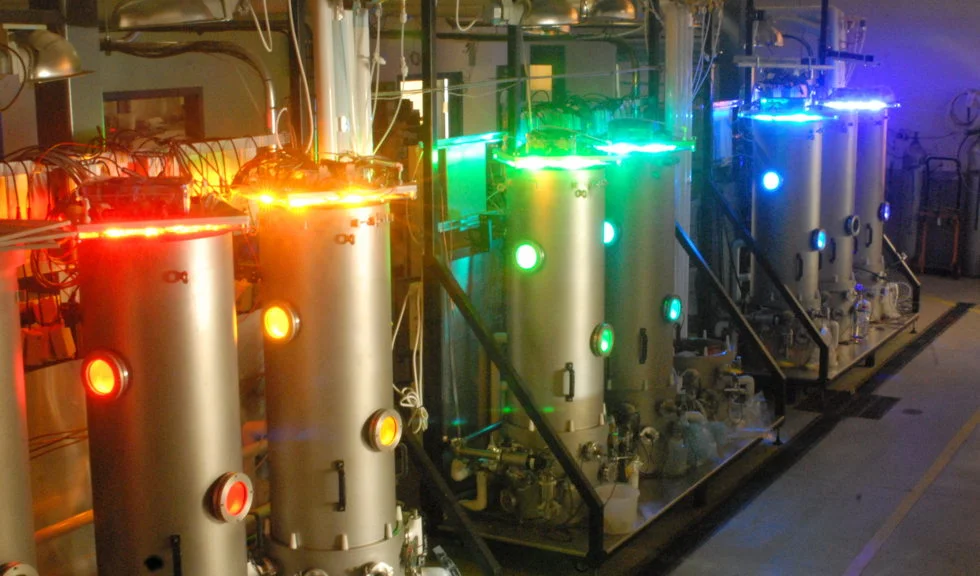

As Indoor Ag-Con (indoor agriculture) returns to Asia for their second annual event on January 24-25, 2017, in Singapore, Norwegian entrepreneur Per Aage Lysaa from Intravision Group is among the speakers.

Intravision Group is a bio-light and systems integration company working with new technologies for production of foods and plant made pharmaceuticals. Per Aage will speak during the second day, which focuses on technical aspects. Intravision’s focus is on multi-band and spectrum variable LED lights, enabling biological control and optimization of plant responses to specific wavelengths between UVA and IR light.

Per Aage Lysaa is an Norwegian entrepreneur, artist and architect working with light in multiplicity; at one end of the spectrum creating unique artworks and at the other developing light-tools for photobiology applications.

Ag-Con Asia is hosted in addition to the main event that takes place in Las Vegas. Indoor Ag-Con was founded in early 2013 to provide a meeting place for those who are as passionate as about the promise of the indoor agriculture industry. The event encompasses one person start-ups through to multinational firms.

Indoor Ag-Con’s host, Newbean Capital is a registered investment adviser that manages early stage venture capital mandates. Its founder – Nicola Kerslake – has a longstanding interest in agriculture investment, having previously covered agriculture stocks as an equity analyst and managed institutional portfolios that covered the sector.

Indoor Ag-Con has featured keynotes from leaders in farming, supplier, technology and customer sectors, has sold out each of its events, and looks forward to building on this success as the indoor agriculture industry matures.

Ag-Con Asia, held at Marina Bay Sands, will once more “host the best and the brightest in growing, supplying and advising the hydroponics, aquaponics and aeroponics market.”

Industry leading speakers from academia and industry will address topics from automating indoor farms to developing controls systems to funding an indoor farm..

For this year’s Indoor Ag-Con Asia, the organisers hav been thinking about the various forms of innovation that have come together to create the burgeoning indoor agriculture industry, from plant biology to design to new business models. In celebration of these diverse participants in the indoor agriculture market ‘Indoor Ag-Fest’, a series of events and activities around the theme of innovation, is leading up to Indoor Ag-Con Asia.

Intravision’s work from 1999 to 2017 includes research on- and products for light control of fish in aquaculture, marine biotechnology, micro algae production, turf grass systems, and controlled environment systems for production of Plant Made Pharmaceuticals and food plants. Headquartered in Norway, Intravision Group has branches in Shenzhen, China and in Toronto, Canada.

Introducing A Better Way To Manage Checklists

Introducing A Better Way To Manage Checklists

Operating checklists are critical for a farm’s success. Even airline pilots with decades of experience still run through a checklist before and after each takeoff. Without one, small mistakes become devastating. We took one farm's operating checklist, detailed each step, and set up Agrilyst to manage the farm with our task manager.

You can check out the full 48-step checklist and how we moved paper checklists into our cloud-based platform here.

Want more? Move your checklists over to Agrilyst for free at our website: www.agrilyst.com.

Check out tasks here

Urban Agriculture Pioneer Lufa Farms Opens Third Rooftop Greenhouse Farm

There were two important beginnings in Mo Hage’s world last summer: In July he and his wife, Lauren Rathmell, welcomed their daughter into the world. And in June, work started on construction of the third commercial rooftop greenhouse in the burgeoning urban farming company the couple co-founded, Lufa Farms

Urban Agriculture Pioneer Lufa Farms Opens Third Rooftop Greenhouse Farm

SUSAN SCHWARTZ, MONTREAL GAZETTE

More from Susan Schwartz, Montreal Gazette

Published on: January 18, 2017 | Last Updated: January 18, 2017 11:48 AM EST

There were two important beginnings in Mo Hage’s world last summer: In July he and his wife, Lauren Rathmell, welcomed their daughter into the world. And in June, work started on construction of the third commercial rooftop greenhouse in the burgeoning urban farming company the couple co-founded, Lufa Farms.

Their daughter, Dani, is six months old. And last week Lufa Farms began to harvest produce from that greenhouse, set atop an industrial building in Anjou. The first week brought mega-sized radishes, watercress, Persian cress, arugula and spinach from among more than 40 varieties of greens started out there as seedlings in December; this week, tatsoi, red and green bok choy, Chinese cabbage, romaine and Boston lettuce were added to the mix. Next week there will be more.

The produce is sold to directly to consumers, to subscribers – Lufavores, they are called – who find it in the baskets they order online, along with produce from small family farms, almost all local, and other products including meat, cheese, baked goods, fish and prepared foods, all sourced by Lufa Farms. The year 2016 was a good one: The Lufa Farms subscriber base grew by fully 50 per cent to more than 9,000 families.

Hage and Rathmell, partners in life before they were business partners, had a vision: to create an ecologically — and economically — sustainable model for urban farming and to help to change the way people eat. It took the expertise of many and the investment of $2 million from family friends and others, but in 2011 they opened what was reputed to be the world’s first commercial rooftop greenhouse, atop an industrial building in Ahuntsic.

Radishes are ready for harvest at the rooftop greenhouse built by Lufa Farms in Montreal. PIERRE OBENDRAUF / MONTREAL GAZETTE

A second, in Laval, followed in 2013; the newest, at 63,000 square feet more than double the size of the first, is the largest. Produce is grown hydroponically through a system of plastic tubing that feeds them, recycles the water and reuses it; the circulation system and microclimate are managed by computer software.

Speaking during a Ted-X talk at the Universiteé de Montréal in 2012, Hage observed that our food often travels great distances before it gets to us, losing flavour and nutritional value along the way, that cultivars are often chosen for toughness, and that industrial farms can be “massive consumers of land and water.” A rooftop greenhouse, on the other hand, uses no land. And because it absorbs heat from the building below, it uses 50 per cent less energy than one on the ground – and reduces energy costs for building owners.

How a rooftop farm helps to feed a city

Rathmell, who has a biochemistry degree from McGill University, serves as greenhouse director at Lufa Farms and oversees the farming, plant-science activities and marketing. During a tour on Tuesday of the airy new greenhouse, she pointed out how seedlings are started in small containers of ground-up coconut husks and then planted. Growing times vary, with arugula taking six weeks from seedling to harvest, for instance, and cauliflower twice that. She pointed out four varieties of bok choy, a range of herbs, kohlrabi and mustard greens. Her favourite vegetable, by far, is rainbow chard, with its coloured stems and delicate flavour.

The building on which the Ahuntsic greenhouse sits also contains the Lufa Farms warehouse, where subscribers’ baskets are assembled. Lufavores start out with baskets made up of $30 worth of food, mostly produce, and have until midnight to customize or finalize orders for the following day: The minimum order is $15. At midnight, the “marketplace” is closed and credit cards billed. Partners log in on an online portal to check what was sold that day, then work all night to prepare it.

Lauren Rathmell as a look at fresh greens growing of the rooftop greenhouse built by Lufa Farms in Montreal.PIERRE OBENDRAUF / MONTREAL GAZETTE

“I like the fact that I can customize my baskets and that products are environmentally friendly,” said Verdun resident Sherri Wallace, who has been a Lufavore for about two years. “I get mostly vegetables and, with time, I find the variety has increased. Produce is mostly local but they offer some citrus and collaborate with a farm in Florida so we get a few exotic things like avocados, oranges and grapefruit. And I find the cost reasonable.”

Because only what is sold is harvested, produce is always fresh and both waste and need for storage are eliminated. There are more than 300 pick-up points in cafés, pharmacies and yoga studies around Montreal and, for an extra charge of $5, orders can be delivered to subscribers’ home by a fleet of four electric cars now working at capacity. Recently drop-off points have been added in Quebec City and Trois-Rivières, where the company has growers and producers.

West Island resident Joel Assouline, whose Lufa Farms shopping list includes produce, dairy, some meat, and pasta, said he admires the company’s transparency. “What is cool is that even though they have their own tomatoes, they still carry tomatoes from other farmers. They have products that compete.”

He said he finds the online shopping cart “so user-friendly, with nice pictures. And your basket stays open all week.” Assouline, who has orders delivered to his home, likes also having access “to local and ethical farmers … When you go on their website, you have access to the information of every producer you buy from. For me, if a farmer is disclosing his name and his address, already it’s a good sign.”

Horticulture Lighting Calculator Speeds Grow Light Development

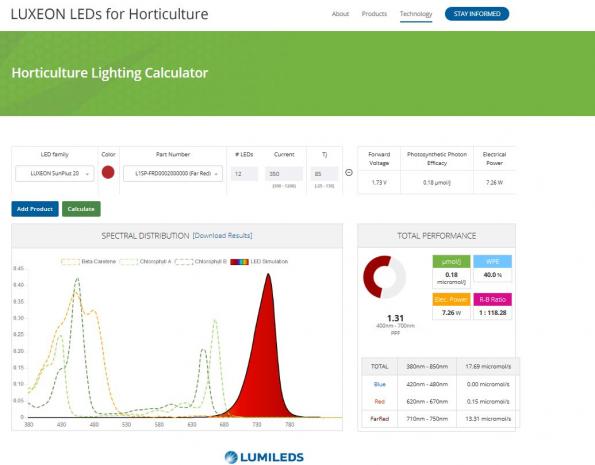

Designers of grow lights for greenhouses, vertical farms and other horticulture applications can speed up their time to market by using an online calculator freely accessible online Lumileds' website

Horticulture Lighting Calculator Speeds Grow Light Development

January 18, 2017 // By Julien Happich

Designers of grow lights for greenhouses, vertical farms and other horticulture applications can speed up their time to market by using an online calculator freely accessible online Lumileds' website.

The calculator allows the user to input various LED combinations and operating conditions to generate the spectral power distribution, photosynthetic photon flux (PPF), and power usage of a fixture using Lumileds LUXEON SunPlus Series LEDs.

Designed to allow easy modifications of LEDs and operating conditions, the calculator facilitates fixture design by generating real-time feedback on spectral power distribution.

“With the Horticulture Lighting Calculator, fixture manufacturers can test many lighting scenarios in a short period of time, so that their optimum designs can be brought to market much more quickly and efficiently than if each potential fixture were built and tested individually,” explains Jennifer Holland, Product Manager of the LUXEON SunPlus Series LEDs and Horticulture Lighting Calculator.

Try out the Horticulture Lighting Calculator atwww.lumileds.com/horticulture/calculator

Urban Farming Tips From Replantable: The Hottest Urban Farming Project on Kickstarter

We interviewed co-founder Ruwan Subasinghe of Replantable to chat about urban farming tips, the beginning of Replantable, and the Nanofarm, their new urban farming project taking kickstarter by storm

Urban Farming Tips From Replantable: The Hottest Urban Farming Project on Kickstarter

We interviewed co-founder Ruwan Subasinghe of Replantable to chat about urban farming tips, the beginning of Replantable, and the Nanofarm, their new urban farming project taking kickstarter by storm

Patrick: Hey guys this is Patrick from Urban Vine and today I have a very special guest, we have Ruwan from Replantable, his company is developing new technology, a new product for growing mixed greens and some other exciting stuff, right in your kitchen, it's a minimalist design, it's meant to be an easy introduction for beginners, for people who may not be as experienced [with urban farming].

How are we doing Ruwan? Are you in Atlanta right now or you guys just got started in Atlanta?

Ruwan: Yeah, in Atlanta right now, and I'm actually home at the moment but we have headquarters downtown in Atlanta and we actually manufacture the appliance here too.

Patrick: Cool, so I guess we could just get started, for people who may not be familiar with Replantable, or especially you and your co-founder, maybe you could talk about how the company started, how you personally got into Urban Farming, where you got introduced to it, and how you progressed.

Ruwan: Sure, so my co-founder and I, my co-founder's name is Alex, we met at Georgia Tech, we studied there, and we cooked a lot, pretty night every much, but, we were tired of our fresh ingredients going bad before we could get a chance to use them, and we wished there was a way to be able to just, pick fresh greens right as you're about to use them, but living in Atlanta, we really didn't have the space to do the backyard gardening, I had a tiny little plot but it really didn't get the right kind of light, and the soil back there, it's a city lot, so not optimal soil for growing.

So that's when we turned to hydroponics, really looking at hydroponics for a solution for urban agriculture, and that is when we started experimenting. We went to the local hydroponics store, and we cooked up a homemade hydroponics unit with fluorescent tubes, and it was a deep water culture system, and yeah, that is kind of how we got started, and we kind of refined it until we got to where we are now.

Patrick: So for people who may not be as familiar, could you talk about what a fluorescent tube and some of the terms you mentioned are?

Ruwan: Sure, so when we were looking for grow lights we started with Amazon, where most searches start for products, but the fluorescents are just one type of bulb you can use to provide plants with the type of light that they need to grow.

Specifically, we used the ones marked as "Daylight", they just have a good spectrum of light for growing plants inside, and there are more professional options, like Sodium lights, metal halide lights, and now LEDs, and actually LEDs are what we use in our product, but we didn't really get into that at first. We started with off the shelf grow light.

Photo courtesy of Replantable

Patrick: Cool, so, for somebody who is kind of, just starting out, what kind of lights would say are best for them , and what do they really need to know, you mentioned how you went through this iterative process of exploring with these different lights and that kind of culminated in what is now your product on Kickstarter, which we will talk about very soon, but can you talk about that process of figuring out what was best and maybe some tips for people who are just getting started.

Maybe somebody just wants to grow one lettuce plant on their fire escape or something, what are some good tips for somebody trying to do that?

Ruwan: Really it's as simple as going to the hardware store, you can buy one of those compact fluorescent tubes, you can buy one that is marked as "Daylight" you can screw it into one of those standing sockets, or like a clamplight or something, and point it at your plant, and the plants love that kind of light.

It sounds simple once you have figured that out, it's actually kind of hard because the spectrum is all invisible, you don't know, light looks like light to us, to plants they use mostly the red colored light or the blue colored light, and a bit of the ultraviolet and infrared spectrum too, so the spectrum that the bulb puts off is really important, for growing the food, but surprisingly, standard fluorescent will do it.

Patrick: As far as the, obviously at Replantable you guys are focusing on several different types of crops, and I know that that has been part of the design, to have a couple different options there, would suggest for somebody just starting out a certain type of crop? Like is there one that is easier than others or is there one that is especially easy, like, is it lettuce, or what do you think regarding that?

Ruwan: Lettuce specifically is really friendly to grow, it is a cool weather crop, so if you are growing in areas kind of on the warm side, you might want to try something like a Bok Choy, or something like that, but in general, salad greens are really easy to get to germinate, they grow super quickly, which is great for someone who is just starting off, because it is really encouraging to see results really quickly.

If you are trying to grow herbs, those are fairly easy to grow too, but have longer germination times, and the germination rate is lower, so you might plant some seeds and they never actually germinate at all.

Lettuce is an easy crop for beginner urban farmers to start off with

Patrick: Could you talk about the difference between growing outside and growing inside? I know that when we get to talking about urban farming, sometimes some people don't have an option to grow outside, or it may be way too cold outside, or there may be other factors, name your factor pretty much in a city, that forces you to grow inside, so how does that change your approach, and are there any easy mistakes there that you can make?

Ruwan: So with growing inside, you have the benefit of a controlled environment, so you don't have to worry about pests, you don't have to worry about the temperature being crazy high or crazy low, but there are some things that are easy to overlook inside, first, lighting, the sun is amazing, it is the original grower of light, it's amazing for growing food, so you really need to make sure you are replicating that type of useful light.

The second thing is ventilation, which often goes overlooked, because, inside you can have stagnant air, and, if the humidity builds up too much around the plant, it can actually suffocate the plant, and you know, keep that gas exchange from happening at the surface.

But these things are pretty easy to overcome, just set up a fan where you are growing, or even just make sure that your house fan is on.

But those are two big things, that can effect (plant growth) inside.

Patrick: So you're saying you could essentially just take a regular house fan, and you would kind of pooint it towards where you are growing, and that would suffice or what specifically is the set up there?

Ruwan: Yeah, you don't need to be rustling the leaves or anything, you just need to be moving air throughout the room. because plants will quickly get a high humidity area around them if the air is standing still.

Patrick: Obviously you are knowledgeable on this (subject), to such a degree that you created this product, I am curious to know, was it a trial and error process, or were there any books that you read, or were there any people that you talked to, or websites that you followed, I know there is a lot of good websites out there, could you talk about how you got this (urban farming) knowledge and how, if someone was also interested in becoming knowledgable, what would they do?

Ruwan: We got a lot of our knowledge by stopping by the local hydroponics shop, here in Atlanta thae one is Atlantis Hydroponics, but there is a lot of really good resources out there, there's (also) actually a lot of misinformation and partially true information out there, about hydroponics, and it's partly because people like to try different things, and it may work anecdotally, but overtime those may not really pan out.

We looked at a lot of, actually, papers.

Patrick: Like, academic papers?

Ruwan: Oh yeah, definitely, especially since NASA is looking into hydroponics a lot, they publish a lot of really good research on how to grow hydroponically, and also there's the farmer resources, if you look up, "farmer growing guides", there are a lot of growing guides for specific crops such as your lettuce, your tomatoes, the things that are really commonly grown hydroponically, there's a wealth of information about those things. If you start with growing those crops, there's a ton of information out there for farmers and hobby growers alike.

Patrick: That's specifically for people interested in hydroponic?

Ruwan: Right.

Patrick: Do you think hydroponic is any more challenging to start with or do in general than soil or what's the comparison there?

Ruwan: So I think that if you just want to buy a few things and get started quickly, soil is even easier, because a fertile soil is made for growing plants, hydroponics just gives you more control, so you can dial in certain factors, where, if you were soil growing, and your plant is having an issue, it is hard to diagnose sometimes what that could be, it could be a pest in the soil, it could be that a certain nutrient is low in the soil, with hydroponics you can kind of test and correct, but they are both great methods.

Patrick: So essentially the key thing to remember here is hydroponics gives you a little bit more control.

Ruwan: Right, but at the same time you need to know what you are doing, you need to research the hydroponic set up, it is not as simple as "buy a few things and throw it together".

You need to have a pH tester, an EC Tester, which is electrical conductivity, that tells you how much nutrients are in the solution.

Patrick: So you would need an EC tester, and a pH pen.

Ruwan: Those are the 2 basic tools that you can get by on with hydroponics, but you have to know how to interpret the results, you need to know, what is too acidic or what is too basic for the water to be, and then, you have to keep the pH up or the pH down mix, so you can put it in there (the water) and correct.

Patrick: In the water?

Ruwan: Yeah, (you are measuring) in the actual water (for hydroponics).

Patrick: So, back to the narrative now, we kind of had this Q and A session here, so you meet your co-Founder at Georgia Tech, you have this problem, and what happens next?

Ruwan: So, like I told you, we cooked up our hydroponic system, at home, we're growing food, you know it's working, but then we thought, and this took months, it took months to get a system where we did not have to think about it too much, and we could grow food continuously, and we thought back on all the trial and error that we had to do, and that's when we thought that there should be something out there that someone can just plug in, and get going, and that is really the inspiration for our product,

Patrick: What were some of the early major mistakes that you made (in the product development)?

Ruwan: We made every mistake you could possibly make, we overfed the plants, we underfed them, we got the pH wrong, we didn't get them enough light, we gave them too much light. At one point we let it get too hot, too humid, there was just all of those factors, which we had to dial in to get it to work.

Patrick: How did the company form once you figured out the ins and outs of the earliest form of the product?

Ruwan: At first we thought that we were not very good at hydroponics, we were just screwing a lot of stuff up, but when we talked to a lot of people, but when we talked to a lot of people that had tried to grow, both hydroponically and in soil, I mean lots of people have tried to grow their own vegetable garden, sometimes it last just a season, or however long it takes for the things to die when you first plant them,

but we noticed that a lot of people have trouble getting food to grow, and that's when we thought that there could be a product based around this, and then we went one by one through all of those variables that I have been talking about, feeding the plants, the amount of nutrients, pH of the soil or the water, we went through all of those problems and we tried to figure out, how can we create a system that corrects itself, and that was another half a year of development, but we eventually came up with these "plant pads".

Those are like layers of paper and fabric with seeds, and nutrients and pH buffers built in, so we kind of cooked all of that stuff into one product, that basically makes it so you just add water, and it takes care of itself.

Patrick: How similar were those pads to the product you have on Kickstarter now? I think most people, anyone who checks out your website or the Kickstarter, the thing that they would remember would probably be the (growing) box, so where did that come into the equation and how did that work?

Ruwan: The "plant pads" that we developed, our kind of our version of the "growing medium", so a growing medium can be soil, or cocoa fiber, or clay pellets, there's lots of growing mediums, so the plant pads are our version of the growing medium, the Nanofarm is the simply the box that the plant pads go into.

The Nanofarm provides light and ventilation, and the plant pads provide nutrients and the pH balancing, and just the place for the roots to grab onto and for the plant to support itself. So that's how they kind of work together to form that total solution.

Patrick: To get a perspective on the timeline, you guys first started working on this project one year ago, or was it two years ago?

Ruwan: Just about a year ago.

Patrick: Your first plant pad was developed then about 6 months ago, and your Kickstarter has been live for about 2 weeks?

Ruwan: Yeah so we have been pretty quick with the development.

Patrick: once you guys developed the product and it came to marketing it, obviously you guys have had lots of success on kickstarter, gotten thousands and thousands of dollars, so I am curious to know how you guys marketing your technology in this niche (so well?), this isn't a software as a service or something like that, or maybe a couple tips on how you guys did that?

Ruwan: We didn't do much paid advertising or we didn't hire a marketing firm or anything like that...Once we thought we had the product ready to go, we built 30 of these units and actually sold them, and I mean, we hand built these, like, I bent the metal for them myself, and we got them all made up, and we sold them to 30 people in Atlanta, and we saw how they interacted with the product and how they liked the food that comes out of it, and just the word of mouth from that, when you actually have product out there in the world, I mean, you can't walk into someones kitchen and see this growbox on their counter, and not ask them, you know, what is that thing, so we got a lot of word of mouth marketing through that way.

Patrick: For someone who is trying to get some hardcore tips for launching a kickstarter (in this specific space), what would you suggest?

Ruwan: Most of our kickstarter traffic has come through 3rd party reporting, so like journalists writing about it, things like that, and that's what I was saying with the uniqueness of the concept, it's not another app, or something like that, so that helps it standout, the publications that I read regularly, like Treehugger, and things like that...

Patrick: What are some other ones?

Ruwan: Digital Trends, Mashable, just those tech blogs, tech websites, there are reporters there that are interested in urban agriculture, since it is something that is coming up quickly, it is getting hot, and you know, it's becoming a topic that people are writing about, it gets attention, and viewers are interested and readers are interested in it too, so it benefits both of us when I write one of these journalists an email, and I let them know what we are doing in the space, in urban agriculture, and a lot of times they are interested enough to publish something on it.

And that kind of reach benefits their readers as well as us.

Patrick: Has the publication coverage been more organic or have you done more outreach for the coverage?

Ruwan: Definitely I am doing outreach, before we launched the campaign, I got a list together of journalists that cover this regularly, and publications that are in the space also, and I just sent an email saying "Hey, this is what we are doing, if you're interested, I'll send you more information", and that's how we got noticed.

Patrick: Did you send product to them, or that didn't happen because you had so few units?

Ruwan: A couple people did request product, we just couldn't send it to them, unfortunately, and a lot of these websites do need to have a product to review to cover you.

Patrick: Would you say that was the more "major" websites (that requested product) or was it more random, some people asked for it and some people didn't?

Ruwan: I think it was more random, there were definitely big publications that were more interested in just finding the cutting edge, before we could even ship them product,

Patrick: Regarding Kickstarter, I know you guys have not quite completed your goal yet but that you are really close...has this been a good channel for you, would you (Kickstarter), would you do it again? Do you think it is a good (channel) for urban agriculture?

Ruwan: I think crowdfunding specifically Kickstarter has been great so far, for us we're so small, we just don;t have the cash to do a manufacturing run, and have product on inventory to sell, so this is the best way to see if you have that demand, and if you have the demand, you now have the money to fulfill that demand. So I think it does a lot of things all at once, not to mention the organic traffic that kickstarter has driven, just because I think there is a lot of overlap between the average kickstarter backer or kickstarter user and that urban agriculture scene.

Patrick: What kind of traffic has kickstarter sent?

Ruwan: Kickstarter has been sending between a thousand and two thousand hits a day, that's when there aren't any articles or anything out, and then that spikes when someone covers us or there is something out.

Patrick: Which article has sent the most traffic to you guys?

Ruwan: Last I checked, according to Google Analytics, it was Treehugger's article on us, and I think that is partly because their readership is really sustainability focused.

Patrick: How much did that drive?

Ruwan: Probably around 15,000 hits so far.

Patrick: and that was over a couple days or?

Ruwan: That was over 1 or maybe a 48 hour span. Yeah, in terms of the internet traffic

(it) drops off super quick.

Patrick: Wow, now that you have come this far, what are some of the main lessons looking back pertaining to urban farming, maybe something that you thought going into it that your belief has kind of changed, or looking back something you would do differently, what are your thoughts after you reflect on what you have done so far?

Ruwan: I think overthinking growing inside or growing in an urban setting, it's really easy to over analyze this stuff, but we didn't give enough credit at first to the biology of the plants, and how much they can actually deal with variability in the environment.

Because at first, we were like, we need to keep the environment at 70 degrees or 68 degrees, exactly, but then, these plants are growing outside and they are fine until it pretty much freezes out there, so I think a lot of urban ags resources are very, maybe, over-analytical about those parameters, including temperature and humidity and stuff like that.

I think allowing your urban environment to swing in a kind of way that mimics the natural environment is totally fine, and it would have saved us a lot of work if we had realized that earlier.

Patrick: Last question, for people who are interested in learning about what you are working on and the kickstarter, what should they do, where should they go? Is this a good product for somebody who is just getting started (with urban farming), and who maybe doesn;t want to mess around with all the stuff that we just talked about?

What is the value prop for a beginner and what do they do if they want to learn more?

Ruwan: I definitely think the Nanofarm is kind of a plug and play way to get started, and some may see that as copping out, but if you just want to get started growing food, with the minimal amount of set up, that's really pretty easy with the nanofarm, and it is just a hydroponic system so if you want to get your EC pen and your pH pen, and want to start using that with the nanofarm, that is totally possible too.

If you want to learn more about the Nanofarm, you can check out the Kickstarter.

Ruwan Subasinghe is the co-founder of Replantable, their product, the Nanofarm, is a easy to use hydroponic grow box designed for urban farming. It is available now on Kickstarter for pre-order, if you liked this interview, be sure to check out the Kickstarter page and contribute or check out Replantable's website at www.replantable.com

China Is Setting An Example For The Entire World

China is setting an example for the entire world. During the visit of a Macfrut delegation to the new Easyhome Ankang supermarket in Beijing, the attention of the visitors was caught by the hydroponic lettuce cultivation system.

Vertical Farms: How To Feed Our Rapidly Growing Cities

Vertical Farms: How To Feed Our Rapidly Growing Cities

By Judith Dubin and Leeron Hoory

Jan 17, 2017 at 4:15 PM ET

“As long as there’s been life on earth, there have been parasites,” says Dickson Despommier, emeritus professor of Public Health and microbiology at Columbia University. And, he says, a lot of us live in one: Cities — which feed off the earth’s resources without replenishing them — basically function as giant parasites. “They take advantage of what’s there and use it for their purposes,” Despommier says.

And they’re growing rapidly. By 2050, nearly 80 percent of the world’s population will be living in cities, and we’ll need a sustainable way to grow enough food to feed everyone. To that end, Despommier proposes vertical farms. Basically greenhouses stacked on top of each other, vertical farming produces food more efficiently to “ease the parasitism of cities on food production.”

These farms in buildings already exist in the real world. Japan, South Korea, Singapore, China and Taiwan, have hundreds of vertical farms, as do several U.S states, including New Jersey and Illinois. And that’s a good thing, since already fully one-seventh of the earth’s land mass (or the entire continent of South America) is devoted to producing food for the 7.3 billion people who live here.

If we don’t keep working to implement sustainable ways to feed our cities, Despommier says, “The parasite will exceed its capacity and collapse under its own weight.”

Urban Farming Poised to Revolutionize Agri-Food Production, says Professor Dickson Despommier and Leaders in This Market Sector

David Stradling

Urban Farming Poised to Revolutionize Agri-Food Production, says Professor Dickson Despommier and Leaders in This Market Sector

David Stradling, Sales Director, Global Forum for Innovations in Agriculture, receives inspiration from a banana boat while getting to grips with the urban and vertical farming movement.

The sands that surround the shores of Koh Tao in Northern Thailand are the colour of golden demerara sugar, the surrounding sea is crystal clear, and the wildlife in the sea and on the land seems as plentiful as it is exotic.

But as I snorkel off the southern tip of this divers’ paradise, something is clearly amiss. The corals are often sun bleached, the diversity of fish has been shown to be in decline, and on the island itself, natural fresh water supplies have fallen to an all-time low.

This little corner of heaven has environmental problems that are as pressing to the local ecosystem, and to its three thousand local inhabitants who depend on tourism for their livelihood, as they are to the rest of the planet.

There is no escaping the blight caused by climate change. At 10.0955 degrees west and 99.84042 east, the challenges faced by this tropical paradise are ongoing. Failure to meet them will potentially have as serious an impact on the local environment and its population, as it’ has had on those who made a living from agriculture in what was one of the most fertile regions of the United States - and is now the American dust bowl.

On holiday in Koh Tao recently, I was working out the approach to take in an article exploring urban agriculture and, as a technology sub-set within that, the future of vertical farming. Then inspiration struck in the shape of a banana boat! I’d been chilling out on a mix of vitamin D-inducing sunshine and coconut and banana smoothies when to my dismay, the island’s stock of the fruit dried up. Suddenly, there was a tap on my shoulder, ‘’Bananas here now, the boat has arrived,’’ declared our friendly beach bar waitress.

I was delighted, but at the same time I pondered the fact the fruit was being shipped in, as I would guess was most of the island’s food. Therein lies one part of the challenge. Not only can agri-food production be a drain on the land and its resources, but shipping it from one destination to another is a contributory factor in climate change.

Enter the age of vertical farming! It’s this that some believe could be the key to many of the problems that come with industrial scale agriculture, and the use of farming methods which fail to show consideration for the environment.

Last week I talked at length with Dickson Despommier, Professor of Microbiology and Public Health at Columbia University, New York City, USA, and author of The Vertical Farm: Feeding the World in the 21st Century. Professor Despommier is widely considered a founder of the vertical farming movement, and is a long-term advocate of urban farming as a potential counterbalance to the negative impact of large scale traditional agri-production. We spoke about the future and he provided me with some useful insights into the positive returns, he, and increasing numbers of experts, foresee will be a direct result of continuing innovation and advancement in vertical food production technology.

Vertical farming; the dawn of a new age

WHILE THE MEDIA'S focus throughout the 1990s and the beginning of this century has been mainly on the role that heavy industry and fossil fuels have played in eroding the ozone layer, the role of agriculture in resource depletion and climate change, has gone relatively unnoticed. Traditional agricultural practices continue to take a major toll on planetary resources and are a key offender in climate change. Transporting produce from one place to another involves the emission of gases that damage the outer atmosphere, while over-farming has a disastrous impact on the soil and acts as the biggest drain on water reserves.

Professor Despommier believes that agri-crop growing in the traditional sense is often inefficient, citing the United States where the biggest crop is wheat, followed by corn and soya beans, as an example. He points out that soya beans are often grown as a means of putting nutrition back into the soil, a practice that is extremely inefficient, and is enthusiastic about the use of climate-smart agriculture in outdoor farming. However, all plant life requires water and if that is not available then the only option is to take growing indoors – and to do this locally where the crops which are grown are consumed, so reducing pollution caused by transportation. The Professor has a stark warning for us if we fail to take action. ‘California is in its sixth year of drought,’ he says. ‘Food prices are going crazy and it’s going to get worse.’ In his view, controlled environment agriculture (CEA) is the solution – and vertical farming is the method which could save our environment from disaster.

An efficient greenhouse hydroponics system uses five percent of the water required in the outdoors and can deliver multiple times the yield of farming outdoors. According to Professor Despommier, a vertical farm can deliver the same yield again, using a fraction of the water the greenhouse system requires. So if vertical farming, with all its obvious advantages, has such a role to play, where does that leave the land farmer? ‘’I have a great answer but it isn’t the one that many people want to hear,’’ he says. ‘’Dirt farmers and the big industrial scale producers are struggling to make a living and this will only get harder, given the climate change issues they face.’’ He believes the time is ripe for change in agricultural crop production on an unprecedented scale. The vertical farming industry is moving at an extraordinary pace and he estimates there are currently about 500 successful vertical farms operating globally. In the next few years the number will grow so fast he will lose count. Technology and innovation in this sector is thriving and there is no stopping the movement toward growing crops in the city – in our homes, at our place of work and within the vertical farms that are emerging as commercial enterprises.

It is an exciting prospect but the advantages of vertical and urban farming do not end here. There are huge social-economic-implications too. He refers to projects like the AeroFarms facility in Newark, New Jersey, USA - a project that is delivering prosperity to a part of the city that was formerly in decay, and which will revolutionise and revitalise that whole area.

AeroFarms hopes to develop 25 more farms in the USA and overseas in the next five years. The company says the new trend amongst consumers is for locally grown produce and it has no problem in meeting demand. It can grow plants within twelve to sixteen days, compared with thirty to forty-five days outdoors. A year round controlled environment ‘grow cycle’ allows it to operate at 75 times the production capacity of an outdoor farm.

Other farms that Professor Despommier is optimistic about, include a flag ship, model three- storey farm in Suwon, South Korea, the leading position taken by Sky Greens in Singapore, and a twelve-storey farm in Moscow – all excellent examples of where the sector is heading. He also cites the case of Pasona Group in Tokyo, Japan, which allocated 43,000 sq feet of office space for crop production that is used to feed employees, although this is more of an example of good urban agriculture production. As well as rice, the Pasona building features over 200 varieties of fruit and vegetables.

Another crucial factor in the advancement of urban agriculture and vertical farming is a preference for urban rather than rural dwelling. At present, the split is about 50/50 country to city dwelling, but by 2050 he believes this will change to 80/20 in favour of the city. ‘’All we need to see now is a shift in the mind-set of people who make policy within our cities. Once they understand the importance and benefits of this movement in urban agriculture then there will be no stopping its growth, nor that of vertical farming as a critical part of that.”

In a global context, the Professor believes that, together with the US, it is Japan and countries in the Far East that are driving the movement in take-up of new technologies and ideas. Factors which have influenced change in these regions have included incidents like the Kobe earthquake and the tsunami that hit Japan in 2011. For South East Asia, it has been the intensity of monsoons and the impact of adverse weather on farming that have forced city policy-makers to realise the importance of growing food in their own back yard. “This is a major food security issue,” he says. “When the logistical infrastructure for the delivery of produce is no longer there, or when crops are washed away, then you have a big problem.’’

A small leap for the imagination; a major step for mankind…

In fact, it does not take a major leap of the imagination to see how quickly vertical farming could develop as the dominant force in urban growing, provided innovators can deliver affordable technology solutions. According to the Food & Agriculture Organisation of the United Nations, about 30% of global food supply comes from urban farms. ‘’Most urban farms are small scale and on home plots or in the urban areas of cities,’’ explains Mr Henry Gordon-Smith, Vice Chair of the Association for Vertical Farming (AVF). AVF was set up to foster the growth and development of the movement and to galvanise the efforts of contributing innovators and leaders through collaboration and knowledge-sharing. He says vertical farms will allow urban agriculture to progress further, so cities are more independent than ever in their own food production. Vertical farms can be integrated with existing food systems and set up anywhere, including schools, institutions and government cafeterias. They can also be merged with food distribution hubs, making them more resilient.

Mr Gordon-Smith sees innovation as key to sector development and feels it is moving forward quickly. LED lighting technology and automation and sensor technology are helping to reduce operation costs. LEDS lower the energy consumption, and automation decreases labour costs. He believes that among the companies that stand out for their leadership in these areas are SPREAD Co of Japan and Urban Crops from Belgium. AVF expects there to be a vertical farm in almost every city within a decade.

Neither Professor Despommier nor Mr Gordon-Smith see any drawbacks to vertical farming if costs associated with operating grow-light can be overcome. Both are convinced the potential advantages are huge, and that with the advance of technology and greater political drive from city policy makers, we can look forward to seismic change. ‘’Vertical farms can be pest-free using strict food safety and bio-security protocols and strategic ventilation,’’ Mr Gordon-Smith explained. He concedes there are challenges ahead, but innovation in technological advancement and bypassing some areas (like lighting and robotics) will pave the way. Vertical farming will become more mainstream as we move to a stage ‘’’where water is no longer considered a ‘free’ resource and when climate change hardens its grip, and when costs for LEDs and robotics drop. ‘’

Among the other challenges he cites are zoning and code interpretation, which is delaying the development of vertical farms in many cities. They are also being hampered by a shortage in skilled labour to operate these facilities. Asked about his vision for urban and vertical farming in the next 10 – 15 years, Mr Gordon-Smith predicts:

- High-tech agriculture will become a central education tool in science, engineering, maths and technology.

- Kitchens will be designed with vertical farming systems embedded as appliances.

- City edges and waterways will become agricultural hubs.

- Restaurants, markets, hotels and office buildings will embed agriculture and it will be a part of a unique experience for tenants and the public .

- Large scale warehouse vertical farms like AeroFarms’ model will be common place on the outskirts of large cities.

Where new ideas are matched by contagious enthusiasm…

Other innovators who are embracing vertical and urban farming enthusiastically are equally ambitious, but their vision of how far the change will go and its relationship to traditional methods varies considerably. Marco Tidona, Managing Director of aponix.eu, based in Heidelberg, Germany (exhibiting in the Vertical Farm Zone at GFIA Europe 2017 in the Netherlands), says, ‘’Urban farming will not replace but will complement, the conventional methods of growing our food which will need to become more sustainable.’’ He believes urban production would become an element within a circular economy in the urban area. It would reduce waste and traffic for distribution and have positive social and nutritional effects. Like Professor Despommier and Mr Gordon-Smith, Mr Tidona believes this will have a positive effect on the fallout from transporting and shipping produce. Food miles would be reduced and commuters collect produce as they pass distribution hubs – perhaps set up inside train stations - so distribution in urban areas would become a part of day-to-day movement in the city ecosystem.

Mr Tidona is the designer and engineer behind Aponix Barrel, a unique system for use in vertical agriculture, which epitomises the kind of exciting innovative concepts that surround this emerging sector of agricultural technology. He explains that the barrel is used as a growing device in an existing nutrient cycle, either hydroponic, using liquid mineral fertilizer, or aquaponics, using fish organic fertilizer.

The aponix barrels are especially suited to growing herbs and lettuces in high density urban farming situations. The parts fit together like a Lego set and provide a means to assemble the barrel and do away with the need for complicated rack-structures. After harvesting, the ring segments can be easily cleaned and immediately replanted. Reflecting on the role of innovators like himself, Mr Tidona points to the nature of urban organic agriculture, an heterogeneous area of business with the challenges faced differing between sites. ‘’All the technologies are already here or developing rapidly, like LED lighting. Many innovators are coming to the market and they are a critical part of how the sector will develop.’’

As well as technological advancement and the political will to implement urban agriculture, he believes there are many areas that will need to change so that produce can find a place in the market. In Germany, there are labels such as ‘Öko’ and ‘Bio’, which cannot be used on labelling because they do not apply to crops grown in soilless environments. He suggests an internationally recognised coding system could be set up to help consumers evaluate the produce and compare it with that grown using more traditional means.

Another impressive example of creative thinking in urban agriculture comes from a Vancouver-based start-up company, AVA technologies. AVA has created a tech-enabled and climate-controlled micro farm called the AVA Smart Garden, a smart home gardening appliance that allows the user to produce fresh herbs, sprouts, mushrooms, fruits and vegetables from the comfort of their own home. It isn’t large scale like a vertical farm, but it is sustainable and reduces our personal ‘food print.’ The company has received a very positive response to the product and will be exhibiting in the Telus World of Science in Vancouver in March 2017.