Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Largest Automated Farm to Open in Japan

GABRIELLE EASTER | @gab_produceplus

Tuesday 23rd May 2017, 08:19 Hong Kong

Largest Automated Farm to Open in Japan

Japanese group Spread has announced it’s opening the world’s largest automated vertical farm, Techno Farm Keihanna

Kyoto-based Spread has announced it will be opening the world’s largest automated vertical farm in Kizugawa, Japan.

Called Techno Farm Keihanna, the farm will produce 30,000 heads, or three tonnes, of lettuce each day once it’s fully operational by the beginning of 2018.

Techno Far Keihanna builds on Spread’s established indoor vertical farm, Kameoka Plant, which was built in 2007 and produces 21,000 heads, or two tonnes, of lettuce each day, all sold under the Vegetus brand.

At the new factory, the company will use automated cultivation to reduce labour costs by 50 per cent compared to the Kameoka Plant, and improve the recycling rate of water used for cultivation by 98 per cent. Using LED lighting developed by Spread itself, the company can reduces energy consumption by 30 per cent compared to existing LED lighting.

Spread aims to grow its share of the Japanese lettuce market to 10 per cent through expanding its production and establishing 20 facilities under a franchise model.

Future of the Prairie

FUTURE OF THE PRAIRIE

October 11, 2017 at 5:00 am | By DEVIN HEILMAN Staff Writer

LOREN BENOIT/Press From left, Coeur CEO Tom McNabb, Coeur Greens operations manager Kelly Lattin and Innovation Collective founder Nick Smoot pose for a photo in front of house at 1915 E. Mullan Ave in Coeur d’Alene. The house is a prototype for a future sustainable living community in Hayden.

A mixed-use sustainable village destined for Hayden is starting with a little old house in downtown Coeur d'Alene.

Coeur, a company that focuses on sustainable resources including power and food, recently purchased the house at 1915 E. Mullan Ave. to serve as a prototype for a sustainable living community and industrial campus in Hayden. Coeur purchased the 35 acres at the southeast corner of Hayden Avenue and Huetter Road in early 2016 and plans to start construction in the spring.

Coeur CEO Tom McNabb and Innovation Collective founder Nick Smoot, a partner in the project, are using the Mullan house as a demo site for the village.

"It's a simple model to see what we can do for starters," McNabb said Tuesday. "The word ‘sustainability,’ you never really know what it is, but we figure we’d try and figure it out."

Smoot said the community will be built on three core principles: outbound, sustainable and intellectual.

"Most people of this next generation want to live an outbound life in nature and having experiences in their community," Smoot said. "The idea of creating a whole village of people who have that mentality is something that's interesting as a housing development."

The "sustainable" principle is built upon dedication to low-cost, low-impact living where power sources such as wind and solar are maximized, gray water (mostly clean waste water from sinks, baths and kitchen appliances) is recycled, and native landscaping is used. Those involved in the project are researching and working on ways to expand even further into the sustainability aspect.

The third principle is "intellectual," meaning home owner associations and covenants, conditions and restrictions would encourage residents to read books, watch documentaries, help pay for educational guest speakers and otherwise maintain an intellectually stimulated community.

Smoot said he can imagine riding his bike into such a community, parking it at the community bike corral and walking to his house through a neighborhood where community fire pits generate conversation and serve as social gathering places. The houses are small (500 to 1,200 square feet), but provide enough space for their residents, and the community dining hall provides even more opportunities for people to meet and get to know each other.

"It makes me very happy," Smoot said. "That's the kind of place you want to live."

The solar-powered Coeur Technology Campus will be located just west of the village. It will house a solar farm to generate power for schools and public buildings, vertical farms to grow local produce, and a bottling plant to bottle local water at the source. It will also serve as a space where entrepreneurs and forward-thinkers can share ideas and put them into action.

"A lot of people don’t know it, but we have more sun hours per year than Florida,” McNabb said, “Solar, about five years ago, was 2 cents off because the rates for hydropower were cheap, but in the last five years the rates (for hydropower) are going up and the rates of hardware have gone down about 40 percent, so all of a sudden it makes sense.”

The 630-square-foot house on Mullan, built in 1930, would probably have been torn down if it had not been selected for this project. McNabb explained that the original structure will be kept as the inside is remodeled to be a studio-type dwelling that can be rented out on a short-term basis to give people an experience in sustainable living.

Tanks will be installed to recycle the gray water and help with temperature. The roof will be lined with solar panels, and energy-efficient appliances and products will be used, among other forward-thinking alterations that will boost the home's sustainability.

McNabb said a more precise estimate could be given near the house's completion date in the spring, but he believes the cost of giving the house a sustainable makeover will be somewhere around $50,000 or $60,000. About 20 people representing a wide variety of talent and expertise have already expressed interest in contributing to the project, he said.

The community is welcome to attend an open house from 11 a.m. to 1 p.m. Saturday to check it out prior to its sustainable makeover and exchange ideas with those leading the project.

Info: www.coeurllc.com

AeroFarms: The Most Interesting Dell IoT Example

AeroFarms: The Most Interesting Dell IoT Example

Rob Enderle | UNFILTERED OPINION | POSTED 13 OCT, 2017

I was at Dell’s big IoT coming out party, which had many working examples, but one really stood out for me. You see, I grew up spending my winters on a ranch and my summers working on a farm. And I quickly concluded that farming sucked. Getting up at an ungodly hour in the morning to fight bugs that had no sense of a decent hour to be awake, set sprinklers, spread pesticides that were known carcinogens, and fight flies for horse crap (I was perfectly happy to let them have it) in hot weather just wasn’t any fun. Oh, and my grandfather had a view that work shouldn’t be fun so if I found a creative way to enjoy the job, like having paint wars while painting the fence, I got punished. So, for me to look at a farming application and think it was cool takes a lot. But AeroFarms was cool.

Making Farming Not Suck

Farms don’t just suck from my perspective. They consume massive amounts of water; they were highlighted as the primary cause for the massive California drought. They are highlighted as massive polluters because the pesticides they use can contaminate ground water and spread beyond the fields being treated (and are often classified as high-level carcinogens). Driving this home, my uncle, who ran the farm I hated working so much, died because of this and the type of cancer he had basically consumed his body. Trust me, it wasn’t a pleasant way to die.

What AeroFarms does is apply IoT technology to farming. It is closer to hydroponics in that they move the fields inside and the result looks more like a factory than a farm. Using below 10 percent of the water, no pesticides, and having yields that, due to optimized environmental conditions and the lack of pests that farmers would die to enjoy, they also don’t use farmers, they use techs.

Now I didn’t like being a farmer, but I’m perfectly fine being a tech.

Rethinking Farming

The advantage of this is that you can place farming inside cities and far closer to the people who consume the produce. This reduces transport cost massively, reduces storage cost massively, reduces spoilage massively, and it also results in a far higher quality product. According to AeroFarms, the cost for producing the product goes down but, due to far higher consistency and the lack of pesticides, the quality and thus the potential price of the produce could go up.

This means increasing margins and reduced risk. Much of what kills a farm is risk. The ranch I lived on grew oranges. California used to lead in orange production, but a disease called Quick Decline wiped out virtually all the orange ranches in the state and now that market belongs to Florida. The poor ranchers either had to change their entire business model or go bankrupt. Many failed. But in a contained environment, you can better isolate and prevent this kind of thing and reduce most act-of-god type risks. Granted, major problems that take out cities like earthquakes and hurricanes would still be issues, but you can harden against these. You generally don’t need or want windows (to better control light), so your structures can be more resistant naturally, and there is at least a reasonable chance that, in a disaster, these things could be functioning lifelines, helping avoid localized starvation, which is now a concern in areas like Puerto Rico.

Labor

One other area where farming is a problem is that that conventional farms tend to employ a high number of illegal aliens. This makes them attractive havens for those who enter the country illegally and allows excessive levels of employee abuse because these employees can’t complain to the police.

As noted above, AeroFarms uses techs, not unskilled labor, and far less of them. Lending itself to robotics and automation, the model directly addresses this problem as well.

Wrapping Up: Making the IoT Work

AeroFarms likely highlights best the kind of potential for the IoT effort that Dell Technologies is trying to roll out. Farming has massive problems in terms of resource usage, pollution, labor and risk. By using current generation IoT technology, AeroFarms has massively addressed each of these areas and created a solution that is far better for the world of tomorrow, with increasing weather risks and higher uses of robotics. I’m kind of wondering how long before someone who is tech forward like Amazon builds this right into a grocery store.

And, from a personal perspective, this could make farming fun. My younger self would have loved to work for AeroFarms and I’m sure I wouldn’t miss the bugs, heat and horse poop.

Rob Enderle is President and Principal Analyst of the Enderle Group, a forward-looking emerging technology advisory firm. With over 30 years’ experience in emerging technologies, he has provided regional and global companies with guidance in how to better target customer needs; create new business opportunities; anticipate technology changes; select vendors and products; and present their products in the best possible light. Rob covers the technology industry broadly. Before founding the Enderle Group, Rob was the Senior Research Fellow for Forrester Research and the Giga Information Group, and held senior positions at IBM and ROLM. Follow Rob on Twitter @enderle, on Facebook and on Google+

These Cold-Weather Container Farms Let Produce Grow In The Arctic

In the subarctic town of Churchill, Manitoba–unreachable by paved roads and best known for its population of polar bears–a head of romaine lettuce can cost as much as $8 without subsidies. Shipments of produce can take weeks from distant farms, and when vegetables arrive, it’s an event. But the town will soon have another option: a shipping container farm growing greens on site.

- 10.12.17

- Fast Company | WORLD CHANGING IDEAS

These Cold-Weather Container Farms Let Produce Grow In The Arctic

As traditional Inuit diets change, they’re being replaced with processed food because it’s so difficult to stock markets with fresh produce. Now, they can grow it themselves, even in sub-zero temperatures.

“The impetus for the whole project was the high cost of food and lack of opportunities for employment in Inuit communities.” [Photo: Vertical Harvest Hydroponics/The Growcer]

In the subarctic town of Churchill, Manitoba–unreachable by paved roads and best known for its population of polar bears–a head of romaine lettuce can cost as much as $8 without subsidies. Shipments of produce can take weeks from distant farms, and when vegetables arrive, it’s an event. But the town will soon have another option: a shipping container farm growing greens on site.

A 40-foot shipping container was repurposed into a hydroponic greenhouse in Spokane, Washington, then shipped to Montreal, where a cargo ship has taken it through the St. Lawrence River, around the coast of Newfoundland, and is now traveling through the Hudson Bay. When the delivery arrives on October 19, Churchill will be the seventh community in the Far North to begin using this type of farm, called the Arctic Growing System.

“If you’re in a community in Northern Canada where it already takes a week for produce to get to an urban center, and another week or two for it to fly to three different communities . . . everything that was fresh is no longer really edible.” [Photo: Vertical Harvest Hydroponics/The Growcer]

“The impetus for the whole project was the high cost of food and lack of opportunities for employment in Inuit communities,” says Corey Ellis, cofounder and CEO of The Growcer, the startup that makes the shipping container farms and works with the small communities that operate the farms.

The company was born out of a project called the Northern Innovation Hub, which aims to find solutions to local problems like food security, housing, and employment. Ellis and others worked with remote communities to brainstorm potential solutions, and landed on local food production as a way both to spur economic development and improve health.

Right now, many people in the area struggle to afford food. Even when grocery stores get subsidies from the Canadian government to offset high produce prices, the cost of shipping extremely long distances and the rates of spoilage on the journey means fruits and vegetables are still quite expensive. That cost means that consumers are more likely to pick unhealthy packaged foods, which have pushed up the rate of diabetes.

And the fresh options that do make it often aren’t very appealing. “If you’re in a community in Northern Canada where it already takes a week for produce to get to an urban center, and another week or two for it to fly to three different communities and kind of bunny hop over to yours, everything that was fresh is no longer really edible,” Ellis says.

The container farms can also create new jobs. “I think they saw an opportunity: Hey, why are we spending money down south to buy food when we could keep it in our community and pay someone local to harvest it?” he says.

“Why are we spending money down south to buy food when we could keep it in our community and pay someone local to harvest it?” [Photo: Vertical Harvest Hydroponics/The Growcer]

Shipping container farms aren’t new, but the startup realized that current options–typically developed for cities in milder climates–wouldn’t work in the region. The farm they designed is insulated enough to withstand days at 60 degrees below zero and blizzards. By splurging on more expensive parts than a typical indoor farm kit, such as the highest-quality lights, the Arctic Growing System can actually be more productive than a similar farm in Boston or New York.

“We ended up with a system that has probably twice the cost but very similar ROI to a unit like Freight Farms, because we were able to basically triple the yields that a Freight Farm unit would get,” says Ellis. (Beyond using more expensive parts, the yield was improved by a unique advantage of farming in the Arctic: The cold, dry air helps make it easier to expel humidity from the greenhouse, which helps plants grow faster.)

“Somebody has to make money for this to grow sustainably, so that’s at the root of everything we do.” [Photo: Vertical Harvest Hydroponics/The Growcer]

The system arrives with everything needed to start the farm, including 14 months’ worth of growing material, seeds, cleaning solution, and multiple spare parts for every major part in the system. The community plugs it in, connects it to water, and it’s ready. The farm managers don’t need prior experience farming; the startup works very closely with customers, helping develop custom business models and monitoring the greenhouses by satellite to help managers troubleshoot any issues. “Somebody has to make money for this to grow sustainably, so that’s at the root of everything we do,” he says.

Six communities in Alaska have started using the farms, some for as long as 18 months, and all have broken even. Even with the relatively high energy bills required to keep the farms warm, the system is far less expensive than shipping produce thousands of kilometers. In one community, for example, growing the produce is roughly 25% of its retail cost. The growers and the grocery store can add margins and customers still pay 30% less than they would have otherwise.

Notably, produce was not traditionally part of the diet of Inuit or other indigenous people. But, then again, neither was soda, candy, or other junk food that has become common. As diets evolve, Ellis says that there’s a growing interest in fresh produce. The startup is also working to develop plans for ready-made meals that combine traditional ingredients with produce, which greenhouse owners will be able to offer as another product.

“What we’re doing is basically creating an environment where the healthy alternative is just as convenient and affordable as the unhealthy one,” he says.

ABOUT THE AUTHOR

Adele Peters is a staff writer at Fast Company who focuses on solutions to some of the world's largest problems, from climate change to homelessness. Previously, she worked with GOOD, BioLite, and the Sustainable Products and Solutions program at UC Berkeley.

AeroFarms - Job Offer

AeroFarms - Job Offer

On behalf of AeroFarms Green Career Consult is looking for a:

Commercial Head Grower

Vertically Controlled Environment Agriculture

AeroFarms is a change-the-world vertical farming company revolutionizing agriculture in the heart of Newark, NJ; just 8 short miles from New York City. AeroFarms mission is to transform agriculture by building and operating environmentally responsible farms throughout the world to enable local production at scale and nourish our communities with safe, nutritious, and delicious food. We use aeroponics to mist the roots of the greens with nutrients, water, and oxygen. AeroFarms’ aeroponic system is a closed loop system, using 95% less water than field farming and 40% less than hydroponics. Our engineered lighting allows tight control of size, shape, texture, color, flavor, and nutrition with razor-sharp precision and increased productivity. AeroFarms can take the exact same seed from the field and grow it in half the time as a traditional field farmer, leading to 390 times more productivity per square foot than a commercial field farm.

The past 12 months have been an exciting time for us. Our team has doubled during this period and we now need a special individual – an experienced and talented problem solver with two green thumbs to lead commercial growing operations in our new, state-of-the-art facility.

Your role:

You will be the onsite growing expert called upon for training, problem solving, and plant health monitoring, and will be responsible for yields and quality in collaboration with the Operations and R&D team. In this role, you will help provide leadership for the facility by working with cross-functional teams to ensure that long-range goals, strategies, plans, and policies are followed. You should be an experienced leader with a strong background in the growing of high quality produce. The ideal candidate will be able to demonstrate experience implementing new processes and facility start-up. You will be an energetic, forward-thinking and creative individual with high standards and good judgment. Our organization is fast-paced: we value individuals who can lead by example and keep focus in a team-centered environment.

Your tasks & responsibilities:

- Manage growing in a large-scale, commercial production facility.

- Ensure product quality, yields, sales volumes and deliveries are achieved.

- Oversee cleanliness, sanitation and organization of all equipment present within the facility.

- Implement and oversee water, media and nutrient solution management, sampling and testing procedures.

- Continue to develop an extensive knowledge base of successful Integrated Pest Management (IPM) strategies.

- Quantify and qualify data regularly, while following company policies and procedures.

- Lead by example and assist with seeding, scouting, irrigation, pest control, plant health, harvesting, etc.

- Contribute and improve upon already-existing operations and processes to improve work-flow, efficiency and provide constructive feedback and recommendations.

- Operate heavy and light horticultural equipment and machinery.

- Facility maintenance and trouble-shooting as necessary.

- Develop methods for reducing costs while optimizing production.

- Comply with all HR policies, including confidentiality and non-disclosure agreements.

- Communicate effectively with supervisors, contractors, and employees.

- Contribute to a fun, team-oriented and challenging work environment in an innovative and pioneering atmosphere.

- Other duties as assigned.

Your profile:

- Minimum five years of experience in a commercial greenhouse with a demonstrated history of success with progressive team management. Experience in hydroponic and aeroponic growing would be considered a plus.

- A four-year degree in Horticulture (BSc.) or closely related discipline; Masters preferred.

- Knowledge of large-scale commercial plant cultivation, including nutrient requirements and delivery systems, plant health, growing mediums, light requirements, temperature and humidity control, air flow, pH, EC and IPM etc.

- Knowledge of plant diseases, insects and fungi, as well as plant treatment options.

- Ability to perform routine equipment maintenance, management and minor repairs.

- Knowledge and experience with Horticulture automation and associated software with the ability to learn new technologies.

- The ability to use data to recommend and implement process improvements that enhance efficiency, yield, and quality.

- A commitment to compliance with Food Safety, HACCP, and Quality Control procedures.

- Experience developing and managing budgets.

- Ability to plan ahead, trouble-shoot, anticipate and solve problems and manage multiple tasks at a time.

- Ability to perform manual labor tasks required for the proper management of a large-scale grow greenhouse.

- Strong interpersonal skills and ability to lead and hold direct and non-direct personnel accountable for meeting daily, weekly and monthly goals.

- An eye for improvement: you will continuously work to improve operating efficiencies, increase learning and develop new skills.

- Leadership skills: you will recruit, train, mentor and motivate the farming team.

- Fluent in spoken and written English

- You are presently located, or willing to relocate to New York, USA

AeroFarms offers:

- An incredible ‘change-the-world’ company with the eyes of the world focused on our success.

- A team of motivated, intellectually curious individuals to support you.

- The backing of some seriously impressive firms including Goldman Sachs, Prudential and other leading venture funds.

- Be eligible to work in USA (Newark), AeroFarms will support you in this matter (working permit, etc.)

Contact: johan@greencareerconsult.nl

Johan Grootscholten (left) and Evert Verboom (right)

Masayoshi Son’s Grand Plan for SoftBank’s $100 Billion Vision Fund

Masayoshi Son’s Grand Plan for SoftBank’s $100 Billion Vision Fund

By KATIE BENNER | OCT. 10, 2017

Eric Gundersen, chief executive of Mapbox, met in July with Masayoshi Son, who led a $164 million investment in Mapbox that was announced on Tuesday. CreditJason Henry for The New York Times

SAN FRANCISCO — When Eric Gundersen, the chief executive of a mapping start-up called Mapbox, met Masayoshi Son, the head of the Japanese conglomerate SoftBank, in late July, he expected to have to sell Mr. Son on what made Mapbox important.

Son recently told Matt Barnard, the chief executive of Plenty, that computers were ushering in a revolution in agriculture not seen since the invention of the plow.

But Mr. Son, 60, did not need to be convinced that Mapbox’s technology — which powers Lyft drivers and companies like Snap and Mastercard — had value. After a whirlwind courtship, Mr. Son’s nearly $100 billion Vision Fund, which SoftBank unveiled last October with money from Saudi Arabia and others, led a $164 million investment in Mapbox that was announced on Tuesday.

In the process, Mr. Son also explained his grand plan for deploying the Vision Fund to Mr. Gundersen. The Japanese billionaire said he believed robots would inexorably change the work force and machines would become more intelligent than people, an event referred to as the “Singularity.” As a result, Mr. Son told Mr. Gundersen, he is on a mission to own pieces of all the companies that may underpin the global shifts brought on by artificial intelligence to transportation, food, work, medicine and finance.

“For Masa, his vision is not just about predictions like the Singularity, which has gotten a lot of hype,” Mr. Gundersen said. “He understands that we’ll need a massive amount of data to get us to a future that’s more dependent on machines and robotics.”

RELATED COVERAGE

SoftBank and Fund to Invest $4.4 Billion in WeWorkAUG. 24, 2017

SoftBank’s $100 Billion Investment Fund Starts to Take Shape JAN. 10, 2017

SoftBank and Saudi Arabia Partner to Form Giant Investment Fund OCT. 13, 2016

What Mr. Son laid out for Mr. Gundersen helps explain why SoftBank and its Vision Fund have invested billions of dollars in a seemingly random sample of more than two dozen companies since the fund was announced. The investments span robotics software start-ups like Brain Corporationand the indoor farming business Plenty, as well as more prominent companies like the business software maker Slack. The deals have run the gamut from smaller investments in start-ups to larger deals with public companies.

Mr. Son is deploying SoftBank’s nearly $100 billion Vision Fund by investing in a network of companies.CreditAlessandro Di Ciommo/NurPhoto, via Getty Images

Yet the companies all have something in common: They are involved in collecting enormous amounts of data, which are crucial to creating the brains for the machines that, in the future, will do more of our jobs and creating tools that allow people to better coexist.

Most recently, SoftBank has been involved in a plan to buy nearly a fifth of the existing stock of Uber, the world’s biggest ride-hailing company and one that has changed the transportation industry. SoftBank is aiming to accumulate Uber’s stock through a tender offer that could value the company at a discount to its current valuation of $68.5 billion, according to people briefed on the negotiations, who spoke on the condition of anonymity because the details were confidential. The tender offer could still fall apart, one of the people said.

If it ends up being completed, Mr. Son would own significant chunks of ride-hailing companies globally because SoftBank already owns stakes in Uber’s rivals like Didi Chuxing in China and Ola in India. Altogether, SoftBank would have a network of companies that gather valuable logistics data and operate large, connected fleets that could work well with self-driving car technology.

“Location data is central and mission critical to the development of the world’s most exciting technologies,” Rajeev Misra, who helps oversee SoftBank’s Vision Fund, said about Mapbox in a statement on Tuesday. He added that the investment was part of SoftBank’s plan to put money into “the foundational infrastructure for the next stage of the Information Revolution.”

SoftBank declined to comment further for this article.

For more than three decades, Mr. Son has consistently made over SoftBank with acquisitions and investments to keep it on the cutting edge. The company began in 1981 as a PC software distributor in Japan and expanded to the United States in 1994 with the acquisition of the PC trade show operator Comdex.

Mr. Son later became the largest shareholder of Yahoo, started Yahoo Japan and, in the last decade, invested in broadband and telecommunications companies — SoftBank agreed to buy the majority of Sprint for $21.6 billion in 2012 — anticipating the need for high-speed connectivity. He has also invested in e-commerce companies, including the Alibaba Group of China and Gilt Groupe, as well as video game businesses like Supercell and media like HuffPost and BuzzFeed.

A Mapbox office in San Francisco. The company makes mapping technology that powers fleets of Lyft drivers and companies like Snap.CreditJason Henry for The New York Times

In a speech last month in New York, Mr. Son declared that in 30 years, there would be as many sentient robots on Earth as humans and that those robots, which he called metal collar workers, would fundamentally change the labor market.

“Every industry that mankind ever defined and created, even agriculture, will be redefined,” Mr. Son said. “Because the tools that we created were inferior to mankind’s brain in the past. Now, the tools have become smarter than mankind ourselves.”

Mr. Son is having many of the same conversations with entrepreneurs these days as he looks to spread investments from the Vision Fund. Many entrepreneurs said Mr. Son’s conversations jumped from philosophical discussions about technology’s impact on humanity to the minutiae of a technical problem.

Mr. Son recently told Matt Barnard, the chief executive of Plenty, that computers were ushering in a revolution in agriculture not seen since the invention of the plow. Mr. Son led a $200 million investment in Plenty in July, part of an effort to make it a global leader in indoor farms. Plenty, which has no farms operating at scale, is now planning its first farm in South San Francisco that will open by the end of the year.

“I really do like to believe he likes us a lot,” Mr. Barnard said of Mr. Son. “I’d say the thing we have in common with his other investments is that they are all part of some of the largest systems on the planet: energy, transportation, the internet and food.”

Some entrepreneurs travel the globe to spend time with Mr. Son at his palatial home in Woodside., Calif., and his offices in India, San Francisco and Tokyo. The SoftBank chief is known for almost always smiling and speaking slowly. He rarely picks up phone calls and his email signature includes the whirring fan icon that shows a computer is booting up, or “thinking.”

Many of the entrepreneurs speak of Mr. Son with reverence.

“Only people close to him know how huge his vision is,” said Eugene Izhikevich, the chief executive of Brain Corp., a company based in San Diego that makes the software that controls autonomous robots.

Mr. Son’s engineers stumbled on Brain Corp. when they were looking for self-driving car technology. Mr. Izhikevich was soon seated across from Mr. Son, talking about robotics as well as how Britain operated 200 years ago when the landed gentry did not work, but came up with new inventions and business improvements.

Like many other entrepreneurs, Mr. Izhikevich said SoftBank moved “scary fast” to sew up its investment. Mr. Son’s team swarmed Brain Corp.’s businesses and spent hundreds of hours on due diligence, wrapping up in a few months.

Unlike other investors, Mr. Son, who is already talking about a second Vision Fund, does not insert himself into the day-to-day operations of most of the companies he has invested in. His Sprint deal has yet to pan out and may be dependent on merging with another company. When other investments have lagged, as did his investment in Snapdeal, an online retailer in India, he has invested in competitors, leading a $2.5 billion investment into Flipkart, a rival Indian e-commerce company.

Some entrepreneurs said Mr. Son’s breakneck investing pace with the Vision Fund was unlikely to slow.

“Masa is in a hurry,” said Vijay Sharma, the chief executive of Indian digital payments start-up Paytm, which SoftBank put $1.4 billion into in May. “He sees this once-in-a-lifetime opportunity where everything we touch can become a market, where we’re at the opening up of a new industrial revolution.”

A $140 Million Prototype Of A Mars Colony Is Being Planned For A Desert Near Dubai — Here's What It Looks Like

A $140 Million Prototype Of A Mars Colony Is Being Planned For A Desert Near Dubai — Here's What It Looks Like

- Leanna Garfield

- Oct. 4, 2017

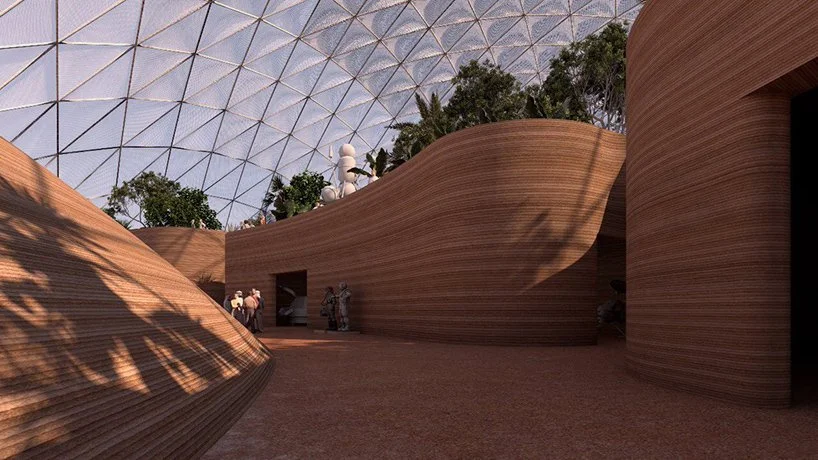

BIG's design for the Mars Science City near Dubai, UAE.Dubai Media Office

What might it be like to live on Mars?

Bjarke Ingels Group — the architects behind the designs for Two World Trade Center in Manhattan and the Hyperloop One — has an idea.

The firm is designing a city in the desert of the United Arab Emirates meant to simulate a Mars colony. The $140 million development near Dubai is slated to be "a viable and realistic model to simulate living on the surface of Mars," according to the local government.

The design for the Mars Science City, as it's called, spans 1.9 million square feet — which would make it the largest of its kind in the world. The plan calls for a team of astronauts to spend a year living in the simulated city after it's completed. However, there's no timeline for construction yet.

A team of Emirati scientists and engineers from the Mohammed bin Rashid Space Centre plan to conduct research about colonizing the red planet at the Mars Science City.

Dubai Media Office

Source: The Government of Dubai

The city is expected to include a giant greenhouse to test agricultural techniques, as well as laboratories designed to explore how to store food, generate energy, and get water.

Dubai Media Office

The greenhouse plan calls for the use of an agricultural technique called vertical farming. Instead of natural sunlight, crops would grow under LEDs on stacked trays in a climate-controlled environment.

Dubai Media Office

The ceiling would be made of materials that can block solar radiation (which is stronger on Mars than on Earth, due to its lack of protective atmosphere). The walls would be 3D-printed.

Dubai Media Office

A portion of the development includes a museum where visitors could learn about achievements in space exploration.

Mars Science City is part of the United Arab Emirates' larger mission to create a viable community on the red planet within the next century.

Dubai Media Office

"The UAE seeks to establish international efforts to develop technologies that benefit humankind ... and that establish the foundation of a better future for more generations to come," UAE's prime minister, Sheikh Mohammed bin Rashid, said at a recent meeting of government officials.

Dubai Media Office

Viability of Indoor Urban Agriculture is Focus of Research Grant

Viability of Indoor Urban Agriculture is Focus of Research Grant

By Krishna Ramanujan | October 12, 2017

A commercial CEA greenhouse operation producing leafy greens in eastern New York. Chris Kitchen/University Photography

Neil Mattson, associate professor in the Horticulture Section of the School of Integrative Plant Science.

Growing crops in controlled environments – in greenhouses, plant factories and in vertical farms – provides alternatives to conventional farming by producing food year-round near metropolitan areas, reducing transportation costs and water use, and improving land-use efficiency. Such local systems also offer valuable educational and psychological benefits by connecting urban people to the food they consume.

At the same time, there is little concrete evidence to show how so-called controlled-environment agriculture (CEA) compares to conventional field agriculture in terms of energy, carbon and water footprints, profitability, workforce development and scalability.

Cornell will lead a project to answer these questions, thanks to a three-year, $2.4 million grant from the National Science Foundation, through its new funding initiative called Innovations at the Nexus of Food, Energy and Water Systems.

“By putting all these pieces together – including energy, water, workforce development and economic viability – we hope to discover if CEAs make sense for producing food for the masses,” said Neil Mattson, the grant’s principal investigator and associate professor in the Horticulture Section of the School of Integrative Plant Science.

Six projects included in the grant will look at:

Case studies: Food system analysis of case studies in metropolitan areas will examine where vegetables are currently sourced and the market channels they go through to reach consumers, such as supermarkets, retailers or restaurants. Researchers will model whether urban CEAs could replace a large fraction of this produce, and whether it makes sense for CEA produce to go through the same market channels or other ones that may suit them better. This project is led by Miguel Gómez, associate professor, and Charles Nicholson, adjunct associate professor, both in Cornell’s Dyson School of Applied Economics and Management.

Computer modeling of energy and water use: Computer models of energy and water use for different crops in greenhouses, vertical farms and plant factories (indoor environments with artificial lighting and racks of plants) will be developed. The models will be calibrated with real-world data from greenhouse growth trials at Cornell and the Rensselaer Polytechnic Institute (RPI). A 2008 study by Lou Albright at Cornell found that based on that year’s technologies, the carbon footprint to produce lettuce in a greenhouse in New York state was twice that of growing it in a field in Arizona or California. Other researchers have reported that CEAs use 20 times less water than field agriculture, since water can be recycled indoors. Mattson leads this effort with research associate Kale Harbick, also in the Horticulture Section of the School of Integrative Plant Science.

Networking: The project will foster industry-to-research networks for facilitating the acceptance, adoption and improvement of metropolitan CEA systems. Anusuya Rangarajan, senior extension associate, will lead this project.

Nutritional value: Researchers will examine the nutritional value of produce from greenhouses and plant factories and comparing those values with CEA systems where lighting might be optimized for more healthful produce. Project leaders include Marianne Nyman, associate professor of civil and environmental engineering, and Tessa Pocock, a senior research scientist, both at RPI.

Workforce needs: Cornell researchers are collaborating with the Association for Vertical Farming to assess the workforce needs of the urban CEA industry and develop programs to meet those needs and test if requirements are being met. Researchers will examine if, for example, all the tomatoes consumed in New York City were to be grown indoors, how many jobs at what education levels and training would be needed. Rangarajan leads this effort.

Training opportunities: Rangarajan and the Association for Vertical Farming will also create workforce training opportunities. They will spearhead outreach through conferences and events to share information. A forthcoming website will house a toolkit to assess the viability and resource availability of proposed urban agriculture projects.

“Urban agriculture is an increasingly touted way to connect producers with consumers, and this grant will help guide full development of this industry and do better to figure out where the best opportunities might be, as well as cases where it doesn’t make sense,” Mattson said.

STORY CONTACTS

Krishna Ramanujan

Agriculture in Space Expert: Deep Horticultural Expertise is Needed for Vertical Farming to Succeed

Dr Gary Stutte is the founder of SyNRGE, a consultancy specializing in Space Agriculture and Controlled Environment Agriculture technology. Stutte, a horticulturalist and university professor, worked at NASA for several years on a program focused on growing crops in space, resulting in some of the first research around vertical farming and LED lighting.

Agriculture in Space Expert: Deep Horticultural Expertise is Needed for Vertical Farming to Succeed

OCTOBER 12, 2017 | LOUISA BURWOOD-TAYLOR

Dr Gary Stutte is the founder of SyNRGE, a consultancy specializing in Space Agriculture and Controlled Environment Agriculture technology. Stutte, a horticulturalist and university professor, worked at NASA for several years on a program focused on growing crops in space, resulting in some of the first research around vertical farming and LED lighting.

Stutte in the Kennedy Space Center growth chamber holding leafy greens grown in self-contained ‘pillows’ (2011)

Today Stutte is actively engaged in developing ground-based applications for space technology in biosciences, protected agriculture, and commercial horticulture. He has published over 150 scientific articles on the effects of growth conditions on crops grown in closed environments, fruit production, space biology, LED lighting systems, and biological life support systems for missions to the Moon and Mars.

We caught up with Stutte ahead of his speaking slot at YFood’s London Food Tech Week at the end of the month (30 October – 3 November), to find out more about his work and thoughts on the development of the indoor agriculture startup scene globally. (Get 20% off tickets with this code! AGFN20.)

How did you come to start working at NASA on indoor agriculture?

It was a bit of luck that allowed me to transition from teaching horticulture and fruit production at a University to working on closed system crop production for NASA. I had been teaching graduate courses in horticulture when I learned of a new program at NASA, which was starting to look growing plants on long-duration space missions. NASA had started the Breadboard project at Kennedy Space Center in Florida as part of the CELSS (Controlled Ecological Life Support System) program that had the objective of demonstrating the feasibility of using higher plants as a renewable life support system for long duration space missions. When the opportunity presented itself to become involved, it was an opportunity I could not pass up.

The Biomass Production Chamber (BPC) at the Kennedy Space Center was the centerpiece of the Breadboard Project in Florida. The BPC was a large (132 m3) closed chamber had been used as a high-altitude test chamber in the Mercury and Gemini programs. The chamber was fitted with lighting, a nutrient delivery system, and air handling systems and provided 20 meters of growing area on four levels. This was one of the first examples of a vertical farm. Incidentally, this design was driven by the constraints of the volume and diminutions of the chamber, not by a desire to design a vertical farm!

Between 1988 and 1996 the chamber operated on a nearly continuous basis — over 1200 days — without any significant failures, and during that time we grew multiple crops of wheat, soybean, rice, lettuce, potatoes and tomatoes in the chamber. Corn was too high for space!

Many other crops were also tested in controlled environment chambers using hydroponic production systems as potential candidate crops for space. Criteria for selection included a short stature, high productivity, short life cycle, nutritional content: criteria nearly identical to those required for successful indoor agriculture operations on Earth.

These tests measured all inputs and outputs including transpiration rates, photosynthetic rates, yield, harvest index and nutrient demand. In addition, the production of volatile organic compounds and ethylene were monitored, as well as the dynamics of the microbial communities associated with each crop.

What were some of the main successes of the program?

The CELSS project in general, and the Breadboard project, in particular, were extremely productive, resulting in over 600 publicly available publications on all aspects of engineering, biochemistry, microbiology, and horticulture associated with controlled environment production. Three area’s I think of great importance were demonstrating the feasibility of the continuous production of crops — not just leafy greens, but tubers like potatoes and staple crops like wheat and soy — hydroponically on a continuous basis, generating detailed data on the nutrient, water, and yield potential of those crops, and pushing the limits of their bioproductivity using electric lighting, nutrient management, and CO2 enrichment.

By the end of the program, we had achieved four-to-five times the world record for field yields of wheat, twice the world record field yields for potatoes in two-thirds of the time, and we exceeded predicted yields from hydroponic lettuce production by 20%.

The data developed by that program on productivity, water use, nutrient demand, and oxygen production are still used as baseline design values for long-duration space missions, including the bases on the Moon and Mars.

What were you using technology-wise?

Lighting was provided by 96 400-W high-pressure sodium lamps in the BPC and crops were grown in recirculating nutrient film hydroponics. The nutrient balance and pH of the solution were controlled, and a number of environmental sensors were installed in the chambers. The BPC itself was designed as a closed system, so the water released by the plants through transpiration was condensed, collected and reused. The atmospheric CO2 was controlled during the day, and all systems were continuously monitored and controlled. There was also a very active resource recovery program in which nutrients from the inedible leaves and stems of crops were recovered and then returned to the plants. By careful management of the nutrient solution and water recovery system, we demonstrated the continuous production of potatoes in the closed system for 418 days in a row; that’s over a year.

There seems to be a lot of development in the lighting space. How did your use of lighting evolve during the project?

The testing began with conventional fluorescent, high-pressure sodium, and metal halide lamps. It was recognized early on that these lighting systems were not suitable for space applications. This was primarily a safety consideration: they are hot to the touch, can explode in low pressure, and contain hazardous gases. Plus, they’re made of glass, that if shattered would mean shards of glass floating around in the vehicle. They are also bulky and have a relatively short lifespan meaning we’d need a lot of replacement bulbs which use up limited storage space and crew mission time.

NASA began funding research on LEDs in the late 1980s, which resulted in the first US patents for growing plants under LEDs in 1991. Subsequently, we used LEDs to examine the effects of light quality on the size, form, and shape of plants, as well as the potential to increase the nutritional content of crops. The use of LEDs is revolutionizing indoor agriculture, and much of the critical research enabling this transformation in horticultural lighting can be clearly tracked to NASA-funded research. I was lucky to be able to participate in some of that work at the Kennedy Space Center in Florida.

LEDs are now being used in all the US plant growth chambers currently on the International Space Station, and the use of LEDs to alter optimize spectral quality through a crops life cycle is becoming a reality.

Do you see any big challenges in how some vertical farms are being developed today?

Controlled environment agriculture faces many challenges, but it is increasing quickly in Asia as well as North America and Europe, and it’s starting to expand into Latin America as well. Vertical farms are driven by the demand for a consistent supply of locally grown, high-quality produce that’s free from pesticides and conserves resources. Much of the growth is enabled by the availability of LED lighting, which can be significantly more efficient electrically than traditional lighting systems, and allows the lamps to be placed close to the plants. However, the challenge remains that it is hard to offset the electrical cost of running LEDs; you often need to sell produce at a big premium, and some early pioneers in the industry have learned that lesson painfully. There are now models for particular crops and markets that I certainly think can succeed. Additional challenges include humidity and temperature control in the facility, as well as excluding pests and achieving sustainability. However, these are all surmountable challenges.

Do you see challenges changing depending on location?

Each site will have its own specific set of challenges, particularly regarding the availability and cost of water, power, and labor. I think the challenge of personnel with training in horticulture is under-appreciated. Vertical farming is an information-intensive enterprise and requires an understanding and appreciation of the fact that you’re growing living things. There is a misconception that using technology to collect data and drive the production of plants makes it relatively easy to automate the production cycle. In theory, it does, but in practice, the biological variables make implementation difficult. The challenge is understanding the environment that each plant species will require; each strain or variety of lettuce, basil, or medicinal plant is a little different.

This understanding of living plants will be the knowledge base that will make or break the next generation of vertical farming facilities; how well the founders pay attention to the selection of species and cultivars and to the horticulture required in the production of plants in an indoor factory.

Have you come across many indoor agriculture operations and startups without horticulture expertise?

Some. Most entrepreneurs are visionaries and have an ideal; they have some information on crops they are growing and some sense of how to grow plants in the field. But once a crop is moved into the control environment of indoor agriculture system, the plant responses can vary greatly depending upon spectral quality, atmospheric composition, and nutrient management. Technology enables indoor agriculture to push the limits of productivity; it becomes far more critical to understand the commodity you’re working with.

Do you think you need a better horticulture understanding growing indoors than outdoors?

In many ways, yes. While indoor agriculture gives you control of the environment, there is less room for error in the decisions that are made.

Why are most vertical farms today purely focused on leafy greens?

Most of the vertical farms focus on leafy greens due to economics. Leafy greens generally have a short production cycle (28-35 days), enabling multiple harvests (9-13 per year per meter squared of production area); short stature maximizing the number of levels that can be grown per m2; have relatively modest lighting density demand (15-17 Moles per m2 day), thus minimizing KW energy required per production cycle, and essentially all of the crop is harvested and sold, minimizing harvesting and processing costs.

It’s hard to do that for wheat; typically the edible grains of wheat makes up less than 20% of a wheat plant. That means you’ve invested all that energy, light and nutrients to grow the inedible roots, leaves, and stems, only to harvest off the seeds that must be processed before they can be sold. In other words, 80% of your investment in the crops not sellable! I anticipate we will start seeing more peppers as shorter season varieties emerge that could be competitive with greenhouse-grown peppers.

I am excited to see that a greater variety of leafy greens, as well as other short cycle vegetables and medically plants produced in indoor farms, are appearing on the market.

We’re not going to feed the world with leafy greens. Are you concerned that there’s not enough research being done on other crops?

I am concerned that there is not enough research being done on other crops. That’s not to say that research is not being done, but it needs to be expanded and conducted in a systematic way to support indoor agriculture. Before I left Kennedy Space Center, our labs had tested over 25 different crops in controlled environments as potential candidate crops for space. It’s imperative to do the research on lighting, nutrient and environmental conditions for new species in vertical farms. While I don’t think that vertical farms will be providing the primary caloric needs for the world, there is certainly potential for it to be a key source of fresh produce that provides critical nutrients and phytochemicals essential to health.

Personally, I’ve yet to see a good business model that would achieve some financial sustainability for a company placing small container type farms in food deserts. That doesn’t mean they don’t exist, but I haven’t seen them. What I can envision is locating a larger scale indoor farm in the economically disadvantaged food desert, in order to stimulate a broader economic impact that could create jobs and generate income for that area. The indoor agriculture model is adaptable to becoming an engine for economic growth and food security in both rural and urban food deserts.

My concern is that many things that indoor agriculture promises are going to be very difficult to deliver, such as the replacement of imported food, fresh food for everybody in large cities, turning food deserts into oases of fresh nutrient vegetables. It is going to be very difficult to do this with the capital and operating costs involved; ultimately you have a perishable product that’s a commodity, and it’s hard to recover the cost of vegetable production unless it is performed at scale.

Philips Lighting Supports MiniCrops’ First Vertical Farm With GreenPower LED Lighting

MiniCrops is the flagship initiative of Vertical Future, a technology start-up aiming to improve health in cities. The MiniCrops initiative provides households, farm shops, catering companies and restaurants with locally distributed boxes of fresh produce, focusing on nutrition, price and sustainability.

October 9, 2017

Philips Lighting Supports MiniCrops’ First Vertical Farm With GreenPower LED Lighting

Eindhoven, The Netherlands – Philips Lighting (Euronext Amsterdam ticker: LIGHT), the global leader in lighting, today announced that it supported MiniCrops, an agriculture technology initiative in the UK, using 200GreenPower LED production modules for its first vertical farm in the center of London. The MiniCrops farm has 65 m2 of production capacity, and triples its growing surface to 195 m2 by rotating crops every 8 hours.

MiniCrops is the flagship initiative of Vertical Future, a technology start-up aiming to improve health in cities. The MiniCrops initiative provides households, farm shops, catering companies and restaurants with locally distributed boxes of fresh produce, focusing on nutrition, price and sustainability. Household customers currently have the choice between boxes totaling either 150 or 300 grams, with each box containing between 6 and 9 different microgreen varieties, such as Rioja Radish, Red Kale, Sorrel, Sweet Genovese Basil and Broccoli. MiniCrops offers fair pricing and free delivery to customers across Greater London, and also recently invested in an electric vehicle fleet, further reducing food miles and environmental impact.

“We see a need for local fresh food with premium quality,” said Udo van Slooten, business leader for Philips Lighting’s horticultural lighting business. “On top of enhancing growth, we now have the ability to influence taste, flavor, nutritional value and shelf life by applying the right growth recipe. This enables our customers to meet the growing demand for fresh consistent quality produce year-round.”

Jamie Burrows, founder of Vertical Future and MiniCrops, realized that with over 70% of people expected to be living in cities by 2050, food sustainability and food security will become bigger and more relevant risk factors. He foresees a significant amount of volatility in food pricing, changes across the farming industry, and temperature variations in food exporting countries. “Consumers expect fresh, locally-sourced, sustainable food – all at the touch of a button. To meet future demands we need to use technology to our benefit, maximizing food production in our own market, close to consumers,” Burrows said, adding that he also thinks that projects like MiniCrops will create local jobs in a new industry.

MiniCrops closely collaborates with Philips Lighting’s horticultural LED lighting partner Cambridge HOK, which supported with the design and build process, resulting in a controlled, uniform, high-quality, maximum yield production facility – minutes from the center of London. MiniCrops is currently in discussions with various parties to develop its second site in London.

For further information, please contact:

Philips Lighting, The Netherlands

Daniela Damoiseaux, Global Marcom Manager Horticulture

There’s An Indoor Farm Growing From 2,000 Solar Panels On A South Philly Roof

The farm is the product of Metropolis Farms, a technology company that specializes in creating both indoor and outdoor vertical farming systems. The idea is to give farmers the chance to grow produce year-round, regardless of weather, while also making the technology affordable for any community.

USER @CLIMATEGROUP/TWITTER

Solar energy prices have dropped significantly as the technology figures to assume a key role in the global energy mix of the future.

OCTOBER 04, 2017

There’s An Indoor Farm Growing From 2,000 Solar Panels On A South Philly Roof

It's the only solar-powered indoor farm the world has ever known

SOLAR URBAN FARMING PHILADELPHIA EQUITY TECHNOLOGY FARMING SOUTH PHILADELPHIAURBAN GARDENING

BY MARIELLE MONDON

PhillyVoice Staff

Not far from the South Philly Target, more than 2,000 solar panels cover about 100,000 square feet of roof – creating the only solar-powered indoor farm the world has ever known.

The farm is the product of Metropolis Farms, a technology company that specializes in creating both indoor and outdoor vertical farming systems. The idea is to give farmers the chance to grow produce year-round, regardless of weather, while also making the technology affordable for any community.

According to a post on the company’s blog, the roof’s solar panels will capture enough sunlight to supply more than half a megawatt of energy, allowing the indoor vertical farm just below on the fourth floor to grow what’s equivalent to 660 acres’ worth of crops.

“Before starting this project, the fourth floor of this building was only growing pigeons,” the company’s blog post reads.

“But now, using our innovative technology that can uniquely grow everything, this solar-powered indoor farm will be growing fresh tomatoes, strawberries, lettuce, herbs, broccoli, and other crops for local Philadelphians.”

Metropolis Farms says there are currently about eight acres of urban farmland in Philadelphia, and that's not unique to many other large cities. If more cities have the opportunity to farm locally, the company posits, it will improve the quality of food across all communities, offer fresher meals and help boost local economies.

Metropolis Farms President Jack Griffin is an ex-banker originally from Philly who launched the company early last year, seeing the project as a method of civic engagement for the city.

“Instead of being a customer, we have to become our own supplier,” Griffin told the Philadelphia Citizen in 2016. “That way, we can keep our money moving within our own city.”

In less than two weeks, Philly will host its first-ever Indoor Ag-Con on Oct. 16, a daylong event scheduled to be held at the Pennsylvania Academy of the Fine Arts that will feature presentations from various indoor agricultural professionals, including Griffin.

Solar energy prices have dropped significantly as the technology figures to assume a key role in the global energy mix of the future.

Your New Indoor garden Could Be A Tree -- A Living Farming Tree, That Is

Your New Indoor garden Could Be A Tree -- A Living Farming Tree, That Is

Derek Markham (@derekmarkham)

Living / Green Food

October 3, 2017

This aeroponic indoor gardening system from the Italian startup Hexagro is modular, scalable, and automated.

In a bid to help make growing some of your own food at home as easy as possible, without needing prior experience or a green thumb, the latest urban gardening product employs LED lights, a suite of sensors, and an automated aeroponics system to keep maintenance (read: gardening) time to a minimum. There are a number of other indoor and countertop grow units on the market, all of which make similar claims, but what seems to set the Hexagro Living Farming Tree apart is its modular nature, which lends itself well to not only customization, but also to scaling up the size of this vertical gardening system.

The Living Farming Tree uses aeroponics, a soil-less growing method that uses a mist of water and nutrients to feed the plants' roots, which is claimed to use up to 95% less water than conventional soil-based agriculture, while also speeding up growth. The basic setup has four growing modules, each of which can hold 6 plant pots, sitting on a framework consisting of a system of tubes and what the company calls "global connectors" that look like they go together like Tinkertoys. An irrigation network is then threaded throughout the tubing, and LED lighting is connected to the upper section of the framework, which together supply light, water, and nutrients to the plants via an automated control system.

According to the company, as many as 13 growing modules can be connected as a single unit, for a total of 78 plants, making it possible to grow more produce in a small physical footprint than a traditional garden bed. This planting density would allow homes, offices, restaurants, and more to have easy access to some freshly grown foods without taking up a lot of space, and the ability to customize its structure to grow different sized plants could make it a more versatile machine than just lettuce and microgreens, which tend to be the staples of indoor gardening systems.

"The modularity of our system lets you produce any plant you want as long as it can be grown aeroponically. I’m sorry, this means you cannot plant a cherry tree there. However, you can go from micro-greens and sprouts up to aromatic herbs, salads, leafy greens and berries. If you want to produce higher plants, you will just need to configure the system in its 2D configuration, and you will immediately be able to produce plants such as tomatoes, cucumbers, medicinal herbs and many more!" - Hexagro

Hexagro Urban Farming has been working on the Living Farming Tree for several years, and was picked as one of the finalists in the 2015 Biomimicry Global Design Challenge, but now the team is looking to take its system to the public with a crowdfunding campaign. Instead of Kickstarter or Indiegogo, Hexagro is participating in the Katana Reward crowdfunding ecosystem, which is part of the EU-funded business accelerator Katana. Early backers of that campaign at the €549 level (~US$645) will receive a 4-module Living Farming Tree when they ship in June of 2018. More information is available at the Hexagro website.

Melbourne Startup Growing Produce Inside Restaurants

Melbourne Startup Growing Produce Inside Restaurants

September 28, 2017

Melbourne-based startup Farmwall is on a mission to transform cities into “food producing ecosystems” with its edible farms that will live and grow inside Melbourne cafes and restaurants.

Melbourne startup crowdfunds journey to grow produce inside restaurants

The crowdfunded venture will produce vertical farms, called Farmwalls, that are installed inside cafes and restaurants to provide a consistent supply of fresh herbs and microgreens at the fingertips of the chef.

Farmwalls bring “farm to plate in under a minute”.

By growing produce on site, Farmwalls aim to reduce packaging waste and high food miles, with a philosophy to bring “farm to plate in under a minute”.

A rendering of a Farmwall inside a restaurant.

The Farmwall team will make weekly visits to venues with the farms, bringing trays of germinated seeds from the company’s aquaponic farm in Alphington. The farm will act as a base for education, welcoming frequent visits from restaurateurs to test, trial and influence produce.

Meet 10 People Who Are Influencing Different Segments of The Produce Industry

In every industry, there are outstanding individuals who go above and beyond to improve the world around them. Produce is no different. From ag-tech to marketing to urban farming, these people are propelling the industry forward. In this month’s cover story, meet 10 of the leading People in Produce.

People In Produce

Meet 10 People Who Are Influencing Different Segments of The Produce Industry

October 3, 2017

In every industry, there are outstanding individuals who go above and beyond to improve the world around them. Produce is no different. From ag-tech to marketing to urban farming, these people are propelling the industry forward. In this month’s cover story, meet 10 of the leading People in Produce.

Do you know someone you think should be recognized in a future issue? Drop us a line at cmanning@gie.net. We’d love to know who you think is making a difference.

Specialty crops

Andrew Carter, CEO and co-founder, Smallhold

Photo courtesy of Andrew Carter

The authority on New York City mushroom production offers customers hyperlocal subscription-based farms.

graduate of the University of Vermont with a degree in ecological design and environmental sciences, Andrew Carter says that in college he learned a lot about mushroom production — a prime educational example of bioremediation. Following graduation, he worked in greenhouses, growing primarily hydroponic leafy greens and herbs, and consulted for vertical, container and warehouse farmers. A couple years ago, things came full-circle when he saw how he could launch the only operating mushroom farm in New York City.

Along with Adam DeMartino, Carter began Smallhold, which grows mushrooms in a container farm by Brooklyn’s East River and ships subscription-based “Minifarms” to restaurants and grocery stores throughout New York City. “I read a lot,” he says about the research he had to conduct before being able to corner the New York mushroom-growing market. “I went out to a few big farms and spoke with the operators there.”

Although Smallhold is still in its early stages, Carter hopes to expand its markets beyond the five boroughs and also potentially begin growing leafy greens and herbs. “In my opinion, as far as the ag market is concerned, you have to be competitive on freshness and price,” he says.

Smallhold’s roughly six-foot-tall Minifarms include rack row chambers that the company has developed in-house that are equipped with WiFi, LED lights, climate control and irrigation, Carter says. “It’s mostly automated, but when we want to update parameters or we want to change anything, we take care of that,” he says.

Carter calls Smallhold’s nine mushroom varieties gourmet and exotic, and they encompass everything from shiitakes to lion’s mane to oyster to pioppino — a delicacy in Italy. The company sells the mushrooms at a competitive price, and due to their proximity to the end consumer, they are very fresh.

“What we’re really figuring out is a way to bring the freshest produce humanly possible to our customers,” Carter says. “By growing it right there, there’s nothing better than that. We’re really working on ways of streamlining that process, making it affordable and making it easy for everyone to have their food growing right there.” — Patrick Williams

Vertical Farming

Photo courtesy of Henry Gordon-Smith

Henry Gordon-Smith,

Founder and managing director, Agritecture Consulting

Henry Gordon-Smith found his niche in agriculture by chasing new opportunities.

enry Gordon-Smith spent his childhood overseas. He was born in Hong Kong, and lived in Japan, Germany, the Czech Republic and Russia before attending university in Canada. While he was not directly engaged in agriculture while growing up, his international experiences primed him for his current career as the managing director of Agritecture Consulting, a company that helps to plan, design and implement urban agriculture projects around the world.

“I grew up in big cities, and big cities force you to think about how you’re using space,” Gordon-Smith says. “You have the chance to engage with so many different cultures and ways of thinking that it forces you to think in a more diverse approach, which I think is a big part of my philosophy.”

Gordon-Smith was first exposed to urban farming and its benefits while studying at a university in Vancouver, Canada. Involvement in local sustainable farming efforts and his own studies lead him to found a blog focused on vertical and urban farming issues called Agritecture (agritecture.com) while also volunteering at various urban ag operations to obtain hands-on- growing experience. Recently, Agritecture merged with Blue Planet Consulting — where Gordon-Smith served as managing director — to form Agritecture Consulting.

After graduation, he bought a one-way ticket to New York City to become an urban farmer. Despite not landing a job immediately, he stayed there, spent time studying at Columbia University under industry pioneer Dickson Despommier and ultimately found his current niche as a consultant. Now, five years after moving to New York, he wants to help people embark on their own journeys into urban agriculture as he continues his own.

“I want to be known as someone who's excited about this [industry], in it for the long-term and is ready to help people progress,” Gordon-Smith says. — Chris Manning

Technology

Dr. Nate Storey

Co-founder and chief science officer, Plenty

Photo courtesy of Plenty

Storey works to bring local, clean produce to communities around the world.

Dr. Nate Storey first made his mark on the produce industry by developing the ZipGrow Tower, a vertical farming system, at Bright AgroTech, a vertical farming equipment manufacturer he founded. Now, as a co-founder and the chief science officer at Plenty, a high-tech indoor farming company, he’s part of a team that’s trying to give everyone access to local food.

Storey started in agriculture by studying aquaculture-integrated hydroponics at the University of Wyoming, where he earned his bachelor’s degree, master’s degree and Ph.D. There, he was able to pursue research projects specific to his interests — projects that lead him to found Bright AgroTech and develop the ZipGrow Towers over a two-year period while he earned his Ph.D.

“[The university] supported my research,” Storey says. “This wasn’t research other universities were interested in or saw as valuable.”

Now, at Plenty, he’s continuing the work he did at Bright AgroTech — which was recently purchased by Plenty — and taking it further. Plenty’s goal is to bringclean, local food to communities across the world that’s grown in its vertical container farms. And, despite only being a young company, Plenty is already a success story.

According to Storey, Plenty is already competitive with field-grown pricing on different greens and herbs and should eventually be able to replace “a good portion” of what field growers currently produce. Publications such as The Wall Street Journal, Fast Company and Bloomberg say Plenty is a model business in a rapidly evolving industry.

This year, it also received a $200 million investment — the largest ever for an ag-tech company, according to TechCrunch — from a venture capital group that includes Amazon founder Jeff Bezos.

And while Storey understands that it’s not “free money,” he knows and appreciates that his work can make an impact beyond the checkbook.

“I love that I’m impacting the future of humanity,” he says. “I am not powerless to see my ideas come to life.” — Chris Manning

Association leadership

Lauren M. Scott

Photo courtesy of Lauren M. Scott

Chief marketing officer, Produce Marketing Association

A foodie from the beverage industry breaks into a leading produce and floral organization.

Self-proclaimed foodie and experienced marketer Lauren M. Scott appears to have found her dream job. A year ago, she was named chief marketing officer for the Produce Marketing Association (PMA). In her new role, she has the unique opportunity to help all businesses in the produce and floral industry prosper.

“I’ve always been a foodie and I’ve worked in the beverage business at Pepsi and Diageo most of my career,” says Scott. “When the PMA opportunity came my way, it gave me the chance to work with leaders in two of the most popular categories in culture today — produce and floral. I wanted to contribute my talent, energy and skills to help these industries grow and prosper worldwide.”

Scott says she’ll be working with her colleagues at PMA to help members by:

- Examining the landscape: consumer/industry research, including the role culture plays in this space.

- Offering actionable insights on strategic marketing: how it complements existing sales and marketing efforts and can be used as a discipline to grow a business.

- Providing resources companies can use to build their businesses, such as eat brighter! (pma.com/events/eat-brighter) and more.

“Our industry is operating in a highly competitive, dynamic food marketplace,” Scott says. “We have to understand that marketplace and then break through the clutter so that our member companies can perpetually thrive.”

In addition to helping established companies prosper, PMA is working to encourage young people to seek careers in the produce industry. It has set up a foundation called the Center for Growing Talent to “attract and retain the best talent for the industry.”

“PMA is committed to making the produce and floral industries the best place to work,” says Scott. “We have significant programs that target college students and we’ve had great success bringing them into member companies where they are contributing to growth.” — Neil Moran

Marketing

Chris Veillon

Photo courtesy of Chris Veillon

Chief marketing officer, Pure Flavor

In a new role with an expanding grower, this marketer conducts a top-down approach to branding.

Chris Veillon, who recently took the position as chief marketing officer for Pure Flavor, sees exciting times ahead for the company and offers some key insights into the future of the produce industry.

Founded in 2003 in Leamington, Ontario, Pure Flavor grows and markets a variety of greenhouse vegetables, including tomatoes, bell peppers, cucumbers, eggplant and living lettuce grown in the United States, Canada and Mexico. In his new role as CMO, Veillon hopes to take the brand to the next level, in part by taking on specific roles with promotions, advertising, content creation and digital marketing.

“The opportunity to grow with Pure Flavor, not only from a brand and product perspective, but professionally, was something I could not pass up,” Veillon says, citing an upcoming $105 million investment into a 75-acre greenhouse build in Georgia as just one growth opportunity for the brand.

Veillon got his start in marketing in the tourism industry. After 10 years in tourism, he was ready for a change. He says he was contacted “out of the blue” by a produce company that was looking to build a marketing department. Over the last 10 years, he was able to “create, strategize and build” a variety of brands that are developing into household names.

At Pure Flavor, Veillon says he gets to see the company from the 10,000-foot level. He sees opportunities to expand the company’s message, but hasn’t lost sight of the most important thing on consumers’ minds: great taste.

“Flavor drives repeat sales, hands down. Great packaging will attract, but what they bite into is what will determine their next move,” Veillon says. “In a space where there is an S-O-S, or ‘sea of sameness’ as I like to call it, there has to be a unique experience for you to retain that customer.”

As consumers become more savvy, they want to know where their fruits and vegetables come from, Veillon says. “Brands that resonate with consumers are the ones that have a unique value proposition,” he says. “It’s not about smoke and mirrors to get the sale, it is about authenticity to create a customer for life.” — Neil Moran

Sustainability

Photo courtesy of Nathan Kaufman

Nathan Kaufman

Director of living systems, The Perennial

This grower feeds flies to fish to fuel an environmentally friendly farm-to-table experience.