Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Where the Mouths Are: A Farm Grows In The City

May 21, 2017

Where the Mouths Are: A Farm Grows In The City

Relatively inexpensive space in underutilized urban areas, close to where the majority of the population will live for the foreseeable future.

It makes too much sense not to seize the opportunity. JL

Betsy McKay reports in the Wall Street Journal:

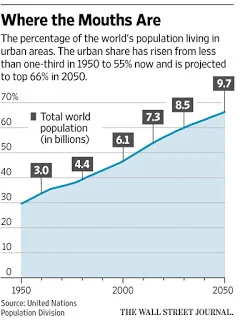

The world’s population is to reach 9.7 billion by 2050, 33% more than today. Two-thirds of them are expected to live in cities. Getting food to people who live far from farms is costly and strains natural resources. Startups and city authorities are finding ways to grow food closer to home. High-tech “vertical farms” are sprouting in rows, fed by water and LED lights, customized to control size, texture or other characteristic of a plant.

Billions of people around the world live far from where their food is grown.

It’s a big disconnect in modern life. And it may be about to change.

The world’s population is expected to reach 9.7 billion by 2050, 33% more people than are on the planet today, according to projections from the United Nations. About two-thirds of them are expected to live in cities, continuing a migration that has been under way around the world for years.

That’s a lot of mouths to feed, particularly in urban areas. Getting food to people who live far from farms—sometimes hundreds or thousands of miles away—is costly and strains natural resources. And heavy rains, droughts and other extreme weather events can threaten supplies.

Now more startups and city authorities are finding ways to grow food closer to home. High-tech “vertical farms” are sprouting inside warehouses and shipping containers, where lettuce and other greens grow without soil, stacked in horizontal or vertical rows and fed by water and LED lights, which can be customized to control the size, texture or other characteristic of a plant.

Companies are also engineering new ways to grow vegetables in smaller spaces, such as walls, rooftops, balconies, abandoned lots—and kitchens. They’re out to take advantage of a city’s resources, composting food waste and capturing rainwater as it runs off buildings or parking lots.

“We’re currently seeing the biggest movement of humans in the history of the planet, with rural people moving into cities across the world,” says Brendan Condon, co-founder and director of Biofilta Ltd., an Australian environmental-engineering company marketing a “closed-loop” gardening system that aims to use compost and rainwater runoff. “We’ve got rooftops, car parks, walls, balconies. If we can turn these city spaces into farms, then we’re reducing food miles down to food meters.”

Moving beyond experiments

Urban farming isn’t easy. It can require significant investment, and there are bureaucratic hurdles to overcome. Many companies have yet to turn a profit, experts say. A few companies have already failed, and urban-farming experts say many more will be weeded out in the coming years.

But commercial vertical farms are well beyond experimental. Companies such as AeroFarms, owned by Dream Holdings Inc., and Urban Produce LLC have designed and operate commercial vertical farms that aim to deliver supplies of greens on a mass scale more cheaply and reliably to cities, by growing food locally indoors year round.

At its headquarters in Irvine, Calif., Urban Produce grows baby kale, wheatgrass and other organic greens in neat rows on shelves stacked 25 high that rotate constantly, as if on a conveyor belt, around the floor of a windowless warehouse. Computer programs determine how much water and LED light the plants receive. Sixteen acres of food grow on a floor measuring an eighth of an acre.

Its “high-density vertical growing system,” which Urban Produce patented, can lower fuel and shipping costs for produce, uses 80% less fertilizer than conventional growing methods, and generates its own filtered water for its produce from humidity in the air, says Edwin Horton Jr., the company’s president and chief executive officer.

“Our ultimate goal is to be completely off the grid,” Mr. Horton says.

The company sells the greens to grocers, juice makers and food-service companies, and is in talks to license the growing system to groups in cities around the world, he says. “We want to build these in cities, and we want to employ local people,” he says.

AeroFarms has built a 70,000-square-foot vertical farm in a former steel plant in Newark, N.J., where it is growing leafy greens like arugula and kale aeroponically—a technique in which plant roots are suspended in the air and nourished by a nutrient mist and oxygen—in trays stacked 36 feet high.

The company, which supplies stores from Delaware to Connecticut, has more than $50 million in investment from Prudential, Goldman Sachs and other investors, and aims to install its systems in other cities globally, says David Rosenberg, its chief executive officer. “We envision a farm in cities all over the world,” he says.

AeroFarms says it is offering project management and other services to urban organizations as a partner in the 100 Resilient Cities network of cities that are working on preparing themselves better for 21st century challenges such as food and water shortages.

The bottom line

Still, these farms can’t supply a city’s entire food demand. So far, vertical farms grow mostly leafy greens, because the crops can be turned over quickly, generating cash flow easily in a business that requires extensive capital investment, says Henry Gordon-Smith, managing director of Blue Planet Consulting Services LLC, a Brooklyn, N.Y., company that specializes in the design, implementation and operation of urban agricultural projects globally.

The greens can also be marketed as locally grown to consumers who are seeking fresh produce.

Other types of vegetables require more space. Growing fruits like avocados under LED light might not make sense economically, says Mr. Gordon-Smith.

“Light costs money, so growing an avocado under LED lights to only get the fruit to sell is a challenge,” he says.

And the farms aren’t likely to grow wheat, rice or other commodities that provide much of a daily diet, because there is less of a need for them to be fresh, Mr. Gordon-Smith says. They can be stored and shipped efficiently, he says.

The farms are also costly to start and run. AeroFarms has yet to turn a profit, though Mr. Rosenberg says he expects the company to become profitable in a few months, as its new farm helps it reach a new scale of production. Urban Produce became profitable earlier this year partly by focusing on specialty crops such as microgreens—the first shoots of greens that come up from the seeds—that enerally grow indoors in a very condensed space, says Mr. Horton, who started the company in 2014.

One of the first commercial vertical-farming companies in the U.S., FarmedHere LLC, closed a 90,000 square-foot farm in a Chicago suburb and merged with another company late last year. “We’ve learned a lot of lessons,” says co-founder Paul Hardej.

Among them: Operating in cities is expensive. The company should have built its first farm in a suburb rather than a Chicago neighborhood, Mr. Hardej says. Real estate would have been cheaper.

“We could have been 10 or 20 miles away and still be a local producer,” Mr. Hardej says.

The company also might have been able to work with a smaller local government to get permits and rework zoning and other regulations, because indoor farming was a new type of land use, Mr. Hardej says. While FarmedHere produced some crops profitably, it spent a lot on overhead for lawyers and accountants “to deal with the regulations,” he says.

Mr. Hardej is now co-founder and chief executive officer of Civic Farms LLC, a company that develops a “2.0” version of the vertical farm, he says—more efficient operations that take into account the lessons learned. Civic Farms is collaborating with the University of Arizona on a research and development center at Biosphere 2, the Earth science research facility in Oracle, Ariz., where it runs a vertical farm and develops new technologies.

Blossoming tech

New technology will improve the economic viability of vertical farms, says Mr. Gordon-Smith. New cameras, sensors and smartphone apps help monitor plant growth. One company is even developing augmented-reality glasses that can show workers which plants to pick, Mr. Gordon-Smith says.

“That is making the payback look a lot better,” he says. “The future is bright for vertical farming, but if you’re building a vertical farm today, be ready for a challenge.”

Some cities are trying to propagate more urban farms and ease the regulatory burden of setting them up. Atlanta Mayor Kasim Reed created the post of urban agriculture director in December 2015, with a goal of putting local healthy food within a half-mile of 75% of the city’s residents by 2020. The job includes attracting urban-farming projects to Atlanta and helping projects obtain funding and permits, says Mario Cambardella, who holds the director title. “I want to be ahead of the curve; I don’t want to be behind,” he says.

Many groups are taking more low-tech or smaller-scale approaches. A program called BetterLife Growers Inc. in Atlanta plans to break ground this fall on a series of greenhouses in an underserved area of the city, where it will grow lettuce and herbs in 2,900 “tower gardens,” thick trunks that stand in large tubs. The plants will be propagated in rock wool, a growing medium consisting of cotton-candy-like fibers made of a melted combination of rock and sand, and then placed into pods in the columns, where they will be regularly watered with a nutrient solution pumped through the tower, says Ellen Macht, president of BetterLife Growers.

The produce will be sold to local educational and medical institutions. “What we wanted to do was create jobs and come up with a product that institutions could use,” she says.

The $12.5 million project is funded in part by a loan from the city of Atlanta, with Mr. Cambardella helping by educating grant managers on the growing system and its importance.

Change at home

Another company aims to bring vertical farming to the kitchen. Agrilution GmbH, based in Munich, Germany, plans to start selling a “plantCube” later this year that looks like a mini-refrigerator and grows greens using LED lights and an automatic watering system that can be controlled from a smartphone. “The idea is to really make it a commodity kitchen device,” says Max Loessl, Agrilution’s co-founder and chief executive officer, of the appliance, which will cost 2,000 euros—about $2,200—initially.

The goal is to sell enough to bring the price down, so that in five years the appliance is affordable enough for most people in the developed world, Mr. Loessl says.

Biofilta, the company Mr. Condon co-founded, is marketing the Foodwall, a modular system of connected containers, an approach that he calls “deliberately low tech” because it doesn’t require electricity or computers to operate. The tubs are filled with a soil-based mix and a “wicking garden-bed technology” that stores and sucks water up from the bottom of the tub to nourish the plants without the need for pumps. The plants need to be watered just once a week in summer, or every three to four weeks in the winter, says Chief Executive Marc Noyce. The tubs can be connected vertically or horizontally on rooftops, balconies or backyards. “We’ve made this gardening for dummies,” Mr. Noyce says.

The Foodwall can use composted food waste and harvested rainwater, helping to turn cities into “closed-loop food-production powerhouses,” Mr. Condon says.

He and Mr. Noyce were motivated to design the Foodwall by a projection from local experts that only 18% of the food consumed in their home city of Melbourne, Australia, will be grown locally by 2050, compared with 41% today, Mr. Noyce says.

“We were shocked,” says Mr. Noyce. “We’re going to be beholden to other states and other countries dictating our pricing for our own food.”

“Then we started to look at this trend around the world and found it was exactly the same,” he says.

Traditional, rural farming is far from being replaced by all of these new technologies, experts say. The need for food is simply too great. But urban projects can provide a steady supply of fresh produce, helping to improve diets and make a city’s food supply more secure, they say.

“While rural farmers will remain essential to feeding cities, cleverly designed urban farming can produce most of the vegetable requirements of a city,” Mr. Condon says.

The Future of Farming: Japan Goes Vertical And Moves Indoors

The Future of Farming: Japan Goes Vertical And Moves Indoors

Spread, Fujitsu and AeroFarms are growing vegetables hydroponically, with successful yields

BY MELINDA JOE

21 MAY 2017

Spread, Fujitsu and AeroFarms are growing vegetables hydroponically, with successful yields

Indoor agriculture is on the rise all over the world – particularly in Asia, where concerns over food safety and pesticide use in recent years have fuelled a boom in so-called plant factories. Spread, Japan’s largest vertical farm, produces more than 20,000 heads of lettuce a day in its 3000-square-metre facility outside of Kyoto.

Spread Co's vertical farms

The vegetables are cultivated hydroponically – without soil, in beds of constantly circulating nutrient solution – under LED lights in a sterile, climate-controlled environment. Later this year, the company plans to open a second facility that will use robot technology to automate tasks such as harvesting and boost total production to a whopping 50,000 heads per day.

Electronics giant Fujitsu is among a number of Japanese technology firms to embrace horticulture, converting factories that had formerly been used to manufacture semiconductors into tightly sealed indoor plantations manned by engineers in white cleanroom suits.

Fujitsu’s cloud-based software allows workers to easily monitor sensors that track the growth of the plants. Nutrient and light levels can be adjusted to develop varieties of lettuce with, for example, low potassium content for people with kidney disease.

AeroFarms

Last year, AeroFarms, located in New Jersey, made headlines for becoming the world’s biggest vertical farm, with the capacity to harvest roughly 1,000 tonnes of greens per year.

The company employs aeroponic technology, a more efficient form of hydroponics, where plants are grown in a mist environment. The company relies on big data to oversee the cultivation of 250 varieties of organically grown herbs and leafy vegetables.

‘Doomsday’ Seed Vault Meant To Survive Global Disasters Breached By Climate Change

‘Doomsday’ Seed Vault Meant To Survive Global Disasters Breached By Climate Change

Fortunately, no seeds were damaged

by Alessandra Potenza@ale_potenza May 19, 2017, 1:48pm EDT

The Global Seed Vault - Crop Trust

The seed bank designed to preserve the world’s crops and plants in the event of global disaster isn’t prepared to withstand the greatest global disaster facing our planet: global warming. Melting permafrost on the Norwegian island of Spitsbergen, where the Svalbard Global Seed Vault is located, has seeped into the seed bank, raising questions of how the structure will be able to survive in the future as the Earth keeps warming.

The seed vault is built in an abandoned Arctic coal mine, deep inside a mountain. It contains about a million packets of seeds from almost every country in the world, representing “the most diverse collection of food crop seeds.” In 2015, the ongoing civil war in Syria prompted researchers in the Middle East to withdraw some seeds to replace those previously stored in a gene bank in war-torn Aleppo.

“BUILT TO STAND THE TEST OF TIME”

The structure was built underneath the permafrost so it could be “a fail-safe seed storage facility, built to stand the test of time — and the challenge of natural or man-made disasters,” as the seed bank’s website says. But oh, the irony. Unusually warm temperatures in the winter have caused rain, and the permafrost has been melting. “It was not in our plans to think that the permafrost would not be there and that it would experience extreme weather like that,” Hege Njaa Aschim, from the Norwegian government, which owns the vault, toldThe Guardian.

Fortunately, the water hasn’t flooded the vault itself. It only got to the entrance of the tunnel, where it froze. (The seeds are stored at minus 0.4 degrees Fahrenheit.) But the incident has raised questions over the durability of a seed bank that was supposed to operate without people’s intervention.

The vault managers are now waterproofing the facility and digging trenches to channel melt and rainwater away, according to The Guardian. They’ve also installed pumps in case the vault floods again. “We have to find solutions. It is a big responsibility and we take it very seriously. We are doing this for the world,” Åsmund Asdal at the Nordic Genetic Resource Centre, which operates the seed vault, told The Guardian. “This is supposed to last for eternity.”

Statement of the Royal Ministry of Agriculture and Food:

The Svalbard Global Seed Vault is the world’s backup for crop collections. It currently safeguards more than 930,000 different varieties. It has been reported that the Seed Vault has seen water intrusion due to melting permafrost. The Royal Ministry of Agriculture and Food in Norway, the Crop Trust, and NordGen would like to assure seed depositors and the public that the seeds are completely safe and no damage has been done to the facility. The Royal Ministry of Agriculture and Food and Statsbygg, Norway, is taking appropriate measures to ensure the protection of the Seed Vault and improve the construction to prevent future incidents. Globally, the Seed Vault is, and will continue to be, the safest backup of crop diversity.

Signed

Pål Vidar Sollie, Director General, The Royal Ministry Of Agriculture And Food, Norway

Marie Haga, Executive Director, The Crop Trust

Lise Lykke Steffensen, Executive Director, Nordgen

Hege Njaa Aschim, Director Of Communications, Statsbygg, Norway

Seeds & Chips 2017 Wraps Up: 13 Prizes Awarded to The Most Cutting-Edge Food Innovation Startups

Seeds & Chips 2017 Wraps Up:

13 Prizes Awarded to The Most Cutting-Edge Food Innovation Startups

John Kerry to be among the Guests of Honor in the 2018 edition

Milano, May 18, 2017 - The closing ceremony of the 2017 edition of Seeds&Chips -The Global Food Innovation Summit – took place in Milano with the winners of the Seeds&Chips 2017 Awards collecting their prizes. The world’s most innovative start-ups in food and AgTech were publicly applauded. At the end of the Award Ceremony, Marco Gualtieri - founder and CEO of Seeds&Chips – took stock of the latest edition of the summit with the extraordinary participation of the 44th US President Barack H. Obama and announced the first of the Guest of Honor of Seeds&Chips 2018, former US Secretary of State John Kerry. Over 200 international speakers, investors, policy makers and startups from all over the world participated in SaC2017 with countries ranging from Italy and Israel to the United States, Jordan and Iraq.

“This exceptional edition of Seeds&Chips and Barack Obama's extraordinary participation have established once and for all that Milan and Italy are the world's hub and global reference point of Food and FoodTech. This, while reaffirming our role as a laboratory focused on finding solutions to the major global challenges, from production and nutrition to the sustainable use of resources and climate change,” stated Marco Gualtieri, founder of Seeds&Chips. “Today, more than ever, especially among the new generations, we have technological tools and skills at our fingertips that make it possible for us to face and overcome these challenges. It is our duty and responsibility to invest in and to support youth and innovation, especially in a key sector such as that of food. This in turn will result in an improvement in our lives and better conditions for the whole planet. President Obama personally asked me to collaborate on the themes of youth, food and innovation. A wonderful opportunity for Milano and Italy as a country and a notable and far-reaching task for Seeds&Chips that next year will host one outstanding keynote speaker each day of the Global Food Innovation Summit. Former US Secretary of State John Kerry has been the first to confirm his participation in 2018”.

Seeds&Chips 2017 Awards

Thirteen prizes for as many categories were awarded to participating startups during the Seeds&Chips Closing Ceremony publicly recognizing Italian and international projects that represent the best of today's innovation in food. The founder of Seeds&Chips, Marco Gualtieri hosted the event with journalist Rula Jebreal, who called the winners to the stage. The 12 startups were acknowledged by their "sponsor" companies that had contributed by supporting and promoting the project. The winner of the NextFood Award by Image Line was applauded by the contest's creators, who were also the leaders of the network awarding the prize. An ad-hoc Jury made up of Seeds&Chips staff, representatives of sponsor companies, by members of the Italian National Research Center in its capacity as a scientific advisor evaluated and selected the winning startups.

Awards and Winners

1. “SEEDS&CHIPS VISIONARY AWARD”

WINNER: Ingredient Optimized by Plasma Nutrition (USA), awarded by Alessandro Russo, President of Gruppo CAP

Plasma Nutrition is transforming the performance of protein powders through our patent-pending Ingredient Optimization process to increase sustainability and improve health outcomes.

2. “BEST DISRUPTIVE STARTUP AWARD”

WINNER: Food Pairing and Tailor Made (Belgium) awarded by Marcello Pincelli, Italy General Manager, PepsiCo

Foodpairing® is a market research automation company identifying the successful flavor combinations of tomorrow, through the combination of scientific flavor insights and unique consumer data.

3. “FUTURE FOOD AWARD”

WINNER: Flatev (Switzerland), awarded by Fabio Ziemssen, Head of Food Innovation and Foodtech, Metro Group

The Flatev Artisanal Bakery and Flatev Dough is Your Personal Baking System (PBS)! The closed baking system expertly prepares single servings of fresh tortillas, rotis, flatbreads, cookies and more with no fuss and no mess. A consumer simply pops a proprietary, recyclable, single serve dough container into the Flatev Artisanal Bakery, selects their desired setting, and soon enjoys a delicious, fresh treat in seconds.

4. “BEST FOOD EXPERIENCE AWARD”

WINNER: The Vegetarian Butcher (Italy), awarded by Niccolo Longoni, Innovation Manager of Just Eat

By 2022, the Meat Substitutes Market will be worth around 6 Billion USD. After a ten-year search, the Vegetarian Butcher team, inspired by our founder Jaap, developed and found innovative meat substitutes with a spectacular bite and texture. Our ideal is to have meat enthusiasts experience the meat free products and to realize they do not have to miss out on anything if they leave meat out of their diet for a couple of days a week. Our mission is also to free animals from the food chain by offering a complete and delicious alternative to meat; by doing that we also aim to reduce the carbon footprint caused by the intensive animal farming.

5. “EAT HEALTHY - BEST HEALTH AND DIET SOLUTIONS AWARD”

WINNER: INDI (Israel), awarded by Gabriella Bartoccelli, Head of Communication and External Relations, CAMST

INDI is the world's first Non Dairy Non Soy infant formula, developed by a team of highly experienced infant nutrition experts with over 60 years of relevant experience. Produced in both powder and liquid forms, INDI is a total solution for allergic, sensitive and vegan infants (0-36m). The Formula is 100% vegan (2 plants composition); Hormones free Antibiotic free GMO free Sustainable with Superior taste. Competitively priced and ready for full scaled production INDI has been approved by the Israeli ministry of health, endorsed by leading infant nutrition medical experts as it is fully conforming to infant nutrition strict intl. standards The formula is Patent Pending in 85 countries around the globe (National phase).

6. “BEST MORNING SOLUTION AWARD”

WINNER: RISE Products (USA), awarded by Franck Bocquet, General Manager Délifrance Italy

RISE is a green startup that upcycles spent barley from microbreweries into flour for bakers. We produce a sustainable, organic, high-protein, nutritious and inexpensive alternative flour that has a wide range of applications –from cookies to pasta.

7. “INCREDIBLE GROWTH - FASTEST GROWING STARTUP AWARD”

WINNER: Blue Cart (USA), awarded by Francesco Spadaro and Giovanni Rebay, KPMG Partner

BlueCart is a SaaS mobile turnkey procurement platform that connects wholesale buyers with their exclusive network of suppliers in the hospitality industry. Every day, wholesale buyers, restaurants, hotels, etc. spend hours, placing orders to each of their suppliers via email or text messages. BlueCart enables orders to be communicated to all distributors with one click on their mobile phone. Distributors receive all orders in one dashboard, eliminating the need for manual data entry. This digital workflow offers transparency, efficiency, and accountability in the wholesale procurement process that simply does not exist today.

8. “FARMING OF TOMORROW - BEST INNOVATION IN FARMING AWARD”

WINNER: Agrologies (Greece), awarded by Anders Nilsson, GROW IT UP Partner

Our products and services offer needed technology solutions to the agriculture sector. Agrologies has developed an automation irrigation platform & device, which combine an IOT device, a cloud service & a mobile app. Agrologies enables farmers to plan the irrigation of their crops depending on weather conditions & other data. Additionally, during Seeds&Chips, in partnership with New Holland Agriculture, growITup has opened the #CallForGrowth tender on Precision Farming: a call for all Italian startups and SMEs involved in developing innovative solutions in the food-value chain. To join the call, startups and SMEs must have significant business in Italy and submit their application by 6 June 2017 atwww.growITup.com .

9. “SMARTER RETAIL EXPERIENCE AWARD”

WINNER: Coffee Hat (Italy), awarded by Federica Palermini - Head of Brand & Communication and Digital Innovation, CARREFOUR

Coffee Hat was born with a clear mission: to deliver the finest specialty coffees with a cosmopolitan brewing approach and in line with our modern lifestyles. Our single-serve coffee capsule represents the synthesis of the values of Coffee Hat: Excellence of aromas, Genuineness & Traceability of the coffee beans.

10. “BEST VERTICAL FARMING INNOVATION AWARD”

WINNER: Robonica (Italy), awarded by Association for Vertical Farming (AVF)

Linfa (Lymph) is Robonica’s smart and beautifully designed home greenhouse, which can have a strong impact on people's habits. It allows you to grow any kind of vegetables, such as herbs, hot peppers or salad, ready to eat in just 5 days. Linfa is a hydroponics culture system with LED lighting to replace natural light, where the recreated microenvironment is fully controlled.

11. “BEST SMART CITY VISION AWARD”

WINNER: AeroFarms (USA) awarded by Marco Moretti, A2A

Aerofarms produces delicious, nutritious leafy greens and herbs without sunlight, soil, or pesticides. Crops get the perfect amount of moisture and nutrients misted directly onto their roots in a completely controlled environment. With our patented technology, we take indoor vertical farming to a new level of precision and productivity with minimal environmental impact and virtually zero risk.

12. “NEXTFOOD AWARD by Image Line”

WINNER: Seamore Food (Netherlands), awarded by Roberto Ghioni, Partner and Graphic Designer at63De-Sign and by Paolo Rumi, Creative Director at63De-Sign

Seamore Food wins a full mentoring package aimed at product placement and industrialization. Seamore Food’s product SEA PASTA, 100% seaweed vegetable noodles -, stood out among participants in this 1st International edition of NEXTFOOD AWARD focused on Food Innovation targeted to all food startups with at least one branded product and which was held in conjunction with Seeds&Chips - The Global Food Innovation Summit. The NEXTFOOD AWARD is promoted by 63DE-SIGN, a team of communication designers with experience in different and converging sectors. Partnering with Seeds & Chips and thanks to the participation of the Politecnico di Torino Department of Architecture and Design and the Ecopak Observatory (OEP), the NextFood Award by Image Line enjoys the support of the main sponsor Image Line …Since 1988 hands on a keyboard, feet in the field ... and eyes on the present and the future of agriculture. With this in mind, Image Line develops digital solutions for professionals: innovative software for the sustainable management of agricultural holdings, vertical portals and search engines for sharing technical knowledge.

13. “BEST SOLUTION FOR A BETTER WORLD AWARD”

WINNER: Impact Vision (United Kingdom) awarded by Hugo Doyle, Head of International Public Affairs, Intesa Sanpaolo

ImpactVision's mission is to build a more transparent and secure global food system using hyperspectral technology. ImpactVision’s software platform provides quick and non-invasive information on the quality and characteristics of different foods, using image recognition and predictive learning. With ImpactVision, a picture of a food product is enough to understand its nutritional content, freshness level, ad protein, fat, sugar, or moisture content. An innovative solution to reduce waste by increasing quality and safety.

Information : www.seedsandchips.com; @SEEDSandCHIPS, #Sac17

For additional information

Close to Media – Seeds&Chips Press Office

Tel +39 02.70006237

michela.gelati@closetomedia.it; davide.dibattista@closetomedia.it; luigi.borghi@closetomedia.it; francesca.pollio@c

An Inside View of Hong Kong’s Hidden Rooftop Farms

An Inside View of Hong Kong’s Hidden Rooftop Farms

Born out of a fear of contaminated foods, the city’s budding interest in high-altitude gardening may help heal an increasingly fractured – and ageing – society.

- By David Robson

17 May 2017

A butterfly perching on a lettuce leaf is not normally a cause for marvel. But I am standing on the roof the Bank of America Tower, a 39-floor building in the heart of Hong Kong’s busiest district, to see one of its highest farms. The butterfly must have flown across miles of tower blocks to reach this small oasis amidst the concrete desert.

“You just plant it out and nature comes and enjoys it,” says Andrew Tsui. We are joined by Michelle Hong and Pol Fabrega, who together lead Rooftop Republic, a social enterprise that aims to turn the city’s dizzying skyline green.

If it weren’t for the fact that we are 146 metres (482ft) above street-level, this farm would look like any allotment site or garden courtyard – row after row of rectangular crates, some with fresh sprouts poking through the surface, others with established plants almost ready for harvest. The loudest noise I can hear is not the traffic below, but the wind.

Although it is only February when I visit, the sun is so strong I end the morning with a slight tan, and Hong tells me that the local climate offers ideal growing conditions for most of the year, meaning that despite the exposure, they can cultivate a range of plants. “We have things like cherry tomatoes, salad, broccoli – all of that can be grown here,” explains Hong. The greens I see today are as lush as anything you would find growing at sea level. Workers from the offices below tend it day-to-day, and after harvest, the fruits of their labour are sent to a food bank, where they fill lunchboxes for the needy. “We want to share the good products – not just the leftovers,” says Tsui. On other projects, however, the farmers would take the produce for themselves.

Truly fresh, locally grown vegetables are something of a luxury in Hong Kong. To demonstrate why, Tsui points from our rooftop to the rings of mountains that encompass the city. In between are the two bands of dense urban development, straddling the harbour. “Five to six million people are squeezed in these two narrow belts,” he says

Thanks to these crammed conditions, the city imports more than 90% of its food – much of it from mainland China. But after some well-publicised cases of food contamination in China, more and more people are now looking for locally grown goods. And if they can’t grow it on the ground, they have to take it to the sky.

The team try to invite the remaining rural farmers from surrounding regions, to come and give classes to the city workers

Food production is only one of the project’s aims, however. Their greater goal is to revolutionise the city’s fast-paced culture. Like most urban areas, Hong Kong’s society is highly stratified, and its citizens are often isolated to their particular niche, formed of their colleagues and close friends. The Rooftop Republic team hope that the farms can help break through those barriers. “It’s a bit of a social experiment,” says Tsui.

The team try to invite remaining rural farmers from surrounding regions, to come and give classes to the city workers, for instance. “We hope that this rich knowledge of organic farming practice isn’t lost with their generation, so they can pass it on and share it with the community.”

In return, they pay the rural farmers to cultivate seedlings to be planted on the rooftop farms, providing them with a steady source of income that is not subject to the whims of the market. “This part of their income is lower risk and they can pre-empt and manage their time,” says Tsui. It’s a small step, perhaps – but one that helps connect two populations who would never normally interact. The team also work with the hard-of-hearing and people with other disabilities, who can find the contact with nature to be therapeutic.

Thirty-nine stories high, the rooftop farm on the Bank of America Tower adds some much needed greenery to the concrete jungle (Credit: Robert Davies)

After we descend from the Bank of America Tower, the team take me to a second project on the Hong Kong Fringe Club – which grows aubergines, tomatoes, oregano, lemongrass, mint and kale for the bar and restaurant below. I will have passed the building a dozen times on my trip so far without realising that it hosted this little haven on its roof.

Here the team tell me about their other goal: education. By running regular workshops, the team hope that Hong Kong’s city-dwellers will become a little more aware of the resources needed to grow the food they are eating. Pointing to a bed of broccoli, for instance, Hong remembers one recent group who had never seen the whole plant. “They didn’t realise that the florets that we eat are actually quite limited,” she says. “And if you look at the quantity we see in the supermarket, you begin to see how much space we would need to grow that,” she says.

We do have a mission, in a way – to make farming cool – Andrew Tsui

Fabrega agrees. He says that when the team give family workshops on farming, the parents often end up learning as much as the kids. “We’re teaching them, even though it’s at a basic level.” By seeing the origins and ecological consequences of their foods, they might just choose to be a little bit less wasteful with their groceries – encouraging greater overall sustainability.

Ultimately, Tsui’s dream is that a restful break on a rooftop farm will become ingrained in everyone’s daily routine. “I use the analogy of coffee,” says Tsui – something that was once a luxury, but which became a lifestyle, through sheer convenience. If he had his way, a trip to the farm would be as essential as a morning caffeine fix. “We do have a mission, in a way – to make farming cool.”

The rooftop farm at the Hong Kong Fringe Club provides ingredients for the bar and restaurant below (Credit: Robert Davies)

To better understand the broader potential for rooftop farming, I later met up with Matthew Pryor at the Division of Landscape Architecture of the University of Hong Kong (HKU). Originally from the UK, Pryor moved to Hong 25 years ago. “The pace of it, the intensity become addictive – you don’t love it but you can’t do without it.”

I catch Pryor when he is hard at work on his current project, as he attempts to model the city to estimate the total space that could be devoted to rooftop farms. His first estimates are surprisingly vast – 695 hectares in total, nearly five times the size of London’s Hyde Park or twice the size of New York’s Central Park. “Now the total ground level farmable land in Hong Kong was about 420 hectares,” he says. “So there’s more on the roof than there is on the ground.”

They are spending a huge amount of time on the street. Couldn’t they be spending that time on the roof?

As part of this work, Pryor has conducted a series of surveys of the rooftop farms in Hong Kong – finding around 60 in progress so far. “What attracts me to this is that they are completely unconnected, spontaneous – 60 groups who have had the same idea, at the same time, and they’ve gone out there and done it.”

Like Tsui, he sees the rooftop farms as an efficient form of social welfare – particularly for the elderly. “Life expectancy in Hong Kong is now at 90 – we outlive the rest of the world,” he says. “But there’s nowhere for the elderly to go. They are spending a huge amount of time on the street – particularly the low-income elderly. Couldn’t they be spending that time on the roof?” Light exercise and regular social contact, are, after all, two of the best ways to stave off dementia.

As a bonus, he says, the rooftop farms can also provide thermal insulation and sound insulation – saving the building’s overall energy consumption through air conditioning. “I’d like to persuade the government to recognise rooftop farms as a legitimate use,” he says – so they could be integrated into the city planning.

Hong Kong's climate makes it ideal for growing vegetables all year round (Credit: Robert Davies)

After chatting in his office, we potter around HKU’s own rooftop farm, which Pryor helped found with students and other staff members. He recalls that when he first got permission to build the farm, he had to lug tonnes of soil and compost up the final flight of stairs – while remaining silent for an exam in progress. Everything I see up here is recycled or reclaimed from construction sites, and they even have a wormery to produce their own compost. He has made sure that that each pot is anchored by the weight of its own soil – a crucial measure come typhoon season. So far, there have been no disasters during the heavy storms.

The biggest challenge is protecting the crops from sulphur-crested cockatoos

Recently, his biggest challenge is protecting the crops from sulphur-crested cockatoos. “They are a real pest – really noisy, aggressive animals.” When I visit this February afternoon, however, the university farm is astonishingly peaceful, with an extraordinary view into the mountains ringing the city. “Most people come in the late afternoon and watch the sunset,” he says.

Could this be a glimpse of the future for city-dwellers everywhere? “Hong Kong offers a kind of laboratory,” Pryor says. “When we’re teaching, we say ‘Don’t take Hong Kong as the norm, take it as the extreme.’” If the rooftop farms can catch on here – and become as popular as coffee – it seems only a matter of time before they become a regular fixture across the world.

David Robson is BBC Future’s feature writer. He is @d_a_robson on Twitter.

Join 800,000+ Future fans by liking us on Facebook, or follow us on Twitter.

If you liked this story, sign up for the weekly bbc.com features newsletter, called “If You Only Read 6 Things This Week”. A handpicked selection of stories from BBC Future, Earth, Culture, Capital, and Travel, delivered to your inbox every Friday.

From Moscow: A ‘City Farm’ Home Appliance

From Moscow: A ‘City Farm’ Home Appliance

The body is completely leak-tight, made of sound eight-layered composite aluminum. You can select out of 9 coloring options.

Regulated «smart» tinting coating of a farm’s glass door enables to turn down the glaring light RainbowSpectrum ™. Tinting coating is controlled with the use of the INTELLIGENT EXPERT application.

Module body is made of Softtouch plastic due to which it is highly wear-resistance and possesses elegant appearance.

Innovative module structure with in-built drip watering system enables to

control the level of the nutrients and minerals supply to the plants as well as enables to easily change the glasses for growing.

Rainbow Spectrum ensures efficient process of plant photosynthesis at the expense of using solely the blue and red spectrum colors. Innovative light-emitting diode unit is automatically adjusted to the croppings grown in the city farm creating the most favorable conditions for their growth and fruiting.

Automatic climate control system ensures favorable air temperature and humidity for the croppings development inside a city farm. Measurements by all parameters are displayed in the INTELLIGENTEXPERT application.

A Farm Grows In The City

Startups are leading the way to a future in which more food is grown closer to where people live

At AeroFarms’ indoor vertical farm in Newark, N.J., greens grow on shelves 36 feet high Bryan Anselm for The Wall Street Journal

A Farm Grows In The City

Startups are leading the way to a future in which more food is grown closer to where people live

By: Betsy McKay | Photographs by: Bryan Anselm for The Wall Street Journal

May 14, 2017 10:05 p.m. ET

Billions of people around the world live far from where their food is grown.

It’s a big disconnect in modern life. And it may be about to change.

The world’s population is expected to reach 9.7 billion by 2050, 33% more people than are on the planet today, according to projections from the United Nations. About two-thirds of them are expected to live in cities, continuing a migration that has been under way around the world for years.

That’s a lot of mouths to feed, particularly in urban areas. Getting food to people who live far from farms—sometimes hundreds or thousands of miles away—is costly and strains natural resources. And heavy rains, droughts and other extreme weather events can threaten supplies

Now more startups and city authorities are finding ways to grow food closer to home. High-tech “vertical farms” are sprouting inside warehouses and shipping containers, where lettuce and other greens grow without soil, stacked in horizontal or vertical rows and fed by water and LED lights, which can be customized to control the size, texture or other characteristic of a plant.

Companies are also engineering new ways to grow vegetables in smaller spaces, such as walls, rooftops, balconies, abandoned lots—and kitchens. They’re out to take advantage of a city’s resources, composting food waste and capturing rainwater as it runs off buildings or parking lots.

“We’re currently seeing the biggest movement of humans in the history of the planet, with rural people moving into cities across the world,” says Brendan Condon, co-founder and director of Biofilta Ltd., an Australian environmental-engineering company marketing a “closed-loop” gardening system that aims to use compost and rainwater runoff. “We’ve got rooftops, car parks, walls, balconies. If we can turn these city spaces into farms, then we’re reducing food miles down to food meters.”

Moving beyond experiments

Plants at AeroFarms receive light of a specific spectrum

Urban farming isn’t easy. It can require significant investment, and there are bureaucratic hurdles to overcome. Many companies have yet to turn a profit, experts say. A few companies have already failed, and urban-farming experts say many more will be weeded out in the coming years.

But commercial vertical farms are well beyond experimental. Companies such as AeroFarms, owned by Dream Holdings Inc., and Urban Produce LLC have designed and operate commercial vertical farms that aim to deliver supplies of greens on a mass scale more cheaply and reliably to cities, by growing food locally indoors year round.

At its headquarters in Irvine, Calif., Urban Produce grows baby kale, wheatgrass and other organic greens in neat rows on shelves stacked 25 high that rotate constantly, as if on a conveyor belt, around the floor of a windowless warehouse. Computer programs determine how much water and LED light the plants receive. Sixteen acres of food grow on a floor measuring an eighth of an acre.

Its “high-density vertical growing system,” which Urban Produce patented, can lower fuel and shipping costs for produce, uses 80% less fertilizer than conventional growing methods, and generates its own filtered water for its produce from humidity in the air, says Edwin Horton Jr., the company’s president and chief executive officer.

“Our ultimate goal is to be completely off the grid,” Mr. Horton says.

The company sells the greens to grocers, juice makers and food-service companies, and is in talks to license the growing system to groups in cities around the world, he says. “We want to build these in cities, and we want to employ local people,” he says.

An AeroFarms employee inspects a tray of greens.

AeroFarms has built a 70,000-square-foot vertical farm in a former steel plant in Newark, N.J., where it is growing leafy greens like arugula and kale aeroponically—a technique in which plant roots are suspended in the air and nourished by a nutrient mist and oxygen—in trays stacked 36 feet high.

The company, which supplies stores from Delaware to Connecticut, has more than $50 million in investment from Prudential, Goldman Sachs and other investors, and aims to install its systems in other cities globally, says David Rosenberg, its chief executive officer. “We envision a farm in cities all over the world,” he says.

AeroFarms says it is offering project management and other services to urban organizations as a partner in the 100 Resilient Cities network of cities that are working on preparing themselves better for 21st century challenges such as food and water shortages.

The bottom line

Still, these farms can’t supply a city’s entire food demand. So far, vertical farms grow mostly leafy greens, because the crops can be turned over quickly, generating cash flow easily in a business that requires extensive capital investment, says Henry Gordon-Smith, managing director of Blue Planet Consulting Services LLC, a Brooklyn, N.Y., company that specializes in the design, implementation and operation of urban agricultural projects globally.

AeroFarms packaged greens await shipment.

The greens can also be marketed as locally grown to consumers who are seeking fresh produce.

Other types of vegetables require more space. Growing fruits like avocados under LED light might not make sense economically, says Mr. Gordon-Smith.

“Light costs money, so growing an avocado under LED lights to only get the fruit to sell is a challenge,” he says.

And the farms aren’t likely to grow wheat, rice or other commodities that provide much of a daily diet, because there is less of a need for them to be fresh, Mr. Gordon-Smith says. They can be stored and shipped efficiently, he says.

The farms are also costly to start and run. AeroFarms has yet to turn a profit, though Mr. Rosenberg says he expects the company to become profitable in a few months, as its new farm helps it reach a new scale of production. Urban Produce became profitable earlier this year partly by focusing on specialty crops such as microgreens—the first shoots of greens that come up from the seeds—that enerally grow indoors in a very condensed space, says Mr. Horton, who started the company in 2014.

One of the first commercial vertical-farming companies in the U.S., FarmedHere LLC, closed a 90,000 square-foot farm in a Chicago suburb and merged with another company late last year. “We’ve learned a lot of lessons,” says co-founder Paul Hardej.

Among them: Operating in cities is expensive. The company should have built its first farm in a suburb rather than a Chicago neighborhood, Mr. Hardej says. Real estate would have been cheaper.

“We could have been 10 or 20 miles away and still be a local producer,” Mr. Hardej says.

The company also might have been able to work with a smaller local government to get permits and rework zoning and other regulations, because indoor farming was a new type of land use, Mr. Hardej says. While FarmedHere produced some crops profitably, it spent a lot on overhead for lawyers and accountants “to deal with the regulations,” he says.

Mr. Hardej is now co-founder and chief executive officer of Civic Farms LLC, a company that develops a “2.0” version of the vertical farm, he says—more efficient operations that take into account the lessons learned. Civic Farms is collaborating with the University of Arizona on a research and development center at Biosphere 2, the Earth science research facility in Oracle, Ariz., where it runs a vertical farm and develops new technologies.

Blossoming tech

New technology will improve the economic viability of vertical farms, says Mr. Gordon-Smith. New cameras, sensors and smartphone apps help monitor plant growth. One company is even developing augmented-reality glasses that can show workers which plants to pick, Mr. Gordon-Smith says.

“That is making the payback look a lot better,” he says. “The future is bright for vertical farming, but if you’re building a vertical farm today, be ready for a challenge.”

Some cities are trying to propagate more urban farms and ease the regulatory burden of setting them up. Atlanta Mayor Kasim Reed created the post of urban agriculture director in December 2015, with a goal of putting local healthy food within a half-mile of 75% of the city’s residents by 2020. The job includes attracting urban-farming projects to Atlanta and helping projects obtain funding and permits, says Mario Cambardella, who holds the director title.

“I want to be ahead of the curve; I don’t want to be behind,” he says.

Many groups are taking more low-tech or smaller-scale approaches. A program called BetterLife Growers Inc. in Atlanta plans to break ground this fall on a series of greenhouses in an underserved area of the city, where it will grow lettuce and herbs in 2,900 “tower gardens,” thick trunks that stand in large tubs. The plants will be propagated in rock wool, a growing medium consisting of cotton-candy-like fibers made of a melted combination of rock and sand, and then placed into pods in the columns, where they will be regularly watered with a nutrient solution pumped through the tower, says Ellen Macht, president of BetterLife Growers.

BetterLife Growers will use ‘tower gardens’ like these to grow lettuce and herbs in Atlanta. Photo: Scissortail Farms

The produce will be sold to local educational and medical institutions. “What we wanted to do was create jobs and come up with a product that institutions could use,” she says.

The $12.5 million project is funded in part by a loan from the city of Atlanta, with Mr. Cambardella helping by educating grant managers on the growing system and its importance.

Change at home

Another company aims to bring vertical farming to the kitchen. Agrilution GmbH, based in Munich, Germany, plans to start selling a “plantCube” later this year that looks like a mini-refrigerator and grows greens using LED lights and an automatic watering system that can be controlled from a smartphone. “The idea is to really make it a commodity kitchen device,” says Max Loessl, Agrilution’s co-founder and chief executive officer, of the appliance, which will cost 2,000 euros—about $2,200—initially.

The goal is to sell enough to bring the price down, so that in five years the appliance is affordable enough for most people in the developed world, Mr. Loessl says.

Biofilta’s Foodwall system of connected containers requires minimal watering. Photo: Ben Mulligan

Biofilta, the company Mr. Condon co-founded, is marketing the Foodwall, a modular system of connected containers, an approach that he calls “deliberately low tech” because it doesn’t require electricity or computers to operate. The tubs are filled with a soil-based mix and a “wicking garden-bed technology” that stores and sucks water up from the bottom of the tub to nourish the plants without the need for pumps. The plants need to be watered just once a week in summer, or every three to four weeks in the winter, says Chief Executive Marc Noyce. The tubs can be connected vertically or horizontally on rooftops, balconies or backyards. “We’ve made this gardening for dummies,” Mr. Noyce says.

The Foodwall can use composted food waste and harvested rainwater, helping to turn cities into “closed-loop food-production powerhouses,” Mr. Condon says.

He and Mr. Noyce were motivated to design the Foodwall by a projection from local experts that only 18% of the food consumed in their home city of Melbourne, Australia, will be grown locally by 2050, compared with 41% today, Mr. Noyce says.

“We were shocked,” says Mr. Noyce. “We’re going to be beholden to other states and other countries dictating our pricing for our own food.”

“Then we started to look at this trend around the world and found it was exactly the same,” he says.

Traditional, rural farming is far from being replaced by all of these new technologies, experts say. The need for food is simply too great. But urban projects can provide a steady supply of fresh produce, helping to improve diets and make a city’s food supply more secure, they say.

“While rural farmers will remain essential to feeding cities, cleverly designed urban farming can produce most of the vegetable requirements of a city,” Mr. Condon says.

Ms. McKay is a senior writer in The Wall Street Journal’s Atlanta bureau. She can be reached at betsy.mckay@wsj.com.

Appeared in the May. 15, 2017, print edition.

Developing a Tool to Measure Nutrient Levels in Food

Developing a Tool to Measure Nutrient Levels in Food

The Bionutrient Food Association is working with producers to establish growing practices that yield more nutritious crops, while developing a standard for nutrient-dense foods and a handheld tool to measure those nutrient levels. The idea behind the tool is to use existing technology, like the camera in a Smartphone, to scan produce right in the grocery store, measuring the nutrient-density of the consumer’s food options.

The Association’s mission is to empower consumers to choose the most nutrient-dense foods, ultimately rewarding farmers for their improved growing practices.

Food Tank spoke with Dan Kittredge, founder of the Bionutrient Food Association and an organic farmer himself, to discuss why he thinks we need a definition of nutrient density, and the power he sees in this standard to transform the food system.

Food Tank (FT): What first inspired you to start working on nutrient density in food?

Dan Kittredge (DK): It started when I, as somebody who grew up on an organic farm, when I got married I had no other viable skillsets besides farming. And I came to terms with the fact that my crops were not healthy. They were succumbing to infestation and disease, and I was not economically viable. And I knew I needed to do a better job.

FT: What does the Bionutrient Food Association do to promote nutrient density in our food supply?

DK: Our core work is training growers. We work with growers of all sizes across the country, across North America, in what we call principles of biological systems. And we walk them through the growing season, walk them through the year, and talk about how plants grow in relation to the soil and microbiology, and help farmers identify what the main factors are so they can address them. That’s been our core work.

Our overt mission is to increase quality in the food supply. And by quality, I’m referring to flavor, aroma, and nutritive value, which is often times virtuous to nutrient density. So we’re now at a point where we have, I think, sixteen chapters across the country.

And we’re actually working on a definition of what quality means to density in the amount of nutrients. You know, what is the variation in nutrient levels in crops and trying to give consumers the ability to test that at point of purchase. Something along the lines of a handheld spectrometer, something that would be essentially, if a Smartphone had the right sensors, something that could be in your phone. You know, give the consumer the ability to test quality at point of purchase and then make your decisions accordingly, as an incentive to inspire the supply chain to change its practices.

FT: What does soil have to do with nutrient density?

DK: Well for the general public, I think we need to understand what nutrient density is first, because it’s a term that is thrown around a lot without a clear understanding of what it means. So for us, nutrient density is, you have greater levels of nutrients per unit calorie in a crop, better flavor, better aroma, and better nutritive value.

Basically, those compounds that correlate with nutrition, with flavor, and aroma in crops, are built from the soil and through a well-functioning microbial ecosystem. So plants evolved with a gut flora, in the same way that we have a gut flora, that digests their food for them. The bacteria and the fungi in the soil are fed by the plants. When the plant makes sugar in the leaves, it injects that sugar into the soil to feed the soil life, who then digest the soil and feed the nutrients up to the plant.

So it’s only when you have a well-functioning soil life, when the soil is actually flourishing, with vitality, with life, that’s the only time when you’re going to get the plants having access to the nutrients necessary to have nutrient dense crops.

So in many cases, farmers engage in management practices that are counterproductive. Tillage, bare soil, adding fertilizers, fungicides, insecticides, a lot of the basic practices of agriculture are systemically counterproductive to nutrient density in crops. Which is why we have pretty categorical data from USDA and other sources about the decreasing levels of nutrition in food over time.

FT: Why do consumers need standards and definitions to identify the nutrient density of their food?

DK: Because I think in many cases consumers don’t understand that there is a variation in nutrient levels in crops, and they don’t understand the connection between the nutritional value of food and the health giving attributes of food. I think we have a health crisis in this country that is not entirely due to our decreasing nutrient levels in crops, but in large part connects to that.

So helping to make those connections and give consumers the tools they need to actually use their economic leverage to facilitate solutions is our core agenda, a part of our core agenda.

FT: What benefits can producers gain from a better understanding of the nutrient levels of the food they grow?

DK: My experience as a farmer is that when your plants are healthier, they are more productive; they have better pest and disease resistance; you reduce the need for fungicides, insecticides, fertilizers; you’re sequestering carbon, so you’re building resilience into your system. You know, from the farmer’s perspective it’s really like there’s an octuple bottom line of systemic incentives.

But the issue is we don’t have, in many cases, the awareness as farmers or the humility about what we’re doing wrong, and we don’t have the economic incentives to change our practices.

FT: How does the nutrient density of our food supply impact food security and health?

DK: For us, as an organization, nutrient density is the lens with which we can begin to understand how all of these bigger issues are deeply interrelated. We propose that we have epidemic levels of degenerative disease in large part because we don’t have high-quality nutrition in our food.

We have high levels of toxins in our foods because farmers need to use those toxins to kill the pests because the plants aren’t healthy. When you actually have healthy plants they are physiologically indigestible to insects and bacteria. You don’t need fungicides and insecticides when you have healthy plants, when you’re producing healthy crops. All of the issues with aquifers and the ecosystem are by-products of what we call conventional ag.

We propose that by growing healthy plants you can actually sequester all the carbon necessary to reverse global warming fairly rapidly. If we were to, on a global scale, grow healthy food crops, we could sequester 15 parts per million of C02 per year.

So it’s the correlation between nutrient density in food and the reversing of a number of apparently intransigent social, environmental, and political human health issues. It’s really very exciting, we can solve these problems. If we just ate food that tastes good we would solve these problems.

FT: What is one major change in the food system that could increase the nutrient density of our food supply?

DK: I think if consumers had the ability to test the quality of the foods they purchase that would be all we would need. If consumers had the ability to, at point of purchase, choose between the three bags of carrots available the one that was most nutritious, and then they could use their economic power to inspire the supply chain to focus on quality as opposed to aesthetics, we could drive the solutions through that one point.

That’s what we’re focusing on because it feels like it’s the most plausible, it’s founded on transparency, empiricism, and empowerment. We’re not trying to convince federal agencies or governmental bodies or big corporations in any kind of adversarial way. We’re simply giving consumers the ability to choose the food that tastes good to them.

You know, if you have a carrot that tastes bitter, you’re not going to eat it, especially if you’re a three year old. If you have a carrot that tastes like a wonderful carroty flavor, you will want to eat it, even if you’re a three year old. So if we can provide growers the skills and consumers the understanding to choose the food that tastes good, our thought is that simple economic leverage will drive the solutions we’re looking for.

New Skyscraper Farm Will Feed A Village

NEW SKYSCRAPER FARM WILL FEED A VILLAGE

Posted by Elise Phillips Margulis | May 12, 2017

Nigeria, Somalia, South Sudan, and Yemen are suffering from a famine that affects 20 million people. According to eVolo magazine, over 40 percent of people living in sub-Saharan Africa live in extreme poverty. In the last three decades, absolute poverty has been reduced from 40 percent to 20 percent worldwide. Unfortunately, the green revolution including clean energy, fertilizers, irrigation, and high-yield seeds that doubled grain production between 1960 and 2000 on other continents has failed multiple times in Africa due to limited markets, bad infrastructure, civil wars, and an ineffective government.

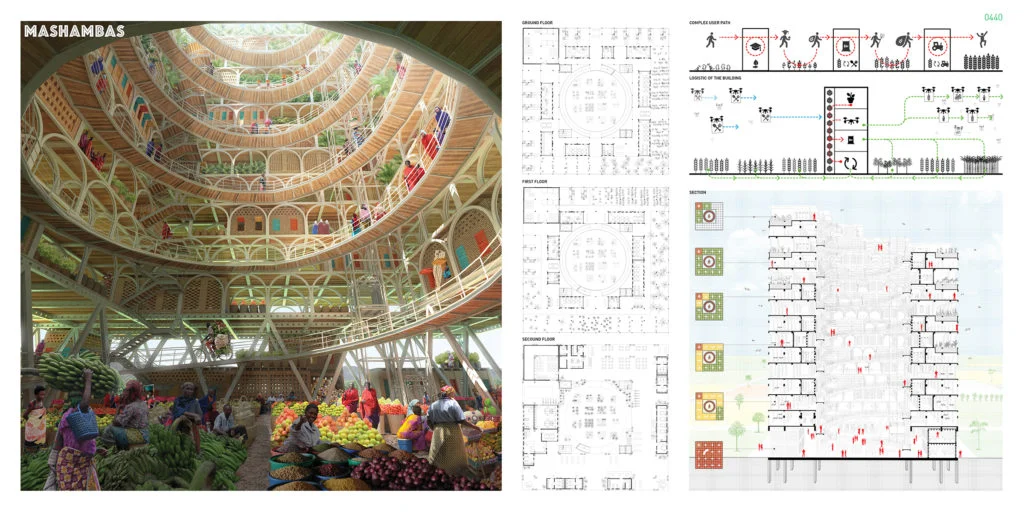

The eVolo magazine presents and discusses architecture embodying technological advances, sustainable concepts, and innovative designs. Each year, eVolo hosts a competition and awards the structures that they admire most. This year’s top prizewinners were two Polish architects, Pawel Lipinski and Mateusz Frankowski. They designed the Mashambas Skyscraper which houses a farm, an education center, and a community center.

The ingenious structure facilitates the training of subsistence farmers in modern farming techniques. Providing the farmers with inexpensive fertilizers and state-of-the-art tools enables them to increase their crop yields dramatically. The skyscraper also creates a local trading area, which helps to maximize profits. The objectives are self-sufficient farming and overcoming poverty and famine.

The top of the proposed skyscraper is comprised of layered fields. There’s a drone docking center in the middle so agricultural products can be flown to isolated locations. The first floor consists of a kindergarten, a doctor’s office, and an information center.

The designers of the Mashambas Skyscraper predict that the combination of training, fertilizer, and seeds will enable small farmers to harvest as many crops per acre as large farms do. This will end famine, as the village will have food for itself and enough to sell to nearby villages. Another amazing feature of the structure is that it can be moved. The base remains in place and the other floors can be relocated to educate other farmers.

According to The Vertical Farm , the world population will increase by three billion people by 2050. Right now, 80 percent of the land that can be used for growing crops has been built on. Vertical farming will use less land to grow more food. We’re going to need a lot of vertical farms!

GrowTO Urban Agriculture Action Plan, Toronto: Urban Food Policy Snapshot

GrowTO Urban Agriculture Action Plan, Toronto: Urban Food Policy Snapshot

Photo credit: Jessica Reeve

Policy name: GrowTO Urban Agriculture Action Plan

Location: Toronto, Canada

- Population: 2.6 million

Food policy category: Sustainable agriculture

Program goals

- Provide urban farmers with more spaces where they can produce food

- Promoting existing education programs and develop new education programs about urban agriculture

- Increase publicity and marketing of urban agriculture

- Direct more funding towards urban agriculture

- Increase composting

- Change local laws to make urban agriculture easier and more profitable

Program initiation

- The GrowTO plan was released by the Toronto Food Policy Council in 2012. The plan was a collaborative effort by multiple food and environmental organizations in the city.

- The Toronto City Council officially adopted the GrowTO plan in 2012, and in 2013 released the Toronto Agricultural Program, which recorded the progress of urban agriculture in Toronto and proposed future actions the city could take to accomplish the goals of the GrowTO plan.

- The Toronto Agriculture Program also led to the establishment of a Steering Committee made up of City Staff from a number of different divisions as well as instrumental community partners. This Steering Committee was tasked with overseeing an outlined initial short-term and long-term work plan.

How it works

The GrowTO Urban Agriculture Action Plan outlines six priorities: linking growers to land and space, strengthening education and training, increasing visibility and promotion, adding value to urban gardens, cultivating relationships, and developing supportive policies.

The first priority, linking growers to land and space, involves taking an inventory of all the public spaces in the city which may be good locations for urban farming, and making those spaces available to groups who want to open new urban farms.

The second priority, strengthening education and training, incorporates multiple goals. One is developing a K-12 curriculum on food literacy and farming skills. Another involves starting community classes that are open to everyone, which would be on topics including composting, food growing, and business planning.

To increase visibility and promotion, the action plan proposes creating a “Grown in TO” brand so customers can easily identify locally grown food. The plan also proposes other marketing strategies, including an expanded, comprehensive website, walking and bike tours, food festivals, and a city awards program, among others.

The section on adding value to urban farms focuses on funding for urban agriculture, with strategies including creating city grants, creating crowd sourcing opportunities, and connecting social investors to farming initiatives. The plan also proposes using city waste to make compost and creating facilities to handle post-harvest food processing.

The action plan proposes cultivating relationships with various institutions, including universities, day care centers, senior housing facilities, city government branches, and various community groups. It includes a commitment to supporting the city’s Growing Food Justice For All Initiative.

Finally, the plan outlines many supportive policies which can stimulate urban agriculture in Toronto. Zoning laws should be updated, and residents should be allowed to keep hens in their back yards and sell the food they grow in their backyards at farmer’s markets, among other changes.

Progress to date

Numerous urban agriculture projects have popped up in Toronto since the GrowTO action plan was adopted. They are located in empty lots, on rooftops, in schoolyards, and on residents’ personal property.

Entrepreneurs and community organizers have looked to urban farming opportunities as a means of supporting economic development, the creation of small businesses, and to build up and enhance communities. Many farmers are now exploring ways to grow indoors or in shipping containers using hydroponics, or other systems, in addition to the many programs and businesses growing outside and in public spaces.

Through the Toronto Agriculture Program, the city has devoted significant time and energy to developing opportunities for urban farmers, such as allowing them to grow their own produce in hydro corridors. This begins to address the dilemma that many would-be farmers face in getting access to land in Toronto and being allowed to sell the food grown on that land.

Toronto has drawn a lot of attention for the development of an urban farm, Black Creek Community Farm, in the City’s Jane and Finch neighbourhood, in partnership with the Toronto and Region Conservation Authority. This farm has become an embedded part of the community and is a hub for food justice work. Based on the success of this farm, the city is currently exploring the feasibility of establishing another farm.

Why the program is important

Research has shown that urban agriculture is beneficial for human health as well as for the environment. Multiple studies have found that gardeners tend to eat more fruits and vegetables than non-gardeners. Urban farming also increases a community’s food security, since their food is less dependent on distant sources.

Urban agriculture can also lower a city’s greenhouse gas footprint. When more food is grown locally, rather than being shipped from hundreds of miles away, less carbon dioxide is burned in order to provide food to an urban population. In addition, urban agriculture offers the opportunity to reduce waste by composting, and to reduce the need to transport waste out of a city.

Evaluation

The Toronto Food Policy Council and Toronto Urban Growers have recently done a review of GrowTO as well as the Toronto Agriculture Program Work Plan, but a formal review of the work plan, making connections back to the goals outlined in GrowTO, needs to be brought back to the Toronto Agriculture Program Steering Committee at the City. This is expected to take place in 2017.

The Toronto Urban Growers, through Toronto Public Health, have also recently completed a report to develop urban agriculture indicators that would be used to measure the impact of urban agriculture within the City of Toronto.

Learn more

http://www.toronto.ca/legdocs/mmis/2012/pe/bgrd/backgroundfile-51558.pdf

http://www.toronto.ca/legdocs/mmis/2013/pe/bgrd/backgroundfile-62375.pdf

Point of contact

tfpc@toronto.ca

Similar practices

- The Michigan Urban Farming Initiative has started a large urban agriculture project in Detroit, to combat both unemployment and food insecurity

- Chicago recently began an urban farming initiative using federal grant money. The city will be hiring its first full-time urban agriculture coordinator to oversee the effort to establish more urban farms.

References

http://www.toronto.ca/legdocs/mmis/2012/pe/bgrd/backgroundfile-51558.pdf

http://www.toronto.ca/legdocs/mmis/2013/pe/bgrd/backgroundfile-62375.pdf

http://www.ecowatch.com/urban-farming-david-suzuki-1984874080.html

Sustainable Food Production Looking Up

Sustainable Food Production Looking Up

Editor: zhangrui 丨Chinadialy

05-08-2017 07:13 BJT

A laboratory worker in full biohazard gear is patrolling rows of rainbow colored LED-lit shelves. The shelves stand about 2 meters and have six levels, each containing trays of lettuce saplings bathing underneath the light, and the room is illuminated in a psychedelic pink.

A laboratory worker in biohazard gear checks the growth of lettuce in the vertical farm in Anxi, Fujian province. ZHAN ZHUO / FOR CHINA DAILY

This is no scene from a science fiction movie, but a common sight for scientists at a plant factory in Anxi, Fujian province, which covers 1 hectare and is the largest vertical farming complex in the world. The second-largest is a 0.64 hectare farm in Newark, New Jersey.

Vertical farming is the practice of growing vegetables and fruits in vertically stacked layers of hydroponic solutions in a controlled, indoor environment. It does not require soil, sun or pesticides, and uses far less water and fertilizer than conventional farms.

However, the farm's high-energy cost has greatly limited its scale and profitability. In recent years, Chinese scientists at the Anxi plant factory have mitigated the issue by inventing energy efficient LEDs and recyclable hydroponic solutions, as well as new energy-conserving methods to maximize a plant's growth potential.

San'an Sino-Science, the company behind the project, says these new methods have cut the factory's overall energy consumption by 25 percent compared with its first facility.

"We hope to cut more energy so vertical farming can become a viable way to feed our population without polluting and straining our already scarce water and soil resources," the factory's executive manager, Zhan Zhuo, said.

"The technology would also allow astronauts, aircraft carrier personnel, and frontier guards on islands or in deserts to grow fresh produce in impossible conditions to fill their daily vitamin and fiber needs.”

China has 160 million hectares of farmland dedicated to growing vegetables. To grow them, farmers use more than 311,000 metric tons of pesticide and 59 million tons of fertilizer a year, said Li Shaohua, director of San'an Sino-Science's Photobiology Industry Institute.

"The excessive yet inefficient use of fertilizers and pesticides has done great harm to our environment," he said. "It's high time we find a sustainable and green way to protect our food security."

San'an Sino-Science was founded in 2015 by San'an Group and the Chinese Academy of Sciences' Institute of Botany. The second-generation plant in Anxi can produce 1.5 tons of vegetables, such as lettuce and cabbage, a day.

At full capacity, when the energy cost is neglected, it can produce 1,000 tons of leafy greens a year in theory, according to Li. "The high productivity is mainly because we try to emulate the most ideal natural conditions for plant growth, and use technologies to cater to their every needs."

Before entering the plant factory, visitors must put on a dual-layered jumpsuit, goggles, a face mask, rubber gloves and boots, and be disinfected from head to toe. Sneezing in the factory is strictly prohibited.

"The standard here is stricter than hospital operating rooms," said Zheng Yanhai, a botany researcher at the institute who works at the plant factory. "Because all the plants are growing in nutrient-filled hydroponic solutions, we do not want germs to get into the liquid and make plants sick."

Thanks to the clean environment, plants can grow without antiseptics or pesticides, "you can even eat it fresh out of the bag", Zheng added.

In addition to sanitation, scientists also take temperature, humidity, air circulation, light, carbon dioxide, nutrients and other elements into account to create the "perfect environment" for growth.

A tightly controlled environment not only maximizes growth potential, but also allows scientists to create food that suits specific needs, Zheng said.

For example, scientists can lower the amount of potassium from lettuce for patients with kidney problems or increase zinc in cabbage for children by altering the nutrient solution and growing conditions.

"This is the fundamental difference between a plant factory and conventional farm," he said. "We simply have extensive control over how and when our plants can grow, and let nature run its course in the most ideal conditions."

The requirements for plant growth fall into two broad categories: photosynthesis and soil nutrients.

The sun accounts for 90 percent of all botanic bioenergy through photosynthesis — a process in which plants combine carbon dioxide and water and turn them into carbohydrates and oxygen. Sunlight is a bundle of different wavelengths of light across a wide spectrum from ultraviolet to infrared.

Plants are "picky eaters that favor blue and red lights", Li said. "If we can figure out what ratio and combination of lights are best suited for each plant's growth, then we can change or create LED lights that shine at that specific intensity and spectrum, saving lots of energy in the process," he added.

While blue and red lights are the "meat and potatoes" of a plant's growth, scientists notice other spectrums of light also play a subtle role in maximizing growth and quality.

For example, scientists discovered that adding some green light to the red-blue recipe could help some vegetables grow, while too much green light puts plants into hibernation, although this is helpful for the plant's nutrient build up.

"Mimicking sunlight using LED is very energy intensive," Li said. "At the end of the day, whoever has the most energy-efficient and productive light recipe wins."