Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Buildings To Generate Their Own Power With Innovative Glass Blocks

News | August 15, 2017

Buildings To Generate Their Own Power With Innovative Glass Blocks

Buildings could soon be able to convert the sun’s energy into electricity without the need for solar panels, thanks to innovative new technology.

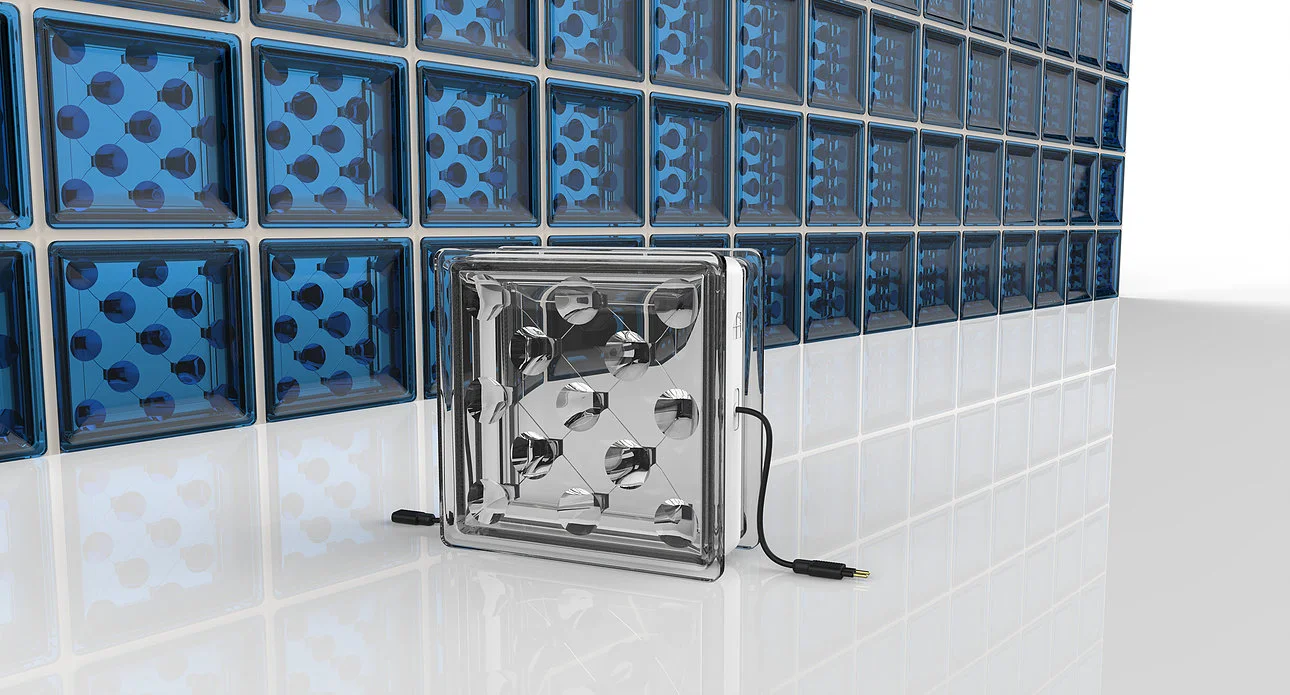

Image courtesy of Solar Squared

Buildings could soon be able to convert the sun's energy into electricity without the need for solar panels, thanks to innovative new technology.

Renewable Energy experts from the University of Exeter are developing a pioneering new technique that could accelerate the widespread introduction of net-zero energy buildings through the latest Building Integrated Photovoltaics (BIPV).

These products, similar to the solar tile created by Tesla, can become a part of a building’s architecture to generate electricity. The team have created an innovative glass block, which can be incorporated into the fabric of a building and is designed to collect solar energy and convert it to electricity.

It is thought that buildings consume more than forty percent of the electricity produced across the globe. This new technology would allow electricity to be produced at the site of use, whilst being seamlessly integrated into the building.

The blocks, called Solar Squared, are designed to fit seamlessly into either new buildings, or as part of renovations in existing properties. They are similar to existing glass blocks by allowing daylight to resonate around a property by replacing traditional bricks and mortar with transparent glass bricks.

Crucially, however, the Solar Squared blocks have intelligent optics that focus the incoming solar radiation onto small solar cells, enhancing the overall energy generated by each solar cell. The electricity generated will then be available to power the building, be stored or used to charge electric vehicles.

The Exeter team, which has created a start-up company Build Solar to market and produce the pioneering product, is now looking to encourage investment to carry out commercial testing of the product, and then aims to take it to market in 2018.

Dr Hasan Baig, founder of Build Solar and Research Fellow from the University of Exeter’s Environment and Sustainability Institute said: “BIPV is a growing industry with a 16% annual growth rate. Setting up a company, which can cater to this growing market shall prove beneficial for the UK economy in the long term.”

“We are aiming to build integrated, affordable, efficient and attractive solar technologies, which have the smallest impact on the local landscape. It’s an exciting venture and one that should capture the imagination of the construction industry, when looking to develop new office blocks and public buildings or infrastructure projects such as train stations and carparks,” said Professor Tapas Mallick, chief scientific advisor for Build Solar.

The Build Solar team believe their blocks have better thermal insulation than traditional glass blocks, as well as providing power to the building. The patent pending technology is at prototype stage and the team are now in the process of fine-tuning their designs in order to test the technology at pilot sites.

Co-inventor and Exeter’s research commercialisation manager in Cornwall, Jim Williams, believes that the timing of the technology is favourable. “It’s now clear that the world is moving to a distributed energy system, of which a growing proportion is renewable. This, coupled with the shift to electric vehicles means that there are substantial opportunities for new ways of generating electricity at the point of use”.

For more information about, visit www.buildsolar.co.uk.

PIDO's Bike Share Farm Is A Community Garden That Can Be Pedalled From Place To Place

The hydroponic farm consists of a triangular steel framework supported by a pair of bikes. Pipes run across the metal base, with holes for pot plants to slot into. A set of solar panels are fastened onto the structure to power a pump that runs water through the entire system

PIDO's Bike Share Farm Is A Community Garden That Can Be Pedalled From Place To Place

Emma Tucker | 6 August 2017 Leave a comment

Beijing architecture firm People's Industrial Design Office has designed a mobile farm that lets the community share responsibility for crops' wellbeing.

Bike Share Farm – which was created and built by People's Industrial Design Office(PIDO) during a 72-hour hackathon in Seoul, South Korea – addresses the lack of space many major cities suffer from, particularly when it comes to room for growing produce.

The hydroponic farm consists of a triangular steel framework supported by a pair of bikes. Pipes run across the metal base, with holes for pot plants to slot into. A set of solar panels are fastened onto the structure to power a pump that runs water through the entire system.

The frame allows for bikes to be easily exchanged, so that a new cyclist can take responsibility for the farm at each stop. The system is designed to encourage a whole community to take part in farming, and offer more people the chance to get involved.

"Urban gardens are now common in many cities but few have access to them," PIDO co-founder James Shen told Dezeen. "The Bike Share Farm marries the bike share model with urban farming. A vertical and mobile farm addresses the land constraints found in dense cities like Seoul and Beijing."

According to Shen, the structure is light enough to be lifted by two people and is easy to control and steer.

"We imagine people would ride to a Bike Share Farm location, hook on their bikes and take it to a convenient location," he added. "This would allow large numbers of Bike Share Farms to spread throughout the city."

The studio is currently working on demonstrating the design with larger numbers of vehicles.

As cities with limited space continue to build upwards, new approaches to farming are being created by designers keen to introduce greenery. These include a vertical farm that would produce food amid Shanghai's skyscrapers and a floating "food forest" that would occupy a barge on New York's waterways.

A Small Missouri Company Has Big Plans For Idle Elevators To Serve As Vertical Farms

A Small Missouri Company Has Big Plans For Idle Elevators To Serve As Vertical Farms

August 7, 2017

Vertical Innovations’ first vertical farm is planned for this elevator. Photos courtesy of Vertical Innovations.

By Ronald Ahrens

Jim Kerns and David Geisler called up the other day from Springfield, Missouri, to ask a question of our readers: Are you aware of any municipally owned, abandoned grain elevators?

Kerns and Geisler run Vertical Innovations, an enterprise formed in December of 2014 to repurpose old elevators, making them into incredibly productive vertical farms for growing leafy green vegetables. They have developed a patent-pending method of hydroponic production, a “structure-driven design” that adapts to the circular shapes.

“The silos tell us what to do,” said Kerns, who has a background in organic farming and leads the company’s innovation, design and construction efforts. “I see them as giant environmental control structures, giant concrete radiators.”

Significant energy savings can result from implementation of circular shapes, which among other things require far less lighting and the corresponding energy use, he said.

Jim Kerns explores elevator guts.

David Geisler, CEO and general counsel, has worked out a lease for a disused elevator in downtown Springfield.

For its next steps, the company has targeted an available elevator in South Hutchinson, Kan., and approached the owner of Tillotson Construction Co.’s Vinton Street elevator in Omaha.

“What an awesome facility,” Geisler wrote in a follow-up email, thinking of Vinton Street.

Geisler and Kerns have cast their eyes far beyond the Midwest, though, from big terminals in Buffalo, N.Y., to San Francisco’s threatened Pier 92.

“We really need to save that facility if it’s structurally sound,” Kerns said. “It could put out about 50 million pounds of green leafy vegetables per year.”

Their most unique discovery source is YouTube videos posted by those who have flown drones around elevators.

But word-of-mouth works, too, and Kerns issues this appeal to readers: “Submit to us pictures and locations of concrete grain terminals in good condition all across the United States, sea to shining sea, north to south.”

Vertical Innovations can be contacted through its website.

Full Automation From Planning To Control For Indoor Farms Is Here

Full Automation From Planning To Control For Indoor Farms Is Here

Montreal, Canada | August 10, 2017

Two leading agtech companies have joined forces to offer award-winning automation software and hardware to indoor farms.

For the first time ever, growers will be able to use technology to automate processes that have previously been decided based on incomplete data.

Motorleaf, based in Montreal, is the market leader in IoT, plug-and-play sensor, and controls hardware and software for hydroponic and greenhouse automation.

Agrilyst, based in Brooklyn, is the market leader in farm management and automation

software for indoor farms. It is now possible to connect Motorleaf devices to Agrilyst’s platform. Growers can visualize all of their climate and nutrient information real-time and alongside

their crop yield data.

“The customer is the most important piece of the puzzle, and facilitating easy

access to critical information in an intuitive and plug-and-play environment are

two of the things that both Agrilyst and Motorleaf customers already experience.

Now for the first time they can do this with both companies working together on

their behalf. Welcome to the new way agtech should work for all customers,”

says Ally Monk, Motorleaf Co-Founder and CEO.

“We believe the open exchange of data between systems is critical for farm

success and have always been committed to helping farmers access and utilize

their data in better ways. We’re excited to work with Motorleaf, who is quickly

becoming a key player in advanced indoor controls technology. Connecting to

top-of-the line devices will help our customers get the best insights into their

operations possible,” says Allison Kopf, Agrilyst Founder and CEO.

For a limited time, growers who sign up for an annual commercial farm

subscription with Agrilyst will receive two free hardware units from Motorleaf worth over $1400 USD.

Growers who are interested in taking the next step in data and automation can

sign up at: https://www.agrilyst.com/motorleaf

About Motorleaf

Motorleaf turns any greenhouse and indoor farm, into a smart connected

operation. From a hobby grower to 100+ acres of greenhouse; Motorleaf has a

suite of hardware and software to allow the Monitoring, Automation, and

AI/Machine Learning enabled discovery to flourish. Motorleaf allows all farmers to

‘Sleep Well <while plants> Grow Well.’Sleep well, grow well,

About Agrilyst

Agrilyst is the virtual agronomist powering the horticulture industry. The company

was founded in 2015 and is based in Brooklyn, NY. The subscription-based

software helps growers automate labor-intensive processes like production

planning, crop scheduling, and task management and drive higher revenues on

the farm. Agrilyst is committed to helping every indoor farmer reach profitability.The Motorleaf Team!

Contact: Alastair Monk - Motorleaf CEO | monk@motorleaf.com

Property Owners Reap Cost Savings With Green Building

Green infrastructure is an umbrella term for anything that helps manage stormwater naturally and often includes rain gardens, green roofs, cisterns and rainwater recycling.

Property Owners Reap Cost Savings With Green Building

June 27, 2017 | Julie Littman, Bisnow Bay Area

Eco-friendly features are cropping up on buildings around the country. In addition to green roofs and solar panels, private-public partnerships are increasingly building more efficient and cost-effective stormwater systems. And owners are reaping major monetary rewards for their efforts.

ULI The roooftop at Gerling Edlen's Meier Frank building in Portland, Ore.

Green infrastructure is an umbrella term for anything that helps manage stormwater naturally and often includes rain gardens, green roofs, cisterns and rainwater recycling. Stormwater runoff, which often contains oil, grease and fertilizer, is among the most consistent pollutants of local waterways, according to the U.S. National Research Council. With more development in urban areas consisting of concrete and other impervious surfaces, stormwater often has no place to go other than down the local sewage channel. Without mitigation, the stormwater can overflow channels, flooding streets.

With this in mind, local governments are starting to require some kind of green infrastructure within commercial development and are creating coordinated green infrastructure networks that include public and private sites.

The Urban Land Institute, which reviewed several water management and green infrastructure systems in a recent report, found in addition to benefiting the city, green infrastructure is adding value for property owners.

“We found that green infrastructure was capable of creating value,” ULI Senior Director of Urban Resilience Katharine Burgess said. “It created an enhanced user experience, improved placemaking opportunity and improved development yield of land to be used more efficiently.”

These additional amenities, such as green roofs, parks and water features, will often lead to rental increases. A 200-unit apartment complex at 1330 Boylston in Boston garnered an additional $300 to $500/month in rent for units that overlooked the green roof. The green roof cost $113K to build and the extra rent nets $120K/year, according to the ULI report.

Savings Initiative

Courtesy of Katharine Burgess ULI Senior Director, Urban Resilience Katharine Burgess

Partnering with private developers creates a more affordable way for cities to address green infrastructure, which studies show is more cost-effective than implementing graywater infrastructure (where sewage mains and tunnels collect and treat stormwater and sewage before discharging). New York City estimates gray strategy would cost $6.8B compared to a green strategy that would cost $5.3B to implement. Burgess said she expects stormwater management and green infrastructure to become increasingly more prominent until one day it is part of business as usual.

"Real estate developers are taking really effective approaches on requirements or desires to achieve sustainability practices,” Burgess said.

Several developers have already noticed savings in building costs since implementing various green infrastructure.

In 2016, Gerling Edlen was able to harvest rainwater at its 180K SF Meier & Frank building in Portland, Oregon, that met 93% of the building’s non-potable water needs. The company saved more money than it paid the city. Annual savings equaled 107% on the building’s total annual water cost, according to Gerling Edlen Director of Sustainability Renee Loveland. The building owner also uses the stormwater system as a marketing tool with tenants. The renovation benefited from a local green investment fund grant.

This historic building, which is LEED Platinum certified, has an underground rainwater collection tank, a 12K SF green roof, a 112-kilowatt solar array and bioswales at grade.

Retail Owners Follow The Trend

ULI Burbank Water and Power EcoCampus

The retail center Market at Colennade in Raleigh, North Carolina, uses three cisterns and a water reuse system, bioretention swales, an efficient irrigation system and a detention basin as part of its water management system. It is so efficient that of the 30.6 inches of rainfall captured in one year, only 0.6 inches flowed out of the system, according to Regency Centers Vice President of Investments Chris Widmayer.

Among the biggest benefits of this project was its ability to partner with anchor tenant Whole Foods, which uses the cistern to help market the grocery store’s green culture, Widmayer said.

For Burbank Water and Power, the green infrastructure helped attract younger employees to the company's campus, Burgess said. The campus, which was renovated in 2000, operates on 100% recycled water, using green roofs that absorb 70% of rainwater and save the facility about $14K/year, according to ULI’s report.

These 5 Technologies Are On The Verge of Massive Breakthroughs

These 5 Technologies Are On The Verge of Massive Breakthroughs

A new report highlights a few promising fields that could explode in the near future.

By Kevin J. Ryan |Staff writer, Inc.@wheresKR

An Aerofarms employee uses a scissor-lift to check the vertically-growing greens within the company's Newark, NJ headquarters.

CREDIT: Ellise Verheyen

Here's a glimpse of what the future will look like.

This week, Scientific American published its annual report on emerging technologies. The list is a compilation of what the publication calls "disruptive solutions" that are "poised to change the world." To qualify, a particular technology must be attracting funding or showing signs of an imminent breakthrough, but must not have reached widespread adoption yet.

Here are a few of the cutting-edge technologies that made the list--and the companies that are already making strides with them.

1. Noninvasive Biopsies

Cancer biopsies, which entail removing tissue suspected of containing cancerous cells, can be painful and complicated. Analyzing the results takes time. Sometimes, the tumor can't be reached at all.

Liquid biopsies could be the solution to all those issues. By analyzing circulating-tumor DNA--a genetic material that travels from tumors into the bloodstream--the technique can detect the presence of cancer and help doctors make decisions about treatment. It can potentially go even further than traditional biopsies, identifying mutations and indicating when more aggressive treatment is necessary. Grail, which spun out from life sciences company Illumina earlier this year, currently has $1 billion in funding from investors including Jeff Bezos and Bill Gates. The startup is working toward developing blood tests that could detect cancer in its earliest stages.

2. Precision Farming

Farming doesn't have to be an inexact science. Thanks to artificial intelligence, GPS, and analytics software, farmers can now be more precise in managing their crop yields. This makes agriculture a more efficient operation, which is especially critical in parts of the world where resources or climate aren't conducive to growing. Indoor farming startups including Aerofarms, Green Spirit Farms, and Urban Produce all closely analyze their crops using these types of tools to maximize output and flavor. Blue River Technology and others use computer vision to cut down on wasted fertilizer--sometimes by 90 percent.

3. Sustainable Design of Communities

Creating sustainable neighborhoods isn't just be good for the environment--it might be good business, allowing companies and residents to reduce their energy costs. Google spinou Sidewalk Labs is scouting locations for a huge feasibility study that would use one neighborhood to showcase what the city of the future might look like, creating infrastructure for self-driving electric cars and sustainable energy sources like solar. Last year, Denver and Detroit were rumored to be front-runners for the project.

4. Deep Learning For Visual Tasks

Artificial intelligence has become shockingly successful at identifying images across a range of applications. Facebook already can recognize many of the people and objects in your photos and allows you to search for images by describing their contents. Google's image recognition software is the basis for its new platform, called PlaNet, which can in some cases predict the locations where photos were taken based on clues in signage, landmarks, and vegetation. Earlier this year, researchers at Stanford revealed that they'd trained A.I. to correctly identify skin cancer with 90 percent accuracy--higher than the dermatologists it went head to head with.

5. Harvesting Clean Water From Air

What if moisture could be pulled from the air, even in arid climates? Scientific American reports that research teams at University of California-Berkeley and M.I.T. are developing systems aimed at accomplishing just that. The scientists customize crystals called metal-organic frameworks to be extra porous and thus able to collect large amounts of water, which are then deposited into a collector.

An Arizona-based startup called Zero Mass Water harvests water using a different method. According to the publication, the company creates a system that uses solar energy to push air through a moisture-absorbing material. A unit with one solar panel, which runs about $3,700, produces between two and five liters of water per day. The company has performed installations in the southwestern U.S. as well as in Jordan, Dubai, and Mexico. It also recently sent panels to Lebanon to provide water to Syrian refugees.

Artemis Takes on The World

We’re currently helping indoor farmers get to profitability and beyond in 8 markets around the world.

Artemis Takes on The World

It’s no secret — the indoor farming market is huge… and growing! As Allison detailed in this blog post, indoor farms in the US produce over $21B in revenue annually. And the US only represents 0.2% of the global greenhouse vegetable market. This is the the same industry that is aggressively growing to help increase food production by 70% to feed 9B people by 2050.

Global Expansion

Artemist has set out to provide the world’s best management software from its inception. In order to be the world’s best, you have to be a global company. Within just a few months of our launch, we were proud to support incredible customers in South America, Sri Lanka, Canada, and the United States.

We’re not stopping there — we’re excited to announce that in addition to continuing to add customers in our existing markets, this month we’ve entered new markets, adding customers in Europe, the Middle East, and Asia!

Supporting Customers

The biggest challenge any growing company faces in adding new customers is supporting them while keeping existing customers both excited and engaged. Over the past month we’ve introduced a new onboarding process to ensure customers see value from Day 1 as well as easier ways for our customers to use our software. We’ve also welcomed Regina Bellows to our team as our dedicated Customer Success Manager.

Managing customers across so many time zones can lead to sleepless nights. One of the things I love about Artemis is everyone here is customer-obsessed. We take turns monitoring support channels all hours of the day and night so a customer never feels like they’re left in the dark when they run into a question. I think it’s probably one of our customers’ favorite things about us.

Let’s Chat!

While we’re excited with our progress to-date, we’re not stopping here. We continue to be excited about how we can use data to evolve one of the world’s largest legacy industries. I’d love to understand more about your farm, your challenges, and how we can help you solve your problems with data. Please email me at jschmitz@agrilyst.com or call at +1 646–719–0304.

Take-aways

The global greenhouse market is large and growing.

Agrilyst is growing along with the market, now working with clients across four continents.

We‘re keeping a close eye on support to ensure our customers are getting the most out of their software investment.

Artemis is the virtual agronomist powering the horticulture industry. We invite you to join the #DigitalHorticulture movement on social media and share your stories of farm innovation.

If you enjoyed this story, tune in for more here and be sure to check out our website: https://artemisag.com/

Award-Winning Re-Nuble Lays Waste To Malnutrition

Re-Nuble Inc., founded by scientifically oriented business IT specialist Tinia Pina, has snagged a 2017 American Entrepreneurship Award and the $25,000 interest-free loan that accompanies it – the latest feathers in the cap of a 2015 startup that transforms food waste into fresh produce.

Award-Winning Re-Nuble Lays Waste To Malnutrition

Growth mode: Founder Tinia Pina's (multiple award-winning) biotech Re-Nuble is pacing the waste-to-table field.

JULY 17, 2017

By GREGORY ZELLER //

An outer-borough biotech with a Long Island lineage is racing to the head of the organic-fertilizer field.

Re-Nuble Inc., founded by scientifically oriented business IT specialist Tinia Pina, has snagged a 2017 American Entrepreneurship Award and the $25,000 interest-free loan that accompanies it – the latest feathers in the cap of a 2015 startup that transforms food waste into fresh produce.

The American Entrepreneurship accolades are doled out by the Libra Group, an international business group containing 30 subsidiaries across several core sectors, including finance, energy, real estate and shipping. The awards program is exclusive to the borough of the Bronx and Florida’s Miami-Dade County, communities that “face disproportionate lack of opportunity,” according to the program website.

That’s similar thinking to the mindset that first set Re-Nuble in motion. Concerned equally by chemical fertilization, the massive waste of “leftover” food and the poor nutritional choices available in Harlem, where she taught an SAT prep class, Pina began researching anaerobic digesters, biological processes in which microorganisms break down biodegradable materials.

That creates both harvestable energy and a residue goop that turns out to be a plus-grade fertilizer – and a super-effective hydroponics growth accelerant.

The leftover liquid is also a rocket fuel for Pina’s primary mission to convert individual communities’ leftover consumables into a renewability-focused product promoting healthier eating within that community, all with zero environmental effect.

The innovator and her research teams have fine-tuned the science as a “virtual tenant” of Stony Brook University’s Clean Energy Business Incubator Program and an actual tenant of the Harlem Biospace biotechnology incubator. Re-Nuble outgrew the uptown incubator in the fall of 2015 and split its operations in two – formulation in a large Long Island City-based shipping container, front office in the Brooklyn Navy Yard industrial park.

Neither of those locations are in the Bronx, obviously, but Re-Nuble was close enough: The $25,000 capital infusion will be used primarily to deepen the biotech’s longtime connection with Baldor Specialty Foods, a regional distributor based in the South Bronx’s Hunts Point section.

Christopher Upperman: Inspirational journeys.

In fact, the award was granted with the specific understanding that at least part of the $25,000 loan would be used to co-locate some Re-Nuble operations at Baldor’s distribution center – something “we haven’t had the working capital to do sooner,” Pina noted.

Such forward thinking (and geographic preferences) perfectly match the sentiment behind the American Entrepreneurship Award, according to awards program CEO Christopher Upperman, who said Re-Nuble and the other AEA winners “remind us of the importance in continuing to work on their behalf.”

“Hearing their inspiring entrepreneurial journey, I’m reminded why more emphasis should be placed on communities such as the Bronx,” Upperman said in a statement. “There are eager business owners and those with aspirations to become successful business owners in communities … all throughout the United States who will take advantage of continued support and additional resources, if offered.

“I commend each of the finalists, and certainly the winners, for their commitment to serving the Bronx and building successful businesses in the process.”

The other Bronx-area AEA winners include Duro UAS, which manufactures drone systems, sensors and components for marine-based industries; NoLogo Backpacks, focused on wearable technology for students, cyclists and pedestrians; Spadét, which is modernizing a 19th century extra virgin olive oil formula into a line of safe and sustainable skin, body and hair products; and Sustainable Snacks, a natural-foods company serving up gluten-free, vegan dark chocolate treats packed with plant-based protein, Omega-3s and fiber.

In addition to the $25,000 interest-free loan from Libra Group, winners receive business support including legal, accounting, communications and IT consultancy services. Each is also assigned a business mentor to provide guidance through the startup and early developmental stages.

While Re-Nuble is several steps beyond the typical startup stage – and gaining speed fast – Pina said she expects the advice to come in handy as she continues to fine-tune her growth-accelerant formulas and expand her product line.

The $25,000 capital infusion, she added, will also help the B2B enterprise – Re-Nuble sells primarily to specialty retailers, with some direct-to-farm business – expand its market horizons.

One key objective sure to offer a bottom-line boost is third-party organic certification, and “part of the $25,000 will definitely go toward that endeavor,” according to Pina.

The entrepreneur is also aligning her enterprise with Cornell Cooperative Extension researchers and “definitely” plans to continue leveraging SBU’s laboratory resources through Re-Nuble’s ongoing CEBIP affiliation.

“We’re B2B and we’re not deviating from that,” Pina told Innovate LI. “What we want to do right now is strengthen the efficiency of our products and get more published research.”

And while teams of scientists maximize the hydroponics growth formulas to deliver exacting nutrient levels during plants’ changeable growth cycles and otherwise tinker with the delicate intricacies of microbial science, they’ll also investigate some “deodorizing” options, according to Pina, who senses another important step in the commercialization process.

“On the hydroponics side, which is a soilless system, the vegetative growth comes from the nitrogen,” she said. “And the nitrogen comes from a fish hydrolysate.

“Not everyone has the tolerance.”

TOPICS:American Entrepreneurship AwardBaldor Specialty FoodsCEBIPChristopher UppermanCornell Cooperative Extension Of Suffolk CountyDuro UASHarlem BiospaceLibra GroupNewsNoLogo BackpacksRe-NubleSpadetSustainable SnacksTinia Pina

This Shipping-Container Farm Could Someday Solve The Food Desert Problem

This Shipping-Container Farm Could Someday Solve The Food Desert Problem

By Maura Judkis July 7, 2017

The inside of one of Local Roots’ shipping container farms. (Courtesy of Local Roots)

There’s a farm opening soon in Laurel, Md., that can grow strawberries in January. It could grow rare tropical fruits from Asia and Central America on our native soil. It could produce custom-designed lettuce, more peppery or sweet. It’s a hydroponic farm in a shipping container, and its owners hope it could eventually put an end to food deserts, including our biggest one: outer space.

Local Roots, a California company, has created an indoor farm that can turn any produce into local produce, anywhere. They grow fruits and vegetables in shipping containers that are stacked in old warehouses or parking lots, which can either be connected to the grid or, eventually, powered by solar energy. Local Roots has designed the custom growing technology and hardware, and it owns and operates the farms, selling its produce to restaurants and food distributors under its own brand. The fact that the company is vertically integrated differentiates it from other container farming systems, like Freight Farm, which sells their containers to others, including novice farmers.

[Want to get more people to eat their veggies? Make them sound like they’re bad for you.]

“You can start to bring that farm into communities that historically had to import their food due to geography, climate, weather, soil or light.” chief executive Eric Ellestad said.

Every 40-foot shipping container can yield the annual equivalent of three to five acres of farmland. Ellestad says his company can grow plants twice as fast as a conventional farm while using 97 percent less water.

Here’s how they do it: Every farm is hydroponic, meaning the plants are grown in nutrient-rich water instead of soil. Leftover water is recirculated, so each container only uses between 5 to 20 gallons each day. They also use sensors to keep tabs on how the plants are growing, and can give them exactly the nutrients they need at that phase in the growing cycle, speeding it up. It’s “almost a growing algorithm in some ways,” Ellestad said. “You can use that software platform to drive that farm as efficiently as possible.”

Included in that are LED lamps that give the plants exactly the right wavelengths of light they need to grow and which can bring out certain qualities in their appearance and flavor. Chlorophyll, the molecule that causes photosynthesis in plants, absorbs red and blue light, so the farms usually look pink or purple. With its rows of lights and repetition, a container farm that was on display at the South by Southwest conference in March felt a bit like stepping into a Yayoi Kusama infinity room.

A Local Roots farm at South by Southwest (Maura Judkis/TWP)

When they tool around with different growing conditions, they can bring out certain qualities in their produce — the same way that terroir gives grapes grown in California a different taste than ones grown in France.

[“Souping," birch water and Gochujang: 9 up-and-coming food trends]

“You can sit down and say, ‘What do you want your lettuce to taste like? Do you want it to be more peppery?’ ” Ellestad said. “Especially with basil, you can really accentuate some of those flavors. You can really sit down and co-design a product with a chef.”

All of the produce is grown organically, and there’s little risk of the types of E. coli scares that pop-up in conventional farming. “Occasionally a fly will get in, and that’s as serious as it gets,” Ellestad said.

Another key fact: Local Roots has figured out how to make the farm efficient enough that it can sell produce at a comparable cost to conventionally-grown fruits and veggies.

A Local Roots container farm on the move. (Courtesy of Local Roots)

“If you can only sell produce to affluent customers in the Northeast, then that’s a fantastic business but you’re not really going to change how the food system functions for most Americans,” Ellestad said.

They already have a farm of several dozen containers up and running in Los Angeles, and later this year, they’re bringing one to D.C. It will be located in Laurel because it’s adjacent to Coastal Sunbelt Produce, a major food distributor in the area that has partnered with Local Roots. Co-locating the farms means that they won’t have to worry about transportation time or costs — which also means the produce will be selected for its flavor, rather than its hardiness, as many vegetables that must travel long distances are.

“We’re pretty excited about the freshness, just having it grown about as local as it can get,” said Jason Lambros, vice president of purchasing for Coastal Sunbelt. “We can be a neat place for them to experiment and grow anything we can dream of, because we have the customers for it.”

The flexibility and scalability of the farms has huge implications for food deserts, a term for communities that have many fast food restaurants, but few places to purchase fresh, nutritious food. Once Local Roots has scouted a location and set up a farm, its first harvest can take place only four weeks later. The company could drop a farm in the middle of Alaska, where a bag of lettuce can cost nearly $6, or in famine-stricken South Sudan, or here in Anacostia, where there are only three full-service grocery stores in Ward 3.

[The next big march in Washington should be for food, celebrity chefs say]

So why don’t they? It’s about having the infrastructure to distribute the food properly, Ellestad said.

“I think simply helicoptering a farm into a food desert could be part of the solution,” Ellestad said. “We would want to partner with the groups that are already working in that community … we can’t operate in isolation. The food system is far too complex and localized.”

For example, they could put a container farm in a neighborhood with few amenities and sell their produce to corner stores, but if the corner stores don’t have refrigerated cases for produce, it would rot. They are currently seeking partners that work in food deserts, as well as literal ones — “In the Middle East, there’s obviously huge food-supply-chain issues in those areas,” he said. Container farms could be a solution for disaster relief after earthquakes, floods or humanitarian crises.

But they’re also looking a bit further. The company is talking to aerospace manufacturer Space X because these types of growing systems could one day be used to feed astronauts on long-term missions to other planets. “The opportunities are global and intergalactic at the same time,” said Ellestad.

For now, they’re going to begin growing lettuce, herbs and microgreens in the area, while expanding to other cities in the United States. And as efficient as indoor growing is, Ellestad doesn’t think it will replace good, old-fashioned rain, sun and soil.

Freight Farms Builds Farms In Shipping Containers, And NASA Wants To Launch Them To Space

This Boston-based sustainable agriculture company grabbed NASA's attention along with Elon Musk's brother, Kimbal.

Getty Boston Globe

July 7, 2017

If we built farms in space, they'd look nothing like the vast wheat fields of Kansas. But they just might look something like urban farms being used today—modular closed-loop hydroponic farms, actually. These compact, efficient grow houses could be the life-giving answer to keeping astronauts fed, a solution The Martian's Mark Watney could only dream of. The idea is less science fiction than you might think, too.

Freight Farms, based in Boston, is trying to revolutionize the global food system with its Leafy Green Machines. These shipping containers filled with racks of planted crops, grow lights, and environmental control systems can be installed anywhere in the world and make fresh produce available in even the densest urban neighborhoods.

Although Freight Farms initial intentions were much more down to Earth, the company inadvertently built a prototype farm that NASA wants to study for future applications on other planets. And NASA isn't the only one. Google and modern farming entrepreneurs including Kimbal Musk, brother to Martian hopeful Elon Musk, have also shown interest in the project.

A single Leafy Green Machine (LGM) can house the equivalent of roughly two acres of produce. One LGM can produce an astonishing 1,000 heads of restaurant-ready lettuce a week, and restaurants like B.Good in Boston are taking advantage of fresher, less expensive produce grown in their own backyard LGMs.

"The demand now is farm to table. It's all about local," co-founder Jon Friedman told Popular Mechanics. "Which is great for summer for select geographies, but for the rest of the year, that isn't possible." Boston winters have as little as 3 hours of daylight, and the massive snow load would ruin the delicate frames of most modular indoor farm prototypes. Friedman calls the shipping containers "magnificent structures for their thermal properties" as well as for their robust structural integrity and easy-to-manage unit size.

With this compelling proof-of-concept on Earth, Freight Farms and Clemson University recently received a grant from NASA to develop the next generation of off-the-grid systems using as many renewables as possible with an ultimate goal of providing "life support for human exploration of deep space." Future LGMs could be even more self-regulating as Freight Farms looks to incorporate technologies like water capture from the ambient air and automatic compost systems. Eventually, Freight Farms would like to build LGMs that are entirely autonomous and run on 100 percent renewable energy.

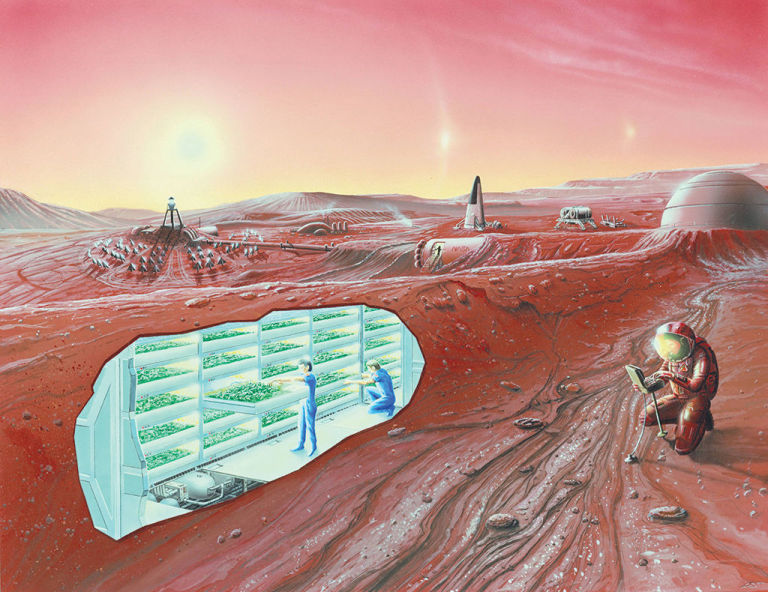

A NASA concept image with an indoor Mars farm that looks something like the inside of a Leafy Green Machine. NASA

The NASA grant—under the agency's research initiative, "Closed-Loop Living System for Deep-Space ECLSS with Immediate Applications for a Sustainable Planet"—is designed to help Freight Farms advance their LGM technology to the point that the space agency could adapt the farms and launch them into space. In addition to providing food for astronauts, NASA wants to work with Freight Farms to study the production of proteins and medicines, develop lightweight containers with inflatable materials or 3D printing, and ultimately design a similar system to the LGM that could be incorporated into "space exploration vessels."

Freight Farms' largest customer on this planet, however, is Brooklyn-based Square Roots Grow, founded by Kimbal Musk and Tobias Peggs. Square Roots operates a whole parking lot full of LGM units for local growers and entrepreneurs. Because the containers are self-contained, they can program the simulated daytime hours inside the farms to run at night when energy costs are lower. It's a sustainable system that has legs.

"My hope is that we are in every metro area in America as fast as we can get there," Musk told Popular Mechanics in an email.

The inside of a Leafy Green Machine.Freight Farms

Beyond fresh greens, Freight Farm founders Jon Friedman and Brad McNamara say that it's also popular to grow radishes, edible flowers, peppers, tomatoes, and pumpkins. What's more, given the closed-loop system of a LGM, it can sustain the crops on just 10 gallons of water a day. The efficiencies of Leafy Green Machines are an astonishing 90 percent improvement over traditional farming, according to the USDA.

Maintaining a single LGM takes roughly 20 hours per week. That's only 10 hours per acre, per week. To sustain the plants, columns of hanging LED strips with blue and red diodes in the grow lights require an average of between 90 and 110 kWh per day—about the equivalent of 3 average U.S. households. Many LGMs are outfitted with solar panels as well to minimize the required energy input.

Freight Farms' LGMs are currently operating across America, Canada, Europe, and Japan. Atlantic island nations are among the first in the developing world do adopt the technology in an effort to become more food-independent. These areas are heavily reliant on imports, and even though they have tropical climates, food production is difficult. The result is high prices and low variety from imported produce. Pilot projects are currently sprouting up throughout the Middle East and Africa as well. And yes, the units can be shipped out on trucks, freighters, and railroads, traveling anywhere you can send an intermodal container—so basically anywhere in the world.

Freight Farms

And it's not just restaurants or remote islands that have opted for the Leafy Green Machine. Institutions around America are harnessing the power of these units not only for food but also for educational purposes. Corporate campuses like Google were eager early adopters. Schools including the University of Michigan and UMass Dartmouth are using the LGMs as part of their curriculum to teach students about sustainable agriculture.

The benefit of distributed small farms is that they're vastly more sustainable than larger options in terms of conserving land and minimizing transport. Between production and shipping, the global food system accounts for about one-third of all human-induced greenhouse gas emissions. It also helps that the local produce passes through fewer hands, which means more affordable food. "The most exciting thing about Square Roots and urban farming is getting back to knowing our farmer and trusting our food again," says Musk.

With Leafy Green Machines spreading across the world, it might not be too long until NASA builds the very first variant—the Leafy Red Machine, perhaps?—and launches it to Mars.

Staying Competitive With New Edible Crops

Staying Competitive With New Edible Crops

Greenhouse Management highlights ice plant and purslane, new opportunities in produce, with Dr. Richard Fu, president of of the Connecticut-based agriculture technology company Agrivolution.

June 28, 2017

Patrick Williams

Ice plant has a unique crunchy texture, and a briny, yet lemony flavor.

Photo courtesy of Dr. Richard Fu

By taking advantage of new lighting technologies and experimenting with unique produce offerings such as ice plant and purslane, ornamental growers can effectively move into the produce space, says Dr. Richard Fu, president of Agrivolution, a Connecticut-based agriculture technology company.

After hearing him speak at Indoor Ag-Con in Las Vegas this past May, Greenhouse Management recently spoke with Fu to learn more about these new opportunities in the produce market. If you would like to know more about growing produce in a controlled environment, subscribe to sister publication Produce Grower magazine at bit.ly/2sxThRU

Greenhouse Management: What does Agrivolution do?

Richard Fu: Agrivolution is a supplier of controlled environment agriculture [CEA] equipment, mostly in LED products at this moment.

We also engage in consultation works for our clients in setting up a vertical farm and greenhouse lighting. We have been doing this for a couple years now, and we hope to establish ourselves further here in North America.

GM: At Indoor Ag-Con, you discussed ice plant as a crop that is becoming more popular in Asia and that can offer opportunities for indoor growers in the United States. Can you explain what ice plant is, and why more growers in the United States should consider growing it?

RF: One of the challenges, I think, in any kind of farming, is a product differentiation. Even though there is certainly a large demand for lettuce and kale and basil and so on, there is only so much you can produce while somebody else is going to do that same thing. Eventually, you’re going to be competing on the price amongst the other growers. Even in a remote area, you’re still going to be competing against others, including much lower-priced imported field-grown produce from California.

Conventional crops are very seasonal also, to some extent. Price fluctuation is very unpredictable sometimes — it depends on the geographical location and climate, obviously. But in the majority of the markets in the U.S., you have to compete with the California and Mexico produce, and locally, you may be competing with other greenhouses or vertical farms. The demand may be there, but the margin may not be the greatest.

Dr. Richard Fu

Photo courtesy of Dr. Richard Fu

We believe by differentiating and offering unique products, you control the supply and pricing. The advantage of a controlled environment is that you can grow crops others cannot in certain locations. Ice plant is a succulent that is considered to be a unique crop and new to the market, so people are very curious but it is hard to grow steadily in a field. It has unique crunchy texture and briny, but lemony flavor. And it has some nutritional benefits compared to lettuce. Those are some of the unique attributes of ice plant and that makes it a good introductory crop, especially for vertical farming growers. In greenhouses, it might be a little bit harder to grow ice plant because of the temperature management, but if you are able to maintain the temperature within a certain range, then ice plant definitely can be a crop to consider as well.

In addition to that, as I mentioned about the nutritional side of it, ice plant contains a rich amount of inositol, which is a substance that helps to reduce insulin resistance, so that can help people with prediabetic conditions and PCOS, or polycystic ovary syndrome. Also, it’s rich in beta-Carotene and vitamin K. We were able to take this crop, and through a controlled environment agriculture technique, enhance the level of d-pinitol concentration and extract it to turn into a supplement. So there was a secondary value-added product that we were able to produce from ice plant. Those are some of the interesting things we can do through CEA that we were promoting at Indoor Ag-Con.

Purslane contains rich amounts of Super Omega-3 and alpha-linolenic fatty acids.

Photos courtesy of Dr. Richard Fu

GM: Purslane is another crop you mentioned. It has Omega-3 fatty acids and antioxidants, and it aids in cancer prevention and allergy control. Are you currently working with that crop?

RF: Yes. Well, I’m not directly working with this crop, but the company in Japan — the company that I partner with — is involved with it, and they have developed a technique to use this crop, which is known to contain rich amounts of Super Omega-3 and alpha-linolenic fatty acids, into a secondary supplement product, which helps to alleviate allergies.

GM: Is that something that greenhouses or controlled environment growers could grow in the United States?

RF: Yes, if there are growers in the U.S. that are interested, then ice plant and purslane certainly can be an introductory edible crops, in CEA, especially.

GM: What advice do you have for greenhouse ornamental growers entering the produce space?

RF: Whether to grow leafy greens such as lettuce and kale or flowering crops such as tomatoes and peppers is dependent on the geographical location, but the produce segment is definitely an option greenhouse growers should be considering because the local food movement is strong today. I think that’s a great opportunity, except as I mentioned before, no matter what industry you may be in, you want to have a certain competitive advantage, and having differentiating products like ice plants will definitely help to maintain your competitive edge over other growers. And you can still grow conventional crops like lettuce and kale and so on, but you want to mix a unique crop or two into your offering. Microgreens are becoming popular crops, so that’s a good option as well. But you need to find products that have high value and high margin to survive in the environment that’s becoming very crowded.

The other thing is, consumers are looking for produce year-round, so you want to be able to supply crops in demand. In order to maintain a competitive edge, your production needs to be year-round with CEA when the demand is year-round. From a CEA perspective, the challenge is to control your environmental parameters in order to grow crops at a steady production rate — especially in greenhouses where the advantage is that you take advantage of free natural light, but the disadvantage is that you’re dependent on the natural light. If you’re in a climate zone where you have shorter daylight in winter, that becomes very disadvantageous because your crop efficiency — production efficiency — can be cut in half in some cases compared to summer. So you definitely want to consider adding supplemental lighting. There are several lighting choices, but LED lighting is definitely one good option.

The other way to keep the edge is to consider adding a seedling incubator, which can promote the growth in the early stages of crop production so you have very healthy seedlings of, for example, tomatoes and peppers. Even in winter months, your crops will have an early start, and then transition into greenhouses as healthy and strong plants. Those are some of the things that you can definitely consider to maintain your competitiveness.

A Life And Career Unexpected

A Life And Career Unexpected

Dr. James Rakocy didn’t plan to spend his life in aquaponics, but it turned into a life-long passion.

June 28, 2017 | Chris Manning

Photo courtesy of James Rakocy

As a child growing up in Milwaukee, Wisconsin, Dr. James Rakocy did not plan on a career in aquaponics. While his family had a home garden and he enjoyed fishing and raising fish in an aquarium, his life took him in other directions. First, he joined the Peace Corps and served in Africa by teaching at a secondary school. Then, he was a teacher in Poughkeepsie, New York, before getting a master’s degree in environmental biology at the University of North Carolina. Finally, he took a job in environmental consulting with a focus on water quality.

Rakocy, now retired and living in Thailand, says he didn’t really like any of the jobs he had before his career in aquaponics started. While working at his consulting job, he came across a magazine about aquaculture, an article detailed a program at Auburn University where the students helped save a pond's ecosystem by using an aquaculture system. This sparked his interest, and as a result, he applied to Auburn’s Ph.D. program. He embarked on studies that would ultimately lead him to a 30-year career at the University of the Virgin Islands and a lifetime of studying and advancing aquaponics at events like the recent National Greenhouse Manufacturers Association Spring Meeting, where he was a presenter.

“I never had a plan B,” he says with a laugh.

An Unexpected Career

In 1980, when Rakocy graduated from Auburn with his Ph.D. in aquaculture, the timing was perfect. A job opening at the University of the Virgin Islands (UVI) in aquaculture seemed to fit exactly what he wanted to do next, so he accepted the position. Unknown to Rakocy, a professor already working at the university had built an aquaponics system in his backyard.

“It was a really basic system,” Rakocy says. “It was one of the first tries at an aquaponics system. [The previous professor] was growing tomatoes in it and raising tilapia in a swimming pool. He had some pretty good results, and the university wanted him to begin incorporating that work at the [research] station.”

That professor, however, quit right around the time Rakocy started at UVI. Upon hearing the news, Rakocy proposed taking on the aquaponics project, as he knew the university wanted to continue it even as the professor who had built the rudimentary system had left.

“It helped that I knew that supervisor, who also had a degree from Auburn,” he says.

Rakocy also notes that other fortunate circumstances bolstered his ability to spend his career researching aquaponics. When he needed funds for new research endeavors, he rarely faced any pushback — resulting in 30 years of uninterrupted funding. And after seven years, Rakocy found himself in charge of the entire University of the Virgin Islands research station. At other land grant universities with more competition, he feels he may have never had a chance to study aquaponics for as long, and as thoroughly, as he did.

“Although [the director job] did cut into my research time because of all the administration work,” he says with a laugh.

Dr. James Rakocy

The Virgin Islands also proved to be an ideal place for the research. Rakocy says the island is fairly dry and there aren’t many ponds or much running water in the area to draw water from.

“What we were trying to do was create an industry from scratch,” Rakocy says. “I was forced to use something that utilized very little water, and aquaponics was it.”

Now, he sees more people interested in it both as a hobby and commercially. The benefits he learned about back the 1980s are going mainstream.

A Pioneering Career In Research

At UVI, Rakocy’s work focused on vegetables and herbs; his previous forays into aquaponics focused on water chestnuts and some edible plants. The first aquaponics system he and his team at UVI constructed used three and half oil barrels — a production setup Rakocy says has become more widely used in recent years. In four and a half months, the first system produced 100 pounds of food.

“We made a ton of mistakes, but we reduced it,” Rakocy says. “We had no idea how to design it, how many fish we needed or what kind of plants would work.”

Next, he and his team built six systems for controlled experiments. According to his notes, each system contained two hydroponic tanks with a total growing area of 154 ft2 (14.3 m2), and a 3,000-gal (11.4 m3) fish tank. After experimenting with those tanks, Rakocy and his team built another system with two hydroponic tanks with a total growing area of 768 ft2 (71.4 m2) with a 3,000-gal (11.4 m3) fish tank.

Years of trialing ultimately lead to UVI developing the first-ever commercial scale system in 1999. It contained six hydroponic tanks and had a growing area 2,303 ft2 (214 m2) and four fish rearing tanks, each with a water volume of 1,320 gal (5.0 m3). Per Rakocy’s notes, the goal was to stagger fish production in the aquaponics system to keep nutrient generation relatively consistent. After more long-term trialing — including one trial that lasted three years — larger fish tanks were installed.

It was this initial commercial system that is the basis for the current commercial-scale UVI aquaponics system.

“I had three professional researchers working for me,” Rakocy says. “I wasn’t able to do as much of the field work once I started directing the research, but I was still involved.”.

Rakocy’s interests stem from a love of fishing

Photo courtesy of James Rakocy

While at UVI, Rakocy authored or co-authored 96 papers on aquaponics research. He also co-edited Volumes 1 and 2 of the Tilapia Aquaculture in the Americans and wrote “Aquaponics Q&A,” a 235-page book primer with basic information for those interested in aquaponics.

At the time Rakocy started his career at UVI, he says there was not much aquaponics research being pursued by universities in the U.S. or elsewhere. He remembers there only being a small trial and paper from Southern Illinois University and another paper from a small university in Germany. According to Rakocy, the work he was doing was back in 1980 was not understood the way it is now.

“It was absolutely in its infancy,” he says. “No one knew what aquaponics was. In fact, no one called it aquaponics. We just called it an integrated system."

Rakocy says he isn’t sure what he would have ended up doing had his career in aquaponics not manifested itself in the way and time that it did. All he knows is that he wouldn’t have been happy in any of his jobs before his job at UVI. He goes as far as to compare his career, and ultimate success studying aquaponics, to the 2005 Woody Allen movie “Match Point.” The film examines the impact of luck and circumstances on life.

“You know how a tennis ball could fall on one side or the other?” he says. “The whole premise of that movie is that a lot of what happens in your life has to do with luck. And I lucked out.”

Looking At The Future

From his base in Thailand — he says he retired there because he didn’t want to retire in Florida like everyone else — Rakocy now works on a project called The Aquaponics Doctors. Along with Dr. Wilson Lennard, an Australian with a background in biology who started research aquaponics in the mid-2000s. Together, they offer consulting on everything from how to set up an aquaponics system to what crops to grow to what system components might be cheaper and more efficient. Their goal is to help make aquaponics a larger part of the growing community. On the research side, UVI no longer has a dedicated program as when Rakocy ran it, but there are six universities in North America with fully functioning aquaponics programs.

One area of the world Rakocy says he hopes embraces aquaponics fully is in the Middle East. He and Lennard have consulted on projects in Abu Dhabi and Rakocy says that region of the world is perfect for aquaponics because of its relative lack of water. Not unlike the Virgin Islands, Rakocy says, the Middle East lacks the water necessary to produce food in the quantities it needs.

“They don’t have any water and aquaponics is very conservative on water,” he says. “The only water we lose is from vaporization and some from removing sludge. But there are techniques where you can get water back into the system.”

“All you do is harvest your plants and feed your fish and plants,” he says. “It’s a very stable system.”

In addition to his work consulting and helping plan projects, Rakocy travels the world and speaks on aquaponics at different conferences while also squeezing in some well-deserved travel time for himself. To date, he has been invited to speak on aquaponics in countries like Canada, Norway and Saudi Arabia. He has also given presentations in Brazil, China and Thailand. In short, Rakocy has been all over the world lecturing on aquaponics. His hope now is for aquaponics to expand beyond hobbyists and smaller growers producing one or two bays of crops. Currently, he says commercial growers using aquaponics are confined to niche markets and specialty crops. Most aquaponic food sales, he says, are direct, local and in relatively small quantities.

“What’s so appealing about aquaponics to people — especially to home gardeners — is that you can raise plants easily and incredibly productively,” Rakocy says. “There’s no weeding. And if you follow the UVI method, there’s very little monitoring.”

One day, Rakocy hopes, bigger commerical growers will also adopt aquaponics and more researchers will take on the challenge of improving the technology. But he’s also happy to have gotten this far.

Infarm Wants To Put A Farm In Every Grocery Store

Infarm Wants To Put A Farm In Every Grocery Store

By Steve O'Hear (@sohear)

Imagine a future where you go into a grocery store to buy some fresh basil, and, as you traverse the aisle, instead of polythene bags containing mass-produced snippets of the herb that have been flown in from thousands of miles away, in front of you are a stack of illuminated containers, each housing a mini basil farm.

The plants themselves are being monitored by multiple sensors and fed by an internet-controlled irrigation and nutrition system. Growing out from the centre, the basil is at ascending stages of its life, with the most outer positioned leaves ready for you, the customer, to harvest.

Now imagine no more, because, to paraphrase science fiction writer William Gibson, the farm of the future is already here, it’s just not evenly distributed.

When we presented our idea three or four years ago, people looked at us and thought we [had] lost our mind — Infarm co-founder Erez Galonska

Infarm, a 40-plus person startup based in Berlin is developing an “indoor vertical farming” system capable of growing anything from herbs, lettuce and other vegetables, and even fruit. The concept might not be entirely new — Japan has been an early pioneer in vertical farming, where the lack of space for farming and very high demand from a large population has encouraged innovation — but what potentially sets Infarm apart, including from other startups, is the modular approach and go-to-market strategy it is taking.

This means that the company can do vertical farming on a small but infinitely expandable scale, and is seeing Infarm place farms not in offsite warehouses but in customer-facing city locations, such as grocery stores, restaurants, shopping malls, and schools, enabling the end-customer to actually pick the produce themselves.

“When we presented our idea three or four years ago, people looked at us as though we [had] lost our mind,” says Infarm co-founder Erez Galonska. “We are the first company in the world that has put vertical farming in a supermarket. We did it last year with Metro Group, which is one of the biggest wholesalers in Europe, and now we are facing very big demand from other supermarkets that want to do the same”.

Each farming unit is its own individual ecosystem, creating the exact environment our plants need to flourish— Infarm co-founder Osnat Michaeli

That demand — which has also seen Infarm recently partner with EDEKA, Germany’s largest supermarket corporation — is driven by a change in consumer behaviour in which “people are seeking more fresh produce, more sustainable produce,” says Osnat Michaeli, another of Infarm’s three founders (the other is Guy Galonska, brother to Erez). More generally, she says, the food industry is looking to technology that can help solve inefficiencies in the supply chain and reduce waste.

“Our eating habits have created a demand for produce that is available 365 days a year, even though some varieties may only be seasonal and/or produced on the other side of the globe… The food that does survive the long journey is not fresh, lacks vital nutrients, and in most cases is covered in pesticides and herbicides”.

In contrast, the Infarm system is chemical pesticide-free and can prioritise food grown for taste, colour and nutritional value rather than shelf life or its ability to sustain mass production. Its indoor nature means it isn’t restricted to seasonality either and by completely eliminating the distance between farmer and consumer, food doesn’t get much fresher.

“Behind our farms is a robust hardware and software platform for precision farming,” explains Michaeli. “Each farming unit is its own individual ecosystem, creating the exact environment our plants need to flourish. We are able to develop growing recipes that tailor the light spectrums, temperature, pH, and nutrients to ensure the maximum natural expression of each plant in terms of flavor, colour, and nutritional quality. Weather that be an arugula from Provence, Mexican tarragon or Moroccan mint”.

The Infarm vertical farming system has been designed to enable a “perpetual daily harvest”. Taking inspiration from the petal constellation of the sunflower, the growing trays move plants from the centre to the outer perimeter according to their size and growth. Replenishing the plant food is as simple as changing a cartridge and water supply can also be automated.

In addition, a matrix of sensors collect and record data from each farm so that Infarm’s plant experts and tech team can remotely monitor crops and optimise the plants’ growth in real-time or troubleshoot any peculiarities, such as a change in atmosphere.

“The system is smart. It can guide you where to harvest and can notify you when the produce needs to be harvested, and this is your part in the game,” says Galonska. “Machine learning can help us understand and predict future problems”.

When a new type of herb or plant is introduced, Infarm’s plant experts and engineers create a recipe or algorithm for the produce type, factoring in nutrition, humidity, temperature, light intensity and spectrum, which is different from system to system depending on what is grown.

The resulting combination of IoT, Big Data and cloud analytics is akin to “Farming-as-a-Service,” whilst , space permitting, Infarm’s modular approach affords the ability to keep adding more farming capacity in a not entirely dissimilar way to how cloud computing can be ramped up at the push of a button.

This makes Infarm potentially scalable, both in terms of biodiversity and supply: from a small number of units in-store, where customers can get up close to the produce, to additional capacity at the back of a supermarket, to a large online retailer that may require 1000s of units and grow 100s of varieties.

None of which has gone unnoticed by investors.

The startup has just closed a €4 million funding round led by Berlin’s Cherry Ventures. Impact investor Quadia, London’s LocalGlobe, Atlantic Food Labs, design consultant Ideo, Demand Analytics, and various business angels also participated.

Christian Meermann, Founding Partner at Cherry Ventures, says the distributed nature of Infarm’s system is one of the things that made the startup stand out from other vertical farming companies the VC firm looked at. This, he says, is seeing Infarm create a network of farms that are centrally controlled and monitored from the cloud and do not require the startup to build huge farming warehouses of its own.

Meermann also talked up the machine learning behind Infarm, which he says is enabling it to figure out the most optimum recipe for different plant types to not only significantly enhance flavour but also let crops grow in parts of the world they otherwise wouldn’t be able to.

“When we started out, we were looked at as ‘idealistic dreamers’. In part, this might have been because we were self-taught and not many believed that we had the necessary expertise needed to invent a new agricultural solution,” adds Michaeli.

“The challenge [now] is in finding the right partners. Our initial focus is on supermarket chains, online food retailers, wholesalers, hotels, and other food-related businesses, for whom the superior quality and range of produce — with no fluctuation in costs — makes Infarm an attractive partner. In return, we can reintroduce the joy of growing to the urban population”.

A Night of Chamber Music On Brooklyn’s Floating Food Forest Showed What Cities Can Be

A Night of Chamber Music On Brooklyn’s Floating Food Forest Showed What Cities Can Be

Music platform Groupmuse brought chamber music lovers to the Brooklyn waterfront Wednesday night. It was nice.

By Tyler Woods / REPORTER

Warp Trio's Josh Henderson plays violin on Swale | (GIF by Tyler Woods).

There is something about being on top of the water, surrounded by plants and music to remind you that New York is actually a place on land on the Earth and not a mindset or abstraction.

That was the case Wednesday night, as classical music ensemble the Warp Trio played violin and piano on Swale, New York’s floating food forest, currently docked on Pier 6 at Brooklyn Bridge Park. The ensemble played Ernest Bloch, an improvisation on water, and “Estrellita (My Little Star)” by Manuel Ponce, in an event organized by the online performance platform Groupmuse.

The location was Swale, a farm located on a barge in the East River. It’s both an art piece and a urbanist project, spearheaded by the artist Mary Mattingly. Visitors to Swale are able to explore the forest of edible, perennial plants. The idea is to create a hugely collaborative project that brings together different communities working toward the same goal, and to provide a sort of minimum viable product for how to conceive of a greater system of locally grown food in big cities.

Swale won our Brooklyn Innovation Award last year as the best artist/creative group in the borough working in the innovation space.

The Warp Trio plays Swale. (Photo by Tyler Woods)

“We’re interested in hosting and being a platform for communities that gather and care about each other,” Marisa Prefer, Swale’s education manager, explained. “Groupmuse found us and we were happy to host.”

Groupmuse is a fairly new platform for hosting classical music concerts in small venues like living rooms or other small, nontraditional spaces. We covered Groupmuse, cofounded by a 27-year-old chamber music lover living in Bushwick, late last year.

“Once in a while we decide to do one in public places, but in keeping with the same ethos, which is informal and intimate,” Groupmuse’s cofounder Sam Bodkin explained.

Swale’s Marisa Prefer explains clover and nitrogen. (Photo by Tyler Woods)

As the sun set behind the statue of liberty Wednesday night and the air cooled, the 50 or so attendees on the barge nestled into the wood chips on the ground, steadied themselves on the edges of the barge, and leaned up against the apple trees on Swale.

“It’s a great way to meet new people,” explained Dennis Lin, one of those sitting on the wall of the barge. Lin is also a Groupmuse performer. He’s played living room concerts around Brooklyn and the city. “It’s being able to perform in a nontraditional way and knowing you’re introducing people to classical music who aren’t used to classical music.”

At the end of the evening, after the lights had come on in the Manhattan skyline, one of the Groupmuse organizers asked each member of the audience to shake the hand of someone near them and say one word about how they were feeling.

“Nice,” the person next to me, Elyse, said. Then the audience disembarked from the barge, walking up a metal gangplank, and went their separate ways into the Brooklyn night.

Syngenta Looks To The Future

Syngenta Looks To The Future

June 27, 2017 07:30 AM Eastern Daylight Time

BASEL, Switzerland--(BUSINESS WIRE)--Syngenta today announced its new ambition and priorities following the completion of the transaction with ChemChina. The company aims to profitably grow market share through organic growth and collaborations, and is considering targeted acquisitions with a focus on seeds. The goal is to strengthen Syngenta’s leadership position in crop protection and to become an ambitious number three in seeds. Key drivers for the next phase of growth will be further expansion in emerging markets, notably China, the stepping up of digital agriculture offers, and ongoing investment in new technologies to increase crop yields while reducing CO2 emissions and preserving water resources.

Syngenta looks to the future: Our new ambition & priorities following completion of the transaction w/ ChemChina

After being elected Chairman of the Board of Directors on June 26, Ren Jianxin, Chairman of ChemChina, reaffirmed that Syngenta’s operational independence will be maintained and the existing management team will continue to run the company. He said: “We share Syngenta's strategic and long-term vision and look forward to supporting Syngenta's growth, product offering and services. Together with its Board and Management and all its employees, we will work for the benefit of growers and to enhance food security and fight famine around the world - based on principles of technological leadership, environmental safety and sustainability.”

Michel Demaré, Vice Chairman of Syngenta and Lead Independent Director, said: “This transaction is historic for many reasons. Not only is it the largest acquisition ever made by a Chinese company, but also it is a deal focused on growth. All our stakeholders are benefiting from this change of ownership. Jobs have been safeguarded and farmers will continue to have a choice and enjoy the benefits of our investments in technology. Syngenta will continue to be headquartered and to pay taxes in Switzerland, with major manufacturing and R&D sites in the country. Syngenta remains a standalone company, with a new owner who has a long term vision for our industry and will invest accordingly. The company will maintain the highest corporate governance standards with four Independent Directors on the Board. I look forward to working with Ren Jianxin and the rest of the Board to further develop Syngenta leadership in growth and sustainability. Together, ChemChina and Syngenta will make a significant contribution to global food security.”

Erik Fyrwald, CEO of Syngenta, said: “We play a vital role in the food chain to safely feed the world and take care of our planet. Our ambition is to be the most collaborative and trusted team in agriculture, providing leading seeds and crop protection innovations to enhance the prosperity of farmers, wherever they are. With ChemChina we have a stable new owner who will help us to achieve this ambition. At the same time we will sustain our focus on productivity and on improving the customer experience. We are excited by the global prospects and particularly those in China, where we will utilise and build on our technology and know-how to promote the highest agriculture, food safety and environmental standards, as well as to increase productivity.”

About Syngenta

Syngenta is a leading agriculture company helping to improve global food security by enabling millions of farmers to make better use of available resources. Through world class science and innovative crop solutions, our 28,000 people in over 90 countries are working to transform how crops are grown. We are committed to rescuing land from degradation, enhancing biodiversity and revitalizing rural communities. To learn more visit www.syngenta.com and www.goodgrowthplan.com. Follow us on Twitter® at www.twitter.com/Syngenta.

About ChemChina

ChemChina, which is headquartered in Beijing, China, possesses production, R&D and marketing systems in 150 countries and regions. It is the largest chemical corporation in China, and occupies the 234th position among the Fortune Global 500. The company’s main businesses include materials science, life science, high-end manufacturing and basic chemicals, among others. Previously, ChemChina has successfully acquired 9 leading industrial companies in France, United Kingdom, Israel, Italy and Germany, etc. To learn more visit www.chemchina.com and www.chemchina.com/press.

Cautionary statement regarding forward-looking statements