Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

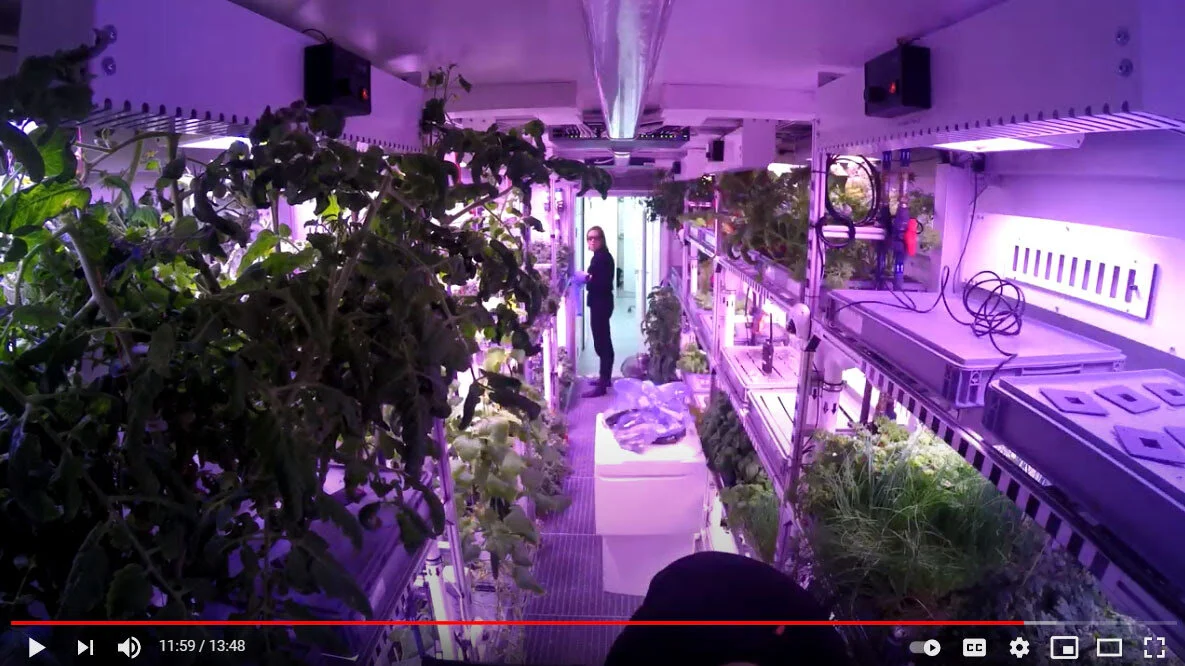

Growing Vegetables In Antarctica In the EDEN ISS Project

Scientific research studies to determine how to grow plants in extreme environments on Earth will help NASA understand how to grow plants in extreme conditions on the moon or Mars

Status Report From NASA Biological & Physical Science

July 1, 2021

Scientific research studies to determine how to grow plants in extreme environments on Earth will help NASA understand how to grow plants in extreme conditions on the moon or Mars. Growth of crop plants in lunar or Mars habitation systems will be essential for meeting astronaut nutritional needs and maintaining astronaut health during long-duration exploration missions. To facilitate these studies, an international agreement between NASA and DLR (German Space Agency) has been signed to enable research collaboration on the EDEN (Evolution and Design of Environmentally-Closed Nutrition-Sources) ISS project at the German Neumayer III Station in Antarctica.

The EDEN module is designed to simulate a plant production system that might operate in a surface setting in space and is used to provide fresh food to the 10 “over-wintering” EDEN crew members. Biological and Physical Sciences research has been conducted at the EDEN site under the Space Biology grant titled “Spectral Imaging within the EDEN ISS Project - An Antarctic Analog for Enhancing Exploration Life Support.” For this Space Biology grant, PI Dr. Robert Ferl and Co-I Dr. Anna-Lisa Paul (both from the University of Florida) traveled to Antarctica to conduct their research.

Kennedy Space Center (KSC) continues to support EDEN ISS. For this project, KSC contractor Jess Bunchek is in residence in Antarctica as one of the crew members at Neumayer III where she is operating and maintaining the plant chamber with the help of DLR colleagues at Bremen, Germany. She is growing crops that have been grown on ISS for BPS-funded experiments to compare growth in the two settings. She is tracking her time spent on horticultural activities, measuring the yields of the different crops, taking microbial samples for post-mission analysis, and helping administer surveys to the crew to obtain their opinions on having fresh food in their diet. Jess arrived in Antarctica in January 2021 and will be there until February 2022. Follow Jess as she journals her account of the journey to EDEN ISS.

Watch the video about the EDEN ISS project

Meet The Extra-Terrestrial Aquaponics Pioneer

Former salmon farmer Dr. Carl Mazur aims to design an aquaponics system that could one day be used on Mars. In the meantime, he aims to use it to produce high-value fish and flowers on Earth

Rob Fletcher

May 8, 2021

Former salmon farmer Dr. Carl Mazur aims to design an aquaponics system that could one day be used on Mars. In the meantime, he aims to use it to produce high-value fish and flowers on Earth.

Can you tell us a bit about your aquaculture experience?

Dr. Carl Mazur, founder of Terra-Mars

My aquaculture experience is primarily with saltwater salmon production on the east and west coast of Vancouver Island, in Canada. I gained hands-on experience immediately after graduation from McGill University with a degree in marine biology. This was in the mid-1980s and the issues we had with fish loss due to bacterial kidney disease at the time lead me to pursue a master’s and then a Ph.D. at UBC, focused on the effects of rearing and environmental fish stressors on their immune systems and disease susceptibility.

The Terra-Mars project may be ambitious in the long run but it aims to start with more modest goals

Why did you decide to return to the sector and what inspired you to look into aquaponics specifically?

I returned to the sector after owning and operating a national licensing, sales, and distribution in Canada focused on providing human tissue regeneration products to dental and medical specialists across Canada for 15 years. I returned as I had always intended to do so and had gone to the biotech sector to support my family and to learn business lessons that I could then bring back to the aquaculture/aquaponics sector. My first love is “all things marine” and it’s great to be back in a sector where I feel at home.

The reason for migrating a short step from aquaculture to aquaponics is that I feel aquaponics is more holistic in that a well-conceived aquaponic system can essentially be near-closed and self-sustaining. Aquaponics systems today do need external input in the form of fish feed which then provides carbon, nitrogen, and phosphorous (and other trace elements) for plant growth. The next step in closing the loop will be to produce fish feed from the carbon, nitrogen, and phosphorous delivered from the system in the form of human food, fish offal, and the inedible stem and root plant products.

From aquaponics to aquaponics on Mars, that sounds like quite a leap. What's the logic?

The simple premise behind developing an aquaponic system for use on Mars [as part of the Terra-Mars project] is that a system advanced enough to be on Mars will be able to grow food anywhere on Earth, with modifications. The ultimate goal is to have a system that can provide food security for any environment on Earth and thereby end the suffering that still occurs in some developing countries. Having the ambitious goal of developing a food production system for Mars should provide ample PR exposure which can then be leveraged to promote the project and help to carry it forward.

It must be noted that the initial systems will be produced on a small scale and will be developed to produce high-value fish for the ornamental aquarium fish sector and high-value plants for the fine dining and floral industries. The technologies developed for these high-valued products will later be used for larger projects which will produce higher volume, lower value products for middle class consumers. Eventually, we will transition to industrial-scale operations for low price, mass consumption products. This model is borrowed from the automotive industry, as demonstrated and proven by Tesla motors.

What species of fish are you thinking of growing in your system on Mars?

The three species of fish we’ve shortlisted to date for Mars are tilapia, barramundi and Arctic char. We’ll need to test many species under the simulated Earth environment that we’ll attempt to create in our simulated Martian environment.

Are you able to apply the skills that you gained in the conventional aquaculture sector for the project?

Yes, many of the skills gained in the conventional aquaculture sector (especially related to fish health and nutrition) can certainly be used with this project.

Who are your key collaborators and what do they bring to the project?

The key collaborator for this project is Dr. James Rakocy, known worldwide as the “father of aquaponics”. Dr. Rakocy has had a distinguished 30-year career at the University of the Virgin Islands and his UVI aquaponic system is known worldwide as the best researched and established system for growing tilapia and a variety of greens including lettuces and herbs. Dr. Rakocy is the author of the seminal book Aquaponic Q&A. His educational aquaponic systems are used in over 1,100 high schools across America for foundational teaching in the STEM areas of biology, chemistry, math, and food systems.

Other key collaborators are Garth Wardell, CEO / owner of Allsite IT, a digital intelligence firm currently dedicated to the advancement of intense data solutions for the hospitality and healthcare sectors. Garth is very keen about this project and has been a trusted advisor since 2018. Several other advisors in the areas of law, engineering, computer science, multimedia technologies, education, urban farming, and accounting are also on standby and eager to begin work on this project.

The other noteworthy collaborator is Dr. Christopher McKay, an astrobiologist at the NASA Ames research centre in California, who has offered assistance at the academic level and must sit as an unpaid advisor, as is mandated for all full-time NASA employees.

How have your plans been received to date?

The plans have been very well received to date, most notably by Elon Musk who was informed of the intentions several years ago and stated that “this will be very important down the road”. Mr Musk was presented the concept for informational uses only and was not approached for funding or resources, as he had intense funding and resource requirements at Tesla and SpaceX at the time.

How the system might one day appear

How much money are you hoping to raise for the project and what will you use this for?

The initial round of financing for this project will be for $2.6 million and will be used to:

Develop a first aquaponic system prototype.

Secure an IP patent portfolio of aquaponic patents.

Build a physical model of the Space Exploration Theme park

Develop a mixed reality (VR&AR) tour of the park

Perform an extensive feasibility study for the project.

What are the key milestones for your project?

Obtain the initial round of seed funding.

Become cash-flow positive with the acquisition of existing ancillary businesses in the fish, vegetable and floral, growth, packaging, distribution, retail, media and entertainment sectors.

Building global brand recognition for Terra-mars products and entertainment facilities.

Acquisition of real estate (primarily distressed suburban shopping malls) where the aquaponic facilities will be installed to grow the fish and plants for local distribution to populations in North America and Europe.

Series A financing round to raise $100 million in 2023 or 2024 at the latest.

What is the end goal for your project and do you think that this is feasible to achieve in your own lifetime?

The end goal for phase one of the project is to have four Space / Mars exploration theme parks – one in North America, one in Europe, one in MENA, and one in China. These will have the dual purpose of entertainment and providing research facilities for Mars colonization technologies, featuring the aquaponic food production system. Other technologies for Mars colonization will be in the fields of transportation, communications, housing, healthcare, and recreation.

If you don’t make it to Mars, where will you target using your aquaponics systems on the Earth?

If we don’t make it to Mars, the aquaponic system will first be used to produce high value fish and plants for Western markets and eventually be developed in for larger commercial operations to be used anywhere on earth.

What are the major challenges that you still need to overcome?

The major challenges which we need to overcome are to raise the initial round of financing and to become cashflow positive in the shortest time possible.

Rob Fletcher

Senior editor at The Fish Site

Rob Fletcher has been writing about aquaculture since 2007, as editor of Fish Farmer, Fish Farming Expert and The Fish Site. He has an MA in history from the University of Edinburgh and an MSc in sustainable aquaculture from the University of St Andrews. He currently lives and works in Scotland.

Start of A New Series of Tests For Plant Cultivation on The Moon And Mars

The EDEN ISS greenhouse uses particularly robust varieties that were selected by the EDEN ISS Project team and from experiments at NASA’s Kennedy Space Center and as part of the VEGGIE project on the ISS

MAY 4, 2021

NASA Seeds Germinate in

DLR’s EDEN ISS Greenhouse

Start of a new series of tests for plant cultivation on the Moon and Mars

Nine weeks of darkness and temperatures down to minus 50 degrees Celsius. Under these harsh conditions of Antarctica, NASA and the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) have begun a joint series of experiments on vegetable cultivation techniques for use on the Moon and Mars. Until early 2022, NASA guest scientist Jess Bunchek will research how future astronauts could grow lettuce, cucumbers, tomatoes, peppers, and herbs, using as little time and energy as possible.

To this end, she will be working at DLR’s EDEN ISS Antarctic greenhouse, where she will put greenhouse technologies and plant varieties to the test. She is also recording any effects the greenhouse and its yield have on the isolated hibernation crew in the perpetual ice. Bunchek is part of the 10-person overwintering crew on Neumayer Station III, operated by the Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI).

First harvest – Lettuce, mustard greens, radishes and herbs

“The polar night will soon begin here on the Antarctic Ekström Ice Shelf. With the nine other members of the overwintering crew, it almost feels like we are alone on another planet,” says Bunchek. “In this hostile world it’s fascinating to see the greenery thrive without soil and under artificial light.” Bunchek is a botanist from the Kennedy Space Center, where she has primarily supported the VEGGIE project on the International Space Station (ISS) She was able to sow the first seeds in recent weeks, following a technical reconditioning of the EDEN ISS platform conducted by her and the DLR team. The first harvest, which included lettuce, mustard greens, radishes, and various herbs, followed a few days ago.

NASA seeds and new nutrient supply system

The EDEN ISS greenhouse uses particularly robust varieties that were selected by the EDEN ISS Project team and from experiments at NASA’s Kennedy Space Center and as part of the VEGGIE project on the ISS. The DLR/NASA mission also aims to record and compare the growth and yield of the crop varieties under the conditions of the Antarctic greenhouse. An additional focus will be studying which microbes thrive in the greenhouse alongside the cultivated plants.

NASA will also be testing a plant watering concept in the EDEN Module that can operate in u-gravity settings, like the ISS. The system contains the water and delivers it to the plants by a passive method. “This will provide a side-by-side comparison with the aeroponically grown plants of EDEN ISS” says Ray Wheeler, plant physiologist at NASA’s Kennedy Space Center. In aeroponic irrigation, the roots of the plants without soil are regularly sprayed with a nutrient solution.

Crew time – a precious commodity

Sowing, harvesting, tending, cleaning, maintaining, calibrating, repairing and conducting scientific activities. Bunchek records every second of her activities in the Antarctic greenhouse with a special time-recording eight-sided die, as crew time will be a precious commodity on future missions to the Moon and Mars. “In an initial test run of the greenhouse during the 2018 mission, we found that operations still took too much time,” explains EDEN ISS project leader Daniel Schubert from the DLR Institute of Space Systems in Bremen. “Now we are working on optimizing processes and procedures. We have learned a lot about operating a greenhouse under extreme conditions. We’re applying all this during the current joint DLR/NASA mission.” In addition to the crew’s time, the focus is on their well-being. The overwinterers regularly answer questions about their eating habits or how the plants affect their mood. “We hope to increase our understanding of having plants and fresh food for crews in remote, isolated settings like Neumayer III and ultimately for space” says Wheeler.

Eight months in isolation

On 19 January, Jess Bunchek reached the Antarctic continent on board the research vessel Polarstern. Since 19 March, the 10-person overwintering crew has been on their own at Neumayer Station III. “EDEN ISS is an asset for the crew in many ways,” says Tim Heitland, Medical Coordinator and Operations Manager at AWI. “I know from my own overwintering experience just how much you can begin to miss fresh produce. It’s not just about the taste, but also the smells, the colors, and the fascinating fact that something can grow in this inhospitable environment. That’s why there are always volunteers in the overwintering teams to help cultivate and harvest the plants.” The polar night at Neumayer Station III begins on 21 May, and the first rays of sunlight will not reach the station again until 23 July. Researchers for the summer season and new supplies will end the isolation of this year’s overwintering crew around the beginning of November.

The activities at the EDEN ISS Antarctic greenhouse can be followed on social media using the hashtag #MadeInAntarctica. The Antarctic greenhouse has Facebook and Instagram accounts, as well as a flicker image gallery. Jess Bunchek also writes about her personal experiences of the Antarctica mission in the dedicated DLR blog.

AUSTRALIA: NSW Architect’s Idea For Sustaining Life on Mars is a Winner

Calabrese’s submission outlined how rockets would send robotic self-building farms a year prior to the first human landing. Using Artificial Intelligence and 3D printing, these buildings, preloaded with seeds, would then assemble autonomously and begin growing enough fruits and vegetables to sustain nine astronauts for up to two years

7/12/2020

Architecture news & editorial desk

A proposal conceptualized by an NSW architect for an international design competition that sought ideas for sustaining life on Mars has won the top prize.

Giuseppe Calabrese, the senior architect at Council Approval Group – a small Australian town planning and architecture firm – was placed first at the international competition launched by the Californian smart city development company, Mars City Design, and backed by NASA. The primary objective of the competition was to source ideas to sustain human life on Mars for more than two years.

Calabrese’s submission outlined how rockets would send robotic self-building farms a year prior to the first human landing. Using Artificial Intelligence and 3D printing, these buildings, preloaded with seeds, would then assemble autonomously and begin growing enough fruits and vegetables to sustain nine astronauts for up to two years.

Last month, Calabrese was shortlisted in the top 10 designs, competing against international firms from the USA, Germany, United Arab Emirates, and Taiwan. On the live-streamed awards night recently, his submission was announced as the winner for ‘Mars City Design Urban Farming Challenge 2020’, which was presented by NASA astronaut, Col. Terry Virts.

Until less than a year ago, Calabrese spent his time designing granny flats, duplexes and boarding houses for investors. Following the COVID pandemic, he was able to keep his job thanks to the Job Keeper program. During this period, he was also able to use his surplus design time on a passion project – town planning on Mars. When the competition came up, he decided to apply his architectural skills to the challenge.

Competition founder Vera Mulyani was very impressed with the Australian submission, not only for the visually appealing designs but also for the fact that every detail was supported by hundreds of pages of research and scientific data.

“Our next step is to secure funding, so we can build a prototype of the winning designs, which include Calabrese's proposal, in the Californian desert,” Mulyani added.

Calabrese’s smart farm idea couldn’t have come at a more perfect time given that NASA’s latest high-tech Rover will be reaching Mars in February 2021 while Elon Musk is considering a mission to the red planet as early as 2024.

“Australia already leads the world in many farming practices. So why not in space? And when billionaire Elon Musk needs an architect to design his mansion on Mars, he now knows who to call,” Calabrese said with a smile.

VIDEO: Vertical Farms Heading For Mars

In this video interview, Paul Millett, Co-Founder, and COO at Invertigro talks about the main trait he looks for in new hires, what their vision is for 2021, and the incredible applications vertical farming has not just on this planet

In this video interview, Paul Millett, Co-Founder, and COO at Invertigro talks about the main trait he looks for in new hires, what their vision is for 2021, and the incredible applications vertical farming has not just on this planet.

Check it out here:

What is InvertiGro ?

Fully-integrated, cost-effective, and flexible indoor vertical farming solutions that enable sustainable and reliable production of fresh and healthy produce. Everywhere.

InvertiGro indoor vertical farming solutions apply innovative design and leading-edge technologies to profitably and pragmatically solve the real-world challenge of sustainable and affordable food production.

We design, build, supply, and support cost-effective and flexible indoor vertical farming solutions that enable customers around the globe to quickly convert indoor spaces into highly efficient fresh produce farms.

InvertiGro indoor vertical farms are capable of growing a vast number of different crops; from herbs and leafy greens to microgreens, berries, fruits, vegetables, fibers, feed-stock, and more. Our hydroponically grown produce is also herbicide- and pesticide-free.

Modular growing units and their supporting smart technology systems are able to grow (and switch between) a variety of crops with superior yields, consistent quality, and greater resource efficiencies (water, land, labor, and capital).

InvertiGro’s fully integrated indoor vertical farming solutions provide everything required to quickly begin producing hassle-free, profitable, and reliable supplies of quality fresh produce well into the future.

Our indoor vertical farming systems are available in two different configurations:

The fully-integrated and supported InvertiCube system is designed to enable businesses to produce reliable rural-scale fresh produce. InvertiCube indoor vertical farming systems are modular and scalable by design making them equally well-suited to purpose-built warehouses or manufacturing spaces as to under-utilized existing spaces such as disused carparks and basements – of any size, shape or location. Unique pallet-size modular growing units can be configured for (and easily switched between) horizontal or vertical growing to suit a variety of different crops and applications. Their supporting smart technology operating and monitoring systems ensure clients benefit from our on-going R&D advancements.

The InvertiWall system is a productive green-wall designed for smaller-scale commercial and community applications. The space-efficient and aesthetically pleasing design also lends itself to installation in shared indoor spaces (such as foyers, food courts, and restaurants).

Both InvertiGro indoor vertical farming systems are designed to be scalable, flexible, affordable and smart, enabling businesses and communities to become successful and sustainable modern farmers.

Contact InvertiGro: info@invertigro.com

Farming On Mars Will Be A Lot Harder Than ‘The Martian’ Made It Seem

Growing plants in Red Planet soil will require adding nutrients and removing toxic chemicals. To prepare for a future where astronauts could grow their own food on Mars, researchers are trying to grow crops in the lab with fake Martian dirt

Growing Plants In Red Planet Soil Will Require

Adding Nutrients And Removing Toxic Chemicals

To prepare for a future where astronauts could grow their own food on Mars, researchers are trying to grow crops in the lab with fake Martian dirt.

NOVEMBER 18, 2020

In the film The Martian, astronaut Mark Watney (played by Matt Damon) survives being stranded on the Red Planet by farming potatoes in Martian dirt fertilized with feces.

Future Mars astronauts could grow crops in dirt to avoid solely relying on resupply missions, and to grow a greater amount and variety of food than with hydroponics alone (SN: 11/4/11). But new lab experiments suggest that growing food on the Red Planet will be a lot more complicated than simply planting crops with poop (SN: 9/22/15).

Researchers planted lettuce and the weed Arabidopsis thaliana in three kinds of fake Mars dirt. Two were made from materials mined in Hawaii or the Mojave Desert that look like dirt on Mars. To mimic the makeup of the Martian surface even more closely, the third was made from scratch using volcanic rock, clays, salts and other chemical ingredients that NASA’s Curiosity rover has seen on the Red Planet (SN: 1/31/19). While both lettuce and A. thaliana survived in the Mars-like natural soils, neither could grow in the synthetic dirt, researchers report in the upcoming Jan. 15 Icarus.

“It’s not surprising at all that as you get [dirt] that’s more and more accurate, closer to Mars, that it gets harder and harder for plants to grow in it,” says planetary scientist Kevin Cannon of the Colorado School of Mines in Golden, Colo., who helped make the synthetic Mars dirt but wasn’t involved in the new study.

Soil on Earth is full of microbes and other organic matter that helps plants grow, but Mars dirt is basically crushed rock. The new result “tells you that if you want to grow plants on Mars using soil, you’re going to have to put in a lot of work to transform that material into something that plants can grow in,” Cannon says.

Biochemist Andrew Palmer and colleagues at the Florida Institute of Technology in Melbourne planted lettuce and A. thaliana seeds in imitation Mars dirt under controlled lighting and temperature indoors, just as astronauts would on Mars. The plants were cultivated at 22° Celsius and about 70 percent humidity.

Seeds of both species germinated and grew in dirt mined from Hawaii or the Mojave Desert, as long as the plants were fertilized with a cocktail of nitrogen, potassium, calcium, and other nutrients. No seeds of either species could germinate in the synthetic dirt, so “we would grow up plants under hydroponic-like conditions, and then we would transfer them” to the artificial dirt, Palmer says. But even when given fertilizer, those seedlings died within a week of transplanting.

In lab experiments, lettuce was able to grow in Mars-like soil from the Mojave Desert (pictured) as long as the soil was fertilized with nitrogen, potassium, calcium, and other nutrients. NATHAN HADLAND

Palmer’s team suspected that the problem with the synthetic Mars dirt was its high pH, which was about 9.5. The two natural soils had pH levels around 7. When the researchers treated the synthetic dirt with sulfuric acid to lower the pH to 7.2, transplanted seedlings survived an extra week but ultimately died.

The team also ran up against another problem: The original synthetic dirt recipe did not include calcium perchlorate, a toxic salt that recent observations suggest makeup to about 2 percent of the Martian surface. When Palmer’s team added it at concentrations similar to those seen on Mars, neither lettuce nor A. thaliana grew at all in the dirt.

“The perchlorate is a major problem” for Martian farming, says Edward Guinan, an astrobiologist at Villanova University in Pennsylvania who was not involved in the work. But calcium perchlorate may not have to be a showstopper. “There are bacteria on Earth that enjoy perchlorates as a food,” Guinan says. As the microbes eat the salt, they give off oxygen. If these bacteria were taken from Earth to Mars to munch on perchlorates in Martian dirt, Guinan imagines that the organisms could not only get rid of a toxic component of the dirt but perhaps also help produce breathable oxygen for astronauts.

What’s more, the exact treatment required to make Martian dirt farmable may vary, depending on where astronauts make their homestead. “It probably depends where you land, what the geology and chemistry of the soil is going to be,” Guinan says.

To explore how that variety might affect future agricultural practices, geochemist Laura Fackrell of the University of Georgia in Athens and colleagues mixed up five new types of faux Mars dirt. The recipes for these fake Martian materials, also reported in the Jan. 15 Icarus, are based on observations of Mars’ surface from the Curiosity, Spirit, and Opportunity rovers, as well as NASA’s Mars Global Surveyor spacecraft and Mars Reconnaissance Orbiter.

Each new artificial Mars dirt represents a mix of materials that could be found or made on the Red Planet. One is designed to represent the average composition across Mars, similar to the synthetic material created by Cannon’s team. The other four varieties have slightly different makeups, such as dirt that is particularly rich in carbonates or sulfates. This collection “expands the palette of what we have available” as test-beds for agricultural experiments, Fackrell says.

She’s now using her stock to run preliminary plant growth experiments. So far, a legume called moth bean, which has similar nutritional content to a soybean but is more drought-resistant has grown the best. “But they’re not necessarily super healthy,” Fackrell says. Future experiments could explore what nutrient cocktails help plants survive in the various fake Martian terrains. But this much is clear, Fackrell says: “It’s not quite as easy as it looks in The Martian.”

Questions or comments on this article? E-mail us at feedback@sciencenews.org

CITATIONS

A. Eichler et al. Challenging the agricultural viability of martian regolith simulants. Icarus. Vol. 354, January 15, 2021. doi: 10.1016/j.icarus.2020.114022.

L.E. Fackrell et al. Development of martian regolith and bedrock simulants: Potential and limitations of martian regolith as an in-situ resource. Icarus. Vol. 354, January 15, 2021. doi: 10.1016/j.icarus.2020.114055.

About Maria Temming

Maria Temming is the staff reporter for physical sciences, covering everything from chemistry to computer science and cosmology. She has a bachelor's degrees in physics and English, and a master's in science writing.

Lead photo: OSTAPENKOOLENA/ISTOCK/GETTY IMAGES PLUS

Purdue University Mechanical Engineering Technology Grad Developing Food Technology For NASA’s Mars Missions

A graduate student who gained experience growing plants for a Purdue Polytechnic research project is now helping NASA develop microgravity food production technology to sustain astronauts during long missions to Mars

August 19, 2019

NASA Technical and Horticultural Scientist Jacob Torres works in the water for microgravity test bed at the Kennedy Space Center’s Space Station Processing Facility in Merritt Island, Fla. Thanks to Torres’ suggestion, the Española chile pepper will be the first fruiting plant to be grown in space this November on the International Space Station. (Photo courtesy Jacob Torres)

A graduate student who gained experience growing plants for a Purdue Polytechnic research project is now helping NASA develop microgravity food production technology to sustain astronauts during long missions to Mars.

Jacob Torres graduated from Purdue in May 2018 with a master’s degree in mechanical engineering technology. During his studies, he worked on the Biowall, an eco-friendly air filtration system that can be used in residential buildings to improve air quality. That experience proved beneficial when he applied for an internship at Kennedy Space Center in Merritt Island, Florida.

“I did the application and never thought I’d hear anything back from them, straight up,” said Torres. “On the application, there just happened to be one line that said, ‘plant growth for food production in microgravity.’ I thought that was pretty cool and in my research at Purdue, I made a biowall, and it uses plants to filter indoor air.”

After that 10-week internship, NASA (the National Aeronautics and Space Administration) invited Torres to continue his work for an additional four months. In December 2018, his position as a technical and horticultural scientist became permanent.

Torres’ path to becoming a research scientist at NASA has been anything but traditional. He moved from New Mexico to Las Vegas immediately after graduating from high school, found a job at a restaurant and worked his way into a management position. A chance encounter with actors Bill Murray and Billy Crystal led to several years as manager of three of Murray’s restaurants in South Carolina and Florida.

“It was such a rough ride,” said Torres. “I told myself I couldn’t run restaurants for the rest of my life. I was like, ‘Is this all I have to do, is this as far as I could go?’ No way.”

Read the full Rio Grande Sun article.

Student Design for Space Colony Greenhouse Wins NASA Praise

Student-designed inflatable dome folds and collapses for transport, racks plants vertically.

IMAGE COURTESY OF DARTMOUTH THAYER SCHOOL OF ENGINEERING

May 8, 2019

A radiation-shielded, inflatable greenhouse with a hydroponic growing system designed by undergraduate students at Dartmouth College’s Thayer School of Engineering could sustain four astronauts on a 600-day mission to Mars as soon as 2030.

The students’ Deployable, Enclosed Martian Environment for Technology, Eating and Recreation (DEMETER) concept—the acronym is also the name of the Greek goddess of the harvest—won first place in the 2019 NASA Breakthrough, Innovative and Game Changing (BIG) Idea Challenge, the agency announced on April 24.

The team pitched their idea to scientists at NASA and the National Institute of Aerospace (NIA) in competition with four other finalist teams.

NASA and NIA are seeking innovative ideas for the design, installation and sustainable operation of a habitat-sized Mars greenhouse, with the primary purpose of food production, according to NASA. The agency says an efficient and safe greenhouse design could assist with Mars missions and long-term lunar missions.

The 8-meter-high by 16-m-wide DEMETER includes an automated hydroponic growing system that uses a 3-m-tall cylinder inside of a torus, with the cylinder storing the water and nutrient delivery and recycling systems. A running track for astronaut recreation circles the vertically integrated assembly of growing trays.

The team used a 1⁄6-scale prototype to show folding methods for 1.5-m-long hydroponic growing trays, which nest against the central cylinder during transport. It also tested growing crops in a nutrient film technique hydroponic system to refine their design.

Dartmouth edged ahead when scored on the completeness of the proposed design, low system mass, optimization for food production and design simplicity, says Kevin Kempton, NASA program element manager and one of seven judges.

The team used “top-notch systems engineering throughout,” Kempton says. “That began with a systems overview that identified their system of interest relative to external systems, such as sunlight, heat, and water in the Martian environment.”

Kempton says another strength is that the components all appear relatively low risk and are based largely on a habitat design developed in a 2017 NASA feasibility study, which was the basis for the competition. “The team estimates it would take three to four missions to become a cost-effective option,” versus the cost of transporting food from Earth, Kempton says.

The team also scored high marks for innovation for the proposed concept of operations and for system deployment, which begins with robotic transport of the packaged greenhouse payload from the landing site to the deployment site. The design “seemed to have the highest level of technical maturity and it would likely require less technology development effort to get a DEMETER-base design up and running for the initial Martian outpost,” Kempton says.

NASA plans to send astronauts to the moon by 2024, with future missions in the 2030s, when a Mars greenhouse concept would potentially be viable, says Drew Hope, NASA program manager.

MIT placed second for its Biosphere Engineered Architecture for Viable Extraterrestrial Residence (BEAVER) concept. Plans include a spiral hydroponic design track in a multilevel facility featuring an enclosed waterfall for astronaut relaxation. Other finalists included designs from three state universities, California Davis, Colorado Boulder and Michigan Ann Arbor.

The finalist teams receive a shot at five NASA internships, recognition and a $6,000 stipend to travel to NASA’s Langley, Va., research center to present. All original ideas and concepts are credited to the student teams, but NASA has the option to take any portion of the ideas for use in future NASA mission planning, Hope says.

KEYWORDS Greenhouse /Hydroponic / Mars / NASA /Space Colony