Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

I Ate The Freshest Lettuce You’ll Find In N.J. And It Was Grown In A Metal Garden

A giant lime-green storage container parked behind Robbinsville Township’s Senior Center is not what I imagined I’d be looking at when I learned the town had a public garden. But that’s exactly what it is and the magic happening inside the 40-foot-long space might surprise you

July 23, 2019

Visitors exit the Robbinsville Hydroponic Farm, a vertical hydroponic shipping container – called the Leafy Green Machine (LGM). TT Michael Mancuso

A giant lime-green storage container parked behind Robbinsville Township’s Senior Center is not what I imagined I’d be looking at when I learned the town had a public garden. But that’s exactly what it is and the magic happening inside the 40-foot-long space might surprise you.

Affectionately called the “leafy green machine” by the staff that runs the garden in a box, it operates on a hydroponics system, which, after stepping inside, made me feel like I was inside a sci-fi movie with its eery lights and machinery.

The storage container-turned-garden, which cost the town $104,000, was first installed in 2017. Its main focus is to provide local residents with fresh vegetables that are able to be grown year-round in nutrient-rich water without the need for dirt or pesticides.

Lettuce being prepared for packaging at Robbinsville's hydroponic garden.

“This is really a great urban solution to bring localized greens to residents,” said Kyle Clement, the farm’s coordinator. Clement was hired shortly after graduating from Rutgers to oversee the farm’s production.

Despite its tiny size, the storage container allows them to grow the same amount of crops as a 32,000-square-foot plot of land, which amounts to about 500 heads of lettuce harvested a week. The majority of the produce — lettuce and kale, and eventually herbs like basil — is donated to the town’s senior center and the Mercer Street Friends food bank. The rest is sold to residents who sign up through the town’s program and pay $20 for four weeks of veggies.

I got a tour of the space on a recent afternoon. The inside of the container was mostly dark and was almost solely lit by blue and red LED lights. The closest I’ve come to have an experience like this is when I took a darkroom photography workshop in middle school.

The sides of the storage box are lined with rows and rows of white vertical shelves, which is where the heads of lettuce grow.

As Clement walked me through the process of farming, he pulled one of the inward-facing shelves off its stop to reveal the most perfect and symmetrical heads of lettuce that I’ve ever seen.

The reason these veggies look so perfect has to do with their growing process, which goes a little something like this:

Everything is grown from seeds. They first start out in the seed nursery for about three weeks until the lettuce bulb is big enough to fit into the vertical rack. From there, the entire growing process is controlled and monitored by the farm’s computer system.

“The sensors take all of the readings of water, temperature and pH levels, which are sent to the farm computer, and the computer reads it and adjusts the environment as needed,” Clement said.

The vertical growing system requires no soil and uses a drip water method that conserves 90% of the water used. Any water that isn’t absorbed by the vegetables is collected by the box’s irrigation system to be reused.

Instead of sunlight, the LED lights provide the energy the plants need to grow. The red and blue wavelength lights provide optimal light to the leafy vegetables growing in each garden.

Once the vegetables are fully grown, they are harvested by Clement and a team of volunteers each week. The heads of the lettuce are pulled from the vertical stacks and are cleaned on a workbench before being bagged and prepared for customers.

On my way out of the tour, Clement handed me a bag of lettuce and a flyer promising me the best vegetables I had ever tasted. So I obviously had to put the claim to the test.

I went home and made myself a salad for lunch. I added some tomatoes and cucumbers with chicken and balsamic dressing. This is pretty much my go-to salad recipe but the super fresh greens really pushed it to the next level.

To start, washing off all the heads of lettuce was super easy because there was no lingering dirt particles clinging to the leaves, so I managed to get things prepared in only a couple of minutes.

The taste and texture were also great and I give that credit to knowing the lettuce was just harvested a few days ago and hadn’t been sitting on a truck and going through shipping for weeks at a time.

When I was done with my lunch I still had enough lettuce left over for at least one or two more meals, and I definitely intend on making them last. Robbinsville residents who want to sign up can register online. Customers will be able to pick up their vegetables at the senior center.

Olivia Rizzo may be reached at orizzo@njadvancemedia.com. Follow her on Twitter @LivRizz. Have a tip? Tell us.nj.com/tips.

GP Solutions Creates New "Living Soils" For Consumers, Gardeners and Farmers

GP Solutions created a unique growth medium called "Prolific" that contains no native soil. Prolific is composed of a diverse population of beneficial bacteria and fungi, which create an ideal environment for abundant, healthy crops of all types

New Bio-Technologies Give Rise To A New Product Formulation That

Will Disrupt The $262 Billion Organic Food Market

CORONA, Calif., July 22, 2019 /PRNewswire/ -- GP Solutions (GWPD), a leading developer of modular automated micro-farms, has created a category-disrupting, proprietary lineup of premium "living soils."

GP Solutions created a unique growth medium called "Prolific" that contains no native soil. Prolific is composed of a diverse population of beneficial bacteria and fungi, which create an ideal environment for abundant, healthy crops of all types.

An article in The Scientist reported, "Plants are populated by a cornucopia of diverse microorganisms," and that adding beneficial microbes in the form of a "plant probiotic" could produce healthier, more robust harvests.

A research study published by Microbial Biotechnology, confirmed that these probiotics enhance crop production.

"Plant-associated microbiomes have tremendous potential to improve plant resilience and yields in farming systems," the scientific journal reported.

GP Solutions developed this proprietary growth medium with accountability and traceability for each ingredient.

"As consumers become aware of the differences between dirty farming, which contains contaminated human and sewage waste byproducts in the soil, and clean farming, which contains a diverse beneficial microbial population that produces mineral rich crops, the demand for our living growth medium will increase exponentially," said George Natzic, President of GP Solutions.

GP Solutions will be providing Prolific to customers of GrowPod™ automated farms, as well as to the general public within the near future.

"This is not just disrupting the organic and farming industries, it is the dawning of a new era in agriculture," Natzic added.

For information, visit: www.growpodsolutions.com, or call (855) 247-8054.

ABOUT GP SOLUTIONS:

GP Solutions developed "GrowPods" – portable, modular, automated indoor micro-farms that provide optimum conditions for plant cultivation with total environmental control.

Forward-Looking Statements

This release includes predictions or information that might be considered "forward-looking" within securities laws. These statements represent Company's current judgments but are subject to uncertainties that could cause results to differ. Readers are cautioned to not place undue reliance on these statements, which reflect management's opinions only as of the date of this release. The Company is not obligated to revise any statements in light of new information or events.

Connect:

Email: info@growpodsolutions.com

Website: www.growpodsolutions.com

Facebook: facebook.com/GrowPodTechnology

Twitter: @GrowPodSolution

Media:

hello@inov8.us

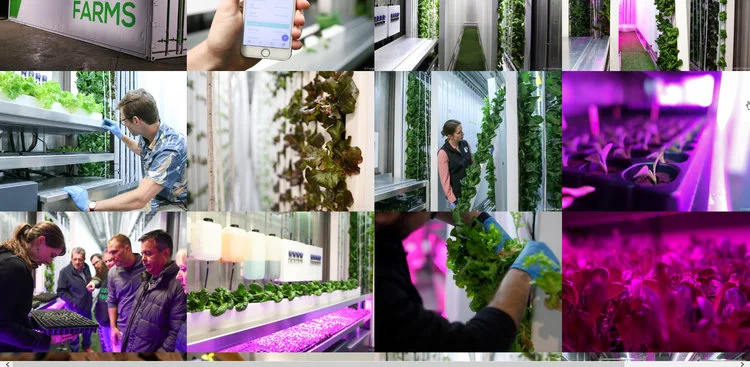

Case Study From Freight Farms

A conversation with Steve Huntley of Enlightened Crops on how he discovered Freight Farms and leveraged previous business experience into his new venture of Container Farming

A conversation with Steve Huntley of Enlightened Crops on how he discovered Freight Farms and leveraged previous business experience into his new venture of Container Farming

07/18/19

Launching a Successful Second Career With Container Farming

Case Study From | Freight Farms

Steve wasn’t always a farmer. After some years in the corporate world, he started a small service business with his wife Cathy. The business focused on plumbing, heating, and cooling, and the couple ran it successfully for 18 years. In 2017, Steve and Cathy decided that they were interested in moving on to something that would be more flexible as they looked towards retirement.

They set out looking for a new venture that would benefit the community–especially in the downtown area. One thing they found was a lack of fresh produce availability in Downtown; They decided to explore that route and ran into the concept of hydroponic farming.

A friendly face

Steve wasn’t the only person in Grand Rapids interested in hydroponics. Brian Harris had previously purchased a Leafy Green Machine (LGM) and was a long-time friend of Steve’s from a job 30 years ago! Steve had been thinking of pursuing hydroponics with a free-standing warehouse system, but after seeing Brian on local TV, he reached out and saw the LGM for himself. After working at the farm with Brian a few times, Steve was convinced this is was what he was looking for.

Fellow Freight Farms Brian Harris of Green Collar Farms

“We were very impressed with the Freight Farm, how efficient everything was–it was already pre-set up and there was great support. We did some calculations and, with good yields, we could supply a lot of product to the urban area.”

— Steve Huntley

No experience, no problem

Steve felt comfortable pursuing a new farming career in spite of having almost no agricultural background. While he had grown up in a farming community, the closest Steve had gotten to commercial food production was a small personal garden at home. However, he was sure that with the farm’s smart set up, and the support of Brian, fellow farmers, and the Freight Farms team, he could be successful.

THE BUSINESS

Previous business experience helped Steve think strategically about his market.

“First thing you want to find out is if the market’s available: It could be a great idea, but if the market’s not ready or saturated, it won’t work.”

With this in mind, Steve created a market research form with questions for chefs and sous chefs, their initial target customers. The goal was to get a sense of the market, and they came away with a resounding yes, especially for access to good quality produce year-round in Michigan’s seasonal climate.

Knowing that the demand was there, Steve and Cathy looked at their potential yields, calculated potential expenses and profits, and decided they were ready to start farming.

Taking a leap of faith

Before the arrival of his farm, Steve had marketed the produce to chefs that were excited about the idea of local, chemical-free produce. However, without samples, he wasn’t able to finalize any agreements. At that point, he had to trust that his due diligence had been enough.

“The leap of faith is necessary for anyone starting any business. You can get all the data, but nothing is guaranteed. You have to just make an educated guess...If you’re passionate about it...it will work out for you.”

— Steve Huntley

Friends > competitors

In spite of the fact that Steve and Brian are both Freight Farmers in the same city, Steve doesn’t believe they’re anywhere near saturating the market and becoming direct competitors. Steve explains: “The Freight Farm is such a unique concept that there’s enough to go around in our area. We do experience competition from other types of–mainly larger–hydroponic farms, but we’re carving out our niche.”

Finding customers

Since launching his farm, Steve’s customers include several high end restaurants, an urban fresh food grocery store, and–most recently–a fresh food distribution company that delivers Steve’s greens to stores around the city.

Steve initially focused on restaurants because they had smaller demands that would be more achievable while him and Cathy were getting comfortable in the farm. He approached several high end restaurants (the ones that would want to pay a premium for greens) with samples from his newly-arrived farm and some informative brochures.

These he either mailed or, more successfully, dropped off in person during off-peak restaurant hours. Once Steve’s farm was producing higher yields, he approached retail stores in his area with the same tactic.

“I was surprised that a lot of these chefs were willing to talk with me and try out our samples. You don’t get everyone of them, but if you go back every couple of months, at some point they’ll need your product.”

— Steve Huntley

Steve also runs a small farm stand for friends and neighbors. Since he frequently schedules more production than he needs to make sure regular customers always get their demands met, this means that there are usually crops left over. Steve sells surplus produce through a simple online portal (using Eat from Farms) that customers can use to order whatever Steve has in stock. He also uses surpluses as an opportunity to donate to local food banks.

Crops and yields

So what is Steve actually selling to this wonderfully diverse customer base?

After lots of feedback and testing, Steve has narrowed his production down to a few superstar crops: Arugula and basil form 80 percent of the farm’s production, while artisanal lettuces make up the remainder of the farm’s weekly output. Steve differentiates his produce for his different customers: the grocery store sells a selection of everything he grows, while the restaurants mainly purchase arugula and lettuce.

When it comes to yields, Steve is always looking to optimize. Currently he grows 8-10 ounces of basil and 16 ounces of arugula per tower.

Determining Price

Steve begins his price negotiations by calculating all of his expenses–seeds, electricity, etc–to get a sense of the overall and unit costs of the farm. This helps him go into meetings with a good idea of what price he needs to make a profit. After a few rounds of negotiating, Steve and his buyer are able to land on a price that works for everyone.

Thanks to the quality of his produce, Steve is able to negotiate a premium price for his crops. Steve also gets higher prices by promising his customers that he will keep the price consistent.

“[Customers] like the fact that they can budget, they don’t have to worry about prices going up and down; We can give them a price that is consistent all year long.”

Marketing

Steve relies on the popularity of local food as a way to differentiate himself at the store, saying “Local is huge” for consumers, who increasingly want locally-sourced food that is fresher, cleaner, and more transparently-grown.

Demos are one of Steve’s greatest marketing strategies: every time they’re able to give people a taste they see their sales go up. When people ask if the produce is organic, Steve doesn’t skip a beat. He tells them: “We’re not certified organic, but we don’t have any contaminants in our soil because we don’t use soil, there are no toxins from the air or the rain…We’re better than organic.”

SITE & OPERATIONS

Convenient Location

The Enlightened Crops farm is located on the west side of Downtown Grand Rapids, Michigan in a parking lot near the expressway. The site is very convenient–it’s kiddy-cornered with the grocery store Steve sells to, and is just a few minutes driving distance away from the restaurant customers.

Steve shares the site with Brian–in fact, Brian already had the site set up by the time Steve was ready to buy. All Steve had to do when his farm arrived was set up an electrical connection. Since there’s no running water, Steve uses a water reservoir tank and is able to pump water directly into the farm.

Ramping Up

The Leafy Green Machine was delivered mostly pre-assembled, so the first few days were spent on the finishing touches: hanging towers, calibrating sensors, and connecting pumps. Steve was able to rely on his new neighbor, Brian, and the Freight Farms team for support througout.

Even with the support, the first few months had their challenges. Steve and Cathy had trouble finding the right watering and harvesting schedules, which led them to over-water the plants and leave them in their towers for too long. However, by tracking their operations carefully they were able to learn from their mistake. Steve advises new farmers to do the same: “Use analytics as much as you can to track how long you have certain towers in, what plants in what towers, and what area of the farm...It all helped us to go back and look at that data as we were learning those first six months.”

Day-to-day Operations

Most days, it’s just Steve and Cathy working in the farm, with occasional help from their son. Together they’re able to share the farm work, which on top of seeding, transplants, harvesting, and cleaning also includes keeping careful track of their plants, all the way from the seeds’ log numbers, to the final destination. This not only helps the Huntleys track their yields, but is important in staying transparent with their customers.

Steve and Cathy spend a combined 20 hours working on their business. This involves a general 70-30 split of time spent in the farm compared to meetings or marketing activities; These proportions can change when Steve is actively working on winning new business.

Packaging

Steve’s customers have varied packaging requirements. Restaurants simply ask for the crops to be delivered in 1-2 lb bags. Retail outlets require much more specific packaging, including food-safe clamshells, UPC codes, barcodes, and printed labels with product specifications. This sounds complicated, but Steve encourages new farmers not to be intimidated: “There’s a lot more work getting started with a retail chain, but once it’s up and going, it’s really not that bad at all.”

As with other parts of the business, Steve is constantly looking ahead at ways to make his product better. With packaging, this means moving away from plastic as much as possible. To that end, Steve is working with the University of Michigan to develop plant-based clamshells, as well as with the store itself to find ways to display and sell the produce in a way that doesn’t require any plastic.

Delivery

Delivery is simple for Steve since all his customers are located nearby. He delivers to the grocery store three times a week, usually by walking the produce across the street, and then makes one-time weekly deliveries to his restaurant customers. Individuals purchasing online will come to the farm or to Steve’s house to grab their orders.

COMMUNITY

Many of the people in Steve’s life where justifiably surprised when he announced he was starting a farming business. However, once they learned more about the technology, the surprise turned into excitement.

The community reaction

“The more educated people get, the more interested they become in our kind of farming: local, no chemicals, and fresh.”

The customers’ reactions

“[My customers] are drawn to the taste and the smell–they take a bite and they love how fresh it is, the appearance of it is beautiful and green.”

LIFESTYLE

Not only does Enlightened Crops create a benefit for the community, but it has also had a positive impact in Steve’s life. Steve exalts, “For most of my life, I was working the 8-5, if I was lucky! The farm gives us a lot of flexibility which, as we slide into retirement age, was very important to us. I love working down at the farm–it’s quite and relaxing, not physically demanding, plus we can plan our day!”

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

07/18/19, 08:50 AM | Indoor & Vertical Farming | case study

Coworking Produce Subscriptions - Wework And Freight Farms Are Offering Members Fresh Greens

Unconventional partnerships often bring about the best ideas, and this rings true with a collaboration formed between WeWork and Freight Farms, in which members of the coworking space are able to receive fresh and locally grown produce

By: Ellen Smith - Jul 19, 2019

References: freightfarms

Unconventional partnerships often bring about the best ideas, and this rings true with a collaboration formed between WeWork and Freight Farms, in which members of the coworking space are able to receive fresh and locally grown produce.

This partnership follows the announcement that WeWork is making moves in the agricultural space, as the brand announced the WeWork Food Labs at the beginning of 2019.

In this particular partnership with Freight Farms, WeWork is aligning its brand with conscious consumerism and sustainability, allowing its members to subscribe to a weekly delivery of fresh greens delivered to WeWork locations.

The subscription program is available for $12.50 weekly, or $50 monthly, effectively bridging accessible food, with convenience and affordability

WEWORK X FREIGHT FARMS

A UNIQUE FARM-TO-OFFICE PROGRAM DIRECTLY AT YOUR WEWORK LOCATION

PROGRAM BASICS

Weekly delivery of fresh greens

Pick up at your WeWork location

Greens delivered less than 24-hours after harvest

$50/month (only $12.50 per box!)

Start date week of July 8th, 2019

24 deliveries between July and December

REGISTER TODAY

FREQUENTLY ASKED QUESTIONS

+ How long is the program?

Each session is 6 months (24 weeks) long. The program starts the week of July 8th through the week of December 16th. You’ll be setup to auto-renew and we’ll be sure to remind you with plenty of time if you’d prefer to cancel instead.

+ How does pick-up work?

For WeWork offices we’ll be delivering shares on Tuesday afternoons after harvesting that same morning. Shares will be delivered between 2 - 4 pm close to your community manager’s desk.

+ What if I’m out during pick-up?

Since we deliver only once a week, we will not be able to defer pick up on an individual basis (we will find alternate days and notify you if pick-up conflicts with a holiday). If there’s no way around picking up your share, we recommend gifting it to someone in your office.

+ How does payment work?

The cost for the full subscription is due upon sign-up. At $50/month, the full subscription cost is $300.

+ How frequently will I be charged?

Your subscription will automatically renew at 24 weeks unless you decide to cancel. If you don’t cancel in time, we will have already planted your shares of the greens and we won’t be able to retroactively cancel your subscription or issue a refund.

+ How does cancellation work?

All of the program dates are scheduled around the farm’s growing schedule. As an early adopter, you will have the option to cancel within the first month (July 8 - August 2) for a $250 refund and you would still receive shares through those four weeks. After August 2nd, there is no cancellation allowed. However, you would be able to transfer the remainder of your subscription to someone else at a WeWork office.

+ How do I provide input?

After your first month, we’ll begin soliciting periodic feedback to influence what we grow in the WeWork farm. You will see the direct impact roughly 2 months after providing feedback since that is the typical time it takes to grow new crops.

+ How can I get in contact with Freight Farms about my share?

For any and all questions, simply email weworkgrown@freightfarms.com and the WeWork designated member of our Grown Ops team will provide you with an answer.

+ How often will you be emailing me directly?

We will be reaching out… Once a week, to remind you about pick up and share recipes. Once a month, with reminders to collect feedback. As needed, if there’s any change to the pick up schedule. Towards the end of your subscription, with information about auto-renewal and the cancellation window. And ASAP, in response to any of your emails!

US (MA): Hydroponic Growing Graduates Learned With Lettuce, Seek Jobs in Cannabis

"The skills they learn in the (shipping containers) are transferable to the cannabis industry," Morse said.

Ernesto Hernandez Martin graduated Thursday from the Freight Farms Hydroponic Growing apprenticeship program at Holyoke Community College, having learned how to grow lettuce in the controlled environment of two shipping containers. But that’s not all he can grow.

“I’m looking forward to getting a job in the new industries, either in marijuana or in growing vegetables,” Hernandez Martin said while leading a tour of Freight Farms on Race Street in the city’s industrial Flats neighborhood and adjacent to the HCC MGM Culinary Arts Institute.

Neither college officials or Holyoke Mayor Alex Morse were shy Thursday about linking the hydroponic program with the city’s new marijuana industry and its need for skilled labor. They also said the program has the potential to help feed Holyokers who have trouble affording healthy meals.

"The skills they learn in the (shipping containers) are transferable to the cannabis industry," Morse said.

The college has no plans to grow anything but vegetables. The city, though, has embraced the newly legal cannabis industry.

Just this month, seed-to-sale marijuana company Trulieve Cannabis Corp., formerly Life Essence, bought a 150-year-old mill building at 56 Canal St. for $3.2 million with plans to build a 126,000-square-foot growing, processing, testing and retail operation there.

Source: MassLive (Jim Kinney)

Publication date: 7/1/2019

Square Roots Is Bringing NYC’s Freshest Herbs To Whole Foods

Three times a week, Square Roots delivers fresh herbs from our indoor farms in Bed-Stuy to grocers all over New York City. We’re now adding stops at Whole Foods Markets!

Square Roots | 06.28.19

Three times a week, Square Roots delivers fresh herbs from our indoor farms in Bed-Stuy to grocers all over New York City. We’re now adding stops at Whole Foods Markets!

Square Roots e-trike delivering hyper-local herbs to grocery stores across New York City and Brooklyn.

Herbs make cooking easy and delicious. Especially when they’re fresh and grown in the perfect climate—which Square Roots indoor farms guarantee, all year round. So we’re really excited to bring our herbs to Whole Foods shoppers!

Our expansion into Whole Foods has an impact way beyond the grocery aisle. National grocers who act locally have the opportunity to promote change in our food systems. For instance, when Whole Foods works with Square Roots, they’re not only bringing more local produce to New Yorkers, they’re also directly supporting a new generation of local farmers. The Square Roots Next-Gen Farmer Training Program is at the heart of our business. It creates opportunities for young people to become farmers and future leaders in sustainable, urban food communities—and trains them how to grow delicious food.

Initially, Square Roots will have chives and mint available at Whole Foods’ Gowanus and Williamsburg stores. We’ll be popping up at both locations to better get to know Whole Foods shoppers, talk to people about what they love to cook, and introduce people to herbs they may have never used before.

Come taste our herbs, and get to know a farmer, at one of our in-store pop-ups. And keep an eye out for our blue labels on your next Whole Foods trip!

Come by Whole Foods in Gowanus and Williamsburg to taste our herbs and get to know a farmer.

Whole Foods In-Store Events

Whole Foods Gowanus | Tues July 9 | 10 am - 2 pm

Whole Foods Williamsburg | Tues July 9 | 10 am - 2 pm

Whole Foods Gowanus | Tues July 9 | 3 pm - 7 pm

Whole Foods Gowanus | Thurs July 11 | 3 pm - 7 pm

Whole Foods Williamsburg | Tues July 15 | 10 am - 2 pm

Whole Foods Gowanus | Tues July 15 | 3 pm - 7 pm

Whole Foods Williamsburg | Fri July 19 | 10 am - 2 pm

Whole Foods Gowanus | Fri July 19 | 10 am - 2 pm

Whole Foods Williamsburg | Mon July 22 | 3 pm - 7 pm

Whole Foods Gowanus | Wed July 24 | 3 pm - 7 pm

Whole Foods Williamsburg | Sat July 27 | 3 pm - 7 pm

Whole Foods Williamsburg | Mon July 29 | 10 am - 2 pm

Whole Foods Gowanus | Mon July 29 | 3 pm - 7 pm

Find Square Roots herbs at a store near you via our store locator and subscribe to our newsletter for updates.

Futuristic Farming Takes Root In Georgia

Agriculture is Georgia’s number one industry, but there is one local farmer innovating the way growers do business in the Peach State

by: Martin Staunton

June 27, 2019

SAVANNAH, Ga. (WSAV)

Agriculture is Georgia’s number one industry, but there is one local farmer innovating the way growers do business in the Peach State.

Grant Anderson, owner of BetterFresh Farms, says traditional farming goes back countless generations for his family in Effingham County. But many family, friends, and neighbors near Guyton thought he was taking a huge risk when he walked away from his job in finance to start BetterFresh Farms two years ago.

“A lot of them thought I was a little crazy,” Anderson said with a chuckle, recounting their reaction to his decision to grow lettuce hydroponically.

The Agriculture Commissioner’s Office reports BetterFresh is the first commercial hydroponics farm to be established in Georgia. Anderson is investing in a new hydroponics container that’s state-of-the-art and it will double his lettuce production.

The new equipment was built in Canada by a company called Local Food Champions. Jason Carrier, President and owner, was on hand for delivery, his first to the Peach State.

“This is absolutely the future and this is bigger than all of us,” Carrier said. “So we are hoping we can get out there and feed some people. Farm to table in record time. This is farming for everybody.”

Hydroponics requires no soil, 90% less water than pivot irrigation, and eliminates the need for chemicals to control weeds and insects. Anderson only needed enough land to place two growing units — each is roughly the size of a shipping container — to bring this futuristic farming method to Effingham County.

“It doesn’t require the soil. It just requires the moisture to germinate,” he explained. “From there, we give it a nutrient recipe that supplies it enough nutrient to grow for a few weeks until it matures to a point where we can move it into our towers.”

The grow towers are the real game-changers for farming when it comes to harvest.

“It takes the seasonality out of harvesting, which is huge from a farm operation, as far as being able to cash week-in and week-out every year and not worry about the bumper crop or the drought that may impact your crop,” Anderson said. “We have consistent volume each week.”

BetterFresh Farms is moving operations to Candler County after joining a partnership with the City of Metter and Georgia Southern University, launching an Agri-Business Incubator. It’s got the backing of the Agriculture Commissioner’s Office under their “Georgia Grown” branding.

“Georgia Grown is going to be a tremendous partner, as far as the marketing of our product and helping people becomes aware of how we do what we do,” said Anderson.

City leaders in Metter say their new partnership with Anderson does more than just bring his farm to their town, it helps them lead the way in terms of one of the future paths for farming. Heidi Jeffers, the Tourism & Business Development Director for the City of Metter, says hydroponic farming can be a powerful weapon in the fight against hunger.

“It changes how we feed our people in Georgia and all over the United States. Hydroponics is a great technology that’s coming about with some great new changes and we are certainly excited to have this in Metter,” Jeffers said, adding that the city is proud to partner with a farming pioneer in Georgia.

“We’re excited to be on the cutting edge of hydroponics,” she said. “With this, it’s completely organic, uses less water, and really changes, a game-changer for this type of produce.”

Thinking of his ancestors, Anderson believes it might have taken some real convincing to bring them onboard when it comes to launching BetterFresh Farms, but he says he’s sure they are proud he’s carrying the family tradition in agriculture forward.

“It may not be the way my ancestors would have envisioned farming working out, but I feel like, with time, we’re all supposed to try and improve,” he said. “I feel like this was my opportunity to maybe pick the torch up and run with it.”

Georgia grown hydroponic crops a hit with Savannah chefs

The choice of lettuce as a crop was a no brainer for Anderson, given his proximity to Savannah and the hundreds of restaurants in business in the Hostess City.

“Virtually every restaurant needs lettuce,” Anderson said. His clients rave about his product being locally grown and organic.

Chef Andrew Wilson with the Emporium Kitchen and Wine Market is most pleased to have a produce vendor who can customize his crop to meet the needs of his recipes.

“The really cool thing is that, not only can say that we are supporting a local farm, but I can also say that they are growing what I ask them to grow specifically for this menu, which in turn means specifically for you the guest. It’s like you’re getting exclusivity,” Wilson explained.

One of Savannah’s newest pizza parlors, Squirrel’s Pizza on Bull Street, is nuts about BetterFresh lettuce.

“It flies outta here. The product that comes in, we can barely hold on to it,” said Jimmy Powell, Managing Partner with Squirrels. “We’re making phone calls the next day asking for special deliveries and requests.”

Anderson says his customer list is growing. He adds that he’s never missed a delivery in two years, and even though he’s up against giants in the industry — he likes his chances for future growth.

“Personally, I believe I have a competitive advantage, even if I am a small fish in a big pond, so to speak,” Anderson said with a grin on his face and a gleam in his eye.

Learn more about his work at betterfreshfarms.com

Transforming Parking Garages to Serve On-Demand Economy

Miami-based parking network REEF Technology has announced plans to transform parking lots and garages across the country into tech-forward hubs geared towards the on-demand economy

June 28, 2019

Miami-based parking network REEF Technology has announced plans to transform parking lots and garages across the country into tech-forward hubs geared towards the on-demand economy.

The company owns more than 4,500 parking facilities across the United States, and has now expanded to offer space for businesses specializing in last-mile and delivery-only food services, bike- and scooter-rental stations and ride sharing. The company also plans to include micro fulfilment centers and spaces for pop-up businesses at its properties.

“At REEF, we believe a parking lot should be more than a place to store your car.” said Ari Ojalvo, CEO of REEF Technology. “Rather, it can be a hub for the community, connecting people to the businesses and services that keep us all moving forward. REEF will completely transform what people, cities and businesses can expect from parking garages, in the same way the introduction of smartphone apps completely changed the way we think about cellphones.”

A key component of the company’s plans involves last-block, delivery-only kitchen facilities for restaurant partners. Housed in proprietary containers, REEF Kitchens allows restaurant partners to open and quickly expand their businesses, while also providing faster delivery to customers. Each container is able to accommodate from one to five restaurant brands or concepts. Restaurants can run operations directly, or contract with REEF to staff and prepare delivery-only menu items. The concept is already active in Miami and London, with plans to open several hundred additional kitchens across North America and the U.K.

“There’s explosive growth and opportunity in the food delivery business,” said Aziz Ihsanoglu, head of strategy at REEF Technology. “Based on the success of our REEF KITCHENS in the U.K. and Miami, we’re confident restaurants and consumers will enjoy the possibilities our business creates.”

Automated Containers Make Organic Urban Farming Feasible

Commercial containers such as those from Seedo would expand the potential for urban farming to anywhere, anytime. Plants can be cultivated 24/7, regardless of location

The future of agriculture can be found in commercial containers, in which plants can be grown hydroponically.

Hydroponic farming has many benefits, including saving the resources involved in soil cultivation and avoiding the uncertainty of weather conditions, according to Seedo, an innovator in the field of commercial growth containers.

Approximately 40 percent of the costs of produce in large city supermarkets are used to cover logistics and shipping. Commercial containers such as those from Seedo would expand the potential for urban farming to anywhere, anytime. Plants can be cultivated 24/7, regardless of location.

For example, the automated urban farm is ideally suited to the growing market for medical cannabis and medical cannabis products. Seedo is the technology behind the world's first automated medical cannabis farm, which will yield significantly more plants than traditional controlled greenhouses.

Another opportunity for the Seedo technology is to improve the agriculture of at-risk countries, where global warming and other concerns threaten consistent farming and food production.

In some areas, farmers can use Seedo equipment and technology for growing not only medicinal herbs, but also greens such as lettuce, kale, and wheatgrass; herbs such as parsley, dill, and basil; and vegetables such as cherry tomatoes and bell peppers, and even strawberries. In the home, individuals can set up a small unit that grows plants easily and effectively without intervention.

Seedo, a pioneer in agriculture and technology with 20 years of experience, is now delivering indoor growth systems to homes and businesses across the country. Currently, Seedo has sold more than 3,000 home units through pre-orders.

The Seedo products use artificial intelligence software to control and monitor plant development from the moment the seed is planted. The software tracks each plant's development, and responds by taking action to optimize growth. The hermetically sealed systems are designed to yield consistent results regardless of the local climate.

Growers need only to plant seeds or seedlings and monitor the growth process via the Seedo app.

Other features of the Seedo system include a unique lighting system that self-adjusts based on an individual plant's stage of growth, and a smell-proof cover with built-in CO2 cartridges to prevent smell leaks.

Equally important to note is that all produce cultivated with Seedo's technology (both home and commercial) is pesticide-free, of high quality, and has a significantly extended shelf life.

Visit seedo.com for more information about investing in the growth industry of indoor gardening, and to learn more about the Seedo technology and products.

Seedo is a publicly traded company with the ticker symbol OTCQB:SEDO.

Micro Lab Farms in Needles, CA Helps Individuals Get Started With Modular Farming With Shipping Container Greenhouses

America’s medical cannabis industry is growing at a steady pace, with marijuana sales expected to amount to $50 billion in the upcoming decade

America’s medical cannabis industry is growing at a steady pace, with marijuana sales expected to amount to $50 billion in the upcoming decade. Micro Lab Farms is a California based company that empowers anyone to efficiently launch or expand a high-quality marijuana operation.

Needles, CA - America’s medical cannabis industry is growing at a steady pace, with marijuana sales expected to amount to $50 billion in the upcoming decade. This explosive growth has been driven largely in part due to all the legislative changes around the herb that have taken place recently. Entrepreneurs looking to capitalize on the numerous business opportunities can jump into the “green rush” and get started almost immediately with today’s technology. Micro Lab Farms is a California based company that empowers anyone to efficiently launch or expand a high-quality marijuana operation.

Micro Lab Farms is known for their cutting-edge, eco-friendly growing systems which are optimized for productivity and profitability. Entrepreneurs from all backgrounds are looking into container farms from Micro Lab Farms to streamline the start-up process. Micro Lab Farms in California has gained recognition for their turnkey solutions that provide a full-featured environment to grow in any climate and any season.

These plug and grow systems are designed for automation and easy operation, allowing users to begin generating revenue almost immediately. Micro Lab Farms retrofits shipping containers and specifically modifies them to provide a controlled environment that allows for year-round production. A spokesperson for their company said, “Our grow lab is an affordable, scalable, efficient, and automated system. As a full turnkey solution, a grower can be up and running in a short amount of time. The return on investment can be achieved in as little as 6 months.”

Micro Lab Farms has developed ecological grow labs that utilize 90% less water and 80% less fertilizer. Since these are food-grade containers, no pesticides or pollutants are required to harvest high-grade medicinal cannabis. The California company offers soil, soilless, and hydroponic high yield and low impact solutions. Their 20’ and 40' shipping container greenhouses come equipped with an LED expert series lighting system, a rolling table system, a reverse osmosis water purification system, an HVAC system, a steel man door, and both, a dehumidifier and humidifier. Micro Lab Farms can develop a personalized solution to fit each individual’s growing needs, as they can include additional features such as clean rooms, shelving systems, prep stations, additional sensors and controls, as well as flower, clone and drying labs. Their grow labs are modular, stackable, and can be self-contained with solar and natural gas energy solutions.

Each grow lab is a completely secure and monitored environment. They are equipped with a mobile device compatible cloud-based control system, allowing users to seamlessly oversee their product from seed to harvest, through Micro Lab Farms’ remote monitoring and controlling app. The app provides real-time data of all the key components of the farm including the air, water, humidity, nutrients, and plant growth. Giving users clear visibility and maximum control over every aspect of their grow operation and eliminating all surprises.

Micro Lab Farms is located at 3353 Needles Hwy, Needles, CA 92363. For inquiries, contact their team via phone at (951) 266-6096 or via email at info@microlabfarms.com. Visit their website for additional information regarding their services.

Tech Farming Is Making Its Way To Grand Rapids, Michigan

Square Roots, an urban indoor farming company, will bring its Next-Gen Farmer Training Program to Grand Rapids in September. The goal of the program is to train young people in indoor urban farming and grow localized food and herbs year-round in technology-driven environments

Partnering With Gordon Food Service, Square Roots

Aims To Train Young People In Indoor Urban Farming

June 21, 2019

| By Danielle Nelson |

Jacque Kirila and Em Helle harvest sage at a Square Roots indoor farm, which is comprised of repurposed shipping containers. Courtesy Square Roots

One company is hoping to shake up the landscape of farming.

Square Roots, an urban indoor farming company, will bring its Next-Gen Farmer Training Program to Grand Rapids in September. The goal of the program is to train young people in indoor urban farming and grow localized food and herbs year-round in technology-driven environments.

The company will partner with Gordon Food Service to distribute food that is grown by farmers enrolled in the training program to its consumers and retailers across the country.

“Customers want an assortment of fresh, locally grown food all year-round,” said Rich Wolowski, CEO of Gordon Food Service. “We are on a path to do that at scale with Square Roots and are excited to be the first in the industry to offer this unique solution to our customers.”

According to Square Roots, 10 full-time farmers will be chosen through an application process to learn all aspects of farming, from the planting of the seeds to the selling of the produce. They will receive a wage, subsidized health care coverage and other benefits.

The year-long program enables farmers to study the molecular level of the plant as it grows, get hands-on experience with the business side of farming so they can pursue a start-up indoor urban farm and get involved with the community.

Square Roots’ training program was created with advice from experts in farmer education, controlled environment agriculture, regenerative agriculture and urban agriculture, including Glynwood, New York University, Cornell University and the University of Arizona. There will be guest lecturers who will talk about farming and entrepreneurship. There also will be workshops, which will cover a variety of topics, such as pest management practices to real food entrepreneurship frameworks.

The farmers will work in indoor vertical farms that are constructed in 10 specially designed Square Roots shipping containers that will occupy less than 2 acres of Gordon Food Service’s 50-acre headquarters site in Grand Rapids, but it is expected to produce more than 50,000 pounds of herbs annually. Each container will have its own controlled climate that is optimized for growing certain crops. The cloud-connected modular farms will have hydroponic growing systems to water the plants.

“Because we grow in a completely closed environment, we have full control over each climate parameter — from CO2 in the air to the number of hours of light,” Square Roots officials said. “We research the best natural climate for a certain variety of plant, recreate it inside the farm and grow the best tasting produce 365 days a year.”

Gordon Food Service will not only provide a place for urban indoor farms, but farmers from the training program will work with the food service company. The farmers are expected to grow food on a consistent basis to meet the standard of Gordan Food Service and the demand of its consumers.

Additionally, Next-Gen farmers will have the opportunity to represent Square Roots at customer-focused engagements, marketing activities and community events, where farmers can connect directly with customers.

The Next-Gen Farmer Training Program was started in Brooklyn, New York, in 2016. So far, 16 farmers have completed the program, according to Square Roots. Some farmers in the program have either started their own urban farming businesses, taken jobs at companies in urban agriculture or moved into permanent positions on the Square Roots team.

According to the Michigan Department of Agriculture and Rural Development, the food and agriculture industry contributes $104.7 billion annually to the state’s economy and accounts for about 22% of the state’s employment.

Square Roots said its end goal is to be a pathway for future farmers in the urban farming industry in cities around the world. More information can be found at squarerootsgrow.com/program.

Danielle Nelson

Danielle Nelson is a Grand Rapids Business Journal staff reporter who covers law, startups, agriculture, sports, marketing, PR and advertising and arts and entertainment. She is also the staff researcher who compiles the weekly lists.

Email: Danielle at: dnelson@grbj.com

Follow her on Twitter @Dan_Nels

TAGS GORDON FOOD SERVICE / NEXT-GEN /SQUARE ROOTS

Program Provides A Low-Cost Way For Businesses To Obtain The Advanced GrowPod Cultivation System

CORONA, Calif.

June 18, 2019 /PRNewswire/

GP Solutions (GWPD), a leading developer of automated micro-farms, announced it is now offering financing to provide businesses with a quick, low-cost pathway to begin growing profitable herbs and vegetables with the advanced "GrowPod" system.

GrowPods are portable, automated, perfectly-tuned cultivation environments that use significantly less space and water than conventional methods. The proprietary plug-and-play system allows a business to have a sustainable, efficient, and environmentally-friendly farm located virtually anywhere.

GP Solutions' new financing plans offer a variety of options for businesses to enter the highly profitable world of micro-farming.

GrowPods can be customized to provide the perfect environment for a wide variety of cash-crops, herbs and vegetables.

The system features a number of advanced technologies, including optimized photosynthesis, high level security, 24/7 remote control, video monitoring via a cloud-based platform, and precision environmental controls for temperature, humidity, and other vital factors.

Unlike other growing systems that use fixed greenhouses or require enormous capital for large indoor "warehouse farms," GrowPods are modular, scalable, indoor micro-farms that can be placed virtually anywhere. The pods have been shown to outperform other methods of cultivation, providing quicker harvest times with higher yields and greater consistency.

GrowPod farmers are provided with data, insights and other tools to further refine and improve their crops. As a sealed environment, GrowPods give farmers the ability to keep crops and strains separated, eliminating contaminants, pathogens, and pesticides.

For more information on GP Solutions' financing options or the GrowPod system, visit: www.growpodsolutions.com, or call (855) 247-8054.

ABOUT GP SOLUTIONS:

GP Solutions developed "GrowPods" – portable, modular, automated indoor micro-farms that provide optimum conditions for plant cultivation with total environmental control.

Forward-Looking Statements

This release includes predictions or information that might be considered "forward-looking" within securities laws. These statements represent Company's current judgments, but are subject to uncertainties that could cause results to differ. Readers are cautioned to not place undue reliance on these statements, which reflect management's opinions only as of the date of this release. The Company is not obligated to revise any statements in light of new information or events.

Connect:

Email: info@growpodsolutions.com

Website: www.growpodsolutions.com

Facebook: facebook.com/GrowPodTechnology

Twitter: @GrowPodSolution

Media:

hello@inov8.us

Software For Farming Inside A Shipping Container!

Welcome to the world of hydroponic farming – growing vegetables and fruits, using water as the main source of ingredients and nutrition

By SiliconIndia | Tuesday, 18 June 2019, 05:51 Hrs

Agriculture is responsible for more than 25 percent of global greenhouse gas emissions (United Nations Food and Agriculture Organization) About 30 to 40 percent of produce (vegetables and fruits) is lost because of spoilage while transporting (Local Roots, California) Can we do something about this? Is it possible to reduce the emission and spoilage?

Additionally, can water consumption be cut down by 95 percent, yes, startling 95 percent. Above all, in megacities like Boston, Chicago, and New York where outdoor farming is done only during summer months, how nice would it be to garnish your salad with fresh leaves of lettuce in February – in the middle of winter? Welcome to the world of hydroponic farming – growing vegetables and fruits, using water as the main source of ingredients and nutrition.

While this proven technology has been in use for a long time, information technology has given it a big fillip. It has also brought the farms to downtown, gated communities and big commercial complexes. Conventional farming has many disadvantages. It is not possible to maintain uniform soil conditions. The use of fertilizers, pesticides and herbicides is almost inevitable. In the long term, these not only add to the cost, but are also harmful to health. Even the certified organic growers use organic pesticides. Seasons control the produce. Water consumption is high. There could be loss due to drought, floods and high temperatures. Animals can trample and damage the crops. Birds eating the crops will help in crosspollination and dispersion of seeds but may also transmit bacteria.

The supply chain involving fresh produce is time-consuming and expensive. On the average, in USA, a head of lettuce travels about 2000 miles before it is consumed. It results in putrefaction, loss of taste and reduction in nutritional value. One cannot guarantee consistency in quality. Variation in the types of produce is limited. Genetically Modified Plants are not that much welcomed. Container farming is the use of shipping containers (20, 40, 53 feet long) to do farming. Those ‘innocuous looking giant boxes’ can be parked in a corner of the parking lot while lettuce, greens and strawberries are growing inside.

Local Roots is a small company (headquartered in Vernon, California) engaged in hydroponic farming inside a shipping container with extensive use of information technology to maximize when possible and optimize when needed to deliver high quality fresh produce throughout the year. They call these TerraFarms. People can see light across the entire visible spectrum but for photosynthesis, plants need light in the range of 400 – 700 nm wavelengths. The most important ones are blue light (430 to 450nm and red light 640 to 680nm). The company uses custom-engineered LED lights to select the wavelengths and the intensity of light needed. Thus, by altering these early in the growth phase, they can even change the color of the plant. By using wireless sensors to monitor and control the temperature, humidity, lighting and nutrient level, the company increases productivity significantly.

With efficient design, they are able to recycle water up to 99percent, a very significant saving. Using computer vision and deep learning techniques, a neural network based software monitors and diagnoses plant health. Thus, prophylactic measures can be taken very early to ensure good and consistent quality of yield. No herbicides or pesticides are used because bugs and weeds have a very low probability of entering the container. A 40-foot container can produce 4000 heads of lettuce every ten days. In traditional farms, it takes about 55- 70 days to grow lettuce. 2 These containers can be parked anywhere and their numbers increased incrementally. Thus, fresh produce is available almost at or vey near the place of consumption; thereby eliminating transportation costs while ensuring high quality and good taste.

The company intends to use solar or wind power to minimize the use of electricity (generation of which contributes to global warming). Tiger Corner farms in South Carolina is another company specializing in aeroponics type of farming inside a shipping container. Aeroponics refers to the growing of plants in an air or mist environment while in hydroponics, the mist is replaced by water solvent and mineral solutions; both do not use soil. NASA uses aeroponics to grow plants in space station. Tiger Corner Farms has received Good Agricultural Practices (GAP) certification from the U.S. Department of Agriculture for all its operating container farms.

Boxcar central is a company involved in supplying the controls, sensors and the software to monitor and maintain the farm. Light, air temperature, water temperature, water flow rate, pH, CO2 level, nutrients, are monitored. They can be controlled by a Smartphone or a tablet and crops can be viewed on a webcam. Every 10 minutes, mist from hundreds of tiny sprayers is sprayed on the plants’ roots for 3 to 4 seconds. The software tracks all activities from “seed to sale”. Thus, algorithms can specify the amount of nutrients, wavelength and intensity of light, and humidity levels needed for different types of plants. Ritz Carlton Hotel in Naples, Florida uses a container parked in its parking lot to grow lettuce and microgreens.

A company called CropBox manages the container farm. The chef picks the fresh lettuce and greens from the farm. It is the first hotel in US to do so. Freightfarms, Growtainer, and Containerfarm are a few companies that specialize in fitting a shipping container with sensors, and converting it to a farm. Each farm takes approximately 15 working days to build from start to finish. Each container costs about $85000 but it is not high compared to farm equipments that are needed. What can beat garden fresh lettuce for salads and plump strawberries for dessert?

By: Dr. S. Chellaiah, Professor of Systems, Loyola Institute of Business Administration (LIBA)

SOLD - December, 2015 Freight Farm Premium - Computer Controlled Hydroponic Grow System - Southern Connecticut - $37,500

December, 2015 Freight Farm Premium Leafy Green Machine (LGM)

Manufacturer - Freight Farms

Location - Southern Connecticut

Price - $37,500

Description

Original owner well maintained December, 2015 LGM.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

US: South Carolina: Hamby Catering And Vertical Roots Team Up To Bring Locally Grown Lettuce To An Event Near You

Jun 12, 2019

Posted by Sara Srochi

As of Mon. June 10, Vertical Roots has partnered with Hamby Catering & Events, Charleston’s oldest local catering company, to be their exclusive lettuce provider in a shared effort to increase the amount of locally grown food consumed in Charleston.

Vertical Roots is a hydroponic farm that produces fresh, chemical-free lettuce year- round in recycled shipping containers. Perhaps the most exciting aspect about this new partnership is the environmental impact it has.

Vertical Roots is only 16 miles away from the catering company's home base in West Ashley. By teaming up with this little new age farm, Hamby is taking steps in being environmentally conscious (goodbye imported products delivered from hundreds of miles away) while improving the quality of their produce at the same time.

The farm is able to produce above average veg because of their high-tech growing method: seedlings grow in automated "growing pods," that are climate controlled, which reduces excess water (in fact, it uses about 98 percent less water than traditional agricultural methods). The pods require no soil and use LED lights to mimic sunlight, so lettuce can grow inside all year long without any interference from mercurial Mother Nature.

“Being part of the Charleston community for 40 years makes it all the more important for us to support the community that has so graciously supported us,” said Hamby Catering President Candice Wigfield in a press release. Vertical Roots lettuce will be used for all Hamby catered-events, as well as the Market at Hamby, located at their West Ashley location.

You can find Vertical Roots lettuce (we love the Bibb) at Harris Teeter, Food lion, Whole Foods, Lowes Foods, Earth Fare, and soon, Publix.

We Are EXCITED To Introduce You To Our Newest Partner! Meet DANI!

A Non-Profit Organization that creates opportunities for adults with physical and/or cognitive challenges so that they can participate fully as valued members of the community and enjoy a meaningful and dignified quality of life! DANI offers vocational training and the partnership with Ripple Farms provides employment to adults with disabilities.

We Have Helped To Create Their Newest Opportunity! A Vertical Hydroponic Microgreen Farm! The Produce Is Now FOR SALE On 100km Foods!

Click the link to learn more about DANI! https://dani-toronto.com/

Our Micrgogreens Are Available Through 100Km Foods!!

Chefs, Restaurants, Caterers! You can now add Ripple Farms Microgreens to your 100KM Foods Order!

Pea Shoots, Radish, Fenugreek, and Kale are available!

Our Vertical Farming Bootcamp was a SUCCESS!

Thank you to all of our participants and supporters!

Interested in participating in future Bootcamps? Send an email to opasut@ripplefarms.ca to make sure you get Bootcamp updates!

GP Solutions Installs State-of-the-Art Growth Chamber at University of California, Riverside

Specially configured “GrowPod” will be used to expand knowledge into advanced agricultural methodologies

Corona, CA – May 14, 2019 – GP Solutions (OTC: GWPD), developer of GrowPod modular automated micro-farms, announced it has installed one of its state-of-the-art Growth Chambers at the University of California, Riverside. The growth chamber will be utilized for agricultural and horticultural research at the University.

Grow Pod Solutions developed the specialized system to meet the need for a large walk-in growing system that offers researchers a precision-controlled environment to conduct sophisticated research at laboratories and universities across the country.

Grow Pod Solutions offers one of the finest walk-in growth chambers available, and features a number of advanced technologies, including optimized photosynthesis, high level security, 24/7 remote control and video monitoring via a cloud-based platform, and precision environmental controls for temperature, humidity, and other vital factors.

The GrowPod system provides an optimum solution for research with a clean environment that is free of contaminants, pathogens, and pesticides.

The University of California, Riverside, College of Natural and Agricultural Sciences, is one of preeminent institutions of its kind in the world. Known for its cutting-edge research, the campus is at the forefront of ag-science and operates several prominent institutions, including The California Agriculture and Food Enterprise, The Citrus Research Center, The Center for Conversation Biology, and The Center for Integrative Biological Collections.

GP Solutions is proud to be a provider of technology and expertise to the University, and looks forward to becoming an integral partner in the ongoing development of advanced cultivation methodologies.

For more information, visit: www.growpodsolutions.com, or call (855) 247-8054.

ABOUT GP SOLUTIONS:

GP Solutions is at the forefront of clean agriculture. The company developed “GrowPods” – innovative indoor clean micro farms that provide optimum conditions for plant cultivation with total environmental control. GrowPods are modular and automated for ease of use and scalability.

Forward-Looking Statements

This release includes information considered “forward-looking” within securities laws. These statements represent Company’s current judgments, but are subject to uncertainties that could cause results to differ. Readers are cautioned to not place undue reliance on these statements, which reflect management’s opinions only as of the date of this release. Company is not obligated to revise statements in light of new information.

Connect:

Email: info@growpodsolutions.com

Website: www.growpodsolutions.com

Facebook: facebook.com/GrowPodTechnology

Twitter: @GrowPodSolution

First Clarke Freight Farm Harvest in Massachusetts Exemplifies the Importance of Fresh Food and Superior Food Preservation

Source: Clarke

05/07/19

Clarke, New England’s Official Sub-Zero/Wolf/Cove Showroom and Test Kitchen, once again exemplifies kitchen industry innovation with its investment in a 40-foot self-contained hydroponic farm to exemplify the importance of fresh food as part of a healthy lifestyle. “Our farm was delivered outside our Milford, Massachusetts showroom eight weeks ago and our farmer Francesca Mazzilli has been planting and tending to our crops inside the corrugated shipping container ever since,” said Sean Clarke, president of the family-owned company. “We are really excited about our first harvest happening on May 7th.”

Built by Freight Farms, an innovative Boston-based company launched in 2010, Clarke’s exciting initiative will allow every showroom visitor to go home with a gift of fresh butter bibb lettuce. The farm will also supply fresh produce (delicately preserved in Sub-Zero refrigerators) to be used by the Clarke Culinary Team for cooking demonstrations, events and daily tastings in all three of its showroom locations (Boston Seaport, Milford, MA and South Norwalk, CT.) In addition, every Clarke employee will enjoy a weekly share of the produce to take home for their own families.

Farmer Francesca’s first harvest will include a lettuce mix, mint, parsley, thyme, swiss chard, mixed radishes, red veined sorrel, sorbet mix viola and arugula. She will continue to add new crops to the mix and harvest fresh vegetables every week throughout the year.

“When I learned about Freight Farms, I could think of no better way to exemplify the Sub-Zero and Wolf mission of superior food preservation and preparation than launching a year-round Freight Farm right here,” said Clarke. “As New Englanders, we crave fresh food year-round and many of our own employees can’t wait to get back into their gardens each year. Now we will have fresh produce all year round to cook with in our showrooms and share with customers and employees.”

The arrival of Clarke’s Freight Farm launched their “Live Deliciously” initiative to encourage all members of the design community and the homeowners they serve to remember that kitchens are about gathering to enjoy fresh, delicious meals. As the icing on the cake, Clarke is powering the farm with the solar panels that provide electricity for their entire Milford complex. “We achieved net zero electrical consumption in Milford when we installed 2304 solar panels on our Milford headquarters in 2011,” said Clarke. “It makes it all the more satisfying that we are now also able to power a hydroponic farm from this source.”

For more information on Clarke’s “Live Deliciously” campaign featuring Sub-Zero, Wolf and Cove appliances, visit clarkeliving.com.

About Clarke

Clarke is New England's Official Sub-Zero & Wolf Showroom and Test Kitchen, with locations in Milford, MA, Boston Seaport and South Norwalk. Clarke's hallmark is an exclusive Appliance Test Drive, where homeowners can actually cook on Wolf appliances to best select the models that will enhance their lives. Visitors can see more models of Sub-Zero and Wolf at Clarke than anywhere else in New England.

Clarke sells its brands through a network of authorized retail dealers in all six New England states. In addition, the company also offers Clarke Customer Care, a dedicated Sub-Zero, Wolf, Cove and ASKO repair service that has earned them top customer satisfaction ratings in the U.S. For more information, visit clarkeliving.com.

Indoor & Vertical Farming, Processing & Supply Chain | Containers

USDA National Organic Program Holds Firm Against Efforts to Impose Special Restrictions Against Growers Using Container and Hydroponic Methods

Groups opposed to certification of production systems incorporating containers and hydroponics failed in their most recent attempts in the last few weeks to convince the USDA and the National Organic Standards Board to initiate the process for new standards for those production systems.

Several groups including the Real Organic Project, the Organic Farmers Association, the National Organic Coalition and others presented testimony at the recent National Organic Standards Board meeting in Seattle and in recent press campaigns to call for a moratorium on certifications for organic production systems using containers and hydroponics. The moratorium would be followed by the revocation of certification for existing operations. However, if the USDA does not agree to those terms, the groups insist that new more restrictive regulations must be drafted, implemented and then applied to container and hydroponic organic production systems.

Those groups have begun the tactic of inventing hypothetical scenarios about production practices, and they then ask for clarification from USDA regarding the legality of such an approach. USDA indicated that they would not likely give opinions regarding hypothetical situations, but USDA will look at specific cases and instances of operations performing actual activities to review for compliance. The CSO expects that opponents of certifications for containers will refer operations for review, and USDA will respond regarding those practices.

However, this activity will not be unofficial rule making or regulations that are created without any opportunity for public input. USDA does not have the authority to implement standards through the guidance process that would create special restrictions for container operations. Any new restrictions would have to go through the formal rule making process.

Organic producers must follow all applicable USDA standards for organic production systems. Specifically, growers need to show that their production system is managed to respond to site-specific conditions by integrating cultural, biological, and mechanical practices that foster cycling of resources, promote ecological balance, and conserve biodiversity.

Here are the requirements copied from 7 CFR 205.201 that lay out the elements required to be included in the organic production and handling systems plan.

§205.201 Organic production and handling system plan.

(a) The producer or handler of a production or handling operation, except as exempt or excluded under §205.101, intending to sell, label, or represent agricultural products as “100 percent organic,” “organic,” or “made with organic (specified ingredients or food group(s))” must develop an organic production or handling system plan that is agreed to by the producer or handler and an accredited certifying agent. An organic system plan must meet the requirements set forth in this section for organic production or handling. An organic production or handling system plan must include:

(1) A description of practices and procedures to be performed and maintained, including the frequency with which they will be performed;

(2) A list of each substance to be used as a production or handling input, indicating its composition, source, location(s) where it will be used, and documentation of commercial availability, as applicable;

(3) A description of the monitoring practices and procedures to be performed and maintained, including the frequency with which they will be performed, to verify that the plan is effectively implemented;

(4) A description of the recordkeeping system implemented to comply with the requirements established in §205.103;

(5) A description of the management practices and physical barriers established to prevent commingling of organic and non organic products on a split operation and to prevent contact of organic production and handling operations and products with prohibited substances; and

(6) Additional information deemed necessary by the certifying agent to evaluate compliance with the regulations.

(b) A producer may substitute a plan prepared to meet the requirements of another Federal, State, or local government regulatory program for the organic system plan: Provided, That, the submitted plan meets all the requirements of this subpart.

Your Membership and Activity Still Needed

The efforts of growers and other members of the organic community like yourself helped to create more regulatory certainty and to safeguard your rights to select the most appropriate growing methods in your organic operations continues.

Join the CSO if you have not done so already. Our sustained efforts on behalf of the hydroponic, aquaponics and container industry around the country and in Washington, DC rely on dues from farming operations like yours.

Vertical Farming For Cannabis Gets Trial Run in Langley

Leo Benne, chief growing officer of Zenabis, with the converted shipping container that will become a testbed for a vertical cannabis farm. (Matthew Claxton/Langley Advance Times)

Grower Zenabis Will Start With Industrial Hemp And May Move to

Commercial Marijuana

Jun. 6, 2019

Zenabis, which merged with longtime Langley greenhouse firm Bevo last year, has received a hemp cultivation license from Health Canada, with growing to take place in Langley, Pitt Meadows, and Aldergrove facilities.

“We expect the seed to come in this week,” said Leo Benne, chief growing officer for Zenabis.

A small portion of that seed will be planted not in one of the greenhouses facilities, but in a converted shipping container, as a test on whether cannabis can be vertically farmed.

Bevo has already helped develop a vertical farming system through CubicFarms, a Pitt Meadows-based spin off.

Vertical farming involves growing large amounts of crops on small amounts of space, indoors, and usually without any soil.

Plants are reared in racks, stacked as high as the building or container can accommodate, and grown either hydroponically or aeroponically.

Energy efficient LED lights allow the plants to grow 24 hours, seven days a week, in any weather.

In theory, the cost of the equipment and intensive rearing is offset by the ability to grow non-stop and to place the growing site much closer to the end-consumer. Rather than trucking lettuce from California or Mexico, it could be grown just a few miles outside of Canadian cities and shipped just a few kilometres.

The hemp vertical farm is just a test at this point, said Benne. A single converted shipping crate has been hauled into one of the Zenabis greenhouses in Langley and will be ready for its test run at about the same time as 20 acres of industrial hemp is planted in the three facilities, from Langley to Pitt Meadows.

While most crops planted in vertical farms are extremely low-growing, allowing for many racks close together, cannabis is usually a tall-growing crop.

Benne said that a combination of the plants chosen and growing practices is expected to keep the plants shorter for the vertical farm project.

If the project goes well, vertical farming facilities could be used for growing commercial marijuana, said Zenabis CEO Andrew Grieve.

The industrial hemp isn’t being grown for commercial marijuana sales. Instead, the hemp will be processed into CBD oil, fibre, or other derivatives. The project is separate from Zenabis’s plans for growing commercial cannabis in Langley.

While Langley’s other large cannabis cultivator has caused controversy in Aldergrove over smell issues, Benne doesn’t believe that will be an issue for Zenabis.

“We’re doing things a lot differently,” he said. “First of all, we’re constructing a closed greenhouse facility. We’re able to keep most of the air inside the greenhouse.”

There are to be no roof vents, which should not only control odour, it helps the growers control humidity and other issues.

“Because we don’t have that exchange of air with the outside, we don’t have a lot of pest issues,” he said.

Air exhaust is to be controlled through carbon filters, and if those aren’t sufficient, biofiltration. That means basically pumping all the air exhaust through a big box full of bark and cedar chips to absorb the smell.