Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Roof Gardens Plant Seeds of Recovery For Pollinating Insects

Roof Gardens Plant Seeds of Recovery For Pollinating Insects

The Scottish government’s pollinator strategy encourages owners of flats and offices to create rooftop, balcony and window-ledge gardens for insects GETTY IMAGES

Gabriella Bennett | July 27 2017, 12:01am, The Times

Homeowners are being urged to create rooftop gardens to help reverse a devastating decline in the insects that pollinate plants.

The number of pollinating insects such as bees and butterflies has halved since the 1980s because of climate change and a loss of habitat.

The Scottish government’s new “pollinator strategy” encourages owners of flats and offices to create rooftop, balcony and window-ledge gardens to help the insects thrive.

Food crops rely on pollinating insects and research has shown that fewer bees and butterflies mean stable production of fruits and vegetables cannot be guaranteed.

Insects pollinate about a third of the world’s agricultural crops, and the cost of losing all UK pollinators has been estimated at up to £440 million per year. The economic value of honey bees and bumble bees to commercially-grown crops alone has been estimated at more than £200 million a year.

Pesticides, pollution, disease and climate change are all thought to be contributing factors in the decline of pollinating insects.

As well as targeting city dwellers, the government scheme will call for more flower-rich habitats to be restored around Scotland. New insect-friendly pesticides will also be developed, and more research will be done on climate change.

Dougal Philip, a judge at the Royal Horticultural Society’s shows at Chelsea and Hampton Court, also runs New Hopetoun Garden Centre in West Lothian with his wife Lesley Watson, a former presenter of The Beechgrove Garden. He said: “Lesley and I have been championing this cause for the past 20 years. We have been challenging myths of wildlife gardens, such as [that] they need to be a bit of a mess, they need to be in the country, and they have to have native plants. They can just as easily be in the suburbs or cities.”

Housebuilders are also contributing to environmental improvements by putting in rooftop gardens as part of new developments.

At the New Lanark world heritage site, a former 18th-century cotton spinning mill village, a 9,000 sq ft green space has been created on the roof of an A-listed mill building, around which seven restored townhouses will go on the market later this year.

Roseanna Cunningham, the Scottish government’s environment secretary, called the country’s biodiversity one of its “key assets” and highlighted a commitment to ensuring it becomes a more “pollinator-friendly place”.

“Pressures such as pesticides, pollution, disease and climate change are threatening these life-giving insects, so we must act now to protect the pollinators and in turn safeguard our environment, our food and our health,” she said. Scottish Natural Heritage (SNH), the body responsible for preserving and promoting the country’s landscape, led the development of the new strategy with environmental and land management organisations.

Mike Cantlay, chairman of SNH, said there was evidence proving that Scotland’s native bees and insects were facing “tough times”.

“This strategy, a key part of the Scottish Biodiversity 2020 route map, sets out what needs to be done to ensure these bees and insects survive and thrive for generations to come,” he said.

Indigenous Hydroponics System A Boon For Organic Farming

Agrico, a private local Qatari agricultural development company established in 2011 with the aim of helping Qatar achieve food security, operates a 120,000sqm (12 hectare) organic farm in Al Khor. Its first production was in May 2012.

Agrico managing director Nasser Ahmed al-Khalaf at his organic hydroponics farm in Al Khor. PICTURE: Joey Aguilar

Indigenous Hydroponics System A Boon For Organic Farming

July 25 2017 10:15 PM | QATAR | Joey Aguilar

A local farm in Qatar has developed a highly sophisticated hydroponics system capable of producing various types of organic vegetables and fruits in a bid to help the country achieve food security, it is learnt.

Organic eggplants at the 120,000sqm hydroponics farm in Al Khor

Speaking to Gulf Times, Agrico managing director Nasser Ahmed al-Khalaf said they made a lot of modifications in hydroponics farming to produce an all-organic fresh produce to meet the growing demand in Qatar.

Agrico, a private local Qatari agricultural development company established in 2011 with the aim of helping Qatar achieve food security, operates a 120,000sqm (12 hectare) organic farm in Al Khor. Its first production was in May 2012.

“The Asians, European or Western people have not developed a system that would be suitable for this area, especially for Qatar,” he stressed. “What we did is to develop our own system which is suitable for our environment.”

The local farm owner noted that vegetable-exporting countries in Asia, Europe, and America have the technology and knowhow in their region but inapplicable in the Gulf.

Al-Khalaf explained that regions with winter seasons such as Europe, especially those in the northern part, only have heating systems.

But in Qatar, he said they developed a cooling system that can reduce the temperature inside the greenhouse down to 16 degrees, depending on the variety of vegetables and fruits.

Some varieties need 16, 18 or 20 degrees, during a certain time of the day, for the plant to give the right texture, size, and taste, among others.

“Our vegetables they can last for a month on shelf without changing,” he said, adding that they can produce an average of 6 tonnes daily during the summer, which is 30% less compared to their production in the winter. The farm plans to produce more in the near future.

With this technology, he said Qatar has become one of the largest producers of organic vegetables in the world using what he described as a very promising and one-of-its-kind hydroponics technology.

Agrico Organic Farm in Al Khor produces 14 types of tomatoes.

“As long as you are providing the right temperature, right humidity, right amount of light (sun radiation), right fertiliser, and right amount of water, then you can grow anything,” al-Khalaf added. “I guarantee that all types of vegetables can be grown, I have tried this myself and we have been successful on this.”

Agrico has started growing five types of fruits, including papaya and lemon (experimental stage). It expects the plants to bear fruits in a year or two.

As Agrico products continue to supply more than 150 supermarkets and small outlets in Qatar, he said “there will be a lot of surprises soon.”

“We are going to produce root crops, fresh leaf and herbs such as coriander, parsley, green onion, basil, and mint, among others,” he said, adding that producing iceberg lettuce and other types, carrots, potatoes, and white onion, in the next few months.

While Qatar currently imports various types of fresh vegetable and fruits from European, Asian, and American countries, he expressed confidence that the country will soon achieve self-sufficiency.

He noted that even before the economic blockade imposed by the Saudi-led group on June 5, Qatar already has plans to import fresh produce in the future.

System suitable for livestock, poultry, fish farming

Apart from vegetables and fruits, local farm owner Nasser Ahmed al-Khalaf said the cooling system they developed is also suitable for livestock, poultry and fish farming.

“It is an integrated system, we take advantage of the vegetable greenhouses and in between we cool an empty wasted area using the cold air that comes out from the greenhouse,” he added.

Al-Khalaf explained that they harness this cold air, which comes out of the greenhouse, for testing an area of his farm for growing fruits. This can bring down the temperature from 45 degrees, for example, to 27 degrees in an open field.

The system, from temperature, humidity to sun radiation and water irrigation, has to be monitored round-the-clock seven days a week, according to the farm owner.

“Even if I am abroad I get a warning from my mobile phone if any abnormality happens,” he noted.

Greenhouses In The Arctic Will Reduce Food Insecurity In Canada's North

Greenhouses In The Arctic Will Reduce Food Insecurity In Canada's North

Growing North’s Greenhouse in Naujaat, Nunavut. Image: Growing North

Jul 26 2017, 10:41am

Greenhouses grow food at a fraction of what it would normally cost.

In Nunavut, in Canada's Arctic, shoppers pay $12.44 for for a kilogram of celery, almost four times more than the $3.38 national average, and $6.90 for a kilogram of potatoes. It's just one of many examples of food inaccessibility in the region, which severely affects 18.5 percent of Nunavut households, a problem the government is addressing by investing $13.8 million per year to support isolated Northern communities.

To address this problem, not-for-profit Growing North built a greenhouse in the Inuit hamlet of Naujaat in September 2015 to increase accessibility to fresh food.

The greenhouse produced 13,250 lbs of food last year for the local community of 1,082 people, an amount that "could feed just over 50 percent of the Naujaat population Health Canada's daily recommended amount of produce," explained Stefany Nieto, co-founder of Growing North. With the success of the Naujaat greenhouse, the organization is expanding to Arviat, Nunavut's third-largest community, in August.

"It is completely unacceptable that many northern and Indigenous families cannot afford to put healthy food on the table," the Office of the Minister of Indigenous and Northern Affairs Canada told Motherboard in an email. In an effort to "support families and hunters - and improve access to country foods," in 2016, the Canadian government invested an additional $64.5 million over five years, and $13.8 million per year ongoing, and have now expanded full subsidies to an additional 37 isolated northern communities. Investments in local greenhouses could help grow fresh food and make it more accessible.

Bright Agrotech's ZipFarm System. Image: Bright Agrotech

Growing North is exploring alternative and sustainable ways of feeding Canada's north by using some of the latest in vertical farming techniques.

What was a once far-fetched idea is now a sustainable option for providing food to a growing population. Vertical farming allows farmers to have a 365-day season without having to use pesticides or worry about traditional farming concerns like sunlight, rain, or drought.

Over the last ten years, a number of companies have popped up around the world using old warehouses and other unconventional urban spaces to grow fresh produce. Many of these farms operate in densely populated places like China, Japan, Belgium, and the United States. The largest floor-to-ceiling farm is currently in New Jersey at nearly 70,000 square feet. And the phenomenon is only going to get bigger. By some estimates, the vertical farming industry is projected to be worth USD $13 billion by 2024.

Bright Agrotech, a Wyoming startup, allows small urban and suburban farmers to grow crops through its vertical hydroponic farming systems. Hydroponic refers to soilless growing, in which the plants are grown using only nutrient-rich water. The water flows across the root structure and is taken up by the plants. Bright Agrotech's systems, which focus on greens and herbs is being used in Growing North's Naujaat greenhouse.

"Nunavut has the highest rate of food insecurity in Canada," Nieto told Motherboard in an interview. The organization estimates the price reductions on fresh produce grown in their greenhouses to be anywhere from 50 to 70 percent, depending on whether the produce is sold to local grocers or sold directly to consumers through places like the farmer's market.

"You can face food insecurity even living in a city like downtown Toronto if there is not a grocery store for miles around," explained Ben Canning, co-founder of Growing North.

Food inaccessibility persists in northern Canada, in large part, due to the cost of getting food to the region. Fresh food has to be flown in from the south. Each community faces its own challenges. Some are only accessible by road and not by air, which adds time and money. "Whether it's food or construction goods that need to shipped in, the farther north you go, the longer the supply chain gets and the more it costs. Even a lot of our food consumed in Toronto is shipped in. To get to the North, they spend an extra two weeks in cargo freights, craters, and planes," said Canning.

Growing North's current greenhouse is 75 percent hydroponic and 25 percent soil-based agriculture. The hydroponic system can grow any herb as well as greens like lettuce, kale, collard greens and swish chards. The agricultural side grows vegetables like radishes, potatoes, and carrots.

But the cost to construct these systems is extremely high—much higher than soil-based farming. For example, the 1300-square-foot dome shaped greenhouse in Naujaat cost Growing North about $100,000. For poor communities, especially in developing countries, vertical farming can be unaffordable. In addition to the initial costs, there are other ongoing expenses related to paying tech-savvy workers needed to run the farms. Currently, Growing North is working on lowering that cost through in-house research and development which would make project implementation in smaller communities with limited access to funds, possible.

Still, local greenhouses may be a viable answer to the problem of food accessibility in the north.

Selected Kaufland Romania Shops To Turn Roofs, Parking Lots Into Urban Gardens

Selected Kaufland Romania Shops To Turn Roofs, Parking Lots Into Urban Gardens

By Georgeta Gheorghe News July 18, 2017 16:50

Kaufland Romania will turn its roofs, parking lots and the outer walls of in urban gardens, the food retailer announced. The vegetables, fruit, flowers will be used by the community.

The project, “Gradinescu,” developed through a partnership with the Association of the research Institute for Permaculture in Romania, is a first in Romania and promotes care towards nature, community spirit and supports the development of urban agriculture, company representatives say.

Moreover, the project is designed to introduce children and adults to gardening and the possibility to have a healthy diet even in an urban environment. “The project consists of a network of nine urban community gardens, three of them located on the roofs of three Kaufland shops, four in the parking lots or behind the shops and two in schools” company representatives said.

The first Kaufland store with the roof and outer walls transformed in urban gardens is that on Bucurestii Noi Blvd., and by the end of summer those on Barbu Vacarescu, Tudor Vladimirescu, Aparatorii Patriei, and in schools.

The first urban garden set up as part of the Kaufland store in Bucurestii Noi has 2,300 square meters and is designed to be used by the community. The garden will serve as a teaching space for schools and gardens in the area.

The company presented the results of the first study on the presence of urban gardening in Romania. According to the survey,7 out of 10 Romanians are involved in urban gardening, by cultivating at their home vegetables, greens or fruit, in order to enjoy natural produce. While the balcony is the preferred spot for urban gardening for almost 50 percent of Romanians, 14 grow their produce in front of their block of flats, 8 percent in the suburbs and the rest headed for areas outside of the cities.

Startup Launches GrowChef – The Ultimate Hydroponic Food Generator

Startup Launches GrowChef – The Ultimate Hydroponic Food Generator

An optimized garden solution at home – harvest delicious fresh greens every single day!

Tallinn, Estonia July 23, 2017 - Now, it’s possible to grow nutritious, tasty and fresh food at home faster and easier than ever, thanks to GrowChef, an easy-to-use hydroponic garden, specially designed to let users harvest one pot of greens per day. GrowChef is designed to be used wherever it best suits its user, be it on a wall, on the floor, on a window sill, or in a closet. With its three-color LED illumination, GrowChef produces enough light on its own so there’s no need for additional daylight. Requiring minimal space, it produces the same harvest as a 3 meter long garden bed. Easy to operate, app-supported, and designed to save users time and money, the GrowChef is the optimal growing solution for anyone who wants to successfully grow greens at home.

GrowChef has 51 pot slots, and can provide users with one pot of greens daily. GrowChef doesn’t have any soil, only nutrient solution and vermiculite, allowing for a twice as fast maturation rate. Once a month a nutrient solution is poured into the slot at the bottom level of the device, and it’s then pumped to fill all three levels automatically every 20 minutes. It then flows back to the lowest level and gets aerated by a non-pressure system, specially developed by GrowChef. The lighting works by a timer which automatically turns the lights on in the morning and off in the evening, but timer settings can be easily changed using the GrowChef app on a smartphone.

GrowChef is designed in three levels, allowing plants to thrive – the grow pots are placed at the top, and stay there until the seeds have germinated and reached 3-5 cm. The pots are moved to the middle level and kept until they reach a height of 10-12 cm, before being moved to the bottom level where they ripen.

The level design and a carefully calculated spacing system ensures sure the plants get the most light when they need it the most, and that the plants have enough space to grow and don’t block light from each other, ensuring a lush and healthy produce.

“I’m delighted to bring people a new original opportunity to have fresh herbs on your plate every day! GrowChef helps you to eat healthier, reduce your shopping list and expenses. After two and a half years of experiments we’ve figured out how to perfect the hydroponic farm to constantly provide you with ready-to-eat plants", says founder Viktor Pjatnitski.

About GrowChef:

Tallinn-based startup GrowChef was founded in 2017 by engineer Viktor Pjatnitski who was 6 years experience in metal structure production. CEO is Liana Guntaisvili, CMO is Jelena Kazakova and Nik Gut is the company’s agronomist.

To bring GrowChef to large scale production, the team has decided to launch the GrowChef on Kickstarter, where it’s available to pre-order until August 30 2017.

Campaign page: https://goo.gl/tim4im

For additional information about GrowChef please visit our website, follow us on Facebook, Twitter, and Instagram.

Room To Grow More Local Veggies At Panasonic's Farm

Room To Grow More Local Veggies At Panasonic's Farm

PUBLISHED - JUL 10, 2017, 5:00 AM SGT | Updated July 25, 2017

S'pore Farm Now Yields 40 Varieties, Aims to More Than Double Production

Consumers here can look forward to more home-grown leafy greens from Panasonic, which plans to expand its high-tech indoor vegetable farm and more than double its production by next year.

The Japanese electronics giant is also looking into cultivating seasonal fruit usually grown in temperate climates.

It runs a 1,154 sq m indoor farm, about the size of 11/2 soccer fields, at Panasonic Factory Solutions Asia-Pacific's premises in Jalan Ahmad Ibrahim.

The farm produces up to 40 crop varieties, amounting to 81 tonnes of vegetables annually.

Plans are under way to increase farm size to 1,710 sq m, which will allow it to produce up to 180 tonnes at optimum capacity. The cultivated varieties include mizuna, oba, leafy lettuce, mini red radish, Swiss chard and baby spinach.

Mr Paul Wong, managing director of Panasonic Singapore, said the company embarked on vertical farming as a viable and efficient means of producing vegetables in a limited space.

Mr Wong said: "We started with eight types of crops. Through constant research and development, we now produce 40 varieties of leafy greens and we want to expand that list with seasonal fruits.

"Increasing our overall crop production is also in line with our goal to contribute to Singapore's food security through a stable local supply of leafy greens."

Latest figures from the Agri-Food and Veterinary Authority (AVA) show that last year, 11,300 tonnes of vegetables were locally produced, which accounts for 12 per cent of the total vegetable supply. Singapore imports over 90 per cent of its food supply.

Mr Melvin Chow, group director of AVA's Food Supply Resilience Group, said local food production provides a crucial buffer in the event of disruptions in overseas food supply.

The AVA encourages the use of technology that can help local farms optimise land use, boost capability and raise production.

Mr Chow said: "The most important step is for our industry to adopt a progressive mindset and improve productivity."

Panasonic's indoor vegetable farm was the first of its kind to be licensed by the AVA in 2013.

It utilises both soil cultivation and hydroponics. No pesticides are used. Seeding and potting are automated, which doubles productivity compared with traditional farming methods. An intelligent lighting system using LED lights helps to accelerate plant growth.

Through a system of automated irrigation, controlled temperature, humidity and carbon dioxide, the farm is able to increase crop growth and achieve a high yield rate of 95 per cent.

The farm is also licensed by the AVA to process salads. Panasonic produces three ready-to-eat salad mixes, which are sold at major supermarkets. It also supplies vegetables to hotels, restaurants and catering companies.

Japanese restaurant chain Ootoya placed its first order of vegetables with Panasonic in 2014.

Mr Yusuke Shimizu, 39, managing director of Ootoya Asia-Pacific, said: "Our customers... complimented us on the freshness and some even asked us where to buy the vegetables."

Ootoya orders an average of 150kg of vegetables from Panasonic every month for its three outlets. Mr Shimizu said: "Freshness is a priority at our restaurants and Panasonic supplies us with vegetables that are harvested on the same day."

A version of this article appeared in the print edition of The Straits Times on July 10, 2017, with the headline 'Room to grow more local veggies at Panasonic's farm'.

Organization Turning Vacant Toronto Properties Into Mobile Urban Farms

Organization Turning Vacant Toronto Properties Into Mobile Urban Farms

By Susan HayAnchor/Producer Global News

The Bowery Project is taking vacant lots in downtown Toronto and transforming the properties into mobile urban farms. It’s the brainchild of longtime friends Rachel Kimel and Deena DelZotto. Susan Hay has the story.

Longtime friends Rachel Kimel and Deena DelZotto have a passion for growing food and giving back to the community. Their joint love for food prompted them to start the Bowery Project, an organization that takes vacant lots in downtown Toronto and transforms the properties into mobile urban farms.

“The developer here, Oben Flats, wanted to do something that gave back to the community and that transformed his site,” said co-founder Rachel Kimel.

“People come and they learn new things and they walk away with something fresh, organically grown and sustainable.”

READ MORE: Urban farming: not just growing food but communities

Currently there are three sites in Toronto growing produce in re-purposed milk crates that sit above the land. This allows for an easy change of location when the land is sold or developed.

“It’s like a pop-up mobile farm,” said Kimel. “There’s something called square-foot gardening and so whatever you can occupy in a crate, we do. Herbs, veggies, edible flowers, lots of greens, mixed greens.”

Several community organizations like the Native Women’s Resource Centre benefit from what’s grown on the sites and from the weekly programming and educational workshops.

“Every year from a site this big (at Sherbourne Street and Gerrard Street East), we grow at least 400 pounds of produce and that gets given away to people who are hungry in the city,” said Kimel.

NatureFresh Farms Mobile Greenhouse Pushes Past Heat

NatureFresh Farms Mobile Greenhouse Pushes Past Heat

By Kate Walz July 2017

Two people check out the mobile greenhouse education center. The mobile greenhouse also has a live bumblebee eco-system.Photo by NatureFresh Farms

NatureFresh Farms mobile greenhouse tour (#GreenInTheCity) is continuing across the Midwest despite the heat.

The mobile greenhouse, which has done almost 50 events since mid-April, teaches consumers how greenhouse vegetables are grown.

“The mobile greenhouse has not only been a conversation starter but a difference maker in how we connect with our customers,” Ray Wowryk, director of business development of the Leamington, Ontario, greenhouse company, said in a news release.

The Greenhouse Education Center (GEC) is a 38-foot mobile unit equipped with fruit bearing plants and a live bumblebee eco-system.

“We care about the future of fresh and all that it entails; we need to collectively increase fresh produce consumption,” Wowryk said in the release. “NatureFresh can help do that with the GEC and by getting front and center with consumers, we share our story to help inform them of the value of greenhouse vegetables.” Knowing who grows what you buy is important, understanding how it’s grown is just as important if not more.”

Five college students are serving as brand ambassadors at each event, conducting event day operations and interacting with retail partners. The group has varied backgrounds including agribusiness, environmental science, marketing and biology.

“We are able to immediately impact consumers purchasing decisions at store level with the knowledge we share about how we grow greenhouse vegetables,” said Cole Burkholder, a third-year environmental science major from Ohio State University. “The look on people’s faces when we explain the greenhouse growing process and they see the live plants with real fruit, it’s priceless. You kind of see that ‘a-ha’ moment in their eyes. We’ve even had customers show us their shopping carts when leaving to show us the tomatoes or bell peppers they have purchased because of our conversation.”

This is the third mobile greenhouse tour, which has completed more than 200 events since its inception, including events at retail stores, summer camps, schools and community fairs. The 2017 tour will end Nov. 12 at the Royal Agriculture Winter Fair in Toronto, Ontario.

Philips Lighting Begins Largest LED Horticultural Lighting Project In The World

Philips Lighting Begins Largest LED Horticultural Lighting Project In The World

2017

LED grow lights will illuminate greenhouses occupying an area the size of 40 soccer pitches

Project indicative of trend for large-scale horticultural LED lighting projects supporting domestically grown produce

Eindhoven, the Netherlands – Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting, today announced that it will provide LLC Agro-Invest, Russia’s most innovative greenhouse produce company, with LED grow lights to support cultivation of tomatoes and cucumbers in greenhouses covering an area of more than 25 hectares (equivalent in size to about 40 soccer pitches). The project, which is the largest LED horticultural lighting project ever undertaken, will enable year-round growing, help boost yields - especially in the winter - and will save 50 percent on energy costs compared to conventional high-pressure sodium lighting. The project also underlines a global trend for large-scale LED horticultural lighting implementations that can support demand for locally grown produce.

Philips Lighting is working with Dutch partner Agrolux and Russian installer, LLC ST Solutions, which will equip greenhouses in Lyudinovo, Kaluga Oblast, 350 km south west of Moscow, during the next three months. Philips Lighting will provide ‘light recipes’ optimized for growing tomatoes and cucumbers, training services and 65,000 1.25m long Philips GreenPower LED toplights and 57,000 2.5m long Philips GreenPower LED interlights. Laid end to end, they would stretch 223 km, the equivalent of crossing the English Channel from Dover to Calais more than five times.

“We have a reputation for innovation on a large scale and LED grow lights are definitely the future. They deliver the right light for the plant, exactly when and where the plant needs it the most, while radiating far less heat than conventional lighting. This allows us to place them closer to the plants,” said Irina Meshkova, Deputy CEO and General Director, Agro-Invest. “Thanks to this technology we will be able to increase yields in the darker months of the year, and significantly reduce our energy usage,” she added.

“This LED horticultural project is the largest in the world. It will reduce the electricity consumed to light the crop by up to 50 percent compared with conventional horticultural lighting and uses light recipes designed to boost quality and crop yields by up to 30 percent in the dark period of the winter,” said Udo van Slooten, business leader for Philips Lighting’s horticultural lighting business. “Our grow lights are the perfect supplement to natural daylight so that crops can be grown efficiently throughout the year. The project also highlights a growing international trend to replace imports with domestically grown produce, reducing food miles and ensuring freshness,” he added.

About Agro-Invest

LLC Agro-Invest is Russia’s most innovative greenhouse produce company. Its 43 hectare modern greenhouse complex grows more than 15 varieties of vegetables with an annual production capacity of 25,000 tons. The company acts ecologically, collecting rainwater to water the plants which are pollinated by bees from special beehives within the greenhouse complex. The latter helps improve harvests by 20-25 percent. Protection of the plants is undertaken by natural biological methods. Since 2016, Agro-Invest has sold and marketed its produce under the “Moyo Leto.” trademark. The company works with all the federal trade networks in the Russian Federation and is expanding its operations.

About Agrolux

Agrolux is a worldwide supplier of assimilation lighting for horticulture. It is one of the biggest dealers in Philips LED horticultural lighting worldwide. It distinguishes itself based on advice, service and quality. It also produces its own luminaires and exports them to clients worldwide. The company's broad knowledge, extensive experience and innovative technology, make it stand out as a leader in the horticulture sector. It combines good, honest advice with the fast and dependable delivery of lighting luminaires and parts. Established in 2002, Agrolux has grown in size and production numbers annually. Its employees come from diverse sectors within horticulture and offer a wealth of practical experience, providing the best advice and most efficient lighting for horticulture.

For more information on Philips horticultural lighting: www.philips.com/horti

For further information, please contact:

Philips Lighting, Global Media Relations

Neil Pattie

Tel: +31 6 15 08 48 17

Email: neil.pattie@philips.com

Philips Lighting Horticulture LED Solutions

Daniela Damoiseaux

Tel: +31 6 31 65 29 69

Email: daniela.damoiseaux@philips.com

About Philips Lighting

Philips Lighting (Euronext Amsterdam ticker: LIGHT), a global leader in lighting products, systems and services, delivers innovations that unlock business value, providing rich user experiences that help improve lives. Serving professional and consumer markets, we lead the industry in leveraging the Internet of Things to transform homes, buildings and urban spaces. With 2016 sales of EUR 7.1 billion, we have approximately 34,000 employees in over 70 countries. News from Philips Lighting is located at http://www.newsroom.lighting.philips.comand on Twitter via @Lighting_Press.

A Behind-the-Scenes Look at Europe’s Huge New Vertical Farm

GrowWise is a vertical farming research facility, and in conjunction with Dutch fresh food distributor Staay Food Group, it’s laying the groundwork for the first commercial vertical farm in Europe, slated to open north-east of Amsterdam in a town called Dronten later this year.

A Behind-the-Scenes Look at Europe’s Huge New Vertical Farm

July 20, 2017

The Eindhoven High Tech Campus, a 90-minute train ride south of Amsterdam, consists of two rows of nondescript mid-rise office buildings on either side of a wide, tree-lined road. In typical Dutch fashion, there’s more parking for bikes than cars, and the campus is flanked by stretches of neatly-maintained green fields and canals.

The place doesn’t have an especially high-tech feel to it. But on the third floor of a building near the end of the road, a division of Philips Lighting called GrowWise is using technology to tackle a crucial question: what are we going to eat once there are over nine billion people on Earth?

GrowWise is a vertical farming research facility, and in conjunction with Dutch fresh food distributor Staay Food Group, it’s laying the groundwork for the first commercial vertical farm in Europe, slated to open north-east of Amsterdam in a town called Dronten later this year.

During a tour of GrowWise, I spoke with Gus van der Feltz, Global Director of City Farming, about the ins and outs of vertical farms and the opportunities and challenges the field will face in coming years.

No Sun + No Soil = Organic Plants?

Since the beginning of growing food, sunlight, water, and soil have been essential ingredients. If you take away two of these most basic of inputs, how do plants grow?

“You can think of a vertical farm as a black box,” van der Feltz said. “We look at it as an integrated system, trying to create vegetables in a closed environment.”

Before going into said ‘black box’—otherwise known as the growth rooms—we slip light blue covers over the soles of our shoes and sanitize our hands. These are minor protective measures, and they don’t prevent pathogens from entering the chamber. “If we were going into the actual growth facility we’d need to put on full protective gear,” van der Feltz said.

Outside the growth room is a winding, humming network of pipes, screens, and dials. Van der Feltz pulls back a large sandwich panel door, and when we step inside, the air is noticeably warmer and more humid. It smells like a farm, except without the manure, and it feels a little like being on a spaceship—trays of plants are stacked four levels high, hundreds of blue and red pinpoints of light beaming down on them from above. The light on the bottom two levels is white, while the top two give off a purplish glow.

We have to raise our voices to talk over the hum of the regulators. Solar light, van der Feltz explains, is spread across a spectrum ranging from UV to infrared. In photosynthesis, red and blue wavelengths of light interact with chlorophyll to help form glucose and cellulose, the structural material in cell walls.

LEDs can reproduce this effect, and can do it faster than the sun; time from seed to harvest at GrowWise is 30-40 days, as compared to 60-65 days in a typical greenhouse, according to van der Feltz.

“What we’ve done with LEDs is optimize the conditions for growth. There are elements of sunlight that plants don’t use as efficiently, and those can be reduced or taken out,” van der Feltz said. One of those elements is heat—when I wave a hand under the lights, they feel no warmer than the rest of the room.

The crops need different intensities of light as they pass through stages of growth, and they’re constantly monitored by sensors and software that tweak their conditions as necessary. Van der Feltz explains that triggering the right combination of processes in photosynthesis, in combination with other growth factors, can also create desired effects. “With the right lighting conditions we can make lettuce turn purple or red. We can make strawberries sweeter,” he said.

Each plant sits in a thimble-sized container of sterilized coconut bark, which serves as a substrate for germination and root development. From there the roots extend into shallow troughs of nutrient-rich water—the plants are constantly in water rather than being periodically sprayed or on a timed drip, making this hydroponic farming.

Food And The Future

The Dronten facility will be 900 square meters (9,680 square feet), with a total cultivation area of 3,000 square meters (32,290 square feet).

Though this pales in comparison to the biggest vertical farm in the world—AeroFarms’ 70,000-square-foot facility in Newark, New Jersey—it will be the largest in Europe. Outside Europe and the US, vertical farms also exist in Japan, Korea, Singapore, and Canada, and a facility much larger than Aerofarms is planned in Shanghai.

It’s no coincidence most of these farms are near big, densely-populated cities. The UN’s 2014 World Urbanization Prospects report predicts population growth and urbanization will add 2.5 billion people to the world’s big cities by 2050. That’s a whole lot of people who’ll be buying all their food rather than producing any of it.

Agricultural yields, then, will have to increase significantly, and since much of the world’s farmable land is already being farmed, we’ll need to get a bit more resourceful with our food supply.

Right now, vertical farming is still expensive—a bag of GrowWise lettuce costs more than a bag of organic lettuce, which costs more than a bag of regular lettuce—and it requires a lot of energy; those LED bulbs aren’t lighting themselves.

But continued research and investment will gradually drive prices down, and as ironic as it sounds, vertical farms will eventually get all their energy from solar panels.

This will leave us with an organic growing method that requires no fertilizer or pesticides, produces no agricultural runoff or other pollution, uses a fraction of the water traditional farms use (same goes for land), and yields consistent harvests year-round, even in extreme or unusual weather.

“You can create optimal growing conditions for the crop and you don’t need to wash it,” van der Feltz said. “The washing process damages the leaves and causes them to decay faster. Having the growth facility nearby decreases travel time and means the food will be fresher.”

The Consumer’s Still King

As rosy as this all sounds, it doesn’t mean people will embrace vertically-farmed food with open arms. Food is a sensitive topic many consumers take very seriously; if we are, in fact, what we eat, people may not love the idea of eating food that, for all its merits, is grown under decidedly artificial conditions.

As we stood peering at the neatly glowing rows of plants, van der Feltz reached out, plucked one from its roots, and handed it to me. “Try it,” he said. So I did. I tasted the green-leaf lettuce and the basil. Both seemed to have a stronger flavor and aftertaste than the store-bought greens I’m used to, though it was nothing I’d have noticed had I not been aware of what I was eating.

Van der Feltz recognizes widespread adoption of vertically-farmed food may be a challenge. “We understand some people may feel uneasy about food grown with no sunlight,” he said. Consumer education will play a key role in getting people comfortable with purchasing and eating LED-grown greens.

At the same time, though, food preferences are shifting, and for the better as far as vertical farming is concerned. “In the Western world there’s a growing demand for convenience products that have already been washed and are ready to use,” van der Feltz explained.

His confidence in GrowWise’s products, for one, is unwavering. “We test our produce regularly for pathogens and nutritional quality, and each time the results are excellent,” he said. “They serve this lettuce here in our cafeteria. I take it home to my family. My kids love it.”

Image Credit: Vanessa Bates Ramirez

Global Use of Wastewater To Irrigate Agriculture At Least 50 Percent Greater Than Thought

According to the study, farmers' use of wastewater is most prevalent in regions where there is significant wastewater generation and water pollution.

Global Use of Wastewater To Irrigate Agriculture At Least 50 Percent Greater Than Thought

Credit: CC0 Public Domain

July 24, 2017

The use of untreated wastewater from cities to irrigate crops downstream is 50 percent more widespread than previously thought, according to a new study published this week in the journal Environmental Research Letters.

The study relies on advanced modeling methods to provide the first truly comprehensive estimate of the global extent to which farmers use urban wastewater on irrigated cropland. Researchers analyzed data with geographic information systems (GIS) rather than depending on case study results, as in previous studies.

The researchers also assessed for the first time 'indirect reuse', which occurs when wastewater gets diluted but still remains a dominant component of surface water flows. Such situations account for the majority of agricultural water reuse worldwide, but have been difficult to quantify on a global level due to different views of what constitutes diluted wastewater versus polluted water.

Considering consumer safety the foremost priority, study authors highlight the need to mitigate public health risks through measures taken along the entire food supply chain. This includes improved wastewater treatment, but also preventive steps on farms and in food handling, since capacity for water treatment is increasing only slowly in developing countries.

According to the study, farmers' use of wastewater is most prevalent in regions where there is significant wastewater generation and water pollution. In these circumstances, and where safer water is in short supply, wastewater offers a consistent and reliable means of irrigating fields, including high-value crops, such as vegetables, which often require more water than staple foods. Where raw wastewater is available, farmers may tend to prefer it because of its high concentrations of nutrients, which can lessen the need to apply purchased fertilizers. In most cases, however, farmers' use of this water is motivated by basic needs; they simply do not have alternatives.

"The de facto reuse of urban wastewater is understandable, given the combination of increasing water pollution and declining freshwater availability, as seen in many developing countries," said Anne Thebo, a recent graduate at the University of California, Berkeley in the USA and lead author of the study. "As long as investment in wastewater treatment lags far behind population growth, large numbers of consumers eating raw produce will face heightened threats to food safety."

Results show that 65 percent of all irrigated areas are within 40 km downstream of urban centers and are affected by wastewater flows to a large degree. Of the total area of 35.9 million hectares, 29.3 million hectares are in countries with very limited wastewater treatment, exposing 885 million urban consumers as well as farmers and food vendors to serious health risks. Five countries - China, India, Pakistan, Mexico and Iran - account for most of this cropland. These new findings supersede a widely cited 2004 estimate, based on case studies in some 70 countries and expert opinion, which had put the cropland area irrigated with wastewater at a maximum of 20 million hectares.

"Gaining a better grasp of where, why and to what extent farmers use wastewater for irrigation is an important step toward addressing the problem," said second author Pay Drechsel of the International Water Management Institute (IWMI), who leads the CGIAR Research Program on Water, Land and Ecosystems. "While actions aimed at protecting human health are the first priority, we can also limit the hazards through a variety of tested approaches aimed at safely recovering and reusing valuable resources from wastewater. These include the water itself but also energy, organic matter and nutrients, all of which agriculture needs. Through such approaches, we have been helping the World Health Organisation (WHO) respond to the wastewater challenge over the years."

"We hope this new study will focus the attention of policy makers and sanitation experts on the need to fulfill Sustainable Development Goal 6, particularly target 3, which calls for halving the proportion of untreated wastewater, and increasing recycling and safe water reuse," added Drechsel.

"One major challenges is to cultivate behavior change from farm to fork, especially where risk awareness is low. Another consists of larger scale efforts to put the recovery and reuse of resources from wastewater and other waste on a business footing to make its management more attractive for the public and private sectors. Safe resource recovery and reuse have significant potential to address the health and environmental risks, while at the same time making cities more resilient and agriculture more sustainable, contributing to more circular economies."

Explore further: Drugs in wastewater contaminate drinking water

More information: A L Thebo et al, A global, spatially-explicit assessment of irrigated croplands influenced by urban wastewater flows, Environmental Research Letters (2017). DOI: 10.1088/1748-9326/aa75d1

Journal reference: Environmental Research Letters

Provided by: Institute of Physics

Read more at: https://phys.org/news/2017-07-global-wastewater-irrigate-agriculture-percent.html#jCp

An IGA In Montreal Is Growing Its Own Vegetables On The Roof

More than 30 different kinds of produce, including lettuce, kale, garlic and basil, are being grown on 25,000-square-foot roof. All of the produce is certified organic.

Required by Saint-Laurent to install a green roof, Richard Duchemin, the co-owner of IGA Extra Famille Duchemin, decided to plant a garden on it. ALLEN MCINNIS / MONTREAL GAZETTE

An IGA In Montreal Is Growing Its Own Vegetables On The Roof

JACOB SEREBRIN, MONTREAL GAZETTE

More from Jacob Serebrin, Montreal Gazette

Published on: July 19, 2017 | Last Updated: July 19, 2017 5:27 PM EDT

Required by Saint-Laurent to install a green roof, Richard Duchemin, the co-owner of IGA Extra Famille Duchemin, decided to plant a garden on it. ALLEN MCINNIS / MONTREAL GAZETTE

An IGA store in the Saint-Laurent borough says it’s the first grocery store in Canada to sell produce grown on its own roof.

More than 30 different kinds of produce, including lettuce, kale, garlic and basil, are being grown on 25,000-square-foot roof. All of the produce is certified organic.

Required by Saint-Laurent to install a green roof, Richard Duchemin, the co-owner of IGA Extra Famille Duchemin, said he decided to go a bit further.

Duchemin said he likes to offer locally grown produce to his customers and this was a chance to offer them the most local products possible. He said also he wanted to set an example for other grocery stores.

“Why don’t supermarkets plant vegetables on their roofs?” he said.

A garden bed ready for expansion at the huge rooftop garden at an IGA store in the Saint-Laurent district of Montreal. ALLEN MCINNIS / MONTREAL GAZETTE

A garden bed ready for expansion at the huge rooftop garden at an IGA store in the Saint-Laurent district of Montreal. ALLEN MCINNIS / MONTREAL GAZETTE

While the costs are higher, due to the small scale of the project, Duchemin said the produce grown on the store’s roof is being sold at the same price as any other organic produce.

The project is part of a partnership with The Green Line: Green Roof, a Montreal-based company that installs green roofs.

The Green Line is responsible for managing the actual growing of produce on the roof.

While many rooftop gardens opt for hydroponic systems, this one uses soil on the roof — which allows it to be certified organic.

However, because the soil is quite shallow, it limits the type of produce that can be grown, said Tim Murphy, a project manager for The Green Line. Large root vegetables, for example, aren’t an option.

Do-It-Yourself Farmer Grows Strawberries In The Air

The system has a number of advantages. Elevated strawberries stay warmer than strawberries in the ground, which means a relatively long season, from November through April. And the plants grow downward, so the berries are easy to harvest. Outdoor strawberry farms yield about 12 tons of strawberries per acre; hanging strawberry plants in greenhouses yield three times as much.

Do-It-Yourself Farmer Grows Strawberries In The Air

July 18, 201712:50 PM ET

SHAINA SHEALY

An elevated strawberry farms in the West Bank city of Tulkarum, funded by a USAID program.

Shaina Shealy for NPR

Hezam Kittani didn't want U.S. handouts to help him grow strawberries.

He wanted to be a do-it-yourself berry farmer — and to teach others to follow in his footsteps.

Strawberries were barely grown in the West Bank, where Kittani lives, before 2009. Today they're a 250-ton yearly crop. And that's because of $705,358 in grants from USAID for farmers in this "lower middle income region" (as classified by the World Bank).

The USAID money offered a helping hand for farmers to set up a new way to grow the fruits — in hanging planters where pests can't get to them as easily as on the ground and with "a computerized automated drip irrigation system that accurately measures the optimum amount of water needed." The berries grow in a mix of perlite and peat moss.

The system has a number of advantages. Elevated strawberries stay warmer than strawberries in the ground, which means a relatively long season, from November through April. And the plants grow downward, so the berries are easy to harvest. Outdoor strawberry farms yield about 12 tons of strawberries per acre; hanging strawberry plants in greenhouses yield three times as much.

Hezam Kittani (left), the do-it-yourselfer who created his own aerial strawberry system, and Mustafa Barakat, the Palestinian Ministry of Agriculture's strawberry expert.

Shaina Shealy for NPR

But Kittani thinks there's a big disadvantage to the current setup. He doesn't want local farmers to rely on foreign aid. He wants them to succeed — to help themselves and the economy — without outside help. That's why Kittani set out to design a version of the USAID elevated strawberry system that Palestinian farmers could easily (and inexpensively) replicate themselves.

He began watching YouTube videos and doing trial-and-error experiments to find a system that farmers could pay for themselves and that would still yield lots of berries. First, Kittani built planters from the same plastic boards used in USAID-assisted strawberry farming, but the process was labor-intensive, Kittani says. "It was hard to construct because you have to cut it in pieces and find how to stick it together."

One video suggested sewage pipes as planters. So Kittani bought pipes, drilled holes in them and lined them with plastic cups full of strawberry plants. But the pipes ended up costing more than the plastic boards.

Kittani kept experimenting. Eventually he settled on wooden beams wrapped with white plastic sheets — the cheapest materials he found. "I try to make it more practical and easy to construct to train neighbors how to do it," he says.

Kittani fills his channels with soil he calls "ideal," a mix of coconut shells, peat moss and foam balls. He learned about it on a video series on the University of Arizona website.

The biggest challenge was building a computer-based irrigation system similar to the expensive USAID model. Kittani asked his daughter's high school science teacher for advice; she told him about a market that sold irrigation timers for around $30 each. He taught himself how to code and programmed a computer with similar nutrient and water measurements as the USAID system. The result was a $500 automated irrigation computer, about a third of the cost of the USAID model.

USAID's objective is the same as Kittani's: to boost the local economy, create jobs and make Palestinian agriculture globally competitive. In response to Kittani's project, a USAID spokesperson said the organization applauds innovation and is pleased that an entrepreneur is trying to develop a new system: "Our goal is to make this program self-sustaining so that farmers will be able to do this work in the future without USAID's assistance."

Strawberries and almonds (pictured, raw) are popular crops in the West Bank.

Shaina Shealy for NPR

Kittani is still fine-tuning his strawberry operation. He's working with local researchers to develop a strawberry plant tissue culture, a technique used to grow whole plants from plant cells. And Kittani recently rigged a smartphone app that's connected to a device in the soil to track irrigation and pH levels. He's researching solar panels and wants to install internet using local SIM cards instead of a wireless router so farmers without internet or electricity can send and receive information from smartphones.

"It's called smart irrigation," Kitanni says. He pauses. "No," he continues. "We will call it smart farming."

This year marked the first full strawberry harvest in Kittani's backyard. Five farmers have come to him for advice. None of them have replicated his strawberry system from scratch, but they are asking him how to make their farms more affordable and resource-efficient.

And the strawberry is just the beginning, Kittani says. Next up: "We need to study the pineapple."

Shaina Shealy is an American journalist living in Jerusalem. Her work focuses on religion, community development and women's health. Find her on twitter @shainashealy

Affinor Growers Highlights Accomplishments in Fiscal Year End and Outlines Future Plans

Affinor Growers Highlights Accomplishments in Fiscal Year End and Outlines Future Plans

Vancouver (Canada), July 17 2017 - Affinor Growers (CSE:AFI, OTC:RSSFF, Frankfurt:1AF) (“Affinor” or the “Corporation”) is pleased to provide our shareholders with a summary of the Company's accomplishments in the past year and Affinor's plans for the current year.

Affinor's fiscal year end was May 31, 2017. Our ultimate goal continues to focus on becoming the leading technology developer and supplier of vertical farming equipment dramatically increasing the economics of farming, improving food security and increasing agriculture production for high value crops. With the help of our strategic partners and our technical team, Affinor's immediate plans include continuing the development and commercialization of our patented technology and equipment, validation through third party partners, proving revenue models, and crop diversification.

Over the last year, Affinor has focused on strawberry development as fresh strawberries account for 80% of the total strawberry production in North America valued at $2.6 billion annually with several industry challenges making traditional strawberry growing an ongoing concern for long term viability. Affinor will continue to grow and harvest strawberries with our beta prototypes installed at the University of Fraser Valley throughout the summer, fall and winter of 2018. The focus will continue on standardizing crop models and determining best practices for commercialization. Other notable achievements over the last fiscal year included testing cannabis on a small 4 level vertical growing tower to determine if the high value crop can be utilized with the technology, increasing yields and production per square foot, with initial success.

Affinor's goal over the next year is to shift from a development to an operational company focusing on generating revenue from vertical tower sales, license agreements and introducing new agriculture technologies. Our revenue models will include selling systems to growers resulting in a margin on the equipment, license fees, and collecting royalties on the revenues from production; as well as potentially using the equipment ourselves to grow and sell crops.

Project updates:

Commercial Farm in Abbotsford

Affinor expects to commission 32 towers in a commercial farm in Abbotsford British Columbia in late 2017 capable of growing over 21,000 plants. The facility will be one of our first license holders to commercially produce products using Affinor technology. We have partnered with a large strawberry producer in California that will supply the strawberry plants and help oversee the initial growing with an "On-Farm Test Agreement" executed March 27, 2017 (see news release "Affinor Growers Signs an "On-Farm Test Agreement" with California Berry Company")

Beta Prototype Testing Update

Two 4 level beta prototype towers were installed installed in April, 2016, and December, 2016, at the University of the Fraser Valley (“UFV”) Surrey BC location in the agriculture research greenhouse (see news release Dec 6 2016, "Affinor Installs Second Tower at the Agriculture Research Demonstration Greenhouse BioPod Initiative"). One tower holds 128 strawberry plants within 100 square feet and the other 256 within 100 square feet. All crop model information, data, procedures and harvest quality is being documented to help prove operational and financial assumptions, revenue models, and best practices to standardize commercialization. The protocols and developed methods will help catalyze the commercial farm in Abbotsford when ready.

Affinor's next objective is to produce strawberries throughout the winter with customized LED supplemental lighting for fruiting crops and diversify the crop trials with kale during the fall 2017.

Affinor and Cannabis Production

As cannabis becomes more established in North America, cost effective commercial production and greenhouse systems will be needed to improve production. Affinor sees this as an opportunity to diversity our technology into other markets with high value crops and be the first vertical system actively growing cannabis in Canada. Our first trial growing cannabis was completed in February 2017, with a grower in Mission BC (see news release Feb 27 2017 "Affnor Growers Installs Vertical Farming System for Medical Cannabis in Mission BC") with encouraging results within four months (see news release May 29 2017 "Affinor Growers Completes Initial Medical Cannabis Growth Trial with 200% Production Increase.") Affinor will continue to test cannabis, furthering yields and output by developing new crop models for short, high producing cannabis plants specific to the needs of the technology, at licensed sites. We are negotiating with cannabis growers throughout North America to help facilitate a larger pilot plant cannabis growth trial.

BC Tree Seedlings Development.

Affinor executed a research and development license agreement to develop vertical growing systems to mass produce high quality, high stress resistance seedlings for the BC forestry market (see news release May 22 2017 "Affinor Growers Signs and "On-Site Test Agreement" to Develop Vertical Farming with Coniferous Tree Seedling"). 259 million trees were planted in 2016 with 266 million planned for 2017. Reforestation and silviculture are a large and growing market throughout North America requiring new technological solutions to keep up with demand.

License Agreements and Sales

Affinor has signed several license agreements throughout the fiscal year with various companies to use our technology based on our beta prototype concepts and preliminary production results. Each license agreement has the potential to generate significant equipment sales, long term royalties, ownership options and joint venture partnerships. For a complete list, please visit our website. We are also under license agreement negotiations with several international companies looking to build commercial facilities throughout the Caribbean, Europe, and Middle East.

For More Information, please contact:

Jarrett Malnarick, President and CEO

contact@affinorgrowers.com

About Affinor Growers Inc.

Affinor Growers is a publicly traded company on the Canadian Securities Exchange under the symbol ("AFI"). Affinor is focused on growing high quality crops such as romaine lettuce, spinach, strawberries using its vertical farming techniques. Affinor is committed to becoming a pre-eminent supplier and grower, using exclusive vertical farming techniques.

On Behalf of the Board of Directors

AFFINOR GROWERS INC.

"Jarrett Malnarick"

President & CEO

The CSE has not reviewed and does not accept responsibility for the adequacy or accuracy of this release.

FORWARD LOOKING INFORMATION

This News Release contains forward-looking statements. The use of any of the words "anticipate", "continue", "estimate", "expect", "may", "will", "project", "should", "believe" and similar expressions are intended to identify forward-looking statements. Although the Company believes that the expectations and assumptions on which the forward-looking statements are based are reasonable, undue reliance should not be placed on the forward-looking statements because the Company can give no assurance that they will prove to be correct. Since forward-looking statements address future events and conditions, by their very nature they involve inherent risks and uncertainties. These statements speak only as of the date of this News Release. Actual results could differ materially from those currently anticipated due to a number of factors and risks including various risk factors discussed in the Company's disclosure documents which can be found under the Company's profile on www.sedar.com. This News Release contains "forward-looking statements" within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E the Securities Exchange Act of 1934, as amended and such forward-looking statements are made pursuant to the safe harbor provisions of the Private Securities Litigation Reform Act of 1995.

Pure Flavor®’s Growth Prompts Leadership Team Addition

Pure Flavor®’s Growth Prompts Leadership Team Addition

Leamington, ON (July 19th, 2017) – Building on consistent year over year growth, greenhouse grower & marketer Pure Flavor® announced the addition of Chris Veillon as Chief Marketing Officer to the company’s executive leadership team.

“As we continue to grow our retail & foodservice business, we needed to strategically evolve our marketing direction to support our premium line of greenhouse vegetables. In adding Chris to our executive team, we have added a seasoned strategic marketer who not only understands the industry but has been successful in building consumer facing brands over the last 20 years “, said Jamie Moracci, President.

Under the Pure Flavor® brand, the company grows & markets an extensive variety of greenhouse tomato, bell pepper, cucumber, eggplant, and living lettuce that is grown in Canada, USA, and Mexico. Founded in 2003, Pure Flavor® has experienced significant growth year over year with its expanding product offering.

“This is a fantastic career opportunity, I am very excited to join the leadership team at Pure Flavor®. The company culture and growth opportunity is unique which made it even more of a reason to join the Pure Flavor® team “, said Chris Veillon. “The product base is vast and expanding year after year to meet retail demand, I’m very excited to work with the team to strengthen the Pure Flavor® brand position “, commented Chris. As Chief Marketing Officer, Veillon will be responsible for all initiatives related to conceptualizing and implementing market strategy while providing strategic direction for promotion & advertising.

With the addition of Veillon as Chief Marketing Officer, the company also promoted Matt Mastronardi to Executive Vice-President. Mastronardi is one of the founding partners of Pure Flavor® and is part of the sales team.

“These are exciting times for our company. The strategic partnerships we have built with our growers, retail, and foodservice partners, is allowing us to continually extend our reach across North America”, said Matt Mastronardi. Mastronardi, Jamie Moracci, and Jeff Moracci, Pure Flavor’s CFO founded Pure Flavor® in 2003. With its corporate headquarters in Leamington, ON the company now operates in 3 countries with multiple distribution center locations providing year-round production.

Pure Flavor® will be exhibiting at the upcoming PMA Foodservice Trade Show in Monterrey, CA July 30. Stop by Booth #1106 to see Pure Flavor’s product line.

To learn more about Pure Flavor®, please visit Pure-Flavor.com

-30-

About Pure Flavor® - Pure Flavor® is a privately held greenhouse vegetable company providing year-round production of premium vegetables to retail & foodservice partners throughout North America.

SOURCE: Jamie Moracci | Jamie@pure-flavor.com

President | Pure Flavor®

T: 519 326 8444

Chris Veillon

Chief Marketing Officer

Pure Hothouse Foods Inc.

PO Box 607, Leamington, ON N8H 3X4

p: 519.326.8444 | p: 866.326.8444 | m: 519.878.1905 | f: 519.326.7960

Vertical Farming May Be About To Take Off

Vertical Farming May Be About To Take Off

20 Jul, 2017 5:00am

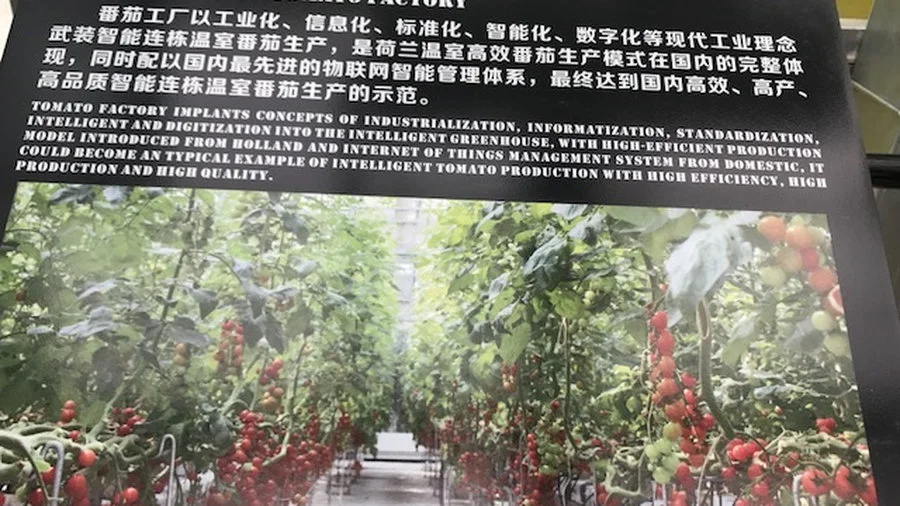

Vertical farming at Cofco's Intelligent Farm in Beijing.

NZ Herald

As nations endeavour to produce higher-value crops and land availability becomes ever more scarce, looking forward is beginning to mean looking up for the most plugged in farmers.

A report earlier this year from Global Market Insights suggested the market size for vertical farming would exceed US$13 billion (NZ17.7b) by 2024.

The technology involves stacked layers of produce in an indoor, controlled environment - often skyscrapers, but also warehouses and even disused bomb shelters in one case. This means farms can be found in urban areas and food may be produced in some of the least traditionally agrarian economies.

For example, Singapore has been a leader in the development of vertical farming as it attempts to reduce its dependency on overseas food sources despite the challenge of being just 720 square kilometres in size.

New Zealand does not face such challenges in terms of land mass. However, Jason Wargent, Associate Professor at Massey University and Chief Science Officer of BioLumic (a start-up that develops yield-stimulating light treatments for agricultural crops, and which has vertical farming on its radar) says New Zealand could still profit from the technology.

"One of the clearest opportunities for New Zealand is in the development of technology, which may support indoor farming system development, and have world-wide value," says Wargent. "New Zealand has a great ag-innovation landscape and developing cross-sector ag-innovation, that may be applicable or originally aimed at indoor, is a win-win for New Zealand."

Jaskirat Matharu last year wrote a research paper on the topic from an architectural perspective, and suggests New Zealand farmers should be exploring the technology too.

"I believe that vertical farming in New Zealand is not needed at this stage," says Matharu.

"Having said that, we should not wait to become a dense country for vertical farming to be used."

"It's more about being future-proof and laying the groundwork for the future. Like with most new things, society needs to educated for it to be taken seriously and it needs to happen sooner rather than later."

Agricool Raises $9.1 Million To Grow Fruits And Vegetables In Containers

Agricool Raises $9.1 Million To Grow Fruits And Vegetables In Containers

Posted Jul 11, 2017 by Romain Dillet (@romaindillet)

French startup Agricool is using containers to grow strawberries around big cities. The company just raised a $9.1 million (€8 million) funding round from Jacques-Antoine Granjon, Thibault Elziere as well as existing investors Henri Seydoux and Daphni.

The great thing about growing fruits in containers is that you can control everything. The company tweaks the temperature, humidity, CO2 level, color spectrum and day/night cycle to get the most out of the strawberries.

For instance, the company wanted to find the perfect LEDs to provide the right shade of light. It bought dozens of LEDs and tried them all, but even the best LED model was disappointing. Agricool ended up hiring someone to design its own LED with a specific shade.

Another interesting example, if you want to imitate the real world, you turn the lights on and off and on again every 24 hours. But do strawberries really need a 24-hour day cycle? Maybe 22 hours are enough and strawberries end up growing more quickly.

In order to do this, Agricool now has a warehouse outside of Paris where it can A/B test all these things using refrigerated rooms. Then, it can manufacture containers tailored to Agricool’s needs — think about it as the concept cars of containers. The company has produced 6 prototypes over the last 12 months.

But that was just step one. Agricool wants to go from concept cars to industrialized processes. Eventually, Agricool wants to outsource the production of those containers and put them around big cities globally.

This summer, the startup is going to put five containers around Paris. One in Bercy, another one next to Vente-Privée’s office, another one on Asnière’s market, etc.

“At first they tell you that strawberries are not going to have a great taste with LEDs, but they like them when they try them,” co-founder and CEO Guillaume Fourdinier told me. “Then they tell you that you can’t scale production, but you scale. And then they tell you you can’t distribute and now we’re going to distribute.”

A 250g pack of strawberries is going to cost €4. On average, Fourdinier says that organic strawberries coming from France cost around €6.70 for 250g.

The main reason why those strawberries are cheaper is because you don’t have to pay middlepersons. There’s no importing company, transportation company, central purchasing, supermarket, etc. Agricool grows strawberries where end customers are going to buy them.

“Our challenge is to find an industrial model that lets us grow quickly from 1 to 1,000 containers,” Fourdinier said. In order to do this, Agricool could eventually become a franchise. The company would focus on research & development, containers and branding, while partners would manage those containers and sell fruits and vegetables.

While the strawberry market is huge, the company is also thinking about producing common vegetables and fruits, such as lettuce, tomatoes, cucumbers, zucchinis and bell peppers. The same model can be used across all those vegetables.

“We want to build the biggest brand for fruits and vegetables,” Fourdinier said. “No pesticide, a lot of flavor, no GMO, harvested and sold on the same day.”

SoftBank Vision Fund Leads $200 Million Bet on Indoor Farms

SoftBank Vision Fund Leads $200 Million Bet on Indoor Farms

By Selina Wang

July 19, 2017, 8:00 AM CDT July 19, 2017, 9:02 AM CDT

Masayoshi Son is betting on San Francisco startup Plenty

The investment will help Plenty expand around the world

Masayoshi Son has discovered a green thumb.

The SoftBank Group Corp. chief’s Vision Fund is leading a $200 million investment in Silicon Valley startup Plenty, which says it has cracked the code on growing crops indoors super efficiently. Other participants in the round include Moore Capital Management founder Louis Bacon as well as existing backers such as DCM Ventures and funds that invest on behalf of Alphabet’s Eric Schmidt and Amazon’s Jeff Bezos.

Plenty vertical farming | Source: Plenty

This is Son’s first big bet on agricultural disruption and something of a departure from his recent investments in giant startups like office-space startup WeWork Cos. and Chinese ride-hailing provider Didi Chuxing, but he was attracted by Plenty’s potential to help boost food production near big cities.

“We believe Plenty’s team will remake the current food system to improve people’s quality of life,” Son said in an emailed statement.

Matt Barnard, Plenty’s co-founder, is scheduled to appear Thursday in Tokyo at SoftBank World, the company’s annual two-day event aimed for customers and suppliers. In previous years, Son has shared the stage with Alibaba Group Holding Ltd. co-founder Jack Ma and the company’s Pepper robot.

Son’s backing could give a big boost to vertical farming, a much-hyped concept that so far has failed to revolutionize crop production. In recent years several companies including Atlanta-based Podponics, Vancouver’s LocalGarden and Chicago-area FarmedHere have shut down indoor farms because they weren’t economically viable.

’Plant Factories’ Churn Out Clean Food in China’s Dirty Cities

Barnard, who grew up on a commercial farm in Wisconsin, founded Plenty in 2014 with Nate Storey, a crop scientist who previously started another indoor farm. Plenty does things differently from its rivals. Where most grow plants on shelves like a tall dresser, Plenty uses 20-foot-tall columns from which the plants jut horizontally; picture poles lined up in rows, carpeted in plants from top to bottom. Nutrients and water drip down the columns. Plenty scientists also figured out how to more cheaply remove excess heat emitted by the LED grow lights–a problem Barnard says tripped up other operations.

The company says it can cultivate many more crops per square foot than competitors and uses less energy because the plant food is mostly gravity-fed rather than pumped. “Because we work with physics, not against it, we save a lot of money,” Barnard says. An internet-connected system delivers specific types of light, air composition, humidity and nutrition, depending on which crop is being grown. Plenty says it can yield up to 350 times more produce in a given area than conventional farms -- with 1 percent of the water.

During a recent visit to the company’s facility in San Francisco, the columns are covered in heirloom varietals of purple Siberian kale, red leaf lettuce, sorrel and special species of basil and chives. Barnard says these are more nutritious and flavorful varieties than the mass-produced seeds that were bred to survive the vagaries of commercial production. The company selects which plants to grow based on taste tests with consumers and professional chefs. (A sampling during the tour confirms that the produce is tastier than store-bought.)

“We select stuff that people love because we have the freedom to do that because our supply chain is so short and simple,” Barnard says. “The field doesn’t have that option. It has to grow things that can survive 3,000 miles in a truck. That’s why the field grows iceberg lettuce.”

Skeptics of vertical farms note that they are best suited to growing leafy produce. “Rooting and fruiting” vegetables like carrots, beets, tomatoes, peppers, eggplants and cucumbers are harder to grow under such circumstances and hence more costly. Barnard says Plenty is working on growing cucumbers. So far, most of the startup’s plants are donated to food banks or used for consumer tests, including at a Google campus kitchen. Plenty will start distribution in the San Francisco Bay Area this year. International expansion is the next step and that’s where Son comes in.

A few months ago DCM Ventures co-founder David Chao introduced Barnard to the SoftBank chairman and CEO in California. The meeting was supposed to take 15 minutes but ended up lasting 45 because Son was excited about Plenty’s vision. Two weeks later, Barnard and Chao flew to Tokyo for another meeting with Son, who was skeptical at first, Chao says, but ended up sold on Plenty’s prospects.

“Ever since the Egyptian period, farming has been done one way: flat on the ground, outdoors,” Chao says. “But with indoor farming Masa realizes it’s revolutionary.”

Masayoshi Son | Photographer: Akio Kon/Bloomberg

Son is particularly interested in how Plenty can help nations grow sufficient food to support the population. His Vision Fund backers include sovereign wealth funds from the Middle East, where drought, population growth and a lack of arable land are fueling concerns about food shortages and political instability. Japan, Son’s home country, imports much of its own food and lost farmland after the nuclear power accident six years ago. Sonny Ramaswamy, director of the National Institute of Food and Agriculture at the U.S. Department of Agriculture, says indoor farming will play a significant role in easing shortages of green vegetables.

Chao says the $200 million Vision Fund investment will be used mostly to help Plenty expand domestically and internationally. Eventually, the company hopes to erect pre-fabricated farms outside major cities around the world. SoftBank has extensive connections around the world, Chao says, and wants “to help Plenty expand very quickly, particularly in China, Japan and the Middle East.”

Dickson Despommier, a Columbia professor who wrote “The Vertical Farm: Feeding the World in the 21st Century,” says indoor farming will never completely replace conventional outdoor agriculture but will supplement a growing portion of certain kinds of produce.

“In places where there is no ready access to what they’re growing, then they can corner the market,” he says. “If they do it where the price is right and the demand is right, there’s no reason why they couldn’t go wander into the sunset laughing as they go.”

Deptford Has Its First Vertical Farm And It Could Hold The Key To Our Urban Future

Published by Bdaily Editor Billy Woodon 07 JUL 2017

Deptford Has Its First Vertical Farm And It Could Hold The Key To Our Urban Future

#London #Funding #Agriculture #Innovation #Technology

A new vertical farm has opened its doors in Deptford housed within a previously disused warehouse.