Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Polygreens Podcast Episode: 007 - Jim Pantaleo

In mid-2014, Jim made a move away from a 20-year career in technology to indoor vertical farming for food and non-traditional crop production

POLYGREENS PODCAST EPISODE 007

JIM PANTALEO

In mid-2014, Jim made a move away from a 20-year career in technology to indoor vertical farming for food and non-traditional crop production.

Indoor farming (growing plants for food consumption in totally enclosed environments using only LED lights for photosynthesis) plays a part in directly addressing water, land, population, and natural ecosystem challenges borne from current, large-scale (unsustainable and harmful) agricultural practices.

In order to move from tech to indoor farming, He took a full year to immerse himself in the subject, learning as much as he possibly could while directly engaging with the industry's credible difference-makers and organizations.

Over the past six years, he has been a large-scale, commercial operator/indoor farmer, speaker, writer, business developer, investigative C-level start-up team member, plant science nerd, and conference organizer/MC. Jim seeks to create positive change, shift the paradigm of sustainable indoor plant production, and disrupt (and enhance) supply chains to meet the challenges of modern, large-scale agriculture.

Listen

Horticultural Glass Price Doubles From Growth In Solar Market

Since September, the price of horticultural glass has changed dramatically. “The glass price has been almost stable for ten years, it only drops a little bit year after year. Yet a couple of months ago, the price almost doubled,” says Michael Lee with Planti

Since September, the price of horticultural glass has changed dramatically. “The glass price has been almost stable for ten years, it only drops a little bit year after year. Yet a couple of months ago, the price almost doubled,” says Michael Lee with Planti. “It’s bad news for everybody, not in the least for growers and builders.” The cause for the price change is the high demand for low-iron glass from the solar industry.

Low-iron glass is a type of glass with – the name might give it away – very low amounts of iron, meaning that it is much clearer than glass with a high iron rate. This type of glass is highly in demand for greenhouses and is also being used in the solar industry.

“This summer the solar business in China developed a lot. It’s a very volatile market usually, but since this summer it has been a strong market, meaning that solar manufacturers are buying a lot of glass for their future business. Many factories like ours, have seen orders from solar panel buyers. The demand for the raw goods is high, and so is the pressure on the factories,” Michael explains. Planii solely serves the horticultural market and does not focus on the solar business. “But since solar panels come in a fixed size and are much easier and quicker to produce, suppliers can make more profit by delivering glass for them, instead of growers. There’s a big shortage of glass in the market.”

The higher price has an effect on greenhouse builders and on growers, depending on whether the price is enclosed in their services or whether they made a fixed price. “Then also we used to deliver glass within a month when we had an order, but due to the pressure on the market the delivery time is higher now: two months or even more.” And it’s not the end of the story. Also, the price of shipping has increased. “Shipping costs from China to Ontario have been stable for many years, yet on top of everything also these costs are higher than before. With a 50% increase, it’s a big issue with great effect on the project prices.”

It’s another unexpected trend that Planti, a relatively young company, is dealing with. Starting in 2017 with HPS and LED lights and expanding rapidly in horticultural glass, the company has seen fast growth. Although they started with the lights as their core business, the horticultural glass now is the majority of the business. “Although last year we delivered more than 10,000 sets of HPS lights in Middle Asia – another reason for the growth we’re enduring,” Michael says. “Yet the demand for horticultural glass rises even faster.”

“We see that diffused glass is being used on every market. Before mainly America and Europe opted for it, nowadays we also send it to Saudi Arabia. Growers all over the world are buying diffused glass instead of clear glass. Then also more growers opt for high haze instead of low haze,” Michael says.

In Europe, most growers buy medium haze, but in the rest of the world, they go for 70% haze, which is a high haze. “Once they’ve made up their mind about the benefits of diffused glass, they want the high diffusion and the higher the haze, the more the light is diffused. This is good for the crops, for the plants to grow in a uniform way – both in flowers and vegetables.”

2020 has of course been challenging for the company as well – both in terms of production and in terms of logistics, yet fortunately, the delays caused by COVID were overcome over the summer. In order to help more growers, the company has decided to keep their focus solely on the horticultural industry, not supplying glass to the solar business. “It’s a stable business. Of course, this market provides challenges, but that’s why we work hard – to deal with these challenges”, Michael says. “We’re working hard to develop the market and believe this is possible since we have more orders every year.”

Yet despite their dedication to the greenhouse industry, they are still dealing with the higher prices for raw materials and pressure on the market. “Horticultural glass is difficult to make, whereas solar glass is easier since it’s a fixed size. Robots can be used to produce glass for solar panels, so nowadays many glass factories are expanding their production. It will take two to three months to start a new line and another two before it runs smoothly, meaning that the prices will stay high until summer next year.”

For more information:

Planti

info@plantiinc.com

www.plantiinc.com

Publication date: Wed 23 Dec 2020

Author: Arlette Sijmonsma

© HortiDaily.com

Things To Think About Before Purchasing A Freight Farm

In this article, I will detail all the steps, hurdles, and bureaucracy I endured trying to start and bring a Freight Farm into my local community in Canada

Connor McGoran

In this article, I will detail all the steps, hurdles, and bureaucracy I endured trying to start and bring a Freight Farm into my local community in Canada. While this may not be the same experience for everybody, I will share what I learned and how I failed at starting a Freight Farming business. This process took me approximately three months to go through. The goal of this article is not to dissuade anyone from trying to start a Freight Farm business but to learn from my shortcomings so that the next individual who embarks on this journey will succeed and know what to expect.

Background

I had just finished my degree in Technology Management from NAIT and the early phase of COVID-19 hit which caused community lockdowns across Canada. During the lockdown, I stumbled upon an article from the MIT Technology Review about a unique way to grow roughly 1.5 acres of food in a retrofitted sea-can using LEDs, hydroponics, and specialized HVAC. My curiosity got the best of me and I asked myself if there was a feasible business case for this type of innovation in my home town. This to me seemed like a well-timed idea due to the broken food supply chain across North America due to COVID-19. With further research, I even found that Elon Musk’s younger brother Kimbal used multiple Freight Farm’s to grow his produce for his restaurants. This led me to read more to see if this magic box would be feasible from an economics and business perspective.

Step 1 : Research

The first thing I did was reach out to Freight Farms in Boston where I had a wonderful experience dealing with the Freight Farm Team. They gave me all the documentation I would need to get started detailing the cost of a brand new unit to be 115,000 USD. I also reached out to another company called FarmBoxFoods to see how their technology differed and what their price was set at 125,000 USD. Due to the high cost and the poor CAD-USD currency conversion (1.4), I looked at purchasing a used Freight Farm from the iGrow Group which re-sells used units online.

LGM Freight Farm Operating Costs

Step 2: Business Spreadsheet

I then created my own spreadsheet-based upon the numbers provided to me by the Freight Farm team and my own research to see if it would be feasible from a business perspective. There are some numbers included in this spreadsheet which I will talk about later in the article.

LGM Calculator Tab 1

LGM Calculator Tab 2

LGM Calculator Tab 3

After building my spreadsheet, I determined that the only way for me to make money and pay off any debt in Canada with the CAD-USD conversion rate was to purchase a used unit through the iGrow Group. Different brands of hydroponic growing sea-cans and units ranged from 55,000 USD to 150,000 USD depending on the model and year.

Step 3: Business Plan

After creating my spreadsheet I called other Freight Farmers within Canada to ask about their experience running a company. The expertise of people who already operated their own Freight Farms was extremely insightful because they were able to share their difficulties, what they learned, and what I should anticipate. This helped me write a modified version of the business plan below. I decided to call my company KLC Greens.

KLC Greens Business Plan

KLC Greens is a hydronic farming company that would provide the highest quality local produce to the local industry in Canada 365 days a year! It has the capability to turn around over 1000 heads of lettuce or other leafy greens after a 6-week initial phase.

Demand for local produce is booming and KLC Greens would be perfectly positioned to increase the availability of “hyper local” foods for our customers. By utilizing the very best hydroponic farming technology, Freight Farms’ Leafy Green Machine would grow high value cash crops year-round with consistent high quality that is not possible with outdoor farming in the local community.

Marketing Strategy:

KLC Greens marketing strategy would focus on selling their produce to wholesale grocery stores, a retail CSA program, and local restaurants that want the best produce available year-round. KLC Greens has been in contact with different local grocery stores that have shown interest to our product.

Company Description

KLC Greens is a hydroponic farming company that would provide fresh produce to the local vegetable industry in Canada. We will grow different lettuce varieties for restaurants, wholesalers, and retail through CSA that would aim to support the growing local food movement in Canada.

Our world is changing. More people than ever are now living in tightly populated, urban areas, and there’s an increasing demand for locally grown and sustainably produced food. People want to know the story behind the meal on their plates. And even city dwellers want their food to be fresh and full of nutrients, not pre-packaged and shipped from thousands of miles away.

Our climate is also continuing to evolve. Extreme weather conditions are becoming more common, and land and water are becoming scarcer. Large-scale food production and distribution has had a significant impact on the earth’s ecosystem, and it’s continuing to affect our water levels and biodiversity.

Transparency is key to understanding where and how food is produced and KLC Greens is committed to improving transparency in the produce industry by growing ‘hyper-local’ produce in one of the most innovative hydroponic system available, Freight Farms’ Leafy Green Machine. Growing in the Leafy Green Machine enables us to provide unparalleled transparency in all operations from seed to harvest and provides our customers with the certainty that they are eating, receiving, buying Okanagan produce grown via the best agricultural practices available.

Our Product

We will initially grow different lettuce varieties and sell it to wholesalers and restaurants at an expected price of 2$ per head of lettuce. This type of cash crop takes 6 weeks to reach maturity and we estimate harvesting 4044 heads per month. For details on harvest volumes, see Appendix A for revenue calculation data and assumptions.

Our lettuce is hyper-local, meaning that our lettuce is grown in the community where it will be consumed, and is thus considered a premium and differentiated product by the market, commanding a higher price point than even organic foods. This differentiation is what enables us to command the higher price of 2$ as opposed to the general wholesale price of 1.50–1.75$.

Market Breakdown

KLC Greens will specifically target high-end restaurants in the Canada area. Our target customers are chefs and restaurant owners in the farm-to-table movement who already provide information to customers about their sourcing policies and chefs and restaurant

owners in the ethnic cuisine space who require specific fresh greens for their dishes that are not available year-round through traditional farming.

Our competitors in the restaurant industry include direct competition from other local farmers, and wholesalers who source exclusively from local farms but are constrained by seasonality, and indirect competition from larger wholesalers who bring in low cost produce from around the world and in all seasons. KLC Greens will compete by providing “hyper local” produce to the restaurant industry regardless of season.

KLC Greens plans to sell its lettuce into the wholesale market in Canada. We will target smaller wholesale companies who specialize in local produce as opposed to working with the larger, national companies where we will struggle to meet sufficient volumes to be a relevant partner.

Our competitors for local wholesale are other local farmers growing vegetables and different varieties of vegetables (traditionally or hydroponically). During the summer months, traditional farmers will be KLC Greens greatest competition as the supply of local Lettuce is significantly increased and the price is driven down. During the non-summer months, regional, large-scale hydroponics producers are the greatest competitors for KLC Greens. In both instances, KLC Greens will rely on its freshness and consistent availability to appeal to our wholesale partners.

KLC Greens will sell its produce in farmers markets in the Canada area. We will target markets in middle to upper-middle class areas in order to gain access to consumers who are dedicated to eating fresh, local produce and have the disposable income to purchase our premium Lettuce.

Our competitors fall into two categories, direct competitors from the farmers market community and indirect competitors from outside the farmers market. To date, KLC Greens does not know of another hydroponic farmer participating in farmers markers in the Canada area, meaning that our primary direct competitors will be local farmers growing Lettuce in the traditional way. Outside of the farmers market, our competitors are traditional food retailers who may or may not stock local Lettuce. In both instances, KLC Greens has an advantage as we can differentiate on freshness and availability all year.

KLC Greens will also target middle to upper-middle class customers who already participate in CSA programs and demonstrate a commitment to eating local produce.

While most of KLC Greens competitors are not “hyper local” producers, it is worth briefly discussing the different methods of urban farming that may eventually enter the market as direct competitors. The four main competitors to KLC Greens Leafy Green Machine growing method in the urban farming space are indoor warehouses farms, urban greenhouses, rooftop farms, and small plots of land transformed into farms. Each have their benefits, however KLC Greens firmly believes that the Leafy Green Machine provides the best combination of protection from natural elements, cost effective production, and reliable crop yields that will make urban farming a profitable venture now and into the future.

Competitive Advantage

KLC Greens main competitive advantages are the farming technology we will use to produce our lettuce and the support of a network of small business hydroponic farmers.

We are in the process of purchasing a Leafy Green Machine from Freight Farms to use as our primary farming tool. A Leafy Green Machine is a turnkey hydroponic farm built inside of an insulated shipping container, enabling it to produce fresh vegetables in any climate for a full 365 days per year. To help ensure success, the Leafy Green Machine is equipped with sophisticated environmental controls which allow KLC Greens to easily grow consistently high-quality lettuce while simultaneously eliminating the guesswork inherent in traditional farming. The Leafy Green Machine only requires 20 hours a week to operate.

In addition to the benefits of the Leafy Green Machine itself, our purchase of a Leafy Green Machine provides us with access to the many resources Freight Farms offers to its extensive and ever-growing network of small business farmers. Freight Farms’ commitment to KLC Greens success includes:

· Comprehensive in-farm and online training

· A resident plant expert who is available to all beginning farmers

· Monthly shipments of customized nutrients and seeds

· Software designed to optimize harvest yields and allow remote monitoring of crops and control of the Greenery

· And most importantly, access to Freight Farms’ very active network of small business farmers who are available for assistance and advice

The strength of the Freight Farms network cannot be overstated. Each small business farmer has faced similar business challenges to those that KLC Greens will inevitably face. By leveraging the solutions of fellow Greenery farmers, KLC Greens can significantly reduce the risk associated with a new venture and move through challenges quickly and successfully.

Marketing and Sales Plan

KLC Greens sales plan is to target Restaurants, Retail (CSA) and wholesalers. Our company will target chefs and owners of high-end farm-to-table restaurants who have already demonstrated a desire to provide customers with transparency in food sourcing. Our Retail CSA program will target middle to upper-middle class customers who already participate in CSA programs and demonstrate a commitment to eating local produce. KLC Greens will also target wholesalers who are looking for consistent quality produce that can be supplied year-round.

KLC Greens has discussed our hyper-local lettuce with Natures Fare, Sysco, and Valley Green Foods and they are very excited about the possibility of buying year-round, local lettuce.

In order to obtain customers KLC Greens will implement the following marketing strategies of utilizing digital marketing tools, word of mouth, social media campaigns, and attending local regional industry events. KLC Greens will use a combination of digital marketing, via add words and a company website, and networking at industry events to identify and network with farm to-table restauranteurs, grocery chains and wholesalers. We will operate a booth at local conferences to better spread the word about our hyper-local lettuce, give potential customers the opportunity to try the lettuce for themselves, and direct further inquiries to our website for more information about the benefits of hydroponic produce.

KLC Greens will have a variety of different packaging for products depending on industry or consumer needs. If wholesalers require clam shell or hard plastic containers for packaging, our business will source that out. KLC Greens will package its lettuce in grams or kg in either rectangular clamshell packages or hard plastic containers for it’s wholesale partners.

Management Team

Key Partners:

· Accounting/Tax Partner: TBD

· Legal Advisor: TBD

· Insurance Provider: TBD

Use of Funds

KLC Greens is requesting $150,000 CAD for the purchase, transportation, and installation of a Greenery and for the cash flow necessary to get started. In addition to the requested loan amount, Farm Credit Canada has granted KLC Greens 80% of the funds to purchase the Leafy Green Machine. The 80% of the funds provided by Farm Credit Canada would be paid back to the loan.

A detailed breakdown of our planned use of funds is below:

· Greenery Purchase: $88,000

· Greenery Transportation: $9000

· Customs Tax (5%): $4375

· Greenery Installation: $3000

o Leveling: $1000

o Electric: $1000

o Plumbing: $1000

· Training: $4000

o Cost of training: $2500

o (if applicable) Cost of flight to Boston: $1000

o (if applicable) Cost of hotel in Boston: $500

· Business Materials Purchase: $1000

Financial Projections

KLC Greens financial projections are derived from the proven operations and profit models of fellow Leafy Green Machine small business farmers. Based on their experiences, collected, and consolidated by Freight Farms, we have constructed the following financial projections forecasting our first five years of operations.

Key Assumptions of Projected Financial Statements

· One month is 31 days (the Leafy Green Machine operates every day) or four weeks

· Year 1 begins on the day of Leafy Green Machine purchase

· Tax payments are not included in our calculations

· KLC Greens is a cash-based business so we will not offer terms to our customers and pay our bills upon receipt, therefore we have not calculated for Accounts Receivable or Accounts Payable

· We have elected to exclude inventory from our asset calculations however, there will be a nominal amount of work-in-progress and materials inventory at any given time

Step 5: Finding a Freight Farm

After creating my business plan I was ready to try and find a used unit that would fit within my budget through the iGrow Group. The team at iGrow was also super helpful and narrowed down the best unit that was close to where I lived to reduce shipping costs and help pair me with another business owner. I had to WhatsApp call the seller multiple times to ask questions and to inspect the unit due to COVID-19 as I was unable to cross the border. I was able to put a down payment on the unit until I secured further funding.

Step 6: Finding Capital (Funding)

In order to fund my business venture, I had to try and find different avenues for funding which led me on a rabbit trail for approximately two months. At the time of trying to obtain funding I was 22 and had no assets in my name but actually had little difficulty in getting approved funding. The only problem that occurred was that no bank in Canada would give me a bridge loan to bring the used Freight Farm into Canada. I called every single bank over the span of two months that I could possibly think of and tried to brainstorm creative ways to bypass the process. My seller was growing impatient so this led the seller to agree to send the unit across the border on the condition I would pay the remaining 90% and provide letters from the different financial institutions that I was approved for funding. I was able to obtain funding three different financial institutions called Farm Credit Canada, Community Futures, and RBC. Farm Credit Canada is a farm lender that is subsidized by the government which has a special young farmers loan for ages under 40 that can approve loans of up to a million dollars. Community Futures is a community-based organization that helps aspiring entrepreneurs within the Okanagan and RBC is a bank within Canada.

I reached an agreement with Farm Credit Canada after dealing with their business analyst’s and scrutinizing my business plan they would grant me 80% funding for the Freight Farm once it crossed the border, Community Futures would provide the operating expenses and other equity, and RBC would provide me a business account with an operating line of credit. Once I obtained the letters from all three financial institutions I was able to bring the Freight Farm across Canada.

Step 7: Logistics, Logistics, Logistics

Growing up in the Okanagan Valley in Canada which has an abundance of agriculture land and plenty of farming, I did not think I would have such a difficult time finding a place to put the Freight Farm. I reached out to numerous farmers, tried my contacts, and tried door knocking to try and find some land. What I found was that majority of old farmers did not want the hassle of having this on their property, did not understand the technology or it was not worth their time for the money. Being on a budget and knowing where I wanted my profit margins it was proving to be quite difficult. The Leafy Green Machine I was purchasing also required a certain power supply, access to water and it has to be leveled. If the land did not have these pre-requisites I would have to pay to have a sub-meter installed, the piping for water, and a contractor to have the unit leveled.

I ended up using a service called Young Agrarians which is a farmer educational resource network for new and young ecological, organic, and regenerative farmers in Canada. They had a local representative that assisted me with their land matching program and helped guide me through making a lease agreement. I ended up finding a landowner by door knocking who would allow me to put my Freight Farm on his land for a reasonable price and had the Young Agrarian Organization help build the lease agreement.

Step 8: Incorporation and Accounting

Due to my limited expertise and from the wisdom of other mentors I thought it would be best to get the advice from an accountant and lawyer to help me best set up my business. I know from other experiences that the CRA is not the most forgiving and can cause major headaches if you do not submit the proper paperwork. I consulted my local accountant where he advised me on the pros and cons of doing a sole proprietorship or incorporating and helped draft me a letter to my lawyer. I chose to incorporate and then sent the letter to my lawyer who set up the business to best suit my companies needs. A few weeks later KLC Greens was approved and incorporated.

Step 9: Website and Logos

While I was trying to find suitable land and was waiting for my business to be incorporated I decided to design my company logo and build a website. I utilized Fiverr as a platform to build my logo as it cost 60 CAD and was created within 48 hours. These were some of the designs created within 48 hours.

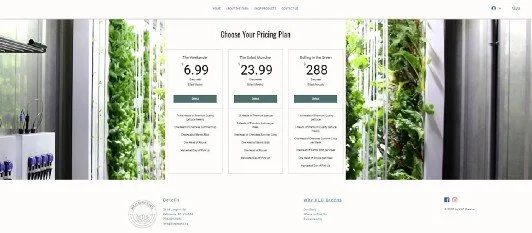

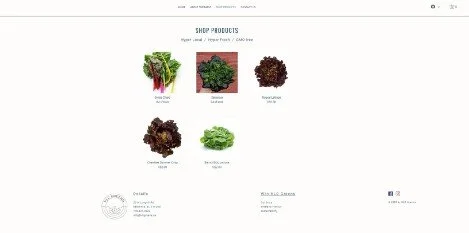

To build my website I decided to go through Wix. I used Wix because it was the most reasonably priced 25 USD and it had the best functionality for what I needed. I was able to create this website.

Step 10: Apply for a City Business License

Applying for a city license was an easy process as there was an online portal where I had to describe my business and what I was planning on selling. The estimated time to obtain a response was approximately 48 hours. I contacted my local city a few months prior to ask if there would be any concerns with having a Freight Farm within the city limits. So I expected my business license to be approved without any obstacles.

Step 11: Customs Broker/Shipping/Crane

While completing the last few steps I had to find a customs broker that would deal with the transaction so that the Freight Farm would come across the border without any difficulty. I also contacted numerous shipping companies with the IGrow Group to find the best deal. Once this was secured I could then schedule the crane companies in the seller's city and my home town. Now that everything was set, my Freight Farm was scheduled to come in three weeks' time.

Step 12: Bureaucracy

My assumption that obtaining a city business license was going to be easy proved to be wrong due to my city’s bylaws and bureaucracy. My application was forwarded to the agriculture department, the city planner, and the building inspector where I was met with the following response. I had numerous conversations about if there was any variance that could happen and how someone at the city three months ago told me they did not see anything wrong with my Freight Farming idea.

Hi Connor,

I was forwarded your email to help answer. The Planning Department and ALC both allow hydroponics to be grown on site (A1/ALR), however, the sea-can is not permitted. We only allow sea-cans/shipping containers on a permitted basis if they meet BC Building Code, which will require an engineer or an architect to make the sea-can structural sound. Sea-can’s are not permitted structures and won’t be given a Building Permit unless they are altered to meet the BC Building Code.

Please let me know if you have any other questions, I’m happy to help.

This was my response to the email above

To whom it may convern,

I talked with an associate at the city of Canada about three months ago about my business plan and any concerns I should foresee in the future, this associate saw no problems with my business and freight farm being in Canada. When I went to apply for a business license a week ago I ran into a few hurdles with the City about the freight farm meeting the BC Building Code and certain bylaws and obtaining a building permit. My understanding was that this container would be deemed a temporary unit on ALR land and should not need a building permit.I have reached an agreement with the business license team at the City and planners that this will be deemed a temporary structure for 6 months (as it can be moved readily at any time).

My container will be delivered in the next two weeks and I did not foresee these hurdles and I am looking for guidance on what to do next. I am a young entrepreneur and have taken a loan to start this business and would love to reach an agreement with the City and make the necessary legal changes to make my business work. I really appreciate how supportive the City has been and the amazing staff I have dealt with.

I have attached a pdf describing the leafy green machine, as well as the bylaw pdf on steel containers.

Here was the city’s reply;

Hi Connor,

I see from the web site link that you provided that this product comes from a USA based manufacturer. Do you have any support documentation from the supplier/manufacturer that references a Canadian standard for the electrical system, water system and building standard(s) that these are built to? We will require this information as part of a Building Permit & Plumbing Permit application along with a site plan showing where this container will be installed on the property

The bulletin that you have copied and referenced as allowable under exception, clearly identifies the exception for the use of the container as storage and not as an occupied/semi occupied building for the production of plants with a dedicated water system and electrical system. The British Columbia Building Code (2018 edition) is the Provincial standard that needs to be meet once the structure is being used as a building, which is what you are proposing. The A277 standard in BCBC 2018 is for factory built units, similar to modular homes that are factory inspected for compliance during construction and certified as compliant. The storage container can be stored on the site if approved by City of planning staff for 6 months, but would not be allowed connection to city water or electrical without meeting the minimum standard set by BC BC 2018. I would suggest that you reach out to the modular factory representatives to see if they can have a factory inspector come to do an on-site evaluation of the container unit to certify it or help provide information to cross reference Canadian to the USA based standards, so that you can apply for a building permit. https://www.kelowna.ca/homes-building/agricultural-land/dwellings is the link to the requirements for Building Permit application. A plumber will be required to apply for a plumbing permit if/when the building permit is issued and a proper back flow preventor will be required to protect the city water source.

This process may seem overwhelming but is no different than importing a USA built car into the Canadian market. The car would need to meet the standards set in Canada for the car to be registered and used in Canada. If the USA company has built these containers to meet or exceed Canadian standards and can prove this with valid documentation, the application process should be straight forward. An application for building permit can be made at 2nd floor city hall and the permit would be for an accessory building on farm land.

This response led me on another rabbit trail of trying to figure out if the Freight Farm I was purchasing would meet any of the building standards in Canada and so forth. At this point in time, my container was two weeks away, I had already purchased all my supplies for the Freight Farm and was going to sign my lease agreement. Freight Farm’s provided me with the following information below through an email and was able to confirm their shipping containers were ISO certified.

All LGMs are upcycled reefer containers. What this means is that they were previously used to ship produce to and from other countries. Once the refrigeration unit no longer worked, they were decommissioned. We would remove that unit, and retrofit our equipment. I bring this up, because the container itself will likely have some dents and marks from its usage as a freight container. This does not impact the structural integrity of the container at all. We have frequently had these container re-certified to be seaworthy, and safe for use from a structural standpoint. Additionally, the company that would have manufactured the farm has a number of certifications (CE, UL, etc.) that would apply to the actual assembly.

With this information, I called a few inspection agencies about what it would cost to bring the Freight Farm up to the BC Building Code or CSA standards where I got numerous replies saying it would cost thousands of dollars and be a very time-consuming process. On top of this, I would then have to be certified by the local building inspector and make sure the Freight Farm was conforming to any local bylaws.

Where it all went wrong

Just as I was confident about my business and thought I had everything prepared, I was hit with the bombshell from the city about bringing the container up to the BC Building Code and the numerous inspections I would have to go through. Also last minute the landowner of the farmland I was going to lease decided he did not want me on his land anymore or to sign a lease. This led me to call off the shipment 10 days before my container was supposed to arrive which caused me to call of the shipment. From my further conversations with the BC Building Inspectors and other consultants who specialized in shipping container homes, they said that any other Freight Farms located in BC that were not CSA approved or up to the BC Building code were illegal. They further elaborated that the only reason they were operating was that the local city or bylaw was turning a blind eye. This was the turning point where I had to decide if the current risks were worth taking with the knowledge that it would cost much more than expected to get the Freight Farm certified and if I didn’t it could be shut down by the city. I went back to crunch the numbers and realized I could not financially risk having the Freight Farm nonoperational for a few months due to the loans payments from the bank. I could not wait to have my container certified by the proper governing bodies and inspections to take place. This led me to painfully decide to not pursue my business plan anymore. I had to contact my seller and the IGrow Group about my situation and unfortunately, three months' progress was now void.

Where I Failed

I did not properly do my due diligence in contacting all the necessary channels in my local city to ask about the local bylaws. I trusted one individual's opinion at the city who did not have the proper knowledge to give me the advice that I relied on.

I did not think of the construction standards of the Freight Farm at the early phase of my business plan. This led to more hurdles when I was asked for information by the city.

I put a 10% down payment on the container before I had secured funding from other financial institutions. This caused the process to take longer than expected and caused my seller to wait over two months to get my finances in order only to have to cancel last minute.

Due to my limited assets, I had to borrow from numerous financial institutions to obtain the financial capital to purchase the Freight Farm. In the last two weeks, before my Freight Farm was expected to arrive, RBC called to inform me that there was too much conflict between the financial agreements between Farm Credit Canada, Community Futures, and RBC. This caused me to have to re-negotiate all my letters with my lenders delaying the purchase further.

I did not sign a lease agreement before arranging the shipment of the container causing the landowner to back out the last minute.

I purchased supplies for the container before it arrives.

I rushed the entire process in three months, leaving little time to carefully think out everything.

What I learned

Before starting the process make sure you know what your city’s bylaws are and talk to a few local representatives to make sure the information you are being told is true.

Read the bylaws to ensure your Freight Farm is up to local standards.

Obtain financing early on before contacting a seller if you have limited assets or can only afford a small down payment.

Make sure that if you borrow from numerous financial institutions there is no conflict of interest between them if they require equity of your Freight Farm until the loan is paid off.

Sign a lease agreement from a landowner, do not go off of their word.

If you want to disregard the city bylaws the best scenario would be to know someone who has land or own it yourself. That way you can hide the Freight Farm and won’t have any complaints, thus reducing the risk of your business being shut down in British Columbia.

Have more certainty of your business before purchasing supplies, creating logos, or a website.

Leave more time to think through each step, because once you are in the chaos it is harder to take a bird’s eye view of your business

Do not be dissuaded by hurdles that come out of nowhere, this is a natural occurrence in business. Learn how to navigate them and reflect on how to make sure they do not happen again. I went through what seemed hundreds of hurdles and learned how to navigate them. Even though I had to decide to give up in the end it was due to huge financial risk and my limited access to capital. The risk of not running my business for four months while making bank payments and the uncertainty of the financial amount to bring the Freight Farm up to BC building code were my deciding factors.

You learn 110% more when you stick your neck out and go through the process. Going into business is not easy and requires a certain mental fortitude and resilience.

Know when to give up and know when to keep on persevering. At certain times you may feel like giving up but that is also where the most learning can be achieved and later on you’ll laugh at the thought that you almost gave up. The flip side is don’t let your ego cause you to make bad business decisions, use logic, and periodically review your business plan and current state of affairs.

Even though I failed to start my company the amount of learning I went through the last three months was invaluable.

Conclusion

My hope is that this article will help the next entrepreneurs who embark on purchasing a Freight Farm and help them build off of my experience. I still believe there is a strong business case for a Freight Farm within my community but currently, I lack the financial capital and political power to cut through the bureaucracy. I hope my three months of trials and tribulations will save you time or help you in your journey.

WRITTEN BY

Connor McGoran

Edumacated Writer, Aspiring Blogger

Technology Farming Hydroponics Farming Startup Entrepreneurship

A Monster Wind Turbine Is Upending An Industry

Twirling above a strip of land at the mouth of Rotterdam’s harbor is a wind turbine so large it is difficult to photograph. The turning diameter of its rotor is longer than two American football fields end to end

G.E.’s Giant Machine, Which

Can Light Up A Small Town,

Is Stoking A Renewable-Energy Arms Race

By Stanley Reed

January 1, 2021

Twirling above a strip of land at the mouth of Rotterdam’s harbor is a wind turbine so large it is difficult to photograph. The turning diameter of its rotor is longer than two American football fields end to end. Later models will be taller than any building on the mainland of Western Europe.

Packed with sensors gathering data on wind speeds, electricity output and stresses on its components, the giant whirling machine in the Netherlands is a test model for a new series of giant offshore wind turbines planned by General Electric. When assembled in arrays, the wind machines have the potential to power cities, supplanting the emissions-spewing coal- or natural gas-fired plants that form the backbones of many electric systems today.

G.E. has yet to install one of these machines in ocean water. As a relative newcomer to the offshore wind business, the company faces questions about how quickly and efficiently it can scale up production to build and install hundreds of the turbines.

But already the giant turbines have turned heads in the industry. A top executive at the world’s leading wind farm developer called it a “bit of a leapfrog over the latest technology.” And an analyst said the machine’s size and advance sales had “shaken the industry.”

A New Generation of Wind Turbines

General Electric’s prototype for a new offshore wind turbine, the Haliade-X, is the largest ever built.

London Eye - Ferris wheel GE Haliade-X 13MW - wind turbine Empire State Building

HEIGHT: 443 feet HEIGHT: 853 feet HEIGHT: 1,050 feet

Source: General Electric

The prototype is the first of a generation of new machines that are about a third more powerful than the largest already in commercial service. As such, it is changing the business calculations of wind equipment makers, developers, and investors.

The turning diameter of the Haliade-X’s rotor is longer than two American football fields.Credit...Ilvy Njiokiktjien for The New York Times

The G.E. machines will have a generating capacity that would have been almost unimaginable a decade ago. A single one will be able to turn out 13 megawatts of power, enough to light up a town of roughly 12,000 homes.

The turbine, which is capable of producing as much thrust as the four engines of a Boeing 747 jet, according to G.E., will be deployed at sea, where developers have learned that they can plant larger and more numerous turbines than on land to capture breezes that are stronger and more reliable.

The race to build bigger turbines has moved faster than many industry figures foresaw. G.E.’s Haliade-X generates almost 30 times more electricity than the first offshore machines installed off Denmark in 1991.

In coming years, customers are likely to demand even bigger machines, industry executives say. On the other hand, they predict that, just as commercial airliners peaked with the Airbus A380, turbines will reach a point where greater size no longer makes economic sense.

“We will also reach a plateau; we just don’t know where it is yet,” said Morten Pilgaard Rasmussen, chief technology officer of the offshore wind unit of Siemens Gamesa Renewable Energy, the leading maker of offshore turbines.

The turbine is so large that it will be able to generate enough power to light up a town of 12,000 homes. Credit...Ilvy Njiokiktjien for The New York Times

Although offshore turbines now account for only about 5 percent of the generating capacity of the overall wind industry, this part of the business has taken on an identity of its own and is expected to grow faster in the coming years than land-based wind.

Offshore technology took hold in Northern Europe in the last three decades and is now spreading to the East Coast of the United States as well as Asia, including Taiwan, China and South Korea. The big-ticket projects costing billions of dollars that are possible at sea are attracting large investors, including oil companies like BP and Royal Dutch Shell, that want to quickly enhance their green energy offerings. Capital investment in offshore wind has more than tripled over the last decade to $26 billion, according to the International Energy Agency, the Paris-based forecasting group.

G.E. began making inroads in wind power in 2002 when it bought Enron’s land-based turbine business — a successful unit in a company brought down in a spectacular accounting scandal — at a bankruptcy auction. It was a marginal force in the offshore industry when its executives decided to try to crack it about four years ago. They saw a growing market with only a couple of serious Western competitors.

Still, G.E.’s bosses figured that to become a leader in the more challenging marine environment, they needed to be audacious. They proceeded to more than double the size of their existing offshore machine, which came to G.E. through its acquisition of the power business of France’s Alstom in 2015. The idea was to gain a lead on key competitors like Siemens Gamesa and Vestas Wind Systems, the Danish-based turbine maker.

A larger turbine produces more electricity and, thus, more revenue than a smaller machine. Size also helps reduce the costs of building and maintaining a wind farm because fewer turbines are required to produce a given amount of power.

These qualities create a powerful incentive for developers to go for the largest machine available to aid their efforts to win the auctions for offshore power supply deals that many countries have adopted. These auctions vary in format, but developers compete to provide power over a number of years for the lowest price.

The prototype is on a piece of land in Rotterdam Harbor, but the Haliade-X is designed as an offshore turbine, to be planted in relatively shallow sea water. Credit...Ilvy Njiokiktjien for The New York Times

“What they are looking for is a turbine that allows them to win these auctions,” said Vincent Schellings, who has headed design and production of the G.E. turbine. “That is where turbine size plays a very important role.”

Among the early customers is Orsted, a Danish company that is the world’s largest developer of offshore wind farms. It has a preliminary agreement to buy about 90 of the Haliade-X machines for a project called Ocean Wind off Atlantic City, N.J.

“I think they surprised everybody when they came out with that machine,” said David Hardy, chief executive of Orsted’s offshore business in North America.

As a huge buyer of turbines, Orsted wants to help “establish this new platform and create some volume for G.E.” so as to promote competition and innovation, Mr. Hardy said.

The G.E. turbine is selling better than its competitors may have expected, analysts say.

On Dec. 1, G.E. reached another preliminary agreement to provide turbines for Vineyard Wind, a large wind farm off Massachusetts, and it has deals to supply 276 turbines to what is likely to be the world’s largest wind farm at Dogger Bank off Britain.

One day turbines will reach a size limit, but “we just don’t know where it is yet,” said Morten Pilgaard Rasmussen of Siemens Gamesa Renewable Energy. Credit...Carsten Snejbjerg for The New York Times

These deals, with accompanying maintenance contracts, could add up to $13 billion, estimates Shashi Barla, principal wind analyst at Wood Mackenzie, a market research firm.

The waves made by the G.E. machine have pushed Siemens Gamesa to announce a series of competing turbines. Vestas, which until recently had the industry’s biggest machine in its stable, is also expected to unveil a new entry soon.

“We didn’t move as the first one, and that of course we have to address today,” said Henrik Andersen, the chief executive of Vestas.

To pull off its gambit, G.E. had to start “pretty much from scratch,” Mr. Schellings said. The business unit called G.E. Renewable Energy is spending about $400 million on design, hiring engineers and retooling factories at St. Nazaire and Cherbourg in France.

To make a blade of such extraordinary length that doesn’t buckle from its own weight, G.E. called on designers at LM Wind Power, a blade maker in Denmark that the company bought in 2016 for $1.7 billion. Among their innovations: a material combining carbon fiber and glass fiber that is lightweight yet strong and flexible.

Offshore turbines account for only about 5 percent of the generating capacity of the overall wind industry, but that number is expected to grow. Credit...Ilvy Njiokiktjien for The New York Times

G.E. still must work out how to manufacture large numbers of the machines efficiently, initially at the plants in France and, possibly later, in Britain and the United States. With a skimpy offshore track record, G.E. also needs to show that it can reliably install and maintain the big machines at sea, using specialized ships and dealing with rough weather.

“G.E. has to prove a lot to asset owners for them to procure G.E. turbines,” Mr. Barla said.

Bringing out bigger machines has been easier and cheaper for Siemens Gamesa, G.E.’s key rival, which is already building a prototype for a new and more powerful machine at its offshore complex at Brande on Denmark’s Jutland peninsula. The secret: The company’s ever-larger new models have not strayed far from a decade-old template.

“The fundamentals of the machine and how it works remain the same,” said Mr. Rasmussen, the unit’s chief technology officer, leading to a “starting point that was a little better” than G.E.’s.

There seems to be plenty of room for competition. John Lavelle, the chief executive of G.E.’s offshore business, said the outlook for the market “gets bigger each year.”

Stanley Reed has been writing from London for The Times since 2012 on energy, the environment and the Middle East. Prior to that, he was London bureau chief for BusinessWeek magazine. @stanleyreed12 • Facebook

A version of this article appears in print on Jan. 2, 2021, Section B, Page 1 of the New York edition with the headline: A Monster Wind Turbine Is Upending an Industry. Order Reprints | Today’s Paper | Subscribe

"Leading The Next Frontier of Farming And This Investment Further Accelerates Our Momentum"

“The addition of our new farm to the network is a critical next chapter in our growth,” said Irving Fain, founder, and CEO of Bowery Farming

“The addition of our new farm to the network is a critical next chapter in our growth,” said Irving Fain, founder, and CEO of Bowery Farming. “It will expand our reach and ability to be a reliable source of local produce for more communities. We’re leading the next frontier of farming, and this investment further accelerates our momentum.”

Bowery Farming is building its newest commercial farm in Bethlehem, Pennsylvania. Joining its network of farms in Kearny, New Jersey, and Nottingham, Maryland, Bowery’s new Bethlehem farm will be its largest, most technologically-advanced commercial farm yet.

Driven by explosive demand for safer, traceable pesticide-free produce, and propelled by the BoweryOS- which integrates software, hardware, sensors, computer vision systems, machine learning models and robotics to orchestrate and automate the entirety of operations - the strategic location of Bowery’s Bethlehem commercial farm will expand the company’s reach in the region.

This farm will feature a number of developments that build on previous Bowery technology, further automating the growing process from seed to store, and enhancing the efficiency of Bowery’s network such as, Water Conservation: A state-of-the-art, comprehensive water transpiration system will recapture almost all water used throughout Bowery’s growing process, with the goal of reclaiming and repurposing nearly all of the water in the farm.

The facility will also focus on more efficient LED Lighting amplifying Bowery’s holistic approach to sustainability and features industry-leading environmental improvements like energy-reducing LED lighting throughout.

"It's the smartest farm yet, powered by the BoweryOS, this farm will leverage billions of data points collected from Bowery’s network of farms to grow a reliable supply of consistently delicious produce year-round. Laying the groundwork for the next chapter in smart, scalable indoor farming, the Bethlehem farm will feature next-level technological capabilities unlike any Bowery farm to date, deepening the integration of the BoweryOS across all aspects of the business."

Furthermore, it offers restoration to the community. Bowery is working with the Commonwealth of Pennsylvania to transform the Bethlehem location from a non-arable industrial site into productive, modern farmland—stimulating economic revitalization that will provide year-round sustainable farming jobs for the community.

Since the beginning of 2020, Bowery has experienced more than 600% brick and mortar sales growth, and more than doubled sales with e-commerce partners, including Amazon. Bowery’s produce is harvested year-round at peak freshness and delivered to stores within a few days of harvest — a stark contrast to the 90% of leafy greens grown in the U.S., which are transported over 3,000 miles to consumers on the East Coast.

With this new farm, Bowery’s Protected Produce will be available to the 49 million people living within the farm’s 200-mile radius, advancing the company’s goal of expanding access to local, traceable, pesticide-free food to people in every major city in the U.S. and around the world.

For more information:

Bowery Farming

Shelby Farahan, Communications

sfarahan@boweryfarming.com

www.boweryfarming.com

Publication date: Fri 18 Dec 2020

Author: Rebekka Boekhout

© VerticalFarmDaily.com

Ready For The Green Revolution? Agrilution Brings The Herb Garden Into The House With The "Plantcube"

The “Plantcube” from Agrilution promises always spring in the kitchen - a fully automated grow cabinet that enables vertical farming even on a small scale

December 20, 2020

The “Plantcube” from Agrilution promises always spring in the kitchen - a fully automated grow cabinet that enables vertical farming even on a small scale. AD spoke with Maximilian Lössl, Co-Founder and CEO, about the first experiments in his parents' cellar, the new features of the 2nd generation “Plantcube” - and about why the basil must never run out in his personal mini-farm.

With your high-tech herb garden in the design closet, you create a closed ecosystem in which it is always spring. What does such a mini vertical farm bring us at home?

As the closed ecosystem mimics the perfect spring conditions every day, herbs, salads and micro-greens grow with a density of up to 30 percent higher nutrients; without any transport routes, cooling chains or plastic waste. The harvest also lands directly on the plate and thus retains the secondary plant substances, vitamins, and minerals that are so important. Thanks to the special light frequency, the controlled climate, and the hydroponic irrigation, optimal ripening conditions exist throughout the year - and without pesticides or seasonal dependencies! Technology and nature go hand in hand.

In 2013, Maximilian Lössl (right) and Philipp Wagner founded “Agrilution” together. (Photo: Agrilution)

You started with the farm-to-table experiments in your parents' basement. How did the idea come about?

The initial spark, the enthusiasm for vertical farming, came from a book by Dr. Dickson Despommier. On the recommendation of the author, I actually went to Den Bosch in the Netherlands to study. But the theory wasn't enough for me, I became impatient and wanted to act. So I took the concept of vertical farming further; the idea of a "mini vertical farm" for your own home was born. Philipp Wagner then came in for the technical implementation. Our friendship goes back to school days, when we played basketball together in a club. We started the experiments in my parents' garage and founded Agrilution together in 2013.

Which salads and herbs exactly grow in the “Plantcube”?

Our portfolio currently includes over 30 different plants - from common kitchen herbs to tatsoi, leaf salads, and mixtures for pesto or stir fry to more unusual microgreens such as bronze fennel and blood sorrel. The selection is based on the needs of the market, but we also want to offer something extraordinary that is not available in the supermarket or organic market. In addition, the speed of growth is decisive so that our customers don't have to wait too long. The harvest time is generally between one and four weeks.

And what needs is the device designed for?

Assuming daily consumption, the capacity ranges from a single person to a small family - depending on how they are planted and planned. Our app provides insight into growth, information about harvesting or maintenance and also enables online orders for new seedbars that carry the seeds.

The target group includes residents of metropolitan areas who still want to harvest fresh, healthy produce. (Photo: The Subdivision)

Doesn't that mean losing some of the feelings of looking after your plants in the field, in the garden or on the balcony?

We do not see ourselves as competition to people who garden on a large scale and want to grow their own plants. We tend to address big city dwellers who do not have a balcony or garden in metropolitan areas, are seasonally restricted due to their location or who simply lack the green thumb. Of course, we are currently focusing on vegetarians, vegans, and flexitarians, but also culinary connoisseurs who are looking for that special aroma. And technology-savvy early adopters who want to equip their smart homes well!

You recently launched the second edition of the “Plantcube”. What exactly has been changed, improved here?

What is new about the optimized “Plantcube”, in addition to its elegant black design, is the revised drawer system, which can now be equipped with nine seed bars on two levels. This offers a much greater variety for the planting, and the new, portion-appropriate seedbars are even more geared towards daily needs, the daily harvest. We have also expanded our plant portfolio and divided it into three categories so that our customers can get a particularly quick overview: Dailies, Essentials, and Chefs. In addition, the substrate of the seed bars is now 100 percent biodegradable thanks to the use of natural materials.

In the living room, the “Plantcube” can also be set to quiet and dark for up to two hours. (Photo: The Subdivision)

There is also a so-called "cinema mode". What can we imagine by that?

The cinema mode is also one of the most recent adjustments - it was created through valuable customer feedback and enables the greenhouse to be set to quiet and dark for up to two hours. Some users position the “Plantcube” as a design statement directly in the living room. Its light can be perceived as annoying when watching a film, for example, which is why we added this option.

Surely you live with a “Plantcube” yourself. What do you like to harvest from there and why?

The “Plantcube” in our private apartment is always well planted. We eat our greens every day. Since I love Asian cuisine, there is always fresh coriander for salads or as a topping for avocado bread. Our regular range also includes Tatsoi and Wasabina leaf mustard - nice and spicy! And don't forget basil! My girlfriend is Italian.

Good harvest! The greens from the new “Chefs Line” from “Agrilution” are beautiful (and) delicious. (Photo: Agrilution)

Are there any cooking recipes specially made with plants from the Plantcube?

We are constantly developing recipes with the greens from the “Plantcube”. Our website provides inspiration, as does the app. We also regularly cook together in our office, which is currently only possible to a limited extent. Otherwise, recommendable creations are always created. We also cooperate with KptnCook and chefs who use the “Plantcube” themselves. My favorite dish is “Asian Pak Choi Stir Fry”, which I modify according to my mood.

How does the lockdown affect interest in your Plantcubes? Fresh green from your own four walls sounds like a tempting option right now!

The paragraph has actually made a leap; because you always have something fresh and healthy in the house, and probably because it is becoming very clear to all of us for the first time that local cultivation cannot always meet the demand for natural products and that we sometimes find ourselves in front of empty vegetable shelves. And otherwise, a more conscious, healthier life is moving more and more into focus.

Over 30 different types of plants can be grown in the “Plantcube”. (Photo: The Subdivision)

Could AI-Controlled Vertical Farms Be The Answer To Feeding The Growing Population?

Vertical farms are becoming a trend these past few years in various countries, like in the US, the UK, and Dubai. Vertical farming makes farming possible even with a scarce land area because it is producing food on vertically inclined surfaces instead of a field or greenhouse

Erika P.

Dec 31, 2020

Scientists said that the Earth had lost one-third of its arable lands in the last 40 years. That means, lesser land to grow crops that will provide food for humanity. But these days, vertical farms have slowly become a trend in cities, growing leafy vegetables inside a controlled room.

In the next 30 years, it is estimated that the world's population will grow to 9.7 billion people, which poses many challenges, such as producing food for everyone. Agricultural lands are slowly vanishing in some countries due to industrial development and urbanization that turn rural areas into cities.

Vertical Farming

Vertical farms are becoming a trend these past few years in various countries, like in the US, the UK, and Dubai. Vertical farming makes farming possible even with a scarce land area because it is producing food on vertically inclined surfaces instead of a field or greenhouse.

In vertical farming, produce is vertically stacked in layers commonly integrated into the other structures, such as a skyscraper, shipping container, and repurposed warehouse or night clubs.

This modern idea of indoor farming uses the Controlled Environment Agriculture technology that controls the room's temperature, light, humidity, and gases. Vertical farming is somewhat similar to greenhouses that use metal reflectors and artificial lighting to augment natural sunlight.

Ultimately, vertical farming's primary goal is maximizing crops in a limited space and providing more food for the whole population.

ALSO READ: Dubai's Green Revolution Starts at Its Vertical Farms in the Middle of the Desert

AI-Controlled Vertical Farms Promise A Revolution in Food Production

Nate Storey, who co-founded the San Francisco agricultural-technical startup called Plenty, uses vertical farming to answer the increasing food demands of the growing population.

His company has constructed climate-controlled vertical farms that have drawn over $400 million funding from Soft Bank, Amazon's Jeff Bezos, and former Google Chairman Eric Schmidt, TechXplore reported.

His vertical farms only use about two acres, yet it can produce 720 acres worth of fruit and vegetables. He uses AI-controlled robots to control the lighting, temperature, and watering. Meanwhile, LED panels to serve as the sunlight, which means that food is grown 24/7 inside his vertical farms, and water is recycled because the evaporated water is recaptured so that there is no waste.

Plenty's vertical farms are so efficient that it uses 99% less land and 95% less water than conventional farming practices. Also, the rows of hanging plants produce 400 times more food per acre. Indeed, a revolution in food production.

The AI-controlled robots monitor the plant growth and constantly adjust the environmental factors to ensure more efficient and economic output.

Vertical farming looks more promising, especially in times like the pandemic when food production is disrupted. In Dubai, their food supply was not affected so much during the pandemic's early days because of their vertical farms. The San Francisco-based company's approach to farming also plays a similar role in the stability of the food chain.

"Free agriculture from the constraints of weather, seasons, time, distance, pests, natural disasters, and climate," Plenty's website reads.

READ MORE: Hydroponics Farming Is the Next-Gen Food Production Technology

Agrify Seeks $25 Million IPO For Indoor Agriculture Growth Plan

The firm develops products and related services for the indoor agriculture market

Written by: Donovan Jones Marketplace

Author of IPO Edge.

Dec. 28, 2020

Summary

Agrify has filed to raise $25 million in an IPO.

The firm sells proprietary products and software to the indoor vertical farming market.

AGFY has grown quickly from a very small revenue base and the industry has promising growth prospects.

Quick Take

Agrify (AGFY) has filed to raise $25 million in an IPO of its common stock, according to an S-1 registration statement.

The firm develops products and related services for the indoor agriculture market.

AGFY is a still tiny firm growing topline revenue quickly while operating in a promising industry.

I’ll provide an update when we learn more about the IPO from management.

Company & Technology

Burlington, Massachusetts-based Agrify was founded to provide proprietary hardware and software to enhance the efficiency of indoor agriculture operations.

Management is headed by CEO Raymond Change, who has been with the firm since 2019 and was previously the founder of GigaMedia (GIGM).

Below is a brief overview video of a vertical farming operation:

To read the full article, please click here.

Note: This report is intended for educational purposes only and is not financial, legal or investment advice. The information referenced or contained herein may change, be in error, become outdated and irrelevant, or removed at any time without notice. You should perform your own research before making any decisions. IPO investing carries significant volatility and risk of loss.

Editor's Note: This article covers one or more microcap stocks. Please be aware of the risks associated with these stocks.

Disclosure: I/we have no positions in any stocks mentioned, and no plans to initiate any positions within the next 72 hours. I wrote this article myself, and it expresses my own opinions. I am not receiving compensation for it (other than from Seeking Alpha). I have no business relationship with any company whose stock is mentioned in this article.

VIDEO: Agroz Aims To Build Malaysia’s Largest Indoor Vertical Farms

Agroz Group Sdn Bhd has announced that it’s building 100,000 square feet of indoor vertical farms in Malaysia throughout 2021, making it the largest of its kind in the country. When completed, the vertical farms can produce 3 tons of clean and fresh vegetables daily

30 DECEMBER 2020

Agroz Group Sdn Bhd has announced that it’s building 100,000 square feet of indoor vertical farms in Malaysia throughout 2021, making it the largest of its kind in the country. When completed, the vertical farms can produce 3 tons of clean and fresh vegetables daily.

The Malaysian-based agriculture technology (agritech) company was founded by serial technopreneuer, Gerard Lim Kim Meng, who has experience in the Malaysian technology and digital industry. The group aims to address the issue of Food Safety, Food Security, and Sustainability in Malaysia with its commercial large scale and industrial-grade indoor vertical farms.

Vertical farms are an efficient way of producing fresh vegetables as it uses less space and water compared to traditional farming on open land. The environment can be controlled accurately which include temperature, humidity and lighting. Since the vegetables are farmed in a well-controlled environment, it also eliminates the need for pesticides and additional chemicals.

According to the press statement from Agroz, it claims that most fresh vegetables including organic ones are several days or weeks old and are preserved “fresh” with large amounts of chemicals and preservatives.

It added that these vertical farms can be built within the community so that they are placed closer to where it’s consumed for a “farm to fork” supply chain. As a result, consumers will be able to enjoy clean, fresh, chemical-free and high quality food within hours.

Agroz will be using a myriad of advanced technologies to ensure that its farming process is repeatable, scalable, and traceable. This would include IoT, big data analytics, artificial and augmented intelligence, machine learning, blockchain, and in the future, 5G, to create a sustainable approach to modern precision agriculture through indoor vertical farming.

The group is seeking to raise RM100 million through issuance of Redeemable Convertible Preference Shares (RCPS), with exit plans in 5 years through a proposed initial public offering (IPO) or via a trade sale to a Special Purpose Acquisition Company (SPAC), if applicable.

According to its founder and CEO, Gerard Lim, they currently have over RM5 million worth of contracts in its order books with millions of dollars more in the pipeline to design, build, operate and manage various indoor vertical farms. He shared that they are currently growing 200kg per month and will soon have the capacity to grow 1 ton per day from their various farms that are already committed.

Gerard added that the indoor vertical farms will create hundreds of new high valued jobs and generate income for local communities in the post-COVID-19 era.

Those who are interested, may drop an email to gerard@agrozgroup.com or visit their official website.

VIDEO: AI-Controlled Vertical Farms Promise Revolution In Food Production

These upright farms take up only 2 acres yet produce 720 acres worth of fruit and vegetables. Lighting, temperature and watering are controlled by AI-controlled robots

DECEMBER 30, 2020

by Peter Grad, Tech Xplore

When you think about it, early civilizations had a rough time when it came to dinnertime. With no supermarkets, McDonald's, or Cheesecake Factories, you pretty much had to find and prepare your own meal every day. And since Uber would not be invented for another 14,000 years, primitive peoples around 12,000 BC had to walk, sometimes for miles, and learn to hunt, fish, gather and cook for their daily meals. In the rain. Even on Sundays.

Farming evolved quite a bit since then. But with a world population hurtling towards 8 billion, we face a problem. As the 18th-century economist Thomas Malthus observed, the human population increases geometrically, while food production increases only arithmetically. That means the more civilization grows and thrives, the more likely it will be unable to keep up with demands for food.

While advances in food technology have helped forestall Malthus' dire predictions, there remains a great concern for the future of food production as the Earth's population soars on a planet with shrinking farming real estate. National Geographic recently predicted that by 2050, there will be more than two billion additional mouths to feed while the Earth's irrigable land remains essentially the same.

A San Francisco agricultural-technical startup thinks it might just have an answer. Nate Storey, who co-founded the appropriately named Plenty, wants to reinvent farming.

To do so, he has constructed climate-controlled vertical farms that are so promising, they have drawn $400 million in funding from former Google Chairman Eric Schmidt, Amazon's Jeff Bezos, and SoftBank.

These upright farms take up only 2 acres yet produce 720 acres worth of fruit and vegetables. Lighting, temperature and watering are controlled by AI-controlled robots. Sunlight is emulated by LED panels, so food is grown in optimal conditions 24/7. And water is recycled and evaporated water recaptured so there is virtually no waste.

The operation is so efficient it uses 99 percent less land and 95 percent less water than normal farming operations.

"Imagine a 1,500-acre farm," Storey says. "Now, imagine that fitting inside your favorite grocery store, growing up to 350 times more. That's efficient."

It is so efficient that these rows of hanging plants produce 400 times more food per acre than a traditional farm.

AI monitors growth patterns and constantly adjusts environmental factors such as temperature, water, and light patterns to ensure ever-more efficient and economical output.

In an era that has seen food production lines disrupted by a pandemic, wildfires, and hurricanes, Plenty's approach will play a key role in ensuring future stability in the food chain.

Plenty's website explains vertical farming "free agriculture from the constraints of weather, seasons, time, distance, pests, natural disasters, and climate."

Also noteworthy is that the crops are grown "GMO-free" and use no pesticides or herbicides, according to Plenty.

Plenty will soon supply more than 400 stores in California with its produce. The company says its packaging is specially designed to keep produce fresh longer and is 100 percent recyclable.

In October, Driscoll's, a leading producer of fresh berries, reached an agreement with Plenty to produce strawberries year-round in its Laramie, Wyoming-based farming operation, currently the largest privately-owned vertical farming and research facility in the world.

The Plenty website lists several products currently offered in stores, including lettuce, arugula, bok choy, mizuna and kale.

If the first civilizations to invent farming back around 12,000 BC only had the convenience of vertical farming, maybe they could have saved 8,000 or so years by spending more time working on inventing the wheel. And ear pods.

Explore further

The yield potential of wheat grown in controlled-environment vertical farms

Lead photo: Credit: Plenty

Welcome To The Future of Food!

A unique form of farming is ‘taking rise’ in the UK with fresh food and other crops being grown indoors on special towers using light, hi-tech food production equipment, and hot water

A unique form of farming is ‘taking rise’ in the UK with fresh food and other crops being grown indoors on special towers using light, hi-tech food production equipment, and hot water.

“We construct energy-efficient buildings and create vertical farms inside of them,” said Dr Paul Hilton, CTO of Solar 2 Food Ltd. “With Brexit and also the current crisis we are living through, people understand the value of hyper-local food production and also the benefits of a secure food supply for our communities. Now we have methods, thanks to advances in horticulture lighting, to be able to grow food within buildings in this way.”

But the key difference with other vertical farming operations elsewhere is the inclusion of solar, and in particularly ‘hybrid solar’ i.e. solar panels that produce both electricity and heat. Solar 2 Food parent company Advanced Solar Technologies Ltd are the developers of the technology and their business model is quite simple: capture the heat energy (as hot water) from the hybrid solar panels and use that to help power the vertical farm units.

Partners

“The solar panels produce the hot water really cheaply, so why not use it to help produce food for our communities at a lower cost?” said Solar 2 Food Chairman, Antos Glogowski. “Our vertical farming units are entirely hydroponic, using no soil whatsoever, so the system is effectively ‘plug and play’ with little waste. Our tech partner is Sananbio, part of one of the largest LED lamp manufacturers in the World and they have developed special LED lamps that give plants exactly the types of light they need to grow, and no more i.e. no wasted energy”.

The vertical farm units allow multiple crops to grow in a small space. And rather than one annual harvest each year, the controlled indoor environment of the Solar 2 Food facilities produce fresh food all year round without worrying about changes in the climate outdoors. “The technology also allows us to grow food locally that may usually grow in only certain parts of the world like Asia or Africa”, said Dr Hilton. “You get hyper-local, fresh produce that doesn’t have to travel halfway around the World to arrive on your dinner table, so we are making our own significant contribution towards sustainable, carbon-neutral societies that use only clean, green energy. Surely every business should operate this way?"

Vertical Farm Produces Kosher Certified No-Insect Produce

In a breakthrough for the kashrut market, a vertical farm company based in the Netherlands has produced and marketed culinary herbs with no need to wash or check for insects as is usually required by Jewish law

The ultra-Orthodox Machzikei Hadas kashrut authority in Antwerp has approved herbs grown in a vertical farm in Holland as ready for use without washing or checking for insects.

DECEMBER 29, 2020

The Future Crops vertical farm company has developed a system of propagating herbs in an entirely insect-free environment. (photo credit: FUTURE CROPS)

In a breakthrough for the kashrut market, a vertical farm company based in the Netherlands has produced and marketed culinary herbs with no need to wash or check for insects as is usually required by Jewish law.