Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Are You Really Ready To Start Your Urban Farm Operation?

Are You Really Ready To Start Your Urban Farm Operation?

AUGUST 15, 2017 | URBAN AG NEWS

By David Ceaser

So, you have been dreaming about starting an urban farm or are about to launch your new career with an indoor farm. You have gotten funding from friends and family (and Kickstarter) but have you really dotted all the i’s and crossed all the t’s as far as what challenges you will be taking on as you get your business up and running?

The truth is that many urban farming operations enter the business from one perspective. They may be started by a grower who knows a ton about growing but little about the business and legal end of things. Or, the operation may be started by someone with a business perspective who wants to see a farming operation thrive, but has little knowledge of the daily ins and outs of running a farm.

Many urban farms fail. It’s good to be as prepared as possible when starting out so you don’t repeat the same mistakes as others.

Here are some important things to think about before getting started. Any one of these roadblocks could delay your project for several months so it’s best to look at these things ahead of time rather than letting them derail your progress.

Zoning, code issues

Since urban agriculture (as it’s known today) is a relatively new field, many municipalities are unfamiliar with it and do not have any sort of code on the books for how to permit your project. If you can’t obtain a permit, then you can’t obtain a business license.

Your options will be to move your project to another location where it is permitted, permit under a different classification such as a food processing facility (if you can convince the planning department), work without a permit (there are work arounds depending on the location of the facility) or wait until legislation is updated. Many city planning departments will not be familiar with indoor agriculture projects so it is very valuable to do your homework first.

It is good to have at least basic drawings to show them how the facility will be laid out and will operate. It is also good to be familiar with cities that have urban farming legislation on the books so that you can show that to local planning departments as needed.

Business model

What is your business model? How will you make money? Will you sell your product wholesale? To restaurants? Direct to consumers? To supermarkets? At farmers markets?

Each of these particular customers may require certifications before they will purchase your product. These might be as simple to obtain as county ag permits or as complex and expensive as organic certification or regular tests for pathogens. It is important to know what your customers will ask of you beforehand so that you are prepared.

Water

Water is a key ingredient in your facility whether hydroponic or soil-based. Important questions to consider are: Can you use the existing municipal water? Will you need to invest in expensive filtering equipment to remove excessive salts or metals? Are there restrictions on water use (such as in California)? Are there disposal issues to be educated about regarding disposal of nutrient-rich water?

Growing medium

Hydroponic farming can be done with different growing media. Do you have a guaranteed supply of that medium, especially for operations where the medium is only used for a short period of time and replaced? If you are looking for organic certification, does the medium meet the requirements for certification? If not, what alternatives are there? If you are using soil, what tests do you need to do and what adjustments will you need to make to the soil?

Electricity, energy

If you are running an indoor farm, energy costs can be one of the most expensive budget items. Using lights and dehumidifiers can really be expensive.

Do you know what your power rates are? Do you know when power is most expensive? Do you know how much light your plants need ? Is the electricity in your area reliable or should you have a back up generator on hand? Do you know how much power your facility needs and how much does the property you are looking at offers? Is the existing electrical system up to code? How much will an upgrade cost?

Floors

If you are running an indoor facility, floor design is of key importance. You need to simultaneously design your floor for multiple factors such as being able to be cleaned easily, drainage, traction and bacterial control.

Input sourcing

Just like when you are baking bread, if you run out of flour, you have a big problem. The same is true with your farm. You will have numerous inputs and if any one of them runs out, your production will be slowed or might even stop. Make sure you have a reliable source for all your inputs and a reliable backup source just in case.

Controllers

So much of indoor farming and even aspects of outdoor farming are based on monitoring data and adjusting as necessary. What controllers will you use for your operation? How will you use the data that are being produced to your advantage?

Are you the type of person that feels more comfortable seeing everything in person and making adjustments on site or are you comfortable with making adjustments to your growing operation remotely? These questions are very important to think about before you get started so that production data can be easily understood and analyzed and the appropriate adjustments can be made to your operation when needed.

Perspective

When looking at your urban farming business, I have found it very valuable to analyze production and costs on a square foot basis. I have a background in real estate and using a square foot methodology has proven very valuable and easy to understand.

Full Cycle Planning

Many operations do intense planning for how to grow their product but don’t think about the best way to harvest and package until it is upon them. Unfortunately, harvesting and packaging can be very labor intensive and if not well planned beforehand, can turn a profitable venture into one that loses money. Talk with your buyers (especially supermarkets) about specific packaging needs they may have from the start and from there, plan a system that reduces labor costs whenever possible.

These are just some of the items that need to be thought about when launching an urban farming operation. There are many more that will undoubtedly arise based on your particular situation. If you are prepared with the ones listed above, it will significantly reduce headaches, time delays and money lost in your urban farming venture.

David Ceaser has over 20 years experience working with plants and agriculture in numerous capacities and countries. He has studied agroecology, horticulture and business along with several years working in real estate development. He currently does consulting work and operates a small outdoor urban farm specializing in herbs and salad greens. To contact David, please e-mail farmer@gsvfarm.com

The author would like to thank Will Kain for his time and insight in participating in this interview. Further gratitude goes to Chris Higgins of Hort Americas and the founder and editor of Urban Ag News.

Jim Pantaleo works to develop all aspects of indoor vertical farming and writes as an industry advocate.

Harlem Grown’s Tony Hillery: “Education Is The Way Out"

Harlem Grown’s Tony Hillery: “Education Is The Way Out”

Tony Hillery, Founder and Executive Director of Harlem Grown, will be speaking at the inaugural New York City Food Tank Summit, “Focusing on Food Loss and Food Waste,” which will be held in partnership with Rethink Food Waste Through Economics and Data (ReFED) and with support from The Rockefeller Foundation and The Fink Family Foundation on September 13, 2017.

Hillery founded Harlem Grown to address the health and academic challenges facing public elementary school students in Harlem. In 2011, he began volunteering at a local elementary school and witnessed first-hand the lack of resources allocated to the schools and the poor nutrition of students. He transformed an abandoned garden, essentially a junkyard, into a thriving community garden. Hillery worked with community members to clean up the garbage, purchase soil, and purchase 400 seedlings for 400 students. As the students’ plants grew, their eating habits were also transformed, and the students developed leadership and teamwork skills. That first season, they grew 38 pounds of produce.

Tony Hillery, Founder and Executive Director of Harlem Grown, will be speaking at Food Tank’s NYC Summit on September 13, 2017.

By 2016, Harlem Grown expanded to partner with six local Harlem schools, reach more than 4,800 youth, and grow more than 2,200 pounds of fruits and vegetables that are then distributed to families-in-need throughout the community. This year, Harlem Grown will open a brand-new farm on 127th Street to continue to reach more youth in Harlem and inspire them to lead healthy and ambitious lives.

Food Tank talked with Hillery about the collective impact these gardens have on the communities of Harlem.

Food Tank (FT): What originally inspired you to get involved in your work?

Tony Hillery (TH): One of my personal passions is education. I truly believe that education is the way out of a lot of situations. Once you have your education, it cannot be taken from you regardless of your socioeconomic position. Education is the way out. I kept reading about schools in the city, and I didn’t understand what I was reading. It didn’t make sense to me that we were living in one of the richest cities in the country, and we had such a disparity in education. I really didn’t understand it. I’m a show-me kind of guy, so I started volunteering at an elementary school in Harlem. That’s what did it. That’s what prompted everything else.

FT: What makes you continue to want to be involved in this kind of work?

TH: To be completely honest, I didn’t have a plan when I started this—it all, excuse the pun, came organically. My original mission was to work with parents on the importance of education in breaking the cycle of poverty, but my focus quickly turned to children. As I spent more time in the schools, the conditions of the underserved communities in this country became crystal clear. As a youth, I used to come to Harlem all the time. We would come to Harlem; we would party in Harlem, but then go home. You see it, but you don’t see it. That’s a lot of us in this country. We’re aware, but we’re not aware. The more time I spent here, the more obvious the problems became. And very quickly it shifted to nutrition, food access, and food justice. I’m convinced that poverty is just lack of access and lack of opportunity. In the schools where we work, there are no services. There’s no extracurriculars. There’s no art. Some of the schools don’t even have gyms or music. The children we serve come to school for reading, writing, and arithmetic as well as breakfast, lunch, and supper. They’re having their three meals in school, and yet they can’t even identify simple vegetables. It’s a huge disconnect. And that’s how this whole thing came to be.

FT: Do you think that working with kids is one of the biggest opportunities to fix the food system?

TH: Absolutely. Early on when I first started this, I did like a lot of people did. I started working in the school, and as fate would have it, across the street was an abandoned community garden. I got the garden and made it a farm. After the first crop, I was sending the kids home with some kale and some chard, and the next day I would ask the children, ‘so how do you like that chard?’ They said, ‘I don’t know, my mother threw it away.’ So mom doesn’t know what it is or how to prepare it. This is part of the problem. A lot of us nonprofits miss the mark. We come into the community to teach that community or to show the community. If you think about how I started this conversation, that’s exactly what I did. I came into this community to teach parents the importance of education. Who am I to come into a community? I’m not from here, and I don’t live here. And if you think about it, that’s insulting on its face. I mean, I’m telling you basically, ‘you’re living wrong, I’m living right. Listen to me, I know better.’

FT: Did you have push back on that from community members?

TH: No, not directly push back, but the delivery was disingenuous. It wasn’t what you would think. It wasn’t what I thought. I thought people would be so welcoming—’Oh yes, tell me, tell me.’ No, no, it’s not that. People will come, they will sit there, and they will listen. But they don’t hear you. People will come to these workshops and things for the endgame. What’s the endgame? Is it a bag of groceries? Is it a gift card? They don’t hear, they’re not taking in what’s being provided. So quickly I pivoted; I focused on the children. We don’t come into the community. We become the community. We’re here seven days a week. We see these children every day, in school, after school, and on the weekends. And from that, through that consistency, we build relationships and trust that is unbelievable. And that’s our method. We went from showing children vegetables, and they’re like ‘what’s that?’ and ‘ew, ew, ew.’ To whatever we pick up and say ‘check this out, taste this,’ they’ll put it right in their mouth without questions and no apprehension at all. And if they do it, their peers do it. There’s a whole ring of trust we’ve created with our children. And it is like the ripple effect, they bring their siblings, they bring their mothers, they bring their friends. And that’s how we’re growing it from the bottom-up—literally grassroots, a bottom-up approach.

FT: So by working with the kids, you have been able to impact the community at large?

TH: Absolutely. The population we serve is very, very challenged. The numbers move up and down, but overall, 80 percent of the children I serve are living in single parent households. Over 90 percent of my children live below the poverty line, 98 percent of our families are on food stamps, and 40 percent of the children we serve are homeless. That’s my population. So if you take a step back, nutrition is low on the list of priorities, if it’s on the list at all. We embrace the whole child. You can’t give a kid kale to take home when he doesn’t have a home or place to eat it.

FT: The work you’re doing is incredibly inspiring. What is the most inspiring experience you’ve had?

TH: Oh my god, there’s so many every day. That’s the beauty of working with children. Children are so genuine. There’s no agenda, and there’s no faking it. You get the unfiltered truth every day from these children. That is what keeps us on our toes. When we first started, we were working with children who not only didn’t eat anything green but couldn’t even identify vegetables other than a tomato and carrot. They got fuzzy on broccoli, and everything else is salad. And they didn’t eat salad. Today, they won’t have a meal without salad. And don’t give them iceberg or romaine; they want other leafy greens. They love chard. They love arugula. They love spinach. To see the change in the children that started with me six years ago is just amazing.

FT: What is one small thing that everyone can do to help make this big difference?

TH: Realize that we are the change. The average person wants to do something tends to get stuck in neutral; they don’t know how to proceed, they don’t know how to take the next step. I just say, take the step. There’s nothing holding you back but you. If you see an injustice, if you see a problem, try to fix it. It’s as simple as that. A lot of us just sit back and wrestle with it. Just get involved, and see where it goes. It’s not a job; it’s a passion, to do something you love is not working. It’s not a talent to make money. Anybody can make money. But who can change a life for the better? That’s what we have to ask ourselves. Who can do that? And that’s what we do here. And oh my goodness, it is so rewarding. Each day is better than the next.

FT: Do you have anything else you want like to share with us?

TH: I must say, the name of my organization is Harlem Grown, but this problem is not unique to Harlem; this is not black, white, or brown. This is poor. This is a poverty issue. I’m all over the country speaking. I see poverty that makes my kids look rich. You see the same landscape. You see miles of fast-food restaurants. The closest supermarket is nine, ten miles away and nobody has a car. It is the same landscape as here in Harlem, as it is in the bayou in Louisiana or in West Virginia. You see the same exact thing: lack of access, lack of opportunity, and lack of education. Our children eat badly because it’s close, it’s cheap, and it’s convenient. In six years of doing this work, I have yet to meet a mother who would not want three organic meals of healthy, fresh vegetables and food for their kids. But you can’t afford it, and you can’t get it. Food is not optional. You have to eat. And if there’s a bodega on every corner selling cheap, processed food, that’s where they go. We have these catch phrases. We always say, ‘children are our future,’ and if that’s true, we really have to do something for these children.

Hillery recently received a CNN Hero award. Read about it HERE.

This interview has been edited for length and clarity.

The NYC Food Tank Summit is now sold out. Register HERE to watch the livestream on Facebook. A few tickets remain for the Summit Dinner at Blue Hill Restaurant with a special menu from Chef Dan Barber. Apply to attend HERE. If you live in New York City, join us on September 14 for our FREE outdoor dance workout led by Broadway performers called Garjana featuring many great speakers raising awareness about food waste issues. Register HERE.

Farming In A Shipping Container: It’s Happening In Grand Rapids

Farming In A Shipping Container: It’s Happening In Grand Rapids

POSTED 7:43 PM, AUGUST 29, 2017, BY JAMES GEMMELL

GRAND RAPIDS, Mich. — Imagine growing food indoors without water, sun or soil – and making a decent living doing so.

Green Collar Farms vertical crops

Green Collar Farms LLC says it is West Michigan’s first indoor hydroponic, vertical micro farm. That’s a 350-square-foot operation inside a re-purposed shipping container, located at 530 Second Street NW in Grand Rapids. Green Collar Farms was founded by Brian Harris, who says vertical farming is a sustainable enterprise that has the potential to grow local food and provide middle income-level jobs in urban areas.

“The ultimate goal,” says Harris, “is that a person could make a middle-income living out of the crops that go to your local farm-to-fork restaurant, and groceries.” He believes that could help grow a community’s vitality, not just grow crops. Under-used spaces like vacant warehouses or dormant garages and basements could be transformed into vertical farms.

The hydroponic farming uses L.E.D. technology that Harris says is 60 percent more efficient, per watt used, than sunlight. How can the plants grow inside a container with no sunlight? Harris says plants “see” light differently than people, who mostly observe it in yellows, greens and oranges. But plants see sunlight in red and blue, and interpret it in terms of radiation. So, the L.E.D.s that are used inside the shipping container are a red-and-blue combination. “So, it gives the plant the little bit of blue it needs to have to wake up in the morning. And the red is really what makes it stretch.”

Green Collar Farms uses automated Controlled Environment Agricultural (CEA) techniques to operate year-round, regardless of season. It can produce hyper-local greens and herbs with a yield equal to the output of a traditional two-acre farm – while using only 10 percent of the water. Green Collar is supplying hydroponic greens like kale, leaf lettuces and herbs to select restaurants in Grand Rapids. And Harris plans to expand distribution to local grocery stores, markets and even school cafeterias.

He figures that will benefit students. And that the L.E.D. technology will attract and introduce them to hydroponic vertical farming: “I think if you bring some kids in here, and they see these lights, it’s like Star Wars. And I think at that point, I’ve got them where I can start talking to them about the biology of plants. Start talking to them about engineering. Introduce them to the ‘what ifs’ of innovation.” He says that spark an interest in science, technology, engineering and math (STEM), as well as plant biology, agriculture and nutrition.

Harris envisions upscaling the vertical-farm concept up to 20,000 square feet, boosting the crop output significantly. He says that will really produce jobs: “At that point…you’re starting to employ hyper-local residents. You can introduce food (for) the under-served community. The idea here is, if we scale this up to the inner-city to provide them local jobs…”.

However, Harris recognizes that the indoor vertical farming has its limitations. “So, you’re not going to grow wheat, corn, barley…this is not an apple orchard…but there are lots of field crops that are grown in muck farms or other soil environments that are not necessarily optimal for the environment. You could bring those in to hyper-local. Because they’re typically consumed hyper-local.”

Japan’s SoftBank Is Investing Billions In The Technological Future

Japan’s SoftBank Is Investing Billions In The Technological Future

By Peter Rejcek | Aug 29, 2017

Remember the 1980s movie Brewster’s Millions, in which a minor league baseball pitcher (played by Richard Pryor) must spend $30 million in 30 days to inherit $300 million? Pryor goes on an epic spending spree for a bigger payoff down the road.

One of the world’s biggest public companies is making that film look like a weekend in the Hamptons. Japan’s SoftBank Group, led by its indefatigable CEO Masayoshi Son, is shooting to invest $100 billion over the next five years toward what the company calls the information revolution.

The newly-created SoftBank Vision Fund, with a handful of key investors, appears ready to almost single-handedly hack the technology revolution. Announced only last year, the fund had its first major close in May with $93 billion in committed capital. The rest of the money is expected to be raised this year.

The fund is unprecedented. Data firm CB Insights notes that the SoftBank Vision Fund, if and when it hits the $100 billion mark, will equal the total amountthat VC-backed companies received in all of 2016—$100.8 billion across 8,372 deals globally.

The money will go toward both billion-dollar corporations and startups, with a minimum $100 million buy-in. The focus is on core technologies like artificial intelligence, robotics and the Internet of Things.

Aside from being Japan’s richest man, Son is also a futurist who has predicted the singularity, the moment in time when machines will become smarter than humans and technology will progress exponentially. Son pegs the date as 2047. He appears to be hedging that bet in the biggest way possible.

Show Me the Money

Ostensibly a telecommunications company, SoftBank Group was founded in 1981 and started investing in internet technologies by the mid-1990s. Son infamously lost about $70 billion of his own fortune after the dot-com bubble burst around 2001. The company itself has a market cap of nearly $90 billion today, about half of where it was during the heydays of the internet boom.

The ups and downs did nothing to slake the company’s thirst for technology. It has made nine acquisitions and more than 130 investments since 1995. In 2017 alone, SoftBank has poured billions into nearly 30 companies and acquired three others. Some of those investments are being transferred to the massive SoftBank Vision Fund.

SoftBank is not going it alone with the new fund. More than half of the money—$60 billion—comes via the Middle East through Saudi Arabia’s Public Investment Fund ($45 billion) and Abu Dhabi’s Mubadala Investment Company ($15 billion). Other players at the table include Apple, Qualcomm, Sharp, Foxconn, and Oracle.

During a company conference in August, Son notes the SoftBank Vision Fund is not just about making money. “We don’t just want to be an investor just for the money game,” he says through a translator. “We want to make the information revolution. To do the information revolution, you can’t do it by yourself; you need a lot of synergy.”

Off to the Races

The fund has wasted little time creating that synergy. In July, its first official investment, not surprisingly, went to a company that specializes in artificial intelligence for robots—Brain Corp. The San Diego-based startup uses AI to turn manual machines into self-driving robots that navigate their environments autonomously. The first commercial application appears to be a really smart commercial-grade version that crosses a Roomba and Zamboni.

A second investment in July was a bit more surprising. SoftBank and its fund partners led a $200 million mega-round for Plenty, an agricultural tech company that promises to reshape farming by going vertical. Using IoT sensors and machine learning, Plenty claims its urban vertical farms can produce 350 times more vegetables than a conventional farm using 1 percent of the water.

Round Two

The spending spree continued into August.

The SoftBank Vision Fund led a $1.1 billion investment into a little-known biotechnology company called Roivant Sciences that goes dumpster diving for abandoned drugs and then creates subsidiaries around each therapy. For example, Axovant Sciences is devoted to neurology while Urovant focuses on urology. TechCrunch reports that Roivant is also creating a tech-focused subsidiary, called Datavant, that will use AI for drug discovery and other healthcare initiatives, such as designing clinical trials.

The AI angle may partly explain SoftBank’s interest in backing the biggest private placement in healthcare to date.

Also in August, SoftBank Vision Fund led a mix of $2.5 billion in primary and secondary capital investments into India’s largest private company in what was touted as the largest single investment in a private Indian company. Flipkart is an e-commerce company in the mold of Amazon.

The fund tacked on a $250 million investment round in August to Kabbage, an Atlanta-based startup in the alt-lending sector for small businesses. It ended big with a $4.4 billion investment into a co-working company called WeWork.

Betterment of Humanity

And those investments only include companies that SoftBank Vision Fund has backed directly.

SoftBank the company will offer—or has already turned over—previous investments to the Vision Fund in more than a half-dozen companies. Those assets include its shares in Nvidia, which produces chips for AI applications, and its first serious foray into autonomous driving with Nauto, a California startup that uses AI and high-tech cameras to retrofit vehicles to improve driving safety. The more miles the AI logs, the more it learns about safe and unsafe driving behaviors.

Other recent acquisitions, such as Boston Dynamics, a well-known US robotics company owned briefly by Google’s parent company Alphabet, will remain under the SoftBank Group umbrella for now.

This spending spree begs the question: What is the overall vision behind the SoftBank’s relentless pursuit of technology companies? A spokesperson for SoftBank told Singularity Hub that the “common thread among all of these companies is that they are creating the foundational platforms for the next stage of the information revolution.All of the companies, he adds, share SoftBank’s criteria of working toward “the betterment of humanity.”

While the SoftBank portfolio is diverse, from agtech to fintech to biotech, it’s obvious that SoftBank is betting on technologies that will connect the world in new and amazing ways. For instance, it wrote a $1 billion check last year in support of OneWeb, which aims to launch 900 satellites to bring internet to everyone on the planet. (It will also be turned over to the SoftBank Vision Fund.)

SoftBank also led a half-billion equity investment round earlier this year in a UK company called Improbable, which employs cloud-based distributed computing to create virtual worlds for gaming. The next step for the company is massive simulations of the real world that supports simultaneous users who can experience the same environment together(and another candidate for the SoftBank Vision Fund.)

Even something as seemingly low-tech as WeWork, which provides a desk or office in locations around the world, points toward a more connected planet.

In the end, the singularity is about bringing humanity together through technology. No one said it would be easy—or cheap.

Formerly the world’s only full-time journalist covering research in Antarctica, Peter became a freelance writer and digital nomad in 2015. Peter’s focus for the last decade has been on science journalism, but his interests and expertise include travel, outdoors, cycling, and Epicureanism (food and beer). Follow him at @poliepete.

Iowa Grocery Grows 10-15 lbs of Produce On Outdoor Vertical Garden – Every Week

Basil, lettuce, and mint flourish on the outdoor Grow Walls at Hy-Vee, installed by FFM in May this year. There’s no soil needed here: the plants are suspended in a growing medium made from recycled plastic bottles and grow in the sunlight.

Iowa Grocery Grows 10-15 lbs of Produce On Outdoor Vertical Garden – Every Week

under Agriculture, Eat & Drink, Features, Gardening and Plants, News

by Lacy Cooke

It doesn’t get much more local than this. In Davenport, Iowa, Hy-Veegrocery store commissioned Friday’s Fresh Market (FFM) to install and maintain two eight-tower Grow Walls, or hydroponic vertical gardens, on the outside of their store – which they then sell inside. Owner Andrew Freitag told Inhabitat they can obtain between 10 and 15 pounds of fresh produce every week, depending on the crop.

Basil, lettuce, and mint flourish on the outdoor Grow Walls at Hy-Vee, installed by FFM in May this year. There’s no soil needed here: the plants are suspended in a growing medium made from recycled plastic bottles and grow in the sunlight. FFM also installed a smaller Grow Wall inside the grocery store in the produce section. They maintain both systems, germinating seeds, transplanting, supplying nutrients and water, harvesting, and packaging the produce for sale in the store.

Related: Berlin grocery with vertical micro-farm reimagines the future of produce departments

FFM manager Chen Freitag told Inhabitat, “We see this disruptive technology becoming more and more popular in our future farming industry. It will help to improve the fresh food desert situation here in the Midwest tremendously and stimulate the local economy.”

The Grow Walls aren’t the only aspect of FFM’s business. They also cultivate indoor farms in shipping containers, using the same towers and irrigation system as a Grow Wall. Freitag said these farms consume around 90 percent less water than traditional methods, and since FFM can control the environment, produce grown inside the shipping container farms is more colorful and flavorful, with a higher nutrient content. She said FFM started pursuing hydroponics as a more efficient, sustainable way to grow fresh food, no matter the weather outside.

“Our goal is to improve the quality of life in our local communities,” Freitag told Inhabitat. “People here deserve to eat better, live better. We believe we are capable of being self-sufficient when it comes to fresh, local food year-round.”

One small Iowa company may not be able to change the entire agriculture industry right away; instead, Freitag said they focus on changing people’s daily lives with better food, and hope the industry evolves from there. “The earth is the resource account we cannot afford to overdraw,” she told Inhabitat. “We need to think about future generations: what we leave them to live with.”

Images via Lacy Cooke for Inhabitat

Future Farm To Double Size and Ramp Up Baltimore Vertical Farming Project With Second Location

SOURCE: Future Farm Technologies, Inc. | August 24, 2017 08:00 ET

Future Farm To Double Size and Ramp Up Baltimore Vertical Farming Project With Second Location

VANCOUVER, BC--(Marketwired - Aug 24, 2017) - Future Farm Technologies Inc. (the "Company" or "Future Farm") (CSE: FFT) (OTCQB: FFRMF) announces an update with respect to its Baltimore farm. As previously announced, Future Farm signed a LOI to lease 25,000-sq ft of commercial space from Volunteers of America ("VOA") Chesapeake to accommodate a vertical farm in Baltimore, MD, which will distribute high value healthy produce to local area retail stores, restaurants, institutional non-profits and other buyers. The Company is pleased to announce that the facility's design and budget are now complete and a second location will double the size of the project to almost 50,000-sq ft and speed up the development.

The Company expects to gain site control of the second location in Baltimore within the next 7-10 days. This particular site is more accommodating to the Company's controlled environment agriculture ("CEA") technology requirements and requires less construction build-out. It is expected that this second location will be operational sooner than the original location and will therefore become Phase 1 of the Baltimore project.

As previously announced, Craig Stanley and CBO Financial will act as the Company's financial advisor with respect to New Market Tax Credits (NMTC) and will be arranging for $5,000,000 in NMTC-based financing for each phase of the Baltimore farms. The NMTC program is a $65 billion federal program designed to incentivize private investment in low-income communities. NMTCs are provided to financial institutions in exchange for equity investments that eligible businesses can use to subsidize project development costs. CBO Financial helps driven organizations, such as Future Farm, to finance facilities that will provide goods and services that benefit populations in need and revitalize communities.

"We are pleased to be working with CBO Financial and Volunteers of America Chesapeake on these projects and believe that their success will be a bellwether for public-private partnerships within the urban farming industry," says Mr. William Gildea, Future Farm's CEO and Chairman. "Our goal was always to create impactful social and corporate programs that are mutually beneficial for all involved, from the community, to the Company and our shareholders. Partnering with Volunteers of America and CBO Financial puts us in the position to achieve that goal."

"This approach to urban agriculture and community development is truly visionary and we are proud to be involved with such a meaningful project," says Tony Azola, General Contractor for Volunteers of America.

The primary objectives of both farms remain the same -- establish economical and environmentally friendly vertical farms; provide job training opportunities (specifically to the VOA's reentry program for ex-offenders in Baltimore, MD) as well as to the local community; provide therapeutic programs, which will be expanded to the disabled population; support entrepreneurship development; and establish a model for replication at other reentry and social services facilities.

One of the primary objectives of the projects is to provide opportunities to develop therapeutic programs involving all aspects of planting, growing/nurturing, harvesting and selling plants. The American Horticultural Therapy Association (AHTA) defines "Horticultural Therapy" as the "engagement of a person in gardening and plant-based activities, facilitated by a trained therapist, to achieve specific therapeutic treatment goals." AHTA believes that Horticultural Therapy (HT) is an active process, which occurs in the context of an established treatment plan where the process itself is considered the therapeutic activity rather than the end product. The therapeutic benefits of garden environments have been documented since ancient times. Today, HT is accepted as a beneficial and effective therapeutic modality and is widely used within a broad range of rehabilitative, vocational, and community settings. HT helps improve memory, cognitive abilities, task initiation, language skills, and socialization. In physical rehabilitation, HT can help strengthen muscles and improve coordination, balance, and endurance. In vocational HT settings, people learn to work independently, problem solve, and follow directions.

For further information, contact William Gildea, Director, at 617.834.9467.

On behalf of the Board,

Future Farm Technologies Inc.

William Gildea, CEO & Chairman

About Future Farm

The Company's business model includes developing and acquiring technologies that will position it as a leader in the evolution of Controlled Environment Agriculture (CEA) for the global production of various types of plants. Future Farm provides scalable, indoor CEA systems that utilize minimal land, water and energy regardless of climate, location or time of year and are customized to grow an abundance of crops close to consumers, therefore minimizing food miles and its impact to the environment. The Company holds an exclusive, worldwide license to use a patented vertical farming technology that, when compared to traditional plant production methods, generate yields up to 10 times greater per square foot of land. The contained system provides many other benefits including seed to sale security, scalability, consistency due to year-round production, cost control, product safety and purity by eliminating environmental variability.

The Company is also in the business of designing and distributing LED lighting solutions utilizing the COB and MCOB technology. The Company is focused on delivering cost efficient lighting to North America via advanced e-commerce sites the Company owns and operates. LEDCanada.com which caters to B2B customers is a supplier of the newest and highest demand LED solutions. The Company also owns and operates COBGrowlights.com which caters to both large and small agriculture green houses and controlled cultivation centers.

Neither the Canadian Securities Exchange nor its Market Regulator (as that term is defined in the policies of the Canadian Securities Exchange) accepts responsibility for the adequacy or accuracy of this release. The Canadian Securities Exchange has not in any way passed upon the merits of the proposed transaction and has neither approved nor disapproved the contents of this press release.

This news release may include forward-looking statements that are subject to risks and uncertainties. All statements within, other than statements of historical fact, are to be considered forward looking. Although the Company believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance and actual results or developments may differ materially from those in forward-looking statements. Factors that could cause actual results to differ materially from those in forward-looking statements include market prices, exploitation and exploration successes, continued availability of capital and financing, and general economic, market or business conditions. There can be no assurances that such statements will prove accurate and, therefore, readers are advised to rely on their own evaluation of such uncertainties. We do not assume any obligation to update any forward-looking statements except as required under the applicable laws.

CONTACT INFORMATION

William Gildea

CEO & Chairman

617-834-9467

bill@futurefarmtech.com

Purdue Student Startup Advances Automated Device With App To Grow Fresh Produce In home Hydroponic Appliance

August 24, 2017

Purdue Student Startup Advances Automated Device With App To Grow Fresh Produce In home Hydroponic Appliance

Scott Massey (left) and John Kissel (right) discuss two different grow-pods in front of their innovative hydroponic appliance called the Alpha III Pod. Massey founded Hydro Grow LLC to design and sell hydroponic, in-home appliances that produce fruits and vegetables. Their newest model, Alpha III Pod, incorporates advanced machine learning algorithms to create an ideal nutrient wash for each of the grow-pod’s plants. (Shannon Kane / Purdue Research Foundation image) Download image

WEST LAFAYETTE, Ind. – Purdue University students who developed an automated device to grow vegetables in consumer’s home have started a company to commercialize their technology and develop an improved third model.

Scott Massey and Ivan Ball, recent graduates of Purdue’s Polytechnic Institute, originally inspired by NASA-funded research into self-sufficient plant life systems, co-founded the company Hydro Grow LLC to commercialize their appliance. Others on the Hydro Grow team are James Carlson, a junior in the Department of Computer Science; and John Kissel, a past student of the Krannert School of Management.

Hydro Grow’s technology offers the Gropod, a self-sustainable refrigerator-sized unit capable of growing fresh produce in a consumer’s home. The system uses advanced machine learning algorithms, which allows the device to be aware of what plants are growing in it and adapt its environmental conditions to the specific preferences of that plant. After several prototypes, the company is developing an Alpha 3 model with improved functionality and a corresponding app.

Massey said the company’s mission is to eliminate consumer’s dependence on grocery stores.

“By 2050 the population is expected to grow to nearly 9 billion people, doubling the world’s food demand and water consumption,” he said. “Additionally, food deserts affect 23.5 million people in the United States. Half of these people are also low-income so if poorer communities do not have access to fresh produce, they are more likely to have health complications and additional expenses.”

Hydro Grow offers two services — a hydroponic appliance capable of growing produce, and seed pods from which the produce grows.

The Alpha 3 model is controlled by a user with the Hydro Grow app. The company will make the new model available to 10 to 30 early adopters.

“Users will be able to order the seed pods of their choice via our phone app, plug the seed pod into their system, update the phone application, and let the produce grow until it’s ready to harvest,” Ball said. “Users can remotely monitor the production of produce within each unit. The system will also have a clean cycle every few months that is activated via the phone application.”

Kissel said the company’s priority is to make the appliance as affordable as possible.

“Our most important goal is reducing the cost of the unit to make it a more sensible investment for most consumers,” he said. “Our system not only fills a need but can also help people who may have small gardens, by providing an alternative that produces 95 percent less waste and grows two to three times faster. Our feedback has been that people are ready for this product.”

A short video about Hydro Grow can be viewed at https://youtu.be/KE-nEQXHn0E.

Hydro Grow hopes to advance its technology as the company moves into its next stages of commercialization.

“We are progressing toward a robust system that can achieve optimal growth rates with the least amount of components and user maintenance,” Carlson said. “We hope to identify plastic or electrical manufacturing partners, with competitive pricing. We’re also working on a software development campaign to facilitate seedling orders on a ‘smart’ platform.”

Hydro Grow has raised over $80,000 through competitions to advance its technology. Hydro Grow hopes to collaborate with hydroponic nurseries in major cities to create and distribute seedpods. The company is also seeking investment funding.

“We’re actively looking for funding to achieve a full-scale commercial launch with our original equipment manufacturer. We hope to accomplish this launch by 2018,” Massey said. “We also are interested in taking on interns as the Hydro Grow’s business rapidly expands.”

About Purdue Foundry

The Purdue Foundry is an entrepreneurship and commercialization accelerator in Discovery Park's Burton D. Morgan Center for Entrepreneurship whose professionals help Purdue innovators create startups. Managed by the Purdue Research Foundation, the Purdue Foundry was named a top recipient at the 2016 Innovation and Economic Prosperity Universities Designation and Awards Program by the Association of Public and Land-grant Universities for its work in entrepreneurship. For more information about funding and investment opportunities in startups based on a Purdue innovation, contact the Purdue Foundry at foundry@prf.org.

Writer: Kelsey Henry, 765-588-3342, kehenry@prf.org

Purdue Research Foundation Contact: Hillary Henry, 765-588-3586, hkhenry@prf.org

Sources: Scott Massey, scott@hydrogrowllc.com

Ivan Ball, ivan@hydrogrowllc.com

Up On The Farm: Ambitious Urban Agriculture In The City’s Hilltop

Up On The Farm: Ambitious Urban Agriculture In The City’s Hilltop

Pittsburgh Post-Gazette | AUG 27, 2017

Eight years ago, the remaining residents of St. Clair Village were mourning the loss of their homes, which the Housing Authority of the City of Pittsburgh had decided to demolish. Now, in a transformation that may be symbolic of the new Pittsburgh, the neighborhood is being reborn as the Hilltop Urban Farm.

No one should minimize the loss and the controversy that accompanied the closing of the apartment complex that once housed 1,000 families. In 2005, the authority razed more than half of the units, and the remaining units were in a state of disrepair. The authority decided to close the community, citing a study that indicated it would cost $27 million to upgrade and maintain the buildings. Residents were displaced, and the supply of affordable housing was reduced.

Now 23 acres of the site are in the early stages of becoming one of the largest urban farms in the country. The nonprofit Hilltop Alliance, with many partners, is spearheading the plan that includes community-supported agriculture, an orchard, a farm market, an education center, greenhouses, storm-water ponds, and community garden plots.

The Hilltop Alliance has conducted a careful planning process lasting more than four years. It involved feasibility work by agriculture experts at Penn State University and discussions with community members. Churches and youth-serving organizations have expressed hope that the development will give neighborhood youth a positive outlet for their energy and a way to earn some money.

Across the nation, urban agriculture is on the rise, with attendant challenges. While Detroit has made great strides, there has been controversy about the proper use of land that is near public transportation and which may be appropriate for housing. Pittsburgh seems to be avoiding these problems, since city council passed an urban agriculture ordinance in 2011 and has monitored progress since then.

The preparation of the soil at the Hilltop Urban Farm has begun, and an abandoned property will literally bear fruit in the coming years.

The Hilltop Urban Farm Report

Best Viewed In Full Screen

Solar-Powered Bike Sharing Farm Is A Mobile Community Garden For The City (Video)

Bike Share Farm has been made with mobility in mind. Using off-the-shelf components, a portable hydroponic system with a series of zigzagging tubes forms a frame into which two different bikes can be slotted as the mobile garden travels from place to place. The hydroponic system's irrigation mechanisms are powered by a series of photovoltaic panels.

Solar-Powered Bike Sharing Farm Is A Mobile Community Garden For The City (Video)

Kimberley Mok (@kimberleymok)

Design / Urban Design

August 17, 2017

© People’s Industrial Design Office

Our long love for the bicycle extends beyond the two-wheeler itself, spilling over into bike-powered inventions, electricity-generating gyms, even whole buildings designed around the bike.

Seen over at Designboom and created by the People’s Industrial Design Office -- the design arm of Beijing firm People’s Architecture Office -- during a three-day design hackathon in Seoul, South Korea, the Bike Share Farm is a solar-powered and bike-propelled mobile hydroponic garden, inspired by the bike sharing concept. The idea was to bring plant life to the citizenry, the designers say:

Seoul is a massive vertical city with minimal garden space. Mobile farms can make shared urban farming possible in such a dense megacity.

Bike Share Farm has been made with mobility in mind. Using off-the-shelf components, a portable hydroponic system with a series of zigzagging tubes forms a frame into which two different bikes can be slotted as the mobile garden travels from place to place. The hydroponic system's irrigation mechanisms are powered by a series of photovoltaic panels.

The Bike Share Farm is a prototype attempts to tackle the issues highlighted during the hackathon of how to "[share an] eco-city with technology." While there may be finer details to work out (such as factoring in how long it will take the plants to mature before harvesting), one could almost imagine a mobile garden like this bringing 'instant' fresh green produce to food deserts or neighbourhoods lacking community gardens. An intriguing idea as well as a powerful symbol of food security and human-powered mobility; see more over at People’s Industrial Design Office.

Hydroponic Farming To Be Tested In Cambodia

August 25, 2017

Hydroponic Farming To Be Tested In Cambodia

Sok Chan / Khmer Times Share:

Japanese company Asian Gateway (Cambodia) will soon conduct a pilot project with a hydroponic farm in Cambodia.

It will be tested at the Royal University of Agriculture (Chamkar Dong campus) in the first stage and after that will be used as a model for farmers and the private sector to implement across the whole nation.

Asian Gateway’s president and founder, Tomonori Kimura, said at a meeting with Agriculture Minister Veng Sakhon on Wednesday that the hydroponic farm will be done in cooperation with the Royal University of Agriculture in Cambodia.

He said Asian Gateway specialised in infrastructure development and maintenance technology to integrate environmentally friendly technology.

He added that the pilot project will soon start and introduce new technology to a hydroponic farm to produce vegetables to supply local markets. He said his company will do research and study the market for hydroponically grown produce.

The project will study how to reduce the costs of production through technology and it will not use chemicals on the vegetables, which it aims to produce safely to target middle income earners.

“It is an indoor farm which will be using solar energy that can manage the temperature and humidity and it will not be a concern if there is not too much rain, drought or disease,” Mr. Kimura said.

Agriculture Minister Mr Sakhon, told Mr Kimura that Cambodian people, particularly urban people, are interested in safety food and chemical free vegetables. He said he hoped the hydroponic farm could be started soon and it could expand and transfer the technology to the provinces.

He added that he wants the farm to produce safe food to supply local market demand and reduce the reliance on imports and asked the company to cooperate with the Royal University of Agriculture on the project.

Ngo Bunthan, the rector of the Royal University of Agriculture, told Khmer Times that no exact date has been set to implement the pilot project, but it will start soon at the university, which researches and teaches people about farming.

“We have not yet finalised the date as we are preparing the plan. It is new to Cambodia and we will study how we can apply it in Cambodia and benefit our people,” Mr Bunthan said.

“It [hydroponic farming] does not depend on the climate, and though rain or drought, we still can produce vegetables,” he added. “If the project succeeds, private companies and farmers can take that model and use it.”

He said the purpose of the project was to find the technology to apply to the indoor farm to grow vegetables at a low price which are safe for people.

Kean Sophea, the deputy director of the department of horticulture and subsidiary crops at the Ministry of Agriculture, welcomed the company’s move, saying it is part of the government’s aim to boost the supply of local vegetables on the market.

He added that Cambodia has not experienced hydroponic farming. However, he said hydroponic farming is good as it could rotate the growing period for the whole year with the products fetching competitive prices.

“Hydroponic farming can be done everywhere as it is done indoors,” Mr Sophea said. “If a hydroponic farm is large, it could contribute to the supply of vegetables in Cambodia’s markets.”

He said Cambodia imports 300 to 400 tonnes of vegetables per day from neighbouring countries.

Mobile Greenhouse Showcases Ontario's Indoor Crops

Mobile Greenhouse Showcases Ontario's Indoor Crops

By Andrew Coppolino, CBC News Posted: Aug 26, 2017 7:00 AM ET Last Updated: Aug 26, 2017 7:00 AM ET

NatureFresh Farms mobile greenhouse travels the U.S. and Canada promoting the commercial greenhouse crops industry. (NatureFresh Farms)

Andrew Coppolino

Food columnist, CBC Kitchener-Waterloo

Andrew Coppolino is a food columnist for CBC Radio in Waterloo Region. He was formerly restaurant reviewer with The Waterloo Region Record. He also contributes to Culinary Trends and Restaurant Report magazines in the U.S. and is the co-author of Cooking with Shakespeare. A couple of years of cooking as an apprentice chef in a restaurant kitchen helped him decide he wanted to work with food from the other side of the stove.

This summer, a mobile squad of cucumbers, tomatoes and green peppers have been travelling throughout Ontario and the United States with the objective of teaching the general public about greenhouse produce.

The one-of-a-kind roaming Greenhouse Education Centre is an initiative of NatureFresh, a Leamington, Ont., produce company that started in the greenhouse growing business in 1999.

Travelling from April to September, the educational unit – a 38-ft. trailer towed by a truck – is essentially a miniature version of a regular greenhouse. It's got a busy schedule of over 100 dates that showcase how produce is grown.

Though you've likely eaten more greenhouse produce than you might know, the balance of produce in Ontario is still grown outside.

For example, according to the Ministry of Agriculture, Food and Rural Affairs and the Ontario Greenhouse Vegetable Growers, in total in Ontario there are about 14,000 acres of tomatoes grown in fields, compared to approximately 1,000 acres of tomatoes grown in greenhouses.

Industry is growing

Greenhouse produce is, however, a growing industry, says Herman Fehr, manager of the NatureFresh mobile greenhouse.

"A lot of produce in grocery stores is greenhouse-grown, especially in the winter. It's an efficient way to grow. With the mobile education centre, people can see the full process of greenhouse growing from start to finish," Fehr said.

The mobile greenhouse has been in operation for three years and visits retail food outlets, summer camps and schools.

The company grows varieties of bell peppers, cucumbers and tomatoes in about 130 acres of greenhouses in Leamington, with 45 acres of tomato greenhouses in Delta, Ohio. The company is one of the largest greenhouse bell pepper growers in North America.

Sunset Produce, located in Kingsville, Ont., is another major greenhouse grower and has been around for six decades. In Waterloo region, Elmira's Own grows vine-ripened greenhouse tomatoes.

High yields, more energy, short distance

As a farming method, greenhouse production can yield as much as 14 times more tomatoes than conventional farming.

The closed-loop growing system of greenhouse facilities (demonstrated in the NatureFresh mobile greenhouse) saves water and requires less fertilizer and pesticides. They grow produce in a modified hydroponic system of recycled coconut fibre, and the mobile facility also has a bumblebee ecosystem, pollinators being an important – and at-risk – component to the growing cycle.

Compared to the five-month growing season of conventional farming, greenhouses have a stable environment that allows the producer to control the temperature and protect plants from harsh precipitation and damaging insects. It is a labour and energy intense process; however, the yields and quality of produce are also high, and transportation to local markets are shorter – much shorter than produce that travels here from the Central Valley of California.

More and more "indoor farms" are popping up in Europe and North America as communities face increasing numbers of retiring farmers, shrinking farmland, increasing costs, depleting soil and changing weather patterns. In Newark, New Jersey, AeroFarms, a "vertical farm," opened in an abandoned urban steel mill in 2015 and produces more than 1,000 tons of greens annually from its 70,000 sq.-ft. operation.

Food security

Whether greenhouse goods are the result of farming or "manufacturing," the reality is that we need to produce a lot of food as securely and inexpensively as possible, as populations continue to grow around the world.

Consumers get the benefit of a year-long supply of local produce grown by Ontario companies. Some of the input costs aside, the greenhouse environment is "a much more efficient way to grow," that gives customers good quality produce and minimizes the variables of what conventional farming faces, said Fehr.

"In a field, you're exposed to disease and pests and general environmental factors that a greenhouse grower really doesn't have to worry about."

You can visit the NatureFresh mobile greenhouse at Zehrs at 450 Erb Street West, Waterloo on Saturday, August 26, from 10 a.m. to 6 p.m. There's more information available at www.naturefresh.ca.

Philips Lighting Signs New Horticultural LED Lighting Project With Longtime Partner Wim Peters

In total, Philips Lighting will install over 26,000 GreenPower LED interlighting modules in the two rebuilt greenhouses and the greenhouse that is scheduled to be built in October 2017.

Philips Lighting Signs New Horticultural LED Lighting Project With Longtime Partner Wim Peters

August 24, 2017

Wim Peters rebuilds two greenhouses after hail storm and chooses for GreenPower LED interlighting

The higher light level gives him more uniform production in winter and better quality and taste

Eindhoven, The Netherlands – Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting, today announced it has been awarded a new project with longtime partner Wim Peters, one of the largest high wire tomato growers in The Netherlands. Philips Lighting will again provide Peters with LED lighting for two greenhouses that he’s rebuilding after they were destroyed during a hailstorm in June 2016. The company will also provide LEDs for one new greenhouse that Peters is building to expand his business and meet the growing demand for LED grown tomatoes by his customers. The LED lighting will have higher light levels than the twenty kilometers of LED grow lights that Philips Lighting installed in the two greenhouses in 2013.

Higher light levels

Over the last 10 years, light levels in tomato cultivation (actually all vegetables) have continued to rise. In his previous installation, Peters had a light level of 55 µmol/m²/s LED interlighting. With the new project, he chose for 75 µmol/m²/s LED interlighting, a significant increase in light level. “A higher light level gives me more uniform production in winter and better quality and taste,” Peters said. “It also gives me a better balance between vegetative and generative phases, so leaf versus production.”

“This is in line with the trend we are seeing from other tomato growers who want to go to higher light levels,” said Udo van Slooten, Managing Director of Philips Horticulture LED Solutions. “To meet this demand, we launched the new Philips GreenPower LED interlighting module earlier this year with a system efficacy of up to 3.0 µmol/J. The modules are easier to install and maintain, bringing the total cost of project installation down significantly.” Several other Belgian, Russian and French tomato growers have recently moved to higher light levels as well.

Over 26,000 GreenPower LED interlighting modules

In total, Philips Lighting will install over 26,000 GreenPower LED interlighting modules in the two rebuilt greenhouses and the greenhouse that is scheduled to be built in October 2017. The new hybrid lighting installation combines HPS toplighting with Philips GreenPower LED interlighting High Output, spanning a total area of 10.6 hectare. The entire lighting installation will be installed by Philips Lighting’s Horti LED partner Codema B-E de Lier, who has been working with Horti LED partner Agrolux to come up with the best hybrid lighting system for the customer.

For further information, please contact:

Daniela Damoiseaux, Global Marcom Manager

Philips Horticulture LED Solutions, Nederland

E-mail: daniela.damoiseaux@philips.com

www.philips.com/horti

About Philips Lighting

Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting products, systems and services, delivers innovations that unlock business value, providing rich user experiences that help improve lives. Serving professional and consumer markets, we lead the industry in leveraging the Internet of Things to transform homes, buildings and urban spaces. With 2016 sales of EUR 7.1 billion, we have approximately 34,000 employees in over 70 countries. News from Philips Lighting is located at the Newsroom, Twitter and LinkedIn. Information for investors can be found on the Investor Relations page.

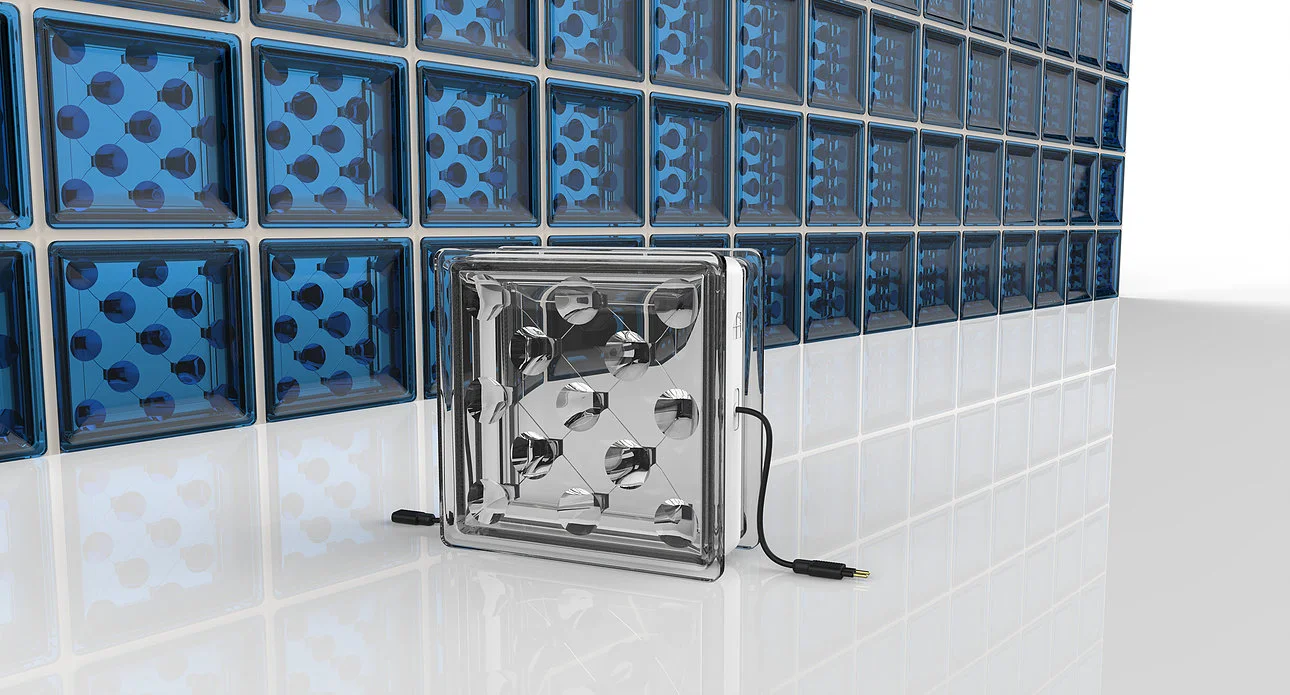

Buildings To Generate Their Own Power With Innovative Glass Blocks

News | August 15, 2017

Buildings To Generate Their Own Power With Innovative Glass Blocks

Buildings could soon be able to convert the sun’s energy into electricity without the need for solar panels, thanks to innovative new technology.

Image courtesy of Solar Squared

Buildings could soon be able to convert the sun's energy into electricity without the need for solar panels, thanks to innovative new technology.

Renewable Energy experts from the University of Exeter are developing a pioneering new technique that could accelerate the widespread introduction of net-zero energy buildings through the latest Building Integrated Photovoltaics (BIPV).

These products, similar to the solar tile created by Tesla, can become a part of a building’s architecture to generate electricity. The team have created an innovative glass block, which can be incorporated into the fabric of a building and is designed to collect solar energy and convert it to electricity.

It is thought that buildings consume more than forty percent of the electricity produced across the globe. This new technology would allow electricity to be produced at the site of use, whilst being seamlessly integrated into the building.

The blocks, called Solar Squared, are designed to fit seamlessly into either new buildings, or as part of renovations in existing properties. They are similar to existing glass blocks by allowing daylight to resonate around a property by replacing traditional bricks and mortar with transparent glass bricks.

Crucially, however, the Solar Squared blocks have intelligent optics that focus the incoming solar radiation onto small solar cells, enhancing the overall energy generated by each solar cell. The electricity generated will then be available to power the building, be stored or used to charge electric vehicles.

The Exeter team, which has created a start-up company Build Solar to market and produce the pioneering product, is now looking to encourage investment to carry out commercial testing of the product, and then aims to take it to market in 2018.

Dr Hasan Baig, founder of Build Solar and Research Fellow from the University of Exeter’s Environment and Sustainability Institute said: “BIPV is a growing industry with a 16% annual growth rate. Setting up a company, which can cater to this growing market shall prove beneficial for the UK economy in the long term.”

“We are aiming to build integrated, affordable, efficient and attractive solar technologies, which have the smallest impact on the local landscape. It’s an exciting venture and one that should capture the imagination of the construction industry, when looking to develop new office blocks and public buildings or infrastructure projects such as train stations and carparks,” said Professor Tapas Mallick, chief scientific advisor for Build Solar.

The Build Solar team believe their blocks have better thermal insulation than traditional glass blocks, as well as providing power to the building. The patent pending technology is at prototype stage and the team are now in the process of fine-tuning their designs in order to test the technology at pilot sites.

Co-inventor and Exeter’s research commercialisation manager in Cornwall, Jim Williams, believes that the timing of the technology is favourable. “It’s now clear that the world is moving to a distributed energy system, of which a growing proportion is renewable. This, coupled with the shift to electric vehicles means that there are substantial opportunities for new ways of generating electricity at the point of use”.

For more information about, visit www.buildsolar.co.uk.

New Downtown Dallas Restaurant Will Devote Entire Room To Indoor Farm

New Downtown Dallas Restaurant Will Devote Entire Room To Indoor Farm

By Teresa Gubbins - 8.25.17

This is the kind of setup they'll have at Bullion. Photo courtesy of Dallas Urban Farms

The new downtown Dallas restaurant Bullion, from former Mansion on Turtle Creek chef Bruno Davaillon, opens in October with a feature you won't find at other restaurants in town: an indoor farm.

Bullion is opening at 400 S. Record St. in downtown Dallas, in the former Belo Building, which is being given a massive upgrade by the Hartland-Mackie family, with a new lobby, sky garden, fitness center, and conference center.

Bruno has partnered with Dallas Urban Farms owners Jody and Max Wall to install an indoor vertical farm where he will hydroponically grow herbs, vegetables, and lettuces to service the restaurant. Bullion is the first Dallas restaurant to grow plants from seedlings on the property.

[Read More →]

Beyond the Hype: AI in Agtech

Beyond the Hype: AI in Agtech

Google “AI in agriculture” right now and you’ll see tons of articles about startups raising money, established big players wading into the space, and the occasional bovine artificial insemination article (we’re in ag after all).

AI is hot. And rightfully so. Agriculture is a low-margin, labor intensive industry. Technology can help farmers increase margins and decrease operational risk (crop loss, disease, food safety, pests, etc.). AI becomes increasingly exciting as we think about feeding our growing global population in more sustainable ways.

With a lot of attention, comes a lot of hype. We’ve been focused on using data to automate farming workflow since early 2015. Building good algorithms isn’t easy. You have to collect the right data points, reach data saturation, understand how the past influences the future, and know what your user’s primary objectives are throughout their workflow.

The stages of AI from least automated to fully automated.

Agrilyst has always been focused on one thing: helping growers increase profits significantly.

To do this, we have a few theses:

Data related to one function alone isn’t going to move the needle. I think it’s great that there are companies improving sensing technologies for smarter climate control. But better climate control isn’t going to push farms past profitability. I think it’s great that companies are creating algorithms to predict disease in crops using imaging. But imaging without climate and nutrient data isn’t going to be the most accurate predictor.

Indoor farming is the best application for AI in ag. There are over 6 million greenhouse growers around the world growing shorter cycle crops than commodity crops. That’s a massive data set. If a corn farmer has 40 chances in their lifetime to apply data to increase yields, an indoor lettuce grower might have 40 chances in 40 days if they’re planting and harvesting on a daily basis. It’s a faster and more consistent data set. Plus because growers are controlling their environment the controllable inputs are variables in an equation as opposed to uncontrollable factors.

Always build value. Our customers are farmers. They’re not cheap. They’re not tech-averse. They’re building a business on incredibly low margins. So technology has to work for them. No exceptions. AI for AI’s sake is not going to work in agriculture. Everything we build serves a specific value-added purpose for our customers — always.

How does Agrilyst collect data?

Agrilyst is a workflow management system. We’re focused on using data to automate the non-mechanical processes on a farm. Processes like production planning, crop scheduling, quality optimization, risk management (disease, pest, crop success), labor planning, sales, and inventory management all fall into our domain. We don’t make hardware and we’re not focused on automating processes that can be replaced by machines, like seeding, harvesting, processing, and packaging.

Our software is a critical part of running daily operations on a farm. Growers use Agrilyst to track crops from seed to harvest, store yield data, track pests, record nutrient metrics, and more. All of this user-generated data makes up the core of our data set.

Agrilyst’s data flywheel

We also have an open API to connect to any device a grower has on their farm. Growers who have sensors, climate control systems, nutrient dosing systems, or connected lighting can connect to Agrilyst through the API for real-time data collection.

All of this data combines to build a proprietary network of data that strengthens as it interacts.

Descriptive Analytics — What happened?

The first step in building an AI-driven workflow is digitizing all of the manual data collection processes our users used to write down on paper (thesis point: data related to one function alone isn’t going to move the needle).

That all starts with growth cycles in Agrilyst. Production planning used to take hours out of a grower’s day. Now growers drag and drop stages of a plant’s lifecycle into a template and then tell the system how often the template should repeat. This saves growers an average of 1 hour and 15 mins per week in manual work (thesis point: always build value).

We use this data as the foundation for showing growers what’s going on in their farm. In Agrilyst’s dashboard and with reporting tools, growers can drill down into their operational data to understand what is going on at all times.

Visual of a grower’s water metrics.

Diagnostic Analytics — Why did it happen?

The next step is using the foundational data to understand why something happened. This is what drives the training for algorithms and helps us get to the next step: predicting what’s going to happen.

Let’s say a grower sees a decrease in yield. We want to know why that happened. If the pH for a lettuce crop falls beyond the accepted range of 6–6.5, certain nutrients become unavailable to the plants. A common thing for our growers to analyze is pH trends against yield to see if this is the root cause for changes in yield.

Predictive Analytics — What could happen?

Now comes the fun stuff. At data saturation, roughly a few million harvest data points for us, our algorithms start to look forward to the future. How are crops going to perform? What factors are going to impact performance the most? How is space going to be utilized months out in the future? Do we have enough space to meet sales demands in the winter and summer? All of these questions are able to be answered once a system understands how the plants grow and all of the variables that affect that growth. Our most utilized algorithm is our yield forecast, which helps growers understand their expected harvest yield 30-days in advance at 90% accuracy.

Prescriptive Analytics — What should happen?

All of this leads to providing growers with recommendations. If I break down production planning into it’s variable inputs, you have:

- Crop selection (what crops are you growing?)

- Crop growth rate (how fast does it grow?)

- Growing area (how much space do I allocate to my crop?)

- Climate

- Nutrients

- Customer needs (how much am I selling, to whom, when?)

Once you have those pieces, you can create a production plan pretty easily. If I know Whole Foods needs 100 pounds of kale in 30 days and that kale in my system takes about 30 days to grow at roughly 1 pound per square foot, I’ll seed enough to fill 100 square feet of space today. And that’s how production planning happens today (without tech).

With Agrilyst, growers can understand which of their crops are the highest performers based on yield, growth rate, or both and run production scenarios with higher performers having more space allocation. These recommendations help growers optimize the space on their farm and drive significantly higher revenues.

Cognitive Analytics — Make it happen.

Here’s where the real magic happens. Because Agrilyst is focused on automating all processes that rely on human decision-making and are non-mechanical, we’re primarily focused on three operational areas: production management, inventory supply, and marketplaces.

Over the next few months, we’re going to be introducing the next component of our production management tool, moving from prescription to automation. We’re using machine vision to determine actual growth rates and germination rates. By feeding these rates into the production planning, growers won’t have to create growth cycles manually. The production plans will adjust based on seasonality and climate conditions on their own, with a focus on optimizing yields among crop selection. That means we can fully automate the planning component of farming.

What’s Next?

One of the biggest struggles for indoor farm operators is ensuring stable sales supply. We’re building a data set of market demand by primary buyers to help growers understand real-time demand. We’re focused on creating the marketplace for stable local purchasing.

We’re also focused on automating inventory control. Using AI, we can predict when growers are running low on various consumables and automate purchasing processes.

Agrilyst is the virtual agronomist powering the horticulture industry. We invite you to join the #DigitalHorticulture movement on social media and share your stories of farm innovation.

If you enjoyed this story, tune in for more here and be sure to check out our website: www.agrilyst.com.

Bowery Farming Receives VC boost From Google, Others

Bowery Farming Receives VC boost From Google, Others

Jun 14, 2017, 1:31pm EDT Updated Jun 14, 2017, 3:17pm EDT

Anthony Noto | ReporterNew York Business Journal

In Feb. 2017, Bowery raised… more

COURTESY OF BOWERY

Irving Fain, CEO and… more

Bowery Farming Inc., the company known for growing the world’s first post-organic produce indoors, raised $20 million in new funding from General Catalyst and GGV Capital.

GV, or Google Ventures (NASDAQ: GOOG), also participated in the effort.

Bowery Farms is the innovator behind the scalable indoor vegetation system that can be… more

Prior to this round, Bowery Farming raised $7.5 million.

Previous investors include First Round Capital, Box Group, Lerer Hippeau Ventures, SV Angel, Homebrew, Flybridge, Red Swan, RRE, and Urban.us. Blue Apron founder and CEO Matt Salzberg, Plated chair Sally Robling, Gramercy Tavern co-founder Tom Colicchio and DigInn CEO Adam Eskin were also involved as angel investors.

To learn more about the new funding round and the current state of Bowery's produce business, we reached out to 37-year-old co-founder and CEO Irving Fain.

Here's what the Manhattan-based entrepreneur had to say:

How has the company expanded over the past couple years?

We raised our seed round in 2015. In a little over two years, we’ve assembled an incredible team of experts passionate about the problem we’re solving, developed BoweryOS — our proprietary software platform — from the ground up, and built a fully operational farm eight miles outside of New York City that supplies restaurants and grocery stores throughout the region. We are proud of what we’ve been able to accomplish so far, but there’s a lot more we want to accomplish.

Why is this funding round for Bowery Farming important?

This round will allow us to expand our operations, continue to innovate and invest in our proprietary technology, and hire world-class employees across the organization. We’re in the process of expanding our partnership with Whole Foods (NASDAQ: WFM) to serve more locations throughout the Tri-state area, and have already begun work on our next farm, which will allow us to deliver the freshest, purest produce to more people in urban areas.

We’re also actively hiring across the organization from engineering to agricultural science and business operations. It’s a great time to join our team!

Where can Bowery's produce be purchased?