Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Purdue Grad Wants His Invention To Reduce Food Deserts

Purdue Grad Wants His Invention To Reduce Food Deserts

May 24, 2018, by Randy Spieth

INDIANAPOLIS, Ind. – A new appliance for the home could soon get mass produced, allowing owners to grow fresh fruits and vegetables without ever leaving their homes. Scott Massey, the CEO and co-founder of Heliponix, has just unveiled his first GroPod and wants to see it become an appliance to tackle hunger.

A GroPod is a little smaller than a standard dishwasher or oven. It uses hydroponic technology to grow seed pods, similar to single-serve coffee containers.

“When you buy a pod for it, and you plug it in, your GroPod already knows what you put in," Massey said. "Different plants have different environmental preferences and the unit will find the average temperature, light cycle, humidity for your variety, among many other variables, and give you specifically the best growing conditions based of what you like to eat.”

Massey first worked on self-sufficient plant growing while on a NASA project as a student at Purdue. He has also used hydroponic technology to start farms in the western Africa country of Togo. Today, he has help start one of the largest farm systems in the region, with space at two Togo universities, a co-working space, and at the U.S. Embassy compound.

“One system for $300 can grow about 500 pounds of vegetables, annually," said Massey. "That’s enough to feed a family.”

Massey said once you see a child suffer from malnutrition, it's a difficult image to get out of your head. That's why he wanted to help.

The creator of the GroPod said he'd like to see the appliance come hand-in-hand with federal housing assistance programs. He came up with the idea after an internship on the El Paso, Tex. and Juarez, Mexico border. There he was building Section 8 housing and saw what a food desert can do to people.

The SNAP program could serve as financial assistance to have seed pods mailed to the homes of low-income families.

"The only thing they had was a McDonald's and a convenience store," Massey said. "After time, you just get obese."

Massey unveiled his first finished GroPod Thursday. He's using it as part of a demonstration to people and organizations working to improve food options in the city at the Flanner House. Some investors were also expected to be on hand.

The finished product is being given to his customer later Thursday night. He added he has many more orders in for the appliance.

Massey, who is from Evansville, is discussing selling the invention to a mass producer of kitchen and household appliances. He said he believes his creation could be on shelves everywhere in a little over a year.

“This is designed to be a common appliance that can be integrated into any home," said Massey. "It does not to be plumbed in. It does not need a special outlet. It only requires Wi-Fi and a standard 110-volt outlet.”

Filed in: News

After Soilless Babyleaf, Here's Hand-Less Babyleaf

After Soilless Babyleaf, Here's Hand-Less Babyleaf

Little Leaf Farms, one of the largest growers of hydroponic baby greens in North America, has officially opened its expanded greenhouse in Devens, Mass this week. The expansion doubles the size of the greenhouse from 2.5 acres to 5 acres, and more than doubles its annual production of baby greens. Thanks to their innovative growing system the greens are grown fully automated, without any chemicals and without any human hand touching the produce. Little Leaf Farms also announced it has purchased adjacent land for a third expansion project set to begin in 2019, which will further increase the size of the greenhouse to approximately 10 acres.

Baby lettuce

Opened in 2016, Little Leaf Farms produces locally grown, fresh baby greens year-round that are delivered to New England consumers within hours of being harvested. Little Leaf Farms grows multiple varieties of baby lettuce at its greenhouse. “Our ability to deliver fresh, great tasting and safe baby greens to consumers that can be easily traced back to the Massachusetts greenhouse has led to our rapid growth and expansion”, said Paul Sellew, CEO and founder of Little Leaf Farms. “We are passionate about transforming the way food is grown. Our process is clean from the start, so consumers can be confident they’re purchasing a safe product, grown in an environment that employs the most advanced food safety practices.”

For doing so, Little Leaf Farms is using a fully automated growing system. The system is optimized for growing of baby leaf lettuce and makes it possible to grow leafy greens fully automated without any human hand touching the produce from medium filling and seeding to harvesting. The seeding is done directly into the gutters to avoid the need of transplanting. Germination takes place under the growing line. After germination the gutters are lifted up to the growing line. During the growing process the gutters are moved automatically through the greenhouse toward the harvesting area. As plants grow the distance between the gutters continuously is adjusted - giving each plant as much space as necessary, but as little as possible. Once ready for harvesting the gutters are transported per conveyor belt to the harvesting area and guided into the cutting machine for a fresh cut.

The system is developed by Green Automation and has recently been upgraded and updated. “The growing lines are now even more robust, offers more precise and easier operations resulting in reduced maintenance needs as well as noise levels”, Patrik Borenius of Green Automation explains. Making the system more durable with increased frame thickness and additional steel components also allows for longer greenhouse growing lines to be designed and for increased gutter capacity.”

Seeding directly into the narrow gutters – eliminating the need for transplantin

Electric lift moving the gutters from the germination level to the growing line in one smooth movement.

New generation harvesting end with more space efficient conveyor design

Sustainability

The system is an important part of the Little Leaf hydroponic growing process, using mineral nutrient solutions in water without soil. “We incorporate principles of sustainability in everything we do, all to provide consumers with delicious, local baby greens at a fair price”, Paul explains. “The growth is completely sustainable, utilizing natural sunlight, a computer-controlled growing environment and a rainwater-based irrigation system that uses 90 percent less water than field-grown lettuce companies”, Paul shows. “The system enables the baby greens to be seeded, grown, cut and packaged without ever being touched by human hands. The production system is free from chemical pesticides, herbicides and fungicides, ensuring that what customers purchase is safe.”

LED lighting

The greenhouse is to be lighted with LED and the company opted for Oreon Grown Light 2.1, water-cooled fixtures by Lemnis. The complete installation of both water and electricity was provided by PB Techniek, Sellew’s installation partner for many years.

Salad mixes

Little Leaf Farms grows multiple varieties of baby lettuce at its greenhouse that are blended into salad mixes and sold in more than 1,000 Northeast grocery stores and to many restaurants, Universities and institutional customers. “More than 98 percent of the lettuce we eat in this country is grown on the West Coast and shipped for days, which means customers in New England are not receiving the highest quality or freshest product,” said Andrew W. Kendall, executive director of the Henry P. Kendall Foundation, an organization focused on creating a resilient and healthy food system in New England to increase the production and consumption of local, sustainably produced food. “Little Leaf Farms has cracked the code on providing the region with fresh baby greens within hours of being harvested. It’s exciting to see that consumers appreciate the value of the product, which will drive the company’s growth for years to come.”

For more information:

Little Leaf Farms

Green Automation

Patrik Borenius

Publication date: 5/25/2018

Author: Arlette Sijmonsma

Copyright: www.hortidaily.com

Philips Lighting Is Now Signify

May 16, 2018

Philips Lighting Is Now Signify

Eindhoven, the Netherlands - Signify (Euronext: LIGHT), the world leader in lighting, has today launched its new company name, following the amendment of the company's articles of association changing its name from Philips Lighting N.V. to Signify N.V.

"The choice of our new company name originates from the way light becomes an intelligent language, which connects and conveys meaning," said Eric Rondolat, CEO of Signify. "It is a clear expression of our strategic vision and purpose to unlock the extraordinary potential of light for brighter lives and a better world."

Signify will continue to use the Philips brand for its products, the most trusted lighting brand in the world, under the existing licensing agreement with Royal Philips. The company expects the name change to be implemented in all the countries where it is active by the beginning of 2019.

Founded as Philips in Eindhoven, the Netherlands, we've led the lighting industry with innovations that serve professional and consumer markets for more than 127 years. In 2016, we spun off from Philips, becoming a separate company, listed on Amsterdam's Euronext Stock Exchange. We were included in the benchmark AEX index in March 2018.

With operations in more than 70 countries and 32,000 people worldwide, Signify generated sales of EUR 7 billion and invested EUR 354 million in Research and Development in 2017.

"We are driven by the principle that light is essential," Eric Rondolat added. "And by connecting it to networks, software, sensors and IoT platforms, we open the door to a smarter world."

News from Signify is located at the Newsroom, Twitter and LinkedIn. Information for investors can be found on the Investor Relations page.

--- END ---

For further information, please contact:

Signify Investor Relations

Robin Jansen

Tel: +31 6 1594 4569

E-mail: robin.j.jansen@signify.com

Signify Corporate Communications

Elco van Groningen

Tel: +31 6 1086 5519

E-mail: elco.van.groningen@signify.com

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings and public spaces. With 2017 sales of EUR 7.0 billion, approximately 32,000 employees and a presence in over 70 countries, we unlock the extraordinary potential of light for brighter lives and a better world. News from Signify is located at the Newsroom, Twitter and LinkedIn. Information for investors can be found on the Investor Relations page.

Growing Up - Why The UAE's First Vertical Farm Could Be A Regional Gamechanger

Growing Up - Why The UAE's First Vertical Farm Could Be A Regional Gamechanger

RABIYA JAFFERY

REUTERS

Abu Dhabi | Thu, May 10, 2018

Vertical farming is taking off elsewhere too: Europe's first commercial farm opened near Amsterdam last year, and Shanghai will next year start a 250-acre agricultural district with skyscrapers dedicated to growing fruit and vegetables. (Reuters/Mike Segar)

When people picture the United Arab Emirates, what likely comes to mind are desert sands, skyscrapers and a blue sea under a shimmering sun. Agriculture does not.

There are good reasons for this: the federation of seven emirates is hampered by high temperatures, a lack of arable land, salty soil and steep production costs. And that is without accounting for the occasional voracious locust swarm.

So it is hardly surprising that the UAE imports nearly 90 percent of its food needs, according to the Abu Dhabi Global Environmental Data Initiative, a data research organization.

This reliance on the global food trade brings opportunity, said Saudi Arabian entrepreneur Omar Al Jundi, who has built the Middle East's first commercial vertical farm in Dubai.

Badia Farm - the word means 'oasis' in Arabic - grows greens like radish, kale, mustard, basil and arugula in a controlled, indoor environment using hydroponic technology and LED lights.

"As a region that has struggled to grow crops due to largely hostile desert landscapes, our farm offers a viable solution to farming that produces harvests 365 days of the year," he said.

"The produce will not only be cheaper than imported goods but fresher too, as the farms will be producing all year round."

The farm, which began production late last year, is on an 800-square-meter plot of land in one of Dubai's main industrial areas and produces two hundred boxes of green vegetables a day.

Though this pales in comparison to the world's largest vertical farm - which operates on 6,500 square meters of a former steel factory in New Jersey in the United States - it marks a big step for alternative farming in this region.

Vertical farming is taking off elsewhere too: Europe's first commercial farm opened near Amsterdam last year, and Shanghai will next year start a 250-acre agricultural district with skyscrapers dedicated to growing fruit and vegetables.

Vertical farming brings some important benefits, said Al Jundi: because produce is grown in a controlled environment there is no need for pesticides or chemicals. And they use much less water - 90 percent less than open-field farming.

Growing food locally for the firm's 30 UAE clients - mainly restaurants and hotels - means a smaller carbon footprint, and saves on transport costs.

"It makes no sense to order produce that arrives in boxes in the back of a ship from as far tens of thousands of miles away when it can be grown at home," he said.

Food Security

Even though the UAE imports most of its food, the emirates are food secure, according to the United Nations Food and Agriculture Organization (FAO).

However, its food security is not without risk, said Hina Kamal, a research analyst at the UAE University's College of Food & Agriculture, as it is reliant on vulnerabilities in supplier countries and on the international food trade market.

Another concern is climate change, which is likely to increase food prices in the years ahead, said Majid Sultan Al Qassimi of the UAE's ministry of climate change and environment.

Although the UAE has strategic reserves in place to protect it from short-term disruptions, he said, "ensuring global food security will be challenging in the future due to impacts of climate change".

Part of the solution, he said, is to boost domestic production through sustainable means; another is "to diversify imports and investments to ensure that the country is food secure in the long-run".

Other solutions include setting up storage facilities abroad and acquiring farmland in Africa, Europe, and Asia. Emirates NBD, a large regional bank, says UAE investors were part of at least 28 deals in the past 50 years covering about 1 million hectares of farmland globally.

The Emirates' drive to secure land abroad to assure its food supply is not risk-free, Kamal said and could be undone by political conditions in those countries or by climate change.

"It is possible that some of (the countries) will be highly affected by climate change - both through more extreme weather events and reduced productivity over time."

Droughts or food shortages could, for example, see host governments impose export bans, she said, which is why boosting productivity at home is the lowest-risk way to ensure food security in the decades to come. It is also more sustainable.

Future-proofing

The UAE will need to improve its agricultural productivity in the coming decades to meet demand, said Qassimi, and to do so in the face of rising global temperatures that are expected to worsen extreme weather events.

"All of this has a direct impact on agricultural production, affecting both food producers and those who depend on them. The UAE is no exception," he said.

Nor, for that matter, is the Gulf region, noted a report last year from the Emirates Wildlife Society and World Wildlife Fund (EWS-WWF), which evaluated the likely effects of climate change on food security.

The UAE is a major regional hub for the re-export of food commodities, it pointed out, and the consequences of climate change, including hotter weather, could affect those facilities.

Any resultant food price spikes would hurt the poorest the most, and that could drive a long-term need for food subsidies.

There are other factors too, not least water. The UAE's agricultural sector accounts for just 1 percent of its economy, the EWS-WWF report noted, yet uses about one-third of its water - vastly disproportionate to its GDP contribution, said Fanack Water, a research group.

Given that water is more expensive than electricity in the UAE - and given that regular farmers benefit from subsidies for water - Al Jundi of Badia Farm said ending such breaks would make vertical farming a cheaper solution.

"The money spent on powering vertical farms is relatively much lower than of the cost of water used in open fields."

That said, Badia does use plenty of electricity: from pumping water to powering the artificial lighting and computers that monitor temperatures. But looking ahead, said Al Jundi, it is working with the government on a shift to renewable energy.

The impact one vertical farm can have, though, is limited, and will be felt only on the margins: it will not change the UAE's reliance on countries such as Brazil, India, Iran and South Africa for cereals, sugar and food oils, for example.

But what it represents - a better way of growing produce in a region that is facing significant challenges from climate change - is important, Al Jundi said.

"This technology will be a major contributor to agriculture sustainability, food diversity, and security as it enhances crop production and lowers their cost," he said.

Eco-Friendly Farming In A Shipping Container

May 11, 2018

The vertical farming market in 2016 was valued at somewhere between $1.5-$2 billion and it has people growing food in places like skyscrapers, warehouses, and yes, shipping containers, which is just what Boston-based Freight Farms is doing. Bloomberg's Caroline Hyde looks at what it's like to farm in a box. (Source: Bloomberg)

CoBank: Controlled Environment Agriculture Experiencing Rapid Growth

CoBank: Controlled Environment Agriculture Experiencing Rapid Growth

USAgNet - 05/16/2018

Technological advancements and consumer demand for fresh, local and year-round supplies of high-quality produce are growing the controlled environment agriculture (CEA) industry across the U.S., according to a new report from CoBank's Knowledge Exchange Division.

CEA, a technology-based approach toward food production to use optimal growing conditions, often indoors, occurs in all 50 states, but the vast majority of the large facilities growing tomatoes, cucumbers and peppers are in the Northeast, West, and Southwest.

"The rising demand for local, high-quality food and the need for a year-round supply of it-is creating market opportunities," said Christine Lensing, senior analyst for CoBank's KED. "Although there is a steep learning curve, high cost and other barriers to CEA, this segment is likely to continue growing for the next five years."

Those barriers are not stopping CEA growers from entering the market at high rates according to the report, partially due to the realization of price premiums and significantly higher yields that the technology, such as hydroponics, provides.

"What has happened with tomatoes over the last 20 years, where about 50 percent of all domestic tomatoes are grown using CEA, is starting to happen in other industries," said Lensing. "There are significant opportunities in leafy greens, microgreens, herbs and other novelties such as turmeric and ginger. However, as new ventures are coming online, they must be very aware of three things, the high cost of operating, fluctuations in the market and competition in this growing space."

According to the report, CEA is an efficient way to produce food locally, save on costs like transportation, meet consumer demands and diversify current operations. This technology will not likely take place of the conventional agriculture of the future, but all indications point to it being an important tool for meeting rising consumer demand for quality produce year-round.

Click for a brief video synopsis of "Controlled Environment Agriculture: Farming for the Future?"

The full report is available at cobank.com.

Princeton University’s Vertical Farming Project Partners With Hopewell Elementary

Princeton University’s Vertical Farming Project Partners With Hopewell Elementary

By MercerMe May 23, 2018

Vertical Farming at HES

Princeton University’s Vertical Farming Project announced they will partner with Hopewell Elementary School in Hopewell, New Jersey to develop their vertical farm-to-cafeteria program.

Fifth grade teacher at Hopewell Elementary, Helen Corveleyn, oversees the school’s outdoor garden beds, six indoor vertical hydroponics towers, and has been instrumental in their new vertical farming initiative partnership with Princeton. Corveleyn will work closely with Princeton University’s Dr. Paul Gauthier, founder and director of the Princeton Vertical Farming Project to develop the program at the elementary school. The on-site, indoor classroom will be fully functioning in September 2018 and will allow preschool through fifth grade kids to mirror Princeton’s program while providing kids with fresh, organic produce for lunch and an invaluable introduction to hands on, cutting edge scientific development.

The Princeton Vertical Farming Project focuses on the sustainability and energy efficiency of vertical farming as they study production rates of hydroponic engineering systems along with marketing and economic feasibility. Gauthier says, “Two of the main challenges that vertical farms are facing revolve around awareness and data sharing. Through establishing a resonant collaboration with the Hopewell Elementary School, the Princeton Vertical Farming Project hopes to educate new generations about the benefits of vertical farming, and to inspire them to expand their knowledge through the application of new, groundbreaking research and technologies, which the farm has been producing. Furthermore, this collaboration will create citizen science datasets, which will contribute to the improvement of the vertical farming field as a whole. By inspiring students today, we hope to shape the future of farming and reduce human impacts on the environment.”

Room to Grow–Princeton Vertical Farming Project Video:

Elementary students and teachers have embraced the homemade, nutritious lunch options infused with organic ingredients served in Hopewell Elementary’s cafeteria. Their community is excited for the new vertical farming initiative with the goal of featuring 100% of the lettuce in the cafeteria grown at the school. Additional vegetables and herbs will be grown, harvested and featured as well.

Principal David Friedrich’s passion for locally sourced, homemade, organic food for his students is evident in the Organic Menu offered at Hopewell. The menu is now in its third year and has seen a 50% increase in participation from the start.

Principal Friedrich said, “At Hopewell Elementary School, we are thrilled to expand the vertical farming initiative which reinforces our commitment to sustainability. As the first public school in New Jersey to offer an organic menu featuring homemade entrees, we will now be able to prepare more nutritious meals infused with our own vegetables and herbs grown and harvested by students. The project also supports hands-on, relevant and high-quality science instruction aligned to Next Generation Science Standards.”

Dr. Thomas Smith, Superintendent of Schools, said, “Lead by Mrs. Corveleyn and Principal David Friedrich, the Hopewell Elementary School has been a driving force in our district-wide sustainability efforts. The vertical farming project has captivated the interest of students and staff. By bridging the gap between science and nature, students can observe the real-life connection between farming and food by seeing what is necessary to grow and produce the food we eat. An important part of this project is that virtually all of the food grown in the vertical farm will be used in our school lunches.”

Children respond to living organisms in the classroom with excitement and passion. Typically in an elementary setting, animals and insects are a wonderful way to promote living organism studies, but at Hopewell Elementary School, they have captured a unique Next Generation Science Standards (NGSS)–aligned curriculum that is plant-based and integrates both life science and chemistry.

Corveleyn remarked, “No child is too young to understand hydroponics. The bottom line is, kids love planting something they know they can eat! Creating an opportunity for sustainable gardening for the future at a young age makes hydroponics not just a buzzword, but a way of life.”

Hopewell Elementary secured several grants to sustain the vertical farming project (click links for articles):

Key Factors For Optimal Crop Production In Greenhouses And Vertical Farms By Professor Leo Marcelis of Wageningen University

Key Factors For Optimal Crop Production In Greenhouses And Vertical Farms By Professor Leo Marcelis of Wageningen University

By urbanagnews

April 16, 2018

Greenhouses and vertical farms around the world are faced with many of the same questions and obstacles when learning to manage crop production in controlled environment agriculture systems. Listen to Professor Leo Marcelis discuss trends, opportunities and other key factors in creating optimal crop production systems for greenhouses and vertical farms.

Lawrenceville, NJ - Lawrence H.S. Freshman Wins International Video Contest

A freshman from Lawrence High School was a first place winner from among 5,000 students participating in the international video contest, Population Connection's "World of 7 Billion".

Lawrenceville, NJ - Lawrence H.S. Freshman Wins International Video Contest

May 18, 2018

By Michelle Dryden mdryden@themediapub.com,

For NJ Advance Media

A freshman from Lawrence High School was a first place winner from among 5,000 students participating in the international video contest, Population Connection's "World of 7 Billion".

Arjun Agarwal was among just 18 first or second place winners. He competed in the Feeding 10 Billion People category that addressed sustainable ideas for feeding a growing population, while educating viewers about the topic.

Arjun Agarwal

He also won a $1,000 prize.

"I didn't expect to win because I knew it was a big contest that thousands of other students entered," said Arjun "I just wanted to create a fun video."

Arjun's one-minute winning video is called "Eating Up By Thinking Up," where he tries to persuade populations to think about transitioning from eating meat to a more sustainable plant-based diet.

"It's a very pressing concern that the meat industry has. There simply won't be enough land, water, and energy for animals," Arjun said. "We need a slow transition from meat to plants, because plants use less land, water, and energy. The statistics are in my video," he added.

Arjun's video suggests that designing vertical farms for growing the plants would help to provide more food for a growing population in a sustainable manner. Later he talked about examples of plants such as "fruits, vegetables, lentils, and beans."

He also said that he is not sure that vertical farms are the same as greenhouses and if they would have an undesirable effect on the ozone.

"These aren't just great young filmmakers," said John Seager, president of Population Connection. "All of the winners are inspirational voices for a sustainable and compassionate future."

Arjun found out about the contest through involvement in his school's STEM club. He felt inspired to tackle the challenge because he saw hunger firsthand while traveling in India with his parents who are in the food industry and teach nutrition.

He also said being a vegetarian himself was also an inspiration.

Other winning students hail from the U.S., Canada, Belgium, and Slovenia.

The contest was organized and promoted during the 2017-18 school year by Population Education, a program of Population Connection.

"We select themes each year that not only address timely global issues but also dovetail nicely with the content in many middle and high school social studies and science classes," said Pam Wasserman, senior vice president for education at Population Connection.

Other winning videos and student bios are available here: worldof7billion.org/student-video-contest

Follow NJ.com on Twitter @njdotcom. Find NJ.com on Facebook.

US (WY): Vertical Harvest Celebrates Second Anniversary

US (WY): Vertical Harvest Celebrates Second Anniversary

Publication date: 5/16/2018

Author: Jan Jacob Mekes

Content Sourced From www.hortidaily.com

On the verge of completing Hearts of Glass, the feature-length documentary following the first 15 months of Vertical Harvest’s operation, JenTen Productions wishes Jackson Hole’s vertical farm with a social mission, “Happy 2nd Anniversary.” The production company put together a short video for the celebration:

Vertical Harvest

Startup Founder Demonstrates Importance of STEM Entrepreneurship to Elementary Students

Media Manager for Purdue@WestGate | Founder of Lodgepole Pine Productions

May 15, 2018

Startup Founder Demonstrates Importance of STEM Entrepreneurship to Elementary Students

“Not many careers give you the freedom to unleash your creative potential.” -Scott Massey, CEO and Co-founder of Heliponix

Scott Massey performs STEM demonstration to fourth through sixth grade STEM Club members at Our Lady of Providence Junior/Senior High School late March. (Image courtesy of Laura Swessel and Our Lady of Providence Jr./Sr. High School)

Scott Massey was introduced to science, technology, engineering, and math (STEM) at a young age.

“My grandfather was an electrical engineering professor at Notre Dame and MIT,” Massey said. “He was a cryptologist who studied information theory for NASA.”

Like many kids, he often played with Legos, building planes and ships while developing an early interest in mechanical engineering.

Through his relationship with his grandfather, Massey was exposed to being creative with STEM.

“I built a radio with basic electrical components from a kit he had bought when I was younger,” Massey said. “I really enjoyed piecing together the radio, turning it on, and hearing the radio work.”

Scott Massey and his grandfather pictured in 2010. (Image courtesy of Scott Massey)

Massey continued to pursue his love of STEM at Purdue University, where he studied mechanical engineering technology. He then explored entrepreneurship as a viable career path and enrolled in the Entrepreneurship and Innovation Certificate Program.

It wasn’t until he discovered his passion for hydroponics that he had the idea to start his own venture. Massey and Ivan Ball co-founded Heliponix their senior year at Purdue and built the GroPod to solve the global food crisis.

“I was originally introduced to the technology of hydroponics and indoor agriculture while working on NASA-funded research at Purdue to develop their own life support systems. As amazing as the introduction to the technology was, it left me really disappointed that there weren’t any jobs in this industry yet because these giant, commercial farming factories you see in media, aren’t that viable.”

“Energy can be one of the most expensive components, if not the most expensive, of a completely indoor growing operation. This is a large part of the input costs of a labor efficient, completely indoor, growing operation,” from ‘How to Invest in Leafy-Green Indoor Agriculture.’

“They consume so much energy it becomes very expensive to operate. So, I realized the final frontier for agriculture was not farm-to-table, but farm-and-table, through hydroponic food computers you can have in your home. This way, you can grow all of the food you need in-house.”

“…I realized the final frontier for agriculture was not farm-to-table, but farm-and-table…”

The Industrial Roundtable at Purdue University is one of the largest career fairs in the country, with more than 400 recruiters last year and attracting around 12,000 students. Though these career fairs offer diverse employment opportunities, Massey didn’t find careers where he was able to prototype his own technological theories with hydroponics.

Massey started filing for patents for the GroPod his senior year. He and the Heliponix (formerly Hydro Grow LLC) team created their first prototype and built a company around the technology.

The Heliponix, formerly Hydro Grow, team winning the 30th Annual Burton D. Morgan Business Plan Competition February 28, 2017. (Image courtesy of Scott Massey)

“Although I was required to work 100 hours a week as a student to generate enough funds to cover just our patent expenses, I felt more free than any of my classmates.”

Massey in college with one of the original GroPods. (Image courtesy of Scott Massey)

Though the path of entrepreneurship hasn’t necessarily been easy, Massey said it is rewarding to be able to follow his passion for solving a real, global problem.

“Not many careers give you the freedom to unleash your creative potential. What’s unique about entrepreneurship is that it gives an innovator the rare opportunity to incubate new technological leaps that existing companies may not be able to envision or fear would challenge their status quo. For those willing to take that leap, they can make disruptions profitable enough to continue funding their initial ideas into established companies.”

This summer, the ag-tech startup company turns two. Through his journey with his STEM business, Massey said he understands the value of educating the next generation.

“It’s important that kids understand they have the power to solve problems their communities face; they don’t have to follow a traditional professional path to find success and better society. They have options. In fact, the tech-enabled world is changing so rapidly, it is not only important to be able to think about entrepreneurship, but it’s also critical if we are going to creatively solve global issues.”

Laura Swessel, a physics and earth/space teacher at Our Lady of Providence Junior/Senior High School in Clarksville, Indiana, organizes the STEM clubs at the school. Swessel said that since she started her 20-year career as a mechanical systems engineer, she believes it is important to expose young children to all aspects of STEM, including careers.

“I asked Scott to come talk about Heliponix because we have been stressing the entrepreneur side of careers this semester,” Swessel said. “I was very eager to have him explain the units and how they work, because it is my hope to purchase a unit to use with the club members and high school students next year.”

Students listen to Scott Massey during STEM Demo Day at Our Lady of Providence Jr./Sr. High School. (Image courtesy of Laura Swessel and Our Lady of Providence Jr./Sr. High School)

Massey held a STEM demonstration for the fourth through sixth grade STEM Club students about indoor agriculture technology. Massey also discussed the tech behind the Heliponix GroPod and the importance of the self-sustaining unit capable of growing fresh produce in a consumer’s home.

“There will be an additional 3 billion people on this planet by the year 2050,” Massey said. “We need to increase our global food output by 70 percent if we are going to avoid a global food crisis, according to the United Nations. However, this will be very difficult to achieve considering agriculture already accounts for 50 percent of our land use and 80 percent of our freshwater consumption in the U.S.”

Indiana as a state has become increasingly invested in STEM education as well as supporting entrepreneurs, like Massey.

In 2012, the Indiana Department of Education began a statewide STEM education plan, identifying the need for ‘rigorous and engaging’ STEM education in schools. The plan includes resources, funding, and information so local schools may better implement STEM education into curriculum and provide options to become further involved in STEM focused, extracurricular activities. The STEM Teacher Recruitment Fund, a $10 million grant program, has also been initiated to grow the number of STEM teachers in classrooms across the state. Applications for the 2018 Governor’s STEM Team are open, honoring four high school students for their exemplary performance in a STEM subject, where winning students receive a $1,000 college scholarship.

The I-STEM Resource Network is a partnership of public and private higher education institutions, K-12 schools, businesses, and government, hosted by Purdue University. Learn more at www.istemnetwork.org

TechPoint Foundation for Youth ensures Indiana’s underserved K-12 students

have access to experiential learning opportunities

that inspire the pursuit of STEM careers. Learn more at www.techpointyouth.org

Indiana has also recognized the importance of supporting entrepreneurship and the important role it plays in economic development.

The Indiana Economic Development Corporation organizes several programs and consolidates resources that support businesses and entrepreneurs, such as Elevate Ventures, the Indiana Small Business Development Center, as well as the state’s network of more than 150 coworking spaces, incubators, accelerators, and maker spaces. Across the state are seven different coworking ecosystems through Purdue Research Foundation’s park locations. The state also supports the Battery Innovation Center, a WestGate@Crane Technology Park tenant, which leverages Indiana’s public and private-sector assets in advanced technologies, Elevate Ventures Kinetic Conference which showcases Indiana’s high growth business, as well as the Next Level Fund which supports innovation in Indiana by making strategic investments in high-growth, high-potential companies.

Entrepreneurship education has been a focus at the university level, such as the Burton D. Morgan Business Model Competition at Purdue University and the Clapp IDEA Competition at Indiana University Kelley School of Business. Together, these competitions alone award more than $50,000 each year to student entrepreneurs.

This year, the first statewide student pitch competition for high school students, the Innovate WithIN 2018 Pitch Competition, awarded prizes totaling $100,000 and will expand in 2019. The inaugural competition drew 86 applicants from nearly 300 students at 65 high schools.

Startup activity is a ‘vital indicator of economic growth’ and having entrepreneurs demonstrate their ideas and businesses enhances Indiana’s entrepreneurial ecosystem, as expressed in “The long view: Fostering Indiana’s innovation and entrepreneurship.”

As a young entrepreneur, Massey believes in the value of STEM entrepreneurial education.

“Being introduced to hydroponic technology as a Purdue University student engineer on a NASA funded research study motivated me to create the original designs that became Heliponix,” Massey said. “Through events such as STEM Demo Day at Our Lady of Providence, I hope that we can continue to demonstrate the importance of STEM and entrepreneurial education to enrich our future workforce. As these events are replicated, the quality of life and career opportunities across Indiana will continue to grow.”

(Image courtesy of Laura Swessel and Our Lady of Providence Jr./Sr. High School)

Thank you to the resources and staff at the Indiana State Library, the Office of Governor Eric J. Holcomb, and the Indiana Economic Development Corporation for their help in researching information for this article. A special thank you to Laura Swessel and the students at Our Lady of Providence Jr./Sr. High School for allowing us to share their entrepreneurial education story.

Sarah Miller

Media Manager for Purdue@WestGate | Founder of Lodgepole Pine Productions

Purdue@WestGate

Purdue@WestGate offers tools for startups, entrepreneurial experts, programs, educational opportunities and workforce development to help southern Indiana businesses grow and thrive.

Arctic Farmer Defies Icy Conditions To Grow Vegetables

Arctic Farmer Defies Icy Conditions To Grow Vegetables

Benjamin Vidmar

On the icy Norwegian islands of Svalbard, located well above the Arctic Circle, the maximum temperature was just 13°C last year and the minimum temperature a frosty -24°C.

For more than three months of the year, the sun doesn't even rise over Svalbard.

And yet, one farmer/chef has taken it upon himself to try to grow food there. FRANCE 24's team went to meet him.

"Svalbard will become an example for the world"

A while ago HortiDaily published an article about Benjamin Vidmar, who grows vegetables in Svalbard. Read that article here.

Source: France24

Publication date: 5/2/2018

Author: Jobke den Hertog

Copyright: www.hortidaily.com

A Crack In The Pavement: Growing Dreams

A Crack In The Pavement: Growing Dreams

New Stories From 'Urban Agriculture Notes'

Linked by Michael Levenston

A Crack in the Pavement: Growing Dreams, Gwynne Basen & Jane Churchill, provided by the National Film Board of Canada

A Crack in the Pavement is a two-part video set that shows children, teachers, and parents how they can work together to ‘green’ their school grounds and make positive changes in their communities.

Gwynne Basen & Jane Churchill

2000 | 19 min

This short documentary shows initiatives kids take to transform bare pavement into dream schoolyards. Some grow trees for shade, and vegetables for a food bank. Others build a greenhouse or a rooftop garden, while others yet construct a courtyard pond as an outdoor classroom and refuge for wildlife.

A Crack in the Pavement: Digging In

A Crack in the Pavement: Digging In, Gwynne Basen & Jane Churchill, provided by the National Film Board of Canada

Gwynne Basen & Jane Churchill

2000 | 18 min

This short documentary follows students from Toronto’s Jesse Ketchum School as they take steps towards the greening of their schoolyard. Along the way they get how-to advice and inspiration from kids across the country; from Pauline Public School, where students raised $10,000, to Broadacres School, where a family of wild ducks found a home in their pond.

San Antonio, Texas - Idea Public Schools Program Shows Middle School Students Hydroponic Farming

Idea Public Schools Program Shows Middle School Students Hydroponic Farming

Idea East Side is the first K-12 school in the nation to have the program

Posted: May 03, 2018

SAN ANTONIO, TEXAS - Idea Public Schools unveiled its first “Leafy Green Machine” on Thursday in an effort to connect school cafeterias and students with local farmers and ranchers.

The modified shipping container grows various kinds of crops using minimal electricity and water. All the produce goes to the school cafeteria.

The machine is part of a pilot program for hydroponic farming. Officials said the technology will engage students, especially those in sixth, seventh and eighth grades.

The program goes hand-in-hand with classes such as biology, chemistry and math.

“It’s a great addition to our program because it's showing students the tech side of agriculture, fully automated. Students are able to see firsthand how tech plays a role in agriculture by using computers (and) chemistry of chemicals,” said Hernan Colmemero, CNP farm manager for Idea Public Schools.

Idea East Side is the first K-12 school in the nation to have this kind of program

This Automated Greenhouse Fits In An Apartment

This Automated Greenhouse Fits In An Apartment

Posted by Mike Williams-Rice May 11th, 2018

To improve access to vegetables among urban apartment dwellers, engineering students have created an indoor, automated greenhouse.

“This allows them to grow fresh produce, everything from leafy greens to herbs to root vegetables,” says Harrison Lin, a member of the team from Rice University.

Växthus (Swedish for greenhouse) comes from the HSB Living Lab at Chalmers University of Technology in Gothenburg, Sweden. The lab is a residential community of 29 apartments for students and visiting researchers, all of whom are involved in finding solutions for more sustainable living. The Living Lab partnered with Rice on a previous project to develop a device to simplify composting at home.

The Rice students say their greenhouse project furthers that mission by enhancing city life.

The team worked at Rice’s Oshman Engineering Design Kitchen with guidance from Matthew Elliott, a lecturer in mechanical engineering, and Gary Woods, a professor in the practice of computer technology and electrical and computer engineering. The goal was to produce an efficient and attractive prototype small enough for an apartment. The result is a wood-paneled greenhouse with a clear acrylic front.

“I think we did really well, thinking about how it would feel as an outside user,” says team member Mike Hua. “We wanted to create a product that made the user interface easy.”

The greenhouse uses soil, as opposed to a hydroponic system. That allows users to grow a greater variety of vegetables, as hydroponic systems don’t have the space for the deep-root systems that vegetables like carrots require.

(Credit: woodleywonderworks/Flickr)

The fully automated Växthus design controls lighting and watering with a closed-loop system. Moisture, temperature, and humidity sensors collect data and send them to a touchscreen display, with on and off switches for water and light. When the soil is dry, the greenhouse releases water for the plants. When it senses that the soil’s moisture level is fine, it turns off. The team added manual controls so users can override the automatic functions.

Scientists grow sweet potatoes in Martian greenhouse

A pump system lets water drip from the ceiling to mimic rain and reclaims it from the drip tray below. “Any excess water will percolate through into the tank below,” says team member Jack Kaplan. That allows the device to recycle water.

During the design phase, the team grew kale and herbs, and now has carrots and radishes growing in the greenhouse.

The team is building two more of the devices and will ship them to Sweden, and in June it will install them at the Living Lab, where residents and researchers will continue testing the units, tweaking the automated system as necessary and growing different vegetables.

Source: Rice University

LifeLab Is Making The World’s Smallest Hydroponic Modules In Lebanon

LifeLab Is Making The World’s Smallest Hydroponic Modules In Lebanon

by Agrytech | Apr 13, 2018 | In The News |

We talked to Ali Makhzoum, co-founder of LifeLab, to have his in-depth insight on the hydroponics sector, the solutions LifeLab is providing and where it stands in the international scene.

LifeLab provides the world’s smallest turnkey vertical hydroponic modules. These modules connect to each other and then ultimately to an industrial grade automation system that runs the entire grow process with very little human intervention. LifeLab joined the Agrytech Accelerator Batch I in the Bootcamp and Acceleration phases. Their work with the Agrytech team continues.

Q: What are the specificities of your hydroponics system?

A: It’s 2 things: 1) Modularity: Our systems are modular, and I’m not talking about a 20-ft container module, but a 0.5 cubic meter module, which makes our LiveCube™ system the smallest, and hence, most flexible, vertical hydroponic module in the world, and it’s specifically designed for commercial (B2B use).

Besides its modularity factor, we’ve technically invented a new measurement unit in the world of commercial agro production to highlight the benefits of vertical farming. People still measure in square meters, we measure in LiveCubes, factoring in the entire volume of any given farm space instead of only its area. 2) Hybrid Technique: Loosely based around NFT (Nutrient Film Technique), yet surpassing it by drawing on the strong points of several other hydroponic growing methods, our technology is a hybrid model that combines the best parts from each known technique, and adds our own magic touch to them to create a robust, dependable growing environment that maximizes the advantages and minimizes the known disadvantages/weaknesses of hydroponics.

Q: What are the elements of the LifeLab solution?

A: Our solution is a 360-degree approach that aims at tackling the entire farm-to-fork chain. It’s composed of 3 parts:

I) The Physical Tech: This is the actual farm, composed of the combination of our proprietary modules and their governing control mechanism in which the plants grow: BaseCube™ modules + LiveCube™ modules + Command & Control Module = LifeLab UpFarm™

II) The LifeLine™ Dashboard: To control quality (and generate recurring income) we supply the farms with everything they need to grow their produce. Currently this is a simple on-the-ground system whereby customers order the supplies they need and we deliver them, but we’re developing it into an online dashboard connected to the farm, that tracks the operators inventory (plugs, seeds, nutrients, and all other growing supplies) and connects to our supply system to inform the farmer/operator, and us, of current inventory levels and imminent requirements, which will enable the farmer/operator to automatically replenish their inventory with great ease.

III) The ‘Community’ OTMP (Online Trade Management Platform): This is a fully online platform currently in early phases of design, which will be composed of a virtual marketplace, connecting our operators/producers directly to buyers.

Q: Is anyone else working on something similar in Lebanon?

A: That really depends on what you mean by “similar”. We come across new attempts at commercial hydroponic farms on a weekly basis. All of them are set up within traditional greenhouses, which constitute a very poor environment for hydroponics and an even poorer one for vertical growing since they depend on sunlight coming from a single source at the highest point of the structure, leaving the lower layers partially or completely shaded. Not to mention the insects, and radical environmental changes with the change of the external climate, which totally defeats the purpose of CEA (controlled environment agriculture).

Q: How does LifeLab’s innovation compare to international solutions in hydroponics?

A: Besides the small handful of global players with the right idea in mind, most international attempts are focusing either on B2C grow-your-own food-on-your-bookshelf- type products, which is not our market, or on “Urban farming”, which is nice in theory but ridiculously unsustainable in reality.

Because of their modularity and flexibility, our systems can thrive anywhere, particularly in suburban and rural areas, where actual farmers are more likely to be available. Even if the investors behind the farms were large food companies, which fits quite well into our business model, you still need farmers with green thumbs to run these places. So we’d be creating a new breed of partnerships.

Literature aside, and on a more technical note, there are generally two types of hydroponic technologies in the world: Very high tech, very expensive, high maintenance, good results, but terrible payback period, and there’s the low tech, less expensive, low maintenance model set up in traditional greenhouses, which is significantly less productive, problem-ridden, and yields average to mediocre results.

From day one, our goal was to optimize vertical hydroponics for commercial feasibility, and we did exactly that. Our technology strikes the perfect balance between the available options, bringing together the best of both worlds: Robust, dependable technology that’s designed around the most important aspect of the farm: The farmer/operator.

Our technology is a well rounded combination of hardware, software, and intuitive design; sophisticated enough to automate most of the work saving over 75% of the labor otherwise required, yet simple and practical enough to allow easy operation and still allow the farmer/operator their own input and personal touch into the process, putting their growing experience to good use, resulting in a seamless combination of human know-how and experience on one hand, and technology that does the heavy lifting on the other hand; creating standard, predictable results with a payback period that trumps the competition by years, not months.

(The smallest LifeLab UpFarm yields 100% ROI in 2.3 years with OPEX included, this period goes down as the area of the farm increases; compared to ~4.5 years for our closest European Competitors “Urban Crop Solutions” and 8.8 years for our closest American Competitor “Freight Farms” – based on CAPEX alone. I’m not even going to bring up the Japanese competition because then it just gets embarrassing, but just for your reference: Japanese Container Farms – Qatar listen for the price in the first few seconds of commentary).

Q: What are the setup costs vs revenue compared to conventional farming?

A: A traditional plastic greenhouse costs less than $100 per square meter to set up without any sophisticated features, and depending on climate and availability of water, the operational cost varies, rendering the average COGS (cost of goods sold) per plant at around 25 cents, not factoring in the pesticides/herbicides or labor required to run the operation which would drive the cost up even more.

Produce from such a greenhouse would be considered gourmet if the plant sells for $1, which is rarely the case as most local farmers sell their greens at 60-75 cents per plant and are restricted by seasonality, which means they can produce 3-4 harvests a year on average for most types of crops.

Compare that to one of our farms, where one square meter costs approximately $1,000 to set up (at 5 levels; 3M height) , and around 30 cents COGS per plant, produces the equivalent of 30 Square Meters, 365 days a year, with near zero crop losses. No pests, no weeds, and hence no pesticides or herbicides.

90% less water consumption. Fully climate controlled which means they can be used to grow produce specifically when it’s out of season, and sell it for premium prices, and when said produce gets back in season and the competition increases, our farmers/operators can immediately switch (within 24 hours) to producing whatever else has now gone out of season and sell THAT at a premium price when nobody else around them can grow it.

Q: Who is your target market? Who are you planning to sell your product to?

A: At first we wanted to target traditional farmers. Needless to say that didn’t fly. However, their educated children who are now doctors, engineers…etc and have inherited the family land/business are loving the concept of a farm that fits in a small space, operates year-round, produces 30 times as much in a fraction of the time (4 hours a day instead of 10-12), a fraction of the labor, and requires no tractors/harvesters/other heavy machinery, weeding, dirty work or heavy lifting, controlled by a touchscreen and can be monitored from anywhere through their smartphones. This allows them to invest their savings in a family business that makes them several times the profit their fathers used to make while still keeping their jobs.

Besides these individual neo-farmers, we want to target a wide range of F&B companies, supermarket chains, and governmental agencies specialized in agro-development & subsidization. In the future, we can create private-sector consotrium-type cooperatives, where we pair investors with farmers. The investors put in the money, the farmer operates the farm and is a partner, our system handles the rest, and everyone makes money.

Our GTM strategy involves creating strategic partnerships with existing companies (mainly agriculture equipment/supplies providers) who’s staff we would train to handle sales and maintenance on our behalf using their already existing infrastructure instead of us investing heavily in every new geography/market we want to penetrate.

Q: What is the dollar value of the hydroponics sector internationally?

A: Global Annual Fresh Produce Imports:

MENA: $92.4 Billion

USA: $70 Billion

Europe: $45 Billion

Global Hydroponics Market (2017):

Equpiment & Supplies: $ 340 Million

Produce Market: $ 114 Billion

Medical Cannabis: $ 52 Billion

Q: Where are you now? Where are you planning to be? What do you need to achieve that?

A: We recently finished our very intensive foundation phase of R&D and product + market validation. Our technology has been installed and performing very well for over 2 years now, we did all the necessarily polishing & debugging to have a viable, commercially feasible, market-ready product that can produce 70+ types of greens as well as strawberries* with very stable and predictable results. It’s now time for us to start selling our first product and capitalize on all the product development we’ve done over the past few years.

While starting to sell our first product, we want to be working in parallel on developing our second hardware product, the OmniHive™, which is a vertical hydroponic system capable of growing everything else our current product (and all our global competitors products) cannot grow: 40+ varieties of fruiting plants, berry bushes, and dwarf fruit trees.

To achieve all that we need a new, sizeable round of funding, and a network of strategic partners to help us achieve our goals.

Watch Ali’s video

Agrytech is a program by Berytech jointly funded by Berytech and the Embassy of the Netherlands in Lebanon. Applications are now open for Batch II of the Agrytech Accelerator.

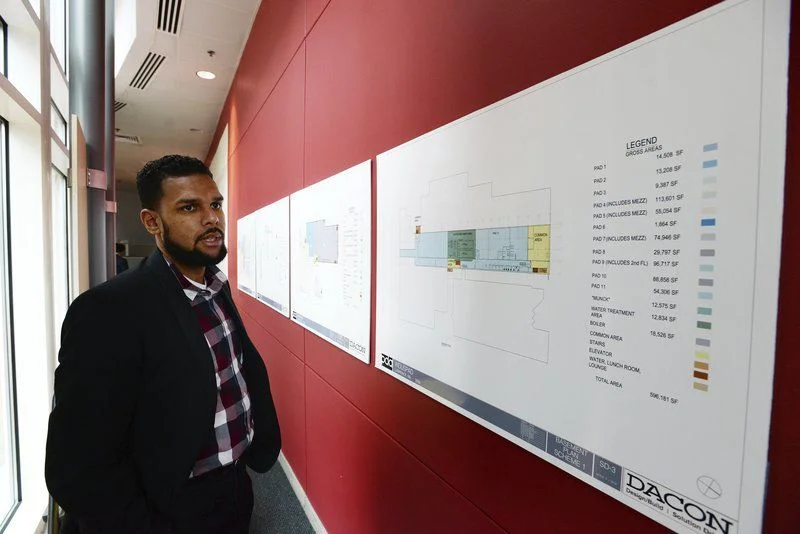

Envisioning Innovation Buyer Building Mixed-Use Community Center At Former Polartec Plant

Envisioning Innovation

Buyer Building Mixed-Use Community Center At Former Polartec Plant

April 22, 2018

LAWRENCE — Voices echo through the empty spaces inside 46 Stafford St., joining the thrum of the air ducts that weave a labyrinth overhead. Daylight spills in from rectangular windows that on the outside look massive, but on the inside only manage to illuminate small pools on the expansive stretches of vacant factory floor.

Jitender Makkar walks along the remnants of the rows where workers once produced textiles for Polartec, until the manufacturer announced its plans to close up shop at the facility that straddles Lawrence and Methuen and move its operations to Tennessee.

Polartec put its 559,868-square-foot, two-building site up for auction last spring. Makkar, a California-based real estate broker who got his start with construction and industrial design in India, bought it for $5.35 million.

Makkar's vision for the facility is as vast as the building is large. Touring the space with his fiance Purnima Dey, the two spoke of their plans to turn the facility into an innovation hub and community gathering place. Fittingly, Makkar has renamed the building IndusPAD.

“We want to create an ecosystem where these innovators really thrive,” Makkar said.

The IndusPAD facility includes a basement and two floors of manufacturing and office spaces that Makkar is dividing into 11 “pads” for companies to build out to suit their needs.

The idea is to have innovators and entrepreneurs come to IndusPAD to “develop their ideas and prototypes and go into manufacturing here,” Makkar said, going along with the IndusPad motto: “Innovate. Actualize. Succeed.”

There's plenty of room for industrial uses, like a massive space just through the visitor's entrance on the first floor with 31-foot-high ceilings and 15 loading docks, and another expanse leading off of it that stretches deeper into the cavernous building.

Makkar envisions community spaces, too. A row of huge windows on the side of the building facing Stafford Street would be the ideal setting for a restaurant or sports bar. Another space across the building, near the visitor's entrance, would be great for a brewery, he said.

Ultimately, Makkar envisions the building becoming an industrial mall with “different sections, different businesses doing their different ventures,” filled with both local entrepreneurs and outside companies wanting to make inroads in the area.

Among those expected to set up shop at IndusPAD is Beyond Organic, a Dutch indoor agriculture company, which is working to open a 30,000-square-foot hydroponic vertical farming facility to produce a range of lettuces and herbs. Makkar said he hopes the company will bring in machines in the next few months to start growing “clean” produce, without the chemicals typically found in fruits and vegetables imported to Merrimack Valley grocery stores, bodegas and restaurants from across the nation and world.

“This is going to feed the Merrimack Valley, that's the idea,” said Dey, who is also IndusPAD's public relations director.

Another prospective tenant is working on prototypes to treat diseases affecting the world's banana crop, Makkar said. A medical equipment company has expressed interest in the location, too.

Makkar and Dey spoke of working with area educational institutions to bolster the young workforce with the skills and technical training that would fit the jobs they hope to bring to IndusPAD. They are keen on bringing manufacturing back to the Merrimack Valley, modernized for the 21st-century.

“The people of Lawrence and Methuen, they're hardworking people,” Makkar said. “It is time (for us) to contribute.”

Makkar and Dey intend IndusPAD to be a community partner. Already, they've held events for local groups including the Merrimack Valley Chamber of Commerce and the Lawrence Partnership.

They also want to be patrons of the arts by providing studio space for local artists to grow and thrive, and eventually hope to focus on “industrial art,” according to Makkar.

IndusPAD already has one artist-in-residence: 24-year-old Jonathan Henriquez, a New York native who moved to Lawrence as a child.

Henriquez, who as an artist goes by Jon Hen, is a painter who creates large, colorful and abstract pieces he said are borne from “what surrounds me, the energy that surrounds me, the ups and downs” of emotion.

IndusPAD is allowing him to use space rent-free for several months as the building is renovated. Henriquez, who also works at cafe El Taller on Essex Street, has already set up a studio on the second floor.

As deals are being finalized with businesses, crews are working to remove the equipment and scrap materials Polartec left behind.

Some things will remain, however, like the massive air ducts and pipes. They'll be preserved for aesthetic purposes and industrial uses if needed, but will also serve as a testament to the building's manufacturing history.

While Makkar and Dey are new to the Merrimack Valley, they understand the importance of the building they purchased, and how manufacturing was for so long the bedrock of the region. For years, the plant served as “a manufacturing building of great intensity,” Dey said, with a nod to the Malden Mills buildings before it, which were infamously destroyed by fire in the mid-1990s.

“It's important to preserve it,” she said.

Follow Lisa Kashinsky on Twitter @lisakashinsky.

Tags Commerce Jitender Makkar Agriculture Economics Induspad Building

How Elon Musk’s Brother Kimbal Musk Is Reimagining Farming

April 5th, 2018

How Elon Musk’s Brother Kimbal Musk Is Reimagining Farming

Kimbal Musk, brother of Tesla founder Elon Musk, has set up 10 sustainable farms in shipping containers that produce 50 to 100 pounds of food every week, the equivalent of that traditionally produced by 2 acres of farmland. He talks about his Square Roots urban farming project and reveals how you could enter a raffle to win his Tesla Mode

The Princeton Vertical Farming Project

The Princeton Vertical Farming Project (PVFP), located in Moffett Laboratory, was launched by Dr. Paul Gauthier, an associate research scholar in plant physiology and environmental plant metabolism in the geosciences department.

The project is funded by the High Meadows Fellowship through the Office of Sustainability as part of the Campus as Lab initiative.

The Princeton Vertical Farming Team, lead by Paul Gauthier, has been steadily growing since the project’s start in the spring of 2017. The team consists of faculty, students, and members of the Office of Sustainability. Coming from a wide range of academic backgrounds, the students on the team were all drawn to PVFP for different reasons, and continue to expand the potential of the vertical farm as a hub for student research and activity. Meet the team and learn about the many ways students and faculty have gotten involved in the project.

Paul discusses sustainability in his research with the Office of Sustainability. Read the interview »

MEET THE TEAM

Paul Gauthier

I am an Associate Research Scholar in the Department of Geosciences at Princeton University. I obtained my PhD from the University of Paris Sud in plant physiology and plant metabolism. I am broadly interested in the regulation of leaf carbon balance and the relation source-sink in the whole plant from the molecular to the ecosystem scale. In the past few years, my interest for the challenges associated with food security has grown and I see vertical farming as a way to answer a growing demand for healthier and tastier vegetables. The development of this project is an opportunity to answer new questions related to the impact of vertical farms on the environment and find new solutions to make them more affordable and sustainable.

Jesenia Haynes (’18)

My name is Jesenia Haynes and I am in the class of 2018 studying Ecology and Evolutionary Biology with a certificate in Environmental Studies. I enjoy learning about all aspects of biology, but recently I have been focusing more on sustainable agriculture. In the future I hope to work both domestically and internationally to promote sustainable agriculture and ecological conservation.

Rozalie Czesana (’18)

I am a senior at Princeton majoring in the Woodrow Wilson school with certificates in Environmental and Urban Studies. Because of my interest in sustainable development and food, I got involved in the Vertical Farming project right in the initial, planning stages. So far my role has revolved mainly around establishing connections across campus and raising awareness about the project, for example by working with Forbes College and Terrace F. club, where I coordinated a parallel study in the greenhouse. In the near future I am excited about exploring the scalability of the farm, particularly its potential use in nearby food deserts such as Trenton.

Aamir Zainulabadeen (’18)

I am currently a senior in the Computer Science department and I’m working on Princeton’s Vertical Farming Project for my senior thesis. The goal of my project is to develop a software/hardware system that automates certain aspects of the farm – data collection, feedback cycles, and data analysis. I’m mainly interested in this project because sustainable agriculture is a key issue for addressing climate change. The great thing about software is that it may be repeatedly used at low cost, so I hope that my thesis will be useful not only for Princeton’s Vertical Farming Project but also for anyone else interested in sustainable agriculture.

Seth Lovelace (’20)

I am a Sophomore in Princeton’s Mathematics Department, and am from New Orleans, Louisiana. I originally grew up in rural California, and grew up growing fruit on an acre and a half of land. As such, seeing both city life and country life growing up, I’ve always had a strong connection to sustainability. As part of the Vertical farm, I am analyzing nutrient uptake by plants, and how this nutrient uptake changes over time. I hope that this will allow for me to optimize the manner in which we supply nutrients to plants in a vertical farm environment. My background is very quantitative, and I hope to bring a rigorous and methodical perspective to the farm, increasing the quality of food through the components that make them up.

Kyra Gregory (’19)

My name is Kyra Gregory, I’m in the Department of Art & Archeology, Program 2 with a certificate in Gender and Sexuality Studies. I work for the Office of Sustainability as a Communications Assistant and have always had a passion for environmental science and sustainability. My job for the Vertical Farming Project is to design and manage the website and blog the progress of the farm.

Natalie Grayson (’20)

My name is Natalie Grayson and I am in the class of 2020 planning to study Ecology and Evolutionary Biology with a certificate in Environmental Studies. I am newly interested in the field of sustainable agriculture and I think that vertical farms will be playing a larger and larger role in this. I have been managing the day to day aspects of the farm thus far, but I have been planning to begin conducting some additional research at the farm.

Allison Huang ’21

As Farm Manager, I upkeep and monitor the farm’s overall progress, which is really an excuse to watch the plants grow and change in their ‘intuitive’ way. In the future, I hope to conduct research on how fluctuations in pH and nutrient availability translate to a more controlled, artificial environment like the Vertical Farm. I am a first-year student and a prospective Woody Woo major.

Hydroponics: The Future of Agriculture

Hydroponics: The Future of Agriculture

— By Jescilia Karayamparambil & R N Bhaskar | Mar 14, 2018

Mumbai : In one of the many offices of HiMedia Laboratories in Mumbai, there is a lab that is working on basic research relating to plants – as an aid to promote hydroponics. Hydroponics, or vertical farming, is not a new concept. But the techniques that are being adopted in hydroponics are improving every day. HiMedia has now opted to create another company – Higronics – to focus on providing plant-specific nutrients.

In some ways, HiMedia is an unusual company. It has focussed on the study of the structure, physiology, genetics, pathogenicity, ecology, and taxonomy of microorganisms in a simulated growth environment and has enabled researchers to isolate the typical behaviour of microbes that affects humans in different ways. Today, with a turnover of over Rs 500 crore, it is one of the top three brands in microbiology in the world. It has been in the forefront of assisting microbiological research by providing essential culture media that are easy to use, safe, and comparable with world standards.

It is with this background that it decided to focus on food, through the development of plant nutrients, which would be immensely useful for hydroponic farms. Dr. Vishal G Warke, from the promoter family, believes that “the area of hydroponics requires continuous research and development for it to become the future of farming. “

Unlike conventional farming, hydroponics uses little soil but uses cocopeat – coconut fibre and vermiculture – during the growth phase of the plant. Thereafter, it allows the plants to grow in a soil-less environment, thus taking away 70 percent of pests from the agri-system. This is because over 70 percent of all pests are soil based – including weeds. The absence of pest allows for significantly less use of pesticides. Thus you have healthier plants, using less water and hardly any pesticides. Moreover, while conventional agriculture believes that sunlight is important, hydroponics works on the principle that what plants need is spectrum – particularly blue and red – and not sunlight. Using LED lamps, they create an environment where the plant gets all that it needs for growth in a controlled and healthy manner. Hydroponics thus reduces the chances of crop failures due to drought, thanks to the minimal use of water.

With the vision of providing excellence at the doorstep, HiMedia Biosciences began its journey about 35 years ago. Today, the company has an ambitious target to provide a one-stop solution for farmers looking for soil-less farming. Recalling the plight of farmers, Warke said, “The idea to conduct a research on hydroponics developed merely as a CSR thought. But after understanding the functions of hydroponics, we realized that it needs to reach out to a larger number of farmers.” With CSR, the scope of expansion is limited.

There is a great divide among farmers in India— while some are rich, there are some who are trying to make their ends meet, he said. He pointed that while rich farmers are getting richer with passing day, the small and marginalized ones are taking suicidal route.

“This is where we want to come in,” stated Warke, whose company is famous player in developing microbiology products. The rich farmers fail to transfer the technology to marginalized farmers, he added. “We would like farmers to allow one-fourth of the land they have to be developed for hydroponics. That would allow farmers to de-risk themselves from dependence on just one crop to offering high-quality crops in a carefully managed controlled environment.” Hydroponics with soil-less farming is immensely popular in South Korea where more than half the crop is produced using these techniques.

According to recent reports by MarketInsightsReport, the global hydroponics market is expected to grow at a CAGR of 6.5 percent during the period between 2018 and 2023. In 2016, it was estimated to have crossed $2,120.35 crore. Even though the report brands Europe as the largest market, it goes on to predict Asia-Pacific region, second largest market for hydroponics, to grow at a steady pace.

Higronics, product specialist, Manish Raut stated there are 50 plus hydroponic companies out there. However, we have a clear vision to become a one-stop destination for all hydroponic needs. He said that 2016-formed company has conducted research and development (R&D) with over 350 crop-types and have derived some productive conclusion. Raut revealed that the company shows positive results with leafy veggies and some fruits like strawberry and its variants, for vertical farming. Globally, major veggie production via hydroponic is of tomato, lettuce and leafy vegetables, pepper, cucumber, others.

HiMedia is currently working on developing other modules: “We are working on a various spectrum of light to understand how the vegetables and fruits react to different lights.” Warke believes that this temperature-controlled atmosphere will prove successful for exotic vegetables and also flowers.

Warke strongly believes that hydroponics would be a perfect marriage between industries and agriculture. He advocates the need to de-risk the farmers by introducing various methods and increase profitability which is the need of the hour. Hydroponics would also reduce the loss of agri-produce as the market will be very close to the consumers. Of course, this will require state support. And that is why he has gone around explaining to people why the future of farming will have to be hydroponics – using less land, water, and pesticides, yet ensuring higher output. With climate change, unseasonal rains, and the quest for food without pesticides, hydroponics could be the solution for the future.