Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

World’s First Underwater Vegetable Garden Reopens Growing Lettuce And Basil In Perfect Temperature

From the ancient rice terraces of Yunnan to modern vertical hydroponics, agriculture comes in many different forms. Now a group of Italian brainiacs have created the world’s first underwater garden for terrestrial plants

By Andy Corbley

July 13, 2021

From the ancient rice terraces of Yunnan to modern vertical hydroponics, agriculture comes in many different forms. Now a group of Italian brainiacs have created the world’s first underwater garden for terrestrial plants.

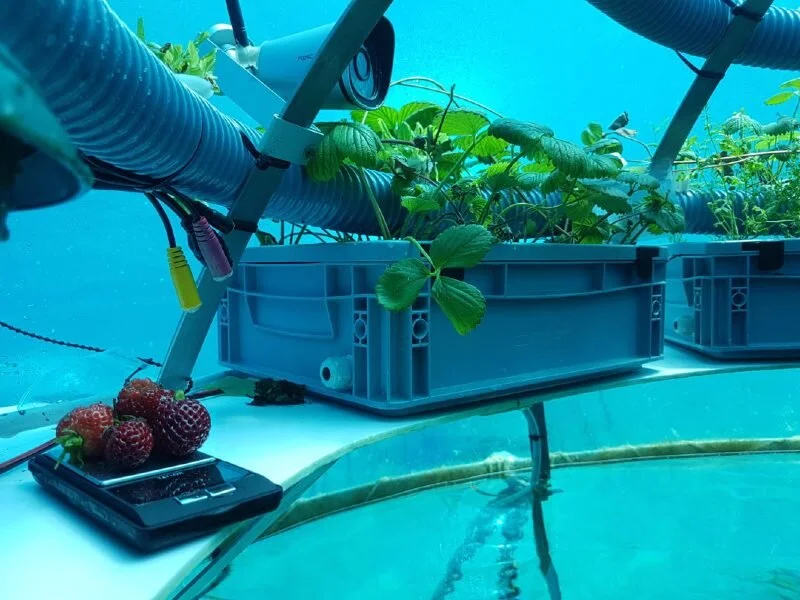

Seaweed and kelp have been cultivated along shorelines for centuries, but in small submersible glass domes, pots of basil, lettuce, tomatoes, and even zucchini flowers, green peas, aloe vera, and mushrooms are growing like in any other home garden.

Called Nemo’s Garden, the project was launched by the Ocean Reef Group as a means to experiment with food supply diversity, should climatic changes make parts of Italy too dry to farm.

The large self-sustaining, totally-contained biospheres would in theory be scalable, and perhaps in the future might look like the underwater city from Star Wars: The Phantom Menace.

The challenges inherent in growing plants underwater, given that they are normally at home in soil, was but one hurdle Nemo has had to overcome. The six air-filled greenhouses (or should that be bluehouses?) suffered major storm damage in October 2019, and before they could be fully repaired, COVID-19 had all the researchers sheltering in place.

Yet the team never gave up hope, as Euronews reports, and the months of abandonment did not harm the facility in any way. June 6th saw the garden fully-operational again, including their livestream where one can watch the plants literally grow.

The biospheres, which sit eight meters under the surface off the coast of Noli in Liguria, use solar energy for their minimal electrical needs, and evaporated seawater condenses on the glass of the ceiling which waters the plants. A diver swims under and up into the air pocket of the pod to harvest what’s ready to eat.

The project website says that increased pressure like that found under the ocean is actually beneficial to the speed at which plants can germinate, though they admit very little research has been published on the topic—after all, not so many people are currently trying to grow strawberries underwater.

The conditions create a really intense flavor in the vegetables, and also allow the plants’ environment to be completely controlled, with nothing impacting their life that the growers don’t want.

Nemo’s Garden, OceanReef

For now Nemo’s Garden is essentially a research lab, but if the idea were expanded, it’s expected to be able to reinforce food security for the peninsula, and the world.

(SEE Inside Nemo’s Garden in the video below.)

AUSTRALIA: Sydney's First Underground Farm Reducing Distance Between Paddock And Plate

From pink kale, spicy radish, coriander, basil, and cabbage, the vertical garden is controlled almost entirely by artificial means including fans which imitate a light breeze to help the plans grow

Underneath Sydney's bustling CBD, a group of savvy farmers have designed the city's first underground commercial farm. Four basement levels below the city streets in Barangaroo, in an office tower car park, Urban Green is now the largest vertical farm in Sydney. It features 35 verities of microgreens - seedlings of plants that are usually harvested early before being fully grown.

From pink kale, spicy radish, coriander, basil, and cabbage, the vertical garden is controlled almost entirely by artificial means including fans which imitate a light breeze to help the plans grow. Just four years on from when it first began, Urban Green now provides fresh produce to restaurants and chefs around the city.

Watch the video at 9news.com.au

26 Nov 2020

VIDEOS: Vertical Farming Goes High-Tech And Underground

Vertical Farms Are Evolving Into A Major

Food Industry Powered by Sophisticated

Technologies And Production Methods

Growing fresh produce in underground areas

Transforming a tunnel into a vertical farming operation

Infarm allows customers to pick the produce themselves

Vertical farming companies are facing an array of challenges

Technology and lower costs are critical for the industry’s sustainability

Innovation is vital to solving the world’s greatest challenges

Farmers around the world are heading towards an uncertain future. Apart from the prospect of feeding the global population that’s set to reach around 10.9 billion by 2100, they are also facing climate change-induced floods, droughts, and heatwaves. Fertile land is in ever shorter supply as soil erosion intensifies. Farming is also to blame for some of these problems as the CO2 footprint of food accounts for 17 percent of total global emissions. And by the time plants get transported to supermarkets, they lose 45 percent of their nutrients. As it becomes increasingly apparent that traditional agriculture is unsustainable, growing food in an artificial environment is emerging as a potentially better way forward.

Instead of plowing fields, farmers would produce food in vertically stacked trays. Soil would be replaced by nutrient-rich water, while LED lights would act as the sun to ensure plants photosynthesize. This practice, known as vertical farming, offers many benefits. The indoor environment protects crops from extreme weather events and pests, which means that food grows fast and there’s no need for pesticides. Also, food is grown close to cities, which not only reduces food miles and the related carbon footprint but also provides consumers with fresh and tasty crops.

However, vertical farming faces certain challenges as well. Companies have to constantly innovate to cut production costs and turn a profit, which is vital for the survival of this industry. But entrepreneurs remain optimistic. The global vertical farming market is forecasted to reach $12.77 billion by 2026 and people are becoming increasingly aware that there’s a better way to feed the populGrowing fresh produce in underground areas

High rents and the lack of space have prompted some modern urban farmers to go underground. In London, for instance, a farm called Growing Underground operates from a World War II bomb shelter located 33 metres below Clapham High Street. Owned by Stephen Dring and Richard Ballard, the vertical farming facility produces an array of herb and salad mixes, including parsley, red mustard, coriander, and pea shoots. Fresh produce is then sold through Marks & Spencer, Waitrose, Ocado, and several other retailers. Some restaurants have also expressed interest in buying fresh produce, says Ballard.

He also points to many advantages of vertical farming. For instance, his farm delivers 60 harvests a year, compared with around seven that can be achieved in traditional agriculture. Furthermore, Growing Underground is carbon neutral and uses 70 percent less water than typical farms. The only major cost he’s trying to reduce is the electricity that powers the lights. And his ambitions are global. “The UK is the hardest market for growing salad. We’ve got very low prices in the supermarket, so if we can make it work here we can make it work anywhere,” says Ballard.

Underground vertical farming is thriving in other British cities as well. The Liverpool-based social enterprise Farm Urban, for example, provides customers with a weekly box of living salad leaves, edible flowers, and fragrant herbs. Jens Thomas, the company’s technical director, says that the product is pesticide-free and “it’s grown using 90% less water than if it was grown in a field; it’s zero-waste; and it’s hyper-local.” Farm Urban is trying to promote healthy and sustainable living. For each box of greens customers buy, the company delivers a box of greens to a local school. This activity is part of the Greens for Good campaign that aims to reconnect people with locally-grown food.

In New York, the vertical farming business Farm. One is also growing. Its underground farms produce over 500 different herbs, edible flowers, and microgreens year-round, using specialized software to manage multiple operations, such as seed, harvest, and flavor optimization. Founded by Rob Laing, the company supplies fresh produce to various New York-based restaurants, including Atera, Ai Fiori, Benno, and Flora Bar. All deliveries are made by bike and subway. Also, visitors can book a tour of the farm or take a class in hydroponics to learn how to grow vegetables in a soil-free environment.

Transforming a tunnel into a vertical farming operation

Successful vertical farming businesses can also be launched outside of cities. NEXTON, a South Korea-based startup, has built vertical farms in a former highway tunnel, located 190 kilometres south of the capital city of Seoul. Growing salads, leafy greens, and strawberries beneath mountains has many advantages. For one, the 6,500-square-metre facility naturally maintains a temperature that ranges between 10 to 20 degrees Celsius, which translates into lower energy spend for cooling or heating. Furthermore, labor costs are reduced by automating various operations. And as farming is done without pesticide or herbicide, with sensors monitoring humidity and CO2 concentrations, customers receive both healthy and affordable products.

Choi Jae-bin, the CEO of NextOn, also uses non-tech tactics to boost production. For instance, the music of Beethoven and Schubert is played in the 600-metre-long tunnel as Jae-bin believes it will help plants to grow faster. And his plan is to build more farms in urban areas. “Plants easily grow at home, at nearby stores, at hamburger restaurants, or even at metro stations. I think the system to grow crops far away from a city and transporting it will disappear,” he says.

Infarm allows customers to pick produce themselves

Infarm, a Berlin-based startup, has already achieved in several European countries what Jae-bin plans to do in South Korea. The German company builds modular farms that are placed in customer-facing locations, such as schools, grocery stores, restaurants, and shopping malls, enabling customers to pick the produce themselves. Clients can also add more modules if they want to increase the farming output, while the production is monitored and controlled through a cloud-based platform. Essentially, the whole thing functions as a ‘farming as a service’ operation that combines the IoT, Big Data, and cloud analytics.

The company is working with 25 major food retailers in Germany, France, and Switzerland, including Migros, Casino, Intermarche, Auchan, Selgros, and AmazonFresh. Furthermore, it has installed more than 200 in-store farms, as well as 150 farms in distribution centres. And in 2019, Infarm raised $100 million in Series B investment round. The funding will be used to expand research and development, sales, and operation teams. Also, the startup plans to increase its presence in the UK and negotiate partnerships with retailers in the US and Japan.

Vertical farming companies are facing an array of challenges

While the rise of vertical farming companies has been impressive, the industry is facing many challenges and its survival depends on reducing costs and increasing productivity. Take, for example, the fact that deploying even a small, low-tech vertical farm with the 1st generation technology costs around $280,000. On the other hand, the cost of setting up more complex farms with advanced tech can go over $15 million. There are also operating expenses such as lighting and labour that can further pressure companies’ bottom line, making it hard to compete with organic and traditional producers.

So it comes as no surprise that return on investment (ROI) in vertical farming projects is mediocre at best. The current market prices don’t make the situation any easier either. A kilogram of vertically-grown leafy greens is around $33, while organic produce costs $23. To gain a competitive edge, vertical farming startups need to take several measures.

Technology and lower costs are critical for the industry’s sustainability

The first step in ensuring the long-term profitability of vertical farms is transitioning to 2nd generation technology. This means that in addition to automatic control of irrigation, humidity, lighting, CO2, and other relevant parameters, farms should also be capable of autonomously collecting data and optimizing growing processes. They also need to implement cutting-edge machines that will autonomously run planting and weeding operations in the facility, and harvest sort and package produce for shipping. These improvements can enable the second generation of vertical farms to yield 55 times more produce than conventional farms.

Increased automation will also cut labour expenses. Intelligent Growth Solutions, a UK-based agritech business, has reportedly developed an automated farming system that uses modular structures to reduce labour needs by up to 80 percent. Furthermore, LED lighting efficiency is likely to improve by an additional 70 percent by 2030, reducing the energy spend. Boaz Toledano, a business consultant specializing in vertical farming, says that “lighting improvements should reduce OPEX [operating expenses] by 12%, and automation should cut OPEX by a further 20%+”.

Companies can also reduce costs by setting up farming operations underground. This would not only help them avoid the high cost of renting in urban centres but also enable them to enjoy the benefits of having a steady temperature. Underground facilities also offer better protection against natural disasters and can be more easily adapted to producers’ needs.

Innovation is vital to solving the world’s greatest challenges

New technologies are moving the food industry forward. Vertical farming, though still gaining traction, could help solve some of the world’s greatest challenges, such as food shortage. Tasked with feeding the growing global population, today’s agriculture producers still primarily rely on farming practices that hurt the environment. As it becomes clear that traditional farming is unsustainable, innovative entrepreneurs and scientists have come up with a potential solution. Vertical farming is increasingly hailed as an alternative food production method that can provide people with healthy and fresh produce. Thriving in undergrounds, stores, and restaurants around the world, vertical farms are becoming a major industry. But their survival depends on the ability of businesses to lower food production costs and increase productivity.

This article is written by Richard van Hooijdonk

Trendwatcher, futurist, and international keynote speaker Richard van Hooijdonk takes you to an inspiring future that will dramatically change the way we live, work, and do business. All lectures

UNITED KINGDOM: Underground Farm Based In Former Clapham Air Raid Shelter To Open New Site In Suburbs

Growing Underground cultivates micro herbs and salad leaves in a former Second World War air raid shelter, 33 metres beneath the streets of the capital. Using LEDs, hydroponics, data analytics, and 100 percent renewable energy, the 65,000sq farm has been delivering fresh produce to hundreds of restaurants and supermarkets since 2015

Growing Underground cultivate micro herbs and salad leaves in its 65,000sq urban farm located 33m below the streets of London.

It is now pushing for new investors in a bid to expand its operations and revolutionize Britain’s agriculture

REBECCA SPEARE-COLE

The Evening Standard

A massive underground farm in Clapham is set to open a new site on London’s outskirts in a bid to ramp up its sustainable agriculture operations.

Growing Underground cultivates micro herbs and salad leaves in a former Second World War air-raid shelter, 33 metres beneath the streets of the capital.

Using LEDs, hydroponics, data analytics, and 100 percent renewable energy, the 65,000sq farm has been delivering fresh produce to hundreds of restaurants and supermarkets since 2015.

Now, it is looking to open a new site, at an undisclosed location in the city suburbs, to grow produce next to distribution centres that supply supermarkets across the UK.

Growing Underground

The farm’s corresponding push for investors comes at a time when the pandemic has exposed systemic problems and vulnerabilities in global supply chains.

It also chimes with David Attenborough’s recent warning about the critical importance of moving away from exhaustive farming practices to innovative solutions, in his new film A Life on Our Planet.

Growing Underground’s COO Richard Ballard told the Standard: “Any business starting today has got to think about its impact on the environment and society, and that is one of the key drivers for us.”

Growing Underground is farm in WW2 air-raid shelters under the streets of Clapham (Growing Underground)The underground farm has become a pioneer in the UK’s controlled environment agriculture industry (CEA) — a technology-based approach towards food production.

Mr. Ballad said: “Technology around LED lights has really evolved so it has become possible to grow an enormous amount of produce in a small space.“

We also recirculate water with a hydroponic system so we reduce our impact on resources. We don’t use pesticides and in terms of transportation we grow very close to the point of consumption, so we reduce food miles and food waste.

We use recycled products for our substrates and the carpets that hold the seeds, so we are working within a circular economy concept,” he added.

The farm also uses only renewable energy from the provider Good Energy, and Mr. Ballad said they plan to become entirely carbon neutral by 2021.

But what distinguishes Growing Underground from other CEA operations is that they chose a redundant underground space, which does not require them to use up resources on air movement and temperatures like a greenhouse would.

“Being underground we get a consistent temperature all year round so we don’t need a lot of electricity and power for controlling the environment,” he said.

The farm is run on operation shifts seven days a week, with at least seven people working a day, harvesting greens like Thai basil, coriander, pea shoots, rocket, and mustard leaf. The produce is also grown to be very high in nutrition.

Clapham underground is home to 'Growing Underground', the UK’s first underground farm. (Getty Images)

Besides selling the produce and (before the pandemic struck) running tours of the underground farm, Growing Underground has also amassed a huge amount of valuable data over the last five years.

The environment is measured with data points around the farm, which is used to find “the perfect temperature, perfect yield, pH of the water, oxygenation of the water and the spectrum of the lights” for growing a product.

For example, in the last five years, Growing Underground has reduced the number of days for cultivating coriander by 50 percent as well as increasing its yields by 25-30 percent.

"The data has meant we can tailor environment recipes for the products, giving us a very efficient method”.

Mr. Ballad also said that technology and innovation behind CAE is making agriculture a more attractive industry for young people in developed economies, citing research that found the average age of farmers across the world is 60-years-old.

He said: “This is a new trained way of agriculture — looking at data, looking at the science of growing and intensifying yields and getting the most of a small space as opposed to traipsing across fields and pulling things out.”

Now, after five years of building and growing under Clapham North, Mr. Ballard said it is the “right place and the right time to take agriculture to the next level”.

Growing Underground is taking a “two-pronged” approach, Mr. Ballard said.

“We already have our first London site and Clapham is big enough to supply a huge amount to the capital’s foodservice market through places like New Covent Garden Market,” he added.“

But we want to get out there to the wider market as well and we feel that building a second site that supplies into the retail markets and the wider foodservice is where we want to be.”

This new second site, which is still in the final stages of negotiations, will be on the outskirts of London in order to easily supply the rest of the country.

The company is also looking at other sites where they can build fully automated production lines with seeds in at one end and products out the other.

Mr. Ballard said: “We have a few potential sites in our sights and we are just in negotiations at the moment.”

“The plan is to use space close to a current distributor of produce so we are building a proximity farm that feeds directly to that customer.“

And we only need a small space within the current infrastructure of a building to grow produce.”

Upscaling will also mean that the farm can start producing a wider range of crops, that are too costly to grow in CEA at the moment, he said.

For Mr. Ballard, Growing Underground is not just about making a profitable and sustainable method of agriculture but it's about building a business that tunes into a changing world.

Growing Underground is looking to expand

(Photo: Paul Marc Mitchell)

“We are facing massive problems with the global food production system and we have seen empty fresh product shelves in supermarkets,” he said.“

We’ve had Brexit, the pandemic, and many more once-in-a-lifetime extreme weather events than we used to see. In the UK, there have been more storms and extreme weather affecting crops as well as hotter summers.

“And all related to this is climate change. Statistics from the UN saying we have got 40 harvests left due to soil degradation and intensive farming practices.“

So this is a really good time to be looking at alternative sustainable agriculture methods to take us into the middle of this century.“

This probably going to be one of the most disruptive things that has happened in Agriculture since the Agricultural Revolution itself,” he said.

More about: | Growing Underground | Clapham | Controlled Environment Agriculture | farm

VIDEO: Growing Underground

Best job title EVER! Food Futureologist Morgaine Gaye on the importance of technology and farms like ours for the future of food. With our co-founder Richard and Ben Thompson for BBC Breakfast

Growing Underground@GrownUnder

Best job title EVER! Food Futureologist Morgaine Gaye on the importance of technology and farms like ours for the future of food. With our co-founder Richard and Ben Thompson for BBC Breakfast @BBCBreaking @BBCBreaking @BBCWorld

To View The Video, Please Click Here

On Rooftops And In Tunnels, City Farms Lead Food Revolution

Salad plants are already being grown in old bomb shelters but floating dairy farms and 16-storey food towers could be next

Growing Underground produces food 33 metres beneath Clapham High Street in a wartime bomb shelter. Photograph: Roca London Gallery

10 February 2019

Only the Northern line tube trains rumbling through tunnels overhead provide any clue that Growing Underground is not a standard farm.

The rows of fennel, purple radish and wasabi shoots could be in almost any polytunnel, but these plants are 100 feet below Clapham High Street and show that urban agriculture is, in some cases at least, not a fad.

The underground farm has occupied a section of the second world war air-raid shelters for nearly five years, and Richard Ballard, one of the founders, is planning to expand into the rest of the space later this year.

“The UK is the hardest market for growing salad,” he said. “We’ve got very low prices in the supermarket, so if we can make it work here we can make it work anywhere.”

The Growing Underground experience is being highlighted at two exhibitions this year: Roca London Gallery’s investigation into “agritecture”, London 2026, which opened on Saturday, and the V&A’s Food: Bigger Than the Plate in May, which will also showcase micro-farming methods such as Grocycle’s hanging mushroom bags.

Urban commercial farming – as opposed to Britain’s 330,000 allotments – is a regular topic of interest at places like the World Economic Forum in Davos, where policymakers consider whether the world’s food system, blamed for causing both obesity and malnutrition, can be fixed.

There are already plenty of urban farming projects around the world, particularly in the US, Japan and the Netherlands, ranging from aquaponics – urban fish and plant farms – to vertical farming, where plants are grown in stacked trays, a method Growing Underground also uses.

ReGen eco-villages would power and feed self-reliant families. Photograph: Roca London Gallery

“It’s definitely becoming an expanding industry,” Ballard said. “There’s several other businesses starting up in London in containers, smaller projects, and there are several around the country now, other vertical farms.”

Growing Underground supplies herb and salad mixes – pea shoots, garlic chives, coriander, rocket, red mustard, basil and parsley – to Marks & Spencer, Waitrose, Ocado, Whole Foods and Planet Organic, as well as restaurateurs including Michel Roux. Being in London creates an advantage, Ballard says, as they can harvest and deliver in an hour.

He reels off other advantages. Being underground means temperatures never go below 15C – surface greenhouses need to be heated. They can do more harvests: 60 crops a year, compared with about seven in a traditional farm or about 25 in a polytunnel. Electricity to power the lights is a major overhead, but the firm believes renewable energy will become cheaper.

Similar British ventures include the Jones Food Company in Lincolnshire, while in the US AeroFarms has several projects in New Jersey, and Edenworks in Brooklyn uses the nitrogen waste from the tilapia and striped bass in its aquaponic fish farm to feed its herb crop.

For Clare Brass of Department 22, a sustainability consultancy which curated the Roca London exhibition, projects like Growing Underground are vital pointers to the future.

“We are living in the most ridiculously wasteful system,” she said, citing research that shows about a third of the world’s food is lost. “We need to transition to a circular economy. Business and government are not going to do it. These are people who are innovating, and we need these people to show us the way.”

Some of the ideas presented include rooftop bee-keeping, an insect breeding farm for roundabouts in Stockholm, home food recycling in 24 hours, and a floating dairy farm in Rotterdam that is due to open later this year – a real-life interpretation of the children’s book The Cow Who Fell In the Canal.

Futuristic food tech companies may look like a great investment, but when venture capital runs out, many businesses fold. Paignton Zoo in Devon was one of the first to try vertical farming in 2009, using a system known as VertiCrop to grow leafy greens such as Swiss chard and pak choi for its monkeys. Five years later, the system was gone. The company behind it, Valcent, which later became Alterrus and set up rooftop greenhouses on carparks in Canada, went bankrupt in 2014.

“Vertical farming makes sense for microgreens,” Carolyn Steel, a London-based architect and author of Hungry City, said. Herbs are about 200 times as valuable per kilo as grains. “But why farm grain in a city when it can grow 20 miles away and spend three years in a grain store. Grain stores are one of the reasons cities emerged in the first place.”

For Steel, urban farming should be encouraged as an important reminder for city dwellers where their food comes from. “We have become very remote from our food,” she said, pointing out that London’s geography shows how it was built on its food supply. Grains came along the Thames to Bread Street, chicken entered from the east to Poultry, while beef went to Smithfield.

“Ultimately we need to pay more for food,” Steel said. “Ever since industrialisation we’ve been externalising the true cost of food, and now we’re seeing the true cost of that in terms of climate change, mass extinctions, water depletion, soil erosion and diet-related disease. Where does vertical farming sit in that?”

A hydroponics unit for the home provides water and light for plants. Photograph: Roca London Gallery

UK: London's Underground Farm Opens Doors To The Public

To View Video, Please Click Here

Ever wondered what’s going on beneath your feet under the streets of London? Well, now is your chance to enter another world by visiting Growing Underground. This urban farm is situated 33 meters underneath the streets of Clapham, London in a World War II air raid shelter.

For the first time ever and for a limited time, these tunnels will open to give you a tour of the depths of the underground farm, on November 27.

Growing Herbs And Vegetables Under The Sea

Near Genoa, Italy

Underwater agriculture might be one of the solutions to help eradicate world food shortages. That is the idea behind the latest project of the Ocean Reef Group in Italy. According to the Food and Agriculture Organization, at present only some 11 percent of the globe's land surface (13.4 billion ha) is used in crop production.

As the world population is expected to grow from 7.6 billion to 9.8 billion in 2050, according to the United Nations, using water, which covers about 75% of the world surface, could help enormously. That is why the marketing manager of the research group Luca Gamberini and his team have set out to prove it is possible to grow herbs and vegetables under the sea.

In the video below we visit the first underwater farm in the coastal waters near Genoa, Italy.

Source: euronews.com

Publication date: 7/17/2018

Italian Agrinauts Develop Underwater Greenhouses

Controlled-environment agriculture has pushed the boundaries, making it possible to grow crops in the most unlikely of locations. We've already seen cultivation take root on the North Pole, in space, and underground. An Italian scuba enthusiast adds another dimension to the list: underwater greenhouse

Italian Agrinauts Develop Underwater Greenhouses

Controlled-environment agriculture has pushed the boundaries, making it possible to grow crops in the most unlikely of locations. We've already seen cultivation take root on the North Pole, in space, and underground. An Italian scuba enthusiast adds another dimension to the list: underwater greenhouses.

The history of Nemo’s Garden begins in the Noli’s Bay in 2012, when Mr. Sergio Gamberini, President of Ocean Reef Group, came up with this funky idea, trying to combine two of his passions: scuba diving and gardening.

The first experiment, project coordinator Gianni Fontanesi tells us, was conducted during the summer of 2012, with one very small biosphere anchored to the sea bottom in which green basil was planted and successfully grew. In this structure no “agrinauts” could get inside.

From herbs to stevia

The Nemo's Garden team already tested many different plants: green basil, oregano, sage, mint, thyme and other herbs, various types of salads, tomatoes, beans, peas, zucchini, and goji berries. They don't just limit themselves to edible plants, however - examples of medical and cosmetic crops include stevia, melissa, calendula, aloe vera, etc.

"Our target is not selling veggies/herbs on the market", Gianni says. "Indeed, we are not focused on fixing a price for a kg of plants. Our goal now is to investigate which plant is growing better, together with the fresh water production and the complete auto sustainability of the system. Product maximization will be the next step."

New and traditional techniques

"The unique conditions inside the biospheres (especially higher pressure and high level of humidity) are acting positively on the plants' growth", according to Gianni. He says they've noticed a faster germination and different chemical compositions with different composition of essential oils.

Being underwater requires new ideas and solutions, but the agrinauts are also adapting common growing methods, albeit in a completely different environment. For instance, one winter the team tested a few LED lights that could be used during the low season when the sunlight is reduced and the day are short.

Although Nemo's Garden borrows certain techniques from 'land growers', the agrinauts want to work with their colleagues on terra firma, not against them. "We get positive feedback from all over the world, from many different realities", Gianni says, emphasizing: "We do not want to compete with conventional growers, that is not our goal."

Customized underwater structures

Nemo’s Garden is a pilot project created and entirely sponsored by Ocean Reef Group. The company manufactures diving equipment, snorkeling full face masks (inventors), protection equipment, and electronics. "The other projects are related to the different activities we are running", Gianni tells us.

Right now, the team at Nemo's Garden is still investigating which crop grows better, together with fresh water production/collection and self-sustainability of the system. They also have ambitious plans for the future.

"We are now ready to replicate this underwater habitat or to create customized options. Through the years we understood the many possible applications for this type of habitat: not only an underwater greenhouse, but an underwater observatory, an uw lab with a higher pressure, a new touristic attraction." They're receiving requests from all over the world, and have already installed one biosphere at the TODI center in Belgium.

For more information:

Nemo's Garden

www.nemosgarden.com

Publication date: 3/27/2018

Author: Jan Jacob Mekes

Copyright: www.hortidaily.com