Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Going Indoors To Grow Local

Going Indoors To Grow Local

Alberta company wants to license its hydroponics-aquaponics system to others

Posted Jun. 15th, 2017 by Barbara Duckworth

Nutraponics employees include aquaculturalist Geoff Harrison, left, plant specialist Stephanie Bach and CEO Tanner Stewart. The company grows fresh produce at its facility near Sherwood Park, Alta. | Barbara Duckworth photo

SHERWOOD PARK, Alta. — Providing fresh local produce to Canadians year round could be achieved with a new farming concept that combines horticulture with aquaculture.

NutraPonics, which opened in 2015 near Sherwood Park, is dedicated to supplying the local produce market and supporting local suppliers.

Since last December, it has been selling fresh romaine lettuce, kale, Swiss chard, basil and arugula every week.

The produce is marketed through the Organic Box, a privately owned company in Edmonton that supplies its customers with individually selected orders of locally grown food through online sales and from a store front.

“Everything is marketed as local. We are 32 kilometres from the Organic Box, so that is as local as you can get,” said Stephanie Bach, a plant scientist with the company.

Added chief executive officer Tanner Stewart: “We are hoping to provide less need for products from very far away.”

Stewart, who invested in the company three years ago, is among about 50 private shareholders in the company, which plans to franchise the concept of growing produce indoors in a controlled environment.

“Our model is to not build our own farms and create a massive amount of in-house production,” Stewart said.

“Our business model is to build and license these facilities.”

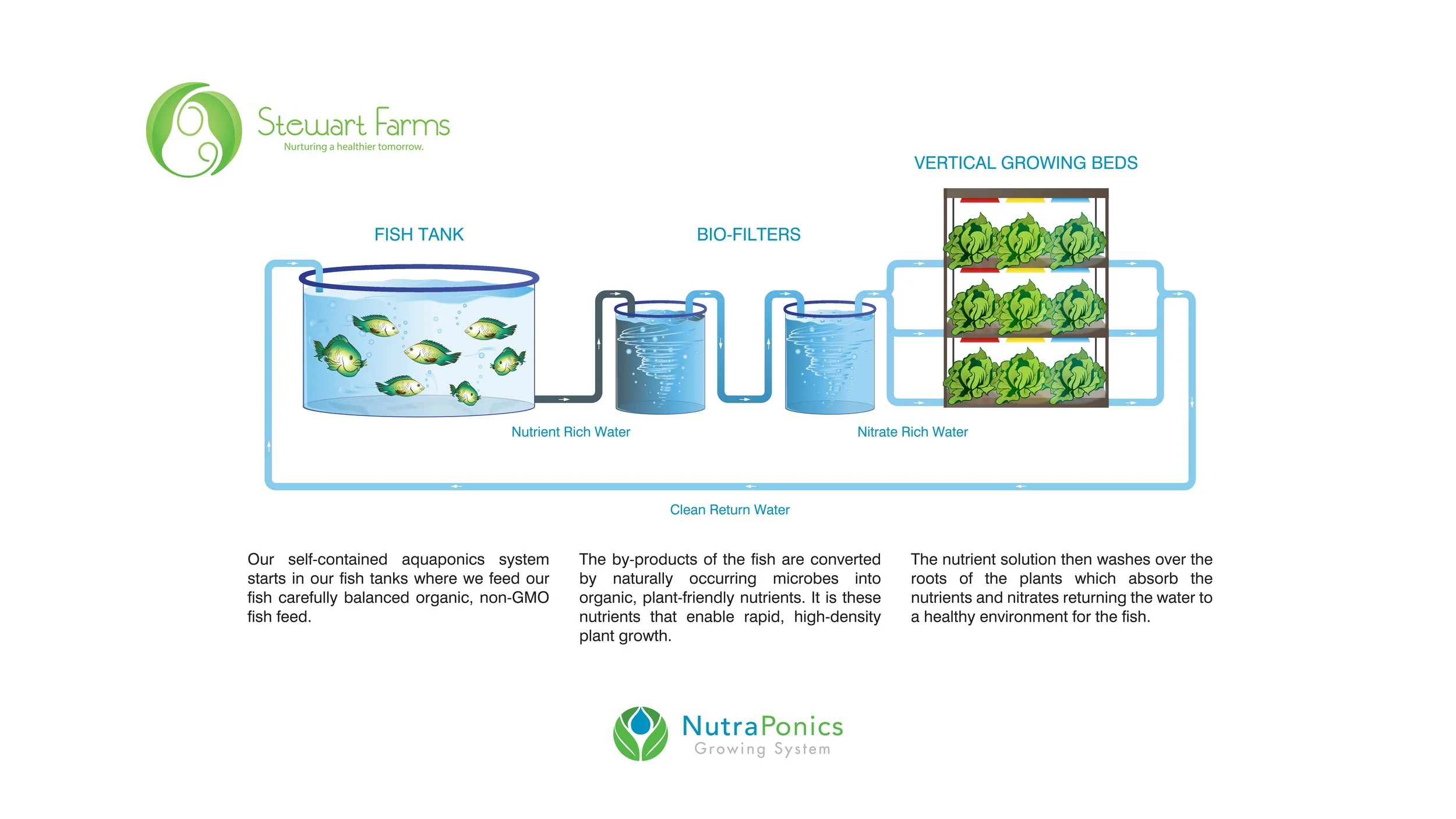

Former CEO Rick Purdy and a company owner started the system. Purdy researched hydroponics to grow food in water and added aquaponics to use byproducts from fish to create a new growing system.

This farm is considered a demonstration facility, where staff can research the best use of the fish, water and plant development.

There are three tanks full of tilapia fish. The nutrient-enriched water from the tanks is delivered to the plants, which are grown in five layers in a controlled atmosphere.

About 1000 sq. metres of growing space are available, where plants are under red and blue LED lights and fed hydroponically.

Under Bach’s supervision, seeds are planted in a special volcanic rock growing medium from Ontario. They sprout within a week and are then transplanted to the main growing rooms. The plants can be harvested within four weeks for same day pickup by clients.

The company employs about 10 people and while each person might have an official job description, the reality is everyone helps with the fish as well as planting and harvesting.

There is no plan at this time to sell the fish.

“The economics of land-based fish farms is fairly fixed,” said Stewart.

“In order to do business, you really have to look at 200 tonnes of production per year to reach economies of scale. This is two tonnes a year.”

This farm sits on 19 acres, but Stewart envisions any empty urban warehouse as a viable growing operation.

NutraPonics is an agriculture company which sells proprietary growing technologies. These technologies utilize symbiotic relationships between plants and fish known as aquaponics to grow nutrient-rich herbs, vegetables and fish in an enclosed, controlled environment. For more information please visit http://www.nutraponics.ca/home

Whitehorse, Yukon, will be the location of the next farm. The goal in the northern community is to grow and sell produce year round at a competitive price with less freight and a longer shelf life.

Stewart also hopes to develop a facility near his hometown in New Brunswick.

The produce is sold at a competitive price. For example, a bundle of romaine lettuce is offered at $6.25 in a 284 gram package.

“You have to be careful in an emerging industry like ours.” Stewart said.

“You really have to make sure you are focused on this as a business, you need to grow your produce at a certain price and you need to make sure your consumers are going to be happy to buy it at that price.”

He estimated that start-up costs are comparable to any new farm and considers this a stable business model with a decent rate of return on investment.

The difference could be a faster turnaround time from construction to the time saleable product is ready.

“Once we get up and running and all the capital costs are done, then we can produce on a consistent basis, week after week, in fairly short order after we turn the building on,” he said.

FreshTEC Achievement Award for Peter Quiring

NatureFresh Farms' TOMZ Best New Vegetable Finalist

FreshTEC Achievement Award for Peter Quiring

Thousands of produce industry executives are arriving in Chicago this week to attend the United Fresh Produce Association’s Annual FreshMKT & FreshTEC Expos & Convention June 13-15. During the festivities on Tuesday, June 13, greenhouse vegetable grower and NatureFresh Farms owner & president Peter Quiring will be receiving the FreshTEC Achievement Award for his contributions to the produce industry over the last 20 years.

“Peter’s contributions to greenhouse technology have advanced the industry significantly,” said United Fresh President & CEO Tom Stenzel. “His competitive drive and commitment to invest in technology advancements in controlled growing environments are what set him apart. We’re proud to honor Peter with this FreshTEC Achievement Award.”

“It is a great honor to be recognized by your peers,” said Peter Quiring. “Innovation in the way we build our greenhouses and how we grow our vegetables is what has driven my companies for many years. Implementing the latest in technology has allowed us to be a more efficient operation from start to finish”, stated Quiring.

In addition to receiving the FreshTEC Award for Achievement, NatureFresh™ Farms has been named a Finalist for the Best New Vegetable Award for its TOMZ® Snacking Tomato Program.

“We saw a need in the market place to create a category wide program that would give consumers consistent quality, regardless of the season”, said Chris Veillon, Director of Marketing. The TOMZ® Program is unique in that it provides consumers up to 7 different types of specialty tomatoes under one brand: Red/Yellow/Orange Grape, Red Cherry, Mixed Snacking, Mixed Grape, and Sweet Red Cocktail Tomatoes. Grown in NatureFresh™’s new state of the art greenhouse in Delta, OH from October to July and in NatureFresh™’s high tech greenhouses in Leamington, ON March to November, the company is ensuring that locally grown snacking tomatoes are available year-round.

“Consumers want summer-like flavor in July, November, and February and the TOMZ® Program does just that!”, commented Veillon.

The TOMZ® Program is built on the following principles:

- TOMZ® is promoting the category as a whole, not just one item

- Driven by Flavor; 7 unique products under one brand

- Reduced food miles creates extended shelf life

- Creating a consumer connection with multiple flavors

- Same seed | same grower | same farms = consistency

- High impact packaging colors to brighten the produce aisle

- Geo-targeted consumer facing digital content to raise awareness

- Available year-round: Delta, OH & Leamington, ON

“We believe that the TOMZ® Program can strengthen the snacking category as a whole. It is not just about one tomato with flavor, it is a complete line of fresh tomatoes with flavor”, said Ray Wowryk, Director of Business Development.

NatureFresh™ Farms continues to sample its TOMZ® Tomatoes at all #GreenInTheCity tour stops this year with the company’s mobile Greenhouse Education Center.

NatureFresh™ Farms will have its complete line of greenhouse grown tomatoes, bell peppers, and cucumbers on display at the FreshMKT Trade show during the United Fresh Convention in Chicago, June 14-15. Attendees are invited to visit Booth 3231.

To learn more about NatureFresh™ Farms, visit naturefresh.ca.

The First Online Marketplace That Connects Buyers and Sellers

For The Fresh Produce Industry Worldwide

The First Online Marketplace That Connects Buyers and Sellers

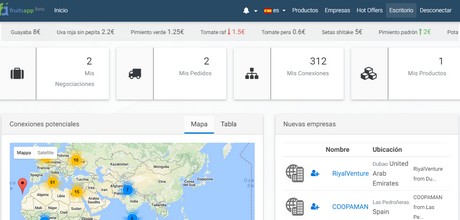

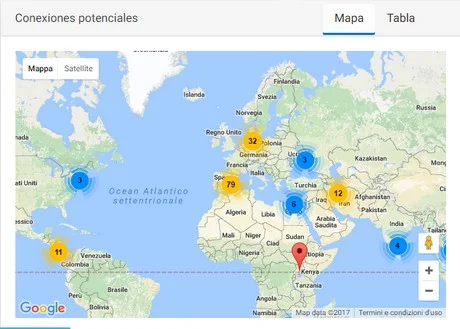

"We are a new company that was founded six months ago and we already have more than 800 companies from all over the world involved in the fresh fruits and vegetables sector," said Elena Molinaro, from Fruitsapp.

Until now, the way to communicate with other sellers, buyers, and merchants had been through telephone calls, emails, and faxes. "This is costly and inefficient because there is no quick way to reach all the buyers and producers in the world to compare options," said Elena. "However, we can solve this problem. Through our platform, you can have access to a global market and get to know other companies around the world," she said.

This website also provides the possibility to sell the products more quickly through an innovative 'Hot Offer' service. FruitsApp, notifies other web users who may be interested in those products. Producers and buyers are connected through algorithms and Artificial Intelligence, which unite them according to their common interests.

For example, if you have avocados to sell, you register for free on the platform and once you are registered you can include your interests. The algorithms will then look for other companies that are interested or that are looking for avocados and an interactive map indicating that you have a match with a company will appear in your personal profile. Then, users can contact the company by clicking on it and entering their profile. If you are an avocado vendor, you can directly send your offer to all potential clients, such as wholesalers, importers, exporters, and supermarkets around the world that already use the platform.

The security system checks all companies that are registered to avoid fraud, in addition, at the time of registration, they verify that the company is real, that it can guarantee its transactions, and that their products meet the minimum quality requirements through Global GAP or HACCP certificates.

Currently, the greatest difficulty is modernizing a traditional sector through new technologies. Fortunately, the new generations are helping this change a lot, as they are more used to using these types of innovative platforms and Applications.

The registration is totally free and the sellers only pay a small commission if they manage to make a sale through the platform. In addition, logistics are integrated and buyers can choose between the logistics proposed by Fruitsapp or the logistics that the seller proposes.

It also includes a section of advice and forecasts on demand, trends, and prices to help companies optimize their buying decisions.

For more information:

Elena Molinaro

Fruitsapp

T: +393275496390

elena.molinaro@fruitsapp.com

www.fruitsapp.com

Philips Lighting Horticulture LED Solutions Adds Horticoop Scandinavia A/S to its Partner Network

Philips Lighting Horticulture LED Solutions Adds Horticoop Scandinavia A/S to its Partner Network

Eindhoven, The Netherlands – Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting, has signed a partnership agreement with Horticoop Scandinavia A/S, a specialist supplier of technologies for greenhouse products and services to professional growers in Denmark. This partnership strengthens the offering of Philips Lighting Horticulture LED Solutions to meet the growing demand for LED lighting in Scandinavia.

“Our decision to partner with Horticoop Scandinavia A/S is made after we recently completed our first project in Denmark for Queen Flowers, a high quality producer and breeder of Kalanchoe,” explained Udo van Slooten, Managing Director of Philips Lighting Horticulture LED Solutions. “The market has good potential, especially in segments for potted plants and high wire crops. With potted plant growers, we can build on our experience completing numerous LED projects in Europe, the Americas, Asia and Australia There is a growing demand for LED lighting in this segment because it offers benefits such as radically higher propagation rates, faster rooting, lower energy costs and a rapid return on investment. As for high wire crops we have seen a long history of positive results already, like higher yields and better heat management resulting in more control over the crop.”

This latest partnership brings together Horticoop Scandinavia’s experience in selling and installing LED lighting at some of the largest Danish greenhouses with Philips Lighting`s innovative greenhouse lighting technologies. Together, the partners plan to expand the base of LED installations in Denmark and the rest of Scandinavia.

For further information, please contact:

Daniela Damoiseaux, Global Marcom Manager Horticulture

Philips Horticultural LED Lighting, Nederland

E-mail: daniela.damoiseaux@philips.com

www.philips.com/horti

About Philips Lighting

Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting products, systems and services, delivers innovations that unlock business value, providing rich user experiences that help improve lives. Serving professional and consumer markets, we lead the industry in leveraging the Internet of Things to transform homes, buildings and urban spaces. With 2016 sales of EUR 7.1 billion, we have approximately 34,000 employees in over 70 countries. News from Philips Lighting is located at http://www.newsroom.lighting.philips.com and on Twitter via @LightingPress.

About Horticoop Scandinavia A/S

Horticoop Scandinavia A/S supplies goods and equipment for operating greenhouses, nurseries and open field growing. The company is recognized as the preferred one-stop-shop for many Danish companies in the horticulture industry. Horticoop Scandinavia A/S has a great deal of experience in selling and installing assimilation light and has carried out projects for many of the biggest Danish greenhouses. In the future Horticoop Scandinavia A/S aims to further improve its services to its many clients and expand into other markets throughout Scandinavia.

Philips Lighting Begins Largest LED Horticultural Lighting Project in The World

Philips Lighting Begins Largest LED Horticultural Lighting Project in The World

June 14, 2017

- LED grow lights will illuminate greenhouses occupying an area the size of 40 soccer pitches

- Project indicative of trend for large-scale horticultural LED lighting projects supporting domestically grown produce

Eindhoven, the Netherlands – Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting, today announced that it will provide LLC Agro-Invest, Russia’s most innovative greenhouse produce company, with LED grow lights to support cultivation of tomatoes and cucumbers in greenhouses covering an area of more than 25 hectares (equivalent in size to about 40 soccer pitches). The project, which is the largest LED horticultural lighting project ever undertaken, will enable year-round growing, help boost yields - especially in the winter - and will save 50 percent on energy costs compared to conventional high-pressure sodium lighting. The project also underlines a global trend for large-scale LED horticultural lighting implementations that can support demand for locally grown produce.

Philips Lighting is working with Dutch partner Agrolux and Russian installer, LLC ST Solutions, which will equip greenhouses in Lyudinovo, Kaluga Oblast, 350 km south west of Moscow, during the next three months. Philips Lighting will provide ‘light recipes’ optimized for growing tomatoes and cucumbers, training services and 65,000 1.25m long Philips GreenPower LED toplights and 57,000 2.5m long Philips GreenPower LED interlights. Laid end to end, they would stretch 223 km, the equivalent of crossing the English Channel from Dover to Calais more than five times.

“We have a reputation for innovation on a large scale and LED grow lights are definitely the future. They deliver the right light for the plant, exactly when and where the plant needs it the most, while radiating far less heat than conventional lighting. This allows us to place them closer to the plants,” said Irina Meshkova, Deputy CEO and General Director, Agro-Invest. “Thanks to this technology we will be able to increase yields in the darker months of the year, and significantly reduce our energy usage,” she added.

“This LED horticultural project is the largest in the world. It will reduce the electricity consumed to light the crop by up to 50 percent compared with conventional horticultural lighting and uses light recipes designed to boost quality and crop yields by up to 30 percent in the dark period of the winter,” said Udo van Slooten, business leader for Philips Lighting’s horticultural lighting business. “Our grow lights are the perfect supplement to natural daylight so that crops can be grown efficiently throughout the year. The project also highlights a growing international trend to replace imports with domestically grown produce, reducing food miles and ensuring freshness,” he added.

About Agro-Invest

LLC Agro-Invest is Russia’s most innovative greenhouse produce company. Its 43 hectare modern greenhouse complex grows more than 15 varieties of vegetables with an annual production capacity of 25,000 tons. The company acts ecologically, collecting rainwater to water the plants which are pollinated by bees from special beehives within the greenhouse complex. The latter helps improve harvests by 20-25 percent. Protection of the plants is undertaken by natural biological methods. Since 2016, Agro-Invest has sold and marketed its produce under the “Moyo Leto.” trademark. The company works with all the federal trade networks in the Russian Federation and is expanding its operations.

About Agrolux

Agrolux is a worldwide supplier of assimilation lighting for horticulture. It is the biggest dealer in Philips LED horticultural lighting worldwide. It distinguishes itself based on advice, service and quality. It also produces its own luminaires and exports them to clients worldwide. The company’s broad knowledge, extensive experience and innovative technology, make it stand out as a leader in the horticulture sector. It combines good, honest advice with the fast and dependable delivery of lighting luminaires and parts. Established in 2002, Agrolux has grown in size and production numbers annually. Its employees come from diverse sectors within horticulture and offer a wealth of practical experience, providing the best advice and most efficient lighting for horticulture.

For more information on Philips horticultural lighting: www.philips.com/horti

For further information, please contact:

Philips Lighting, Global Media Relations

Neil Pattie | Tel: +31 6 15 08 48 17 | Email: neil.pattie@philips.com

Philips Lighting Horticulture LED Solutions

Daniela Damoiseaux | Tel: +31 6 31 65 29 69 | Email: daniela.damoiseaux@philips.com

About Philips Lighting

Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting products, systems and services, delivers innovations that unlock business value, providing rich user experiences that help improve lives. Serving professional and consumer markets, we lead the industry in leveraging the Internet of Things to transform homes, buildings and urban spaces. With 2016 sales of EUR 7.1 billion, we have approximately 34,000 employees in over 70 countries. News from Philips Lighting is located at http://www.newsroom.lighting.philips.com and on Twitter via @Lighting_Press.

Vertical Farming Startup Plenty Acquires Bright Agrotech to Scale

Vertical Farming Startup Plenty Acquires Bright Agrotech to Scale

California-based vertical farming company Plenty, previously See Jane Farm, has acquired Bright Agrotech in an effort to reach “field-scale.”

Bright Agrotech is an indoor ag hardware company that’s focused on building indoor growing systems for small farmers all over the world, in contrast to Plenty, which is aiming to become a large-scale indoor farming business and currently has a 52,000 sq. ft farm in South San Francisco.

“The need for local produce is not one that small farmers alone can satisfy, and I’m glad that with Plenty we can all work toward bringing people everywhere the freshest food,” said Nate Storey, founder and chairman of Bright Agrotech.

The move to acquire Bright Agrotech will give Plenty the breadth of expertise and intellectual property (IP) to scale with rapid speed, and is a natural move after a four-year relationship, according to Matt Barnard, cofounder and CEO.

“We have a great portfolio of system level IP. They have a great portfolio of component level IP,” he told AgFunderNews. “We’re getting a fire hose of demand from around the globe right now. This is an industry that is emergent, but the way to truly lift it off the ground is to do a whole set of things extraordinarily well.”

Bright Agrotech was founded in 2010 in Laramie, Wyoming, and sells a wide range of indoor farming equipment for indoor vertical farms as well as greenhouses along with smaller systems suitable for homes and business development tools – most of which are under the trademark brand “ZipGrow.”

The relationship between the two businesses started in 2013. Later Storey, the former CEO of Bright Agrotech, became chief science officer at Plenty in a part-time capacity in 2015 and went on to join the team full time earlier this year.

Barnard would not confirm to what extent Plenty already uses Bright Agrotech’s hardware in its farm, which consists of 20-foot high towers with vertical irrigation channels and facing LED lights. Leafy greens ready for picking end up looking similar to a solid wall of green.

Plenty claims to use 1 percent of the water and land of a conventional farm with no pesticides or synthetic fertilizers. Like other large soilless, hi-tech farms growing today, Plenty says it uses custom sensors feeding data-enabled systems resulting in finely-tuned environmental controls to produce greens with superior flavor.

Based on the West Coast, it plans to compete with the existing supply of greens from the salad bowl of California, by choosing premium seeds and catering growing conditions for optimal taste. Barnard says most greens growing in the field are bred to be hardy enough to last the 3,000 mile journey to the east coast and beyond.

He would not share specific growth goals for the near-term, but said that eventually they expect to be able to build two to six farms per month. The plan is to build these farms just outside major cities where retailers have distribution centers and real estate is more affordable. Barnard also said that an announcement about a major retail partnership is forthcoming.

Zack Bogue, an investor in Plenty through San Francisco venture capital fund Data Collective, agreed that the Bright Agrotech acquisition will help the startup scale. “By vertically integrating parts of their component supply chain, it will make the most efficient system out there more efficient,” he said.

Plenty claims to get 350 times the crop yield per year over an outdoor field farm. Or, as Barnard described, “It is the most efficient in terms of the amount of productive capacity per dollar spent, period.”

Plenty was the first indoor ag investment for big data-focused Data Collective, which participated in its $24.5m Series A in July 2016. “We’re pretty excited about that space because some of the hardest problems in agriculture are now lending themselves to an algorithmic or computational or applied machine-learning solution,” he said. But he added that the ability to scale was paramount, because scale is what allows data to be useful for machine-learning applications. “I came away feeling this was an endeavor that could truly achieve global scale pretty quickly,” he added.

Bogue said that though this match was a natural fit, he doesn’t expect more consolidation in the space.

Plenty has raised $26 million to date in a seed and Series A Round, both in 2016. The startup’s other investors are Innovation Endeavors , Bezos Expeditions , Finistere Ventures, Data Collective, Kirenaga Partners, DCM Ventures, and Western Technology Investment

High-Tech Farms Give A New Meaning To ‘Locally Grown’

High-Tech Farms Give A New Meaning To ‘Locally Grown’

Published: June 8, 2017 4:58 a.m. ET

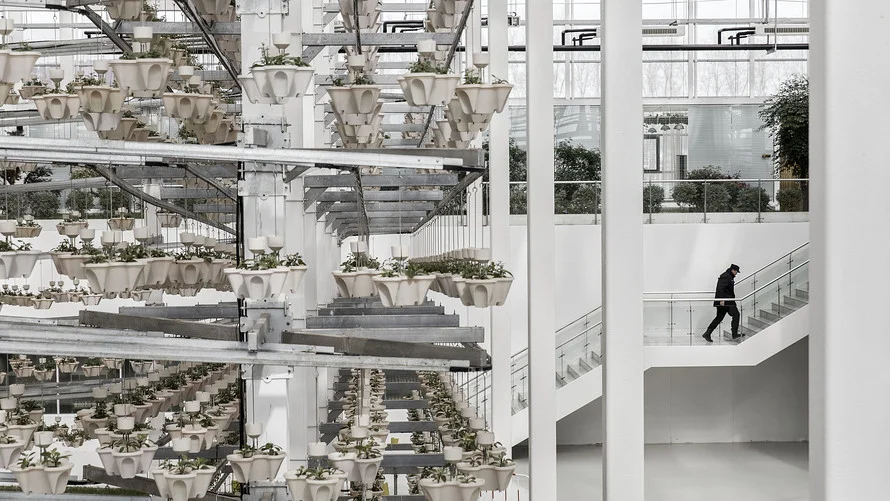

This is the new urban farm

Bloomberg

Plants growing in a rotary light-tracking system inside a greenhouse at a high-tech indoor farm on the outskirts of Beijing. China is turning to technology to make its land productive again.

By Betsy McKay

Billions of people around the world live far from where their food is grown.

It’s a big disconnect in modern life. And it may be about to change.

The world’s population is expected to reach 9.7 billion by 2050, 33% more people than are on the planet today, according to projections from the United Nations. About two-thirds of them are expected to live in cities, continuing a migration that has been under way around the world for years.

That’s a lot of mouths to feed, particularly in urban areas. Getting food to people who live far from farms—sometimes hundreds or thousands of miles away—is costly and strains natural resources. And heavy rains, droughts and other extreme weather events can threaten supplies.

Now more startups and city authorities are finding ways to grow food closer to home. High-tech “vertical farms” are sprouting inside warehouses and shipping containers, where lettuce and other greens grow without soil, stacked in horizontal or vertical rows and fed by water and LED lights, which can be customized to control the size, texture or other characteristic of a plant.

Companies are also engineering new ways to grow vegetables in smaller spaces, such as walls, rooftops, balconies, abandoned lots — and kitchens. They’re out to take advantage of a city’s resources, composting food waste and capturing rainwater as it runs off buildings or parking lots.

“We’re currently seeing the biggest movement of humans in the history of the planet, with rural people moving into cities across the world,” says Brendan Condon, co-founder and director of Biofilta Ltd., an Australian environmental-engineering company marketing a “closed-loop” gardening system that aims to use compost and rainwater runoff. “We’ve got rooftops, car parks, walls, balconies. If we can turn these city spaces into farms, then we’re reducing food miles down to food meters.”

Moving beyond experiments

Urban farming isn’t easy. It can require significant investment, and there are bureaucratic hurdles to overcome. Many companies have yet to turn a profit, experts say. A few companies have already failed, and urban-farming experts say many more will be weeded out in the coming years.

Getty Images

In London, former air raid shelters are home to 'Growing Underground', the UK’s first underground farm, shown here in 2016. The farm grows pea shoots, rocket, wasabi mustard, red basil, red amaranth, pink stem radish, garlic chives, fennel and coriander, and supply to restaurants across London.

But commercial vertical farms are well beyond experimental. Companies such as AeroFarms, owned by Dream Holdings Inc., and Urban Produce LLC have designed and operate commercial vertical farms that aim to deliver supplies of greens on a mass scale more cheaply and reliably to cities, by growing food locally indoors year round.

At its headquarters in Irvine, Calif., Urban Produce grows baby kale, wheatgrass and other organic greens in neat rows on shelves stacked 25 high that rotate constantly, as if on a conveyor belt, around the floor of a windowless warehouse. Computer programs determine how much water and LED light the plants receive. Sixteen acres of food grow on a floor measuring an eighth of an acre.

Its “high-density vertical growing system,” which Urban Produce patented, can lower fuel and shipping costs for produce, uses 80% less fertilizer than conventional growing methods, and generates its own filtered water for its produce from humidity in the air, says Edwin Horton Jr., the company’s president and chief executive officer.

“Our ultimate goal is to be completely off the grid,” Horton says.

The company sells the greens to grocers, juice makers and food-service companies, and is in talks to license the growing system to groups in cities around the world, he says. “We want to build these in cities, and we want to employ local people,” he says.

AeroFarms has built a 70,000-square-foot vertical farm in a former steel plant in Newark, N.J., where it is growing leafy greens like arugula and kale aeroponically — a technique in which plant roots are suspended in the air and nourished by a nutrient mist and oxygen — in trays stacked 36 feet high.

The company, which supplies stores from Delaware to Connecticut, has more than $50 million in investment from Prudential, Goldman Sachs and other investors, and aims to install its systems in other cities globally, says David Rosenberg, its chief executive officer. “We envision a farm in cities all over the world,” he says.

AeroFarms says it is offering project management and other services to urban organizations as a partner in the 100 Resilient Cities network of cities that are working on preparing themselves better for 21st century challenges such as food and water shortages.

The bottom line

Still, these farms can’t supply a city’s entire food demand. So far, vertical farms grow mostly leafy greens, because the crops can be turned over quickly, generating cash flow easily in a business that requires extensive capital investment, says Henry Gordon-Smith, managing director of Blue Planet Consulting Services LLC, a Brooklyn, N.Y., company that specializes in the design, implementation and operation of urban agricultural projects globally.

The greens can also be marketed as locally grown to consumers who are seeking fresh produce.

Other types of vegetables require more space. Growing fruits like avocados under LED light might not make sense economically, says Gordon-Smith.

“Light costs money, so growing an avocado under LED lights to only get the fruit to sell is a challenge,” he says.

And the farms aren’t likely to grow wheat, rice or other commodities that provide much of a daily diet, because there is less of a need for them to be fresh, Gordon-Smith says. They can be stored and shipped efficiently, he says.

The farms are also costly to start and run. AeroFarms has yet to turn a profit, though Rosenberg says he expects the company to become profitable in a few months, as its new farm helps it reach a new scale of production. Urban Produce became profitable earlier this year partly by focusing on specialty crops such as microgreens—the first shoots of greens that come up from the seeds—that generally grow indoors in a very condensed space, says Horton, who started the company in 2014.

One of the first commercial vertical-farming companies in the U.S., FarmedHere LLC, closed a 90,000 square-foot farm in a Chicago suburb and merged with another company late last year. “We’ve learned a lot of lessons,” says co-founder Paul Hardej.

Among them: Operating in cities is expensive. The company should have built its first farm in a suburb rather than a Chicago neighborhood, Hardej says. Real estate would have been cheaper.

“We could have been 10 or 20 miles away and still be a local producer,” Hardej says.

The company also might have been able to work with a smaller local government to get permits and rework zoning and other regulations, because indoor farming was a new type of land use, Hardej says. While FarmedHere produced some crops profitably, it spent a lot on overhead for lawyers and accountants “to deal with the regulations,” he says.

Hardej is now co-founder and chief executive officer of Civic Farms LLC, a company that develops a “2.0” version of the vertical farm, he says—more efficient operations that take into account the lessons learned. Civic Farms is collaborating with the University of Arizona on a research and development center at Biosphere 2, the Earth science research facility in Oracle, Ariz., where it runs a vertical farm and develops new technologies.

Blossoming tech

New technology will improve the economic viability of vertical farms, says Gordon-Smith. New cameras, sensors and smartphone apps help monitor plant growth. One company is even developing augmented-reality glasses that can show workers which plants to pick, Gordon-Smith says.

“That is making the payback look a lot better,” he says. “The future is bright for vertical farming, but if you’re building a vertical farm today, be ready for a challenge.”

Some cities are trying to propagate more urban farms and ease the regulatory burden of setting them up. Atlanta Mayor Kasim Reed created the post of urban agriculture director in December 2015, with a goal of putting local healthy food within a half-mile of 75% of the city’s residents by 2020. The job includes attracting urban-farming projects to Atlanta and helping projects obtain funding and permits, says Mario Cambardella, who holds the director title.

“I want to be ahead of the curve; I don’t want to be behind,” he says.

Many groups are taking more low-tech or smaller-scale approaches. A program called BetterLife Growers Inc. in Atlanta plans to break ground this fall on a series of greenhouses in an underserved area of the city, where it will grow lettuce and herbs in 2,900 “tower gardens,” thick trunks that stand in large tubs. The plants will be propagated in rock wool, a growing medium consisting of cotton-candy-like fibers made of a melted combination of rock and sand, and then placed into pods in the columns, where they will be regularly watered with a nutrient solution pumped through the tower, says Ellen Macht, president of BetterLife Growers.

The produce will be sold to local educational and medical institutions. “What we wanted to do was create jobs and come up with a product that institutions could use,” she says.

The $12.5 million project is funded in part by a loan from the city of Atlanta, with Cambardella helping by educating grant managers on the growing system and its importance.

Change at home

Another company aims to bring vertical farming to the kitchen. Agrilution GmbH, based in Munich, Germany, plans to start selling a “plantCube” later this year that looks like a mini-refrigerator and grows greens using LED lights and an automatic watering system that can be controlled from a smartphone. “The idea is to really make it a commodity kitchen device,” says Max Loessl, Agrilution’s co-founder and chief executive officer, of the appliance, which will cost 2,000 euros—about $2,200—initially.

The goal is to sell enough to bring the price down, so that in five years the appliance is affordable enough for most people in the developed world, Loessl says.

Biofilta, the company Condon co-founded, is marketing the Foodwall, a modular system of connected containers, an approach that he calls “deliberately low tech” because it doesn’t require electricity or computers to operate. The tubs are filled with a soil-based mix and a “wicking garden-bed technology” that stores and sucks water up from the bottom of the tub to nourish the plants without the need for pumps. The plants need to be watered just once a week in summer, or every three to four weeks in the winter, says Chief Executive Marc Noyce. The tubs can be connected vertically or horizontally on rooftops, balconies or backyards. “We’ve made this gardening for dummies,” Noyce says.

Biofilta

Biofilta's Foodwall

The Foodwall can use composted food waste and harvested rainwater, helping to turn cities into “closed-loop food-production powerhouses,” Condon says.

He and Noyce were motivated to design the Foodwall by a projection from local experts that only 18% of the food consumed in their home city of Melbourne, Australia, will be grown locally by 2050, compared with 41% today, Noyce says.

“We were shocked,” says Noyce. “We’re going to be beholden to other states and other countries dictating our pricing for our own food.”

“Then we started to look at this trend around the world and found it was exactly the same,” he says.

Traditional, rural farming is far from being replaced by all of these new technologies, experts say. The need for food is simply too great. But urban projects can provide a steady supply of fresh produce, helping to improve diets and make a city’s food supply more secure, they say.

“While rural farmers will remain essential to feeding cities, cleverly designed urban farming can produce most of the vegetable requirements of a city,” Condon says.

Betsy McKay is a senior writer in The Wall Street Journal’s Atlanta bureau. She can be reached at betsy.mckay@wsj.com.

The article “A Farm Grows in the City” first appeared in The Wall Street Journal.

Company Overview: INFARM - Grow Where You Are

Company Overview: INFARM - Grow Where You Are

INFARM is pioneering on-demand farming services to provide urban communities with fresh, nutritious produce, by distributing smart vertical farms in strategic centers of consumption. Our modular farms are highly efficient and can be easily deployed in any given space whether that be a supermarket, a restaurant, a school or a vacant warehouse.

Our Vision

We believe our food system should be decentralized and food production should get closer to the consum-er. INFARM offers an alternative food system that is responsive, transparent, and accessible, while allowing for significant improvement in the safety, quality, and environmental footprint of our food.

INFARM is bringing farming into the city, directly where people live and eat. Our vertical farming technology is the foundation for building urban farm-ing networks that will help cities become resilient and self-sufficient in their food production, while providing city-dwellers fresh, affordable, healthy produce all year round.

Our Farms

Our farms are comprised of modular hydroponic farming units that can be stacked and expanded, depending on the needs of our clients. All parameters of the farming unit are automated and constantly optimize the growing environment to ensure each plant gets the best conditions to thrive. Each individual farm is connected to our central farm-ing platform through IoT technology, that allows us to respond in real-time to fluctuations in demand.

Farming-As-A-Service™

Our clients pay a monthly subscription fee for farm capac-ity while INFARM’s dedicated team of professional growers operate the farms and care for the life of the plants. We work closely with each client to understand their needs and the demands of their customers to deliver a tailored assortment of fresh produce.

Our Produce

We grow the freshest, most nutritious, flavorful and beautiful produce, year round. Our grow-on-site approach means our plants have zero food miles and replace the need to import products from abroad.

We grow plants that are well known and loved, as well as rare and heirloom species which are forgotten or are hard to find. To ensure the maximum natural expression of each plant, our team of plant specialists develop unique growing recipes; tailoring the light, temperature, pH and nutrients to perfectly suit the plant type.

Our Story

INFARM was founded by Osnat Michaeli and brothers Erez and Guy Galonska when they came to Berlin in 2013. When they started out, they were motivated by what they wanted from their own lives – to be more independent, to eat healthier, and to experience the excitement of growing their own food. They built their first hydroponic farm in their apartment in Berlin, harvesting fresh vegetables on a snowy day in February. The empow-erment that came about from growing their own food, motivated them to explore urban farming further.

Over the following months, the trio began investigating the challenges facing farming in urban environments. They started to research and test methods to tackle these issues, from both a technological and strategic perspective until they arrived at a product and business model that they believed could truly shift the paradigm of food production.

Today, INFARM has grown to a 30 person company based in a large industrial warehouse in Kreuzberg, Berlin.

Our Team

Our home town of Berlin attracts like-minded individuals who are committed to making real change. This has allowed us to gather a diverse team with backgrounds in plant science, industrial design, engineering, architecture, IT, marketing and business.

Our Core Team Includes:

CEO: Erez Galonska

CTO: Guy Galonska

CMO: Osnat Michaeli

CFO: Martin Weber

Chief Science Officer: Pavlos Kalaitzoglou

Chief Growing Officer: Nico Domurath

Chief Information Officer: Alain Scialoja

News Coverage

Over the past few years, INFARM has been covered by publications including Tagesspiegel, Germany Trade & Invest, Fast Co Exist, The Guardian, Venture Village, Zeit and Inhabitat, amogst others.

– For complete press information, contact us.

Contact Information

Rebecca Griffiths

Head of Marketing & Communications Email: press@infarm.de

Phone: +49 30 55 63 00 48

Company Highlights

- Secured international patents on key technology.

- Built and operating the first in-store farms in the world in the METRO Cash & Carry in Berlin & Makro Antwerp.

- The first vertical farming company to be certified with GLOBALG.A.P.

- INFARM has received funding from the H2020 SME Instrument for the project “The vertical farming revolution, urban Farming as a Service.

- Selected by the European Commission as one of the top 4% of Europe’s leading innovators in the field of agriculture and technology.

- First prize in the Innovation Weekend Startup Competition in Tokyo, Japan.

- First prize in the Vision Award Competition 2016 Munich, Germany.

Indoor Urban Farming GmbH | Glogauer Str. 6, 10999 Berlin | www.infarm.com

EU Awards Greek Patent for Automated Indoor Farming

EU Awards Greek Patent for Automated Indoor Farming

By Philip Chrysopoulos | Jun 11, 2017

The European Commission on Wednesday awarded Christos Raftogiannis and Evriviadis Makridis for their invention of an Automated Indoor Farming device with which you can grow 40 different fruits and vegetables in your home.

CityCrop offers a fully automated indoor garden based on the technique of hydroponics. The two Greek men were awarded as best startup in the category “Smart Cities”.

The company was incorporated in 2015 and is based in London. CityCrop created the mobile device and application that allows users to grow fresh and healthy food all year-long as well as control and monitor their crops. Users can grow leafy green vegetables, herbs, fruits, edible flowers, and microgreens.

The device can take up to 40 glass cubes and the owner can grow spinach, cherry tomatoes, kale, radish, strawberries, basil, cilantro, lettuce and more. CityCrop can take 10 liters of water and its power consumption does not exceed five euros per month. Inside the glass cube the appropriate humidity, temperature and lighting conditions of plant growth are ensured. Furthermore, the device should be connected on the internet so that the grower can have constant contact with the plants to cater to their needs, such as add more water or adjust the temperature.

The cost of CityCrop is currently 1,000 euros, but could be reduced significantly if it is mass-produced.

The World's Largest Dedicated Showcase of Sustainable Agriculture Innovations

The World's Largest Dedicated Showcase of Sustainable Agriculture Innovations

In 2018 GFIA Europe will be co-located with VIV Europe and Future Food Manufacturing to bring over 29,000 key buyers and decisions makers concerned with smart food production from around the world to Utrecht, the Netherlands.

The world's largest dedicated showcase of sustainable agriculture innovations, GFIA is your platform to do business with thousands of buyers and procurement managers from food producers and growers, agribusinesses, governments and resellers & distributors.

WHO WILL BENEFIT FROM EXHIBITING AT GFIA EUROPE?

Any company that sells solutions for sustainable agriculture. Visitors that want to make their businesses smarter and more productive without damaging our environment or climate.

They want to save water and natural resources, improve soil quality, protect livestock health and increase yields in all areas of food production.

If you can help food producers and growers do that, you should book a stand at GFIA Europe..

GFIA EUROPE REVIEW

Including emerging markets of Egypt, Former Soviet Union, India, Kenya, Nigeria, Russia, Sri Lanka, Taiwan, UAE

COMPANIES ALREADY CONFIRMED TO EXHIBIT INCLUDE

THREE MAJOR NEW INITIATIVES FOR 2018

Co-located with VIV Europe: the European trade show for the international Feed to Meat industry

Co-located with Future Food Manufacturing Expo: Europe’s first major international trade fair dedicated to essential sustainable technologies in food processing and production

Smart Agri Mechanisation Zone: the latest in connected machinery and digital farm equipment revolutionising precision agriculture will be showcased

CONTACT:

David Stradling, Sales Director

E: d.stradling@turretme.com | T: +971 (0)2 234 8486 | www.GFIAEurope.com

ChemChina Completes The Second Settlement of the Tender Offers for Syngenta

ChemChina Completes The Second Settlement of the Tender Offers for Syngenta

June 07, 2017 11:45 AM Eastern Daylight Time

BASEL, Switzerland--(BUSINESS WIRE)--China National Chemical Corporation (ChemChina) today announced the successful completion of the Second Settlement of ChemChina’s tender offers for Syngenta. Shareholders who tendered their shares after 4 May 2017 received the consideration of US$465 per share, and holders of American Depositary Shares ("ADSs") who tendered their ADSs received US$93 per ADS, on June 7, 2017. In the First and the Second Settlement, ChemChina acquired 94.7 percent of Syngenta shares in aggregate.

As soon as permitted by law and applicable regulation, it is intended to de-list the shares from the SIX and to de-list the ADSs from the NYSE.

About Syngenta

Syngenta is a leading agriculture company helping to improve global food security by enabling millions of farmers to make better use of available resources. Through world class science and innovative crop solutions, our 28,000 people in over 90 countries are working to transform how crops are grown. We are committed to rescuing land from degradation, enhancing biodiversity and revitalizing rural communities. To learn more visit www.syngenta.com and www.goodgrowthplan.com. Follow us on Twitter® at www.twitter.com/Syngenta.

About ChemChina

ChemChina, which is headquartered in Beijing, China, possesses production, R&D and marketing systems in 150 countries and regions. It is the largest chemical corporation in China, and occupies the 234th position among the Fortune Global 500. The company’s main businesses include materials science, life science, high-end manufacturing and basic chemicals, among others. Previously, ChemChina has successfully acquired 9 leading industrial companies in France, United Kingdom, Israel, Italy and Germany, etc. To learn more visit www.chemchina.com and www.chemchina.com/press.

Additional information and where to find it

This press release is for informational purposes only and does not constitute an offer to purchase or a solicitation of an offer to sell Common Shares or ADSs. The solicitation and offer to buy Common Shares or ADSs was only made pursuant to the Swiss Offer Prospectus and the U.S. Offer to Purchase and other documents relating to the U.S. Offer that were filed with the U.S. Securities and Exchange Commission ("SEC"), including the Tender Offer Statement on Schedule TO filed by ChemChina and CNAC Saturn (NL) B.V. ("Purchaser") and the Solicitation/Recommendation Statement on Schedule 14D-9 with respect to the U.S. Offer filed by Syngenta. A free copy of these materials and other documents filed by ChemChina, Purchaser and Syngenta with the SEC can be obtained at the website maintained by the SEC at www.sec.gov. Free copies of the Solicitation/Recommendation Statement and other documents filed with the SEC by Syngenta can be obtained at www.syngenta.com.

Cautionary statement regarding forward-looking statements

Some of the statements contained in this press release are forward-looking statements, which involves a number of risks and uncertainties discussed in Syngenta’s public filings with the SEC, including the "risk factors" section of Syngenta's Form 20-F filed on February 16, 2017 as well as the U.S. Offer documents filed by ChemChina and Purchaser and the Solicitation/Recommendation Statement filed by Syngenta. These statements are based on current expectations, assumptions, estimates and projections, and involve known and unknown risks, uncertainties and other factors that may cause results, levels of activity, performance or achievements to be materially different from any forward-looking statements. These statements are generally identified by words or phrases such as "believe", "anticipate", "expect", "intend", "plan", "will", "may", "should", "estimate", "predict", "potential", "continue" or the negative of such terms or other similar expressions. If underlying assumptions prove inaccurate or unknown risks or uncertainties materialize, actual results and the timing of events may differ materially from the results and/or timing discussed in the forward-looking statements, and you should not place undue reliance on these statements. ChemChina, Purchaser and Syngenta disclaim any intent or obligation to update any forward-looking statements as a result of developments occurring after the period covered by this press release or otherwise.

Innovative Thinking and Technology: The Key to Solving Global Problems

Innovative Thinking and Technology: The Key to Solving Global Problems

Austin Belisle - June 1, 2017

This blog was guest-written by Brandi DeCarli, Founding Partner of Farm from a Box. She’ll be guest-speaking during the “Global Problem Solvers Who are Guardians of Our Planet” session of the Women Rock-IT series on June 15th.

Every aspect of our modern-day lives has been impacted by technology. From cloud and robotics to digital currency and drones, our lives are inextricably tied to the technology that surrounds us. While farming may not be the first thing that comes to mind when thinking of technology, it has played a key role in changing the face of agriculture and our global food system.

In the past 50 years, the Green Revolution has pushed to increase crop yields through large-scale intensification of single crops. Advances in mechanized farming allowed for larger and larger acreage to be farmed. By focusing on the large-scale intensification of a single crop, the natural checks and balances that diverse ecosystems provide were no longer in place.

To maintain production, it required heavy use of fertilizers and pesticides, which has directly impacted soil fertility and ecosystems around the globe. Now, with 40% of our agricultural soil degraded and 70% of our freshwater resources being gulped up by agriculture, it is clear that our current approach is not sustainable.

While advances in technology have enabled global agricultural production to increase with our growing population, those gains came at an unprecedented environmental cost. As we work to feed a growing global population, the environmental pressures will continue to increase.

By 2050, the world’s population is expected to grow by more than two billion people. Half will be born in Sub-Saharan Africa, and another 30 percent in South and Southeast Asia. Those regions are also where the effects of climate change are expected to hit hardest.

So, how can make sure that the growing need for food worldwide is met in an ecologically sustainable way? And what role can technology play? The opportunity may be in shifting our focus from mass production to production by the masses.

An estimated 70% of the world’s food comes from small, rural farms that are no bigger, on average, than two acres. And despite the increase in large-scale industrialized farms, small, rural farms are still the backbone of our global food supply. But these rural areas are often the most vulnerable to the effects of climate change.

The challenges of drought, degraded soil, and inefficient and labor-intensive methods contribute to and exacerbate low and unreliable crop production. Without access to the infrastructure or technologies that can support a productive farm, farmers will either struggle with low yields, depend on chemical inputs that further deplete the soil, or rely on outside aid.

This is where Farm from a Box comes in.

Farm from a Box works to bridge the “access” gap by providing a complete, off-grid toolkit for sustainable, tech-powered agriculture. Built from a modified shipping container, each unit contains a complete ecosystem of smart farm technologies to enhance agricultural productivity; from renewable power and micro-drip irrigation to Information and Communications Technology equipment.

Designed as the “Swiss-Army knife” of farming, this mobile infrastructure provides all the tools needed to support a two-acre farm. By empowering farmers to grow and sustain food production at the community level, we build greater resilience to climate shocks, boost livelihoods, and help bridge the access gap by making healthy food locally available.

With its own off-grid power, Farm from a Box can act as its own micro-grid in remote locations; drip irrigation helps save water and stabilize crops through drought conditions while also extending the growing season; internal cold-storage helps keep crops fresher longer, reducing post-harvest loss by 80%; Wi-Fi connectivity improves information access and exchange; and a cloud-based IoT system helps monitor production and efficiencies.

By introducing micro-irrigation, we can extend the growing season and better support a wide variety of crops throughout the year, while lowering the amount the water used by applying it directly to the plant. The off-grid power array and storage provide a reliable energy source to power the pump, move the water through the irrigation lines, cool the internal cold storage area, and support the charging of auxiliary needs.

We have also connected each unit with Wi-Fi capabilities and a complete IoT system to improve operational efficiency, optimize water and energy use, and provide guidance on farm management and market information. Because we have integrated sensors on all of the primary systems, we can monitor and control the performance of the system, and also set alerts for when a component dips below or exceeds certain levels.

Let me give you an example of how this applies in a real-world situation. We recently teamed up with the United Nations World Food Programme Tanzania and WFP’s Innovation Accelerator to support food and nutrition security for refugee and host communities. Our Farm from a Box system will be used to increase the availability of nutritious crops, provide low-cost agricultural commodities and, through increased production, boost the income levels for both refugees and the surrounding host communities.

Because the farm is operating in a remote location in eastern Tanzania, information becomes a vital component to ensuring the system is working as it should be, and the farmers have the data they need to know what is happening and why. Through our cloud-based IoT system, both the community and the WFP has open access to see how much energy the solar panels are producing, how much water is being used, and if the overall system is functioning properly.

Now, technology for the sake of technology isn’t a standalone solution; how it is utilized in overall value creation is where we find the real impact. By marrying technology with small-scale regenerative farming practices, we can improve soil quality, reduce dependence on outside inputs, conserve water, and build up nutrients.

Techniques like composting, crop rotation and diversification, cover cropping, and no-till practices nurture the soil’s fertility and help produce a healthier crop. By shifting our focus from industrialized agriculture to local organic agriculture, we can potentially convert carbon from a greenhouse gas into a food-producing asset.

Farm from a Box is just one of many innovations that are working to empower smallholder farmers with sustainable solutions; there are vertical farm systems, small farm robots that automate field work, drones that use near-infrared and thermal sensors to “see” how plants are doing. Technological innovations like these can help us achieve better health, well-being, and equity throughout our planetary system as a whole.

But we need creative solutions, and sometimes that requires thinking outside of the box. I don’t come from a technological background, nor does my business partner, but we saw a problem and thought, “There must be a better way.” We all have the power to change our world for the better. Food is something that connects us all and has a direct impact on our everyday lives and environment.

When we first set out to start Farm from a Box, our intention was to create a mobile infrastructure that could provide people with the tools they need to grow their own nutritious food. Over time, that idea has grown; we now see Farm from a Box as a tool that could transform local production and nutritional security globally.

Whether it is a local school, community group, or remote village in an underdeveloped country, smallholder farmers are the ecological gatekeepers to building a more sustainable and equitable food supply. Technology has the potential to help solve the intractable problems facing humanity and will continue to play an increasingly vital role in global food security and planetary health. But it will require innovative thinking from all of us to achieve it.

Freight Farms Lands $7.3M As Agriculture Meets Data & Automation

June 6th, 2017

Investors have planted $7.3 million in Freight Farms to help the Boston-based startup bring its micro-farms to more places around the globe—and potentially even beyond.

The investors in the Series B round include return backer Spark Capital, also based in Boston. The news was first reported by the Wall Street Journal on Monday. Freight Farms’ total venture capital haul now exceeds $12 million, according to SEC filings.

The company sells shipping containers filled with hydroponic farming systems that can grow a variety of lettuces, herbs, and other greens. The system is designed to operate with minimal hands-on work by humans. It employs LED lights and automated watering and fertilizing technology. Operators can monitor the farm through a live camera feed, and they can use an app to control the climate within the shipping container and shop for growing supplies. The company has said the system uses less water than traditional farming methods, and because it’s housed inside a shipping container, it doesn’t require pesticides or herbicides.

Freight Farms has deployed more than 100 of these farming systems across the U.S. and in several countries. Customers include urban farmers, traditional farms, produce distributors, and universities.

The startup was formed in 2010 by Brad McNamara and Jon Friedman, who previously worked on rooftop hydroponic gardens.

Freight Farms is trying to take advantage of the growing interest in local food sourcing, as its shipping containers can be set up close to where food gets sold or consumed. It also aims to enable year-round food production in challenging locales—think the snowy mountains of Colorado, or even space. Freight Farms and Clemson University are working on a NASA-funded project exploring ways to grow food in harsh climates and, potentially, deep space.

Freight Farms also fits with trends in agriculture around automation and using digital tools. That’s a key reason why Spark made another investment.

“Modular, Internet-connected, and highly automated commercial farms will play an important role in bringing local and affordable produce to communities all over the world,” Spark’s Todd Dagres and John Melas-Kyriazi wrote in a blog post about the new investment. “Value will accrue to those who own the technology layer of this farming stack (hardware + software) as data and automation become increasingly important drivers of low-cost production.”

Agricultural technology companies are taking various approaches to indoor farming. Like Freight Farms, Atlanta-based PodPonics sells tech-enabled mini-farms inside shipping containers. Businesses such as New York-based BrightFarms and Harrisonburg, VA-based Shenandoah Growers produce food inside greenhouses. And startups like Grove and SproutsIO, two Boston-area firms, sell micro-farming systems to consumers for growing food inside their homes.

Houses Squeezing Out Farms

Mike Chapman.

If too many houses replace vegetable growing operations, we may have to look at alternatives such as vertical farming, says Horticulture NZ chief executive Mike Chapman.

He has always been sceptical about such methods for NZ, but we may be “stuck with it” if urbanisation keeps taking productive land, he warns.

Vertical farming was among the most interesting sessions at the Produce Marketing Association (PMA) ANZ conference in Adelaide, he says.

A New York urban agriculture consultant, Henry Gordon-Smith, spoke about why vertical farming has taken off in the US; “one simple reason is fresh,” says Chapman.

In the US, leafy greens may often need transporting long distances to large cities. “So you can get reasonably priced old buildings where you can set up vertical farming close to large cities.

“In the States that is becoming quite economical as opposed to shipping in leafy greens for days in trucks. The degree of freshness with vertical farming is very acceptable to consumers.

“The cost of rentals for your warehouses can be quite prohibitive to a successful programme, and the cost of LED lighting and efficiency. But if you get the right building, LED efficiency is also increasing.”

But you can’t vertical farm, say, onions and potatoes.

“You are talking about leafy greens, but even in the States where there are lots of vertical farms, there will always be a place for soil-grown vegetables. It just gives you a bit of diversification, especially where the vegetables aren’t grown close to the cities.”

He knows of nobody vertical farming in New Zealand.

“NZ may not have the need because of the proximity of our growing operations to the cities, but as houses [replace] growing vegetables this may become one of the options.

“I have always been a little sceptical about it because we should be able to grow in our soil, but as we move forward we may find we’re stuck with it.”

Meanwhile, robots will replace some jobs but innovative people will always be needed in the workforce, says Chapman on another message from the conference.

“But the innovation is different from that required 10 years ago and even today. The skills for the future are creativity, problem solving, advanced reasoning, complex judgments, social interaction and emotional intelligence.

“In the workforces that are developing, a whole different set of skills is required which we should be training for and working on for the future.

“Robots will take away quite a few functions in future and the skills you must look to are skills that robots can’t do. Robots don’t have emotional intelligence, etc.”

Chapman says there was also much discussion about R&D in Australia, which is complicated. Much was said about research being dislocated from growers because of the complexity of the system. And too much research money is being spent on bureaucracy rather than the actual work.

“So you are not getting growers and researchers having the strong interaction we have in NZ to a far, far greater degree.

“In NZ we haven’t got federal versus state. We might think our system is complicated but the Australian system makes ours look rudimentary and straightforward.”

EAT-Lancet Commission On Their Way To Transform The Food System

EAT-Lancet Commission On Their Way To Transform The Food System

Food Planet Health was recently launched to showcase news, case studies, data tools, and ongoing research updates from the EAT-Lancet Commission for Food, Planet and Health. The website focuses on the need to transform the food system in order to improve human health and health of the planet.

The EAT-Lancet Commission, a partnership between the EAT Foundation and the Lancet, is delivering the first full scientific review of what constitutes a healthy diet from a sustainable food system, and which actions can support and speed up food system transformation. The results will be presented in The Lancet in Spring 2018. There are 20 EAT-Lancet Commissioners, each of which are experts in the fields of food, health, agriculture, environment, and policy.

The Commission’s areas of expertise are sustainable food, healthy diets, and dietary trends, modelling food systems and developing supporting policies. These working groups are led by prominent researchers, practitioners, academicians, and policymakers from across the world, such as Walter-Willet, Anna Lartey, Lindiwe Majele Sibanda, Johan Rockström, Srinath Reddy, Christopher Murray, Jessica Fanzo, Tara Garnett, and Sunita Narain.

The launch of the website comes just prior to the EAT Food Forum 2017. Last year, Dr. Gunhild A. Stordalen, President of EAT Foundation, acknowledged the challenges of the current agricultural system with respect to the environment, health, and nutrition. Similarly, Johan Rockström, Co-founder of the EAT Foundation reiterated the goal of feeding a population of more than 9 billion in 2050 through sustainable means.

Follow the Commission’s updates and related news on their website, Facebook, and Twitter.

'Plant Factories' Churn Out Clean Food in China’s Dirty Cities

'Plant Factories' Churn Out Clean Food in China’s Dirty Cities

Researchers build urban farms, crop labs to combat contamination

Bloomberg News | May 25, 2017, 4:00 PM CDT

Yang Qichang walks through his “plant factory” atop the Chinese Academy of Agricultural Sciences in Beijing, inspecting trays of tomato vines that may help farmers slip the stranglehold that toxins have on China’s food supply.

The containers are stacked like bunk beds, with each vine wrapped in red and blue LED lights that evoke tiny Christmas trees. Yang is testing which parts of the visible-light spectrum are optimal for photosynthesis and plant growth while using minimal energy.

He’s having some success. With rows 10 feet high, Yang’s indoor patches of tomatoes, lettuce, celery and bok choy yield between 40 and 100 times more produce than a typical open field of the same size. There’s another advantage for using the self-contained, vertical system: outside, choking air pollution measures about five times the level the World Health Organization considers safe.

Rows of tomato seedlings are monitored in an experimental greenhouse at the Chinese Academy of Agricultural Sciences. Photographer: Qilai Shen/Bloomberg

“Using vertical agriculture, we don’t need to use pesticides and we can use less chemical fertilizers—and produce safe food,” said Yang, director of the Institute of Environment and Sustainable Development in Agriculture.

Yang’s government-funded research on vertical farming reflects the changing mindset of China’s leaders, who for decades preoccupied themselves with raising incomes for 1 billion-plus people. Runaway growth created the world’s second-biggest economy, yet the catalyzing coal mines and smokestacks filled the environment with poisons and ate up valuable farmland.

That stew inhibits the nation’s ability to feed itself, and is one reason why China increasingly relies on international markets to secure enough food. For example, it imported about $31.2 billion of soybeans in 2015, an increase of 43 percent since 2008, according to the National Bureau of Statistics. About a third of that came from the U.S.

Given the fluctuating state of trade relations with U.S. President Donald Trump’s administration and the increasing global competition for resources, China is turning to technology to make its land productive again.

“We will undertake rigorous investigations on soil pollution, and develop and implement category-based measures to tackle this problem,” Premier Li Keqiang told the National People’s Congress in March.

The silver bullet would be to eliminate emissions and industrial waste, an unrealistic option for a developing $11 trillion economy. Yet inventors and investors believe there are enough promising technologies to help China circumvent—and restore—lost agricultural productivity.

Government money backs a variety of efforts to modernize farming and improve growers’ livelihoods. The state-run Agricultural Development Bank of China pledges 3 trillion yuan ($437 billion) in loans through 2020 to finance key projects promoted by the Ministry of Agriculture.

By comparison, the value of U.S. agricultural production last year is forecast to be $405.2 billion.

Favorable terms will be offered to projects trying to improve efficiency, increase the harvest, modernize farming operations and develop the seed industry to ensure grain supplies, the bank said.

The loan program also intends to stimulate overseas investment in agriculture by Chinese companies. The biggest example would be state-owned China National Chemical Corp.’s planned acquisition of Switzerland’s Syngenta AG for $43 billion. That will give ChemChina access to the intellectual property, including seed technology, of one of the largest agri-businesses.

Yet China is reluctant to unleash genetically modified foods into its grocery stores. The government doesn’t allow planting of most GMO crops, including pest-resistant rice and herbicide-resistant soybeans, especially as an October survey in the northern breadbasket of Heilongjiang province showed that 90 percent of respondents oppose GMOs. China will carry out a nationwide poll on the technology next month.

“China’s past food-safety problems have caused the public to distrust the government when it comes to new food technologies,” said Sam Geall, an associate fellow at Chatham House in London.

A researcher transplants rice seedlings in a greenhouse of the Chinese Academy of Agricultural Sciences. Photographer: Qilai Shen/Bloomberg

About a fifth of China's arable land contains levels of toxins exceeding national standards, the government said in 2014. That's more than half the size of California.

About 14 percent of domestic grain is laced with such heavy metals as cadmium, arsenic and lead, scientists at government-affiliated universities wrote in 2015. The danger is most evident in industrial coastal provinces, where many of the world’s iPhones and Nikes are manufactured.

The government of Guangdong province, adjacent to Hong Kong, said in 2013 that 44 percent of the rice sampled locally was laced with excessive cadmium, which can damage organs and weaken bones if consumed regularly in high quantities.

That’s where Yang’s “plant factories” would come in. For now, the greenhouse-like structures are mostly demonstrations as he tries to improve their energy efficiency and make their produce more affordable to consumers—and a better investment for the government. Yang’s work is supported by an $8 million government grant.

“With the challenges our agriculture is facing, including China’s rapid urbanization and the increasing need for safe food, plant factories and vertical agriculture will undergo a big development in China,” he said. “There will be many ways to farm in big cities.”

He isn’t alone in hunting for techniques to grow untainted food in the concrete jungle. A Beijing startup called Alesca Life Technologies is using retrofitted shipping containers to farm leafy greens.

Roots of a kelp plant grow through a sponge under artificial light at an Alesca Life shipping-container farm in Beijing. Photographer: Qilai Shen/Bloomberg

A demonstration model is parked atop metal stilts in an alley between a Japanese restaurant and a block of office buildings in Beijing.

Inside, co-founder Stuart Oda, a former investment banker for Bank of America Merrill Lynch in the U.S. and Japan, checks on rows of planters sprouting peas, mustard, kale and arugula under LED bulbs. Alesca Life’s smartphone app allows growers to monitor air and water conditions remotely.

“Agriculture has not really innovated materially in the past 10,000 years,” Oda said. “The future of farming—to us—is urban.”

The containers can sell for $45,000 to $65,000 each, depending on the specifications, Oda said. Alesca Life sold portable, cabinet-sized units to a division of the Swire Group, which manages luxury hotels in Beijing, and the royal family of Dubai. The startup hasn’t publicly disclosed its fundraising.

Shunwei Capital Partners, a Beijing-based fund backed by Xiaomi Corp. founder Lei Jun, has invested in 15 rural and agriculture-related startups in China, including one that makes sensors for tracking soil and air quality.

Shunwei manages more than $1.75 billion and 2 billion yuan across five funds.

“For agriculture technology to be adopted on a wider scale, it needs to be efficient and cost-effective,” said Tuck Lye Koh, the founding partner.

That’s one reason why Shunwei is backing agricultural drones, which more precisely spray fertilizers and the chemicals that ward off crop-destroying pests and diseases.

Clockwise from top: Trays of wheat grass grow in one of Alesca Life's converted containers; Kelp seedlings are cultivated in a foam mat at the urban farm; An employee carefully places each seed.

Photographer: Qilai Shen/Bloomberg

As China’s farmland dwindled because of urbanization, the remaining growers attempted to boost yields by soaking fields with fertilizers and pesticides, degrading the soil and contaminating the crops.

Farmers in China use four-and-a-half times more fertilizer per hectare (2.4 acres) of arable land than farmers in North America, according to the World Bank.

“There’s overuse of fertilizers in every country, but especially China,” said Jeremy Rifkin, whose books include “The Third Industrial Revolution.” “The crops can’t even absorb the amount of fertilizers that are being dumped.”

As dawn squints over cornfields on Hainan island, a pastel-blue truck rumbles down the gravel road and stops. Workers emerge with a pair of drones made by Shenzhen-based DJI and a cluster of batteries.

Zhang Yourong, the farmer managing 270 mu (44 acres), arrives in a pickup loaded with pesticide bottles. The crew adds water and pours the milky concoction into 10-liter plastic canisters suspended under the drones.

The stalks part like the wake of a boat as the drones fly over. Every 10 minutes, the eight-armed machines return, and the crew refills canisters and changes batteries.

Trays of kelp, a vitamin and mineral-rich seaweed, are ready to be transplanted to bigger growing spaces at Alesca Life's demonstration farm. Photographer: Qilai Shen/Bloomberg

Zhang used to hire four or five workers to walk the fields with backpack sprayers for five days. Now, the drones cover his crops in a morning and use 30 percent less chemicals, he said.

That’s what the government needs to hear as it tries to make China’s food supply safer.

“This is much easier and much faster than before,” Zhang said. “This is the future. Many farmers are switching.”

Who’s Really Benefiting From Sustainable Food and Agriculture Technologies?

In his first official speech since leaving office, Barack Obama stated a truth that many in the sustainable food and ag worlds have been wanting him to say for years

Who’s Really Benefiting From Sustainable Food and Agriculture Technologies?

By Ariel Lauren Wilson June 1, 2017

After Obama’s address in Milan, food and ag sustainability experts Danielle Nierenberg and Danielle Gould assess this powerful—and still very young—space.

Editor’s note: We kicked off our first annual Food Loves Tech event last summer in Chelsea—here’s a recap. We’re bringing a taste of the food and farming future back this year, but just across the East River at Industry City. Leading up to the event, this story is part of an ongoing series about technology’s effects on our food supply.

In his first official speech since leaving office, Barack Obama stated a truth that many in the sustainable food and ag worlds have been wanting him to say for years. Last month in front of an elite international cohort of entrepreneurs, investors and thought leaders in the field at the third annual Seeds&Chips in Milan, he publicly acknowledged that climate change will “define the contours of this century perhaps more than any other [modern global challenge],” agriculture and food production are the second largest culprits and, finally, this must change.

As president, Obama’s climate change agenda mostly targeted energy sector regulation. He didn’t dwell too much on government responsibility in Milan, though, despite Trump making headlines that day for delaying his decision on whether or not the United States would keep its Paris climate pact. Obama instead addressed his immediate audience while calling for the empowerment of young activists along with innovation in science and industry to help us reduce emissions and mitigate the present and future issues. “I believe these are problems that were caused by man and can be solved by man,” he affirmed.