Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

World’s First Vertical Farming Congress

The first Vertical Farming World Congress will be held from 22nd to 24th September at London’s Heathrow Airport

By urbanagnews

April 8, 2020

The first Vertical Farming World Congress will be held from 22nd to 24th September at London’s Heathrow Airport. Eminent industry-leading speakers have confirmed their participation from North America, the Middle East, and Asia as well as Europe. The chosen theme is ‘Shaping Food’s Future’.

“Vertical farming really can help shape the future of food production,” explained Richard Hall, Chairman of the food and drink experts Zenith Global and the event’s organizer. “By being indoors and with completely controlled conditions, there are no floods, droughts, winds or pesticides. You can grow 30 crops a year locally, right next to a supermarket or city distribution centre. Growing to perfection in a stress-free environment means greater freshness, better nutrition and a longer storage life.”

Topics on the program include: market opportunity; an industry leadership panel; strategic alternatives between aeroponic, aquaponic and hydroponic systems; technology briefings ranging from lighting and robotics to overall system design; a nutrition briefing; a funding panel; and key innovator

case studies.

Among the speakers are:

Industry leaders, such as AeroFarms, Intelligent Growth Solutions, Jones Food Company, Root AI and Square Roots

Association heads from Germany and Japan

Investment experts from Ashfords, S2G Ventures and Innovate UK

Technology developers, including GE and Wageningen University.

There will also be a visit to Vertical Future’s vertical farm operation in East London and a reception with vertically farmed fresh produce tasting.

The event has also attracted sponsorship from GE, LED lighting experts, and YesHealth, which has pioneered vertical farming in Taiwan.

Full program details and booking information are available at www.zenithglobal.com/events/vfwc2020 or contact the events team at events@zenithglobal.com.

The Future Of Farming Might Already Be Here, Inside A Shipping Container

"We are completely protected from any natural disasters, rainstorms, pests, weeds even -- there's no pollution because all of the air is filtered," the CEO of Sprout Stack said

Ali Donaldson

10 News First Senior Reporter, 25 Mar 2020

On Hugh McGilligan's farm, it's a perfect summer's day, 16 hours a day, every single day of the year.

"We are completely protected from any natural disasters, rainstorms, pests, weeds even -- there's no pollution because all of the air is filtered," the CEO of Sprout Stack said.

It's the farming of the future, packed inside converted shipping containers on Sydney's Northern beaches.

Sprout Stack runs five farms at Brookvale -- in five shipping containers --producing as much as five hectares of traditional mainland agriculture. The shipping container farms run as closed circuits, using about five percent of the water.

But it takes just five seconds to walk from one end to the other.

And depending on the crop, they can harvest within a week to five weeks.

"Here we have purple radish," Hugh says brushing his hand across the top of a miniature forest of lush leafy greens. "That's our fastest growing crop and it takes about a week from planting through to harvesting."

"That compares to traditional farming where it takes 40 percent longer to achieve the same results."

And they're not just saving on the environment.

Sprout Stack's Mick Harder has pulled off some amazing farming equipment hacks.

"I made a harvester out of a hedge trimmer from Bunnings and some steel offcuts lying around that only cost us $1000 instead of the industrial machine that's around $100,000," Mick said while feeding his ingenious machine with the latest crop.

They don't even use soil.

Instead, everything is planted into coconut husks, which are mulched in a concrete mixer -- another hack that has saved them thousands of dollars in equipment.

And they've even tinkered with Mother Nature and the precious light she provides.

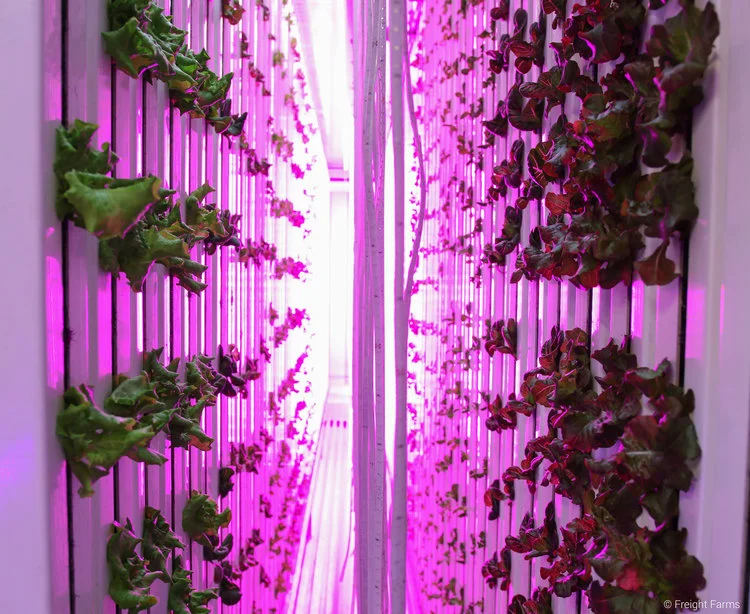

Plants only use red and blue light -- mixed together it forms a beautiful fuchsia -- for all the protein and nutrients they need. So that's all that's used on these farms.

It's about customizing the best of nature in a box, including cutting out a big chunk of the rainbow.

The farms can even be controlled over a mobile phone.

Nestled in between Sprout Stack's plant beds is its "nervous system".

"It's a farm management system that tracks the environmental conditions of the farm and the computer keeps the CO2, the temperature and the humidity of the farm ideal for growing plants," Hugh said.

"It's all run by a computer so we don't have to make any decisions -- the computer is providing the plants with the ideal growing conditions."

As we talked, the lights inside the container started switching off.

"I just go an alert," he laughs, peering through the dark at his phone.

"We turned off the air-conditioning and because we are in here the farm has got a little bit warmer and shut everything down, to ensure there are no deleterious effects on the plants."

Sprout Stack poses some interesting solutions to the modern plagues on our food bowls.

"We know that we need to provide an awful lot more food and we can't do that just throwing more resources at a strained system," Hugh says.

"We've got to get more efficient about the way that we produce food and use scarce resources like water, and we have got to produce our food closer to where it's consumed."

He then runs through the traditional vegetable supply chain -- or, as he says -- "the reason why the tomato you buy at the supermarket tends not to have very much flavour."

Hugh explains it's generally picked green about a week ago, transported cold chain from the country to the capital city you live in where it sits in a distribution centre for a day.

It then gets redistributed to another distribution centre that sends it out to your supermarket.

"At that point, it's often hit with ethylene to ripen -- basically it turns red -- but in ripening it's not really ripening it's just changing colour and in the meantime the nutritional quality of that product has declined."

He claims Sprout Stack's produce is fresher and tastier because they harvest closer to where it is being consumed.

"On average we take about 16 hours between our harvest to store, which compares to about a week for traditional agriculture."

Coronavirus Pandemic Highlights Vital Need For Vertical Farms In World Cities

Although the sources and sourcing of food in North America and Western Europe are currently generally secure, what might soon become a prodigious concern is that their workers in the production, distribution and retail segments of the food supply chain may eventually succumb to coronavirus infection

MARCH 25, 2020

by Professor Joel Cuello, Ph.D.

Image modified from Martin Sanchez/Unsplash

The speed with which the coronavirus outbreaks in Asia, Europe, and North America metastasized into a full-blown global pandemic — catching many world governments by surprise and with little preparation — underscores just how our world today is highly interconnected and how, in order to contain and stem the surging pandemic, temporary disconnection from the physically-networked world by cities, regions and even entire nations has become an urgent imperative.

With confirmed coronavirus cases globally now exceeding 370,000 and the number of deaths surpassing 16,000, many world cities have become throbbing epicenters of the surging pandemic. Accordingly, various countries, states, and cities have enforced lockdown or stay-at-home orders with drastic measures including banning public gatherings, restricting restaurants to take-out and delivery only, and closing schools, bars, theaters, casinos and indoor shopping malls, among others.

Such orders, or their looming possibility, have consequently intensified the panic-buying urges of consumers for food and household essentials particularly in North America and Western Europe, giving occasions for daily photos of empty grocery-store shelves splashed ubiquitously from across news networks to social media platforms. The availability of food in North America and Western Europe during the ongoing coronavirus pandemic, however, remains generally secure, at least in the near term of the pandemic.

Food Sourcing

New York City, for instance, normally has food supply amounting to approximately 8.6 million tonnes (19 billion pounds) annually as purveyed by a network of regional and national food distributors, which then is sold at about 42,000 outlets across the city’s five boroughs, according to a 2016 study sponsored by the city.

Over half of the outlets are made up of approximately 24,000 restaurants, bars, and cafes through which consumers access almost 40 percent of the city’s food by volume annually. The rest of the outlets are chain supermarkets, bodegas, and online grocery stores. The study reported that the city’s annual food supply feeds over 8.6 million city residents, over 60 million tourists plus daily commuters in the hundreds of thousands from the tri-state area of New York, New Jersey, and Connecticut.

With millions of tourists and commuters now staying away from the city, however, and with the city’s hotels at just 49 percent occupancy for the week ending March 14, an excess of the food supply is readily available for diversion into the city’s grocery stores and other retailers to meet the surge in demand by local residents. In the case of Germany, the country imports food that accounts for nearly 8 percent of its US$1.3 Trillion imported goods in 2018. Germany procures from abroad about 3 million tonnes of fresh vegetables annually — with cucumbers and tomatoes accounting for 40 percent of the import volume — at a value of around 3.5 billion Euros, mainly from the Netherlands and Spain. Indeed, approximately 30 percent of the 2.6 million tonnes of exported Dutch-grown fresh vegetables go to Germany.

Meanwhile, approximately 80 percent of the United Kingdom’s food and food ingredients are imported. The U.K. imports approximately 2.4 million tonnes of fresh vegetables each year from Spain (33 percent), the Netherlands (28 percent), France (10 percent) and from various parts the world (29 percent).

Access to Food

Although the sources and sourcing of food in North America and Western Europe are currently generally secure, what might soon become a prodigious concern is that their workers in the production, distribution and retail segments of the food supply chain may eventually succumb to coronavirus infection. In such events, coupled with the potential for lockdown bureaucracies to slow down the flow of cargo between countries and between cities, severe delays in delivery — or real delivery shortages — could well become an actual possibility.

Local Vertical Farms

The coronavirus pandemic lockdowns have laid bare if fortuitously, the crucial importance of partial local food production in or around world cities in the context of urban resilience. The following salient features of vertical farms have become especially significant toward buttressing a city’s resilience in the event of a pandemic lockdown:

(1) Local — production of safe and fresh produce can take place within the lockdown zone, obviating the hurdles and perils of going in and out of the red zone;

(2) Automation-Amenability — impact of severe labor shortage which can be expected as the pandemic surges as well as direct physical contact between workers and fresh produce can be significantly minimized or eliminated;

(3) Controlled-Environment — infection risks to both workers and crops are significantly reduced through clean and controlled operations;

(4) Modular Option — crops may be grown in modular production units, such as shipping containers, which may be conveniently transported to neighborhoods located either farther away or in areas of stricter isolation; and,

(5) Reliability — Dependability, and consistency of high-yield and high-quality harvests throughout the year is virtually guaranteed independently of season and external climate conditions.

Fortunately for New York City, even as it sources most of its fresh vegetables from California and Arizona, the New York greater area now serves as host to the highest concentration in the United States of commercial urban vertical farms — including Aerofarms, Bowery Farming, Bright Farms, Farm.One, Square Roots and Gotham Greens, among others — that operate as controlled-environment farms year-round and independently of the variable effects of climate and geography. While conventional outdoor farming can produce three vegetable harvests per year, some of these vertical farms can achieve up to 30 harvests annually.

New York City and other world cities could certainly use more vertical farms.

Indeed, the urban planning and design of every world city should incorporate vertical farms, in and/or around it, not only for promoting food security — but for fostering disaster resilience as well. During a pandemic when a temporary period of social distancing between cities and nations becomes critically necessary, vertical farms can serve as helping outposts of resilience for cities and regions on lockdown as they brave the onslaught of the pandemic until it runs its course and duly dissipates — at which time the enfeebled ties of cooperation between cities, states and nations across the globe can once again be mended and made even stronger than before. Thus, not only locally, but in fact also globally, vertical farms can serve as helping vanguards of protection for all of our communities.

Dr. Joel L. Cuello is Vice-Chair of the Association for Vertical Farming (AVF) and Professor of Biosystems Engineering at The University of Arizona. In addition to conducting research and designs on vertical farming and cell-based bioreactors, he also teaches “Integrated Engineered Solutions in the Food-Water-Energy Nexus” and “Globalization, Sustainability & Innovation.” Email cuelloj@email.arizona.edu.

FOR SALE - 2018 Freight Farm Computer Controlled Hydroponic Grow System - Atlanta, Georgia

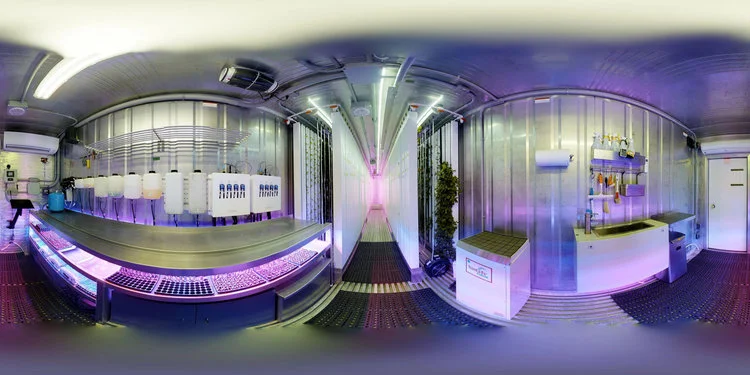

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Make & Model - 2018 Freight Farm Computer Controlled Hydroponic Grow System

Manufacturer - Freight Farms

Location - Atlanta, Georgia

Price - $75,000

Description

Well maintained 2018 LGM purchased from Freight Farms.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

LGM Accessories

Replaced sink with a 4 row, direct lighting microgreen station.

Website of previous owner being sold at additional cost. The website is currently set up for the business of this local farmer, and upon purchase can be changed to the meet the purchaser’s new brand.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit Freight Farms (Website) for more information.

2018 - Freight Farms LGM Information Booklet

For Additional Information And To Arrange A Viewing:

(909) 942-9594

Spencer.Hoff@iGrow.News

1. ALL-WEATHER CONSTRUCTION

Steel frame with stainless interior, 40' x 8' x 9.6' overall footprint.

2. AUTOMATIC DOSING

Programmable nutrient & pH dosing for perfect growing conditions.

3. CUSTOM WORKBENCH

TIG-welded stainless workbench with integrated seedling growth stage.

4. COMMERCIAL VOLUME

Thousands of growing sites across 256 irrigated vertical towers.

5. HIGH-EFFICIENCY LED ARRAY

5:1 red / blue LED lighting optimized for green leafy growth.

6. INSULATED ENTRY

Padlock-proof safety door with controlled-environment insulation.

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by the customer.

Farms Inside Shipping Containers Could Grow More Local Produce

Instead of trucking vegetables across the country, one company wants to help food service providers grow food right where they are, no matter how little experience or land they have

The Crops Grow Vertically Under LED Lights

Tuesday, February 18, 2020

Four rows of panels on a flexible moving rack system house more than 8,000 living plants at once, creating a dense canopy of fresh crops. (Photo: Courtesy of Freight Farms)

Instead of trucking vegetables across the country, one company wants to help food service providers grow food right where they are, no matter how little experience or land they have.

“That’s at corporate campuses, university campuses, health care facilities,” says Brad McNamara, CEO of Freight Farms. The company sells what it calls the Greenery.

“It’s a 320-square-foot shipping container like you would see on a boat, a train, a truck, outfitted with an automated growing system,” he says, “to grow about 3.5 acres worth of produce with no pesticides, no herbicides, and about 98.5% less water.”

Inside the Greenery, plants grow vertically, with their roots in a nutrient solution instead of soil. Sensors, pumps, and LED lights automatically maintain ideal growing conditions, so you don’t have to be an expert to start farming.

“You plug it in and you’re growing the same day,” McNamara says.

As the climate changes and the world’s population grows, McNamara says it makes sense to farm in a way that produces more food with fewer resources and less transportation.

“Instead of making more bigger farms,” he says, “We make hundreds, then thousands, then millions of people into independent successful farmers where they live and work.”

Reporting credit: Stephanie Manuzak/ChavoBart Digital Media.

Containerized Vertical Farming Company Freight Farms Secures $15 Million

Freight Farms — a global innovation leader of containerized vertical farming — announced that it has raised $15 million in Series B funding

By Noah Long ● February 15, 2020

Freight Farms — a global innovation leader of containerized vertical farming — announced that it has raised $15 million in Series B funding

Freight Farms — a global innovation leader of containerized vertical farming — announced that it has raised $15 million in Series B funding led by Ospraie Ag Science. Spark Capital also participated in the round. Including this funding round, the company has raised over $28 million.

“It’s a big step forward for the industry when financial markets recognize and champion the value of creating a distributed food system,” said Freight Farms CEO Brad McNamara. “Aligned on mission-driven growth as a team, there is a massive opportunity before us to scale across global markets, propelling meaningful technology that’s already doing good.”

Freight Farms’ Greenery is able to produce over 500 varieties of crops like calendula at commercial scale year-round using 99.8% less water than traditional agriculture. Four rows of the company’s panels on a flexible moving rack system are able to house more than 8,000 living plants at once thus creating a dense canopy of fresh crops.

This round of funding will be used for advancing the Freight Farms’ platform through continued innovation with new services designed to benefit its growing global network of farmers and corporate partners. And this investment follows the announcement of Freight Farms’ strategic national partnership with Sodexo to grow food onsite at educational and corporate campuses nationwide and will support ongoing contributions to collaborative research projects and partnerships.

“Freight Farms has redefined vertical farming and made decentralizing the food system something that’s possible and meaningful right now, not in the ‘future of food,'” added Jason Mraz, President of Ospraie Ag Science. “Full traceability, high nutrition without herbicides and pesticides, year-round availability – these are elements that should be inherent to food sourcing. Freight Farms’ Greenery makes it possible to meet this burgeoning global demand from campuses, hospitals, municipal institutions, and corporate businesses, while also enabling small business farmers to meet these needs for their customers.”

Launched in 2010 by McNamara and COO Jon Friedman, Freight Farms debuted the first vertical hydroponic farm built inside an intermodal shipping container called the Leafy Green Machine with the mission of democratizing and decentralizing the local production of fresh, healthy food. And this innovation, with integral IoT data platform farmhand, launched a new category of indoor farming and propelled Freight Farms into the largest network of IoT-connected farms in the world.

Freight Farm’s 2019 launch of the Greenery raised the industry bar, advancing the limits of containerized vertical farming to put the most progressive, accessible, and scalable vertical farming technology into the hands of people of diverse industry, age, and mission.

“With the Greenery and farmhand, we’ve created an infrastructure that lowers the barrier of entry into food production, an industry that’s historically been difficult to get into,” explained Friedman. “With this platform, we’re also able to harness and build upon a wider set of technologies including cloud IoT, automation, and machine learning, while enabling new developments in plant science for future generations.”

Freight Farms has been an integral part of scientific and academic research studies in collaboration with industry-leading organizations, including NASA (exploring self-sustaining crop production) and Cold Spring Harbor Laboratory (exploring the integration of CRISPR seed genetics and vertical farming to create commercial opportunity).

The company’s customers hail from education, hospitality, retail, corporate, and nonprofit sectors across 44 states and 25 countries, and include independent small business farmers — who distribute to restaurants, farmers’ markets, and businesses such as Central Market, Meijer, and Wendy’s.

21 Reasons To Start Container Farming In 2020

With container farming, you are not limited to the crops that grow naturally in a location or crops that are seasonal

January 3, 2020

The beginning of a new year is a great time to pick up new hobbies, interests and maybe even start a new career!

If you’ve been thinking about getting into container farming, there has never been a better time.

In this article, you’re going to learn 21 reasons why you should start container farming in 2020.

Let’s get started!

1. Be your own boss! One of the main benefits of container farming is that you make the rules. You decide what you grow, and how you grow it. Starting a container farm can be a side hustle to make a little more money or it can become a new career! It’s really all up to you.

2. Create your perfect lifestyle. Are you struggling with finding the right work/life balance? Starting a new career in container farming could be the perfect solution. You’ve probably heard the saying “If you love what you do, you’ll never work a day in your life.” With container farming, you can turn your passion into a real, sustainable business.

3. Stop sitting all day. It’s been said that “sitting is the new smoking.” Starting a container farm business will get you out from behind a desk. With container farming, you will be working in your container every day! Planting, harvesting, and monitoring your crops. Starting a container business is a great way to move away from a sedentary lifestyle towards a more active one!

4. Support your local community. Starting a container farm business is really starting a local food business. As a container farmer, you will be selling mostly to your local community at farmer’s markets, local restaurants, and even local grocery stores that want to add fresh local produce to their selections. Through this process, you will get to know your local community as you provide them with fresh, delicious nutritious food!

5. Help people eat healthier! Locally grown food is fresher, more nutritious, and safer! When you sell local produce, you grow in your container farm, you are improving the health of your community. Especially if you live in what’s known as a food desert. A food desert is an urban area where it can be difficult to buy affordable or good quality food. Food deserts happen for a variety of reasons from harsh climates that make it difficult to grow produce to communities not having good quality roads to allow in food trucks. With a container farm business, you can set up shop in a food desert and be the only supplier of quality affordable produce.

6. Save water. Container farms use less water than traditional farming techniques. Traditional farming is responsible for 80% of the entire US’s water usage! What you might not know is that growing a normal head of lettuce using traditional farming, uses a whopping 3.5 gallons of water! Now contrast that with a head of lettuce grown on a container farm which only uses about 1/10th of a gallon of water total! Every head of lettuce grown with a container farm saves more than 3 gallons of water! And as we all know water is a consumable resource, not a renewable one, so every gallon of water saved helps the planet in a big way!

7. Give people safer food. Remember when Chipotle had that E-coli outbreak in 2016? How about in November of 2019, when an E-coli outbreak got so bad that it lead to the recalling of Romaine lettuce in California? Just because the food comes from a supermarket or a fast-food chain doesn’t make it safe. In fact, a quick google search for “produce recalls” will show you exactly how unsafe some of the food you are being sold truly is. When you start container farming, you can be sure that you are providing safe food that won’t make people sick.

8. Save money on taxes. Starting a business is tax-deductible. That means that you can write off or depreciate a portion of all the money you spend on your container farm business.

9. Fill a missing niche in the market. Most produce is grown and sold seasonally, which is why cherries, for example, are only available for a very short time period. But when you use a container farm, you don’t have to worry about seasons or weather. That means that you can harvest crops that would normally be out of season, filling a niche in the existing food marketplace in your city.

10. Join the local food movement. According to Wikipedia “Local food movements aim to connect food producers and consumers in the same geographic region, to develop more self-reliant and resilient food networks; improve local economies; or to affect the health, environment, community, or society of a particular place. The term has also been extended to include not only the geographic location of supplier and consumer but can also be “defined in terms of social and supply chain characteristics.” For example, local food initiatives often promote sustainable and organic farming practices, although these are not explicitly related to the geographic proximity of producer and consumer.” By starting a container farm, you join with the local food movement in your city.

11. Provide jobs to your local community. When you start a container farm business, you’re going to need some help. Which means you will be providing jobs to your community. But more than that you will be creating a sustainable, beneficial job that helps bring safe, nutritious, healthy food to your community. That’s what we call paying it forward.

12. There are therapeutic benefits to farming! Gardening has long been renowned for its relaxing qualities but there are tangible therapeutic benefits to farming as well. “A ten percent increase in nearby green space was found to decrease a person’s health complaints in an amount equivalent to a five-year reduction in that person’s age” according to the Gardening Matters nonprofit of Minneapolis’ page, “Multiple Benefits of Community Gardens.” Farming also reduces stress! An experiment published in the Journal of Health Psychology compared the relaxation benefits of reading and gardening and found that farming subjects experienced more relaxation than those that read.

13. Grow food across generations. With a container farm, you can spread your love for farming to your parents, kids, and even grandkids. A container farm business is perfect for anyone of any age who wants to learn more about growing food. Some container farm owners we know even set up camps to teach kids how to farm and earn a nice profit in the process! Plus, you can pass down your container farm to your kids just like any other business.

14. Container Farms can be set up and ready to go in a few hours. With most business opportunities you must wait a long time to get started. For example, if you were to buy a McDonald’s franchise, you would need to wait for the permits, construction, hiring, and delivery of equipment like fryers and soda machines. But with a container farm, you can have everything set up and ready to deploy in just a few hours. No muss, no fuss.

15. Manage your crops from your smartphone. With regular farming you need to get out there and see what’s going on with things like pests, watering and monitoring ph. levels. With a container farm, you can monitor everything from your smartphone with the growlink app.

16. Grow more food in less space. Another reason to start container farming in 2020 is that you can grow a lot of food in a little space. With an 8 X 40 container farm you can harvest up to 400lbs of herbs or leafy greens per month!

17. Save on water and energy. Container farming is WAY more energy efficient than traditional farming! A report by Urban Agnews showed a Swedish based company Spisa Smaker saved 48% more electricity than when compared with traditional farming! Additionally, using a closed-loop irrigation system like those found in most container farms saves around 50% more water than traditional farming as well. Container farming helps you save money and consume fewer resources while producing high-quality food.

18. Reduce your footprint by planting without soil. One of the main reasons traditional farming uses so much space, energy and water is because it requires soil. Every crop planted using traditional farming monopolizes the land that they are planted on at least for the growing season if not forever. Soil can also affect where and when you can and cannot plant crops. For instance, areas with limited soil, icy or snow-covered soil or even soil that has become contaminated can be difficult for crops to grow in. But with a container farm, you don’t have to worry about the soil at all! With a hydroponic system like the ones, we use here at Pure Greens AZ plants absorb nutrients directly from a water-based nutrient delivery system.

19. Grow pesticide and herbicide-free crops! With traditional farming, you’ll need to use pesticides or herbicides to protect your crops from a variety of pests. Most farmers do this with pesticides or herbicides. Now some of these pesticides are natural and not that harmful, while others like Roundup have been linked to cancer. With container farming, you can use all-natural pesticides like Neem leaves, salt sprays, and Eucalyptus oil. Growing crops without harsh pesticides and herbicides is a great way to produce safer food for your community.

20. You can grow a wide variety of crops. With container farming, you are not limited to the crops that grow naturally in a location or crops that are seasonal. Container farming allows you to grow a wide variety of crops based on what you want to grow, not other factors like soil conditions or weather patterns.

21. Experience fast and consistent growth. Container farms can grow crops incredibly quickly as you can see in this video of the Pure Greens team harvesting 14 lbs. of Kale in an hr.! But it’s not just speed, container farming also allows you to grow crops consistently in areas where otherwise you would not be able to like areas with heavy winters or food deserts!

There you have it 20 great reasons why you should start container farming in 2020!

And if you need some help or want to learn more about the state-of-the-art turnkey container farms, we build here at Pure Greens head over to our website or give us a call at 602–753–3469.

FOR SALE - 2017.5 Freight Farm - Computer Controlled Hydroponic Grow System - Ann Arbor, Michigan

Make & Model - 2017.5 Leafy Green Machine (LGM) - Winterized" for Cold Climates.

Manufacturer - Freight Farms

Location - Ann Arbor, Michigan

Price - $70,000

Description

Well maintained 2017.5 LGM purchased from Freight Farms.

This LGM has been a reliable producer of healthy produce.

LGM Included Accessories:

Harvest Track

CO2 Booster

Storage Cabinet

Video Camera

Blue Tooth Audio Speakers

Hand Sink Package

Dehumidifier w/Reclamation Package

Water Filter Package

ELFA shelves installed

AC condensate water recycling system in place with Filters

Farm tutorial

Farm Hand App setup

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit Freight Farms (Website) for more information.

1. ALL-WEATHER CONSTRUCTION

Steel frame with stainless interior, 40' x 8' x 9.6' overall footprint.

2. AUTOMATIC DOSING

Programmable nutrient & pH dosing for perfect growing conditions.

3. CUSTOM WORKBENCH

TIG-welded stainless workbench with integrated seedling growth stage.

4. COMMERCIAL VOLUME

Thousands of growing sites across 256 irrigated vertical towers.

5. HIGH-EFFICIENCY LED ARRAY

5:1 red/blue LED lighting optimized for green leafy growth.

6. INSULATED ENTRY

Padlock-proof safety door with controlled-environment insulation.

Product Booklet

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by the customer.

Disclaimer of Warranty - The 2016 Freight Farms LGM hydroponic farming container is being sold “as is” and the Seller disclaims all warranties of quality, whether express or implied, including the warranties of merchantability and fitness for a particular purpose.

FarmBox Foods - Container Farming, Differently

We’re taking shipping and truck containers, and breathing life into them, starting with the magical combination of light and water

Rooted In Truth, Our Mission

We’re taking shipping and truck containers, and breathing life into them, starting with the magical combination of light and water. From there, we’ve created 100% self-contained farming units that come with tracking systems, LED lighting, and water purification to ensure your vertical container ecosystem is successful, meeting all requirements of organic, sustainable farming today. These containers can be integrated into any community, with any kind of climate, and provide a natural, beautiful, leafy green product that is the essential of life.

Think Inside The Box

Farm Box Foods provides a complete grow system to be placed anywhere in the world. With future models compatible with solar technology, Plant Force One can we placed anywhere. Plant Force One is capable of growing a variety of lettuces, herbs, and greens at a large scale production anywhere. Our container allows companies, communities, government agencies to grow and produce fresh organic greens.

“Feeding The World, One Container At A Time.”

To provide humanity with high quality, fresh, healthy, nutritionally superior, clean, chemical-free REAL food. While preserving our planet’s limited resources and reducing pollution for future generations. It is our goal to provide you with a direct link between you and the food you and your family is eating. No longer are you going to the supermarket, relying on and trusting your purveyors to provide you with the best greens, you grow them yourselves, knowing exactly what’s going into your body!

“What’s One Man’s Trash Is Another Man’s Treasure.”

Digital Farming Entrepreneurs

Our Story

FarmBoxFoods was founded in 2017 by Tony English, Jake Savageau & Jason Brown, whose singular focus was to develop a way to provide fresh organic nutritionally healthy food while reducing the use of earth’s valuable resources and reducing pollution simultaneously. They envisioned up-cycling unused shipping containers into very efficient greenhouses that could truly alter the way the world grows food.

By up-cycling those unused shipping containers – they could accomplish all of these goals at a lower cost than traditional farming and reduce the environmental impact of pesticides and the pollution of producing/transporting traditional vitamin devoid produce that we have all grown accustomed to consuming.

Introducing “Plant Force One”

Our Commitment

Our initial product is “Plant Force One.” This self-contained greenhouse in a shipping container farm is equivalent to 2 ½ acres of farmland that uses about 95% less water than traditional farming. Crops are grown using the latest technology in a perfect climate-controlled environment. Free of any pesticides, herbicides and any other toxic chemicals that humans should not be ingesting. Our crops are by far the most nutritious and delicious produce available today that also conserve our planet’s resources and reduces pollution associated with the growing, maintenance, and transportation of traditional farming.

FarmBoxFoods is currently developing new ways to supply humanity with other food products that will revolutionize how future generations will produce food forever.

Any Size, Any Location

From warehouse to full-scale farm

As the earth’s fertile soil becomes more scare every day, the importance of fresh foods and proper nutrition becomes paramount. Farmbox Foods’ unique ecosystem allows scalability in any environment. A city warehouse can easily be turned into a mass-producing commerce

FarmBox Foods is Excited to Announce its Partnership with GulfCarib

GulfCarib is the ONLY company dedicated to fulfilling the food security needs in both Jamaica and the Gulf States.

Its Principals and Consultants, all experts in their fields, are award-winning architects and engineers who deliver cutting edge solutions, such as FarmBox Foods, in agriculture, waster to energy and renewables.

The Use of these solutions and ‘best practices’ in agricultural techniques will endure availability of products and also prevent spiking of food prices.

We Are Half Farmers And Half Scientists

It comes down to what’s inside, the “Plant Force One” is built inside of a recycled 40-foot container. Helping the environment and help you change the way your farm

FOR SALE - 2014 Freight Farm - Computer Controlled Hydroponic Grow System - Texas

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

FOR SALE - 2014 Freight Farm - Computer Controlled Hydroponic

Grow System - Texas

Manufacturer - Freight Farms

Model - 2014 Leafy Green Machine (LGM)

Price - $29,950

Location: Texas

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Freight Farms technology makes it easy to bring farming closer to where people live. The result is local, year-round production featuring fresh, sustainably-grown, and flavorful greens.

Freight Farms is exactly what it sounds like–a farm in a repurposed freight container.

These old containers are retrofitted with vertical, hydroponic components to make farming possible anywhere in the world, regardless of the outside climate.

LGM Included Accessories:

2 (two) new Freight Farm chem panels; with AgrowDose pumps. Pumps where primed with water but never used. New sensors also.

2 (two) A/C units: Unit #1 is Factory the other is a MrCool Oasis ES Series Ductless Mini-

Split Heat Pump System 230V 19 SEER - 24,000 BTU. If you don’t need 2nd A/C unit remove it & reinstall exhaust fan. All tubing, wires where run into the farm through exhaust port hole so as to keep farm integrity.

1 Dehumidifier Model HCWH-90 Whole Home Dehumidifier

1 (one) ClearView pump to manage the condensate.

2 (two) (Floor fan tubes (2ea. for both sides)

2 (two) 800cfm fans; only one installed

4 (four) Westpointe fans not installed

2 (two) Co2 Generators, 1 MiniGen; 1 Autopilot

1 (one) Evolution RO1000 High Flow Reverse Osmosis Water Filter by HydroLogic

1 (one) BIGboy Ultra Violet Sterilizer Kit by HydroLogic.

2 (two) Seedling Doser Panel & Main Doser Panel w/sensors

2 (two) sets pH probe - EC probe - Temp probe -

Seedling & Main delivery tanks; replaced All of them 8 are new

Illumitex - Eclipse Gen2 8 LED Grow lights & Eclipse Gen2 12 LED Grow lights - 3ea. Over the seedlings area NEW

10 LED light strips 7 replacements

Agrowtek – Hydro Transmitter and sensors; (All New)

Cradle Point (AT&T) Cell for Internet into LGM has ??? router that works with Farmhand.

4 port switch

Laptop cradle w/swing arm not installed

Lots of spare parts

Misc. PVC fittings most treaded a few slip on

2 aux pumps, small volume, 2 air pumps,

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

Everything You Will Need To Grow Seedling And Microgreens And Then Some

Materials For Growing Hydroponic Plants - Additional $7,500.00 USD

Seedling Cart & Racks (DIY) 6 trays, 1 sump, lights (mix of LED’s & T5) Bright Agrotech design ($500)

Illumitex - Eclipse Gen2 8 LED Grow lights & Eclipse Gen2 12 LED Grow lights** ($4,000)

20 (twenty) K5 fluorescents lights 4’

Agrobrite 2’x1’ 4 bulbs

Multiponics High-End Cycle Timer in waterproof box ($250)

Multiponics Aquatec CDP 8800 pump w/psi guage in waterproof box ($300)

ProSeries 5 stage Reverse Osmosis Water Filter System 1 ea. w/expansion tank (5gal.); 50GPD ($350)

4 stage Reverse Osmosis Water Filter System 1 ea. w/expansion tank (4.4gal) ($250)

Trays w/holes 50 ea. Trays w/ holes (diamond pattern)

Trays seedling (200ea. cells) 20ea. Trays w/o holes $20 ea.

Q Plugs 20/60 4K per case 1ea. case by IHort

Microgreen grow Pads & roll

Propagating Chamber model PC-22 by PRO-GROW ($2,200)

Zipgrow Farm Walls: 2ea. 4’ & 1ea. 8’ complete by Bright Agrotech ($1,500)

Tower Garden growing system ($500)

1ea. 30”x30”x6” tub

Pumps; Aerators; Timers; Tubing and fittings (1/4” / 3/8” / ½”)

PSI gauges

pH & EC probes handheld w/solution

Light Meter (Apogee Instruments) Full-Spectrum Quantum sensor ($500)

** (Seeds Included 1 Year Old)

Attached Documents:

Freight Farm Twitter Feed

LGM Cut Sheets

See All Photos And Videos Here

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by the customer.

Disclaimer of Warranty - The 2017 Freight Farms LGM hydroponic farming container is being sold “as is” and the Seller disclaims all warranties of quality, whether express or implied, including the warranties of merchantability and fitness for particular purpose.

FOR SALE: 2016 Computer Controlled "Modular Farm" - Hydroponic Grow System - Canada

The “Modular Farm” is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Location: Canada

Price: $59,000 USD

Exterior Farm Dimensions: 40' x 10' x 10'.

AutoGrow technology with IntelliGrow support. This allows for remote control of the farm (climate, lights, nutrients, etc.) from anywhere using your mobile phones or computer. Also, gives a history report.

Upstart University, a Facebook group, has been a great resource tool to connect with other hydroponic growers or Upstart personnel, for assistance in whatever it may be.

There are four (4) cameras installed to remotely view the interior of the farm.

240 x 8' zipgrow towers allowing for 2800+ plants. This is in 4 rows (2 sections) with 60 towers in each. As you can see in the picture with the table.

Farm labor is 15-20 hours per week for harvesting and upkeep.

There is a large 9' x 3', stainless steel working table accessible on 3 sides. 4 adults working can work in the farm at one time with plenty of space.

The farm has been able to maintain a healthy climate in the middle of the Alberta winters. The farm’s first winter experienced -40 Celsius for 2 weeks.

FOR SALE - 2017.5 Freight Farm - Computer Controlled Hydroponic Grow System - St. Johns, Newfoundland and Labrador, Canada

Make & Model - 2017.5 Leafy Green Machine (LGM) - Winterized" for Cold Climates.

Manufacturer - Freight Farms

Location - St. Johns, Newfoundland and Labrador, Canada

Price - $65,000

Description

Well maintained 2017.5 LGM purchased from Freight Farms.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

LGM Included Accessories

Upgraded Dehumidifier

1/3 hp main pump

Constant flow drip emitters to prevent the wasting of water

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit Freight Farms (Website) for more information.

1. ALL-WEATHER CONSTRUCTION

Steel frame with stainless interior, 40' x 8' x 9.6' overall footprint.

2. AUTOMATIC DOSING

Programmable nutrient & pH dosing for perfect growing conditions.

3. CUSTOM WORKBENCH

TIG-welded stainless workbench with integrated seedling growth stage.

4. COMMERCIAL VOLUME

Thousands of growing sites across 256 irrigated vertical towers.

5. HIGH-EFFICIENCY LED ARRAY

5:1 red / blue LED lighting optimized for green leafy growth.

6. INSULATED ENTRY

Padlock-proof safety door with controlled-environment insulation.

Product Booklet

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by customer.

FOR SALE - 2016.5 Premium Freight Farm (LGM) - Computer Controlled Hydroponic Grow System - Florida

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Make & Model - 2016.5 Premium Leafy Green Machine (LGM)

Manufacturer - Freight Farms

Location - Florida

Price - $57,500

Description

Well maintained late 2016.5 LGM purchased from Freight Farms.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included. (Original cost approx., $5,000.)

All standard Premium components

Custom stacked microgreens production module (in place of sink), programmed into control system

Additional back dehumidifier

Upgraded FF LEDs for propagation

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

1. ALL-WEATHER CONSTRUCTION

Steel frame with stainless interior, 40' x 8' x 9.6' overall footprint.

2. AUTOMATIC DOSING

Programmable nutrient & pH dosing for perfect growing conditions.

3. CUSTOM WORKBENCH

TIG-welded stainless workbench with integrated seedling growth stage.

4. COMMERCIAL VOLUME

Thousands of growing sites across 256 irrigated vertical towers.

5. HIGH-EFFICIENCY LED ARRAY

5:1 red / blue LED lighting optimized for green leafy growth.

6. INSULATED ENTRY

Padlock-proof safety door with controlled-environment insulation.

Product Booklet

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by the customer.

Disclaimer of Warranty - The 2016.5 Freight Farms LGM hydroponic farming container is being sold “as is” and the Seller disclaims all warranties of quality, whether express or implied, including the warranties of merchantability and fitness for a particular purpose.

FOR SALE - Two - 2017 Custom Built - Hydroponic Grow Systems - Miami, Florida

Two 40’ Insulated Container

Vertical Farming / Hydroponic Grow Systems

Two - 2017 Custom Built - Hydroponic Grow Systems - Can Be Sold individually.

Price: $45,000 each - Seller will finance with 20% down payment

Location: Miami, Florida

Electrical Work/Components

Plumbing Work/Components

HVAC Work/Components

2 x Air Conditioners (3.5 Tons)

Hydroponics Lights- 300 x 8’ Growing Tubes - 300 x Growing Medium/Sponges

Commercial Water Filtration System

Commercial Self Sustaining Sink

Stainless Steel Table

1 - Refrigerator

1 - Remote Switch via App

Stainless Steel Shelves x 10

55 Gallon Tank

Water Pump

Security Alarm (ADT)

Wireless Internet

Highlights:

Capacity to Grow +100K Plants

Self-Sustaining Water System

Hydroponic Light System - Proven Concept

Permitted by Dept. Agriculture

Permitted by Miami Dade County

Local Business Tax Receipt

Property Insurance Policy

General Liability Policy

Product Liability Policy

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by the customer.

Disclaimer of Warranty - The hydroponic farming greenhouse container is being sold “as is” and the Seller disclaims all warranties of quality, whether express or implied, including the warranties of merchantability and fitness for a particular purpose.

Videos: Freight Farms - Container Farming

To learn more about how to get started with your own Freight Farm go to Freight Farms, or to inquire about a pre-owned Freight Farm Container go to iGrow News

FREIGHT FARMER SPOTLIGHT: PATRICK STOFFER

In a lot of ways, Patrick Stoffer isn't your average 28-year old. To start with, he is a hydroponic farmer, but perhaps even more unusual, he is roommates with a 90-year old, Harrie, just one of the members of his community he is passionate about serving. Patrick lives at Humanitas Independent Senior Living Facility in Deventer, The Netherlands. In exchange for room and board, Patrick spends time with the residents, who help him grow, harvest and prepare the fresh produce from his Freight Farms operation, Grow Local. To learn more about how to get started with your own Freight Farm go to Freight Farms, or to learn more about pre-owned Freight Farm LGM container, got to iGrow News.

GROW FOOD HERE: SPRINGDALE, ARKANSAS | VET VEGGIES

4 STEPS TO GROWING IN OUR CONTAINER FARM

FREIGHT FARMER SUPPORT

MEET THE FARMERS AT AGORA GREENS

2015 LEAFY GREEN MACHINE BY FREIGHT FARMS

INSIDE A SHIPPING CONTAINER VERTICAL HYDROPONIC FARM

INTRODUCTION TO THE LEAFY GREEN MACHINE

FREIGHT FARMS X KARMA FARM

THE STORY BEHIND FREIGHT FARMS

INSIDE THE LEAFY GREEN MACHINE

FARMPRO: Fully Automated And Climate Controlled 40' Container Farming

The Urban Crop Solutions FarmPro is a 40 ft fully automated freight container with a state-of-the-art leafy green growing system. This system gives you a fully automated 4-layer growing solution

FARMPRO by Urban Crop Solutions

A FULLY AUTOMATED AND

CLIMATE CONTROLLED 40' FREIGHT CONTAINER

The Urban Crop Solutions FarmPro is a 40 ft fully automated freight container with a state-of-the-art leafy green growing system. This system gives you a fully automated 4-layer growing solution.

HYDROPONICS AND OWN GROWTH RECIPES FOR 200+ CROPS

To deliver healthy crops, our closed-loop irrigation system:

Minimizes the use of fresh water

Increases plant nutrient uptake and can work with up to 70 organic nutrients and minerals

Provides optimal root growth, aeriation and nutrient delivery

Allows to grow microgreens and super-large crops

CLIMATE CONTROLLED ENVIRONMENT

In/outflow of air is controlled to limit unwanted elements while optimizing climate conditions.

Closed production plants have minimal external elements influencing the indoor climate

Monitoring the in- and outflow of air allows for the best possible crops

Flavour can be tailored to market demand by influencing climate, light and nutrients

CUSTOM-MADE LED TECHNOLOGY

Our own LED lights provide the optimal spectrum for your plants, using limited energy.

The photosynthetic active radiation (PAR) range, enables photosynthesis in the 400-700nm range

Using energy-efficient LEDs, our crops receive just the right light spectrum to grow efficiently

ROBOTIZED AND CONTROLLED PROCESS

Our top-notch industrial standards allow full control over monitoring and automation.

Minimize human intervention to achieve higher levels of pro

STANDARD FUNCTIONS

40 ft insulated container

Climate control

SIZE: 40” - LAYERS: 4

1 irrigation system

Continuous monitoring

Custom-made LEDs

4 cultivation layers

Handling area and technical room

Fully automated growing process

Online crop and process management

OPTIONS

Custom outside colour

Personalized logo on container

Up to 2 different water systems

1 or multiple windows

1 or multiple webcams

Back-up power system

WHAT YOU GET

80 M² GROWING SURFACE

1.6K- 3.6K CROPS PER GROWING CYCLE

24K - 54K CROPS PER YEAR

To View Our Videos, Please Click Here

ARE YOU INTERESTED IN A FARMPRO?

Would You Like To Receive Additional Information?

FOR SALE - Two - 2015.5 Freight Farm - Computer Controlled Hydroponic Grow Systems - Location: Colorado

Manufacturer - Freight Farms

Model - (2) 2015.5 Leafy Green Machine (LGM) - Winterized" for Cold Climates.

Price - $50,000 Each - Can be sold individually

Location: Colorado

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

LGM Included Accessories:

Zebra Printer and Bar Code System + Case of Ribbons & Paper

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

<br/>

Attached Documents:

LGM Cut Sheets

See All Photos And Videos Here

FOR SALE - 2015.5 Freight Farm - Computer Controlled Hydroponic Grow System - Minnesota

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

2015.5 Freight Farm - Computer Controlled

Hydroponic Grow System

FOR SALE

Location: Minnesota

Price: $40,000

2015.5 Freight Farm Leafy Green Machine (LGM)

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

LGM Included Accessories:

Zebra Printer and Bar Code System + Case of Ribbons & Paper

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

FOR SALE - November, 2016 Freight Farm - Computer Controlled Hydroponic Grow System - Colorado

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Make & Model - November, 2016 Leafy Green Machine (LGM)

Manufacturer - Freight Farms

Location - Colorado

Price - $60,000

Description

Well maintained late 2016 LGM purchased from Freight Farms.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

1. ALL-WEATHER CONSTRUCTION

Steel frame with stainless interior, 40' x 8' x 9.6' overall footprint.

2. AUTOMATIC DOSING

Programmable nutrient & pH dosing for perfect growing conditions.

3. CUSTOM WORKBENCH

TIG-welded stainless workbench with integrated seedling growth stage.

4. COMMERCIAL VOLUME

Thousands of growing sites across 256 irrigated vertical towers.

5. HIGH-EFFICIENCY LED ARRAY

5:1 red / blue LED lighting optimized for green leafy growth.

6. INSULATED ENTRY

Padlock-proof safety door with controlled-environment insulation.

Product Booklet

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by the customer.

Disclaimer of Warranty - The 2016 Freight Farms LGM hydroponic farming container is being sold “as is” and the Seller disclaims all warranties of quality, whether express or implied, including the warranties of merchantability and fitness for a particular purpose.